Page 1

DLT™4000 Tape Drive

Product Manual

November 10, 2003

81-60043-04

Page 2

Quantum reserves the right to make changes and improvements to its products, without incurring

any obligation to incorporate such changes or improvements in units previously sold or shipped.

Quantum reserves the right to make changes to this product manual without incurring any

obligation to notify recipients of earlier versions of the product manual.

You can request Quantum publications from your Quantum Sales Representative or order them

directly from Quantum.

Publication Number: 81-60043-04, November 10, 2003

SERVICE CENTERS

Quantum Service Center Quantum Asia-Pacific Pte. Ltd. Quantum Customer Service

715 Sycamore Avenue 50 Tagore Lane #b1-04 Quantum Ireland, Ltd.

Milpitas, California 95035 Singapore, 2678 Finnabair Industrial Park

Phone (888) 827-3378 Phone: (65) 450-9333 Dundalk

FAX: (800) 4DISKFAX FAX: (65) 452-2544 County Louth, Ireland

BBS: (800) 472-9799 Phone: (353) 42-55350

Fax: (353) 45-55355

Copyright 1995-2001 by Quantum Corporation. All rights reserved. Printed in U.S.A.

Quantum and the Quantum logo are trademarks of Quantum Corporation, registered in the U.S.A.

and other countries. DLTtape and the DLTtape logo are trademarks of Quantum Corporation.

Products mentioned herein are for identification purposes only and may be trademarks or

registered trademarks of their respective companies.

Page 3

USER MANUAL STATEMENTS FOR CLASS A EQUIPMENT (INTEGRATIBLE TAPE SYSTEM)

This equipment generates, uses, and may emit radio frequency energy. The equipment has been

type tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of

FCC rules, which are designed to provide reasonable protection against such radio frequency

interference.

Operation of this equipment in a residential area may cause interference in which case the user at

his own expense will be required to take whatever measures may be required to correct the

interference.

Any modifications to this device - unless expressly approved by the manufacturer - can void the

user’s authority to operate this equipment under part 15 of the FCC rules.

Note: Additional information on the need to interconnect the device with shielded (data) cables or

the need for special devices, such as ferrite beads on cables, is required if such means of interference

suppression was used in the qualification test for the device. This information will vary from device

to device and needs to be obtained from the EMC group or product manager.

Warning!

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

Achtung!

Dieses ist ein Gerät der Funkstörgrenzwertklasse A. In Wohnbereichen können bei Betrieb dieses

Gerätes Rundfunkstörungen auftreten, in welchen Fällen der Benutzer für entsprechende

Gegenmaßnahmen verantwortlich ist.

Warning!

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Attention!

Ceci est un produit de Classe A. Dans un environnement domestique, ce produit risque de créer des

interférences radioélectriques, il appartiendra alors à l'utilisateur de prendre les mesures spécifiques

appropriées.

Page 4

USER MANUAL STATEMENTS FOR CLASS A EQUIPMENT (continued)

USER MANUAL STATEMENTS FOR CLASS B EQUIPMENT (TABLETOP VERSION)

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. Any modifications to this device unless expressly approved by the manufacturer - can void the user’s authority to operate this

equipment under part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference and (2) This device must accept any

interference that may cause undesirable operation.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected

• Consult the dealer or an experienced radio/TV technician for help.

Note: Additional information on the need to interconnect the device with shielded (data) cables

or the need for special devices, such as ferrite beads on cables, is required if such means of

interference suppression was used in the qualification test for the device. This information will

vary from device to device and needs to be obtained from the EMC group or product manager.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Page 5

USER MANUAL STATEMENTS FOR CLASS B EQUIPMENT (continued)

Page 6

Page 7

TABLE OF CONTENTS

Revision History........................................................................................................ xix

About This Manual .................................................................................................. xxi

Chapter 1: General Description and Specifications.................................................... 1-1

1.1 Product Description.............................................................................. 1-1

1.2 Product Features ................................................................................. 1-3

1.3 Product Specifications .......................................................................... 1-3

1.3.1 Physical Specifications ................................................................. 1-3

1.3.2 Interface Type............................................................................. 1-4

1.3.3 Storage Capacity......................................................................... 1-4

1.3.4 Performance Data....................................................................... 1-4

1.3.5 Environmental Specifications....................................................... 1-5

1.3.6 Power Requirements................................................................... 1-7

1.3.7 Electromagnetic Emissions........................................................... 1-7

1.3.8 EMI and Safety Certifications....................................................... 1-8

1.3.9 Reliability (Projected) ................................................................... 1-8

1.3.10 Acoustic Noise Emissions.............................................................. 1-9

1.3.11 Tape Drive Recording Type .......................................................... 1-9

1.3.12 DLTtape Recording Media Specifications...................................... 1-10

Chapter 2: Hardware Implementation ..................................................................... 2-1

2.1 Safety, Handling and Electrostatic Discharge (ESD) Protection ................ 2-1

2.1.1 Safety Precautions ...................................................................... 2-2

2.1.2 Handling .................................................................................... 2-2

2.1.3 Electrostatic Discharge (ESD) Protection ....................................... 2-3

2.2 Drive Setup .......................................................................................... 2-3

2.2.1 Set the Rackmount Drive SCSI ID.................................................. 2-4

2.2.2 Configure the Rackmount Drive for TERMPWR

(Single-Ended Only)..................................................................... 2-6

2.2.3 Configure the Rackmount Drive for Parity Checking ..................... 2-7

2.2.4 Configure the Tabletop Drive ...................................................... 2-7

2.3 Drive Installation................................................................................... 2-8

2.4 Drive Connections ................................................................................ 2-10

2.4.1 SCSI and Power Connectors (Rackmount)..................................... 2-11

2.4.2 Optional Loader Connector (Rackmount) ..................................... 2-14

2.4.3 Tabletop Drive Connectors.......................................................... 2-15

2.5 Drive Controls and Light Emitting Diodes (LEDs)..................................... 2-17

2.5.1 Front Panel Controls and LEDs..................................................... 2-17

Quantum DLT 4000 Tape Drive vii

Page 8

Table of Contents

2.5.2 Selecting Density......................................................................... 2-21

2.6 Power On Self Test (POST).................................................................... 2-23

2.7 Troubleshooting................................................................................... 2-25

Chapter 3: SCSI Description..................................................................................... 3-1

3.1 SCSI Overview ...................................................................................... 3-1

3.2 SCSI Commands.................................................................................... 3-1

3.3 Signal States ........................................................................................ 3-4

3.3.1 Signal Values .............................................................................. 3-4

3.3.2 SCSI ID Bits.................................................................................. 3-6

3.4 SCSI Signals.......................................................................................... 3-6

3.4.1 SCSI Signal Definitions................................................................. 3-6

3.4.2 Signal Bus Timing........................................................................ 3-7

3.5 SCSI Bus Phases .................................................................................... 3-10

3.5.1 BUS FREE Phase ........................................................................... 3-10

3.5.2 ARBITRATION Phase ..................................................................... 3-12

3.5.3 SELECTION Phase ........................................................................ 3-13

3.5.4 RESELECTION Phase ..................................................................... 3-15

3.5.5 Information Transfer Phases........................................................ 3-17

3.6 SCSI Bus Conditions.............................................................................. 3-24

3.6.1 Attention Condition.................................................................... 3-24

3.6.2 Reset Condition .......................................................................... 3-25

3.6.3 Queued Unit Attentions.............................................................. 3-26

Chapter 4: Messages............................................................................................... 4-1

4.1 Message Format ................................................................................... 4-1

4.2 Supported SCSI Messages..................................................................... 4-5

4.2.1 ABORT Message (06h)................................................................. 4-5

4.2.2 BUS DEVICE RESET Message (0Ch) ............................................... 4-5

4.2.3 COMMAND COMPLETE Message (00h) ........................................ 4-5

4.2.4 DISCONNECT Message (04h) ....................................................... 4-6

4.2.5 IDENTIFY Message (80h - FFh)...................................................... 4-7

4.2.6 INITIATOR DETECTED ERROR Message (05h) ................................. 4-8

4.2.7 LINKED COMMAND COMPLETE Message (0Ah) ............................. 4-9

4.2.8 LINKED COMMAND COMPLETE, with Flag Message (0Ah).............. 4-9

4.2.9 MESSAGE PARITY ERROR Message (09h)....................................... 4-9

4.2.10 MESSAGE REJECT Message (07h)................................................. 4-9

4.2.11 NO OPERATION Message (08h).................................................... 4-10

4.2.12 RESTORE POINTERS Message (03h) .............................................. 4-10

4.2.13 SAVE DATA POINTER Message (02h)............................................ 4-10

4.2.14 SYNCHRONOUS DATA TRANSFER REQUEST Message ..................... 4-10

viii Quantum DLT 4000 Tape Drive

Page 9

Table of Contents

Chapter 5: SCSI Commands..................................................................................... 5-1

5.1 Overview of Command and Status Processing........................................ 5-1

5.1.1 SCSI Pointers............................................................................... 5-3

5.1.2 Command Descriptor Block.......................................................... 5-4

5.1.3 Status/Error Reporting ................................................................ 5-7

5.1.4 DATA-Phase Command Components............................................ 5-8

5.1.5 Unit Attention Condition ............................................................ 5-11

5.1.6 Behavior At Power-On and SCSI Bus Reset.................................... 5-11

5.1.7 Data Cache and Tape Write Interaction........................................ 5-12

5.2 SCSI Command Descriptions.................................................................. 5-13

5.3 ERASE Command (19h) ......................................................................... 5-15

5.4 INQUIRY Command (12h)...................................................................... 5-17

5.4.1 Standard Inquiry Data Page......................................................... 5-18

5.4.2 Vendor Unique Inquiry Data........................................................ 5-21

5.4.3 Supported Vital Product Data Page (00h)..................................... 5-24

5.5 LOAD UNLOAD Command (1Bh)........................................................... 5-27

5.6 LOCATE Command (2Bh)...................................................................... 5-31

5.7 LOG SELECT Command (4Ch)................................................................. 5-33

5.7.1 Log Detection Summary in LOG SELECT Command

Descriptor Block .......................................................................... 5-35

5.7.2 Operation of LOG SELECT............................................................ 5-35

5.7.3 LOG SELECT Page Format ............................................................ 5-36

5.7.4 Error Detection Summary in LOG SELECT Pages............................ 5-39

5.8 LOG SENSE Command (4Dh).................................................................. 5-41

5.8.1 Error Detection Summary in LOG SENSE Command

Descriptor Block .......................................................................... 5-44

5.8.2 Supported Pages Log Page (00h)................................................. 5-45

5.8.3 Read (Page 03h)/Write (Page 02h) Error LOG SENSE Page.............. 5-46

5.8.4 Last n Error Events Page (07h) ..................................................... 5-49

5.8.5 Read/Write Compression Page (32h)............................................. 5-52

5.8.6 Device Wellness Page (33h).......................................................... 5-57

5.8.7 Device Status Page (3Eh) ............................................................. 5-60

5.9 MODE SELECT (6) / (10) Command (15h / 55h)....................................... 5-63

5.9.1 Mode Parameter List ................................................................... 5-65

5.9.2 Read/Write Error Recovery Page (01h) .......................................... 5-72

5.9.3 Disconnect/Reconnect Page ........................................................ 5-73

5.9.4 Control Mode Page (0Ah)............................................................ 5-77

5.9.5 Data Compression Page (0Fh) ...................................................... 5-79

5.9.6 Device Configuration Page (10h).................................................. 5-81

5.9.7 Medium Partition Page (11h)....................................................... 5-84

5.9.8 EEPROM Vendor Unique Page (3Eh)............................................. 5-86

5.9.9 Changeable Parameters within MODE SELECT .............................. 5-93

Quantum DLT 4000 Tape Drive ix

Page 10

Table of Contents

5.10 MODE SENSE (6) / (10) Command (1Ah / 5Ah)....................................... 5-95

5.10.1 MODE SENSE Data Headers......................................................... 5-98

5.10.2 MODE SENSE Block Descriptors....................................................5-100

5.10.3 MODE SENSE Mode Pages...........................................................5-102

5.11 PREVENT / ALLOW MEDIUM REMOVAL Command (1Eh)..........................5-119

5.12 READ Command (08h)...........................................................................5-121

5.13 READ BLOCK LIMITS Command (05h) .....................................................5-125

5.14 READ BUFFER Command (3Ch)..............................................................5-127

5.14.1 Combined Header and Data Mode ..............................................5-128

5.14.2 Data Mode ................................................................................5-129

5.14.3 Descriptor Mode ........................................................................5-129

5.15 READ POSITION Command (34h)............................................................5-131

5.16 RECEIVE DIAGNOSTIC RESULTS Command (1Ch)......................................5-135

5.17 RELEASE UNIT Command (17h)..............................................................5-137

5.18 REPORT LUNS Command (0Ah).............................................................. 5-139

5.19 REQUEST SENSE Command (03h)...........................................................5-141

5.20 RESERVE UNIT Command (16h).............................................................5-151

5.21 REWIND Command (01h).......................................................................5-153

5.22 SEND DIAGNOSTIC Command (1Dh).......................................................5-155

5.23 SPACE Command (11h)........................................................................5-161

5.24 TEST UNIT READY Command (00h).........................................................5-163

5.25 VERIFY Command (13h).........................................................................5-165

5.26 WRITE Command (0Ah).........................................................................5-167

5.27 WRITE BUFFER Command (3Bh)..............................................................5-169

5.27.1 Write Combined Header and Data Mode (000b) ...........................5-170

5.27.2 Write Data Mode (010b)..............................................................5-170

5.27.3 Download Microcode Mode (100b)..............................................5-171

5.27.4 Download Microcode and Save Mode (101b) ...............................5-171

5.28 WRITE FILEMARKS Command (10h) .......................................................5-173

Appendix A: Definition of Vendor Unique Sense Data Information ...................................................... A-1

Appendix B: EEPROM-Resident Bugcheck and Event Logs .................................................................... B-1

B.1 EEPROM Packets (Last n Events)........................................................................................ B-1

B.2 Bugcheck Packets................................................................................................................ B-1

B.2.1 POST Failure Packets............................................................................................... B-2

B.2.2 Event Log Packets................................................................................................... B-3

Appendix C: Updating the Firmware.......................................................................................................... C-1

C.1 Overview .............................................................................................................................. C-1

C.2 Creating a Firmware Update Tape .................................................................................... C-1

C.3 Firmware Update Procedure.............................................................................................. C-2

C.4 Interpreting the Results of a Firmware Update ............................................................... C-4

Appendix D: The Tape Cartridge ................................................................................................................ D-1

D.1 Tape Cartridge Handling Guidelines ................................................................................ D-1

D.2 Tape Cartridge Inspection Procedure................................................................................ D-4

x Quantum DLT 4000 Tape Drive

Page 11

Index

Table of Contents

D.3 Tape Cartridge Write-Protect Switch ..................................................... D-8

D.4 Loading a Tape Cartridge ..................................................................... D-10

D.5 Unloading a Tape Cartridge .................................................................. D-11

D.6 Using a Cleaning Tape Cartridge ........................................................... D-12

Quantum DLT 4000 Tape Drive xi

Page 12

Table of Contents

Figures

Figure 1-1. Quantum DLT 4000 Tape Drive (Rackmount)............................................ 1-2

Figure 1-2. Quantum DLT 4000 Tape Drive (Tabletop) ............................................... 1-2

Figure 2-1. DLT 4000 SCSI ID Jumper Location (Rackmount Version Shown)............... 2-4

Figure 2-2. DLT 4000 TERMPWR and Parity Check Jumper Locations

(Rackmount Version Shown) .................................................................. 2-6

Figure 2-3. Tabletop (Version 1) Back Panel Controls................................................. 2-7

Figure 2-4. Tabletop (Version 2) Back Panel Controls................................................. 2-8

Figure 2-5. Rackmount Drive Mounting Locations – Side and Bottom Views .............. 2-9

Figure 2-6. SCSI and Power Cable Connectors (Rackmount Version Shown)............... 2-11

Figure 2-7. Loader Connector Block Location (Rackmount Version Shown)................ 2-14

Figure 2-8. Tabletop (Version 1) Back Panel Connectors............................................ 2-15

Figure 2-9. Tabletop (Version 2) Back Panel Connectors............................................ 2-16

Figure 2-10. DLT 4000 Front Panel............................................................................ 2-17

Figure 4-1. Extended Message - Data Format............................................................ 4-4

Figure 4-2. IDENTIFY Message - Data Format............................................................. 4-7

Figure 4-3. SYNCHRONOUS DATA TRANSFER REQUEST Message - Data Format........... 4-11

Figure 5-1. Typical Command Descriptor Block - Data Format .................................... 5-4

Figure 5-2. Command Descriptor Block Control Field - Data Format ........................... 5-6

Figure 5-3. ERASE Command Descriptor Block - Data Format..................................... 5-15

Figure 5-4. INQUIRY Command Descriptor Block - Data Format .................................. 5-17

Figure 5-5. Standard Inquiry Data Page - Data Format .............................................. 5-19

Figure 5-6. INQUIRY Vendor Unique Bytes Definitions................................................ 5-22

Figure 5-7. Supported Vital Product Data Pages Page - Data Format ......................... 5-24

Figure 5-8. Unit Serial Number Page - Data Format................................................... 5-25

Figure 5-9. Firmware Build Information Page - Data Format ...................................... 5-26

Figure 5-10. LOAD UNLOAD Command Descriptor Block - Data Format....................... 5-28

Figure 5-11. LOCATE Command Descriptor Block - Data Format................................. 5-31

Figure 5-12. LOG SELECT Command Descriptor Block - Data Format........................... 5-33

Figure 5-13. LOG SELECT Log Page Header Format ................................................... 5-36

Figure 5-14. LOG SELECT Log Parameters Format...................................................... 5-37

Figure 5-15. LOG SENSE Command Descriptor Block - Data Format............................ 5-41

Figure 5-16. Supported Pages Page - Data Format.................................................... 5-45

Figure 5-17. Read/Write Error LOG SENSE Header Format.......................................... 5-46

Figure 5-18. Log Parameters Format for Read/Write Error LOG SENSE Page................ 5-47

Figure 5-19. Last n Error Events LOG SENSE Header Format....................................... 5-50

Figure 5-20. Log Parameters Format for Last n Error Events LOG SENSE Page ............ 5-51

Figure 5-21. Read/Write Compression Ratio LOG SENSE Header Format...................... 5-52

Figure 5-22. Log Parameters Format for Read / Write Compression Ratio LOG SENSE

Page (Parameter Codes 00h and 01h) ..................................................... 5-53

xii Quantum DLT 4000 Tape Drive

Page 13

Table of Contents

Figure 5-23 Log Parameters Format for Read / Write Compression Ratio LOG SENSE

Page (Parameter Codes 02h through 09h)............................................... 5-54

Figure 5-24. Device Wellness LOG SENSE Header Format ........................................... 5-57

Figure 5-25. Log Parameters Format for Device Wellness LOG SENSE Page

(Parameters 0000h – 000Fh) ................................................................... 5-58

Figure 5-26. Device Status LOG SENSE Header Format................................................ 5-60

Figure 5-27. Log Parameters Format for Device Status LOG SENSE Page

(Parameters 0000h, 0001h, or 0002h) ..................................................... 5-61

Figure 5-28. Log Parameters Format for Device Status LOG SENSE Page

Parameter 0001h (Cleaning Related) ....................................................... 5-62

Figure 5-29. MODE SELECT (6) and (10) Command Descriptor Blocks - Data Format ..... 5-64

Figure 5-30. MODE SELECT Mode Parameter List - Data Format.................................. 5-65

Figure 5-31. MODE SELECT Mode Parameter Header - Data Format............................ 5-66

Figure 5-32. MODE SELECT Mode Parameter Block Descriptor - Data Format............... 5-68

Figure 5-33. MODE SELECT Page Descriptor – Page Format ........................................ 5-70

Figure 5-34. Error Recovery Page - Data Format......................................................... 5-72

Figure 5-35. Disconnect / Reconnect Page - Data Format............................................ 5-74

Figure 5-36. Control Mode Page Format Descriptor - Data Format.............................. 5-77

Figure 5-37. Data Compression Page Format Descriptor - Data Format........................ 5-79

Figure 5-38. Device Configuration Page - Data Format............................................... 5-81

Figure 5-39. Medium Partition Page Format Descriptor - Data Format......................... 5-84

Figure 5-40. EEPROM Vendor Unique Page - Data Format .......................................... 5-86

Figure 5-41. EEPROM Vendor Unique Page “Vendor ID” Example - Data Format.......... 5-91

Figure 5-42. EEPROM Vendor Unique Page “Forced Density” Example - Data Format ... 5-92

Figure 5-43. MODE SENSE (6) Command Descriptor Block - Data Format..................... 5-95

Figure 5-44. MODE SENSE (10) Command Descriptor Block - Data Format ................... 5-96

Figure 5-45. MODE SENSE (6) Data Header - Data Format .......................................... 5-98

Figure 5-46. MODE SENSE (10) Data Header - Data Format......................................... 5-98

Figure 5-47. MODE SENSE (6) Block Descriptor - Data Format .....................................5-100

Figure 5-48. MODE SENSE Page Descriptor - Data Format ..........................................5-102

Figure 5-49. Read / Write Error Recovery Page - Data Format......................................5-104

Figure 5-50. Disconnect / Reconnect Page - Data Format............................................5-106

Figure 5-51. Control Mode Page - Data Format .........................................................5-108

Figure 5-52. Data Compression Page - Data Format .................................................5-110

Figure 5-53. Device Configuration Page - Data Format.............................................5-112

Figure 5-54. Medium Partition Page - Data Format ..................................................5-115

Figure 5-55. PREVENT / ALLOW MEDIUM REMOVAL Command Descriptor Block -

Data Format ..........................................................................................5-119

Figure 5-56. READ Command Descriptor Block - Data Format .....................................5-121

Figure 5-57. READ BLOCK LIMITS Command Descriptor Block - Data Format ................5-125

Figure 5-58. READ BLOCK LIMITS Data - Data Format .................................................5-126

Figure 5-59. READ BUFFER Command Descriptor Block - Data Format..........................5-127

Figure 5-60. READ BUFFER Header - Data Format .......................................................5-128

Quantum DLT 4000 Tape Drive xiii

Page 14

Table of Contents

Figure 5-61. READ BUFFER Descriptor - Data Format...................................................5-129

Figure 5-62. READ POSITION Command Descriptor Block - Data Format ......................5-131

Figure 5-63. READ POSITION - Data Format................................................................5-132

Figure 5-64. RECEIVE DIAGNOSTICS RESULTS Command Descriptor Block –

Data Format ..........................................................................................5-135

Figure 5-65. RECEIVE DIAGNOSTICS RESULTS - Data Format ........................................5-136

Figure 5-66. RELEASE UNIT Command Descriptor Block - Data Format.........................5-137

Figure 5-67. REPORT LUNS Command Descriptor Block - Data Format .........................5-139

Figure 5-68. LUN Reporting Parameter List — Data Format.........................................5-140

Figure 5-69. REQUEST SENSE Command Descriptor Block - Data Format......................5-141

Figure 5-70. REQUEST SENSE - Data Format...............................................................5-143

Figure 5-71. RESERVE UNIT Command Descriptor Block - Data Format.........................5-151

Figure 5-72. REWIND Command Descriptor Block - Data Format..................................5-153

Figure 5-73. SEND DIAGNOSTIC Command Descriptor Block - Data Format..................5-155

Figure 5-74. SEND DIAGNOSTIC Parameter List - Data Format .....................................5-157

Figure 5-75. SPACE Command Descriptor Block - Data Format....................................5-161

Figure 5-76. TEST UNIT READY Command Descriptor Block - Data Format....................5-163

Figure 5-77. VERIFY Command Descriptor Block - Data Format....................................5-165

Figure 5-78. WRITE Command Descriptor Block - Data Format ....................................5-167

Figure 5-79. WRITE BUFFER Command Descriptor Block - Data Format.........................5-169

Figure 5-80. WRITE FILEMARKS Command Descriptor Block - Data Format ...................5-173

Figure A-1. Internal Status Bits................................................................................. A-4

Figure B-1. Directory Failure Event Package – Data Format........................................ B-5

Figure D-1. Location of the Two Reel Lock Tabs on the DLTtape Cartridge ................ D-4

Figure D-2. Location of Reel Lock Opening and Spring-Loaded Hub on

Bottom of DLTtape Cartridge ................................................................. D-5

Figure D-3. Opening the Door on a DLTtape Cartridge Showing Tape

Leader Loop in its Correct Position ......................................................... D-6

Figure D-4. Three Examples of Tape Cartridges with Damage Visible During

Visual Inspection.................................................................................... D-7

Figure D-5. Write-Protect Switch on Tape Cartridge.................................................. D-8

xiv Quantum DLT 4000 Tape Drive

Page 15

Table of Contents

Tables

Table 1-1. DLT 4000 Physical Dimensions................................................................. 1-3

Table 1-2. DLT 4000 Storage Capacity..................................................................... 1-4

Table 1-3. DLT 4000 Performance Data ................................................................... 1-4

Table 1-4. DLT 4000 Environmental Specifications ................................................... 1-5

Table 1-5. DLT 4000 Non-Operating Shock Specifications ........................................ 1-6

Table 1-6. DLT 4000 Non-Operating Vibration Specifications.................................... 1-6

Table 1-7. DLT 4000 Power Requirements ............................................................... 1-7

Table 1-8. EMI Emission Certificates........................................................................ 1-8

Table 1-9. Safety Certifications............................................................................... 1-8

Table 1-10. Acoustic Noise Emissions, Nominal (English) ........................................... 1-9

Table 1-11. Acoustic Noise Emissions for German Noise Declaration Law.................... 1-9

Table 1-12. DLTtape Media Specifications................................................................. 1-10

Table 2-1. SCSI ID Address Selections...................................................................... 2-5

Table 2-2. Single-Ended SCSI Pin Assignment .......................................................... 2-12

Table 2-3. Differential SCSI Pin Assignment............................................................. 2-13

Table 2-4. 4-Pin Power Connector Pin Assignment .................................................. 2-14

Table 2-5. LED Functionality ................................................................................... 2-18

Table 2-6. Density LED Functionality ....................................................................... 2-19

Table 2-7. Control Functionality ............................................................................. 2-20

Table 2-8. LED Activity During Density Selection...................................................... 2-23

Table 2-9. POST/Media Ready Activity ..................................................................... 2-24

Table 2-10. Tape Drive States Following Initialization ................................................ 2-24

Table 2-11. Troubleshooting Chart........................................................................... 2-25

Table 3-1. Implemented ANSI SCSI-2 Commands...................................................... 3-2

Table 3-2. Signal Sources....................................................................................... 3-5

Table 3-3. SCSI-2 Bus Signal Definitions................................................................... 3-6

Table 3-4. SCSI Bus Timing Values........................................................................... 3-8

Table 3-5. Information Transfer Phases................................................................... 3-19

Table 3-6. Status Bytes........................................................................................... 3-23

Table 3-7. Drive MESSAGE OUT Phase Response ...................................................... 3-25

Table 4-1. Message Format .................................................................................... 4-2

Table 4-2. Supported Messages.............................................................................. 4-3

Table 4-3. Extended Message - Field Description ..................................................... 4-4

Table 4-4. Drive Response to DISCONNECT Message ................................................ 4-6

Table 4-5. IDENTIFY Message - Field Description....................................................... 4-7

Table 4-6. Drive Response to INITIATOR DETECTED ERROR Message .......................... 4-8

Table 5-1. Supported SCSI Commands.................................................................... 5-1

Table 5-2. Command Descriptor Block - Field Descriptions........................................ 5-5

Quantum DLT 4000 Tape Drive xv

Page 16

Table of Contents

Table 5-3. Command Descriptor Block Control Field - Field Descriptions.................... 5-6

Table 5-4. Status Codes ......................................................................................... 5-8

Table 5-5. Length Field Name Units ........................................................................ 5-9

Table 5-6. DATA-Phase Command Contents............................................................ 5-9

Table 5-7. ERASE Command Descriptor Block - Field Descriptions ............................. 5-16

Table 5-8. INQUIRY Command Descriptor Block - Field Descriptions........................... 5-18

Table 5-9. Vital Product Data - Page Codes............................................................. 5-18

Table 5-10. Standard Inquiry Data Page - Field Descriptions....................................... 5-20

Table 5-11. Vendor Unique Inquiry Data Page – Field Descriptions............................. 5-23

Table 5-12. Unit Serial Number Page - Field Descriptions........................................... 5-25

Table 5-13. Firmware Build Information Page - Field Descriptions.............................. 5-26

Table 5-14. LOAD UNLOAD Command Descriptor Block - Field Descriptions................ 5-29

Table 5-15. LOCATE Command Descriptor Block – Field Descriptions.......................... 5-32

Table 5-16. LOG SELECT Command Descriptor Block - Field Descriptions..................... 5-34

Table 5-17. LOG SELECT Log Page Header Field Descriptions ..................................... 5-36

Table 5-18. LOG SELECT Log Parameters Field Descriptions........................................ 5-37

Table 5-19. LOG SENSE Command Descriptor Block - Field Descriptions...................... 5-42

Table 5-20. Read / Write Error LOG SENSE Header Field Descriptions.......................... 5-46

Table 5-21. Log Parameters for Read / Write Error LOG SENSE Page Field

Descriptions........................................................................................... 5-47

Table 5-22. Last n Error Events LOG SENSE Header Field Descriptions......................... 5-50

Table 5-23. Log Parameters for Last n Error Events LOG SENSE Page Field

Descriptions........................................................................................... 5-51

Table 5-24. Read / Write Compression Ratio LOG SENSE Header Field Descriptions...... 5-52

Table 5-25. Log Parameters for Read / Write Compression Ratio LOG SENSE Page

Field Descriptions (Parameter Codes 00h and 01h)................................... 5-53

Table 5-26. Log Parameters for Read / Write Compression Ratio LOG SENSE Page

Field Descriptions (Parameter Codes 02h through 09h)............................ 5-54

Table 5-27. Device Wellness LOG SENSE Header Field Descriptions ............................. 5-57

Table 5-28. Log Parameters for Device Wellness LOG SENSE Page Field Descriptions ... 5-59

Table 5-29. Device Status LOG SENSE Header Field Descriptions................................. 5-60

Table 5-30. Log Parameters for Device Status LOG SENSE Page Field Descriptions....... 5-61

Table 5-31. Log Parameters for Device Wellness LOG SENSE Parameter 0001h

(Cleaning Related) Field Descriptions....................................................... 5-62

Table 5-32. MODE SELECT (6) (10) Command Descriptor Block - Field Descriptions...... 5-65

Table 5-33. MODE SELECT Mode Parameter List - Field Definitions............................. 5-66

Table 5-34. MODE SELECT Mode Parameter Header - Field Descriptions..................... 5-67

Table 5-35. MODE SELECT Mode Parameter Block Descriptor - Field Descriptions........ 5-69

Table 5-36. MODE SELECT Page Descriptor - Field Descriptions.................................. 5-71

Table 5-37. Error Recovery Page - Field Descriptions.................................................. 5-73

Table 5-38. Disconnect / Reconnect Page - Field Descriptions..................................... 5-75

Table 5-39. Control Mode Page Descriptor – Field Descriptions ................................. 5-78

xvi Quantum DLT 4000 Tape Drive

Page 17

Table of Contents

Table 5-40. Data Compression Page Descriptor – Field Descriptions ........................... 5-80

Table 5-41. Device Configuration Page - Field Descriptions........................................ 5-82

Table 5-42. Medium Partition Page Descriptor - Field Descriptions............................. 5-85

Table 5-43. EEPROM Vendor Unique Page Parameters ............................................. 5-86

Table 5-44. Changeable Parameters within MODE SELECT......................................... 5-93

Table 5-45. MODE SENSE Command Descriptor Block - Field Descriptions................... 5-97

Table 5-46. MODE SENSE Data Header - Field Descriptions........................................ 5-99

Table 5-47. MODE SENSE Block Descriptor - Field Descriptions...................................5-101

Table 5-48. MODE SENSE Page Descriptor - Field Descriptions ...................................5-103

Table 5-49. Read / Write Error Recovery Page - Field Descriptions...............................5-105

Table 5-50. Disconnect / Reconnect Error Recovery Page - Field Descriptions..............5-107

Table 5-51. Control Mode Page – Field Descriptions..................................................5-109

Table 5-52. Data Compression Page - Field Description..............................................5-111

Table 5-53. Device Configuration Page - Field Descriptions........................................5-113

Table 5-54. Medium Partition Page - Field Descriptions .............................................5-116

Table 5-55. PREVENT/ ALLOW MEDIUM REMOVAL Command Descriptor Block –

Field Descriptions...................................................................................5-120

Table 5-56. READ Command Descriptor Block - Field Descriptions ..............................5-122

Table 5-57. READ BLOCK LIMITS Data - Field Descriptions .........................................5-126

Table 5-58. READ BUFFER Command Descriptor Block - Field Descriptions...................5-128

Table 5-59. READ BUFFER Header - Field Descriptions ................................................5-129

Table 5-60. READ POSITION Command Descriptor Block - Field Descriptions ...............5-131

Table 5-61. READ POSITION Data - Field Description..................................................5-133

Table 5-62. RECEIVE DIAGNOSTIC RESULTS Command Data – Field Descriptions..........5-135

Table 5-63. RELEASE UNIT Command Data - Field Descriptions..................................5-138

Table 5-64. REPORT LUNS Command Data - Field Descriptions ..................................5-139

Table 5-65. REQUEST SENSE Command Data - Field Descriptions................................5-141

Table 5-66. REQUEST SENSE Data - Field Descriptions................................................5-143

Table 5-67. Supported Sense Keys ...........................................................................5-146

Table 5-68. Supported ASC / ASCQ in Hex................................................................5-147

Table 5-69. RESERVE UNIT Command - Field Descriptions...........................................5-151

Table 5-70. REWIND Command Data - Field Descriptions............................................5-153

Table 5-71. SEND DIAGNOSTIC Command - Field Descriptions....................................5-155

Table 5-72. SEND DIAGNOSTIC CDB Bits Selftest, DevOfl, and UnitOfl ........................5-157

Table 5-73. SEND DIAGNOSTIC Parameter List – Field Descriptions .............................5-158

Table 5-74. Sense Keys Used for SEND DIAGNOSTIC ..................................................5-159

Quantum DLT 4000 Tape Drive xvii

Page 18

Table of Contents

Table 5-75. ASC / ASCQ for SEND DIAGNOSTIC .........................................................5-159

Table 5-76. SPACE Command Data - Field Descriptions..............................................5-161

Table 5-77. VERIFY Command Data - Field Descriptions..............................................5-166

Table 5-78. WRITE Command Data - Field Descriptions ..............................................5-168

Table 5-79. WRITE BUFFER Command Data - Field Descriptions...................................5-170

Table 5-80. WRITE FILEMARKS Command Data - Field Descriptions.............................5-174

Table A-1. Internal Status Codes............................................................................. A-1

Table A-2. Internal Status Bit Flags.......................................................................... A-4

Table B-1. Bugcheck Packet Error Codes (Bytes 9 - 10) ............................................. B-2

Table B-2. Event Log Error Codes (Bytes 9 – 10)....................................................... B-3

Table B-3. Directory Failure Event Package – Field Descriptions ................................ B-5

Table C-1. Block Size Used for Firmware Update Type.............................................. C-2

Table C-2. Results of Firmware Update ................................................................... C-5

Table D-1. Write-Protect Switch Positions................................................................ D-9

Table D-2. When to Use a Cleaning Tape Cartridge ................................................. D-12

xviii Quantum DLT 4000 Tape Drive

Page 19

REVISION HISTORY

This Revision History provides a concise publications record of this manual. It lists the manual’s

revision levels, release dates, and a summary of changes for each release.

Manual Number

- Revision Level

81-108336-01 May 5, 1995 Original issue

81-108336-02 Caution added for unloading a tape cartridge

81- 60043- 01 March 10, 1996

Date of Release Summary of Changes

Part number 81-108336-02 obsoleted

Manual-wide, trademark copyrights, and other changes.

Fast Data Transfer Rate correction.

Figure 2-1 and 3-6 corrected.

Section E added to POST testing.

Table 3-2 corrected.

Description of tape cartridge corrected.

Notes added to Loading a Cartridge section.

Added a caution to Unloading a Cartridge section.

Chapter 4 rewritten.

POST description updated.

Figure 5-2 updated, page 5-6.

Table 5-1 updated, page 5-11.

Table 5-2 updated, page 5-14.

Table 7-1 added, page 7-4.

Table 7-1 consolidated, page 7-8.

Caution message added, page 7-9.

Table 8-1 modified, page 8-8.

Table 8-2 modified, page 8-15.

Table 8-6 modified, page 8-21.

Product Family description and table added, page 8-22.

Density Code updated, page 8-49.

Table 8-3, additions and modifications, pages 8-65 and 8-67.

Tables A-1, A-5, A-8, A-9, A-10, A-12, A-14, A-16, A-17, A-20,

and A30 changed (pages A-3, A-1, A-13, A-14, A-15, A-17, A-18,

A-23).

Quantum DLT 4000 Tape Drive

xix

Page 20

Revision History

Manual Number

- Revision Level

81-60043-02 April 08, 1999 Entire manual rewritten to conform to corporate standard for product

81-60043-03 September 18, 2000 Revised.

81-60043-04 April 4, 2001 Updated corporate address and reader comment address.

81-60043-04 A02 November 10, 2003 Changed Service Center contact number from (800) 826-8022 to

Date of Release Summary of Changes

manuals. Manual updated to include new version of the DLT4000

tape drive (Chapters 1 and 2); SCSI command updates (Chapter 5);

consolidation of Request Sense ASC/ASCQ codes into one complete

table (Chapter 5) and tape cartridge additions (Appendix D).

Chapter 2: Pinout tables corrected for 50-pin single-ended and

differential SCSI connector signals (Tables 2-2 and 2-3).

Chapter 5: Corrections made to LOG SENSE command’s DEVICE

STATUS page (Log Parameter Format and TSD, ClnQ, and ClnR bits).

Appendix A: Changed field descriptions in Table A-2.

(888) 827-3378 per ECO C008218.

xx

Quantum DLT 4000 Tape Drive

Page 21

ABOUT THIS MANUAL

“About this Manual” outlines the scope and contents of this manual. It contains information about

the intended audience, purpose of the manual, document organization, and document conventions.

AUDIENCE

This manual is written for original equipment manufacturers (OEMs) that are

integrating the Quantum DLT4000 tape drive and into a system or subsystem.

Its primary audience is the OEM technical staff that makes tape drive purchase

and configuration decisions, and system integrators that are responsible for the

SCSI interface. Additionally, the manual can be used by technically astute endusers for installation and operation of the tape drive, although that is a

secondary audience.

PURPOSE

This manual describes the rackmount and tabletop versions of the DLT 4000

tape drive. It is intended to provide the information necessary to integrate the

tape drive into a computer system or subsystem.

DOCUMENT ORGANIZATION

This product manual contains five chapters, a number of appendixes of related

useful information, and an index. It includes an overview of the Small Computer

System Interface (SCSI) and detailed descriptions of the messages and SCSI

commands as used by the tape drive. The manual is organized as follows:

Chapter 1 General Description and Specifications

This chapter contains a brief description of and specifications for the

drive.

Quantum DLT 4000 Tape Drive xxi

Page 22

About This Manual

Chapter 2 Hardware Implementation

This chapter contains configuration and installation information for the

tape drive, descriptions of the drive controls and LEDs, and information

on running the self-test.

Chapter 3 SCSI Description

This chapter provides a detailed description of the logical interfaces of

the tape drive. It describes the products’ compliance with the ANSI

SCSI-2 specification. The drive’s many optional features are described

here and throughout the manual.

Chapter 4 Messages

This chapter provides a list and description of most messages supported

by the tape drive. The SCSI message system allows communication

between SCSI initiators and SCSI targets (the tape drive, in this case)

for interface management and for command elaboration and

qualification.

Chapter 5 SCSI Commands

This chapter describes in detail each command supported by the tape

drive. The SCSI command system enables an initiator to direct a tape

drive to perform a wide range of operational and diagnostic functions.

This chapter also provides sense key information for the REQUEST

SENSE SCSI command.

Appendix A Definition of Vendor Unique Sense Data Information

Appendix A provides a list of internal status codes related to the

REQUEST SENSE SCSI command.

Appendix B EEPROM-Resident Bugcheck and Event Logs

Appendix B provides an explanation of the error and event logs stored in

semi-permanent, non-volatile memory.

Appendix C Updating the Firmware

Appendix C provides a step-by-step procedure for updating a tape drive’s

PCBA controller-resident firmware.

Quantum DLT 4000 Tape Drivexxii

Page 23

About This Manual

Appendix D The Tape Cartridge

Appendix D provides tape cartridge handling and inspection procedures,

information on the write-protect switch, how to load and unload a tape

cartridge, and how to use a cleaning tape cartridge.

CONVENTIONS

This manual uses the following conventions to designate specific elements:

Element Convention Example

Commands Uppercase (unless case-sensitive) FORMAT UNIT

Messages Uppercase INVALID PRODUCT NUMBER

Hexadecimal Notation Number followed by lowercase h 25h

Binary Notation Number followed by lowercase b 101b

Decimal Notation Number without suffix 512

Acronyms Uppercase POST

Abbreviations Lowercase, except where standard

usage requires uppercase

READER COMMENTS

Quantum is committed to providing the best products and service. Our manuals

are important components of our products. We encourage your comments,

suggestions, and corrections for this manual. Please send all comments to:

Quantum Technical Publications

4001 Discovery Drive, Suite 1100

Boulder, CO 80303

Quantum DLT 4000 Tape Drive xxiii

Mb (megabits)

MB (megabytes)

Page 24

About This Manual

Quantum DLT 4000 Tape Drivexxiv

Page 25

Chapter 1

GENERAL DESCRIPTION AND SPECIFICATIONS

This chapter provides a description and gives specifications for the Quantum DLT™4000 Tape Drive.

1.1 PRODUCT DESCRIPTION

The Quantum DLT 4000 tape drive is a high-performance, high-capacity,

streaming cartridge tape product designed for efficient data back-up for midrange

and high-end computing systems. With Quantum’s DLT advanced linear

recording technology and a precision tape guide system, the drive is ideally

suited for high-end workstation, server, and network backup requirements.

Using data compression, the DLT 4000 tape drive features a formatted capacity

of 40.0 GB* and a sustained user data transfer rate of 3.0 MB/second* (native

capacity is 20.0 GB; native data transfer rate is 1.5 MB/second).

The device is an extended-length, 5.25-inch form factor, half-inch cartridge tape

drive. The design includes a two-channel read/write head, Lempel-Ziv (LZ)

high-efficiency data compression, and tape mark directory to maximize data

throughput and minimize data access time.

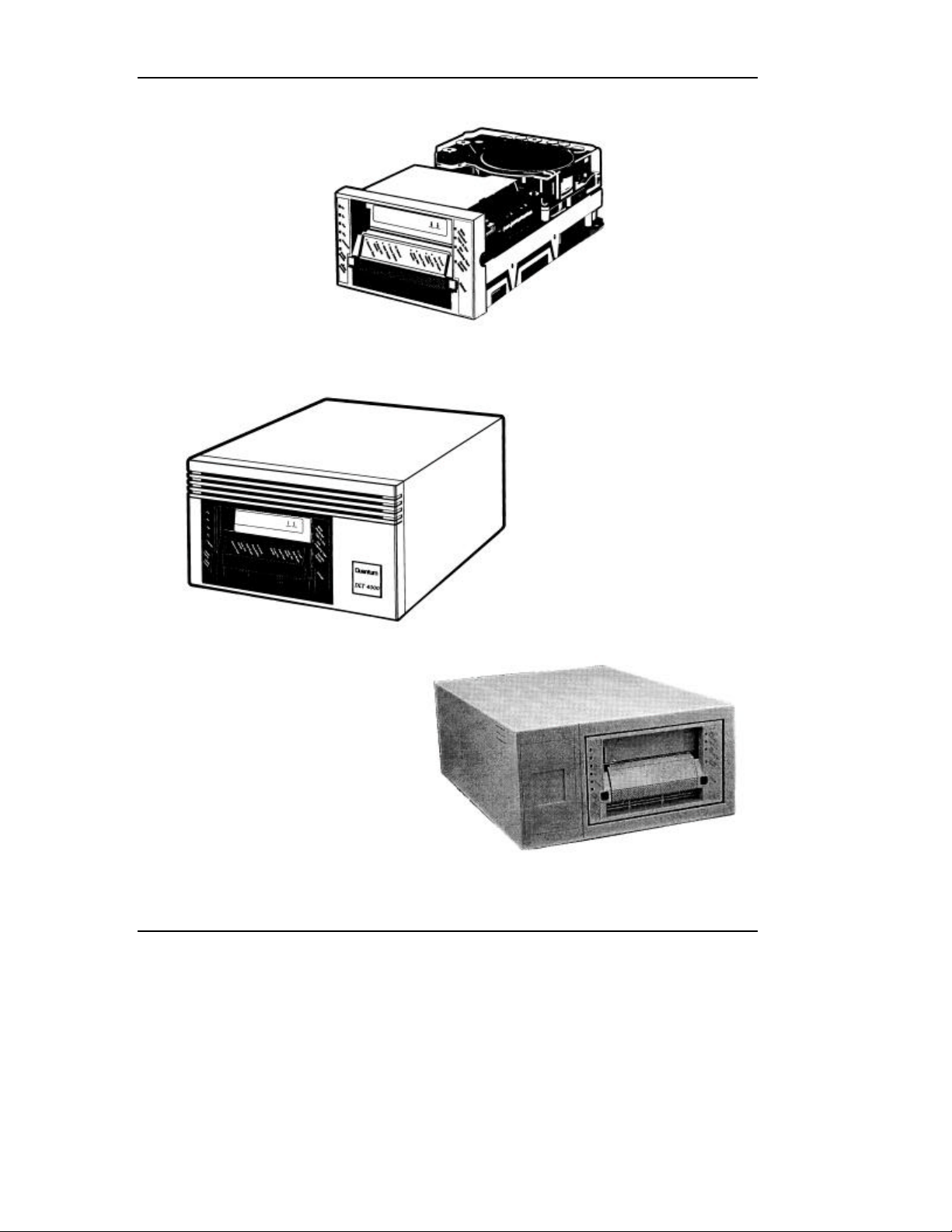

The tape drive is available in rackmount (Figure 1-1) or tabletop (Figure 1-2)

form. The tabletop versions of the drive are packaged in a housing that includes

its own cooling fan and power supply, requiring ac power.

Quantum DLT 4000 Tape Drive 1-1

Page 26

General Description and Specifications

Figure 1-1 Quantum DLT 4000 Tape Drive (Rackmount)

Tabletop Version 1

Figure 1-2 Quantum DLT 4000 Tape Drive (Tabletop)

1-2 Quantum DLT 4000 Tape Drive

Tabletop Version 2

Page 27

1.2 PRODUCT FEATURES

The DLT 4000 tape drive offers the following product features:

• 20.0 GB Native, 40.0 GB Compressed Capacity (Formatted capacity

assuming a 2:1 data compression ratio. Note that actual compression ratio

depends on the type of data, SCSI bus limitations, and system

configuration.)

• Superior Error Detection and Correction

• Extensive Embedded Diagnostic/Self-Test Software

• Tape-Loadable Firmware

1.3 PRODUCT SPECIFICATIONS

The following subsections contain full specifications for the Quantum DLT 4000

tape drive. Specifications for the DLTtape tape media cartridges are also

included.

1.3.1 Physical Specifications

The following table provides physical dimensions for the DLT 4000.

General Description and Specifications

Table 1–1 DLT 4000 Physical Dimensions

Dimension Rackmount Tabletop

(Version 1)

Height 3.25 in. (8.26 cm) without front

bezel; 3.40 in (8.64 cm) with front

bezel.

Width 5.70 in. (14.48 cm) behind front

bezel; 5.84 in (14.83 cm) with front

bezel.

Depth 9.00 in. (22.86 cm) measured from

back of front bezel; 9.60 in. (24.38

cm) including front bezel

Typical Weight: 6 lb., 7 oz (2.9 kg) (14 lb., 9 oz) 6.63 kg

Note: Mounting hole pattern for the bottom and sides of the drive is industry standard.

5.77 in.

(14.66 cm)

9.25 in.

(23.50 cm)

13.08 in.

(33.22 cm)

Tabletop

(Version 2)

4.88 in.

(12.40 cm)

9.06 in.

(23.01 cm)

12.60 in.

(32.00 cm)

Quantum DLT 4000 Tape Drive 1-3

Page 28

General Description and Specifications

1.3.2 Interface Type

DLT 4000 tape drives are available with narrow SCSI-2 fast single-ended or

differential high voltage interfaces.

1.3.3 Storage Capacity

The following table provides the ranges of capacity (native and compressed) for

the tape drive, depending on which DLTtape cartridge is used.

Table 1–2 DLT 4000 Storage Capacity

DLTtape Cartridge

(Length of Medium)

DLTtape IV

(extended 1780 foot tape)

DLTtape IIIxt

(extended 1780 foot tape)

DLTtape III

(standard 1167 foot tape)

Note: A compression factor of 2:1 can be attained, depending on the data type and

subject to the limitations of the SCSI bus design and the configuration of the

system in which the tape drive is installed.

Native

Storage Capacity

20.0 GB User Data

15.0 GB User Data

10.0 GB User Data

Compressed

Storage Capacity

40.0 GB User Data

(compressed 2:1)

30.0 GB User Data

(compressed 2:1)

20.0 GB User Data

(compressed 2:1)

1.3.4 Performance Data

The following table provides performance data for the DLT 4000 tape drive.

Table 1–3 DLT 4000 Performance Data

Feature Description

Transfer Rate, User Native

Transfer Rate, Raw Native

Transfer Rate, Compressed *

Error Rates Recoverable READ Error Rate = 1 in 1x107

* = Depending on data type and SCSI bus limitations/system configuration.

Note that data is typical; times may be longer if error recovery time is needed.

1.5 MB/second 2.5

MB/second More

than 3.0 MB/second maximum write, 10 MBburst

mode; More than 2.5 MB/second maximum read, 10

MBburst mode

Recoverable WRITE Error Rate = 1 in 1x10

Uncorrected Error Rate = 1 in 1x1017 bits read

Undetected Error Rate = 1 in 1x1027 bits read

6

1-4 Quantum DLT 4000 Tape Drive

Page 29

General Description and Specifications

Table 1–3 DLT 4000 Performance Data (continued)

Feature Description

Tracks 128; 64 pairs

Linear Bit Density 81,600 bpi per track

READ / WRITE Tape Speed 98 inches/second

Rewind Tape Speed 150 inches/second

Linear Search Tape Speed 150 inches/second

Average Rewind Time 70 seconds

Maximum Rewind Time 140 seconds

Average Access Time (from BOT) 45 seconds

Maximum Access Time (from BOT) 90 seconds

Load to BOT (typical) 48 seconds - previously written (slightly longer if using

a blank tape)

Load to BOT (max time using V120

firmware or greater)

Unload from BOT 17 seconds

Nominal Tape Tension 3.0 +/- 1 oz when stationary; 4.7

* = Depending on data type and SCSI bus limitations/system configuration

Note that data is typical; times may be longer if error recovery time is needed.

5.2 minutes with blank tape that fails calibration (time

includes calibration retries)

+/- 1 oz at operating speed

1.3.5 Environmental Specifications

The following table lists operating and non-operating environmental

specifications for the DLT 4000 tape drive.

Table 1–4 DLT 4000 Environmental Specifications

Specification Operating Limits Non-Operating Limits

(Power On; No Tape Loaded)

Wet Bulb Temperature 25°C (77°F) 25°C (77°F)

Dry Bulb Temperature

Range

Temperature Gradient 11°C (52°F) /hour (across range) 15°C (59°F) /hour (across range)

Temperature Shock 10°C (50°F) (over two minutes) 15°C (59°F) (over two minutes)

Relative Humidity 20 to 80% (noncondensing) 10 to 95% (noncondensing)

Humidity Gradient 10% / hour 10% / hour

10°C to 40°C (50°F to 104°F) -40°C to 66°C (-40°F to 151°F)

Quantum DLT 4000 Tape Drive 1-5

Page 30

General Description and Specifications

Table 1–4 DLT 4000 Environmental Specifications (continued)

Specification Operating Limits Non-Operating Limits

(Power On; No Tape Loaded)

Altitude Normal pressure from -500 feet to

30,000 feet

Airflow Velocity 125 linear feet per minute

measured directly in front of the

front bezel

Shock 5 G peak, half-sine; 11 ms

duration; 10 G each direction of

each axis, 35 sec between shocks,

60 shocks total; 3 axes

Vibration 5 to 500 Hz @ 0.25 G; sweep rate

=1 octave per minute

See Table 1-5

See Table 1-6

Table 1–5 DLT 4000 Non-Operating Shock Specifications

Description Rackmount and Tabletop

Shock (Unpackaged) 40 G, 10 ms, square wave;

140 G, 2 ms, half-sine; X,Y,Z

axes, twice in each axis, total of

6 shocks.

Shock (Packaged) Drop: 42

inches (items < 20.0 lbs.)

16 drops total

Table 1–6 DLT 4000 Non-Operating Vibration Specifications

Description Rackmount and Tabletop

Sine (Unpackaged) 1-500-10 Hz; 1 G acceleration level; X,Y,Z axes, sweep rate =½

octave/minute

Random (Unpackaged) 5-500 Hz; 2 G acceleration level; X,Y,Z axes, sweep rate = 60

min/axis

Random (Packaged)

Power Spectral Density

(Vertical)

5 to 10 Hz

10 to 50 Hz

50 to 300 Hz

0.003 G2/Hz @ 5, to 0.020 @ 10

Flat @ 0.020 G2/Hz

0.020 G2/Hz @ 50 with 8 dB/octave rolloff

1-6 Quantum DLT 4000 Tape Drive

Page 31

Table 1–6 DLT 4000 Non-Operating Vibration Specifications (continued)

Description Rackmount and Tabletop

Power Spectral Density

(Horizontal)

5 to 10 Hz

10 to 50 Hz

50 to 200 Hz

Each of the X, Y, and Z axes for one hour (3 hours total)

1.3.6 Power Requirements

The following table provides the applicable power requirements for rackmount

and tabletop versions of the DLT 4000 tape drive. Note that the tabletop DLT

4000 requires ac power.

Table 1–7 DLT 4000 Power Requirements

Requirement Rackmount Tabletop

Electrical Rating (Auto Ranging) Not Applicable 100 to 240 VAC

Power Requirements 25 W, steady state;

27 W, maximum

Power Consumption:

+5 V (±5%) bus * 2.0 A, steady state;

2.5 A, maximum

+12 V (±5%) bus * 0.8 A, steady state;

1.5 A, maximum

* = Voltage measured at the power bus connector pins.

General Description and Specifications

0.0011 G2/Hz @ 5, to 0.007 @ 10

Flat @ 0.007 G2/Hz

0.007 G2/Hz @ 50 with 8 dB/octave rolloff

50 W, maximum

Not applicable

Not applicable

1.3.7 Electromagnetic Emissions

The rackmount version of the drive complies with FCC Class A in a standard

enclosure; the tabletop version complies with the FCC Class B limits.

Quantum DLT 4000 Tape Drive 1-7

Page 32

General Description and Specifications

1.3.8 EMI and Safety Certifications

Table 1−8 provides the certifications held by the rackmount and tabletop

versions of the tape drive. Table 1−9 provides the safety certification held by the

tape drives.

Table 1–8 EMI Emission Certificates

Rackmount Tabletop

CEmark Class A

VCCi Class 1

CISPR 22 Class A

FCC Class A Devices

Table 1–9 Safety Certifications

Rackmount and Tabletop

UL CSA

TÜV “BG”

MARK IEC

CEmark Class B

VCCi Class 2

CISPR 22 Class B

FCC Class B Devices

1.3.9 Reliability (Projected)

Mean time between failures (MTBF) for the tape drive is projected to be 200,000

hours at 100% duty cycle. Head life is 10,000 tape motion hours.

Media durability is projected to be 1,000,000 passes of the tape medium across

the read/write heads (15,000 uses).

Quantum Corporation does not warrant that predicted MTBF is representative

of any particular unit installed for customer use. Actual figures vary from unit

to unit.

1-8 Quantum DLT 4000 Tape Drive

Page 33

General Description and Specifications

1.3.10 Acoustic Noise Emissions

The following tables provide the tape drive’s acoustic noise emission levels, both

as noise power and sound pressure. Information about acoustic emissions is also

provided in German to fulfill an international requirement.

Table 1-10 Acoustic Noise Emissions, Nominal (English)

Acoustics – Preliminary declared values per ISO9296 and ISO 7779/EN27779

Noise Power Emission Level Sound Pressure Level

(LNPEc) (LPAc)

Product Idle Streaming Idle Streaming

Rackmount Not applicable Not applicable Not applicable Not applicable

Tabletop 4.6 B 5.1 B 30.0 dB 41.0 dB

[Current values for specific configurations are available from Quantum representatives.

1B = 10 dBA.]

Table 1-11 Acoustic Noise Emissions for German Noise Declaration Law

Schallemissionswerte - VorläufigeWerteangaben nach ISO 9296 und ISO

7779/DIN EN27779:

Schalleistungspegel Schalldruckpegel

LwAd, B LpAm, dBA (Zuschauerpositionen)

Gerfdt Leerauf Betrieb Leerauf Betrieb

Rackmount N/A 5,5 B N/A 45,0 B

Tabletop 5,2 B 5,3 B 39,0 dB 40,0 dB

[Aktuelle Werte für spezielle Ausrüstungsstufen sind über die Quantum Equipment

Vertretungen erhältlich. 1 B = 10 dBA]

1.3.11 Tape Drive Recording Type

The tape drive uses 2 - 7 RLL code with DLT 2000, DLT 2000xt, or DLT 4000

formats; MFM with 2.6 GB / 6.0 GB DLT 260 and DLT 600 formats.

Quantum DLT 4000 Tape Drive 1-9

Page 34

General Description and Specifications

1.3.12 DLTtape Recording Media Specifications

The following table provides specifications for tape media.

Table 1-12 DLTtape Media Specifications

DLTtape

Media Type

DLTtape III Width: 0.5 in., metal particle

DLTtape IIIxt Width: 0.5 in., metal particle

DLTtape IV Width: 0.5 in., metal particle

Specifications

Length: 1200 feet (standard 1167 ft. tape)

Cartridge Dimensions: 4.1 in x 4.1 in x 1.0 in

Shelf Life: 30 years min. @ 20°C & 40% RH (non-condensing)

Usage: 1,000,000 passes (typical office/computer environment)

Length: 1800 feet (extended 1780 ft tape)

Cartridge Dimensions: 4.1 in x 4.1 in x 1.0 in

Shelf Life: 30 years min. @ 20°C & 40% RH (non-condensing)

Usage: 1,000,000 passes (typical office/computer environment)

Length: 1800 feet (extended 1780 ft. tape)

Cartridge Dimensions: 4.1 in x 4.1 in x 1.0 in

Shelf Life: 30 years min. @ 20°C & 40% RH (non-condensing)

Usage: 1,000,000 passes (typical office/computer environment)

1-10 Quantum DLT 4000 Tape Drive

Page 35

Chapter 2

HARDWARE IMPLEMENTATION

This chapter describes how to install the internal tape drive or “brick” into a rackmount system. This

includes configuration jumper settings, connector pin assignments, installation instructions, power

and signal cabling descriptions, and operating instructions. This chapter also includes information

on configuring and connecting the tabletop version of the drive into a system.

This chapter covers the following topics:

• Safety, Handling and Electrostatic Discharge (ESD) Protection (Section 2.1)

describes appropriate guidelines when working with the tape drive.

• Drive Setup (Section 2.2) describes how to set up the tape drive for SCSI ID,

TERMPWR, and parity checking.

• Drive Installation (Section 2.3) describes how to mount and install the tape

drive into the system.

• Drive Connections (Section 2.4) identifies the connectors on the tape drive

including the SCSI, power and optional loader connectors.

• Drive Controls and Light Emitting Diodes (LED’s) (Section 2.5) identifies

the front panel controls and LED’s and describes their functionality. It also

explains density selection.

• Power On Self Test (POST) (Section 2.6) describes the activities that occur

when power is first applied to the drive.

• Troubleshooting (Section 2.7) lists troubleshooting tips in the event that the

tape drive fails.

2.1 SAFETY, HANDLING AND ELECTROSTATIC DISCHARGE (ESD) PROTECTION

Inappropriate or careless handling of tape drives may result in damage to the

product. Follow the precautions and directions to prevent damaging the tape

drive.

Quantum DLT 4000 Tape Drive 2-1

Page 36

Hardware Implementation

2.1.1 Safety Precautions

For your safety, follow all safety procedures described here and in other sections of

the manual.

• Remove power from the computer system (or expansion unit) before

installing or removing the tape drive to prevent the possibility of electrical

shock or damage to the tape drive. Unplug the unit that contains or is to

contain the drive from ac power to provide an added measure of safety.

• Read, understand, and observe any and all label warnings.

2.1.2 Handling

Damage to the drive can occur as the result of careless handling, vibration, shock,

or electrostatic discharge (ESD). Always handle the tape drive with care to avoid

damage to the precision internal components.

Follow these guidelines to avoid damage to the drive:

• Always observe prescribed ESD precautions.

• Keep the drive in its anti-static bag until ready to install.

• Always use a properly fitted wrist strap or other suitable ESD protection

when handling the drive.

• Hold drive only by its sides. Do not touch any components on the PCBA.

• Always handle the drive carefully and gently. A drop of ¼ inch onto a bench

or desktop may damage a drive.

• Do not bump, jar, or drop the drive. Use care when transporting the drive.

• Always gently place the drive flat, PCB side down, on an appropriate ESD-

protected work surface to avoid the drive being accidentally knocked over.

• Do not pack other materials with the drive in its anti-static bag.

• Place the drive in the anti-static bag before placing it in a shipping

container.

• Do not stack objects on the drive.

• Do not expose the drive to moisture.

• Do not place hands or foreign objects inside the tape drive’s door/receiver

area.

2-2 Quantum DLT 4000 Tape Drive

Page 37

Hardware Implementation

2.1.3 Electrostatic Discharge (ESD) Protection

Various electrical components on/within the tape drives are sensitive to static

electricity and Electrostatic Discharge (ESD). Even a static buildup or discharge

that is too slight to feel can be sufficient to destroy or degrade a component's

operation.

To minimize the possibility of ESD-related damage to the drive, we strongly

recommend using both a properly installed workstation anti-static mat and a

properly installed ESD wrist strap. When correctly installed, these devices reduce

the buildup of static electricity that might harm the drive.

Observe the following precautions to avoid ESD-related problems:

• Use a properly installed anti-static pad on your work surface.

• Always use a properly fitted and grounded wrist strap or other suitable ESD

protection when handling the drive and observe proper ESD grounding

techniques.

• Hold the drive only by its sides. Do not touch any components on the

PCBA.

• Leave the drive in its anti-static bag until you are ready to install it in the

system.

• Place the drive on a properly grounded anti-static work surface pad when it

is out of its protective anti-static bag.

• Do not use the bag as a substitute for the work surface anti-static pad. The

outside of the bag may not have the same anti-static properties as the

inside. It could actually increase the possibility of ESD problems.

• Do not use any test equipment to check components on the PCBA. There are

no user-serviceable components on the drive.

2.2 DRIVE SETUP

Drive setup for DLT 4000 tape drive includes the following:

• Set the SCSI ID for the drive (default = SCSI ID 5)

• Configure the drive to provide TERMPWR

• Set parity checking for the drive (default = parity checking enabled)

If you want to change any of the settings, go to the applicable subsection;

otherwise, proceed directly to section 2.3.

Quantum DLT 4000 Tape Drive 2-3

Page 38

Hardware Implementation

129

2.2.1 Set the Rackmount Drive SCSI ID

Each device on the SCSI bus must have a unique SCSI ID address assigned to it.

For specific recommendations for assigning SCSI IDs, refer to the system or SCSI

controller documentation.

Rackmount drives can be configured for SCSI ID addresses that range from 0 to 7

(default=5) in one of two ways:

a) jumper the 10-pin SCSI ID jumper block shown in Figure 2-1, or

b) set the IDs through firmware. If the firmware is set to SCSI ID = 5, then no

jumpers are installed on the SCSI ID jumper block.

This subsection discusses setting the SCSI ID on the rackmount drive via the

jumper block. Table 2-1 lists the SCSI ID address and jumper settings.

NOTES

The default setting for the tape drive is SCSI ID 5; the host adapter is

typically SCSI ID 7.

A jumper must be installed across Pins 9-10 (Remote ID Present pins)

for the host to recognize any SCSI ID selections from this jumper

block.

SCSI ID Jumper Block (J13)

10

(default SCSI ID 5 shown)

Figure 2-1 DLT 4000 SCSI ID Jumper Location (Rackmount Version Shown)

2-4 Quantum DLT 4000 Tape Drive

Front Panel

Loader Connector (J12)

Page 39

Hardware Implementation

Table 2-1 SCSI ID Address Selections

SCSI ID Jumper Across Pins:

9-10 7-8 5-6 3-4 1-2

0 1 0 0 0 0

1 1 0 0 0 1

2 1 0 0 1 0

3 1 0 0 1 1

4 1 0 1 0 0

5 (default) 1 0 1 0 1

6 1 0 1 1 0

7 1 0 1 1 1

0 = No Jumper installed 1 = Jumper installed

Quantum DLT 4000 Tape Drive 2-5

Page 40

Hardware Implementation

1

1

252617

18

2.2.2 Configure the Rackmount Drive for TERMPWR (Single-Ended Only)

A SCSI bus must be terminated at each end of the bus. At least one device must

supply terminator power (TERMPWR). Quantum recommends that every device

on the SCSI bus be configured to supply TERMPWR to ensure that there is a

sufficient level of voltage along the SCSI bus.

Install a jumper across Pins 3 and 4 (Figure 2-2) to enable TERMPWR.

Front Panel

ALDR (J26)

TERMPWR (J24)

Not used

Parity Check (J25)

2

Install Jumper on Pins 3-4

to enable TERMPWR.

Install Jumper on Pins 1-2

to disable Parity Checking.

Figure 2-2 DLT 4000 TERMPWR and Parity Check Jumper Locations (Rackmount

Version Shown)

2-6 Quantum DLT 4000 Tape Drive

2