QuickLabel RW-P1 User Manual

THREE-YEAR LIMITED WARRANTY

Your new RW-P1 or RW-P2 Label Rewinder (the Unit) is guaranteed to the

original end-user purchaser to be free from defects in materials and workmanship

under normal use for a period of three (3) years from original date of purchase.

(The AC power supply warranty period is one 1 year.) This Warranty begins when

you purchase the Unit and continues for the Warranty period unless you sell or

rent the Unit, in which case the Warranty terminates.

In the event Warranty service is required, please contact QuickLabel Systems for

a Return Material Authorization (RMA) number and the location to which the Unit

should be shipped. The Unit must be packed securely for shipment to avoid

damage. Original packaging is recommended if available. Proof of original

purchase must accompany the Unit. The customer assumes all costs incurred in

transporting the Unit to an authorized service center. Upon examination, if the

Unit is found to be defective, it will be repaired or replaced without charge during

the Warranty period.

QuickLabel Systems disclaims any implied warranty , including the warranty of

merchantability and the warranty of fitness for any particular purpose, and assume no responsibility or liability for any special, incidental or consequential

damages.

This Warranty does not cover damage resulting from accident, misuse, abuse,

improper installation or operation, connection to inappropriate power source, lack

of reasonable care, unauthorized modification, the affixing of any attachment not

provided by QuickLabel Systems, or loss of parts. This W arranty is voided in the

event any unauthorized person opens, alters, or attempts to repair the Unit.

RW-P1 Label Rewinder 120V 60Hz

RW-P2 Label Rewinder 220-240V 50Hz

The QuickLabel Systems RW-P1 and RW-P2 are low-cost Universal Label Rewinders

capable of rewinding or unwinding any width labels up to 4.5” (1 14mm) wide at

speeds of up to 10-inches per second. Label rolls up to 8” (203mm) in diameter can

be accommodated. No speed adjustments are required. Torque (Rewind Force) is

switch adjustable. The RW-P1 or RW-P2 (The Unit) is bi-directional and rated for

continuous duty . No damage will occur even if The Unit is left “ON” indefinitely after

the printer has stopped. A switch on the Power Supply Module conveniently controls

the amount of rewind or unwind force. The Unit automatically adjusts itself to your

printer speed and allows for back feeding labels if the printer requires this.

The Unit uses proprietary Constant Adjustable Torque™ (“CA T”) technology to

achieve impressive, reliable performance at an unprecedented low price.

Labels can be conveniently wound directly onto the takeup shaft with The Unit

eliminating the need for cardboard rewind cores. Fins to hold a 3” core are also

included. The Unit is supplied with an inner label flange to keep the edge of the

labels aligned as they are being rewound. Rugged, heavy-duty steel construction

allows The Unit to be simply set in place near the exit path of the label printer .

Special anti-slip feet prevent the unit from moving.

UNPACKING

QuickLabel Systems

an Astro-Med, Inc. Product Group

World Headquarters:

600 East Greenwich A venue

West Warwick, RI 02893

T oll Free: 877-757-7978

Telephone: 401-828-4000

Fax: 401-822-2430

E-mail: info@QuickLabel.com

Website: www.QuickLabel.com

Verify contents of the shipping cont ainer:

____ RW-P1 or RW-P2 Unit

____ 120VAC or 220-240VAC Power Supply Module

____ Plastic Bag containing (1) Allen Wrench, (3) Met al Fins, (6) Slotted Screws,

(1) Hook-shaped Bail, (6) Lockwashers in bag, and the User Manual

(this document).

Please keep the shipping container and inserts for future use in case the unit is to be

shipped or moved to a new facility .

W ARNING!

This equipment is for indoor use only.

Not for use in wet locations.

SETUP

(1) Place The Unit so that the rewind shaft is perpendicular to the web of the labels

to be rewound, and near where the labels come out of the printer. The Unit is bidirectional, so can be operated in either direction, as you prefer. See S tep 6.

(2) Verify that the Power Switch (0 - 1) on the rear of The Unit is in the 0 (OFF)

position.

(3) Set the VOL T CHANGE SW slide switch on the Power Supply Module to 4.5 as

an initial setting.

(4) Insert the Power Cord into the Power Jack on the rear of The Unit.

(5) Plug the Power Supply Module into a suitable 120 V AC / 60Hz electrical outlet. It

can be left plugged in at all times.

(6) The Rewinder has a combination Power and Direction Switch on the rear panel.

The Center Position of the Switch is “OFF” (0). To make the Rewinder run to the

right (looking from the rear of the Rewinder), press the Power / Direction Switch in

the direction of the right arrow. To make the Rewinder run to the left, press the

Power / Direction Switch in the direction of the left arrow .

LABEL REWINDING

Rewinding Directly Onto the Shaft - “Coreless” (See Fig. 2)

(1) Slide the hook-shaped metal Bail onto The Unit Shaft. The straight end goes into

the hole in the plastic Flange plate. The curved end fits into the small hole in the

outer end of the Shaft.

(2) Insert the label web under the metal Bail and turn the rewind Shaft by hand to

secure the labels.

(3) Place The Unit Power Switch (0 - 1) in the 1 (ON) position. If necessary , reverse

The Unit rotation direction as described in SETUP section, step 6.

(4) Start the printer and observe that the labels are being rewound correctly. You can

adjust the VOL T CHANGE SW slide switch on the Power Supply Module to provide

more or less rewind force. A lower numerical setting result s in less force and a

higher numerical setting results in greater force.

(5) When rewinding is finished, place The Unit Power Switch (0 - 1) in the 0 (OFF)

position.

(6) To remove the labels, first pull out the hook-shaped Bail from the center of the

label roll. Then remove the labels.

The Unit rotation direction as described in SETUP section, step 6.

(5) St art the printer and observe that the labels are being rewound correctly . You can

adjust the VOL T CHANGE SW slide switch on the Power Supply Module to provide

more or less rewind torque.

(6) When rewinding is finished, placeThe Unit’s Power Switch (0 - 1) in the 0 (OFF)

position.

(7) Slide the cardboard core and the labels off The Unit.

UNWINDING LABELS

(1) Verify that The Unit’s Power Plug is set to wind away from the printer (See

SETUP section, step 6). Place the Power Switch (0 - 1) to the 0 (OFF) position and

set the VOL T CHANGE SW to 1.5.

(2) Slide the roll of labels to be unwound over the Fins on the Rewind Shaft and up

against the plastic Flange Plate.

(3) Feed the labels into the printer and start the printer .

(4) To provide a small amount of back tension on the label supply roll, place The

Unit Power Switch (0 - 1) in the 1 (ON) position.

MAINTENANCE

The Unit requires no periodic or preventative maintenance.

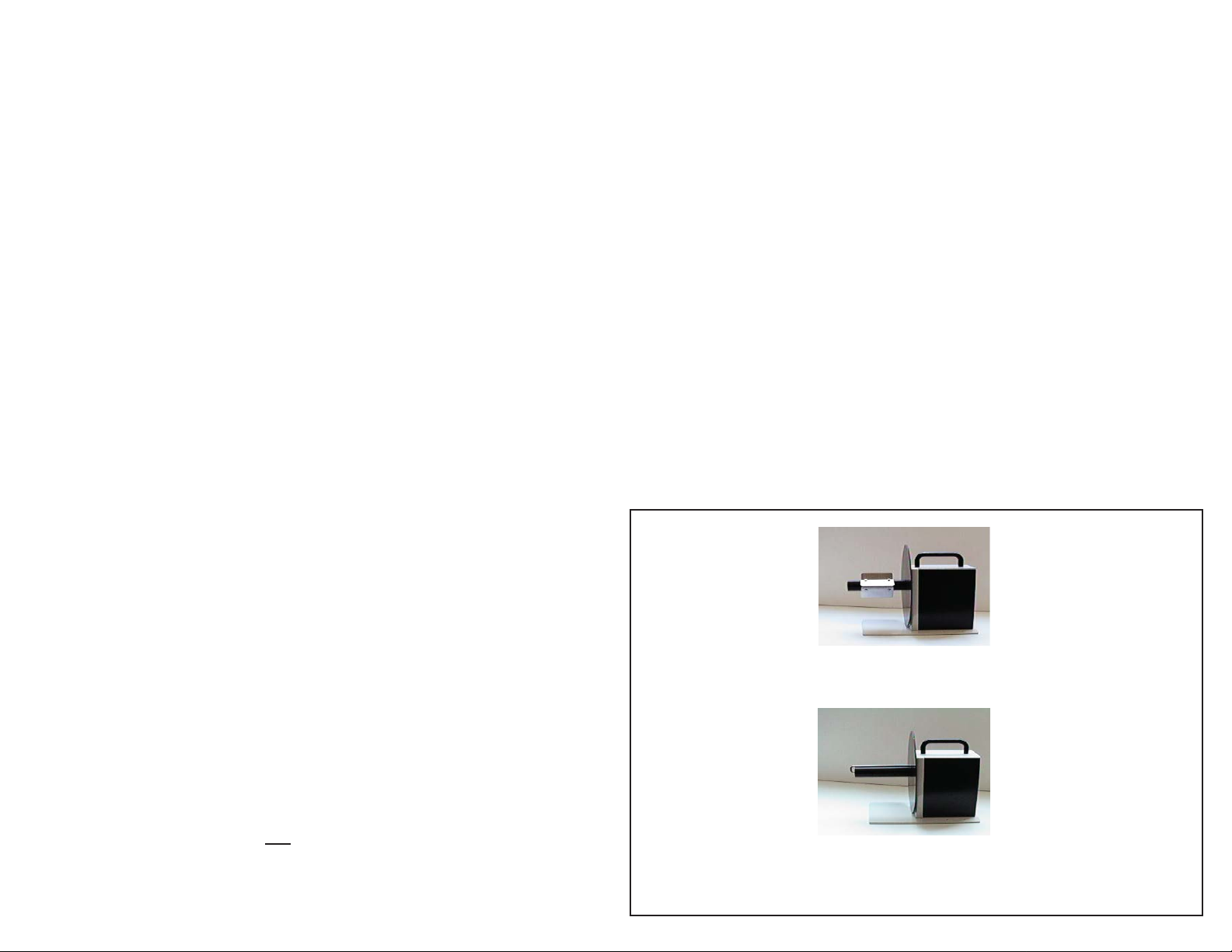

Fig. 1 The Unit with Fins installed to accept a

standard 3” core for rewinding or unwinding.

Rewind onto a 3” Cardboard Core (See Fig. 1)

(1) To use a 3” cardboard core, install the three stainless steel Fins onto the Shaft

of The Unit using the six screws provided. DO NOT USE THE LOCKWASHERS.

The curved sides of the Fins face the Shaft. For narrow cores, orient the Fins next

to the plastic Flange. Slide an empty cardboard core over the Fins and up against the

plastic Flange Plate.

(2) If the core is too loose, remove one of the Fins and place a supplied Lockwasher

on each screw between the vane and the shaft. Retighten the screws securely . Add

Lockwashers under additional Fins if necessary .

(3) Use a piece of masking tape to secure the label web to the cardboard.

(4) Place The Unit Power Switch (0 - 1) in the 1 (ON) position. If necessary , reverse

Fig. 2 The Unit shown with supplied Bail for

direct “on-shaft,” “coreless” label rewinding.

Loading...

Loading...