Page 1

Rain Bird. Conserving more than water.

® Registered trademark of Rain Bird Corporation

® 2002 Rain Bird Corporation 2/02

P/N 232153

Rain Bird Corporation

Contractor Division

970 West Sierra Madre Avenue

Azusa, CA 91702

Phone: (626) 963-9311

Fax: (626) 812-3411

Rain Bird Technical Services

(800) 247-3782 (U.S. only)

Rain Bird Corporation

Commercial Division

6991 East Southpoint Road

Tucson, AZ 85706

Phone: (520) 741-6100

Fax: (520) 741-6522

Specification Hotline

(800) 458-3005 (U.S. only)

Rain Bird International, Inc.

145 North Grand Avenue

Glendora, CA 91741 USA

Phone: (626) 963-9311

Fax: (626) 963-4287

www.rainbird.com

200PRV Valve

Installation and Operation Instructions

Troubleshooting Guide

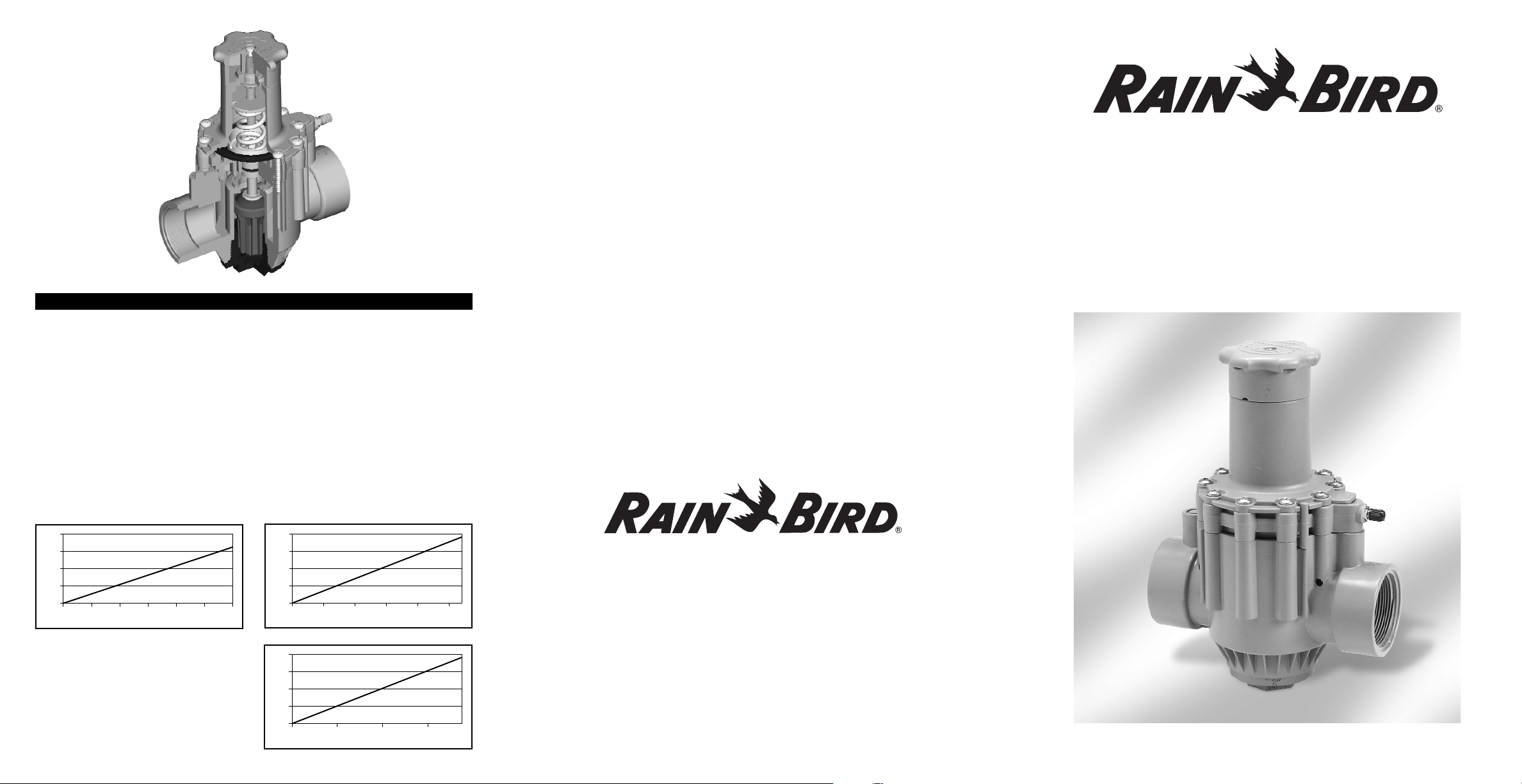

200PRV Fall-Off Characteristics

Fall-Off (PSI)

Flow (GPM)

0

0

5

10

15

20

20 40 60 80 100 120

Fall-Off (Bar)

Flow (m3/hr)

0

0

0.3

0.6

0.9

1.2

510152025

Fall-Off (Bar)

Flow (l/s)

0

0

0.3

0.6

0.9

1.2

246

Reduced pressure fall-off is inherent to direct acting regulators and a key factor relating

valve characteristics to system requirements. Fall-off is the difference between the static and

dynamic pressures downstream of the regulator. It varies with flow and represents the pressure change that occurs when the valve opens.

The following chart depicts the fall-off characteristics of the 200PRV. The zero point represents the valve when there is no flow (valve in lock-up condition) and can be any setting

within the outlet pressure adjustment range. As water flows through the open valve, fall-off is

the dynamic pressure reduction associated with a given flow.

Example: The regulator is set at 60 psi (4,2 bar) static outlet pressure. If a downstream control valve opens and water flows at 80 gpm (18,2 m

3

/h; 5,1 l/s), the fall-off will be approxi-

mately 10 psi (0,7 bar) making the dynamic outlet pressure approximately 50 psi (3,5 bar).

Page 2

Thank you for purchasing a Rain Bird

200PRV valve. When a pressure reducing valve is desired for commercial irrigation purposes, Rain Bird’s PRV pressure regulator provides quality, performance and economy. This normally

open valve designed for point-of-connection applications is rugged and reliable. By reducing high inlet pressures

to lower outlet pressures, the PRV

improves irrigation system performance

and conserves water.

NOTES

• The PRV is shipped in a globe configuration and is designed for globe

installation/operation only.

• The PRV is a normally open valve. It is

not a control valve. Rain Bird recommends at least one on/off control

valve before and/or after the PRV.

Install a shut-off valve upstream of the

PRV so water can be conveniently

turned off if the regulator needs servicing.

• This valve should only be used on irrigation systems and should be

installed downstream of the backflow

prevention device (according to local

code).

• Proper operation requires inlet pressure to be a minimum of 15 psi (1 bar)

higher than desired outlet pressure.

Installation Refer to F1.

1. Flush main line thoroughly before

installing the valve.

2. Use two wraps of Teflon tape along

the full length of the inlet and outlet

pipe threads. Do not apply pipe

thread or pipe dope compound.

3. Thread inlet pipe into the inlet port of

the valve

●

A and hand tighten.

Thread outlet pipe into the outlet port

of the valve

●

B and hand tighten.

Tighten with wrench but do not

exceed two turns beyond hand tight.

4. Ensure inlet side is connected to

main line. Note arrows on valve body

indicating direction of water flow.

Schrader valve

●

C should be on the

downstream side of the valve.

5. After installing the valve, slowly open

the water supply at point-of-connection. Remember this is a normally

open valve and water will continue to

flow unless an on/off control valve is

in place downstream.

6. For dirty water systems be sure to

install a 100 mesh (or finer) WYE filter

or screen filter before the PRV valve.

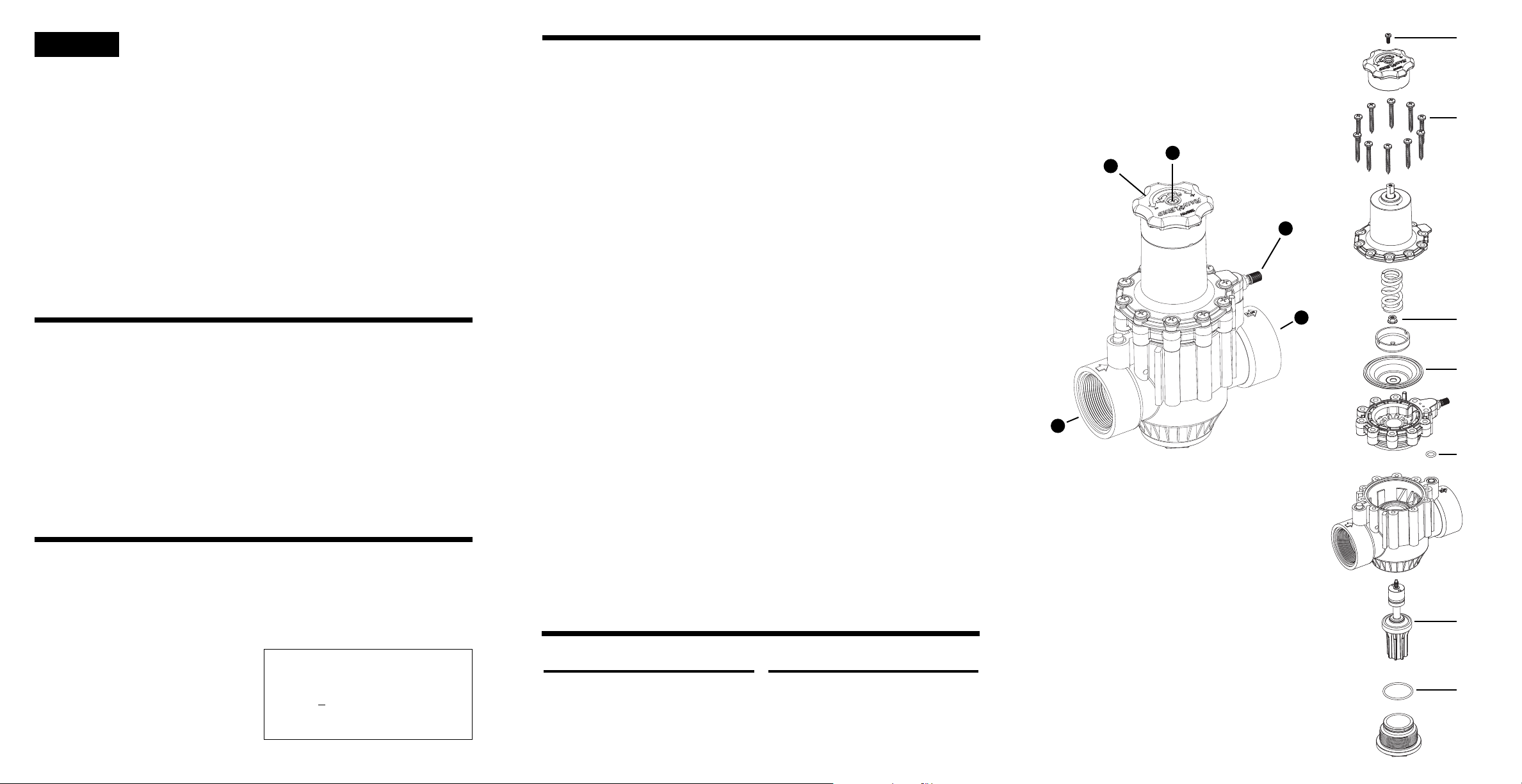

200PRV

1 Poppet/Seat/Plunger Assembly 232295

2 Diaphragm 232296

3 Bonnet Screws 232297

4 Handle Screw 232298

200PRV

5 O-Ring, Body 232299

6 O-Ring, Plug 232300

7 Locknut 204968

Replacement Parts Refer to F2.

English

D

E

C

A

B

F1

200PRV Valve

Operating Instructions

The valve comes from the factory preset at 60 psi (4,1 bar) static outlet pressure. To change the outlet pressure setting, loosen the screw on the top of the

valve handle

●

D by turning one turn

counter-clockwise. Connect a pressure

hose gauge to the Schrader valve stem

●

C located just above the outlet port of

the valve

●

B . Turn the handle●E

counter-clockwise to decrease the outlet pressure setting, or clockwise to

increase the outlet pressure setting.

When the outlet pressure is at the

desired setting, remove the pressure

gauge from the valve stem and tighten

the screw on the valve handle to lock-in

the setting.

Troubleshooting Guide

Difficulty adjusting valve to

desired outlet pressure.

• Verify that the inlet pressure is at least

15 psi (1 bar) above the desired outlet pressure.

• Attempting to adjust the outlet pressure when the inlet pressure is too low

can cause the valve spring to

become fully compressed. This may

deform and permanently damage the

bonnet, thereby causing external

leaks.

With no downstream flow, the

outlet pressure increases to

equal the inlet pressure.

• Lock-up pressure is not in effect. The

valve seat cannot fully close against

the valve body throat.

• Check to see if there is debris lodged

between the seat and the body throat.

• Check to see if the seat is damaged.

Water leaks from the top of the

bonnet, near the handle.

• Loose diaphragm lock nut. Remove

the bonnet and tighten the nut to 25

inch-pounds of torque.

• Torn or damaged diaphragm. Replace

the diaphragm.

Water leaks from between the

body and the bonnet.

• Bonnet retaining screws are loose.

Re-tighten the screws.

• Valve spring is compressed to solid

height by attempting to set the outlet

pressure too high. Turn the adjustment handle counter-clockwise to

lower the outlet pressure setting, and

verify that the inlet pressure is at least

15 psi (1 bar) above the desired outlet pressure.

Water leaks from inlet or outlet

threads.

• Valve is not properly tightened on

mating pipe threads. Re-tighten valve

connections or re-connect valve to

line according to installation

instructions.

• Threads are damaged by crossthreading or contaminated by debris.

Inspect threads and repair or clean as

needed.

Low or inadequate flow

condition.

• System gate or master valve is not

fully open. Locate the gate or master

valve and open.

• Obstruction in the main pipeline.

Isolate obstruction and remove.

• Water pressure is being used elsewhere on the site. Too many downstream control valves and sprinklers

operating at one time. Do not exceed

maximum flow capabilities.

Technical Questions:

• Inside the U.S., please call Rain Bird

Technical Services at (800) 247-3782

or the Rain Bird Spec Hotline at (800)

458-3005.

• Outside the U.S., please refer to the

back page for contact information.

• Visit www.rainbird.com

Operating Range:

Pressure: up to 200 psi (13,8 bar)

Regulation: 25 to 85 psi (1,7 bar to 5,9 bar)

Accuracy: + 5 psi (0,3 bar)

Flow: up to 120 GPM (27,3 m3/h; 7,6 l/s)

Water temperature: up to 110° F (43° C)

4

3

7

2

5

1

6

F2

Loading...

Loading...