Page 1

®

DLT2000/DLT2500/DLT2700

Cartridge Tape Subsystem

Product Manual

Date: 19 January 96

Order Number: 81-109132-03

Page 2

Quantum reserves the right to make changes and improvements to its products, without

incurring any obligation to incorporate such changes or improvements in units previously sold

or shipped.

You can request Quantum publications from your Quantum Sales Representative, or order them

directly from Quantum.

Publication Number: 81-109132-03

SERVICE CENTERS

Quantum Service Center

715 Sycamore Avenue

Milpitas, California 95035

Phone (408) 894-4000

Fax: (408) 894-3218

Quantum Gmbh

Genferstrasse 4B

60437 Frankfurt am Main 56

Germany

Phone: (49) 69-509-1080

Fax: (49) 69-509-10891

Quantum Asia-Pacific Pte.

Ltd.

50 Tagore Lane #b1-04

Singapore, 2678

Phone: (65) 450-9333

Fax (65) 452-2544

CompacTape is a trademark of Quantum Corporation.

DLT is a trademark of Quantum Corporation.

Copyright

1996 by Quantum Corporation. All rights reserved. Printed in USA.

Page 3

The following FCC Notice applies to the DLT2000 drive:

FCC NOTICE: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference in residential installation. Any

changes or modifications made to this equipment may void the user’s authority to operate this

equipment.

This equipment generates, uses, and radiates radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by tuning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

4. Consult the dealer or an experienced radio/TV technician for help. The shielded

interconnect cable shipped with the unit should not be altered or modified in any way. The

unit shipped without a shielded interconnect cable must use a shielded interconnect cable.

The user may find the following booklet prepared by the Federal Communications Commission

helpful: How to Identify and Resolve Radio-TV Interference Problems. This booklet is

available from the U.S. Government Printing Office, Washington D.C., 20402. Stock No. 00400398-5.

All external I/O cables connecting to this unit need to be shielded. See the User Manual or

installation instructions for more options.

This digital apparatus does not exceed the Class B limits for radio noise emissions set out in

the radio interference regulations of the Canadian Department of Communications.

This equipment is in the 2nd Class Category (information equipment to be used in a residential

area or an adjacent area thereto) and conforms to the standards set by the Voluntary Control

Council For Interference by Data Processing Equipment and Electronic Office Machines aimed

at preventing radio interference in such residential area.

This equipment meets or exceeds requirements for safety in the U.S. (UL 1950), Canada (CSA

C22.2 N0. 950) and Europe (EN60950/IEC 950) requirements, and is certified to bear the GS

mark by TUV.

Page 4

The following FCC Notice applies to DLT2500 and DLT2700 mini-library:

FCC NOTICE: This equipment has been tested and found to comply with the limits for a

Class A device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Any changes or modifications made to this

equipment may void the user’s authority to operate this equipment. Operation of this equipment

in a residential area may cause interference in which case the user at his own expense will be

required to take whatever measures may be required to correct the interference. The shielded

interconnect cable shipped with the unit should not be altered or modified in any way. The unit

shipped without a shielded cable must use a shielded interconnect cable.

Warning! This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Achtung! Dieses ist ein G erat der Funksto rgenzwertklasse A. In Wohnbereicghen konnen bei

Betrieb dieses Gerate s Runfunkstorungen auftreten, in welchen Fallen der Benutzer fur

entsprechende GengenmaBnahmen verantwortlich ist.

Attention! Ceci est un produit de Classe A. Dans un environment do mesti que, ce pro duit

risque de creer des interferences radioelectriques, il appartiendra alors a l'utilisateur de prendre

les mesures specifiques appropriees.

Page 5

Table of Contents

. CHAPTER 1: OVERVIEW AND FEATURES OF THE DLT2000/DLT2500/DLT2700

PRODUCT

1.1 I

N THIS CHAPTER.............................................................................................................1-1

1.2 P

RODUCT OVERVIEW.......................................................................................................1-1

1.3 F

AST DATA TRANSFER RATE ...........................................................................................1-2

1.4 H

IGH-CAPACITY............................................................................................................... 1-2

1.5 C

OMPACTION...................................................................................................................1-2

1.6 S

TRONG MEDIA................................................................................................................ 1-2

1.7 C

OMPATIBILITY................................................................................................................1-2

1.8 F

IRMWARE UPDATE CAPABILITY......................................................................................1-3

1.9 E

MBEDDED DIAGNOSTICS ................................................................................................1-3

. CHAPTER 2: INSTALLING AND CONFIGURING THE DLT2000

2.1 I

N THIS CHAPTER.............................................................................................................2-1

2.2 P

REPARE FOR THE INSTALLATION ....................................................................................2-1

2.2.1 Before You Start.....................................................................................................2-1

2.2.2 Installation Setup....................................................................................................2-2

2.2.3 Site Setup................................................................................................................2-2

2.2.4 Site Guidelines........................................................................................................2-2

2.3 I

NSTALL THE SUBSYSTEM ................................................................................................2-4

2.4 C

ONFIGURE THE DLT2000 TABLETOP.............................................................................2-4

2.4.1 Configuration Guidelines........................................................................................2-4

2.4.2 DISABLE PARITY Checking................................................................................2-5

2.4.3 Changing the SCSI ID............................................................................................2-5

2.5 C

ONNECT THE CABLES.....................................................................................................2-5

2.5.1 Examine the DLT2000 Rear Panel.........................................................................2-6

2.5.2 Connect the SCSI Signal Cable..............................................................................2-6

2.5.3 Terminate the SCSI Bus.........................................................................................2-7

2.5.4 Connect the Power Cord.........................................................................................2-7

2.6 T

EST THE INSTALLATION..................................................................................................2-8

2.6.1 Run POST...............................................................................................................2-8

2.6.2 What to Do after POST ..........................................................................................2-9

2.7 DLT2000 T

ROUBLESHOOTING CHART...........................................................................2-10

. CHAPTER 3: CONFIGURING AND OPERATING THE DLT2000

3.1 I

N THIS CHAPTER.............................................................................................................3-1

3.2 B

EFORE YOU INSTALL THE DLT2000 DRIVE...................................................................3-1

3.2.1 Disabling Parity Checking......................................................................................3-2

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-v

Page 6

Table of Contents

3.2.2 Changing the SCSI ID ............................................................................................3-4

3.2.3 Setting the TRM ENB (Single-ended only)/TRM PWR Jumpers...........................3-5

3.2.4 Locating the SCSI Cable and Power Connectors....................................................3-6

3.3 S

ELECTING DENSITY ........................................................................................................3-7

3.4 O

VERVIEW OF THE FRONT PANEL...................................................................................3-10

3.5 D

ESCRIPTION OF CONTROLS AND INDICATORS...............................................................3-11

3.5.1 Beeper...................................................................................................................3-11

3.5.2 Unload Button.......................................................................................................3-11

3.5.3 Cartridge Insert/Release Handle...........................................................................3-11

3.5.4 Indicator Action during Power-On Self Test and Operation.................................3-12

3.6 D

ESCRIPTION OF THE TAPE CARTRIDGE .........................................................................3-17

3.6.1 Cartridge Write-Protect Switch.............................................................................3-17

3.6.2 Data Protection.....................................................................................................3-19

3.7 L

OADING A CARTRIDGE..................................................................................................3-20

3.7.1 Tape in Use...........................................................................................................3-22

3.8 U

SING THE CLEANING TAPE CARTRIDGE........................................................................3-23

3.9 U

NLOADING A CARTRIDGE .............................................................................................3-24

3.10 P

RESERVING CARTRIDGES............................................................................................3-26

. CHAPTER 4: CONFIGURING AND OPERATING THE DLT2500 MINI-LIBRARY

4.1 I

N THIS CHAPTER.............................................................................................................4-1

4.2 I

NTRODUCTION TO THE MINI-LIBRARY.............................................................................4-6

4.3 C

ONFIGURE THE DLT2500...............................................................................................4-7

4.3.1 Configuration guidelines.........................................................................................4-7

4.3.2 Connecting the SCSI Signal Cable ......................................................................... 4-7

4.4 I

NSTALLATION TESTING....................................................................................................4-8

4.4.1 Run POST...............................................................................................................4-8

4.4.2 What to Do after POST ..........................................................................................4-8

4.5 O

PERATOR CONTROL PANEL............................................................................................4-9

4.6 K

EY LOCK......................................................................................................................4-13

4.6.1 OCP, locked or OCP, Disabled.............................................................................4-13

4.6.2 OCP, Unlocked or Enabled...................................................................................4-13

4.6.3 SCSI ID, setting....................................................................................................4-13

4.7 S

ELECTING DENSITY.......................................................................................................4-14

4.7.1 Front panel, density select....................................................................................4-15

4.7.2 Host selection, density..........................................................................................4-16

4.7.3 Native default, density..........................................................................................4-16

4.8 D

EFAULT OPERATING MODES .........................................................................................4-17

4.8.1 Mode, normal........................................................................................................4-17

4.8.2 Density Select Mode.............................................................................................4-18

4.8.3 SCSI ID Select Mode ...........................................................................................4-19

4.8.4 Code update mode................................................................................................4-19

4.9 D

ESCRIPTION OF THE TAPE CARTRIDGE .........................................................................4-20

vi-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 7

Table of Contents

4.9.1 Tape Cartridge, positioning the write-protect switch............................................4-20

4.9.2 Data protection..................................................................................................... 4-21

4.10 D

ESCRIPTION OF THE MAGAZINE..................................................................................4-22

4.10.1 Insert cartridge, magazine...................................................................................4-23

4.10.2 Removing cartridge ............................................................................................4-25

4.10.3 Magazine, removing from mini-library...............................................................4-26

4.10.4 Magazine, installing............................................................................................4-26

4.10.5 Selecting a Cartridge from the Magazine ...........................................................4-27

4.10.6 Loading cartridge into the Drive.........................................................................4-27

4.10.7 Unloading cartridge from the drive ....................................................................4-28

4.10.8 Opening the Magazine Door...............................................................................4-28

4.11 W

HEN TO USE THE CLEANING TAPE CARTRIDGE .........................................................4-29

. CHAPTER 5: CONFIGURING AND OPERATING THE DLT2700 MINI-LIBRARY

5.1 I

N THIS CHAPTER.............................................................................................................5-1

5.2 I

NTRODUCTION TO THE MINI-LIBRARY ............................................................................5-1

5.3 C

ONFIGURING THE DLT2700...........................................................................................5-2

5.3.1 Configuration Guidelines........................................................................................5-3

5.3.2 Disable Parity Checking.........................................................................................5-3

5.3.3 Change the SCSI ID ...............................................................................................5-3

5.4 M

ODE SELECT KEY..........................................................................................................5-5

5.4.1 OCP Disabled Mode...............................................................................................5-5

5.4.2 Automatic Mode.....................................................................................................5-7

5.4.3 Manual Mode .........................................................................................................5-7

5.4.4 Service Mode..........................................................................................................5-8

5.5 S

ELECTING DENSITY........................................................................................................5-9

5.6 O

PERATOR CONTROL PANEL..........................................................................................5-12

5.7 P

OWER-ON PROCESS .....................................................................................................5-15

5.8 S

LOT SELECT, LOAD/UNLOAD .......................................................................................5-17

5.8.1 Selecting a Cartridge ............................................................................................5-17

5.8.2 Loading the Cartridge...........................................................................................5-17

5.8.3 Unloading the Cartridge.......................................................................................5-18

5.8.4 Opening the Receiver...........................................................................................5-19

5.9 M

AGAZINE .....................................................................................................................5-20

5.9.1 Inserting a Cartridge.............................................................................................5-20

5.9.2 Removing a Cartridge from the Magazine............................................................ 5-23

5.9.3 Removing the Magazine from the Receiver..........................................................5-23

5.9.4 Installing the Magazine into the Receiver.............................................................5-23

. CHAPTER 6: TROUBLESHOOTING GUIDE FOR THE DLT2500/DLT2700 MINI-

LIBRARY

6.1 I

N THIS CHAPTER.............................................................................................................6-1

6.2 C

ONDITIONS NECESSARY FOR BUTTON OPERATION.........................................................6-1

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-vii

Page 8

Table of Contents

6.3 BACKUP OPERATION FAILURE..........................................................................................6-3

6.4 A

VOIDING BASIC PROBLEMS............................................................................................6-4

6.5 DLT2500 E

RROR CONDITIONS ........................................................................................6-5

6.5.1 DLT2500 Magazine Error......................................................................................6-5

6.5.1.1 DLT2500 Clearing a Magazine......................................................................6-5

6.5.2 DLT2500 Loader Error Description.......................................................................6-5

6.5.3 DLT2500 Drive Error Description.........................................................................6-5

6.5.4 DLT2500 Controller Error Description..................................................................6-5

6.5.5 DLT2500 Unknown Error Description...................................................................6-6

6.5.5.1 DLT2500 Clearing a Loader, Drive, Controller, or Unknown.......................6-6

6.6 DLT2700 E

RROR CONDITIONS ........................................................................................6-6

6.6.1 DLT2700 Magazine Fault Cases............................................................................6-6

6.6.2 DLT2700 Loader Fault Description.......................................................................6-8

6.7 P

OWER PROBLEMS...........................................................................................................6-8

. CHAPTER 7: FIRMWARE UPDATE

7.1 I

N THIS CHAPTER.............................................................................................................7-1

7.2 DLT2000 F

IRMWARE UPDATE OVERVIEW.......................................................................7-1

7.2.1 Before Doing the Procedure...................................................................................7-2

7.3 C

REATING A FIRMWARE UPDATE TAPE ............................................................................7-4

7.3.1 On UN*X Systems..................................................................................................7-4

7.4 F

IRMWARE UPDATE PROCEDURE .....................................................................................7-5

7.4.1 Updating the Firmware on DLT2000 (Drive Only Configuration).........................7-5

7.4.2 Updating the Firmware on the DLT2500 (Drive and Loader Configuration).......7-10

7.4.3 Updating the Firmware on the DLT2700 (Drive and Loader Configuration).......7-14

. CHAPTER 8: DLT2000 SCSI INTERFACE

8.1 O

VERVIEW .......................................................................................................................8-1

8.2 G

ENERAL SCSI BUS OPERATIONS....................................................................................8-1

8.2.1 Data Transfer..........................................................................................................8-1

8.2.2 Initiator/Target Operations .....................................................................................8-2

8.2.3 SCSI IDs and Logical Unit Numbers (LUNs) ........................................................8-2

8.2.4 Unit Attention Condition........................................................................................8-3

8.2.5 Behavior Around Power-On and SCSI Bus Reset..................................................8-3

8.2.6 Data Cache and Tape Write Interaction..................................................................8-4

8.2.7 Other SCSI Functionality........................................................................................8-4

8.2.8 Bus Phases..............................................................................................................8 -4

8.2.9 ATTENTION Signal Response..............................................................................8-5

8.2.10 STATUS phase.....................................................................................................8-5

8.2.11 BUS FREE............................................................................................................8-7

8.2.12 BUS PARITY ERRORS.......................................................................................8-7

8.3 SCSI M

8.4 T

ESSAGE SYSTEM ..................................................................................................8-8

APE DRIVE SCSI COMMANDS......................................................................................8-14

viii-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 9

Table of Contents

8.4.1 Control Byte - Flag and Link Bits.........................................................................8-14

8.4.2 Summary of Supported Sequential-Access Device Commands............................8-15

8.4.3 ERASE (19h)........................................................................................................8-16

8.4.4 INQUIRY (12h) ...................................................................................................8-17

8.4.4.1 Drive Inquiry Response ...............................................................................8-18

8.4.4 2 Vendor Unique Inquiry................................................................................8-21

8.4.4.3 Vital Product Data Pages.............................................................................8-22

8.4.4.4 Media Loader Inquiry Response..................................................................8-24

8.4.5 LOAD-UNLOAD (1Bh).......................................................................................8-25

8.4.6 LOCATE (2Bh)....................................................................................................8-27

8.4.7 LOG SELECT (4Ch)............................................................................................8-28

8.4.7.1 Operation of LOG SELECT........................................................................8-30

8.4.8 LOG SENSE (4Dh)..............................................................................................8-34

8.4.8.1 Supported Pages Page Format.....................................................................8-37

8.4.8.2 Read/Write Error Log SENSE Page Format (Page 2 and 3)........................8-38

8.4.8.3 Last n Error Events Page (07h)....................................................................8-41

8.4.8.4 Read/Write Compression Ratio Page Format (32h).....................................8-42

8.4.9 MODE SELECT (15h).........................................................................................8-46

8.4.9.1 MODE SELECT Parameter List..................................................................8-47

8.4.9.2 MODE SELECT Pages................................................................................8-50

8.4.9.3 Control Mode Page (0Ah)............................................................................8-51

8.4.9.4 Data Compression Page (0Fh).....................................................................8-53

8.4.9.5 Device Configuration Page (10h) ................................................................8-55

8.4.9.6 Disconnect/Reconnect Page.........................................................................8-58

8.4.9.7 Medium Partition Page (11h).......................................................................8-60

8.4.9.8 Read/Write Error Recovery Page (01h).......................................................8-61

8.4.9.9 EEROM Vendor Unique Page (3Eh)...........................................................8-63

8.4.9.10 MODE SELECT Changeable Parameters..................................................8-69

8.4.10 MODE SENSE (1Ah /5Ah)................................................................................8-70

8.4.10.1 MODE SENSE Parameter List..................................................................8-73

8.4.10.2 MODE SENSE Pages................................................................................8-77

8.4.10.3 Control Mode Page (0Ah)..........................................................................8-78

8.4.10 4 Device Configuration Page (10h) ..............................................................8-80

8.4.10 5 Data Compression Page (0Fh)...................................................................8-82

8.4.10 6 Disconnect/Reconnect Page.......................................................................8-84

8.4.10 7 Medium Partition Page (11h).....................................................................8-85

8.4.10 8 Read/Write Error Recovery Page...............................................................8-86

8.4.10 9 EEROM Vendor Unique Page (3Eh).........................................................8-88

8.4.11 PREVENT/ALLOW MEDIUM REMOVAL (1Eh)...........................................8-89

8.4.12 READ (08h) .......................................................................................................8-90

8.4.13 READ BLOCK LIMITS (05h)...........................................................................8-92

8.4.14 READ BUFFER (3Ch).......................................................................................8-93

8.4.14.1 Combined Header and Data Mode.............................................................8-94

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-ix

Page 10

Table of Contents

8.4.14.2 Data Mode .................................................................................................8-94

8.4.14.3 Descriptor Mode........................................................................................8-94

8.4.15 READ POSITION (34h) ....................................................................................8-96

8.4.15.1 READ POSITION Data Format.................................................................8-97

8.4.16 RECEIVE DIAGNOSTICS RESULTS (1Ch) ...................................................8-99

8.4.17 RELEASE UNIT (17h).....................................................................................8-100

8.4.17.1 Medium Changer Considerations.............................................................8-100

8.4.18 REQUEST SENSE (03h) .................................................................................8-101

8.4.18 1 Sense Information Format........................................................................8-102

8.4.19 RESERVE UNIT (16h)....................................................................................8-112

8.4.19.1 Medium Changer Considerations.............................................................8-113

8.4.20 REWIND (01h) ................................................................................................8-114

8.4.21 SEND DIAGNOSTIC (1Dh)............................................................................8-115

8.4.22 SPACE (11h).................................................................................................... 8-120

8.4.23 TEST UNIT READY (00h)..............................................................................8-122

8.4.23.1 Medium Changer Considerations.............................................................8-122

8.4.24 VERIFY (13h)..................................................................................................8-123

8.4.25 WRITE (0Ah)..................................................................................................8-124

8.4.26 WRITE BUFFER (3Bh)...................................................................................8-126

8.4.26.1 Header and Data Mode............................................................................8-127

8.4.26.2 Write Data................................................................................................ 8-127

8.4.26.3 Download Microcode...............................................................................8-127

8.4.26.4 Download Microcode and Save...............................................................8-127

8.4.27 WRITE FILEMARKS (10h)............................................................................8-129

8.5 S

UPPORTED SCSI-2 MEDIUM CHANGER DEVICE COMMANDS.....................................8-131

8.5.1 INITIALIZE ELEMENT STATUS (07h)..........................................................8-132

8.5.2 READ ELEMENT STATUS (B8h) ...................................................................8-133

8.5.2.1 Element Status Data Header.......................................................................8-134

8.5.2.2 M

8.5.2.3 Storage Element Status Page......................................................................8-136

8.5.2.4 Data Transfer Element Status Page............................................................8-137

8.5.3 MODE SENSE/SELECT (1Ah/15h)..................................................................8-138

8.5.3.1 Device Capabilities Page (1Fh)..................................................................8-138

8.5.3.2 Element Address Assignment Page (1Dh).................................................8-140

8.5.3.3 Transport Geometry Parameters Page (1Eh)..............................................8-142

8.5.4 MOVE MEDIUM (A5h)....................................................................................8-143

EDIUM TRANSPORT ELEMENT STATUS PAGE ......................................................8-135

. A: TECHNICAL SPECIFICATIONS

A.1 I

N THIS APPENDIX......................................................................................................... A-1

A.2 P

HYSICAL DESCRIPTION................................................................................................ A-2

A.2.1 Identifying the Correct AC Power Cord............................................................... A-4

A.3 P

ERFORMANCE SPECIFICATIONS.................................................................................. A-11

A.3.1 Nominal Tape Tension....................................................................................... A-11

x-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 11

Table of Contents

A.3.2 DLT2000 Timing Characteristics...................................................................... A-11

A.3.3 DLT2500xt Media Loader Timing Characteristics............................................ A-12

A.3.4 DLT2700 Media Loader Timing Characteristics............................................... A-12

A.4 E

NVIRONMENTAL SPECIFICATIONS.............................................................................. A-12

A.4.1 Temperature and Humidity................................................................................ A-13

A.4.2 Altitude.............................................................................................................. A-14

A.5 V

IBRATION AND SHOCK SPECIFICATIONS .................................................................... A-15

A.5.1 Operating Shock and Vibration......................................................................... A-15

A.5.2 Nonoperating Shock and Vibrattion .................................................................. A-16

A.6 E

LECTROMAGNETIC INTERFERENCE (EMI) SUSCEPTIBILITY ....................................... A-19

A.6.1 Electromagnetic Emissions................................................................................ A-19

A.6.2 Conducted Emissions......................................................................................... A-19

A-6.3 Radiated Emissions ........................................................................................... A-20

A.6.4 Magnetic Radiated Susceptibility...................................................................... A-20

A.6.5 Radiated Susceptibility...................................................................................... A-21

A.6.6 Conducted Susceptibility................................................................................... A-21

A.6.7 ESD Failure Level Limits.................................................................................. A-22

A.6.8 Acoustic Noise Emissions.................................................................................. A-22

A.7 R

EGULATORY REQUIREMENTS.................................................................................... A-24

A.7.1 Safety Requirements.......................................................................................... A-24

A.7.2 Electromagnetic Emission Requirements........................................................... A-24

A.8 D

RIVE RELIABILITY FACTORS...................................................................................... A-25

A-9 C

OMPACTAPE RECORDING MEDIA SPECIFICATIONS.................................................... A-26

. B: DEFINITION OF VENDOR UNIQUE SENSE DATA INFORMATION

B.1 I

N THIS APPENDIX.......................................................................................................... B-1

B.2 I

NTERNAL STATUS.......................................................................................................... B-1

. C: SENSE KEY INFORMATION

C.1 I

N THIS APPENDIX...........................................................................................................C-1

. D: EEROM RESIDENT BUGCHECK AND EVENT LOGS

D.1 EEROM P

D.2 B

UGCHECK PACKETS .....................................................................................................D-2

D.3 PO/ST

D.4 E

VENT LOG PACKETS .....................................................................................................D-4

ACKETS (LAST N ERROR EVENTS).................................................................D-1

FAILURE PACKETS...............................................................................................D-4

D.4.1 Directory Failure Event Logs................................................................................D-5

D.5 P

RIMARY STA TUS/SECONDARY STATUS.........................................................................D-7

D.6 C

ODE UPDATE (CUP) STATUS PACKET..........................................................................D-8

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-xi

Page 12

Table of Contents

List of Figures

2-1 DRIVE FRONT PANEL .......................................................................................................2-3

2-2 C

HANGING THE SCSI ID VIA THE PUSHBUTTON SWITCHPACK (LATER MODEL)..............2-5

2-3 R

EAR PANEL COMPONENTS .............................................................................................2-6

3-1 DLT2000 D

3-2 SCSI ID C

3-3 J

UMPER POSITIONS...........................................................................................................3-4

3-4 J

UMPER SETTINGS FOR TRM PWR/TRM ENB CONNECTOR ..........................................3-5

3-5 DLT2000 R

3-6 DLT2000 I

3-7 T

APE CARTRIDGE...........................................................................................................3-18

3-8 L

OADING A CARTRIDGE .................................................................................................3-21

3-9 U

NLOADING A CARTRIDGE.............................................................................................3-25

4-1 L

OOSENING THE SHIPPING SCREW....................................................................................4-2

4-2 R

OTATE THE LOCKING LEVER..........................................................................................4-3

4-3 M

INI-LIBRARY REAR PANEL COMPONENTS .....................................................................4-4

4-4 F

RONT OF THE DLT2500 .................................................................................................4-5

4-5 M

INI-LIBRARY OPERATOR CONTROL PANEL ...................................................................4-9

4-6 W

RITE-PROTECT SWITCH ON A CARTRIDGE................................................................... 4-20

4-7 DLT2500 M

4-8 I

NSERTING A CARTRIDGE INTO THE MAGAZINE..............................................................4-24

4-9 R

EMOVING A CARTRIDGE FROM THE MAGAZINE............................................................ 4-25

5-1 C

HANGING THE SCSI ID VIA THE PUSHBUTTON SWITCH .................................................5-4

5-2 DLT2700 O

5-3 W

RITE-PROTECT SWITCH ON A CARTRIDGE................................................................... 5-21

5-4 I

NSERTING A CARTRIDGE INTO THE MAGAZINE..............................................................5-22

5-5 R

EMOVING A CARTRIDGE FROM THE FRONT OF THE MAGAZINE ....................................5-24

5-6 R

ECEIVER OPENED ........................................................................................................5-26

6-1 O

PENING THE CARTRIDGE DOOR TO CHECK THE TAPE LEADER ......................................6-4

7-1 DLT2700 S

7-2 J

UMPER SETTINGS FOR TRM PWR/TRM ENB CONNECTOR ..........................................7-4

8-1 E

XTENDED MESSAGE FORMAT ......................................................................................8-10

8-2 SDTR E

8-3 ERASE CDB.................................................................................................................8-16

8-4 INQUIRY CDB.............................................................................................................8-17

8-5 INQUIRY R

8-6 INQUIRY V

8-7 S

UPPORTED VITAL PRODUCT DATA PAGES....................................................................8-22

8-8 U

NIT SERIAL NUMBER PAGE ..........................................................................................8-23

8-9 F

IRMWARE BUILD INFORMATION PAGE..........................................................................8-23

RIVE CONNECTORS.......................................................................................3-2

ONNECTOR PINS ..............................................................................................3-3

EAR CONNECTORS ........................................................................................3-6

NDICATORS ..................................................................................................3-10

AGAZINE ....................................................................................................4-22

PERATOR CONTROL PANEL...........................................................................5-6

UBSYSTEM CONNECTORS ..............................................................................7-3

XTENDED MESSAGE FORMAT ...........................................................................8-13

ESPONSE DATA ..........................................................................................8-18

ENDOR UNIQUE BYTES DEFINITION ...........................................................8-21

xii-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 13

Table of Contents

8-10 LOAD-UNLOAD CDB..............................................................................................8-25

8-11 LOCATE CDB............................................................................................................8-27

8-12 LOG SELECT CDB ...................................................................................................8-28

8-13 LOG P

8-14 C

8-15 R

8-16 P

AGE CONTROL DEFINITIONS..............................................................................8-29

LEARABLE LOG PAGES ..............................................................................................8-30

EAD/WRITE ERRROR LOG SELECT PAGE FORMAT..................................................... 8-31

ARAMETER CODES SUPPORTED ................................................................................. 8-32

8-17 LOG SENSED CDB...................................................................................................8-34

8-18 LOG P

8-19 LOG SENSE P

8-20 S

8-21 R

8-22 P

8-23 T

8-24 L

8-25 P

8-26 R

8-27 R

8-28 R

AGE CONTROL DEFINITIONS..............................................................................8-35

AGES SUPPORTED ................................................................................8-36

UPPORTED PAGES PAGE FORMAT...............................................................................8-37

EAD/WRITE ERROR LOG SENSE PAGE FORMAT.......................................................8-38

ARAMETER CODES SUPPORTED ................................................................................. 8-39

HRESHOLD MET CRITERIA.........................................................................................8-40

AST N ERROR EVENTS PAGE ......................................................................................8-41

ARAMETER CODES SUPPORTED ................................................................................. 8-42

EAD/WRITE COMPRESSION RATIO PAGE HEADER .....................................................8-42

EAD/WRITE COMPRESSION RATIO LOG SENSE PAGE FORMAT...............................8-43

EAD/WRITE BYTES TRANSFERRED LOG SENSE PAGE FORMAT..............................8-44

8-29 MODE SELECT CDB................................................................................................8-46

8-30 MODE SELECT P

8-31 MODE SELECT P

8-32 C

ONTROL MODE PAGE (0AH)......................................................................................8-51

8-33 D

ATA COMPRESSION PAGE ..........................................................................................8-53

8-34 D

EVICE CONFI GURATION PAGE FORMAT .....................................................................8-55

8-35 D

ISCONNECT/RECONNECT PAGE FORMAT...................................................................8-58

8-36 D

ATA TRANSFER DISCONNECT CONTROL....................................................................8-59

8-37 M

EDIUM PARTITION PAGE FORMAT.............................................................................8-60

8-38 E

RROR RECOVERY PAGE FORMAT...............................................................................8-61

8-39 EEROM V

8-40 EEROM V

8-41 EEROM V

ENDOR UNIQUE PAGE FORMAT ..................................................................8-63

ENDOR UNIQUE PAGE EXAMPLE 1..............................................................8-67

ENDOR UNIQUE PAGE EXAMPLE 2..............................................................8-68

ARAMETER LIST.............................................................................8-47

AGES SUPPORTED ..........................................................................8-50

8-42 MODE SENSE CDB (6).............................................................................................8-70

8-43 MODE SENSE CDB (10)...........................................................................................8-71

8-44 MODE SENSE P

8-45 MODE SENSE (6) D

8-46 MODE SENSE (10) D

8-47 MODE SENSE B

8-48 MODE SENSE P

8-49 MODE SENSE P

8-50 C

ONTROL MODE PAGE (0AH)......................................................................................8-78

8-51 D

EVICE CONFI GURATION PAGE FORMAT .....................................................................8-80

8-52 D

ATA COMPRESSION PAGE).........................................................................................8-82

AGE CONTROL DEFINITION...............................................................8-71

ATA HEADER .............................................................................8-73

ATA HEADER ...........................................................................8-74

LOCK DESCRIPTOR...........................................................................8-74

AGE DESCRIPTOR.............................................................................8-74

AGES SUPPORTED.............................................................................8-77

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-xiii

Page 14

Table of Contents

8-53 DISCONNECT/RECONNECT PAGE FORMAT ...................................................................8-84

8-54 M

EDIUM PARTITION PAGE FORMAT.............................................................................8-85

8-55 E

RROR RECOVERY PAGE FORMAT...............................................................................8-86

8-56 PREVENT/ALLOW MEDIUM REMOVAL CDB....................................................8-89

8-57 READ CDB.................................................................................................................8-90

8-58 READ BLOCK LIMITS CDB.................................................................................... 8-92

8-59 READ BLOCK LIMITS.............................................................................................8-92

8-60 READ BUFFER CDB.................................................................................................8-93

8-61 READ BUFFER M

8-62 READ BUFFER D

8-63 READ BUFFER D

ODES SUPPORTED..........................................................................8-93

ATA HEAD ..................................................................................... 8-94

ESCRIPTOR.....................................................................................8-95

8-64 READ POSITION CDB .............................................................................................8-96

8-65 READ POSITION D

ATA FORMAT..............................................................................8-97

8-66 RECEIVE DIAGNOSTICS RESULTS CDB.............................................................8-99

8-67 R

ECEIVE DIA GNOSTIC RESULT DATA FORMAT ............................................................8-99

8-68 RELEASE UNIT CDB .............................................................................................8-100

8-69 REQUEST SENSE CDB..........................................................................................8-101

8-70 REQUEST SENSE D

ATA .........................................................................................8-102

8-71 RESERVE UNIT CDB.............................................................................................8-112

8-72 RESERVE UNIT CDB.............................................................................................8-114

8-73 SEND DIAGNOSTIC CDB......................................................................................8-115

8-74 SEND DIAGNOSTIC P

ARAMETER LIST FORMAT ....................................................8-117

8-75 SPACE CDB.............................................................................................................8-120

8-76 SPACE C

ODE DEFINITION .........................................................................................8-120

8-77 TEST UNIT READY CDB.......................................................................................8-122

8-78 VERIFY CDB...........................................................................................................8-123

8-79 WRITE CDB.............................................................................................................8-124

8-80 WRITE BUFFER CDB.............................................................................................8-126

8-81 WRITE BUFFER M

ODES SUPPORTED......................................................................8-126

8-82 WRITE FILEMARKS CDB.....................................................................................8-129

8-83 I

NITIALIZE ELEMENT STATUS.....................................................................................8-132

8-84 READ ELEMENT STATUS CDB...........................................................................8-133

8-85 E

LEMENT TYPE CODE DEFINITIONS ...........................................................................8-133

8-86 E

LEMENT STATUS DATA HEADER..............................................................................8-134

8-87 M

EDIUM TRANSPORT ELEMENT STATUS PAGE ..........................................................8-135

8-88 S

TORAGE ELEMENT STATUS PAGE.............................................................................8-136

8-89 D

ATA TRANSFER ELEMENT STATUS PAGE.................................................................8-137

8-90 D

EVICE CAPABILITIES PAGE FORMAT ........................................................................8-138

8-91 E

LEMENT ADDRESS ASSIGNMENT PAGE FORMAT......................................................8-140

8-92 T

RANSPORT GEOMETRY PAGE FORMAT ....................................................................8-142

8-93 MOVE MEDIUM CDB............................................................................................8-143

A-1 P

OWER CORD................................................................................................................ A-5

A-2 M

OUNTING HOLE DIMENSIONS (TOP VIEW).................................................................. A-9

xiv-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 15

Table of Contents

A-3 MOUNTING HOLE DIMENSIONS (SIDE VIEW)............................................................... A-10

D-1 EEROM L

D-2 B

UGCHECK LOG PACKET LAYOUT................................................................................D-3

D-3 POST LOG P

D-4 EVENT LOG P

D-5 D

IRECTORY R/W ERROR EVENT LOG LAYOUT.............................................................D-6

D-6 C

ODE UPDATE (CUP) LOG PACKET LAYOUT ...............................................................D-9

OG AREA LAYOUT ........................................................................................D-2

ACKET LAYOUT.......................................................................................D-4

ACKET LAYOUT ....................................................................................D-5

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-xv

Page 16

Table of Contents

List of Tables

2-1 ADDING A TERMINATOR ..................................................................................................2-7

2-2 POST--R

2-3 A

FTER POST ...................................................................................................................2-9

2-4 DLT2000 T

3-1 R

ESULTS OF DENSITY SELECTION ....................................................................................3-9

3-2 POST S

3-3 D

ETERMINING THE DRIVE'S OPERATING CONDITION......................................................3-14

3-4 B

EFORE LOADING THE CARTRIDGE ................................................................................3-19

3-4 A

FTER LOADING THE CARTRIDGE AND OPERATING .......................................................3-19

3-5 W

3-6 W

4-1 M

4-2 D

ISPLAY MESSAGES ....................................................................................................... 4-11

4-3 D

ENSITY SELECT MODE.................................................................................................. 4-16

4-4 C

ARTRIDGE, BEFORE LOADING.......................................................................................4-21

4-5 A

FTER LOADING THE CARTRIDGE .................................................................................. 4-27

4-6 W

5-1 R

ESULTS OF DENSITY SELECTION USING A COMPACTAPE III TAPE ................................ 5-11

5-2 DLT2700 O

5-3 L

OADER POWER-ON SHELF-TEST ..................................................................................5-15

5-4 L

OAD/UNLOAD FUNCTIONS ...........................................................................................5-17

6-1 DLT2500 OCP B

6-2 DLT2700 OCP B

7-1 R

ESULTS (DLT2000 CODE UPDATE)...............................................................................7-9

7-2 R

ESULTS (DLT2500 CODE UPDATE).............................................................................7-11

7-3 R

ESULTS (DLT2700 CODE UPDATE).............................................................................7-17

8-1 S

UPPORTED SCSI MESSAGES ..........................................................................................8-8

8-2 DLT2000 S

8-3 EEROM V

8-4 C

HANGEABLE MODE PARAMETERS ...............................................................................8-69

8-5 S

ENSE KEYS USED.......................................................................................................8-106

8-6 A

DDITIONAL SENSE CODES/QUALIFIERS USED ............................................................8-107

8-7 S

END DIAGNOSTICS PARAMETERS ...............................................................................8-117

8-8 D

EFINITION OF PATTERN NUMBERS DEFINITION O F PATTERN NUMBERS .....................8-118

8-9 S

ENSE KEYS USED.......................................................................................................8-119

8-10 A

8-11 M

8-12 M

A.1 DLT2000 P

IGHT SIDE INDICATORS......................................................................................2-8

ROUBLESHOOTING CHART...........................................................................2-10

EQUENCE OF EVENTS ........................................................................................3-13

HAT IS HAPPENI NG DURING CARTRIDGE USE (RIGHT SIDE LIGHTS.............................3-22

HEN TO USE THE CLEANING CARTRIDGE ....................................................................3-23

INI-LIBRARY OPERATOR CONTROL PANEL .................................................................4-10

HEN TO USE THE CLEANING CARTRIDGE ....................................................................4-29

PERATOR CONTROL PANEL.........................................................................5-12

UTTON CONDITIONS .............................................................................6-2

UTTON CONDITIONS .............................................................................6-3

UPPORTED SCSI COMMANDS......................................................................8-15

ENDOR UNIQUE PAGE PARAMETERS.............................................................8-64

DDITIONAL SENSE CODES.......................................................................................8-119

EDIUM CHANGER COMMANDS................................................................................8-131

EDIUM CHANGER ELEMENT ADDRESSES ................................................................8-141

HYSICAL SPECIFICATIONS ........................................................................... A-2

xvi-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 17

A.3 DLT2500 MINI-LIBRARY PHYSICAL SPECIFICATIONS................................................... A-7

A.4 DLT2700 M

A-5 DLT2000 T

A-6 DLT2500

A-7 DLT2700 M

A-8 O

PERATING RANGES ................................................................................................... A-13

A-9 P

OWER-ON RANGES—NO TAPE LOADED (UNPACKED - 72 HOURS) ........................... A-13

A-10 S

TORAGE RANGES (UNPACKED OR PACKED) ............................................................ A-14

A-11 S

HIPMENT RANGES ................................................................................................... A-14

A-12 O

PERATING VIBRATION SPECIFICATIONS .................................................................. A-15

A-13 O

PERATING SHOCK SPECIF ICATIONS......................................................................... A-15

A-14 N

ONOPERATING SHOCK OVERSTRESS (BENCH HANDLING - UNPACKAGED) SPECIFICATIONS

INI-LIBRARY PHYSICAL SPECIFICATIONS................................................... A-8

IMING CHARACTERISTICS......................................................................... A-11

XT MEDIA LOADER TIMING CHARACTERISTICS........................................... A-12

EDIA LOA DER TIMING CHARACTERISTICS............................................... A-12

........................................................................................................................................... A-16

A-15 N

ONOPERATING (PACKAGED) VIBRATION SPECIFICATIONS ...................................... A-16

A-16 N

ONOPERATING (PACKAGED) REPETITIVE SHOCK SPECIFICATIONS.......................... A-17

A-17 N

ONOPERATING (PACKAGED) SHOCK (DROP) SPECIFICATIONS ................................ A-17

A-18 N

ONOPERATING (UNPACKAGE) VIBRATION SPECIFICATIONS.................................... A-17

A-19 N

ONOPERATING (UNPACKAGED) SHOCK SPECIFICATIONS ........................................ A-18

A-20 C

ONDUCTED EMISSIONS............................................................................................ A-20

A-21 R

ADIATED EMISSIONS, 30 MHZ TO 30 GHZ............................................................... A-20

A-22 L

OW FREQUENCY, MAGNETIC FIELDS, 10 TO 3000 KHZ .......................................... A-20

A-23 H

IGH FREQUENCY, ELECTRIC FIELDS, 1 TO 1000 MHZ ............................................ A-21

A-24 F

AST TRANSIENT (BURSTS) FOR POWER AND DATA CABLES.................................... A-21

A-25 H

IGH ENERGY TRANSIENT VOLTAGE FOR POWER CABLES ....................................... A-21

A-26 L

OW-LEVEL CONDUCTED INTERFERENCE ................................................................. A-21

A-27 ESD F

A-28 A

A-29 R

A-30 C

B-1 I

B-2 I

D-1 EEROM LOG P

D-2 B

D-3 E

D-4 D

D-5 D

D-6 68020 C

D-7 S

AILURE LEVEL LIMITS .................................................................................... A-22

COUSTIC NOISE EMISSIONS, NOMI NAL ................................................................... A-22

ELIABILITY FACTORS .............................................................................................. A-25

OMPACTAPE RECORDING MEDIA SPECIFICATIONS.................................................. A-26

NTERNAL STATUS CODE................................................................................................B-1

NTERNAL STATUS BIT FLAGS ........................................................................................B-3

ACKET TYPES.......................................................................................D-2

UGCHECK ERROR CODES.............................................................................................D-3

VENT LOG CODES........................................................................................................D-5

IRECTORY EVENT LOG FLAGS .....................................................................................D-7

IRECTORY EVENT STATUSES .......................................................................................D-7

ODE UPDATE STATUS .....................................................................................D-10

ERVO CODE UPDATE STATUS.....................................................................................D-10

Table of Contents

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-xvii

Page 18

Table of Contents

xviii-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 19

REVISION HISTORY

This Revision History provides a concise publication record of this manual. It lists

the manual revision levels, release dates, and reasons for the revisions.

Manual No. - Rev Level Date Summary of Changes

81-109132-01 April 14, 1995 Original issue

81-109132-02 August 18, 1995 Specifications and illustrations

were upgraded.

DLT2500 Mini-library section

add.

81-109132-03 January 19, 1996 Caution added for unloading a

tape cartridge.

AC Power Cord spec’s added.

FCC Statement upgraded.

Upgraded Chapters 1 to 8 and

appendix A.

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem - xix

Page 20

Revision History

xx - DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 21

To the Reader:

QUANTUM makes every effort to ensure the accuracy of information. However, some

errors may have been introduced inadvertently; they will be corrected in the next

release. QUANTUM recognizes that some users may require additional content. We

welcome your feedback and your suggestions for enhancements and we will evaluate

your input for a future release. Please send your comments to:

Technical Publications

Quantum Corporation

333 South Street

Shrewsbury, MA 01545

Purpose of This Manual

This manual is isssued for the DLT2000 Cartridge Tape drive, and DLT2500 and

DLT2700 Cartridge Tape Subsystems. The manual describes operating procedures,

code update, and SCSI protocol features.

All care is taken to ensure accuracy. However, some of the parameters, drawings, and

specifications being under constant review, and enhancement, may change.

Preface

Who Should Use This Manual

This manual is written for the subsystem or system integrator and users of the

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem.

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem-xxi

Page 22

Preface

Structure of This Manual

Chapter 1, Overview and Features of the DLT2000/DLT2500/DLT2700 Product,

gives a product overview and lists the product features of the DLT2000/DLT2700 tape

subsystem.

Chapter 2, Installing and Configuring the DLT2000 Tabletop Drive, describes

installing and configuring the DLT2000 tabletop tape drive.

Chapter 3, Configuring and Operating the DLT2000 Tape Drive, includes selecting

density, configuration, and other operation information for the tape drive, such as front

panel indicators and controls, Power-on Self-test, the tape cartridge write-protect

switch, loading a cartridge, using t he cleaning tape, unloading a cartridge, and

preserving cartridges.

Chapter 4, Configuring and Operating the DLT2500 Mini-Library, includes

configuration, selecting density, and other operation information for the loader, such as

the power-on process, the loader Mode Select key, the operator control panel, and

functions of the Slot Select, Load/Unload, and Eject buttons.

Chapter 5, Configuring and Operating the DLT2700 Mini-Library, includes

configuration, selecting density, and other operation information for the loader, such as

the power-on process, the loader Mode Select key, the operator control panel, and

functions of the Slot Select, Load/Unload, and Eject buttons.

Chapter 6, Troubleshooting Guide for the DLT2500/DLT2700 Mini-Library, gives

instructions on how to clear failures and describes the necessary conditions to ensure

the loader OCP pushbuttons operate effectively.

Chapter 7, Firmware Update (From Tape), provides an overview on updating the

firmware, describes how to create a firmware update tape, and tells how to update the

firmware.

Chapter 8, DLT2000 SCSI Interface, details the SCSI protocol features of the

DLT2000 tape subsystem.

Appendix A, Technical Specifications, gives product specifications including physical

dimensions, performance specifications, power requirements, environmental

specifications, vibration and shock requirements, electromagnetic interference

susceptibility, regulatory requirements, and reliability factors.

Appendix B, Definition of Vendor Unique Sense Data Info rmation, describes the

internal status codes for the DLT2000/DLT2500/DLT2700 product.

Appendix C, Sense Key Information, lists the sense key information for the

DLT2000/DLT2500/DLT2700 product.

-DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 23

Overview and Features of the

DLT2000/DLT2500/DLT2700 Product

1.1 In This Chapter

Chapter 1 includes the following main topics and sections:

Topic Section

Product Overview 1.2

Fast Data Transfer Rate 1.3

High-Capacity 1.4

Compaction 1.5

Strong Media 1.6

Compatibility 1.7

Firmware Update Capability 1.8

Embedded Diagnostics 1.9

1.2 Product Overview

The DLT2000/DLT2500/DLT2700 is a high-performance, high-capacity, streaming

cartridge tape product designed for use on midrange and high-end computing systems.

Using data compression and compaction, the DLT2000 drive features a formatted

capacity of 30 GB and a sustained user data transfer rate of 2.5 MB/s.

1

The DLT2000 is a 5.25 inch form factor, half-inch tape drive. The design includes a

dual-channel read/write head, Lempel-Ziv (LZ) high-efficiency data compression, and

tape mark directory to maximize data throughput and minimize data access time.

The DLT2500 is a tape mini-library that performs automatic tape operations. The

DLT2500 includes the tape drive and a 5-cartridge SCSI-2 medium changer device

(loader). The mini-library provides unattended backup of 100 GB in less than 16 hours

or up to 50 GB in an 8-hour shift in a compressed mode.

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem 1-1

Page 24

Overview and Features of the DLT2000/DLT2500/DLT2700 Product

The DLT2700 is a tape mini-library that performs automatic tape operations. The

DLT2700 includes the tape drive and a 7-cartridge SCSI-2 medium changer device

(loader). The mini-library provides unattended backup of 140 GB in less than 16 hours

or up to 70 GB in an 8-hour shift in a compressed mode.

The drive and mini-libraries are available in a rackmountable form factor. Also, the

DLT2000, DLT2500 and DLT2700 are available with either single-ended or

differential, fast driver/receivers.

1.3 Fast Data Transfer Rate

Used for unattended backups or archiving, the DLT2000/DLT2500/DLT2700 allows

the user to back up a higher data capacity at a high speed. The

DLT2000/DLT2500/DLT2700, when operating in a non-compressed mode, has a

maximum transfer rate of 1.25 MB/s. When operating in the compressed mode, the

maximum transfer rate is 2.5 MB/s write and 3.0 MB/s read.

1.4 High-Capacity

The amount of data the user can store on a tape CompacTape III cartridge can be up to

10.0 GB native capacity or 20.0 GB compressed, depending on whether you select

compression mode. Built-in data compression increases cartridge capacity and drive

transfer rate 2 to 2.5 times. Compression can be selected on the loader or drive front

panel or fro m the host by using the SCSI MODE SELECT command.

1.5 Compaction

The compaction feature of the DLT2000 helps you to store data efficiently. A

read/write data cache of 2.0 MB allows working space for the compaction, enabling

maximum use of available tape space.

1.6 Durable Media

The CompacTape III tape media can endure 500,000 passes and has a shelf life of 30

years, which provides superior media durability and data reliability.

1.7 Compatibility

Quantum is committed to maintaining compatibility within the DLT family of tape

drives. DLT2000/DLT2500/DLT2700 tape products are the fourth generation of tape

products, started with the DLT260 and DLT600 drives.

The DLT2000/DLT2500/DLT2700 complies with the ANSI standard for SCSI-2. The

tape media format follows ECMA approved and ANSI proposed standards.

1-2 DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 25

Overview and Features of the DLT2000/DLT2500/DLT2700 Product

The user can select tape density for the CompacTape III cartridge on the loader or drive

front panel or by using the SCSI MODE SELE CT command. The

DLT2000/DLT2500/DLT2700 can write 2.6, 6.0, and 10.0 GB tape formats for 100%

interchange compatibility with earlier DLT drives using the CompacTape III cartridge.

On a write from BOT, the DLT2000/DLT2500/DLT2700 reformats the CompacTape

III cartridge recorded at 2.6, 6.0, or 10.0 GB format to the new specified format using

the new specified format.

1.8 Firmware Update Capability

The DLT2000 includes Flash EEPROM technology that allows easy on-site installation

of microcode updates from tape.

1.9 Embedded Diagnostics

The DLT2000 has embedded diagnostic software that tells you when head cleaning is

required, and indicates diagnostic results, and drive operating status. The drive has

embedded data logging of errors for failure analysis.

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem 1-3

Page 26

Overview and Features of the DLT2000/DLT2500/DLT2700 Product

1-4 DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 27

Chapter 2

Installing and Configuring the DLT2000

Tabletop Drive

2.1 In This Chapter

Chapter 2 includes the following main topics and sections:

Topic Section

Prepare for the Installation 2.2

Install the Subsystem 2.3

Configure the DLT2000 Tabletop 2.4

Connect the Cables 2.5

Test the Installation 2.6

DLT2000 Troubleshooting Chart 2.7

2.2 Prepare for the Installation

This section describes how to prepare for the installation of the DLT2000 cartridge tape

subsystem including:

Topic Section

Before You Start 2.2.1

Installation Setup 2.2.2

Site Setup 2.2.3

Site Guidelines 2.2.4

2.2.1 Before You Start

Installing the DLT2000 tabletop cartridge tape subsystem requires no special tools. If

you need to change the switchpack settings on the rear panel, you will need a pen.

If you have problems during the installation, see Table 2-4 for troubleshooting.

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem 2-1

Page 28

Installing and Configuring the DLT2000 Tabletop Drive

2.2.2 Installation Setup

The steps for installation setup are:

Step Action

1

2

3

Unpack and check your shipment.

Choose a site for the DLT2000 tabletop subsystem.

Power off the system on which the DLT2000 tabletop

subsystem is to be installed.

2.2.3 Site Setup

Place the DLT2000 on a flat, sturdy, level area such as a desk or tabletop.

2.2.4 Site Guidelines

Be sure to follow these guidelines for your DLT2000:

• The DLT2000 is designed to operate in harsh environments. However, use care in

placing the drive in an environment that is free of dust and humidity.

2-2 DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem

Page 29

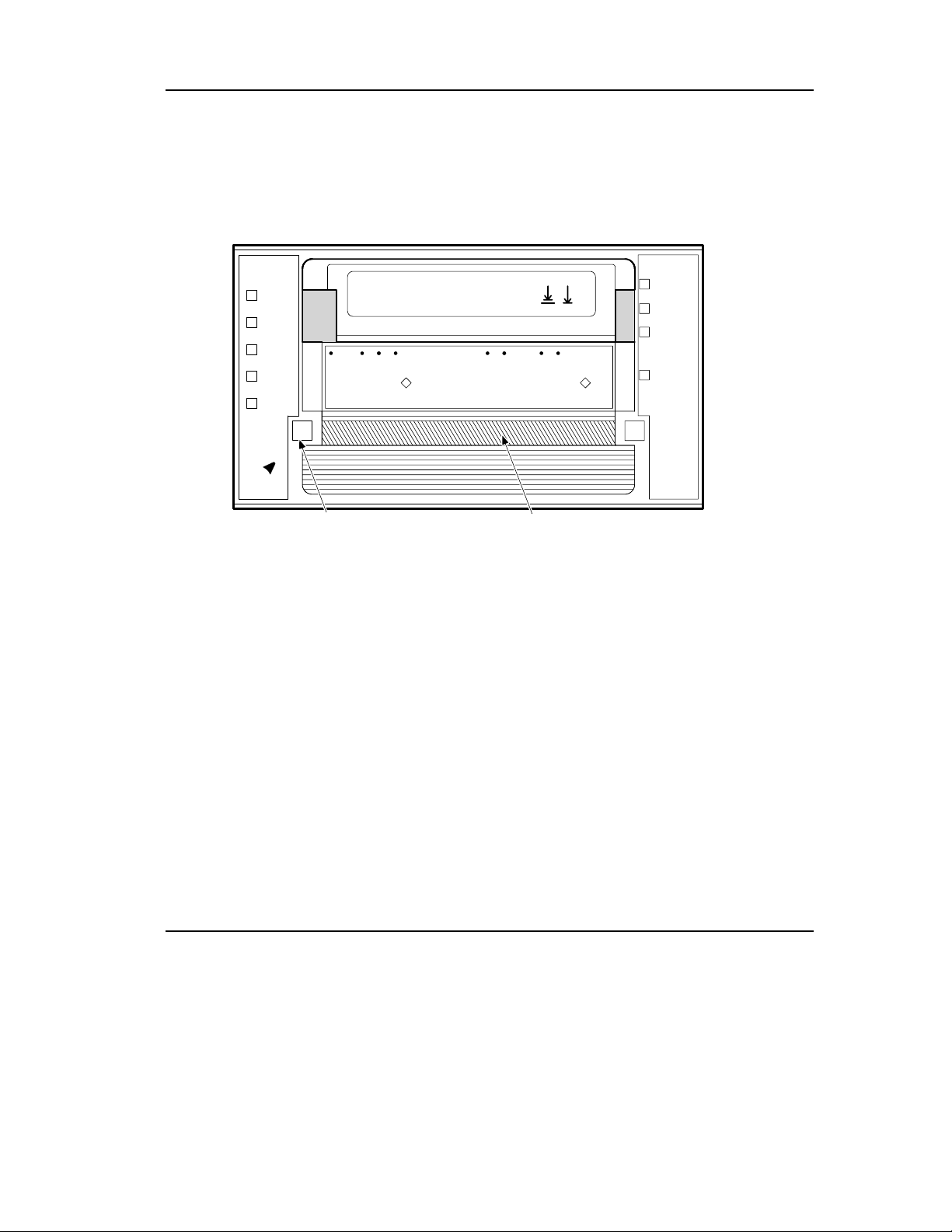

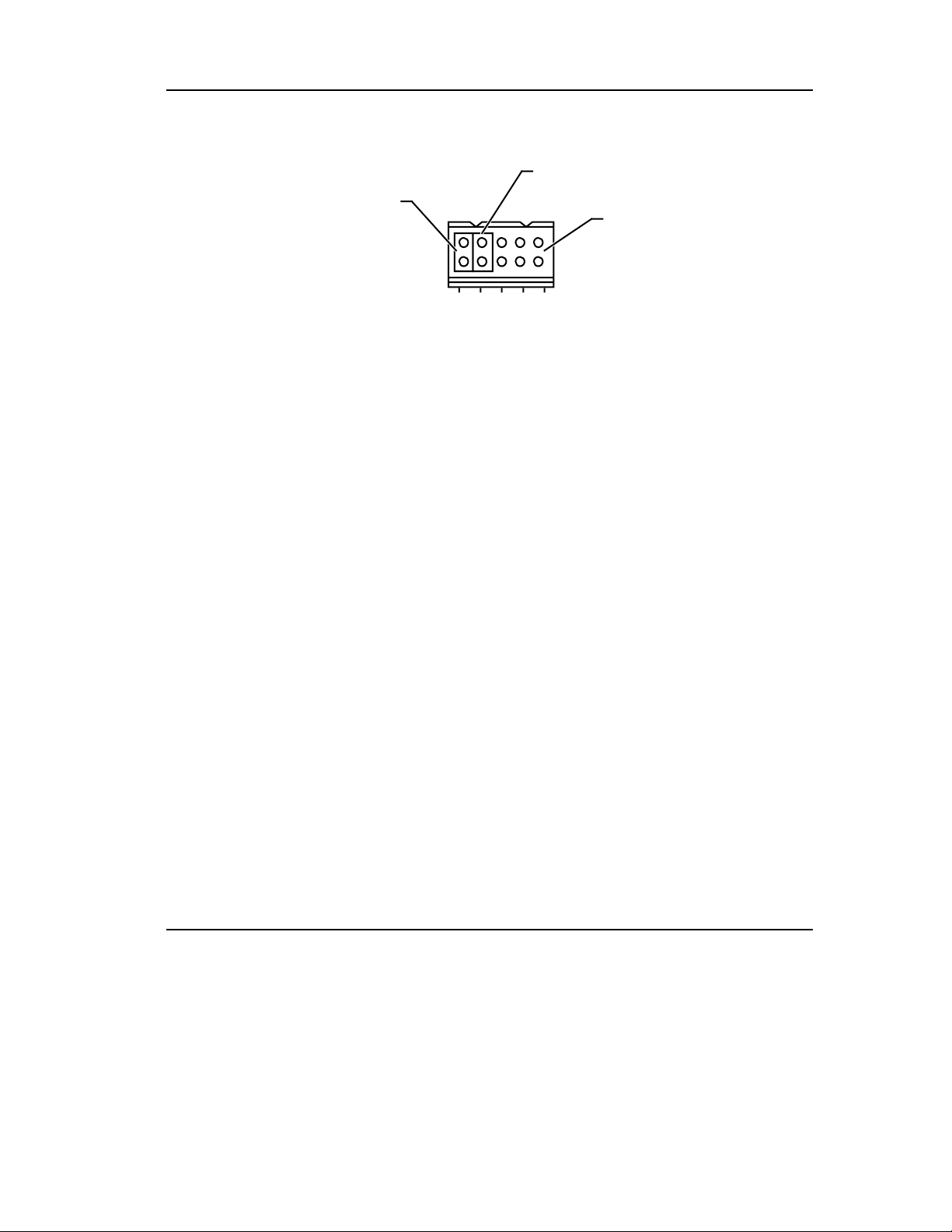

Figure 2-1 shows the DLT2000.

2.6

6.0

10.0

Compress

Density

Override

Density

Select

Handle

Open this

Remove Tape

Wait

To Unload

Press Button

Light

Installing and Configuring the DLT2000 Tabletop Drive

Write

Protected

Tape in Use

Use

Use

Cleaning

Handle

Close this

Handle

Open this

Insert Tape

Wait

To Load

Light

Tape

Operate

Handle

Unload

SELECT BUTTON

CARTRIDGE INSERT/RELEASE HANDLE (DOWN)

ZKO-1217-02-DG

Figure 2-1 Drive Front Panel

DLT2000/DLT2500/DLT2700 Cartridge Tape Subsystem 2-3

Page 30