Page 1

Service Manual

Electric FM & PW Bi-Parting Sliders

ELECTRIC FM & PW BI-PARTING

SLIDERS

FM-42E

FM-54E

PW-54E

Contents

Operation and Maintenance Procedures 2

Trouble Shooting 3-5

Limit Switch Adjustment 6

Component Rack Removal 7

Parts Description 8

Window hardware Detail 9

PC Board Components 10

Wiring Diagrams 11-12

Warranty Service Policy 13

Quikserv Corp. quikserv.com

• 1-800-388-8307 • Fax (713) 849-5708

1

Page 2

Service Manual

Electric FM & PW Bi-Parting Sliders

ELECTRIC FM & PW BI-PARTING SLIDERS

Operaon and Maintenance Procedures

Remove access cover panel to service electrical and

mechanical components

Operation Procedures:

Unlock all locking mechanisms and ensure

that the doors are free of obstructions.

Turn the power Switch to the “on” position,

located on the upper left hand corner.

(Some windows the switch may be located

behind the access cover.)

Proper operation of the “Up-Eye” unit re-

quires the attendant to be directly in front

of and over all 3 photoelectric sensors

while serving. Proper operation of the

“Thru-Beam” unit requires the attendant to

stand between the Emitter and Receiver

eyes.

General Maintenance:

Always disconnect the power supply before

servicing.

Slide rail system should be kept clean and

re-oiled with light weight oil every six (6)

months.

<Note> The outside edge of the photo-bar

should be lined up with the inside edge of

the locking jamb.

General Cleaning Guidelines:

All weather-stripping should be checked

and cleaned weekly.

All glass, aluminum framing, stainless

steel, and plastic eye covers & lens should

be kept clean at all times. All cleaning flu-

ids and applicators should be nonabrasive.

The eye-sets should be checked weekly to

make sure they are fully fastened to unit or

wall. They should also be cleaned of any

dirt or debris daily with non-abrasive cleaner.

Please refer to the trouble shooting section for

additional information on the window adjustments or service procedures.

Contact us at (800) 388-8307 for assistance or

for information on the nearest service center in

your area.

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

2

Page 3

Service Manual

Electric FM & PW Bi-Parting Sliders

ELECTRIC FM & PW BI-PARTING SLIDERS

TROUBLE SHOOTING REFERENCE

PAGE

Trouble Probable Cause Probable Soluon

1. No power to the unit Check the Circuit breaker

Window

Does

Not Operate

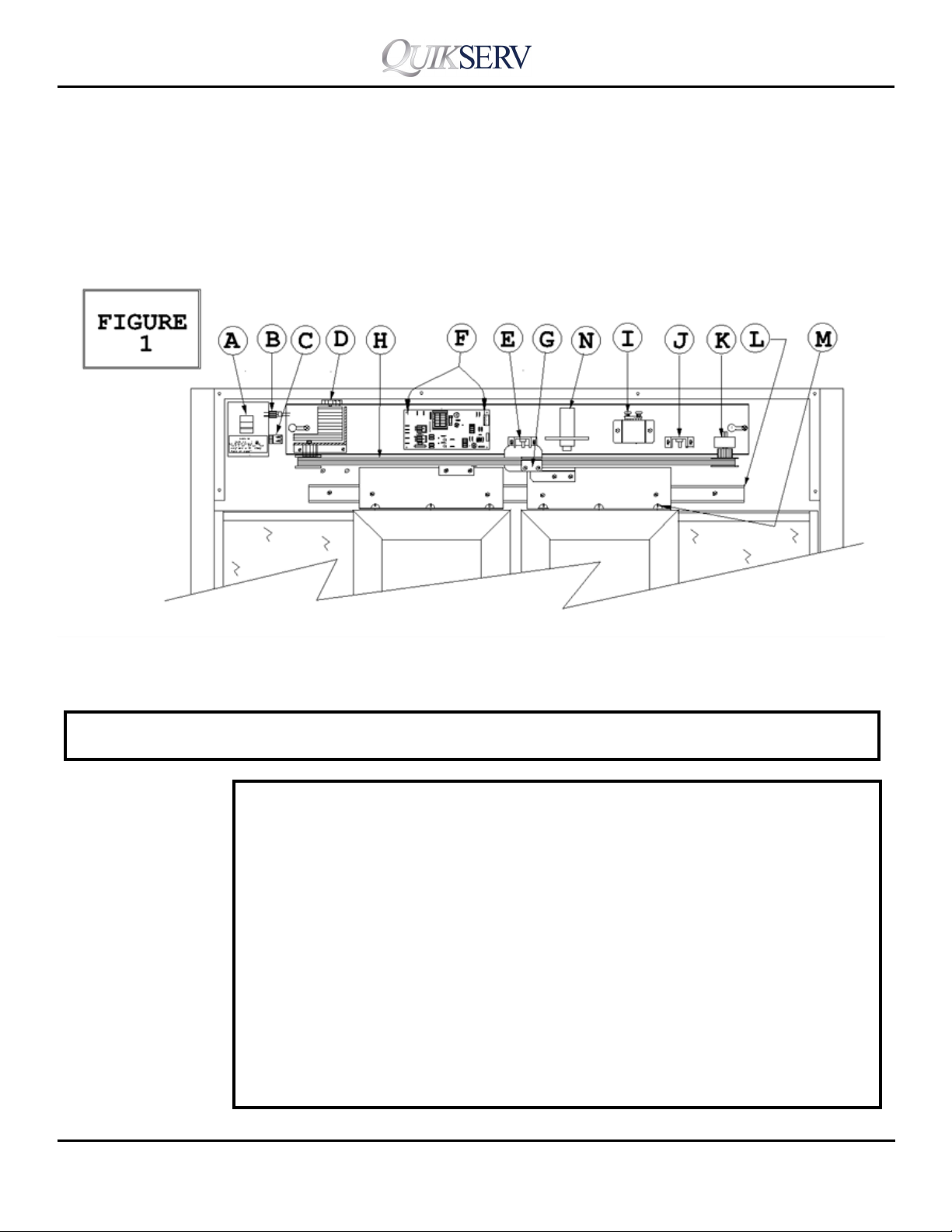

2. Power Switch is o or defecve Turn on switch or replace (Fig. 1-A)

3. Fuse in switch or pc board blown Check and Replace (Fig. 1-C or 6-B)

4. Component Rack not plugged in Check and plug in (Fig. 1-B)

5. Open limit switch defecve or discon-

nected

6. Defecve eye set Replace defecve part (Fig. 5-E or G)

7. Obstrucon in door movement Check locks, slide rail, and remove

Connue Page 4

3

Replace or reconnect (Fig. 1-E & J)

obstrucons.

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 4

Service Manual

Electric FM & PW Bi-Parting Sliders

Trouble Shoong Electric FM & PW BI-Parng Sliders

Trouble Probable Cause Probable Soluon

8. Defecve motor or capacitor Replace motor (Fig. 1-D & I)

Window

9. Thermal overload tripped in motor Replace or adjust limit switches (Fig. 2)

Does

Not Operate

10. Defecve PC Board Replace (Fig. 1-F)

11. Defecve slide rail Replace (Fig. 1-L)

12. Electric lock defecve or adjusted Adjust or replace (Fig. 1-N)

Trouble Probable Cause Probable Soluon

Doors stay in

the open

posion

1. Closed limit switch is defecve or dis-

connected

2. Eye assembly is unplugged or discon-

nected

3. Photo-eye is obstructed or misaligned Remove obstrucon (Fig. 5-E)

4. Faulty eye wire connecon Check all connecons-repair or replace

5. Defecve PC board Replace (Fig. 1-F)

6. Handicap buon on eye-set defecve Replace switch on side of up-eyes

Replace or reconnect (Fig. 1-E & J)

Check connecon point (Fig. 5)

(Disconnued aer serial number

35700)

7. Reverse gear in motor bad Replace (Fig. 1-D)

8. Door misaligned Adjust door (Fig. 1-M)

Trouble Probable Cause Probable Soluon

Motor runs

but the doors

does not

operate

1. Motor sha pulley or pulley block

loose

2. Broken drive belt Replace (Fig. 1-H)

3. Belt bracket loose or missing Tighten or replace (Fig. 1-G)

4. Bad motor Replace (Fig. 1-D)

4

Tighten or replace (Fig. 1-D or K)

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 5

Service Manual

Electric FM & PW Bi-Parting Sliders

Trouble Shoong Electric FM & PW BI-Parng Sliders

Trouble Probable Cause Probable Soluon

Window will

run for short

1. Thermal overload in the motor has

been tripped

Limit switch or switches may not be set

properly (Fig. 2) & (Fig. 1-E & J)

period then

stop

Trouble Probable Cause Probable Soluon

Doors are

dragging or

binding

1. Slide rail is dirty or defecve Clean and oil or replace if needed. (Fig.1-

L)

2. Loose door bracket Tighten screws and make sure inserts in

door are not loose. (Fig.1-M)

3. Doors misaligned Adjust door (Fig.1-M)

3. Drive Belt too ght Loosen Drive Belt. (Fig. 1-H)

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

5

Page 6

Service Manual

Electric FM & PW Bi-Parting Sliders

The locaon of the limit switch can be ad-

justed by loosening the two (2) screws in

the bracket and by moving the bracket up

or down in the adjustment slots. When set

properly the switch should clear the ag

bracket by approximately 1/16”. When the

ag bracket is posioned within the

switch, the red LED (open - close) or (LED 2

or 3) Depending on which PC board is in

the unit should be OFF.

Note: LED2 or LED3 or the (OPEN or

CLOSE) LED lights on the PC Board should

only be “ON” when the doors are moving.

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

6

Page 7

Service Manual

Electric FM & PW Bi-Parting Sliders

Warning : Turn power switch OFF before

removing access panel. CAUTION: Power Supply

120Volts

Component Rack

To remove component rack assembly– see

Figure 3 :

1. Unplug power cord from internal outlet.

2. Remove the boom 5-pin connector.

3. Disconnect the ag bracket(s) from the

door bracket.

Please refer to the TROUBLE SHOOTING

PAGES in this manual for addional infor-

maon on window adjustments or parts

replacement.

4. Loosen the (2) 7/16” nuts at each end

of the component rack and slide rack to

the right and liing out.

Contact us a (800)388-8307 for assis-

tance or for informaon on the nearest

service center in your area.

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

7

Page 8

Service Manual

Electric FM & PW Bi-Parting Sliders

ELECTRIC FM & PW BI-PARTING SLIDERS

PARTS

8

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 9

Service Manual

Electric FM & PW Bi-Parting Sliders

WINDOW HARDWARE DETAIL

9

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 10

Service Manual

Electric FM & PW Bi-Parting Sliders

10

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 11

Service Manual

Electric FM & PW Bi-Parting Sliders

11

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 12

Service Manual

Electric FM & PW Bi-Parting Sliders

12

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

Page 13

Service Manual

Electric FM & PW Bi-Parting Sliders

Warranty Service Policy

1 Quikserv Corp. MUST be notified of a warranty

situation before any work is performed.

Otherwise, Quikserv Corp. will not be responsible

to pay for unauthorized work.

2. Quikserv Corp. requires the following on each

invoice submitted: an itemized account of work

performed detailing hours charged and parts

used, along with a short detailed description

of the problem noted.

3. Quikserv Corp. will authorize a set dollar

amount to be invoiced prior to performing services

that will be rendered. This amount will

be determined from the initial call to the service

parts - either to be sent back or to be kept

by the service technician. Any parts that were

replaced must be returned to Quikserv Corp.

if required verbally or on the service work order

copy supplied with the parts sent by Quikserv

Corp. If the parts are not returned, the

part cost + mark up will be deducted from the

service invoice.

8. A purchase order number will be given either

verbally or on the service work order from

Quikserv Corp. Please use this on all invoicing.

9. Work required on a window unit not covered

under Quikserv’s warranty must be reported

company as a fair maximum. If additional

amounts are to be invoiced, they must be discussed

with Quikserv Corp. prior to invoicing.

4. A service technician on a warranty service call

needs to call our customer service department

at (800) 388-8307 or (713) 849-5882 before

leaving the job site.

5. A service company representative needs to

call the store where the work is to be performed

prior to going to that store. Set up a

date and approximate time of arrival and if it

is foreseen that the agreed upon time cannot

be met, contact the store and make other arrangements.

6. Warranty parts sent to service companies are

parts previously decided on that should cover

to Quikserv Corp. before work is begun.

10. Quikserv’s payment terms are net 30. The infor-

mation above will help us assure the fastest

and most efficient service possible. For

further information or if you have any questions,

please do not hesitate to contact us at

(800) 388-8307.

Customer Service Department

the necessary repairs. Additional parts will be

sent upon notification to Quikserv Corp

7. Quikserv Corp. needs to be notified of any extra

• 1-800-388-8307 • Fax (713) 849-5708 Quikserv Corp. quikserv.com

13

Loading...

Loading...