CONTENTS

Page

Introduction

..........................................................................

1

Specifications

..........................................................................

2

...............................................................................

General 4

Description

of

Function

..................................................................

7

.......................................................................

Modem Interface 12

.....................................................

Description Keyboard Interface Circuit 18

........................................

Power Slupply and Power Supply Protective Circuits

19

................................................

Operational Description of the Control Unit

20

..............................................................

RS-232C Interface (Option) 33

Block Diagram

.........................................................................

36

Maintenance Procedure

.................................................................

37

................................................................

Disassembly Instructions 38

Components

...........................................................................

38

Disassembly of PT-210 Portable Data Terminal

............................................. 39

..................................................

Replacement and Adjustment within PCB

47

................................................................

Description of Assembly 47

Replacement

...........................................................................

47

............................................................................

Adjustment 54

Troubleshooting

........................................................................

59

....................................................

Problems at Power-ON (Restore) Time 59

..................................................................

Problems in Operation 60

...................................................................

Printed Circuit Boards 64

........................................................................

Wiring Diagram 70

.............................................................................

Parts Lists 71

........................................................................

Exploded Views 83

....................................................................

Schematic Diagrams 86

Introduction

Model

PT-210

is a Portable Data Terminal that combines a thermal printer, a keyboard, and an acoustic

coupler. Electronic circuits are used for its control; its main control comes from a one-chip microcomputer

(hereinafter abbreviated as pCPU).

Separate units are provided for different functions. Pulse motors and solenoid are used as drive sources

for mechanicals. Simplification is achieved by minimizing the number of mechanical parts, Accordingly, the

number of points which require adjustment is extremely small and maintenance is easy.

Other units also incorporate electronics. Electronic circuits are simplified for improving reliability and

stability, and the number of parts is minimized.

I

/

Specification

Data Transmission

.......................

Communication method Start-Stop Asynchronous

.........................

Communication speed

1 10/300 bps; Switch selectable

1 10 bps

(1 1 bit/character)

300 bps

d

Obitlcharacter)

.........................

Communication mode

Half/Full duplex; Switch selectable

ASCII for Information Interchange

...................................

Line status

On line/Off line; Switch selectable

................................

Line buffer..

.48 characters; On received

....................................

Interface. Acoustic coupling

RS232C (Optional) (CAT. No. 76-1 002)

.......................................

Parity.

Odd., Even, Ignore; User selectable

....................................

Keyboard Matrix full keyboard

99

codes generated

67 printable characters

32 control characters

Printer

.....................................

Method. Non-impact, thermal-paper printing

..................................

Head life.. .20 million word

......................................

Paper.

.8-

1

/2" (1

00

ft) (CAT. No. 76- 1003)

.............................

Character size..

.2.7 mm

X

2.0 mm (7 X 5 dot-matrix)

................................

Line length.. .8 inches

10 character per inch

80 character per line

...............................

Line spacing..

.6 lines per inch

Printing rate

50 characters per second; except CR time

.......................................

CR/LF

Automatic at column 81

;

no code is transmitted

....................................

CR time

.0.80 seconds (OFF LINE)

0.86 seconds <ON LINE)

...................................

LF time..

.0.05 seconds (single step)

0.03 seconds (continuous step)

Acoustic Coupler

.................................

Compatibility Bell System 103A (equivalent)

Telephone (CAT No. 43-301)

.......................................

Mode. Oriainate

..................................

Modulation. Frequency shift keying (FSK)

..........................

Receive Frequencies. Originate

Mark 2225

Hz

Space 2025 Hz

.......................

Transmitter Frequencies. Originate

Mark 1270 Hz

Space 1070 Hz

Receive Sensitivity

............................

-

35 dBm

Transmit Power.

..............................

-

15 dBm

Â

(within 15 dBm difference between transmit level and

receive level)

I

Physical

Size (overall)

.................................

1 5.7"

X

14.6" X 4.9"

(40.0 cm

X

37.2 cm X 12.5 cm)

Weight (Overall)

..............................

15.0 pounds (6.8

kg)

Power Requirements

Voltage.

.....................................

105 through 1 35 volts

Frequency..

.................................

.47 through 63 Hz

Power (Overall)

...............................

75 watts maximum

Environment

Temperature

.................................

Operating 50° to 95OF (10° to 35OC)

Storage 40° to 104OF (-4O0C to 7 1 OC)

(not including paper)

40° to 1 OZ° (-40"C to 40°C

(including paper)

Humidity.

....................................

Operating 10% to 80% (no condensation)

Storage 10% to 90% (no condensation)

Duplex

Line

Duplex

(Optional Cat. No.

76-1002)

LOca'

1

Remarks

Network

-A

Electric Typewriter

Modem

Modem

I

Note:

d)

Keyboard : ASCII

.....

99

codes generated.

@

Printer: Non-impact, thermal-paper printing five by seven,

80

characters

per

line.

@

Acoustic Coupler: Compatibility

.....

Bell system 103A (or equivalent).

(?)

Self Test: Turning Power on while holding REPT key starts self test.

(MODE S.W-HALF, SPEED S.W-300)

All printable characters are printed. Self test ends by turning power off.

MODEL PT-210 COMMUNICATION DIAGRAM

OFF-LINE

IÑÑÑÑÑÑÑÑÑÃ

I

1

1

KEYBOARD CONTROL PRINTER

!

1

use

as electric typewriter.

I

I

I

I

1

Either Transmit or Receive at one

time

I

'

KEYBOARD CONTROL PRINTER

1

I-

COMPUTER

1

I

I

I

I.

1

ACOUSTIC

1

I

COUPLER

1

MODEM

1

KEYBOARD CONTROL PRINTER

1

1

Transmit and Receive at same time

I

I

I

*

r---

I

'

I

L----

'

I

-I--------

I

I

-

Telephone-

-

I

I

I

I

I

-

--

COMPUTER

LÑÑÑÑ

---

--

--

--

ÑÑ

Line

b

ON-LINE

I

I

I

I

RS-232C INTERFACE (OPTIONAL)

!

KEYBOARD CONTROL PRINTER

1

ACOUSTIC

1

COUPLER

I

MODEM

Figure

2.

6

1

_^

1

I

Telephone-

-

!-------

--___

------

J

Line

*

Character print

One character is composed of the 7

X

5

matrix dots. Assume letter

"H"

is to be printed. When Carriage

Return and data

"H"

signals reach the printer, the line feed motor runs and the thermal head is caused

to move in the direction indicated in the figure on the left.

When the thermal head moves and the row of dots reaches position A, alt dots (1

-

7) are heated and

(

the color. of the paper is changed. When the thermal head advances to position

B,

only dot (4) is

heated. Identically, as the thermal head advances and the row of dots reaches positions C,

D,

and

E,

dots (41, (4) and (1

-

7)

are heated, and pattern

"H"

is printed on the printing paper.

Direction of movement of the thermal head

:>

A

=

E/print

1

uaam

2IUDOI

31nna1

411111

51nnnm

6innaI

71nou1

Figure

5.

The relationship between thermal head feed and dot printing positions is as shown below. (Since control signals are controlled by the pCPU,

it

is not possible to make adjustment.)

1

Character

Carriage Return

Motor

Thermal Head

Figure

6.

8

Keyboard Unit

Â

When a key that corresponds to the data to be input is pressed, its contact operates and a signal is sent

to the control unit.

Printer Unit

The printer unit is controlled by the control unit.

It

prints data to be transmitted and receives data on ther-

mosensitive paper (in roll). In the OFF-LINE mode, the printer can be used as an ordinary typewriter.

CR

motor assembly

The

CR

motor controls movement of the thermal head. When a control signal is input to the

CR

motor,

the motion of the motor is transmitted to the head assembly@ fixed by the

CR

timing belt

(2)

through

the motor timing pulley

(l)

on the motor shaft.

Assembly

Figure

7.

The motor causes the thermal head

(A)

to move, in the direction of X-axis, a distance that corresponds

to the size of one character, and to do so within

6

pulses of the motor control signal. Therefore, its

moving distance is

2.54

rnrn

(1

/lo'').

The motor reverses when the head has travelled the distance of

203.2

mm, which is the effective

travel of the thermal head good for

80

characters, and the head assembly

(3)

is caused to return to the

start point. The start point is determined by the photo interrupter assembly

(5)

While the thermal head

is returning to the start position,

it

is not in contact with the thermosensitive paper because of the op-

eration of a relief solenoid.

@

LF

motor assembly

The

LF

motor controls the feeding of the thermosensitive paper.

Figure

8.

The motion of the

LF

motor is transmitted to the motor timing pulley

(4)

set on the platen shaft

(3)

through the motor timing pulley @and the

LF

timing belt

(2)

and is further transmitted to the platen

(5)

The thermosensitive paper is led in by the friction force of the platen@ and then is fed by the ro-

tation of the platen

(5)

as pressure is applied to the paper by pinch rollers.

The

LF

motor feeds paper in the direction of Y-axis by a distance of 1 line; that is, it moves

4.23

mm

(1/6")

after 6 pulses of the

LF

motor control signal. The thermal head is not in contact with the thermosensitive paper during line feed, due to the operation of a relief solenoid.

Solenoid assembly

The solenoid assembly controls printing motions by causing the thermal head to make contact with

thermosensitive paper and to make a relief from the paper.

When a control signal

is

input to the solenoid, the solenoid is actuated and a rotary motion is trans-

mitted to the head shaft

(3)

through the head lever

(2)

which is coupled with the plunger

@

The

underhead

(4)

is coupled to the head shaft

(3\

and the thermal head assembly @ is set to the under-

head.

Solenoid Assembly

1

'

(2)

to^)

Figure

9.

A

gap is produced between the thermal head

(5)

and the paper by the rotary motion of the head shaft

0.

While the solenoid is not actuated, the thermal head is in contact with the thermosensitive paper so

that

a

print can be made at any time.

It is possible to adjust the pressure of the thermal head applied to the thermosensitive paper by changing the tension of the tension spring

@located at the end of the

Control Unit

The control unit controls the recording of input/output data, the transformation of signal levels

(TTL

level

-

sound) and the transmission and receiving of data. Refer to the description of circuits and interface for

details.

Modem

Interface

This equipment modulates digital signals transmitted from the control side into analog signals, and then

transmits them to the mouth side of the handset.

On the other hand,

it

demodulates analog signals received from the ear side of the handset into digital

signals, and then transmits them to the control side.

The configuration can be divided into

a

speaker output unit, a microphone input unit, and a modem board

unit. Coupling transmission/receiving is made with the speaker output unit attached to the transmission

side of the handset and with the microphone input unit mounted to the receiving side of the handset. The

modem board mounts modulation and demodulation circuits.

Figure

10.

Configuration

CN2

I

T

-

~TXD

-

BUFFER

-

-

MODULATOR

-

I

I

CONTROL

UNIT

CN3

Figure

1 1.

Modem Logic Block Diagram

l-

-

DSR

Names used in the modem logic are described below.

DSR (Data Set Ready): This signal indicates that the modem is in the status that permits operation in

the case where exchange of data is made between a modem and its control unit. This signal becomes

"L"

level about 2- 4 seconds after input of data to MIC IN, and operation is enabled.

RxD (Required Data): Receives data signals transmitted from the modem and transfers them to the control side.

TxD (Transmitted Data): Transmits data signals

-

data signals produced from the control side are

transmitted to the modem.

INH (Inhibit): Signal for discontinuing transmission of data. Transmission is made while this input is at

level

"L".

MIC IN (Microphone Input Data):" The following analog frequencies are received from the telephone

handset.

Mark: 2,225

Â

5

Hz

Space: 2,025

Â

5

Hz

SP

OUT (Speaker Output Data): The following analog frequencies are transmitted to the telephone

handset.

Mark: 1,270

&

5

Hz

Space: 1,070

Â

5

Hz

DEMODULATOR

1

RxD

I

-

I

BANDPASS.

FILTER

i

-

Description of Operation

Modulator

Jl

A*.

I

TxD

-

INH

SP

7405 OUT

Figure

12.

Audible sound data is output to

SP

OUT,

and a digital signal is input to TxD when signal

"L"

(transmis-

sion enable) is input to

INH.

The timing chart is as follows:

SP OUT

Figure

13.

Demodulator

COMPARETER

RxD

0

Â

+5V-+12V

-

Figure

14.

The analog data signal input through

MIC

IN is amplified by the amplifier, its noise is cut by the band

pass filter, and it is then input to the demodulator. The demodulator contains

a

frequency comparison

circuit, and it outputs the difference in frequency by

a

digital signal.

33.3

ms

I

33.3

ms

1 -1 300 Baud

Mark

.

.

RxD., TxD

(Odd., Even Parity)

-START

Bit

1

-STOP

Bit

-

Parity Bit: Odd

or

Even

Mark

1-2

110 Baud

100

mS

Mark

1

DATA Bit

(7

Bits)

START Bit

Parity Bit: Odd

or

Even

,

Mark

RxD., TxD

(Odd, Even Parity)

Space

1

Bit1

DATA Bit

(7

Bits)

11

Bit1 2 Bits

I

I

STOP Bit

start Bit

NON-Parity Bit

I

1

I

Figure

15.

Timing

Chart

@

Receiver

ON-LINE

OFF-LINE

-

I

L

CARRIER

(MIC IN)

DSR (OUT)

-

RxD

%

(OUT)

2

*--!--T

Space

I

DATA Bit

START Bit

-STOP

Bit

(1

10

BPS)

@

Transmitter

STOP Bit

(1

10, 300

BPS)

Parity Bit

I

ON-LINE

OFF-LINE

=

(IN)

-

DSR: Data Set Ready

RxD:

-

Received Data

INH: Inhibit

TxD:

Transmitted Data

TxD

(IN)

DATA Bit

'cSTART Bit

STOP STOP Bit Bit

(1 (1 10, 10

BPS)

300

BPS)

-parity Bit

/

Figure

16.

-7

-1

!

i

Description

of

Keyboard Interface Circuit

Key

Board

LINE FEED

Â¥

1

ESC

I

-D

BACK SPACE

1

-m

I

RETURN

I-

PAPER ADV

1-

Key

Matrix

I

SPEED

t

I

SHIFT

1

I

CTRL

1-

Control

--

Key

Board

nterface

S379C-5

-

MODE M

Figure

17.

Power Supply

and

Power Supply Protective Circuits

*

Power supply

The standards of DC voltages are as follows.

+5V is-supplied to pCPU, the digital circuits, the modem, and the RS-232C interface. 4-5.0

-

6.1V is

supplied to the thermal head,+7.5Vis supplied to motors and solenoids, and k12V is supplied to the

analog circuit elements of the modem.

*

Power supply protective circuits

A

protective function is actuated when abnormal current flows at the time of power ON or when the

PT-210 Portable Data Terminal operates.

Item

I

Protective function

5 short

1

protection by IC3 on the power supply board.

AC line primary

side short

1

Protection by NFB (No Fuse Breaker).

Â

1 2V short

+

7.5V and

4-

5.0-6.1 V short

Caution: Immediately turn the power switch to the OFF position if the specified DC voltage is not pro-

duced.

Check fuse 1, fuse 2, and the NFB for blowing before turning the power switch back to the

ON position after repair and recovery. If any of them is blown, replace it with a spare.

protection by

ICI, IC2 on the power supply board.

Protection by fuse 1 or furse

2

or by the

circuit breaker on the power supply board.

Operational Description

of

the Control Unit

Symbols used in the description of control logic are listed in the following table:

Symbol Description

Key matrix output signals

Key matrix input signals

SHIFT

Shift input character select signal

CNTL

Control key: special codes may be used

1

10 BPS/300 BPS select signal

Half/Full-duplex select signal

SPEED

DUPLEX

MODE

NUMERIC

REPEAT

CARRIER LEAD

ERROR LED

POWER LED

+5V

(VCC)

On/Off-line select signal

Numeric; 10-key mode select signal

Repeat signal

Carrier indicating LED

Error indicating LED

Power indicating LED

+

5V power supply for logic

+

12V power supply for logic

-

12V power supply for logic

+8V power supply for motor

4-

5.0 - 6.1 V power supply for thermal head

GND

Signal ground

MGND

Magnet ground

Frame ground

Transmitter data

Receive data

Data set ready

TxD

RxD

-

DSR

-

INH

Inhibit

Modem/RS232C receive data select switch sianal

SD

RD

-

DTR

-

X1

I

-

X4

Send data

Receive data

Data terminal ready

Drive signals to transistors of the X-motor

Drive signals to transistors of the Y-motor

-

-

--

..

photo interrupt signal

I

1

6

1

Head release solenoid signal

1

Drive signals to transistors of the thermal matrix

Figure

1-10.

Control Logic Block Diagram

-0

.-

-

<0

0

c

Ill

0

Ev

-

0

Illco

0

J-

J-01

05

rL

I-=

Figure

18

22

I

POWER ON Reset

I

When the POWER switch is ON, a Reset signal of about

20

ms is produced by causing a delay in activa-

!!@

tion of lC*s input voltage "d" by C and

R.

A Reset signal resets the encoder, USART, and the data gate,

and a Reset signal resets pCPU and the clock. The timing chart as of POWER ON Reset is as follows:

POWER

ON

+

5v

RESET

RESET

Schmitt Trigger Inverter

RESET

-K

Figure

$9.

kt@

pCPU

and

Peripheral Circuits

The pCPU is made up of the block composition shown below:

Programmable Keyboard Control: Keyboard interface used for an @-bit pCPU.

It

scans each signal input

through the keyboard and converts

it

into ASCII code in accordance with the instruction from the

pCPU control.

8

EP ROM: 4K-byte EP ROM.

USART {Universal

Synchronous/Asynchronous

Receiver/Transmitter) USART is used for the peripheral

circuit, and programming is done through the CPU. USART receives parallel data from the CPU and,

after conversion, transmits

it

into serial data.

It

also receives serial data and, after conversion into

parallel data, transmits

it

to the CPU.

pCPU: The pCPU is an 8-bits microcomputer for parallel processing with RAM 128

X

8

bits, an l/O

port, an 8-bit timer/counter, a control circuit, etc. on one chip.

ROM and l/O port may be externally connector

l/O Port (l/O expansion port:

It

is possible to expand a 4-bit l/O port of I set to a 4-bit l/O port of four

sets by one chip.

Data

is

input from port 2 at the activati~n of the PROG terminal, processing is made in accordance

with the mode, and the data is then output through the designated port.

+CPU Controls the

l/F

Circuit

INITIAL

PRINT

OUT

0

NUM

S.W

SEARCH

DG

OUT

I

FIFO

FULL

*

MODEM

F\

CHARAC%ER

GENEFtATOR

ADDRESS

SET

1

CHARACTER

Fl

Carriage

Return

and

Line Feed Motor Control

Two pulse motors are used in the printer unit.

XI - X4

make carriage returns, and

Y1 - Y4

make line

CN

I

Carriage

I

Retu&Motor

Figure

20.

1

Method for excitation of the carriage return and line feed motors:

When

'*L"

is input to the PROG terminal in accordance with an instruction from the

pCPU, a

motor

0x-

citation signal is output to an

110

expansion port.

Port

4

(P40 - P431

is for carriage return signals, and port 5

tP50

-

P531 is for line feed signds.

A

signal output to port 4 or port 5 is driven by a transistor and drives the applicable motor.

Carriage

Return

Motor

Excitation in

4-

X

direction

Excitation in

-

X

direction

Line Feed

Motor

Figure

21.

Timing

Chart

28

Head Release Solenoid

The solenoid releases the head from the platen when:

0

The carriage is returning.

0

The

PAPER

ADV

key

is

kept pressed.

11

I/O

Port

8243

f7t

Jr

MGND

Figure

22.

VMM +7.5V, which is commonly used for the carriage return motor and the line feed motor, is also

used as the power supply for driving the solenoid. When P70 becomes low, the transistor turns on and

the solenoid is activated.

Thermal

Head

The thermal head is used for printing with dots when the thermal head is heated by data pulses which are

processed by the

pCPU

and then driven by the transistors.

Control Logic

I

Head

Figure

23.

VTT

4-5.0-6.1V

is used as the power supply for driving the thermal head.

Photo

Interrupt

The photo interrupt determines the print start position.

a

During carriage return, it detects an

signal, sends a signal to the

pCPU,

and causes the carriage return

motor to stop.

Light emitting element

Light emitting

Light receiving element

(Photo Transistor)

11

I/O Port

P60

8243

Figure

24.

unit

Figure

25.

Parity

Check

and

Error

Indication

This equipment is provided with the parity check function. Parity check has three modes (i.e., EVEN. ODD,

and NONE) and any one of them may

be

selected by moving a switch to the desired choice.

*

Parity Check

-%-'\

/--+-'-v-'-

START

^V

Parity STOP (STOP

Bit)

Bit

DATA

Bit Bit Bit

Figure

26.

EVEN check:

Parity error lamp lights up when DATA Bit

-I-

Parity

Bit

=

Odd number.

ODD check:

Parity error lamp lights up when DATA Bit

4-

Parity Bit = Even number.

NONE:

No parity check is made. (No error indication is made.)

(Caution: Parity error lamp will not go out if the parity check mode is switched to NONE

while

it

is lit.)

Error Indication

When a parity error occurs, the following situations arise.

1.

The error lamp (LED) is kept

lit.

2.

The printer prints backward question marks.

NOTE: Reset cannot be made unless power is OFF.

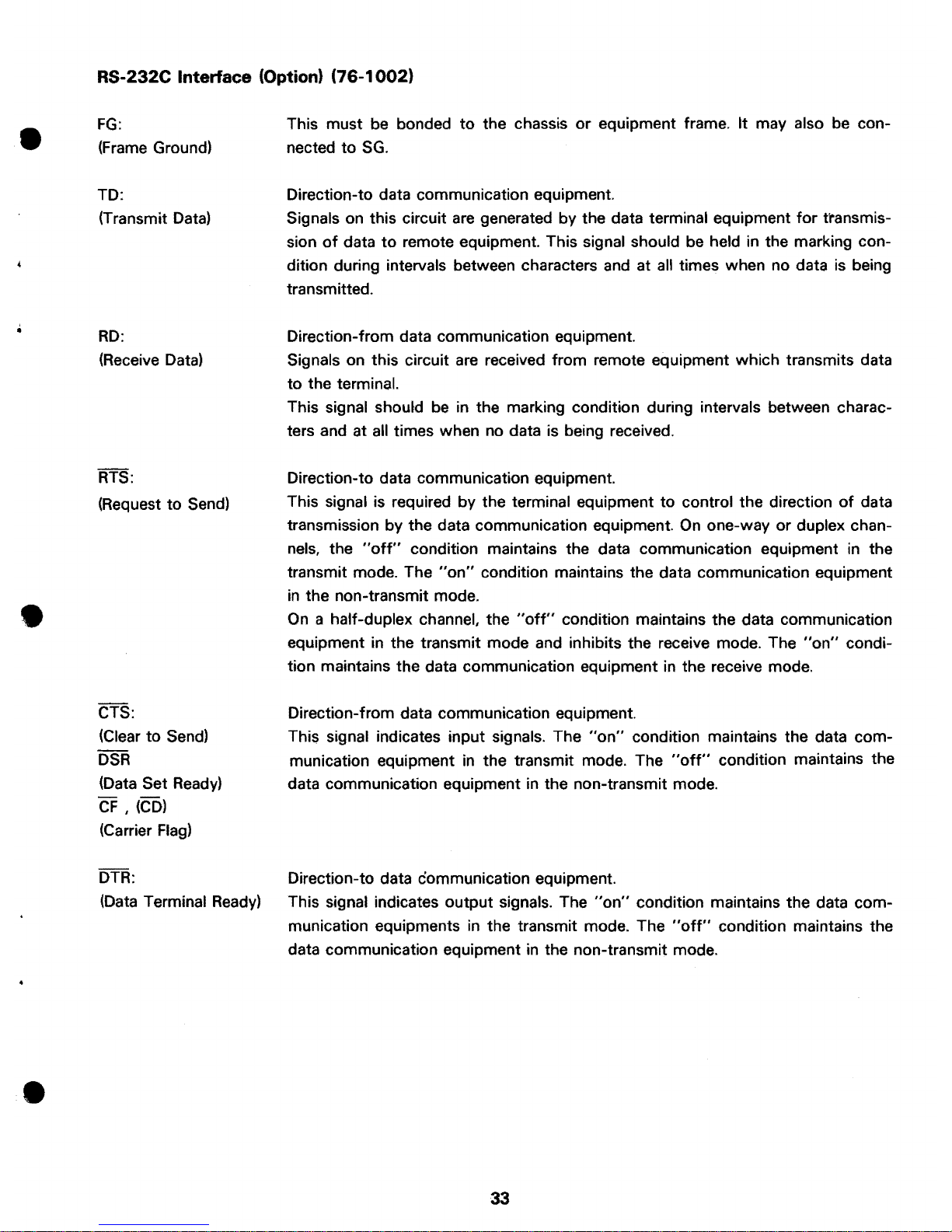

RS-232C

Interface

(Option)

(76-1

002)

FG:

(Frame Ground)

TD:

(Transmit Data)

0

RD:

(Receive Data)

-

RTS

:

(Request to Send)

-

CTS:

(Clear to Send)

-

DSR

(Data Set Ready)

-

CF

,

(CD)

(Carrier Flag)

-

DTR:

(Data Terminal Ready)

This must be bonded to the chassis or equipment frame.

It

may also be con-

nected to SG.

Direction-to data communication equipment.

Signals on this circuit are generated by the data terminal equipment for transmission of data to remote equipment. This signal should be held in the marking condition during intervals between characters and at

all

times when no data is being

transmitted.

Direction-from data communication equipment.

Signals on this circuit are received from remote equipment which transmits data

to the terminal.

This signal should be in the marking condition during intervals between characters and

at

all times when no data is being received.

Direction-to data communication equipment.

This signal is required by the terminal equipment to control the direction of data

transmission by the data communication equipment. On one-way or duplex chan-

nels, the "off" condition maintains the data communication equipment in the

transmit mode. The "on" condition maintains the data communication equipment

in the non-transmit mode.

On a half-duplex channel, the "off" condition maintains the data communication

equipment in the transmit mode and inhibits the receive mode. The "on" condition maintains the data communication equipment in the receive mode.

Direction-from data communication equipment.

This signal indicates input signals. The "on" condition maintains the data com-

munication equipment in the transmit mode. The "off" condition maintains the

data communication equipment in the non-transmit mode.

Direction-to data c'ommunication equipment.

This signal indicates output signals. The "on" condition maintains the data com-

munication equipments in the transmit mode. The "off" condition maintains the

data communication equipment in the non-transmit mode.

Interface Signal Pin Assignment

Pin 13

Pin

1

Figure

27.

I

1

pin

1

Signal name Signal name

4

RTS

17 NC

5

CTS

18 NC

7 SG

20

DTR

--

8 CD

2

1 NC

Figure

28.

Timing

Chart

-

RTS

(Request

to

Send)

1-1

300BPS

RD.,

SD

(Odd, Even Parity)

'

1

Bit

DATA bit

(7

Bits)

1

Spacep,

;

I

-START Bit

1

LSTOP

Bit

-Parity Bit: Odd.

Even

Mark

100

mS

Mark

--

RD.,

SD

(Odd, Even Parity)

-

START Bit

"Parity

Bit:

Odd,

Even

Mark

I

I

!

(NON-Parity)

DATA Bit

(7

Bits)

I

(

'STOP

Bit

+

-START

Bit

-NO"-parity

Bit

-

CTS

(Clear

to Send)

L

-

-

DTR

(Data

Terminal Ready)

I

i-7

space

I

(Data Set Ready)

1

Bit DATA Bit

(7

Bits)

1

Bit 1 Bit

START Bit

i

-

-

1-

-

power supply unit

T-

Printer Unit

Fro

Board

4-5.0-6.1V

Control Unit

J

(Handset)

4/

Disassembly

Instructions

Components

Portable Data Terminal

Upper Cover Unit

Keyboard Unit

Modem PCB Unit

Control Unit

'-A

Power supply Unit

I

b------d

RS-232C (Cat.No.76-1002)

Optional Board

Figure

31.

Base Cover

38

0

Removal of the Upper Cover Unit

Removal of Front Cover. Unfasten both right and

left clips and open the front cover

(2)

slightly. Pull

up and remove the front cover from the Upper

Cover Unit

@.

Removal of Rear Cover.

Open the rear cover at a

45'

angle to the Upper

Cover.

Bend the rear cover

(3)

as shown in Figure

33

and

remove the axis of rotation from the Upper Cover

unit.

Removal of Option Cover.

Insert a finger in to the concavity of the option

cover

(4),

pull up, and remove the option cover.

Removal of Inner Cover.

Loosen the two screws

(6)

and remove the inner

cover

(.

Figure

33.

*

Disassembly of the Base Cover Unit

The Base Cover Unit is composed of seven units.

G)

Keyboard Unit

(2)

Printer Unit

@

Modem Unit

@

Control Board Unit

@

Power Supply Unit

(6)

Optional Board

@

Base Cover

Note: There

is

need to loosen any screws to remove the above unit except the one for the

Power Supply Unit.

Figure

35.

Removal of the Keyboard Unit

Remove the connector

(T)

connected to the Control

Board Unit.

Figure

36.

Figure

37.

0

How to Dismount the Printer Unit

1.

For dismounting the Printer Unit from the Base Cover Unit, first remove the printer rocks

yQ)

on the

side

of

the

catch, and

second

disengage

the catch

@

from the printer frame

@.

The catch at-

taches the Printer Unit to the Printer frame

(2)

at two places on the side of the CR motor assembly

(T)i

While holding the top of the catch, turn

it

in the direction shown by arrow @ in Figure

38.

Figure

38.

2

Remove the two screws@ on the side of the CR motor assembly and the LF motor assembly, and

then, remove the two screws, at the frame ground wire of the CR motor assembly and the LF

motor assembly.

3.

Disconnect the CR motor's lead wires @and the LF motor's lead wires

(5)

from the Control Unit at

the connectors.

4.

Disconnect the solenoid assembly's lead wires @and the photo-interrupter's lead wires

(?)

from the

Control Unit at the connectors.

5.

Extract the flexible printed circuit board of the thermal head assembly from the Control Unit.

6.

Upon completion of these steps, disengage the Printer Unit from the catch on the side of the LF

motor

0.

Now the Printer Unit may be dismounted from the Base Cover Unit.

How to Dismount the Modem Unit

1.

Dismount the Keyboard Unit and the Printer Unit from the Base Cover Unit. The location of the

Modem Unit will become clear.

Modem

Interface

Cable

Figure

39.

2.

Extract the modem interface cable from the Control Unit.

3.

The Modem Unit is held in place by catches

@

-

(4)

located on the Base Cover as shown in Figure

40.

Figure

40.

4.

In rt-der to dismount the Modem Unit, deform the front portion of the Base Cover by forcing

it

in

the direction of arrow

(K)

(shown in Figure

41)

and disengage the Modem Unit from catches

@I

and

@).

Although the Modem Unit is held by catches

(3)

and

0,

as shown in enlarged view

@

(Figure

41),

the Modem Unit may be disengaged from them, as shown in enlarged view

(c)

(Figure

411,

when the ower cover is deformed. The lower cover will return to its original shape when

it

is

released.

Figure

41.

5.

Then disengage the Modem Unit from catches

(T)

and

(2)

on the other side. The Modem Uni

becomes free.

How

to Dismount the Control Unit

1.

In

order to dismount the Control Unit, first dismount the Printer Unit and the Keyboard Unit frc

the Base Cover Unit.

Figure

42.

2.

The Control Unit is held in place by catches

@

-

0,

located on the base cover

(S).

and by screws

0-

3.

Extract the modem interface cable

@,

which is used for connection with the modem unit, from the

9

Control Unit, and remove the Control Unit set screws

(Q.

4.

If an optional board is located, remove

it

from the board guides@)and the connector

(.

5.

Disconnect the power line from the Power Unit from the connector

0.

6.

Be sure that all of the lead wires for connection with other units have been disconnected from the

keyboard connector

$2).

the CR motor connector

0,

the photo-interrupter connector

04)'

the

LF

motor connector

OS),

the solenoid connector

@,

etc.

7.

Push the Control Unit against catches

@

and@

8.

Disengage the Control Unit from catches

@

and

(?)

by deforming the rear portion of the lower

cover (force

it

in the direction shown by the arrow). When force is applied to a point of the lower

cover adjacent to catch@, catch (?)will be shifted from location

@

to location@ and the Control

Unit can be disengaged from catch

(7)

The Base Cover @will return to its original shape when

it

is

released.

9.

When the Control Unit is disengaged from catches @and@, disengage

it

from catches @and

(5)

The Control Unit is then free.

0

How to Dismount the Power Unit

1.

In order to dismount the Power Unit, first dismount the printer unit from the base cover unit.

2.

Disconnect the fan motor lead wires from terminal

0.

3.

Disconnect connector@ from the Control Unit,

4.

If an optional board is located, remove

it

from its guides and connector.

5.

Remove the four screws

(2)

retaining the Power unit@.

6.

Disengage the Power Unit

(5)

from catches

(3}

and

(4).

The Power Unit

CS)

is then free and can be

removed when

it

is gently lifted upward.

The Base Cover Unit

The Base Cover Unit is the base unit to which all units except the Upper Cover Unit are mounted. It is

equipped with catches for attaching these units. Only the Cover Unit is left when all of these units are

dismounted from

it.

Replacement of the Paper Cutter

I

1.

Remove the Paper Lock Spring from the Head Shaft Lock E-ring.

2.

Remove E-rings from both sides of the Holder Shaft and take out the Holder Shaft.

3.

Separate the Lower Guide and the Paper Cutter.

Remove the Paper Lock Spring from the Paper Cutter and install it on the new Paper Cutter.

Figure

46.

5.

Combine the upper Paper Cutter with the Lower Guideand install

it

on

the Frame with the Holder

Shaft.

6.

Hook the E-ring to the Holder Shaft.

0

Replacement of the

CR

Motor

-

The Timing Belt

can

be

detached by removing two

screws

((2)

and

(3))

and taking out the Motor

Timing Pulley.

Take out screw

(1)

(Motor Set Screw) and remove

the Motor from the Frame Unit. Disconnect the

connector to control P.C.B.

Install the

new

CR Motor on the Frame Unit (do not

tighten the Motor Set Screws yet).

Hook the Timing Belt to the Motor Timing Pulley

and install the Timing Pulley on the Motor Shaft.

Set the position of Motor Timing Pulley so that

it

is

10 mm from the Motor Supporter or 13 mm

from the Motor face.

Move the head

till

the left edge of platen.

(see

Figure

47)

Push the middle of timing belt by the tension gaze.

Set the position of

CR

motor

till

the tension gaze

indicate 30

-

60

g.

Tiahten the Motor Set Screws.

CR

Motor

Assembly

Figure

47.

Figure

48.

Replacement of the LF Motor

1.

Remove the two mount screws

(0

and

@1

on the Motor Timing Pulley. Separate the Motor Timing

Pulley and Belt.

2.

Take out the LF Motor Set Screw

@,

and disconnect the connecter from the control

P.C.B.

Motor

Timing

Pulley

ÑÑÑÑÃ

Figure

49.

3.

Attach the New LF Motor to the Motor Timing Pulley. The distance between motor shaft and platen

shaft is

37.6

Â

0.2

mm

(see

Figure

5-41.

\

The Motor timing Pulley should

be

installed 3 mm from the Motor Supporter, or 6 mm from the

Motor face.

Install the Belt to both Motor Timing Pulleys. (Install

the Platen side first.) Attach the LF Motor with

screw

Motor

Timing

Pulley

,/

I,

I

0

3

Motor

Timing

Pulley

L/F

Motor

Timing

Belt

Figure

50.

Replacement of the Belt (LF Motor Timing)

1.

Take out the two mount screws @and@) from the Motor Timing Pulley. Remove the Motor Timing

Pulley

and

Belt.

(see

Figure

50)

2.

Install the new Belt on the Motor Timing Pulley.

Mount the Motor Timing Pulley on the Motor Shaft and tighten screws @and@

Motor Timing Pulley should

be

installed 6 mm from the Motor face. (see Figures

49

&

50)

Replacement of the Solenoid (Refer to Figure 49)

1.

Remove the Tension Spring from the Solenoid plunger.

2.

Take out the two screws

@

Remove the Solenoid from the Frame Unit.

Disconnect the connector from the control P.C.B.

3.

Take out the two screws

(@)

and remove the Head Lever from the Head Shaft.

4. Take out the Spring Pin

Q).

Remove the Plunger and the Head Lever.

5.

Install the new Solenoid Plunger and the ~ead' Lever with the Spring Pin

(7).

6.

Attach the Head Lever to the Head Shaft with the two screws

0.

7.

Insert the plunger and the Head Lever in to the new Solenoid and tighten the set screws

@.

8. Head Lever adjustment

Establish the working position of the Solenoid; then adjust the gap between the head of the Hood

Assembly and the platen.

Attach the two mounting screws

<.

The plunger should move smoothly.

9.

Hook the Tension Spring to the Head Lever.

Adjust the Thermal Head pressure with the adjustment Nut

@.

(Refer to Figure

49.

Thermal Head

Assembly

Replacement.)

10. Adjust the Thermal Head Assembly pressure as follows:

Using a Spring Gauge, push on the bottom of the Thermal Head Assembly at point B.

Adjust the pressure level with Nut

(6).

A pressure level of 150 - 185g should

be

required to move

the head. (use tension gaze)

NOTE: Item

10

adjustment is related to printing Density. Therefore, this adjustment should

be

done

with regard to Printing Density Adjustment on the P.C.B. If the Pressure is high. printing should

be dark.

8

Replacement of the CR Timing Belt

In order to remove the

CR

timing belt, first reverse the Printer Unit. Remove position plate 1 from

the thermal head assembly.

Printer

Frame

\~ead shaft

Figure

51.

As heads of position plate set screws@ are seen only partly in this state,

push the thermal head

assembly

(3)

in the direction of arrow

@

so that the screw heads are exposed. Then remove the

position plate set screws and the position plate.

Return the Printer Unit to its original position and remove the

CR

Motor Timing Pulley. (Follow the

instructions given earlier in this section.)

The CR timing belt can be separated from the Printer Unit. In order to install a new belt, fit the belt

on the motor timing pulley on the left-hand side of the Printer Unit; then fit it on the motor timing

pulley on the right-hand side; and, finally, install the motor timing pulley on the motor shaft. (Refer

to instructions given earlier in this section under "Replacement of the

CR Motor" regarding the in-

stallation procedures.)

Again, reverse the Printer Unit, attach the CR timing belt to the Thermal Head Assembly, and set

position plate

1

with the belt suitably held.

Replacement of the

CR

timing belt is then completed.

Adjustment

Print Contrast

Note:

When making adjustments, the specified Roll Paper

should be installed.

Improper paper may cause damage to the Thermal

Head.

Open the cover to make contrast adjustments to the

Variable Resistor {VR-1). (see Figure

53.)

Turn clockwise to increase contrast. To decrease contrast turn counterclockwise.

Power Switch

n

PSU

Figure

52.

Variable Resistor (VR

1

)

(\

OFF

[

CONTRAST

Figure

53.

54

a

FSK Frequency Adjustment

10

CN1

1

VR2

0-

0

VR3

VR

1

CN3g CN2

g

ffg

-I

mo

z

Figure

54.

Figure

55.

Note:

Do not touch Variable Resistors (VR1, VR2, and VR3)

except for maintenance purposes. (Precise adjustment

was made at the factory before shipment.)

*

A

Frequency Counter capable of measuring frequencies

from 1 to 3

k

Hz

is required for adjustments.

Receiving Frequency Adjustment (VR1)

(See Figure 55.)

Power ON

I

i

Set Speed SW

to

300

Baud

i

Set Mode SW

to ON LINE

+

Ready to Adjustment

Connect to

4-7

telephone line

Y

Receive Test Data

from Remote Computer

I

I

Note:

Repetition of the

Alphabet

(A.B.C.D

.....

X.Y.Z.A.B.C.D

...I

Ã

Print Received

is

recommended for

Data

test

data

I

t

Turn

VR1

so the

I

1

Test Data printing correctly.

1

1

Adjust for correct printing

1

Adjustable range

I

I

Figure

56.

Center

Adjust

for correct

printing

Adjustable range

Figure

57.

Remarks:

The reference frequency is determined by time constants of VR1, R16, and C11. For making adjustments, input an analog data signal to MIC

IN

and turn VR2.

Remarks:

Audible sound of

1,070

Hz

is determined by time constants of

VR2, R26,

and

C17.

When adjust-

ment is required, set TxD terminal to

"H:

level and turn

VR2.

Identically, audible sound of

1,270

Hz

is determined by time constants of

YR2, R26, VR3, R27,

and

C17.

For adjustment, set TxD terminal to

"L"

level and turn

VR3.

Note:

In order to make an adjustment in audible sound of

1,070

Hz

and

1,270

Hz,

make a setting of

1,070

Hz

by turning

VR2.

If an adjustment of

1,270

Hz

by

VR3

is made first and an adjustment of

1,070

Hz

by

VR2

is made

next, the setting of

1,270

Hz

will be deviated.

61'

Troubleshooting

1

Problems at Power-ON 03estore) Time

1

POWER

ON

1

Jump to

the

step following

operation

Input

voltage

the power

connector

the power

unit

Replace

the contml

9roblerns

in

Operation

Reset

the CR-motor

connector

Reset

the LF-motor

(OPTION)

(E

1

Replace the

host computer

control

ves

Replace

the

RS-232Gcontrol

connector

EXCHANGE

S.W

w

Replace the

RS-232C

EXCHANGE S.W

I

unit

I

Power

Supply Board

Assembly

(Top

View)

GRN

-FG

GRN ACN ACH

WHI BLK

l

2

BLK WHI

ON

SWI

OFF

T

l

JPI JP2

C14

-41-

I I

C12 ClI

Ill

C13

[ITT

F2

FAN

BLUE

&^

RED

5

BLUE

6

v

I0

7

YEL

>WER

9

BRN

cia

3

RED

4

ORN

8/

Wiring Diagram

FAN

Modem

Unit

------IÑ----

*----

---

I

I

Power

Supply

Board

1

1

-

AC Line

---

DC Line

-

Signal Line

Keyboard

Unit

ELECTRICAL PARTS LIST

CONTROL UNIT

W.

NO.

R 1

R2

R3

R4

R5

R6

R 7

R8

R9

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

R2 1

R22

R23

R24

R25

R26

R27

R28

R29

R30

R3 1

R32

R33

R34

R35

DESCRIPTION

CONTROL UNIT

RESISTORS

2.2K

0

Â

5% 1 /4W : CARBON FILM

3.3Kfl ±5 1/4W

:

CARBON FILM

10K0 ±5 1 /4W

:

CARBON FILM

1 KO

Â

5% 1 /4W : CARBON FILM

10KH ±5 1 /4W

:

CARBON FILM

1 KII ±5 114W

:

CARBON FILM

3.3K

0

Â

5% 1 /4W : CARBON FILM

470

0

Â

5% 1 /4W : CARBON FILM

47011 ±5 1/4W

:

CARBON FILM

5.1KH ±5 1/4W

:

CARBON FILM

2KH 25% 1/4W

:

CARBON FILM

1 K

Il

Â

5% 1 /4W : CARBON FILM

10K0 ±5 1 /4W

:

CARBON FILM

4.7K0 ±5 1 /4W

:

CARBON FILM

4.7K0 ±5 1/4W

:

CARBON FILM

10K0 ±5 1/4W

:

CARBON FILM

5.1K11 ±5 1/4W

.

CARBON FILM

4.7K0 ±5 1 /4W

:

CARBON FILM

10Kfl ±5 1 /4W

:

CARBON FILM

1 OK

0

Â

5% 1 /4W : CARBON FILM

4.7K

0

Â

5% 1 /4W : CARBON FILM

4.7K

0

Â

5% 1 /4W : CARBON FILM

4.7KI1 ±5 1/4W

:

CARBON FILM

100K0 ±5 1 /4W

:

CARBON FILM

2200 ±5 1/4W

:

CARBON FILM

2200 ±5 1/4W

:

CARBON FILM

220

H

Â

5% 1 /4W : CARBON FILM

2200

Â

5% 1 /4W : CARBON FILM

220Il 25% 1 /4W

.

CARBON FILM

2200 ±5 1 /4W

:

CARBON FILM

2200 25% 1 /4W CARBON FILM

1

OK

0

Â

5% 1 /4W : CARBON FILM

10KIl ±5 1 /4W

:

CARBON FILM

10KO ±5 1/4W

:

CARBON FILM

220O ±5 1 /4W

:

CARBON FILM

RS PART NO.

MANUFACTURER

PART NUMBER

REF. NO.

R36

R37

R38

R39

R40

R4 1

R42

R43

R44

R45

R46

R47

R48

R49

R50

R5 1

R52

R53

R54

R55

R56

AR 1

AR2

AR3

C 1

C2

C3

C4

C5

C6

C 7

C

8

C 9

C10

C11

C12

DESCRIPTION

4700 ±5 1W

:

METAL FILM

2200 ±5 1/4W

:

CARBON FILM

100K0

Â

5% 1 /4W : CARBON FILM

330

Â

5% 1 /4W : CARBON FILM

470

0

Â

5% 1 /4W : CARBON FILM

4700 ±5 1/4W

:

CARBON FILM

33011 ±5 1 /4W

:

CARBON FILM

22011 ±5 1/4W

:

CARBON FILM

2200 ±5 1/4W

:

CARBON FILM

220l1 ±5 1/4W

:

CARBON FILM

220

0

Â

5% 1/4W : CARBON FILM

220

0

Â

5% 1 /4W : CARBON FILM

2200 ±5 1 /4W

:

CARBON FILM

220a ±5 114W

:

CARBON FILM

22011 ±5 1/4W

:

CARBON FILM

470O ±5 1W

:

METAL FILM

22011 25% 1/4W

:

CARBON FILM

1 KO

Â

5% 1 /4W : CARBON FILM

47011 25% 1 W

:

METAL FILM

22011 ±5 1/4W

:

CARBON FILM

2200 ±5 1/4W

:

CARBON FILM

33K0 ±5 8 ELEMENTS

:

ARRAY

4.7K0 ±5 8 ELEMENTS

:

ARRAY

3.3K11 ±5 8 ELEMENTS

:

ARRAY

CAPACITORS

470pF

Â

10% : CERAMIC

820pF

Â

10% : CERAMIC

33pF ±5

:

CERAMIC

0.1p.F -20

to

+80% 25V : CERAMIC

0.1 FF -20

to

+80% 25V : CERAMIC

0.1 p.F -20

to

+80% 25V : CERAMIC

0.1p.F -20

to

+Book 25V : CERAMIC

0.1yF -20

to

+80% 25V : CERAMIC

0.1yF -20

to

+80% 25V : CERAMIC

0.1p.F -20

to

+80% 25V : CERAMIC

0.1p.F -20

to

+80% 25V : CERAMIC

0.1 p.F -20

to

+80% 25V : CERAMIC

RS PART NO,

AN01 69EGE

AN01 49EEB

AN01 49EEB

AN01 49EEB

AN01 49EEB

AN01 49EEB

AN0 149EEB

AN01 49EEB

AN01 49EEB

AN01 49EEB

AN01 69EGE

AN01 49EEB

AN01 69EGE

AN0 149EEB

AN01 49EEB

ARX0305

ARX0306

ARX0305

ACC471 JNGP

ACC821 JNGP

ACC330JNGP

MANUFACTURER

PART NUMBER

1601 1762

161 14221

16114104

161 14331

161 14471

16114471

16114331

16114221

16114221

161 14221

161 14221

161 14221

16114221

16114221

16114221

1601 1762

16114221

161 14102

1601 1762

16114221

16114221

1601 7055

1601 7056

1601 7055

REF.

NO.

DESCRIPTION

lOpF 220% 25V

:

ELECTROLYTIC

0.1 pF -20 +80% 25V

:

CERAMIC

0.1 pF -20 +80% 25V

:

CERAMIC

0.1 pF -20 +80% 25V

:

CERAMIC

0,lpF -20 +80% 25V

:

CERAMIC

0.1pF -20 +80% 25V

:

CERAMIC

0.1 pF -20 +80% 25V

:

CERAMIC

0.1pF -20 +80% 25V

:

CERAMIC

10pF *20% 100V

:

ELECTROLYTIC

10pF ±20 100V

:

ELECTROLYTIC

10pF ±20 100V

:

ELECTROLYTIC

TRANSISTORS

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SC2655Y

2SA1020Y

2SC2655Y

2SC2655Y

2SA1020Y

2SC2655Y

2SC2655Y

2SC2655Y

CONNECTORS

7P

:

5045-07A

7P

:

5045-07A

8P

:

350212-1

FF-09B-003

RS PART NO.

W1ANUFACTURER

PART NUMBER

1EF. NO. DESCRIPTION

HEADER

:

34P

FF- 10-001

HKP-16FD2-3AT

4P

:

5045-04A

3P

:

5045-03A

.C.'S

HD74LS93P : TTL

HD7404

:

TTL

SN74LS32N

:

TTL

HD74LS03P

:

TTL

HD74LSOO

:

TTL

SN74LS161N

:

TTL

HD74LS93P

:

TTL

HD74LS93P

:

TTL

HD74LS93P

:

TTL

SN74LS08N

:

TTL

HD74LS93P

:

TTL

SN74LS74N

:

TTL

SOFT ASS'Y

:

PT-210

SN74LS374

:

TTL

HD74LS20P

:

TTL

HD74LS93P

:

TTL

HD74LS02

:

TTL

SN74LS04

:

TTL

SN74LS 126AN

:

TTL

HD74LS14

:

TTL

MPD 8251AC

:

MOS LSI

TMP-8039-6

MPD-8279C-5

SN74LS30N

:

TTL

HD7416P

:

TTL

MPD 8243C

:

LSI I/O

HD7416P

:

TTL

HD7416P

:

TTL

HD7416P

:

TTL

SN74145

:

TTL

RS PART NO.

MANUFACTURER

PART NUMBER

REF. NO.

DESCRIPTION

DIODES

100V 1A

:

SILICON

100V 1A

:

SILICON

100V 1 A

:

SILICON

100V 1 A

:

SILICON

100V 1 A

:

SILICON

100V 1 A

:

SILICON

100V 1A

:

SILICON

100V

1

A : SILICON

100V 1A

:

SILICON

'

100V 1 A : SILICON

100V 1A

:

SILICON

1

00v

1

A

:

SILICON

100V 1A : SILICON

100V 1A

:

SILICON

100V 1A

:

SILICON

100V 1A

!

SILICON

100V 1A

:

SILICON

100V 1A

:

SILICON

MISCELLANEOUS

1C SOCKET

:

24P : ICT-246-S-T

CERAMIC RESONATOR

TOGGLE SWITCH

:

3TL-101 E-B/M

BUZZER

:

PKB8-4A0

CRYSTAL OSCILLATOR

RS PART NO.

MANUFACTURER

PART NUMBER

MODEM

PCB

UNIT

-

REF. NO DESCRIPTION

MODEM PCB UNIT

RESISTORS

100O

Â

5% 1 /4W : CARBON FILM

4700

Â

5% 1 /4W : CARBON FILM

220KO 25% 1 /4W

:

CARBON FILM

1 K O

Â

5% 1 /4W : CARBON FILM

68KO ±5 1 /4W

:

CARBON FILM

21KO

Â

1% 1 /4W : METAL FILM

825

(1

Â

1 % 1 /4W : METAL FILM

374KO

Â

1% 1/4W : METAL FILM

1 8.9~0

Â

1 % 1 /4w

:

METAL

FILM

732O Â 1% 1 /4W : METAL FILM

309KO

Â

1 % 1 /4W : METAL FILM

9.31 KO

Â

1

%

1

/4W : METAL FILM

1.78KO

Â

1

%

1 /4W : METAL FILM

169KO

Â

1

%

1 /4W : METAL FILM

2.2KO ±5 1/4W

:

CARBON FILM

18.2KO

Â

1 % 1 /4W : METAL FILM

200Kft ±5 1/4W

:

CARBON FILM

100K O

Â

5% 1 /4W : CARBON FILM

5 1 OK O

Â

5% 1 /4W : CARBON FILM

51OKO 25% 1 /4W

:

CARBON FILM

33KO ±5 1 /4W

:

CARBON FILM

220KO ±5 1 /4W

:

CARBON FILM

5.1KO ±5 1/4W

:

CARBON FILM

220O ±5 1 /4W

:

CARBON FILM

3.9KO ±5 1/4W

:

CARBON FILM

162KO ±I 1 /4W: METAL FILM

27KO ±5 1/4W

:

CARBON FILM

100ft 25% 1/4W

:

CARBON FILM

22KO

±5

1/4W : CARBON FILM

10KO ±5 1/4W

:

CARBON FILM

100KO ±5 1 /4W

:

CARBON FILM

56KO 25% 1/4W

:

CARBON FILM

1 OKft ±5 1 /4W

:

CARBON FILM

120KO ±5 1 /4W

:

CARBON FILM

B2KO ±5 1 /4W

:

CARBON FILM

RS

PART NO.

AX9267

AN01 69EEB

AN021 46EE

AN0653BEE

AN654BEE

AN655BEE

AN0656BEE

AN0657BEE

AN0658BEE

AN0659BEE

AN0660BEE

AN021 1 BEE

AN0392EEB

AN0252EEB

AN0237EEB

AN0589BEE

AN0330EEB

AN0360EEB

MANUFACTURE!

PART NUMBER

REF. NO.

R37

R3B

R39

R40

R41

VR 1

VR2

VR3

C 1

C2

C3

C4

C5

C6

C7

CB

C9

C10

C11

C12

C13

C14

C15

C17

C18

C19

C20

C2 1

C22

C23

C24

C25

C26

DESCRIPTION

1 OK

ft

Â

5% 1 /4W : CARBON FILM

470Kft ±5 1 /4W

:

CARBON FILM

2.7MO 25% 1 /4W

:

CARBON FILM

10KO 25% 1 /4W

:

CARBON FILM

470O ±5 1/4W

:

CARBON FILM

10KO +5%

:

VARIABLE

10KO ±5

:

VARIABLE

10KO ±5

:

VARIABLE

CAPACITORS

100pF

+

20% 1 6V : ELECTROLYTIC

0.1 pF

Â

10% 50V : POLYESTER FILM

4700pF ±2 50V

:

POLYESTER FILM

4700pF ±2 50V

:

POLYESTER FILM

4700pF ±2 50V

:

POLYESTER FILM

4700pF ±2 50V

:

POLYESTER FILM

4700pF ±2 50V

:

POLYESTER FILM

4700pF 22% 50V

:

POLYESTER FILM

0.047pF

Â

10% 50V : POLYESTER FILM

0.1

uf

Â

10% 50V : POLYESTER FILM

22000pF ±5 50V

:

POLYESTER FILM

0.047pF

2

10% 50V : POLYESTER FILM

0.01 pF

Â

10% 50V : POLYESTER FILM

0.1 pF

Â

10% 50V : POLYESTER FILM

0.0047pF

-8-

10% 50V : POLYESTER FILM

0.0047pF ±5 50V

:

POLYESTER FILM

0.1 pF

2

10% 50V : POLYESTER FILM

10pF

Â

20% 1 6V : ELECTROLYTIC

1 0pF ±20 1 6V

:

TANTALUM

ELECTROLYTIC

1 0pF ±20 16V

:

TANTALUM

ELECTROLYTIC

0.01 pF

2

10% 50V : POLYESTER FILM

1 pF 220% 35V

:

TANTALUM

ELECTROLYTIC

1pF 220% 35V

:

TANTALUM

ELECTROLYTIC

100pF 220% 16V

:

ELECTROLYTIC

22pF ±20 16V

:

ELECTROLYTIC

RS PART NO.

QN0625EEB

QN0169EEB

QP7306

QP7306

QP7306

ACC104JJBP

ACC472JJGP

ACC472JJGP

ACC472JJGP

ACC472JJGP

ACC472JJGP

ACC472JJGP

ACC473JJGP

ACC104JJBP

ACC223JJGP

ACC473JJGP

ACC 104JJBP

ACC475MDAP

ACC104JJBP

ACC 106mDAP

ACC226mDAP

UANUFACTURER

PART NUMBER

8621 6300

8621 631 2

8621 6304

862 1 6300

8621 5995

8621 631 4

86216314

86216314

IDIDr-mmm

CMCM(MCMCMm

mmmmm-

(0IDID:no

-7-

r-

CMCMCMCMCMO

IDIDIDIDID't

mmmmm-

000

in

mmCM

r-

00

m

CM

TOTO%

5

EEE

E

a44

a

'2

(0

CM

0 0

CM

CM CM

r- r- r-

7

7 7

aaa

POWER

SUPPLY

UNIT

?Ef. NO.

R

1

R2

R3

R4

R5

VR

1

C1

C2

C 3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

C17

C18

C19

C20

C2

1

C22

C23

DESCRIPTION

POWER SUPPLY UNIT

RESISTORS

1

OK

ft

Â

5% 1 /4W : CARBON FILM

20Kft ±5

1

/4W : CARBON FILM

10

ft

Â

5% 1 /4W : CARBON FILM

47Kft ±5 1/4W

:

CARBON FILM

1

Oft ±5 1/4W : CARBON FILM

10KO ±20 1/2W

:

VARIABLE

CAPACITORS

0.01

pF -20

to

+80% 125V : CERAMIC

0.01 pF -20

to

+80% 125V : CERAMIC

0.022pF -20

to

+80% 125V : CERAMIC

0.022pF -20

to

+80% 125V : CERAMIC

470pF -10

to

+30% 35V

:

ELECTROLYTIC

470pF -1 0

to

+30% 35V

:

ELECTROLYTIC

ELECTROLYTIC

15000pF -10

to

+30% 16V

:

ELECTROLYTIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1pF

-20

to

+80% 50V : CERAMIC

0.1

uf

-20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1pF -20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1pF -20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.1 pF -20

to

+80% 50V : CERAMIC

0.01 MF -20

to

+80% 125V : CERAMIC

RS PART NO.

AX9268

AN0306EE8

AP7307

ACC103ZmCP

ACC 103ZrnCP

ACC474ZMCP

ACC474ZMCP

ACC477RGAP

ACC477RGAP

ACC338RFAP

ACC 159RDAP

ACC103ZmCP

MANUFACTURED

PART NUMBER

W.

NO.

DESCRIPTION

TRANSISTORS

2SD844-Y

2SA 1020-Y

2SD844-Y

2SA1020-Y

l.C.'S

AN78 1 2

:

LINEAR

pPC791 2H

:

LINEAR

AN7805

:

LINEAR

AN6531

:

LINEAR

AN6531

:

LINEAR

DIODES

I848 1

10461

6B48 1

CONNECTOR

1-480283-0

:

8P

INDUCTOR

SC-02-107 (SC-02-101)

:

COIL

MISCELLANEOUS

SOCKET CONTACT

:

170148-1

SOCKET CONTACT

:

1701 48-1

SOCKET CONTACT

:

1 701 48-1

SOCKET CONTACT

:

1 701 48-1

SOCKET CONTACT

:

1 701 48-1

SOCKET CONTACT

:

1

701 48-1

SOCKET CONTACT

:

170148-1

SOCKET CONTACT

:

1701 48-1

AC PLUG SOCKET

:

NC174

RS PART NO.

AA2SD844

AA2SA1020Y

AA2SD844

AA2SA 1 020Y

Amx5221

Amx5222

Amx5223

Amx5224

Amx5224

ADX 1777

ADX1777

ADX1778

AJ7209

ACA8262

AJ7213

AJ7213

AJ7213

AJ7213

AJ7213

AJ72 13

AJ7213

AJ7213

AJ7215

MANUFACTURES

PART NUMBER

REF. NO

F2

F

1

NFB

SW 1

T 1

DESCRIPTION

HEAT SINK

FUSE

:

0.5A

FUSE

:

4A

CONTACT

:

5298T

CONTACT. 5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

5298T

CONTACT

:

R1.25-3

'40 FUSE BREAKER

POWER SWITCH : U21 L3D9-V60-Q

TRANSFORMER

EONTACT

:

171 255-1

CONTACT

:

171 255-1

RS PART NO.

AHF1247

AHF1248

AJ7216

AJ7216

AJ72 16

AJ7216

AJ7216

AJ7216

AJ7216

AJ7216

AJ7216

AJ72 16

AJ7216

AJ7216

AJ7216

AJ7216

AJ7216

AJ7216

AJ7217

AHF- 1246

AS 1 623

ATA0993

MANUFACTUREF

PART NUMBER

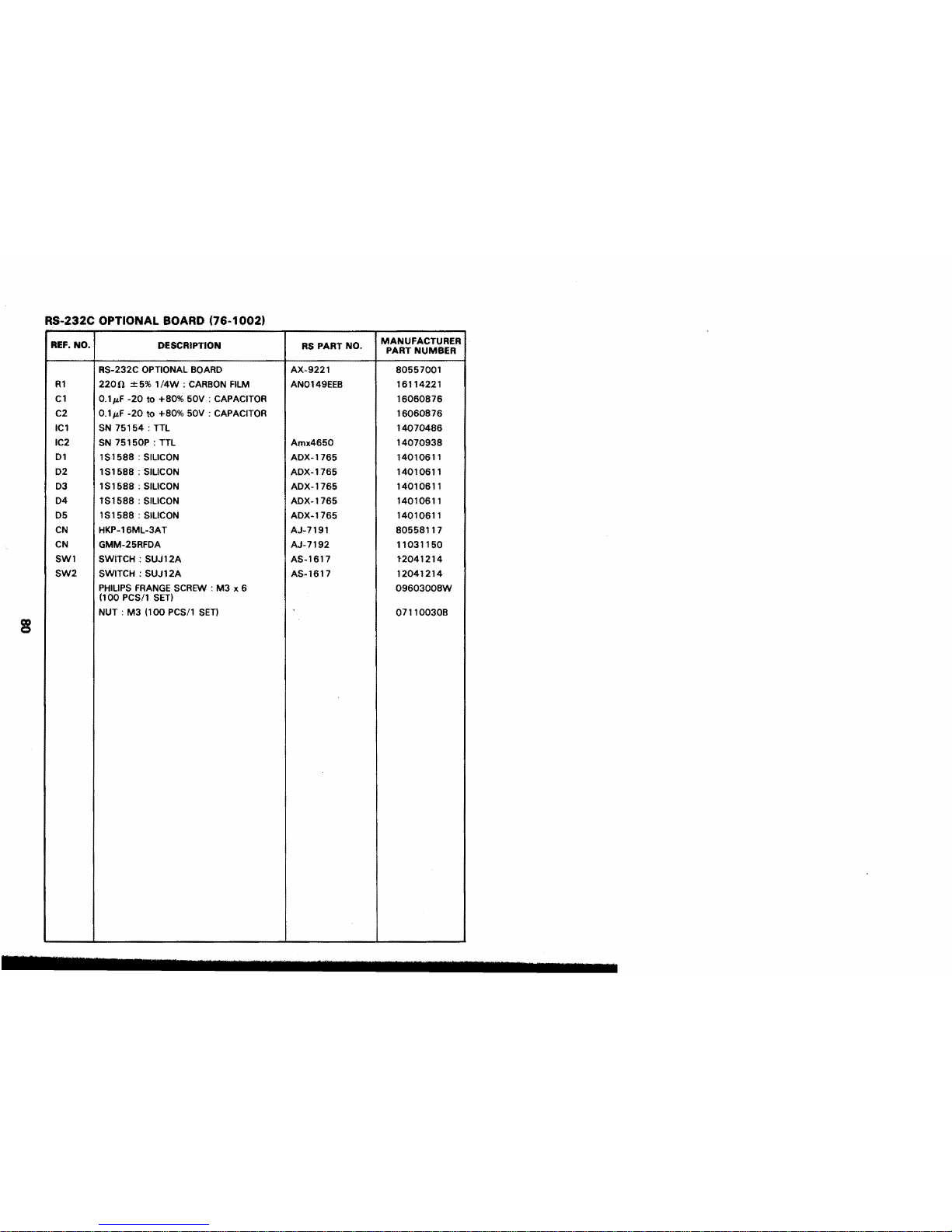

RS-232C OPTIONAL BOARD

(76-1

002)

REF.

NO,

R1

C1

C2

IC 1

IC2

D

1

D2

03

D4

D5

CN

CN

SW1

SW2

DESCRIPTION

US-232C OPTIONAL BOARD

2200

2

5% 114W : CARBON FILM

S.lp,F -20

to

+80% 50V : CAPACITOR

3.1uF -20

to

+80% 50V : CAPACITOR

SN 75154: TTL

SN 751 SOP

:

TTL

IS1588

:

SILICON

IS1588

:

SILICON

IS1 588

:

SILICON

TS1588

:

SILICON

IS1 588

:

SILICON

dKP-16ML-3AT

GMM-25RFDA

SWITCH

:

SUJ12A

SWITCH

:

SUJ12A

PHILIPS FRANCE SCREW

:

M3 x 6

(1 00 PCSII SET)

WJ

:

M3 (100 PCS11 SET)

RS

PART NO.

AX-9221

AN0149EEB

Amx4650

ADX-1765

ADX-1765

ADX- 1765

ADX-1765

ADX-1765

AJ-7191

AJ-7 192

AS-1617

AS-1617

MANUFACTURER

PART NUMBER

MECHANICAL

PARTS

LIST

COVER

UNIT

-

REF.

NO.

DESCRIPTION

UPPER COVER UNIT

UPPER COVER ASSEMBLY

REAR COVER

OPTION COVER (DUST PLATE)

UPPER COVER

FRONT COVER ASSEMBLY

FRONT COVER

MOUTH ASSEMBLY

(NON-REPAIRABLE ASS'Y)

EAR ASSEMBLY

(NON-REPAIRABLE ASS'Y)

INNER COVER

BASE COVER UNIT

BOTTOM COVER

RETAINING PLATE

RUBBER FOOT

AC CAP

FAN ASSEMBLY

FAN MOTOR

PROPERA FAN

FAN BRACKET (FAN ANGLE)

HANDLE

RUBBER BUSH

VARIABLE RESISTOR (VOLUME)

COLOR

:

FAN MOTOR

RUBBER WASHER

:

FAN MOTOR

SCREW

:

M3

x

8

(100 PCSII SET)

SCREW

:

M4 x 16 (100 PCSII SET)

SCREW

:

M3

x

8

(100 PCS11 SET)

HEXAGON HEADLESS SCREW

:

M3

x

6

(100

PCSII SET)

SCREW

:

M3

x

8

(100

PCS11 SET)

PHILIPS SCREW WITH WASHER

:

M3 x 10 (100 PCS/l SET!

RS PART NO.

1

MANUFACTUREF

PART NUMBER

PRINTER UNIT

1EF. NO.

DESCRIPTION

PRINTER UNIT

:

PT-210

LOWER GUIDE

HOLDER SHAFT

PAPER CUTTER ASSEMBLY

PAPER LOCK SPRING

LF MOTOR ASSEMBLY

BELT

:

LF MOTOR TIMING

MOTOR TIMING ASSEMBLY

MOTOR

SHAFT

CR PULLEY

CR TIMING PULLEY

TENSION SPRING LEVER

TENSION SPRING

HEAD LEVER

SOLENOID ASSEMBLY

(NON-REPAIRABLE ASS'Y)

PLATEN SUPPORT

PLATEN

FRAME ASS'Y

:

PT-2 1 0

CABLE ASSEMBLY

(PHOTO INTERRUPT ASS'Y)

TENSION ROLLER

SHAFT

:

TENSION ROLLER

DANCING PIPE

DANCING PIN

PRINTER FRAME

HEAD

:

SHAFT SUPPORT

CR MOTOR ASSEMBLY

MOTOR TIMING PULLEY

HEAD ASS'Y

:

PT-210

HEAD

:

SHAFT

BELT

:

CR TIMING

HEAD SPRING

POSITION PLATE

UNDER HEAD ASSEMBLY

(NON-REPAIRABLE ASS'Y)

THERMAL HEAD ASS'Y

(NON-REPAIRABLE ASS'Y)

TENSION PLATE

FG CABLE

:

LF-SOLENOID-CR

RS PART NO.

Axx5036

AHC1751

AHC1752

ART4373

ARB7602

Am4695

AB6566

ARA0455

AHC1750

ARA0456

AHC1746

ARB7603

AHC 1745

AS9183

AHC 1 748

ART4375

AZ67 19

ART4372

AHC 1749

AH4496

ART4376

AB6565

AHC1743

MANUFACTURER

PART NUMBER

REF. NO,

DESCRIPTION

FG CABLE

:

LF-CR

FG CABLE

:

CR-PSU

HEAD GUIDE

PRINTER LOCK

SCREW M3 x 10

(1

00

PCS11 SET)

SCREW M3 x 5 (1

00

PCS11 SET)

RETAINING RING

:

2MM (100 PCS11 SET)

SCREW

:

M2.5 x 4 (100 PCS11 SET)

SPRING PIN

:

2 x 8 (100 PCS11 SET)

RETAINING RING

:

5MM (100 PCS11 SET)

NUT

:

M4 (100 PCS11 SET)

SCREW

:

M3 x 8 (100 PCS11 SET)

SCREW

:

M3 x 6 (100 PCS11 SET)

WASHER

:

3MM (100 PCS11 SET)

WAVE WASHER

SCREW

:

M4 x 8 (1 00 PCSI1 SET)

RS PART NO.

MANUFACTURER

PART NUMBER

KEYBOARD

UNIT

REF. NO. DESCRIPTION

KEY BOARD UNIT

KEY TOP

:

SPACE

KEY TOP

:

SHIFT

KEY TOP

:

SHIFT

KEY TOP

:

RETURN

KEY TOP

:

CTRL

KEY TOP

:

BREAK

KEY TOP

:

RUB

OUT

KEY TOP

:

ESC

KEY TOP

:

LINE FEED

KEY TOP

:

PAPER ADV

KEY TOP

:

BACK SPACE

KEY TOP

:

REPT

RS PART NO,

MANUFACTURER

PART NUMBER

860037 13

8621 5900

8621 5901

8621 5901

8621 5902

8621 5903

8621 5904

8621 5905

8621 5906

8621 5907

8621 5908

8621 5909

86215910

1 2 1

KEY TOP : !,

I

1

86215911

1

1

2

1

KEY TOP

:

3

I

86215912

I

2

KEY TOP

.'$

2

KEY TOP

:

$

1 2 1

KEY TOP

:

$

8621 591 5

I

1 2 1

KEY TOP

:

1

86215916

1

1

2

1

KEY TOP

:

<fi

1 1

86215917

1

KEY TOP

:

Q

KEY TOP : W

KEY TOP

:

E

KEY TOP

:

R

KEY TOP

:

T

KEY TOP

:

Y

KEY TOP

:

A

KEY TOP : S

KEY TOP

:

D

KEY TOP

:

F

KEY TOP : H

REF. NO,

DESCRIPTION

1

RS PART NO.

KEY TOP

1

+

KEY TOP : Z

KEY TOP

:

X

KEY TOP : C

KEY TOP

:

V

KEY TOP

:

8

KEY TOP

:

KEY TOP : +7c

KEY TOP

:

-8'

KEY TOP : 'g

KEY TOP

:

9&

8

I

KEY TOP:

7

{

KEY TOP

:

KEY TOP

:

6>

MANUFACTURER

PART NUMBER

8621 5932

8621 5933

8621 5934

8621 5935

8621 5936

86215937

'1

1 2 1

KEY TOP:

3>

1

86215947

1

KEY TOP : 2>

1

I

KEY TOP:

,,,,

KEY TOP

:

A

KEY TOP

:

KEY TOP

:

5K'

SLIDE SWITCH

SLIDE SWITCH

SLIDE SWITCH

SLIDE SWITCH

DIODE

:

GREEN

DIODE

:

RED

10/

Exploded

Views

1

I/

Schematic Diagrams

wow

PHOTO

SUPPLY

14LSOZ

P

73

Pie

Vet

vcc

8

Pa

7,-

PROS

PW

23

CPU

7

8039

'Dl

Ill

CONTROL LOGIC

2/2

c

MIC

1H

201

0

2BZ2.7

SP

OUT

MODEM

LOGIC

2/2

POWER

SUPPLY LOGIC

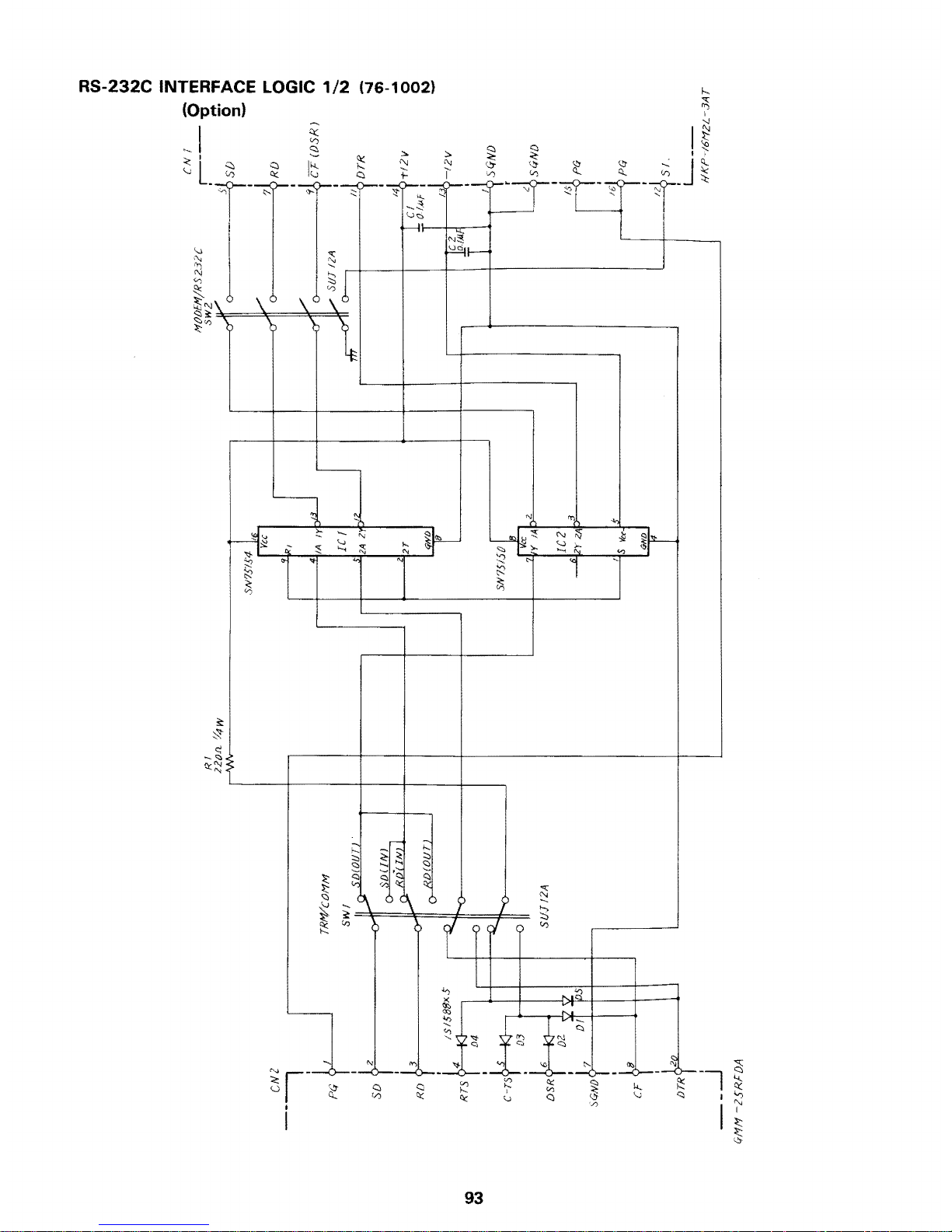

RS-232C INTERFACE LOGIC 1 /2

(76-

1

002)

(Option)

RS-232C INTERFACE LOGIC 2/2

(Option)

(76-1

002)

RADIO SHACK A DIVISION OF TANDY CORPORATION

U.S.A. FORT WORTH. TEXAS

76102

CANADA: BARRIE. ONTARIO

L4M

4W5

TANDY CORPORATION

AUSTRALIA BELGIUM U.

K.

280316 VICTORIA ROAO PARC INDUSTRIEL DE NANINNE BILSTON ROAD WEONESBURY

RYDALMERE N.S.W. 2116 5140 NANINNE WEST MIDLANDS WS10 7JN

Printed

in

Japan