Page 1

QUICK FUEL TECHNOLOGY®

Installation Instructions

MARINE SERIES CARBURETORS

! M-650 650 CFM, w/Electric Choke ! M-750 750 CFM, w/Electric Choke

! M-800 800 CFM, w/Electric Choke ! ! M-850 850 CFM, w/Electric Choke

! ! ! ! M-4710 1050 CFM, QFX, 2 Circuit

Please Stop and Read these Instructions before proceeding. If you do not fully

understand the installation and tuning instructions you should seek professional

help. Failure to follow the proper installation and tuning may result in damage or

injury.

Quick Fuel Technology®

129 Dishman Lane

Bowling Green, KY 42101

270-793-0900

www.quickfueltechnology.com

©2012 P/N 99-MSeries

Page 2

Quick Fuel Technology would like to congratulate and thank you for purchasing this carburetor. We feel you have

purchased the finest marine performance carburetor currently on the market. If you need assistance please call the

QFT Sales and Tech Support staff @ 270-793-0900, Monday through Friday 8AM – 5PM central time.

This QFT™ carburetor has been ran on an engine to insure all components are functional. The calibration should be

very close for all adjustments. Different engine combinations could require adjustment of idle mixture, idle speed

and main jets. The fuel level was set with 6 ½ lbs. of fuel pressure. The recommended fuel pressure for this

carburetor is 6 ½ PSI.

Note: This QFT™ carburetor has not been submitted for emission testing, therefore it is not C.A.R.B. (California Air

Resources Board) legal in all 50 states - please check with local authorities regarding the use of this carburetor.

Remove old carburetor:

1. Disconnect negative battery terminal to prevent any accidental arcing in the presence of fuel.

2. Remove air cleaner, PCV hose and any other vacuum lines connected to the carburetor. For future reference identify

the vacuum lines to ensure proper re-connection.

3. Remove fuel line(s)…be careful not to twist fuel line(s) when removing fuel inlet fitting(s), use penetrating oil or similar

chemical to assist in breaking the fuel inlet fitting nut loose. Protect the open ends of the fuel lines, so no foreign

particles can enter.

4. Disconnect electric choke wires if equipped (identify if necessary).

5. Disconnect all linkage and return springs.

6. Remove the 4 hold down nuts and washers (if used).

7. Remove carburetor from intake manifold.

8. Cover intake manifold carburetor flange with a clean rag or towel to prevent any foreign objects from falling into the

engine.

Installation of New Carburetor

1. Set old carburetor and new carburetor side-by-side on work bench.

2. Examine linkage connection (throttle cable [rod] and kickdown cable [if applicable]) transfer to new carburetor in

same location if possible.

3. Install flange gasket over intake manifold studs on intake manifold, then install your new carburetor. Install throttle

cable bracket on driverʼs side rear stud if applicable.

4. Install hold down nuts and washers (if used), tighten in a criss-cross pattern DO NOT TIGHTEN HOLD DOWN NUTS

COMPLETELY.

5. Attach throttle linkage then operate from inside the vehicle to be certain there is no interference of throttle plates,

throttle linkage, accelerator pump arms or fast idle cam lever.

6. If there is no interference or resistance in throttle operation then you can tighten the hold down nuts to their final

torque value, 100 Inch Lbs. (8 Ft. Lbs.). Most intake manifold studs are a fine thread and therefore tightening the

hold down nuts must be tightened in a criss cross pattern and in a number of steps before arriving at the final torque

value. Rapidly tightening the hold down nuts to the final torque spec or over-tightening will cause performance

problems as this process can warp or potentially break the throttle body.

7. Install vacuum hoses. If the PCV was originally attached to the carburetor it should be installed the same way on

your new carburetor. Vacuum connections to the new carburetor as shown below:

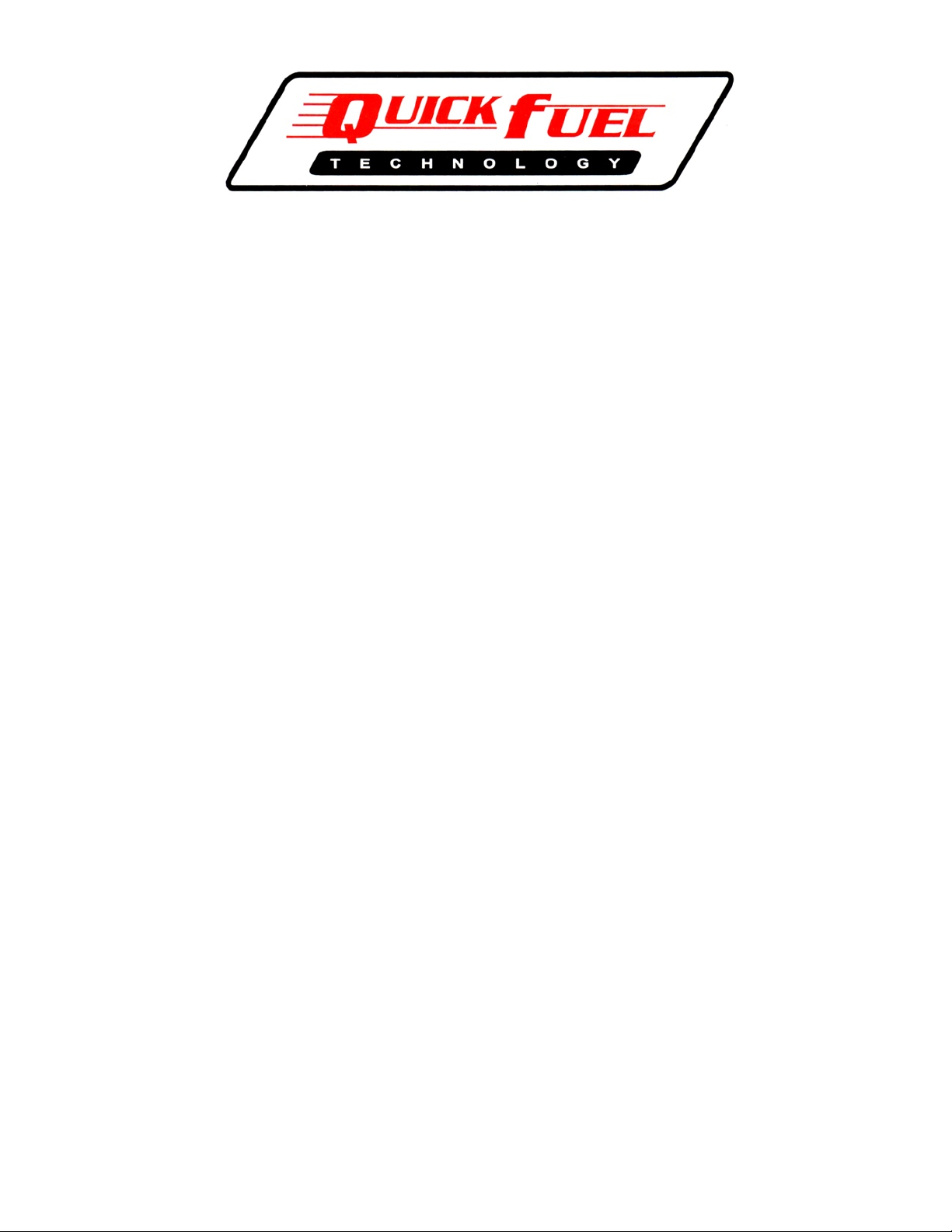

Timed Spark

Port

Distributor vacuum advance may also be connected to the tube in the primary metering block.

Full Manifold

Vacuum

Timed Spark Port PCV (rear of carburetor)

Page 3

" Manifold vacuum is typically used for transmission modular or any accessory

that requires a full manifold vacuum signal, i.e. heat and/or A/C control, vacuum actuated fresh air induction, etc. . The

Ported or timed vacuum is typically used for the vacuum advance canister on the distributor if applicable. NOTE: some

distributor vacuum advance canisters require full manifold vacuum, not ported or timed vacuum.

Check the specifications for your distributor.

8. Install fuel inlet fittings DO NOT USE TEFLON® TAPE ON INVERTED FLARE FUEL INLET FITTINGS. Clean

threads and flare of any dirt and debris before installation. Check to be certain the fuel inlet fittings in the fuel bowl

are tight, then install the fuel line nuts. Tighten sufficiently to prevent fuel leakage.

9. Connect positive (+) wire for electric choke to an key on 12 volt voltage source. DO NOT CONNECT TO THE

BATTERY SIDE OF THE IGNITION COIL. Preferably check voltage with a volt meter to determine the correct

voltage. NOTE: battery voltage will be 12 volts or greater. You need to recheck the voltage reading when the engine

is running to be certain the voltage does not drop below 12.6 volts. (Some engines use a field wire from the

alternator that only produces 9.5 volts which does not allow the choke to operate properly.)

(-) Grounded to carburetor

(+) Ignition activated 12V source

Starting the Engine

1. Reattach the negative battery cable, you are now ready to start the engine.

2. You are now ready to start the engine.

3. Before attempting to start; the fuel bowls need to be filled with fuel. Whether you have an electric fuel pump or a

mechanical pump, it is necessary to operate the fuel pump for 15 seconds or so, a couple of 10 second cranks for

mechanical pumps, to enable the bowls to fill with fuel.

4. Before starting the engine make an initial check of the float level. If fuel is not visible in the sight glass. This

carburetor was pre-set at the factory to be in the middle of the sight glass at 6.5 P.S.I. Fuel pressure greater than 6.5

P.S.I. will cause the float level to be too high. Conversely, if the fuel pressure is significantly below 6.5 P.S.I. the float

level will be too low. For the carburetor to operate correctly the float levels must be in the middle of the sight glass.

The most accurate way to establish the correct float level is to check it while the engine is running. If the initial float

level is not visible in the sight glass then it might be necessary to re-adjust the float level before starting the engine.

Raise or Lower Float with a 5/8” wrench

Set fuel level in middle of window with engine running at

idle speed with proper fuel pressure

(note the arrows in the casting)

DO NOT ADJUST WITH ENGINE RUNNING

5. With the float level verified and correct, rotate the throttle to wide open twice. If the temperature is below 72 degrees,

the choke will close and the accelerator pump nozzles should discharge fuel. You can now start the engine.

6. It should not be necessary to continue operating the throttle while attempting to start the engine. If it does not start on

the first attempt, rotate the throttle a couple of additional times, then try starting the engine again.

7. If the engine still will not start, try holding the throttle open slightly while starting in the event to much fuel entered the

engine while operating the throttle or the idle speed might be too low for your application.

Page 4

8. Let it idle for approximately 5 minutes. The choke should open on its own during this time and be fully open (vertical

position) after approximately 3 minutes (will vary with outside temperature).

9. If possible using a manifold vacuum gage, set the idle mixture screws to attain the highest manifold vacuum reading

at idle. It is not necessary to keep all four mixture screws at exactly the same number of turns from seated, but they

should be close to the same number of turns. Make adjustments in small increments of ¼ turn per adjustment. See

how the engine responds then adjust the mixture screws to smooth out the idle. Turning in one mixture screw could

not have any noticeable effect, if the other three mixture screws are out too far. The mixture screws should be

adjusted in conjunction with each other to achieve the proper mixture. When engineʼs RPM increases during the

adjustment process, adjust it back down to the desired rpm and continue mixture screw adjustment until the engine

RPM or vacuum drops. When the engine RPM or vacuum drop, the idle mixture is too lean and the mixture screws

will need to be backed out to the highest vacuum or RPM.

10. Turning the mixture screws in (clockwise) leans the mixture, turning the mixture screws out (counter-clockwise)

richens the mixture.

11. After you have attained the highest manifold vacuum (or best idle quality), shift the transmission into gear. This will

create a load on the engine and may change the idle characteristics. With performance camshafts with longer

duration it is often necessary to add a little more fuel because the engine is not as efficient and therefore must be

over fueled slightly to keep the engine from laboring when a load is placed on the engine such as shifting the

transmission into gear.

12. You are now ready to drive the vehicle. It may require some minor adjustments with the mixture screws and idle

speed but the engine should drive smoothly and have good throttle response.

13. Once you are satisfied with the general drivability, determine how well the engine runs while holding a steady RPM.

Generally any RPM above 2,000 RPM the carburetor is operating off the main metering system. The air fuel ratio in

this system is usually controlled by the main metering jets. If the engine surges while driving at a steady RPM on flat

ground then the mixture is probably too lean and the main jets need to be increased in size. If the engine labors and

has difficulty holding a steady speed without opening the throttle more, then the mixture is probably too rich.

Ultimately, you should look at the spark plug color after one (1) hour of runtime to help determine the general air/fuel

mixture the carburetor is delivering and the engine is operating. White plug color indicates a lean mixture, dark gray

or black indicates a rich mixture.

This carburetor has been calibrated to operate on a broad cross-section of engine combinations. While it is not

possible for a single calibration to work virtually every conceivable application it should work on most engines and it

will not be necessary to make any additional adjustments and/or tuning. Should it be necessary to alter the fuel

curve in our Hot Rod Series there is plenty of tuning capability available with changeable air bleeds, power valve

channel restrictions, and idle feed restrictions.

Adjustments & Tuning

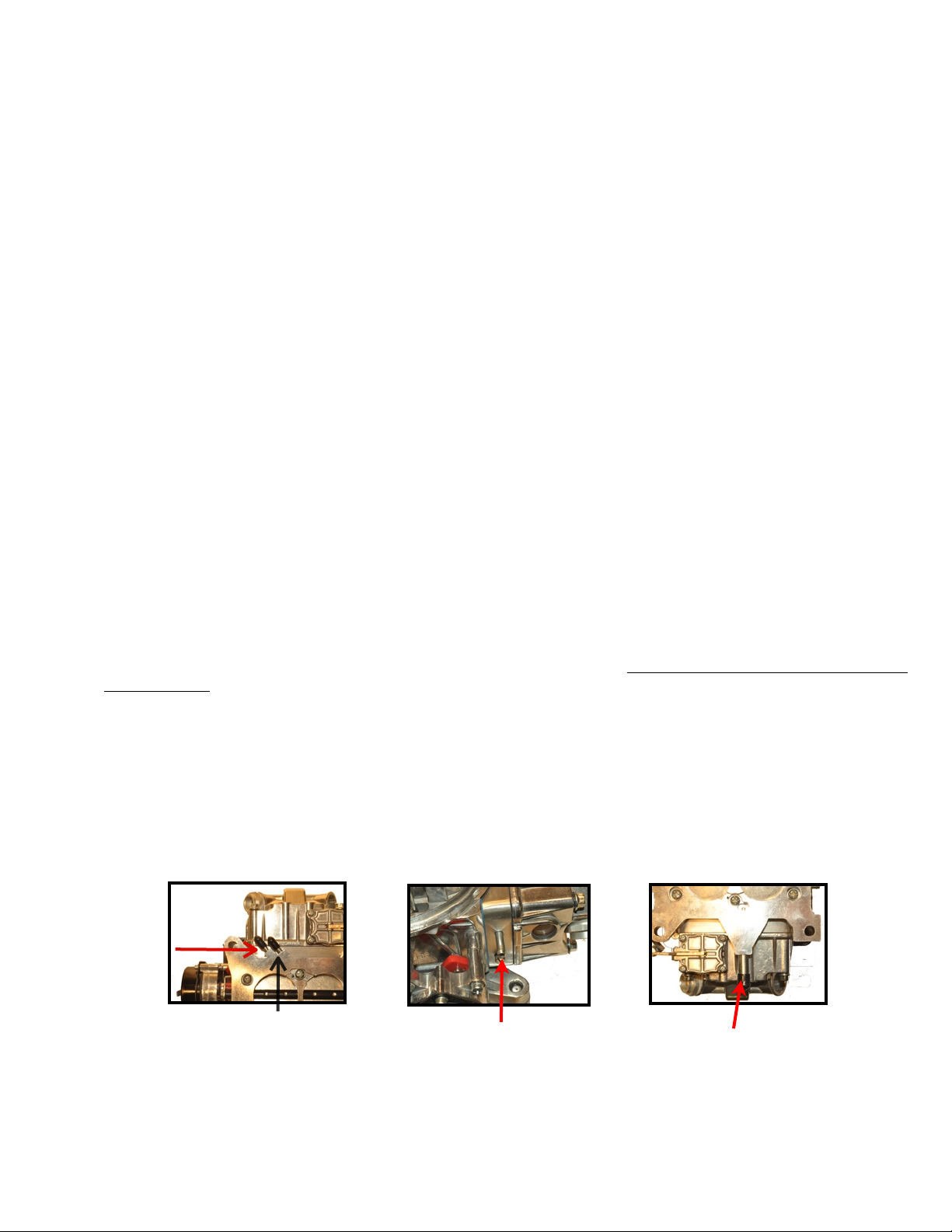

Choke Adjustments - Choke Indexing

The electric choke cap is adjustable for varying conditions and personal preference should you desire. The normal choke

setting is for the choke plate to just barely close at 72 degrees Fahrenheit. Loosening the three screws securing electric

choke spring will allow the choke cap to rotate. Rotating the choke cap clockwise reduces the choke effect (lean) whereas

rotating the choke cap counter-clockwise increases the choke effect (rich).

Clockwise Rotation Leans Choke (closes higher temperature, opens faster)

Rotate to

adjust

Loosen three screws

that secure cap

!!

Clockwise rotation reduces temperature for choke to close and shortens the time for the choke plate to completely open. Full

clockwise rotation the choke will never close. Counter-clockwise rotation raises the temperature for the choke to close and

lengthen the time the choke plate is closed, so it will take longer for the choke plate to open to full vertical position.

Loading...

Loading...