Page 1

CERTANCE

Online User's Guide

DAT 72/DDS-4 6-Slot Autoloader

i

Page 2

Copyright and Trademarks

Copyright © 2003 by Certance LLC. All Rights Reserved.

Part Number 50000999

August, 2003

Certance and the Certance logo are trademarks of Certance LLC. Seagate is a trademark of Seagate

Technology LLC. Other product names are trademarks or registered trademarks of their respective owners.

Certance reserves the right to change, without notice, product offerings or specifications. No part of this

publication may be reproduced in any form without written permission from Certance LLC.

Certance provides this manual “as is,” without warranty of any kind, either expressed or implied, including, but

not limited to, the implied warranties of merchantability and fitness for a particular purpose. Certance reserves

the right to change, without notification, the specifications contained in this manual.

Certance assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of this manual, nor

for any problem that might arise from the use of the information in this manual.

Page 3

Warnings

All safety and operating instructions should be read before this product is operated, and should be retained for

future reference. This unit has been engineered and manufactured to assure your personal safety. Improper use

can result in potential electrical shock or fire hazards. In order not to defeat the safeguards, observe the

following basic rules for installation, use and servicing.

CAUTION: This symbol should alert the user to the presence of “dangerous voltage” inside the

product that might cause harm or electric shock.

Caution! Risk of electric shock! Do not open!

To reduce the risk of electric shock, do not remove the cover (or back). No user-serviceable parts

are inside. Refer servicing to qualified service personnel.

• Heed warnings — All warnings on the product and in the operating instructions should be adhered to.

• Follow instructions — All operating and use instructions should be followed.

• Ventilation — The product should be situated so that its location or position does not interfere with proper

ventilation.

• Heat — The product should be situated away from heat sources such as radiators, heat registers,

furnaces, or other heat producing appliances.

• Power sources — The product should be connected to a power source only of the type directed in this

document or as marked on the product.

• Power cord protection — The power cord should be routed so that it is not likely to be walked on or

pinched by items placed upon or against it, paying particular attention to the cord at the wall receptacle,

and the point where the cord exits from the product.

• To complete the disconnection of the electricity, please remove the power (electric) cord and the SCSI

cable from their connections in the back of the product. The plugs should be placed near the product for

easy access.

• Object and liquid entry — Care should be taken to insure that objects do not fall and liquids are not

spilled into the product's enclosure through openings.

• Servicing — The user should not attempt to service the product beyond that described in the operating

instructions. All other servicing should be referred to qualified service personnel.

Page 4

Precautions

• Do not use oil, solvents, gasoline, paint thinners, or insecticides on the unit.

• Do not expose the unit to moisture or to temperatures higher than 104 °F (40 °C) or lower than -40 °F (-

40°C).

• Keep the unit away from direct sunlight, strong magnetic fields, excessive dust, humidity, and electronic/

electrical equipment, which generate electrical noise.

• Hold the power cord by the head when removing it from the AC outlet; pulling the cord can damage the

internal wires.

• Use the unit on a firm level surface free from vibration, and do not place anything on top of the unit.

Page 5

FCC Notice

This equipment generates and uses radio frequency energy and, if not installed and used properly — that is, in

strict accordance with the manufacturer's instructions — may cause interference to radio communications or

radio and television reception. It has been tested and found to comply with the limits for a Class B computing

device in accordance with the specifications in Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause interference to radio or

television reception, which can be determined by turning the equipment on and off, you are encouraged to try

to correct the interference by one or more of the following measures:

• Reorient the receiving antenna.

• Relocate the computer with respect to the receiver.

• Move the computer into a different outlet so that the computer and receiver are on different branch

circuits.

If necessary, you should consult the dealer or an experienced radio/television technician for additional

suggestions. You may find the booklet, How to Identify and Resolve Radio-TV Interference Problems, prepared

by the Federal Communications Commission, helpful. This booklet (Stock No. 004-000-00345-4) is available

from the U.S. Government Printing Office, Washington, DC 20402.

WARNING: Changes or modifications made to this equipment, which have not been expressly

approved by Certance, may cause radio and television interference problems that could void

the user's authority to operate the equipment.

Further, this equipment complies with the limits for a Class B digital apparatus in accordance with Canadian

Radio Interference Regulations.

The desktop device drive described in this manual requires shielded interface cables to comply with FCC

emission limits.

WARNING: To prevent fire or electrical shock hazard, do not expose the unit to rain or

moisture.

To avoid electrical shock, do not open the cabinet.

Refer servicing to qualified personnel.

Page 6

Contents

List of Figures ..................................................................... 8

List of Tables........................................................................ 9

Chapter 1 - Introduction ................................................... 10

Features ............................................................................. 10

Capacity and Transfer Rates ................................................... 11

Applications ........................................................................ 11

Using This Guide .................................................................. 12

Chapter 2 - Quick Start Installation ................................ 13

Before you begin .................................................................. 13

Autoloader Components ........................................................ 14

Installing a Desktop Autoloader ............................................... 14

Installing an Internal Autoloader .............................................. 15

Chapter 3 - Installing the Autoloaders .......................... 16

Unpacking and Inspection ...................................................... 16

Installing the Desktop Autoloader ............................................. 16

Installing the Internal Autoloader .............................................. 20

Chapter 4 - Operating Your Autoloader ........................ 28

Using the Appropriate Media .................................................. 28

Starting the Autoloader .......................................................... 29

Handling Cartridges ............................................................. 29

Applying Labels ................................................................... 30

Loading a Cartridge ............................................................. 30

Ejecting a Cartridge or Magazine ............................................ 31

Write-Protecting a DAT Cartridge and Magazine ......................... 33

Cleaning the Tape Path .......................................................... 34

Preparation for Shipping ........................................................ 35

Chapter 5 - Understanding the Drive LEDs .................... 37

Front Panel LEDs ................................................................... 37

LED Summary ...................................................................... 38

Clean LED ........................................................................... 39

6

Page 7

Media LED .......................................................................... 39

Drive LED ............................................................................ 40

About the Operator Panel LCD Display ...................................... 41

Chapter 6 - Configuration for Novell and UNIX ........... 44

Operating System Configuration .............................................. 44

Chapter 7 - Troubleshooting ........................................... 53

Missing or Damaged Parts ..................................................... 53

SCSI ID Problems ................................................................. 53

SCSI Termination Problems ..................................................... 54

Drive Does Not Work ............................................................ 54

Power On Self Test Fails ......................................................... 54

Computer Does Not Boot ....................................................... 54

Computer Does Not Recognize Drive ........................................ 54

Backup Program Does Not Recognize Drive ............................... 55

Write Error .......................................................................... 55

Hardware Error .................................................................... 55

Appendix A - Loading Revised Firmware ...................... 56

Firmware Upgrade Methods ................................................... 56

Using Firmware Cartridges ..................................................... 56

7

Page 8

List of Figures

Figure 1. Front Panel Components ......................................................................... 14

Figure 2. Autoloader Rear Panel............................................................................ 18

Figure 3. SCSI Termination Examples..................................................................... 19

Figure 4. Jumper Pins on the Back of the Internal Autoloader..................................... 21

Figure 5. DIP-Switch Settings for the Internal Autoloader ........................................... 23

Figure 6. Locations of Mounting Holes.................................................................... 25

Figure 7. Interface Connectors on the Internal Autoloader......................................... 26

Figure 8. Two SCSI Termination Examples for the Internal Autoloader ........................ 26

Figure 9. Loading a Cartridge into the Autoloader Magazine ................................... 30

Figure 10. Loading a Magazine into the Autoloader................................................ 31

Figure 11. Write-protecting a DAT Cartridge .......................................................... 33

Figure 12. Write-protect switch on autoloader magazine.......................................... 33

Figure 13. Front Panel LEDs .................................................................................. 37

Figure 14. LCD display features............................................................................. 41

Figure 15. Operating System DIP Switches ............................................................. 45

8

Page 9

List of Tables

Table 1. DDS-4 and DAT 72 Autoloader Capacity and Transfer Rates........................ 11

Table 2. Default Configuration (Desktop Drive)........................................................ 17

Table 3. Default Configuration (Internal Drive)......................................................... 20

Table 4. Matching Drives with the Media They Support............................................ 28

Table 5. Cartridge Guidelines and Pitfalls............................................................... 29

Table 6. Cleaning the Autoloader.......................................................................... 34

Table 7. LED Quick Summary................................................................................ 38

Table 8. Clean LED.............................................................................................. 39

Table 9. Media LED ............................................................................................. 39

Table 10. Drive LED............................................................................................. 40

9

Page 10

1. Introduction

The Certance DAT 72 and DDS-4 tape autoloaders are fully integrated, intelligent, multi-cartridge

tape systems that support the (Digital Data Storage) DDS-2 (DDS-4 autoloader only), DDS-3, DDS-4,

and DAT 72 (DAT 72 autoloader only) 4mm tape formats. They include a magazine that can

accommodate up to six (6) data cartridges.

These autoloaders are an internal or standalone desktop subsystem that connects to a host system

using an LVD 2 68-pin shielded SCSI cable.

The autoloader combines established DDS technology, high-density recording and hardware data

compression capability to provide unmatched reliability and performance.

NOTE: These autoloaders will not work in a SCSI-1 environment.

Features

The following list summarizes the key features of the DDS-4 and DAT 72 autoloader drives.

• Compatibility

• DDS-4: Supports DDS-2, DDS-3, and DDS-4 recording formats.

• DAT 72: Supports DDS-3, DDS-4, and DAT 72 recording formats.

• Support for various native data-storage capacities

• High-speed transfer rates for fast backups

• Advanced onboard DDS-DC hardware using Lempel-Ziv (DCLZ) data-compression, doubling

the drive’s uncompressed capacity (e.g., a 20 GB uncompressed drive can be 40 GB with

compression)

• High-performance SCSI burst transfer rates

• Three levels of error-correction code (ECC) and four-head design for read-after-write (RAW)

15

error detection and correction (uncorrectable error rate of less than 1 in 10

• “Flying” preamplifier for greater signal-to-noise ratio

• Flash memory to store setup parameters and enable field firmware upgrades

• Automatic Power On Self Test

• State-of-the-art sealed drive mechanism and tape handling components for improved immunity

to airborne contaminants and extended media life.

bits)

10

Page 11

Introduction Capacity and Transfer Rates

Capacity and Transfer Rates

The Certance DAT 72 and DDS-4 autoloaders provide the following capacities and sustained data

transfer rates, depending upon the type and length of tape media used. These capacities and

transfer rates are based on an assumed 2:1 data compression rate. Uncompressed (native)

capacities are one-half these values

Table 1. DDS-4 and DAT 72 Autoloader Capacity and Transfer Rates

Tape format DDS-2* DDS-3 DDS-4 DAT-72

Tape Length (meters) 120 125 150 170

Single-Cartridge Capacity

(Gbytes)

.

8 24 40 72

Six-Cartridge Magazine Capacity (Gbytes)

Sustained Data Transfer Rate

(Mbytes/sec)

* Applies to DDS-4 drives only

NOTE: 60-meter DDS data cartridges cannot be used with these autoloaders. The use of 90meter DDS data cartridges is not recommended for these products. The DAT 432 autoloader will

reject 90-meter tapes if they are inserted.

Applications

The Certance DAT 72 and DDS-4 autoloaders are ideal for server and network/enterprise

applications, including:

• Backup of high-capacity hard drives or disk arrays

• Automated storage management

• On-line, unattended data collection

48 144 240 432

2.2 5.5 5.5 7.0

• Near-line secondary storage for text, graphics or multimedia data of all types

• Archival storage.

11

Page 12

Introduction Using This Guide

Using This Guide

This User’s Guide describes how to install, configure, and care for the DDS-4 and DAT 72

autoloader tape drives. Please read the appropriate chapters and appendixes carefully, and keep

this Guide handy for future reference.

• Chapter 2 provides quick-start instructions for getting the drives up and running in the

shortest possible time.

• Chapter 3 describes how to install the DDS-4 and DAT 72 autoloader drives.

• Chapter 4 describes how to operate the drives.

• Chapter 5 describes the autoloader LEDs.

• Chapter 6 describes the configuration for Novell and UNIX operating systems.

• Chapter 7 provides troubleshooting procedures you can follow in the unlikely event you

encounter a problem with your drive.

• Appendix A describes how to upgrade firmware for your tape drive.

12

Page 13

2. Quick Start Installation

This chapter provides quick-start instructions for getting the autoloader tape drives up and running in

the shortest possible time.

Topics in this chapter are:

• “Before you begin” on page 13

• “Autoloader Components” on page 14

• “Installing a Desktop Autoloader” on page 14

• “Installing an Internal Autoloader” on page 15

NOTE: If you prefer more detailed instructions, see Chapter 3 for drive installation

instructions.

Before you begin

Precautions

• Do not remove the drive from the antistatic bag until you are ready to install it.

• Before you remove the drive from the antistatic bag, touch a grounded metal surface to

discharge any static electricity buildup from your body.

• Hold the drive only by its edges and avoid direct contact with any electronic components.

• If you need to put down the drive, lay it on top of the antistatic bag or place it inside the bag.

CAUTION: Observe the following precautions to avoid electrostatic damage to the internal

autoloader.

13

Page 14

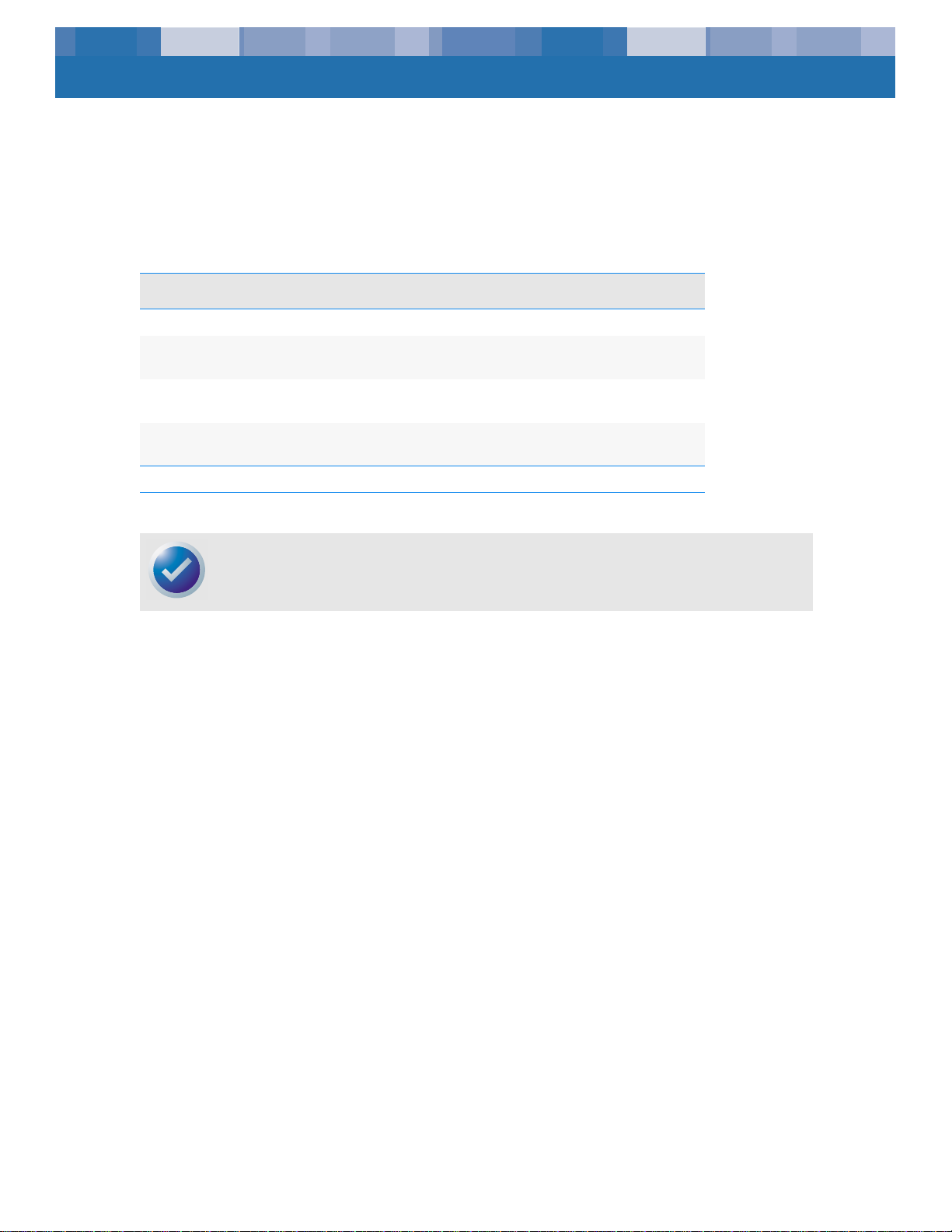

Quick Start Installation Autoloader Components

Autoloader Components

The following describes the major components of the autoloader.

EJECT

EJECT

button

button

SELECT

SELECT

button

button

ENTER

ENTER

button

button

LCD

Clean

Clean

LED

LED

(green)

(green)

Media

Media

LED

LED

(green)

(green)

Drive LED

Drive LED

(amber)

(amber)

LCD

Display

Display

Figure 1.

Front Panel Components

For more information on LEDs and their meaning, see “Front Panel LEDs” on page 37.

Installing a Desktop Autoloader

Use the following procedure to install a desktop autoloader. Print this page and check each step as

you complete it. If you need more information about a step, turn to the section referenced in the step.

Unpack the contents of your drive package, and check for missing or damaged items.

❑

❑

1.

See “Unpacking and Inspection” on page 16.

Review the drive’s default settings and change them if necessary:

2.

• SCSI ID: 6

• Parity Checking: Enabled

• Terminator Power: Disabled

• Data Compression: Enabled

• Media Recognition (DDS-4 drives only): Enabled

• Power On Self Test (POST): Enabled

• Host Operating System: Windows 98 SE/ME/XP/NT/2000/Windows Server 2003

• SCSI Interface Compatibility: Ultra 2 Wide SCSI for DDS-4 and DAT 72 autoloader

•Vendor ID: SEAGATE DAT

See“Configuring the Desktop Autoloader” on page 17.

❑

❑

❑

Connect a SCSI interface cable to the drive.

3.

See “Connecting the SCSI Interface Cable” on page 18.

Be sure the tape drive is not the last device on the SCSI bus (the drive does not provide

4.

SCSI termination).

See “Installing SCSI Termination” on page 19.

Connect a power cable to the drive.

5.

See “Connecting the Power Cord” on page 19.

14

Page 15

Quick Start Installation Installing an Internal Autoloader

Installing an Internal Autoloader

Use the following procedure to install an internal autoloader. Print this page and check each step as

you complete it. If you need more information about a step, turn to the section referenced in the step.

Unpack the contents of your drive package, and check for missing or damaged items.

❑

❑

❑

❑

1.

See “Unpacking and Inspection” on page 16.

Review the drive’s default settings and change them if necessary:

2.

• SCSI ID: 6

• Parity Checking: Enabled

• Terminator Power: Disabled

• Data Compression: Enabled

• Media Recognition: Enabled

• Power On Self Test (POST): Enabled

• Host Operating System: Windows 98 SE/ME/XP/NT/2000/Windows Server 2003

• SCSI Interface Compatibility: Ultra 2 Wide SCSI for DDS-4 and DAT 72 autoloader

•Vendor ID: SEAGATE DAT

See“Configuring the Internal Autoloader” on page 20.

Mount the drive horizontally in a 5.25-inch, full-height drive bay.

3.

See “Mounting the Internal Autoloader” on page 24.

Connect a SCSI interface cable to the drive.

4.

See “Connecting the SCSI Interface Cable” on page 25.

❑

❑

Be sure the tape drive is not the last device on the SCSI bus (the drive does not provide

5.

SCSI termination).

See “Installing SCSI Termination” on page 26.

Connect a power cable to the drive.

6.

See “Connecting the Power Cord” on page 27.

15

Page 16

3. Installing the Autoloaders

This chapter describes how to install the desktop and internal DDS-4 and DAT 72 autoloaders.

Topics in this chapter are:

• “Unpacking and Inspection” on page 16

• “Installing the Desktop Autoloader” on page 16

• “Installing the Internal Autoloader” on page 20

Unpacking and Inspection

Although Certance autoloaders are inspected and carefully packaged at the factory, damage may

occur during shipping. Follow these steps for unpacking the autoloader.

1. Before you unpack the contents of your autoloader package, inspect the shipping containers

for damage. If you spot damage to the container, notify your shipper immediately.

2. Place the shipping container on a flat, clean, stable surface. Then carefully remove the

contents and compare the items received with those on the packing list. If any item is missing

or damaged, please contact your place of purchase immediately.

3. Save the drive container and packing materials in case you ever need to ship the drive.

Installing the Desktop Autoloader

The following sections describe how to install a desktop autoloader.

Desktop Autoloader Installation Summary

The desktop DAT 72 and DDS-4 autoloader connects to the host computer as a turnkey subsystem.

Installing the desktop autoloader involves the following steps:

1. Configuring the Desktop Autoloader

2. Setting the SCSI ID

3. Connecting the SCSI Interface Cable

4. Installing SCSI Termination

5. Connecting the Power Cord

16

Page 17

Installing the Autoloaders Installing the Desktop Autoloader

Configuring the Desktop Autoloader

Table 2 shows the default configuration for the desktop autoloader.

Table 2. Default Configuration (Desktop Drive)

Parameter Default Setting

SCSI ID 6

Data Compression Enabled

Media Recognition System (MRS) Verification Enabled

Power On Self Test (POST) Diagnostics Enabled

Host Operating System Windows 98 SE/ME/NT 4.0/

2000/XP/Windows Server 2003

SCSI Termination Power Disabled

Parity Checking Enabled

If these default settings are appropriate for your computer, skip to “Connecting the SCSI Interface

Cable” on page 18.

NOTE: These settings can be changed by accessing the switches located on the bottom of the

autoloader. Turn the autoloader over and gently pull the tab on the access door to release it.

Once the door is open, the switches will be accessible. See page 23 and page 45 for details

on switch settings.

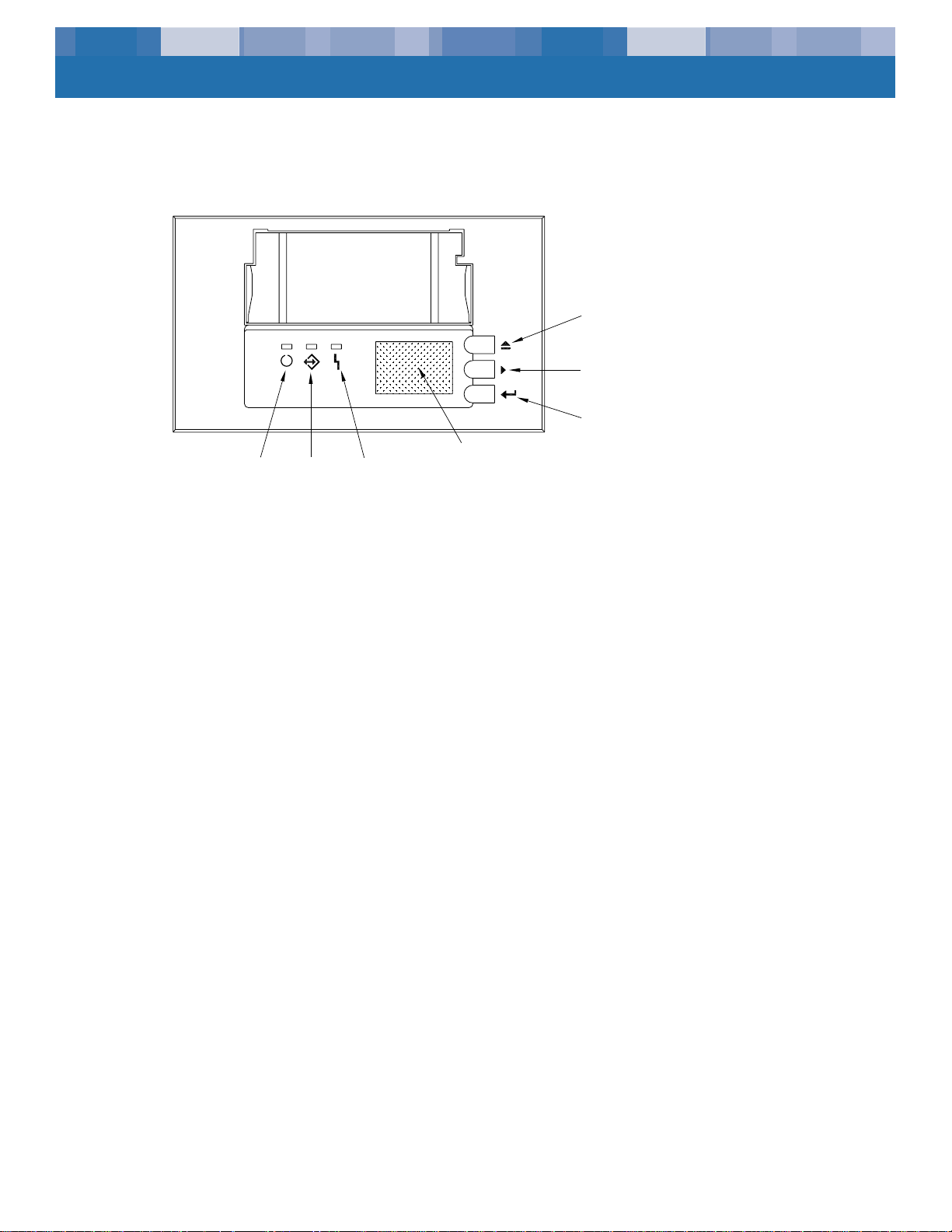

Setting the SCSI ID

Make sure that the autoloader is turned off; then set the SCSI ID using the push-button switch on the

back of the autoloader. The following figure shows this switch, as well as the two SCSI interface

connectors, on/off switch, and the power cord connector.

NOTE: The autoloader must be restarted for any change in SCSI ID to take effect.

17

Page 18

Installing the Autoloaders Installing the Desktop Autoloader

68 pin wide SCSI

68 pin wide

SCSI connectors

connectors

SCSI ID connector

SCSI ID connector

AC Power connector

AC Power connector

On/Off switch

On/Off switch

Figure 2. Autoloader Rear Panel

Connecting the SCSI Interface Cable

Your autoloader provides two (2) High-Density 68-pin, shielded connectors on the rear panel of the

enclosure. Either connector can be used as a SCSI IN or SCSI OUT connection (you can use either

connector to attach the autoloader to the host computer or to another SCSI device).

Turn off your computer and all SCSI devices. Then attach a SCSI cable from the host adapter or from

another (unterminated) SCSI device to the autoloader.

NOTE: This autoloader will not work in a SCSI-1 environment.

18

Page 19

Installing the Autoloaders Installing the Desktop Autoloader

Installing SCSI Termination

If the autoloader is the last device or the only device in a SCSI chain, you must install a terminating

plug on the unused SCSI connector. See the following figure for two SCSI termination examples.

External SCSI

Device

External Tape

Drive

External SCSI

Device

SCSI Controller

(termination enabled)

Example 1:

SCSI termination in a

system that has only

external SCSI devices.

Figure 3. SCSI Termination Examples

External Tape

Drive

SCSI Controller

(termination enabled)

Internal SCSI

Device

(termination enabled)

Example 2:

SCSI termination in a

system that has both internal

and external SCSI devices.

Connecting the Power Cord

Attach the power cord securely to the power connector on the back of the autoloader. The location

of the power connector on the autoloader is shown in Figure 2 and Figure 3.

19

Page 20

Installing the Autoloaders Installing the Internal Autoloader

Installing the Internal Autoloader

The following sections describe how to install an internal autoloader.

Internal Autoloader Installation Summary

The internal autoloader is installed horizontally in a 5.25-inch, full-height drive bay. Installing the

internal autoloader involves the following steps:

1. Configuring the Internal Autoloader

2. Mounting the Internal Autoloader

3. Connecting the SCSI Interface Cable

4. Installing SCSI Termination

5. Connecting the Power Cord

Configuring the Internal Autoloader

The internal autoloader is configured using jumpers and DIP switches. Table 3 shows the default

configuration for the internal autoloader.

Table 3. Default Configuration (Internal Drive)

Parameter Default Setting Configuration Method

SCSI ID 6 Jumpers

Parity Checking Enabled Jumpers

SCSI Termination Power Disabled Jumpers

Data Compression Enabled DIP switches

Media Recognition System

(MRS) Verification

Power On Self Test (POST)

Diagnostics

Host Operating System Windows 98 SE/ME/NT 4.0/

2000/XP/Windows Server 2003

If these default settings are appropriate for your computer, skip to “Mounting the Internal

Autoloader” on page 24.

Enabled DIP switches

Enabled DIP switches

DIP switches

20

Page 21

Installing the Autoloaders Installing the Internal Autoloader

Changing Jumper Settings

Jumpers on the back of the internal drive let you change the following drive settings (see Figure 4 ):

• SCSI ID

• Parity checking

• SCSI termination power

NOTE. Power down the drive before changing jumper settings. Changes take effect when the

drive restarts.

Default jumper settings shown

Default jumper settings shown

(SCSI ID 6, parity checking enabled,

(SCSI ID 6, parity checking enabled,

and termination power disabled)

and termination power disabled)

Pins: Function:

Pins: Function:

1-2 SCSI ID bit 0

1-2 SCSI ID bit 0

3-4 SCSI ID bit 1

3-4 SCSI ID bit 1

5-6 SCSI ID bit 2

5-6 SCSI ID bit 2

7-8 SCSI ID bit 3

7-8 SCSI ID bit 3

9-10 Parity checking

9-10 Parity checking

11-12 Termination Power

11-12 Termination Power

SCSI ID=0

SCSI ID=1

SCSI ID=2

SCSI ID=3

SCSI ID=4

SCSI ID=5

SCSI ID=6

SCSI ID=7

SCSI ID=8

SCSI ID=9

SCSI ID=10

SCSI ID=11

SCSI ID=12

SCSI ID=13

SCSI ID=14

SCSI ID=0SCSI ID=15

Parity enable

Term. Power

Figure 4. Jumper Pins on the Back of the Internal Autoloader

SCSI Address Selection (pins 1 through 8)

21

Page 22

Installing the Autoloaders Installing the Internal Autoloader

Each SCSI device on a SCSI bus must have a unique SCSI ID. The SCSI controller or host adapter

generally uses ID 7. In some systems, the boot drive uses ID 0 or ID 1.

You can select an appropriate SCSI address for the drive by placing the appropriate jumpers on pin

pairs 1-2 through 7-8, as shown in Figure 4 on page 21 .

NOTE: SCSI ID numbers 8 through 15 will only be recognized if DIP switch 9 is “ON.” See

“SCSI Wide/Narrow (switch 9) - DDS-4 autoloader only” on page 24 for more information.

Parity Checking (pins 9 and 10)

If a jumper is installed on pins 9 and 10, parity checking is enabled. If no jumper is installed, parity

checking is disabled, but parity is still generated by the drive.

Terminator Power (pins 11 and 12)

If a jumper is installed on pins 11 and 12, terminator power is enabled.

NOTE: The internal autoloader drive does not provide SCSI termination, and therefore should

not be installed as the last device in a SCSI chain. See ““Installing SCSI Termination” on

page 19 for more information.

If the terminator power jumper is installed, be careful not to short the TERMPWR signal to ground. In

the event of a short, terminator power to the bus will be interrupted. After the short is removed, a

fuse in the drive will automatically reset, restoring terminator power.

Changing DIP Switch Settings

DIP switches on the underside of the internal autoloader let you change the following drive settings

(see Figure 5 on page 23 ):

• Data compression

• MRS checking (DDS-4 autoloader only)

• POST diagnostics

• Operating system settings

• Wide/Narrow SCSI selection

• Inquiry string

NOTE. Power down the drive before changing DIP switch settings. Changes take effect when the

drive restarts.

22

Page 23

Installing the Autoloaders Installing the Internal Autoloader

O

Data compression (DC)

1

2

3

4

5

6

7

8

9

10

Default settings shown

Default settings shown

O

Data compression (DC)

N

N

SCSI DC control

SCSI DC control

Media recognition

Media recognition

Self Test

Self T est

Operating-system

Operating-system

configuration

configuration

switches

switches

Wide/Narrow SCSI

Wide/Narrow SCSI

Inquiry String support

Inquiry String support

Figure 5. DIP-Switch Settings for the Internal Autoloader

Data Compression (switches 1 and 2)

Switch 1 enables or disables hardware data compression. Switch 2 determines whether SCSI

commands can be used to enable or disable hardware data compression.

• Switch 1 ON: Hardware data compression is enabled when drive is powered on. (default)

• Switch 1 OFF: Hardware data compression is disabled when drive is powered on.

• Switch 2 ON: SCSI commands can be used to enable or disable hardware data

compression (default)

• Switch 2 OFF: SCSI commands cannot be used to enable or disable hardware data

compression

Media Recognition System (switch 3) - DDS-4 autoloader only

The Media Recognition System (MRS) allows the drive to determine whether a given tape cartridge

conforms to the DDS tape standard. Switch 3 determines how the drive works with MRS and nonMRS media. Using non-DDS media may appear to give satisfactory results, but the inferior

specifications of such media can cause data-integrity problems.

• Switch 3 ON: Drive reads from and writes to MRS media, and reads from but does not write

to non-MRS media (default)

• Switch 3 OFF: Drive reads from and writes to both MRS and non-MRS media.

Power On Self Test Enable/Disable (switch 4)

Switch 4 enables or disables execution of Power On Self Test (POST) diagnostics when the drive is

powered on.

• Switch 4 ON: Drive performs POST when powered on. (default)

• Switch 4 OFF: Drive does not perform POST when powered on.

23

Page 24

Installing the Autoloaders Installing the Internal Autoloader

Operating System configuration (switches 5 through 8)

Switches 5 through 8 configure the drive for use with UNIX, Novell, and Windows NT operating

systems. These procedures are described in Chapter 6, “Configuration for Novell and UNIX” on

page 44. The default setting for these switches is ON.

SCSI Wide/Narrow (switch 9) - DDS-4 autoloader only

Switch 9 enables or disables SCSI Wide operation on the SCSI bus.

• Switch 9 ON: Drive can operate in Wide (16-bit) SCSI mode. (default)

• Switch 9 OFF: Drive can only operate as a Narrow (8-bit) SCSI device.

NOTE: If switch 9 if set to OFF, the drive can only use SCSI ID values 0 through 7.

Inquiry String (switch 10)

Switch 10 selects the Vendor ID that the drive returns when queried with a SCSI Inquiry command.

• Switch 10 ON: Vendor ID is “SEAGATE DAT.” (default)

• Switch 10 OFF: Vendor ID is “ARCHIVE Python.” This ID can be used by independent software

vendors to provide software compatibility with previous Seagate DDS tape drives.

Mounting the Internal Autoloader

The internal autoloader drive is mounted horizontally in a 5.25-inch, full-height drive bay. Mount the

drive using four M3.0 metric screws on the sides or bottom of the drive, as shown in Figure 6 on

page 25 . Do not use screws longer than 4 mm or you may damage the drive.

NOTE. When mounting the drive, make sure that nothing blocks the exhaust fan or the

ventilation slots on the bottom and rear of the autoloader.

24

Page 25

Installing the Autoloaders Installing the Internal Autoloader

± 0.3

11.9

± 0.3

21.8

± 0.6

82.6

7.0

± 0.25

86

± 0.3

± 0.25

1.8

45.5

± 0.25

1.8

± 0.25

79.5

203.2

± 0.25

± 0.25

224.0 max

MOUNT HOLE

M3 (4 PLACES)

± 0.25

149.6

MOUNTING HOLE

45.5

± 0.25

79.5

± 0.25

203.2

224.0 max

M3 (4 PLACES)

± 0.5

Figure 6. Locations of Mounting Holes

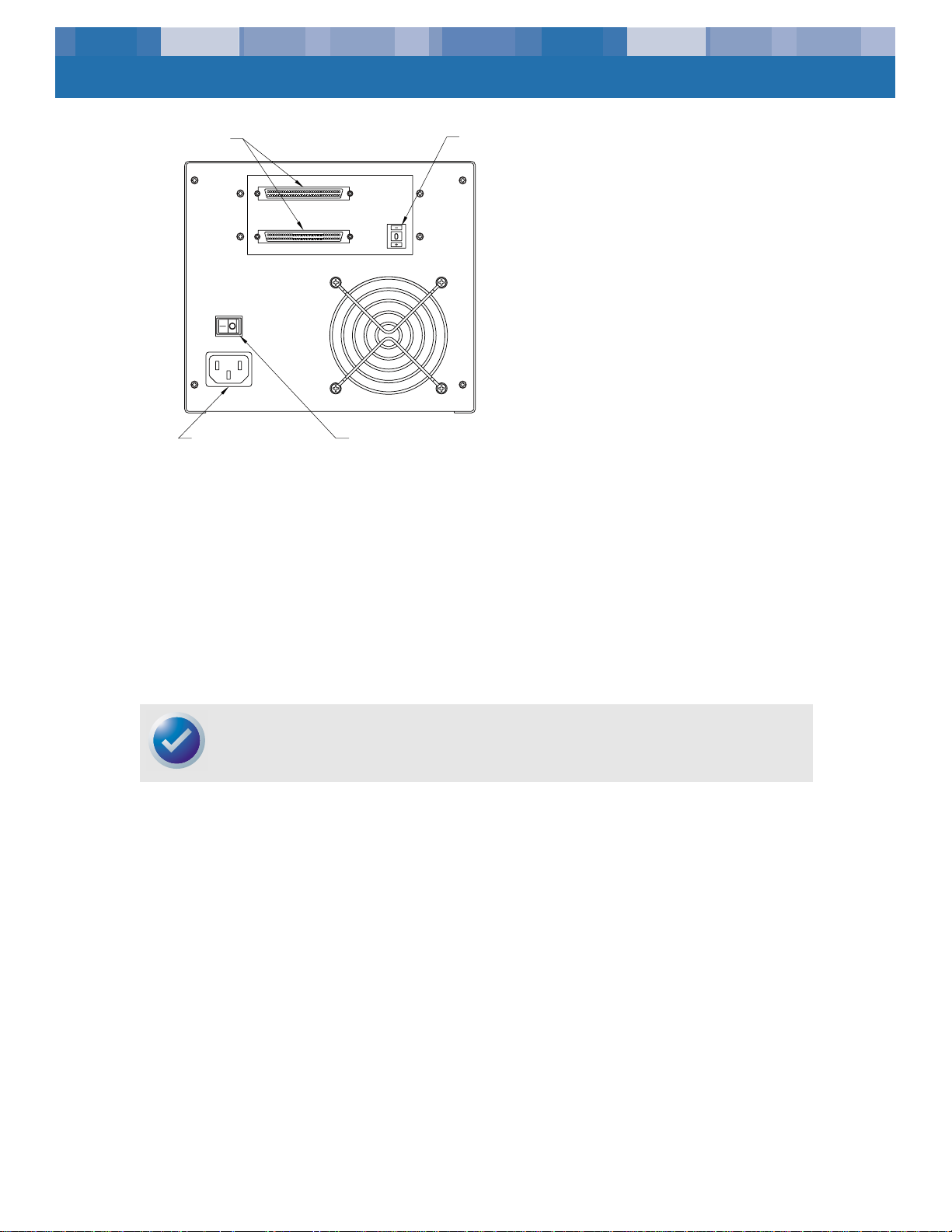

Connecting the SCSI Interface Cable

Turn off all power to your computer and drive. Then connect a 68-pin wide internal SCSI cable from

your SCSI controller to the SCSI connector on the back of the autoloader. Be sure pin 1 on the SCSI

controller and cable is connected to pin 1 on the drive. Figure 7 on page 26 shows the location of

SCSI pin 1 on the drive’s SCSI connector. Pin 1 on the SCSI cable should be indicated by a colored

stripe.

The internal autoloader drive can be used with two types of SCSI interfaces:

• Ultra2 SCSI (LVD)

± 0.3

139.7

.5 –0.5

146 +1

• “Wide” (16-bit) single-ended SCSI

The drive can automatically detect whether it is connected to an LVD or single-ended wide SCSI bus.

NOTE: The internal autoloader will not operate properly in a SCSI-1 environment.

25

Page 26

Installing the Autoloaders Installing the Internal Autoloader

pin 34

pin 34

pin 68

pin 68

Ultra2 SCSI 68-pin high-

Ultra2 SCSI 68-pin

density connector

high-density connector

pin 1

pin 1

pin 35

pin 35

pin 3: GND

pin 3: GND

(+5V return)

(+5V return)

Figure 7. Interface Connectors on the Internal Autoloader

Installing SCSI Termination

The internal autoloader does not provide SCSI termination. For this reason, it should not be the last

device on a SCSI chain. However, if the drive is the only SCSI device, attach the drive to the

connector which is next to last on the SCSI chain and attach an LVD/single-ended multi-mode

terminator to the last connector in the chain. Two termination examples are shown in Figure 8 on

page 26 .

SCSI Terminator

Internal Tape

Drive

(no

termination)

Power connector

Power connector

pin 4

pin 4

+5V

+5V

Internal Tape

Internal Tape

(no

termination)

pin 1

pin 1

12V

12V

pin 2: GND

pin 2: GND

(+12V return)

(+12V return)

SCSI Device

(termination enabled)

Drive

Drive

SCSI Device

(termination

disabled)

SCSI Controller

(termination enabled)

SCSI Device

(termination

disabled)

SCSI Controller

(termination enabled)

Figure 8. Two SCSI Termination Examples for the Internal Autoloader

26

Page 27

Installing the Autoloaders Installing the Internal Autoloader

Connecting the Power Cord

Attach a 5/12-volt, four-pin power cable to the power connector on the back of the drive. Figure 7

on page 26 shows the location of the power connector.

The recommended 4-pin power connector for the internal drive is an AMP 1-48024-0 housing with

AMP 60617-1 pins or equivalent.

27

Page 28

4. Operating Your Autoloader

This chapter describes how to operate your autoloader.

Topics in this chapter are:

• “Using the Appropriate Media” on page 28

• “Starting the Autoloader” on page 29

• “Applying Labels” on page 30

• “Loading a Cartridge” on page 30

• “Ejecting a Cartridge or Magazine” on page 31

• “Write-Protecting a DAT Cartridge and Magazine” on page 33

• “Cleaning the Tape Path” on page 34

• “Preparation for Shipping” on page 35

Using the Appropriate Media

The DDS-4 and DAT 72 autoloaders are designed to use datagrade DAT cartridges, such as those

listed below.

NOTE: 60-meter DAT cartridges cannot be used with these autoloaders. The use of 90-meter

DAT cartridges is not recommended for these products.

Table 4. Matching Drives with the Media They Support

Media Tape Length DDS-4 Drives DAT 72 Drives

DDS-2 120 meters, 4-Gbyte

uncompressed capacity

DDS-3 125 meters, 12-Gbyte

uncompressed capacity

DDS-4 150 meters, 20-Gbyte

uncompressed capacity

DAT 72 170 meters, 36-Gbyte

uncompressed capacity

P

P P

PP

P

28

Page 29

Operating Your Autoloader Starting the Autoloader

Starting the Autoloader

Turn on all external SCSI devices attached to your computer before you turn on the computer. When

the autoloader is first started, the following events should occur:

1. The Clean, Media, and Drive LED’s light up for two seconds, then start flashing.

2. The LCD display shows the current SCSI ID.

3. If a magazine is loaded, the LCD display shows the message “SCAN X” while the autoloader

determines which slots in the magazine contain cartridges.

4. As each cartridge is identified by the autoloader, the cartridge’s slot number is displayed on

the LCD. If there is no cartridge in a slot, the slot number will not be displayed.

5. When all tests are completed, the LCD display shows the message “READY” if a magazine is

loaded. If no magazine is loaded, the message “NO MAGAZINE” is shown.

NOTE: If your computer does not recognize the autoloader, you may need to load the

appropriate autoloader module for your backup software. See your backup software installation

manual for additional information.

Handling Cartridges

To protect your data cartridges and the information on them, observe the guidelines and avoid the

pitfalls in the following table.

Table 5. Cartridge Guidelines and Pitfalls

Guidelines to Follow... Pitfalls to Avoid

Use DAT cartridges at temperatures from 5° C (40° F)

to 40° C (104° F). Cartridges can be stored at

temperatures down to -40° C (-40° F).

Handle cartridges gently. Do not treat cartridges roughly or drop them.

Keep cartridges in plastic cases when they are not in

use.

Apply just one label to the designated area on the

cartridge. Affixing more labels can jam the drive.

If your data is important, consider reading data off of

tapes and rewriting to new and perhaps more

modern tapes every few years.

If cartridges are exposed to temperatures or

humidities outside the specified operating

environment, expose them to the operating

environment for a time equal to the period that the

cartridges were exposed to the out-of-specification

environment (up to a maximum of 24 hours).

Do not expose cartridges to direct sunlight, moisture,

excessively dry or humid places, extreme changes in

temperature or humidity, or X-rays.

Do not try to clean the tape guides or tape path

inside the cartridge.

Never touch the exposed tape media with your

fingers.

Never leave cartridges close to magnetic fields, such

as near a monitor or telephone handset.

Do not read from or write to cartridges when a

temperature change of 10° C per hour is occurring.

29

Page 30

Operating Your Autoloader Applying Labels

Applying Labels

When applying labels to a cartridge, observe the following precautions to prevent the cartridge

from getting stuck in the autoloader:

• Apply labels firmly, only in recessed label areas on the top side of the cartridge.

• Do not let labels extend beyond label areas or fold over the edge of a cartridge.

• Do not apply labels over other labels.

CAUTION: Do not place any labels on the autoloader magazine, since this may cause the tape

mechanism to jam.

Loading a Cartridge

Use only approved DAT cartridges in the autoloader. To load cartridges into the magazine, follow

these steps:

1. Make sure that the cartridges are write-protected or write enabled, as necessary. For more

information, refer to “Write-Protecting a DAT Cartridge and Magazine” on page 33.

2. Hold the magazine so that the slot numbers on the side of the magazine are right-side-up.

3. Insert cartridges with the cartridge door facing the magazine slot, as shown in the following

figure.

Figure 9. Loading a Cartridge into the Autoloader Magazine

30

Page 31

Operating Your Autoloader Ejecting a Cartridge or Magazine

Loading a Magazine into the Autoloader

CAUTION: Do not load a magazine if all the LED’s are flashing; this indicates that the

autoloader is performing a Power On Self Test (POST).

1. Make sure the autoloader is powered on and operating normally.

2. Hold the magazine so that the slot numbers are right-side-up.

3. Write-protect or write-enable the magazine as appropriate. For more information, refer to

“Write-Protecting a DAT Cartridge and Magazine” on page 33.

4. Insert the magazine into the autoloader with the triangles facing into the autoloader bay, as

shown below. Gently push the magazine into the autoloader bay until the autoloader

mechanism senses the magazine and pulls it inside.

Figure 10. Loading a Magazine into the Autoloader

Ejecting a Cartridge or Magazine

To eject the magazine from the autoloader, press the Eject button. If the drive mechanism contains a

cartridge, the LCD display shows the message “EJECT? PRESS ENTER”. Press the Enter button, and

wait for the following events to complete:

1. The tape rewinds to the beginning-of-partition (BOP) mark.

2. If the data cartridge is not write-protected, the operating system writes the updated copy of the

tape log back to the tape.

3. The tape rewinds to the beginning-of-media (BOM) and is unthreaded.

4. The changer places the cartridge back into the magazine.

31

Page 32

Operating Your Autoloader Ejecting a Cartridge or Magazine

5. The magazine is ejected.

If there is no cartridge loaded in the autoloader mechanism, the magazine is ejected without delay.

Forcing an Eject

If you press the Eject button when the autoloader is busy, the autoloader will complete the current

task before responding to the eject request. This way no data is lost.

However, in extreme cases, you may need to force an eject operation to unload a cartridge, even at

the risk of losing the data on the cartridge. A forced eject should only be tried when there is no other

way to recover a cartridge.

CAUTION: If you force an eject, the cartridge may become unreadable and therefore require

erasing or re-initialization by the application software.

To force an eject, hold down the Eject button for at least five seconds, then release the button. When

you force an eject, the following occurs:

If there is a cartridge loaded, the Status Panel displays the message “UNLOAD TAPE X” (where X is

the number of the magazine slot which held the cartridge currently in the autoloader). After the

cartridge has been returned to the magazine, the display changes to “EJECTING MAGAZINE” and

the magazine is ejected.

NOTE: Because forcing an eject can interrupt an operation, the autoloader might not write the

end of data (EOD) mark on the tape before the cartridge is ejected. If the EOD mark is not

written on the tape, the cartridge might be formatted incorrectly and the data on the tape might

be lost. However, the data can usually be read up to the point where the error occurred.

Automatic and Manual Cartridge Loading

After cartridges have been loaded into the magazine and the magazine has been inserted into the

magazine bay, the autoloader can be left indefinitely for unattended write or read operations

(controlled by your backup software).

To load a cartridge manually, press the SELECT button repeatedly until the desired slot location is

identified, then press the ENTER button.

32

Page 33

Operating Your Autoloader Write-Protecting a DAT Cartridge and Magazine

Write-Protecting a DAT Cartridge and Magazine

Write-protecting a DAT cartridge protects the data on the cartridge from being changed,

overwritten, or deleted. To write-protect a cartridge, slide the write-protect tab on the back of the

cartridge to the open position. To write-enable the cartridge, slide the write-protect tab so the hole is

closed.

Write enabled Write protected

Write enabled

Figure 11. Write-protecting a DAT Cartridge

The following figure shows how to write-protect a magazine. To enable writing to the magazine,

move the switch upward. To protect all cartridges in the magazine from being written to, move the

switch down.

Write protected

Write enabledWrite-enabled

Write-enabled

Write-disabled

Write-disabled

Figure 12. Write-protect switch on autoloader magazine

33

Page 34

Operating Your Autoloader Cleaning the Tape Path

Cleaning the Tape Path

If excessive magnetic dust or debris collects at one or more of the tape heads, the autoloader may

not be able to read from or write to tape, or may experience excessive errors. When the cleaning

threshold is exceeded, the autoloader will display the cleaning request in two ways:

• The LCD display will show the message “CLEANING REQUIRED.”

• The Clean LED will remain ON continuously.

NOTE: A slowly flashing Clean LED may indicate that a tape is damaged or is nearing the end

of its life. If cleaning the tape path does not correct the flashing LED condition, replace the

cartridge.

Table 6. Cleaning the Autoloader

Daily Usage

(hours).

0-4 Three times per month

4-8 Weekly

8-12 or more Twice a week

Optimum Cleaning

Frequency

Cleaning Procedure

To clean the tape heads on your DAT 72 and DDS-4 autoloader, use only a Certance-approved

cleaning cartridge. You can purchase a Certance DDS Cleaning Cartridge on the internet at: http:/

/shop.certance.com (U.S. only).

NOTE: The autoloader cannot recognize audio DAT cleaning cartridges.

Manual Cleaning

You can clean the autoloader manually using the following procedure:

1. Place the cleaning cartridge in a magazine slot and insert the magazine into the autoloader.

2. Use the Select button to select the slot where you placed the cleaning cartridge.

3. Press the Enter button to load the cleaning cartridge into the autoloader. The autoloader starts

the cleaning cycle automatically.

4. When the cleaning cycle is complete, the cartridge will automatically eject. If the cartridge is

not automatically ejected, press the Eject button to return the cleaning cartridge to the

magazine. Press the Eject button again to unload the magazine and remove the cleaning

cartridge.

5. Record the date of the cleaning on the cleaning cartridge label.

34

Page 35

Operating Your Autoloader Preparation for Shipping

Each time the cleaning cartridge is loaded, a new, unused portion of cleaning tape is advanced

over the entire tape path. The drive does not rewind a cleaning cartridge. After about 30 cleaning

cycles, the entire tape is used up, and you must purchase a new cleaning cartridge.

If you insert a cleaning cartridge that has been used up, the cleaning cycle will not be carried out.

Instead, the Clean LED will flash rapidly and the LCD will display the message, “REPLACE

CLEANING TAPE.” The cleaning cartridge will not be returned to the magazine, the Clean LED will

stay on, and the LCD will display the message, “CLEANING REQUIRED.” In this case, press the Eject

button to remove the magazine and replace the spent cleaning cartridge with a new one.

Automated Cleaning

If your backup-and-restore software includes a tape drive head-cleaning feature, you can use the

software to clean the autoloader. Some software packages are preprogrammed to use the cartridge

in slot 6 to clean the tape path automatically. The software prompts the autoloader to load the

cleaning cartridge and initiate the cleaning cycle. When the cleaning cycle completes, the tape

drive ejects the cleaning cartridge and automatically returns it to the original magazine slot. Refer to

your software documentation for details.

If, during automated cleaning, a cleaning cartridge is loaded that has been used up, the cleaning

cycle will be aborted. Instead, the LCD will display the message “REPLACE CLEANING TAPE”, and

the cleaning cartridge will be returned to the magazine. The Clean LED will stay lit, and the LCD will

display the messages “REPLACE CLEANING TAPE” and “CLEANING REQUIRED”. After the software

operations are complete, you may use the Eject button to remove the spent cleaning cartridge and

insert a new one.

Preparation for Shipping

Before shipping the autoloader, you must secure the autoloader door to prevent damage to the

device. Follow the procedure below to secure the door as the last step before switching off the

autoloader:

1. Make sure there is no magazine in the autoloader. The LCD should display the message “NO

MAGAZINE.”

2. Press and hold the Select button for 5 seconds. The LCD should show the following menu:

>VERSION

LANGUAG

CONTRAST

3. Press the Select button four times. The cursor (>) will move down to the word “DOOR,” as

shown below:

CONTRAST

AUTO/LD

>DOOR

4. Press the Enter button. The LCD should display the following sub-menu:

DOOR

>LOCK

UNLOCK

5. Press the Select button once to move the cursor to “LOCK” and then press the Enter button. The

display returns to the menu shown in step 3 above.

35

Page 36

Operating Your Autoloader Preparation for Shipping

6. Wait 5 seconds. The LCD screen will again display the message “NO MAGAZINE.” After

another 5 seconds, the LCD will display the message, “DOOR LOCKED.”

7. Switch off the autoloader.

8. Tap the door to make sure it has been successfully locked.

The door is now locked in the closed position and the autoloader is ready to be packed and

shipped. The door is automatically unlocked when the autoloader is restarted.

36

Page 37

5. Understanding the Drive LEDs

This chapter describes the LEDs on the front panel of the DDS-4 and DAT 72 autoloader. These LEDs

provide information about both normal and error conditions.

Topics in this chapter are:

• “Front Panel LEDs” on page 37

• “LED Summary” on page 38

• “Clean LED” on page 39

• “Media LED” on page 39

• “Drive LED” on page 40

• “About the Operator Panel LCD Display” on page 41

Front Panel LEDs

The following figure shows an example of the LEDs on the drive front panel of the DDS-4 and DAT

72 autoloaders.

Clean

Clean

LED

LED

(green)

(green)

Media

Media

LED

LED

(green)

(green)

Figure 13. Front Panel LEDs

Drive LED

Drive LED

(amber)

(amber)

LCD

LCD

Display

Display

EJECT

EJECT

button

button

SELECT

SELECT

button

button

ENTER

ENTER

button

button

37

Page 38

Understanding the Drive LEDs LED Summary

Eject Button

You can use the Eject button to eject the magazine or to unload a cartridge from the drive. After

pressing the Eject button, you must press the Enter button to confirm your request.

Select Button

You can use the Select button to select individual cartridges by their slot numbers (1 through 6), to

scroll through items from menus on the LCD display, and to access loader menus if no magazine is

installed.

Enter Button

You can use the Enter button to select specific items from menus on the LCD display, to load a

cartridge into the autoloader (after you have selected the cartridge using the Select button), or to

confirm that you want to eject the magazine when there is a cartridge in the autoloader

LED Summary

The following table summarizes the actions of the front-panel LEDs.

Table 7. LED Quick Summary

LED Color Action Description

Clean Green ON (Lit) Cleaning is required because the autoloader has been

operating for at least 25 hours (DDS-2) or 50 hours

(DDS-3, DDS-4, or DAT 72).

Slow Flashing Internal error rate threshold has been exceeded and

cleaning is required.

Flashing Cleaning cartridge in the drive has exceeded its useful

life. Replace the old cleaning cartridge with a new one.

Media Green ON (Lit) An inserted cartridge is operating properly.

Flashing Drive could not write the tape correctly (write error).

Use a DDS cleaning cartridge to clean the drive.

Drive Amber ON (Lit) Drive is reading or writing the tape normally.

Rapid Flashing A hardware fault has occurred.

38

Page 39

Understanding the Drive LEDs Clean LED

Clean LED

The Clean LED indicates whether a drive needs to be cleaned.

Table 8. Clean LED

LED Status Description

ON continuously Drive requires cleaning. Use only an approved DDS cleaning cartridge.

Flashing slowly (approximately

ON 2 seconds, OFF 1 second)

Flashing rapidly A cleaning cartridge that has exceeded its useful life has been inserted

Tape cartridge in use has exceeded a predefined soft-error threshold.

This signal is a warning only and does not indicate that data has been

compromised. Remove the tape and clean the drive using an approved

DDS cleaning cartridge. If the Clean LED still flashes after cleaning and

reinserting the original data cartridge, use a new cartridge for future

backups.

into the drive. Replace the cleaning cartridge with a new approved

DDS cleaning cartridge.

Media LED

The Media LED indicates whether a DAT cartridge is operating normally.

Table 9. Media LED

LED Status Description

ON continuously A DAT cartridge has been inserted and the drive is operating normally.

Flashing rapidly Drive could not write the tape correctly (maximum rewrite count

exceeded) and the write operation failed. Clean the drive heads using

an approved DDS cleaning cartridge. If you reinsert the original data

cartridge and the LED continues flashing, insert a new data cartridge

and retry the operation.

NOTE: As routine maintenance, follow the cleaning recommendations listed in Table 5.

39

Page 40

Understanding the Drive LEDs Drive LED

Drive LED

The amber Drive LED lets you know when data is being read from or written to tape. It also informs

you when a hardware fault occurs.

Table 10. Drive LED

LED Status Description

ON continuously The drive is reading or writing the tape (SCSI or tape movement is

present).

Flashing rapidly A hardware fault occurred. If the fault occurs immediately after

powering on the drive, the Power On Self Test (POST) switch (switch 4)

is enabled and a POST has failed. If the front panel LEDs are flashing

together, contact the Technical Support department.

If the Drive LED is flashing rapidly during drive operation, press the

Eject button to remove the tape. If the tape does not eject within 2

minutes, press and hold the Eject button for more than 5 seconds. The

tape should eject within 40 seconds. Contact Technical Support for

more information.

CAUTION: If you push the Eject button while the Drive LED is ON, you will interrupt any host

operation, causing an application error. It may not be possible to append to the tape if a write

operation is aborted in this way.

NOTE: If your backup software issues a SCSI “Prevent Media Removal” command, the Drive

LED remains ON and the Eject button is disabled, so that the tape cannot be ejected

accidentally. To eject the tape, use your backup software’s Eject command.

40

Page 41

Understanding the Drive LEDs About the Operator Panel LCD Display

About the Operator Panel LCD Display

The following figure shows the types of information shown on the operator panel LCD display.

Indicates slot

Indicates whether

active cartridge or

magazine is writeprotected

LINE 1

LINE 1

LINE 2

LINE 2

Bar graph indicating

current position of

tape head relative to

beginning of

partition

number of active

cartridges

Indicates whether

data-compression

is active

Message display

Indicates whether

tape is in motion

Figure 14. LCD display features

LCD Display Backlighting

Backlighting on the LCD display is turned on automatically when the autoloader is first powered on

and whenever an operator panel button is pushed. The backlight remains on for two minutes, and

then shuts off automatically (unless an operator panel button is pressed).

LCD Display Messages

The table on the following pages describes the messages that may be shown on the LCD display. The

messages are listed in alphabetical order. An “X” indicates the number of the currently active

cartridge slot.

LCD Message Description

CASSETTE INSTALL PROBLEM A cartridge has been inserted into the magazine incorrectly. Eject the

CHECK DOOR The autoloader door is open.

CLEANING The autoloader is loading a cleaning cartridge into the drive.

magazine from the autoloader; then remove the cartridge from the

magazine and reinsert it correctly.

CLEANING REQUIRED The tape drive mechanism requires cleaning.

DOOR LOCKED The autoloader door is locked.

DOOR UNLOCKED The autoloader door is unlocked.

41

Page 42

Understanding the Drive LEDs About the Operator Panel LCD Display

LCD Message Description

DRIVE ERROR04/XX/XX There is a problem with the autoloader. For additional information,

contact Certance Technical Support.

ERASE TAPE X The tape drive is erasing the data cartridge from slot X.

EJECTING MAGAZINE The autoloader is ejecting the cartridge magazine.

EJECT? PRESS ENTER A cartridge resides in the drive and the Eject button has been pressed.

Eject confirmation is required before the cartridge can be ejected.

EJECT PREVENT The autoloader is preventing you from ejecting the magazine because

the software has enabled PMR (Prevent Media Removal).

FAN FAILU RE There is a problem with the autoloader fan.Contact Certance Technical

Support.

INSERT EMPTY MAGAZINE The autoloader cannot unload a cartridge from the tape drive to the

magazine because the magazine in the autoloader is fully loaded. Eject

the magazine; then insert an empty magazine into the autoloader

LOADER ERROR04/XX/XX There is a problem with the autoloader hardware. For additional

information, contact Certance Technical Support.

LOAD TAPE X The tape drive is loading the cartridge from slot X.

MEDIA ERROR03/XX/XX There is a problem with the data cartridge. For additional information,

contact Certance Technical Support.

NO MAGAZINE There is no magazine in the autoloader.

READ TAPE X The tape drive is reading from a data cartridge.

READY The autoloader has scanned all cartridge slots in the magazine and is

ready to perform an action.

READY TAPE X There is a cartridge (from slot X) in the tape drive and the autoloader is

ready to accept commands.

REPLACE CLEANING TAPE The cleaning cartridge has been used up and must be replaced with a

new cleaning cartridge.

REWIND TAPE X The tape drive is rewinding the data cartridge from slot X.

SCAN X The autoloader is sequentially scanning the cartridge slots in the

magazine.

SEARCH TAPE X The tape drive is searching the data cartridge from slot X.

SELECT XPUSH ENTER This message displays when the Select button is pressed. Press the

Select button repeatedly to display the desired cartridge location

number (X); then press the Enter button to load the selected cartridge

into the drive.

SELECT PREVENT The autoloader is prevented from ejecting the magazine because the

software has enabled PMR (Prevent Media Removal). Use your backup

software to eject the tape, then press the Eject button to eject the

magazine.

UNLOAD TAPE X The tape drive is unloading the cartridge from slot X.

UPDATING FIRMWARE The autoloader firmware is being updated.

WAITING SELF TEST This message displays while the autoloader is performing a POST

during startup.

WRITE TAPE X The tape drive is writing to the data cartridge from slot X.

42

Page 43

Understanding the Drive LEDs About the Operator Panel LCD Display

Configuring Autoloader Features Using the LCD Display

To configure the autoloader using the LCD, first make sure that there is no magazine installed in the

autoloader; then press and hold the Select button for five seconds. You can then use the Select button

to cycle through the following menus: VERSION, LANGUAG (Language), CONTRST (Contrast),

AUTO/LD (Auto Load), and DOOR. Each of these is described below. To display a particular menu,

select the menu item and press the Enter button.

Version Menu

In the VERSION menu, you can use the Select button to view the name of the autoloader, its SCSI ID,

its firmware level, and the autoloader serial number.

Language Menu

In the LANGUAG menu, you can enable the autoloader to display messages on the LCD in English,

French, German, Italian, Portuguese, Japanese, or Spanish by scrolling to the appropriate language

and pressing the Enter button.

Contrast Menu

In the CONTRST menu, you can make the LCD display brighter by pressing the Enter button

repeatedly until the desired contrast is displayed. To make the LCD darker, press the Select button

repeatedly until the desired contrast is displayed.

Autoload Menu

In the AUTO/LD menu, you can enable or disable automatic loading of cartridges from the

magazine into the tape drive.

NOTE: This feature should only be used to automate cartridge loading if application software to

support the loader operation is not available.

Most software available for the Windows NT/2000 platform does support the SCSI commands

necessary for loader operation. In this environment we suggest leaving automatic load disabled

(the default state). Check with your software vendor if you are unsure about your particular

software application.

In Unix/Linux environments backup software may not support autoloader operation directly. In

this case, the 'offline' command is used to change cartridges sequentially (in numerical order by

slot number). In Unix/Linux environments, enabling automatic cartridge loading can allow you

to setup an unattended backup.

To enable cartridge autoloading from within the autoload menu, select “ON” and then press the

Enter button. After the magazine is inserted, cartridge 1 will automatically be loaded into the drive.

When autoloading is enabled, the Select button can still be used to exchange cartridges, but only in

a sequential manner (in numerical order, by slot number).

To turn off autoload mode, display the autoload menu, select “OFF”, and then press the Enter button.

When autoloading is disabled, cartridges can only be loaded or unloaded via the operator panel or

using application software that has autoloader support.

Door Menu

In the DOOR menu, you can lock the autoloader door by selecting “LOCK” and pressing the Enter

button. You can unlock it by selecting “UNLOCK” and pressing the Enter button.

43

Page 44

6. Configuration for Novell and UNIX

This section explains how to configure the DAT 72 and DDS-4 autoloader for use with various Novell

and UNIX operating systems.

Topics in this chapter are:

• “Operating System Configuration” on page 44

• “Configuration for Novell Environment” on page 45

• “Configuration for DEC UNIX Environment” on page 45

• “Configuration for Sun UNIX Environment” on page 47

• “Configuration for SGI Environment” on page 48

• “Troubleshooting Installations on the SGI Platform” on page 50

• “Configuration for HP-UX Environment” on page 50

• “Configuration for IBM AIX Environment” on page 51

• “Configuration for SCO UNIX” on page 52

• “Configuration for LINUX” on page 52

Operating System Configuration

The following figure shows the location of the operating system configuration DIP switches (switches

5 through 8) on the underside of the autoloader.

NOTE: If the autoloader is to be used with an operating system other than those described here,

these switches should be left in their default positions.

44

Page 45

Configuration for Novell and UNIX Operating System Configuration

O

1

2

3

4

5

6

7

8

9

10

Default settings shown

Figure 15. Operating System DIP Switches

HW data comp

N

SW data comp

Media recognition system

Power ON self test

Operating system

configuration

switches

Wide/Narrow SCSI

Inquiry String support

Configuration for Novell Environment

There are two possible ways to configure the DAT 72 and DDS-4 autoloader to work with the

NetWare native backup application, depending on which tape driver you use.

Configuration 1: If you are using the original Novell NWTAPE driver or any version created before

11/3/99, you must change the Operating System Configuration DIP switches so that switches 5

and 8 are OFF. This is different from their default settings (switches 5 through 8 ON).

Configuration 2: If you use the latest Novell NWTAPE driver (available on the Novell web site), the

Operating System Configuration DIP switches can be left in their default positions (switches 5

through 8 ON).

Configuration for DEC UNIX Environment

DIP Switch Settings

Before using the DAT 72 or DDS-4 autoloader in a DEC UNIX environment, set the operating-system

DIP switches as shown below:

S5 S6 S7 S8 S10

Setting OFFONONONON

45

Page 46

Configuration for Novell and UNIX Operating System Configuration

Digital UNIX Version 4.0 and Later

With Version 4.0 of the Digital UNIX operating system, DEC introduced a new method of

configuring the CAM SCSI driver. Modify the file /etc./ddr.dbase as follows:

1. Look through the file and locate the database entry for the DEC TLZ07 DAT drive

2. Copy this entry and paste it later in the file, taking care to maintain the file syntax.

3. Modify this new entry as shown below.

SCSIDEVICE

#

Type = tape

Name = “ARCHIVE Python” “DAT”

#

PARAMETERS:

TypeSubClass = rdat

TagQueueDepth = 0

MaxTransferSize = 0x0ffffff # (16MB - 1)

ReadyTimeSeconds = 60 # seconds

DENSITY:

#

DensityNumber = 0,3,4,5,6,7

DensityCode = default

CompressionCode = 0x0

Buffered = 0x1

DENSITY:

#

DensityNumber = 1,2

DensityCode = default

CompressionCode = 0x1

Buffered = 0x1

4. Save the database file.

5. Run the following command: ddr_config -c. This takes the default input file, ddr.dbase,

and builds a new device database. The new device database is effective immediately, and

there is no need to rebuild the kernel.

Digital UNIX Versions Earlier Than 4.0.

Configure the system by modifying the file cam_data.c. This is located in either /usr/sys/data or

/sys/data, depending on the system configuration. The cam_data.c file should be modified as

shown below:

1. Look through the file to locate the database entry for the “TLZ07 – RDAT” drive.

2. Make a copy of this entry and paste it later in the file, taking care to maintain the syntax of the

C source.

3. Modify the new entry as shown below.

/* Iomega DAT Drive Returning “ARCHIVE Python DAT” Inquiry

*/

{“ARCHIVE Python DAT”, 14, DEV_TLZ07,

(ALL_DTYPE_SEQUENTIAL << DTYPE_SHFT) | SZ_RDAT_CLASS,

46

Page 47

Configuration for Novell and UNIX Operating System Configuration

(struct pt_info *)ccmn_null_sizes, SZ_NO_BLK, (DEC_MAX_REC - 1),

&tlz07_dens, NO_MODE_TAB, SZ_NO_FLAGS,

NO_OPT_CMDS, SZ_READY_DEF, SZ_NO_QUE,

DD_REQSNS_VAL | DD_INQ_VAL, 36, 64

},

4. Rebuild the kernel using the doconfig script. Then reboot the system.

Configuration for Sun UNIX Environment

DIP switch settings

Before using the DAT 72 or DDS-4 autoloader in a Sun UNIX environment, set the operating-system

DIP switches as shown below:

S5 S6 S7 S8 S10

Setting ON OFF ON ON OFF

Sun OS 4.1.x

To configure SunOS 4.1.x to use the DAT 72 or DDS-4 autoloader, you must modify the stdef.h

and st_conf.c files (in the directory /usr/sys/scsi/ targets), then rebuild the kernel, as

described below:

1. Modify the stdef.h file by adding a define statement for the Iomega drive like the one shown

below:

#define ST_TYPE_ARCHIVE Python_DAT <value>

This statement should be added after the last ST_TYPE_ define statement in the file. <value>

should be the next unused hexadecimal value. This value will depend on the release and number of devices supported by the system. For example, if the last value for an existing device is

0x2d, then use a value of 0x2e.

2. Modify the st_conf.c file by adding the following lines at the end of the device definition

list:

{

“ARCHIVE Python”,7,“ARCHIVE Python”,ST_TYPE_ARCHIVE_Python,10240,

(ST_VARIABLE|ST_BSF|ST_BSR|ST_LONG_ERASE|ST_KNOWS_EOD),

5000,5000,

{0x0,0x8c,0x8c,0x8c},

{0,0,0,0}

}

3. Use the config command to rebuild the kernel and include the new device definition. Refer to

the config command page for details.

47

Page 48

Configuration for Novell and UNIX Operating System Configuration

Solaris 2.x

1. To configure Solaris 2.x for compatibility with the DAT 72 or DDS-4, add the following lines to

the file st.conf in the directory /kernel/drv.

tape-config-list=

“ARCHIVE Python”,“Iomega DAT Drive”,“ARCHIVE Python DAT”;

ARCHIVE Python DAT = 1,0x34,0,0xd639,4,0x00,0x8C,0x8C,0x8C,3;

2. After modifying the file st.conf, you must reconfigure the kernel by booting the system using

the boot -r command.

Configuration for SGI Environment

DIP Switch Settings

Before using the DAT 72 or DDS-4 autoloader in a SGI UNIX environment, ensure that the DIP

switches are set as shown in the following table:

Switch 5Switch 6Switch 7Switch 8Switch

Setting ON ON ON ON OFF

NOTE: The main difference between tape autoloader support in Irix 5.x and 6.x is the

introduction of Data Compression switching via software in Irix version 6.2. When running Irix

5.x, the autoloader will operate in the compression setting determined by switches 1 and 2,

accessible through a removable panel on the bottom of the autoloader.

10

Irix V5.x

To configure Irix 5.x to use the DAT 72 and DDS-4 autoloader, you must modify the file /var/

sysgen/master.d/scsi as described below:

1. Edit the file /var/sysgen/master.d/scsi and add the following entry:

{DATTAPE,TPDAT,7,3, “ARCHIVE

Python",“DAT"/*DAT*/,0,0,{0,0,0,0},

MTCAN_BSF|MTCAN_BSR|MTCAN_APPEND|MTCAN_SETMK|MTCAN_PART|MTCAN_

PREV|

MTCAN_SYNC|MTCAN_SPEOD|MTCAN_CHKRDY|MTCAN_VAR|MTCAN_SETSZ|

MTCAN_SILI|MTCAN_SEEK|MTCAN_CHTYPEANY,

/* minimum delay on i/o is 12 minutes, to allow the Drives

* full error recovery sequence to be performed. */

40, 12*60, 12*60, 12*60, 512, 512*512 }

2. Rebuild the kernel using the autoconfig command (see the autoconfig man page for

details). After the kernel is rebuilt you will need to reboot the system again to bring the

changes into effect.

NOTE: Irix 5.3 and later will detect the changes made and automatically rebuild the kernel the

next time the system boots.

48

Page 49

Configuration for Novell and UNIX Operating System Configuration

Irix V6.x through V6.5

To configure Irix 6.x-6.5 to use a DAT 72 or DDS-4 autoloader, you must modify the files /var/

sysgen/master.d/scsi and /dev/MAKEDEV.d/TPS_base, as described below. After

modifying these files you must rebuild the kernel.

1. Edit the file /var/sysgen/master.d/scsi and add one of the following entries,

depending on your version of Irix:

Irix V6.x through V6.4:

{ DATTAPE, TPDAT, 7, 3, “ARCHIVE Python”,“DAT”/*DAT*/, 0, 0, {0},

/* This drive uses mode select page 0xf for compression control;

* most of the other drives supporting compression use page 0x10 */

MTCAN_BSF|MTCAN_BSR|MTCAN_APPEND|MTCAN_SETMK|MTCAN_PART|MTCAN_PREV|