Page 1

1

MODE D’EMPLOI

ISTRUZIONI PER L’USO

BEDIENUNGSANLEITUNG

M AN U A L D E INS T RU Ç Õ E S

ATENÇÃO:

MÁQUINA EXLUSIVAMENTE

PARA USO PROFISSIONAL

M AN U A L D E INS T RU C C IO N ES

ATENCIÓN:

MAQUINA DE USO

EXCLUSIVAMENTE PROFESIONAL

ATTENTION:

MACHINE FOR

PROFESSIONAL USE ONLY

ATTENTION:

MACHINE D´UTILISATION

PROFESSIONELLE SEULEMENT

ATTENZIONE:

MACCHINA AD USO

ESCLUSIVAMENTE PROFESSIONALE

WARNUNG:

NUR FÜ PROFESSIONELLE

ANWENOUNG GEEIGNET

R

O PER ATIN G INS T RU C T IO N S

ES

IT

DE

PT

FR

GB

08504300

MÁQUINA DE CAFÉ CON GAS INCORPORADO

COFFEE MACHINE WITH BUILT IN GAS

MACHINE À CAFÉ AVEC GAZ INTÉGRÉ

MACCHINE DA CAFFÈ CON GAS INCORPORATO

GASBETRIEBENE KAFFEEMASCHINE

MÁQUINAS DE CAFÉ COM GÁS INCORPORADO

Page 2

2

Page 3

3

MANUAL PARA EL INSTALADOR AUTORIZADO

Se recomienda seguir fielmente las indicaciones recogidas en el presente manual y se recuerda que deben

comunicar al S.A.T. cualquier anomalía que pudieran encontrar durante los procesos de instalación o

mantenimiento.

PRESTE ATENCIÓN A LOS RIESGOS DE ESTE APARTADO Y SUS RECOMENDACIONES

DE SEGURIDAD

● Todas las conexiones deben efectuarse con la llave general de gas cortada.

● El tubo de conexión debe ser de una única pieza desde la llave de paso a la toma de la máquina.

● Una vez efectuadas las conexiones debe verificarse la ausencia de fugas de gas en la instalación

efectuada.

El fabricante declina toda responsabilidad, caso de incumplimiento de la legislación vigente en el

lugar de instalación de la máquina.

INSTRUCCIONES PARA LA INSTALACION EN MODELOS CON GAS INCORPORADO

NORMATIVA TECNICA

Las máquinas de café cumplen con la norma UNE-EN 203-1:2006+A1:2008 y UNE-EN 203-2-6:2006

ATENCION: La presión de entrada de agua debe de estar entre Max.0,5 y Min.0,2 Mpa.

La máquina debe de ser instalada según la Norma EN 1717 (Protección contra la contaminación del agua

potable).

La instalación de gas deberá cumplir con la legislación y normas de seguridad vigentes en el lugar de instalación

de la máquina.

La instalación de gas deberá incorporar una llave de paso para uso exclusivo de la máquina.

Para efectuar la conexión de la instalación de gas, la máquina dispone en dotación de un racor para la conexión

de un tubo homologado de diámetro interior 9 mm

ATENCION: Recuerde respetar los periodos de caducidad del tubo de conexión según indica la legislación

vigente

Para máquinas con equipo de gas incorporado y que se instalen con dicha energía, se debe tener en cuenta que

la máquina esté dispuesta para GAS BUTANO (G30). En caso de usar otro tipo de Gas seguir las siguientes

instrucciones:

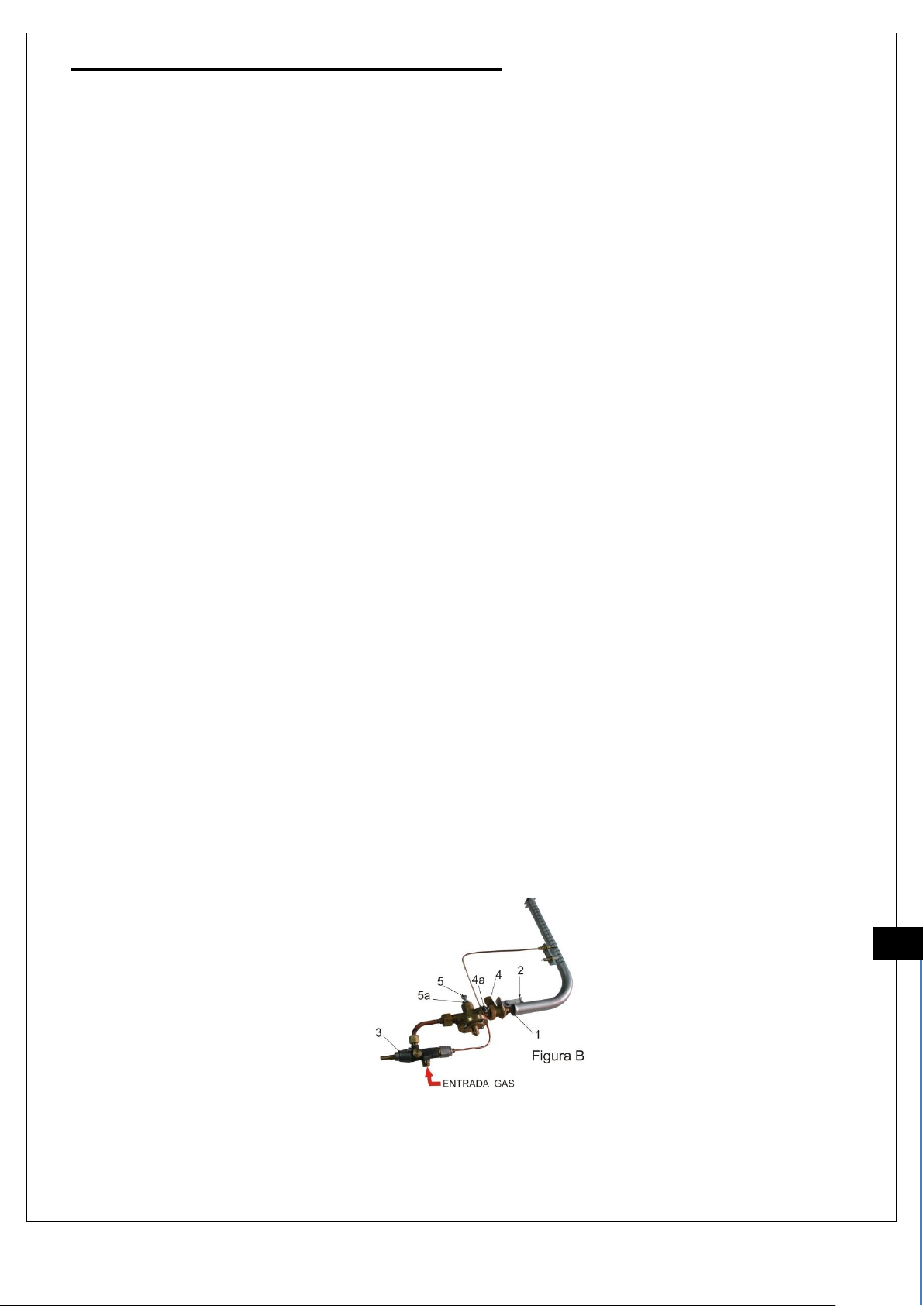

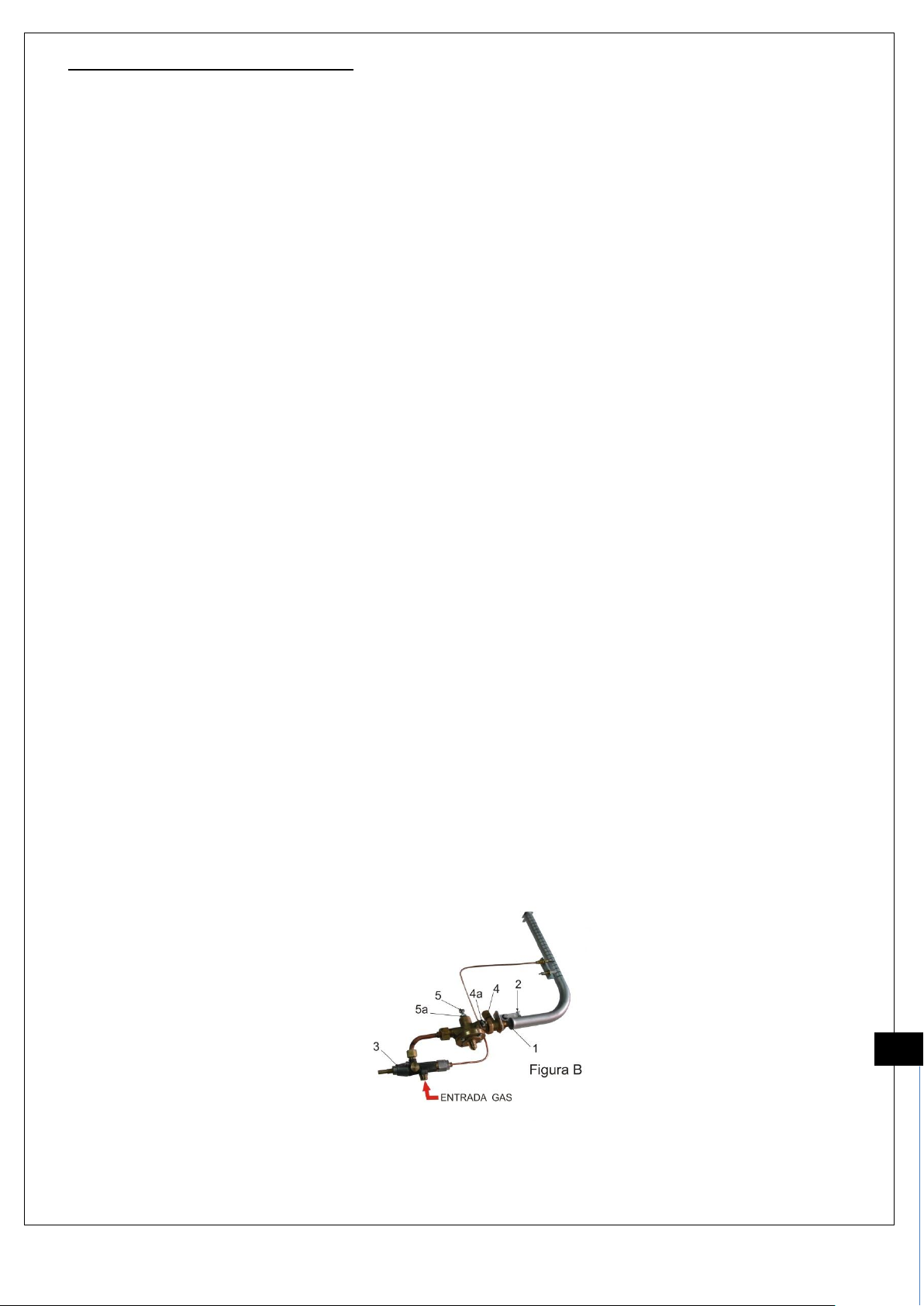

Para otro tipo de gas, desenroscar y sustituir el inyector (1) (Fig. B) por el que corresponde al tipo de gas elegido.

Según tabla adjunta. ( TABLA – A ) . Utilizar únicamente inyectores originales suministrados por el fabricante.

TABLA – A

GAS Y

PRESION

DE

FUNCIONAMIENTO

POTENCIA CALORIFICA

Kcal/h según quemador nº de

Grupos (s /Hi)

CONSUMO Y POTENCIA S/Nº GRUPOS

Ø inyector en mm.

s/nº grupos

CONSUMO

nº grupos

Potencia

KW

CONSUMO

nº grupos

Potencia

KW

CONSUMO

nº grupos

Potencia

KW

CONSUMO

nº grupos

Potencia

KW

1 2 3 4 1 2 3 4 1 2 3

4

G30 a 30

mbar

820

1890

2320

3010

70,97g/h

0,9

173,5g/h

2,2

212,9g/h

2,7

276.01g/h

3,5

0,50

0,75

0,85

1

G20 a 20

mbar

990

1890

2320

3010

0,117 m³/h

1,1

0,233 m³/h

2,2

0,286 m³/h

2,7

0,371 m³/h

3,5

0,80

1,15

1,2

1,5

Una vez hecho el cambio de gas por el instalador autorizado, modificar la placa características de la maquina

marcando el nuevo gas utilizado.

CONEXIÓN A GAS

Conectar la máquina al circuito de gas, asegurando la ausencia de fugas en el circuito. El aparato debe estar

instalado en un lugar bien ventilado para que no haya riesgo para la salud. El caudal de aire necesario para

garantizar una combustion correcta debe ser (≥ 10 m³/h) kW

La instalación de gas, agua y las conexiones, deben estar conformes a las legislaciones vigentes

Page 4

4

PRESOSTATO MODULADOR DE GAS

Controla y regula la presión del vapor en la caldera, aumentando o disminuyendo la llama del quemador, en

función de la presión de la caldera.

Las variaciones de presión actúan sobre una membrana de goma, que acciona la válvula reguladora. Esta abre y

cierra el paso principal del gas.

En derivación con el paso principal del gas, un paso mínimo permite circular una pequeña cantidad de gas, aun

cuando el paso principal esté cerrado.

NOTA: Periódicamente atornillar a fondo ( 2 ó 3 vueltas seguidas ) el tornillo del mínimo; con esta operación se

mantiene limpio el paso, propenso a obstruirse por posos debidos del flujo del gas.

Regulación del presostato modulador del gas ( Fig. B ), partiendo de la máquina fría y sin presión

a) Llenar la caldera de agua.

b) Aflojar las tuercas (4a) y (5a) cerrar completamente el tornillo (4) del mínimo del presostato

modulador del gas y abrir el tornillo del tarado (5).

c) Encender las fuentes de energía

d) Cuando la presión sea de 0,2 bar, inferior al valor deseado para el tarado (normalmente 1 bar en

máquinas semiautomáticas y 1,4 bar en máquinas a palanca ) del presostato modulador del gas,

desconectar la resistencia eléctrica, manteniendo el quemador de gas encendido.

1º Si el presostato modulador de gas está correctamente tarado, la llama del gas se apaga cuando la

aguja del manómetro caldera alcanza el valor deseado.

2º Si la llama del gas se apaga a un valor inferior al deseado, aflojar el tornillo ( 5) y volver a

encender el quemador. Repetir la operación hasta que la llama se apague cuando el manómetro

indique la presión deseada.

3º Si el tarado está demasiado alto, la llama del gas se apaga a valores superiores a los deseados.

Descargar parcialmente la presión de la caldera, apretar el tornillo ( 5 ) y volver a encender el

quemador.

e) Repetir la operación hasta que la desconexión sobrevenga a la presión deseada, y una vez finalizada la

operación bloquear la contratuerca (5a )

f) Terminada la primera fase , regular el tornillo del mínimo (4)

1º Aflojar el tornillo del mínimo ( 4 ) y volver a encender el quemador.

2º Aflojar progresivamente el tornillo del mínimo ( 4 ) hasta que la llama alcance una altura sobre el

plano del quemador de 10 mm. Aproximadamente.

3º Verificar que con esta llama, la presión indicada por el manómetro permanece constante y una

vez finalizada la operación bloquear la contratuerca ( 4a ).

NOTA: Normalmente en el caso de funcionamiento mixto gas ó electricidad, dada la mayor conveniencia del gas,

tarar el presostato a 0,8 bar y el presostato modulador de gas a 1 bar en las máquinas

semiautomáticas y automáticas; en las máquinas a palanca tarar el presostato a 1,2 bar y el presostato

modulador de gas a 1,4 bar.

MÉTODO DE VERIFICACIÓN DE FUNCIONAMIENTO DEL QUEMADOR.

La llama tiene que tener un color azul y sin bordes amarillentos.

La llama no tiene que alejarse del quemador.

Cuando el quemador se encuentra con la llama en su posición de mínimo, ésta debe alcanzar una altura sobre el

plano del quemador de 10 mm. aproximadamente

ES

Page 5

5

MANUAL PARA EL USUARIO

Solo los Servicios Técnicos Autorizados, pueden darle la máxima garantía en cuanto a servicio y recambios

originales. Exija los Recambios Originales, la Instalación y Mantenimiento al Servicio Técnico Oficial.

PRESTE ATENCIÓN A LOS RIESGOS DE ESTE APARTADO Y SUS RECOMENDACIONES DE

SEGURIDAD

● Esta máquina no tiene componentes que pueda reparar el usuario. Solo debe ser manipulada por

personal del Servicio Técnico Autorizado.

● Antes de proceder a cualquier operación de mantenimiento, dejar la máquina sin energía eléctrica

ya sea a través del interruptor general de la instalación o desconectando el cable alimentación.

● Los niños no reconocen los peligros ligados a las maquinas, por lo que deben de mantenerse

alejados de ellas e impedir que las puedan manipular.

● Las personas con las capacidades físicas, sensoriales o mentales disminuidas o el personal sin

experiencia, no deben utilizar esta máquina sin la supervisión de personal cualificado para tal fin.

● Para las operaciones de limpieza, atenerse exclusivamente a las instrucciones del presente

manual.

● Para asegurar un mejor funcionamiento de la máquina, exigir la utilización solo de Recambios

Originales, que puede suministrar el Servicio Técnico autorizado o el fabricante.

El fabricante declina toda responsabilidad, caso de incumplimiento de la legislación vigente en el lugar

de instalación de la máquina.

INSTRUCCIONES DE USO

Para el encendido del quemador de gas, proceder de la siguiente manera:

1º Abrir la llave de gas general ó válvula si es botella.

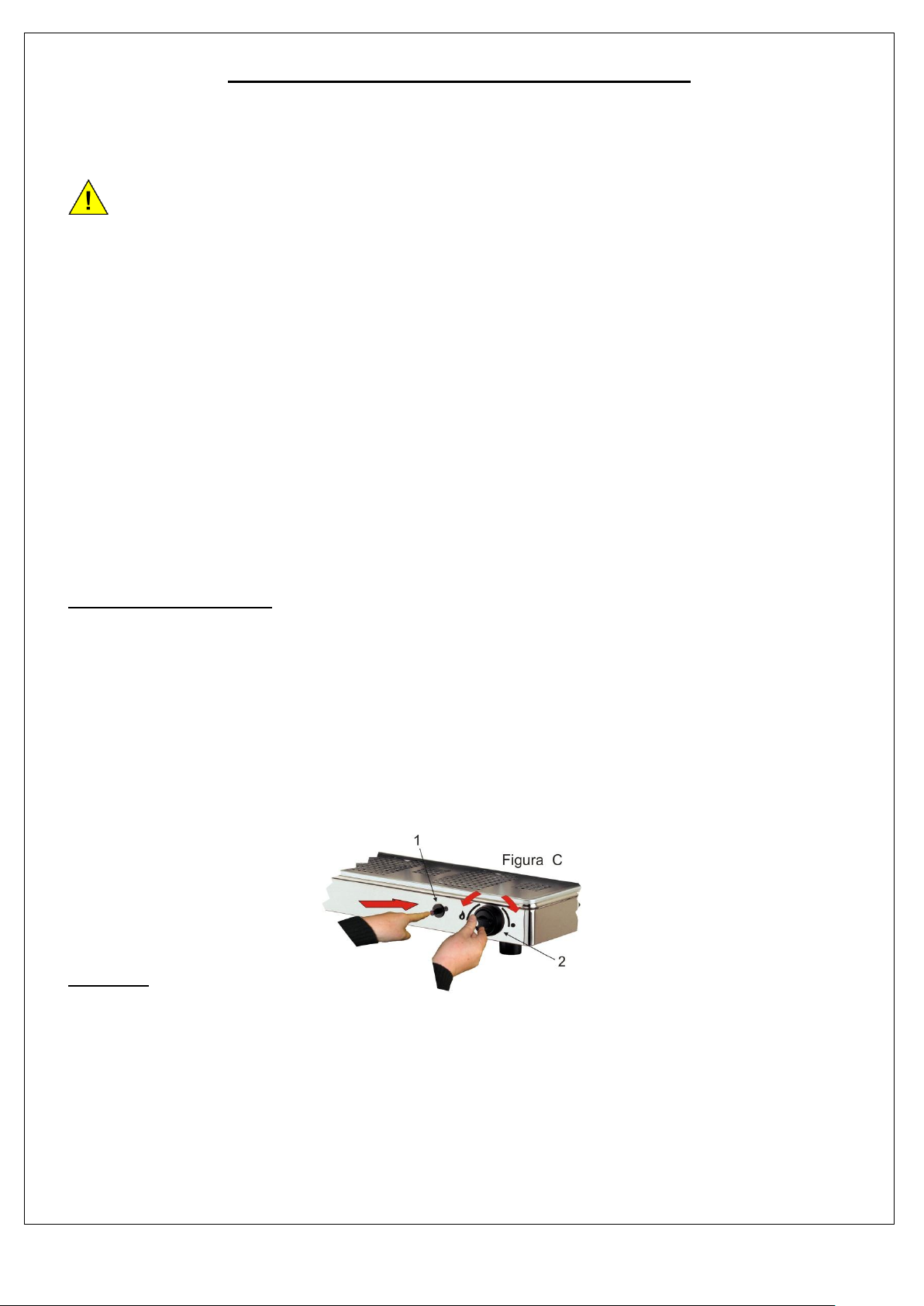

2º Girar el mando gas ( 2 ) hacia la izquierda según ( Fig. C) y pulsar. Prender el quemador pulsando

el pulsador ( 1 ) manteniendo pulsado el mando gas durante 10 segundos. Soltar lentamente.

En caso de querer mantener la presión de la caldera solo con el quemador de gas, colocar el

interruptor general ( 2I, según dibujo del manual de instrucciones general según modelo de

máquina ) en la posición ( “2” ) con lo que quedará desconectada la resistencia.

Al finalizar la jornada de trabajo cerrar la aportación de gas haciendo girar el mando de gas ( 2 )

hacia la derecha hasta la posición ( • )

MANTENIMIENTO

Mantenga las zonas próximas al quemador limpias de polvo u otros elementos.

Con una periocidad semanal y ayudado de un cepillo y con el quemador apagado y frio, limpie las salidas de la

llama, así como la zona donde se ubica el termopar y la zona del inyector del presostato modulador.

Con una periocidad anual, atornillar a fondo ( 2 ó 3 vueltas seguidas ) el tornillo de regulación del mínimo.

Con esta operación se mantiene limpio el paso, propenso a obstruirse por posos debidos al fluido del gas.

No es necesario el engrasado de las llaves de paso.

ATENCION: ESTA OPERACIÓN DEBE SER REALIZADA POR UN INSTALADOR AUTORIZADO

Page 6

6

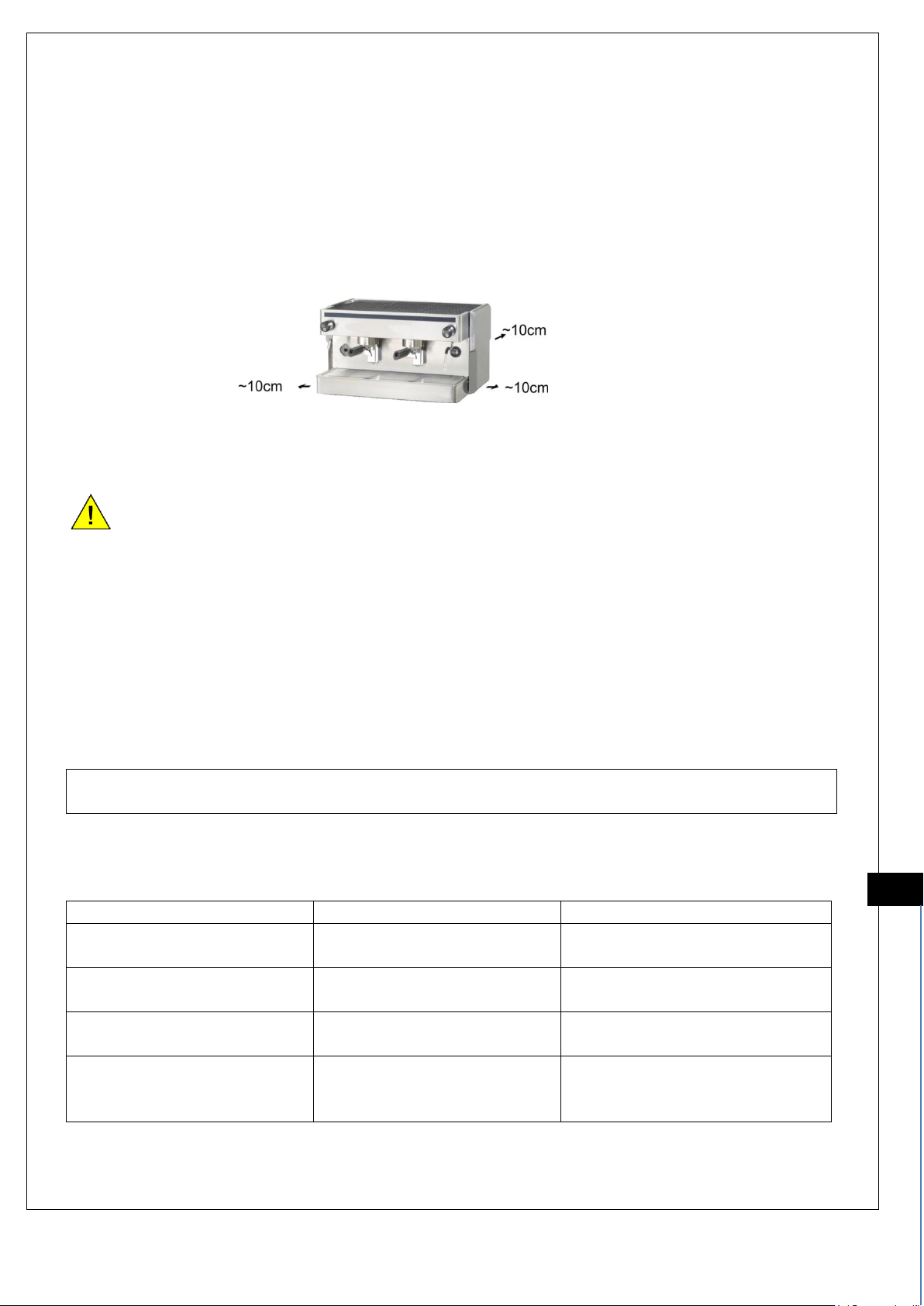

Medidas aproximadas para el espacio de ventilación de las maquinas con gas

ATENCION : El embalaje debe eliminarse de acuerdo con la reglamentación vigente

PRESTE ATENCIÓN A LOS RIESGOS DE ESTE APARTADO Y SUS RECOMENDACIONES DE

SEGURIDAD

● No almacene materiales explosivos ni inflamables cerca de la máquina.

● Mantenga las rejillas de ventilación libres de obstáculos que impidan una adecuada ventilación.

¡ATENCION¡ Si percibe olor a gas:

● Cerrar la llave del gas

● No accionar ningún interruptor eléctrico

● No usar el teléfono en la zona de peligro

● Abrir ventanas y airear el local

● Llame inmediatamente al Servicio Técnico

EL FABRICANTE DECLINA TODA RESPONSABILIDAD POR UN MAL USO DEL EQUIPO

AVERIAS

POSIBLES CAUSAS

OBSERVACION

l quemador no se enciende

No llega gas a la máquina

Comprobar que la llave de paso o

válvula de la botella está abierta

El quemador se apaga cuando

se suelta el mando de gas (2)

El termopar está averiado o

desajustado

Avisar a un instalador autorizado

La llama mínimo no se

mantiene

Presostato modulador de gas

está desajustado o averiado

Avisar a un instalador autorizado

La llama tiene un color amarillo

y la caldera se ahúma

Regulador aire desajustado o

presostato modulador de gas

desajustado

Avisar a un instalador autorizado

ES

Page 7

7

MANUAL FOR THE AUTHORIZED INSTALLER

We recommend closely following the instructions in this manual. Any irregularity encountered during installation

or maintenance should be reported to Authorized Technical Service.

CAREFULLY READ THE RISKS AND SAFETY GUIDELINES IN THIS SECTION

● All the connections should be made with the general gas key closed.

● The connection tube should be one piece from the stopcock to the machine intake.

● Once the connections have been established a check should be done to ensure there are no gas leaks.

The manufacturer accepts no responsibility in the case of failure to comply with the valid legislation

in the location where the machine is installed.

INSTRUCTIONS FOR INSTALLATION OF MODELS WITH BUILT IN GAS

TECHNICAL STANDARDS

The espresso machines comply with regulations UNE-EN 203-1:2006+A1:2008 and UNE-EN 203-2-6:2006

ATTENTION: The pressure of the water inlet should be between Max. 0.5 and Min. 0.2 MPas.

The machine should be installed according to Regulation EN 1717 (Protection against potable water pollution).

The gas installation should comply with the current valid legislation and safety regulations applicable in the

region/country where it is installed.

The gas installation shall incorporate a stopcock for exclusive machine use.

To carry out the gas installation, the machine is outfitted with an adapter for the connection of a standardized 9

mm interior diameter tube.

ATTENTION: It is important to pay attention to the expiration date of the connection tube in accordance with

what the current valid legislation indicates.

For the machines with built-in gas equipment that are installed with gas, keep in mind that the machine is set up

for BUTANE GAS (G30). If another type of gas is used follow these instructions:

For other types of gas, unscrew and replace the injector (1) (Fig. b) with one suited to the type of gas selected,

according to the table (TABLE – A) below. Use only original injectors supplied by the manufacturer.

TABLE – A

GAS AND

OPERATIONAL

PRESSURE

HEAT RATE

Kcal/h according to burner

Group No. (per/Hi)

USAGE AND POWER ACCORDING TO GROUP No.

Ø injector in mm.

per group No.

USAGE

No. groups

Power

KW

USAGE

No. groups

Power

KW

USAGE

No. groups

Power

KW

USAGE

No. groups

Power

KW

1 2 3 4 1 2 3 4 1 2 3

4

G30 to 30

mbar

820

1890

2320

3010

70.97g/h

0.9

173.5g/h

2.2

212.9g/h

2.7

276.01g/h

3.5

0.50

0.75

0.85

1

G20 to 20

mbar

990

1890

2320

3010

0.117 m³/h

1.1

0.233 m³/h

2.2

0.286 m³/h

2.7

0.371m³/h

3.5

0.80

1.15

1.2

1.5

Once the gas change is completed by the authorized installer, update the machine´s data sheet by noting the

new type of gas used.

GAS CONNECTION

Connect the machine to the gas circuit, checking to make sure there are no leaks in the circuit. The device

should be installed in a well-ventilated place to avoid health risks. The necessary airflow should be (≥ 10 m³/h)

kW to ensure correct combustion.

The installation of gas and water and the connections should comply with the current valid legislation

Page 8

8

GAS REGULATOR PRESSURE SWITCH

Control and regulate the steam pressure in the boiler, increasing or decreasing the burner flame according to the

steam boiler pressure.

The pressure changes act on a rubber membrane, which triggers the regulating valve. This opens and closes

the main gas passage.

In addition to the main gas passage, a smaller passage permits a small quantity of gas to circulate, even when

the main passage is closed.

NOTE: Periodically tighten (2 or 3 full rotations) the screw of the smaller passage so as to keep the passage

clear, as it tends to get obstructed by residue from the gas flow.

Adjustment of the gas pressure switch ( Fig. B ), starting with the machine cold and without pressure

a) Fill the boiler with water.

b) Loosen the nuts (4a) and (5a) completely tighten the screw (4) of the smaller passage of the gas

regulator pressure switch and loosen the calibration screw (5).

c) Turn on the power sources.

d) When the pressure reaches 0.2 bars, less than the desired value for the calibration (normally 1 bar for

semi-automatic machines and 1.4 for lever machines) of the gas regulator pressure switch, disconnect

the electrical resistance, keeping the gas burner lit.

1st If the gas regulator pressure switch is correctly calibrated, the gas flame will go out when the water

from the boiler pressure gauge reaches the desired value.

2nd If the gas flame goes out at a lower value than desired, loosen the screw (5) and turn on the burner

again. Repeat the procedure until the flame goes out when the pressure gauge reads the desired

pressure.

3rd If the calibration is too high, the gas flame will go out at higher levels than desired. Partially

decrease the boiler pressure, tighten the screw (5) and turn the burner on again.

e) Repeat the procedure until the disconnection reaches the desired pressure, and once the procedure is

complete lock the locknut (5a).

f) Once the first phase is complete, adjust the screw of the smaller passage (4).

1st Loosen the screw of the smaller passage (4) and turn the burner on again.

2nd Gradually loosen the screw of the smaller passage (4) until the flame reaches a height over the

burner surface of approximately 10 mm.

3rd Verify that with this flame the pressure read on the pressure gauge is constant, and once the

procedure is complete lock the locknut (4a).

NOTE: Normally, if using mixed gas and electricity, calibrate the pressure gauge to 0.8 bars and the gas

regulator pressure switch to 1 bar for semi-automatic and automatic machines; in lever machines, calibrate the

pressure gauge to 1.2 bars and the gas regulator pressure switch to 1.4 bars.

VERIFICATION OF BURNER FUNCTIONING.

The flame must be blue in colour with yellowish edges.

The flame should not be far from the burner.

When the burner flame is at its minimum position, the flame should reach a height of approximately 10 mm

above the burner surface.

GB

Page 9

9

USER MANUAL

Only Authorized Serviced Technicians are qualified to provide the maximum guarantee with regard to service

and original replacement parts. Request Original Replacement Parts, Installation and Maintenance from

Official Technical Service.

CAREFULLY READ THE RISKS AND SAFETY GUIDELINES IN THIS SECTION

● This machine does not have components for the user to make repairs. It can only be manipulated

by personnel from Authorized Technical Service.

● Before starting any maintenance procedure, cut off the electricity either through the general

installation switch or disconnecting the electricity supply cable.

● Children do not recognize the dangers of machines, thus they should be kept out of their reach and

they should be prevented from handling the machines.

● Individuals with diminished physical, sensory or mental capacities, or who are untrained, should not

operate this machine without the supervision of qualified personnel.

● To clean the machine, follow the instructions in this manual.

● To ensure the optimum functioning of the machine, request that only Original Replacement Parts are

used, which can be supplied by authorized Technical Service or the manufacturer.

The manufacturer accepts no responsibility in the case of failure to comply with the valid legislation in

the location where the machine is installed.

INSTRUCTIONS

To turn on the gas burner, follow these instructions:

1st Open the general gas key or valve if it is bottled gas.

2nd Turn the gas switch (2) to the left (as indicated in Fig. C) and press. Turn on the burner pressing the

button (1) and maintaining it for 10 seconds. Release slowly.

If you want to maintain the pressure in the boiler with the gas burner alone, turn the general switch

(2I, as indicated in the general instruction manual drawing according to the machine model) to

position (“2”) which will disconnect the resistance.

At the end of the work day shut off the gas supply by turning the gas switch (2) to the right to position

(•).

MAINTENENCE

Keep the areas immediately surrounding the burner clean and dust-free.

Once a week, with the burner turned off and cooled, clean the flame outlets as well as the areas around the

thermocouple and the pressure switch regulator injector with a brush.

This will keep the passage clear, as it tends to become obstructed by residue from the gas flow.

It is not necessary to grease the stopcocks.

ATTENTION: THIS PROCEDURE SHOULD BE PERFORMED BY AN AUTHORIZED INSTALLER

Page 10

10

Approximate measurements for ventilation space for machines with gas

ATTENTION: Packaging should be disposed of in accordance with the applicable regulations.

CAREFULLY READ THE RISKS OF AND SAFETY GUIDELINES IN THIS SECTION

● Keep explosive and flammable materials at a safe distance from the machine.

● Keep ventilation vents unblocked so as not to hinder adequate ventilation.

ATTENTION! If you detect the smell of gas:

● Close the gas key

● Do not turn on any electrical switches

● Do not use the telephone in the area

● Open the windows and air out the area

● Call Technical Service Immediately

THE MANUFACTURER ACCEPTS NO RESPONSIBILITY IN THE CASE OF IMPROPER

USOFTHE EQUIPMENT

PROBLEM

POSSIBLE CAUSES

COMMENTS

The burner does not turn on

Gas is not reaching the

machine

Check that the stopcock or bottled

gas valve is open

The burner turns off when the

gas switch is released (2)

The thermocouple is broken or

loose

Contact an authorized installer

The minimum flame will not

stay lit

The gas regulator pressure

switch is loose or broken

Contact an authorized installer

The flame is yellow - coloured

and the boiler is smoking

The air regulator is loose or the

gas regulator pressure

switch is loose

Contact an authorized installer

GB

Page 11

11

MANUEL DE L’INSTALLATEUR AGRÉÉ

Il est recommandé de suivre fidèlement les indications rassemblées dans ce manuel et de vous rappeler de

communiquer au Service Après Vente toute anomalie que vous pourriez rencontrer pendant les processus

d’installation ou de maintenance.

FAITES ATTENTION AUX RISQUES ET AUX RECOMMANDATIONS DE CE PARAGRAPHE

DE SÉCURITÉ

● Tous les raccordements doivent être effectués avec le robinet de gaz fermé.

● Le tuyau de raccordement doit être constitué d’une seule pièce depuis le robinet à la prise de la machine.

● Une fois les raccordements effectués vous devez vérifier l’absence de fuites de gaz dans l’installation

terminée

Le fabricant décline toute responsabilité en cas de violation de la législation en vigueur

dans le lieu d’installation de la machine.

INSTRUCTIONS POUR L’INSTALLATION DES MODÈLES AVEC GAZ INTÉGRÉ

NORMES TECHNIQUES

Les machines à café se conforment aux normes UNE-EN 203-1 : 2006+ A1 : 2008 et UNE-EN 203-2-6 : 2006

ATTENTION : La pression d’entrée de l’eau doit être au maximum entre 0,5 et 0,2 Mpa au minimum.

La machine doit être installée selon la norme EN 1717 (Protection contre la contamination de l’eau potable).

Le système de gaz devra être conforme à la législation et aux normes de sécurité en vigueur dans le lieu

d’installation de la machine.

Le système de gaz doit comporter un robinet d’arrêt à usage exclusif de la machine.

Pour établir le raccordement au système de gaz, la machine est fournie avec un raccord pour la connexion d’un

tuyau agréé d’un diamètre intérieur de 9 mm.

ATTENTION : Rappelez-vous de respecter les périodes d’expiration du tuyau de connexion selon la législation en

vigueur

Pour les machines avec équipement de gaz intégré et qui s’installent avec cette énergie, vous devez prendre en

compte que la machine soit prévue pour du GAZ BUTANE (G30). Si vous utilisez un autre type de gaz, suivez les

instructions ci-dessous :

Pour un autre type de gaz, dévissez et remplacez l’injecteur (1) (Fig. B) par celui qui correspond au type de gaz

choisi. Selon le tableau suivant. (TABLEAU – A). Utilisez uniquement les injecteurs originaux fournis par le

fabricant

TABLEAU-A

GAS ET

PRESSION

DE

FONCTION

NEMENT

PUISSANCE THERMIQUE

Kcal/h selon brûleur n˚ de

Groupes (s/Hi)

CONSOMMATION ET PUISSANCE SELON N˚ GROUPES

Ø injecteur en mm.

s/nº groupes

CONSOM.

nº groupes

Puissance

KW

CONSOM.

nº groupes

Puissance

KW

CONSOM.

nº groupes

Puissance

KW

CONSOM.

nº groupes

Puissance

KW

1 2 3 4 1 2 3 4 1 2 3

4

G30 à 30

mbar

820

1890

2320

3010

70,97g/h

0,9

173,5g/h

2,2

212,9g/h

2,7

276,01g/h

3,5

0,50

0,75

0,85

1

G20 à 20

mbar

990

1890

2320

3010

0,117 m³/h

1,1

0,233 m³/h

2,2

0,286 m³/h

2,7

0,371 m³/h

3,5

0,80

1,15

1,2

1,5

Une fois effectué le changement de gaz par l’installateur agréé, modifier les caractéristiques de la plaque en

indiquant le nouveau gaz utilisé.

RACCORDEMENT AU GAZ

Connectez la machine au circuit de gaz, en vous assurant de l’absence de fuites dans le circuit. L’appareil doit

être installé dans un endroit bien ventilé pour éviter tout risque pour la santé. Le débit de l’air nécessaire pour garantir

une combustion correcte doit être (≥ 10 m³/h) kW

L’installation du gaz, de l’eau et des raccordements doivent être conformes aux législations en vigueur.

Page 12

12

PRESSOSTAT MODULATEUR DE PRESSION DE GAZ

Il contrôle et régule la pression de la vapeur dans la chaudière, en augmentant ou diminuant la flamme du brûleur,

en fonction de la pression de la chaudière.

Les variations de pression agissent sur une membrane de caoutchouc, laquelle active la soupape régulatrice de

pression. Celle-ci ouvre et ferme le passage principal du gaz.

En dérivation avec le débit de gaz principal, un débit minimal permet de faire circuler une petite quantité de gaz,

même si le débit principal est fermé.

NOTE : Régulièrement, vissez à fond (2 ou 3 tours consécutifs) la vis du débit minimal. Avec cette opération le

robinet restera propre car il a tendance à se boucher à cause des dépôts dus au flux du gaz.

Réglage du pressostat modulateur de pression du gaz (Fig. B), à partir de la machine à froid et sans

pression

a) Remplissez la chaudière avec de l’eau.

b) Desserrez les écrous (4ª) et (5ª) fermez complètement la vis (4) du débit minimal du pressostat

modulateur de gaz et ouvrez la vis d’étalonnage (5).

c) Allumez les sources d’énergie

d) Lorsque la valeur est de 0,2 bar, en-dessous de la valeur souhaitée pour l’étalonnage (normalement 1 bar

dans les machines semi-automatiques et 1,4 bars dans les machines à levier) du pressostat modulateur de

gaz, déconnectez la résistance électrique, en gardant le brûleur de gaz allumé.

1º Si le pressostat modulateur de gaz est étalonné correctement, la flamme du gaz s’éteint quand

l’aiguille du manomètre de la chaudière atteint la valeur souhaitée.

2º Si la flamme du gaz s’éteint à une valeur inférieure à celle souhaitée, desserrez la vis (5) et

rallumez le brûleur. Refaites l’opération jusqu’à ce que la flamme s’éteigne quand le manomètre

indique la pression souhaitée.

3º Si l’étalonnage est trop élevé, la flamme du gaz s’éteint à des valeurs supérieures à celles

souhaitées. Déchargez partiellement la pression de la chaudière, serrez la vis (5) et rallumez le

brûleur.

g) Répétez l’opération jusqu’à ce que la déconnexion se produise à la pression souhaitée, et une fois

l’opération finalisée bloquez le contre-écrou (5a)

h) la première phase étant terminée, réglez la vis du débit minimal (4)

1º Desserrez la vis du débit minimal (4) et rallumez le brûleur.

2º Desserrez progressivement la vis du débit minimal (4) jusqu’à ce que la flamme atteigne une hauteur

au-dessus du plan du brûleur de 10 mm environ.

3º Vérifiez qu’avec cette flamme la pression indiquée par le manomètre reste constante et une fois

l’opération terminée, bloquez le contre-écrou (4a).

NOTE : Normalement, dans le cas d’un fonctionnement mixte au gaz ou électricité, compte tenu de la commodité

du gaz, étalonnez le pressostat à 0.8 bar et le pressostat modulateur de gaz à 1 bar dans les machines

semi-automatiques et automatiques; dans les machines à levier étalonnez le pressostat de à 1,2 bars et

le pressostat +modulateur de gaz à 1,4 bars.

MÉTHODE DE VÉRIFICATION DE FONCTIONNEMENT DU BRÛLEUR.

La flamme doit avoir une couleur bleue et sans bords jaunâtres.

La flamme ne doit pas s’éloigner du brûleur.

Quand la flamme du brûleur se trouve en position minimale, elle doit atteindre une hauteur au-dessus du plan du

brûleur de 10 mm environ.

FR

Page 13

13

MANUEL DE L’UTILISATEUR

Seuls les Services Techniques Agréés peuvent vous offrir le maximum de garantie en termes de service et pièces

de rechange originales. Exigez des Pièces de Rechange Originales, l’Installation et la Maintenance par le Service

Technique Officiel.

FAITES ATTENTION AUX RISQUES ET RECOMMANDATIONS DE SÉCURITÉ DE CE PARAGRAPHE

● Cette machine n’a pas de composants pouvant être réparés par l’utilisateur. Elle doit être manipulée

uniquement par le personnel du Service Technique Agréé.

● Avant de procéder à toute opération de maintenance, veuillez déconnectez la machine

soit avec l’interrupteur général de l’installation soit en déconnectant le câble d’alimentation

● Les enfants ne se rendent pas compte des dangers liés aux machines, ils doivent donc être gardés

éloignés d’elles afin d’empêcher leur manipulation.

● Les personnes souffrant de handicaps physiques, sensoriels ou mentaux ou le personnel

inexpérimenté ne doivent pas utiliser cette machine sans le contrôle de personnel qualifié.

● Pour les opérations de nettoyage, conformez-vous exclusivement aux instructions de ce manuel.

● Pour garantir un meilleur fonctionnement de la machine, exigez uniquement l’utilisation de Pièces de

Rechange Originales, fournies par le Service Technique Agréé ou le fabricant.

Le fabricant décline toute responsabilité en cas de violation de la législation en vigueur dans le lieu

d’installation de la machine.

INSTRUCTIONS D’USAGE

Pour l’allumage du brûleur de gaz, procédez de la manière suivante :

1º Ouvrez le robinet de gaz général ou le clapet s’il est en bouteille.

2º Tournez la commande du gaz (2) vers la gauche selon (Fig. C) et appuyez. Allumez le brûleur en

appuyant sur le bouton-poussoir (1) en maintenant appuyée la commande du gaz pendant

10 secondes. Lâchez doucement.

Dans le cas où vous voulez maintenir la pression de la chaudière uniquement avec le brûleur de gaz,

placez l’interrupteur général (2I, selon le dessin du manuel d’instructions général du modèle de la

Machine) dans la position (« 2 ») ce qui gardera la résistance déconnectée.

À la fin de la journée de travail, fermez l’entrée de gaz en tournant la commande de gaz (2)

vers la droite jusqu’à la position ( • )

MAINTENANCE

Veillez à maintenir les zones proches du brûleur sans poussière ou autres éléments.

Chaque semaine et avec l’aide d’une brosse, le brûleur éteint et froid, nettoyez les sorties de la flamme, ainsi que

la zone où se trouve le thermocouple et la zone de l’injecteur du pressostat modulateur.

Chaque année, vissez à fond (2 ou 3 tours consécutifs) la vis de régulation du débit minimal.

Grâce à cette opération, le robinet reste propre, car il a tendance à se boucher à cause des dépôts dus au flux du gaz.

Il n’est pas nécessaire de graisser les robinets d’arrêt.

ATTENTION : CETTE OPÉRATION DOIT ÊTRE RÉALISÉE PAR UN INSTALLATEUR AGRÉÉ

Page 14

14

Mesures approximatives pour l’espace de ventilation des machines à gaz

ATTENTION : L’emballage doit être éliminé conformément à la règlementation en vigueur.

FAITES ATTENTION AUX RISQUES ET RECOMMANDATIONS DE SÉCURITÉ DE CE PARAGRAPHE

● N’entreposez pas de matériels explosifs ni inflammables près de la machine.

● Maintenez les grilles d’aération sans obstacles car ils empêcheraient une ventilation appropriée.

ATTENTION ! Si vous sentez une odeur de gaz :

● Fermez le robinet de gaz

● N’actionnez aucun interrupteur électrique

● N’utilisez pas de téléphone dans la zone de danger

● Ouvrez les fenêtres et aérez le local

● Appelez immédiatement le service technique

LE FABRICANT DÉCLINE TOUTE RESPONSABILITÉ EN CAS DE MAUVAISE UTILISATION DE

L’ÉQUIPEMENT

LPANNES

CAUSES POSSIBLES

OBSERVATIONS

Le brûleur ne s’allume pas

Le gaz n’arrive pas à la

machine

Vérifiez que le robinet ou le clapet

de la bouteille est ouvert

Le brûleur s’éteint quand la

commande de gaz est lâchée (2)

Le thermocouple est en panne

ou déréglé

Appelez un installateur agréé

La flamme minimale ne se

maintient pas

Le pressostat modulateur de

gaz est déréglé ou en panne

Appelez un installateur agréé

La flamme a une couleur

jaunâtre et la chaudière fume

Le régulateur d’air ou le

pressostat modulateur de gaz

est déréglé

Appelez un installateur agréé

FR

Page 15

15

MANUALE DI ISTRUZIONI PER L’INSTALLATORE AUTORIZZATO

Si raccomanda di seguire fedelmente le indicazioni contenute nel presente manuale e di comunicare al Centro di

Assistenza Tecnica ogni eventuale anomalia che si dovesse verificare durante il processo di istallazione o

manutenzione.

SI PREGA DI PRESTARE LA MASSIMA ATTENZIONE AI RISCHI DI SEGUITO INDICATI

COMPRESE LE AVVERTENZE DI SICUREZZA

● Prima di effettuare qualsiasi tipo di collegamento, chiudere il rubinetto generale del gas.

● Il tubo di collegamento deve comporsi di un unico pezzo; dal rubinetto di arresto alla presa della macchina.

● Una volta eseguiti i collegamenti, è necessario verificare che l’impianto non presenti fughe di gas.

Il fabbricante declina ogni responsabilità per casi di violazione della normativa vigente nel luogo di

installazione della macchina.

ISTRUZIONI PER L’INSTALLAZIONE DI MODELLI CON GAS INCORPORATO

NORMATIVA TECNICA

Le nostre macchine da caffè sono conformi alle norme UNE-EN 203-1:2006+A1:2008 e UNE-EN 203-2-6:2006.

ATTENZIONE:

La pressione di ingresso dell’acqua deve essere compresa fra un max. di 0,5 MPa e un min. di 0,2 MPa.

La macchina deve essere installata secondo la normativa EN 1717 (Protezione contro l’inquinamento dell’acqua potabile).

L’allacciamento alla rete gas deve avvenire in ottemperanza sia della legislazione che delle disposizioni di

sicurezza vigenti nel luogo di installazione della macchina.

L’allacciamento alla rete gas deve prevedere un rubinetto di arresto esclusivo per la macchina.

Per l’allacciamento alla rete gas, la macchina ha in dotazione un raccordo per il collegamento di un tubo

omologato dal diametro interno di 9 mm.

ATTENZIONE: È essenziale rispettare il periodo di scadenza del tubo di collegamento così come indicato dalla

legislazione vigente.

Per macchine con impianto del gas incorporato ed installate per essere alimentate da tale fonte di energia, si

deve tener presente che l’apparecchio è predisposto per GAS BUTANO (G30). Qualora si utilizzi un tipo di gas

diverso, occorre osservare le seguenti istruzioni:

Svitare e sostituire l’iniettore (1) (Fig. B) con uno adeguato al tipo di gas in questione. Cfr. tabella sottostante

(TABELLA – A). Usare unicamente iniettori originali forniti dal fabbricante.

TABELLA – A

GAS E

PRESSIONE DI

ESERCIZIO

POTENZA TERMICA

Kcal/h secondo bruciatore e

n. gruppi (s /Hi)

CONSUMO E POTENZA SECONDO N. GRUPPI

Ø iniettore in mm.

secondo n. gruppi

CONSUMO

n. gruppi

Potenza

KW

CONSUMO

n. gruppi

Potenza

KW

CONSUMO

n. gruppi

Potenza

KW

CONSUMO

n. gruppi

Potenza

KW

1 2 3 4 1 2 3 4 1 2 3

4

G30 a 30

mbar

820

1890

2320

3010

70,97g/h

0,9

173,5g/h

2,2

212,9g/h

2,7

276.01g/h

3,5

0,50

0,75

0,85

1

G20 a 20

mbar

990

1890

2320

3010

0,117 m³/h

1,1

0,233 m³/h

2,2

0,286 m³/h

2,7

0,371 m³/h

3,5

0,80

1,15

1,2

1,5

Una volta effettuato il cambio ad opera dell’installatore autorizzato, modificare l’etichetta di identificazione della

macchina specificando il tipo di gas utilizzato.

COLLEGAMENTO ALLA RETE GAS

Collegare la macchina alla rete, assicurandosi che non ci siano fughe di gas. L’apparecchio deve essere installato

in un punto ben ventilato, in modo da evitare rischi per la salute. La portata d’aria necessaria a garantire una

corretta combustione dovrà essere non inferiore a (≥ 10 m³/h) kW.

L’allacciamento all’impianto del gas e dell’acqua così come ogni altro tipo di collegamento

devono essere conformi alle norative vigenti.

Page 16

16

PRESSOSTATO GAS A MODULAZIONE

Serve a controllare e regolare la pressione del vapore nella caldaia, aumentando o riducendo la fiamma del

bruciatore in funzione ad essa.

Le variazioni di pressione si ripercuotono su una membrana di gomma che aziona la valvola di regolazione.

Questa, a propria volta, apre e chiude il condotto di alimentazione principale del gas.

In derivazione al condotto principale del gas, un condotto di alimentazione minima permette l’afflusso di una

quantità ridotta di gas anche quando il condotto principale è chiuso.

NOTA: Con periodicamente, avvitare a fondo (2 o 3 giri di seguito) la vite di regolazione del minimo; in questo

modo, si mantiene pulito il condotto, soggetto a ostruirsi a causa dei depositi lasciati dal flusso di gas.

Regolazione del pressostato gas a modulazione (Fig. B), da effettuare con la macchina fredda e senza

pressione

a) Riempire d’acqua la caldaia.

b) Allentare i dadi (4a) e (5a), chiudere completamente la vite del minimo (4) del pressostato gas a

modulazione e aprire la vite per la taratura (5).

c) Accendere le fonti di energia.

d) Quando la pressione raggiunge un valore di 0,2 bar inferiore a quello previsto per la taratura del

pressostato gas a modulazione (generalmente 1 bar per le macchine semiautomatiche e 1,4 bar per i

modelli a leva), scollegare la resistenza elettrica e lasciare acceso il bruciatore di gas.

1º Se il pressostato gas a modulazione è tarato correttamente, la fiamma si spegnerà quando la

lancetta del manometro della caldaia segnerà il valore prefissato.

2º Se la fiamma si spegne in corrispondenza di un valore inferiore a quello prestabilito, allentare la

vite (5) e riaccendere il bruciatore. Ripetere l’operazione fino a far sì che la fiamma si spenga quando

il manometro indica la pressione stabilita.

3º Se il pressostato è tarato su un valore troppo alto, la fiamma si spegnerà una volta raggiunta

una pressione superiore a quella desiderata. Scaricare parzialmente la pressione della caldaia,

stringere la vite (5) e riaccendere il bruciatore.

i) Ripetere l’operazione fino ad ottenere la disattivazione del bruciatore in corrispondenza della pressione

voluta, poi serrare il controdado (5a).

j) Conclusa la prima fase, regolare la vite del minimo (4).

1º Allentare la vite del minimo (4) e riaccendere il bruciatore.

2º Allentare progressivamente la vite del minimo (4) fino a ottenere una fiamma alta circa 10 mm

rispetto al piano del bruciatore.

3º Verificare che con questa fiamma la pressione indicata dal manometro si mantenga constante, poi

serrare il controdado (4a).

NOTA: In considerazione della maggiore convenienza del gas, nelle macchine a funzionamento misto, a gas o

elettrico, si consiglia la seguente taratura: nel caso di apparecchi semiautomatici o automatici, pressostato

a 0,8 bar e pressostato gas a modulazione a 1 bar; in caso di modelli a leva, pressostato a 1,2 bar e

pressostato gas a modulazione a 1,4 bar.

VERIFICA DEL CORRETTO FUNZIONAMENTO DEL BRUCIATORE

La fiamma deve essere azzurra e non avere bordi tendenti al giallo.

La fiamma non deve allontanarsi dal bruciatore.

Quando è al minimo, la fiamma deve raggiungere un’altezza di circa 10 mm. rispetto al piano del bruciatore.

Page 17

17

MANUALE DI ISTRUZIONI PER L’UTENTE

Solo i Centri di Assistenza Tecnica autorizzati possono offrire l’assoluta garanzia di qualità del servizio e fornire

pezzi di ricambio originali. Per i ricambi, l’installazione e la manutenzione, rivolgersi sempre a un Centro di

Assistenza Tecnica Ufficiale.

SI PREGA DI PRESTARE LA MASSIMA ATTENZIONE AI RISCHI QUI DESCRITTI E ALLE

AVVERTENZE DI SICUREZZA

● Nessuno dei componenti di questa macchina può essere riparato dall’utente. L’apparecchio

deve essere maneggiato unicamente dal personale del Servizio di Assistenza Tecnica Autorizzato.

● Prima di qualsiasi intervento di manutenzione, scollegare l’apparecchio dalla rete elettrica, spegnendo

l’interruttore generale dell’impianto o staccando il cavo di alimentazione.

● I bambini non riconoscono i pericoli potenziali di una macchina. Pertanto, non gli si deve permettere

di avvicinarsi e toccarla.

● L’apparecchio non è destinato a essere utilizzato da persone con ridotte capacità fisiche, sensoriali o

mentali, o prive della sufficiente esperienza e conoscenza, senza la supervisione di personale

qualificato.

● Per la pulizia della macchina, attenersi esclusivamente alle istruzioni fornite dal presente manuale.

● A garanzia di un migliore funzionamento dell’apparecchio, richiedere sempre pezzi di ricambio

originali, che possono essere forniti dal Centro di Assistenza Tecnica Autorizzato o dal produttore.

Il fabbricante declina ogni responsabilità per casi di violazione della normativa vigente nel luogo di

installazione della macchina.

ISTRUZIONI PER L’USO

Per accendere il bruciatore di gas, procedere come segue:

1º Aprire il rubinetto generale del gas o la valvola, qualora si tratti di una bombola.

2º Ruotare il comando del gas (2) verso sinistra (cfr. Fig. C) e premere. Accendere il bruciatore usando

il pulsante (1) e tenere premuto il comando del gas per 10 secondi. Rilasciare lentamente.

Se si desidera mantenere la pressione della caldaia solo con il bruciatore di gas, posizionare

l’interruttore generale (2I, secondo il disegno del manuale generale di istruzioni del modello

corrispondente alla propria macchina) sul ("2"), in modo da scollegare la resistenza.

Alla fine della giornata di lavoro, bloccare l’afflusso di gas ruotando il comando del gas (2) verso destra

fino a portarlo nella posizione contrassegnata dal punto (•).

MANUTENZIONE

Mantenere pulita da polvere o elementi di altro tipo l’area circostante al bruciatore.

Una volta alla settimana, usando una spazzola e facendo attenzione che il bruciatore sia spento e freddo, pulire i

fori di uscita della fiamma, la zona della termocoppia e quella dell’iniettore del pressostato a modulazione.

Una volta all’anno, avvitare a fondo (2 o 3 giri di seguito) la vite di regolazione del minimo.

In questo modo, si mantiene pulito il condotto, incline a ostruirsi a causa dei depositi lasciati dal flusso di gas.

Non è necessaria la lubrificazione dei rubinetti di arresto.

ATTENZIONE: QUESTA OPERAZIONE DEVE ESSERE ESEGUITA DA UN INSTALLATORE AUTORIZZATO

Page 18

18

Misure approssimative dello spazio necessario a garantire una corretta ventilazione di un apparecchio a gas:

ATTENZIONE: Lo smaltimento dell’imballaggio deve avvenire in conformità alle normative vigenti.

SI PREGA DI PRESTARE LA MASSIMA ATTENZIONE AI RISCHI QUI DESCRITTI E ALLE

AVVERTENZE DI SICUREZZA

● Non conservare materiale esplosivo o infiammabile in prossimità della macchina.

● Mantenere le griglie di ventilazione libere da ostacoli che ne impediscano un’adeguata ventilazione.

ATTENZIONE! Se si sente odore di gas:

● Chiudere il rubinetto principale

● Non azionare nessun interruttore elettrico

● Non utilizzare il telefono nella zona di pericolo

● Aprire le finestre e arieggiare il locale

● Chiamare immediatamente il Centro di Assistenza Tecnica

IL FABBRICANTE DECLINA OGNI RESPONSABILITÀ PER UN USO IMPROPRIO DELL’APPARECCHIO

AVARIE

POSSIBILI CAUSE

OSSERVAZIONI

Il bruciatore non si accende

Non arriva gas alla macchina

Controllare che il rubinetto di arresto o

la valvola della bombola siano aperti

Il bruciatore si spegne quando si

rilascia il comando del gas (2)

Termocoppia guasta o non

regolata correttamente

Rivolgersi a un installatore autorizzato

La fiamma minima non è stabile

Pressostato gas a modulazione

non regolato correttamente o

guasto

Rivolgersi a un installatore autorizzato

La fiamma è gialla e la caldaia si

riempie di fumo

Regolatore dell’aria o pressostato

gas a modulazione non regolati

correttamente

Rivolgersi a un installatore autorizzato

Page 19

19

BEDIENUNGSANLEITUNG FÜR ZUGELASSENE INSTALLATEURE

Es wird empfohlen die in dieser Bedienungsanleitung enthaltenen Anweisungen genau zu befolgen und darauf

hingewiesen, dass dem Technischen Dienst jegliche Anomalie mitgeteilt werden muss, die während des

Installationsprozesses oder der Wartungsarbeiten festgestellt wird.

ACHTEN SIE AUF DIE GEFAHREN DIESES GERÄTS UND DIE SICHERHEITSRATSCHLÄGE

● Alle Verbindungen und Anschlüsse müssen mit geschlossener Hauptabsperreinrichtung der Gasleitung

durchgeführt werden.

● Das Verbindungsrohr muss aus einem einzigen Stück bestehen, vom Absperrventil bis zum Anschlussteil

der Kaffeemaschine.

● Nachdem die Anschlüsse vorgenommen worden sind, ist zu überprüfen, ob die Gasinstallation undichte

Stellen aufweist.

Der Hersteller lehnt jegliche Verantwortung ab, wenn der Installationsstandort für die Maschine nicht die

Bestimmungen der geltenden Gesetzgebung erfüllt.

ANWEISUNGEN FÜR INSTALLATIONEN AN GASBETRIEBENEN MODELLEN

TECHNISCHE BESTIMMUNGEN

Die Kaffeemaschinen erfüllen die Norm UNE-EN 203-1:2006+A1:2008 und die Norm UNE-EN 203-2-6:2006

ACHTUNG: Der Wasserdruck darf am Eingang bei maximal 0,5 und bei mindestens 0,2 Mpa liegen.

Die Maschine muss gemäß der Norm EN 1717 (Schutz des Trinkwassers gegen Verunreinigungen) installiert werden.

Die Gasinstallation muss die Gesetzgebung und die geltenden Sicherheitsbestimmungen für den

Installationsstandort der Maschine erfüllen.

Die Gasinstallation muss ein Absperrventil zur ausschließlichen Nutzung der Maschine aufweisen.

Um den Anschluss der Gasinstallation durchzuführen, verfügt die Maschine über ein Verbindungsstück für den

Anschluss an ein amtlich geprüftes Rohr mit 9 mm Durchmesser.

ACHTUNG: Vergessen Sie nicht das Haltbarkeitsdatum des Verbindungsrohrs gemäß der geltenden

Gesetzgebung einzuhalten.

Für Maschinen mit eingebauten Gasgeräten, die mit dieser Energieform installiert werden, muss darauf geachtet

werden, dass die Maschine zur Nutzung von BUTANGAS (G30) gefertigt ist. Für den Fall, dass eine andere

Gasart verwendet wird, befolgen Sie bitte die nachfolgenden Anweisungen:

Für eine andere Gasart die Düse (1) (Abb. B) abschrauben und entsprechend der ausgewählten Gasart gegen

eine andere austauschen. Gemäβ der beigefügten Tabelle. ( TABELLE - A ). Nur die vom Hersteller gelieferten

Original-Düsen verwenden.

TABELLE – A

GAS UND

BETRIEBS

DRUCK

WÄRMELEISTUNG

Kcal/h gemäβ Brenner

Anzahl Brühgruppen. (g /Hi)

VERBRAUCH UND LEISTUNG G/ ANZAHL BRÜHGRUPPEN

Ø Düse in mm.

g/ Anzahl Brühgruppen

Anzahl

Brühgruppen

Leistung

KW

Anzahl

Brühgruppen

Leistung

KW

Anzahl

Brühgruppen

Leistung

KW

Anzahl

Brühgruppen

Leistung

KW

1 2 3 4 1 2 3 4 1 2 3

4

G30 bei

30 mbar

820

1890

2320

3010

70,97g/h

0,9

173,5g/h

2,2

212,9g/h

2,7

276.01g/h

3,5

0,50

0,75

0,85

1

G20 bei

20 mbar

990

1890

2320

3010

0,117 m³/h

1,1

0,233 m³/h

2,2

0,286 m³/h

2,7

0,371 m³/h

3,5

0,80

1,15

1,2

1,5

Nachdem der Gaswechsel von einem zugelassenen Installateur vorgenommen wurde, werden die Eigenschaften

der Maschine auf der Plakette geändert und die neu verwendete Gasart dort angeben.

GASANSCHLUSS

Die Maschine an den Gaskreislauf anschließen und sicherstellen, dass es keine undichten Stellen im

Leitungssystem gibt. Das Gerät muss an einem gut gelüfteten Ort installiert werden, damit keine

Gesundheitsrisiken bestehen. Die erforderliche Luftmenge, um eine korrekte Verbrennung zu gewährleisten, liegt

bei (≥ 10 m³/h) kW

Die Gas- und Wasserinstallation und alle Anschlüsse müssen gemäß der geltenden Gesetzgebung

vorgenommen werden.

Page 20

20

DRUCKREGLER/GASMODULATOR

Dieser prüft und regelt den Dampfdruck im Kessel, erhöht oder reduziert je nach Druck im Kessel die Flamme des

Brenners.

Die Druckschwankungen wirken auf eine Gummi-Membran ein, die das Regelventil betätigt. Dieses wiederum

öffnet und schlieβt den Haupt-Gasdurchlauf.

In einer Ableitung der Haupt-Gasleitung ermöglicht eine Kleinststufen-Einstellung den Durchlauf einer kleinen

Gasmenge, auch wenn der Hauptdurchlauf verschlossen ist.

HINWEIS: Die Kleinststufen-Einstellschraube regelmäßig bis zum Anschlag festschrauben (2 oder 3 Drehungen

nacheinander); mit dieser Operation wird der Durchlauf sauber gehalten, denn dieser ist anfällig für Verstopfungen

durch Reststoffe, die sich infolge des Gasstroms ansammeln.

Regulierung des Druckreglers/Gasmodulators (Abb. B), die bei kalter Maschine ohne Druck vorgenommen

werden muss.

a) Den Kessel mit Wasser füllen.

b) Die Schrauben (4a) und (5a) lösen, die Kleinststufen-Einstellschraube (4) des Druckreglers/Gasmodulators

vollständig schließen und die Kalibrierschraube (5) öffnen.

c) Die Energiequellen zünden

d) Wenn der Druck bei 0,2 bar liegt, unterhalb des erwünschten Eichwerts (normalerweise 1 bar bei

halbautomatischen Maschinen und 1,4 bar bei Hebelmaschinen) des Druckreglers/Gasmodulators, dann

schalten Sie den elektrischen Widerstand ab, lassen den Gasbrenner jedoch gezündet.

1. Wenn der Druckregler/Gasmodulator sachgerecht kalibriert ist, erlischt die Gasflamme wenn der

Zeiger auf dem Manometer des Kessels den erwünschten Wert erreicht.

2. Wenn die Gasflamme bei einem geringeren Wert als dem erwünschten erlischt, dann muss die

Schraube (5) etwas gelöst und der Brenner erneut gezündet werden. Diese Operation solange

wiederholen, bis die Flamme erlischt, wenn das Manometer den erwünschten Druck anzeigt.

3. Wenn die Kalibrierung zu hoch ist, erlischt die Gasflamme bei Werten, die oberhalb der erwünschten

Werte liegen. Den Kesseldruck teilweise reduzieren, die Schraube ( 5 ) anziehen und den Brenner

neu zünden.

k) Die Operation so oft wiederholen, bis die Abschaltung bei dem erwünschten Druck eintritt und nachdem die

Operation beendet ist, mit der Sicherungsmutter (5a) kontern.

l) Wenn die erste Phase abgeschlossen ist, die Kleinststufen-Einstellschraube (4) regulieren

1. Die Kleinststufen-Einstellschraube (4) etwas lösen und den Brenner erneut zünden.

2. Die Kleinststufen-Einstellschraube (4) nach und nach lösen bis die Flamme eine Höhe von ungefähr

10 mm über der Oberkante des Brenners erreicht.

3. Es ist zu überprüfen, dass mit dieser Flamme der auf dem Manometer angegebene Druck

konstant beibehalten wird und nachdem die Operation abgeschlossen ist, mit der Sicherungsmutter

(4a) zu kontern.

HINWEIS: Normalerweise ist im Falle eines gemischten Betriebs mit Gas oder Strom, aufgrund der größeren

Zweckmäßigkeit von Gas, der Druckregler auf 0,8 bar zu kalibrieren und der Druckregler/Gasmodulator bei

halbautomatischen und automatischen Maschinen auf 1 bar; bei Hebel-Kaffeemaschinen sollte der Druckregler auf

1,2 bar eingestellt werden und der Druckregler/Gasmodulator auf 1,4 bar.

BETRIEBSPRÜFVERFAHREN DES BRENNERS.

Die Flamme muss blau sein und darf keine gelblichen Ränder aufweisen.

Die Flamme darf sich nicht vom Brenner entfernen.

Wenn die Flamme des Brenners auf Kleinststufe eingestellt ist, muss diese eine Höhe von ca. 10 mm über der

Oberkante des Brenners aufweisen.

DE

Page 21

21

BEDIENUNGSANLEITUNG FÜR DEN BENUTZER

Nur zugelassene Technische Dienste können Ihnen beim Service und dem Austausch von Original-Ersatzteilen

eine maximale Garantie gewährleisten. Verlangen Sie Original-Ersatzteile und lassen Sie die Installation sowie

die Wartung vom offiziellen Technischen Dienst durchführen.

ACHTEN SIE AUF DIE GEFAHREN DIESES GERÄTS UND DIE SICHERHEITSRATSCHLÄGE

● Diese Maschine enthält keine Bestandteile, die vom Benutzer repariert werden können. Sie darf

ausschlieβlich von dem Fachpersonal des zugelassenen Technischen Dienstes gehandhabt werden.

● Bevor eine jegliche Wartungsarbeit vorgenommen wird, muss die Energiezufuhr der Maschine

abgeschaltet werden, sei es über den Hauptschalter der Installation oder durch Herausziehen des

Stromkabels.

● Kinder erkennen die von Maschinen ausgehenden Gefahren nicht und müssen daher von diesen fern

gehalten werden, es muss auβerdem vermieden werden, dass Kinder an diesen herumhantieren.

● Personen, deren körperlichen, sensoriellen und geistigen Fähigkeiten eingeschränkt sind, oder

unerfahrenes Personal, dürfen diese Maschine ohne die Aufsicht von geschultem Personal nicht

verwenden.

● Für Reinigungsoperationen halten Sie sich ausdrücklich an die in dieser Anleitung aufgeführten

Anweisungen.

● Um einen besseren Betrieb der Maschine sicher zu stellen, verlangen Sie nur Original-Ersatzteile, die

von dem zugelassenen Technischen Dienst oder dem Hersteller geliefert werden.

Der Hersteller lehnt jegliche Verantwortung ab, wenn der Installationsstandort für die Maschine nicht die

Bestimmungen der geltenden Gesetzgebung erfüllt.

NUTZUNGSANWEISUNGEN

Zur Zündung des Gasbrenners gehen Sie auf folgende Weise vor:

1º Den Hauptgashahn oder das Ventil öffnen, wenn es sich um eine Gasflasche handelt.

2º Den Regelknopf (2) gemäβ (Abb. C) nach links drehen und drücken. Den Brenner zünden, indem der

Druckknopf (1) gedrückt wird und der Regelknopf 10 Sekunden lang gedrückt bleibt. Danach

langsam loslassen.

Für den Fall, dass der Kesseldruck nur mit dem Brenner beibehalten werden soll, ist der Hauptschalter

(2) gemäβ der Abbildung der Bedienungsanleitung mit den allgemeinen Anweisungen je nach

Maschinenmodell) auf die Position („2“) zu stellen, wodurch der Widerstand abgeschaltet wird.

Nach Beendigung des Arbeitstags die Gaszufuhr abschalten, indem der Regelknopf (2) nach rechts

bis zur Position ( • ) gedreht wird.

WARTUNG

Die Bereiche in der Nähe des Brenners sauber und frei von Staub und sonstigen Elementen halten.

Einmal wöchentlich und mithilfe einer Bürste bei abgeschaltetem und kaltem Brenner die Flammöffnungen sowie den

Bereich, an dem sich das Thermoelement befindet und der Bereich der Düse des Druckreglers/Modulators reinigen.

Einmal jährlich muss die Kleinststufen-Einstellschraube bis zum Anschlag angezogen werden (2 oder 3

Drehungen hintereinander).

Mit dieser Operation wird der Durchlauf sauber gehalten, denn dieser ist anfällig für Verstopfungen durch

Reststoffe, die sich infolge des Gasstroms ansammeln.

Die Absperrventile müssen nicht eingefettet werden.

ACHTUNG: DIESE OPERATION MUSS VON EINEM ZUGELASSENEN INSTALLATEUR VORGENOMMEN

WERDEN.

Page 22

22

Ungefähre Abmessungen für den Belüftungsraum der gasbetriebenen Kaffeemaschinen

ACHTUNG : Die Verpackung ist in Übereinstimmung mit den geltenden Vorschriften zu entsorgen

ACHTEN SIE AUF DIE GEFAHREN DIESES GERÄTS UND DIE SICHERHEITSRATSCHLÄGE

● Lagern Sie keine explosiven noch leicht entzündbare Stoffe in der Nähe der Kaffeemaschine.

● Halten Sie die Lüftungsgitter frei von Hindernissen, die eine angemessene Lüftung verhindern.

ACHTUNG! Wenn Sie Gasgeruch wahrnehmen:

● Den Gashahn schlieβen

● Keinen elektrischen Schalter betätigen

● Kein Telefon in dem Gefahrenbereich verwenden

● Fenster öffnen und das Lokal durchlüften

● Rufen Sie umgehend den Technischen Dienst an

DER HERSTELLER LEHNT JEGLICHE VERANTWORTUNG FÜR EINE UNSACHGEMÄβE

NUTZUNG DES GERÄTS AB.

STÖRUNGN

MÖGLICHE GRÜNDE

BEMERKUNGEN

Der Brenner zündet nicht

Das Gas gelangt nicht in die

Maschine

Überprüfen, ob der Gashahn oder

das Absperrventil der Gasflasche

geöffnet sind.

Der Brenner geht aus, wenn

der Regelknopf (2) losgelassen

wird

Das Thermoelement ist

beschädigt oder falsch

eingestellt

Einen zugelassenen Installateur

benachrichtigen

Die Kleinststufen-Flamme hält

sich nicht

Der Druckregler/Gasmodulator

ist beschädigt oder falsch

eingestellt

Einen zugelassenen Installateur

benachrichtigen

Die Flamme weist eine gelbe

Farbe auf und der Kessel riecht

nach Rauch

Der Luftregler oder der

Druckregler/Gasmodulator sind

verstellt

Einen zugelassenen Installateur

benachrichtigen

DE

Page 23

23

MANUAL PARA O INSTALADOR AUTORIZADO

Recomenda-se seguir fielmente as indicações recolhidas no presente manual e lembramos que deve comunicar

ao S.A.T. qualquer anomalia que possa encontrar durante os processos de instalação ou manutenção.

PRESTE ATENÇÃO AOS RISCOS DESTA SECÇÃO E ÀS SUAS RECOMENDAÇÕES DE

SEGURANÇA

● Todas as ligações devem ser efectuadas com a chave geral de gás desligada.

● O tubo de ligação deve ser de uma única peça desde a chave de passagem à tomada da máquina.

● Depois de efectuadas as ligações deve verificar-se a ausência de fugas de gás na instalação efectuada.

O fabricante declina qualquer responsabilidade, no caso de não cumprimento da legislação vigente no

local de instalação da máquina.

INSTRUÇÕES PARA A INSTALAÇÃO EM MODELOS COM GÁS INCORPORADO

NORMATIVA TÉCNICA

As máquinas de café cumprem com a norma UNE-EM 203-1:2006+A1:2008 e UNE-EM 203-2-6:2006

ATENÇÃO: A pressão de entrada de água deve estar entre Max.0,5 e Min.0,2 Mpa.

A máquina deve ser instalada segundo a Norma EM 1717 (Protecção contra a contaminação da água potável).

A instalação de gás deverá cumprir com a legislação e normas de segurança vigentes no local de instalação da

máquina.

A instalação de gás deverá incorporar uma chave de passagem para uso exclusivo da máquina.

Para efectuar a ligação da instalação de gás, a máquina dispõe em dotação de uma união para a ligação de um

tubo homologado com diâmetro interior de 9 mm

ATENÇÃO: Lembre-se de respeitar os períodos de validade do tubo de ligação segundo as indicações da

legislação vigente

Para máquinas com equipamento de gás incorporado e que se instalem com a dita energia, deve ter-se em conta

que a máquina está preparada para GÁS BUTANO (G30). No caso de usar outro tipo de Gás siga as seguintes

instruções:

Para outro tipo de gás, desenroscar e substituir o injector (1) (Fig. B) pelo que corresponde ao tipo de gás

escolhido. Segundo a tabela anexa. (TABELA - A) . Utilizar unicamente injectores originais fornecidos pelo

fabricante.

TABELA – A

GÁS E

PRESSÃO

DE

FUNCIONAMENTO

POTÊNCIA CALORÍFICA

Kcal/h de acordo com o

queimador nº de Grupos (s

/Hi)

CONSUMO E POTÊNCIA S/Nº GRUPOS

Ø injector em mm.

s/nº grupos

CONSUMO

nº grupos

Potência

KW

CONSUMO

nº grupos

Potência

KW

CONSUMO

nº grupos

Potência

KW

CONSUMO

nº grupos

Potência

KW

1 2 3 4 1 2 3 4 1 2 3

4

G30 a 30

mbar

820

1890

2320

3010

70,97g/h

0,9

173,5g/h

2,2

212,9g/h

2,7

276.01g/h

3,5

0,50

0,75

0,85

1

G20 a 20

mbar

990

1890

2320

3010

0,117 m³/h

1,1

0,233 m³/h

2,2

0,286 m³/h

2,7

0,371 m³/h

3,5

0,80

1,15

1,2

1,5

Depois de feita a mudança de gás pelo instalador autorizado, modificar a placa de características da máquina

marcando-a com o novo gás utilizado.

LIGAÇÃO A GÁS

Ligar a máquina ao circuito de gás, assegurando a ausência de fugas no circuito. O aparelho deve estar instalado

num local bem ventilado para que não haja riscos para a saúde. O volume de ar necessário para garantir uma

combustão correcta deve ser (≥ 10 m³/h) kW

A instalação de gás, água e as ligações, devem estar conformes às legislações vigentes

Page 24

24

PRESSOSTATO MODULADOR DE GÁS

Controla e regula a pressão do vapor na caldeira, aumentando ou diminuindo a chama do queimador, em função

da pressão da caldeira.

As variações de pressão actuam sobre uma membrana de borracha, que acciona a válvula reguladora. Esta abre

e fecha a passagem principal do gás.

Em derivação com a passagem principal do gás, uma passagem mínima permite circular uma pequena

quantidade de gás, mesmo quando a passagem principal estiver fechada.

NOTA: Periodicamente aparafusar a fundo (2 ou 3 voltas seguidas) o parafuso do mínimo; com esta operação

mantém-se a passagem limpa, propensa a obstruir-se por sedimentos causados pelo fluxo do gás.

Regulação do pressostato modulador do gás (Fig. B), partindo da máquina fria e sem pressão

a) Encher a caldeira de água.

b) Afrouxar as porcas (4a) e (5a) fechar completamente o parafuso ( 4 ) do mínimo do pressostato modulador

do gás e abrir o parafuso de tensão (5).

c) Ligar as fontes de energia

d) Quando a pressão for de 0,2 bar, inferior ao valor desejado para a tensão (normalmente 1 bar em

máquinas semi-automáticas e 1,4 bar em máquinas a alavanca) do pressostato modulador de gás,

desligar a resistência eléctrica, mantendo o queimador de gás aceso.

1º Se o pressostato modulador de gás estiver com a tensão correcta, a chama do gás apaga-se

quando a agulha do manómetro da caldeira atingir o valor desejado.

2º Se a chama do gás se apagar a um valor inferior ao desejado, afrouxar o parafuso (5) e voltar a

acender o queimador. Repetir a operação até que a chama se apague quando o manómetro indicar

a pressão desejada.

3º Se a tensão estiver demasiado alta, a chama do gás apaga-se a valores superiores aos desejados.

Descarregar parcialmente a pressão da caldeira, apertar o parafuso ( 5 ) e voltar a acender o

queimador.

e) Repetir a operação até que a desconexão chegue à pressão desejada, e uma vez finalizada a operação

bloquear a contraporca (5a)

f) Terminada a primeira fase, regular o parafuso do mínimo (4)

1º Afrouxar o parafuso do mínimo (4) e voltar a acender o queimador.

2º Afrouxar progressivamente o parafuso do mínimo (4) até que a chama atinja uma altura sobre o

plano do queimador de 10 mm. Aproximadamente.

3º Verificar se com esta chama, a pressão indicada pelo manómetro permanece constante e uma vez

finalizada a operação bloquear a contraporca (4a).

NOTA: Normalmente no caso de funcionamento misto de gás ou electricidade, dada a maior conveniência do gás,

colocar a tensão do pressostato a 0,8 bar e o pressostato modulador de gás a 1 bar nas máquinas semiautomáticas e automáticas; nas máquinas a alavanca colocar a tensão do pressostato a 1,2 bar e o pressostato

modulador de gás a 1,4 bar.

MÉTODO DE VERIFICAÇÃO DE FUNCIONAMENTO DO QUEIMADOR.

A chama tem que ter uma cor azul e sem bordas amareladas.

A chama não tem que se afastar do queimador.

Quando o queimador se encontrar com a chama na sua posição de mínimo, esta deve atingir uma altura sobre o

plano do queimador de 10 mm. Aproximadamente.

PT

Page 25

25

MANUAL PARA O UTILIZADOR

Apenas os Serviços Técnicos Autorizados, lhe podem dar a máxima garantia quanto a serviço e peças

sobresselentes originais. Exija as Peças Sobresselentes Originais, a Instalação e Manutenção ao Serviço

Técnico Oficial.

PRESTE ATENÇÃO AOS RISCOS DESTA SECÇÃO E ÀS SUAS RECOMENDAÇÕES DE

SEGURANÇA

● Esta máquina não tem componentes que o utilizador possa reparar. Só deve ser manipulada por

pessoal do Serviço Técnico Autorizado.

● Antes de proceder a qualquer operação de manutenção, deixar a máquina sem energia eléctrica quer

seja através do interruptor geral da instalação ou desligando o cabo de alimentação.

● As crianças não reconhecem os perigos relacionados com as máquinas, pelo que devem manter-se

afastados delas e impedir que as possam manipular.

● As pessoas com capacidades físicas, sensoriais ou mentais diminuídas ou pessoal sem experiência,

não devem utilizar esta máquina sem a supervisão de pessoal qualificado para tal fim.

● Para as operações de limpeza, cumpra exclusivamente as instruções do presente manual.

● Para assegurar um melhor funcionamento da máquina, exija a utilização só de Peças Sobresselentes

Originais, que o Serviço Técnico autorizado ou o fabricante possa fornecer.

O fabricante declina qualquer responsabilidade, no caso de incumprimento da legislação vigente no

local de instalação da máquina.

INSTRUCÇÕES DE UTILIZAÇÃO

Para a ignição do queimador de gás, proceder da seguinte maneira:

1º Abrir a chave de gás geral ou a válvula se for garrafa.

2º Girar o comando de gás ( 2 ) para a esquerda segundo a ( Fig. C) e premir. Prender o queimador

premindo o botão (1) mantendo premido o comando de gás durante 10 segundos. Soltar lentamente.

No caso de querer manter a pressão da caldeira só com o queimador de gás, colocar o interruptor

geral ( 2I, segundo o desenho do manual de instruções geral segundo o modelo da máquina ) na

posição ( “2” ) na qual a resistência ficará desligada.

Ao finalizar o dia de trabalho fechar a entrada de gás fazendo girar o comando de gás ( 2 ) para a

direita até à posição ( • )

MANUTENÇÃO

Mantenha as zonas próximas ao queimador limpas de pó ou outros elementos.

Com uma periocidade semanal e com a ajuda de uma escova e com o queimador desligado e frio, limpe as

saídas da chama, bem como a zona onde se localiza o termopar e a zona do injector do pressostato modulador.

Com uma periocidade anual, aparafusar a fundo (2 ou 3 voltas seguidas) o parafuso de regulação do mínimo.

Com esta operação mantém-se limpa a passagem, propensa a obstruir-se por sedimentos causados pelo fluxo

do gás.

Não é necessário lubrificar as chaves de passagem.

ATENÇÃO: ESTA OPERAÇÃO DEVE SER REALIZADA POR UM INSTALADOR AUTORIZADO

Page 26

26

08504300

Medidas aproximadas para o espaço de ventilação de máquina com gás

ATENÇÃO: A embalagem deve ser eliminada de acordo com a regulamentação vigente

PRESTE ATENÇÃO AOS RISCOS DESTA SECÇÃO E ÀS SUAS RECOMENDAÇÕES DE

SEGURANÇA

● Não armazene materiais explosivos nem inflamáveis próximo da máquina.

● Mantenha as redes de ventilação livres de obstáculos que impeçam uma ventilação adequada.

ATENÇÃO Se perceber o cheiro a gás:

● Fechar a chave do gás

● Não accionar nenhum interruptor eléctrico

● Não usar o telefone na zona de perigo

● Abrir janelas e arejar o local

● Chame imediatamente o Serviço Técnico

O FABRICANTE DECLINA QUALQUER RESPONSABILIDADE POR UMA MÁ UTILIZAÇÃO DO

EQUIPAMENTO

AVARIAS

POSSÍVEIS CAUSAS

OBSERVAÇÕES

O queimadorão liga

O gás não chega à máquina

Verificar que a chave de

passagem ou válvula da garrafa

está aberta

O queimador apaga-se quando

se solta o comando de gás (2)

O termopar está avariado ou

desajustado

Avisar um instalador autorizado

A chama mínima não se

mantém

Pressostato modulador de gás

está desajustado ou avariado

Avisar um instalador autorizado

A chama tem uma cor amarela

e a caldeira deita fumo

Regulador de ar desajustado

ou pressostato modulador de

gás desajustado

Avisar um instalador autorizado

PT

Page 27

27

Loading...

Loading...