QuickLabel CU-30 User Manual

™

CU-30, CS-40, CTS-45

Operation & Setup Guide

CU-30 CUTTER AND CS-40 / CTS-45 CUTTER-STACKER 1

Setting up the stacker (CS-40 and CTS-45 only) 2

Cutting short tags 6

Assembing the CU-30, CS-40, or CTS-45 7

Setting up the cutter unit with the printer 9

Cutter-stacker adjustments and tag stock 11

Adjusting the cut-pulse potentiometer 13

Changing fuses/voltage selection 14

Clearing a cutter-blade jam 16

Replacing the cutter blade 17

Removing the side panels and front attachment 18

Replacing the cutter-blade assembly 19

APPENDIX A: GUIDELINES FOR BEST PERFORMANCE 1

APPENDIX B: SPECIFICATIONS 2

© Copyright 1998

This manual is copyrighted with all rights reserved. No part of

this manual may be reproduced, transmitted, transcribed, stored

in a retrieval system, or translated into any language in any form

by any means without written permission of QuickLabel® Systems, a division of Astro-Med, Inc.

Limited Warranty

QuickLabel® Systems warrants the cutting blade of the CS-40 or

CTS-45 Cutter-Stacker and the CU-30 Cutter from the date of

original purchase for one million cuts when using 7-point card

stock. Other materials are subject to verification.

QuickLabel® Systems warrants all other portions of the CS-40 or

CTS-45 Cutter-Stacker and the CU-30 Cutter against defects in

materials or workmanship for a period of one year from the date

of original purchase. If you discover a defect, QuickLabel® Systems will, at its option, repair or replace this product at no additional charge except as set forth below. Repair parts and replacement parts will be furnished on an exchange basis and will be

either reconditioned or new. All replaced parts become the

property of QuickLabel® Systems.

This warranty does not apply if the product has been damaged by

accident, abuse, misuse, or misapplication, or has been modified

without the written permission of QuickLabel® Systems.

To obtain warranty services, call (401) 828-4000 for information.

QuickLabel® Systems is not responsible for your product if it is

lost or damaged in transit.

QuickLabel® Systems makes no warranty, either express or

implied, with respect to this product’s fitness for a particular

purpose.

Canadian Emissions Requirements

This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus set out in the Radio

Interference Regulations of the Canadian Department of Communications.

Le present appareil numérique n’emet pas de bruits

radioelectriques depassant les limites applicables aux appareils

numériques de la class A prescrites dans le Règlement sur le

brouillage radioelectrique edicte par le ministere des Communications du Canada.

FCC Compliance Statement

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Shielded cables must be used with this unit to ensure compliance

with the Class A FCC limits.

WARNING

Changes or modifications to this unit not expressly approved by

the party responsible for compliance could void the user’s authority to operate the equipment.

NOTE

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the operation guide, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference,

in which case the user will be required to correct the interference

at his own expense.

Trademarks

QuickLabel® is a registered trademark of Astro-Med, Inc.

CU-30 Cutter

CS-40 / CTS-45 Cutter-Stacker

The CU-30 Cutter and the CS-40 and CTS-45 Cutter-Stackers are

designed for use with QuickLabel Systems' QLS-Series printers:

• The CU-30 automatically cuts tags, tickets, care tags, etc.

as they emerge from the printer, then drops them in a

collector bin or basket.

The CU-30 can handle tag sizes from 3/8 inch long by 1

inch wide to 22 inches long by 45/8 inches wide.

• The CS-40 and CTS-45 automatically cut and neatly stack

tags, tickets, care tags, etc. as they emerge from the

printer.

The CS-40 and CTS-45 can handle tag sizes from 3/4 inch

long by 11/2 inches wide to 5 inches long by 45/8 inches

wide.

This guide instructs you in setting up the cutter-stacker or cutter for

use with one of the QLS-Series printers and in procedures for maintaining the unit's optimal performance.

1

Setting up the stacker (CS-40 and CTS-45 only)

Using the stacker portion of the CS-40/CTS-45 Cutter-Stacker

requires that you attach the stacking tray to the stacker base and

correctly position the stacker for the size tags to be cut.

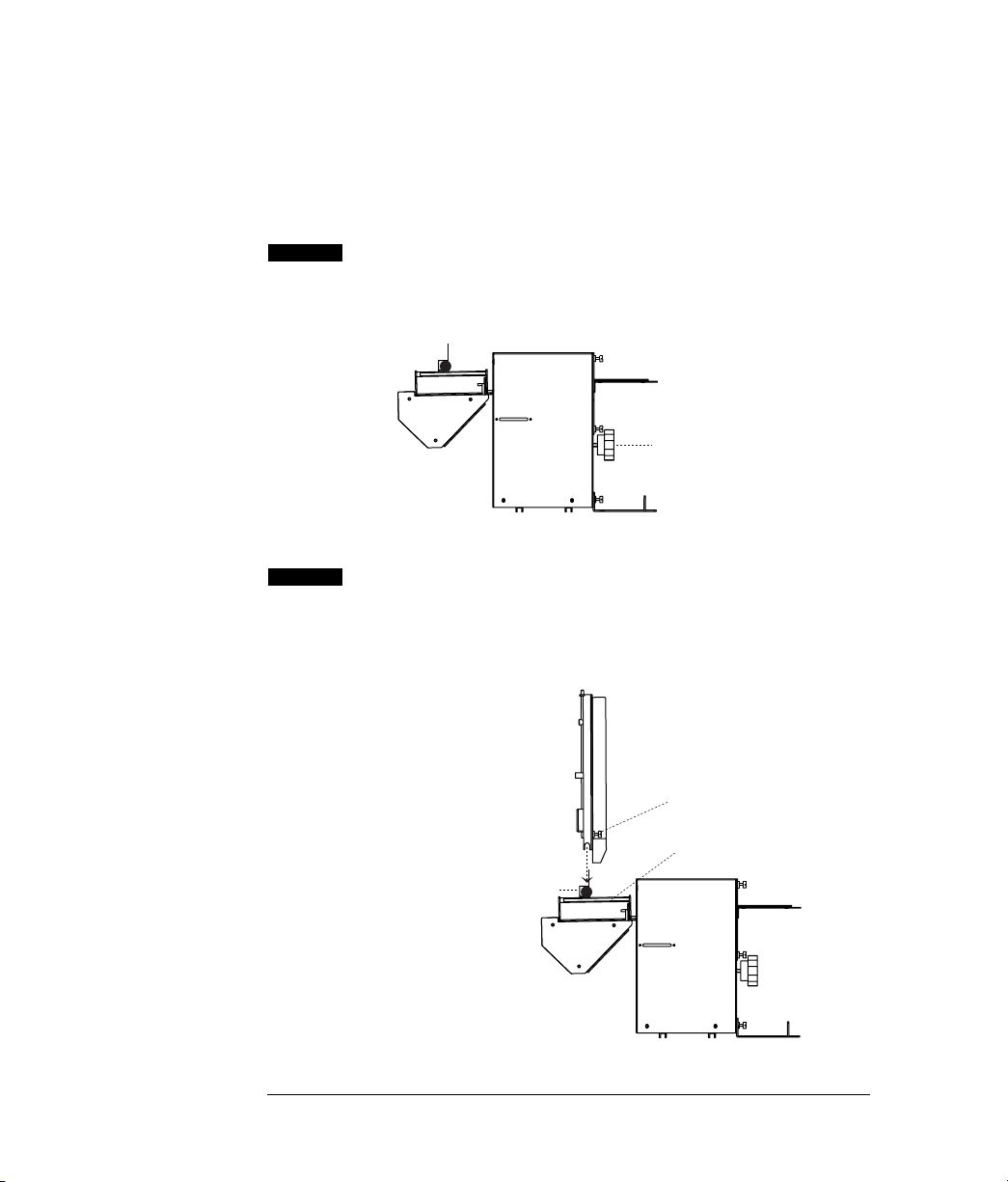

1 Turn the tray-angle adjustment knob counterclock-

wise to fully raise the tray base. This will simplify

attaching the stacking tray to the base.

raise tray base to

horizontal position

angle adjustment knob

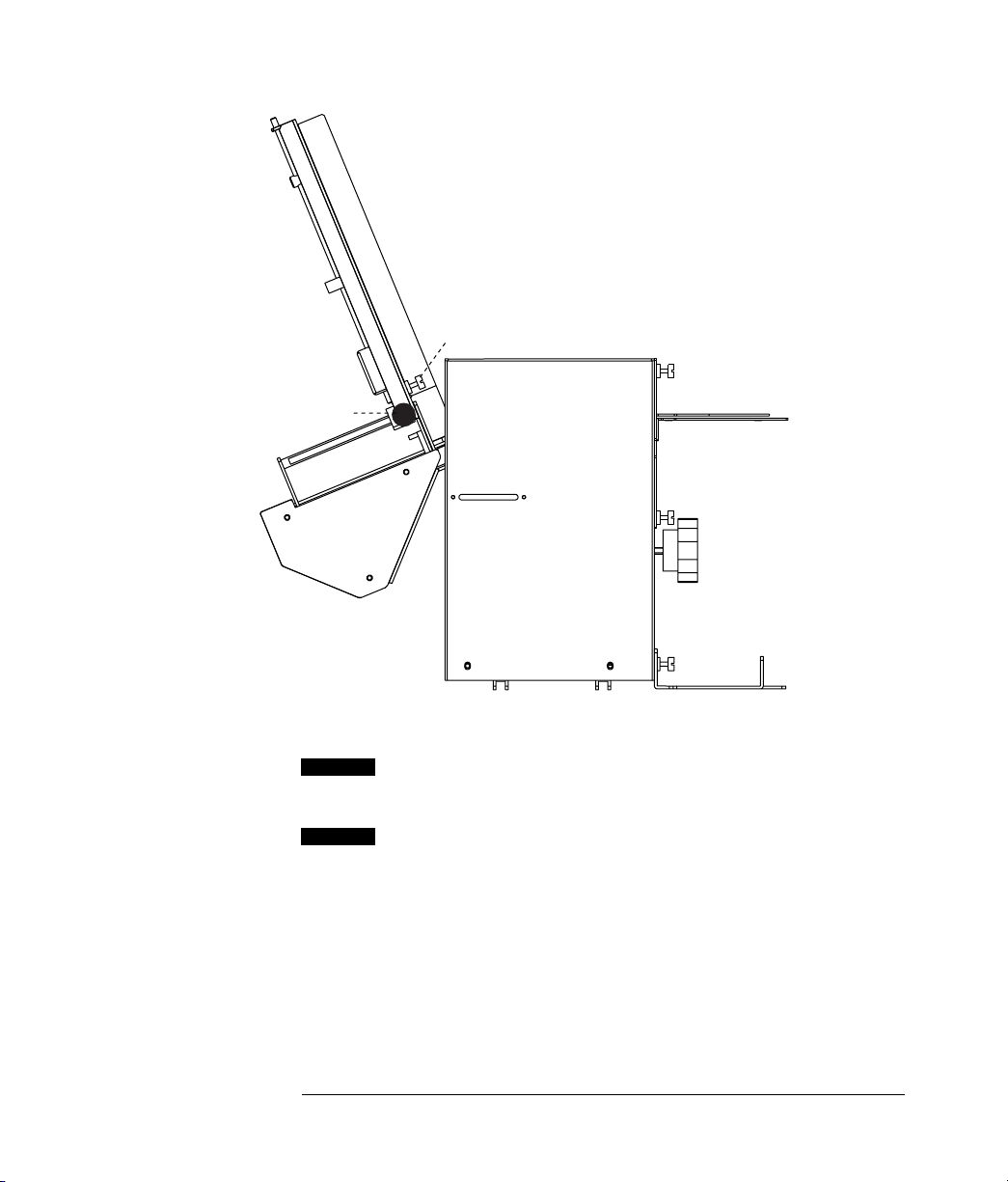

2 Slide the stacking tray onto the two tray adjust-

ment collars on the stacking-tray mounting posts.

Secure the tray by pressing in and tightening the

two thumb screws on the front of the tray.

2

tray securing screw

tray mounting post

tray adjustment collar

tray adjustment knob

tray base

stacking tray

tray securing screw

angle adjustment knob

3 Turn the angle adjustment knob clockwise to lower

the stacking tray.

4 Using the two tray adjustment knobs, adjust the

position of the stacking tray for the cut tag length.

The stacking tray should be positioned so that cut,

stacked tags are stopped at least 5 mm (1/8 inch)

above the cutter-stacker’s belt drive roller. The

objective is to allow each tag to pass under the

previous tag to build a neat stack from the bottom up.

3

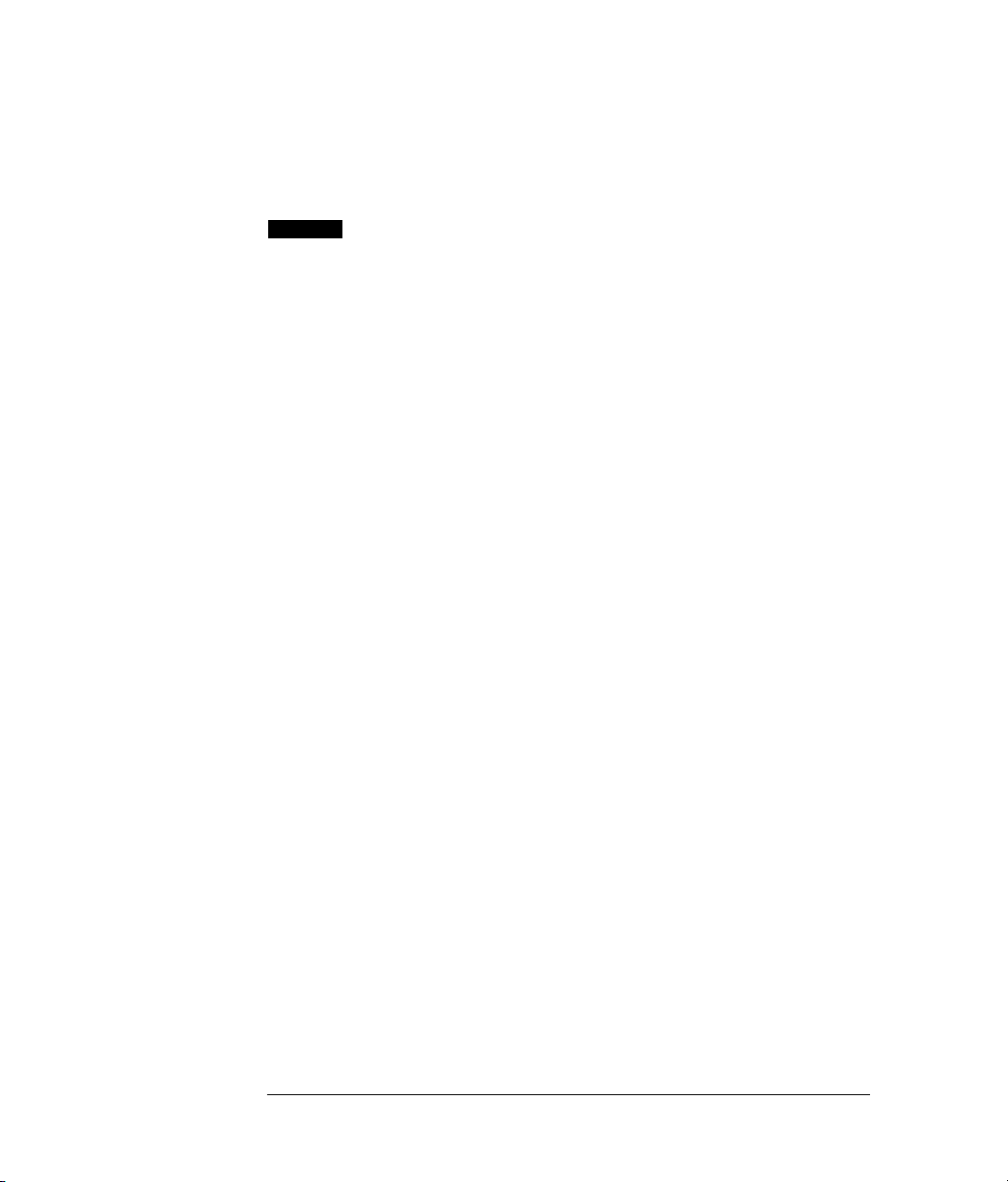

After adjusting the position of the stacking tray,

observe the formation of the stack as tags are

printed and cut. Adjust the angle of the tray for

best performance.

5 Position the adjustable tray guide to help ensure

that accumulating tags form a neatly stacked

column.

Only one of the tray guides is adjustable. It attaches to the tray with a removable wing nut

located behind the width-adjustment slot.

The adjustable guide needs to be positioned so

that the guides are narrower at the top and wider

at the bottom. This will cause the accumulating cut

tags to form a neat stack. How narrow the tray

guides should be at the top and how wide they

should be at the base of the tray is relative to the

width of the tags being cut.

The distance between the tops of the tray guides

should be only slightly wider than the width of the

tags.

4

The distance between the bottoms of the tray

guides should be wider than the tags and slightly

wider than the distance between the tops of the

guides.

tray full switch

Rear of Stacking Tray

wing nut

stacking tray

adjustable

Adjust tray guide with the wing

nut located behind the width-

adjustment slot

fixed guide

guide

Front of Stacking Tray

5

Cutting short tags

If you will be cutting and stacking tags that are 1 inch long or less,

the tags will not stop above the cutter-stacker’s belt drive roller and

the tags will not form a neat stack. To allow the short tags to stack

properly, you should install the Short-Tag Adaptor Plate that was

included with your cutter. This plate will correctly position the tags

for stacking.

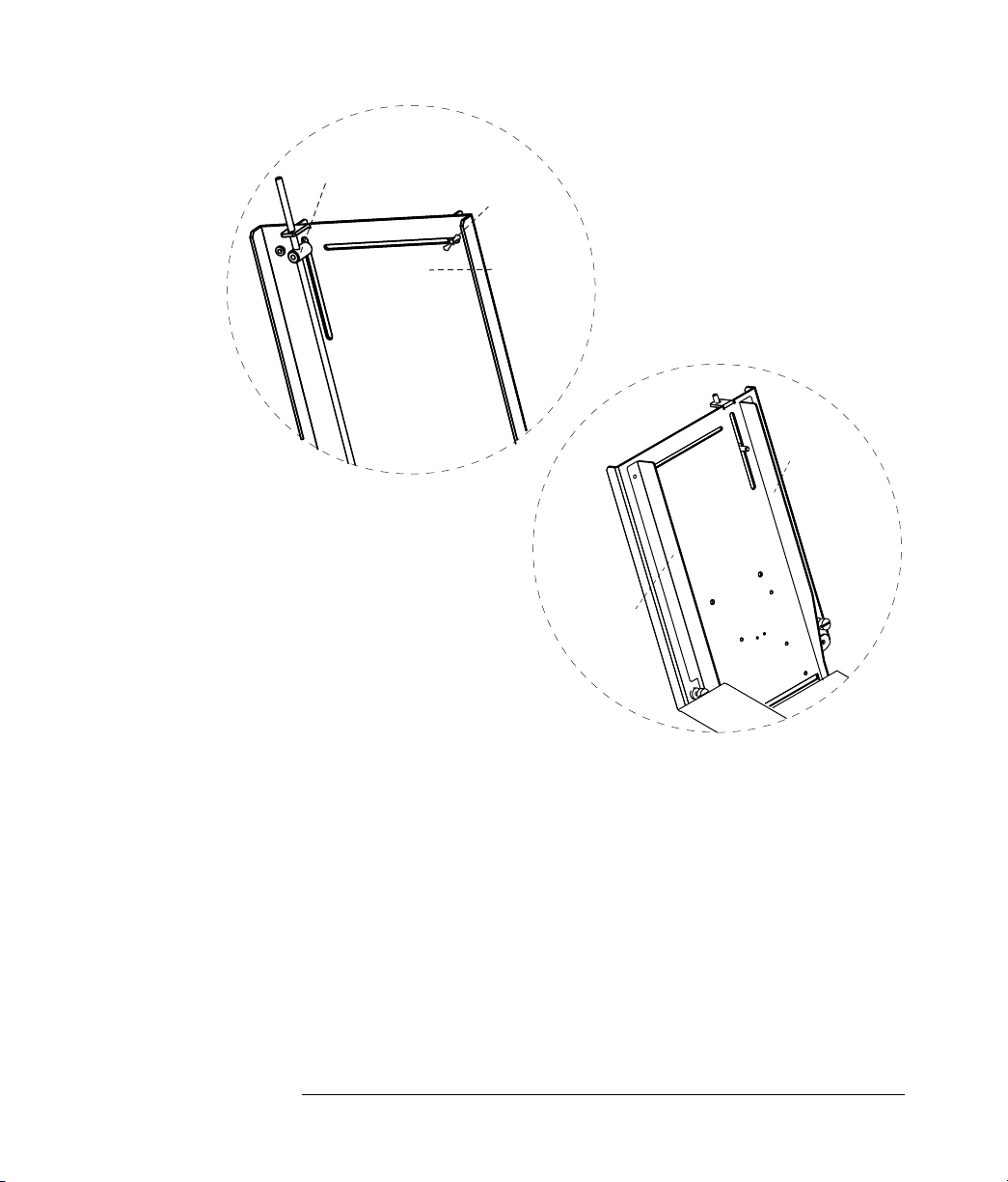

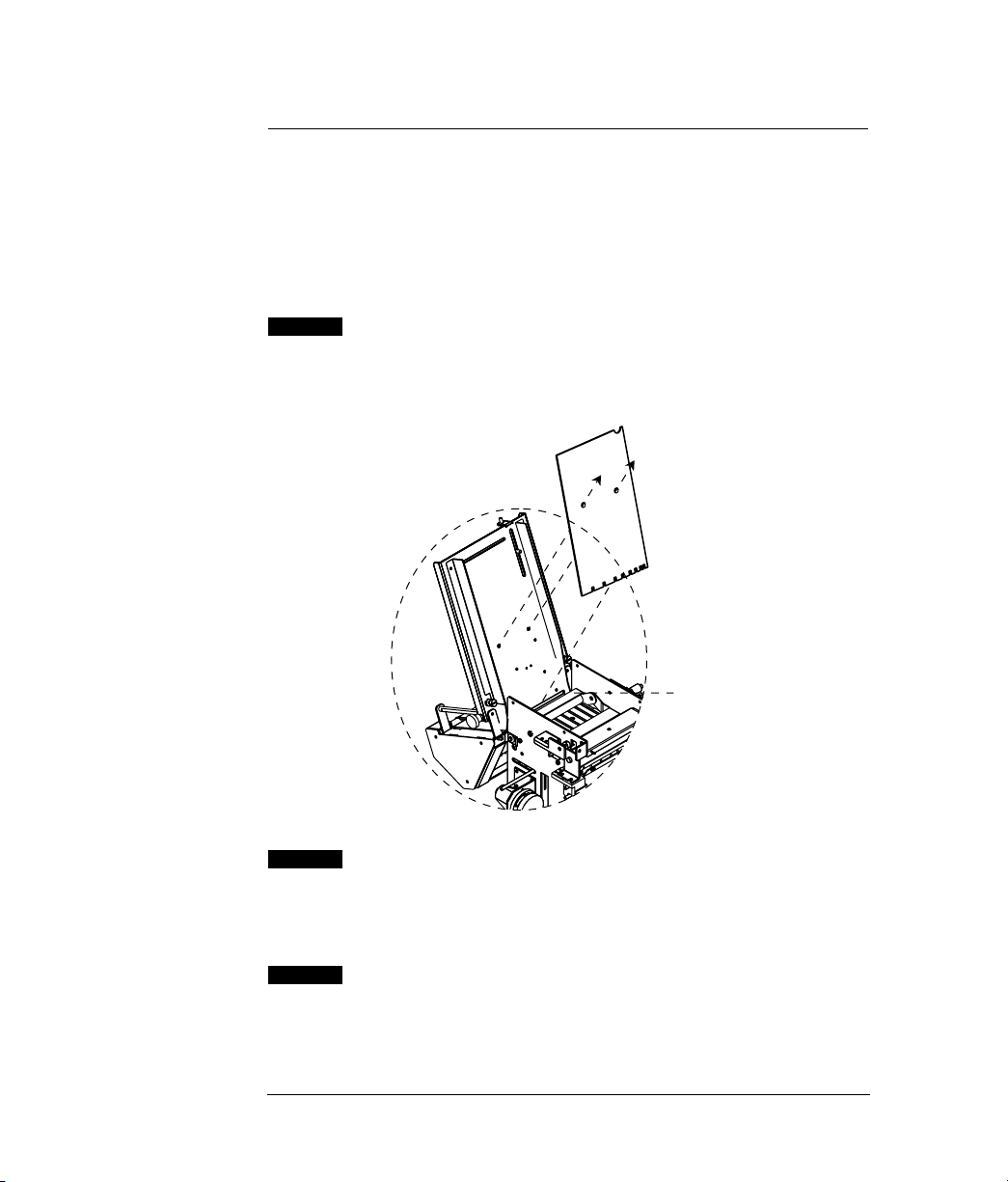

1 Slip the Adaptor Plate onto the front of the stacking

tray, making sure the bottom of the plate rests over

the edge of the white plastic comb-like guide at the

bottom of the stacking tray.

fasten the two screws

into the standoffs in back

6

swing rear guide roller

assembly over front

assembly

2 Align the two standoffs on the plate with the

corresponding holes in the stacking tray. Use a

Phillips screwdriver and two screws to fasten the

Adaptor Plate to the stacking tray from the back.

3 Lift the guide roller assembly nearest the stacking

tray and swing it over the front guide roller assembly.

Loading...

Loading...