Page 1

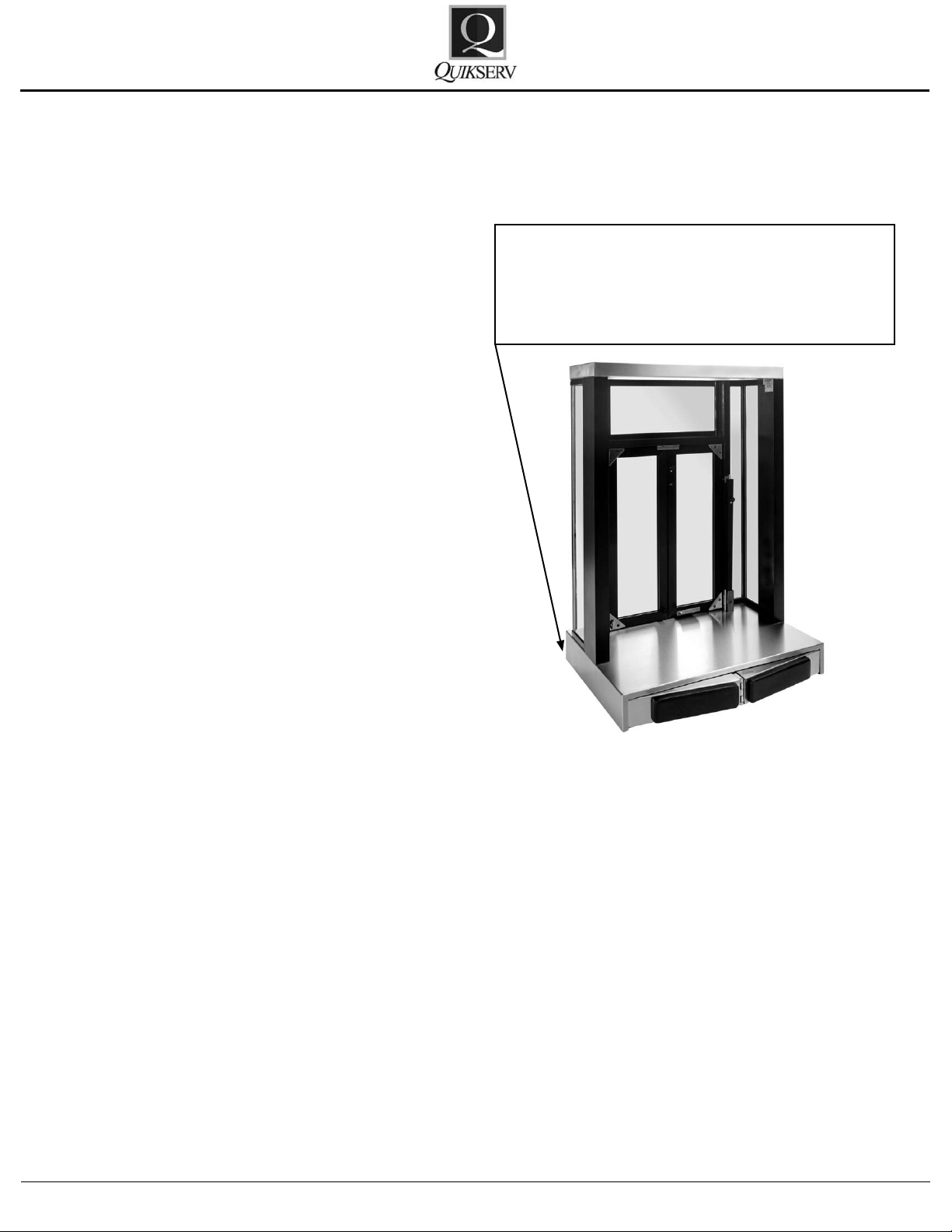

Service Manual

PW 1 & 2

PW 1 & 2

Semi-Automatic Bi-Fold Units

Click the Procedure to View

Operation and Maintenance Procedure 2

Only Right or Left Door Opens 3

Doors Are Misaligned 4

Door Does Not Open 5

Push Bar Remains Under Base 5

Doors are Not Closing 6

Hardware Details 7-8

Strap Details 9

Adjustment Details 10-11

Replacement Procedure 11-13

Warranty Service Policy 14

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

1

Page 2

Service Manual

PW 1 & 2

Semi-Automatic Bi-Fold Units

Operation and Maintenance Procedures

Pre-Operation Procedures:

• Unlock all locking mechanisms and ensure

that the doors are free of obstructions.

General Cleaning Guidelines:

• All weather-stripping should be checked and

cleaned weekly.

• All glass, aluminum framing, and stainless

steel should be kept clean at all times. All

cleaning uids and applicators should be non-

abrasive.

General Maintenance:

• Straps should be checked for fraying and for

the correct tension every 6 months.

• Straps noted as frayed or loose should be replaced or adjusted.

• The Upper and Lower sections of the pushbar assembly should be kept clean of dirt or

grease build-up.

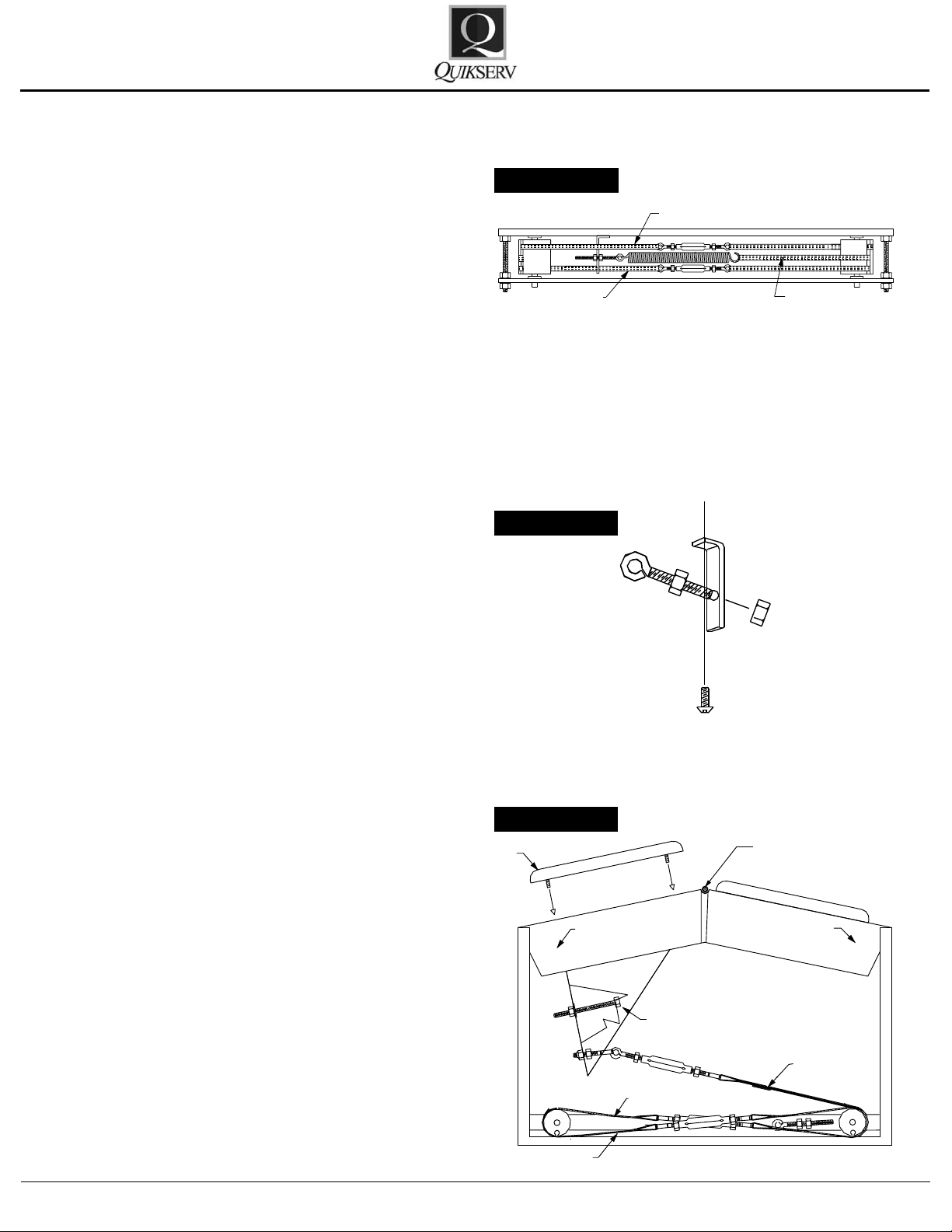

To gain access to the internal components for each window the access panel

must be removed from the exterior of the

window - see arrows below.

• Bottom hinge bearings should be oiled every 6

months.

Please refer to the TROUBLE SHOOTING

CHARTS in this section for additional information on the window adjustments or service procedures.

Contact us at (800) 388-8307 for assistance or

for information on the nearest service center in

your area.

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

2

Page 3

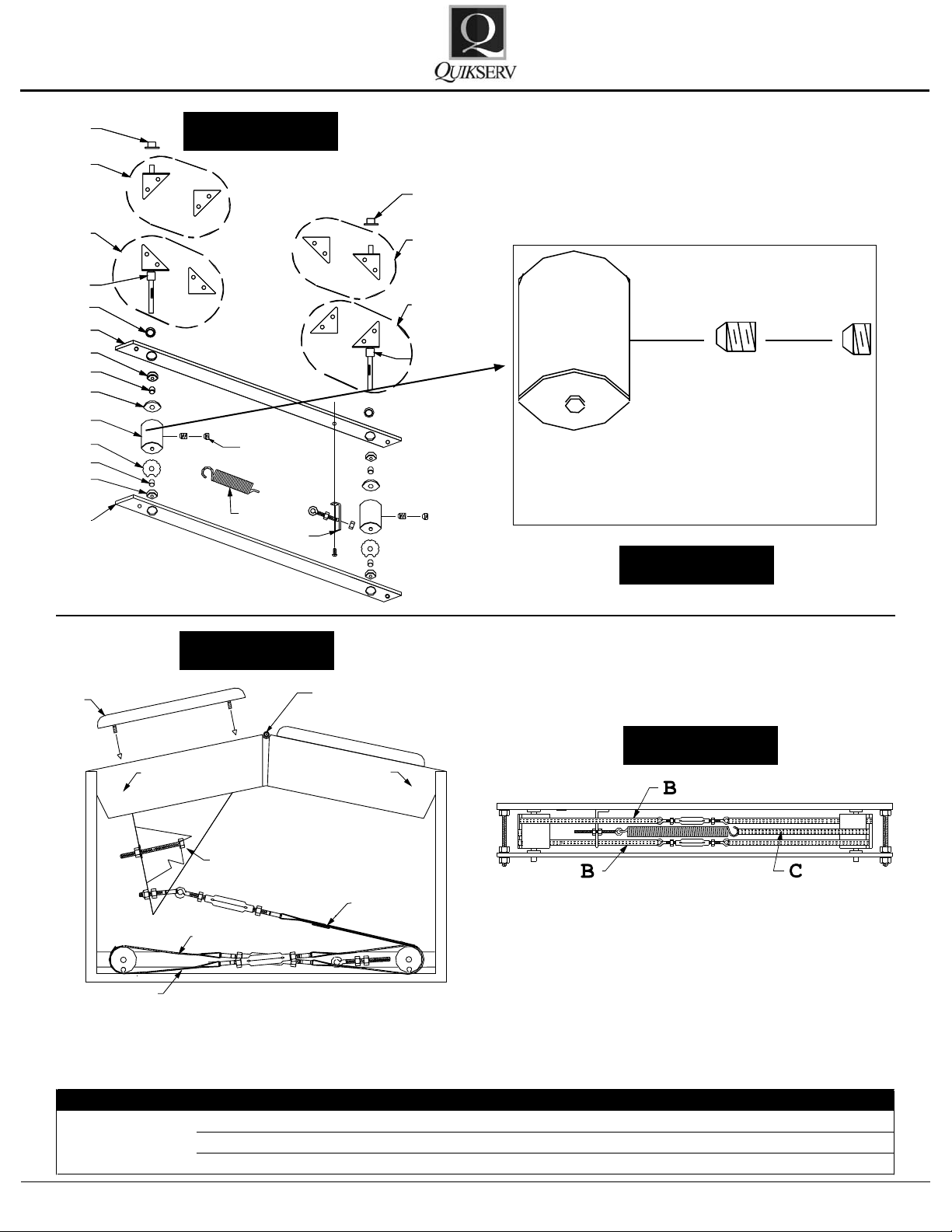

Trouble Probable Cause Probable Solution

1. Loose roller strap assembly (Part # 5566) Adjust and tighten (Fig. 8-B)

2. Broken roller strap assembly (Part # 5566) Replace and adjust (Fig. 8-B)

3. Loose roller set screws(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

Only the Right

or Left Door

Opens

P

J

K

M

I

C

O

D

P

B

F

L

A

C

N

SET SCREWS

I

P

F

C

D

O

E

D

B

L

M

2 EA.

G

H

P

K

J

M

Set of Screws

2 Each

H

F

B

B

D

E

F

A

Service Manual

PW 1 & 2

Figure 7

Figure 7-E

Figure 8

Bottom View

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

3

Figure 8-B

Front View

Page 4

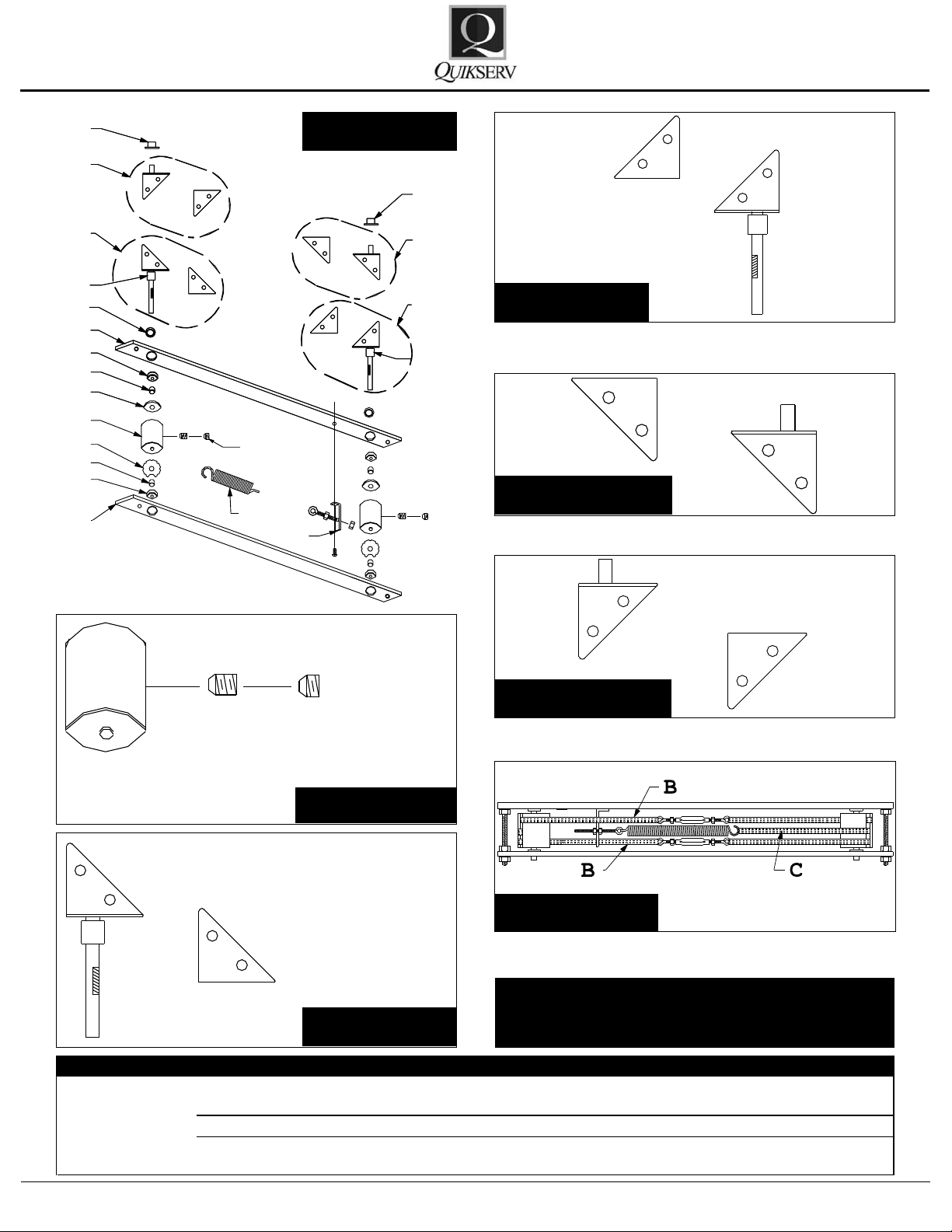

Trouble Probable Cause Probable Solution

1. Loose roller strap assembly (Part # 5566) Adjust and tighten (Fig. 8-B)

2. Broken roller strap assembly (Part # 5566) Replace and adjust (Fig. 8-B)

3. Loose roller set screws(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

Trouble Probable Cause Probable Solution

1. The roller strap assembly, upper or lower, is

loose or stretched

(

Part # 5566

)

Adjust and tighten (Fig. 8-B)

2. Loose set of screw(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

3. Bent hinge (Part # - 5590, 5591, 5592 & 5593)

Replace (Fig. 7-I, J, K, L)

Only the Right

or Left Door

Opens

Doors are Misaligned

P

J

K

M

I

C

O

D

P

B

F

L

A

C

N

SET SCREWS

I

P

F

C

D

O

E

D

B

L

M

2 EA.

G

H

P

K

J

M

Set of Screws

2 Each

Service Manual

PW 1 & 2

Figure 7

Figure 7 - J

Figure 7 - K

Figure 7 - L

Figure 7 - E

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

Figure 7 - I

Figure 8 - B

All left and right designations are shown from the

operator’s point of view, or inside looking out of the

window unit

4

Page 5

Trouble Probable Cause Probable Solution

1. Loose roller strap assembly (Part # 5566) Adjust and tighten (Fig. 8-B)

2. Broken roller strap assembly (Part # 5566) Replace and adjust (Fig. 8-B)

3. Loose roller set screws(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

Trouble Probable Cause Probable Solution

1. The roller strap assembly, upper or lower, is

loose or stretched

(

Part # 5566

)

Adjust and tighten (Fig. 8-B)

2. Loose set of screw(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

3. Bent hinge (Part # - 5590, 5591, 5592 & 5593)

Replace (Fig. 7-I, J, K, L)

Trouble Probable Cause Probable Solution

Door Does Not

O

p

en

1. The pull-strap assembly is loose or broken

(

Part # 5567

)

Replace. Or, adjust and tighten (Fig. 8-A)

Only the Right

or Left Door

Opens

Doors are

Misaligned

Trouble Probable Cause Probable Solution

1. Loose roller strap assembly (Part # 5566) Adjust and tighten (Fig. 8-B)

2. Broken roller strap assembly (Part # 5566) Replace and adjust (Fig. 8-B)

3. Loose roller set screws(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

Trouble Probable Cause Probable Solution

1. The roller strap assembly, upper or lower, is

loose or stretched

(

Part # 5566

)

Adjust and tighten (Fig. 8-B)

2. Loose set of screw(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

3. Bent hinge (Part # - 5590, 5591, 5592 & 5593)

Replace (Fig. 7-I, J, K, L)

Trouble Probable Cause Probable Solution

Door Does Not

O

p

en

1. The pull-strap assembly is loose or broken

(

Part # 5567

)

Replace. Or, adjust and tighten (Fig. 8-A)

Trouble Probable Cause Probable Solution

1. Return spring nees adjustment (Part # 1009) Adjust and tighten (Fig. 7-G & 7-H)

2. Return spring or strap is broken (Part # 1009 &

5568

)

Replace and adjust (Fig. 7-G or 8-C)

3. Push bar is dragging Check bottom plate for proper installation -

if not install properly contact Quikserv

Cor

p

.

4. Doors are dragging

Loosen hinge screws and realign door

(Fig

. 7-I, J, K, & L

)

Trouble Probable Cause Probable Solution

1. Travel ad

j

uster is loose or broken (Part # 5201

)

Replace or adjust and tighten(Fig. 8-D

)

2. Pull strap is broken (Part # 5567

)

See replacementprocedures

Only the Right

or Left Door

Opens

Doors are

Misaligned

Doors are not

closing

Push Bar Remains Under Base

H

F

B

B

D

E

F

A

Service Manual

Figure 8 - A & 8 - D

PW 1 & 2

Bottom View

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

5

Page 6

Trouble Probable Cause Probable Solution

1. Loose roller strap assembly (Part # 5566) Adjust and tighten (Fig. 8-B)

2. Broken roller strap assembly (Part # 5566) Replace and adjust (Fig. 8-B)

3. Loose roller set screws(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

Trouble Probable Cause Probable Solution

1. The roller strap assembly, upper or lower, is

loose or stretched

(

Part # 5566

)

Adjust and tighten (Fig. 8-B)

2. Loose set of screw(s) (Part # 5587) Adjust and tighten (Fig. 7-E)

3. Bent hinge (Part # - 5590, 5591, 5592 & 5593)

Replace (Fig. 7-I, J, K, L)

Trouble Probable Cause Probable Solution

Door Does Not

O

p

en

1. The pull-strap assembly is loose or broken

(

Part # 5567

)

Replace. Or, adjust and tighten (Fig. 8-A)

Trouble Probable Cause Probable Solution

1. Return spring nees adjustment (Part # 1009) Adjust and tighten (Fig. 7-G & 7-H)

2. Return spring or strap is broken (Part # 1009 &

5568

)

Replace and adjust (Fig. 7-G or 8-C)

3. Push bar is dragging Check bottom plate for proper installation if not install properly contact Quikserv

Cor

p

.

4. Doors are dragging

Loosen hinge screws and realign door

(Fig

. 7-I, J, K, & L

)

Only the Right

or Left Door

Opens

Doors are

Misaligned

Doors are not closing

P

J

K

M

I

C

O

D

P

B

F

L

A

C

N

SET SCREWS

I

P

F

C

D

O

E

D

B

L

M

2 EA.

G

H

P

K

J

M

Service Manual

PW 1 & 2

Figure 7

Figure 7 - I

Figure 7 - J

Figure 7 - K

Figure 7 - G

Figure 7 - H

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

Figure 7 - L

All left and right designations are shown from the

operator’s point of view, or inside looking out of the

window unit

6

Page 7

Set of Screws

2 Each

Service Manual

Hardware Details

Key No. Part No. Description

A 5524 Bottom Bearing Bar (Includes Bearings)

B 5525 Upper Bearing Bar (Includes Bearings)

C 1012 Bearing

PW 1 & 2

D 1004 Roller Spacer Bushing

E 5587 Aluminum Roller - Set Screws

F 1013 Rubber O-Ring

G 1009 Return Spring

H 3702 Return Spring Bracket

All left and right designations are shown from the

operator’s point of view, or inside looking out of the

window unit

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

7

Page 8

Service Manual

Key No. Part No. Description

I 5590 L/H Bottom Hinge Assembly

J 5591 R/H Bottom Hinge Assembly

K 5593 R/H Top Hinge Assembly

PW 1 & 2

L 5592 L/H Top Hinge Assembly

M 1006 Top Hinge Bushing

N 3631 Bottom Retainer Washer

O 3643 Top Retainer Washer

P 1915 Hinge Space Bushing

All left and right designations are shown from the

operator’s point of view, or inside looking out of the

window unit

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

8

Page 9

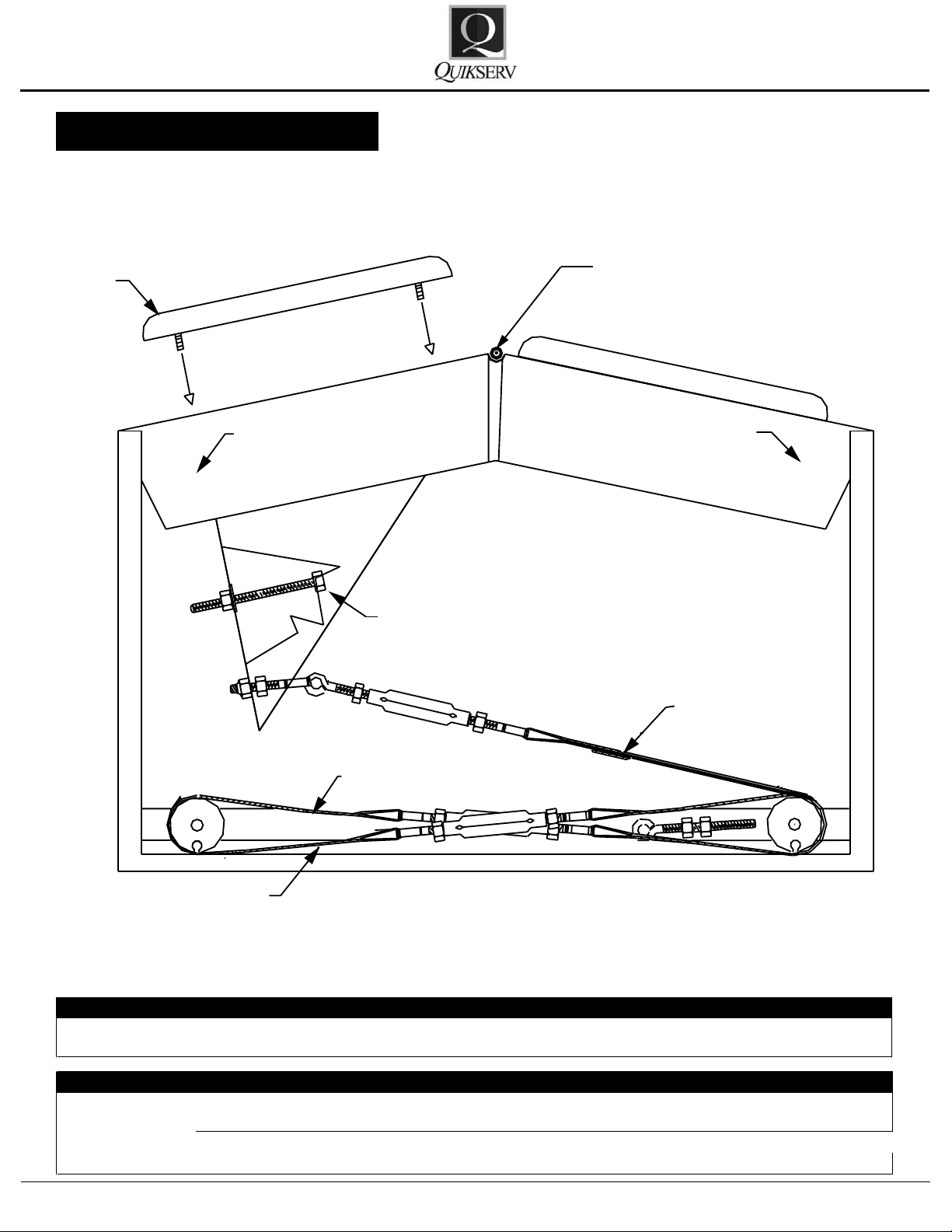

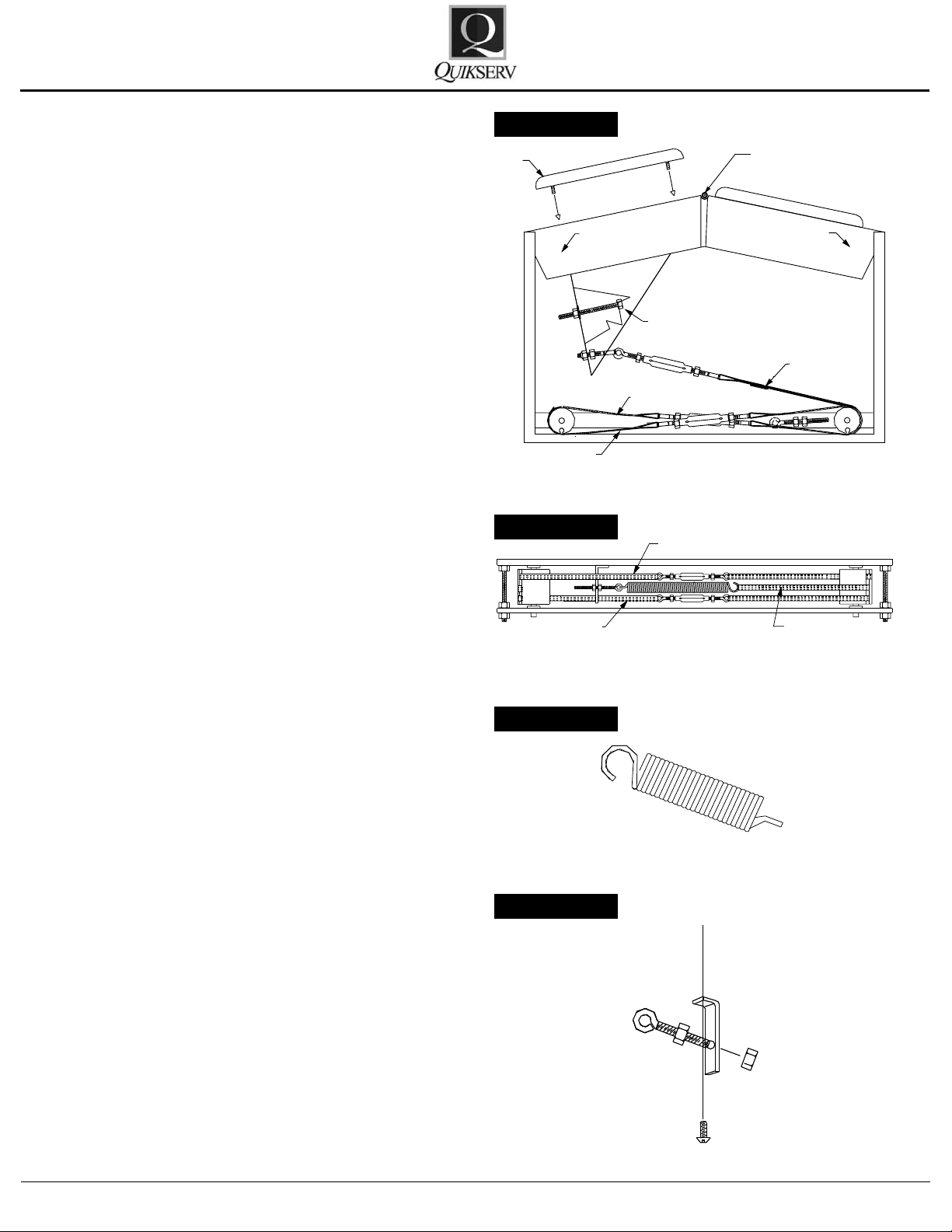

Key No. Part No. Description

A 5567 Pull Strap Assembly

B 5566 Roller Strap Assembly (2)

C 5568 Return Strap Assembly

D 5201 Travel Adjuster

E 2103 Push Pad

F * Push Bar Assembly

G 5596 Complete Set of Straps

H 1914 Hinge Pin

H

F

B

B

D

E

F

A

B

C

B

Service Manual

Bottom View

PW 1 & 2

Strap Details

Exterior View

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

9

Page 10

B

C

B

H

F

B

B

D

E

F

A

Service Manual

PW 1 & 2

Adjustment Procedures

Roller Strap Adjustment:

1. Loosen both 7/16” nuts on Part #5566 (Fig.

8-B).

2. Insert any average size screwdriver through

one eyebolt on Part #5566.

3. Hold the other eyebolt on turnbuckle between

thumb and forenger; turn adjuster body

clockwise or counter-clockwise with a 7/16”

open-end wrench until doors are aligned.

4. Realign eyebolts so they are not rubbing on

the return spring or any other object.

5. Tighten locknuts and apply non-perma

nent thread-lock.

Return Spring Adjustment:

1. Loosen locknut on Part # 3702 with a 7/16”

open-end wrench. (Fig. 7-H)

2. Turn eyebolt clockwise to increase pressure,

counter-clockwise to decrease pressure.

3. Tighten locknuts and apply non-perma-

nent thread-lock.

Figure 8 - B

-

Figure 7 - H

Pull Strap Assembly Tension Adjustment:

1. Loosen both locknuts on Part #5567 using

two 7/16” open-end wrenches. (Fig. 8-A)

2. Holding eyebolt on Part #5567 between thumb

and forenger, turn adjuster body clockwise

or counter-clockwise until slack is out of the

push bar. Caution: Do not over tighten adjuster body, as this will cause door to remain

slightly open.

3. Tighten locknuts and apply non-perma-

nent thread-lock.

Figure 8 - A

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

10

Page 11

Set of Screws

2 Each

B

C

B

Service Manual

PW 1 & 2

Roller Set Screw

1. Using a pair of needle nose pliers, remove return spring from adjuster eyebolt (Fig. 7-G &

H).

2. Align both doors to an equally open position

until you see the roller set screws (Part #5587

- Fig. 7-E).

3. Remove set screw with a 3/16” hex head

wrench (Note: Rollers may have 2 set screws

each).

4.

Apply non-permanent thread lock on the

set screw(s) threads.

5. Replace set screw(s), tighten, and close

doors.

6. Re-install return spring to the eyebolt.

Replacement Procedures

Figure 7 - G

Figure 7 - E

Figure 7 - H

Replacement of Roller Strap Assembly Part

#5566:

1. Turn retainer washers (Part #3631) on bottom of rollers (Part #5587) until you realign

the slots (Fig. 7-N).

2. Remove the frayed or broken strap by loosening the turnbuckle. You (See Fig. 8-B) may

rst need to loosen the opposite strap tension

in order to replace the frayed or broken strap

assembly.

3. Install the new strap set in the reverse order

that the defective strap set was removed.

Once in place, check to make sure that the

top roller strap is wrapped around the rollers

opposite of the bottom roller strap. (See front

view drawing - Fig. 8)

4. Tighten both strap sets by turning adjuster

body about halfway up the threaded eyebolts.

Tighten in sequence - a little at a time until

both roller straps are taut and both doors are

aligned in the closed position.

Figure 7 - N

Figure 8 - B

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

11

Page 12

H

F

B

B

D

E

F

A

B

C

B

Service Manual

PW 1 & 2

Replacement of Pull Strap Assembly Part

#5567:

1. Remove lower door roller strap (Part #5566

(Fig. 8-B) - see above procedures) from the

left side roller.

2. Loosen adjuster body on Part #5567

A) and remove strap. (Fig. 8-A) 3. Insert new

pull strap end with pin into slot on roller body.

Wrap the strap around roller in the same

manner that it was removed. Reconnect turn

buckle to eye bolt and adjust tension.

Replacement of the Return Spring Strap Assembly and Return Spring Part #5568 (Fig. 8C) & Part #1009 (Fig. 7-G):

1. Remove the 7/16” anchor nut on the eyebolt

(Part # 3702 - Fig. 7-H) and remove the broken spring (Part #1009 - Fig. 7-G) or the strap

assembly (Part #5568 - Fig. 8-C). *Note how

the strap wraps around the roller. In order to

remove the return spring strap assembly you

will have to remove the lower roller strap assembly (Fig. 8-B).

2. Insert new strap and spring with pin into roller

body in the same manner it was removed. Install other end of strap onto the return spring.

Reinstall return spring on bracket (Part # 3702

- Fig. 7-H) and adjust tension by adjusting

adjustment nuts and apply non-permanent

thread-lock.

(Fig. 8-

Figure 8 - A

Bottom View

Figure 8 - B

Front View

Figure 7 - G

Figure 7 - H

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

12

Page 13

Service Manual

PW 1 & 2

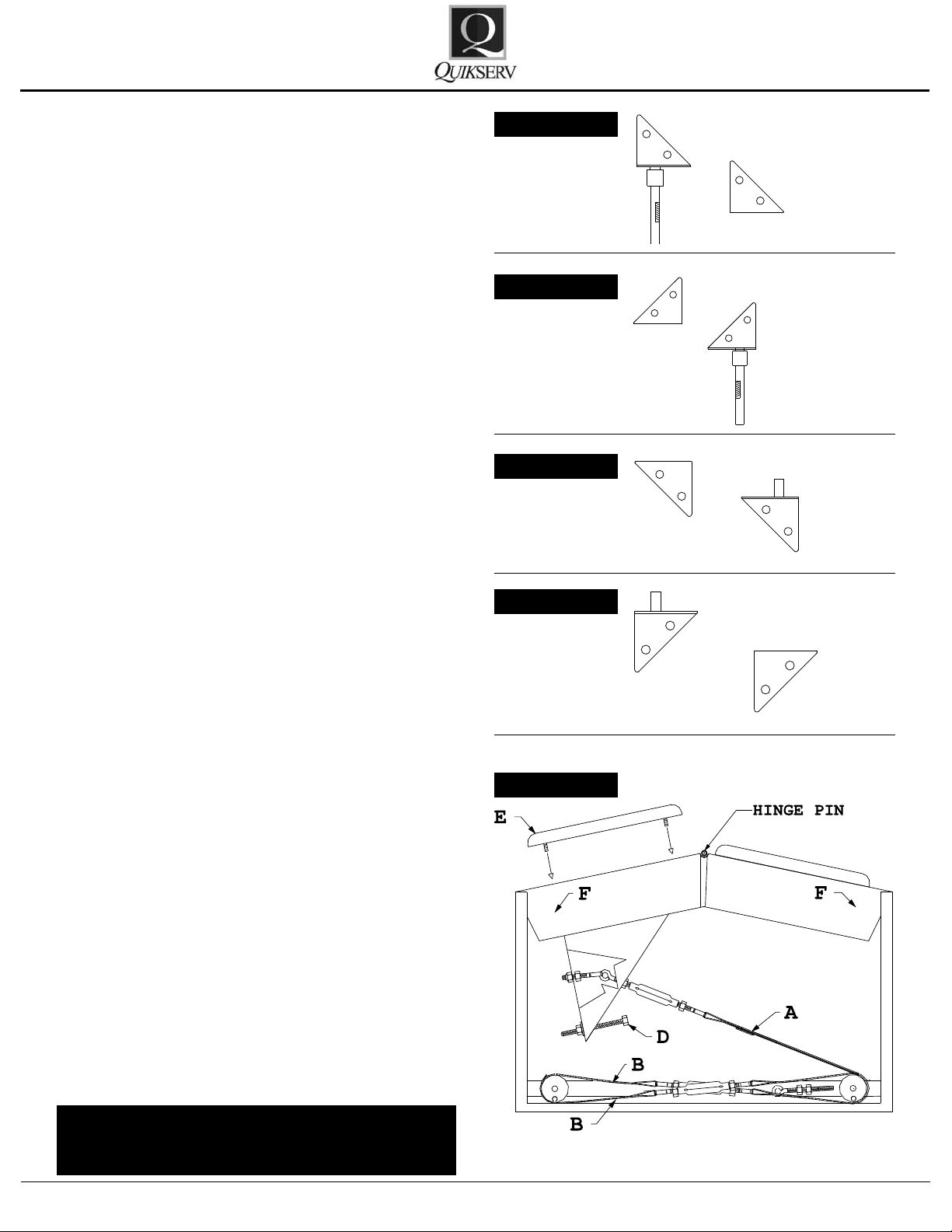

Hinge Replacement:

1. Remove hinge screws on Part #5590, 5591,

5592, and 5593 - (Fig. 7-I, J, K, L).

2. Remove door(s).

3. Remove all strap assemblies (see Replacement Procedures).

4. Remove Roller set screws (2 per roller) - Part

#5587 - Fig. 7-E.

5. Remove hinge by pulling it out of the roller

with upward force. (Note: you may have to

use pliers or vise grips).

6. Install new hinge through the top of the base.

Hinge will go through the hinge spacer, o-ring,

bearing, roller bushing, top retainer washer,

roller, bottom retainer washer, roller spacer

bushing, and bearing. See parts on Fig. 7.

7. Reinstall the hinge screws. Do not fully tighten.

After all screws are installed, align the door(s)

so that the door clearance is the same at the

top as it is at the bottom. Tighten screws.

8. Reinstall the strap assemblies and apply nonpermanent thread-lock (see Replacement

Procedures).

Figure 7 - I

Figure 7 - H

Figure 7 - H

Figure 7 - H

Push Bar Replacement:

1. Insert a small punch into the bottom of the

push bar hinge pin and drive (Fig. 8-F) the

hinge pin out of the hinge. The pin should exit

the hinge from the top.

2. Remove the right side of the push bar - then

the left side.

3. Disconnect the pull strap from the push bar

assembly.

4. Install the new push bar in reverse order.

5. Adjust travel adjuster (Fig. 8-D) so that when

the push bar is operated the push bar pads

do not travel under the base. Proper travel

adjuster alignment should leave the bolt extending out of the push bar arm approximately

1 1/2”.

All left and right designations are shown from the

operator’s point of view, or inside looking out of the

window unit

Figure 8

Bottom View

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

13

Page 14

Service Manual

Warranty Service Policy

PW 1 & 2

1. Quikserv Corp. MUST be notied of a warranty situation before any work is performed.

Otherwise, Quikserv Corp will not be responsible to pay for unauthorized work.

2. Quikserv Corp. requires the following on each

invoice submitted: an itemized account of work

performed detailing hours charged and parts

used, along with a short detailed description

of the problem noted.

3. Quikserv Corp. will authorize a set dollar

amount to be invoiced prior to performing services that will be rendered. This amount will

be determined from the initial call to the service company as a fair maximum. If additional

amounts are to be invoiced, they must be discussed with Quikserv Corp. prior to invoicing.

4. A service technician on a warranty service call

needs to call our customer service department

at (800) 388-8307 or (713) 849-5882 before

leaving the job site.

5. A service company representative needs to

call the store where the work is to be performed prior to going to that store. Set up a

date and approximate time of arrival and if it

is foreseen that the agreed upon time cannot

be met, contact the store and make other arrangements.

7. Quikserv Corp. needs to be notied of any extra parts - either to be sent back or to be kept

by the service technician. Any parts that were

replaced must be returned to Quikserv Corp.

if required verbally or on the service work order copy supplied with the parts sent by Quikserv Corp. If the parts are not returned, the

part cost + mark up will be deducted from the

service invoice.

8. A purchase order number will be given either

verbally or on the service work order from

Quikserv Corp. Please use this on all invoicing.

9. Work required on a window unit not covered

under Quikserv’s warranty must be reported

to Quikserv Corp. before work is begun.

10. Quikserv’s payment terms are net 30. The information above will help us assure the fast-

est and most efcient service possible. For

further information or if you have any questions, please do not hesitate to contact us at

(800) 388-8307.

Customer Service Department

6. Warranty parts sent to service companies are

parts previously decided on that should cover

the necessary repairs. Additional parts will be

sent upon notication to Quikserv Corp.

Quikserv Corp.© quikserv.com • 1-800-388-8307 • Fax (713) 849-5708

14

Loading...

Loading...