QuickLabel RW-P8 User Manual

THREE-YEAR LIMITED WARRANTY

Your new RW-P2 or RW-P8 Label Rewinder (the Unit) is guaranteed to the original

end-user purchaser to be free from defects in materials and workmanship under

normal use for a period of three (3) years from original date of purchase. (The AC

power supply warranty period is one 1 year.) This Warranty begins when you

purchase the Unit and continues for the Warranty period unless you sell or rent the

Unit, in which case the Warranty terminates.

In the event Warranty service is required, please contact QuickLabel Systems for

a Return Material Authorization (RMA) number and the location to which the Unit

should be shipped. The Unit must be packed securely for shipment to avoid

damage. Original packaging is recommended if available. Proof of original

purchase must accompany the Unit. The customer assumes all costs incurred in

transporting the Unit to an authorized service center. Upon examination, if the

Unit is found to be defective, it will be repaired or replaced without charge during

the Warranty period.

QuickLabel Systems disclaims any implied warranty, including the warranty of

merchantability and the warranty of fitness for any particular purpose, and assume no responsibility or liability for any special, incidental or consequential

damages.

This Warranty does not cover damage resulting from accident, misuse, abuse,

improper installation or operation, connection to inappropriate power source, lack

of reasonable care, unauthorized modification, the affixing of any attachment not

provided by QuickLabel Systems, or loss of parts. This Warranty is voided in the

event any unauthorized person opens, alters, or attempts to repair the Unit.

QuickLabel Systems

A Product Group of Astro-Med, Inc.

World Headquarters:

600 East Greenwich Avenue

West Warwick, RI 02893

Telephone: 401-828-4000

Toll Free: 877-757-7978

Fax: 401-822-2430

www.QuickLabel.com

E-mail: info@QuickLabel.com

QLSRW-P8 Operations Manual.p65

Rev. March 2005

RW-P8 (10” width) Label Rewinder

Constant Adjustable Torquetm (“CAT”) technology ensures silent operation and

constant, uniform tension on the label takeup reel without dancer or tensioning arms.

The result is a short leader length, exceptionally easy threading, and no speed

adjustments or troublesome clutches, belts, or gears. Dual torque ranges and a

Torque Control Knob set the desired tension on the RW-P Series Rewinders. The

RW-P8 Rewinder can also be used as a Label Unwinder.

Rugged, heavy-duty steel construction allows the unit to be conveniently set in place

near the label printer. Special anti-slip feet on the base prevent the unit from moving.

This reliable, high-quality, maintenance-free unit features a Limited 3 Year Materials

and Workmanship Warranty (see warranty statement for details).

UNPACKING

Remove all parts from the shipping container and verify the contents:

___ RW-P8 Drive Unit

___ Universal 100 - 240VAC 50-60Hz Power Supply

___ AC Line Cord

___ Rewind Shaft with small Allen head set screw (installed)

___ PLastic Flange Plate (2 each)

___ Metal Fins (6 each)

___ User Manual, 2 Allen Wrenches, #8 Screws & Washers (24 each)

SETUP

WARNING! THIS EQUIPMENT IS FOR

INDOOR USE ONLY.

NOT FOR USE IN WET LOCATIONS.

(1) Identify the Inner Flange Plate as the plastic disc with a center Nylon Hub

containing an Allen head screw. Using the larger Allen wrench, attach the Inner

Flange to the Rewind Shaft.

(2) Slide the Rewind Shaft and Flange Plate assembly onto the Motor Shaft allowing

for clearance to the Chassis and Motor Screws. Align the Set Screw with the flat on

the Motor Shaft. Tighen the Allen screw to secure the Rewind Shaft.

(3) The Metal Fins on the Rewind Shaft hold the Rewind Core. Supplied Washers

can be used under one or more of the fins if the core does not hold securely.

CAUTION: Avoid Accidents! THE RW-P8 Rewinder

EXTERNAL HALT CONTROL

weights up to 28-pounds (13-Kg) plus the weigh of the

labels, so choose only a sturdy surface on which to set

your Rewinder.

QuickLabel Systems has provided an External Halt Control if you wish to stop or

start your Rewinder using an external control. If an external device, such as a

printer, label slitter counter, or other device, opens the control circuit, the RW-P8

Drive Unit will disconnect power to the motor and apply braking.

(4) Set the Unit in place near the label exit path of the printer. The

RW-P8 is bi-directional and can wind labels in either direction.

(5) Verify that the “DIRECTION” Switch on the Control Panel is in the “OFF”

position.

(6) Plug the Power Lead from the Power Supply into the power Input Jack on the

rear of RW-P8 Drive Unit. Plug the AC Power Cord into the Power Supply and into

an appropriate AC power outlet.

Your Rewinder is now ready for use.

LABEL REWINDING

(1) Place the “DIRECTION” Switch on the RW-P8 control panel in the center

“OFF” position.

(2) Slide an empty 3-inch (76-mm) label core over the core holder until the core is

against the Inner Flange plate.

(3) If desired, slide the outer Label Flange plate (Nylon Hub with ball bearing screw)

over the Rewind Shaft and up against the label rewind core.

(4) Feed the label web from the printer and secure it to the take-up roll core with

masking tape. Manually rotate the take-up reel a couple of turns.

(5) Check that the RW-P8 Unit is square with the printer.

(6) Place the RW-P8 “TORQUE RANGE” Switch in the Normal/Rewind position.

NOTE: WHEN THE TORQUE RANGE SWITCH IS IN THE “HIGH (SLIT)” POSITION, THE RW-P CAN DEVELOP HIGH TORQUE. USE THE HIGH (SLIT) POSITION FOR LABEL SLITTING OR WHEN REWINDING LARGE DIAMETER ROLLS.

(7) Rotate the “TORQUE” Control Knob to the minimum position (fully counterclockwise).

(8) Place the RW-P8 “DIRECTION” Switch in the position desired to run left or right.

(9) Start the printer and adjust the “TORQUE” Control Knob for the desired take-up

tension. Use only the minimum Torque setting needed to rewind labels properly.

Excessive torque might pull the labels too hard and cause the printer to lose registration.

(10) When rewinding is finished, place the “DIRECTION” Switch in the “0” (Off)

position. Remove the Outer Flange and label roll from the Unit being careful to avoid

telescoping of the labels.

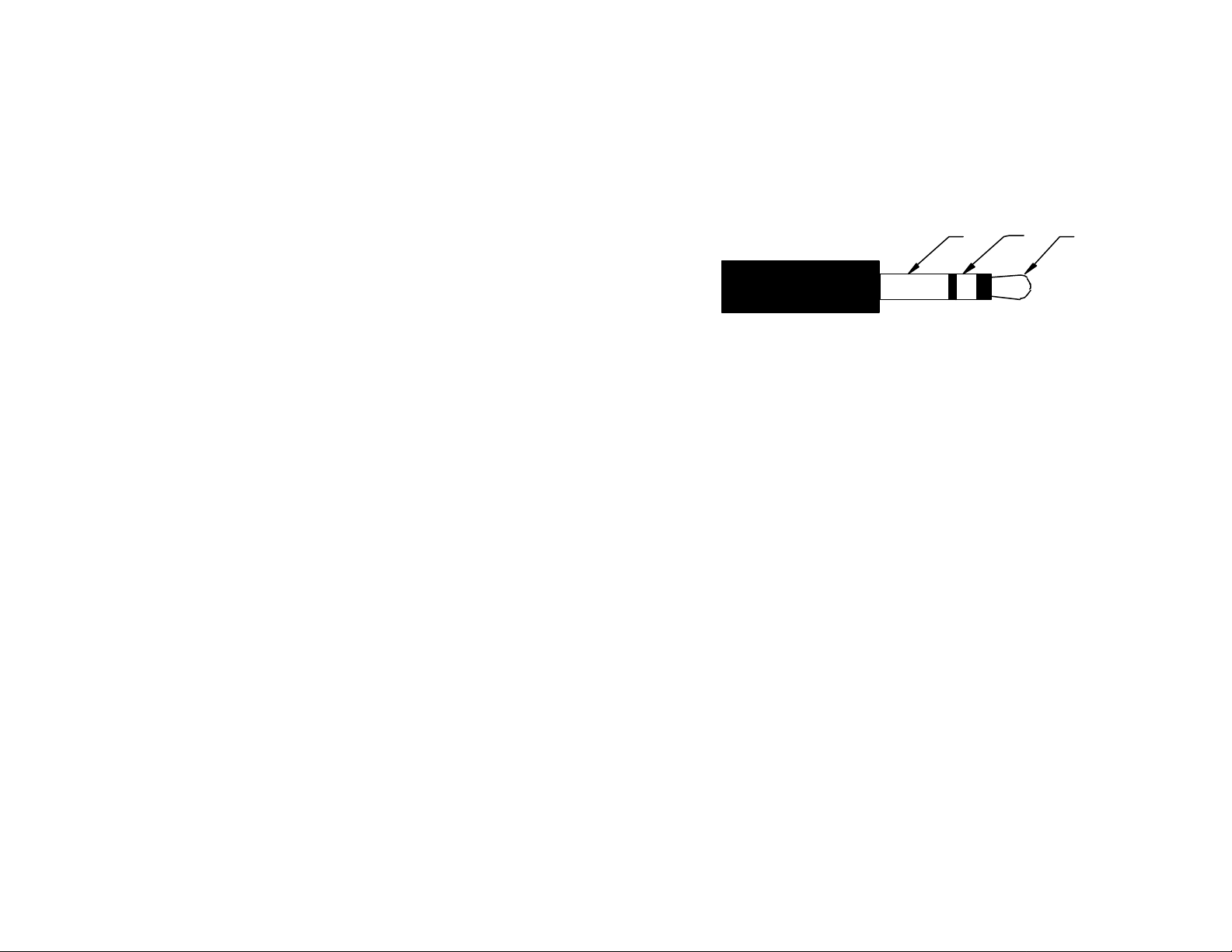

Use a 3.5 mm dual circuit plug and cable plugged into the External Halt Control

Jack. The RW-P8 Control Plug connections are described below.

2 31

3.5mm External Halt Control Plug (dual circuit)

CONTACTS 2 & 3 OPEN: RW-P HALTS

CONTACTS 2 & 3 CLOSED: RW-P RUNS

1 = No connection (Not Used)

2 = Normally Closed (NC) contact return

3 = Normally Closed (NC) contact

MAINTENANCE

Your RW-P8 Label Rewinder requires no periodic or preventative maintenance.

Loading...

Loading...