Page 1

Quantum SuperLoader 3

Rail Installation and Rack

Mounting Instructions

Rail Installation and Rack Mounting Instructions 3

General Preparation for Rack Mounting................................................................4

Stationary Rack Mount Installation ........................................................................4

Installing and Removing the Optional V-Rail Kit 9

Requirements .............................................................................................................9

Accessory Pieces ......................................................................................................11

Installation in a .375 Square Hole Rack ................................................................11

Installation in a .280 Diameter Thru-Hole Rack..................................................12

Installation in a 10-32 Threaded Hole Rack.........................................................13

Chassis-Mounted Rails ...........................................................................................14

Document 81-81316-01, B01, October 2005 1

Page 2

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01, B01

October 2005

Made in the USA.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or implied, including but not limited

to the implied warranties of merchantability or fitness for a particular purpose. Quantum Corporation may revise this publication from

time to time without notice.

COPYRIGHT STATEMENT

© Copyright 2005 by Quantum Corporation. All rights reserved.

Your right to copy this document is limited by copyright law. Making copies or adaptations without prior written authorization of

Quantum Corporation is prohibited by law and constitutes a punishable violation of the law.

TRADEMARK STATEMENT

Quantum, the Quantum logo, and SuperLoader are trademarks of Quantum Corporation, registered in the U.S.A. and other countries.

DLTtape and Super DLTtape are registered trademarks of Quantum Corporation. Products mentioned herein are for identification

purposes only and may be trademarks or registered trademarks of their respective companies.

2

Page 3

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Rail Installation and Rack Mounting Instructions 0

The autoloader can be rack mounted in two ways:

• Attached directly to the cabinet rails (stationary)

• Attached to an optional V-Rail kit

Both installations are included in this manual.

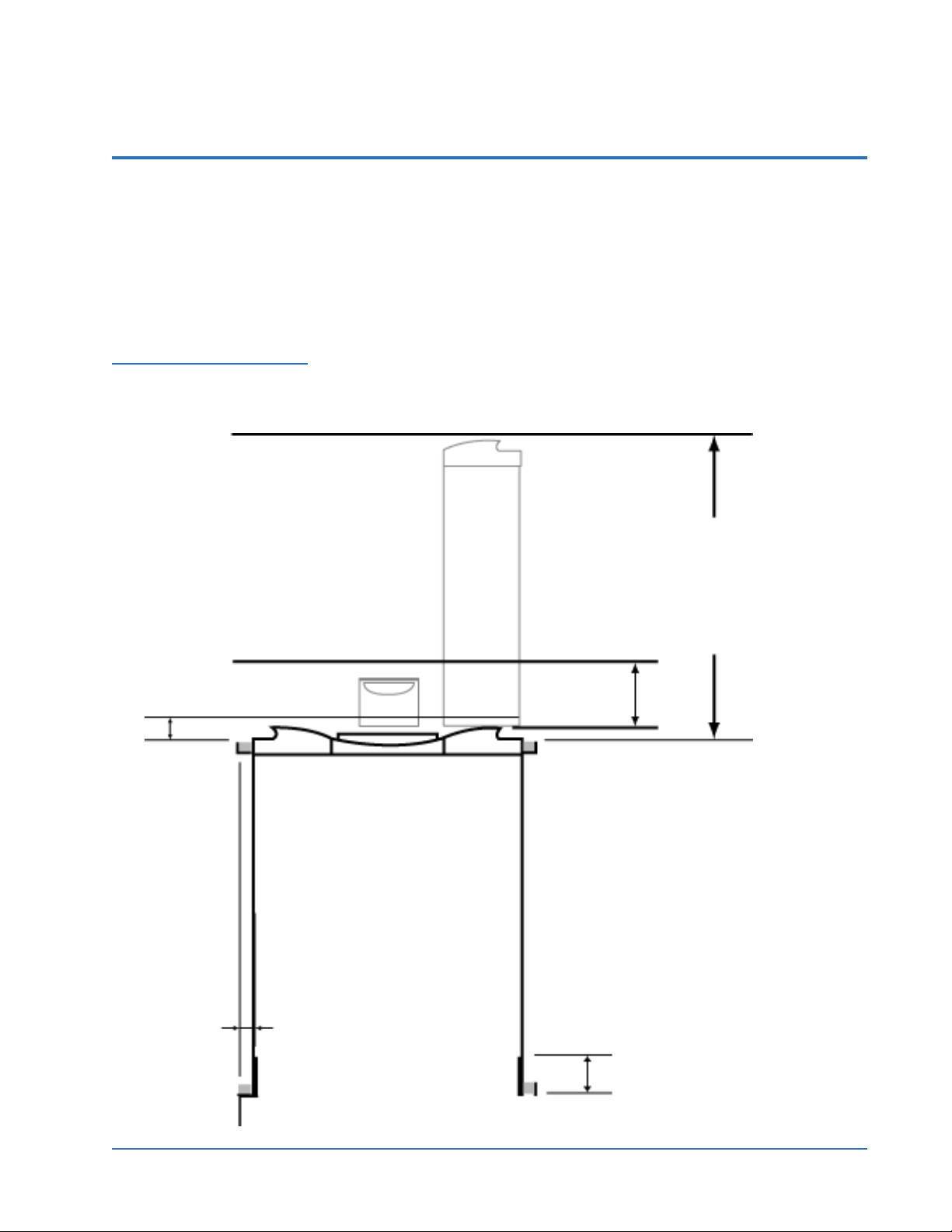

Figure 1 Clearance

Requirements for Rack

Mounting

Clearance to door inside a rack

2.0” [51 mm]

Minimum side

clearance (both

sides)

1.0” [25 mm]

Minimum clearance to load

or unload a magazine from

the system

27.0” [686 mm]

Minimum clearance to load

a tape via the mailslot

6.0” [152 mm]

FRONT

Minimum clearance

between the rear of the

SuperLoader and the

inside of the rack (using

standard mounting

brackets adjusted to their

closest setting)

REAR

3.4” [86 mm]

Rail Installation and Rack Mounting Instructions 3

Page 4

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

General Preparation for Rack Mounting

Take the following general safety steps before beginning either rack mount

0

installation.

1 Lower the cabinet feet.

2 Extend the cabinet anti-tip device, if available.

An anti-tip device may be extendable legs or similar equipment used to

stabilize the cabinet. This ant-tip equipment is to help avoid overbalancing the cabinet when installing or removing equipment.

3 Ensure that the cabinet and all rack mounted equipment have a reliable

ground connection.

4 Verify that the total current of all rack mounted components (including

the SuperLoader) will not exceed the current rating of the power

distribution unit or outlet receptacles.

5 Secure the help of at least one other person. At least two people are

required to safely install the SuperLoader into a rack cabinet.

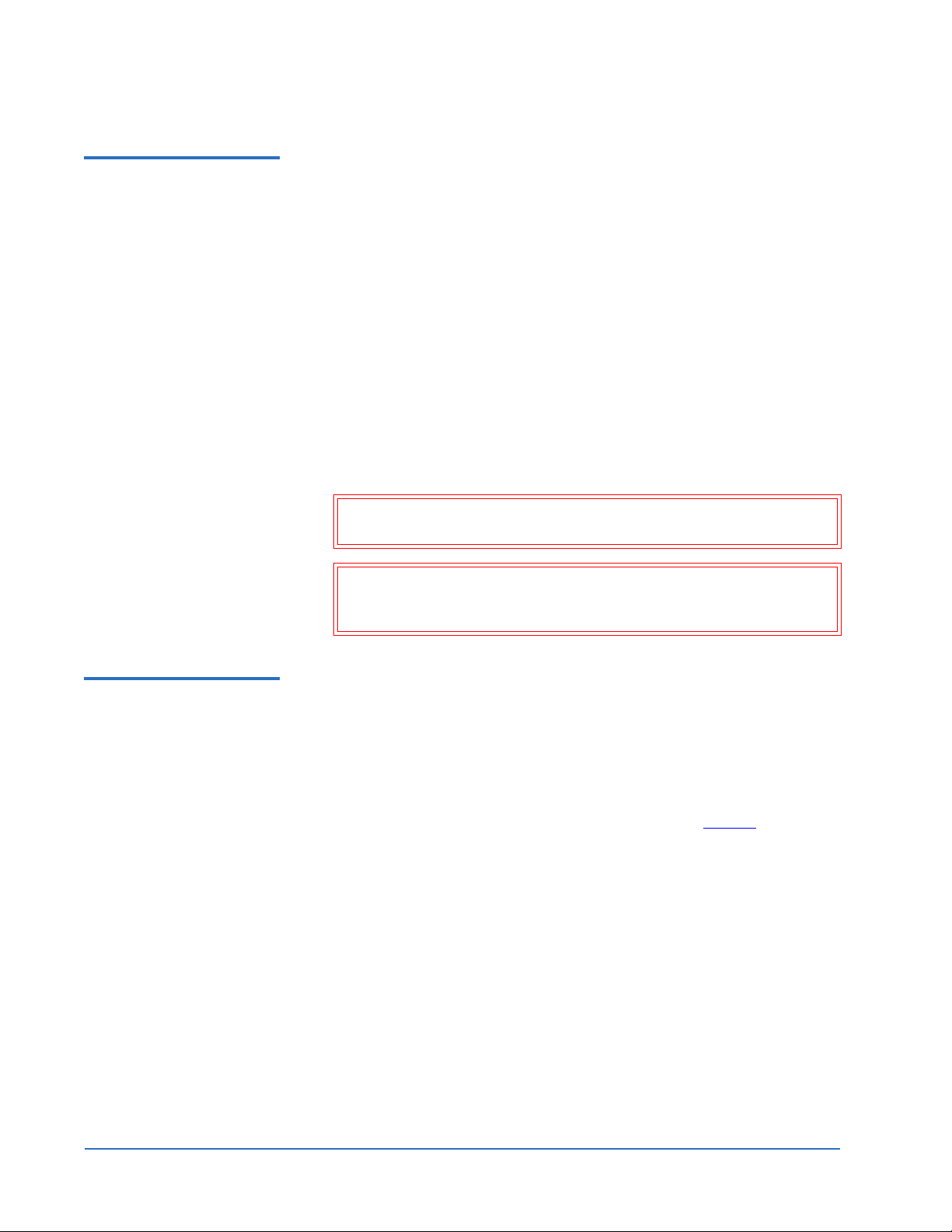

Warning: Failure to take these safety steps may result in personal

injury or equipment damage.

Caution: Do not remove the top cover of the autoloader during the

installation process. Removing the top cover could result

in damage to the autoloader.

Stationary Rack Mount Installation

This section describes the steps for attaching the autoloader directly to the

0

rails of a rack.

1 Make sure you have the following tools and parts:

• #2 PHILLIPS

®

screwdriver

• Level

• The following autoloader accessory kit parts (see figure 2

):

• Four autoloader brackets (two long and two short to

accommodate different rack depths)

• Use the short autoloader brackets (74-60604-03) unless the

distance from the front mounting rail to the rear mounting rail is

less than 30.25 in. (76.84 cm).

• Two support brackets (74-60605-01)

• Eight 10-32 x 1/4 inch button head screws for the support

brackets (four per support bracket)

• The following parts shipped with the rack:

• Eight clip nuts

•Eight screws

4 Rail Installation and Rack Mounting Instructions

Page 5

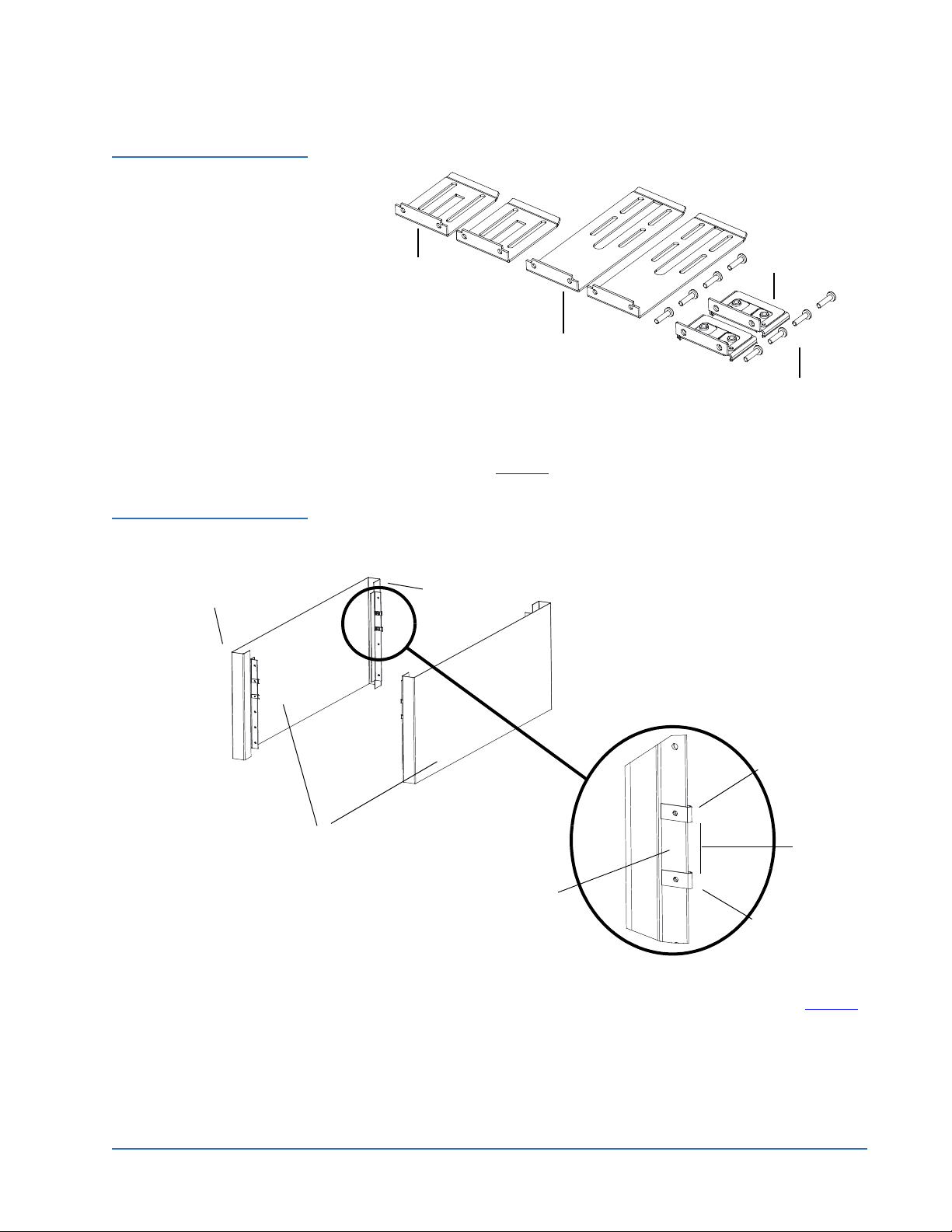

Figure 2 Required Parts

for Installation

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Support brackets

Short autoloader

brackets (74-60604-03)

Long autoloader

brackets (74-60604-01)

Support bracket screws

(74-60605-01)

2 Install two clip nuts, 1.75 in. (44.45 mm) apart, onto each of the four rails

of the rack, making sure that you install each pair of clip nuts at exactly

the same level (see figure 3

).

Figure 3 Installing Two

Clip Nuts

Rail

Outer covers

of the rack

Rail

Clip nut

1.75 in

(44.45 mm)

Rail

Clip nut

3 Select the long or short autoloader brackets (depending on the depth of

the rack), and then attach them to the rear of the autoloader (see figure 4

Rail Installation and Rack Mounting Instructions 5

).

Page 6

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Figure 4 Attaching

Autoloader Brackets

Autoloader

Screws (10-32 x 1/4 only)

Autoloader bracket

4 Using rack screws, attach a support bracket to the clip nuts on each rear

rail (see figure 5

.)

Note: Be sure to attach the support brackets correctly; the side of the

bracket with only two holes should be secured to the rail.

Tighten the screws just enough to hold the support brackets firmly

against the rail while still allowing the support bracket to be slightly

shifted by hand. This shifting will help facilitate the engagement of

autoloader brackets as the autoloader is installed in the rack. You will

fully tighten the screws in step 8

.

6 Rail Installation and Rack Mounting Instructions

Page 7

Figure 5 Attaching Support

Brackets

Outer cover of rack

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Support bracket

Clip nuts

Rack

screws

Rear rail in rack

Figure 6 Sliding

Autoloader into Rack

5 With the help of a second installer, insert the autoloader into the rack so

that the autoloader brackets slide into corresponding support brackets on

the rear rails and the tabs at the front of the autoloader align flush with

the clip nuts on the front rails (see figure 6

).

Caution: Do not release the front end of the autoloader until it can

be secured to the rack.

Autoloader bracket

Support bracket

Rail Installation and Rack Mounting Instructions 7

Page 8

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

6 While the other installer holds the front end of the autoloader, secure the

autoloader in the rack by doing the following:

a Secure the front end of the autoloader to the rack using four rack

screws (two per tab) as shown in figure 7

enough to secure the autoloader to the front rails.

Figure 7 Front Alignment

Front rail

Rack

screws

Tab (one

per side)

. Tighten the screws just

Autoloader (front)

Figure 8 Connecting

Support Brackets

b Install four screws (two per side) to secure the support brackets to the

autoloader brackets (see figure 8

Screws

).

Support bracket

Autoloader

bracket

7 Verify that the autoloader is level. Adjust as needed.

8 When the autoloader is level, tighten all screws securing the autoloader to

the rack. This includes the following:

• Four screws securing the autoloader tabs to the front rails.

• Four screws securing the support brackets to the rear rails.

• Four screws securing the autoloader brackets to the support brackets.

8 Rail Installation and Rack Mounting Instructions

Page 9

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Installing and Removing the Optional V-Rail Kit 0

The V-Rail is a set of rails, plates, and mounting hardware to use as a

stationary mounting unit allowing the autoloader to be contained within a

rack. This is not a slide rail kit, but allows some movement from the rack

cabinet for easier access or removal or the autoloader.

Requirements 0 The V-Rail can be used in many rack cabinet structures.

Front to rear rail spacing range is 25.75 – 34.50 inches (654.05 – 876.30 mm).

This range accommodates varying cabinet depths. The vertical rail thickness

is either 0.080 inch (2.03 mm) or .105 inch (7.14 mm).

Figure 9 Left Rail

Assembly

Vertical Rail Hole Types

The V-Rail can be used with the following rack hole types:

• .375 inch (9.53 mm) square through-holes

• .281 inch (7.14 mm) diameter through-holes

• 10-32 UNF-2B threaded holes

• M6–1-6H threaded holes

0

Installing and Removing the Optional V-Rail Kit 9

Page 10

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Figure 10 Right Rail

Assembly

Figure 11 Front Mount

Features

Figure 12 Rear Mount

Features

10 Installing and Removing the Optional V-Rail Kit

Page 11

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Accessory Pieces 0 Besides the rail parts themselves, there are two plates included with the rail

kit. These plates are used for various rack mountings. The front cover plate is

used on all rack rails. The 10-32 inside nut plate is used on the .375 inch

square rail, the .280 diameter rail, and the M6 rails.

Figure 13 Front Cover

Plate and 10-32 Nut Plates

Installation in a .375 Square Hole Rack

Front cover plate used

on all rack rails

10-32 inside nut plate used on

.375 square hole rail and .280

and M6 rails

To install the rail in a .375 square hole rack:

0

1 Identify the correct mounting holes on the vertical rail, making sure that

the selected holes are on the same level.

Installing and Removing the Optional V-Rail Kit 11

Page 12

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Figure 14 .375 Square

Hole Rack Installation

Installation in a .280 Diameter Thru-Hole Rack

2 Mount the front cover plate to the vertical rail in the identified holes by

using 10-32 x .625 bolts in the center two holes of the plate.

3 Mount the tab of the autoloader to the upper and lower holes in the front

cover plate using 10-32 x .625 bolts.

To install the rail in a .280 diameter thru-hole rack:

0

1 Identify the correct mounting holes on the vertical rail, making sure that

the selected holes are on the same level.

12 Installing and Removing the Optional V-Rail Kit

Page 13

Figure 15 .280 Diameter

Thru-Hole Rack Installation

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Installation in a 10-32 Threaded Hole Rack

2 Mount the front cover plate to the vertical rail in the identified holes by

using M6 (.200”) threaded bolts in the center two holes of the plate.

Note: The upper and lower tabs of the inside plate will not enter the

holes of the rack. They will deform when secured.

3 Mount the side tab of the autoloader to the upper and lower holes in the

front cover plate using M6 (.200”) threaded bolts.

To install the rail in a 10-32 threaded hole rack:

0

1 Identify the correct mounting holes on the vertical rail, making sure that

the selected holes are on the same level.

Installing and Removing the Optional V-Rail Kit 13

Page 14

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Figure 16 10-32 Threaded

Hole Rack Installation

Chassis-Mounted Rails

2 Mount the front cover plate to the vertical rail in the identified holes by

using 10-32 x .625 bolts in the center two holes of the plate.

3 Mount the tab of the autoloader to the upper and lower holes in the front

cover plate using 10-32 x .625 bolts.

The following illustrations show various views of the chassis-mounted rail

0

system.

14 Installing and Removing the Optional V-Rail Kit

Page 15

Figure 17 Chassis Rail

Parts

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Figure 18 Rail Installed on

Chassis

Installing and Removing the Optional V-Rail Kit 15

Page 16

Quantum SuperLoader 3 Rail Installation and Rack Mounting Instructions

Document 81-81316-01 B01

October 2005

Figure 19 Close up of

Chassis Rail

16 Installing and Removing the Optional V-Rail Kit

Loading...

Loading...