Page 1

3URGXFW0DQXDO 3URGXFW0DQXDO3URGXFW0DQXDO 3URGXFW0DQXDO

'/767DSH'ULYH

'/767DSH'ULYH

'/76

$

Page 2

DLT-S4 Product Manual, 81-81278-01 A01, July 2006, Made in USA.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or

implied, including but not limited to the implied warranties of merchantability or fitness for a particular

purpose. Quantum Corporation may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2006 by Quantum Corporation. All rights reserved.

Your right to copy this document is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

Quantum, the Quantum logo, DLT, DLTtape, and the DLTtape logo are registered trademarks of Quantum

Corporation in the U.S. and other countries. The DLT logo, GoVault, DLTSage, and SuperLoader are

trademarks of Quantum Corporation.

All other trademarks are the property of their respective owners.

Page 3

Contents

Preface xiii

Chapter 1 Product Overview 1

Storage Capacity and Transfer Rates.............................................................................2

Tape Drive Models........................................................................................................... 2

Tape Drive Features.........................................................................................................4

Maximum Data Transfer Rate ........................................................................................ 5

Functional Specifications.................................................................................................6

Tape Drive Technology ...................................................................................................7

Tape Drive Components ................................................................................................. 8

Interface Types................................................................................................................ 11

Host Interface........................................................................................................... 11

Physical Characteristics.......................................................................................... 12

Chapter 2 Before You Begin 13

Warranty Note ................................................................................................................ 14

Safety Precautions ..........................................................................................................14

Tape Drive Handling and Storage Guidelines...........................................................15

Electrostatic Discharge Protection ............................................................................... 16

Pre-Installation Guidelines ........................................................................................... 17

DLT-S4 Product Manual iii

Page 4

Contents

Chapter 3 Cartridges 19

Choosing Compatible Cartridges ................................................................................ 19

Using Unsupported Cartridges.................................................................................... 21

Backward-read Compatibility Transfer Rate ............................................................. 22

Cartridge Handling and Storage Guidelines..............................................................23

Inspecting a Cartridge ...................................................................................................25

Write-protecting a Cartridge ........................................................................................ 29

Loading a Cartridge.......................................................................................................32

Unloading a Cartridge................................................................................................... 33

DLTSage WORM............................................................................................................34

DLTSage WORM Features.....................................................................................34

Formatting a Cartridge as DLTSage WORM ...................................................... 35

Chapter 4 Specifications 37

Physical Specifications................................................................................................... 38

Dimensions and Weights .............................................................................................. 39

Electromagnetic Field Specifications........................................................................... 40

Electromagnetic Emissions ....................................................................................40

Electromagnetic Interference and Immunity ...................................................... 41

Acoustic Noise Emissions .............................................................................................42

Chapter 5 Common Interface Information 43

SCSI Command Timeout...............................................................................................44

Rear Panel Connectors...................................................................................................46

Power Connector Pin Assignments...................................................................... 46

Loader/Library Interface Connector....................................................................46

Chapter 6 Parallel SCSI Interface 48

Rear Panel Connectors...................................................................................................49

SCSI Cable Connectors .................................................................................................. 49

SCSI Tape Drive Features..............................................................................................50

SCSI Stub and Cable Lengths ....................................................................................... 50

SCSI Connectors and Pin Assignments....................................................................... 51

DLT-S4 Product Manual iv

Page 5

Contents

Chapter 7 Fibre Channel Interface 55

Rear Panel Connectors...................................................................................................56

Fibre Channel Cable Connector ................................................................................... 56

Fibre Channel Tape Drive Features............................................................................. 57

Practical Considerations................................................................................................ 58

Hot-Swappable Cables ........................................................................................... 58

Power Usage ............................................................................................................58

Power Cycle (Tape Drive On) ............................................................................... 58

Failure to Obtain a Loop Address ........................................................................58

Fibre Channel Speed and Topology ............................................................................ 59

World-wide Names........................................................................................................ 61

Chapter 8 Serial Attached SCSI (SAS) Interface 62

Rear Panel Connectors...................................................................................................63

SAS Cable Connector.....................................................................................................64

SAS Tape Drive Features...............................................................................................64

Practical Considerations................................................................................................ 64

SAS Tape Drive Speed...................................................................................................65

World-wide Names........................................................................................................ 65

Chapter 9 Installing an Internal SCSI Tape Drive 66

Equipment Required...................................................................................................... 67

Installation Steps ............................................................................................................ 67

Rear Panel Connectors...................................................................................................68

Unpacking the Tape Drive............................................................................................69

Setting the SCSI ID ......................................................................................................... 69

Securing the Tape Drive in the System .......................................................................71

Connecting the Cables and Terminating the SCSI Bus.............................................74

Setting TERMPWR......................................................................................................... 77

Confirming the Installation...........................................................................................78

Adding an Additional Device ...................................................................................... 78

Using the Loader/Library Interface Connector......................................................... 79

DLT-S4 Product Manual v

Page 6

Contents

Chapter 10 Installing an Internal Fibre Channel Tape Drive 80

Equipment Required...................................................................................................... 81

Installation Steps ............................................................................................................ 81

Rear Panel Connectors...................................................................................................82

Unpacking the Tape Drive............................................................................................83

Securing the Tape Drive in the System .......................................................................83

Connecting the Cables................................................................................................... 86

Confirming the Installation........................................................................................... 87

Adding Additional Devices..........................................................................................88

Using the Loader/Library Interface Connector......................................................... 88

Chapter 11 Installing an Internal SAS Tape Drive 89

Equipment Required...................................................................................................... 90

Installation Steps ............................................................................................................ 90

Rear Panel Connectors...................................................................................................91

Unpacking the Tape Drive............................................................................................92

Securing the Tape Drive in the System .......................................................................92

Connecting the Cables................................................................................................... 95

Confirming the Installation........................................................................................... 96

Adding Additional Devices..........................................................................................97

Using the Loader/Library Interface Connector......................................................... 97

Chapter 12 Installing the Tabletop Tape Drive 98

Equipment Required...................................................................................................... 99

Installation Steps ............................................................................................................ 99

Rear Panel Connectors.................................................................................................100

Unpacking the Tabletop Tape Drive ......................................................................... 101

Selecting a Location for the Tabletop Tape Drive.................................................... 101

Setting the SCSI ID ....................................................................................................... 102

Connecting the Tape Drive to the Host Computer and Terminating the SCSI Bus.

103

Connecting the AC Power Cable ............................................................................... 105

Confirming the Installation.........................................................................................107

Adding an Additional Device .................................................................................... 107

Configuring the Tape Drive........................................................................................ 109

Using TERMPWR......................................................................................................... 109

DLT-S4 Product Manual vi

Page 7

Contents

Chapter 13 Using the Tape Drive 110

Front Panel Controls and LEDs.................................................................................. 111

Left LED.................................................................................................................. 111

Front Panel Controls.............................................................................................112

Power-On Self-Test ...................................................................................................... 113

Performing a Trial Backup.......................................................................................... 115

Firmware Update via the Host Interface ..................................................................116

Updating Firmware Using the Host Interface .................................................. 116

Creating a CUP/FUP Cartridge From Which to Update Firmware.............. 116

Firmware Update via the Library Tape Drive Interface.........................................118

Cleaning the Tape Drive.............................................................................................. 119

When to Clean the Tape Drive............................................................................ 119

Which Cleaning Cartridge to Use....................................................................... 119

Cleaning Cartridge Life Expectancy...................................................................120

Cleaning Cartridge Compatibility...................................................................... 120

Cleaning Instructions............................................................................................120

Cycle Time for Cleaning Cartridge..................................................................... 121

Optimizing Tape Drive Performance........................................................................ 121

Chapter 14 Troubleshooting 1 23

General Troubleshooting............................................................................................. 123

POST and SCSI Troubleshooting ...............................................................................124

Over Temperature Condition..................................................................................... 128

Chapter 15 Preparing the Tape Drive for Shipping 129

Appendix A Diagnostic Tools 131

Accessing the Tools......................................................................................................132

Device Drivers ..............................................................................................................132

TapeAlert.......................................................................................................................133

Medium Auxiliary Memory........................................................................................ 133

DLTSage.........................................................................................................................134

xTalk Management Console ....................................................................................... 135

DLTSage Dashboard and DLTSage Tape Security..................................................136

DLT-S4 Product Manual vii

Page 8

Contents

Appendix B Environmental Compliance 137

WEEE and RoHS Compliance.................................................................................... 137

Disposal of Electrical and Electronic Equipment .................................................... 138

Appendix C Regulatory Statements 139

Glossary 144

Index 153

DLT-S4 Product Manual viii

Page 9

Figures

Figure 1 Internal Tape Drive..................................................................................... 3

Figure 2 Tabletop Tape Drive...................................................................................3

Figure 3 Tape Drive Integrated Components ...................................................... 10

Figure 4 Receiver Area ............................................................................................ 16

Figure 5 Compatible Tape Cartridges................................................................... 20

Figure 6 Data Cartridge Care .................................................................................25

Figure 7 Cartridge Bottom View............................................................................ 26

Figure 8 Cartridge Reel Locks ................................................................................27

Figure 9 Opening the Media Access Door............................................................28

Figure 10 Inspecting Inside the Media Access Door.............................................28

Figure 11 Cartridge Write-protect Tab.................................................................... 30

Figure 12 Loading a Cartridge ................................................................................. 33

Figure 13 DLTSage WORM Button .........................................................................36

Figure 14 ADI/Loader Port Interface Schematic...................................................47

Figure 15 SCSI Connectors and Jumpers (Rear View)..........................................49

Figure 16 SCSI Connectors........................................................................................ 50

Figure 17 Fibre Channel Connectors and Jumper Block (Rear View) ................ 56

DLT-S4 Product Manual ix

Page 10

Figures

Figure 18 Fibre Channel Cable Connector.............................................................. 57

Figure 19 Fibre Channel Speed and Topology Jumper Block.............................. 59

Figure 20 SAS Connectors and Jumper Block (Rear View)..................................63

Figure 21 SAS Cable Connector ............................................................................... 64

Figure 22 SCSI Connectors and Jumpers (Rear View)..........................................68

Figure 23 Detail of the Empty SCSI ID Connector ................................................ 70

Figure 24 Tape Drive Mounting Holes — Right Side View................................. 72

Figure 25 Tape Drive Mounting Holes — Bottom View ...................................... 73

Figure 26 SCSI Cable with Built-in Terminator .....................................................75

Figure 27 SCSI Interface – Terminator Installation ............................................... 75

Figure 28 SCSI and Power Cable Locations ...........................................................76

Figure 29 Enabling TERMPWR................................................................................ 77

Figure 30 Fibre Channel Connectors and Jumper Block (Rear View) ................ 82

Figure 31 Tape Drive Mounting Holes — Right Side View................................. 84

Figure 32 Tape Drive Mounting Holes — Bottom View ...................................... 85

Figure 33 Connecting the Fibre Channel and Power Cables ...............................87

Figure 34 SAS Connectors and Jumpers (Rear View)...........................................91

Figure 35 Tape Drive Mounting Holes — Right Side View................................. 93

Figure 36 Tape Drive Mounting Holes — Bottom View ..................................... 94

Figure 37 Connecting the SAS and Power Cables ................................................ 96

Figure 38 Tabletop Tape Drive — Rear View ...................................................... 100

Figure 39 Tabletop SCSI ID Selector Switch.........................................................103

Figure 40 SCSI Chain — Single Device .................................................................105

Figure 41 AC Power Cable Connector Types....................................................... 106

Figure 42 SCSI Chain — Multiple Devices .......................................................... 109

Figure 43 Tape Drive Front Panel.......................................................................... 111

DLT-S4 Product Manual x

Page 11

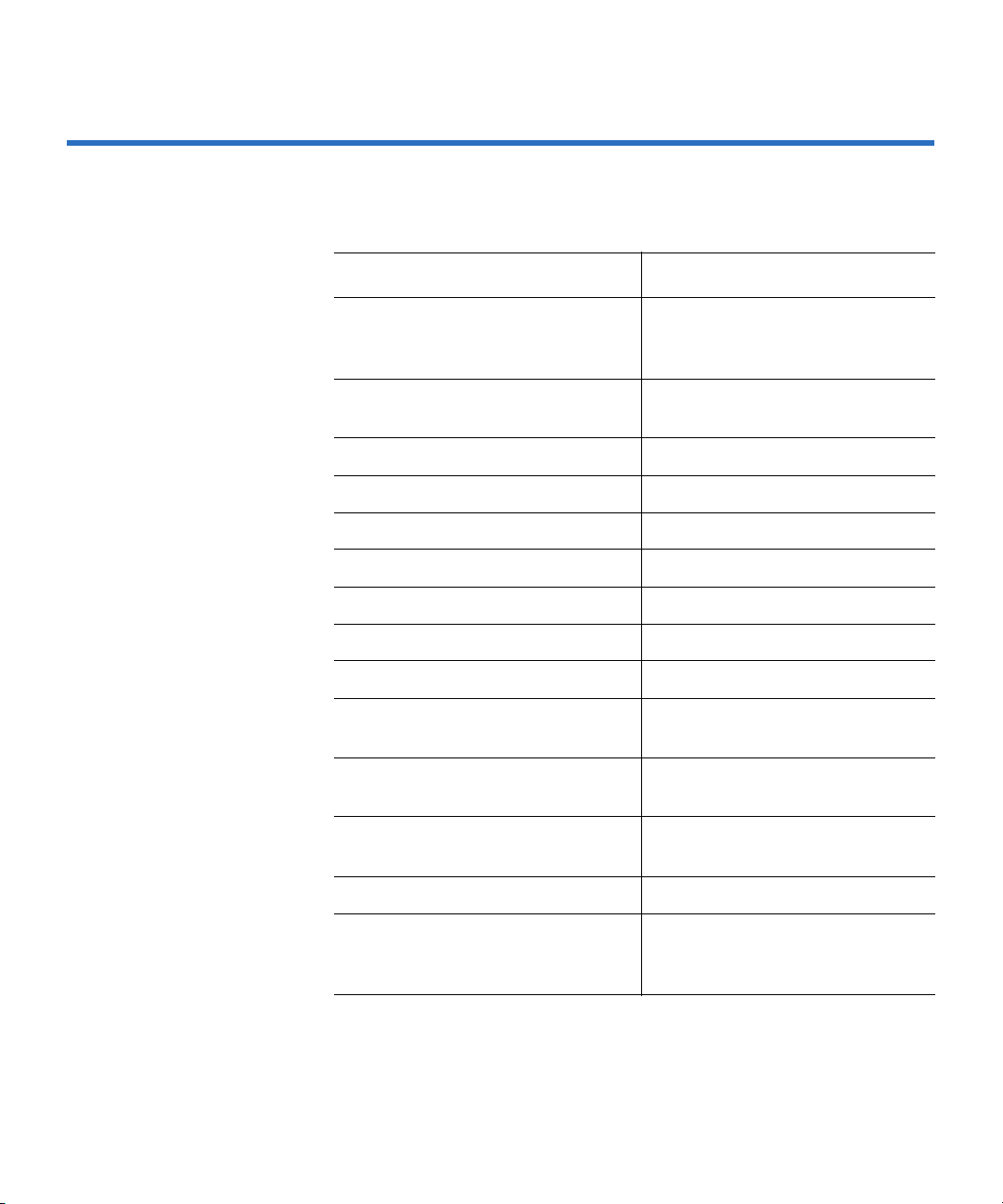

Tables

Table 1 Maximum Transfer Rate............................................................................ 5

Table 2 Tape Drive Technology.............................................................................. 7

Table 3 Tape Drive Components............................................................................ 8

Table 4 Interface Speed and Options................................................................... 11

Table 5 Tape Drive Interface Physical Characteristics...................................... 12

Table 21 Backward-read Compatibility Transfer Rates ...................................... 22

Table 22 Write-protect Tab Positions.....................................................................31

Table 23 Physical Specifications............................................................................. 38

Table 24 Tape Drive Physical Dimensions............................................................ 39

Table 25 Unpackaged and Shipping Weights ......................................................39

Table 26 EMI Regulations and Certifications ....................................................... 40

Table 27 Electromagnetic Interference and Immunity Test Summary............. 41

Table 28 Acoustic Noise Emissions........................................................................42

Table 29 SCSI Command Timeout Values ............................................................ 44

Table 30 MSE Mode SCSI Connector Pin Assignments......................................51

Table 31 MSE LVD Mode SCSI Connector Pin Assignments ............................53

Table 32 Fibre Channel Speed Configuration ...................................................... 60

DLT-S4 Product Manual xi

Page 12

Tables

Table 33 Fibre Channel Topology Configuration................................................61

Table 34 SCSI ID Address Selections..................................................................... 70

Table 35 Interpreting Front Panel LEDs.............................................................. 112

Table 36 LED Lighting Pattern During POST .................................................... 114

Table 37 POST and SCSI Troubleshooting Guidelines .....................................125

Table 1 DLTSage Features................................................................................... 134

DLT-S4 Product Manual xii

Page 13

Preface

This document serves as an easy-to-use information source and product

catalog to familiarize Quantum customers and systems professionals with

the DLT-S4 tape drive system. The DLT-S4 tape drive is an extension of

the Quantum Digital Linear Tape (DLT

Audience The primary audience for this document consists of end users installing

and using the tape drive. The information in this document applies to the

internal tape drive, the library tape drive, and the tabletop tape drive.

Purpose This document provides information on the DLT-S4 tape drive including:

®

) product family.

• Product description

• Installation instructions

• Operation instructions

• Regulatory compliance

DLT-S4 Product Manual xiii

Page 14

Document Organization This document is organized as follows:

Preface

• Chapter 1, Product Overview

, provides an overview of the DLT-S4

tape drive system, including features, tape drive technology,

components, interface types, and functional specifications.

• Chapter 3, Cartridges

, provides information on recognizing,

handling, inspecting, write-protecting, loading, unloading, and

creating secure write-once read-many (WORM) cartridges.

• Chapter 2, Before You Begin

, provides unpacking and safe handling

guidelines you need to know before you begin installing and using

your DLT-S4 tape drive.

• Chapter 4, Specifications

, provides basic physical and emissions

specifications of the DLT-S4 tape drive.

• Chapter 5, Common Interface Information

, provides information

common to all interfaces.

• Chapter 6, Parallel SCSI Interface

, provides information specific to

the SCSI interface.

• Chapter 7, Fibre Channel Interface

, provides information specific to

the Fibre Channel interface.

• Chapter 8, Serial Attached SCSI (SAS) Interface

, provides information

specific to the SAS interface.

• Chapter 9, Installing an Internal SCSI Tape Drive

, provides

instructions for installing the internal SCSI tape drive.

• Chapter 10, Installing an Internal Fibre Channel Tape Drive

, provides

instructions for installing the internal Fibre Channel tape drive.

• Chapter 11, Installing an Internal SAS Tape Drive

, provides

instructions for installing the internal SAS tape drive.

• Chapter 12, Installing the Tabletop Tape Drive

, provides instructions

for installing the tabletop tape drive.

• Chapter 13, Using the Tape Drive

, provides information that you

need to use the tape drive, including front panel controls and LEDs,

POST, performing a trial backup, updating the firmware, cleaning the

tape drive, and information on how to optimize tape drive

performance.

• Chapter 14, Troubleshooting

DLT-S4 Product Manual xiv

, provides troubleshooting information.

Page 15

• Chapter 15, Preparing the Tape Drive for Shipping, provides

information on how the special soft-load mechanism “parks” and

“unparks” the tape drive for safe shipping and moving.

Preface

• Appendix B, Environmental Compliance

, provides information on

how the DLT-S4 tape drive complies with environmental standards,

and information on how to safely dispose of electric and electronic

equipment.

• Appendix A, Diagnostic Tools

, provides information about the

diagnostic tools to use with DLT-S4 tape drives.

• Appendix C, Regulatory Statements

, lists all the regulatory

statements for the tape drive.

This document concludes with a glossary and a detailed index.

Notational Conventions This document uses the following conventions:

Note: Notes emphasize important information related to the main

topic.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety and

are included to prevent injury.

This document uses the following terminology:

• Right side of the tape drive — Refers to the right side as you face the

component being described.

• Left side of the tape drive — Refers to the left side as you face the

component being described.

• Power cycle — Means to turn the tape drive or system off, then on

again.

DLT-S4 Product Manual xv

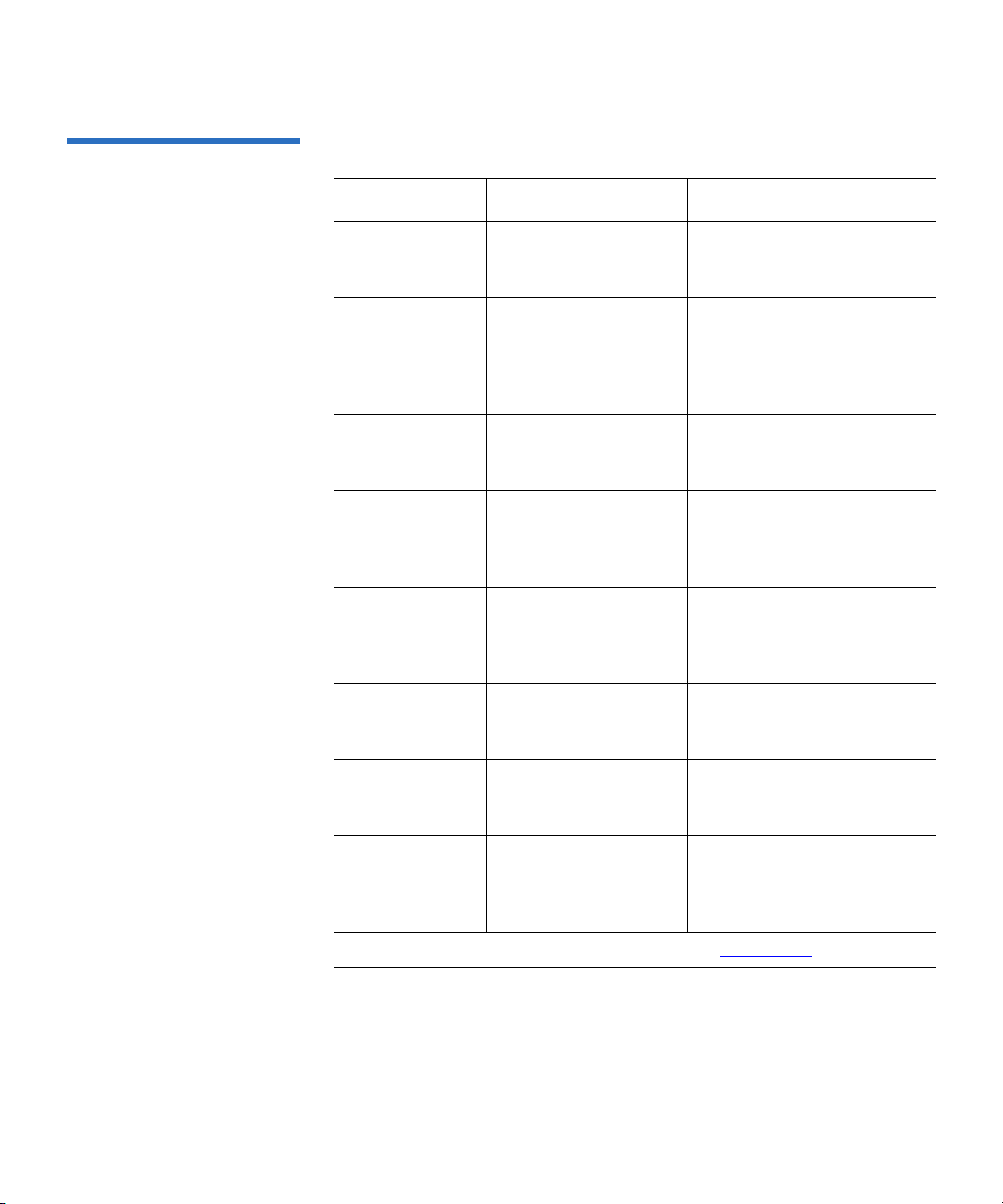

Page 16

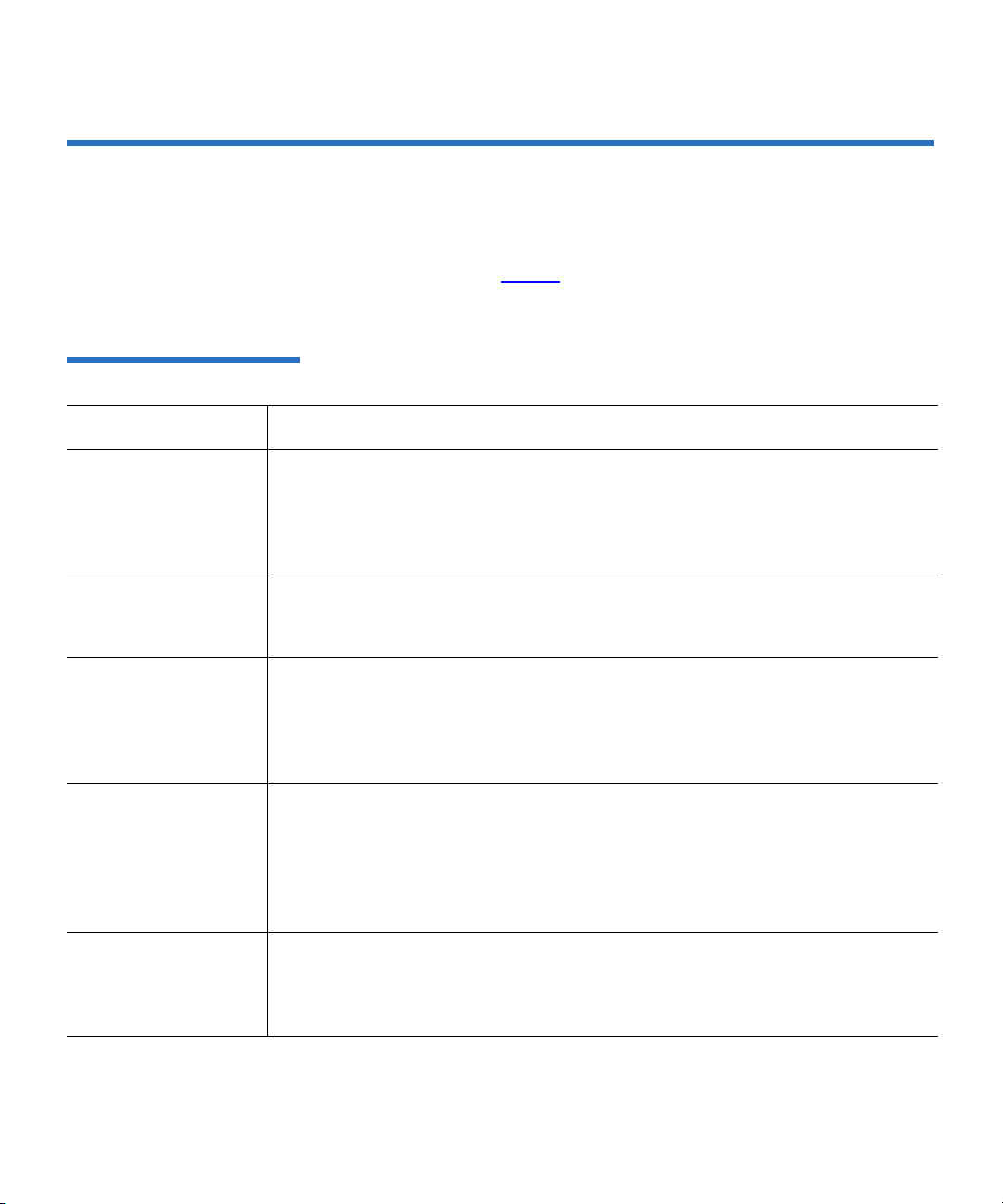

Related Documents The following documents are related to the DLT-S4 tape drive:

Document No. Document Title Document Description

Preface

81-81281-xx DLT-S4 Interface

Reference Guide

81-81279-xx DLT-S4 Product

Specification

81-81283-xx DLT-S4 Quick Start

Guide

81-81639-xx DLTSage Dashboard

and DLTSage Tape

Security Quick Start

Guide

6464162-xx DLT Tape Drive Library

Interface Specification

81-81235-xx 2U Rackmount Quick

Start Guide

Provides command and

reference information on the

tape drive

Provides hardware,

performance, environment,

shock and vibration, and

regulatory specifications for

the tape drive

Provides instructions on how

to install and run the tape

drive

Provides instructions on how

to install and use DLTSage

Dashboard and DLTSage Tape

Security

Describes the interface

implemented for two-way

communication between a

tape drive and a library

Provides instructions on

installing tape drives into the

2U Rackmount unit

81-81610-01 xTalk Management

Console for Windows

User’s Guide

81-81612-01 xTalk Management

Console User’s Guide Command Line

Interface

Current SCSI standards documents available from www.t10.org

DLT-S4 Product Manual xvi

Provides instructions for using

xTalk Management Console

via a Windows interface

Provides instructions for using

xTalk Management Console

via a Linux or Solaris interface

Page 17

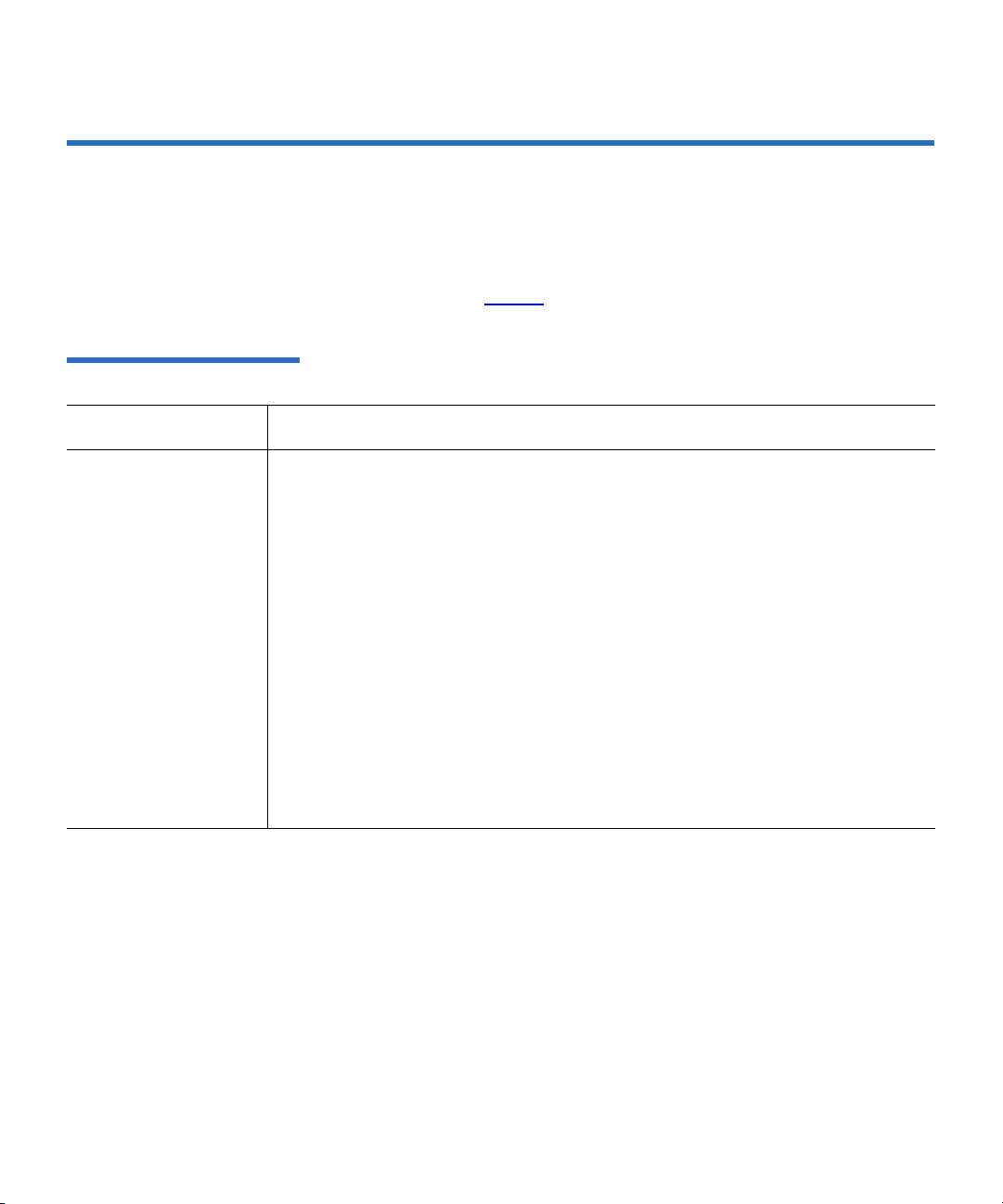

Preface

Document No. Document Title Document Description

• SCSI Architecture Model (SAM-3)

• SCSI Primary Commands (SPC-3)

• SCSI Parallel Interface (SPI-5)

• SCSI Stream Commands (SSC-3)

• Serial Attached SCSI (SAS-1.1)

• Fibre Channel Protocol (FCP-2)

• Fibre Channel Framing and Signaling (FC-FS-2)

• Fibre Channel Arbitrated Loop (FC-AL-2)

• Fibre Channel General Services (FC-GS-5)

SCSI Standards 0

Copies of the approved version of the SCSI standards may be obtained

from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

Contacts Quantum company contacts are listed below.

Quantum Corporate Headquarters

To order documentation on this or other Quantum products, contact:

Quantum Corporation

141 Innovation Drive

Irvine, CA 92617

(949) 856-7800

(800) 284-5101

0

DLT-S4 Product Manual xvii

Page 18

Preface

Technical Publications 0

To comment on existing documentation send e-mail to:

doc-comments@quantum.com

Quantum Home Page 0

Visit the Quantum home page at:

http://www.quantum.com

Customer Support 0

The Quantum Customer Support Department provides a 24-hour help

desk that can be reached at:

North/South America: (949) 725-2100 or (800) 284-5101

Asia/Pacific Rim:

APAC Headquarters: (International Code) + 65 6334 0660

Specific countries: www.quantum.com/ServiceandSupport/

ContactServiceandSupport/DLTSupportAPAC//

Index.aspx

Europe/Middle East/Africa: (International Code) + 44 1256 848 766

Send faxes for the Customer Support Department to:

North/South America: (949) 725-2176

Asia/Pacific Rim: (International Code) + 65 6432 2830

Europe/Middle East/Africa: (International Code) + 44 1256 848 777

Send e-mail for the Customer Support Department to:

North/South America: http://www.quantum.com/am/service_support/

Index.aspx

Asia/Pacific Rim: apachelp@quantum.com

Europe/Middle East/Africa: eurohelp@quantum.com

DLT-S4 Product Manual xviii

Page 19

Chapter 1

1Product Overview

This chapter describes the features of the DLT-S4 tape drive system and

covers the following topics:

• Storage Capacity and Transfer Rates

• Tape Drive Models

• Tape Drive Features

• Maximum Data Transfer Rate

• Functional Specifications

• Tape Drive Technology

• Tape Drive Components

• Interface Types

DLT-S4 Product Manual 1

Page 20

Chapter 1 Product Overview

Storage Capacity and Transfer Rates

Storage Capacity and Transfer Rates 1

The DLT-S4 tape drive system provides:

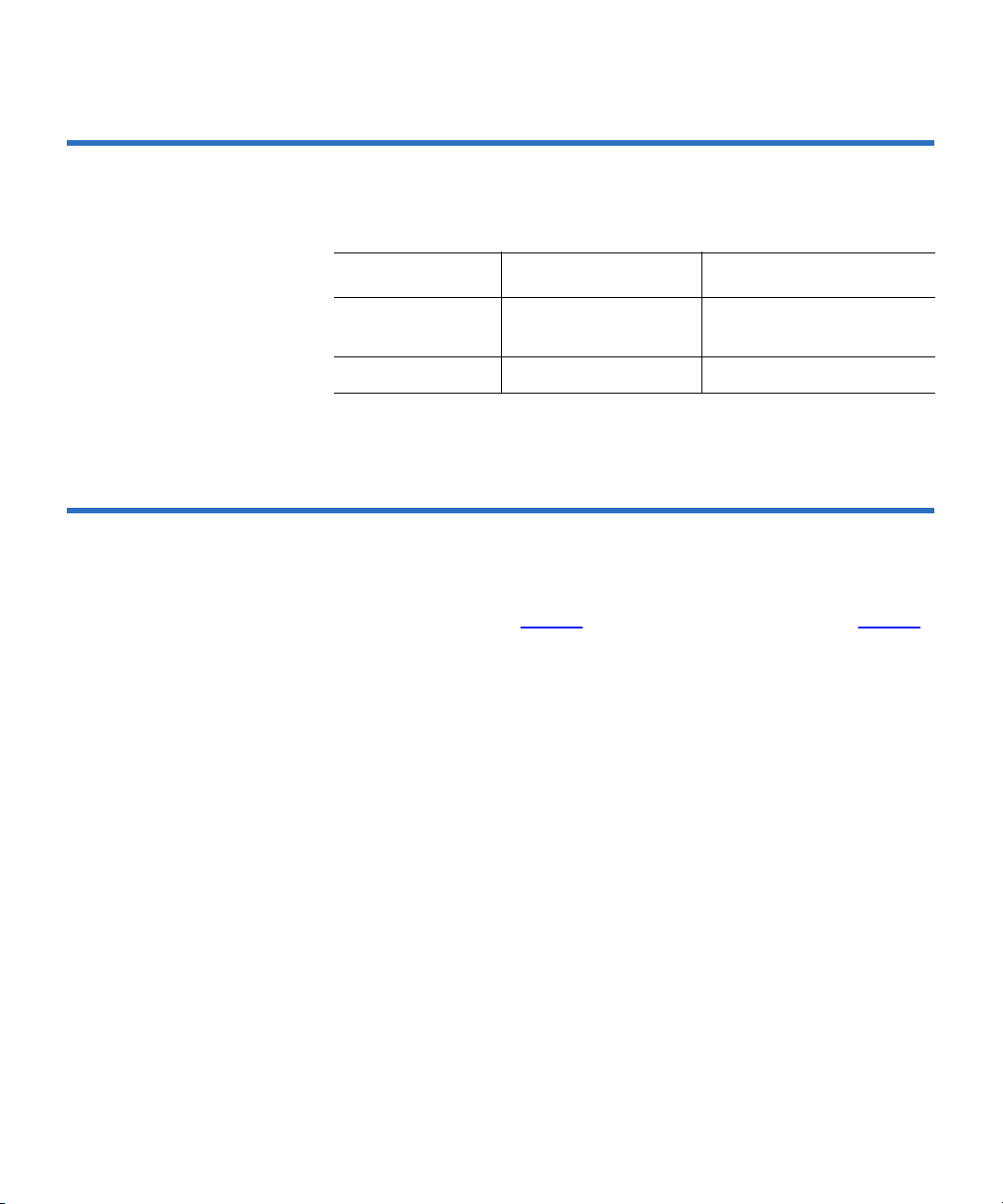

Mode Storage Capacity Transfer Rate

Native 800 Gigabytes (GB) 60 Megabytes per second

(MB/second)

Compressed

a. 2:1 compression ratio.

a

1.6 Terabytes (TB) 120 MB/second

Tape Drive Models 1

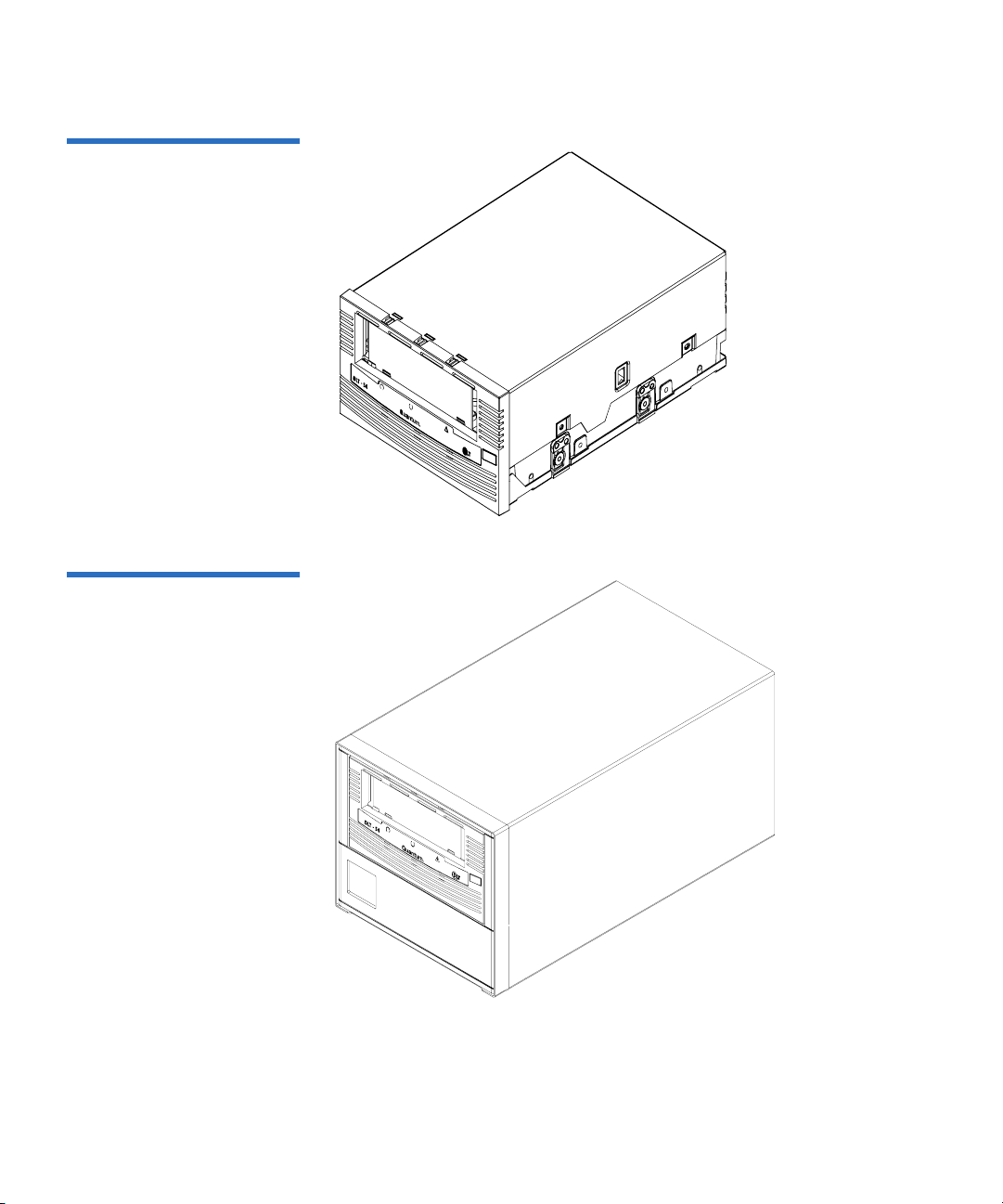

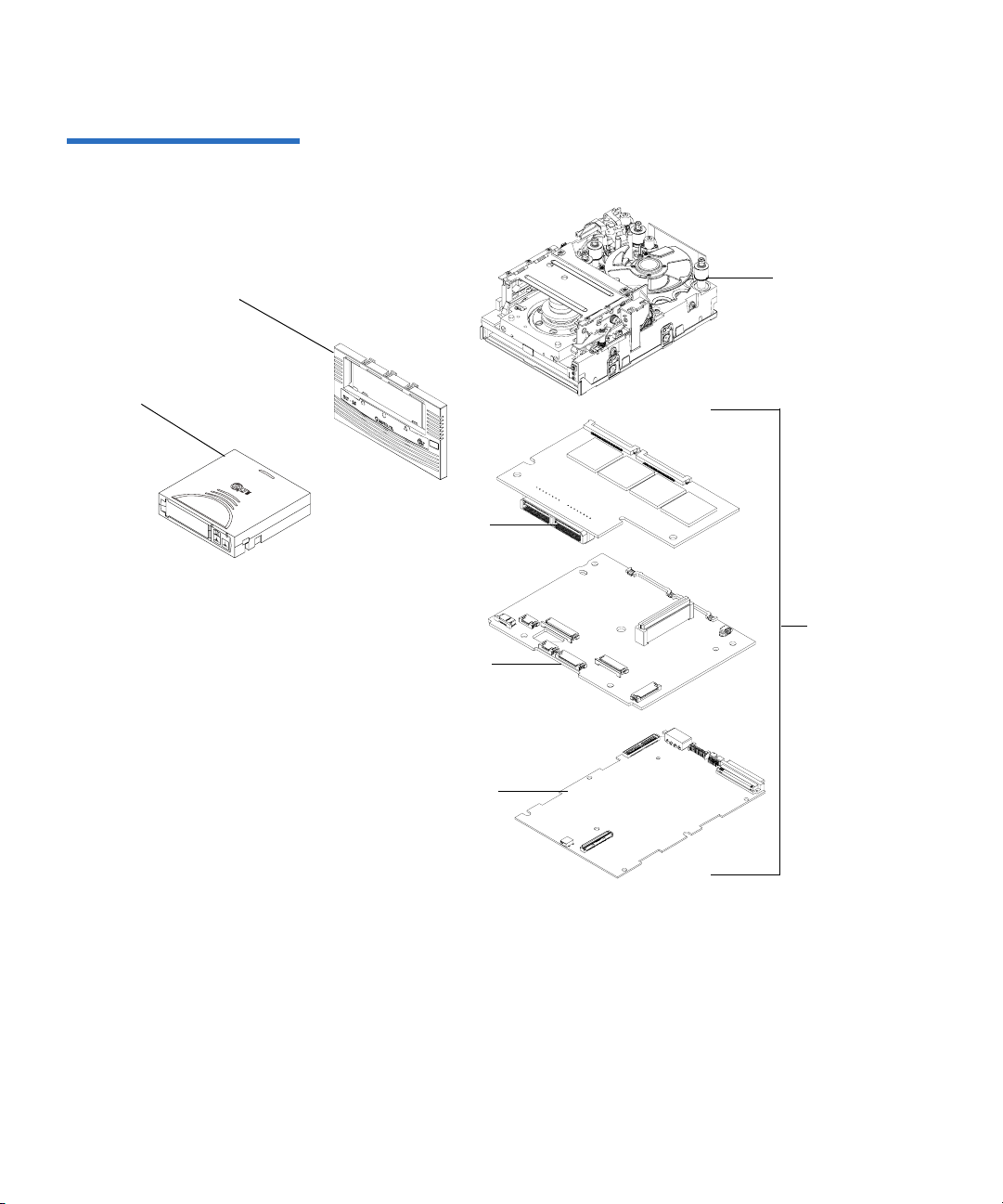

The tape drive system is available in three models: an internal unit for

server installation (see figure 1

and a library model for installing in tape automation systems. The library

model (not shown) is similar to the internal model, but has a different

front bezel.

), a tabletop (or external) unit (see figure 2),

DLT-S4 Product Manual 2

Page 21

Figure 1 Internal Tape Drive

Figure 2 Tabletop Tape Drive

Chapter 1 Product Overview

Tape Drive Models

DLT-S4 Product Manual 3

Page 22

Chapter 1 Product Overview

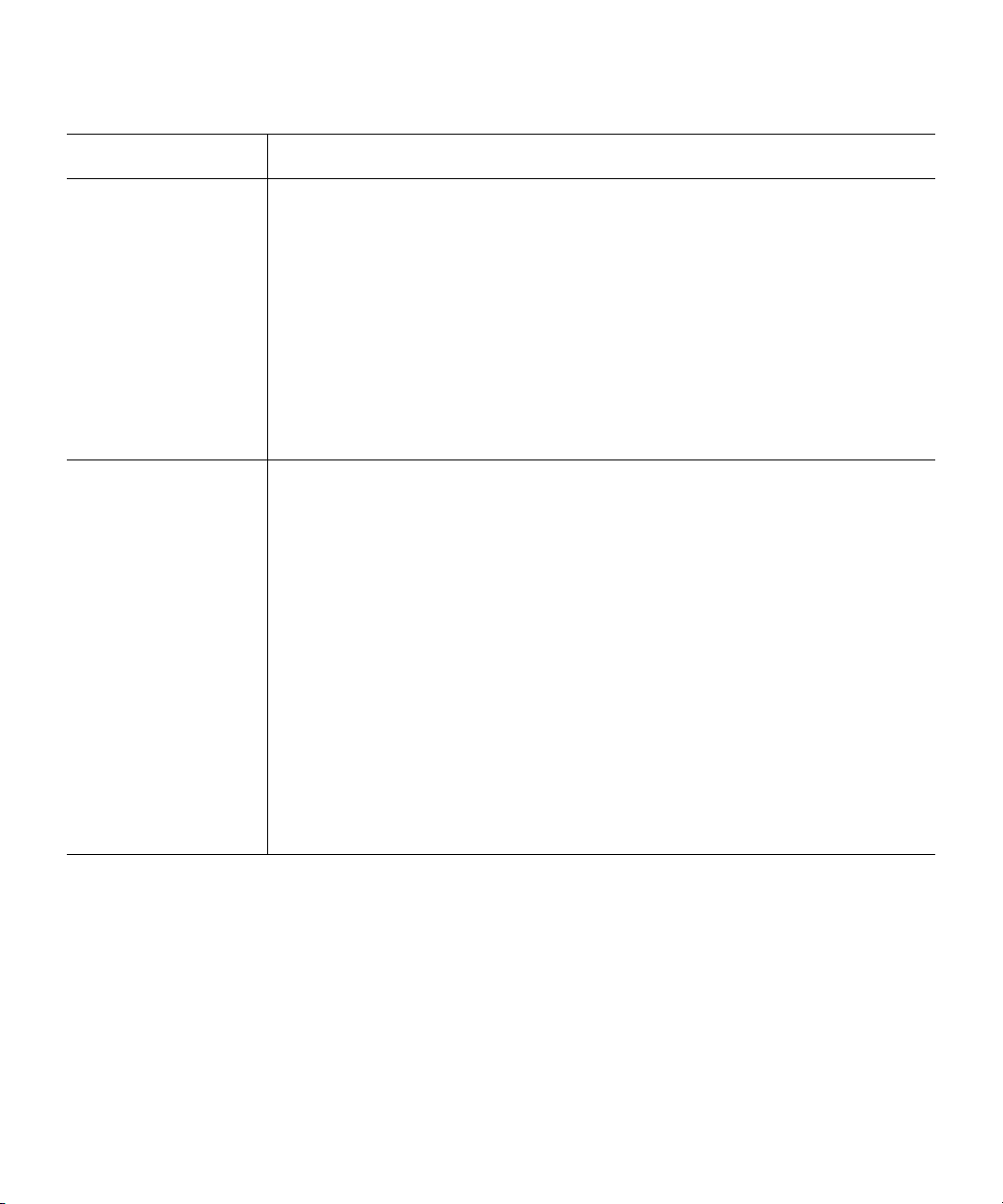

Tape Drive Features

Tape Drive Features 1

The DLT-S4 tape drive system provides the following product features:

Feature Description

Media A streaming tape drive that uses half-inch wide

DLTtape S4 media

Form Factor A standard 5.25-inch full-height form factor to

simplify integration into system and tape library

solutions

Format

Tape Drive Cartridge

Compatibility

DLT-S4 DLTtape S4

(write/read)

SDLT 600 Super DLTtape II

(read only)

SDLT 320 Super DLTtape I

(read only)

Interface

Options

Capacity

Ultra320 SCSI

4 Gigabit (Gb) Fibre Channel

3 Gb SAS-1.1

a

a

Mode Value

Native capacity 800 GB

Compressed capacity 1.6 TB

b

(2:1 compression ratio)

a. Fibre Channel and SAS interfaces are not available with the

tabletop model.

b. In accordance with industry practice, a typical compression

ratio is quoted. Actual compression ratios depend on the

redundancy and kind of data files you write.

DLT-S4 Product Manual 4

Page 23

Chapter 1 Product Overview

Maximum Data Transfer Rate

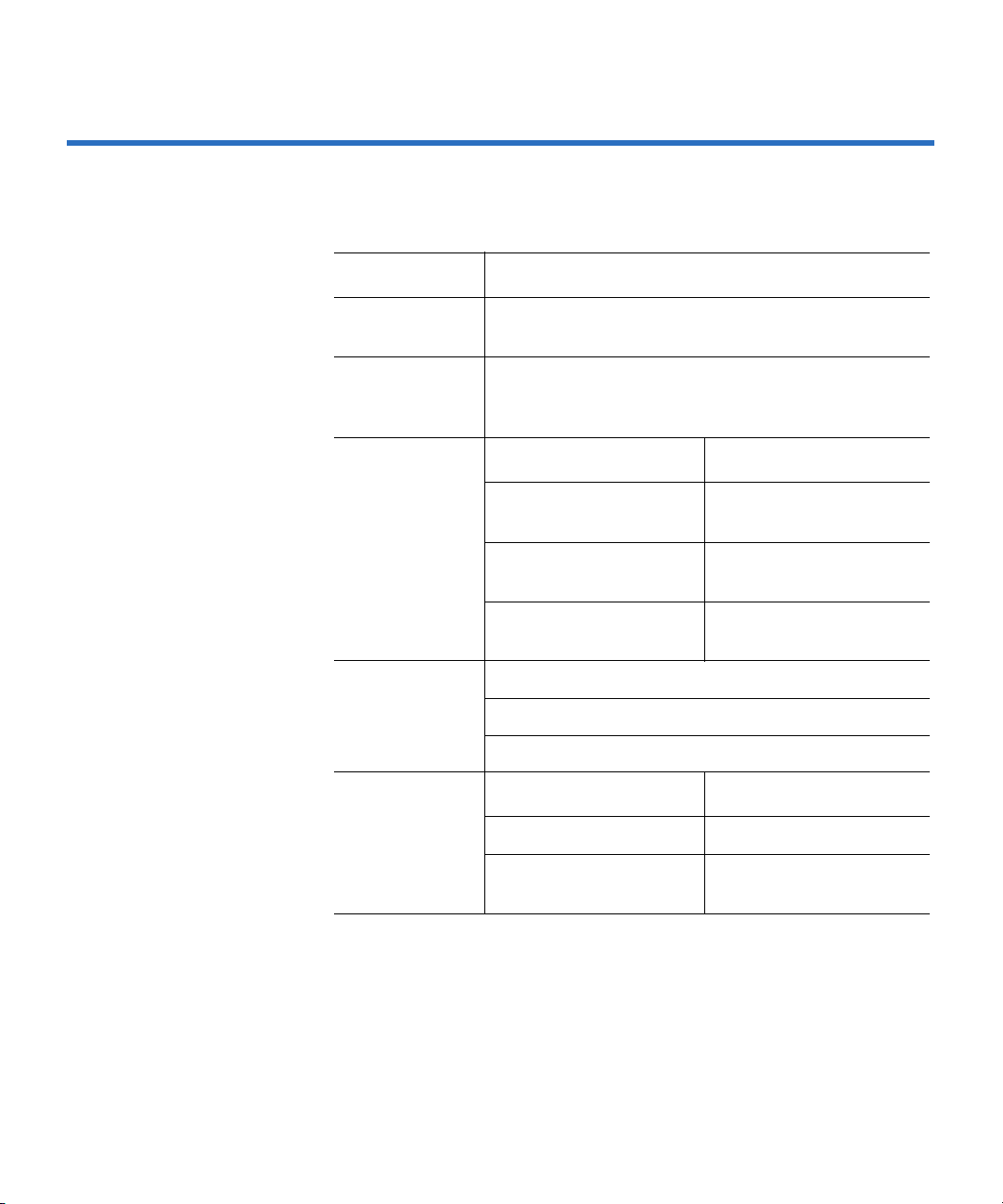

Maximum Data Transfer Rate 1

Table 1 shows the maximum and burst data transfer rates for the DLT-S4

tape drive.

Table 1 Maximum Transfer

Rate

Compressed

Configuration Native

Burst Max

2:1 >4:1

Ultra320 SCSI 60 MB/sec 120 MB/sec 140 MB/sec 320 MB/sec

Fibre Channel 60 MB/sec 125 MB/sec 180 MB/sec 4 Gb/sec

SAS-1.1 60 MB/sec 125 MB/sec 180 MB/sec 3 Gb/sec

Note: Cable lengths and cable type may limit attainable transfer rates.

a. The interface limits burst rates, not the design of the tape drive or the media.

a

DLT-S4 Product Manual 5

Page 24

Chapter 1 Product Overview

Functional Specifications

Functional Specifications 1

This section provides performance data for the DLT-S4 tape drive.

Feature Value

Tape drive read/write transfer

a

rate

Native—60 MB per second

Compressed—120 MB per

second

Tracks 80 logical tracks

1280 physical tracks

Track density 2988 tracks per inch (tpi)

Linear bit density 256 Kb per inch (Kbpi)

Read/Write media speed 155 inches per second (ips)

Rewind media speed 200 inches per second

Linear search media speed 200 inches per second

Average rewind time

Maximum rewind time

Average access time

b

b

b

70 seconds

140 seconds

70 seconds

(from BOT)

Maximum access time

b

142 seconds

(from BOT)

Load to BOT

b

25 seconds

70 seconds (unformatted media)

Unload from BOT

b

25 seconds

Nominal media tension Stationary—3.0 ± 0.5 oz.

Operating speed—3.5 ± 0.5 oz.

Rewind—3.5 ± 0.5 oz.

a. Depending on data type, SCSI bus limitations, and the tape

system configuration.

b. Note that data is typical; times may be longer if error recovery

time is necessary.

DLT-S4 Product Manual 6

Page 25

Chapter 1 Product Overview

Tape Drive Technology

Tape Drive Technology 1

The DLT-S4 tape drive incorporates state-of-the-art technologies that

contribute to the SDLT architecture. Some of these ideas are trademarked,

others are patented. Table 2

comprise the DLT-S4 tape drive system.

Table 2 Tape Drive Technology

Technology Description

lists some of the important technologies that

Laser Guided

Magnetic Recording

Magneto Resistive

Cluster Heads

Advanced Partial

Response Maximum

Likelihood

Advanced Metal

Powder Media

Positive Engagement

Tape Leader

Buckling Mechanism

The DLT-S4 tape drive system is based on Quantum’s Laser Guided Magnetic

Recording (LGMR) technology. LGMR provides a unique combination of the

best optical and magnetic technologies, which results in dramatically higher

capacities by substantially increasing the number of recording tracks on the

data-bearing surface of the media.

Magneto Resistive Cluster (MRC) heads are a densely packed array of small

Magneto Resistive (MR) tape heads precisely positioned using advanced thinfilm processing technology.

Improving on Partial Response Maximum Likelihood (PRML) technology

traditionally used in disk drives and communication systems, Quantum’s

advanced PRML channel technology, co-developed with Lucent Technologies,

brings new levels of performance and capacity to high-performance linear tape

products.

Advanced Metal Powder (AMP) media is a state-of-the-art media using

durable metal powder technology for recording high densities of data. The

back side of AMP media receives a specially formulated coating to accept the

optical servo tracks, which ensures that the entire data-bearing side of the

media is available for recording data and eliminates the need for preformatting.

The positive engagement tape leader buckling mechanism engages the media

leader on cartridge load and disengages it on cartridge unload. It uses a metal

pin attached to the tape drive leader to link with molded clips permanently

attached to the media leader inside the cartridge.

DLT-S4 Product Manual 7

Page 26

Chapter 1 Product Overview

Tape Drive Components

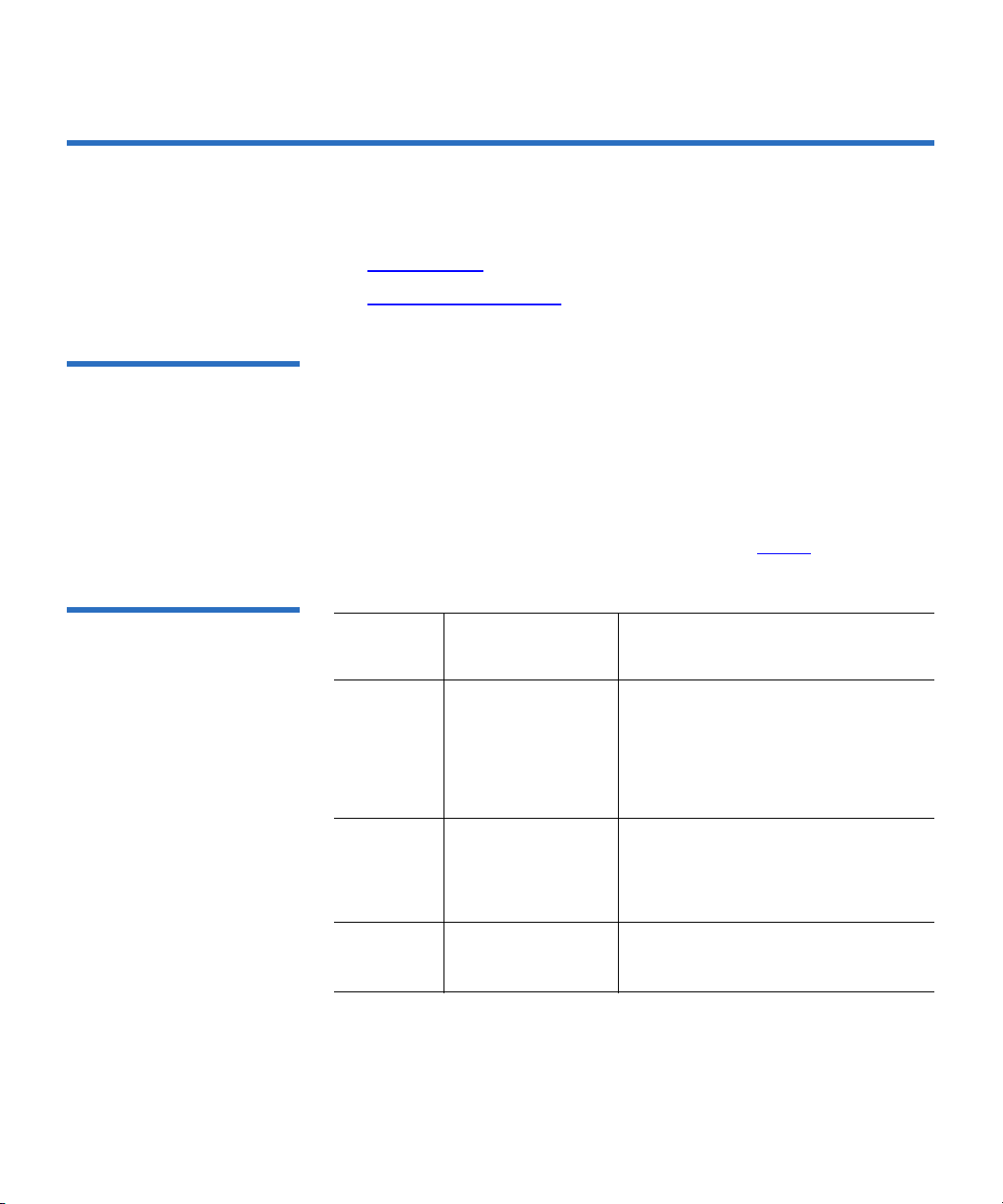

Tape Drive Components 1

The DLT-S4 tape drive is designed as a total system. The system includes

a complex interaction of a number of important components including

the base mechanical assembly, the front panel assembly (bezel), and the

board assemblies. Table 3

Table 3 Tape Drive Components

Components Description

describes these components.

Base mechanical

assembly

The base mechanical assembly houses the tape control mechanical, actuator,

reel motor, load mechanism, eject button, and front-panel indicators. It

positions the actuator servo head over the correct tape track. It implements the

functions required to buckle and unbuckle the media and control the media

motion. It engages the media leader on cartridge load and disengages it on

cartridge unload.

• Auto load—The tape auto load is a soft-load and seating mechanism that is

tolerant of forced media loading; a media sensor is triggered upon cartridge

insertion, and after the media reaches a hard stop point, the auto load sensor

engages, pulling the cartridges the remaining distance onto the motor. On

media ejection, the assembly reverses the process and automatically ejects

the cartridge a fixed distance from the front of the tape drive.

• Base plate—Acts as the support platform for the other modules and for the

tape drive enclosure. It also includes the mounting holes (shock mounts)

used to install the tape drive into a server or tape library.

DLT-S4 Product Manual 8

Page 27

Components Description

Chapter 1 Product Overview

Tape Drive Components

Front panel assembly

(bezel)

The front panel assembly (bezel) performs these functions:

• Protects the front of the drive from physical damage

• Channels air flow through the system

• Aligns the cartridge when it is inserted into the system

• Provides label identifiers for the LEDs mounted on the front of the tape

drive

• Enables cartridge ejection

• Reduces internal environmental contamination with a built-in dust door

(internal and tabletop configurations only)

Board assemblies The board assemblies provide the main control function for the system and the

interface from the system to the host computer, library, or autoloader. This

provides the Advanced Partial Response Maximum Likelihood (PRML) feature

of the Quantum DLT-S technology.

There are three board assemblies:

• Pre-amplifier Board (PAB) — The PAB contains the preamplfier for the read

heads, and the write driver for the write heads.

• Motor Driver Board (MDB) — The MDB interfaces with the reel motor

drivers and hall sensors, actuator driver and sensors, sensor and motor

drivers for the soft load, LEDs for front-panel indicators, and eject button

signals.

• Drive Control Board (DCB) — The DCB is the main control card for the

DLT-S4 tape drive. It sends commands to the MDB to control and drive the

tape mechanism. The board interfaces with the PAB to send signals to the

head for reading and writing.

DLT-S4 Product Manual 9

Page 28

Figure 3 Tape Drive Integrated

Components

Chapter 1 Product Overview

Tape Drive Components

Front panel

assembly (bezel)

Cartridge

Base

mechanical

assembly

PAB

Board

assemblies

MDB

DCB

DLT-S4 Product Manual 10

Page 29

Chapter 1 Product Overview

Interface Types

Interface Types 1

This section contains the following information for the DLT-S4 tape drive:

• Host Interface

• Physical Characteristics

Host Interface 1 The interface supported by an DLT-S4 tape drive is dependent on the

kind of Drive Control Board (DCB) PWA installed. The DLT-S4 tape

drive comes in these interface types:

• Tabletop model with Ultra320 SCSI interface

• Internal model with either an Ultra320 SCSI interface, 4 Gb Optical

Fibre Channel interface, or SAS Interface

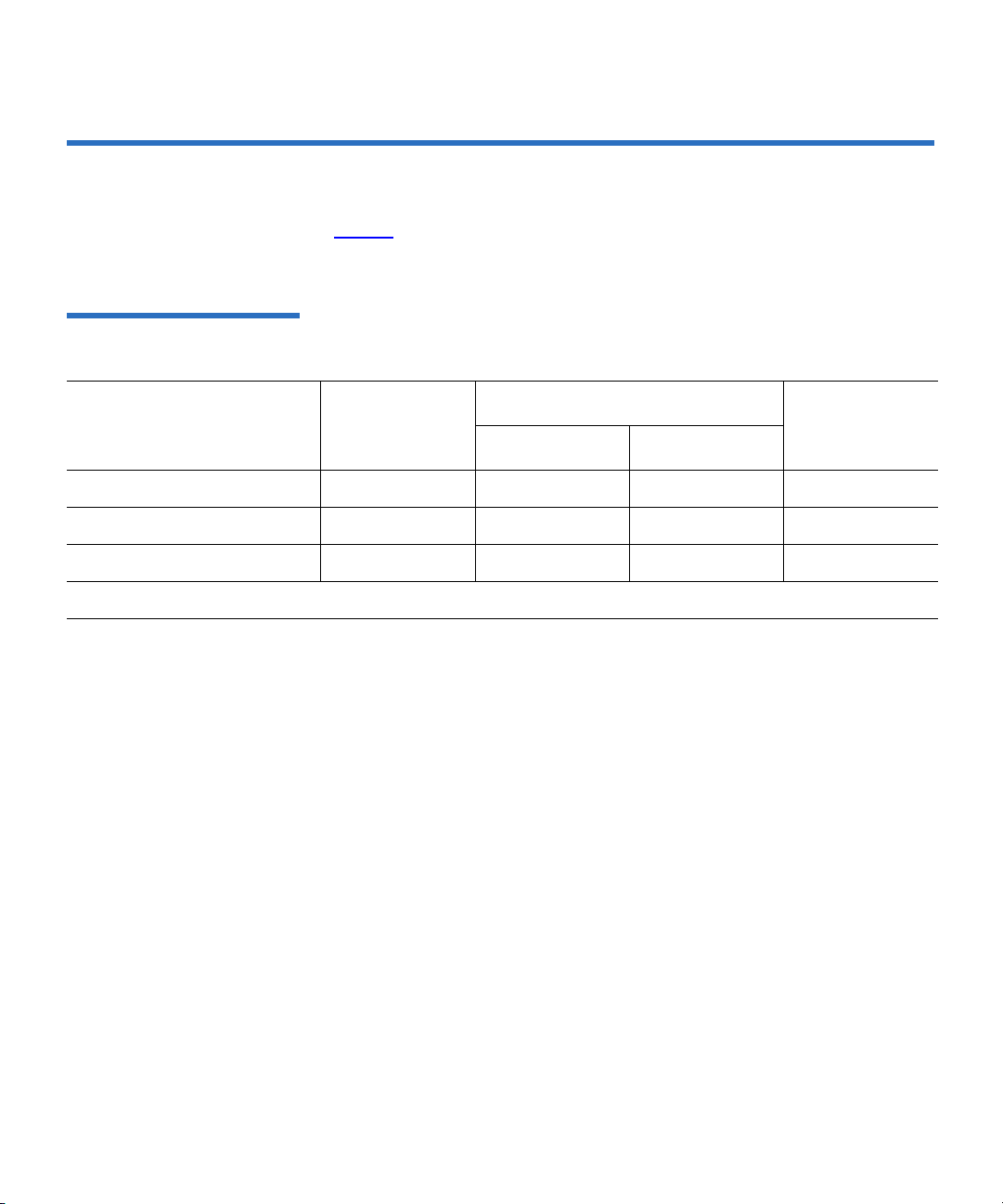

Table 4 Interface Speed and

Options

Interface speeds and protocol options are shown in table 4

Interface

Versions

Ultra320

SCSI

Fibre

Channel

SAS 1.5 Gb/second

a. The SCSI bus itself limits this rate, not the design of the tape

drive or media.

Speed (Maximum

Burst) Protocol Options

320 MB/second

1 Gb/second

2 Gb/second

4 Gb/second

3 Gb/second

a

Low Voltage Differential (LVD)

sense running up to 320 MB per

second burst

Ultra160 2/FAST-20/

Asynchronous

Class3

Connect to N port, NL port,

FL port, and F port

Serial SCSI Protocol (SSP)

.

DLT-S4 Product Manual 11

Page 30

Chapter 1 Product Overview

Interface Types

Physical Characteristics 1 Table 5 lists the physical characteristics for each interface of the tape

drive. These interfaces are available from the rear panel (per type, per

port).

Table 5 Tape Drive Interface

Physical Characteristics

Interface Versions Physical Characteristics

Parallel SCSI Ultra320

LVD

SCSI ID/TERMPWR connector style: 6-pin

Connector style: 68-pin high density SCSI

Fibre

Channel

Topology-constrained (drive automatically detects

topology)

4 Gb interface (drive automatically detects speed)

LC connector with 850 nanometer SFP transceiver

(supplied)

SAS-1.1 Point-to-point topology

3 Gb interface (drive automatically detects speed)

DLT-S4 Product Manual 12

Page 31

Chapter 2

2Before You Begin

Inappropriate or careless handling of DLT-S4 tape drive systems may

result in damage to the product. Follow the precautions and directions to

prevent damaging the DLT-S4 tape drive system. In addition, follow the

steps in Pre-Installation Guidelines

correct hardware for the system configuration.

This chapter provides the following important information you need to

know before you install and use your DLT-S4 tape drive:

on page 17 to ensure that you have the

• Warranty Note

follow so you do not void your warranty

• Safety Precautions

• Tape Drive Handling and Storage Guidelines

• Electrostatic Discharge Protection

• Pre-Installation Guidelines describes proper steps to take before

installing the tape drive in a system

DLT-S4 Product Manual 13

provides a general reminder of certain precautions to

Page 32

Chapter 2 Before You Begin

Warranty Note

W arranty Note 2

See the tape drive warranty before installing the tape drive; the tape

drive’s warranty could be voided if the installation guidelines and

restrictions are not closely followed.

Generally, the Limited Product and Limited Repair Warranties are

contingent upon proper use in the application for which the product is

intended, and do not cover the product if you perform any of the

following actions:

• Modify the product without the manufacturer’s written approval

• Subject the product to unusual physical, environmental, or electrical

stress, including damage caused by handling or shipping in

unapproved containers or packaging

• Disturb any warranty labels, or the integrity of the product in any

other way

• Remove or damage the serial number label to the extent that

warranty status of the product cannot be determined

Safety Precautions 2

For your safety, follow all safety procedures described here and in other

sections of the document.

• Turn off the system into which the DLT-S4 tape drive is to be

installed or attached before installing or removing the tape drive to

prevent the possibility of electrical shock or damage to the tape drive.

• Unplug the system that contains—or is to contain—the tape drive

from AC power before installing the tape drive to provide an added

measure of safety.

• Read, understand, and observe all label warnings.

DLT-S4 Product Manual 14

Page 33

Chapter 2 Before You Begin

Tape Drive Handling and Storage Guidelines

• The DLT-S4 tape drive uses a Class I laser product. This laser product

complies with 29 CFR 1200 and 29 CFR 1910 as applicable on the date

of manufacture.

Warning: If you open the tape drive chassis, you may become

exposed to invisible laser emission which could be

harmful if you are directly exposed to the beam.

Tape Drive Handling and Storage Guidelines 2

Damage to the DLT-S4 tape drive system can occur as the result of

careless handling, vibration, shock, or electrostatic discharge (ESD). For

more details on ESD, see Electrostatic Discharge Protection

Follow these guidelines to avoid damage to the tape drive:

Caution: Never power off the tape drive or the host while the tape

drive contains a cartridge. Failure to remove a cartridge

may result in cartridge or tape drive damage.

on page 16.

• Always handle the tape drive carefully and gently— a drop of ¼ inch

onto a bench or desktop can damage a tape drive.

• Hold the internal tape drive only by its sides.

• Never hold or carry the tape drive by inserting your fingers into the

receiver area on the front of the tape drive. You could damage the

receiver area if you lift or carry it in this manner.

• Do not bump, jar, or drop the tape drive. Use care when transporting

the tape drive.

• Do not place the tape drive so that it rests on its front bezel.

• Always gently place the tape drive flat and horizontal on an

appropriate ESD-protected work surface to keep the tape drive from

accidentally being knocked over.

• Do not stack objects on the tape drive.

DLT-S4 Product Manual 15

Page 34

Chapter 2 Before You Begin

Electrostatic Discharge Protection

• Do not expose the tape drive to dusty, humid, or smoke-filled areas,

or to excessive heat or cold (see Physical Specifications

required temperature and humidity conditions).

• Do not place foreign objects inside the tape drive’s receiver area (see

figure 4

).

on page 38 for

Figure 4 Receiver Area

Receiver area

Electrostatic Discharge Protection 2

Several electrical components of the DLT-S4 tape drive system are

sensitive to static electricity and electrostatic discharge (ESD). Even a

static buildup or discharge that is too slight to feel can be sufficient to

destroy or degrade a component’s operation.

To minimize the possibility of ESD-related damage to the system, the

tape drive’s manufacturer strongly recommends using both a

workstation anti-static mat and an ESD wrist strap. If the devices are

correctly installed and properly used, they reduce the buildup of static

electricity that might harm the system.

Follow these guidelines to avoid ESD damage to the tape drive:

• Use a properly fitted wrist strap or other suitable ESD protection.

• Observe proper ESD grounding techniques.

• Keep the internal tape drive in its antistatic bag until ready to install.

DLT-S4 Product Manual 16

Page 35

Chapter 2 Before You Begin

Pre-Installation Guidelines

• Place the tape drive in the antistatic bag before placing it in a

shipping container.

• Hold the internal tape drive only by its sides.

• Place the tape drive on a properly grounded anti-static work surface

pad while it is out of its protective antistatic bag.

• Do not pack other materials with the tape drive in its antistatic bag.

• Do not use the bag as a substitute for the work surface antistatic pad.

The outside surface of the bag may not have the same antistatic

properties as the inside surface. It could actually increase the

possibility of ESD problems.

• Do not remove either the tabletop tape drive cover or the internal/

library tape drive cover to use any test equipment to check

components on the PCBAs. There are no user-serviceable

components on the tape drive.

Pre-Installation Guidelines 2

Before you install the tape drive in a system, follow these steps. Also,

check the tape drive to be certain it is operating properly before installing

it in a system.

1 Unpack and review the contents of the box for any physical damage.

If you find damaged items, contact the tape drive sales representative

and the shipping company immediately.

2 Save the shipping box and packing materials in case you need to

move or ship the tape drive at a later date.

Caution: When returning a unit to Quantum for repair, you

must use the original or equivalent packing materials

or risk voiding your warranty.

3 Record the model and serial number of the DLT-S4 tape drive system

in the space provided below.

DLT-S4 Product Manual 17

Page 36

Chapter 2 Before You Begin

Pre-Installation Guidelines

These numbers provide specific information on the DLT-S4 tape

drive system and will be helpful if you must contact technical

support. You can find these numbers on the bottom of the tabletop

tape drive enclosure and on the top of the internal and library tape

drives.

Serial Number

Model Number

(usually begins with TC)

4 Check the enclosed SCSI, Fibre Channel, or SAS cable to ensure it is

(usually begins with QP, QX,

or QK)

compatible with the SCSI, Fibre Channel, or SAS controller card in

the host computer.

5 Check the SCSI, Fibre Channel, or SAS interface on the host computer

to ensure that it is compatible with the tape drive (see table 5

on

page 12 for a list of the possible interfaces that are available and the

various options with each).

6 Confirm that your back-up software and operating system are

compatible with the tape drive.

See

www.quantum.com for the most up-to-date compatibility

information.

DLT-S4 Product Manual 18

Page 37

Chapter 3

3Cartridges

This chapter discusses the cartridges that you can use in the DLT-S4 tape

drive. This chapter covers the following topics:

• Choosing Compatible Cartridges

• Using Unsupported Cartridges

• Backward-read Compatibility Transfer Rate

• Cartridge Handling and Storage Guidelines

• Inspecting a Cartridge

• Write-protecting a Cartridge

• Loading a Cartridge

• Unloading a Cartridge

• DLTSage WORM

read-many (WORM) cartridge]

[explains how create a secure archival write-once,

Choosing Compatible Cartridges 3

The only cartridge the DLT-S4 tape drive can both read and write to is the

DLTtape S4 cartridge.

DLT-S4 Product Manual 19

Page 38

Figure 5 Compatible Tape

Cartridges

Chapter 3 Cartridges

Choosing Compatible Cartridges

The DLT-S4 tape drive can read from, but not write to:

• Super DLTtape II cartridges formatted in the SDLT 600 tape drive

• Super DLTtape I cartridges formatted in the SDLT 320 tape drive

The DLTtape S4 cartridge is black and has a distinctive pattern molded

into the plastic, along with the DLTtape logo. The cartridge is made of

wear-resistant materials to reduce the potential for debris generation and

increase the life of the cartridge.

The cartridge’s geometry is similar to previous DLTtape cartridges to

simplify integration with existing tape library designs (see figure 5

). Its

keying feature, however, ensures that it cannot be loaded into previous

generation tape drives.

DLTtape S4 Data Cartridge (BLACK)

Super DLTtape I Data Cartridge (GREEN)

DLT-S4 Product Manual 20

Super DLTtape II Data Cartridge (BLUE)

Page 39

Chapter 3 Cartridges

Using Unsupported Cartridges

Using Unsupported Cartridges 3

DLT-S4 tape drives are intended to be used only with the cartridges

specified in Choosing Compatible Cartridges

Quantum DLT drives are tested with a variety of unsupported cartridges

and are designed to ensure that no damage occurs to either the tape drive

or the cartridge if a user attempts to use an unsupported cartridge.

If you try to insert an unsupported cartridge into the DLT-S4 drive, the

drive will not be able to accept it. Possible results are:

• You may not be able to insert the unsupported cartridge into the

drive.

• The unsupported cartridge may trigger the soft-load mechanism at

an inappropriate time, which may cause the soft-load mechanism to

stop at an improper location. While the soft-load mechanism is

stopped, the unsupported cartridge may not be completely loaded in

the drive, and the drive may not automatically eject the cartridge. (If

this happens, you must manually eject the cartridge by issuing an

EJECT command or by pressing the Eject button.)

on page 19. However,

• If the unsupported cartridge does manage to load properly, the drive

will not be able to buckle, read, or write to it. If this happens, a load

failure will be issued over the interface. (If this happens, you must

manually eject the cartridge by issuing an

pressing the

When a compatible cartridge is loaded correctly, the left LED lights either

green or orange. If you load, or attempt to load, an incompatible

cartridge, the left LED stays off (see Loading a Cartridge

DLT-S4 Product Manual 21

Eject button.)

EJECT command or by

on page 32).

Page 40

Chapter 3 Cartridges

Backward-read Compatibility Transfer Rate

Backward-read Compatibility Transfer Rate 3

The DLT-S4 tape drive includes a backward-read compatibility feature

that enables it to read Super DLTtape I and Super DLTtape II cartridges

(but not write to these cartridges). The following table lists the transfer

rates for backward-read cartridges.

Table 21 Backward-read

Compatibility Transfer Rates

Native Read

Transfer Rate in

DLT-S4 Tape

b

Drive

Format

a

Cartridge Type Native Capacity

Native Read

Transfer Rate

SDLT 600 Super DLTtape II 300 GB 36.0 MB/sec

SDLT 320 Super DLTtape I 160 GB 16.0 MB/sec

a. Tape drives older than the DLT-S4 will eject a data cartridge written with DLT-S4 format.

b. Transfer rates shown are the minimum when reading uncompressed data.

≥ 18.0 MB/sec

≥ 8.0 MB/sec

DLT-S4 Product Manual 22

Page 41

Chapter 3 Cartridges

Cartridge Handling and Storage Guidelines

Cartridge Handling and Storage Guidelines 3

DLTtape S4 cartridges are engineered to be reliable, robust, and durable.

They are manufactured to withstand 1,000,000 head passes and have a

shelf life of 30 years. By following these guidelines, you will greatly

reduce the chance that you will experience problems with the cartridges

or cause damage to the tape drive system.

Caution: The safety of data depends on proper care and handling of

cartridges.

Caution: Never power off the tape drive while it contains a

cartridge. Failure to remove a cartridge prior to power-off

may result in cartridge or tape drive damage.

For best results, follow these guidelines for data cartridge handling and

storage:

• Follow the handling instructions and observe the environmental

specifications provided in the plastic cartridge case.

• Inspect tape cartridges for damage as described in Inspecting a

Cartridge on page 25.

• Store cartridges vertically in their protective cases when not in use or

when archived (see figure 6

• Protect cartridges from shock, vibration, moisture, direct sunlight,

dust, smoke, and magnetic fields.

• Do not stack more than five cartridges on top of each other.

• Do not carry cartridges loosely in a box or any other container.

Allowing cartridges to jostle together exposes them to unnecessary

physical shock.

• When carrying cartridges in their cases, orient the cases so that the

grooves in the cases interlock. This prevents the cases from slipping

apart and falling.

• Do not drop the cartridge. A dropped cartridge may have dislodged,

loosened, or damaged internal components. If you drop a cartridge,

give it a thorough visual inspection (see Inspecting a Cartridge

page 25 for complete instructions).

DLT-S4 Product Manual 23

).

on

Page 42

Chapter 3 Cartridges

Cartridge Handling and Storage Guidelines

• Use only the slide-in labels provided with each cartridge or slide-in

bar code labels designed for use with DLT media. Slide labels into the

label slot on the cartridge (see figure 6

). Never apply adhesive labels

or “sticky” notes on the top, side, or bottom of tape cartridges, and do

not write on the cartridge.

• Do not write on the labels with debris-producing writing

instruments, such as graphite pencils and water-soluble felt pens.

• Other than the bar code label, ensure that nothing else is stuck to the

cartridge before inserting it into the tape drive. Loose labels and other

materials can cling to the bottom of the cartridge and get stuck in the

tape drive.

• Leave unused labels attached to the printed material (called the

u-card) within the cartridge case.

• Store any loose labels or other materials that are smaller than 4.5 x 4.5

inches (114.3 x 114.3 mm) separate from the cartridge. A loose label or

piece of paper accidentally inserted into the tape drive along with a

cartridge can prevent the hub reel and tape drive gear from meshing.

• Never touch the tape or media leader. Dust and oils from your skin

contaminate the tape and affect performance.

• Avoid unnecessarily opening the cartridge media access door (see

figure 9

). This may expose the media to contamination or physical

damage.

• Protect cartridges from shock, vibration, moisture, direct sunlight,

dust, smoke, and magnetic fields. Devices that may produce

magnetic fields, such as computer monitors, motors, or video

equipment can alter or erase data on the media.

• Observe the proper temperature and humidity conditions for

operating and storing cartridges as follows:

Temperature

Operating 10 °C to 40 °C (50 °F to 104 °F)

Storage (with data) 18 °C to 28°C (64 °F to 82 °F)

Humidity

Operating 20% to 80% non-condensing

Storage (with data) 40% to 60% non-condensing

DLT-S4 Product Manual 24

Page 43

Figure 6 Data Cartridge Care

Chapter 3 Cartridges

Inspecting a Cartridge

Note: If storage or transportation of a cartridge has exposed it to

temperature or humidity conditions outside the

specifications shown in the preceding table, allow the

cartridge to acclimate to the proper operating environment

for 24 hours before using it.

Store data cartridges vertically in

plastic cases

Use slide-in labels

Inspecting a Cartridge 3

Improper cartridge handling is the primary reason for tape drive

problems. To avoid losing data or damaging the tape drive, inspect the

cartridges:

• Before loading a new cartridge in the tape drive

• After dropping a cartridge or subjecting it to physical shock

DLT-S4 Product Manual 25

Page 44

Chapter 3 Cartridges

Inspecting a Cartridge

• When the tape drive becomes inoperable after loading a cartridge

• When you receive a shipment of cartridges that show any sign of

shipping damage

Follow these steps to inspect a tape cartridge:

1 Gently shake the cartridge and listen for loose pieces.

2 Remove the cartridge from its protective plastic case.

3 Check for loose debris attached to the cartridge, and for other

contamination (oily, slimy, or sticky substances) that may have built

up on the surface of the cartridge.

4 Check the cartridge for any obvious cracks or other physical damage.

Rotate the cartridge in your hands, looking for broken or missing

parts.

5 Rotate the cartridge to view the bottom (see figure 7).

Confirm that the spring-loaded hub on the bottom of the cartridge is

centered. Press the hub to ensure that the spring is functioning

properly and that the hub returns to its normal position.

Figure 7 Cartridge Bottom

View

Spring-loaded hub

Reel lock

DLT-S4 Product Manual 26

Page 45

Figure 8 Cartridge Reel Locks

Chapter 3 Cartridges

Inspecting a Cartridge

Check that both reel lock tabs (the small plastic tabs inside the reel

6

lock) are partially visible (see figure 8

).

One reel lock is located on the end of the cartridge that is inserted

into the tape drive. The other is on the bottom of the cartridge. The

reel locks are black.

Note: The reel locks can break if you drop the cartridge. If the

reel lock tabs are not visible, do not use the cartridge.

Reel lock

Reel lock

7

Open the media access door by pressing on the tab in the door pivot

notch (see figure 9

DLT-S4 Product Manual 27

). Ensure that you do not touch the media leader.

Page 46

Figure 9 Opening the Media

Access Door

Chapter 3 Cartridges

Inspecting a Cartridge

Tab in the door pivot notch

8 Compare what you see inside the media access door to figure 10.

Look for damage to the cartridge buckling clips, including:

• Bent or “toed-in” appearance on one or both clips

• Improper seating (clips should be fully retracted towards the left

side of the opening)

• Bending of the leader bar that supports the clips

Figure 10 Inspecting Inside the

Media Access Door

Leader bar

DLT-S4 Product Manual 28

Proper position

of cartridge

buckling clips

Cartridge buckling clips

excessively “toed-in”

Page 47

Chapter 3 Cartridges

Write-protecting a Cartridge

Examine the visible media leader (without touching it) for excessive

9

debris, oily or sticky residue, condensed droplets of moisture, or any

other signs of contamination.

10 Finally, check for proper operation of the cartridge’s write-protect tab

(see figure 11

This sliding tab, located on the end of the cartridge used for the label,

should snap smartly back and forth, and the orange tab should be

visible when the cartridge is set to provide write protection (you

cannot write over the data already on the media).

Caution: If a cartridge shows any signs of damage, do not use it.

).

If a cartridge is dropped, retrieve the data, back it up

on a new cartridge, and dispose of the dropped

cartridge. A dropped cartridge should not reused even

if it shows no signs of damage.

Write-protecting a Cartridge 3

Each cartridge has a write-protect tab, which you can use to prevent

accidental erasure of data. Before inserting the cartridge into the tape

drive, position the write-protect tab on the front of the cartridge (see

figure 11

Note: To ensure you don’t erase valuable data already written to a

) according to the kind of operations you expect to perform.

data cartridge, always make sure the cartridge is writeprotected before inserting it into the tape drive.

DLT-S4 Product Manual 29

Page 48

Figure 11 Cartridge Writeprotect Tab

Chapter 3 Cartridges

Write-protecting a Cartridge

Orange

indicator

rectangle

Writeprotect tab

• To enable write protection — Slide the write-protect tab to the left so

that the bright orange rectangle is visible. This is the visual reminder

that you cannot write data to the media.

You can read existing data; however, you cannot write over existing

data on the media, nor append additional data to the media.

•

T o disable write protection — Slide the write-protect tab to the right so

that the orange rectangle is not visible.

You can write over existing data on the media, and you can append

additional data to the media unless the cartridge is write-protected

via firmware (in other words, the cartridge has been formatted as a

DLTSage WORM cartridge; see DLTSage WORM

on page 34 for

details).

For more details about write-protecting a cartridge, see table 22

DLT-S4 Product Manual 30

.

Page 49

Chapter 3 Cartridges

Write-protecting a Cartridge

Table 22 Write-protect Tab

Positions

Write-protect

Tab Position

Orange Writeprotect

Result

Indicator

Before Loading the Cartridge

Enabled

(Slide tab to left)

Visible • You cannot write data to the

media

• You cannot overwrite existing

data on the media

• You cannot append

additional data to the media

Disabled

(Slide tab to

right)

Not Visible Unless the cartridge is write-

protected via firmware:

• You can write data to the

media

• You can overwrite existing

data on the media

• You can append additional

data to the media

After Loading the Cartridge and During Operation

If you move the

write-protect tab

from its right

(disabled)

position to its left

Visible If the tape drive is currently

writing to a cartridge, the writeprotect feature does not take

effect until after the current write

operation completes.

(enabled)

position

If you move the

write-protect tab

from its left

Not Visible The cartridge becomes write-

enabled after a variable number

of seconds.

(enabled)

position to its

right (disabled)

position

DLT-S4 Product Manual 31

Page 50

Chapter 3 Cartridges

Loading a Cartridge

Loading a Cartridge 3

Follow these steps to load a cartridge (see figure 12).

1 Insert the cartridge into the receiver on the front of the tape drive.

2 Push the front center of the cartridge into the tape drive until the soft-

load mechanism engages and mounts the tape.

The middle LED flashes to show that the media is loading. When the

media reaches the Beginning of Tape (BOT) marker, the middle LED

lights steadily.

The cartridge is now ready for use.

To verify that you have loaded a compatible cartridge, look at the left

LED for the following indications.

If the Left LED is... Then this cartridge is loaded...

Green DLTtape S4

Orange Super DLTtape I or Super DLTtape II

Off No cartridge is inserted or an incompatible

cartridge is inserted

For more information on choosing cartridges, see Choosing Compatible

Cartridges on page 19.

DLT-S4 Product Manual 32

Page 51

Figure 12 Loading a Cartridge

Chapter 3 Cartridges

Unloading a Cartridge

Left LED

Eject button

Middle LED

Unloading a Cartridge 3

Follow these steps to unload a cartridge (see figure 12).

Caution: Never turn off the tape drive or the host while the tape

drive contains a cartridge. Failure to remove a cartridge

prior to power-off may result in cartridge or tape drive

damage.

Do NOT rush removal of the cartridge. Wait until the tape

drive ejects the cartridge and the middle LED lights steady

before removing the cartridge.

1 Press the Eject button (or issue an appropriate system software

command).

The tape drive completes any active writing, then rewinds. The

middle LED flashes as the media rewinds. When the media is

finished rewinding, the tape drive ejects the cartridge and the middle

LED lights steadily.

DLT-S4 Product Manual 33

Page 52

Chapter 3 Cartridges

DLTSage WORM

Remove the cartridge from the tape drive and return it to its plastic

2

case to protect it from damage.

DLTSage WORM 3

DLTSage WORM is the firmware compliance management function of

DLTSage. This feature uses a Write Once, Read Many (WORM)

functionality, which allows you to securely archive data stored on a

DLTtape S4 cartridge written on a DLT-S4 tape drive. The firmware

allows you to append data to a cartridge, but you cannot rewrite,

reformat, or erase the data.

DLTSage WORM firmware is a standard feature of the DLT-S4 tape drive

and the DLTtape S4 cartridge. See Formatting a Cartridge as DLTSage

WORM on page 35 for instructions on how to create a WORM cartridge.

DLTSage WORM Features 3 This section details the many features of DLTSage WORM. For more

information, see

http://www.dlttape.com/technology/DLTSageWORM/index.aspx

Feature Description

Security The tape drive’s firmware places an electronic signature key on each cartridge to

ensure that data written to the media cannot be rewritten, reformatted, or erased.

• The key is a unique identifier that cannot be altered.

• The firmware allows you to append new data to the cartridge.

• The cartridge initialization process assures that only unformatted cartridges will

be WORM enabled.

Verification The verification is a two-part process.

• The DLT-S4 tape drive provides best-of-class verification through its ECC

algorithms.

• The firmware provides archive media verification and tamper verification with

time and date signatures.

DLT-S4 Product Manual 34

Page 53

Chapter 3 Cartridges

DLTSage WORM

Feature Description

Identification The identification applies to both the data and the cartridges.

• The storage management software issues a time and date stamp, which enables

you to locate and authenticate specific records using ISV compliant storage

management software.

• The cartridge used for DLTSage WORM is a standard DLTtape S4 cartridge. Use

the special yellow labels provided by Quantum to identify the WORM

cartridges.

Duplication The data stored on the DLTtape S4 cartridge can be downloaded to another storage

media through any ISV-compliant storage management software.

Formatting a Cartridge as DLTSage WORM

Some backup software applications work with DLTSage to allow you to

format a tape cartridge as DLTSage WORM directly via the backup

3

software user interface.

If your backup software application does not allow this, you can use

xTalk Management Console to create the DLTSage WORM cartridge. (See

xTalk Management Console

on page 135 for information about xTalk

Management Console.)

Follow these steps to format a cartridge with DLTSage WORM using

xTalk Management Console:

1 If xTalk Mangement Console is not installed on your computer,

download it now (see Accessing the Tools

on page 132 for

instructions on downloading).

2 Obtain a blank DLTtape S4 cartridge that you want to format as

DLTSage WORM. Ensure that the cartridge contains no data.

3 Insert the cartridge into the drive and wait for the tape drive to come

ready.

4 Launch xTalk Management Console.

5 Click the DLTSage WORM button on the toolbar (see figure 13).

DLT-S4 Product Manual 35

Page 54

Figure 13 DLTSage WORM

Button

Chapter 3 Cartridges

DLTSage WORM

The DLTSage WORM Wizard displays.

6 Click Format to continue.

The cartridge is formatted as a DLTSage WORM cartridge.

Further information and instructions are available in the xTalk

Management Console for Windows User’s Guide found in the

Help menu in

xTalk Management Console.

DLT-S4 Product Manual 36

Page 55

Chapter 4

4Specifications

This chapter provides the following specifications for the DLT-S4 tape

drive:

• Physical Specifications

• Dimensions and Weights

• Electromagnetic Field Specifications

• Acoustic Noise Emissions

The specifications noted are applicable to the drive itself and not as it is

integrated into an automation system. Testing performed to validate

these specifications was done with the internal tape drive and the

tabletop tape drive models.

DLT-S4 Product Manual 37

Page 56

Chapter 4 Specifications

Physical Specifications

Physical Specifications 4

Table 23 lists error types and environmental operating and storage limits

for the DLT-S4 tape drive.

Table 23 Physical Specifications

Data Integrity

Error Type Frequency

Detected, Unrecoverable Read < 1 error in 10

Undetected Read < 1 error in 10

Temperature

Operating 10 °C to 40 °C (50 °F to 104 °F)

Storage -40 °C to 66 °C (-40 °F to 150 °F)

Humidity

Operating 20% to 80% non-condensing

Storage 10% to 95% non-condensing

Safety Certifications

18

bits read

27

bits read