Page 1

1. Introduction

ABL™77 Series

Blood Gas and

Electrolyte

Analyzer

2. Analyzer Description

3. Troubleshooting

4. Test and Calibration

5. Dismantling

6. Replacements

Service Manual

7. Re-Assembly

8. Maintenance

9. Spare Parts

Service Notes

Date of Issue

Page 2

LICENSE AGREEMENT

The software installed and provided with the instrument is comprised of Microsoft®

CE Operating System and SenDx Medical, Inc. developed Software. Each program

is licensed, not sold to you, to be used only under the terms of this Agreement and

the Microsoft End User License Agreement. SenDx Medical, Inc. and its licensors

reserve all rights not expressly granted to you. You may use the software only with

the instrument in which it is installed for your internal purposes. When the instrument

is transferred to others, it must be accompanied by the software and the End User

License Agreements included in the Operator’s Manual. The software may not be

copied. You may not modify, reverse engineer, decompile or disassemble the

programs. By your use of the instrument you agree to the terms of this Agreement

and the Microsoft End User License Agreement. If you do not accept or agree to the

terms you should promptly contact your Radiometer representative for a return of the

instrument and a refund of your money.

TRADEMARKS

ABL™, and RADIOMETER™ are trademarks of Radiometer Medical A/S, Denmark.

ABL is registered in the USA.

COPYRIGHT

The contents of this document may not be reproduced in any form or communicated

to any third party without the prior written consent of Radiometer Medical A/S.

While every effort is made to ensure the correctness of the information provided in

this document Radiometer Medical A/S assumes no responsibility for errors or

omissions which nevertheless may occur.

This document is subject to change without notice.

© Radiometer Medical A/S, DK-2700 Brønshøj, Denmark, 2003. All Rights

Reserved.

Page 3

ABL77 Service Manual Table of Contents

Table of Contents

Introduction

Contents

This manual describes how to service the ABL™77 Series analyzer.

This manual contains the following topics.

1. Introduction.................................................................................................. 1-1

Overview ............................................................................................ 1-1

Service Policy..................................................................................... 1-2

Test Equipment and Tools.................................................................. 1-5

ABL77 Identification.......................................................................... 1-6

Panel Options...................................................................................... 1-7

2. Analyzer Description ................................................................................... 2-1

Overview ............................................................................................ 2-1

Functional Description ....................................................................... 2-2

Installation ................................................................................... 2-3

SCi

Calibration .......................................................................................... 2-5

Sample Analysis ............................................................................... 2-12

Module Descriptions ........................................................................ 2-18

Upper Module......................................................................................... 2-26

Lower Module......................................................................................... 2-30

Electronics Module................................................................................. 2-34

3. Installation .................................................................................................... 3-1

Overview ............................................................................................ 3-1

General Information ................................................................................ 3-2

Cautions and Warnings....................................................................... 3-3

General Guidelines ............................................................................. 3-4

Hardware Screen ................................................................................ 3-5

Reference Table of Problems, Causes and Corrective Actions ............ 3-8

Reference Table.................................................................................. 3-9

System Messages..................................................................................... 3-16

Continued on next page

Rev. F 1

Page 4

Table of Contents ABL77 Service Manual

Table of Contents, Continued

4. Test and Calibration Procedures ................................................................ 4-1

Overview ............................................................................................ 4-1

Verify the Fluid Transport System ..................................................... 4-3

Calibration Lines Procedure ............................................................... 4-5

Testing the Valve Connections......................................................... 4-11

Valve Test Procedures...................................................................... 4-13

Check Valve Fluidics System ................................................ 4-15

Original Fluidics System........................................................ 4-19

Waste Line........................................................................................ 4-26

5 Volt Power Output Setting ............................................................ 4-29

SC/Hematocrit Circuits .................................................................... 4-31

Electronic Zero Offset ...................................................................... 4-34

Heater Circuit ................................................................................... 4-36

Inlet Flap Sensor............................................................................... 4-39

Paper Jam ......................................................................................... 4-40

Battery Charger ................................................................................ 4-43

Battery Pack...................................................................................... 4-45

Touch Screen Panel Calibration ....................................................... 4-48

Reprogramming the CPU BIOS Settings ......................................... 4-50

Re-programming the Barcode Scanner............................................. 4-52

Resetting the Analyzer Serial Number ............................................. 4-56

5. Dismantling................................................................................................... 5-1

Overview ............................................................................................ 5-1

Upper Module........................................................................................... 5-4

Upper Module..................................................................................... 5-4

Backlight Inverter Board .................................................................... 5-7

Disk Drive .......................................................................................... 5-8

LCD Display..................................................................................... 5-10

Touch Screen Panel .......................................................................... 5-12

Lower Module......................................................................................... 5-13

Printer Door...................................................................................... 5-13

Printer Module.................................................................................. 5-14

Lower Module .................................................................................. 5-16

Opt-Sensor........................................................................................ 5-19

Continued on next page

2 Rev. F

Page 5

ABL77 Service Manual Table of Contents

Table of Contents, Continued

Roller Wheel and Roller Pump......................................................... 5-20

Waste Pump Head and Waste Pump ................................................ 5-22

Original Valve Board / Manifold Assembly..................................... 5-25

Valve Board with Replaceable Valves ............................................. 5-27

Valve Board Styles ........................................................................... 5-31

Electronics Module................................................................................. 5-35

Electronics Module........................................................................... 5-35

Analog Board.................................................................................... 5-38

Interface Board ................................................................................. 5-40

Power Distribution Board................................................................. 5-42

Electronic Boards Assembly ............................................................ 5-44

LCD Adapter Board ............................................................... 5-45

Memory Module .................................................................... 5-46

ChipDisk board ...................................................................... 5-47

CPU and Touch Screen Boards.............................................. 5-48

Battery Control Board ...................................................................... 5-49

Fan Assembly ................................................................................... 5-51

6. Replacements ................................................................................................ 6-1

Overview ............................................................................................ 6-1

Main Housing............................................................................................ 6-4

Main Housing Assembly .................................................................... 6-4

Carrying Handle ................................................................................. 6-5

Upper Module........................................................................................... 6-6

Housing Bracket ................................................................................. 6-6

Lower Module........................................................................................... 6-9

Manifold Gasket ................................................................................. 6-9

Valve Board...................................................................................... 6-10

Single Valve ..................................................................................... 6-18

Valve Board Tubing ......................................................................... 6-22

Manifold ........................................................................................... 6-26

Electronics Module................................................................................. 6-29

Coin Cell Battery.............................................................................. 6-29

Rear Panel......................................................................................... 6-30

Battery .............................................................................................. 6-31

Continued on next page

Rev. F 3

Page 6

Table of Contents ABL77 Service Manual

Table of Contents, Continued

Cabling .................................................................................................... 6-33

Disk Drive Cable .............................................................................. 6-36

LCD Display Cable .......................................................................... 6-38

Backlight Inverter Cable................................................................... 6-40

Touch Screen Cable.......................................................................... 6-42

Main Analog Cable........................................................................... 6-43

Analog Power Cable......................................................................... 6-44

Power Board Cable........................................................................... 6-45

A/D Cable – Analog Board to CPU board ....................................... 6-47

Printer Data Cable ............................................................................ 6-48

Printer Power Cable.......................................................................... 6-49

A/D Cable – Analog Board to Battery Control Board...................... 6-50

COM1 Cable..................................................................................... 6-52

Power Switch Cable ......................................................................... 6-53

Barcode Reader / Keyboard Cable ................................................... 6-54

Ethernet Cable .................................................................................. 6-56

7. Re-Assembly ................................................................................................. 7-1

Overview ............................................................................................ 7-1

Upper Module........................................................................................... 7-4

Touch Screen Panel ............................................................................ 7-5

LCD Display....................................................................................... 7-8

Disk Drive .......................................................................................... 7-9

Backlight Inverter Board .................................................................. 7-12

Upper Module................................................................................... 7-13

Lower Module......................................................................................... 7-15

Valve Boards – General Information................................................ 7-15

Valve Board Assembly..................................................................... 7-20

Waste Pump And Waste Pump Head ............................................... 7-24

Roller Pump And Roller Wheel........................................................ 7-27

Opto-Sensor...................................................................................... 7-31

Lower Module .................................................................................. 7-32

Printer Module.................................................................................. 7-35

Printer Door...................................................................................... 7-36

Continued on next page

4 Rev. F

Page 7

ABL77 Service Manual Table of Contents

Table of Contents, Continued

Electronics Module................................................................................. 7-37

Rear Panel Assembly........................................................................ 7-37

Fan Assembly ................................................................................... 7-38

Electronics Chassis And Battery Cage ............................................. 7-39

Battery Control Board ...................................................................... 7-40

Electronics Shelf............................................................................... 7-42

Electronic Boards ............................................................................. 7-44

Touch Screen And CPU Boards Assembly............................. 7-46

ChipDisk Board...................................................................... 7-47

Memory Module ..................................................................... 7-48

Disk Drive Cable.................................................................... 7-49

LCD Adapter Board ............................................................... 7-50

Electronics Boards – Module Assembly .......................................... 7-51

Power Distribution Board................................................................. 7-54

Interface Board ................................................................................. 7-56

Analog Board.................................................................................... 7-58

Electronics Module........................................................................... 7-62

8. Maintenance.................................................................................................. 8-1

Overview ............................................................................................ 8-1

Valve Maintenance............................................................................. 8-2

Cleaning.............................................................................................. 8-6

Long-Term Storage ............................................................................ 8-9

Recommended Service Procedures ....................................................... 8-13

1-Year Service .................................................................................. 8-13

2-Year Service .................................................................................. 8-14

3-Year Service .................................................................................. 8-15

9. Spare Parts.................................................................................................... 9-1

Overview ............................................................................................ 9-1

Modules And Externals ...................................................................... 9-2

Upper Module Components ............................................................... 9-4

Lower Module Components ............................................................... 9-6

Main Housing ................................................................................... 9-12

Electronics Module Components...................................................... 9-15

Recommended Parts And Hardware................................................. 9-21

Continued on next page

Rev. F 5

Page 8

Table of Contents ABL77 Service Manual

Table of Contents, Continued

Service Notes

Date of Issue

6 Rev. F

Page 9

ABL77 Service Manual Chapter 1: Introduction

1. Introduction

Overview

Introduction

Contents

This chapter gives an introduction to the servicing of the ABL™77 analyzer and

important information for understanding the procedures and requirements.

This chapter contains the following topics.

Overview............................................................................................... 1-1

Service Policy ....................................................................................... 1-2

Test Equipment and Tools .................................................................... 1-5

ABL77 Identification ............................................................................ 1-6

Panel Options ........................................................................................ 1-7

Rev. F 1-1

Page 10

Chapter 1: Introduction ABL77 Service Manual

Service Policy

Introduction

Warranty

disclaimer

This section outlines the policies and procedures, which must be followed when

servicing Radiometer Medical A/S instruments.

The service policy for the ABL77 Series has been outlined to obtain a maximum

degree of reliability with minimal repair time.

Further, a combination of comprehensive troubleshooting procedures in the service

manual, a variety of self-check and service programs, and a high degree of

modularization facilitates quick localization of faults in the analyzers.

Using the test equipment, procedures and spare parts listed in this service manual

ensures continuous reliability.

Exceptions from the service policy are not allowed unless special permission or

instructions in writing have been given beforehand by SenDx Medical, Inc.

Radiometer Medical A/S cannot guarantee the instrument’s performance

specifications and safety or accept any warranty claims unless:

Non-original

parts

Electrostatic

discharge

protection

• The recommended maintenance procedures outlined in the Operator’s and

Service Manuals are performed.

• The accessories and spare parts specified by Radiometer Medical A/S are used.

Warranty claims for parts which suffer from physical damage, unauthorized

attempted repair, or exposure to conditions other than those specified by

Radiometer Medical A/S (e.g., temperature, line voltage outside specified limits)

will not be accepted.

Spare parts and accessories

In order to ensure the reliability, durability and operation in accordance with

technical specifications, use only original Radiometer Medical A/S parts, or parts

approved by Radiometer Medical A/S.

This concerns both spare parts and accessories.

Software

Software is considered to be a spare part. Only software distributed by Radiometer

may be installed in the analyzer.

In order to ensure the reliability and durability of the analyzer, ESD protection

precautions must always be taken when handling or exposing ESD sensitive parts.

Parts such as printed circuit boards may be damaged if handled incorrectly during

storage and service. The damage is not visible, and the damaged parts may not fail

immediately but several months later.

Installation test

In connection with the installation, repair and upgrade of an analyzer it is usually

required that an Installation Test be carried out to verify that the analyzer calibrates

correctly and measures correctly using the appropriate quality control solution.

Continued on next page

1-2 Rev. F

Page 11

ABL77 Service Manual Chapter 1: Introduction

Service Policy, Continued

Repair level

The repair level outlines the extent to which it is allowed to dismantle an analyzer

in the process of troubleshooting and repair. This level is limited for several

reasons such as: the need for specialized test equipment, special environmental

requirements etc., and is optimized in relation to cost of parts, time for repair, etc.

The repair level is indicated in the chapters (5) Dismantling, (7) Re-Assembly and

(9) Spare Parts.

Electronics Module

The major components in the electronics module are printed circuit boards. Lowlevel repair of these boards is not allowed in the field. Most of the boards are based

on surface mounted technology, which involves a high component density and

thereby a high complexity. Repair of this type of printed circuit board (PCB)

requires advanced troubleshooting, repair and test facilities, which are only

available at the factory. Some PCBs may be returned to the factory for replacement

under the trade-in agreement for modules. These PCBs are marked with “*” next to

the description in the spare parts list. Since repair is not allowed in the field,

detailed circuit diagrams are not included in the service manual.

Lower Module

Most of the electromechanical and pure mechanical parts of the lower module may

be repaired to the component level. Tubing, the printer, and pump motors are

regarded as components (or component assemblies). The various programs

facilitate checkout and adjustment of these parts and also verification of their

function after repair.

Some mechanical adjustments are critical for their function. Such parts are not to

be dismantled further than indicated in the spare parts list.

Upper Module

The upper module may be repaired to the component level. The various programs

facilitate checkout and adjustment of these parts and also verification of their

function after repair.

Some mechanical adjustments are critical for their function. Such parts are not to

be dismantled further than indicated in the spare parts list.

Continued on next page

Rev. F 1-3

Page 12

Chapter 1: Introduction ABL77 Service Manual

Service Policy, Continued

WARNING/

CAUTION:

Calibration and

measurement

CAUTION: Follow legal requirements and local rules for safe work practices with

chemicals.

CAUTION: Working with blood gas analyzers may result in contact with blood

remnants and with harsh disinfectants. During the various procedures wear suitable

protection gear (gloves, face protection, and protective body clothing) and follow

legal requirements and local rules for safe work practices.

CAUTION: The gloves must be free of pinholes and preferably be puncture

resistant. Please consult the glove manufacturer for further information.

CAUTION: If contaminated materials come into contact with any lesion on the

body, seek medical advice.

While performing calibrations and measurements, the analyzer must be fully

assembled.

ECOMMENDATION: To facilitate troubleshooting procedures, consider purchasing

R

one of each analyzer module to use as a test module.

1-4 Rev. F

Page 13

ABL77 Service Manual Chapter 1: Introduction

Test Equipment and Tools

Required

equipment and

tools

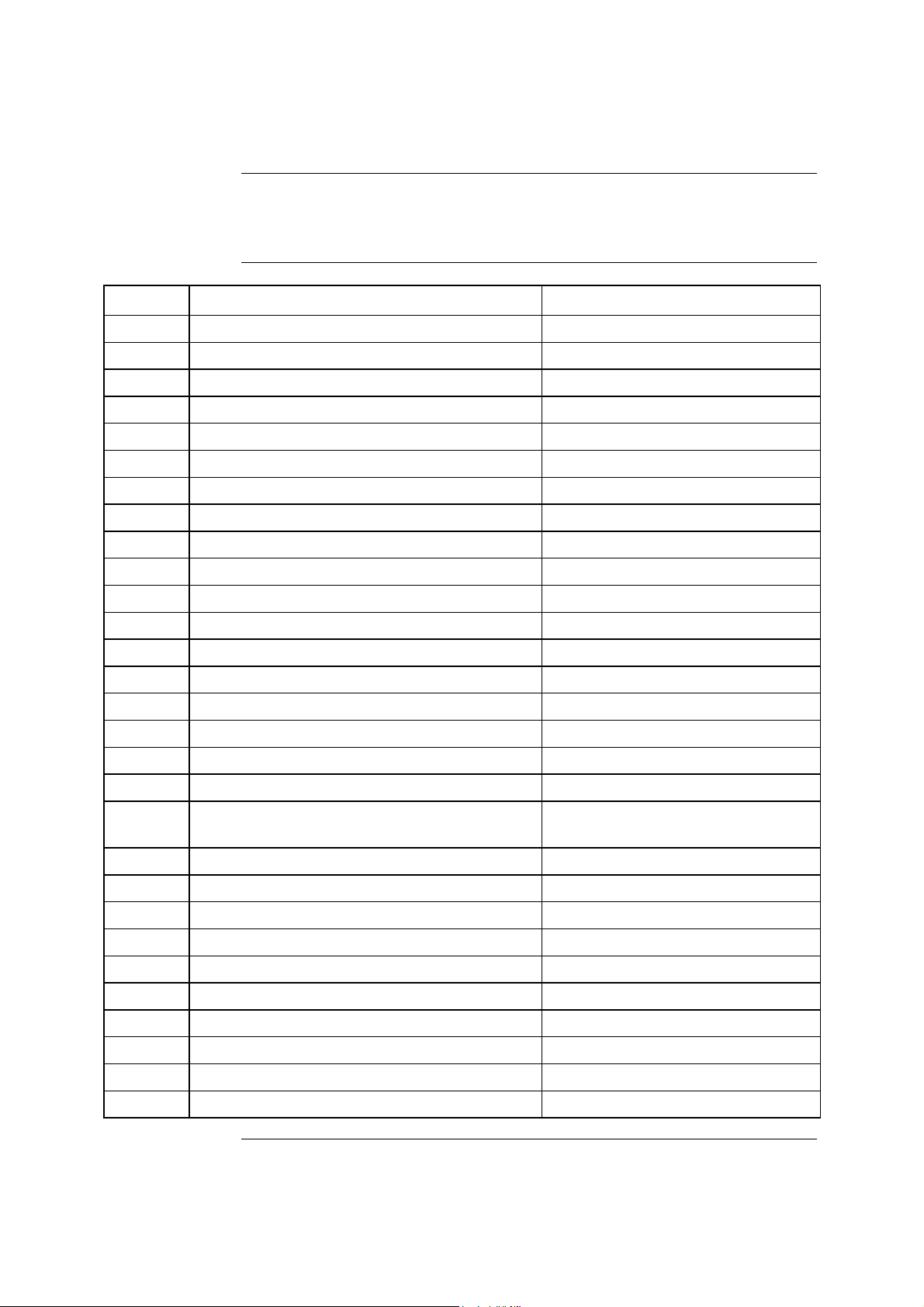

REF Description Use

902-6XX SCi sensor cassette Testing analyzer after repair

944-069 Calibration solutions pack (cal pack) Testing analyzer after repair

902-578 Electronic zeroing fixture Zeroing sensor channels

913-741 Manager setup disk Custom setup of system features

920-721 5/64” ball point Allen wrench Various applications

920-722 1/16” ball point Allen wrench Lower module

920-723 7/64” ball point Allen wrench Lower module

To carry out the procedures for servicing the analyzer, the following test

equipment and tools are required: Parts marked with “N/A” in the REF column are

to be purchased locally.

920-726 5/16” open-end wrench Electronics module

920-727 5/16” nut driver Electronics and Lower modules

920-728 ¼” nut driver Electronics module

920-729 Valve board calibration cassette Calibrating the Hct and SC circuit

991-260 Loctite 401 Adhesive Securing the handle to the housing

991-264 Silicone adhesive, RTV medical grade Securing cables to prevent disconnect

991-265 Loctite 222 Threadlocker Securing assorted screws and nuts

905-674 Sample path obstruction tool kit Various applications

943-906 Cleaning solution Cleaning the waste drain

N/A Deionized water (or sterile water) Various applications

N/A Soft cloth, gauze or other absorbent material Various applications

N/A Protective attire (gloves, safety glasses, and lab

Various applications

coat)

N/A Flat head screwdriver

Lower module

N/A Small flat head screwdriver Adjusting the calibration settings

N/A Phillips head screwdriver Various applications

N/A Needle nose pliers Lower module

N/A Scissors or equivalent trimming tool Various applications

N/A AT style keyboard Entering system commands

N/A Digital multimeter Testing electronics

N/A Digital voltmeter (or multimeter) 5 volt power output setting

N/A 3½” formatted diskettes Downloading data files

N/A Index card or equivalent Block the opto sensor

Rev. F 1-5

Page 14

Chapter 1: Introduction ABL77 Service Manual

ABL77 Identification

Introduction

ABL77

identification

Elements

This section explains the identification system for the ABL77 product.

Each individual analyzer consists of a number of separate elements, some using a

unique identification system. These numbers are used for a large variety of

purposes, e.g. tracking.

An analyzer consists of the following elements:

Element Element ID Syntax

Analyzer Serial number 200001

Sensor Cassette Lot number 52657

Serial number 041403150

Cal pack Lot number 52630

Use of

identification

Electronic serial

number

Serial number 52630124

Bar code scanner Part number / Revision 902-660

Battery Charger Part number / Revision 905-743

Manager Setup disk Part number / Revision 913-741

Operator’s Manual, English Part number / Revision 989-555

The analyzer serial number is the primary identification number, e.g.:

• For tracking purposes (both for the analyzer and it’s modules).

• For logging service actions.

• As a reference on service work orders.

• When ordering service components and modules.

The analyzer serial number is stored electronically in the ChipDisk. When the

ChipDisk or the electronics module is replaced, the serial number must be reprogrammed into the analyzer.

During service the system will recognize that there is no serial number and require

serial number entry upon startup before proceeding. Ensure the serial number

entered matches the serial number label located inside the printer door.

Serial number

label

replacement

1-6 Rev. F

The analyzer serial number label is located inside the analyzer printer door. In the

event that the printer door must be replaced, a new printer door with serial number

label must be ordered and produced at the factory.

Page 15

ABL77 Service Manual Chapter 1: Introduction

Panel Options

Introduction

Available

options

Management

This section explains the panel options available with the ABL77 analyzer. When

servicing an analyzer it should always be returned to the same settings.

The ABL77 can be configured for the following options:

• Blood gas and Hematocrit Only (BG/Hct)

• Electrolytes Only (Lytes)

• Full Panel (BG/Hct/Lytes)

The different analyzer configurations are controlled through the analyzer software

configuration at the time of purchase. The analyzer can be upgraded or

downgraded after purchase.

The same configurations are also available in sensor cassette types. The different

types are controlled through the sensor cassette barcode.

A full panel sensor cassette may be used on any analyzer configuration. The

analyzer will report “ NI ” (Not Installed) for non-configured parameters.

A BG/Hct or Lytes sensor cassette will only report their respective configured

parameters when installed on a full panel analyzer. Other parameters not supported

by the sensor cassette configuration will be reported as “NI”.

When attempting to install a BG/Hct sensor on a Lytes only analyzer (or

vice-versa), the analyzer will reject the installation.

Rev. F 1-7

Page 16

ABL77 Service Manual Chapter 2: Analyzer Description

2. Analyzer Description

Overview

Introduction

Contents

This chapter provides a general description of the analyzer modules, the electronic

boards, the electronics wiring diagrams, and the fluidics system. This chapter

includes various drawings for use during servicing. The drawings indicate the

location of connection points and general identification.

This chapter contains the following topics.

Overview............................................................................................... 2-1

Functional Description.......................................................................... 2-2

SCi Installation...................................................................................... 2-3

Calibration............................................................................................. 2-5

Sample Analysis.................................................................................. 2-12

Module Descriptions ........................................................................... 2-18

Upper Module................................................................................................. 2-26

Lower Module................................................................................................. 2-30

Electronics Module......................................................................................... 2-34

Rev. F 2-1

Page 17

Chapter 2: Analyzer Description ABL77 Service Manual

Functional Description

Introduction

Overview

This section provides a general introduction to the analyzer.

The ABL77 Analyzer is an electromechanical instrument designed to measure

blood gas, pH, and electrolyte concentrations of whole blood.

Intended use

Measuring

principles

The heart of the ABL77 analyzer is a 486 SX single board computer. It operates on

custom software in a Microsoft

®

Windows CE operating system. Peripherals

include a floppy disk, VGA color monitor with touch screen, thermal printer and a

custom board that performs all analog input and output functions.

An external AC to DC power supply provides system power. On board batteries

enable portable operation of the analyzer. An intelligent power control board

monitors system power and battery charge cycles.

After use, the analyzer may contain blood residue. Follow the Long-Term Storage

Procedure in Chapter 8 to decontaminate the analyzer. Following

decontamination, the ABL77 analyzer should be disposed of in a safe and proper

manner.

The ABL77 pH, blood gas and electrolyte analysis system is a portable, automated

analyzer that measures blood oxygen, carbon dioxide, pH, sodium, potassium,

chloride, ionized calcium and hematocrit in whole blood. The ABL77 system is

intended for use by trained technologists, nurses, physicians and therapists. It is

intended for use in a laboratory environment, near patient or point of care setting.

There are three different measuring principles employed.

• Potentiometry: A potential is recorded using a voltmeter, which relates to the

concentration of the sample. A reference electrode is used to provide a stable,

fixed potential against which other potential differences can be measured. Used

for pH, CO

and electrolytes.

2

• Amperometry: The magnitude of an electrical flow of current is proportional to

the concentration of the substance being oxidized or reduced at an electrode.

Used for O

.

2

• Conductivity: The specific impedance of a sample as measured by two

conducting electrodes held at a constant voltage is directly proportional to the

conductive properties of the sample. Used for hematocrit and air-in-sample

detection.

Operating

conditions

The ABL77 system can be operated at an ambient temperature of 12-28 °C

(54-82 °F).

All calibration solution packs should be stored at temperatures between 12-28 °C

(54-82 °F). Do not freeze or expose to excessive heat or direct sunlight.

All sensor cassettes should be stored at temperatures between 5-32 °C (41-90 °F).

Do not freeze or expose to excessive heat or direct sunlight.

Altitude

conditions

2-2 Rev. F

The ABL77 system can be operated at altitudes from sea level to 1600 meters.

Page 18

ABL77 Service Manual Chapter 2: Analyzer Description

SCi Installation

Sensor cassette

installation

Initializationhydration

Initializationcalibration

attempts

When a new sensor cassette is installed on the analyzer, the software will perform

an initialization procedure to prepare the cassette for use. This initialization process

consists of a preparatory hydration phase followed by a number of calibration

attempts.

• Cal1 flush is a preliminary flush to help expel air bubbles. A message “Please

wait….” appears for 10 seconds.

• A second Cal1 flush allows the new sensors to be conditioned with calibration

solution. A message “Hydrating….” appears for 2 minutes.

• Following hydration, the analyzer attempts a series of two point calibrations.

• The number of calibrations performed is dependent on the results of each

attempt. The minimum number of attempts is 1 and the maximum number of

attempts is 4.

Initialization

completed

• There are three failure conditions recognized by the software logic that

determine whether the initialization process continues or terminates, and what

messages are displayed. The three conditions are:

1. A single, mild sensor failure: One sensor sensitivity value falls between

50 – 100% of the minimum acceptable value. This is considered a

condition that may resolve itself with additional calibration attempts.

2. A single, severe sensor failure: One sensor sensitivity value falls between 0

– 50% of the minimum acceptable value. This is considered a condition

that is unlikely to resolve itself.

3. All other failure modes: Multiple sensor sensitivity values fall outside the

acceptable values, no endpoint errors are present, and other conditions

which may indicate air in the measuring chamber.

Following a successful initialization, the first auto calibration is scheduled for 30

minutes after initialization. Second and third calibrations are scheduled for 60

minutes after initialization and 120 minutes after initialization, respectively. From

this point calibrations follow the schedule entered in the Calibration Schedule

screen under Manager Setup / System Setup.

Rev. F 2-3

Page 19

Chapter 2: Analyzer Description ABL77 Service Manual

This page intentionally left blank

2-4 Rev. F

Page 20

ABL77 Service Manual Chapter 2: Analyzer Description

Calibration

Introduction

Hydration

The user can define the frequency of automatic two-point calibrations. The

possible intervals are 1, 2, 3 or 4 hours. The Calibration option on the Main

Menu is used to initiate a manual two- point calibration as desired.

If the calibration is more than 30 minutes past the scheduled time, a preliminary

flush of Cal1 solution is performed prior to the two-point calibration. A message

“hydrating….” will be displayed.

Continued on next page

Rev. F 2-5

Page 21

Chapter 2: Analyzer Description ABL77 Service Manual

Calibration, Continued

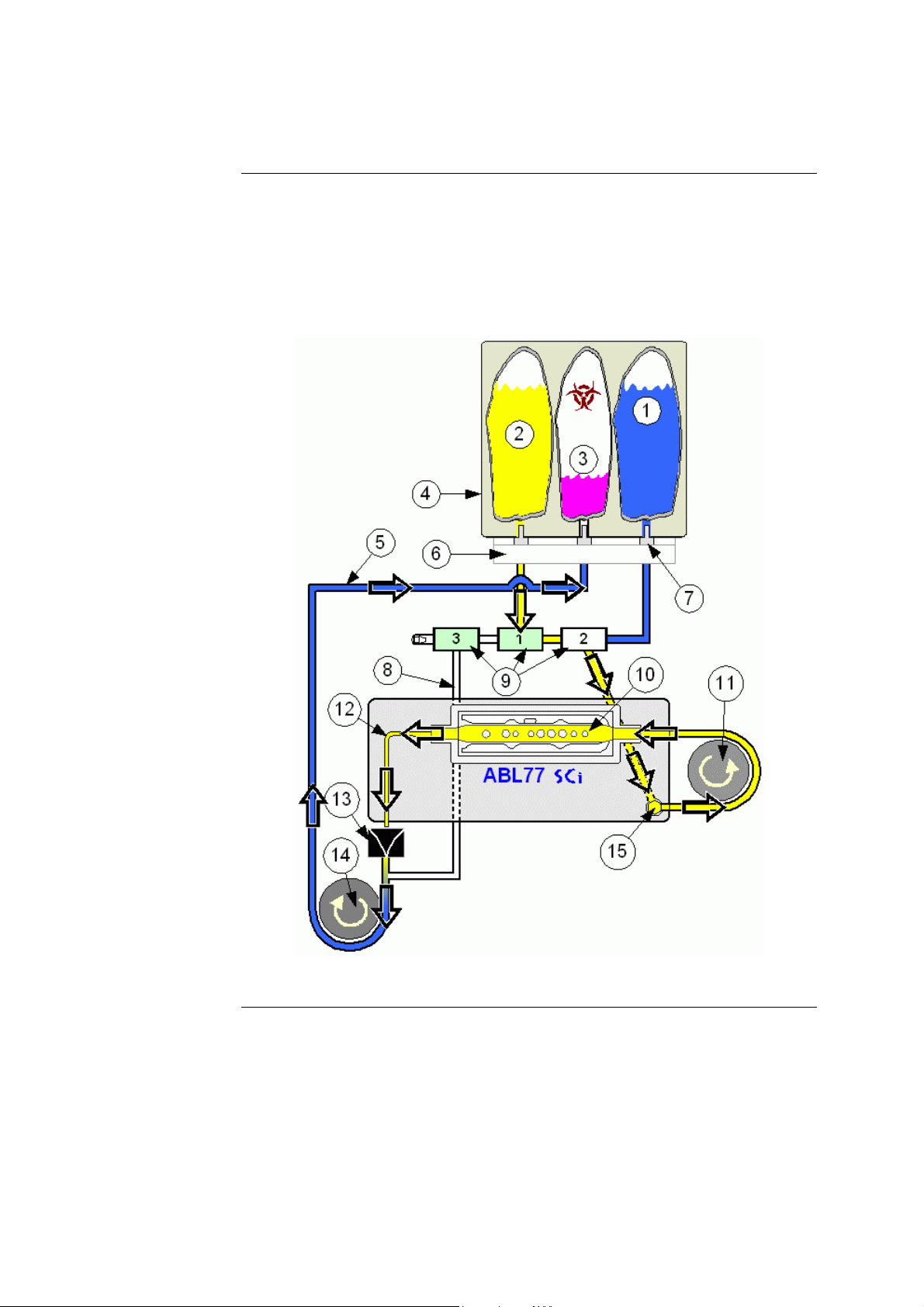

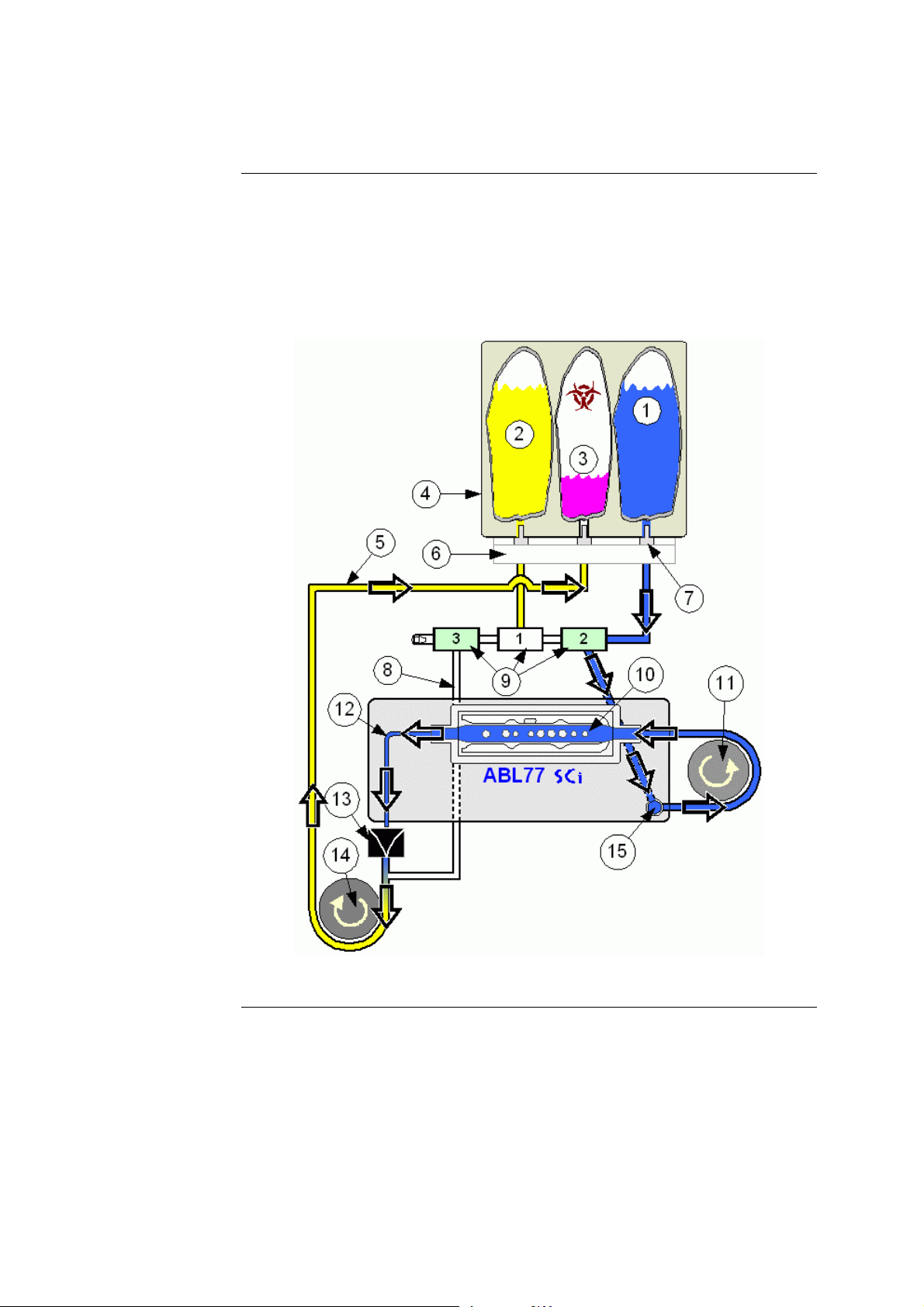

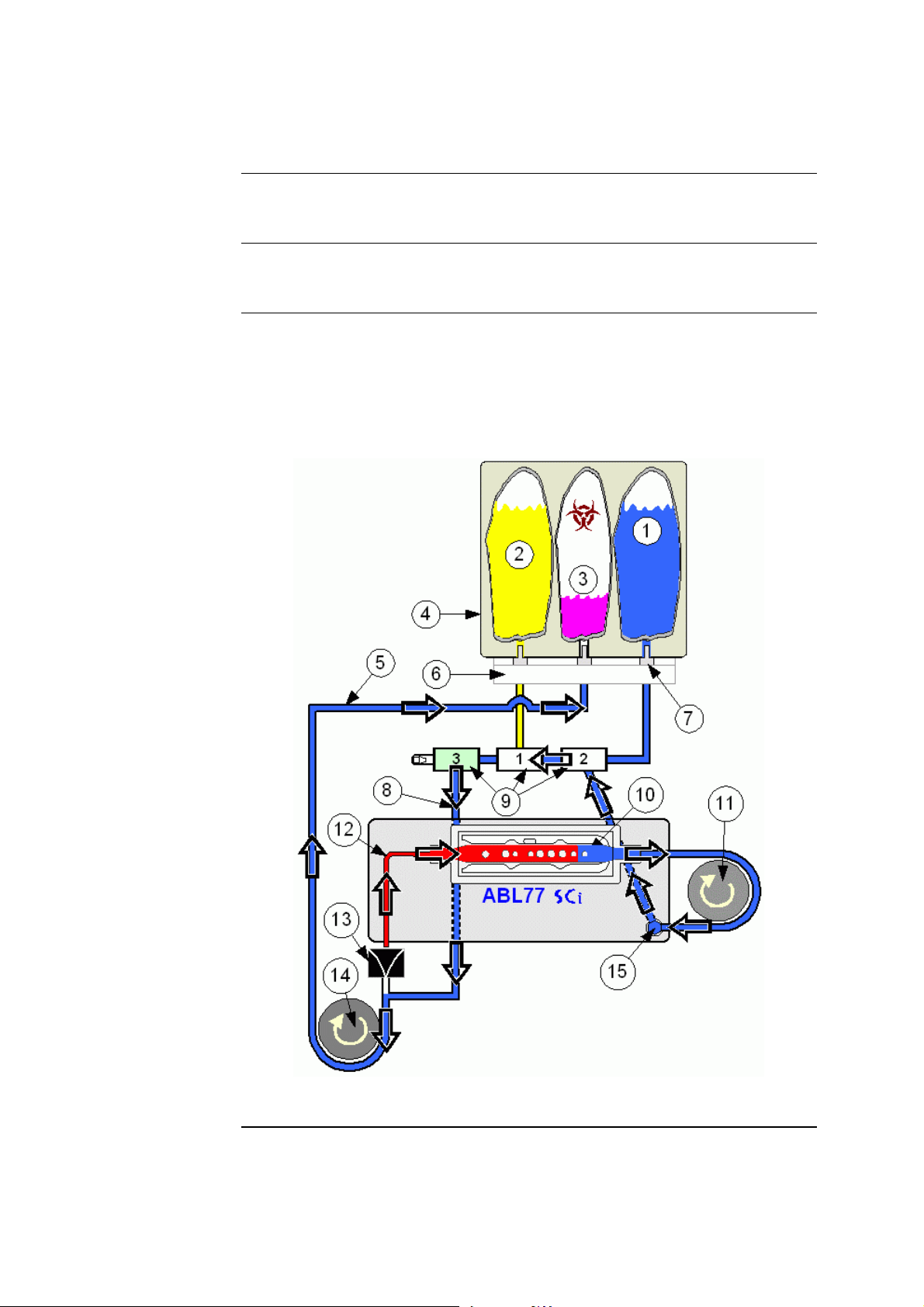

Calibrationphase 1

• During the first phase of the calibration process, the roller wheel is activated

along with valves 1 and 3. This flushes Cal2 solution through the sensor cassette

measuring chamber (see Figure 2-1).

• A measurement is then made on this solution.

• The waste pump is also activated to transport residual flush solution to the waste

pouch.

Figure 2-1

Continued on next page

2-6 Rev. F

Page 22

ABL77 Service Manual Chapter 2: Analyzer Description

Calibration, Continued

Calibrationphase 1

(continued)

Part Function

1. Cal1 solution (Calibration solution – Level 1)

2. Cal2 solution (Calibration solution – Level 2)

3. Waste bag

4. Cal Pack

5. Main waste line

6. Manifold

7. Manifold luers

8. Side waste line

9. Valves L1, L2 and L3

10. Cassette measuring chamber

11. Roller wheel

12. Inlet probe

13. Waste drain

14. Waste pump

15. Cassette luer

Continued on next page

Rev. F 2-7

Page 23

Chapter 2: Analyzer Description ABL77 Service Manual

Calibration, Continued

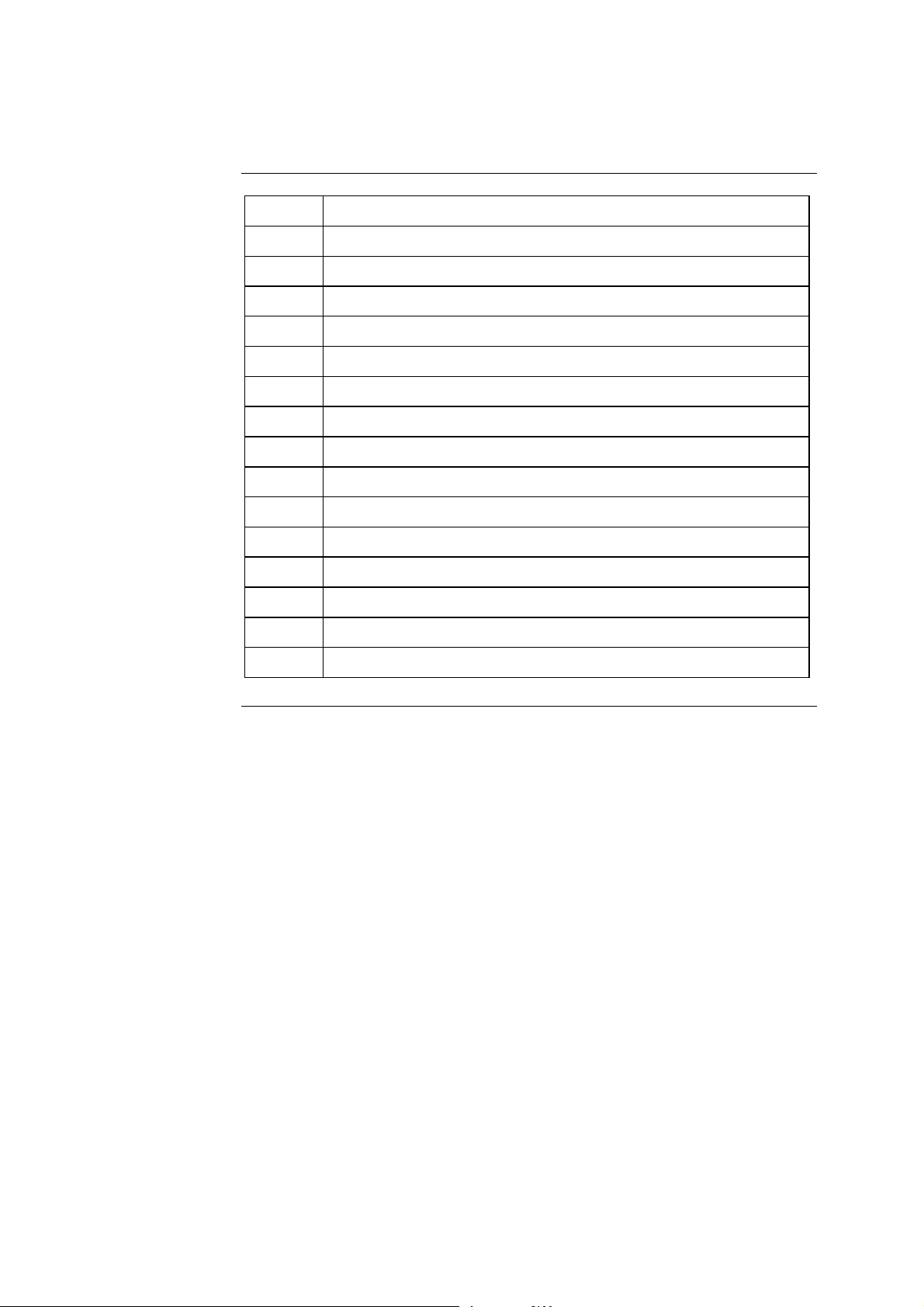

Calibration –

phase 2

• During the second phase of the calibration, the roller wheel is activated along

with valves 2 and 3. This flushes Cal1 solution through the sensor cassette

measuring chamber (see Figure 2-2).

• A measurement is made on this solution.

• The waste pump is also activated to transport residual flush solution to the waste

pouch.

Figure 2-2

Continued on next page

2-8 Rev. F

Page 24

ABL77 Service Manual Chapter 2: Analyzer Description

Calibration, Continued

Calibration –

phase 2

(continued)

Part Function

1. Cal1 solution (Calibration solution – Level 1)

2. Cal2 solution (Calibration solution – Level 2)

3. Waste bag

4. Cal Pack

5. Main waste line

6. Manifold

7. Manifold luers

8. Side waste line

9. Valves L1, L2 and L3

10. Cassette measuring chamber

11. Roller wheel

12. Inlet probe

13. Waste drain

14. Waste pump

15. Cassette luer

Continued on next page

Rev. F 2-9

Page 25

Chapter 2: Analyzer Description ABL77 Service Manual

Calibration, Continued

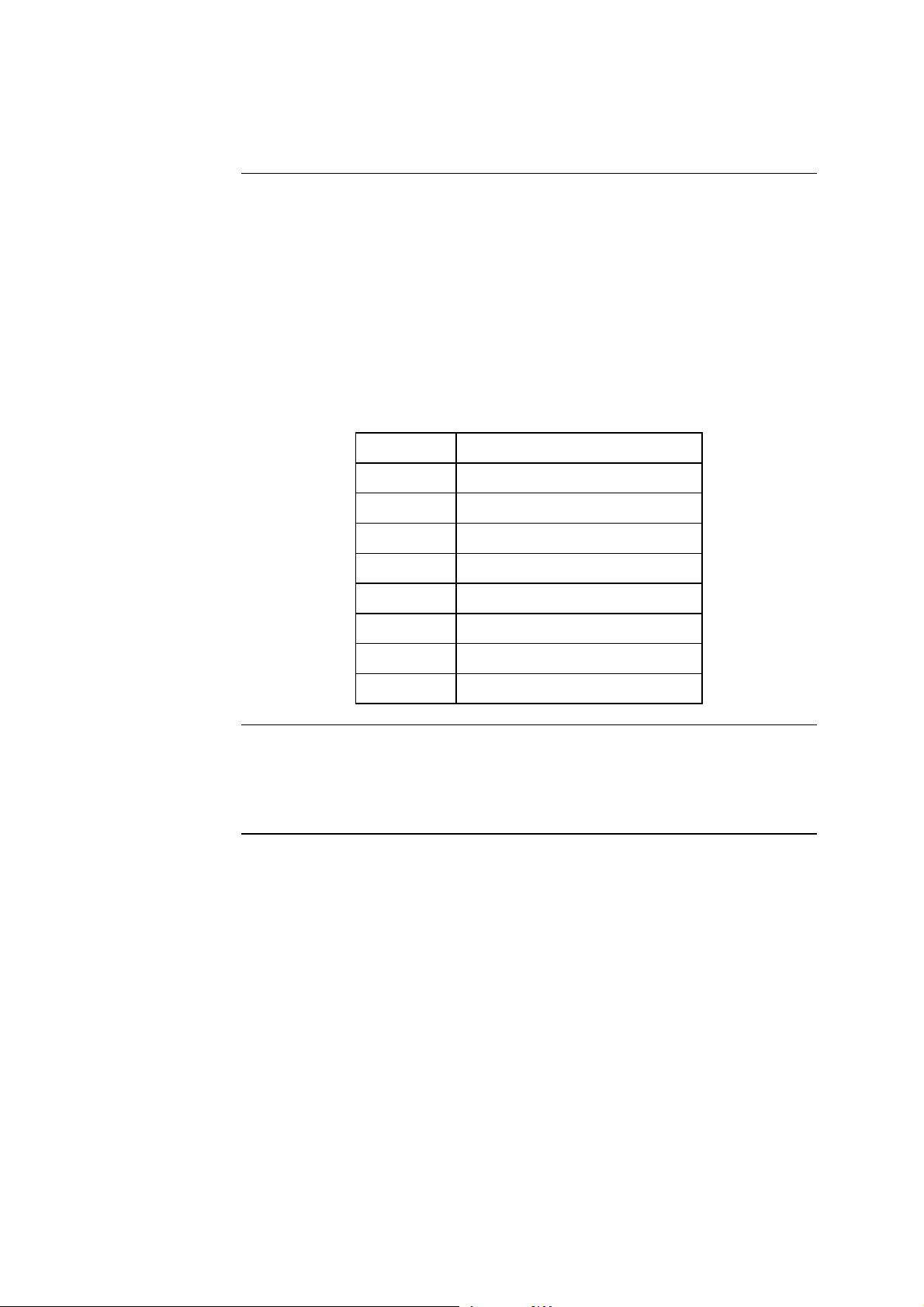

Sensitivity

values

• Calibration sensitivity values are calculated based on these two measurements.

• These sensitivity values are compared to the acceptable range.

• If the values are acceptable, the calibration is complete.

• If one or more sensitivity values are outside the acceptable range, the

calibration is automatically repeated. If repeat calibration also results in one or

more parameter sensitivity values outside the acceptable range, the software

will suggest the appropriate next step. Suggestions include investigating the

fluidic pathways of the analyzer, inactivating the sensor, or replacing the

sensor cassette.

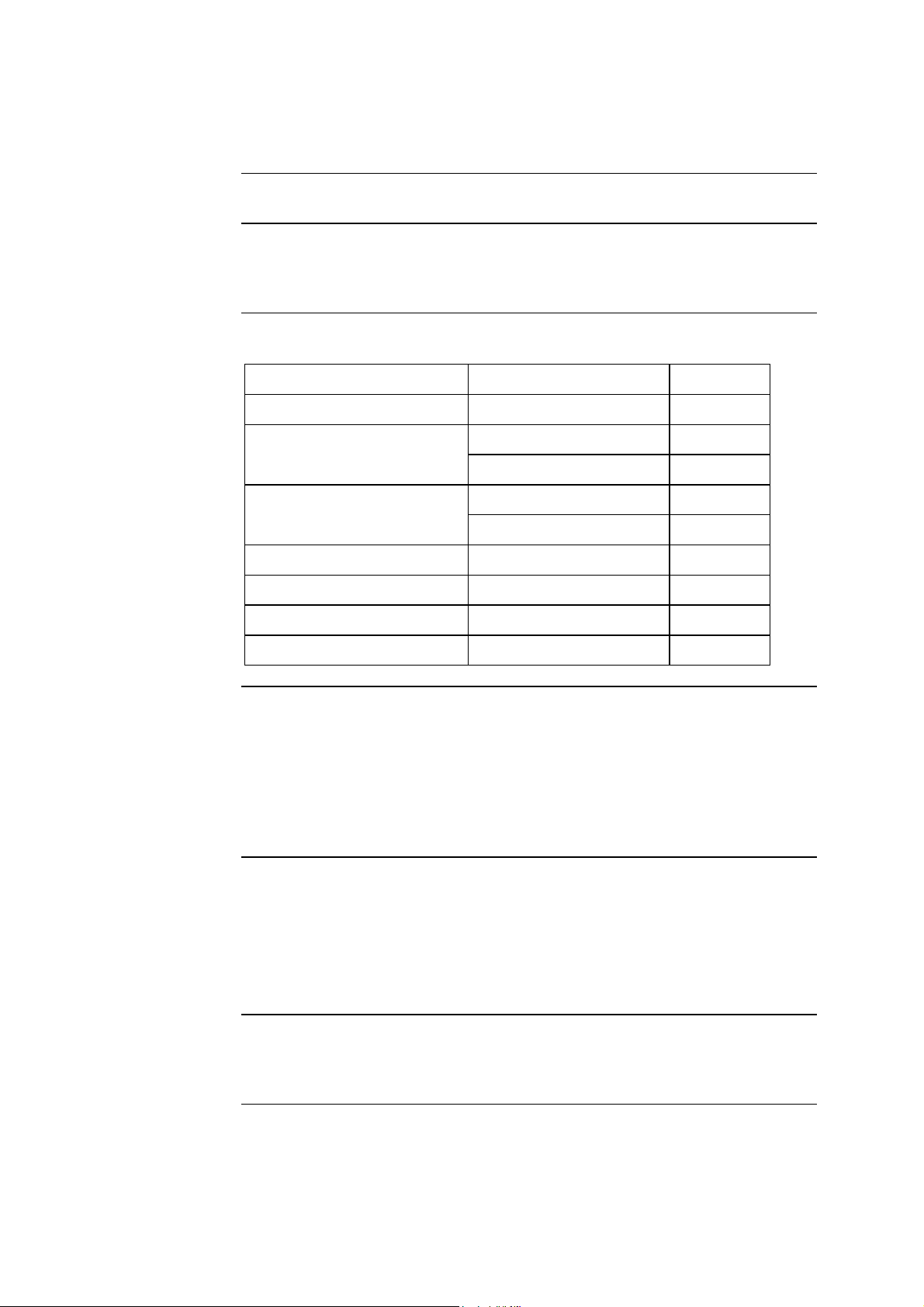

Parameter Acceptable Sensitivity Range

pH 40.0 – 61.5

CO2 30.0 – 61.5

Failed

calibration

status

O2 0.002 – 0.052

Na+ 40.0 – 61.5

K+ 40.0 – 61.5

Ca2+ 20.0 – 31.0

Cl– 30.0 – 61.5

Hct 10.0 – 25.0

If the calibration fails, the system will revert to a mandatory four-hour cycle of

two-point calibrations (without repeating) to maintain the fluidic system. A

successful calibration will return the analyzer to the calibration interval entered

into the Calibration Schedule.

2-10 Rev. F

Page 26

ABL77 Service Manual Chapter 2: Analyzer Description

This page intentionally left blank

Rev. F 2-11

Page 27

Chapter 2: Analyzer Description ABL77 Service Manual

Sample Analysis

Introduction

Analysis – initial

flush

Analysis – phase

1 aspiration

The Analysis option on the Main Menu allows the user to initiate a sample

analysis.

Pressing the Analysis icon initiates a brief flush of Cal1 solution to ensure the tip

of the inlet probe is filled with fluid.

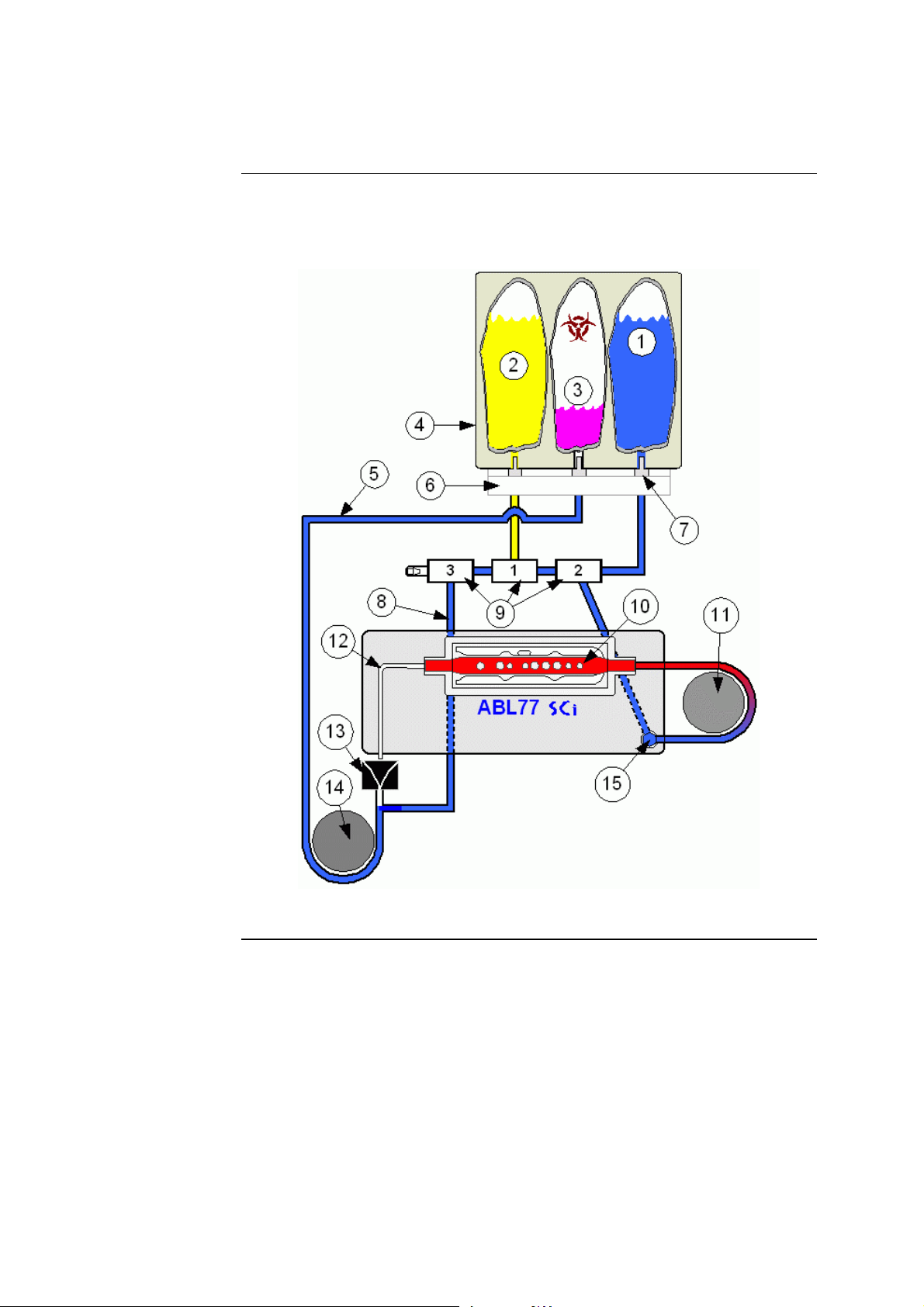

• To begin the sample analysis, the inlet probe flap is lifted to the syringe or

capillary position.

• The Aspirate button is then pressed.

• The primary sample pump then draws in 70 microLiters of sample (see

Figure 2-3).

Figure 2-3

Continued on next page

2-12 Rev. F

Page 28

ABL77 Service Manual Chapter 2: Analyzer Description

Sample Analysis, Continued

Analysis – phase

1 aspiration

(continued)

Part Function

1. Cal1 solution (Calibration solution – Level 1)

2. Cal2 solution (Calibration solution – Level 2)

3. Waste bag

4. Cal Pack

5. Main waste line

6. Manifold

7. Manifold luers

8. Side waste line

9. Valves L1, L2 and L3

10. Cassette measuring chamber

11. Roller wheel

12. Inlet probe

13. Waste drain

14. Waste pump

15. Cassette luer

Continued on next page

Rev. F 2-13

Page 29

Chapter 2: Analyzer Description ABL77 Service Manual

Sample Analysis, Continued

Analysis – phase

2 aspiration

• The analyzer prompts the user to remove the sample and lower the inlet probe

• The analyzer then advances the sample a second time to complete the positioning

of the sample (see Figure 2-4).

Figure 2-4

Continued on next page

2-14 Rev. F

Page 30

ABL77 Service Manual Chapter 2: Analyzer Description

Sample Analysis, Continued

Analysis – phase

2 aspiration

(continued)

Part Function

1. Cal1 solution (Calibration solution – Level 1)

2. Cal2 solution (Calibration solution – Level 2)

3. Waste bag

4. Cal Pack

5. Main waste line

6. Manifold

7. Manifold luers

8. Side waste line

9. Valves L1, L2 and L3

10. Cassette measuring chamber

11. Roller wheel

12. Inlet probe

13. Waste drain

14. Waste pump

15. Cassette luer

Continued on next page

Rev. F 2-15

Page 31

Chapter 2: Analyzer Description ABL77 Service Manual

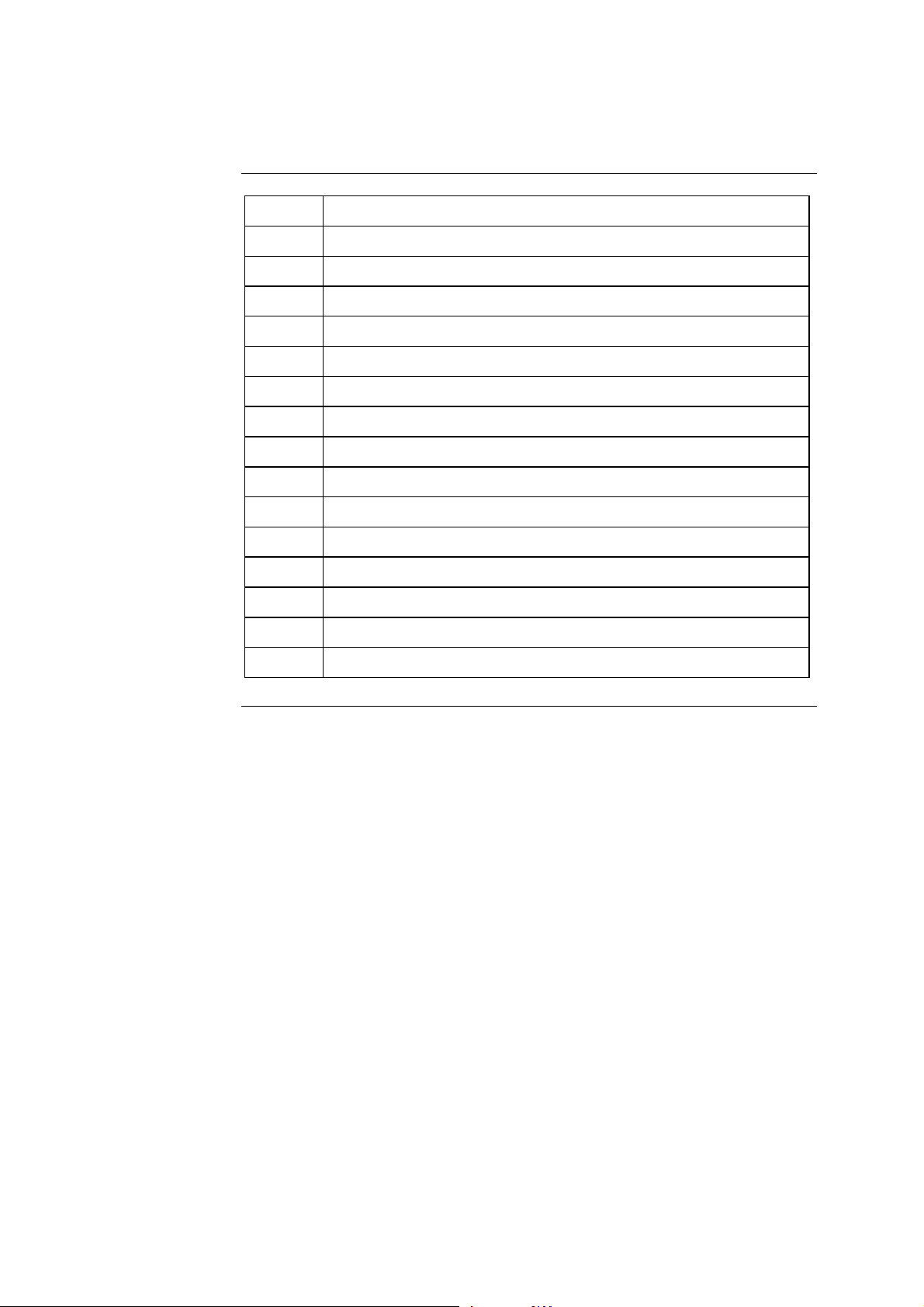

Sample Analysis, Continued

Analysis –

sample flush

• Following the sample measurement, the roller wheel is activated along with

valves 2 and 3 to flush cal 1 solution through the sensor cassette (see Figure 2-5).

• A measurement is performed using this cal solution prior to final results being

displayed ensuring that no drift has occurred.

• The waste pump is activated to transport the flush solution to the waste pouch.

Figure 2-5

Continued on next page

2-16 Rev. F

Page 32

ABL77 Service Manual Chapter 2: Analyzer Description

Sample Analysis, Continued

Analysis –

sample flush

(continued)

Part Function

1. Cal1 solution (Calibration solution – Level 1)

2. Cal2 solution (Calibration solution – Level 2)

3. Waste bag

4. Cal Pack

5. Main waste line

6. Manifold

7. Manifold luers

8. Side waste line

9. Valves L1, L2 and L3

10. Cassette measuring chamber

Quality control

11. Roller wheel

12. Inlet probe

13. Waste drain

14. Waste pump

15. Cassette luer

Routine quality control measurements are suggested to evaluate the performance of

the analyzer. This ensures the reliability, accuracy and precision of patient sample

results.

QC sample measurement follows similar steps as those used for blood sample

analysis.

Rev. F 2-17

Page 33

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions

Overview

ABL77 analyzer

Front view of

analyzer

This section describes the analyzer, individual modules and external components.

Detailed diagrams of the modules and connections are included with each module.

This sub-section describes the analyzer, external components and disposables.

Figure 2-6 shows the front view and sensor cassette of the ABL77 analyzer.

Figure 2-6

Part Function

1. Upper module

2. Sensor cassette

3. Lower module

Continued on next page

2-18 Rev. F

Page 34

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Rear view of

analyzer

Figure 2-7 shows the rear view and cal pack of the ABL77 analyzer.

Figure 2-7

Part Function

1. Main housing assembly

2. Cal pack

3. Electronics module

Continued on next page

Rev. F 2-19

Page 35

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Battery charger

The external battery charger is for use with the ABL77 analyzer only. It provides

the source of AC power to the system when plugged into an active electrical socket

(see Figure 2-8).

Battery pack

Figure 2-8

The battery pack is for use with the ABL77. It provides battery power to the

analyzer when AC power is not available or not desired (see Figure 2-9).

Figure 2-9

Continued on next page

2-20 Rev. F

Page 36

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Barcode scanner

The barcode scanner, shown below, is for use with the ABL77 analyzer only (see

Figure 2-10).

Barcode scanner

holder

Figure 2-10

The barcode scanner holder may be installed on the analyzer in any location that is

convenient (see Figure 2-11).

Figure 2-11

Continued on next page

Rev. F 2-21

Page 37

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Disposables

Sensor cassette

The ABL77 has two key disposable components, a sensor cassette and a cal pack.

These disposable items are designed for a limited number of uses throughout a

specified in-use life. After use, these components are considered a biohazard and

should be disposed of in a safe and proper manner.

The sensor cassette contains the sensor array within a sample flowcell. It transmits

sensor data to the analyzer for interpretation (see Figure 2-12).

Figure 2-12

Part Function

1. Sensor window

2. Peristaltic pump tube

3. Inlet flap

4. Inlet probe

5. Release latch

Continued on next page

2-22 Rev. F

Page 38

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Cal pack

The cal pack contains the solutions used to calibrate and flush the sensor cassette

(see Figure 2-13). The cal pack also contains a waste bag to collect all samples,

solutions and other fluids that are processed through the analyzer.

1

3

2

Figure 2-13

Part Function

1. Cal2 pouch

2. Cal1 pouch

3. Waste bag

Continued on next page

Rev. F 2-23

Page 39

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

ABL77 block

diagram

Figure 2-14 displays the inter-connection of primary and secondary components of

the ABL77 analyzer.

Figure 2-14

2-24 Rev. F

Page 40

ABL77 Service Manual Chapter 2: Analyzer Description

This page intentionally left blank

Rev. F 2-25

Page 41

Chapter 2: Analyzer Description ABL77 Service Manual

Upper Module

Introduction

Components

This section provides a description of the upper module of the ABL77 analyzer.

The upper module contains the display components and disk drive (see the

following figures).

• Resistive Touch Screen: Located in front of the LCD display. It reacts to gentle

pressure from a finger or wand to supply the ABL77 with user input.

• LCD Display: This is a 640 x 480 resolution, backlit, VGA, color display used

as the primary method to provide display information to the user.

• Backlight Inverter Board: This board converts then supplies the power to the

LCD display and the backlight bulb.

• Diskette Drive: This drive is a standard 3.5 inch floppy drive for 1.44 M-byte

diskettes. Its primary use is to download records and settings, and is used to

upgrade software.

Continued on next page

2-26 Rev. F

Page 42

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Diagrams

Figure 2-15

Part Function

1. Upper housing

2. Disk drive

3. Disk drive cable

4. Touch screen cable

5. LCD display cable

6. Backlight inverter cable

7. Backlight inverter

8. Insulating tape

9. Housing bracket

10. Touch screen panel

11. LCD display

Continued on next page

Rev. F 2-27

Page 43

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Diagrams

(continued)

Figure 2-16

Continued on next page

2-28 Rev. F

Page 44

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Diagrams

(continued)

Part Function

1. Backlight inverter board screws

2. Insulating tape

3. Backlight inverter board

4. Housing screws

5. Housing bracket

6. Copper tape

7. Disk drive screws

8. Disk drive washers

9. Copper cloth tape

10. Disk drive

11. LCD display

12. Touch screen panel

13. Upper housing

Rev. F 2-29

Page 45

Chapter 2: Analyzer Description ABL77 Service Manual

Lower Module

Introduction

Components

This section provides a description of the lower module of the ABL77 analyzer.

The lower module contains the following components and related mechanisms.

• The Valve Board routes all fluids through a system of three 3-way valves. The

valve board contains the sensor cassette connector and connections to the analog

board, door sensor, roller pump and waste pump motor.

• The Printer allows printing of sample test and QC reports, using a roll of

thermal paper.

• The Roller Pump draws calibration solutions and other fluids into and out of the

sensor cassette in carefully controlled step increments for accurate placement of

fluids.

• The Waste Pump transports waste fluids from the waste drain to the waste

pouch in the cal pack.

• The Sensor Cassette Nest provides a cavity to accommodate the sensor cassette.

This nest contains the electrical and fluid connections for the sensor cassette,

allowing the analyzer to receive data from the sensor cassette and to move fluids

through the sensor cassette.

• The Manifold is the connection point between the valve board and the cal pack

and provides a fluid pathway. The manifold is considered a separate part from

the lower module but is identified here to show the proper tubing connections.

Continued on next page

2-30 Rev. F

Page 46

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Valve board

Layout of the Valve Board, REF: 902-812 (Figure 2-17).

J5

J5

12 1

13 24

J2

K1

J6

J6

J1

J3

SENSOR

LUER

41449 / B

SENSOR BOSS

L2 L1 L3

R2

R18

J4

J4

J9

J9

2587

PN 902-812

J8

41477

SERVICE BOARD ABL70-77

ASSY REV :

REVISION

J8

J10

J10

J7

J7

Figure 2-17

The Valve Board Assembly (REF: 902-811) includes the valves and tubing

(Figure 2-18).

J5

J5

12 1

13 24

J2

K1

J6

J6

J3

SENSOR

LUER

41449 / B

J1

COM

N.C.

SENSOR BOSS

N.O.

L2

L2 L1 L3

J4

J4

J9

J9

2587

R2

R18

PN 902-811

J8

Figure 2-18

COM

N.O.

41477

ASSY REV :

REVISION

N.C.

L3

COM

N.C.

L1

SERVICE BOARD AB L70-77

J8

N.O.

J10

J10

J7

J7

Continued on next page

Rev. F 2-31

Page 47

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Lower module Front

Figure 2-19

Part Function

1. Waste drain

2. Waste pump

3. Sensor cassette nest

4. Roller pump wheel

5. Printer

Continued on next page

2-32 Rev. F

Page 48

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Lower module Rear

Figure 2-20

Part Function

1. Printer

2. Sensor luer connector

3. Roller pump motor

4. I/O cable connector

5. Valve board

6. Sensor cable connector

7. Opto sensor

8. Manifold

9. Waste pump

Rev. F 2-33

Page 49

Chapter 2: Analyzer Description ABL77 Service Manual

Electronics Module

Introduction

Components

This section provides a description of the electronics module of the ABL77

analyzer.

• Electronics Boards

• Analog board

• Power distribution board

• Interface board

• ChipDisk

• LCD adapter board

• Memory module

• CPU board

• Touch screen controller board

• Battery control board

• Rear Panel with External Connections

• Barcode scanner / keyboard connector

• COM1 port

• Ethernet port

• Power switch

• Charger port

• Battery Pack

Continued on next page

2-34 Rev. F

Page 50

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Electronics Boards

Analog board

The analog board (REF: 902-682) contains a microprocessor and custom

algorithms that control valve, motor, and sensor operations (see Figure 2-21). The

onboard processor performs various operations such as thermistor control, roller

pump motor control, and sensor signal A to D conversions. This remote

intelligence enables the main computer to focus primarily on the operator interface.

Commands are received from the main computer to turn on valves, motors, begin

sensor heating cycle, etc. The analog board returns a character string once a second

to the main computer that contains the output states and sensor characteristics.

Figure 2-21

Continued on next page

Rev. F 2-35

Page 51

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Power

distribution

board

The power distribution board (REF: 902-838) receives power from the battery

control board and routes the power to the electronic boards assembly and the

analog board (see Figure 2-22).

Figure 2-22

Interface board

ChipDisk

The interface board (REF: 902-681) contains the internal speaker and the coin cell

battery that supplies the CPU with power to maintain the computer settings See

Figure 2-23). This board also receives signals from the barcode scanner and routes

data to the printer to produce reports.

SPK

BAT 1

SN

J3

Revision

ASSY 41407

Figure 2-23

The ChipDisk (REF: 365-436) is the mass storage media for all records, settings

and software (see Figure 2-24). It is an electronic based “computer hard drive” The

ChipDisk is a component of the CPU board.

Figure 2-24

Continued on next page

2-36 Rev. F

Page 52

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

LCD adapter

board

Memory module

The LCD adapter board (REF: 902-678) converts signals from the CPU for use by

the LCD display (see Figure 2-25). The LCD adapter board is a component of the

CPU board.

Figure 2-25

The memory module (REF: 365-438) is the active memory (RAM) that the CPU

uses for calculations and command processing (see Figure 2-26). The memory

module is a component of the CPU board.

Figure 2-26

Continued on next page

Rev. F 2-37

Page 53

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

CPU board

The CPU board (REF: 902-679) consists of a 486 SX microcomputer with at least

8 MB memory, VGA, serial and parallel ports, and floppy disk control (see

Figure 2-27). The interface board connects the microcomputer to its battery support

and speaker as well as interfacing with the printer and the COM 1 port. Valves,

motors, and sensor states are controlled by commands sent via the serial

connection to the custom analog board.

Touch screen

controller

Figure 2-27

The touch screen controller (REF: 365-437) processes all signals from the touch

screen and sends these signals to the CPU (see Figure 2-28).

Figure 2-28

Continued on next page

2-38 Rev. F

Page 54

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Battery control

board

The battery control board (REF: 902-680) monitors system power requirements

and diverts the incoming AC power to and from the battery pack accordingly (see

Figure 2-29). The batteries are charged in a controlled manner to prevent overcharging. The battery charge status is sent to the analog board and then

retransmitted to the main computer so that it can be displayed on the screen for the

operator.

J7

J1

R28

J5

U4/1

D7 D6

D1

U4/2

C2

U4/3

U4/4

J2

D2

R19

C1

R12

R23 R24

D9

J3

D10

D4 D3

U2

C13

R2

R21

R22

D5

C14 C15

R20

R9

Q6 Q5

P4

U1

R3

R4

R25

R6

R8

Q3Q4

R27

P5 P7 P6

P1

R5 R10

Q8 Q7

C8

R17

R11

R7

D11

R13

D14

C3

C7

R15

C9

D13

J

4

C5

Q1

R14

U5

C10 C11

D8

P8 P3 P2

U4/9

U4/8

U6

C4

U4/7

C12

U4/6

U4/5

J8J6

Q2

VB5

D12

R18

C6

U3

C19

U7

R1

ASSY 41174

Figure 2-29

Continued on next page

Rev. F 2-39

Page 55

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Electronics

module

assembly

Figure 2-30

Continued on next page

2-40 Rev. F

Page 56

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Rear Panel with External Connections

Diagrams

Figure 2-31

Part Function

1. Barcode / keyboard port cable

2. Power switch cable

3. Ethernet port cable

4. COM1 port cable

5. Fan assembly cable

Continued on next page

Rev. F 2-41

Page 57

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Diagrams

(continued)

Figure 2-32

Part Function

1. COM1 port

2. Barcode / keyboard port

3. Fan

4. Charger port

5. Ethernet port

6. Power switch

7. Battery door

Continued on next page

2-42 Rev. F

Page 58

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Barcode /

keyboard

connector

COM1 port

The barcode scanner port is a 5 pin DIN connector that sends the signals to the

interface board. This port is also used for connecting a keyboard to the analyzer for

testing purposes.

The COM1 port is a serial connection to the CPU board. It allows interaction with

external computers. The RS232 port contains 9 pins. The following table lists the

pin designations and transmission format.

Pin I/O Description

Ethernet port

1.

2.

3.

4.

◄

◄

►

►

5.

6.

7.

8.

9.

◄

►

◄

◄

DCD (Data Carrier Detect)

RX (Receive Data)

TX (Transmit Data)

DTR (Data Terminal Ready)

GND (Signal Ground)

DSR (Data Set Ready)

RTS (Request To Send)

CTS (Clear To Send)

RI (Ring Indicator)

— Connector

The Ethernet port is a connection to the CPU. It allows bi-directional

communication with external computer systems.

Power switch

The power switch is a 2-position switch that places the analyzer in either an On or

Standby mode. There is no Off mode as the analyzer is always charging when it is

connected to an AC power source.

Charger port

The charger port is a 6 pin DIN connector. It allows the ABL77 charger to supply

AC power to the battery control board.

Continued on next page

Rev. F 2-43

Page 59

Chapter 2: Analyzer Description ABL77 Service Manual

Module Descriptions, Continued

Battery Pack

Battery pack

The battery pack contains 12 nickel metal hydride (NiMH) cells (see Figure 2-33).

The pack has a nominal DC voltage of 14.4 and a rated capacity of 3.8 Ah. The

battery pack stores power for use by the analyzer when not connected to an AC

power source. After use, the battery pack should be disposed of in a safe and

proper manner consistent with disposal of any battery.

Charge cycle of

the battery pack

Battery pack

temperature

Figure 2-33

The analyzer controls the charge to the battery pack using a counter and charge

controller. The counter value is reflected in the value displayed in the Bat field on

the Hardware screen.

The input charge increments the charge counter, which reflects the charge capacity

of the pack. The charge rate is a function of the current control circuit. As the

battery charges, the current applied will decrease in proportion to the battery

voltage. As the battery voltage increases, the temperature of the pack increases.

This increased temperature increases the internal pressure of the cells, causing a

higher voltage across the pack. This results in varying charge rates based on the

charge state of the battery pack. To ensure maximum charging of the pack, the

charge controller (on the Battery Control Board) provides a six-hour charge cycle.

For safety purposes, the maximum allowed charge current is 650 mA.

The counter decrements based on the normal operation of the analyzer on battery

power. The counter also decrements based on the self-discharge rate of the battery

with storage and age. The self-discharge rate is accelerated with increased

temperatures.

The battery pack contains an internal safety switch that is triggered based on the

current output over time and monitored by an internal thermistor. This switch

prevents unsafe levels of operation. During charging, if the temperature of the

battery pack rises above 45°C, charging is terminated. In addition, there is an

integral temperature cutoff switch which opens if the pack reaches 70 ± 5 °C. If

this switch is triggered, the battery pack will no longer be operational.

Continued on next page

2-44 Rev. F

Page 60

ABL77 Service Manual Chapter 2: Analyzer Description

Module Descriptions, Continued

Optimal battery

pack life

The lifetime of a battery pack is affected by various conditions. Elevated

temperatures, long periods of inactivity and incomplete charging will diminish the

expected lifetime and operation of the battery pack.

NiMH batteries operate at their optimal capacity when regularly exercised and

allowed to discharge to a level other than full capacity. It is recommended that the

analyzer be operated on battery power routinely or at regular intervals to maintain

optimal performance of the battery pack

Rev. F 2-45

Page 61

ABL77 Service Manual Chapter 3: Troubleshooting

3. Troubleshooting

Overview

Introduction

Contents

This chapter provides troubleshooting information for errors or messages that may

occur during the operation of the ABL77 analyzer.

This chapter contains the following topics.

Overview............................................................................................... 3-1

General Information ........................................................................................ 3-2

Cautions and Warnings ......................................................................... 3-3

General Guidelines................................................................................ 3-4

Hardware Screen ................................................................................... 3-5

Reference Table of Problems, Causes and Corrective Actions .................... 3-8

Reference Table .................................................................................... 3-9

System Messages............................................................................................. 3-16

3-1

Page 62

Chapter 3: Troubleshooting ABL77 Service Manual

General Information

Introduction

This section provides information regarding cautions and warnings as well as

information on normal operation that can be fundamental to understanding error

conditions.

3-2

Page 63

ABL77 Service Manual Chapter 3: Troubleshooting

Cautions and Warnings

Introduction

WARNING/

CAUTION:

This topic emphasizes important safety issues. Please review before proceeding

with any troubleshooting steps.

WARNING: Always turn the power off and unplug the system when cleaning the

analyzer.

CAUTION: Always remember to exercise Universal Precautions when handling

contaminants and biohazardous materials (OSHA standard 1910.1030).

CAUTION: Be prepared to collect fluid flowing from open ports and luers when

flushing analyzer parts. Always exercise Universal Precautions when handling

contaminants and biohazardous materials.

CAUTION: Pushing the syringe plunger too hard can damage internal tubing

connections and cause leakage. When using syringes to clear path obstructions,

whether filled with air or liquid, very gently push the syringe plunger to avoid

detaching internal tube connections.

CAUTION: Do not inject solution or air into the cal pack ports. Injecting solution

or air into the cal pack will alter the calibrant values and may cause erroneous

measurements and/or failure messages.

CAUTION: The cal pack contains two calibration fluid pouches and a waste

pouch. With use, the waste pouch may contain blood and other biohazardous

fluids. Disposal of a used cal pack should comply with all required biohazard

regulations.

CAUTION: Dispose of used cal packs immediately. If immediate disposal is not

possible, lay the cal pack on its side or back and replace the foil cover over the

ports to prevent potentially contaminated ports from contacting other surfaces.

Laying a used cal pack on its side or back can also prevent leakage in the unlikely

event that a cal pack port develops a slight seepage.

3-3

Page 64

Chapter 3: Troubleshooting ABL77 Service Manual

General Guidelines

Introduction

Suggested tools

Warranty

sensor cassette

returns

This topic describes additional information pertinent to the use of the ABL77

analyzer.

• The following tools are recommended for various service procedures:

• A Sample Path Obstruction Tools (REF: 905-674) kit can assist in removing

fluid path obstructions.

• A Zeroing Cassette (REF: 902-578) is used to zero the sensor channels

• A Valve Board Calibration Cassette (REF: 920-729) is used to calibrate the

Hct and SC channels between the valve board and analog board.

Any sensor cassette that fails during use should be returned via the distributor to

SenDx Medical, Inc. Please return all the following items for full warranty credit

and to assist in a complete failure investigation:

Analyzer

component

returns

Cassette pump

tubing

• Sensor cassette

• Foil Pouch

• Printout of the failed Event Record. Only the Event Record contains a complete

set of information important for failure investigation. An Event Record is printed

from the Recall / Event screen.

• Highlight the failed calibration, initialization or QC analysis

• Press the

icon to print an Event Record of this failed event.

Any analyzer component returned for credit or for failure investigation should be

accompanied by a copy of the service work order. Please be as complete as

possible in describing the events that led up to the failure, any troubleshooting

steps taken, and resolution of the problem. Please include the serial number of the

analyzer repaired.

During calibrant pump cycles,

while the roller wheel is

spinning, the cassette pump

tubing can be "snapped"

repeatedly to help dislodge any

air bubbles residing in the

cassette tubing (see Figure 3-1).

This simple step can alleviate a

number of the more common

calibration and initialization

failure experiences.

Figure 3-1

3-4

Page 65

ABL77 Service Manual Chapter 3: Troubleshooting

Hardware Screen

Introduction

Description of

Hardware

screen

This topic describes the various features of the Hardware screen that can assist in

troubleshooting.

• The Hardware screen allows manual control of basic analyzer functions.

• The three soft keys across the bottom of the screen allow the user to initiate a

single flush of Cal1 solution, Cal2 solution, or a single aspiration through the

inlet probe (see Figure 3-2).

Figure 3-2

Continued on next page

3-5

Page 66

Chapter 3: Troubleshooting ABL77 Service Manual

Hardware Screen, Continued

Description of

Hardware

screen

(continued)

• Activate the heater circuit by selecting the check box labelled Heater ON (see

Figure 3-3). The temperature reading as measured by the thermistor (located in

the sensor cassette) is displayed and labelled Th.

Figure 3-3

• The oxygen sensor, which requires an applied current to function, can be

energized by selecting the check box labeled O2(nA).

• The Hematocrit sensors also require an applied current which is activated by

selecting the Hct(AD) choice on the drop-down menu which initially displays

OFF(AD).

• The other selection in this drop-down window refers to the air-in-sample circuit.

SC(AD) is the solution conductivity (SC) value. The units of measure for both

Hct and SC are analog to digital counts.

• The voltage output of the other sensors are displayed and labeled accordingly.

Continued on next page

3-6

Page 67

ABL77 Service Manual Chapter 3: Troubleshooting

Hardware Screen, Continued

Description of

Hardware

screen

(continued)

• A relative charge reading for the battery pack is displayed (Bat) as well as the

function of the battery charger (Pak) (see Figure 3-4). An inlet flap sensor

indicator is also displayed (Door).

Figure 3-4

3-7

Page 68

Chapter 3: Troubleshooting ABL77 Service Manual

Reference Table of Problems, Causes and

Corrective Actions

Introduction

This section summarizes, in table form, the various types of problems and error

conditions which may be encountered during the operation of the ABL77 analyzer.

3-8

Page 69

ABL77 Service Manual Chapter 3: Troubleshooting

Reference Table

Introduction

This table offers a convenient reference to problems, their causes and the

recommended corrective action.

The most frequent cause for each problem is listed first followed by less frequent

causes.

Problem Probable Cause Corrective Action

Calibration Failure – this also

includes failed initializations.

The important first step is to

identify whether the failure is

due to a sensor failure or failure

of the analyzer's fluidic system

Fluidic system blockage in

analyzer. This prevents fresh

calibration solution from

reaching the sensor array or

combines fresh cal solution with

air.

to properly transport the

calibration fluid to the sensor

cassette measuring chamber.

Follow the instructions on the

Sensor failure Inactivate the failed parameter

analyzer screen to help identify

the underlying cause.

Calibration, Initialization, or

QC failures with multiple sensor

Valve board – worn or corroded

pin receptacle

cassettes over time

Valve board – component

failure

Analog board – component

failure

Proceed to Chapter 4, Test and

Calibration Procedures to

investigate the fluidics system

using the Hardware screen and