Page 1

8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH8VHU¶V*XLGH

/728OWULXP6ORW$XWRORDGHU

/728OWULXP

%

Page 2

Quantum LTO Ultrium 8-Slot Autoloader User’s Guide, P/N50002762, B01, July 2005

Made in USA.

Quantum Corporation provides this publication “as is” without warranty of any kind, either express or

implied, including but not limited to the implied warranties of merchantability or fitness for a particular

purpose. Quantum Corporation may revise this publication from time to time without notice.

COPYRIGHT STATEMENT

Copyright 2005 by Quantum Corporation. All rights reserved.

Your right to copy this manual is limited by copyright law. Making copies or adaptations without prior

written authorization of Quantum Corporation is prohibited by law and constitutes a punishable violation of

the law.

TRADEMARK STATEMENT

Quantum and the Quantum logo registered trademarks of Quantum Corporation.

Other trademarks may be mentioned herein which belong to other companies.

Page 3

Warnings

All safety and operating instructions should be read before this product is operated, and should be retained for future

reference. This unit has been engineered and manufactured to assure your personal safety. Improper use can result in

potential electrical shock or fire hazards. In order not to defeat the safeguards, observe the following basic rules for

installation, use and servicing.

A Warning box alerts the user to the presence of “dangerous voltage” inside the product that might cause

harm or electric shock.

Warning: Risk of electric shock! Do not open!

To reduce the risk of electric shock, do not remove the cover (or back). No user-serviceable

parts are inside. Refer servicing to qualified service personnel.

• Heed warnings — All warnings on the product and in the operating instructions should be adhered to.

• Follow instructions — All operating and use instructions should be followed.

• Ventilation — The product should be situated so that its location or position does not interfere with proper

ventilation.

• Heat — The product should be situated away from heat sources such as radiators, heat registers, furnaces, or

other heat producing appliances.

• Power sources — The product should be connected to a power source only of the type directed in this document

or as marked on the product.

• Power cord protection — The power cord should be routed so that it is not likely to be walked on or pinched by

items placed upon or against it, paying particular attention to the cord at the wall receptacle, and the point where

the cord exits from the product.

• To complete the disconnection of the electricity, please remove the power (electric) cord and the SCSI cable from

their connections in the back of the autoloader. The plugs should be placed near the autoloader for easy access.

• Object and liquid entry — Care should be taken to insure that objects do not fall and liquids are not spilled into

the product's enclosure through openings.

• Servicing — The user should not attempt to service the product beyond that described in the operating

instructions. All other servicing should be referred to qualified service personnel.

For example:

Precautions

• Do not use oil, solvents, gasoline, paint thinners, or insecticides on the unit.

• Do not expose the unit to moisture or to temperatures higher than 140 °F (60 °C) or lower than

-40 °F (-40°C).

• Keep the unit away from direct sunlight, strong magnetic fields, excessive dust, humidity, and

electronic/electrical equipment, which generate electrical noise.

• Hold the power cord by the head when removing it from the AC outlet; pulling the cord can damage the internal

wires.

• Use the unit on a firm level surface free from vibration, and do not place anything on top of the unit.

Page 4

FCC Notice

This equipment generates and uses radio frequency energy and, if not installed and used properly that is, in strict

accordance with the manufacturer's instructions — may cause interference to radio communications or radio and

television reception. It has been tested and found to comply with the limits for a Class B computing device in

accordance with the specifications in Part 15 of FCC Rules, which are designed to provide reasonable protection

against such interference in a residential installation. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment on and off, you are encouraged to try to correct the interference by one or more

of the following measures:

• Reorient the receiving antenna.

• Relocate the computer with respect to the receiver.

• Move the computer into a different outlet so that the computer and receiver are on different branch circuits.

Warning: Changes or modifications made to this equipment, which have not been expressly

approved by Certance, may cause radio and television interference problems that could

void the user's authority to operate the equipment.

Further, this equipment complies with the limits for a Class B digital apparatus in accordance with Canadian Radio

Interference Regulations ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

The external device drive described in this manual requires shielded interface cables to comply with FCC emission

limits.

Warning: To prevent fire or electrical shock hazard, do not expose the unit to rain or moisture.

To avoid electrical shock, do not open the cabinet.

Refer servicing to qualified personnel.

Page 5

Contents

Preface xiii

Chapter 1 Quick Start 1

Autoloader Components ................................................................................. 2

Starting the Autoloader.....................................................................................5

Operator's Panel.................................................................................................7

Installing the Data Cartridges .......................................................................... 8

Chapter 2 Introduction 9

Features .............................................................................................................10

Accessories........................................................................................................ 11

Optional Accessories ...................................................................................... 12

Chapter 3 Setting Up the Autoloader 13

Choosing a Location ........................................................................................ 13

Checking the Installation Environment................................................. 15

Unpacking the Autoloader ............................................................................. 15

LTO Ultrium 8-Slot Autoloader User’s Guide v

Page 6

Contents

Installation Options..........................................................................................15

Installing the Autoloader into a Rack............................................................16

Requirements.............................................................................................16

Preparing the Autoloader ........................................................................17

Installing the Support Rails .....................................................................18

Installing the Rack-Mount Brackets .......................................................19

Securing the Autoloader ..........................................................................20

Connecting the Cables .....................................................................................21

Data Cartridges.................................................................................................22

Installing the Data Cartridges ................................................................22

Loading and Unloading a Cartridge .....................................................23

Updating the Cartridge Inventory..........................................................24

Chapter 4 Operating the Autoloader 25

Operator's Panel ...............................................................................................25

Status LEDs ...............................................................................................26

LCD ............................................................................................................27

Keypad .......................................................................................................27

Menu Options ..................................................................................................28

Inventory Status Characters ...........................................................................29

Operating Modes .............................................................................................30

Random Mode ...........................................................................................31

Sequential Mode........................................................................................31

Write-Protected Media .............................................................................32

Autoloader Operations....................................................................................32

Monitoring the Autoloader Operation and Status ...............................32

Performing Autoloader and Tape Drive Operations...........................33

Resetting the Autoloader ........................................................................33

Resetting the Tape Drive..........................................................................33

Maintenance .....................................................................................................34

Cleaning the Tape Drive .........................................................................34

Shipping the Autoloader ................................................................................35

Chapter 5 Troubleshooting and Diagnostics 37

Performing a System Test ..............................................................................37

Error Codes .......................................................................................................38

vi LTO Ultrium 8-Slot Autoloader User’s Guide

Page 7

Contents

Error and Event Log ................................................................................ 41

Log Entry ................................................................................................... 42

Appendix A Specifications 45

Size and Weight................................................................................................ 46

SCSI Interface ................................................................................................... 46

SCSI ID Settings ....................................................................................... 47

Changing the SCSI ID Settings ............................................................. 47

SCSI Cable Requirements ....................................................................... 48

SCSI Terminator Requirements .............................................................49

Performance Specifications.............................................................................49

Capacity ..................................................................................................... 49

Tape Drive Performance.......................................................................... 49

Autoloader Self-Test Times .................................................................... 49

Initial Element Status Time .................................................................... 50

Move Complete Time .............................................................................. 50

Reliability ................................................................................................... 50

Power Specifications ....................................................................................... 50

AC Power................................................................................................... 50

AC Power Cord......................................................................................... 51

Environmental Specifications ........................................................................ 52

Acoustic Noise Limits .................................................................................... 53

Shock and Vibration ........................................................................................ 53

Shock Specifications ................................................................................ 53

Vibration Specifications .......................................................................... 54

Disposal of Electrical and Electronic Equipment ....................................... 55

Index 57

LTO Ultrium 8-Slot Autoloader User’s Guide vii

Page 8

Contents

viii LTO Ultrium 8-Slot Autoloader User’s Guide

Page 9

Figures

Figure 1 Front Panel Components ............................................................2

Figure 2 Back Panel Components.............................................................. 3

Figure 3 Internal Components ..................................................................4

Figure 4 Attaching the Power Cord and a SCSI Terminator ................. 5

Figure 5 Pressing the Power Switch.......................................................... 6

Figure 6 Operator’s Panel ........................................................................... 7

Figure 7 Autoloader.....................................................................................9

Figure 8 Rack Mount Kit........................................................................... 17

Figure 9 Power Switch .............................................................................. 18

Figure 10 Attaching the Rails to the Rack ................................................ 19

Figure 11 Securing the Brackets................................................................. 20

Figure 12 Securing the Autoloader to the Rack....................................... 21

Figure 13 Operator’s Panel ......................................................................... 26

Figure 14 Autoloader Menu Options........................................................ 28

LTO Ultrium 8-Slot Autoloader User’s Guide ix

Page 10

Figures

x LTO Ultrium 8-Slot Autoloader User’s Guide

Page 11

Tables

Table 1 SCSI ID Default Settings.............................................................. 5

Table 2 Physical Characteristics and Features ..................................... 10

Table 3 Parallel SCSI Communication Interface.................................. 11

Table 4 Inventory Status Characters...................................................... 29

Table 5 Oviewview of Error Codes ....................................................... 38

Table 6 Robotic Control Errors............................................................... 38

Table 7 Function Errors ........................................................................... 39

Table 8 Low Level Axis Errors ...............................................................40

Table 9 Electronic Harware Errors ........................................................ 41

Table 10 Drive Errors................................................................................. 41

Table 11 Example of Error/Evemt Log Display .................................... 42

Table 12 Entry Modes................................................................................ 42

Table 13 SCSI ID Default Settlings........................................................... 47

Table 14 AC Power .................................................................................... 51

LTO Ultrium 8-Slot Autoloader User’s Guide xi

Page 12

Tables

xii LTO Ultrium 8-Slot Autoloader User’s Guide

Page 13

Preface

The Quantum LTO Ultrium 8-Slot Autoloader User’s Guide aprovides

automated data storage, archival, backup, and retrieval for a range of

systems, from desktop workstations to small office local area

networksAudience

Audience This document was written for users of the LTO Ultrium 8-Slot

Autoloader.

Purpose This document provides information about the LTO Ultrium 8-Slot

Autoloader including:

Document

Organization

• Installing

• Basic operations

• Operator commands

• Troubleshooting

• Specifications

This User’s Guide describes how to install, configure, and care for the

LTO Ultrium 8-Slot Autoloader autoloader. Please read the appropriate

LTO Ultrium 8-Slot Autoloader User’s Guide xiii

Page 14

chapters and appendixes carefully, and keep this Guide handy for future

reference.

Notational

Conventions

• Chapter 1,

Quick Start provides quick-start instructions for getting

the autoloader up and running in the shortest possible time.

• Chapter 2,

Introduction describes the features and accesories of the

autoloader.

• Chapter 3,

Setting Up the Autoloader describes how to set up the

autoloader.

• Chapter 4,

Operating the Autoloader describes how to use and

maintain the autoloader.

• Chapter 5,

Troubleshooting and Diagnostics describes the

troublshooting and diagnostics operations and error codes..

• Appendix A,

Specifications describes technical and environmental

specifications. The WEEE Compliance Statement is in this appendix.

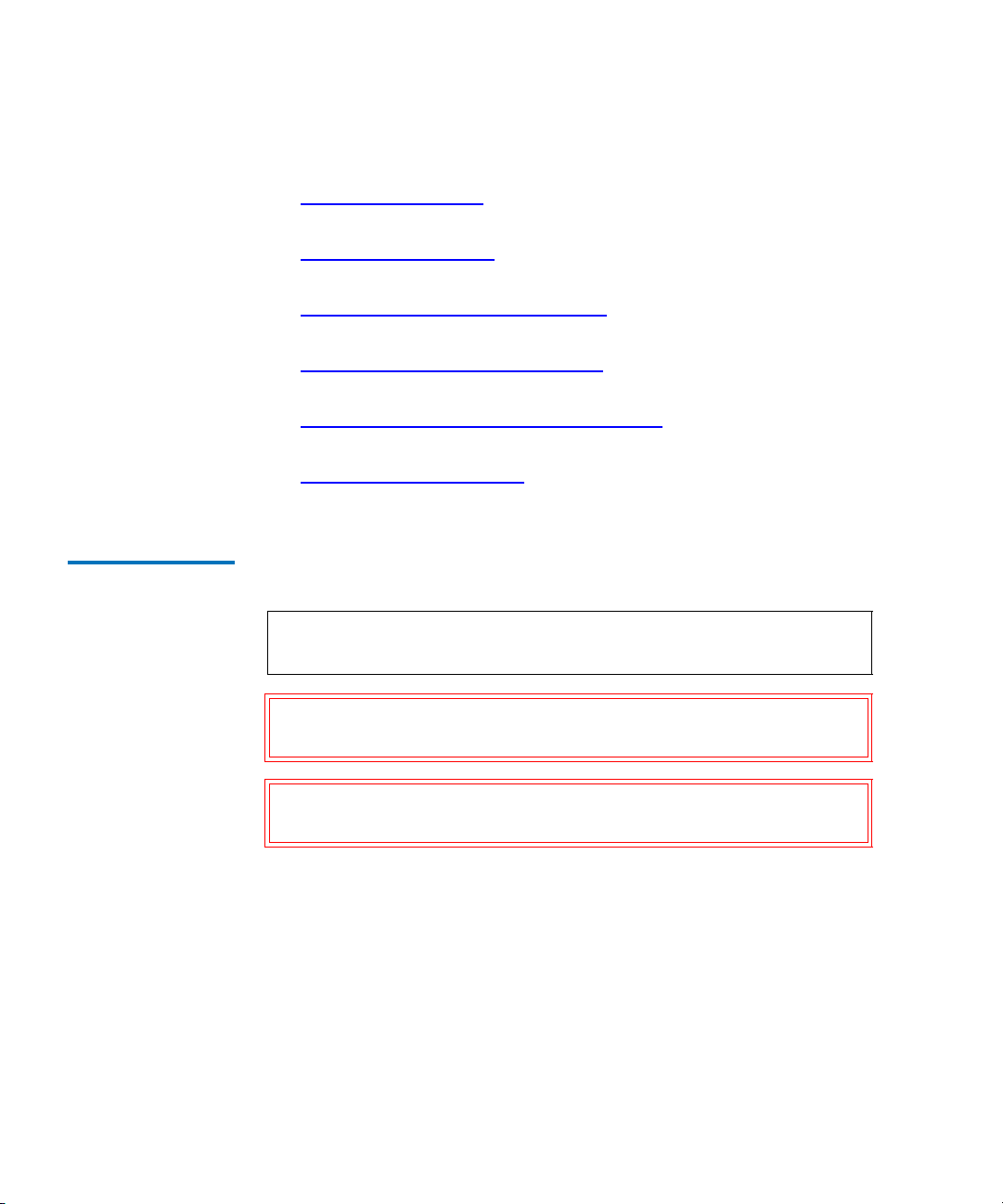

This manual uses the following conventions:

Note: Notes emphasize important information related to the main

topic.

Caution: Cautions indicate potential hazards to equipment and are

included to prevent damage to equipment.

Warning: Warnings indicate potential hazards to personal safety and

are included to prevent injury.

xiv LTO Ultrium 8-Slot Autoloader User’s Guide

Page 15

Related

Documents

Documents related to the LTO Ultrium 8-Slot Autoloader User’s Guide are

shown below:

SCSI-2 Specification

The SCSI-2 communications specification is the proposed American

National Standard for information systems, dated March 9, 1990. Copies

may be obtained from:

Global Engineering Documents

15 Inverness Way, East

Englewood, CO 80112

(800) 854-7179 or (303) 397-2740

Contacts Quantum company contacts are listed below.

Quantum Corporate Headquarters

To order documentation on the LTO Ultrium 8-Slot Autoloader User’s

Guide

or other products contact:

Quantum Corporation

P.O. Box 57100

Irvine, CA 92619-7100

(949) 856-7800

(800) 284-5101

0

0

Technical Publications

To comment on existing documentation send e-mail to:

doc-comments@quantum.com

Quantum Home Page 0

Visit the Quantum home page at:

http://www.quantum.com

LTO Ultrium 8-Slot Autoloader User’s Guide xv

0

Page 16

Customer Support 0

The Quantum Customer Support Department provides a 24-hour help

desk that can be reached at:

North/South America: (949) 725-2100 or (800) 284-5101

Asia/Pacific Rim: (International Code) + 61 7 3839 0988

Europe/Middle East/Africa: (International Code) + 44 (0) 1256 848748

Send faxes for the Customer Support Department to:

North/South America: (949) 725-2176

Asia/Pacific Rim: (International Code) + 61 7 3839 0955

Europe/Middle East/Africa: (International Code) + 44 (0) 1256 848777

Send e-mail for the Customer Support Department to:

Asia/Pacific Rim: apachelp@quantum.com

Europe/Middle East/Africa: eurohelp@quantum.com

Visit our web site:

www.quantum.com/support

xvi LTO Ultrium 8-Slot Autoloader User’s Guide

Page 17

Chapter 1

1Quick Start

This chapter provides quick start information for the LTO Ultrium 8-Slot

Autoloader, including:

• Front Panel Components

• Back Panel Components

• Internal Components

• Starting the Autoloader

• Operator's Panel

• Installing the Data Cartridges

LTO Ultrium 8-Slot Autoloader User’s Guide 1

Page 18

Chapter 1 Quick Start

Autoloader Components

Autoloader Components 1

The following describes the major components of the autoloader.

Figure 1 Front Panel

Components

Cartridge access port Status LEDs

Liquid

crystal

display

KeypadPower switch

• Cartridge access port —Used to insert or remove cartridges from the

autoloader.

•

Status LEDs — Consists of several lights that provide information

about various system functions. See Status LEDs

on page 26 for more

information.

•

Liquid crystal display (LCD) — Displays two lines of text with 16

characters per line. The screen displays actions and status

information, menu items, and error messages, based on the operation

mode. See LCD

•

Keypad — Performs various tasks in interaction mode. See Keypad on

on page 27 for more information.

page 27 for more information.

•

Power switch — Lets you turn the autoloader and the enclosed tape

drive off and on. The switch is recessed into the front panel to

prevent the autoloader from being accidentally turned off during

operation.

2 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 19

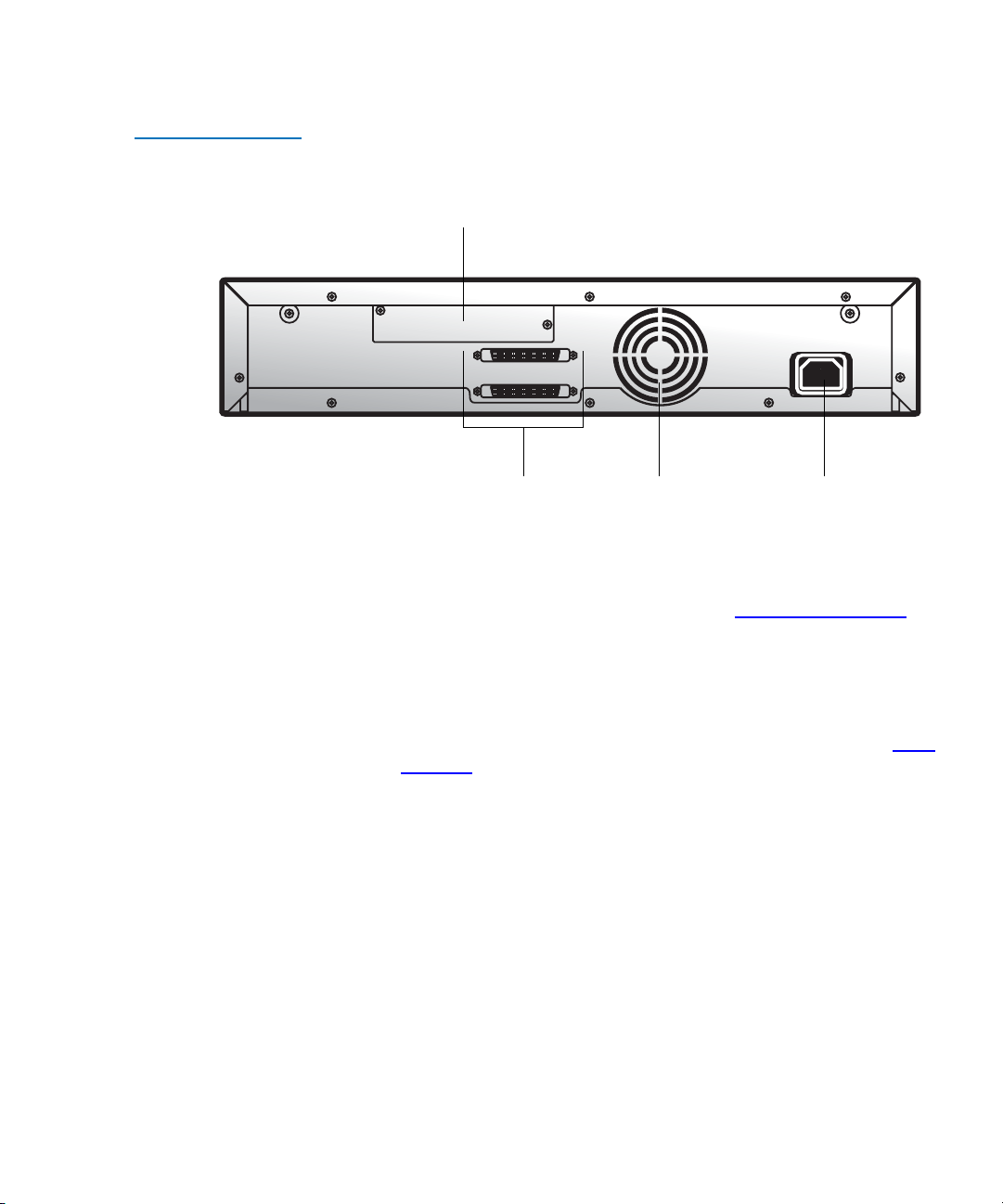

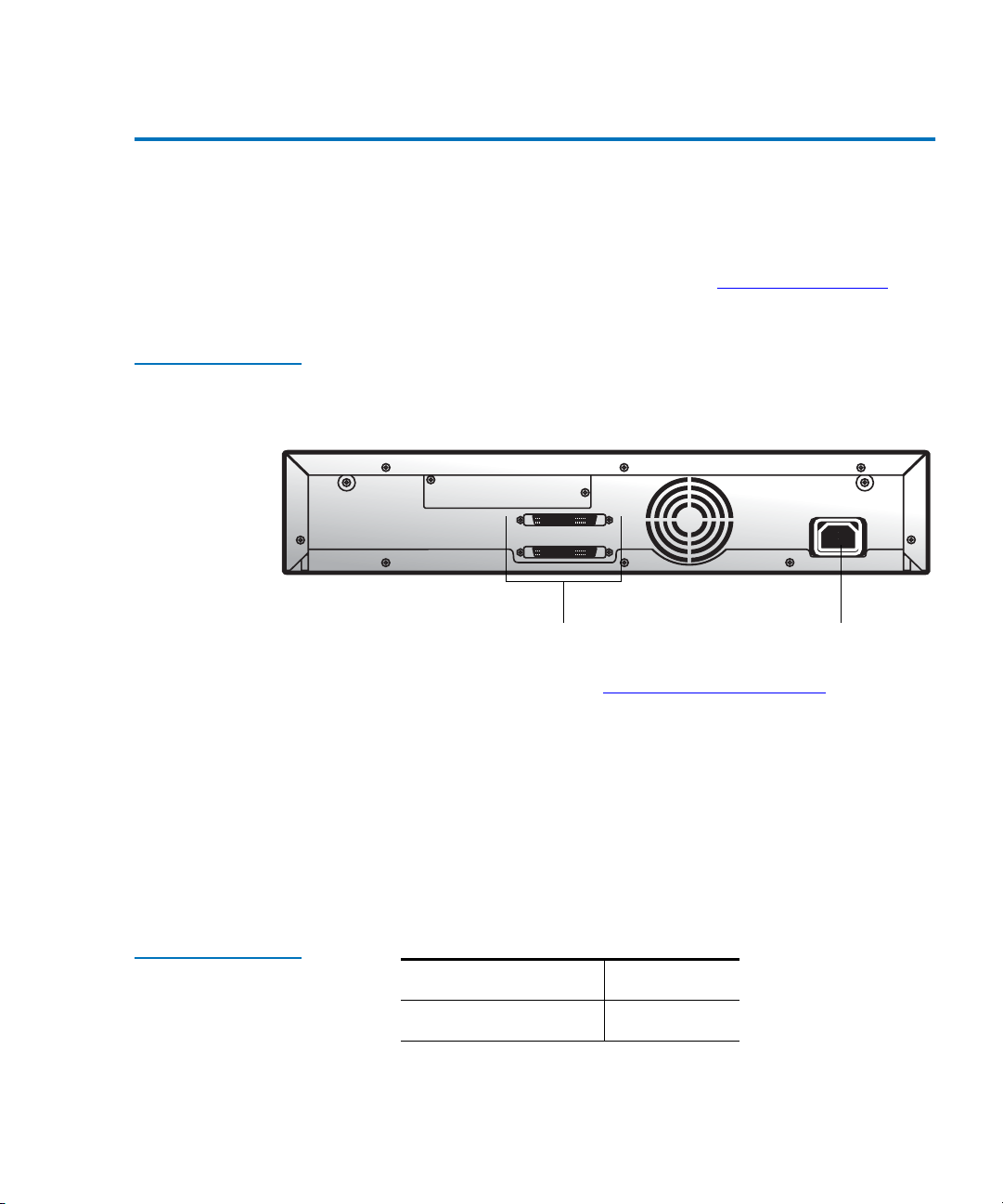

Figure 2 Back Panel

Components

Chapter 1 Quick Start

Autoloader Components

Bar code reader (optional)

SCSI connectors Fan AC outlet

• Bar code reader — The bar code reader is an optional accessory that

automatically scans each cartridge in the carousel. The information

from each bar code label is stored in memory and available through

SCSI to the computer’s operating system or backup application. For

more information on the bar code reader, see Optional Accessories

on

page 12.

•

SCSI connectors — The autoloader has two wide SCSI connectors for

connecting the autoloader and tape drive to a single SCSI bus. The

connectors can accommodate either of the following:

• A shielded male, high-density wide (68-pin) SCSI cable ( see SCSI

Interface on page 46.)

• An LVD or multi-node terminator

The wide SCSI configuration allows up to 16 devices (including one

or more initiators) to be attached to a single SCSI bus.

•

Fan — The system fan provides cooling for the autoloader and the

tape drive.

•

AC outlet — The AC outlet provides AC power and chassis

grounding to the autoloader and the tape drive.

LTO Ultrium 8-Slot Autoloader User’s Guide 3

Page 20

Chapter 1 Quick Start

Autoloader Components

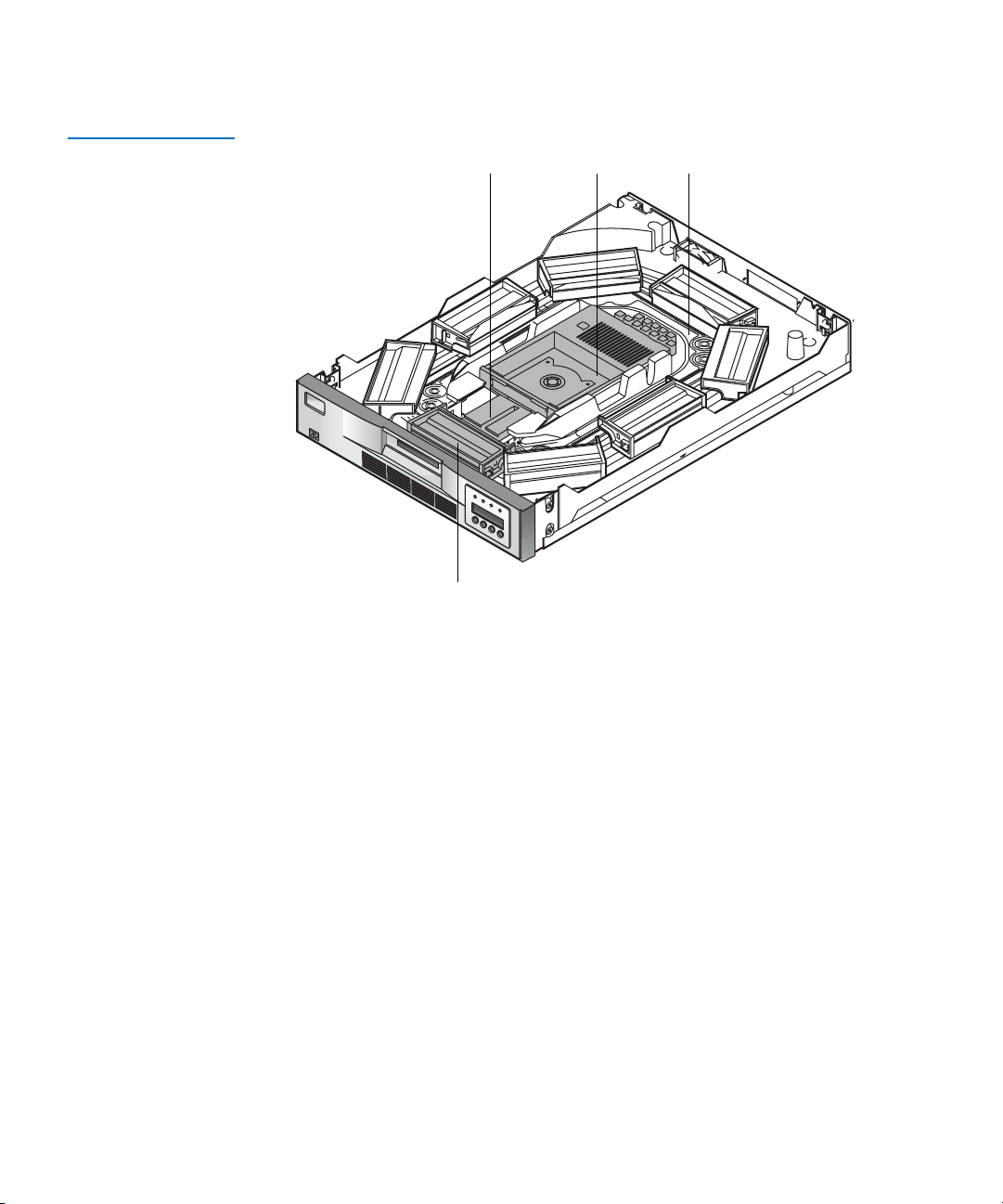

Figure 3 Internal

Components

Cartridge loader Tape drive Carousel

Cartridge slots

• Cartridge loader — The cartridge loader moves cartridges between

the cartridge slots and the tape drive. When a cartridge slot is

positioned in front of the tape drive, the loader grips the sides of the

cartridge and slides it forward or backward, between the slot and

tape drive. The loader then releases the cartridge and pushes it firmly

into the drive or slot.

•

Tap e drive — The autoloader contains one tape drive. Please see the

associated User's Guide for the particular LTO version for details of

tape drive performance and operation.

•

Cartridge slots and carousel — The carousel stores up to eight data

cartridges. The carousel consists of a drive chain, guides, and gears

that move the cartridges into position in front of the tape drive. Each

cartridge is installed in a cartridge slot that ensures that the cartridge

is properly aligned to be inserted into the tape drive. If desired, you

can use one cartridge slot to hold a cleaning cartridge.

4 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 21

Chapter 1 Quick Start

Starting the Autoloader

Starting the Autoloader 1

To start the autoloader:

1 Attach the power cord to the autoloader, and then to the AC outlet.

For more information on power cords, see Power Specifications

page 50.

Figure 4 Attaching the

Power Cord and a

SCSI Terminator

on

Table 1 SCSI ID

Default Settings

AC outletSCSI connectors

2 Connect the SCSI cables and the terminator. For more information

about the SCSI interface, see Performance Specifications

on page 49.

• Connect one end of the SCSI cable to one of the SCSI connectors

on the back of the autoloader.

• Connect the other end of the SCSI cable to the SCSI connector on

the SCSI host bus adapter or on the previous device of the SCSI

bus.

• If this is the last device in the SCSI chain, connect the SCSI

terminator to the remaining SCSI connector on the back of the

autoloader.

Autoloader 5

Tape drive 6

LTO Ultrium 8-Slot Autoloader User’s Guide 5

Page 22

Chapter 1 Quick Start

Starting the Autoloader

Figure 5 Pressing the

Power Switch

To change the SCSI ID settings, see Changing the SCSI ID

Settings on page 47.

3 Use the eraser end of a pencil, or something similar, to press the left

side of the power switch. The autoloader powers up. Never use a

metal object, such as a screwdriver.

Note: The power switch lets you turn the power on and off for

the autoloader and the enclosed tape drive. The power

switch is recessed into the front panel to prevent the

autoloader from being accidentally turned off during

operation.

When the autoloader powers up, or resets, it goes through several

internally controlled processes that allow it to get initialized and

running. While those processes are happening, the Operator’s Panel

displays appropriate information to keep you informed about the

events taking place. After initialization, the autoloader displays the

mount status for the current drive. It also indicates that the sequential

mode is ON by displaying the characters SEQ.

In addition, the appropriate inventory status characters display. For

more information about inventory status characters, see Inventory

Status Characters on page 29.

4 Start the host computer system.

6 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 23

Chapter 1 Quick Start

X

-

+

Operator's Panel

Operator's Panel 1

The Operator's Panel consists of various status LEDs, an LCD, and

keypad buttons that enable you to perform various tasks.

The following keypad buttons are used to navigate the menu options:

•

CANCEL button [X] — Cancel a user action and return to the last

menu item.

•

PREVIOUS button [-] — Navigate through menu items.

•

NEXT button [+] — Navigate through menu items.

•

ENTER button [ø] — Go to a sub-menu or to force a robotic action.

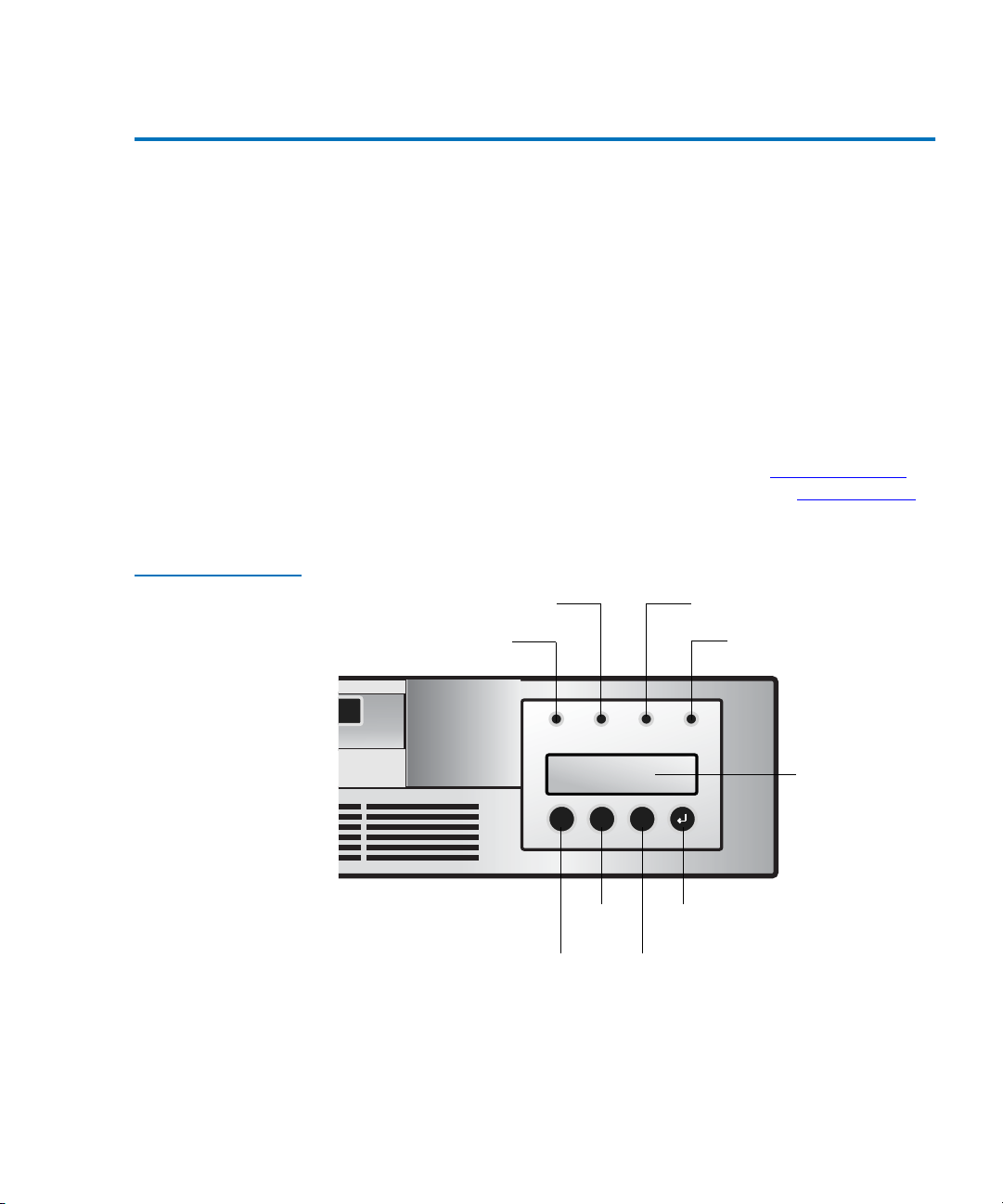

Figure 6 Operator’s

Panel

For more information about the Operator’s Panel, see Operator's Panel

page 25. For more information on the menu options, see Menu Options

on page 28.

Clean Drive LED Media Attention LED

Ready/Activity LED

--

XX

++

EnterPrevious

NextCancel

Error LED

LCD

on

LTO Ultrium 8-Slot Autoloader User’s Guide 7

Page 24

Chapter 1 Quick Start

Installing the Data Cartridges

Installing the Data Cartridges 1

Before using the autoloader, the data cartridges must be installed

properly. For more information on data cartridges, see Data Cartridges

on page 22.

Caution: The tape drive only operates with LTO-3 Ultrium (LTO-3

autoloader only), LTO-2 Ultrium (LTO-3 and LTO-2

autoloaders only), or LTO-1 Ultrium tape data cartridges.

Attempting to use other types of cartridges may damage

the unit. For best performance, Certance-brand cartridges

are recommended.

To install the data cartridges:

1 Press any button on the Operator’s Panel to change to

mode.

2 Choose the

3 Choose

4 Enter the number of the cartridge slot and press

5 Insert the cartridge in the cartridge access port. The cartridge is now

placed in the selected slot.

6 Repeat steps 4 and 5 until all cartridges have been imported.

Commands menu, and then press Enter.

Import and press Enter.

Interaction

Enter.

8 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 25

Chapter 2

2Introduction

The autoloader provides automated data storage, archival, backup, and

retrieval for a range of systems, from desktop workstations to small office

local area networks.

This chapter contains general information about the autoloader,

including:

Figure 7 Autoloader

• Features

• Accessories

LTO Ultrium 8-Slot Autoloader User’s Guide 9

.

Page 26

Chapter 2 Introduction

Features

Features 2

The LTO Ultrium 8-Slot Autoloader includes the following features:

• A carousel that encircles the tape drive and positions the specified

cartridge slot in front of the tape drive. A robotic cartridge loader

moves the cartridges between the cartridge slots and the tape drive.

• Storage for up to eight cartridges. Cartridges are stored in cartridge

slots mounted on the carousel. One of these cartridge slots can

contain a cleaning cartridge.

• A cartridge access port for importing or exporting a single cartridge

from the autoloader.

• A liquid crystal display that lets you monitor autoloader operations,

select configuration options, and control the cartridge loader and

carousel from the front panel.

• The autoloader and the tape drive each include independent Small

Computer System Interface (SCSI) controllers. Each supports

independent sets of SCSI messages and commands. The autoloader

and the enclosed tape drive use a wide, low-voltage differential

(LVD) SCSI interface.

Note: The LVD SCSI interface is compatible with single-ended

SCSI.

Table 2 Physical

Characteristics and

Features

Drive technology LTO Ultrium 3 LTO Ultrium 2 LTO Ultrium 1

Total drives 1 1 1

Total storage elements 8 8 8

Cartridge access port 1 1 1

LCD display size and

type

10 LTO Ultrium 8-Slot Autoloader User’s Guide

Two-line x 32

character, ASCII

Two-line x 32

character, ASCII

Two-line x 32

character, ASCII

Page 27

Chapter 2 Introduction

Accessories

LCD user interface Four-button

keypad

Maximum capacity 6.4TB/ 3/2TB

(Compressed/

Native)

Maximum sustained

data transfer rate

MB/Sec

T able 3 Parallel SCSI

Communication

Interface

132/68

(Compressed/

Native)

Low-voltage differential (LVD) + SE YES

Maximum SCSI bus connections 1

Four-button keypad Four-button keypad

3.2TB/1600GB

(Compressed/

Native)

68/32

(Compressed/

Native)

1.6TB/800GB

(Compressed/

Native)

32/16

(Compressed/

Native)

Accessories 2

The autoloader is shipped with the following accessories:

• Power cord and adapter

•One wide SCSI-3 cable

• One LVD wide SCSI terminator (included in some configurations)

• Resource CD (product documentation). Basic diagnostic software for

the tape drive and autoloader is available at www.quantum.com/

support. Please see the online documentation on the CD for details

about installation and operation.

LTO Ultrium 8-Slot Autoloader User’s Guide 11

Page 28

Chapter 2 Introduction

Optional Accessories

Optional Accessories 2

• Rack-mount kit — If you want to mount the autoloader in a rack,

you can purchase a rack-mount kit. The kit includes all the

necessary hardware to mount the autoloader in a standard 19inch EIA rack. The autoloader occupies two rack units.

•

Bar code reader — Your autoloader may have come equipped

with an optional bar code reader. The bar code reader

automatically scans each cartridge in the carousel upon power

up, after a reset, or when the Re-Inventory command is used.

Beyond that, there is no user interface with the bar code reader

via the front panel operator controls or liquid crystal display.

If utilizing the bar code reader, you must apply bar code labels to

the recessed area on the front of each cartridge. The information

from each label is stored in memory and available through SCSI

to the computer's operating system or backup application, upon

request. The labels must conform to ANSI/AIM BC1 -1995,

Uniform Symbology Specification Code 39.

The bar code reader is enclosed in a plastic housing that

protrudes out the rear panel of the autoloader, just above the

SCSI connectors.

12 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 29

Chapter 3

3Setting Up the Autoloader

This chapter describes how to set up the autoloader, and install the

autoloader into a rack, if desired. Setting up the autoloader involves the

following steps:

1 Choosing a Location

2 Unpacking the Autoloader

3 Installation Options

4 Connecting the Cables on page 21.

5 Data Cartridges

.

.

on page 22

Choosing a Location 3

Choose a location that meets the following criteria (see Specifications on

page 45 for more information on autoloader specifications):

LTO Ultrium 8-Slot Autoloader User’s Guide 13

Page 30

Chapter 3 Setting Up the Autoloader

Choosing a Location

• Select a location that is flat, sturdy, level, and close to a host server.

Do not place the autoloader on the floor or other carpeted surfaces.

Caution: Do not place the autoloader on its side or upside

• Rack requirements — Standard 19-inch rack with 2U of clearance

• Room temperature —

• LTO Ultrium 2 and LTO Ultrium 1: 50-95º F (10-35º C)

• LTO Ultrium 3: 50-104º F (10-40º C)

•Power source —

• AC power voltage: 100-127 VAC

• 200-240 VAC line frequency: 50-60 Hz

Note: Locate the AC outlet at the back of the autoloader. The

down, or stack items that weigh more than 33 lbs.

(15 kg) on top of the autoloader.

power cord is the autoloader's main AC disconnect device

and must be easily accessible at all times.

• Weight — 19.5 lbs. (8.8 kg)

• Air quality — Minimal sources of particulate contamination. Avoid

areas near frequently used doors and walkways, stacks of supplies

that collect dust, printers, and smoke-filled rooms.

Caution: Excessive dust and debris can damage tapes and tape

drives.

• Humidity — 20-80% RH non-condensing

• Clearance —

• Back (minimum of six inches [15.4 cm])

• Front (minimum of 12 inches [30.8 cm])

• Sides (minimum of two inches [5.08cm])

14 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 31

Chapter 3 Setting Up the Autoloader

Unpacking the Autoloader

Checking the Installation Environment

After choosing a location for the autoloader, consider the following:

• The maximum recommended ambient temperature for the

3

autoloader is

in an environment compatible with this temperature.

• The fan opening at the rear of the autoloader and the vent openings

in the front should be free of cables and other obstructions.

• Make sure the supply circuit is suitable for all equipment loads in the

rack.

• Make sure the outlet or power strip that you intend to use is reliably

grounded.

• Make sure that the installation environment is free of conditions that

could cause electrostatic discharge (ESD). If possible, use an antistatic

mat and grounded static protection wristband during installation. If a

mat and wristband are not available, touch a known grounded

surface, such as a computer’s metal chassis.

+50°F to +104 °F (+10 °C to +40 °C). Install the autoloader

Unpacking the Autoloader 3

No special tools are required for unpacking the autoloader. Save all the

original packing materials, including the accessory box, in case you need

to ship or move the autoloader at a later time.

Installation Options 3

You have the option of installing the autoloader into a rack, or using it as

a standalone unit.

• If you are installing the autoloader into a rack, go to Installing the

Autoloader into a Rack.

• If you are using the autoloader as a standalone unit, go to Connecting

the Cables on page 21.

LTO Ultrium 8-Slot Autoloader User’s Guide 15

Page 32

Chapter 3 Setting Up the Autoloader

Installing the Autoloader into a Rack

Installing the Autoloader into a Rack 3

The autoloader can be installed into a standard 19-inch rack.

Requirements 3

To install the autoloader into a rack, you will need the following:

• #2 PHILLIPS® screwdriver

• TORX T-10 screwdriver

• Rack mount kit — Make sure the rack-mount kit contains the

following items:

• Two support rails

• Two rack-mount brackets

•Ten screws

•Ten clip-nuts

16 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 33

Figure 8 Rack Mount

Kit

Chapter 3 Setting Up the Autoloader

Installing the Autoloader into a Rack

Screw

Support rails

Preparing the Autoloader

Rack-mount brackets

If the autoloader is currently in operation as a standalone unit, prepare it

for installation in the rack as follows:

3

Warning: Before performing any installation or maintenance

procedures, be sure that the power switch is off and that

the power cord is disconnected from the autoloader and

the AC outlet.

1 Power off the autoloader by pressing the right side of the recessed

power switch located on the autoloader’s front panel. Use the eraser

end of a pencil or a similar object to press the power switch.

Note: To avoid disrupting communication between the host

computer and other devices on the SCSI bus, make sure

that there is no SCSI activity on the bus before you power

off the autoloader.

Clip-nut

LTO Ultrium 8-Slot Autoloader User’s Guide 17

Page 34

Chapter 3 Setting Up the Autoloader

Installing the Autoloader into a Rack

Figure 9 Power

Switch

2 Remove the power cord and any SCSI cables or terminators attached

to the autoloader. Note the configuration of the cables and

terminator. You will need to reinstall them after installing the

autoloader in the rack.

Installing the Support Rails

To install the support rails in the rack:

3

1 Remove the two support rails from the kit and note how they will be

positioned in the rack. When the rails are installed, the shelf flanges

will face inward to support the autoloader.

2 From the front of the rack, position one of the rails on the appropriate

side. Slide the rail pieces apart to match the depth of your rack.

Position the front flange so that it is on the outside of the strip of

mounting holes in the rack.

3 Using a #2 Phillips screwdriver, attach the rail to the rack with four of

the screws from the kit. If your rack has square mounting holes, or

the holes are larger than the screws provided in the kit, use the clipnuts to secure the screws, as shown in the following figure.

18 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 35

Figure 10 Attaching

the Rails to the Rack

Chapter 3 Setting Up the Autoloader

Installing the Autoloader into a Rack

Clip-nut

Front flange

Front flange

Installing the Rack-Mount Brackets

4 Repeat steps 2 and 3 for the second rail.

To install the rack-mount brackets on the autoloader:

1 Remove the rack-mount brackets from the rack-mount kit and

3

determine on which side of the autoloader you will attach them, as

follows:

• From the front of the rack, slide the autoloader partially onto the

shelf flanges between the support rails you just installed.

• Holding one of the rack-mount brackets against one side of the

autoloader, line up the two holes in the bracket with the two

screw holes on the side of the autoloader. The flange on the

bracket should be toward the front of the autoloader, facing

outward.

LTO Ultrium 8-Slot Autoloader User’s Guide 19

Page 36

Chapter 3 Setting Up the Autoloader

Installing the Autoloader into a Rack

• Slide the autoloader into the rack until the bracket you are

• Determine whether the screw hole on the bracket flange lines up

2 Remove the autoloader from the shelf and place it on the work

surface.

3 Using a TORX T-10 screwdriver, remove the two screws on each side

of the autoloader.

4 Position the correct bracket, as determined in step 1, on each side of

the autoloader. Secure each bracket by replacing the original screws.

Figure 11 Securing

the Brackets

Flange

Rack-mount bracket

holding contacts the rack’s mounting holes.

with a mounting hole in the rack. If it does, you will mount the

bracket on that side of the autoloader. If not, you will mount it on

the other side of the autoloader.

Securing the Autoloader

To secure the autoloader to the rack:

3

1 From the front of the rack, position the autoloader on the shelf

flanges between the support rails. Slide it toward the rear of the rack

until the brackets contact the rack’s mounting holes. Make sure that

the tabs on the back of each shelf flange are fully engaged in the slots

at the rear of the autoloader.

20 LTO Ultrium 8-Slot Autoloader User’s Guide

P

O

W

E

R

M

E

N

U

-

+SE

LE

C

T

Page 37

Figure 12 Securing

the Autoloader to the

Rack

Chapter 3 Setting Up the Autoloader

Connecting the Cables

2 Place one screw from the rack-mount kit into the hole in the front of

each bracket. If your rack has square mounting holes or the holes are

larger than the screws provided in the kit, use the clip-nuts to secure

the screws. Use a #2 PHILLIPS screwdriver to tighten the screws.

P

O

W

E

R

M

E

N

U

-

+

S

E

L

E

C

T

Connecting the Cables 3

To connect the cables to the autoloader:

1 Make sure that the power switch on the front of the autoloader is off

(the right side of the power switch is pressed).

2 Connect the female end of the power cord to the AC outlet on the

back of the autoloader.

Note: The power cord shipped with the autoloader is a 120 VAC

three-conductor power cord for use in the United States

and Canada. An adapter for use outside of the United

States and Canada is also included.

LTO Ultrium 8-Slot Autoloader User’s Guide 21

Page 38

Chapter 3 Setting Up the Autoloader

Data Cartridges

3 Connect the male end of the power cord to the power outlet.

4 Connect the SCSI cables and the terminator. For more information

about the SCSI interface, see SCSI Interface

• Connect one end of the SCSI cable to one of the SCSI connectors

• Connect the other end of the SCSI cable to the SCSI connector on

• If this is the last device in the SCSI chain, connect the SCSI

5 Push the power switch on the front of the autoloader to the ON

position (press the left side of the switch).

6 Power on the host computer system.

on page 46.

on the back of the autoloader.

the SCSI host bus adapter or on the previous device of the SCSI

bus.

terminator to the remaining SCSI connector on the back of the

autoloader.

Data Cartridges 3

Installing the Data Cartridges

22 LTO Ultrium 8-Slot Autoloader User’s Guide

3

Caution: The tape drive only operates with LTO-3 Ultrium (LTO-3

autoloader only), LTO-2 Ultrium (LTO-3 and LTO-2

autoloaders only), or LTO-1 Ultrium tape data cartridges.

Attempting to use other types of cartridges may damage

the unit. For best performance, Certance-brand cartridges

are recommended.

Note: Do not open the front door of the autoloader unless you must

perform interaction mode commands or change media. Use

only the recommended types of media cartridges. Clean the

drive whenever necessary.

Caution: Never insert or remove cartridges from the cartridge slot

unless READY/ACTIVITY is lit.

Page 39

Chapter 3 Setting Up the Autoloader

Data Cartridges

To install the data cartridges:

1 Press any button on the Operator’s Panel to change to interaction

mode.

2 Choose the

3 Choose

4 Enter the number of the cartridge slot and press

Commands menu, and then press Enter.

Import and press Enter.

Enter.

5 Insert the cartridge in the cartridge access port. The cartridge is now

placed in the selected slot.

6 Repeat steps 4 and 5 until all cartridges have been imported.

The

Import command in the Library Commands menu places a cartridge

into a specific cartridge slot through the cartridge access port. When you

use the

Import command, the cartridge carousel moves the specified

cartridge slot into position in front of the cartridge access port and slides

the door open. You can then push the cartridge into the slot through the

door. The cartridge loader then grasps the cartridge, pulls it into the

autoloader, and closes the door.

The

Export command lets you remove a cartridge from a specific

cartridge slot through the cartridge access port. When you use the

Export

command, the cartridge carousel moves the specified cartridge slot into

position in front of the cartridge access port and slides the door open. The

cartridge loader then pushes the cartridge far enough out through the

door to allow you to remove it.

Loading and Unloading a Cartridge

The Load Cartridge command in the Commands menu lets you load the

cartridge in the specified slot into the tape drive. When you use the

Cartridge

3

command, the cartridge carousel moves the specified cartridge

slot into position in front of the tape drive. The cartridge loader then

extracts the cartridge from the cartridge slot and inserts it into the tape

drive.

The

Unload Cartridge command causes the tape drive to unload the tape

from the tape path and eject the cartridge. After the cartridge is ejected,

the cartridge carousel moves the slot from which the cartridge originated

into position in front of the tape drive. The cartridge loader then extracts

the cartridge from the tape drive and returns it to the cartridge slot.

LTO Ultrium 8-Slot Autoloader User’s Guide 23

Load

Page 40

Chapter 3 Setting Up the Autoloader

Data Cartridges

Updating the Cartridge Inventory

After you import or export a data cartridge, you can update the cartridge

inventory using the

menu. The autoloader checks for the presence of a cartridge in each

3

Re-inventory Option command in the Commands

cartridge slot.

24 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 41

Chapter 4

4Operating the Autoloader

This chapter information about using the autoloader, including:

• Operator's Panel

• Menu Options

• Inventory Status Characters

• Operating Modes

• Autoloader Operations

• Maintenance

• Shipping the Autoloader

on 25

on 28

on 29

on 30

on 32

on 34

on 35

Operator's Panel 4

The operator's panel consists of the following:

• Status LEDs

• LCD

• Keypad

on 27

on 26

on 27

LTO Ultrium 8-Slot Autoloader User’s Guide 25

Page 42

Chapter 4 Operating the Autoloader

X

-

+

Operator's Panel

Figure 13 Operator’s

Clean Drive LED Media Attention LED

Panel

Ready/Activity LED

--

XX

++

EnterPrevious

NextCancel

Error LED

Liquid crystal display

Status LEDs 4 The LEDs are updated during power up and reset sequences. Upon

power up or software reset, the autoloader will illuminate all LEDs as

soon as the power-on self-test (POST) allows. This assists you in verifying

that all LEDs are functional.

When mechanical initialization starts, all LEDs will be extinguished and

the

READY/ACTIVITY LED will flash at a reasonable rate of approximately

one second per cycle.

When the mechanical initialization is complete, the

will stop flashing and be constantly illuminated.

If a loader failure occurs, the

the

ERROR LED will be illuminated. The Operation’s Panel will also

READY/ACTIVITY LED will be turned off and

display an appropriate error code to help identify the failure.

Note: The circuitry to illuminate four external LED's is incorporated

into the autoloader.

•

READY/ACTIVITY (Green LED) — Lit any time the unit is powered on

and able to function. It should blink whenever there is autoloader or

drive activity.

26 LTO Ultrium 8-Slot Autoloader User’s Guide

READY/ACTIVITY LED

Page 43

Chapter 4 Operating the Autoloader

Operator's Panel

• CLEAN DRIVE (Amber LED) — Lit when the drive is to be cleaned.

The LED will be turned off after the drive is cleaned successfully.

•

MEDIA ATTENTION (Amber LED) — Lit when there has been a failure

that indicates that there is a piece of media that is bad, marginal, or

invalid. It will be cleared when all invalid cartridges have been

exported from the autoloader.

•

ERROR (Red LED) — Lit when there is an unrecoverable autoloader

or drive failure. A message displays at the same time on the screen. It

will be cleared when the error state is resolved.

LCD 4 The LCD consists of two lines, with 16 characters per line. The screen

displays actions, status information, menu items, and error messages

equivalent to the operation mode.

Keypad 4 The keypad buttons are used for navigating the various menu options

that are available. For more information on the menu options, see Menu

Options on 28.

Note: The keypad buttons are only available for use in interaction

mode. For more information on operating modes, see

Operating Modes

•

CANCEL button [X] — Push the Cancel button to cancel a user action

on 30.

and return to the last menu item.

•

PREVIOUS button [-] — Navigate through menu items.

•

NEXT button [+] — Navigate through menu items.

•

ENTER button [ø] — Push the Enter button to go to a sub-menu or to

force a robotic action.

LTO Ultrium 8-Slot Autoloader User’s Guide 27

Page 44

Chapter 4 Operating the Autoloader

Menu Options

Menu Options 4

Figure 14 Autoloader

Menu Options

Commands Information Configuration Diagnostic

Import

Export

Load cartridge

Unload

cartridge

Clean drive

Re-Inventory

Cycle count

View event log

Product Rev.

Serial numbers

Firmw are

revisions

Reset

Change SCSI

ID

Code update

Circular mode

Autoload mode

System test

The menu options are accessed from the Operator’s Panel by pressing the

Enter button. Use the Previous and Next buttons to navigate through the

menu items. Use the

Cancel button to cancel the last action and return to

the previous menu item.

For most installations, the default configuration for the autoloader does

not need to be changed. However, if necessary, you can use the

Operator’s Panel to change the SCSI IDs for the autoloader and the tape

drive using the

Configuration menu.

Note: The autoloader and the tape drive must each have unique SCSI

IDs. It is your responsibility to make sure you do not assign

duplicate IDs within a bus. For more information on changing

SCSI IDs, see SCSI ID Settings

28 LTO Ultrium 8-Slot Autoloader User’s Guide

on page 47.

Page 45

Chapter 4 Operating the Autoloader

Inventory Status Characters

Inventory Status Characters 4

The inventory status characters represent the status of each slot within

the tape drive. They display in the second line of text in the liquid crystal

display as an eight-character string, with four blank spaces on each side.

Table 4 Inventory

Status Characters

Character Meaning

1 … 8

-

Slot Full: Indicates that slot contains a cartridge

Slot Empty: Indicates the slot does not contain a

cartridge.

1/J A cartridge that is being loaded, unloaded, imported,

exported, or is loaded in the drive is represented by the

slot number alternating with the block (J) character.

! (Exclamation point and the

Media Attention LED is on)

The cartridge in that slot is faulty. An invalid cartridge

is identified the same way.

To clear the faulty status (exclamation point) and the Media Attention

LED, export the faulty cartridge.

If a drive does not contain any cartridges, the following displays in the

liquid crystal display. In this example, there is no cartridge in slot 6.

Drive empty

12345-78 SEQ

If the autoloader detects that a cartridge is loaded when it first powers on,

the following displays in the liquid crystal display. In this example, there

is no cartridge in slot 6. If the cartridge in the drive came from slot 8, the 8

would be alternating with the block character.

LTO Ultrium 8-Slot Autoloader User’s Guide 29

Page 46

Chapter 4 Operating the Autoloader

Operating Modes

Drive loaded

12345-78 SEQ

Operating Modes 4

The System Driven mode is the normal mode of operation. In this mode,

the Operator’s Panel displays the status associated with the actions that

were caused from commands issued via the drive's SCSI interface. Some

of these actions including loading, rewinding, and moving tape display.

When an operator’s panel button is pressed and released, the operator’s

panel changes to

the unit.

Interaction mode. In Interaction mode, you can operate

Interaction mode continues for three minutes after you stop pushing

buttons or the requested robotic action stops. After this time, the

operator’s panel returns to

The autoloader has two operating modes —

System Driven mode automatically.

Random and Sequential. The

operating mode used depends on whether automation software is

controlling cartridges in the autoloader. Initially, the autoloader assumes

you are not using automation software to control cartridge or drive

activity. This is called

Sequential mode. If the autoloader detects that

automation software is controlling tape drive activity, it switches to

Random mode automatically.

Note:

SEQ appears in the operator's panel LCD when the autoloader

is in

Sequential Mode. No message appears during Random

Mode.

The following sections provide more information about

Random modes.

Sequential and

30 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 47

Chapter 4 Operating the Autoloader

Operating Modes

Random Mode 4 Random mode is the normal operating mode when a backup software

application is being used. In

Random mode, the autoloader loads tape

into the drive when it receives the appropriate commands from software.

To use this mode, your backup software must support autoloaders. This

support often requires an autoloader/library software module to be

installed.

Sequential Mode 4 Sequential mode is used when autoloader software is not available. In

Sequential mode, the autoloader loads and unloads tapes automatically.

The operator specifies which tape is to be loaded first by using the

autoloader operator's panel controls. (For more information on loading

cartridges, see Loading and Unloading a Cartridge

on page 23.)

When the first tape is full or unloaded, the autoloader removes the tape

from the drive automatically, returns it to its original slot, and loads

another tape in the next higher numbered slot that is available. For

additional control over loading tapes in

Circular and Autoload options from the autoloader’s front panel.

Sequential mode, you can set

Circular Mode

This option is accessed from the Configuration menu. When Circular mode

is enabled, the autoloader reloads the original first cartridge in the

sequence after it cycles through all available cartridges. If

Circular mode

is disabled, the autoloader stops loading cartridges after the last cartridge

has been unloaded and waits until you load another cartridge manually.

Caution: Use caution with circular mode, as it can overwrite data on

previously written cartridges.

Autoload Mode

This option is accessed from the Configuration menu. When autoload

mode is enabled, the autoloader automatically loads the cartridge from

the lowest numbered full slot into the tape drive when powered on. It

then follows standard sequential operation as described above.

LTO Ultrium 8-Slot Autoloader User’s Guide 31

4

4

Page 48

Chapter 4 Operating the Autoloader

Autoloader Operations

Write-Protected Media

If the drive detects a write-protected media, an internal bit is set and the

autoloader posts the 'WP' string on the display indicating a write

4

protected media is loaded in the drive. The display shows the following

status:

As soon as the write-protected media is ejected, the drive resets the

internal bit and the 'WP' string on the display is cancelled.

Autoloader Operations 4

After you install and configure the autoloader and install your

application software on the host computer, the autoloader performs most

operations automatically. Operator intervention includes the following

activities:

• Monitoring autoloader operation and status

• Performing autoloader and tape drive operations

Monitoring the Autoloader Operation and Status

32 LTO Ultrium 8-Slot Autoloader User’s Guide

During normal operation, the Status screen is displayed on the liquid

crystal display. You can use this screen to monitor autoloader activities.

By default, the

autoloader and tape drive.

4

To set the Operator’s Panel to

lets you use the keypad to display options for issuing commands to the

autoloader, viewing information screens, and configuring the autoloader.

Status screen displays the current operating status of the

Interaction mode, press any key. This mode

Page 49

Chapter 4 Operating the Autoloader

Autoloader Operations

Performing Autoloader and Tape Drive Operations

Resetting the Autoloader

Resetting the T ape Drive

The Commands menu provides options for importing and exporting

cartridges, loading and unloading a cartridge from the tape drive,

cleaning the tape drive, and updating the cartridge inventory. For more

information on data cartridges, see Data Cartridges

4

on page 22.

A reset causes the autoloader to perform its power-on self-test (POST)

and check for the presence of the data cartridges. The autoloader can be

4

reset in any of the following ways:

• Power-on reset — Powering the autoloader off (or unplugging it),

and then back on again, resets the autoloader and the tape drive.

• Operator’s Panel — Choose the

choose

Reset, and then press Enter. For more information about using

the Operator’s Panel, see Operator's Panel

Configuration menu, press Enter,

on page 7.

• Bus device reset message — Issuing a bus device reset message from

the SCSI application program can reset either the autoloader or the

tape drive.

Resetting the tape drive does not cause a cartridge loaded in the drive to

be ejected. If a cartridge is in the tape drive during a reset, make sure that

4

it is safe to overwrite the loaded cartridge before performing a backup. If

you perform a backup without checking the loaded cartridge, you may

lose important data from a previous backup.

LTO Ultrium 8-Slot Autoloader User’s Guide 33

Page 50

Chapter 4 Operating the Autoloader

Maintenance

Maintenance 4

The autoloader requires no routine maintenance. Parts can be serviced

only by the manufacturer, an approved maintenance organization, or by

self-maintenance contract customers.

Caution: Do not clean or lubricate any of the autoloader’s

mechanical assemblies. Lubricating may adversely affect

the function of those parts. All other parts can be serviced

only by the manufacturer, an approved maintenance

organization, or by self-maintenance contract customers.

Note: The autoloader warranty does not apply to failures of the

autoloader when it is repaired by untrained or unauthorized

service personnel.

Cleaning the Tape Drive

34 LTO Ultrium 8-Slot Autoloader User’s Guide

The tape drive requires regular cleaning with an LTO tape cleaning

cartridge to maintain optimal performance. Following a regular cleaning

4

schedule for your tape drive will maximize the reliability of your drive

and the life of your LTO tape data cartridges.

Caution: Do not use cleaning cartridges other than a Quantum-

approved LTO cleaning cartridge. Carefully follow all

instructions and recommendations provided with the

cleaning cartridge.

Note: The tape drive can also report its cleaning requirements to the

application software. Your application may notify you when

the tape drive needs cleaning. Refer to your application

documentation for more information.

To clean the tape drive, make sure there is an empty slot available to hold

the cleaning cartridge. Select the

menu on the Operator’s Panel. When you use this option, the autoloader

imports a cleaning cartridge through the cartridge access port and inserts

it into the tape drive. When the cleaning is complete, the tape drive ejects

Clean drive option from the Commands

Page 51

Chapter 4 Operating the Autoloader

Shipping the Autoloader

the cleaning cartridge and the autoloader returns it to the cartridge access

port for removal.

Alternatively, you can store a cleaning cartridge in one of the cartridge

slots. You use the

slot containing the cleaning cartridge into position and load the cartridge

into the tape drive. When the cleaning is complete, the tape drive ejects

the cleaning cartridge and the autoloader returns it to the slot from which

it originated. Although this alternative lets you always have the cleaning

cartridge in the autoloader, it has following disadvantages:

• You have to remember which slot your cleaning cartridge is in.

• The autoloader's data storage capacity is reduced by one cartridge.

Some software applications may support reserving a slot for a cleaning

cartridge and thereby automate the cleaning process. Refer to your

software documentation if your software has this capability.

Load command from the Commands menu to move the

Shipping the Autoloader 4

If you need to ship the autoloader, use the original shipping carton and

packing materials (or replacement packaging obtained from the vendor)

to prevent damage. The shipping carton and packing materials are not

intended to be used for shipping items other than or in addition to the

autoloader.

LTO Ultrium 8-Slot Autoloader User’s Guide 35

Page 52

Chapter 4 Operating the Autoloader

Shipping the Autoloader

36 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 53

Chapter 5

5Troubleshooting and

Diagnostics

The autoloader includes features to support troubleshooting and

diagnostic operations. If an autoloader error occurs, an error message and

error code are displayed on the Operator’s Panel.

Additional diagnostic tests are included on the diagnostic software on the

Resource CD.

Performing a System Test 5

The System Test option cycles the autoloader through the process of

loading, calibrating, and unloading all cartridges in the carousel.

Running a system test verifies the basic operational soundness of the

autoloader and tape drive. The system test continues indefinitely until

you press the Cancel button. All regular backup or restore operations are

suspended while a system test is in progress.

To run a system test:

1 From the main menu, press the Next [+] or Previous [-] button until

Diagnostics appears on the top line of the LCD screen.

2 Press the Enter button.

LTO Ultrium 8-Slot Autoloader User’s Guide 37

System Test is displayed.

Page 54

Chapter 5 Troubleshooting and Diagnostics

Error Codes

3 Press Enter to begin the test. The Test Count displays the number of

load-calibrate-unload cycles that have been completed during the

test.

4 Press the

Cancel button to end the test.

Error Codes 5

T able 5 Oviewview of

Error Codes

Table 6 Robotic

Control Errors

Error Code Hex Notation Error Belonging to

80 - 8F Robotic control errors

90 - 96 Function errors

A0 - A5 Low level axis errors

B0 - B7 Electronic hardware errors

BA - BF Drive errors

Error Code Hex Notation Description

80 No error.

81 Invalid command error. This error

indicates that the Loader received an

undefined command or an invalid

parameter to a command.

82 Device status not suitable to execute this

command. If the robotics are busy, some

commands can't be executed at the same

time. This error will indicate a probable

violation. This is not an error condition,

but does result in busy being reported to

the host for the requested SCSI

command.

38 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 55

Chapter 5 Troubleshooting and Diagnostics

Error Code Hex Notation Description

83 Inventory not valid. The cartridge

inventory is not valid, because of

manual changes or previous fatal errors.

In such case, the inventory must be

updated by appropriate

commands.

84 Source element not ready. The transport

source element is empty.

85 Destination element not ready. The

destination element is already full.

86 Access door not possible. An attempt to

access the door is rejected, while a media

removal is prevented.

87 Timeout. A timeout condition occurred.

Error Codes

Set Slot Status

Table 7 Function

Errors

88 Communications error during loop-

back.

89 Timeout detected by loader on BHC

testing.

8F No error after autoloader recovery.

Error Code Hex Notation Description

90 Mechanical initialization failure. The

robotic wasn't able to get into its safe

mechanical init position. Manual

intervention will be necessary.

91 Scan failure. Fatal error during cartridge

scan, building up inventory.

92 Preposition failed. Belt positioning error

during the

Preposition command.

LTO Ultrium 8-Slot Autoloader User’s Guide 39

Page 56

Chapter 5 Troubleshooting and Diagnostics

Error Codes

Error Code Hex Notation Description

Table 8 Low Level

Axis Errors

Error Code Hex Notation Description

A0 Belt axis error. Error during cartridge

93 Cartridge mount error. Movement of

cartridge into drive failed.

94 Cartridge dismount error. Failure during

cartridge removal and transport back to

the slot.

95 Import error. Device wasn't able to finish

import of new cartridge without error.

96 Export error. Fatal error during cartridge

export.

carrier movement (position not found).

A1 Slider axis error. Transport slider unable

to reach estimated position.

A2 Gripper position error. Gripper unable to

reach position.

A3 Cartridge pick error. Missing cartridge

during pick operation of gripper.

A4 Door function error. Slider door in front

bezel not in requested position during

device operation.

A5 Fan error. Loader processor has detected

a fan error.

40 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 57

Chapter 5 Troubleshooting and Diagnostics

Error Codes

Table 9 Electronic

Harware Errors

T able 10 Drive Errors

Error Code Hex Notation Description

B0 ROM error.

B1 RAM error.

B2 NVRAM error.

B3 CTC error.

B4 UART error.

B5 Display error.

B6 Memory error.

B7 Timeout on loader command.

Error-Code Hex Notation Description

BA Drive load timeout.

BB Drive unload timeout.

Error and Event Log

BC Over temperature problem.

BD No connection to drive.

BE Generic drive response error.

BF Drive broken, needs repair.

Every autoloader provides an internal error and event log with 64 entries.

This log data is helpful for development and service purposes. The error

5

and event log is accessible through the Operator’s Panel and can be read

out entry by entry.

LTO Ultrium 8-Slot Autoloader User’s Guide 41

Page 58

Chapter 5 Troubleshooting and Diagnostics

Error Codes

Log Entry 5 A negative number in the top line shows the current position in the error

log.

Every log entry consists of a type identifier and two data bytes. This

information is shown on the bottom line of the screen.

Entry: AA BB CC AA type identifier

BB data type 1

CC data byte 2

Table 11 Example of

Error/Evemt Log

Display

EVENT -6

03 A0 00

• Sequence number -6 indicates the position in sequence list, 0 being

the most recent.

• Log shows a belt axis error (type identifier: 03 = error, data byte 1: A0

= belt axis error, data byte 2: 00 is not used).

The following entry modes can be assigned by the type identifier:

Table 12 Entry

Modes

Type Description

01 Internal robotic command message which is received by

RobCtrl Module. Data byte 1 will show the command, data

byte 2 means its first parameter (usually cartridge number).

02 Internal robotic command message which is received by

RobTest Module. Data byte 1 will show the command, data

byte 2 means its first parameter (usually cartridge number).

03 Indicates an error message. Errors are represented by the

same codes as described before in this interface specification.

Data byte 2 is not used in this mode.

42 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 59

Chapter 5 Troubleshooting and Diagnostics

Error Codes

Type Description

04 Represents a motion script information. Data byte 1 points to

the current script number, data byte 2 points to the last line

executed in the script. The provided information is rather

extensive and needs to be verified by the developer of the

particular script.

05 Indicates a debug output. This type can be used by a software

developer to fix special problems. Data byte 1 and data byte 2

are free for any usage and may depend on the investigated

problem. This type will only be used during the development

phase.

LTO Ultrium 8-Slot Autoloader User’s Guide 43

Page 60

Chapter 5 Troubleshooting and Diagnostics

Error Codes

44 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 61

Appendix A

ASpecifications

This chapter provides technical specifications for the LTO Ultrium 8-Slot

Autoloader.

The topics covered in this chapter are:

• Size and Weight

• SCSI Interface

• Performance Specifications

• Power Specifications

• Environmental Specifications

• Acoustic Noise Limits

• Shock and Vibration

• Disposal of Electrical and Electronic Equipment

LTO Ultrium 8-Slot Autoloader User’s Guide 45

Page 62

Appendix A Specifications

Size and Weight

Size and Weight 1

Length

Width 16.9 inches (42.9 cm)

Height 3.3 inches (8.4 cm)

Weight 19.5 pounds (8.8 kg) without cartridges installed

24.0 inches (60.9 cm)

SCSI Interface 1

The autoloader has a standard LVD SCSI interface. One SCSI cable and

one SCSI terminator are included with the autoloader. Additional cables

and terminators can be ordered from the manufacturer.

The LVD SCSI interface is compatible with a single-ended SCSI bus.

• Do not attach the autoloader to a non-LVD SCSI controller, as this

will degrade the performance of the tape drive and the performance

of your backups.

• Do not attach non-LVD SCSI devices to the same bus cable as your

autoloader, as this will degrade the performance of the tape drive

and the performance of your backups.

• Do not connect the tape drive to a disk RAID controller, as this is not

supported.

• If you are installing an adapter, it is recommended that you purchase

a SCSI LVD controller kit that includes a SCSI cable and SCSI

terminator (unless provided with your autoloader).

• It is strongly recommended that the autoloader not be attached to the

same SCSI bus as your SCSI hard drive(s).

46 LTO Ultrium 8-Slot Autoloader User’s Guide

Page 63

Appendix A Specifications

SCSI Interface

SCSI ID Settings 1 The autoloader contains two SCSI ID settings — one for the autoloader’s

SCSI controller and one for the tape drive. If there is another device

already assigned to these IDs, you will need to change the IDs. For

information on how to do this, see Changing the SCSI ID Settings

.

Table 13 SCSI ID

Default Settlings

Changing the SCSI ID Settings

Autoloader 5

Tape drive 6

To change the SCSI ID settings:

1

1 From the main menu, press the

Configuration displays in the liquid crystal display.

2 Press

3 Press the

Enter to select the Configuration menu.

Previous or Next button until Change SCSI ID displays in the

LCD

4 Press

5 Press the

Enter to select the Change SCSI ID option.

Previous or Next button until Loader displays in the LCD. To

change the SCSI ID of the tape drive, press the

button until

6 Press

7 Press the

8 Press the

Drive displays in the liquid crystal display.

Enter to select the Loader option.

Previous or Next button until the desired SCSI ID displays.

Enter button. Cycle Power for New SCSI ID displays on the

LCD screen.

Previous or Next button until

Previous or Next

9 Turn off the autoloader. Wait a few seconds, and then turn the

autoloader on again. The selected SCSI ID is now set.

Note: If you change the SCSI ID, you may also need to cycle power

on the host server and reconfigure your backup software

before you can use the autoloader. The autoloader and the

tape drive must each have unique SCSI IDs. It is your