Page 1

ABL800 FLEX operator’s manual

Page 2

Page 3

ABL800 FLEX

operator’s

manual

Page 4

Page 5

Introduction

Instructions to

user

Note to users of the ABL800 FLEX analyzers

This note to users gathers changes from previous note to users in one document and

outlines some new changes to the operator’s manual of your ABL800 FLEX analyzer

(from software version 6.10).

Please remove the existing note to users from the binder of your manual and place this note

to users in the binder instead.

Brief overview

of the change

Interference –

new interference

results for ClO

4

USB connector

Changes/Description

Limitations of use and known interfering substances:

–

CAUTION - Known interfering substances

Substance Interference

ClO

–

(drugs)

4

For ClO

level), cCl

mmol/L level)

cCa

cCl

cK

– ,

interference on cCa2+ (1.25 mmol/L

4

(110 mmol/L level), and cK+ (4

has been detected:

2+

(1.25 mmol/L level): 0.27*

(110 mmol/L level): 4-30

+

(4 mmol/L level): 0.3.

* Depending on the pH level

Instead of the CD-ROM drive, a USB connector may be available.

USB connector or

CD-ROM drive

The USB connector can be used for storing data on an USB flash

drive (memory stick) or for connecting USB devices. Can also be

used for installation of software.

Radiometer, the Radiometer logo, ABL, AQT, TCM, RADIANCE, PICO and CLINITUBES are

trademarks of Radiometer Medical ApS.

© 2011 Radiometer Medical ApS. All rights reserved. 995-950. 201104A.

Page 6

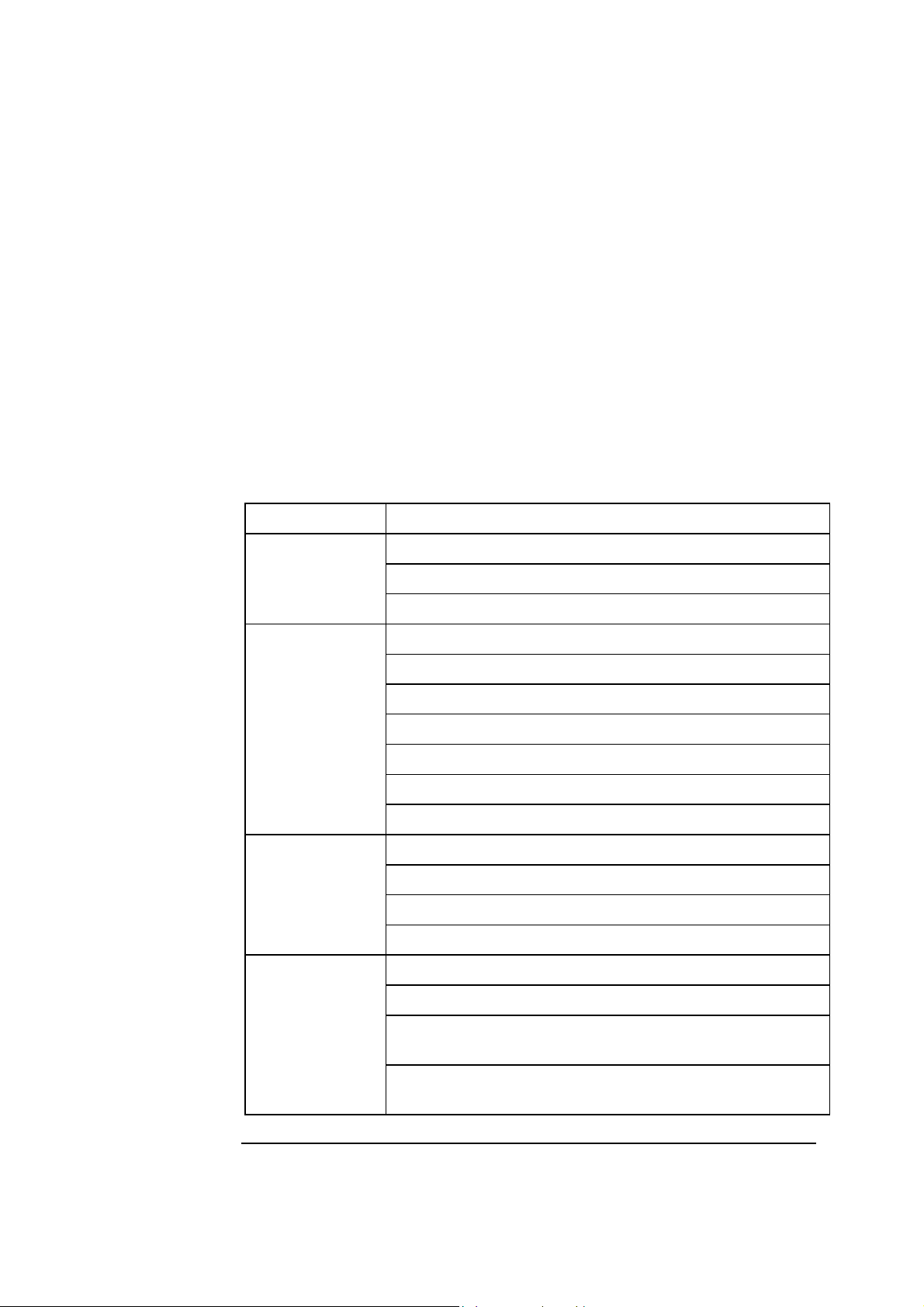

Measured

New table for pleural liquid:

parameters

Parameter Unit Measuring

Range

Test

range

pH pH scale 6.300-8.000 7.0-7.5*

* If the measured values obtained lie outside the test range,

Radiometer advises you to repeat the measurement by means of

another method.

Indoor use statement added according to CSA regulations: Environmental

requirements

Environmental

ratings

Clot detection A new feature is included in software version 6.06 of the following

Location Indoor use only

Pollution degree 2 statement added according to CSA regulations:

Installation category II.

Pollution degree 2.

products:

ABL7xx Series (XPE) analyzers

ABL800 FLEX analyzers

ABL800 BASIC analyzer.

The new feature enables the analyzer to detect clots caught in the

measurement chamber under the pH electrode. This document

describes it.

When to activate the clot-detection feature

It is especially beneficial to activate the clot detection feature in

analyzers frequently used to analyze samples known to be prone to

clotting, for example, samples drawn from umbilical cords. Once

activated clot detection is active during all sample measurements.

NOTICE: It is important to note that activating the feature will

delay measurement results by approximately one minute, even

though it only increases the measurement cycle time by five

seconds. It also increases consumption of Rinse solution, but this is

minimal.

Page 7

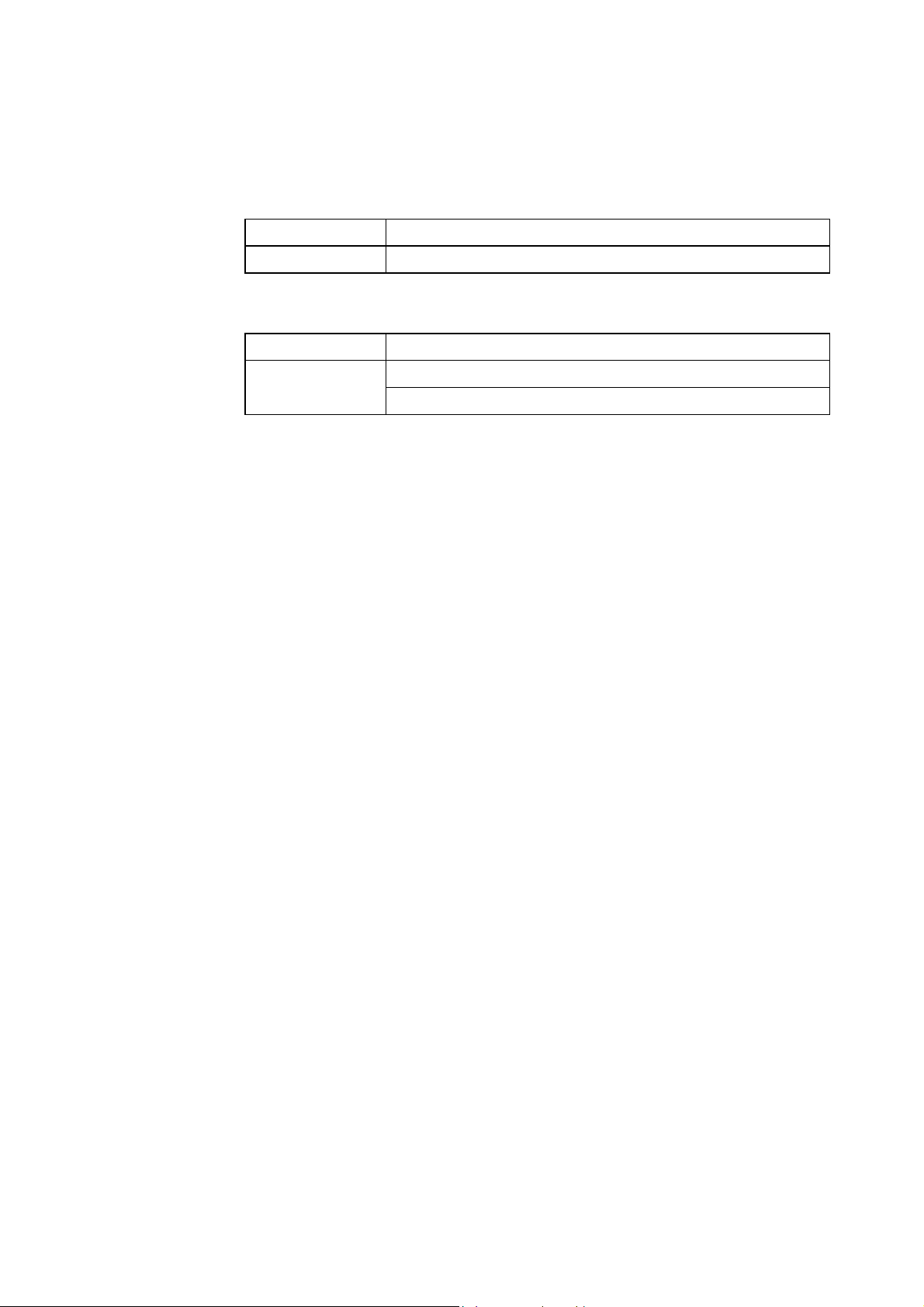

To activate the clot-detection feature

Contact a Radiometer representative and request that clot detection

be enabled via the service program.

Clot-detection process

During calibration the measuring chamber is rinsed and the pH of

the Rinse solution is measured. The value is stored in the analyzer.

During a sample measurement the measuring chamber is also rinsed

and the pH of the rinse solution is measured and compared with the

pH value stored during the last calibration. If the difference between

these values (the pH drift) exceeds a pre-determined maximum

value, it could indicate the presence of a clot beneath the pH

electrode.

When enabled, the clot-detection feature can generate three new

messages that are listed below.

Analyzer messages

NOTICE: Operator actions are listed in order of priority. Perform

the first action in the list and the actions indicated in the "Removal

condition(s) list. If the message persists, perform the next listed

action and the actions indicated in the "Removal condition(s) list,

and so on.

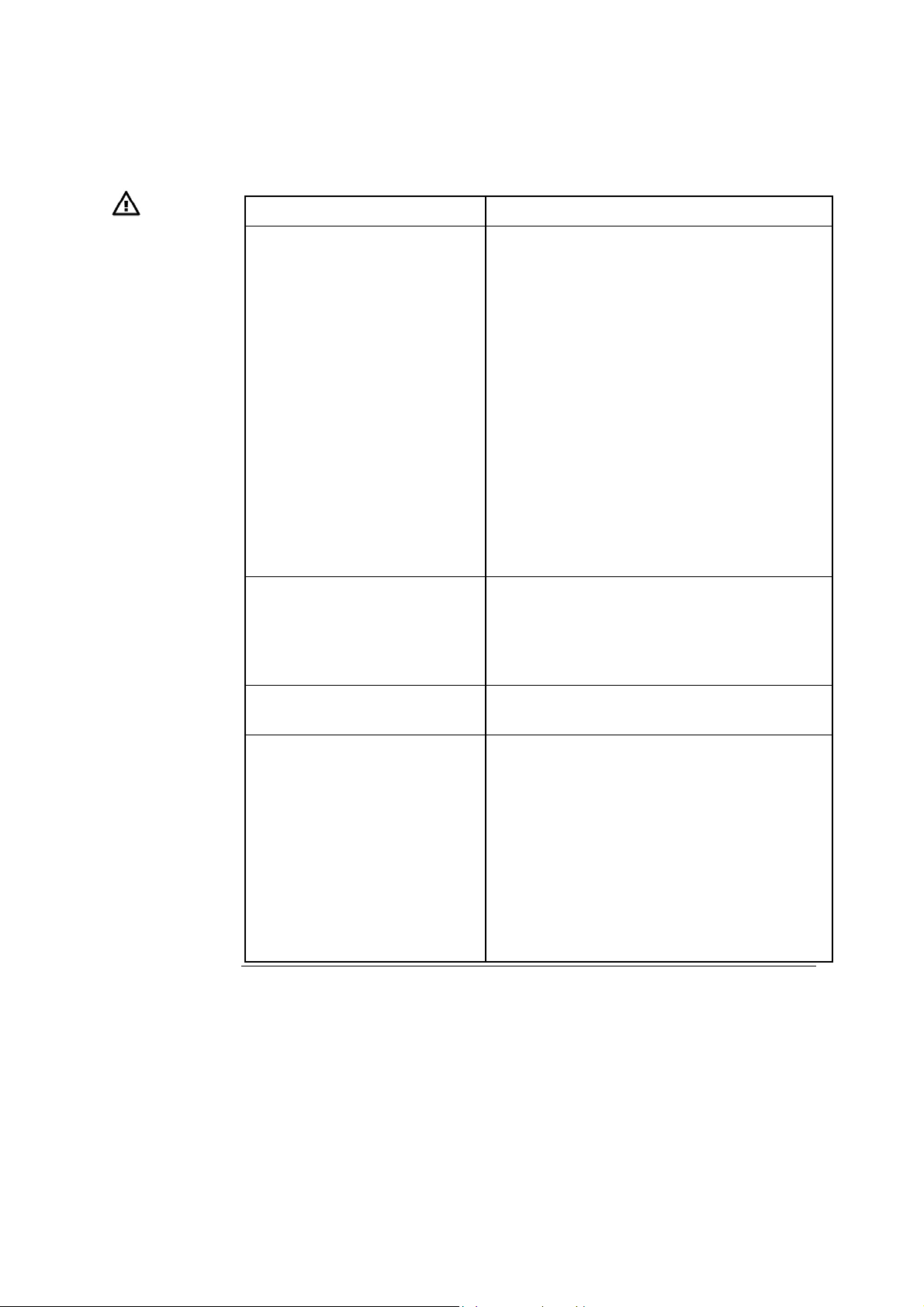

No. Message Interpretation Operator action(s)

1025

Clot suspected

beneath pH

electrode*

The difference

between the pH of

the rinse solution,

measured during the

sample measurement,

and that stored after

the last calibration

exceeds the

Remove the pH electrode and

check the measuring chamber for

clots: clean the measuring

chamber with a cotton stick

moistened with distilled water.

Make sure no cotton fibers are

left in the measuring chamber

Clean pH electrode

maximum al l owable

drift.

This indicates the

presence of a clot in

the measuring

chamber beneath the

pH electrode.

Remembrane Ref electrode

Replace pH electrode

Perform a 1- or 2-point calibration

Removal condition(s):

Acknowledge execution of the

"Clot removal procedure"

Successful 1- or 2-point

calibration

* NOTICE: This is a system message.

Page 8

1026 Clot (pH)

detection not

possible

The pH of the rinse

solution - stored

during the latest

calibration - was

invalidated when

either the Rinse

solution was

replaced, or when

maintenance was

performed on an

electrode.

A new pH value

needs to be

established by

performing a

calibration.

Perform a 1- or 2-point

calibration.

Removal condition(s):

Successful 1- or 2-point

calibration.

1027 Clot suspected

beneath pH

electrode

Acknowledging

execution of a

"Clot-removal

procedure"

The difference

between the pH of

the rinse solution,

measured during the

sample measurement,

and that stored after

the last calibration

exceeds the

maximum al l owable

drift.

This indicates the

presence of a clot in

the measuring

chamber beneath the

pH electrode.

Step Action

Press Analyzer status > Electrodes and others.

1.

Press Replace.

2.

Remove the pH electrode and

check the measuring chamber for

clots: clean the measuring

chamber with a cotton stick

moistened with distilled water.

Make sure no cotton fibers are

left in the measuring chamber

Clean pH electrode

Remembrane Ref electrode

Replace pH electrode

Perform a 1- or 2-point calibration

Removal condition(s):

Acknowledge execution of the

"Clot removal procedure"

Successful 1- or 2-point

calibration

Technical

documentation

Press Clots removed.

3.

Data in this document will be added to the manual next time it is updated.

Radiometer Medical ApS

Åkandevej 21

2700 Brønshøj

Denmark

www.radiometer.com

Page 9

Table of contents

ABL800 FLEX

Operator’s manual

1. Introduction

2. What is what

3. Installation and setup

4. Sample measurements

5. Quality control

6. Calibration

7. Replacements

8. Disk functions

9. Data management

10. Analyzer shutdown

11. Troubleshooting

12. Sampling

13. Specifications

14. Ordering information

15. Radiometer settings

Index - Date of issue

Page 10

System performance

The procedures described in this manual must be observed in order to ensure proper system

performance, and to avoid hazards.

Radiometer cannot provide or verify system performance characteristics if the system is not installed,

used and maintained in accordance with Radiometer procedures or if accessories not meeting the

specifications provided by Radiometer are used.

Radiometer warrants that the data media on which the software included in the system is furnished is

free from defects in material and workmanship under normal use for three (3) months from the date of

delivery as evidenced by a copy of invoice or receipt.

Third-party software and trademarks

The ABL800 FLEX analyzers comprise the Microsoft WindowsXP Embedded, VxWorks and

Sybase SQL Anywhere software.

By using the system, you accept the terms of the Software License Agreement(s) of the provider(s) of

the above software as shown in the End User License Agreement(s) in the analyzer start up picture and

to the terms of the Microsoft WindowsXP Embedded End-User Agreement included in this manual. If

you cannot accept the terms of the Software License Agreement(s), you should not use the system, but

immediately contact your provider for a return of the system and a refund of the purchase price.

Microsoft® and Windows® are trademarks of Microsoft Corporation.

VxWorks is a registered trademark of WindRiver Systems Incorporated.

Sybase SQL Anywhere is a registered trademark of Sybase Incorporated.

Warranties and disclaimer

Radiometer makes no warranties, express or implied, other than expressly stated.

Any warranties expressly stated in this document are conditional upon the system being installed, used

and maintained in accordance with Radiometer procedures, incl uding that only accessories meeting the

specifications provided by Radiometer are used.

Radiometer disclaims any liability for system performance if the system is not installed, used and

maintained in accordance with Radiometer procedures or if accessories not meeting the specifications

provided by Radiometer are used.

Further, Radiometer disclaims any liability for loss of data and direct, consequential or other damages,

including loss of profit or loss of business, whether such claim for damages is based upon contract,

negligence or tort (including strict liability), and even if Radiometer has knowledge of the possibility of the

potential damage or loss.

Confidentiality

The contents of this document shall not be reproduced or communicated to any third party without the

prior written consent of Radiometer.

Changes

This document is subject to change without notice and you are urged to contact Radiometer to verify

whether the document has been changed.

While every effort is made to ensure the correctness of the information provided in this document as

changed from time to time, Radiometer disclaims any liability for errors and omissions.

Radiometer, the Radiometer logo, ABL, AQT, TCM, RADIANCE, PICO and CLINITUBES are trademarks of

Radiometer Medical ApS.

© 2011 Radiometer Medical ApS. All rights reserved.

Page 11

TEnd-User License Agreement for the ABL800 FLEX Analyzers

You have acquired a device ("DEVICE") THAT INCLUDES SOFTWARE LICENSED BY Radiometer

Medical ApS from Microsoft Licensing Inc. or its affiliates ("MS"). Those installed software products of

MS origin, as well as associated media, printed materials and "online" or electronic documentation

("SOFTWARE") are protected by international intellectual property laws and treaties. The SOFTWARE

is licensed, not sold. All rights reserved.

IF YOU DO NOT AGREE TO THIS END-USER LICENSE AGREEMENT ("EULA"), DO NOT USE

THE DEVICE OR COPY THE SOFTWARE . INSTEAD, PROMPTLY CONTACT THE SUPPLIER OF

THE INSTRUMENT FOR INSTRUCTIONS ON RETURN OF THE UNUSED DEVICE(S) FOR A

REFUND. ANY USE OF THE SOFTWARE, INCLUDING BUT NOT LIMITED TO USE ON THE

DEVICE WILL CONSTITUTE YOUR AGREEMENT TO THIS EULA (OR RATIFICATION OF ANY

PREVIOUS CONSENT).

GRANT ON SOFTWARE LICENSE. This EULA grants you the following license:

• You may use the SOFTWARE only on the DEVICE.

• NOT FAULT TOLERANT. THE SOFTWARE IS NOT FAULT TOLERANT. RADIOMETER

MEDICAL ApS HAS INDEPENDENTLY DETERMINED HOW TO USE THE SOFTWARE IN THE

DEVICE, AND MS HAS RELIED UPON RADIOMETER MEDICAL ApS TO CONDUCT

SUFFICIENT TESTING TO DETERMINE THAT THE SOFTWARE IS SUITABLE FOR SUCH

USE.

• NO WARRANTIES FOR THE SOFTWARE. THE SOFTWARE is provided "AS IS" and with all

faults. THE ENTIRE RISK AS TO SATISFACTORY QUALITY, PERFORMANCE, ACCURACY,

AND EFFORT (INCLUDING LACK OF NEGLIGENCE) IS WITH YOU. ALSO, THERE IS NO

WARRANTY AGAINST INTERFERENCE WITH YOUR ENJOYMENT OF THE SOFTWARE OR

AGAINST INFRINGEMENT. IF YOU HAVE RECEIVED ANY WARRANTIES REGARDING THE

DEVICE OR THE SOFTWARE, THOSE WARRANTIES DO NOT ORGINATE FROM, AND ARE

NOT BINDING ON, MS.

• Note on Java Support. The SOFTWARE may contain support for programs written in Java. Java

technology is not fault tolerant and is not designed, manufactured or intended for use or resale as

online control equipment in hazardous environments requiring fail-safe performance, such as in

the operation of nuclear facilities, aircraft, navigation or communication systems, air traffic control,

direct life support machines or weapons systems, in which the failure of Java could lead directly to

death, personal injury, or severe physical or enviromental damage. Sun Microsystems, Inc. has

contractually obligated MS to make this disclaimer.

• No Liability for Certain Damages. EXCEPT AS PROHIBITED BY LAW, MS SHALL HAVE NO

LIABILITY FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES

ARISING FROM OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THE

SOFTWARE. THIS LIMITATION SHALL APPLY EVEN IF ANY REMEDY FAILS OF ITS

ESSENTIAL PURPOSE. IN NO EVENT SHALL MS BE LIABLE FOR ANY AMOUNT IN

EXCESS OF US. TWO HUNDRED FIFTY DOLLARS (US$250.00).

• Limitations on Reverse Engineering, Decompilation and Disassembly. You may not reverse

engineering, decompile, or disassemble the SOFTWARE, except and only to the extent that such

activity is expressly permitted by applicable law notwithstanding this limitation.

• SOFTWARE TRANSFER ALLOWED BUT WITH RESTRICTIONS. You may permanently

transfer rights under this EULA only as a part of a permanent sale or transfer of the DEVICE, and

only if the recipient agrees to this EULA. If the SOFTWARE is an upgrade, any transfer must also

include all prior versions of the SOFTWARE.

• EXPORT RESTRICTIONS. You acknowledge that SOFTWARE is of US-origin. You agree to

comply with all applicable international and national laws that apply to the SOFTWARE, including

the US Export Administration Regulations, as well as end-user, end-use and country destination

restrictions issued by US and other governments. For additional information on exporting the

SOFTWARE, see

http://www.microsoft.com/exporting/.

Page 12

Page 13

Contents

This manual contains the following topics.

1. Introduction...................................................................................................... 1-1

Overview........................................................................................................... 1-1

Names and intended use.................................................................................... 1-2

Limitations of use and known interfering substances....................................... 1-4

Warning/Caution and Notices........................................................................... 1-7

Symbols overview............................................................................................. 1-8

2. What is what ..................................................................................................... 2-1

Overview........................................................................................................... 2-1

Analyzer - front................................................................................................. 2-2

Analyzer - rear .................................................................................................. 2-4

Measuring section.............................................................................................2-5

Inlet module......................................................................................................2-7

FLEXQ module................................................................................................. 2-8

Thermal printer ............................................................................................... 2-10

Communication ports...................................................................................... 2-11

Barcode reader................................................................................................ 2-13

AutoCheck module ......................................................................................... 2-14

Screen elements .............................................................................................. 2-15

Menu structure................................................................................................ 2-24

Analyzer status................................................................................................ 2-28

Online aid facilities......................................................................................... 2-36

Sample counter................................................................................................ 2-39

3. Installation and setup....................................................................................... 3-1

Overview........................................................................................................... 3-1

Installation ........................................................................................................ 3-2

Setup menu structure......................................................................................... 3-3

Analyzer security.............................................................................................. 3-6

Analysis setup................................................................................................. 3-13

Patient reports ................................................................................................. 3-26

Calibration setup............................................................................................. 3-32

Quality control setup....................................................................................... 3-35

Replacement setup.......................................................................................... 3-48

Page 14

Contents ABL800 FLEX Operator's Manual

Parameters and input setup ............................................................................. 3-55

Analyzer settings............................................................................................. 3-62

Communications............................................................................................. 3-68

Printers............................................................................................................ 3-77

Disk Functions setup....................................................................................... 3-80

Corrective actions ........................................................................................... 3-83

Miscellaneous setup........................................................................................ 3-86

4. Sample measurements...................................................................................... 4-1

Overview........................................................................................................... 4-1

General information.......................................................................................... 4-2

Immediately before analysis ............................................................................. 4-9

Measurements with FLEXQ ........................................................................... 4-10

Introducing a blood sample............................................................................. 4-12

Introducing a pleura sample............................................................................ 4-15

Introducing an expired air sample................................................................... 4-16

Patient identification....................................................................................... 4-17

Patient result ................................................................................................... 4-21

Calculation of FShunt and ctO2(a -

_

) ........................................................... 4-25

V

Patient result messages.................................................................................... 4-26

5. Quality control.................................................................................................. 5-1

Overview........................................................................................................... 5-1

General information.......................................................................................... 5-2

Preparing a control solution.............................................................................. 5-4

Manual quality control measurement................................................................ 5-6

AutoCheck measurement.................................................................................. 5-7

Quality control identification............................................................................ 5-8

Quality control result ...................................................................................... 5-10

Quality control result messages ...................................................................... 5-15

6. Calibration........................................................................................................ 6-1

Overview........................................................................................................... 6-1

General information.......................................................................................... 6-2

Unscheduled calibrations.................................................................................. 6-4

Interrupted, pending or expired calibrations..................................................... 6-5

tHb calibration .................................................................................................. 6-6

Calibration result............................................................................................... 6-8

Calibration result messages............................................................................. 6-10

Page 15

ABL800 FLEX Operator's Manual Contents

7. Replacements .................................................................................................... 7-1

Overview........................................................................................................... 7-1

General information.......................................................................................... 7-2

Replacing membranes or electrodes.................................................................. 7-6

Replacing pump tubes....................................................................................... 7-9

Replacing inlet gasket unit and inlet probe..................................................... 7-12

Replacing waste container, fan filter, printer paper........................................ 7-14

Replacing solutions and gases ........................................................................ 7-16

Refilling the AutoCheck carousel................................................................... 7-19

Automatic auxiliary programs ........................................................................ 7-20

Decontamination and Protein Removal programs.......................................... 7-21

Cleaning the analyzer...................................................................................... 7-23

List of references............................................................................................. 7-25

8. Disk Functions .................................................................................................. 8-1

Overview........................................................................................................... 8-1

General information.......................................................................................... 8-2

Creating a WDC report..................................................................................... 8-4

Backing up all data............................................................................................ 8-6

Restoring all data .............................................................................................. 8-8

Exporting data logs........................................................................................... 8-9

Importing/exporting archives.......................................................................... 8-11

Saving setup.................................................................................................... 8-13

Loading/restoring setup .................................................................................. 8-14

9. Data management............................................................................................. 9-1

Overview........................................................................................................... 9-1

General information.......................................................................................... 9-2

Patient Results Log........................................................................................... 9-4

Patient Profiles Log........................................................................................... 9-7

Quality Control Log........................................................................................ 9-11

Calibration Log............................................................................................... 9-17

Activity Log.................................................................................................... 9-20

Replacement Log............................................................................................ 9-23

Archived data logs .......................................................................................... 9-24

RADIANCE browser (optional) ..................................................................... 9-26

10. Analyzer shutdown......................................................................................... 10-1

Overview......................................................................................................... 10-1

General information........................................................................................ 10-2

Page 16

Contents ABL800 FLEX Operator's Manual

Standby mode ................................................................................................. 10-3

Full waste container........................................................................................ 10-5

Temporary Shutdown...................................................................................... 10-6

Long Term Shutdown..................................................................................... 10-8

11. Troubleshooting.............................................................................................. 11-1

Overview......................................................................................................... 11-1

General information........................................................................................ 11-2

Forced Hold causes......................................................................................... 11-5

Analyzer messages.......................................................................................... 11-7

Fluid transport troubleshooting procedure.................................................... 11-74

Inlet probe troubleshooting procedure.......................................................... 11-75

Inlet troubleshooting procedure.................................................................... 11-76

Leak troubleshooting procedure ................................................................... 11-77

Electrode troubleshooting procedures........................................................... 11-78

Pump troubleshooting procedure.................................................................. 11-80

Fluid transport system description................................................................ 11-81

12. Sampling.......................................................................................................... 12-1

Overview......................................................................................................... 12-1

Causes of errors in preanalytical phase........................................................... 12-2

Preparation prior to arterial/venous sampling................................................. 12-5

Preparation prior to capillary sampling........................................................... 12-7

Sampling devices............................................................................................ 12-8

Storage and preparation prior to analysis........................................................ 12-9

Sampling procedures..................................................................................... 12-12

References..................................................................................................... 12-15

13. Specifications .................................................................................................. 13-1

Overview......................................................................................................... 13-1

Measured parameters ...................................................................................... 13-2

Input parameters.............................................................................................. 13-5

Derived parameters......................................................................................... 13-6

Sample handling.............................................................................................. 13-8

Calibration and maintenance programs......................................................... 13-11

Analyzer requirements.................................................................................. 13-13

Analyzer specifications................................................................................. 13-14

Approvals and patents................................................................................... 13-16

Page 17

ABL800 FLEX Operator's Manual Contents

14. Ordering information..................................................................................... 14-1

Overview......................................................................................................... 14-1

Analyzer accessories....................................................................................... 14-2

Quality control................................................................................................ 14-5

Sampling devices............................................................................................ 14-7

15. Radiometer settings........................................................................................ 15-1

Overview......................................................................................................... 15-1

Radiometer default settings............................................................................. 15-2

Contents of setup settings ............................................................................. 15-15

Calibration verification................................................................................. 15-18

Interfacing facilities...................................................................................... 15-20

Index

Date of issue

Page 18

Contents ABL800 FLEX Operator's Manual

Page 19

Overview

Introduction

Contents

1. Introduction

The chapter briefly describes the intended use of the analyzer, lists all measured

parameters and the substances known to interfere with the measurements, and

explains the different notices that appear in the manual.

Throughout this manual, "ABL800 FLEX analyzer" is used for all ABL8xx FLEX

analyzers, i.e.: ABL837/835/830/827/825/820/817/815/810/805 and ABL810 BG

only.

The abbreviation "ABL8x7 FLEX analyzer" is used for the ABL837/27/17 FLEX

analyzers throughout this manual.

This chapter contains the following topics.

Names and intended use................................................................................... 1-2

Limitations of use and known interfering substances...................................... 1-4

Warning/Caution and Notices.......................................................................... 1-7

Symbols overview........................................................................................... 1-8

Page 20

1. Introduction ABL800 FLEX Operator's Manual

Names and intended use

Names

Intended use

Proprietary name: ABL800 FLEX blood gas, oximetry, electrolyte and

metabolite analyzer.

Common name: Blood gas, oximetry, electrolyte and metabolite measuring

system.

The ABL800 FLEX analyzers are intended for:

• In Vitro testing of samples of whole blood for the parameters pH, pO

+

cK

, cNa+, cCa2+, cCl–, cGlu, cLac, cCrea, ctBil, and co-oximetry parameters

(ctHb, sO

2

, and the hemoglobin fractions FO2Hb, FCOHb, FMetHb, FHHb and

FHbF)

• in vitro testing of samples of expired air for the parameters pO

and pCO2

2

• in vitro testing of pleura samples for the pH parameter.

The following parameters can be measured on blood:

Parameter group Parameters

pH/blood gas:

Oximetry:

pH (acidity)

pCO2 (carbon dioxide tension)

(oxygen tension)

pO

2

ctHb (total hemoglobin concentration)

sO2 (oxygen saturation)

FO2Hb (fraction of oxyhemoglobin in total hemoglobin)

FCOHb (fraction of carboxyhemoglobin in total hemoglobin)

FHHb (fraction of deoxyhemoglobin in total hemoglobin)

FMetHb (fraction of methemoglobin in total hemoglobin)

FHbF (fraction of fetal hemoglobin)

, pCO2,

2

1-2

Electrolytes:

Metabolites:

cK+ (potassium ion concentration)

cNa+ (sodium ion concentration)

2+

cCa

(calcium ion concentration)

–

(chloride ion concentration)

cCl

cGlu (D-glucose concentration)

cLac (L(+)-lactate concentration)

ctBil (concentration of total bilirubin, measurement in plasma

is possible, see Limitations of use later in this chapter)

cCrea (concentration of creatinine, measurement on plasma

and serum possible, see Limitations of use later in this chapter)

Continued on next page

Page 21

ABL800 FLEX Operator's Manual 1. Introduction

Names and intended use, Continued

Intended use

(continued)

The following parameters can be measured on pleura samples:

Parameter group Parameters

Measured value pH (acidity)

The following parameters can be measured on expired air samples:

Parameter group Parameters

Measured values pCO2 (carbon dioxide tension)

pO

(oxygen tension)

2

Derived parameters are listed in chapter 13: Specifications and described in detail

in the Reference Manual, chapter 6.

Requirement to

the operator

Measurements

on animal blood

FLEXMODE

Measurements

on pleural fluids

Other fluids

mode

FLEXQ module

NOTICE:

The analyzer should be used by personnel who have received special education and

training with regard to procedures utilizing in vitro diagnostic medical devices.

Animal blood has not been tested on the ABL800 FLEX analyzer. Some

components in animal blood differ from those in human blood, and variations in

the composition of blood from different animal species may also exist.

This mode allows you to analyze a blood sample of 35 μL and higher – up to the

maximum volume accepted by your analyzer. Depending on the available sample

volume, the FLEXMODE provides the highest number of parameters: from all

available to as many as reliably possible.

This mode is not available in the ABL8x7 FLEX analyzers.

Pleura pH can be measured on pleural fluids. Corrections are present in the device.

All parameters available on your ABL800 FLEX analyzers can be measured on

fluids other than heparinized human whole blood

NOTICE: Before using this mode you must establish "user-defined corrections"

for each parameter used, on the fluid in question. The corrections assume a linear

correlation between the measured value and the reference instrument. The data

used for establishing "user-defined corrections" have to cover the desired

measuring range. If no user-defined corrections are entered, you will measure in

this mode as if on heparinized human whole blood.

The FLEXQ module can accommodate up to three samplers simultaneously. It

reads a sampler's barcode, mixes the sample and transports the sampler to the inlet

for aspiration and analysis without any further assistance from the operator.

Results can be delivered via FLEXLINK (for information refer to the RADIANCE

Installation and Setup Manual).

The model ABL810 can also be ordered without oximetry parameters: as ABL810

BG only.

1-3

Page 22

1. Introduction ABL800 FLEX Operator's Manual

r

Limitations of use and known interfering substances

Limitations of

use

The following limitations should be taken into consideration:

The ABL800 FLEX analyzers are designed for measurements of adult and fetal

hemoglobin with normal spectrum characteristics. Some spectra deviate from the

normal characteristics, e.g. for certain hemoglobinopathies and the ABL800 FLEX

analyzers do not compensate for this.

CAUTION - Fulfillment of user-specific analytical needs

The user should review the analyzer performance data to assure that the

performance fulfills the user-specific analytical needs.

WARNING – Clinical decisions

The validity of the test results from this instrument must be carefully

examined by a clinician and related to the patient’s clinical condition,

before any clinical decisions are taken on the basis of the test results.

CAUTION Known

interfering

substances

CAUTION - Risk of erroneous results

Always meticulously follow the sampling procedures described in chapter

12: Sampling. Failure to follow these procedures may introduce clots or air

bubbles in the sample and yield erroneous results.

NOTICE: Bilirubin measurements on plasma and creatinine measurements on

plasma and serum need to be measured in Other fluids mode, as the other modes

are intended for measurement on human whole blood only. Corrections for

Creatinine can be found in the Reference Manual.

FHbF measurement:

The uncertainty in FHbF measurements exceeds the level required to measure

normal HbF levels in the adult range (FHbF reference range is 0-1 %).

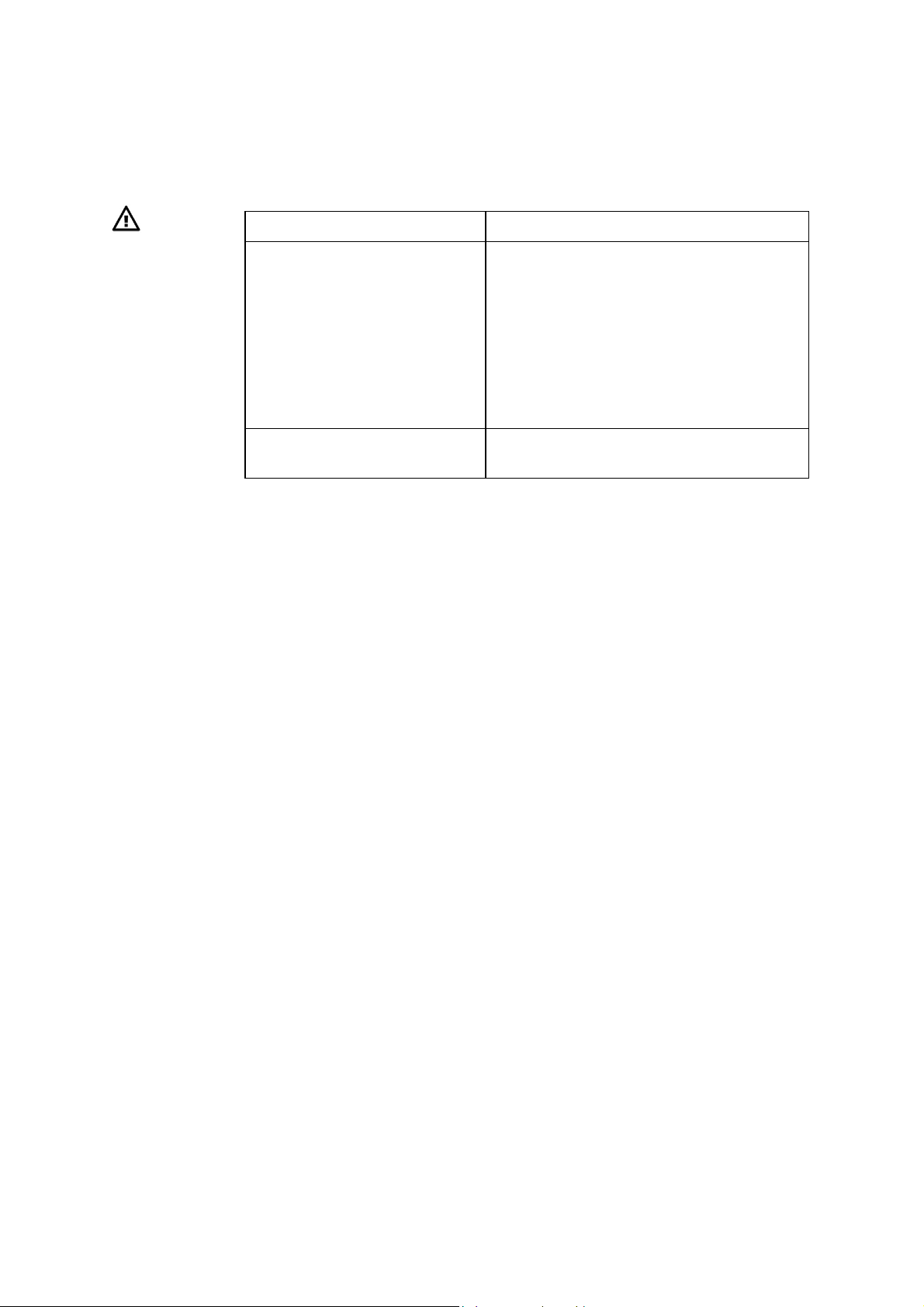

The following substances are known to affect or interfere with measurements on

the ABL800 FLEX analyzers.

Substance Interference

Halothane (anesthetic) May give unreliable pO2 results.

Lipid therapy (treatment) In OXI measurements.

After measurement on blood from a patient who

has received lipid therapy it may be necessary

to clean the analyzer using the Cleaning

program.

Methylene Blue, HiCN

In OXI measurements.

(medication)

Anions: B

−

−S2−

,I , and Cl

−

Erroneously high

O

4

cCl

-

results.

(drugs)

Continued on next page

1-4

Page 23

ABL800 FLEX Operator's Manual 1. Introduction

Limitations of use and known interfering substances,

Continued

CAUTION Known

interfering

substances

(continued)

Anticoagulants (sampling) Anticoagulants that contain sodium salts will

Thiocyanic acid (degradation

product from treatment with

nitroprussid. Also produced in

thiosulphate treatment of cyanide

poisoning)

Substance Interference

+

cNa

give erroneously high

results. Sodium

fluoride with or without EDTA and oxalate

(di Na) influence

gives erroneously high

cGlu and cLac results. Tri sodium citrate

influences

cGlu results. Sodium fluoride

+

cNa

, cK+ and cGlu results.

+

cNa

and low cCa2+,

Thus Radiometer recommends the exclusive use

of heparin as anticoagulant. Solutions containing

organic preservatives may damage the ionselective membranes of the

+

cK

and cGlu

electrodes when introduced into the analyzer.

Do not use EDTA, as it leads to erroneous pH,

pCO

, cNa+, cK+ and cCa2+ results. Use of

2

EDTA will also affect subsequent measurements

on the Ca electrode and it will reduce the

lifetime of this electrode.

Erroneously high

cGlu and cLac measurements.

Glycolic acid (ethyleneglycol

degradation product)

Insufficiently stabilized blood.

Caustic fluids (e.g. strong acids

or bases, detergents, etc.).

Fluids that precipitate.

Fluids that affect the sensor

enzymes.

Fluids that form complexes with

the analyzer solutions (calcium).

High viscosity fluids.

Hydrophobic fluids.

Reactive fluids.

Erroneously high cLac measurements.

Other fluids mode allows you to measure on

fluids other than heparinized human blood.

Be aware that some substances, such as listed in

the left column, measured in the Other fluids

mode may damage the instrument or the

electrodes. This can affect the subsequent

measurement on human blood or quality control

solutions.

Continued on next page

1-5

Page 24

1. Introduction ABL800 FLEX Operator's Manual

Limitations of use and known interfering substances,

Continued

CAUTION Known

interfering

substances

(continued)

Carboxymethyl cellulose (CMC)

Substance Interference

Some auto-venting arterial blood samplers

contain carboxymethyl cellulose (CMC) in

the porous vent. CMC can dissolve into the

sample and give erroneously low

cCa

2+

results. Therefore we recommend

Radiometer accessories together with our

analyzers, e.g. the

safePICO arterial blood

sampler which is specifically designed to

minimize sample contamination with CMC.

Galactose, glucosamine, maltose,

mannose, xylose

For detailed information – see

Reference Manual

.

Interference Tests in chapter 5 of the ABL800 FLEX

Erroneously high cGlu measurements.

1-6

Page 25

ABL800 FLEX Operator's Manual 1. Introduction

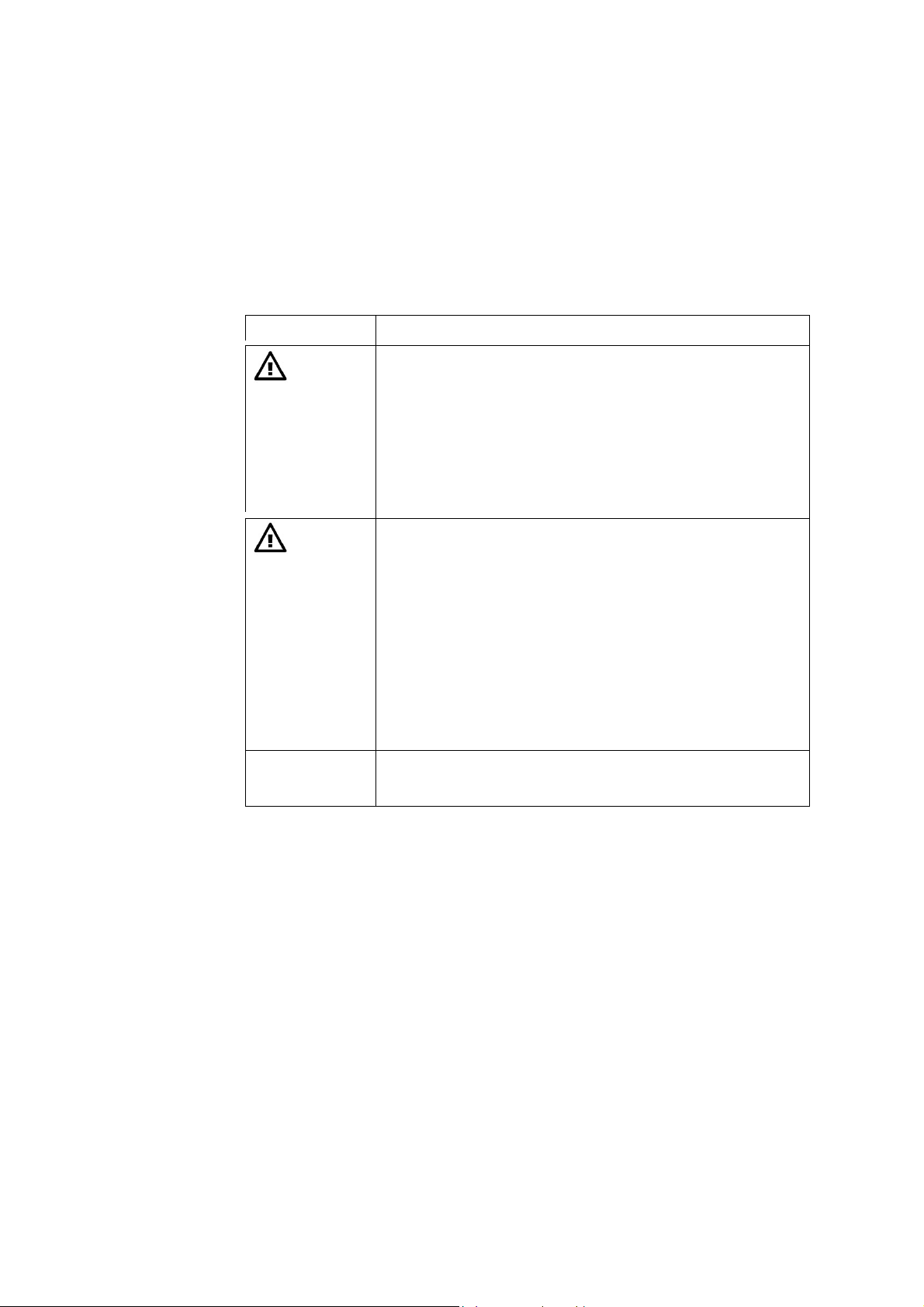

Warning/Caution and Notices

Definitions

Throughout the manual, the various procedures may contain operational cautions

and warnings, which are important and should be read carefully before performing

the related procedures. The manual also contains a number of

NOTICES.

The following table indicates the type of information given in Warnings, cautions

and notes.

Symbol Explanation

WARNING

A warning alerts the reader about a situation, which, if not

avoided, could result in death or serious injury. It may also

describe potential serious adverse reactions and safety

hazards. The designation of a hazard alert as a "warning" is

reserved for the most significant problems. The term

WARNING is generally used as signal word for this type of

hazard alert.

CAUTION

The term precaution is used for the statement of a hazard

alert that warns the reader of a potentially hazardous

situation which, if not avoided, may result in minor or

moderate injury to the user or the patient or damage to the

equipment or other property. It may also be used to alert

against unsafe practices. This includes the special care

necessary for the safe and effective use of the device and the

care necessary to avoid damage to a device that may occur

as a result of use or misuse. The word

CAUTION is

generally used as signal word for a precaution statement.

NOTICE

Notices give practical information.

1-7

Page 26

1. Introduction ABL800 FLEX Operator's Manual

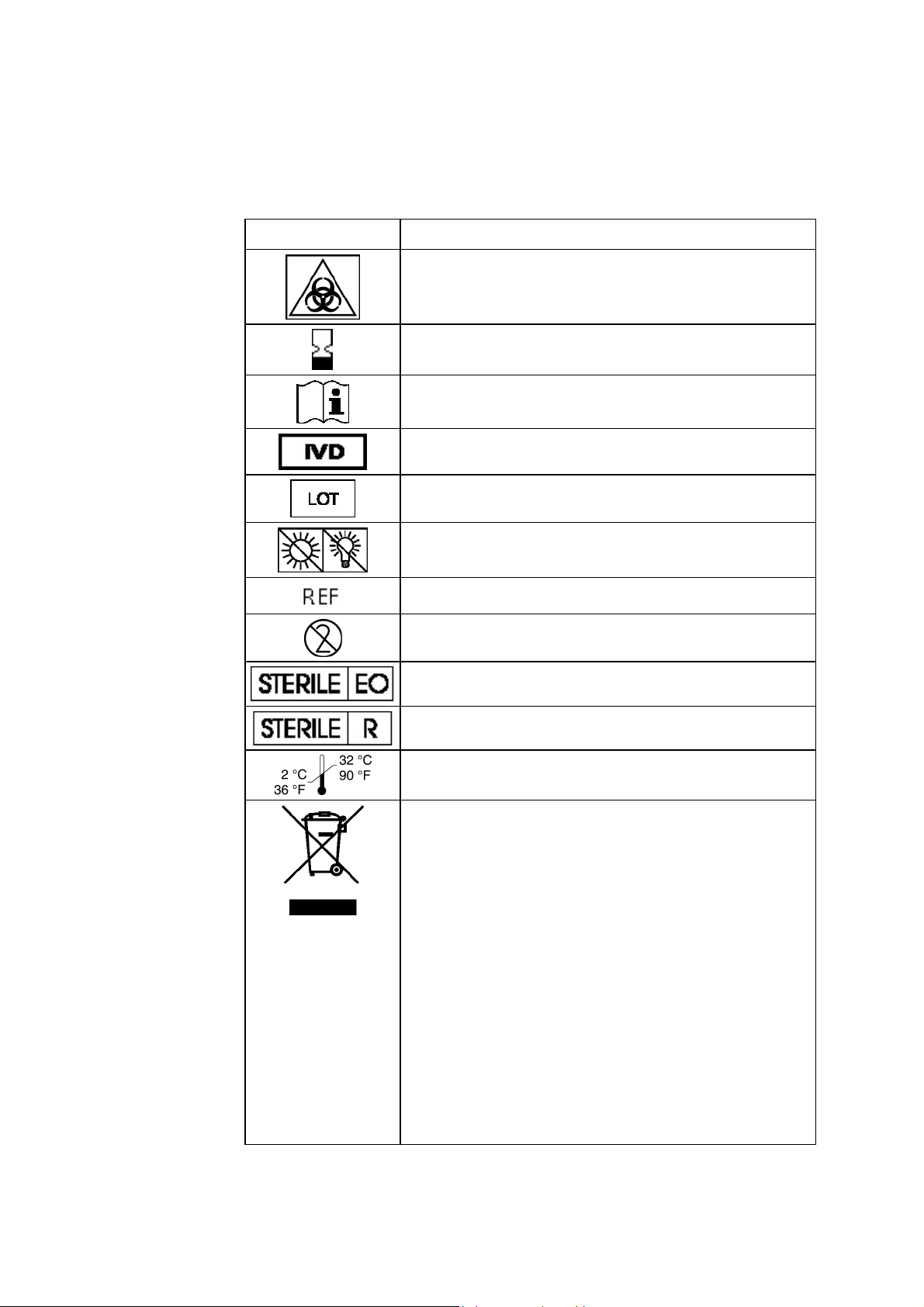

Symbols overview

List of symbols

The symbols below are used by Radiometer.

Symbol Explanation

Biohazard

Expiry date

See instructions for use

For In Vitro Diagnostic Use

Lot number

Sensitive to light. Store in a dark place.

Code number

For single use only

Sterilized by ethylene oxide

Sterilized by irradiation

Storage temperature from 2

°C to 32 °C (36 °F to 90 °F)

Waste of Electrical and Electronic Equipment (WEEE)

The symbol indicates that:

• Radiometer Medical ApS and its distributors

within the European Union (EU) and associated

states have taken the necessary steps to comply

with the directive, 2002/96/EC on waste electrical

and electronic equipment (WEEE).

• The instrument, when reaching its end of life,

must be collected and recycled separately from

other waste according to national requirements.

Please contact your local Radiometer distributor

for instructions.

1-8

Environmental implications:

WEEE contains materials that are potentially hazardous to

the environment and to human health.

Page 27

Overview

Introduction

Contents

2. What is what

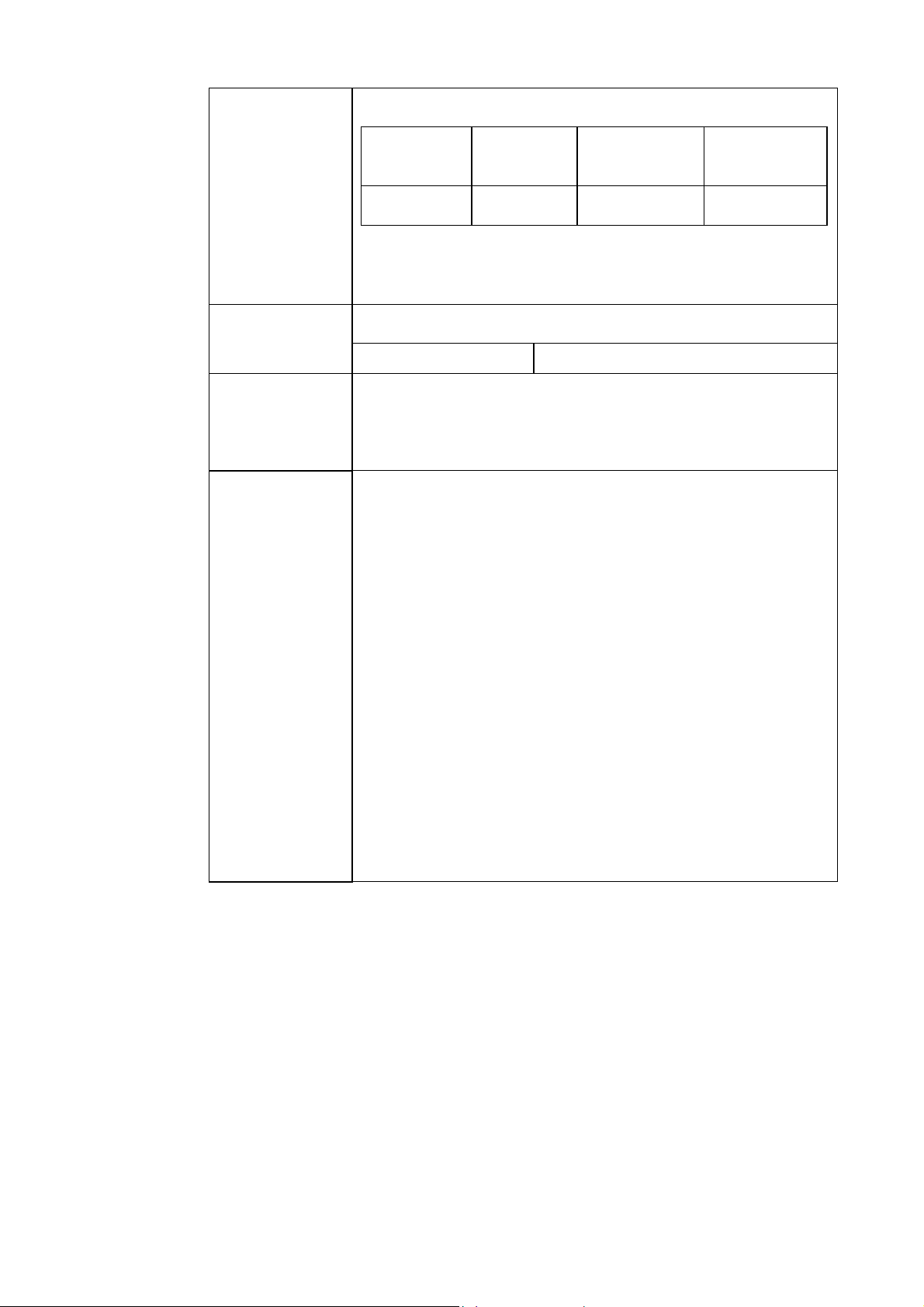

The ABL800 FLEX analyzer is a complete unit comprised of several different

modules each performing a specific function and controlled by comprehensive

software. The modules are collected into well-defined sections according to their

related function.

This chapter describes the basic parts of the ABL800 FLEX analyzer and its

software.

This chapter contains the following topics.

Analyzer - front................................................................................................ 2-2

Analyzer - rear ................................................................................................. 2-4

Measuring section ............................................................................................ 2-5

Inlet module ..................................................................................................... 2-7

FLEXQ module ................................................................................................ 2-8

Thermal printer ................................................................................................ -10 2

Communication ports....................................................................................... -11

Barcode reader ................................................................................................. -13

AutoCheck module........................................................................................... -14

Screen elements................................................................................................ -15

Menu structure ................................................................................................. -24

Analyzer status................................................................................................. -28

Online aid facilities.......................................................................................... -36

Sample counter................................................................................................. -39

2

2

2

2

2

2

2

2

Page 28

2. What Is what ABL800 FLEX Operator's Manual

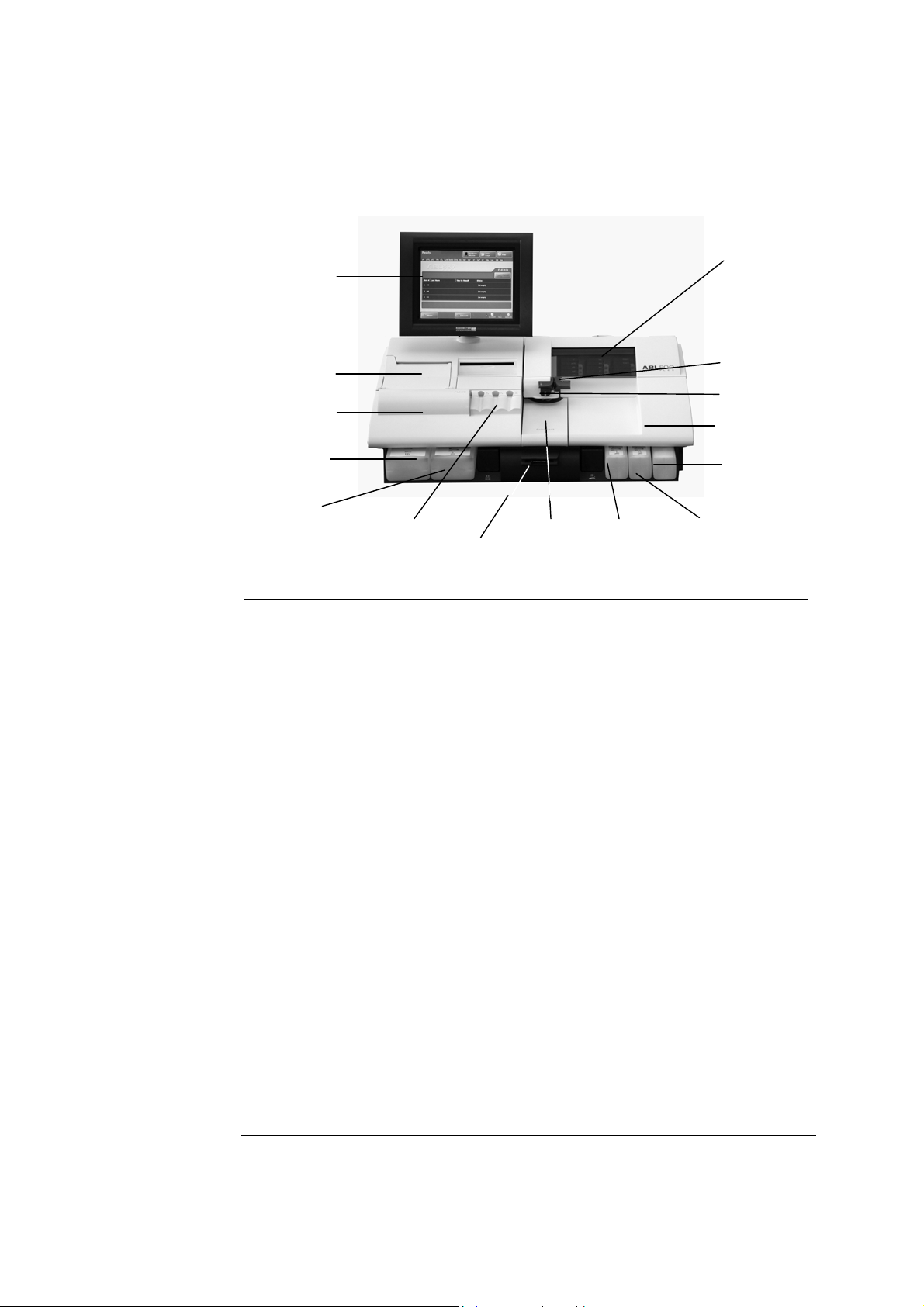

A

Analyzer - front

Parts and

functions

The components of the analyzer front (with covers) is shown below.

Touch screen

Cover with

window

Thermal printer

Left cover

Waste container

Capillary inlet

Syringe inlet

Right cover

Cleaning Solution

Rinse Solution

FLEXQ module

Barcode reader

utoCheck

module

Cal 1

solution

Cal 2

solution

Part Function

Color touch screen 10.4" LCD for operation and management of the

analyzer.

Thermal printer For automatic printout of data.

Left cover To access the waste container/Rinse Solution.

Waste container For waste collection. A sensor detects when container is

full, and a message is displayed on the screen.

Rinse Solution For rinsing the liquid transport system after various

analyzer activities.

2-2

FLEXQ module See FLEXQ module in this chapter.

Barcode reader See Barcode reader in this chapter.

AutoCheck module See AutoCheck module in this chapter.

Cal 1 Solution For performing 1- and 2-point calibrations.

Cal 2 Solution For performing 2-point calibrations.

Cleaning Solution For cleaning the liquid transport system of lipid deposits.

Right cover To access solutions and pumps – see overleaf.

Syringe inlet flap Lift to introduce syringe samples and quality control

solutions.

Capillary inlet flap Lift to introduce capillary samples.

Cover with window See Measuring Section in this chapter.

Continued on next page

Page 29

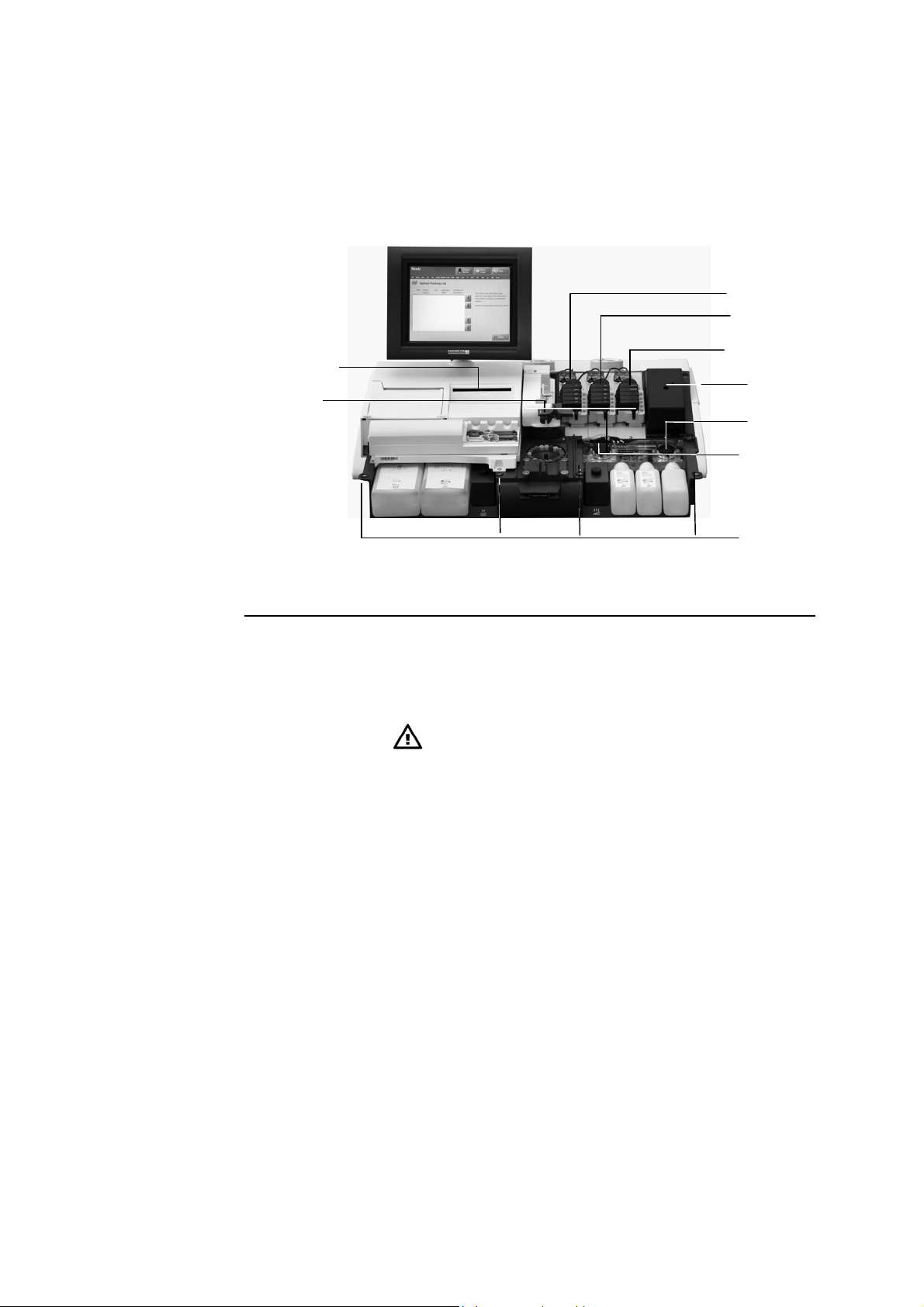

ABL800 FLEX Operator's Manual 2. What Is what

Analyzer - front, Continued

Parts and

functions

(continued)

The components of the analyzer front (without covers) is shown below.

pH/BG module

El/Met module

CD-ROM drive

Inlet module

Met II module

Oximetry module

Solution pump

Waste pump

Magnets

Part Function

Inlet module Accepts samples from a syringe/test tube or a capillary – see

Inlet Module in this chapter.

CD-ROM drive For storing data on a CD-RW disk or retrieving data from a

CD (e.g. installation software).

CAUTION – Installation of correct software

Install only software which is strictly intended for

use with the analyzer. Installation of other types may

affect analyzer performance.

pH/Blood Gas

(BG) module

Electrolyte/Metabolite (El/Met)

Measures pH, pO

component detail.

2+

Measures cCa

, cK+, cNa+, cGlu and cLac. See measuring

section detail.

, pCO2 and cCl–. See measuring

2

module

Met II module Measures creatinine.

(Only available for the ABL8x7 FLEX analyzers)

Oximetry (Oxi)

module

Measures ctHb, sO

FHbF and ctBil. See measuring component detail.

, FHHb, FO2Hb, FCOHb, FMetHb,

2

Solution pump Transports solutions through the liquid transport system.

Waste pump Transports liquid to the waste container.

Magnets Hold the covers in place.

2-3

Page 30

2. What Is what ABL800 FLEX Operator's Manual

r

r

Analyzer - rear

Parts and

functions

The parts and components of the analyzer's rear panel are shown below.

Gas 1 cylinde

Gas 2 cylinde

Communication ports

Fan

Gas cylinder sockets

Power switch

Power socket

Part Function

Gas 1 cylinder Contains a gas mixture of 5.61 % CO

74.64 % N

.

2

, 19.76 % O2; balance

2

Gas 2 cylinder Contains a gas mixture of 11.22 % CO2, < 0.04 % O2;

balance > 88.74 % N

.

2

Fan For cooling internal components.

Gas cylinder

For mounting the gas cylinders.

socket

Communication

See section Communication Ports in this chapter.

ports

Power switch

For turning the analyzer on (position I) and off (position O).

Power socket For connecting the power cord.

In USA: If source is 120 V, use Radiometer cord 615-403

with parallel blade attachment plug.

If source is 240 V, use Radiometer cord 615-405

with tandem blade attachment plug.

2-4

Page 31

ABL800 FLEX Operator's Manual 2. What Is what

Measuring section

Parts and

functions

The modules and components of the measuring section are shown below.

Membrane valves

Electrode module

pumps

pH/BG module

Latch

Sample path

Membrane valves Control the flow of gas and solutions into the measuring

Electrode module

pumps

El/Met module

Met II module

Oximetry module

Part Function

modules.

Transport solutions and gas mixtures through the

measuring modules.

Latch Establishes electric contact between the electrode in the

measuring chamber and the electrode amplifier.

To access an electrode, push inwards on the upper

portion of the latch, and lift upwards.

Sample path Transports samples, solutions and gas mixtures.

pH/BG module Contains the measuring chamber with the pH, reference,

, pO2 and cCl

pCO

2

El/Met module Contains the measuring chamber with the cCa

+

cNa

, cGlu, and cLac electrodes (a filter is installed for

–

electrodes.

2+

, cK+,

the cGlu and cLac electrodes).

Met II module Contains the measuring chamber with the cCrea A and

cCrea B electrodes

(Only available for the ABL8x7 FLEX analyzers)

Oximetry module Contains the hemolyzer with glass cuvette, spectro-

photometer for measuring ctHb, sO

, FHHb, FO2Hb,

2

FCOHb, FMetHb, FHbF, ctBil on 128 wavelengths, and

the lamp unit.

Continued on next page

2-5

Page 32

2. What Is what ABL800 FLEX Operator's Manual

Measuring section, Continued

Electrode

locations

The electrodes are located in the electrode modules as follows:

-

cCl

electrode

cLac electrode

pCO2 electrode

electrode

pO

2

Reference electrode

pH electrode

The table below describes each electrode.

Module Electrode Type

cGlu electrode

+

cNa

electrode

cK+ electrode

cCa2+ electrode

cCrea A electrode

cCrea B electrode

2-6

pH/BG cCl– E744

pCO2 E788

pO2 E799

Reference E1001

pH E777

El/Met cLac E7077

cGlu E7066

cNa+ E755

cK+ E722

cCa2+ E733

Met II cCrea A E8088

cCrea B E8089

NOTICE: An orange filter is placed in the measuring chambers for the cGlu,

cLac, cCrea A and B electrodes.

Page 33

ABL800 FLEX Operator's Manual 2. What Is what

Inlet module

Parts and

functions

The inlet module accepts samples from a syringe/test tube or a capillary (the

syringe and capillary inlet flaps are removed on the picture). Syringe and capillary

inlet flaps are interlocked so that only one may be opened at a time.

Probe

attachment

Preheater

Inlet probe

Capillary inlet flap post

Syringe inlet flap post

Capillary inlet

Syringe inlet

Inlet gasket

unit

Part Function

Probe attachment Secures inlet probe. Open the clip to remove probe.

Preheater

Heats all samples and gases to 37 °C.

Inlet probe Automatically moves into the syringe to aspirate the

required sample.

Capillary inlet flap post Holds the inlet flap for capillary samples.

Syringe inlet flap post Holds the inlet flap for syringe samples.

Capillary inlet Receives sample from a capillary.

Syringe inlet Receives sample from a syringe and test tube.

Inlet gasket unit Provides transfer of samples from a sampling device

to the inlet probe; can be removed.

2-7

Page 34

2. What Is what ABL800 FLEX Operator's Manual

FLEXQ module

Parts and

functions

FLEXQ module for automatic transport of samplers to the inlet is shown below.

FLEXQ position before or after analysis:

Barcode reader

Samplers

Sampler tray

FLEXQ position during analysis:

Indicator

diodes

2-8

Continued on next page

Page 35

ABL800 FLEX Operator's Manual 2. What Is what

FLEXQ module, Continued

Parts and

functions

(continued)

The components are as follows:

Part Function

FLEXQ sampler tray FLEXQ sampler tray moves to the position for

measurement by means of a step motor (not

shown).

The samplers used in the sampler tray should be

safePICO sampler with the safeTIPCAP.

Indicator diodes Change the color from green to yellow when the

optical switch detects the sampler placed in the

slot.

Barcode reader Laser barcode reader reads the sampler barcode. A

short beep indicates that the barcode has been

read. You can scan the Sampler ID on the

analyzer’s scanner and then place it in the sample

tray or you can place the sampler in the sampler

tray and let the FLEXQ scanner read the sampler

barcode.

Sampler tray cover

Mixer tray

The sampler tray cover has three slots for the

samplers; the slots have optical switches for

detecting the sampler. The cover can be removed

(as shown) for cleaning.

The mixer rotates and moves the ball in the

sampler in order to mix the blood sample. The

sample is adequately mixed after 7 seconds.

The mixer tray moves into position under the

sampler immediately before the measurement.

2-9

Page 36

2. What Is what ABL800 FLEX Operator's Manual

r

r

Thermal printer

Parts and

functions

The components of the thermal printer (with the cover open) are shown below.

Release lever

Drive rolle

Paper roll holder

Cove

Paper guide

Part Function

Release lever Push the lever fully back to lift the drive roller from the

printer head and paper guide in order to adjust paper

alignment.

Remember to return the lever to its original position (as

shown) in order to print.

Drive roller Feeds the thermal paper through the printer.

Paper guide Located behind the drive roller, it is between this and the

drive roller that paper is fed.

Paper roll holder Holds the paper roll in place.

Cover Open to replace the paper roll. Contains instructions on

how to make a replacement.

Close the cover when a new paper roll has been mounted

in the printer.

2-10

Page 37

ABL800 FLEX Operator's Manual 2. What Is what

Communication ports

Ports and

functions

The following communication ports are available:

USB ports (two)

Mouse

Keyboard

Fuse for printer

unit

Display unit

The functions of the communication ports are as follows:

Port Function

Display unit port For connection to the analyzer’s display

Mouse port PS/2 connector used for the connection of a standard

mouse (user supplied).

Printer port

Network connector

Ext. VGA monitor

Serial port (COM2)

Main fuse

Keyboard port PS/2 connector used for connection of a keyboard (user

supplied).

Serial port

(COM2)

9-pin serial port used for HIS/LIS communication or

connection of an external barcode reader.

Network RJ45 ethernet interface connection to network.

Printer port Parallel port for connection to a local printer

Continued on next page

2-11

Page 38

2. What Is what ABL800 FLEX Operator's Manual

Communication ports, Continued

Ports and

functions

(continued)

Port Function

External VGA

monitor port

15-pin connector for external monitor (optional; is enabled

by Radiometer service representative).

USB (2 ports) For connecting USB devices, e.g. a removable drive.

USB keyboard supported. Other USB devices need an

approved XP driver (user-supplied mouse or modem, etc.).

Fuse for printer

unit

The compartment contains 1 protective fuse: 5 × 20 mm, 4

Amp, Slow blow (T4AL) (order code number 450-035).

Main fuse The compartment contains 2 protective fuses: 5 × 20 mm,

4 Amp, High break (T4AH). Type Shurter No. 0001.2510

(order code number 450-144).

WARNING – Risk of fire

Fire hazard. Replace fuse as marked.

2-12

Page 39

ABL800 FLEX Operator's Manual 2. What Is what

Barcode reader

Barcoded items

The following items have barcodes that can be read into the analyzer:

Item Location of barcode

All solution containers Label on the container

QC ampoules Insert in the box containing the ampoules

tHb calibration ampoules Insert in the box containing the ampoules

Electrodes Label on the box containing the electrode

Electrode membranes Label on the box containing the membrane unit

Gas cylinders Label on the cylinder

Pump tubing Label on the tubing packaging

Fan filter Label on the box containing the filter

Inlet gasket Label on the box containing the inlet gasket

Reading in a

barcode

In addition to the items above, you can enable every text box on the Patient

Profile, Patient ID, Patient Result, QC ID and Recording Fluid Replacement

screens where it is possible to enter a barcode – refer to Miscellaneous Setup in

chapter 3: Installation and setup.

Hold the barcode of the item you wish to read in parallel to the sensor part of the

barcode reader. A short beep from the barcode reader indicates that the information

has been read in successfully.

Sensor part

2-13

Page 40

2. What Is what ABL800 FLEX Operator's Manual

A

AutoCheck module

Parts and

functions

The AutoCheck module is shown below.

utoCheck carousel

To close

To open

Retractable cover

Part Function

Retractable cover Gives access to the carousel.

You can either slide the carousel cover open or press

Menu - Analyzer Status - AutoCheck - More - Open

Module.

Make sure that no objects prevent the cover from

opening freely.

AutoCheck carousel Contains the AutoCheck ampoules packed according to

the optimal packing list – see Refilling the AutoCheck

carousel in chapter 7: Replacements.

2-14

Page 41

ABL800 FLEX Operator's Manual 2. What Is what

Screen elements

Ready screen

Operation and management of the ABL800 FLEX analyzers is performed via a

touch screen. Almost all commands to the analyzer come from the touch of a

button or area on the screen.

The touch screen is divided into three sections:

Top section

Center section

Top section

Bottom section

For the analyzers without the FLEXQ module, the Ready screen looks as follows:

The Ready screen appears automatically if the touch screen remains idle for more

than 3 minutes. The screen intensity reduces by 50 % when the analyzer is not

used.

The status bar varies slightly, according to which screen you are in and the status

of the analyzer.

Example:

The status describes the current task of the analyzer (e.g. calibration, measurement,

etc.) or its status (e.g. ready for use, on hold, etc.).

Continued on next page

2-15

Page 42

2. What Is what ABL800 FLEX Operator's Manual

Screen elements, Continued

Top section

(continued)

The time bar is present only when the analyzer is performing a task; it follows the

progress of the current task. For example:

The Stop button

is visible only when it is allowed to interrupt an activity

in progress.

The parameter bar lists all measured parameters available and activated on your

analyzer.

It allows you to judge the parameter status at a glance before you have to perform a

measurement.

Green parameter:

Parameter status is okay; no problem is detected on the given

measuring channel.

Yellow

parameter:

Error associated with the given parameter during last

calibration or quality control measurement. The parameter is

unreliable and will have “?” (if requested in Corrective

Red parameter:

Actions) in front of the result.

Serious error associated with the given measuring channel.

Parameter cannot be used at all and will be displayed as

“…..”; or a parameter was repressed in the Parameter Setup

program due to errors during last calibration or quality

control measurement.

NOTICE: A parameter disabled in the Parameter Setup program will be removed

from the parameter bar – see Analysis Setup Programs (Disabled versus

Deselected Parameters) in chapter 3.

2-16

Continued on next page

Page 43

ABL800 FLEX Operator's Manual 2. What Is what

Screen elements, Continued

Center section

The center section is the main information and interaction area of which there are

many different types.

The center section of the Ready screen is described part by part, starting from the

top (for the analyzers without FLEXQ module the center part contains the analyzer

type and – if entered in Miscellaneous Setup (see chapter 3) – analyzer message).

This part of the Ready screen contains the following elements:

• Analyzer name

• The messages to the operator regarding the FLEXQ activities

• Urgent Manual Sample request button. The button allows you to book an inlet

for an urgent measurement while the analyzer performs a task.

The button is grayed out when the analyzer is ready for any measurement.

This part of the Ready screen contains the following elements:

• "Slot #": condition of each sampler tray slot (1, 2 and 3) is indicated with the

arrows that reflect the indicator diodes in the sampler tray:

Green Place the sampler into the slot

or remove it from the slot.

Blinking

green

Wait for the sampler to be

identified.

Yellow Do not remove the

sampler from the slot.

Blinking

yellow

Remove the sampler

from the slot.

• "Sampler ID": appears when the sampler is placed in the sampler tray slot and is

registered. The name of this column can be changed in the Sample Logistics

Setup (see Analysis Setup in chapter 3 of this manual).

• "Time to Result": shows time left till a result will be ready; the clock indicates

that the sample age has exceeded settings selected in Sample Logistics setup.

• "Status": gives information about a sampler in the slot:

Slot empty A slot is ready to accept a sampler.

Ready for processing Sampler has been registered in the slot.

Processing Patient and sampler data are being processed.

Completed Measurement is completed and the result can be

viewed.

Continued on next page

2-17

Page 44

2. What Is what ABL800 FLEX Operator's Manual

Screen elements, Continued

Center section

(continued)

Patient data can be edited.

Result can be viewed.

This part of the Ready screen is reserved for the analyzer messages and is entered

in the Miscellaneous Setup (see chapter 3 in this manual):

Other screen types and their elements are described on the following pages.

Icon and screen name identify each screen. Example:

Icon

Screen name

2-18

The icon and title of a screen are the same as the button that gives access to that

screen.

Continued on next page

Page 45

ABL800 FLEX Operator's Manual 2. What Is what

Screen elements, Continued

Center section

(continued)

Text boxes show a text in the form of

lists, items, tables, etc. Various types

of text boxes and navigation in them

are given on the next page.

The first line is highlighted. To

highlight another line, touch it on the

screen or use up and down arrow scroll

keys displayed on the screen beside a

relevant text box.

A scroll bar scrolls a text box

horizontally when the text box extends

beyond the area available on the

screen.

A single-arrow scroll button

highlights one item at a time upward or

downward.

Scroll bar

Scroll keys

A double-arrow scroll button

highlights an item at the top or the

bottom of the screen.

The first line is highlighted. To

highlight another line, use the up and

down arrow buttons or touch this line

in the box.

Enter the data using the screen keypad

or keyboard.

In this text box you can select one of

the predefined options.

Use the up and down arrow buttons to

select an item.

NOTICE: If the text box already

contains an entry, it will be overwritten

and cannot be retrieved.

Text boxes are designated in quotation marks, e.g. "Operator". The same applies to

the other elements on the center section of the screen: names of the columns (e.g.

"Status"), input fields (e.g. "Draw time"), etc.

Continued on next page

2-19

Page 46

2. What Is what ABL800 FLEX Operator's Manual

N

Screen elements, Continued

Center section

(continued)

Check buttons allow you to enable/disable or select/deselect an item on the

screen. For example:

A function is selected (e.g.

acoustic signal if the inlet

remains open) or activated (e.g.

communication with the

Parameter is

selected.

RADIANCE system)

A function is deselected or

deactivated.

Parameter is

deselected.

Screen keypad allows the entry of numerical data on the screen.

umerical keys

from 0 to 9.

Decimal point.

The buttons listed below have the following functions:

Press to confirm a numerical entry and to highlight the

next line in the text box.

Press to delete a character (from right to left) or to type in

the new data (the box is cleared as soon as the first

character is typed).

Press to display the full alphanumerical keyboard.

Continued on next page

2-20

Page 47

ABL800 FLEX Operator's Manual 2. What Is what

A

Screen elements, Continued

Center section

(continued)

Screen keyboard is used for entering both alphabetical and numerical data − see

the description on the next page.

ctivated text box

The keyboard functions as a normal keyboard with alphabetical and numerical

characters. The typed text appears in the activated text box.

Enter

Press to confirm the entry and to return to the previous screen.

Backspace

Press to delete characters from right to left.

Press to cancel any changes made in the activated text box and

to return to the previous screen

Press to delete an entry in the activated text box.

Shift

Press to type a capital letter or symbol.

Press to lock the keyboard in order to type capital letters and

symbols on the numerical keys. When activated, indicator is

green.

Up/down/left/right arrows move the cursor in the activated text

box in order to edit a text.

Continued on next page

2-21

Page 48

2. What Is what ABL800 FLEX Operator's Manual

Screen elements, Continued

Buttons

Each button has an icon and a name placed on it. When pressed, it opens a screen

or a menu.

Information bar

and icons

The buttons are designated in bold italics in this manual, e.g. Menu, Utilities, etc.

The buttons displayed in full color can be activated. A button in a weaker color,

i.e. grayed-out, is temporarily inactive.

The buttons at the top and the bottom of the screen can be selected in the Setup

program Access Profiles (in the Analyzer Security menu) together with the access

profiles for each operator – for detailed information see the description in chapter

3: Installation and setup.

Note the functions of the following buttons:

Returns you to the previous screen in the same program,

e.g. in the Patient Results log, it will return you from the

Patient Identification screen to the Patient Result

screen.

Returns you to the Ready screen.

The information bar is placed in the lower right corner of the screen.

2-22

Continued on next page

Page 49

ABL800 FLEX Operator's Manual 2. What Is what

Screen elements, Continued

Information bar

and icons

(continued)

The following icons are available on the information bar:

Icon Function

Shows the current time in the selected format.

Shows that an analyzer is connected to the RADIANCE

system.

Shows that an analyzer is connected to the QA Portal.

Shows the time of the next scheduled calibration. The time

changes when a calibration has been completed.

Shows the time of the next scheduled QC measurement.

The time changes when a QC measurement has been

completed.

Shows that the remote operator is connected.

Click to make more icons visible.

Click to reduce the number of visible icons to a clock.

2-23

Page 50

2. What Is what ABL800 FLEX Operator's Manual

Menu structure

Menu at

analyzer startup

When the analyzer is taken into use, only the following limited menu is available:

Press Menu.

Calibration Progs:

1 Point Calibration

2 Point Calibration

Auxiliary Progs:

Rinse

Cleaning

Protein Removal

Decontamination

AutoCheck Programs

Run High Crea Check

(only the ABL8x7 analyzers)

Log on

Analyzer Status Help

Start Progs

Utilities

Standby

Temporary Shutdown

Last patient result

Tutorials

Data Logs

Patient Results Log

Patient Profile Log

QC Log

Calibration Log

Activity Log

Allowed actions

at analyzer

startup

2-24

The following actions are allowed at analyzer startup:

To perform a measurement

•

To call a calibration

•

To edit data in the data logs

•

To perform a replacement

•

To start an AutoCheck measurement

•

The menu above and the scope of actions are suitable for those users whose

activities include performing measurements and occasional replacements.

Continued on next page

Page 51

ABL800 FLEX Operator's Manual 2. What Is what

Menu structure, Continued

Entering

standard

password

To access the complete menu, do the following:

Step Action

Press Menu on the Ready screen.

1.

Then click on Logon.

Type in the standard password: 123456.

2.

Standard password:

123456.

See chapter 3: Installation and setup, Analyzer Security, in this

manual for further information about the logon possibilities.

Confirm with Enter.

Press Menu to access the complete menu – see the next section.

3.

The access possibilities for each user of the analyzer and their passwords are

entered in Setup program Access Profiles – see chapter 3: Installation and setup in

this manual.

Continued on next page

2-25

Page 52

2. What Is what ABL800 FLEX Operator's Manual

Menu structure, Continued

Complete menu

Press Menu.

My results*

Last patient result

Calibration Progs:

1 Point Calibration

2 Point Calibration

tHb Calibration