QuickLabel Kiaro! 200 User Manual

The Labels You Want When You Need Them.

®

USER

GUIDE

Congratulations on owning a Kiaro!

200 inkjet color label printer. This

User Guide will help you start printing

labels, re-load printing supplies,

troubleshoot problems, and

perform routine maintenance.

• Create Custom Labels 4"-8" wide

• Print 1200 dpi at 8" per second

• No wasting labels

QuickLabel.com

Kiaro! 200 User Guide

Part Number 22834630-EN-E

Revision 1.4

8/2016

QuickLabel, An AstroNova™ Division

World Headquarters

600 East Greenwich Ave., West Warwick, RI 02893

Tel: (877) 757-7978 Fax: (401) 822-2430

E-mail: info@QuickLabel.com

www.QuickLabel.com

Technical Support

Tel: (877) 757-7310

E-mail: support@QuickLabel.com

www.QuickLabel.com/support/

© 2016 AstroNova, Inc. All Rights Reserved

This manual is copyrighted with all rights reserved. No part of this manual may be

reproduced, transmitted, transcribe d, stored in a retrieval system, or translated into any

language in any form by any means without written permission of QuickLabel.

Trademarks

Kiaro! 200® and Custom QuickLabel Omni® are registered trademarks of AstroNova,

Inc.

Adobe®, Photoshop®, and Illustrator® are registered trademarks of Adobe Systems,

Inc.

Corel® is a registered trademark of Corel Corporation.

Windows is a registered trademark of Microsoft Corporation in the United States and

other countries.

Kiaro! 200 Limited Warranty

QuickLabel, An AstroNova Division, warrants all components of this product, except

wear parts and consumables, against defects in materials or workmanship for a period

of one (1) year from the date of original purchase. Wear parts include the purge units,

blade cleaners, maintenance cartridge, cutter blades and the like. Consumables

include ink cartridges and labels, which are cove red under a separate warranty. If the

customer discovers a defect, this defect must be reported promptly to QuickLabel.

QuickLabel will, at its option, repair the printer or repair or replace its defective

component(s) at no additional charge under our QuickSwap™ Parts Service. Repair

parts and replacement parts will be furnished on an exchange basis and will be either

reconditioned or new. The customer is responsible for freight to return the printer or

component to our factory. We will ship the repaired or replaced printer or component

back to you via standard ground freight service. All replaced parts be come the property

of QuickLabel. Travel, freight and other expenses related to warranty repairs are not

covered.

In the first year of product ownership, you may be covered by a separate Customer

Support Agreement purchased from or issued by QuickLabel or an authorized

QuickLabel dealer. In such a case, you would be entitled to an on-site installation

and/or training visit. Otherwise, Customer Support Agreements and renewals are

available for purchase and provide on-site support and/or QuickSwap Parts Service.

This warranty is void if the product has been damaged by accident, abuse, neglect or

misapplication or by the use of incompatible consumables or parts, or if the product has

been improperly installed, or if the product has been modified without the express

written permission of QuickLabel. QuickLabel is not responsible for products lost or

damaged in transit.

QuickLabel makes no warranty, either express or implied, with respect to this product's

merchantability or fitness for a particular purpose. In no event shall QuickLabel be held

liable for any direct, indirect, special, incidental, or consequential damages, whether

based on a contract, tort, or any other legal theory and whether advised of the

possibility of such damages.

Ink Limited Warranty

This warranty covers QuickLabel Kiaro! 200 ink cartridge sold by QuickLabel.

Each Kiaro! 200 ink cartridge is warranted to be free from defects in materials and

workmanship for up to 24 months from the date of manufacture if in original u nopened

packaging, or up to 6 months after installation, wh ic he ve r oc cu rs first. This warranty

applies only to the ink cartridges as used in the QuickLabel Kiaro! 200 printing system.

If the customer suspects a defect in a Kiaro! 200 ink cartridge, the customer must notify

QuickLabel within the warranty period. Upon return of the ink cartridge to the

QuickLabel factory and QuickLabel's verification of the defect, QuickLabel will, at its

option, either:

1. Replace the defective ink cartridge; or,

2. If the customer has used the ink, pro-rate the price of a new ink based upon the

estimated life remaining for the ink, as reported by the Kiaro! 200 system. The Kiaro!

200 provides the estimated life remaining, and QuickLabel may obtain this information

from the system remotely or request the customer to furnish this information.

This warranty does not cover Kiaro! 200 ink cartridges that have been emptied, refilled,

remanufactured, modified, refurbished, misused, or tampered with, or that have

expired, or when used to print on label or tag media that is not compatible with the

Kiaro! 200.

This warranty is void if the Kiaro! 200 ink cartridge has been damaged by accident,

abuse, neglect or misapplication, if the product has been improperly installed or

maintained, if the product has been used ou tside of its environmental specifications, or

if the product has been modified without the express written permission of QuickLab el.

QuickLabel makes no warranty, either express or implied, with respect to this product's

merchantability or fitness for a particular purpose. In no event shall QuickLabel be held

liable for any direct, indirect, special, incidental, or consequential damages, whether

based on a contract, tort, or any other legal theory and whether advised of the

possibility of such damages.

Printhead Limited Warranty

QuickLabel warrants the printheads from the date of purchase for a period of 90 days

or for 1 million inches of printing, whichever comes first, contingent upon the use of

QuickLabel ink and labels. The Kiaro! 200 printheads are calibrated for use with

QuickLabel ink and labels and performs optimally only when used with these materials.

This specific printhead warranty does not apply to printheads damaged by accident,

abuse, neglect, misapplication or the like. This warranty is void if the product has b een

damaged by accident, abuse, neglect or misapplication, or if the product has been

improperly installed, or if the product has been modified without th e express written

permission of QuickLabel.

ICC Profile

ICC Profile Powered by X-Rite Incorporated

Obtaining Service

To obtain warranted service, please contac t QuickLabel Technical Support through

one of the Factory Sales and Service Centers.

Contact Information for Factory Sales and Service

QuickLabel USA and World Headquarters

600 East Greenwich Avenue

West Warwick, RI 02893 USA

Toll Free: (877) 757-7978

Toll-Free Sales: (877) 757-7978

Toll Free Technical Support: (877) 757-7310

Tel: (401) 828-4000

Fax: (401) 822-2430

Web Site: www.QuickLabel.com

Sales E-mail: info@QuickLabel.com

Technical Support E-mail: support@QuickLabel.com

QuickLabel Canada

#111 - 3555 Isabelle, Borssard, QC J4Y 2R2 Canada

Tel: (800) 565-2216

Fax: (450) 619-9976

Web Site: www.QuickLabel.ca

Sales E-mail: info@QuickLabel.ca

Technical Support E-mail: support@QuickLabel.ca

QuickLabel Deutschland

Senefelderstraße 1/ T6 D-63110 Rodgau

Tel. +49 (0) 6106-28368-20

Fax: +49 (0) 6106-771121

Web Site: www.QuickLabel.de

Sales E-mail: info@QuickLabel.de

Technical Support E-mail: support@QuickLabel.de

QuickLabel France

Parc Euclide

ZA la Clef de St Pierre

10A Rue Blaise Pascal

78990 ELANCOURT

Tel: 33 1 34 82 09 00

Fax: 33 1 34 82 05 71

Web Site: www.QuickLabel.fr

Sales E-mail: info@QuickLabel.fr

Technical Support E-mail:support@QuickLabel.fr

QuickLabel United Kingdom

11 Whittle Parkway

Slough, Berkshire SL1 6DQ

Tel: 01628 668836

Fax: 01628 664994

Web Site: www.QuickLabel.co.uk

Sales E-mail: info@QuickLabel.co.uk

Technical Support E-mail:support@QuickLabel.co.uk

Ownership Information

Congratulations and thank you for your business. Your purchase of a QuickLabel digital

label printer is an investment in production flexibility and packaging efficiency. Please

record the model number and serial number of your product.

FCC Part 15 Compliance

NOTE: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed

to provide reasonable protection against interference in an industrial installation. This

equipment generates, uses, and can radiate radio frequen cy energy and, if not installed

and used in accordance with the instruction manual, may cause interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna .

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

CAUTION: Changes or modifications to this equipment not expressly approved by the

party responsible for compliance could void the user's authority to operate the

equipment.

Canadian Compliance Statement

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Réglement sur

le matériel brouilleur du Canada.

RoHS2 Compliance

The Kiaro! 200 Label Printer and optional Rewinder accessory do not contain

substances specified within ANNEX II of “Directive 2011/65/EU of the European

Parliament and of the Council of 8 June 2011 on the restriction of the use of certain

hazardous substances in electrical and electronic equipment (RoHS)”, that is, lead,

mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB) and

polybrominated diphenyl ethers (PBDE) exceeding their specified maximum

concentration values tolerated by weight in homogeneous materials, except for the

exemptions set in ANNEX III of the Directive and amendments.

This information is offered in good faith to the best of our knowledge, but is subject to

revision as new information becomes available.

WEEE Directive

European Union (and EEA) only.

These symbols indicate that this product is not to be disposed of with your household

waste, according to the WEEE Directive (2002/96/EC), the Battery Directive

(2006/66/EC) and/or your national laws implementing those Directives.

If a chemical symbol is printed beneath the symbol shown above, in accordance with

the Battery Directive, this indicates th at a heavy metal (Hg = Mercury, Cd = Cadmium,

Pb = Lead) is present in this battery or accumulator at a concentration above an

applicable threshold specified in the Battery Directive.

This product should be handed over to a designated collection point, e.g., on an

authorized one-for-one basis when you buy a new similar product or to an authorized

collection site for recycling waste electrical and electronic equipment (EEE) and

batteries and accumulators. Improper handling of this type of waste could have a

possible impact on the environment and human health due to potentially hazardous

substances that are generally associated with EEE.

Your cooperation in the correct disposal of this product will contribute to the effective

usage of natural resources.

For more information about the recycling of this pr oduct, please conta ct your local city

office, waste authority, approved scheme or your household waste disposal service.

(EEA: Norway, Iceland and Liechtenstein)

WEEE Compliance - India only

This product is not to be disposed of with your household waste, according to the

e-waste (Management and Handling) Rules, 2011. This product sh ould be handed over

to a designated collection point, e.g., to an authorized collection site for recycling waste

electrical and electronic equipment (EEE). Improper handling of this type of waste

could have a possible negative impact on the environment and human health due to

potentially hazardous substances that are generally associat ed with EEE. At the same

time, your cooperation in the correct disposal of this product will contribute to the

effective usage of natural resources. For more information regarding return and

recycling of WEEE products, please contact QuickLabel.

Also, this product complies with the "India E-waste Rule 2011" and prohibits use of

lead, mercury, hexavalent chromium, polybrominated biphenyls or polybrominated

diphenyl ethers in concentrations exceeding 0.1 % by weight and 0.01 % by weight for

Cadmium, except for the exemptions set in Schedule ll of the Rule.

Battery - For CA, USA only

Included battery contains Perchlorate Material ---- special handling may apply.

See http://www.dtsc.ca.gov/hazardouswaste/perchlorate for detail.

European Union (and EEA) only

Contains a preservative to control microbial deterioration.

Contains 1,2-benzisothiazol-3(2H)-one.

May produce an allergic reaction.

Contains less than 30% of components with unknown hazards to the aquatic

environment.

Safety data sheet available on request.

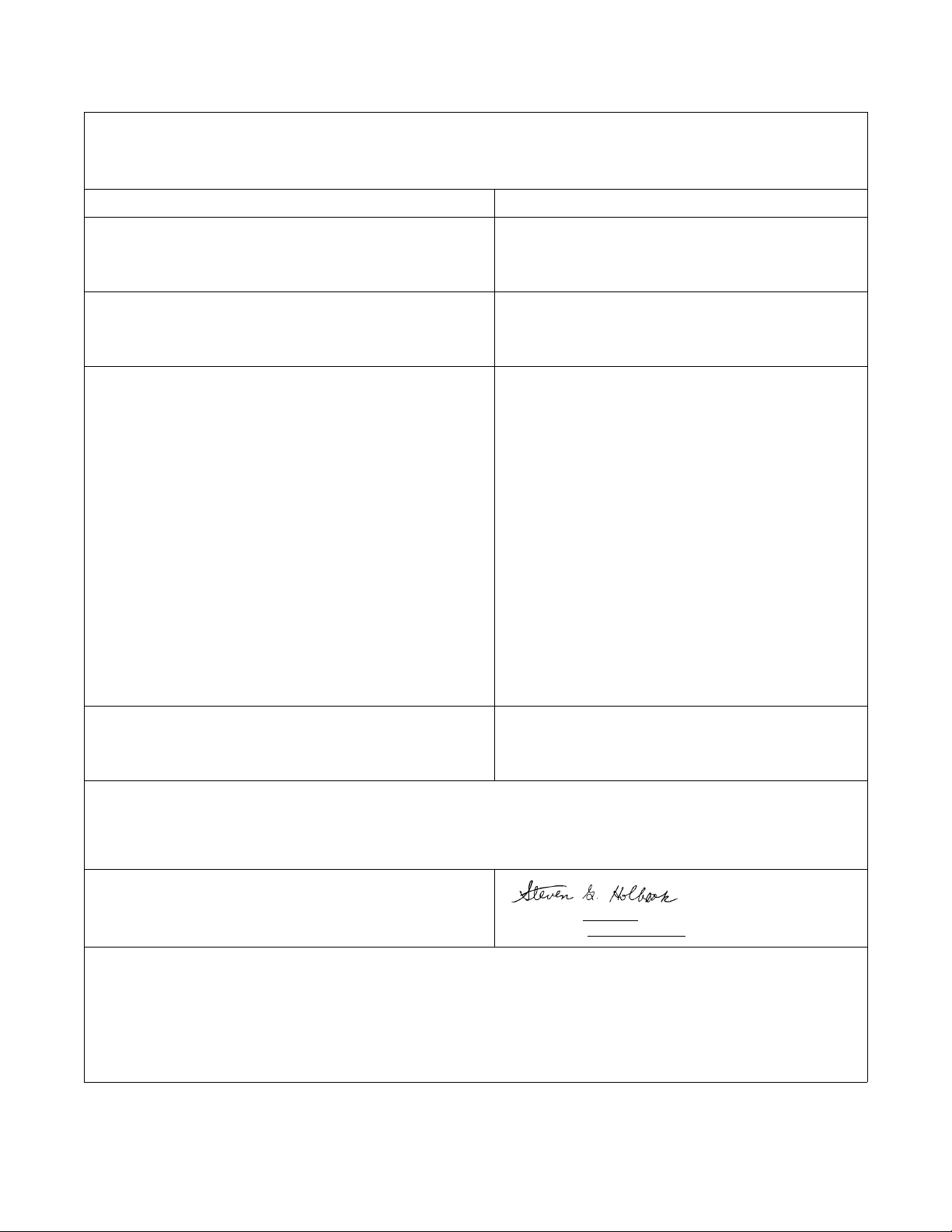

Declaration of Conformity

Declaration de Conformité

Ubereinstimmungserklärung

Dichiarazione di Conformità

ID DoC-22834630

Manufacturer’s name and address

Nom et adresse du fabricant

Hersteller

Nome del costruttore

Model No.

Modele No.

Model Nr.

Modello No.

Standards to which conformity is declared

Standards auquel la conformité appartient

Normen für welche Übereinstimmung erklärt wird

Norme per le quali si dichiara la conformità

AstroNova, Inc.

600 East Greenwich Avenue

West Warwick, RI 02893 USA

Kiaro! 200 & Kiaro! 200E

Kiaro! 200 & Kiaro! 200E with Rewinder

Kiaro! 200D & Kiaro! 200D with Rewinder

ANSI/UL 60950-1,Issued:2007/03/27 Ed:2 Rev:2011/12/19 UL

Standard for Safety for Information Technology Equipment

Safety Part 1: General Requirements

CSA C22.2 No. 60950-1Issued: 2007/03/27 Ed: 2 (R2012)

Information Technology Equipment Safety Part 1: General

Requirements; Amendment 1: 2011

CISPR 22 ed 6.0 (2008-09)

CISPR 24 ed 2.0 (2010-08)

FCC Part 15 Subpart B:2013 “Class A”

ICES-003 Issue 5 August 2012

IEC 61000-3-2 ed 3.2 (2009-04-20)

IEC 61000-3-3 ed 3.0 (2013-05-14)

IEC 61000-4-2:2008

IEC 61000-4-3:2006 +A1:2007 +A2:2010

IEC 61000-4-4:2004

IEC 61000-4-5:2005

IEC 61000-4-6:2008

IEC 61000-4-8:2009

IEC 61000-4-11:2004

Application of Council Directives

Application des Decisions du Conseil

Anwendbar fur die Richtlinien

Applicazione delle Direttive del Comitato

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standard.

Je, Soussigné, déclare que l’équipment spécifié ci-dessus est en conformité avec la directive et le standard ci-dessus.

Ich, der unterzeichnende erkläre hiermit, daß das oben beschriebene Gerät den vorgenannten Richtlinien und Normen entspricht.

Il sottoscritto dichiara che l’apparecchio sopra specificato è conforme alle Direttive e Norme sopra specificate.

Steven Holbrook

Quality Assurance Manager

AstroNova, Inc.

European Contact: Your local AstroNova, Inc. Sales and Service Office.

FRANCE - Parc Euclide, ZA la Clef de St Pierre, 10A Rue Blaise Pascal 78990 Elancourt

Tel: (+33) 1 34 82 09 00, Fax: (+33) 1 34 82 05 71

GERMANY - Senefelderstrasse 1/T6, D-63110 Rodgau

Tel. +49 (0) 6106-28368-20, Fax: +49 (0) 6106-771121

UNITED KINGDOM - 11 Whittle Parkway, Slough, Berkshire, SL1 6DQ

Tel: +44 (0)1628 668836, Fax: +44 (0)1628 664994

Note: The Kiaro! 200D is identical to the Kiaro! 200E except for the ink type used. Kiaro! 200D uses a pigment based aqueous ink while the

Kiaro! 200 & Kiaro! 200E uses a dye based ink.

2004/108/EC

2006/95/EC

Date of issue: 7/13/2016

Place of issue: West Warwick, RI

Contents

Chapter: 1 Quick Start Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Choosing an Installation Location . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpacking the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Checking the Included Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Loading Ink Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Initial Ink Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Verifying Label Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Printer Driver (USB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Resolving Windows 7 and Windows 8 USB Installation Issues . . . . . . . . . 14

Installing the Printer Driver (Network) . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter: 2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

About the Kiaro! 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Printer Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Kiaro! 200 Left Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Kiaro! 200 Right Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Printer Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Inside the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Switching the Printer On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Switching the Printer On . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Switching the Printer Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

QuickLabel Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Kiaro! 200 Label Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

QuickLabel BPO Blanket Purchase Order Program . . . . . . . . . . . . . . 27

Media Specialists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

QuickLabel Kiaro! 200 Support . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter: 3 Designing and Printing Labels . . . . . . . . . . . . . . . . . . . . .29

Designing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Choosing Design Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Disabling Anti-aliasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Planning Full-Bleed and Non-Bleed Labels . . . . . . . . . . . . . . . . . . . 29

Printing Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Verifying Label Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting up the Label Design Software . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting up Labels in Custom QuickLabel Omni . . . . . . . . . . . . . . . . . 30

Setting up Labels in Third-Party Design Applications . . . . . . . . . . . . . . 31

Setting up the Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Selecting a Label Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting up a Custom Label Stock . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting up Appearance Options . . . . . . . . . . . . . . . . . . . . . . . . . 35

Kiaro! 200 User Guide i

Contents

Setting Advanced Color Options . . . . . . . . . . . . . . . . . . . . . . . . 37

Setting up Layout Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Printing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Using the Manual Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Using the Status Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Viewing the Printer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Viewing the Job Status and Cancelling Jobs . . . . . . . . . . . . . . . . . . 45

Viewing Ink and Maintenance Cartridge Levels . . . . . . . . . . . . . . . . . 45

Changing or Replacing Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Removing Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Loading Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter: 4 Kiaro! 200 Maintenance Utility . . . . . . . . . . . . . . . . . . . . .55

About the Maintenance Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Printer Information Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Viewing Printer Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Upgrading the Printer Firmware . . . . . . . . . . . . . . . . . . . . . . . . . 56

Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Position Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Setting the Vertical Baseline . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Setting the Horizontal Baseline . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting the Stop Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Cleaning Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Preparing for Moving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Preparing for Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Priming the Printheads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Refreshing Kiaro! 200D Ink . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Test Print Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Printing a Test Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Adjustments Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Setting the Vertical Printhead Alignment . . . . . . . . . . . . . . . . . . . . 65

Setting up Standard Registration . . . . . . . . . . . . . . . . . . . . . . . . 67

Setting up Manual Registration . . . . . . . . . . . . . . . . . . . . . . . . . 71

Using the Slant Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Using the Missing Nozzle Adjustment . . . . . . . . . . . . . . . . . . . . . . 76

Adjusting the Top-of-Form Threshold . . . . . . . . . . . . . . . . . . . . . . 79

Turning On Auto-Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Adjusting the Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

System Logs Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Viewing the Error History . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Saving Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Parts Replacement Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing the Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . 85

Replacing the Purge Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Replacing the Blade Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Advanced Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Chapter: 5 Printer Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Replacing Ink Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Replacing the Maintenance Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Cleaning the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Upgrading the Printer Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

ii Kiaro! 200 User Guide

Contents

Chapter: 6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Error and Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Operator Call Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . 99

Removing a Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Printer Not Operating Correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Printer Does Not Start or Printer Stops During Print Jobs . . . . . . . . . . 101

Paper is Not Feeding Correctly . . . . . . . . . . . . . . . . . . . . . . . . 102

Status Monitor Does Not Start . . . . . . . . . . . . . . . . . . . . . . . . 102

Print Results are Unsatisfactory . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Random Characters are Printed . . . . . . . . . . . . . . . . . . . . . . . 103

Slow to Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Print Quality is Poor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Printed Colors Appear Incorrect . . . . . . . . . . . . . . . . . . . . . . . . 104

Print Samples and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Spur Gear Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Background Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Printhead Not in Correct Position . . . . . . . . . . . . . . . . . . . . . . . 106

Media Contacting Printheads . . . . . . . . . . . . . . . . . . . . . . . . . 107

Poor Print Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Media Surface Contamination . . . . . . . . . . . . . . . . . . . . . . . . . 109

Scuffing of Surface Material . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Non-Functioning Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Clogged Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Debris on Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Wide Voids in Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Changes in Density Due to Torque . . . . . . . . . . . . . . . . . . . . . . 115

Physical Smearing of Wet Ink . . . . . . . . . . . . . . . . . . . . . . . . . 116

Media Being Pulled at Label Exit . . . . . . . . . . . . . . . . . . . . . . . 117

Printhead Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Setting up Image Placement for Full-Bleed Printing . . . . . . . . . . . . . . . . . . 119

Chapter: 7 Rewinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Before Installing the Rewinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Installing the Rewinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Rewinding Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Adjusting Rewinder Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Chapter: 8 Safety Warnings and Precautions . . . . . . . . . . . . . . . . . . 127

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Power Supply and Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Moving the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Ink Tank and the Maintenance Cartridge . . . . . . . . . . . . . . . . . . . . . . . 131

Chapter: 9 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Kiaro! 200 User Guide iii

Contents

iv Kiaro! 200 User Guide

1

Before Installing the Printer

Choosing an Installation Location

The installation environment must be as described in this section.

• The printer power cord must be able to connect to an outlet (100-240 VAC 50-60

Hz 3.5A). This outlet must be easily accessible.

• Avoid installing the printer near a faucet, water heater, humidifier, or refrigerator.

• Ensure the environment temperature is within 59 to 86 degrees Fahrenheit (15 to

30 degrees Celsius).

• Ensure the environment humidity is within 10% to 90 % relativ e hu m idity.

• Avoid installing printer near fire, in a dusty place, or in a place where ammonia gas

is generated. When installing printer in a place exposed to direct sunlight, it is

recommended that curtains be hung over the window.

• No printer feet should float. The printer must be held level constantly.

Quick Start Guide

• When placing the printer on a desk, table, or other similar surface, it must be sturdy

and stable enough to support the weight of the printer.

• The room must be properly ventilated.

• Install printer at least 3.5 inches (88.9 mm) away from each wall with a sufficient

work space around it.

Kiaro! 200 User Guide 1

Quick Start Guide

Installation Precautions

When installing the printer, observe the following precautions.

• Imaging faults can result from dew condensation that occurs when the printer is

moved from a cold place to a warm place. Leave the unpacked printer as is for at

least two hours before installing it.

• The printer can weigh up to 170 poun ds (77 kilograms). Three persons are required

to lift the printer. Lift only by the black frame on the bottom of the printer. Do not

grasp any other part of the printer to lift it. Do not lift the unit by the print engine.

Attempting to lift the printer in an improper position can result in fall of the printer

or injury.

System Requirements

• 32-bit or 64-bit Microsoft® Windows® XP, Windows Vista®, Windows 7, or

Windows 8

• Microsoft .NET Framework 3.5 SP1

• 350 MB free hard drive space

• CD/DVD drive

• One available USB 2.0 port for USB installation or network connectivity for network

installation

2 Kiaro! 200 User Guide

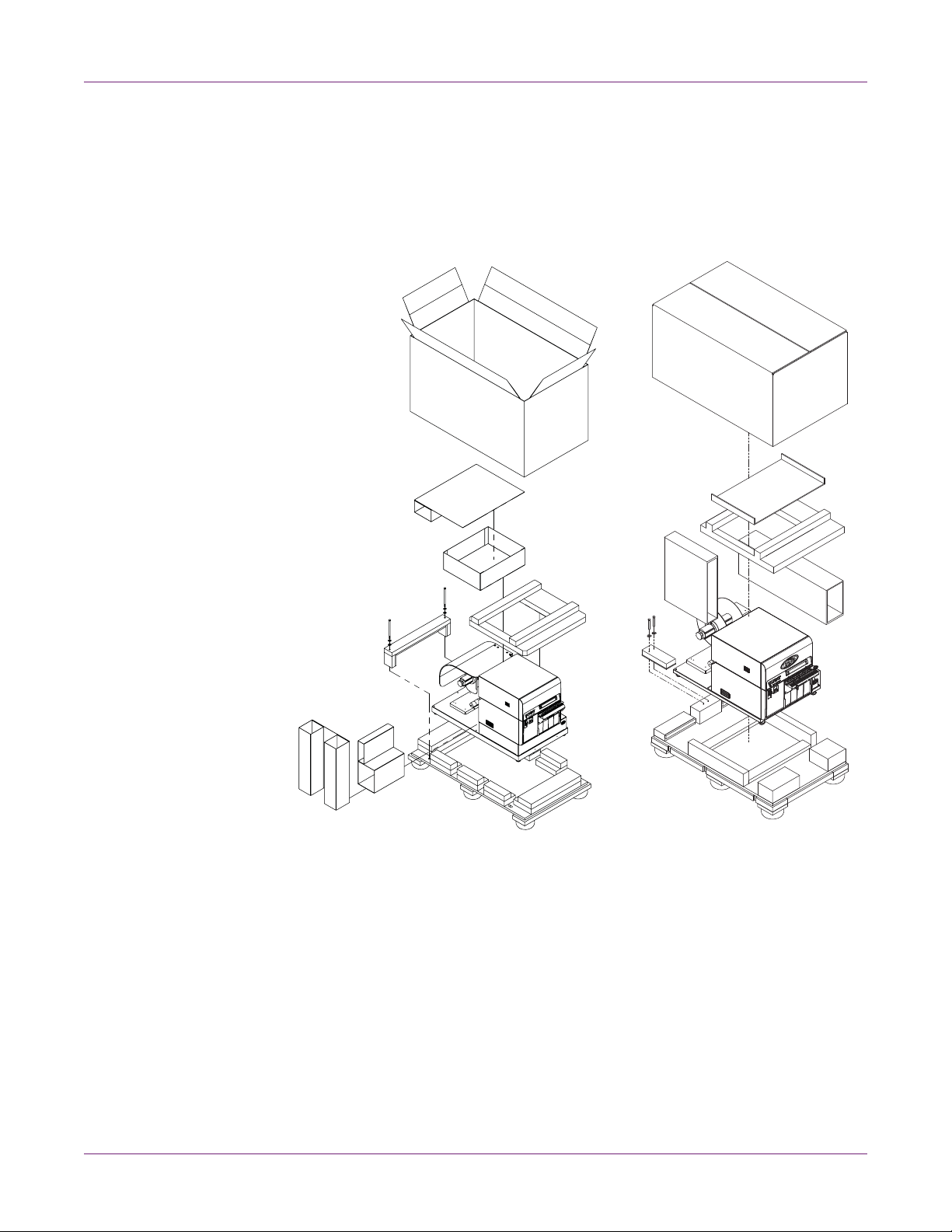

Unpacking the Printer

The printer is secured using cushioning materials to protect it against vibrations and

shock during transportation. Use the following procedure to unpack the printer. Keep

the packing materials for future transportation.

1 Remove the cardboard box and other shipping materials from the pallet.

Quick Start Guide

Note: The printer model on the left has the roll cover. The printer model on the

right does not have the roll cover.

2 Use a wrench to remove the two 9/16” bolts from the bracket that secures the

printer to the pallet. Remove the bracket.

Kiaro! 200 User Guide 3

Quick Start Guide

3 Holding the black frame at the bottom of the printer, lift the printer to take it out from

the pallet base. Lift from the illustrated points. Do not hold the front side of the

printer.

Note: The printer can weigh up to 170 pounds (77 kilograms). Three persons are

required to lift the printer. Lift only by the black frame on the bottom of the printer.

Do not grasp any other part of the printer to lift it. Do not lift the unit by the print

engine. Attempting to lift the printer in an improper position can result in fall of the

printer or injury.

4 Place the printer on a horizontal table. Then remove all pieces of packing tape and

cushioning materials visible on the exterior of the printer.

5 If necessary, you can rotate the feet on the bottom of the frame to adjust the height

of each corner. Use these adjustments to keep the printer level.

Checking the Included Parts

Check to make sure the following items are included with the printer.

• Starter ink tanks (one for each color)

• Starter roll of labels

• AC power cable

• USB cable

• Quick Start Guide

• Installation CD

4 Kiaro! 200 User Guide

Installing the Printer

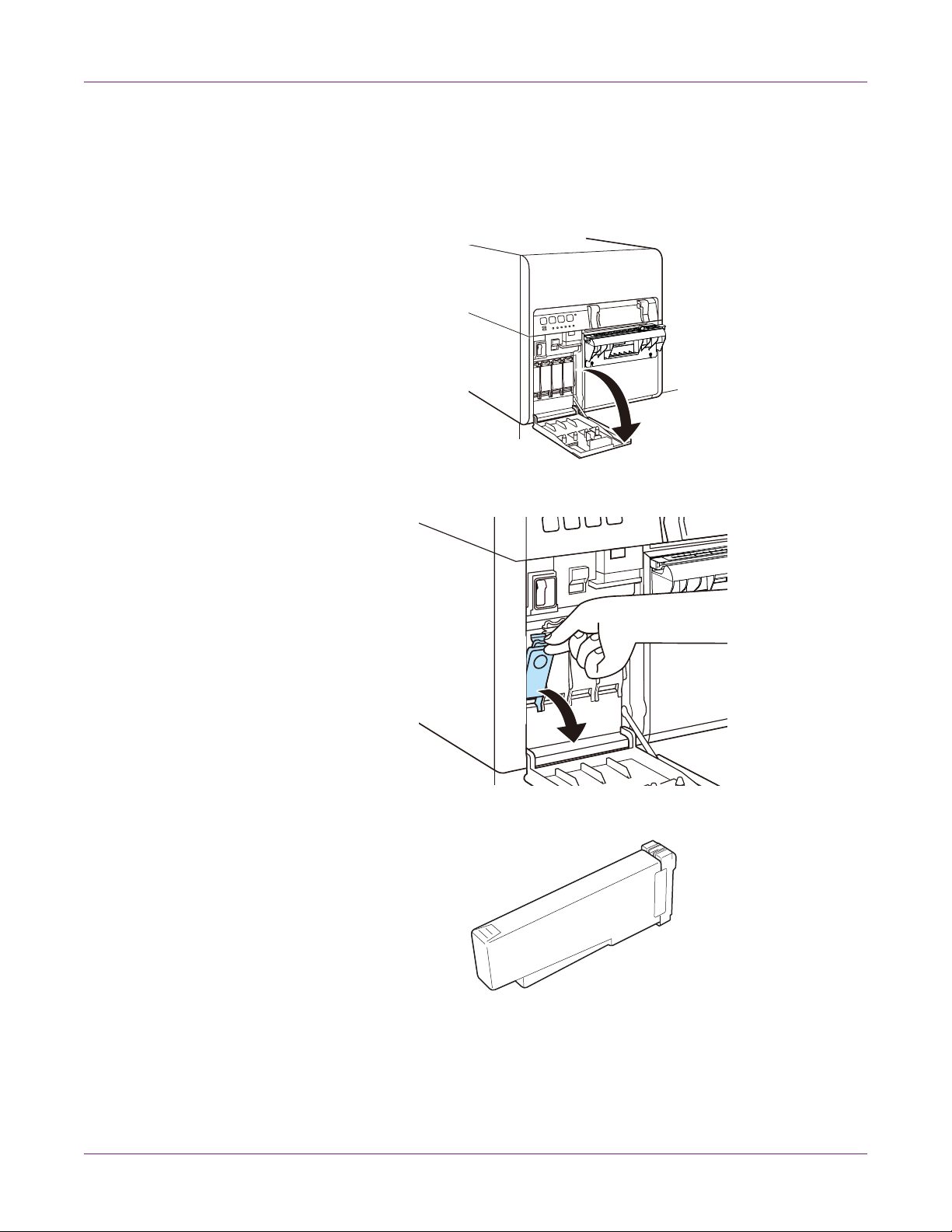

Loading Ink Tanks

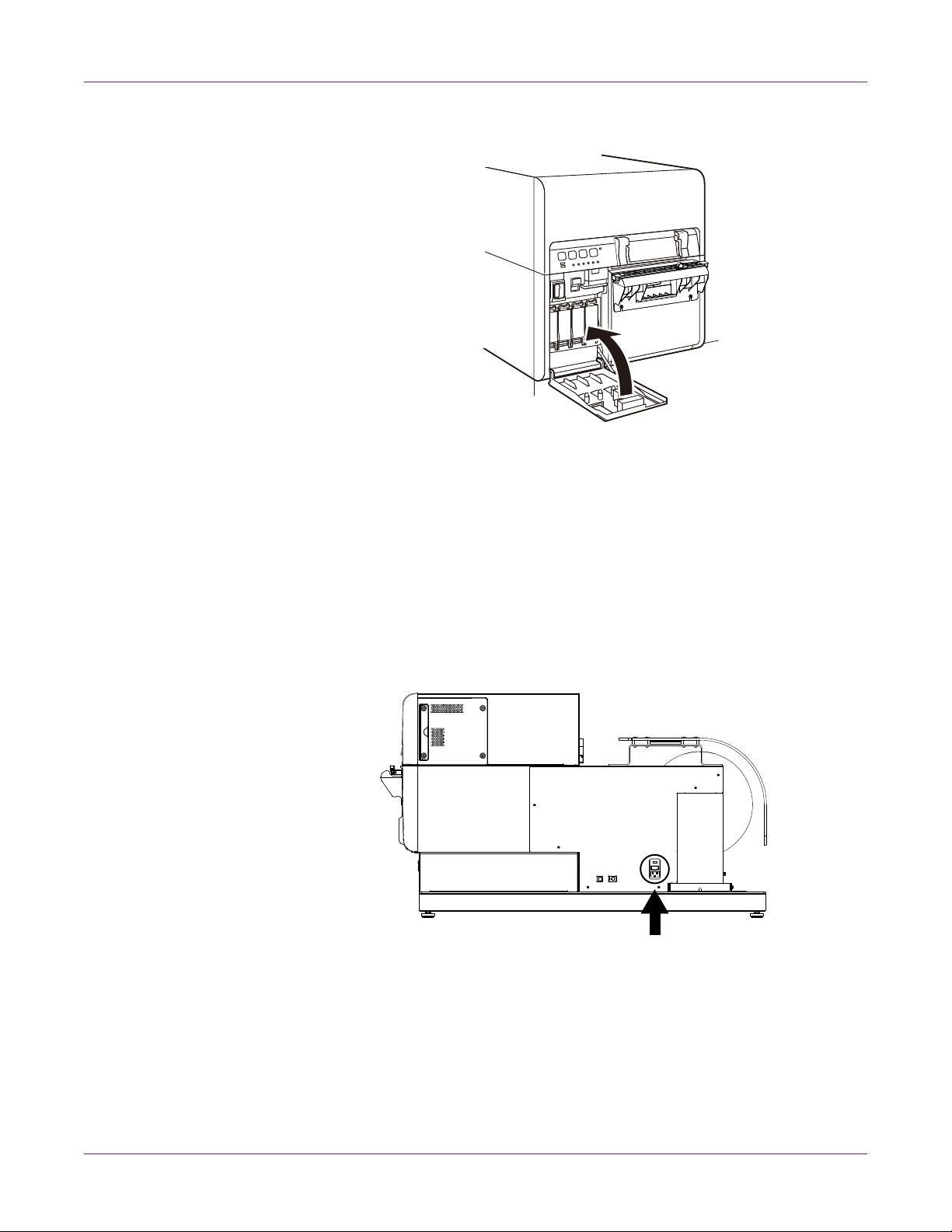

1 Open the ink tank door.

2 Open the ink tank lever for each color while pushing it downward.

Quick Start Guide

3 Take out the ink tanks from the package. Then remove the packing materials.

Do not touch the ink outlet and terminal to prevent soiling of the surrounding work

area, damage to the ink tank, and poor printing. Never drop or apply excessive

force to an ink tank.

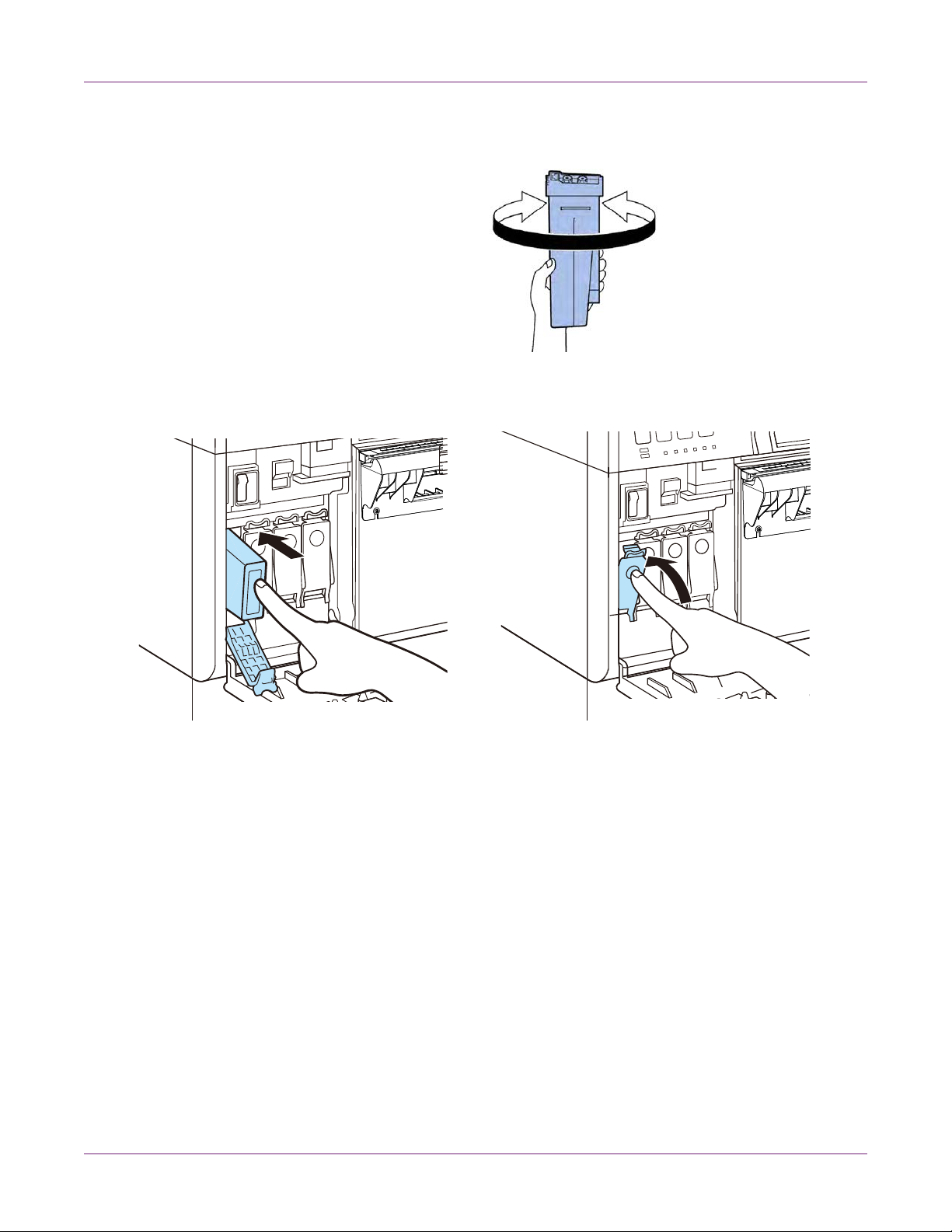

4 If you are using the Kiaro! 200D printer, rotate the ink tank to stir the ink.

Kiaro! 200 User Guide 5

Quick Start Guide

Note: This step applies only to the Kiaro! 200D ink. If you are using the standard

Kiaro! 200, skip this step.

5 Slowly insert the ink tank as far as it will go, and then close the ink tank lever.

Caution: There are sharp pins in the ink tank slot. Never put your fingers in this

area.

Note: The printer is designed so that ink tanks cannot be inserted in wrong ink

tank slots. Do not attempt to insert ink tanks in wrong ink tank slots forcibly.

6 Kiaro! 200 User Guide

6 After loading all ink tanks, close the ink tank door.

Initial Ink Filling

Caution: Do not turn the power off during ink loading.

Quick Start Guide

Caution: If the power is turned off during ink loading, the printer stops ink loading. In

such a case, turn on the power to start ink loading again.

Caution: Restarting the ink loading causes extra ink waste.

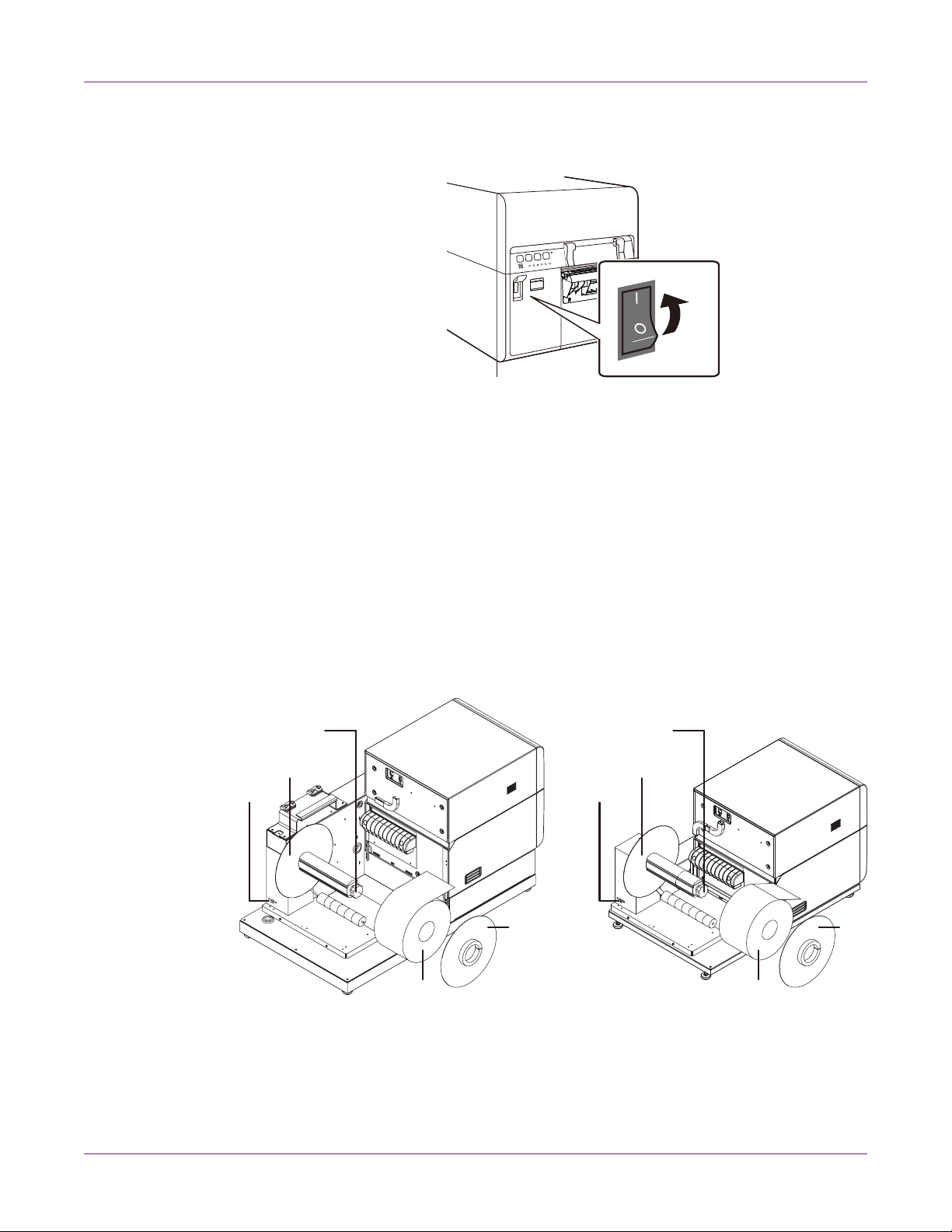

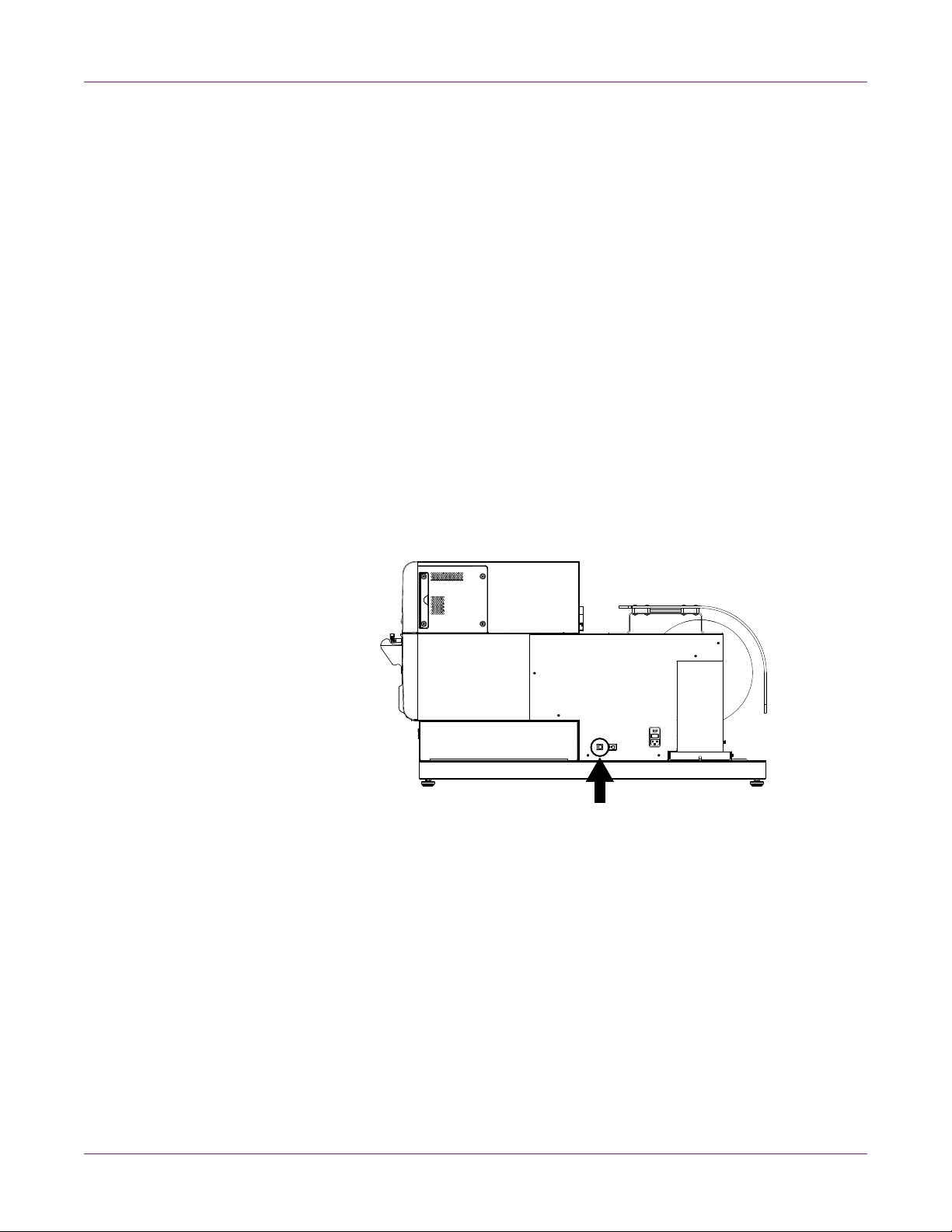

1 Connect the power cord to the printer. Use the power cord appropriate for the

power supply used at the installation site.

Caution: Never use a wrong power cord.

2 Connect the power cord to the outlet.

3 Turn on the main power switch. This switch is located directly above where the

power cord connects to the unit.

Kiaro! 200 User Guide 7

Quick Start Guide

[1]

[2]

[3]

[4]

[5]

[2]

[4]

[3]

[1]

[5]

Loading Media

4 Turn on the printer power switch. Initial ink filling starts automatically when the

power is turned on.

When ink loading is complete, the STATUS LED changes from flashing to lit and a

beep sounds.

Note: Initial ink loading takes about 30 minutes.

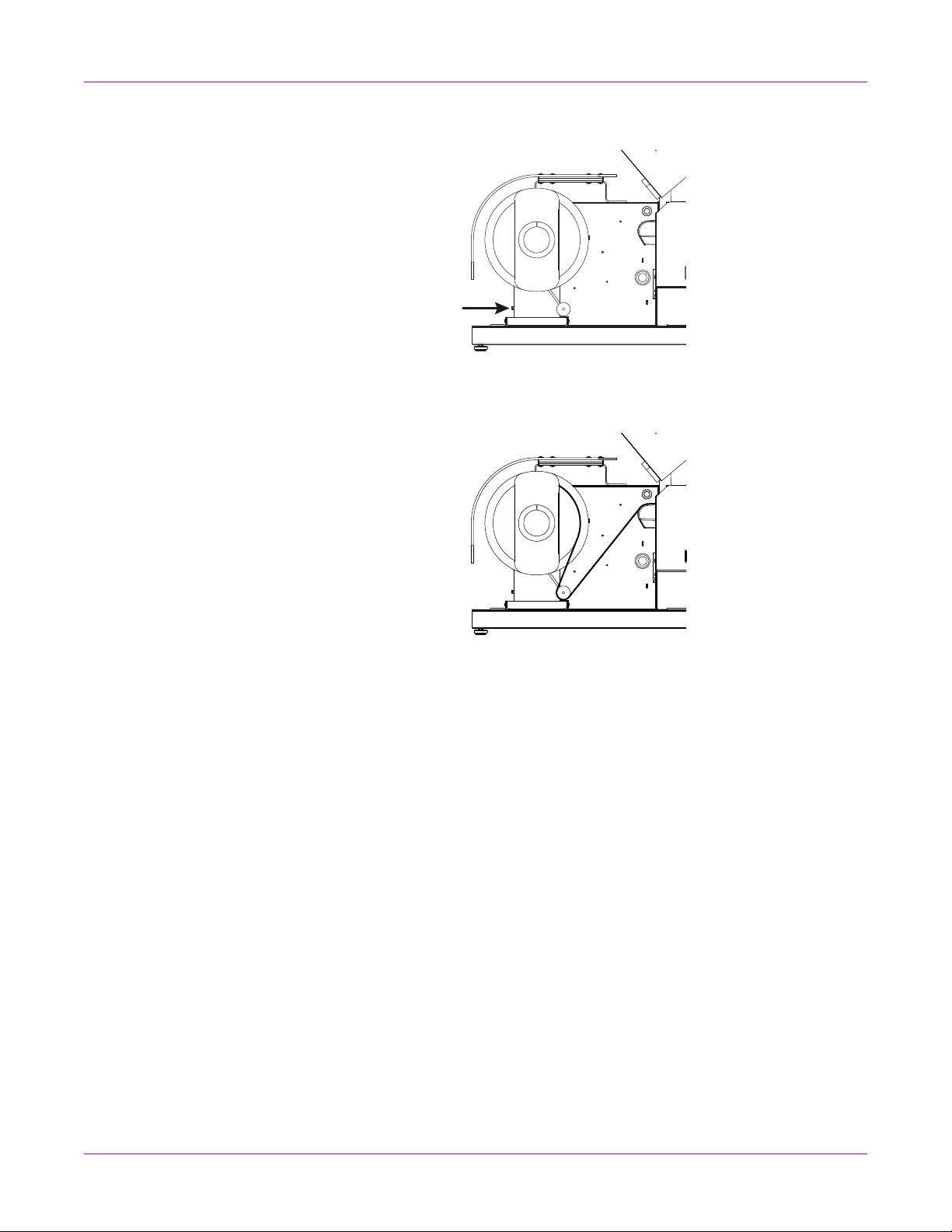

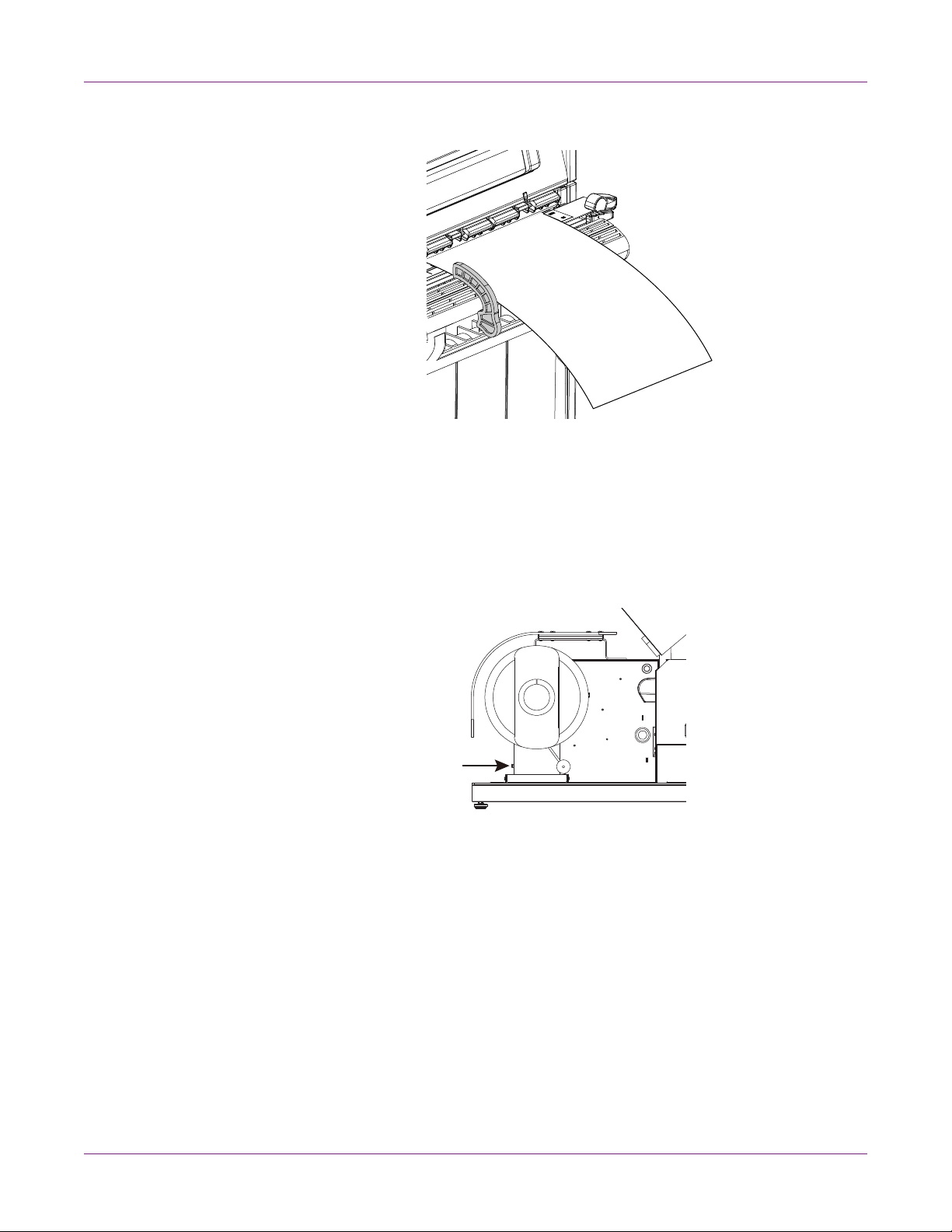

Some steps for loading media will differ slightly depending on the Kiaro! 200 model you

are using. You can identify the Kiaro! 200 model based on whether it has a roll cover

over the supply mandrel area.

1 If your printer model has a roll cover, open it.

2 Ensure the power switch [1] on the supply mandrel is in the off position.

Note: The printer model on the left has the roll cover (not illustrated). The printer

model on the right does not have the roll cover.

Caution: Do not turn the supply mandrel by hand to advance the media. Turning

the mandrel by hand can result in printer damage.

8 Kiaro! 200 User Guide

Quick Start Guide

3 Turn the mandrel adjustment knob [3] counterclockwise to loosen the mandrel.

4 Remove the outer flange [4] from the mandrel.

5 Orient a roll of label media [5] as illustrated and seat it on the mandrel. Ensure the

side of the roll contacts the inner flange [2].

6 Reinstall the outer flange [4]. Refer to the information below to determine whether

to tighten the mandrel.

• If your printer model has a roll cover, turn the mandrel adjustment knob [3]

clockwise to tighten the mandrel.

• If your printer model does not have a roll cover, do not tighten the mandrel at

this time.

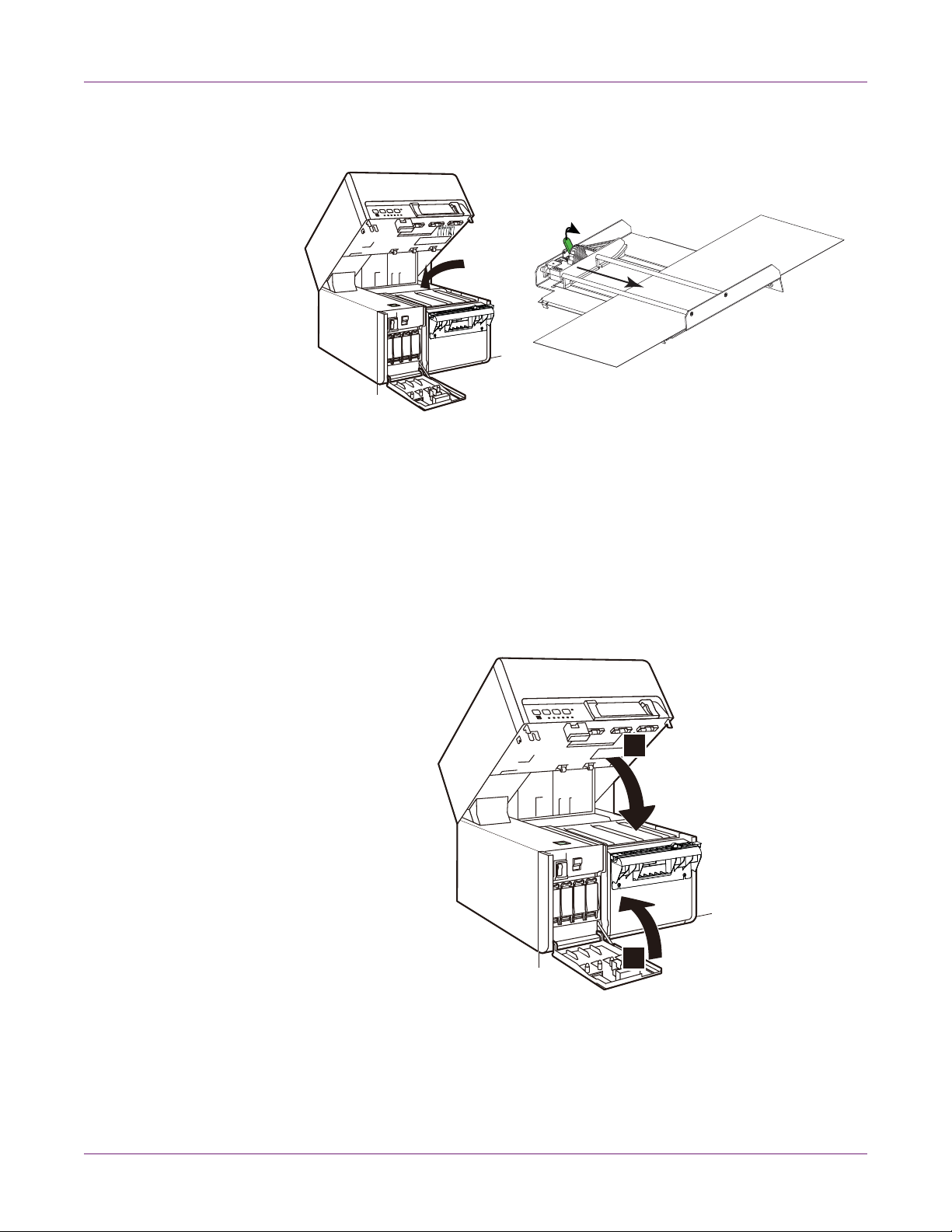

7 Open the ink tank door.

8 Push the upper unit release lever up to open the upper unit.

Kiaro! 200 User Guide 9

Quick Start Guide

9 Turn the power switch on the supply mandrel to the on po sitio n.

10 Feed the media under the dancer arm and up into th e entry slot o n the rear of the

printer. The media path is illustrated below.

• If your printer model has a roll cover, the mandrel will unwind and feed media

as the dancer arm is lifted. Do not turn th e supply mandrel by hand to advance

the media.

• If your printer model does not have a roll cover, ensure the mandrel is not

tightened at this time. The media roll should rotate freely on the mandrel during

this process.

10 Kiaro! 200 User Guide

Quick Start Guide

11 Adjust the input guide inside the upper unit. Press the green lever and slide the

guide just before it contacts the media. Then release the green lever.

1

Label media should be able to move smoothly with out being hind ered by the input

guide.

Note: The guide should be positioned to just touch the edge of the liner and not

cause exposed liner to curl on either side.

12 Pull the media until it advances slightly past the manual cutter.

13 If your printer model does not have a roll cove r, turn the m andrel adjustmen t knob

[3] clockwise to tighten the mandrel.

14 Close the upper unit and then close the ink tank door.

1

2

Kiaro! 200 User Guide 11

Quick Start Guide

15 Position the media exit guide just before it contacts the media.

Label media should be able to move smoothly without being hindered by th e exit

guide.

Note: The guide should be positioned to just touch the edge of the liner and not

cause exposed liner to curl.

16 If your printer model has a roll cover, close it.

17 Ensure the power switch on the supply mandrel is in the on position.

Verifying Label Width

When designing labels, ensure the width of your label design matches the width o f the

media you will be using. If your label file is wider than the media, the printer will attempt

to print the full width of your label. In this situation, ink will be injected into the transport

assembly and will require cleaning.

Use the ruler on the manual cutter to verify the width of your label media before printing.

12 Kiaro! 200 User Guide

Installing the Printer Driver (USB)

Use the following instructions to install the printer via USB 2.0 on Windows XP,

Windows Vista, Windows 7, or Windows 8.

Note: When the Windows logo testing, publisher verification, or digital signing warning

messages appear, choose to continue the installation. These messages indicate that

the driver has not been “logo tested” by Microsoft. However, it has been tested

thoroughly by QuickLabel, and will not cause any of the problems listed in these

messages.

1 Ensure the Kiaro! 200 is powered on but not connected to your computer via the

USB cable.

2 Power on your computer and insert the Kiaro! 200 Installer CD in the CD drive. The

Installer CD wizard will open. Choose Next.

Note: If the autorun program does not start automatically, use Windows Explorer

to launch the “Setup.exe” file located in the root level of the CD.

3 Use the driver installation wizard to install the driver. Refer to the following

information during this process.

Quick Start Guide

• Choose the USB connection method when prompted.

• Select an installation location for the Kiaro! 200 Maintenance Utility when

prompted.

Choose Finish in the installation wizard after successfully installing the Kiaro! 200

Maintenance Utility and driver.

4 Connect the smaller end of the USB cable to the Kiaro! 200 USB type B port.

Connect the larger end of the USB cable to an available USB 2.0 port on your

computer.

5 Once the USB connection is made, the Windows Found New Hardware Wizard will

start. This wizard will guide you through the rest of the installation process. Refer

to the following general guidelines when using this wizard.

• If you are prompted to connect to Windows Update to search for software,

choose no.

Kiaro! 200 User Guide 13

Quick Start Guide

• Choose to install the software automatically when you are presented with this

option.

• If the Windows logo testing or publisher verification warning messages appear,

choose to continue the installation.

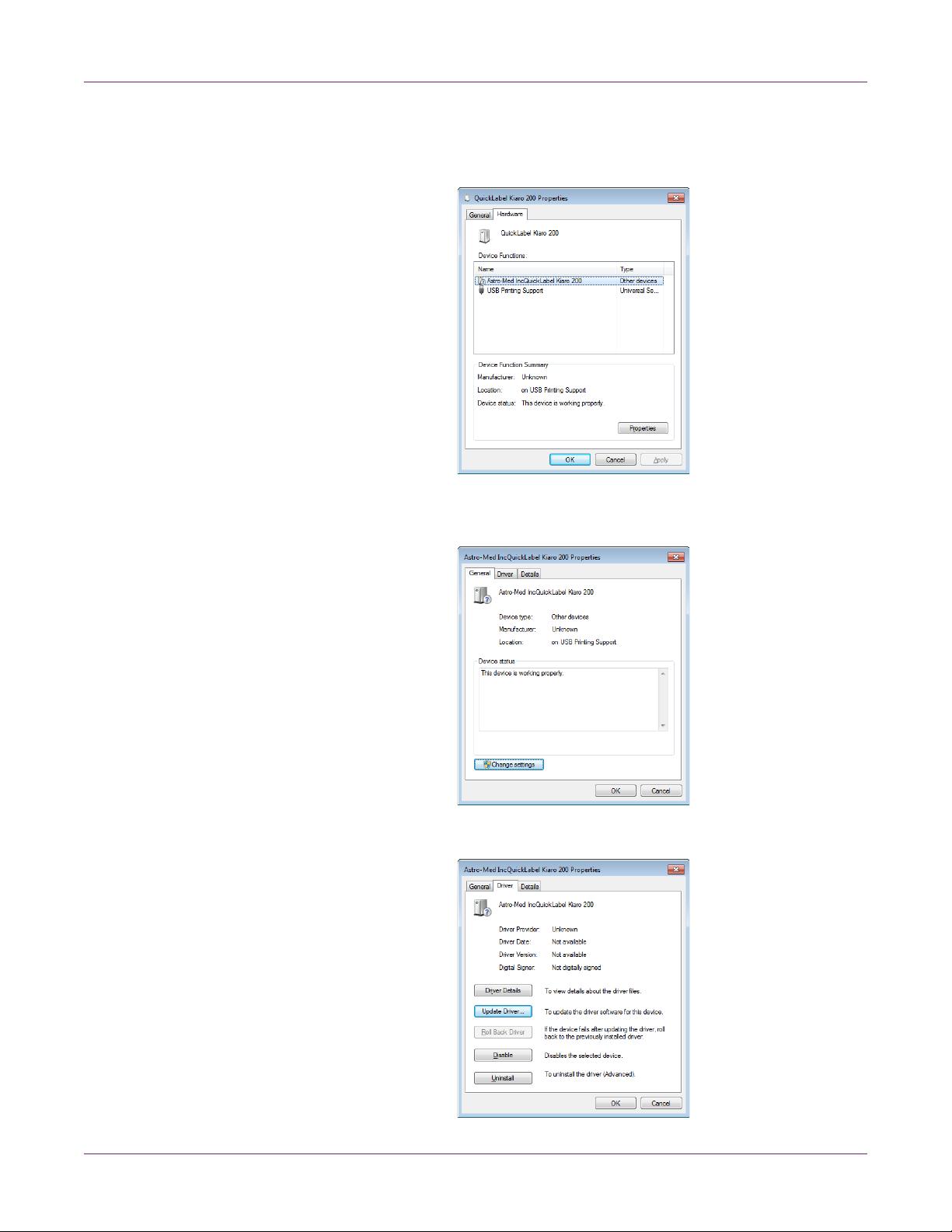

Resolving Windows 7 and Windows 8 USB Installation Issues

When you install the printer driver via USB, you first run the installation wizard on the

Kiaro! 200 Installer CD and then connect the printer to your PC via the USB cable.

If you connected the USB cable before running the installation wizard on the Kiar o! 200

Installation CD, Windows 7 and Windows 8 will not recognize the printer correctly. In

this case, the Kiaro! 200 will be listed as an Unspecified item in the Devices and

Printers window.

Use the following procedure to correct this issue. This procedure assumes you have

already installed the printer driver via the Kiaro! 200 Installer CD.

Note: This procedure requires administrator level access in Windows.

1 Open the Devices and Printers window in Windows 7 or Windows 8.

14 Kiaro! 200 User Guide

Quick Start Guide

2 Right-click the QuickLabel Kiaro 200 in the Unspecified list. Then choose

Properties. The QuickLabel Kiaro 200 Properties window will open. Choose the

Hardware tab.

3 Select Astro-Med IncQuickLabel Kiaro 200 and choose Properties. The Properties

window will open. Choose the General tab.

4 Choose Change Settings. Then choose the Driver tab.

Kiaro! 200 User Guide 15

Quick Start Guide

5 Choose Update Driver. When you are prompted, select the Search automatically

for updated driver software option. Windows will locate the driver on your system

and create a printer item.

Installing the Printer Driver (Network)

Use the following instructions to install the printer via a network connectio n on Windows

XP, Windows Vista, Windows 7, or Windows 8.

For detailed information about the topic of networking, refer to documentation

applicable to your network environment and/or contact your network administrator.

The printer uses the following ports: TCP 50000,50001,9100, UPD 50001,50002. The

printer cannot be used on a network where other devices on the network use the same

ports.

Note: When the Windows logo testing, publisher verification, or digital signing warning

messages appear, choose to continue the installation. These messages indicate that

the driver has not been “logo tested” by Microsoft. However, it has been tested

thoroughly by QuickLabel, and will not cause any of the problems listed in these

messages.

1 Ensure the printer is powered on and connected to the network via a LAN cable.

2 Power on your computer and insert the Kiaro! 200 Installer CD in the CD drive. The

Installer CD wizard will open. Choose Next.

Note: If the autorun program does not start automatically, use Windows Explorer

to launch the “Setup.exe” file located in the root level of the CD.

3 Use the driver installation wizard to install the driver. Refer to the following

information during this process.

• Choose the Ethernet connection method when prompted.

• Allow the installer to access the network if prompted.

• Choose the Kiaro! 200 printer in the printer list when prompted . Alternately, you

can choose to find a specific printer by IP address or MAC address.

16 Kiaro! 200 User Guide

Loading...

Loading...