Page 1

AUTO-EC-3-E-PLC

Electric Filter Backwash Controller

Operation & Maintenance Manual

Page 2

Contents

Controller Basics 3

Controller Components 4

Screen Flow Diagram 5

Controller Functions 6

Installation 7

Warranty 8

AUTO-EC-3-E-PLC Controller Manual

Contents

www.rainbird.com2

Page 3

AUTO-EC-3-E-PLC Controller Manual

EC-3-LP-PLC

Controller Basics

Controller Basics

Auto-EC-3-E-PLC Backwash Controllers are designed to monitor and activate a cleaning cycle

for three Low Pressure Series lters in parallel.

The controller allows the user to adjust the ush

duration, dwell time between backwashes,

and the specied periodic backwash. Other

features include manual start, counter reset,

and alarmreset.

The controller receives an open/closed signal

via terminals 1 through 6. This signal is from the

dierential pressure gauge, and means that the

gauge has reached a preset value. Reaching the

preset value (usually 7 psid) tells the controller

that debris has collected on the screen element,

and that an automatic backwash will activate.

D502

SCR501D501

A2

L1

M

O

V

5

10

F2

F1

MOV503

SW501

L2

115 230

S2

C504

18090

INHIBIT

SW502

S3

D502

SCR501D501

A2

L1

M

O

V

5

0

1

F2

F1

MOV503

SW501

L2

115 230

S2

C504

18090

INHIBIT

SW502

S3

D502

SCR501D501

A2

L1

M

O

V

5

10

F2

F1

MOV503

SW501

L2

115 230

S2

C504

18090

INHIBIT

SW502

S3

13 14

13 14

13 14

13 14

13 14

9

5

1

11 12 13

13 14

9

9

9

5

5

5

1

1

1

9

9

5

5

1

1

5 7

4

321 14 1516171819 20 21 22 23 24 25

109

6

8

D503

SCR502

02

V5

O

M

03

02

1

5

0

C

R5

R5

C501

02

C

I5

A1

SO502

+

C502

IC501

METER

CL

IL501

S1

TORQUEDECELACCEL

MIN SPDMAX SPD

IR COMP

D503

SCR502

02

V5

O

M

03

02

1

5

0

C

R5

R5

C501

02

C

I5

A1

SO502

+

C502

IC501

METER

CL

IL501

S1

TORQUEDECELACCEL

MIN SPDMAX SPD

IR COMP

D503

SCR502

02

V5

O

M

03

02

1

5

0

C

R5

R5

C501

02

C

I5

A1

SO502

+

C502

IC501

METER

CL

IL501

S1

TORQUEDECELACCEL

MIN SPDMAX SPD

IR COMP

26

When a closed signal is sensed on terminals

1 and 2 for a 5 second period, the backwash

sequence begins. The backwash sequence

is: station 1 energizes for the ush duration,

then an idle period for the dwell duration,

then station 2 energizes for the ush duration,

another dwell, and then station 3 energizes for

the ushduration.

Controls

A. Panel enclosure: NEMA 4X

B. Control panel for each lter module shall

include:

1. All required control and power elements

to provide automatic self- cleaning system

operations.

2. Main power disconnect switch

3. Starters

4. Transformer

5. PLC

6. Relays

7. Timers

8. Alarm logic modules

9. TIME & DP, and DP ONLY modes of operation with two position selector switch.

10. Indicating lights

C. Depending on mode of operation, control

Auto-EC-3-E-PLC

panel will be responsible for opening the electric exhaust ball valve and starting the motor to

rotate the cleaning element. After the cleaning

interval is complete, control panel shall stop the

motor, close the exhaust valve, and reset the

cleaning cycle for the next operation.

D. With the selector switch in the TIME&DP

position, timers shall intermittently initiate the

cleaning cycle at preset adjustable intervals

ranging from 0 to 24 hours for the length of

time necessary to complete one cleaning cycle.

E. A dierential pressure switch shall be

arranged on the lter or across the inlet and

outlet piping of the lter to override the timer

in the TIME&DP mode or acting alone in the

DP ONLY mode to initiate the cleaning cycle

whenever a dierential pressure across the lter

exceeds a preset value. The dierential pressure

switch shall continue to operate the cleaning

cycle until the dierential pressure across the

lter returns to normal or an adjustable timer

inside the control panel elapses. If the cleaning

cycle continues until this preset timer elapses,

then the control panel shall shut down the

cleaning operation completely causing the red

alarm FAULT light to glow on the cover of the

control panel and send a 24 volt AC alarm signal

to terminals 17 and 18 inside the control panel.

F. A “TEST” button shall be located on the control panel door that will initiate a cleaning cycle

upon demand.

G. A “RESET” button shall be located on the

control panel door.

H. Control panel and all components of each

control panel shall be Underwriter’s Laboratory

listed.

I. Additional features

1. Flush in progress - relay contact closure

output

2. System fault alarm - relay contact closure

output

3www.rainbird.com

Page 4

EC-3-LP-PLC

TORQUEDECELACCEL

S3

S2

INHIBIT

C504

MIN SPDMAX SPD

18090

SW502

IL501

CL

10

5

V

O

M

L1

L2

F1

MOV503

SW501

F2

SCR501D501

R5

02

SO502

+

METER

-

D502

A2

M

O

V5

02

D503

A1

IR COMP

IC501

C502

S1

C

5

03

C

I 5

02

C501

R5

0

1

SCR502

115 230

TORQUEDECELACCEL

S3

S2

INHIBIT

C504

MIN SPDMAX SPD

18090

SW502

IL501

CL

1

0

5

V

O

M

L1

L2

F1

MOV503

SW501

F2

SCR501D501

R5

02

SO502

+

METER

-

D502

A2

M

O

V5

02

D503

A1

IR COMP

IC501

C502

S1

C

5

03

C

I 5

02

C501

R5

0

1

SCR502

115 230

TORQUEDECELACCEL

S3

S2

INHIBIT

C504

MIN SPDMAX SPD

18090

SW502

IL501

CL

10

5

V

O

M

L1

L2

F1

MOV503

SW501

F2

SCR501D501

R5

02

SO502

+

METER

-

D502

A2

M

O

V5

02

D503

A1

IR COMP

IC501

C502

S1

C

5

03

C

I 5

02

C501

R5

0

1

SCR502

115 230

1

5

9

13 14

1

5

9

13 14

1

5

9

13 14

1

5

9

13 14

1

5

9

13 14

1

5

9

13 14

EC-3-LP-PLC

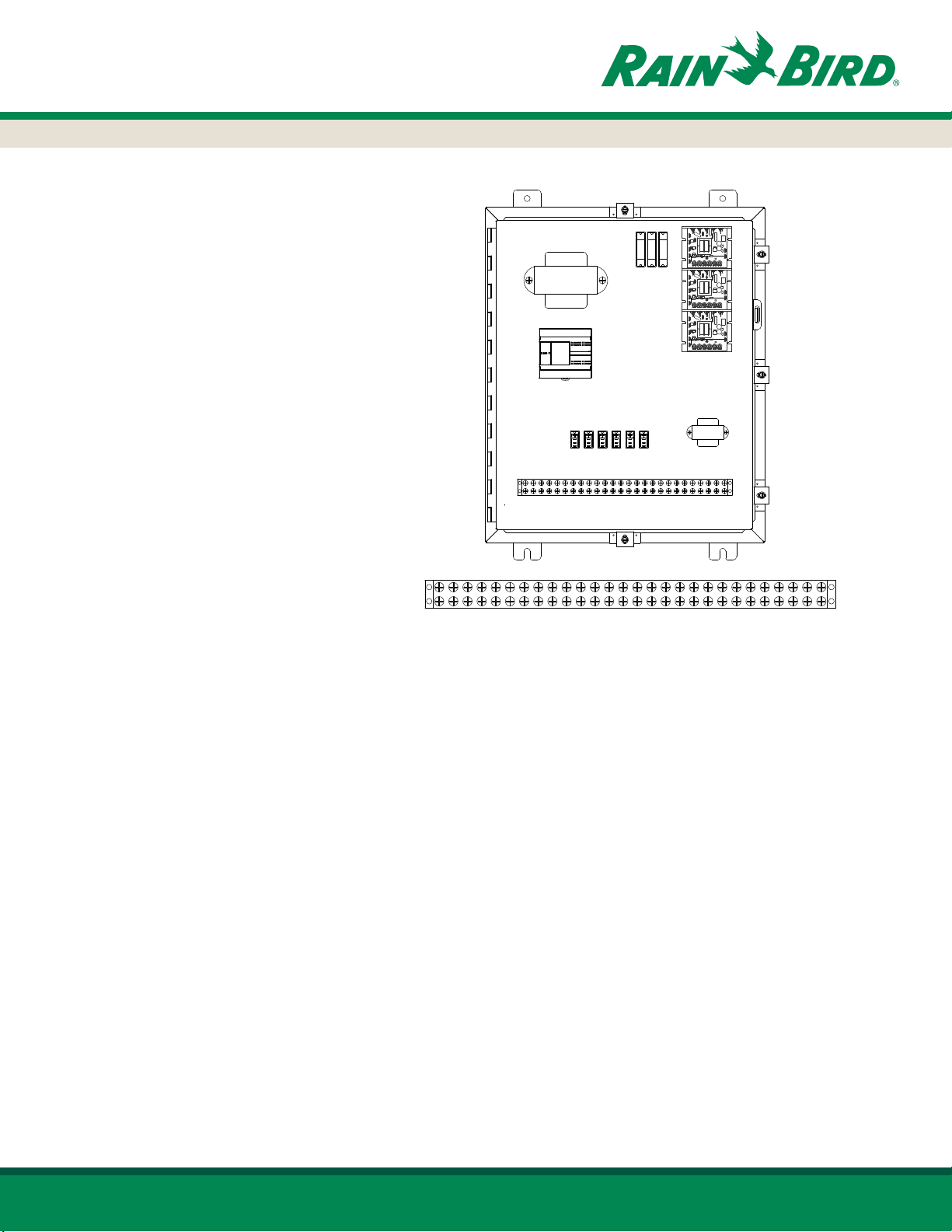

Controller Components

D502

SCR501D501

02

V5

A2

O

M

L1

M

O

V

5

10

F2

F1

MOV503

SW501

L2

115 230

S2

1

4

11

C504

18090

INHIBIT

SW502

S3

MIN SPDMAX SPD

D502

SCR501D501

02

V5

A2

O

M

L1

M

O

V

5

0

1

F2

F1

MOV503

SW501

L2

115 230

S2

C504

18090

INHIBIT

SW502

S3

MIN SPDMAX SPD

D502

SCR501D501

02

V5

A2

O

M

L1

M

O

V

5

10

F2

F1

MOV503

SW501

L2

115 230

S2

C504

18090

INHIBIT

SW502

S3

MIN SPDMAX SPD

17

AUTO-EC-3-E-PLC Controller Manual

Controller Components

D503

SCR502

03

02

1

5

0

C

R5

R5

C501

02

C

I5

A1

SO502

+

C502

IC501

METER

CL

IL501

S1

TORQUEDECELACCEL

IR COMP

D503

SCR502

03

02

1

5

0

C

R5

R5

C501

02

C

I5

A1

SO502

+

C502

IC501

METER

CL

IL501

S1

TORQUEDECELACCEL

IR COMP

D503

SCR502

03

02

1

5

0

C

R5

R5

C501

02

C

I5

A1

SO502

+

C502

IC501

METER

CL

IL501

S1

TORQUEDECELACCEL

IR COMP

7

8

9

3

TEST

HS

FILTER

X

NO.1

TEST

HS

FILTER

X

NO.2

TEST

HS

FILTER

X

NO.3

HS

FAULT

X

RESET

QL

X

QL

X

HS

X

HS

X

CONTROL

POWER

MANUAL

BACKWASH

GEN FAULT

1 FAULT

2

10

5

13

13 14

13 14

13 14

13 14

13 14

16

1

1

9

9

5

5

13 14

9

9

9

9

5

5

5

5

1

1

1

1

6

5 7

4

109

321 14 1516171819 20 21 22 23 24 25

11 12 13

6

8

1. Step-down Transformers. Converts 480

VAC to 110VAC and 110 VAC to 24 VDC.

2. Power. Controls power to the

controllerboard.

3. Fault Reset.

4. Circuit Breaker.

5. Manual Backwash. Manually initiates a

backwash sequence for stations 1-3.

6. Terminal Block: Connections for valves,

motors, and dierential pressure gauge.

7. Test Filter 1. Executes a backwash cycle for

station 1 lter.

12

1

26

8. Test Filter 2. Executes a backwash cycle for

station 2 lter.

9. Test Filter 3. Executes a backwash cycle for

station 3 lter.

10. General Fault. DP fault time exceeded

without relieving dierential pressure.

11. IDEC PLC. Set ush duration, dwell, and

timed backwash

12. DP / DP & Time. Selector switch for DP only

mode or DP & timed interval mode.

13. Fault Filter 1. Indicates fault for station

1lter.

HS

X

DP ONLY

DP & TIME

HS

2 FAULT

X

HS

3 FAULT

X

14. Fault Filter 2. Indicates fault for station

2lter.

15. Fault Filter 3. Indicates fault for station

3lter.

16. 24VDC Relays

17. Motor Drive Boards

14

15

4

321 14 1516171819 20 21 22 23 24 25

Terminals

T1–2. Open/Close terminal for station 1

dierential pressure gauge.

T3–4. Open/Close terminal for station 2

dierential pressure gauge.

T5–6. Open/Close terminal for station 3

dierential pressure gauge.

T7. Motor 1 Red Lead

T8. Motor 1 Black Lead

5 7

6

109

8

T9. Motor 2 Red Lead

T10. Motor 2 Black Lead

T11. Motor 3 Red Lead

T12. Motor 3 Black lead

T13–14. Valves 1-3 Red Lead

T15–16. Valves 1-3 Black Lead

T17. Valve 1 White Lead

T18. Valve 2 White Lead

11 12 13

26

T19. Valve 3 White Lead

T20–21. Input Voltage Hot

T22. Input Voltage Ground

T23–24. Alarm Output

T25–26. Emergency Stop

T27–28. 24VAC for Utility Water Backwash

www.rainbird.com4

Page 5

AUTO-EC-3-E-PLC Controller Manual

Screen Flow Diagram

Screen Flow Diagram

Intro Screen

Home

Manual Operation

Set Times

DP Fault Times

Lifetime Hour Meter

5www.rainbird.com

Page 6

Controller Functions

AUTO-EC-3-E-PLC Controller Manual

Controller Functions

Intro Screen

Advances from Intro to Home screen

DP Limit indicators: Filters 1–3

Controller mode: Auto/Manual

Controller mode: DP only/DP and Time

Activates backwash sequence for lters 1–3

Advance to Set Times screen

Backwashes lters individually

only when manually held

Filter Duration: Sets ush duration (secs)

Advance to DP Fault Times screen

Home

System fault

Manual Operation

System fault

Set Times

Fault indicators: Filters 1–3

Resets controller after fault or emergency stop

Advances to Manual Operation screen

Advances to Set Times screen

Advances to Manual Operation screen

Backwash indication icon: Filters 1–3

Goes back to Home screen

Goes back to Home screen

Advances to Set Times screen

Dwell Time One: Pause between

backwash cycle one and cycle two

Delay after receiving DP, prior to activating backwash

Advances to Manual Operation screen

Dwell Time Two: Pause between

backwash cycle two and cycle three

Timed Interval Delay: Adjustable

setting for timed backwash (secs)

DP Fault Times: Total time reading

DP before triggering fault

Lifetime total backwash per lter

DP Fault Times

Lifetime Hour Meter

Advances to Set Times screen

Advances to Lifetime Hour Meter screen

www.rainbird.com6

Page 7

AUTO-EC-3-E-PLC Controller Manual

5 7

4

321 14 15

Filter 1 Differential Pressure Gauge (Dry)

Output Terminals for Motors (90VDC)

7. Red Lead Motor 1

8. Black Lead Motor 1

9. Red Lead Motor 2

10. Black Lead Motor 2

11. Red Lead Motor 3

12. Black Lead Motor 3

Filter 2 Differential Pressure Gauge (Dry)

3. DP

4. DP

Filter 3 Differential Pressure Gauge (Dry)

5. DP

6. DP

Installation

Installation

Motor 3

Red-11

Black-12

DP Gauge

5 & 6

OUTLET

VALVE 3

Red-13 or 14

Black-15 or 16

White-19

VALVE 2

Red-13 or 14

Black-15 or 16

White-18

Motor 2

Red-9

Black-10

Motor 1

Red-7

Black-8

Isolation

Valve

INLET

DP Gauge

3 & 4

DP Gauge

1 & 2

Differential

Pressure

Gauge

Isolation

Valve

FLUSH

VALVE 1

Red-13 or 14

Black-15 or 16

White-17

Filter

1. DP

2. DP

DP Gauge

1 & 2

Bypass

Valve

7www.rainbird.com

Page 8

AUTO-EC-3-E-PLC Controller Manual

Warranty

Warranty

Rain Bird Filters guarantees all self cleaning water lters, components, and accessories free of defects for one year from the date of installation, or 18 months

from the date of original shipment. Rain Bird will replace any part found defective during the warranty period, provided the equipment in question was

handled, installed, and operated in accordance with the operation and maintenance manual and sound engineering practices. Rain Bird Filters assumes

no liability for incidental or consequential damage resulting from the use of its products, services, or data. Liability is limited to replacement or repair of

products provide by Rain Bird Filters, and no agent or sales representative has authority to extend the warranty period without the express written consent

of Rain Bird Filters, Inc. Shipping charges for returned equipment will be at the expense of the purchaser, and all returned equipment must be sent to Rain

Bird Filters.

www.rainbird.com8

Loading...

Loading...