Page 1

R-310

Label Applicator

Operator’s Manual

Serial #

Page 2

Operator’s Manual

Version: H 8/5/2004

The information in this manual is subject to change without notice. No part of this

manual may be reproduced or transmitted in any form or by any means, for any

purpose other that the purchaser’s personal use, without prior written consent

from Universal Labeling System, Inc.

Universal Labeling Systems, Inc.

th

3501 8

Ave South, Saint Petersburg, FL 33711

Phone (727) 327-2123 Fax (727) 323-4403

Web Site: http://www.universal1.com

2

Page 3

Table of Contents

SECTION 1 OVERVIEW...................................................................................4

INTRODUCTION...........................................................................4

UN-PACKING INSTRUCTIONS....................................................5

PRODUCT WARRANTY...............................................................6

SPECIFICATIONS........................................................................7

SECTION 2 SETUP ..........................................................................................8

ASSEMBLING THE R-310 ........................................................... 8

FUNCTION OF UNWIND ASSEMBLY.........................................9

WEBBING THE R-310................................................................10

WASTE REMOVAL ....................................................................11

CARRIAGE ADJUSTMENT AND PRODUCT PLACEMENT..... 12

SECTION 3 OPERATION...............................................................................18

SECTION 3 OPERATION...............................................................................19

TRI-TRONICS OPTICAL LABEL SENSOR................................19

OPTIONAL LION SENSOR FOR CLEAR LABELS...................20

OFF DELAY................................................................................21

TIMER ADJUSTMENT................................................................22

AIR ASSEMBLY ADJUSTMENTS .............................................23

AIR REGULATOR ......................................................................24

SECTION 4 MAINTENANCE..........................................................................25

GENERAL MAINTENANCE .......................................................25

SECTION 5 RECOMMENDED SPARE PARTS.............................................26

SECTION 6 DRAWINGS AND BILL OF MATERIALS...................................27

MAIN ASSEMBLY......................................................................27

AIR CYLINDER MOUNTING ASSEMBLY .................................27

FRONT PANEL ASSEMBLY......................................................27

REGULATOR ASSEMBLY.........................................................27

LABEL SENSOR/PEELER ASSEMBLY....................................27

OPTIONAL STARWHEEL /PEELER ASSEMBLY.....................27

UPPER IDLER ROLL ASSEMBLY.............................................27

STANDARD CARRIAGE ASSEMBLY .......................................27

13” UNWIND ASSEMBLY..........................................................27

POWER MODULE......................................................................27

DIMENSIONAL DIAGRAM.........................................................27

WEBBING DIAGRAM (OPTICAL)..............................................27

WEBBING DIAGRAM (OPTIONAL STARWHEEL) ...................27

ELECTRICAL DIAGRAM ...........................................................27

TECHNICAL SUPPORT.....................................................................................28

3

Page 4

SECTION 1 OVERVIEW

INTRODUCTION

Thank you for purchasing the R-310 semi-automatic round product label

applicator. The R-310 is known for high quality and operating convenience. With

proper maintenance it will provide many years of dependable and trouble free

service. We wish you much success with this product and will always welcome

any suggestions you may have as to how we may improve our products. Read

this manual and familiarize yourself with the machine before using this

equipment.

Operation:

A round product is placed on the carriage rollers and against the end stop. When

the operator presses the foot switch, a time delay cycle that controls an air

cylinder is activated, the drive roller starts to rotate, and the label starts it’s

dispense cycle. Air supplied to the cylinder causes the carriage holding the

product, to be elevated into contact with the drive roller. When the product

makes contact with the drive roller, it will start to turn. At this point, the label is

being peeled from the backing paper and will contact the product just in front of

the drive roll. As the product continues to turn, the drive roller will press the label

onto the container until the label is completely applied. The carriage will drop,

the product can be removed, and the machine is ready to repeat the cycle.

4

Page 5

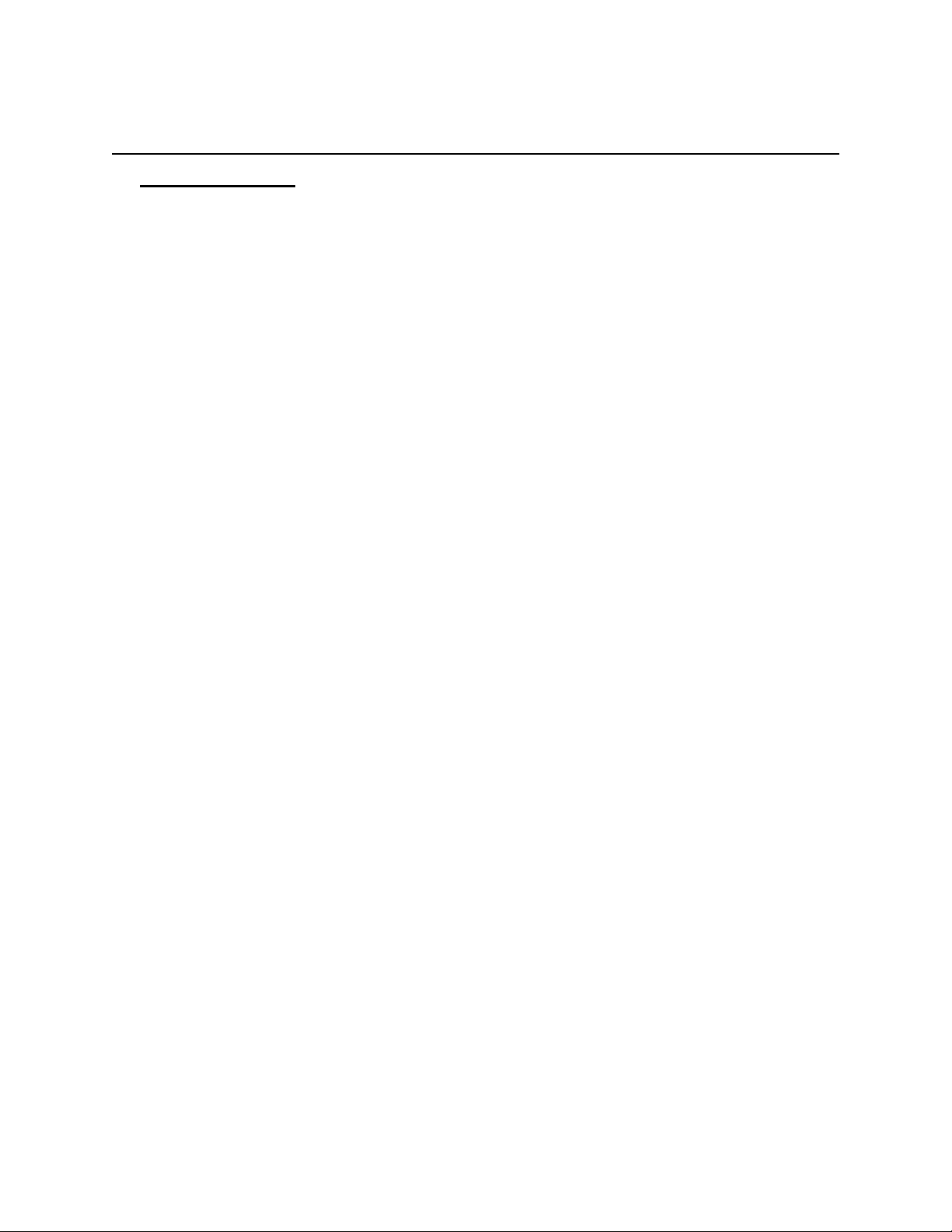

UN-PACKING INSTRUCTIONS

When the machine is received, the shipping carton will contain the following

items (see Fig 1).

1. This Manual in a Manila Envelope.

2. Foot Switch.

3. Unwind Assembly.

4. Unwind backing disc.

5. Removable label disc.

6. R-310 Body.

7. 10’ of 1/4” Air line.

8. Air Fitting, Part # 100220 ¼” NPT x 1/4”.

9. 9/64” Allen Wrench. (inserted in air line for safe keeping)

Carefully unpack the R-310 and place machine on a table or suitable flat surface.

Be sure no small parts are left in box.

Verify contents of box with list above. Inspect machine for any damage. Report

missing components or damage to your distributor immediately.

4

5

6

3

Fig 1

5

Page 6

PRODUCT WARRANTY

Universal Labeling Systems, Inc. warranties all parts to be free from defects in

material and workmanship for a period of one year from the date of shipment

from our facility.

This guarantee is based upon equipment being used 8 hours per day, or 40

hours per week, or in any increment which does not total more than a single shift

operation, or 2,080 hours per year. Warranty will be reduced proportionally.

This warranty does not cover parts failure caused by lack of normal maintenance,

abuse or misuse of the equipment.

PERFORMANCE GUARANTEE

All equipment manufactured by Universal Labeling Systems, Inc. carries a 30day performance guarantee. If your machinery does not perform as described in

our quote to you within 30 days of shipping, Universal Labeling Systems, Inc. will

make every attempt to correct it. If after a reasonable period of time, the

machinery does not meet the specified performance, we will take your machine

back and reimburse you in full.

6

Page 7

SPECIFICATIONS

Electrical Power: 120VAC +/- 10%, 5 Amps, 60Hz

Compressed Air: Clean, Dry, 20-40PSI, 5CFM

Product size: ½” to 6” (12.7mm to 154.2mm)

Web width: 7-1/8” (180.97mm) web capacity

on 3” (76.2mm) core – 12” (304.8mm) diameter roll

Machine Size: 21.24” Wide 27.36” Deep 24.32” Tall

(539.5mm Wide X 695mm Deep X 617.7mm Tall)

Weight: 52 lbs (19.4 Kg)

Shipping Weight: 69 lbs (25.7 Kg)

7

Page 8

SECTION 2 SETUP

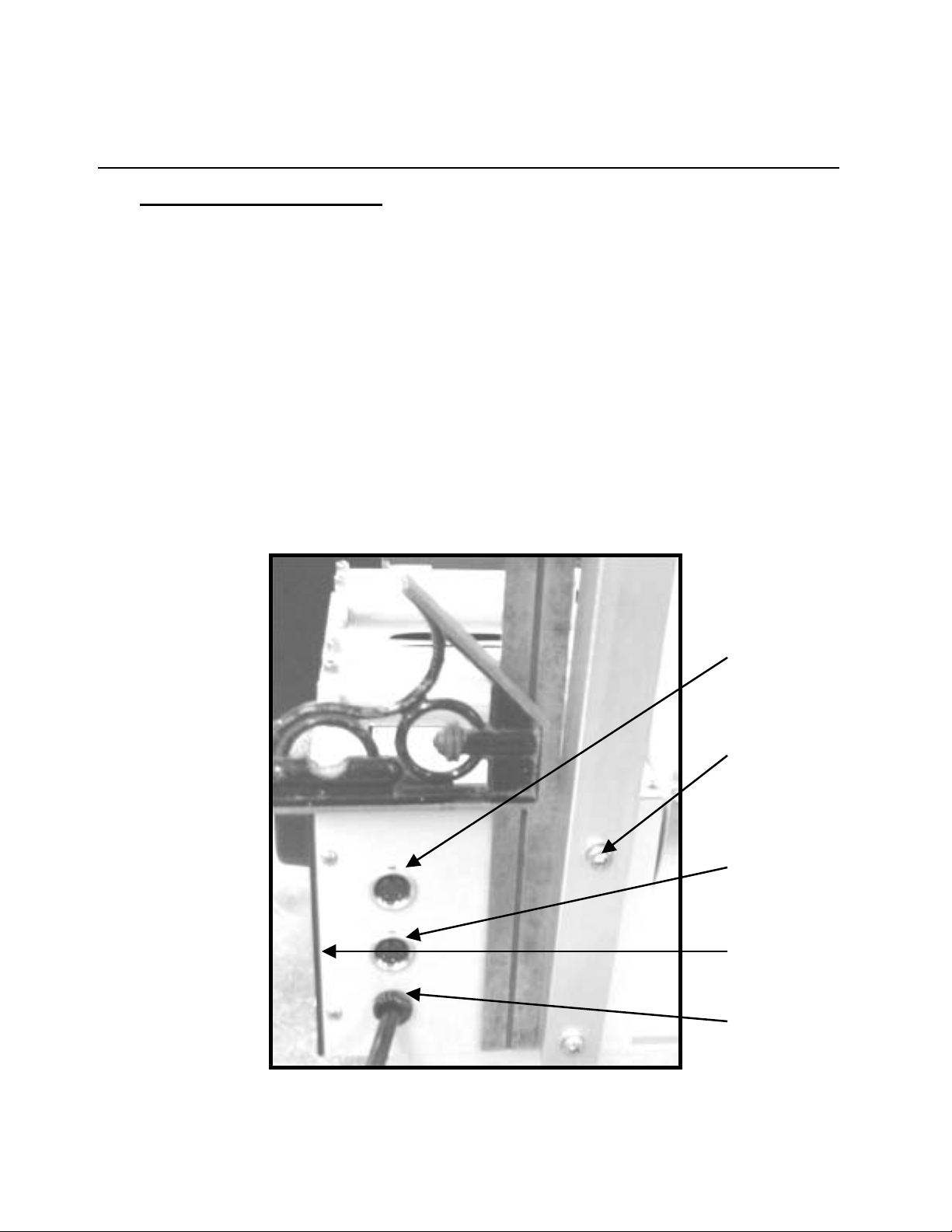

ASSEMBLING THE R-310

The only item that needs to be added to the R-310 is the Unwind Assy.

1. Turn your attention to the back of the R-310 where the AC Electrical cord

is attached.

2. Remove the two screws where the Unwind Assembly will be assembled to

the body using a 3/16” Allen wrench (not provided).

3. Remove the plates from the Unwind to reduce weight and make it easier

to mount the assy.

4. Using a Square, mount the Unwind Assembly as shown below in Fig 2.

The Long screw (¼-20 x 1-1/2”) goes in the top hole. The shorter screw

(1/4-20 x 1-1/4”) is in the bottom.

Note: Double check squareness after the screws are tight and make

adjustments as necessary. The Unwind Assembly needs to be square to insure

proper tracking of the labels onto the product.

Fig 2

Label Sensor

Plug

Longer screw

¼-20 x 1-1/2”

Coder Plug for

Optional Hot

Stamp Coder

Foot Switch

Plug (on side)

AC cord

8

Page 9

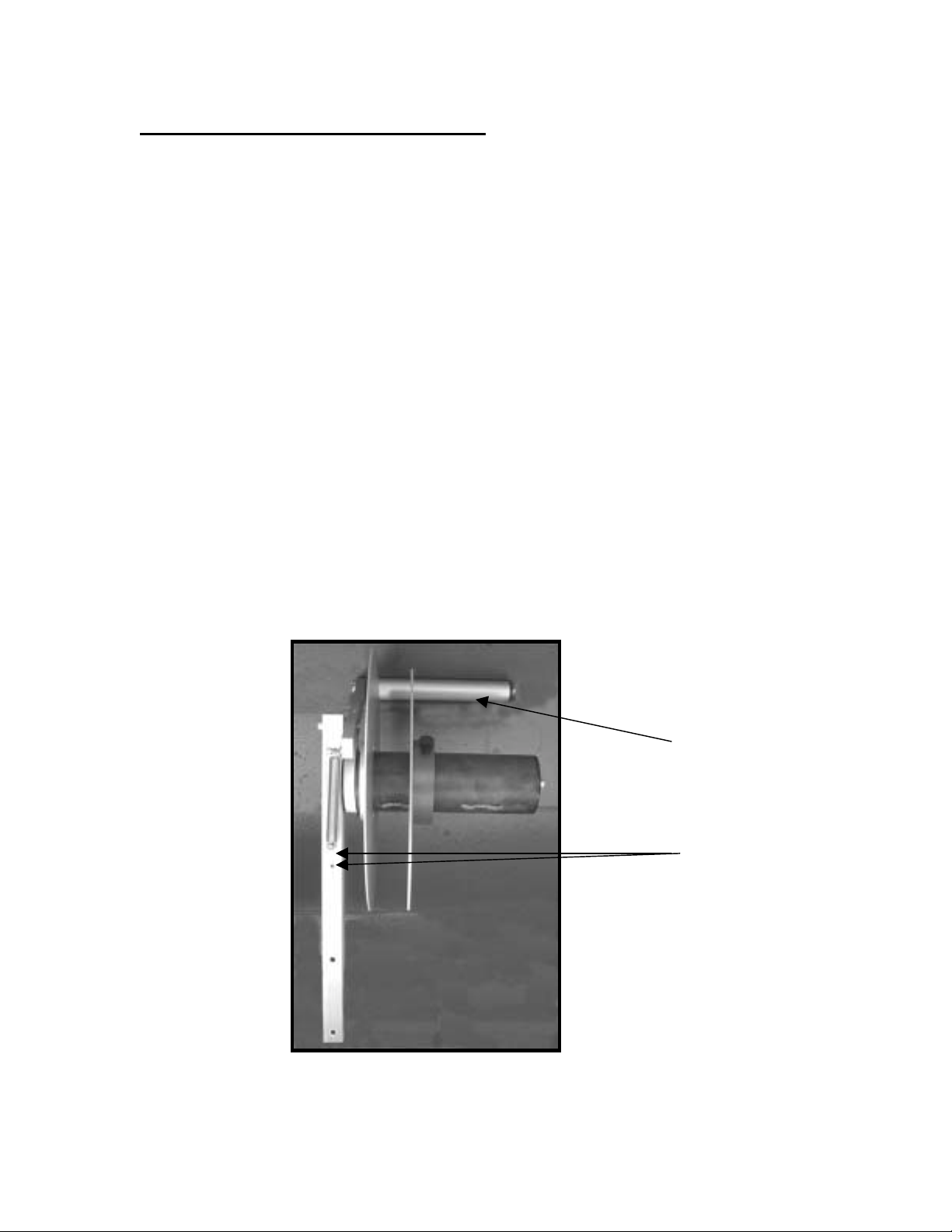

FUNCTION OF UNWIND ASSEMBLY

The unwind is simple, but important to the operation of the R-310 machine.

When the motor starts, the web and labels are pulled through the machine by the

drive roller. The label stock pulls on the brake arm, releasing the brake, and

allows the roll of labels to unwind. When the motor stops, the brake arm returns

to the rest position. This movement tightens the brake band around the 3"

diameter main unwind hub and the roll of labels stops unwinding.

The R-310 has a fixed speed, AC drive motor which transmits power to the drive

roller. The AC drive is directly influenced by the load it is trying to pull. In this

case, the load is the tension of the brake arm spring and the weight of the roll of

labels. The brake arm spring shown below in Fig 3, should be fastened to the

unwind assembly mounting bar in the tapped hole which provides the least

amount of tension at the brake arm. (The hole closest to the hub.)

If the R-310 is dispensing a long label (10" for example), you may have to

increase the tension on the brake arm spring (Move spring attachment point to

lower hole - See Fig 3) to keep the brake arm from bottoming out.

The length and speed figures mentioned above are only examples. Your

observation of the unwind operation will be the best indication of when a tension

change may be needed.

Dancer Arm

Spring located in top

hole. Move to bottom

hole for larger labels.

Fig 3

9

Page 10

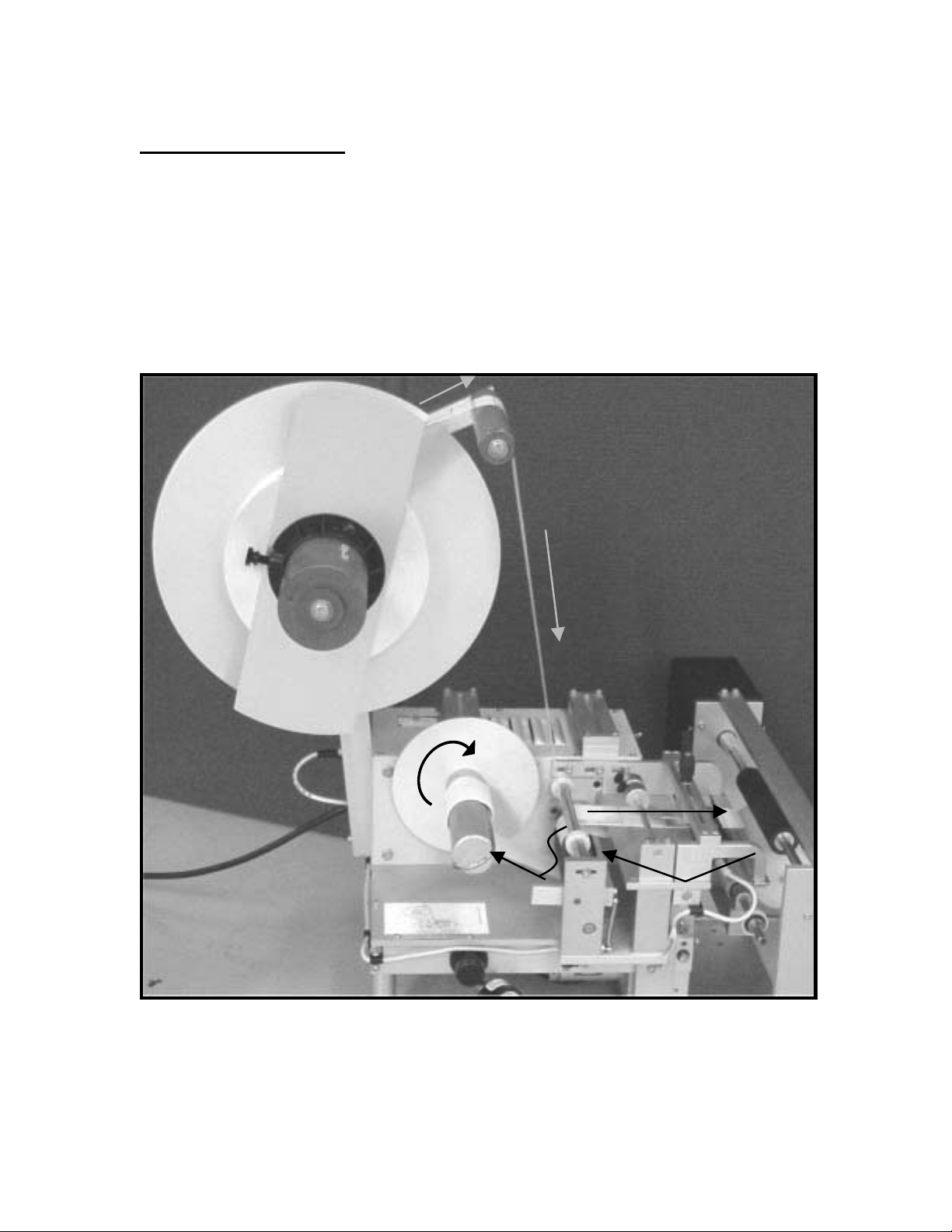

WEBBING THE R-310

Place the roll of labels on the unwind spool. Install the label disc and while

pressing it against the label reel, tighten thumbscrew. Remove enough labels so

only backing paper is threaded from peeler plate back to rewind spool. Pull the

web over the anti-stripper roller and down under the web guide shaft, between

the web guides. Set the web guides so that the web is held with minimum side

play but still moves freely. Pull the web around the peeler plate and the roller

attached to the peeler assembly underneath. Wind the web over the top roller

and between top and bottom roller and back under bottom roller to rewind spool.

Fig 4

10

Page 11

WASTE REMOVAL

To remove waste web, turn off the machine, and remove the waste web retention

clip. Tear the web as shown in Fig 5. While holding the rewind backing plate, turn

the whole waste web in the opposite the direction and pull.

Fig 5

11

Page 12

CARRIAGE ADJUSTMENT AND PRODUCT PLACEMENT

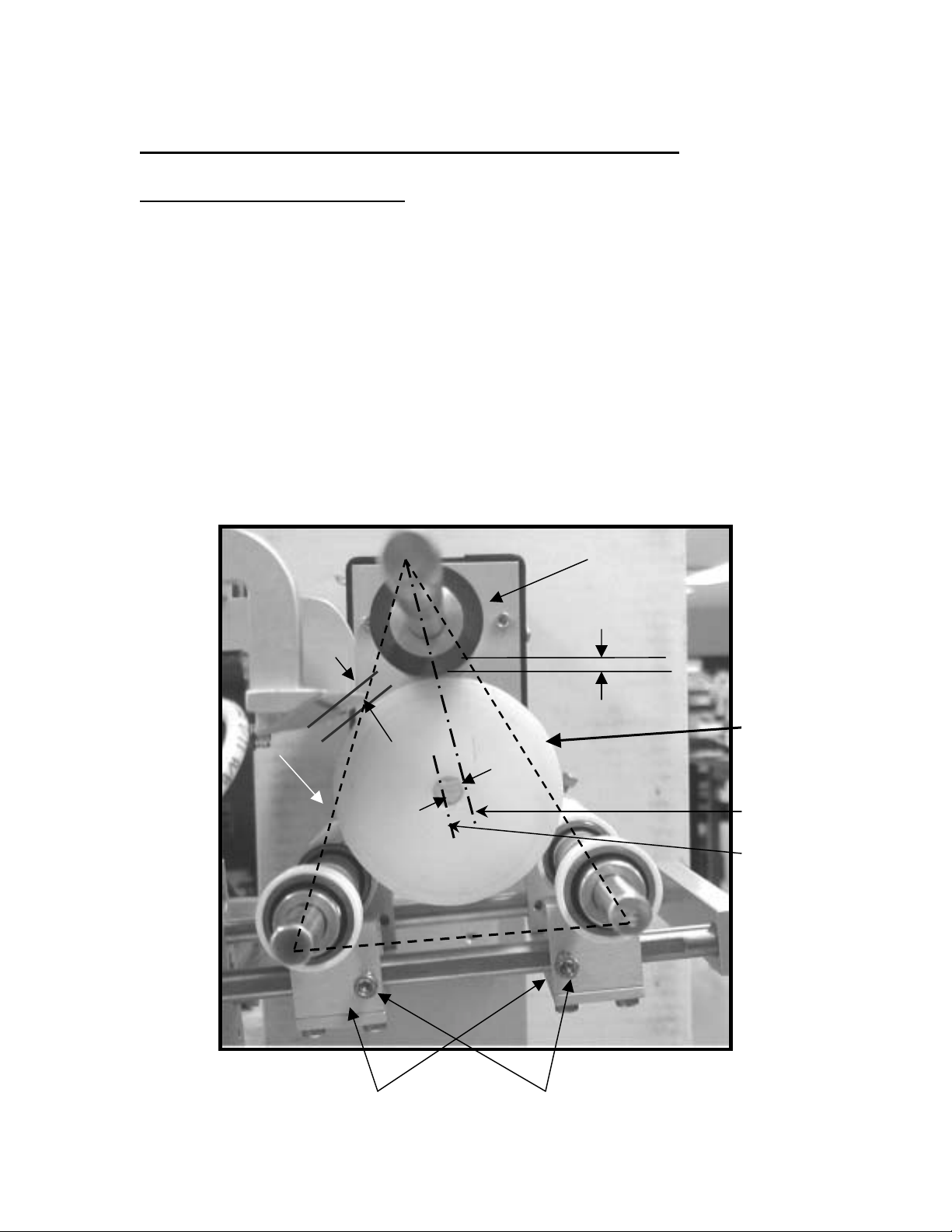

Y

SET CARRIAGE AS FOLLOWS

1. The product centerline should be slightly behind drive roller centerline (a

1/32” or less) when carriage is up, as shown by ‘Y’ in Fig 6;

2. When product “A” is against drive roller, you should have a minimum 3/16”

distance (see ‘Z’ Fig 6) between product and peeler plate for product to sit

well down between carriage idler rollers (see ‘B’ Fig 6).

Use a 9/64 Allen wrench to loosen 4 cap screws “C” and relocate carriage

blocks. Also keeps in mind that moving the lower carriage roller assembly

forward or back in the actuator arm will affect values of ‘Y’ and ‘Z’. Refer to Fig 7

on page 13 for this adjustment. You will have achieved close to equal spacing if

roller centers visually form a triangle as shown by dotted lines in Fig 6.

After verifying that a product works well at a given setting, it would be a good

idea to mark the rods where carriage blocks are set.

Drive

Roller

B

Fig 6

Z

Product “A”

Drive Roller Centerline

Product Centerline

“C” Cap Screws Carriage Blocks

12

Page 13

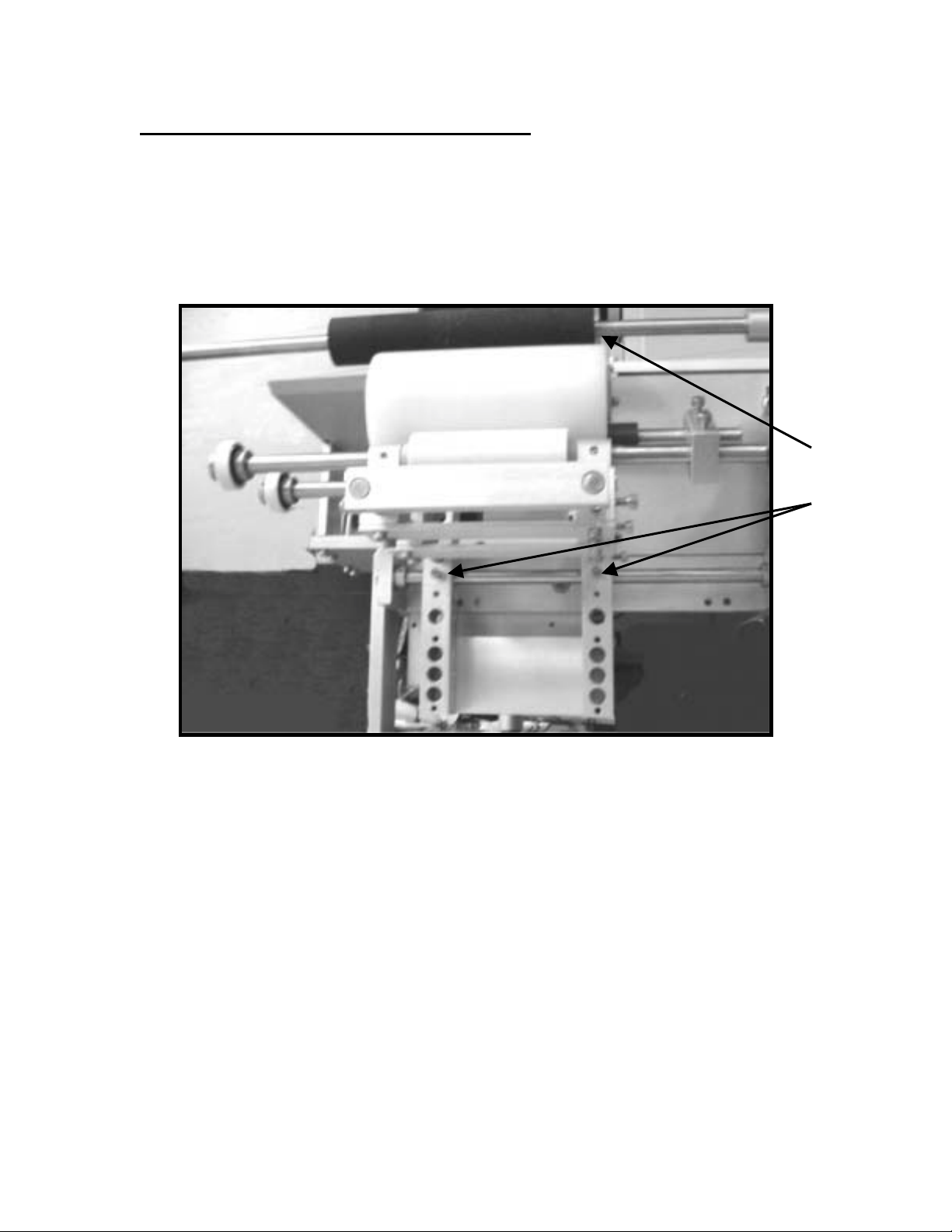

HORIZONTAL CARRIAGE ADJUSTMENT

Using adjusting screws (see ‘D’ Fig 7), you may slide “Standard Carriage

Assembly” left or right to improve or change alignment of product with label.

When making this adjustment, you should check position of product drive roller

(see Fig 6 previous page) to be sure it is still located to properly roll down label.

To adjust drive roller, loosen the set screws (see ‘E’ Fig 7) in the roller and move

left or right as required.

E

D

Fig 7

13

Page 14

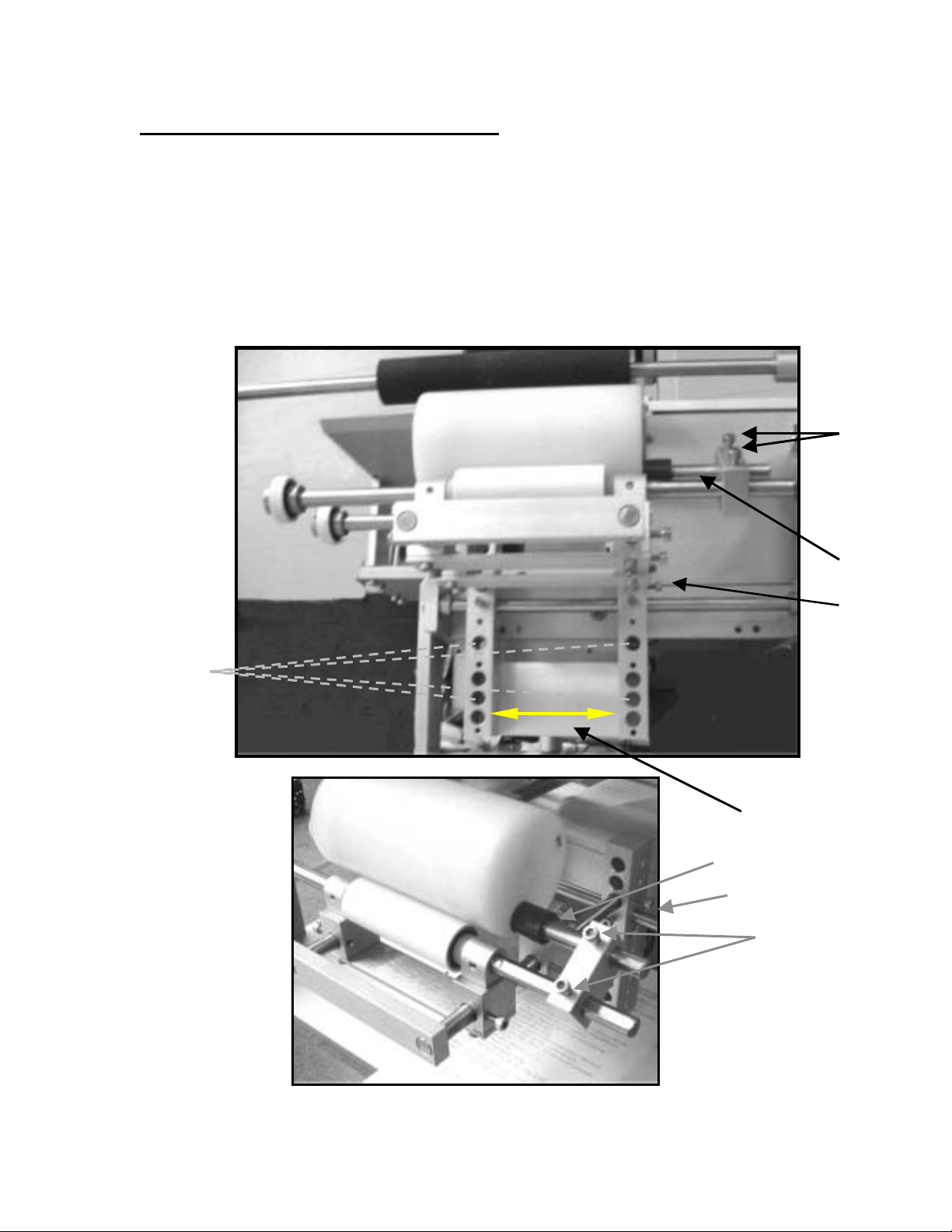

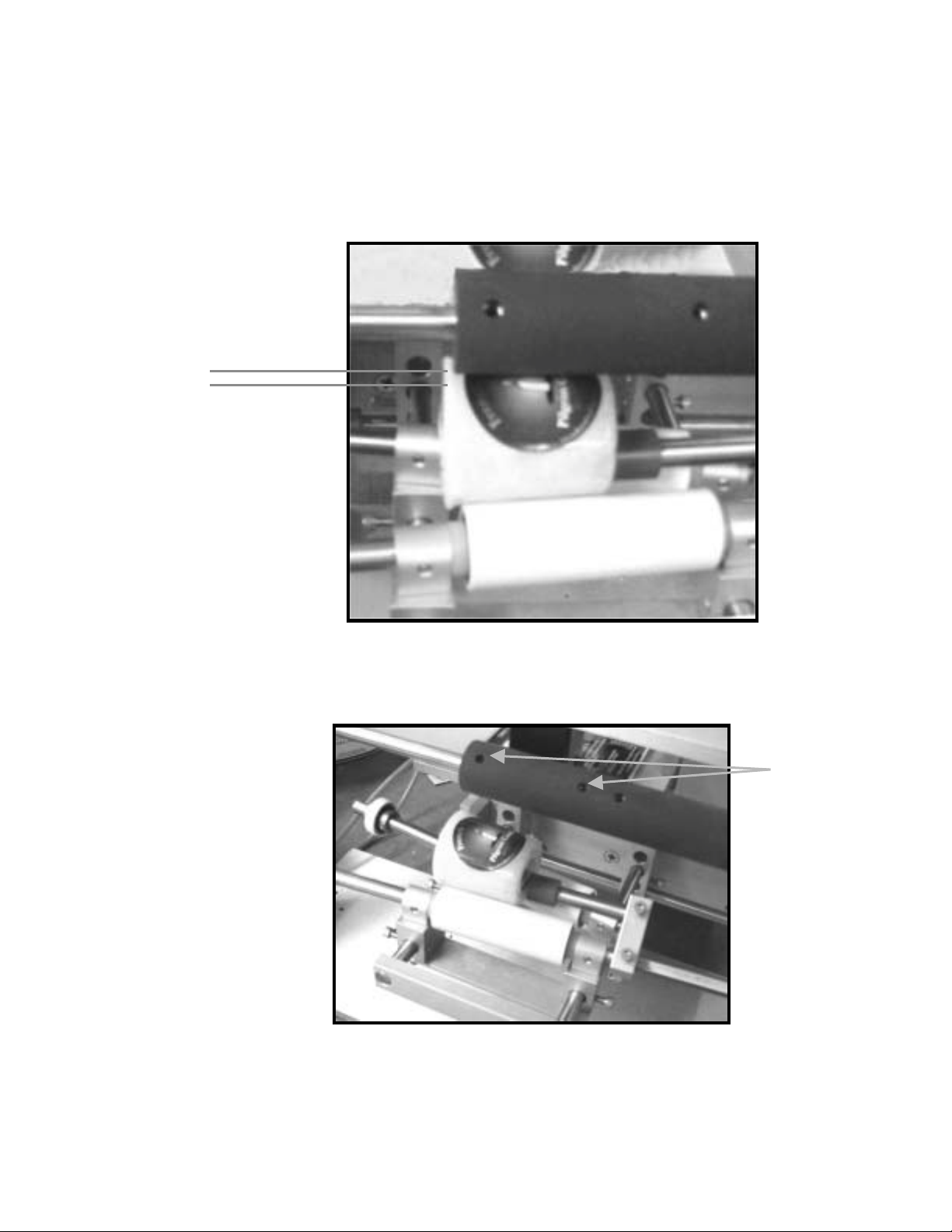

VERTICAL CARRIAGE ADJUSTMENT

This adjustment provides a means to relocate the lower carriage roller assembly

into one of several pair of holes in the actuator arm, as shown by dotted lines in

Fig 8. The purpose is, to minimize the distance the product has to travel to

contact the drive roller (see ‘X’ Fig 6) page 12). To adjust the assembly loosen

the two 8-32 screws (see ‘E’ Fig 8 & Fig 9) on side of actuator arms and relocate

roller assembly. Use 8-32 screws ‘F’ to adjust bottle stop ‘G’ to best position the

label onto the product. The view of the carriage is set to run a Fasson chart #4

(left side off first) die cut label.

F

G

Use one

of several

pairs of

holes

E

Fig 8

Standard

Carriage

Assy.

G

E

F

Fig 9

14

Page 15

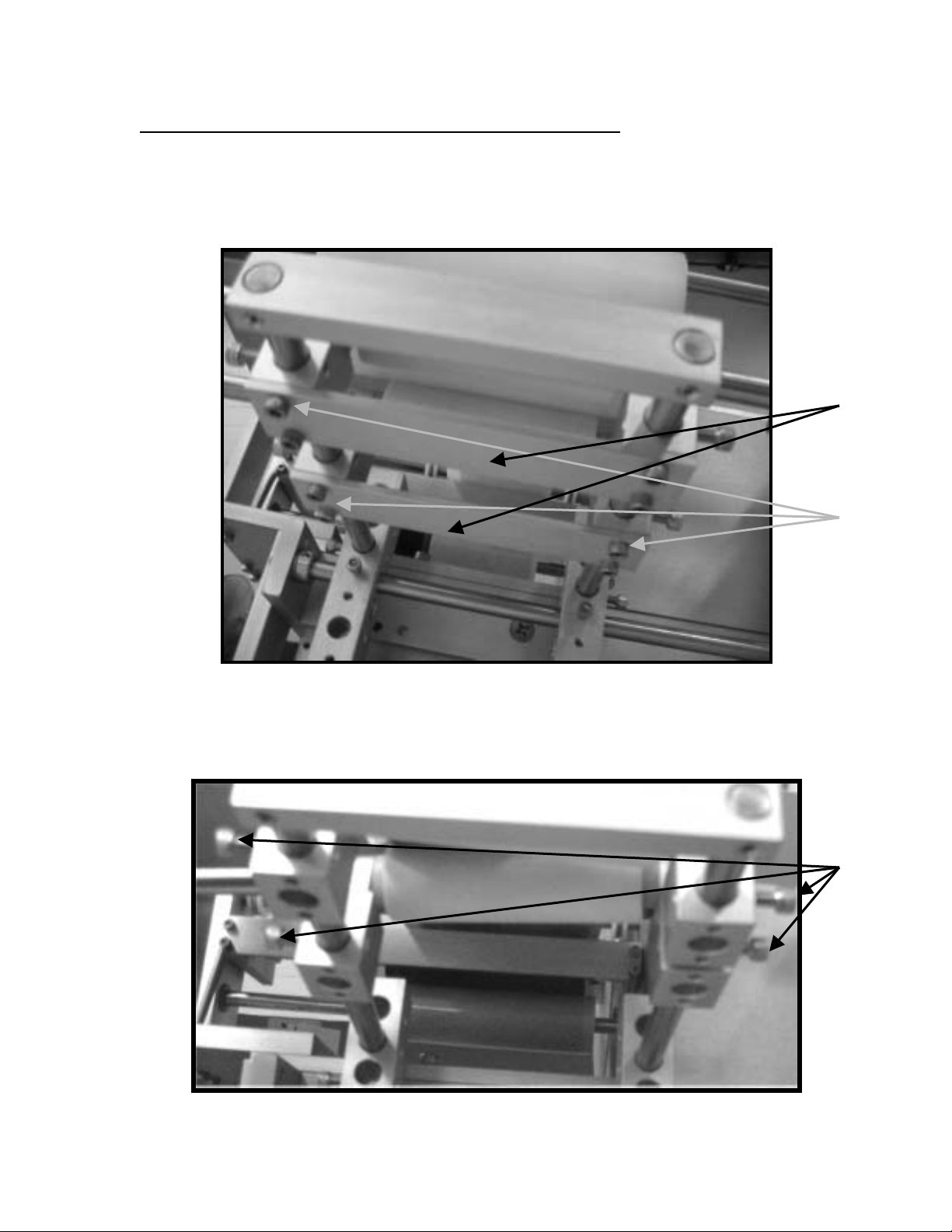

CARRIAGE ADJUSTMENT FOR TAPERED PRODUCTS

A tapered product can be labeled on the R-310 by adjusting the carriage as

follows.

1. Remove the tie bars on the bottom of the carriage assembly (see ‘H’ Fig. 10).

There are 8 screws as shown in (see ‘J’ Fig 10).

H

J

Fig 10

2. Loosen the screws on the carriage blocks (see ‘K’ Fig 10a.)

3. Separate or move closer the rollers on one or both sides of the carriage

depending on the taper of the product.

Fig 10a

K

15

Page 16

4. Place a product on the rollers and move the product and roller assembly so

the product contacts the drive roll evenly.

5. Position the whole carriage at an angle (see Fig 10b). This is so the label

starts onto the product at an angle. This may seem contradictory, but the label

must start at an angle so it ends up looking straight on the product.

Note: Tapered

Product must

contact Drive

roll parallel for

straight label

transfer.

Fig 10b

The Drive roller may need to be moved to allow the product contact the roller

parallel by loosening the 4 set screws (see ‘L’ Fig 10c). Also the bottle stop was

positioned so the product rests against it for consistent label placement.

L

Fig 10c

Snug all screws and label a product or two and examine it for wrinkles or

position. Tighten all screws when adjustments are finished.

16

Page 17

PEELER PLATE ADJUSTMENT

The peeler plate assembly may require adjustment with the change of label

length or product diameter. A short label with a small diameter product would

require the edge (see ‘A’ Fig 11) of the peeler plate to be closer to the Product

Drive Roller ‘B’ than a long label with a larger diameter product and will have to

be adjusted accordingly.

B

Fig 11

A

Move Closer

17

Page 18

ADJUST PEELER PLATE AS FOLLOWS

1. Using the provided 9/64” Allen wrench just loosen – DO NOT REMOVE the two 8-32 SHCS located on the left side of the peeler assy. (see “C” in

Fig 12)

2. Using a 5/32” Allen wrench just loosen – DO NOT REMOVE - the two 10-

32 SHCS located to the right of the peeler assembly (see “D” in Fig 12).

3. Adjust the peeler plate.

4. Re-tighten all screws.

D

Fig 12

C

18

Page 19

SECTION 3 OPERATION

TRI-TRONICS OPTICAL LABEL SENSOR

Normal Label Opacity Autoset Button:

This category includes most paper or metallized film labels adhering to paper or

transparent backing materials.

To implement the one button Autoset routine, utilize the external alignment

guides to position the gap between labels in line with the dot shown in the center

of the detection zone (see ‘A’ Fig 13). Then push the Autoset button marked

“Normal”.

Translucent Label Opacity Autoset Button:

This category includes translucent labels adhering to transparent backing

materials.

First utilize the external alignment guides to position the gap between labels in

line with the dot shown in the center of the detection zone. Then push the

Autoset button marked “Translucent”. The next step is to move the web so that

the translucent label goes in and out of the light beam. The red led output

indicator should go on when the label passes through the detection zone.

Note: The status of the red led and output transistors can be inverted by

pressing both buttons simultaneously. When the output status had been

inverted, the red led and the output transistors will turn off when the label comes

into view.

A

Fig13

19

Page 20

OPTIONAL LION SENSOR FOR CLEAR LABELS

Important:

x Web must remain in contact with mounting plate.

x Label must pass under the sensor indicator

x Small labels should be centered under sensor.

x When properly setup, the lights will move between WEB and LABEL. The

lights in the “X” region should only light briefly during the transition

between WEB and LABEL.

Basic (Low Gain) Setup (effective for 90% of labels):

1. Adjust SPAN to minimum (four turns counter-clockwise)

2. While moving labels through the sensor.

a. Adjust shift toward L

b. Adjust shift toward W (WEB) until the last web light DOES light.

3. Setup complete.

4. If there is any false triggering, missed labels, or lights in the “X” region

except during transition, change to medium gain setup. (See Fig 14)

Basic Gain Setup:

1. Adjust SPAN to mid-point (four turns counter-clockwise, two rotation

clockwise)

2. Repeat steps 2 & 3 from Basic setup above.

3. If there is any false triggering, missed labels, or lights in the “X” region

except during transition, change to high gain setup. (See Fig 14)

High Gain Setup:

1. Adjust

SPAN to maximum (four turns clockwise)

2. Repeat steps 2 & 3 from Basic setup above. (See Fig 14)

(LABEL) until the last web light does NOT light.

Fig 14

Mounting Plate

“SHIFT”

“X” area

“SPAN”

20

Page 21

OFF DELAY

The off delay dial is located on the front panel, below the on/off switch (see ‘A’

Fig 15). When the machine is cycled, the label sensor sends a signal when a gap

between the labels on the web is detected telling the machine to stop. Off delay

is used to adjust where the label stops. To adjust where the label stops, cycle

the machine and adjust the off delay until the label stops at the desired distance

from the peeler edge.

A

Fig 15

21

Page 22

TIMER ADJUSTMENT

Select the product to be labeled and place it on the white carriage rollers. Move

the product to the right against the bottle stop, take your hands away from

carriage area then depress the foot switch. After the carriage drops back down,

remove the product and inspect the label for proper application. If label

placement is correct, continue this procedure and occasionally check label.

Minor adjustments to the machine may increase productivity. For example, the

control knob on top near the back of the dispenser adjusts the time the product is

in contact with the drive roller. This allows the product to drop as soon as label is

applied. Doing so will allow an experience user to label more products during a

period of time. Once the machine is set up properly, the operator’s dexterity is

the key to speed. If you make machine adjustments and are not sure of their

effect, do only one adjustment at a time in small increments.

Timer:

The timer adjustment dial on top of the applier (“J”, Fig 16), allows you to adjust

the time that the carriage is held up to apply a label. For long labels the carriage

assembly. needs to stay up longer to insure the label wraps all the way around

the product. Turn dial clockwise to increase time the carriage stays up. Turn

counterclockwise to decrease the time.

Note: The smaller knobs on the timer are not used at all.

Fig 16

22

Page 23

AIR ASSEMBLY ADJUSTMENTS

A

Turn you attention to the underneath of the R-310. These two valves on the air

regulator control the speed at which the carriage rises to label the product and

falls back to rest. Each can be controlled individually as shown below (see Fig

17).

Turn valve ‘A’ clockwise to slow the speed that the carriage rises.

Turn valve ‘A’ counterclockwise to increase the speed the carriage rises.

Turn valve ‘B’ clockwise to slow the rate at which the carriage falls.

Turn valve ‘B’ counterclockwise to increase rate carriage falls.

B

Red hose

Fig 17 (underneath the R-310)

23

Page 24

AIR REGULATOR

Turn your attention to the side where the air regulator is mounted (see Fig 18).

The Air Regulator is used to raise or lower the air pressure to the machine. This

will allow the R-310 to run connected to virtually any clean air source depending

on how much Air pressure is produced by your compressor. It is also used to

stay within the recommend air pressure of the machine 20-40PSI, 5CFM.

Note: The R-310 is designed to label a variety of items from very small up to and

including a Full Gallon jug. The Air regulator would also be used to increase air

pressure to raise a heavy Full gallon jug. By the same token if a small vial were

being labeled, not nearly as much air pressure would be needed to lift an item

that weighed a few ounces or less. You want the carriage to rise smoothly and

stay engage with the driver roller to insure proper labeling. Then again you don’t

want it to rise so fast that it bang’s against the driver roller and cause damage to

your product or the machine.

The Air pressure takes a few seconds to increase so don’t turn the knob ‘F’ too

much. Also a small amount of turn may increase the pressure a lot.

Turn the regulator knob ‘F’ slowly a ¼ turn and pause a few seconds watching

the gauge as it rises. Try to label the product and then repeat as necessary.

Turning the regulator a small amount then pause.

Adjust knob ‘F’ clockwise to increase air pressure, counterclockwise to decrease

it, watching the Air pressure gauge ‘E’.

F

E

Fig 18

24

Page 25

SECTION 4 MAINTENANCE

GENERAL MAINTENANCE

Drive rolls:

The drive rolls must

recommended solvents to remove gum buildup or small bits of labels adhering to

rollers. Never use razor blade or sharp instruments on rollers. Damaged or

gummy rollers will cause inconsistencies in label application. If they are

damaged, replace them. Part Number “SRL-500-3403875” both rollers are the

same.

Lubrication:

The only part in the applier that requires lubrication are the 2 main shafts (drive

and rewind) that rotate in bushings. These bushings should be oiled once every

2 or 3 years. Remove cover to oil internal bushings as shown below in Fig 19b.

be kept clean. Wash with lacquer thinner or other

Fig 19a

Fig 19b

Fig 19c

Oil here

Oil here

25

Page 26

SECTION 5 RECOMMENDED SPARE PARTS

Part Number Description

100099 VALVE, 120VAC 3WY MAC AIR

100303 CYLINDER, 1" SPRING RETURN AIR

200009 RELAY, 12VDC 10AMP DPDT

200044 FUSE, AGC 5 A

200045 FUSE, AGC 7 A (USED W/ CODER)

200109 SWITCH, MICRO (STARWHEEL) (IF EQUIPPED)

200111 TRANSFORMER, 110VAC TO 15VAC

200113 TIMER, (CROUZET)

200198 MODULE, POWER

300050-2 MOTOR, CW W/BRAKE

300051-2 MOTOR, CCW WO/BRAKE (PRODUCT DRIVE)

300055-1 FAN, #300050 MOTOR

300060-1 FAN, #300051 MOTOR

420210 UNWIND SPRING, ½” X 4” EXTENSION

600300 UHMW, TAPE, 1" X 50' ROLL

820000 THUMBSCREW, 1" BLACK NYLON

200090B ASSEMBLY, R-310 FOOT SWITCH

200374-1 SENSOR, LABEL EYE(TRI-TRONICS)

200376B ASSY. CABLE W/4 PIN M. AMPHENOL

210131B ASS'Y, CLEAR/FOIL LABEL SENSOR (IF EQUIPPED)

420200-01.60 SPRING, EXTENSION

L-128-C-A CLIP, (6-1/2 WEB) RETENTION

L-129-S STARWHEEL, LABEL SENSING (IF EQUIPPED)

SRL-500-3303875 ROLLER, 3-7/8" PRODUCT DRIVE

SRL-500-3306000 ROLLER, PROD. DRIVE 6" LONG

SRL-500-3403875 ROLLER, 3-7/8" UPPER IDLER

26

Page 27

SECTION 6 DRAWINGS AND BILL OF MATERIALS

MAIN ASSEMBLY

See Drawing 310-I-00H

AIR CYLINDER MOUNTING ASSEMBLY

See Drawing 310-I-10

FRONT PANEL ASSEMBLY

See Drawing 310-I-20F

REGULATOR ASSEMBLY

See Drawing 310-I-30

LABEL SENSOR/PEELER ASSEMBLY

See Drawing 310-I-40F

OPTIONAL STARWHEEL /PEELER ASSEMBLY

See Drawing 310-I-41F

UPPER IDLER ROLL ASSEMBLY

See Drawing 310-I-50E

STANDARD CARRIAGE ASSEMBLY

See Drawing 310-I-62

13” UNWIND ASSEMBLY

See Drawing UWA-13R-I-00

POWER MODULE

See Drawing L15-D-02

DIMENSIONAL DIAGRAM

See Drawing 310-F-00F

WEBBING DIAGRAM (OPTICAL)

See Drawing 310-W-00F

WEBBING DIAGRAM (OPTIONAL STARWHEEL)

See Drawing 310-W-00F

ELECTRICAL DIAGRAM

See Drawing 310-E-00H

27

Page 28

TECHNICAL SUPPORT

When calling for Technical Support:

Have your Model #:

And the Serial Number ready (located on main base plate on the same side

where the Air Regulator is).

Email: fjones@universal1.com

Web Site: http://www.universal1.com

R-310H

28

Page 29

Bill of Material

310-I-00H

MAIN ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 SRL-500-42 BRACKET, OUTER BEARING 1

02 L-144-M BLOCK, 3/8" BEARING 1

03 400016 BEARING, 3/8" SEALED 1

04** SRL-500-3306000 ROLLER, PROD. DRIVE 6" LONG 1

05 SRL-500-04-B SHAFT, 3/8 X 15.5" 1

06 SRL-500-03 SHAFT, PIVOT 1

07* 310-I-62 ASSEMBLY, STANDARD CARRIAGE 1

08 SRL-500-43 BRACKET, MACHINE SUPPORT 1

09 SRL-500-40 PLATE, BASE 1

10 SRL-500-23 BAR, LOWER TIE 2

11 SC-006 COLLAR, SET .376 X .62 X .250 4

12 430380 BUSHING,S 500 X 375 X 375 4

13 SRL-500-41 BRACKET, MOTOR MOUNT 1

14* 310-I-30 ASSEMBLY, AIR REGULATOR 1

15* 310-I-10 ASSEMBLY, AIR CYLINDER MNTG. 1

16 SRL-500-60 BAR,OUTSIDE TIE 1

17 SRL-500-61 BAR, INSIDE TIE 1

18 SRL-500-08 COLLAR, PRODUCT DRIVE SHAFT 1

19 300051-2 MOTOR, CCW WO/BRAKE 1

20 300060-1 FAN, #300051-2 MOTOR 1

21 SRL-500-29 COVER, MOTOR 1

22 MD-724-1 SUPPORT, REAR COVER 1

23 MD-723 SUPPORT, TOP COVER 1

24 MD-724 SUPPORT, FRONT COVER 1

25 200021 STRIP, 8 TERMINAL EURO 40.208 1

26 200111 TRANSFORMER, 110VAC TO 15VAC 1

27 MD-700-1 PLATE, BASE 1

28 SRL-500-44 SUPPORT,TOP 1

29* 310-I-20F ASSEMBLY, FRONT PANEL 1

30 810075 PIN, 1/4 X 1 DOWEL 1

31 MD-731 STAND-OFF, MOTOR 3

32* 310-I-40F ASSEMBLY, PEELER/LABEL SENSOR 1

32*** 310-I-41F ASSEMBLY, OPTIONAL STARWHEEL/PEELER 1

33 MD-730-1W SHAFT, BOTTOM DRIVE ROLL 1

34 SRL-500-3403875 ROLLER, 3-7/8" UPPER IDLER 1

35 420200-01.60 SPRING, EXTENSION 2

36 430385 BUSHING,S 500 X 375 X 500 1

37 MD-744-W PLATE, EXTENSION 1

38 JL-200-37-5A ASSEMBLY. REWIND SLIP CLUTCH 1

39 MD-728-1 ASSEMBLY, DRIVE SPROCKET 1

40 410000-13.25 ASSEMBLY. CHAIN,#25 LINK X 13-1/4" 1

41 MD-746-1 SPROCKET, TENSION 1

42 JL-200-42 SPROCKET, REWIND CLUTCH 1

43 300050-2 MOTOR, CW W/BRAKE 1

44 300055-1 FAN, #300050-2 MOTOR 1

45 SRL-500-59-1 LEG, STAND-OFF 4" 2

F:\LABELERS\R-310\Manual\310-I-00H.dwg

MSACCESS Y:\databases\BOM2000.MDE

9/8/2005 4:15:26 PM

Page 30

Bill of Material

310-I-00H

MAIN ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

46 SRL-500-58 FOOT, EQUIPMENT (PACK OF 2)>> 2

47 MD-746-3 BLOCK, PIVOT 1

48 MD-700-2 PLATE, VERTICAL 1

49 430240 BUSHING, 500 X 375 X 375 1

50 MD-743-W SHAFT, UPPER IDLER 1

51 700025 GUIDE, 1/2" SPLIT NYLON WEB>> 2

52 PS-3018 PIN, 1/4"OD X 5/8" DOWEL 2

53* 310-I-50E ASSEMBLY, UPPER IDLER ROLL 1

54 L-172-09 WASHER, UHMW 032 X 257 X 500 2

55 MD-708-W BAR, OUTBOARD SUPPORT 1

56 L-128-C-A CLIP, (6-1/2 WEB) RETENTION 1

57 L-128-D-A SPOOL, (6-1/2 WEB) REWIND 1

58 L-148-M PLATE, REWIND BACKING 1

59 SRL-500-71 SHAFT, REWIND 1

60 200011 SOCKET, 10 AMP RELAY 1

61 200009 RELAY, 12VDC 10AMP DPDT 1

62 MD-722 BRACKET, RELAY 1

63 L-172-03 WASHER, UHMW 062 X 380 X 625 2

64 MD-732 BRACKET, UNWIND MOUNTING 1

65 MD-764 COVER, REAR 1

66 MD-726-1 SUPPORT, REWIND SPINDLE 1

67 400054 WASHER, 3/8" W AVE SPRING 2

68 400010 RETAINER, 3/8" HARDENED BRNG. 2

69 400009 BEARING, 3/8" THRUST 1

70 MD-719-1A COVER, TOP 1

71 MD-733 SPACER, MOUNTING BAR 4

72 MD-734 BAR, HORIZONTAL MOUNTING 2

73* UWA-13R-I-00 ASSEMBLY, R. H. 13" UNWIND 1

74 200015 AMPHENOL, 4 PIN FEMALE 1

75 200017 AMPHENOL, 5 PIN (FEMALE) 1

76 200036 CORD, 18/3 8FT. SJT POWER 1

77 200034 RELIEF, 1/16" STRAIN 1

78 200113 TIMER, (CROUZET) 1

79 200114 SOCKET, SYRELEC TIMER MNTG. 1

80 MD-747 BLOCK, SYRELAC TIMER SUPPORT 1

81 MD-725 SUPPORT, COVER 1

82 MD-718-1 COVER, VENTED SIDE 2

83 200013 AMPHENOL, 3 PIN (FEMALE) 1

84 200090B ASSEMBLY, R-310 FOOT SWITCH 1

85 L-172-21 WASHER, NYLON .125 X .194 X .375 4

F:\LABELERS\R-310\Manual\310-I-00H.dwg

MSACCESS Y:\databases\BOM2000.MDE

9/8/2005 4:15:26 PM

Page 31

Bill of Material

310-I-00H

MAIN ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

* SEE DRAWING

** SRL-500-3306000 IS A STANDARD 6" ROLLER

FOR CUSTOM LENGTH CHANGE LAST 5 DIGITS

I.E. 4-3/8 = 04375

*** OPTIONAL

F:\LABELERS\R-310\Manual\310-I-00H.dwg

MSACCESS Y:\databases\BOM2000.MDE

9/8/2005 4:15:26 PM

Page 32

Page 33

Bill of Material

A

A

AIR CYLINDER MOUNTING ASSEMBLY

ITEM NUM:

01 100099 VALVE, 120VAC 3WY MAC AIR 1

02 100108 FTNG, MINI NEEDLE VALVE 1

03 100109 VALVE, 1/4 x 1/8 METER-IN 1

04 100211 FTNG, 1/8 TO 1/4 STRT CONN. 1

05 100224 FTNG, 10-32M TO 1/4 BARB 1

06 100226 FTNG, 1/8M TO 10-32F REDUCER 1

07 100303 CYLINDER, 1" SPRING RETURN AIR 1

08 SRL-500-12A GUARD, AIR CYLINDER 1

09 SRL-500-19 PLATE, AIR CYLINDER M0UNTING 1

10 100430-9.125

11 100425-7.00

PART NUMBER: PART DESCRIPTION: QTY:

IRLINE, 1/4" X 9-1/8" BLUE 1

IRLINE, 1/4" X 7" RED 1

R310

F:\LABELERS\R-310\310-I-10.dwg

MSACCESS X:\SALES\BOM

Page 34

Page 35

Bill of Material

310-I-20F

FRONT PANEL ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 200044 FUSE, AGC 5 A 1

02 200192-1 DIAL, 10 TURN POT (H-22-6A) 1

03 200059 PLATE, ON/OFF SWITCH 1

04 MD-763 COVER, FRONT 1

05 200030 SWITCH, DPST TOGGLE 1

06 MD-700-1 PLATE, BASE 1

07 600345A RUBBER, CIRCUIT CARD BACKING 1

08 200198 MODULE, POWER 1

09 200175 SPACER, #6 X .75 NYLON 2

10 200022 CONNECTOR, 15 PIN ED GE 1

11 200216 POT, 5K OHM 3-TURN 1

12 200001 GROMM E T, 1/16" X 1/4" 1

13 200005 HOLDER, PANEL MOUNT FU SE 1

F:\LABELERS\R-310\Manual\310-I-20F.dwg

MSACCESS Y:\databases\BOM2000.MDE

8/21/2003 8:06:06 AM

Page 36

Page 37

Bill of Material

A

REGULATOR ASSEMBLY

ITEM NUM:

01 100300 REGULATOR, AIR 1

02 100229 OBSOLETE USE 100209 1

03 100217 OBSOLETE-USE# 100345 2

04 100321 NUT, PANEL MOUNT AIR REGULATOR 1

05 100301 GAUGE, 1.5 DIAMETER AIR 1

06 100210 FTNG, 1/8 COUPLING 1

07 100203 FTNG, 1/8M ELBOW 1

08 100228 FTNG, 1/8 SOCKET PLUG 1

09 100405-120

10 100220 FTNG, 1/4M TO 1/4F 1

PART NUMBER: PART DESCRIPTION: QTY:

IRLINE, 1/4" X 10' WHITE 1

R310

F:\LABELERS\R-310\310-I-30.dwg

MSACCESS X:\SALES\BOM

Page 38

Page 39

Bill of Material

310-I-40F

LABEL SENSOR/PEELER ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 MD-756 BAR, OPTICAL LABEL SENSOR ADJ. 1

02 SRL-500-57-1WA SHAFT, WEB DRAG 1

03 MD-755 BLOCK, PEEL PLATE ADJUSTING 1

04 MP-2500-9 PLATE, WEB DRAG PRESSURE 2

05 MD-762 PLATE, PEELER 1

06 600300-07.500 UHMW, TAPE, 1" x 7-1/2" L. 1

07 MD-758 BLOCK, SENSOR MOUNTING 1

08 200374-1 SENSOR, LABEL EYE(TRI-TRONICS) 1

09* MD-765 BRACKET, SENSOR MOUNTING 1

10* 210131B ASSEMBLY. CLEAR/FOIL LABEL SENSOR 1

11 MD-754 BLOCK, 3/8" SHAFT 2

12 L-172-08 WASHER, UHMW 187 X 375 X 625 2

13 200376B ASSEMBLY. CABLE W/ 4 PIN AMPHENOL 1

14 MD-706-W BAR, STRIPPER PLATE SU PPORT 1

15 500525-7.170 ROLLER, IDLER 1

16 MD-759 SHAFT, DEFLECTION ROLLER 1

17 MD-761 PLATE, PEELER ASSEMBLY 1

18 MD-757 BLOCK, SENSOR ADJUST 1

19 MD-766 BLOCK, WEB DRAG MOUNTING 1

20 L60-0035 BLOCK, WEB DRAG 2

21 850008T THUMBSCREW, 8-32 X 1/2" 2

22 MD-760 BLOCK, PEELER PLATE SUPPORT 1

23 500081 HANDLE, 10-32 MALE RAT CHET 1

* OPTIONAL CLEAR LABEL SENSOR

F:\LABELERS\R-310\Manual\310-I-40F.dwg

MSACCESS Y:\databases\BOM2000.MDE

4/9/2004 2:23:11 PM

Page 40

Page 41

Bill of Material

310-I-41F

OPTIONAL STARWHEEL/PEELER ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 855001 SHOULDER BOLT, 1/4 X 1/2" L. 1

02 L-170 PIN, STARWHEEL PIVOT ARM ASSEMBLY. 1

03 L-129-S STARWHEEL, LABEL SENSING 1

04 SRL-500-73 BUSHING, 313 X 250 X 495 1

05 420175B SPRING, 3/16 X 1-1/8 EXT. SS 1

06 200600-A BOLT, COUPLER MOUNTING 1

07 420175A SPRING, 3/16 X 3/4 EXT. SS 1

08 200109 SWITCH, MICRO 1

09 L-164 SPACER, MICRO SWITCH 1

10 200016B ASSEMBLY, OPTIONAL STARWHEEL SWIT CH CABLE 1

11 200001 GROMMET, 1/16" X 1/4" 1

12 850015T THUMBSCREW, 6-32 X 1-1/4" 1

13 854008 NUT, 6-32 HEX SS 1

14 853008 WASHER, #6 FW SS 1

15 MD-717 COVER, STARWHEEL (BLACK) 1

16 SRL-500-65 BRACKET, LABEL SENS. MOUNTING 1

17 854009 NUT, 10-24 HEX SS 1

18 SRL-500-81 PLATE, PEELER ADJUSTING 1

19 SRL-500-32 BRACKET, STARWHEEL SUPPORT 1

20 SRL-500-64A BRACKET, STARWHEEL MOUNT ING 1

21 600300-07.500 UHMW, TAPE, 1" x 7-1/2" L. 1

22 MD-706-W BAR, STRIPPER PLATE SU PPORT 1

23 SRL-500-31-W PLATE, WL/GALLON PEELER 1

24 SRL-500-57A BLOCK, WEB DRAG MOUNTING 1

25 SRL-500-57-1WA SHAFT, WEB DRAG 1

26 MP-2500-9 PLATE, WEB DRAG PRESSURE 2

27 L60-0035 BLOCK, WEB DRAG 2

28 850008T THUMBSCREW, 8-32 X 1/2" 2

29 SRL-500-66 ARM, STARWHEEL PIVOT 1

F:\LABELERS\R-310\Manual\310-I-41F.dwg

MSACCESS Y:\databases\BOM2000.MDE

4/9/2004 2:40:35 PM

Page 42

Page 43

Bill of Material

310-I-50E

UPPER IDLER ROLL ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 430180 BUSHING, 375 X 313 X 375 2

02 SRL-500-74 BUSHING,S 375 X 313 X 280 2

03 MD-707-1-W BAR, PIVOT TIE (WIDE LABEL) 1

04 MD-707-2 BLOCK, OUTER BEARING 1

05 MD-707-3 BLOCK, INNER BEARING 1

06 SRL-500-3403875 ROLLER, 3-7/8" UPPER IDLER 1

07 MD-730-2-W SHAFT, IDLER WIDE LABEL 1

08 SC-005 COLLAR, SET .313 X .62 X .25 2

09 850005 SCREW, 6-32 X 1/2" L SHC S 4

10 430125 BUSHING, 313 X 250 X 250 2

11 857004 SET SCREW , 10-32 X 1/4" SS 2

12 857003 SET SCREW, 8-32 X 1/8" L SS 2

F:\LABELERS\R-310\Manual\310-I-50E.dwg

MSACCESS Y:\databases\BOM2000.MDE

8/21/2003 8:40:08 AM

Page 44

Page 45

Bill of Material

310-I-62

STANDARD CARRIAGE ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 SRL-500-62A ASS'Y, IDLER ROLLER 2

02 SC-006 COLLAR, SET .376 X .62 X .250 4

03 SRL-500-05-1 SHAFT, LOWER BACK IDLER 1

04 SRL-500-14-D COUPLER, IDLER SHAFT 4

05 SRL-500-14-E CARRIER, LOWER IDLER ROLL 4

06 SRL-500-06-1 SHAFT, LOWER FRONT IDLER 1

07 L-143-D-03.000 ROLLER, 3" LOWER IDLER 2

08 SRL-500-02 SHAFT, CARRIER SIDE 2

09 SRL-500-03 SHAFT, PIVOT 1

10 SRL-500-09 BRACKET, LOWER CARRIAGE 1

11 SRL-500-15-1 PLATE, LOWER IDLER ROLL 2

12 SRL-500-11 BOTTLE STOP, PLASTIC 1

13 SRL-500-52 SHAFT, BOTTLE STOP 1

14 SRL-500-10 BRACKET, BOTTLE STOP 1

15 200600-A BOLT, COUPLER MOUNTING 4

16 SRL-500-45 ARM, ACTUATOR 2

17 SRL-500-46 BAR, ACTUATOR ARM TIE 1

18 L-172-08 WASHER, UHMW 187 X 375 X 625 4

F:\LABELERS\R-310\Manual\310-I-62.dwg

MSACCESS Y:\databases\BOM2000.MDE

8/21/2003 8:48:44 AM

Page 46

Page 47

Bill of Material

UWA-13R-I-00

13" UNWIND ASSEMBLY

MACHINE: R310

ITEM NUM: PART NUMBER: PART DESCRIPTION: QTY:

01 UND-001 BAR, LABEL REEL MOUNTING 1

02 UND-002 SHAFT, UNWIND HUB 1

02 (A) UND-002C SHAFT, 7-1/2" WEB UNWIND 1

02( B) UND-002D SHAFT, 8-1/2" WEB UNWIND 1

03 UND-003 ARM, UNWIND BRAKE 1

04 UND-004 SHAFT, BRAKE ARM 1

04 (A) UND-004-07.50 SHAFT, 7-1/2" WEB BRAKE ARM 1

04 (B) UND-004E SHAFT, 8-1/2" WEB BRAKE ARM 1

05 UND-006 BLOCK, BELT FASTENER 1

06 UND-007 CLAMP, BELT 2

07 UND-008 STUD, BRAKE ARM 1

08 UND-009-1 STRAP, BRAKE 1

09 UND-011C HUB, MAIN UNWIND 1

09 (A) UND-011B HUB, 7-1/2" WEB MAIN UNWIND 1

09 (B) UND-011H HUB, 8-1/2" WEB MAIN UNWIND 1

10 UND-013 DISC, REMOVABLE LABEL 1

11 UND-015 DISC, UNWIND BACKING 1

12 UND-038 ROLLER, BRAKE IDLER 1

12 (A) UND-038-07.50 ROLL, 7-1/2" WEB BRAKE IDLER 1

12 (B) UND-038E ROLL, 8-1/2" WEB BRAKE IDLER 1

13 UND-037 BEARING, BRAKE ARM ROLLER 2

14 UND-019 CLAMP, INNER BACKING DISC 1

15 200409 CLIP, CORE (FOR HUB) 4

16 UND-042 CLAMP, OUTER BACKING DISC 1

17 UND-027 BEARING, END CAP ROLLER 1

18 430306 BUSHING, 750 X 500 X 625" 1

19 420210 SPRING, 1/2 X 3.125" EXTENSION 1

20 UND-046 BEARING, END CAP ROLLER 1

21 820000 THUMBSCREW, 1" BLACK NYLON 1

22 400059 BEARING, 5/8" THRUST W/WASHERS 1

23 856005 RING, 1/2" EXT. RETAINING 1

24 853003 WASHER, 1/4" .050 THK 5/8 ODFW 1

25 851002 SCREW, 1/4-20 X 1/2" HHMS 1

26 853001 WASHER, 5/16" FW SS 1

27 851003 SCREW, 5/16-18 X 1/2" HHMS SS 1

28 852001 SCREW, 10-32 X 1/2" FHMS PHIL 6

29 850002 SCREW, 10-32 X 1" L SHCS 3

30 854001 NUT, 10-32 HEX 2

31 850003 SCREW, 5/16-18 X 1-1/4" L SHCS 1

32 850006 SCREW, 6-32 X 5/8" L SHCS 2

33 850004 SCREW, 5/16-18 X 1" L SHCS 1

34 852501 SCREW, 4-40 X 1/4" L PHMS PHIL 4

35 854007 NUT, 4-40 HEX SS 4

(A)=FOR 7-1/2" WIDE WEB

(B)=FOR 8-1/2" WIDE WEB

F:\ACCESSORIES\UND\MANUAL\UWA-13R-I-00.dwg

MSACCESS Y:\databases\BOM2000.MDE

9/9/2005 7:40:15 AM

Page 48

Page 49

POWER MODULE SETUP SHEET

PLEASE READ CAREFULLY BEFORE INSTALLING

SWITCH #1 DELAY SELECT

OFF - NO DELAY

ON - START AND STOP DELAY SET BY FRONT PANEL CONTROLS

START CONTROL - 0 TO 1 SEC.

STOP CONTROL - 0 TO 0.1 OR 1.0 SEC. (SEE JUMP 9)

SWITCH #2 MACHINE MODE SELECT

OFF - L15 OPERATION

ON - L60 OPERATION

SWITCH #3 CLUTCH / BRAKE DELAY SELECT

[L15] SWITCH #3, W/SWITCH #2 OFF

OFF - 0 mS

ON - 25 mS

[L60] SWITCH #3, W/SWITCH #2 ON

OFF - BLOW-ON

ON - TAMP-ON

SWITCH #4 START SWITCH LOGIC LEVEL SELECT

OFF - FALLING SIGNAL EDGE ACTIVATION

ON - RISING SIGNAL EDGE ACTIVATION

SWITCH #5 STOP SWITCH LOGIC LEVEL SELECT

OFF - FALLING SIGNAL EDGE ACTIVATION

ON - RISING SIGNAL EDGE ACTIVATION

JUMPERS #6 START SWITCH TYPE SELECT

PINS 1 & 2 - SPDT START SWITCH

PINS 2 & 3 - SINGLE POLE INPUT

SWITCHES

CODER DWELL

ADJUSTMENT

R17

J3 J1

JUMPERS

JUMPERS #8 SINGLE POLE START SWITCH POLARITY SELECT

PINS 1 & 2 - SWITCHES TO POSITIVE +5V TO +24V DC (PNP)

PINS 2 & 3 - SWITCHES TO GROUND (NPN)

JUMPERS #9 STOP DELAY SELECT

PINS 1 & 2 - LONG DELAY 0 TO 1 SEC.

PINS 2 & 3 - SHORT DELAY 0 TO 0.1 SEC.

PRINTED CIRCUIT BOARD # OO OOO OO

MONTH / NUMBER / YEAR

DEFAULT SETTINGS

L-15 L-60

R-310 SL-1000

The Universal Power Module is designed to

operate the L15, L20, L30, R310, MP25, L60,

and SL1000 series of label machines. The L15,

L20, L30 and MP25 are set up the same!

The L60, R310 & SL-1000 are different,

SEE DEFAULT SETTINGS.

Coder output is adjusted by (R17) top left board

and operates in all modes. The dwell time is

adjustable from 0 to 0.5 seconds. The next

start signal or product signal will be ignored until

the coder pulse is turned off.

(NOTE) IF YOU HAVE L-60 WITH FRONT & REAR

BOARD,

THE BOARD MUST BE SET UP AS L-15.

Page 50

Page 51

Page 52

Page 53

Loading...

Loading...