Page 1

DISPLAY

04.2008

OPERATING INSTRUCTIONS

Page 2

COFFEE MACHINE DISPLAY

Contents

1. Main functions of display

2. User screens:

2.1 Main (Standby mode)

2.2 System temperatures

2.3 Coffee counter

2.4 Water softener regeneration

2.5 Clock programming

3. Warning screens

4. Screens for authorised personnel

5. General diagram of the system

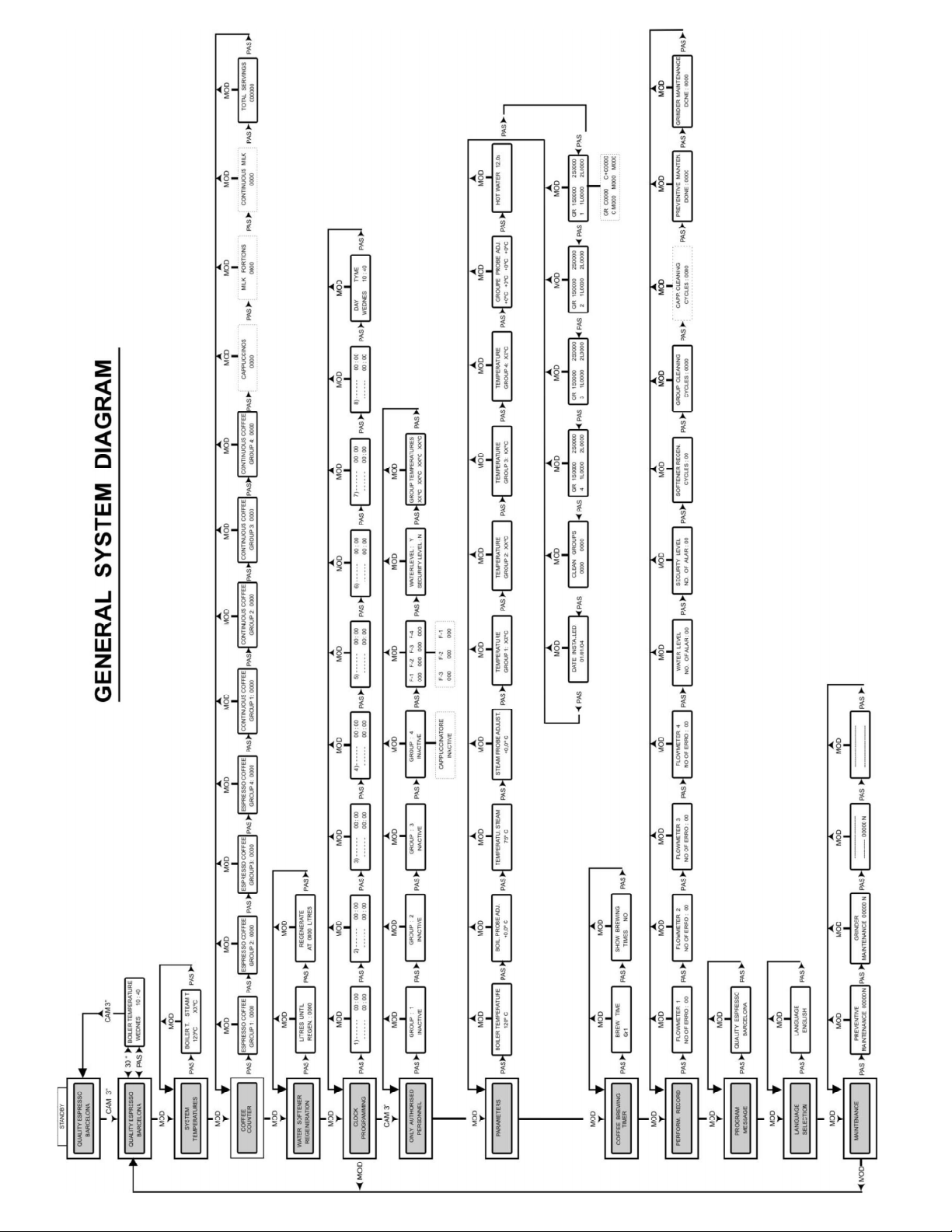

1. MAIN FUNCTIONS OF THE DISPLAY

The system is made up of a group of twelve screens, which in turn are divided into a specific

number of sub-screens, where the data is displayed and modified.

Depending on the model, the text in the displays, can be abbreviated or not.

The MOD key enables movement through the group of screens.

Pressing the PAS key leads to the sub-screens. Pressing the MOD key from any sub-screen

returns the user to the group of screens (see General Diagram of the System).

1

Page 3

2. USER SCREENS

2.1 Main

It automatically alternates between two screens every 30 seconds (Screen- A, publicity and

Screen- B, timer and temperature), the user being able to see either of them when desired, by

pressing PAS.

Standby mode: (Screen unlit, general switch in position - 1)

The machine remains in off position until put into use (normal mode)

Activate Standby:

From the timer screen (Screen-B), keep the CAM key pressed down (4 sec.) until

seeing the display, the publicity screen unlit (Screen-A).

De-activate Standby: (Pass to normal mode)

Keep the CAM key pressed down (4 sec.) until seeing the publicity screen lit up (Screen-A)

2.2 System temperatures

Shows the temperature of the boiler and the steam nozzle (according to the version of the

machine)

element is working.

When, instead of the temperature, it shows XXX, it means that no probe is connected (or it has

broken down).

Consult temperatures:

1. Press the MOD (Screen-C)

2. Press the PAS key to see the sub-screen with the required information. (Sub-screen C1)

a in bold indicates when the heat ing

2

Page 4

2.3 Coffee counter

Consult coffees made:

1. Press the MOD ke (Screen- D)

2. Press the PAS key as many times as required to see the sub-screen with the desired

information.

IMPORTANT NOTE

.- Screens with broken lines above only appear in models with automatic

cappuccino maker incorporated

Setting the coffee counter to zero:

1. Press the MOD (Screen- D)

2. Press the PAS key positioning it on the required sub-screen to be set to zero

3 Press the CAM key (the display digits flash)

4 Press the SET key (the counter goes to zero)

5 Press the CAM key (the display digits stop flashing)

6 Press the PAS key to confirm

It is not possible to set the total servings to zero (Sub-screen - D6)

2.4 Regeneration of water softener.

It shows the litres remaining to be consumed before carrying out the regeneration of the water

softener and the quantity of litres of water programmed that must be consumed before the

regeneration is carried out.

To consult remaining litres and programmed litres:

1. Press the MOD (Screen - E).

2. Press the PAS key the number of times necessary until the desired sub-screen is displayed.

.

3

Page 5

Programming the number of litres of water at which the regeneration of the water softener must be carried

out:

1. Press the MOD

(Screen - E).

2. Press the PAS

(Sub-screen - E2).

3. Press the CAM key (the blinking cursor appears), press again the CAM key to move the cursor

from units to thousands.

4. Press the SET key to change the value of the digit occupied by the cursor. Repeat steps 3 and 4

to set the number of litres of water required.

5. Pressing the PAS key, go to sub- (Sub-screen - E1)

6. Press the CAM key (the digits on the display flash)

7. Press the SET key (the programmed quantity is established on the Sub-screen - E2)

8. Press the CAM key (the digits on the display stop flashing)

9. Press the PAS key to confirm

4

Page 6

2.5 Programming the clock

1. Setting the time: Press the MOD

(Screen - F)

1.1 Press the PAS key the times necessary until displaying the Sub-screen - F9.

1.2 Press the CAM key (the position corresponding to the day of the week flashes).

1.3 Press the SET key until selecting the correct day of the week.

1.4 Press the CAM key (the digits of hours blink), press the key again to move the cursor to

the minute positions, the SET key changes the digits of the blinking cursor.

1.5 Press the PAS key to confirm.

-

Press the MOD (Screen - F).

1. Press the PAS key until seeing the sub-screen corresponding to the desired program

(Sub-screens F1 to F8) for example Sub-screen F1.

2. Press the CAM key (the day of the week blinks) press the key again to go to start hour

and minute; and stop day, hour and minute.

3. To change the values shown by the cursor, press the SET key.

5

Page 7

4. Press the PAS key to confirm the changes made in the sub-screen. (On pressing the PAS

key, as well as confirming the changed data, the next sub-screen will appear).

5. Successively repeat points 2,3 and 4 for each start up / close down that you wish to

program.

NOTE.- In each sub-screen corresponding to each of the eight possible programmes for

automatic start up and close down, the upper line shows the start up condition and the

lower line the close down condition.

6. Examples of programming:

a) Starting and stopping every day.

b) Starting on Monday and stopping on Tuesday.

c) Starting on Monday and stopping on Friday.

d) If the premises close for one or more days each week, the simplest way of programming

is to create an automatic on and off program for each day of activity during the week.

e)

To do this put the machine in Standby Mode (2.1) at the end of the day.

NOTE: The machine always obeys any on-off programme there is on the sub-screens (from F1 to

F8). To cancel any programming carried out, go through points 1 to 4 of this section,

selecting in the position corresponding to the day for starting and stopping the following

symbol: ------- (do not forget to confirm the change made as described in point 4 of this

section).

If the machine is on standby waiting for an automatic start, the power supply is cut and

returns after the programmed start time, the machine will remain on standby and will have

to be started according to point 2.1

Standby Mode (2.1)

In the case of making a coffee (in programmed portions) when there are less than 5

minutes remaining before an OFF programming, 5 minutes will be added from the minute

that the coffee is made: this function does not apply in the case of CONTINUOUS coffee

supply.

6

Page 8

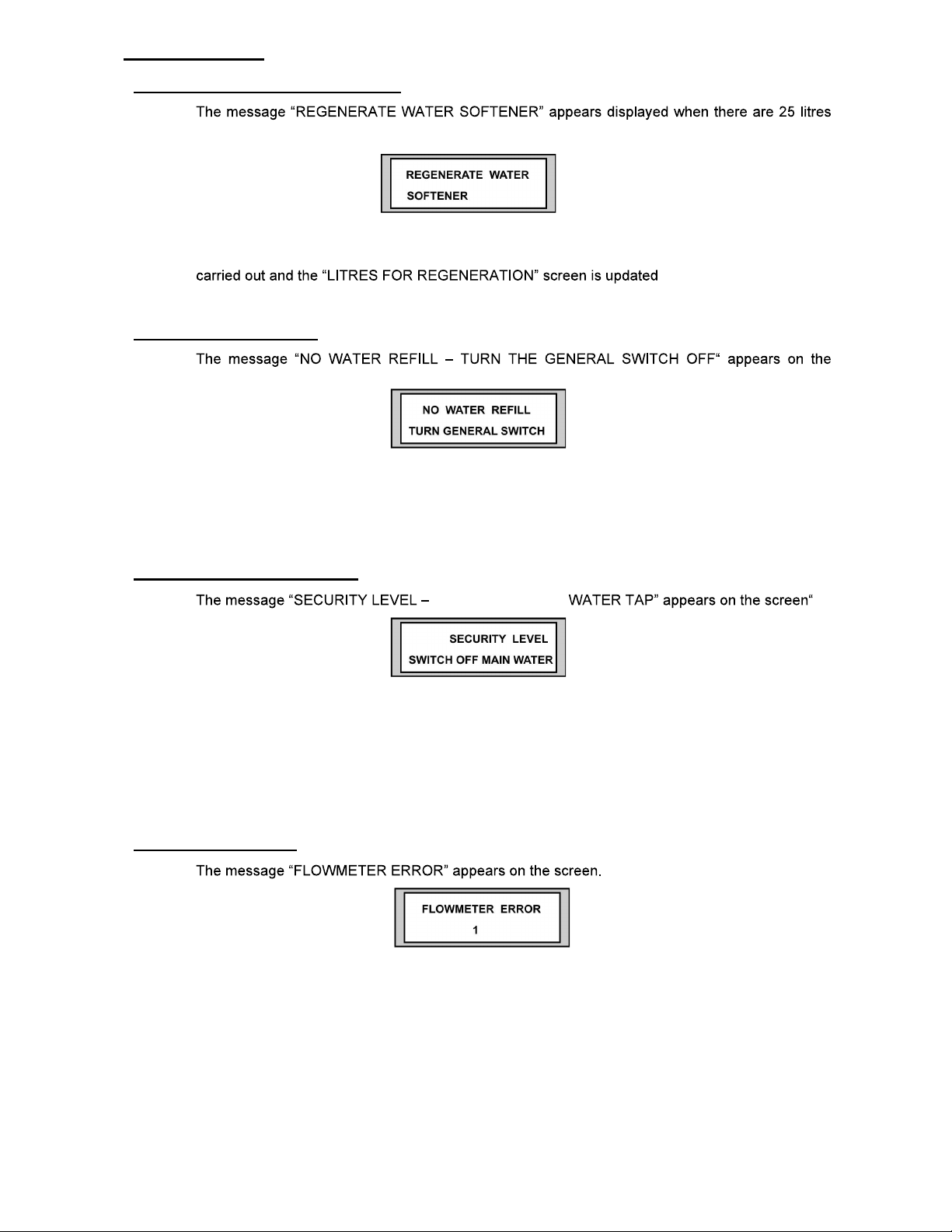

3. WARNING

3.1 Regeneration of water softener

remaining of the programmed quantity.

To erase this message, press the PAS key.

This message will reappear every time a new litre of water is consumed until regeneration is

(Sub-screen - E1).

3.2 Boiler safety level .

screen.

This message appears when the boiler is not at its normal working level (CALL YOUR

AUTHORISED SERVICE TECHNICIAN).

Once the problem is solved, to eliminate the alarm and erase the message from the screen, turn

the general switch to 0 position.

3.3 Maximum security level .

This message appears when there is too much water in the boiler (CALL YOUR AUTHORISED

SERVICE TECHNICIAN). The system also starts up a safety cycle, which opens up the hot water

outlet in order to avoid any possible flooding in the boiler (Intermittently to begin with in order to

advise the machine operator).

Once the problem has been solved, to eliminate the alarm and erase the screen message, turn

the general switch to the 0 position.

3.4 Flowmeter error

This message appears when a dosage error is detected in the corresponding meter (showing the

flowmeter number on the screen).

NOTE: it is possible for this message to appear if the coffee grinding is excessively fine, and the

water does not pass through the coffee at the suitable speed.

This message will disappear on ordering another coffee from the same group.

If the warning continues and this is not the cause, CALL YOUR AUTHORISED SERVICE

TECHNICIAN.

SWITCH OFF MAIN

7

Page 9

3.5 Pressure compensation

When the machine is turne

up a pressure compensation cycle, as shown on the screen, with the aim of avoiding possible

suction of liquids by depression inside the boiler.

Once this cycle has finished, th

can also be eliminated by pressing the PAS or MOD keys.

3.6 Boiler emptying cycle

The user can undertake a partial emptying of the boiler, which will be shown on the screen,

maintaining pressed the hot water outlet button for approximately 6 seconds.

The system will force the hot water out for 25 seconds. After this time, the hot water coming out

will stop, and the cycle can be repeated by maintaining the button pressed within 10 seconds.

NOTE: the boiler emptying cycle can be interrupted by either pressing the hot water outlet button

again when it is emptying or when it has completed a 25-second cycle and the button has not

been pressed again. The warning screen disappears when the emptying cycle has been

completed.

3.7 Clean cappuccino unit (according to model)

This warning screen shows when approximately an hour has passed between a cappuccino or

milk service and the next service.

A cleaning cycle must be carried out by pressing

screen).

on the screen.

To eliminate the display screen, press the PAS key.

NOTE: Remove the tube from the milk container before starting the cleaning cycle.

8

Page 10

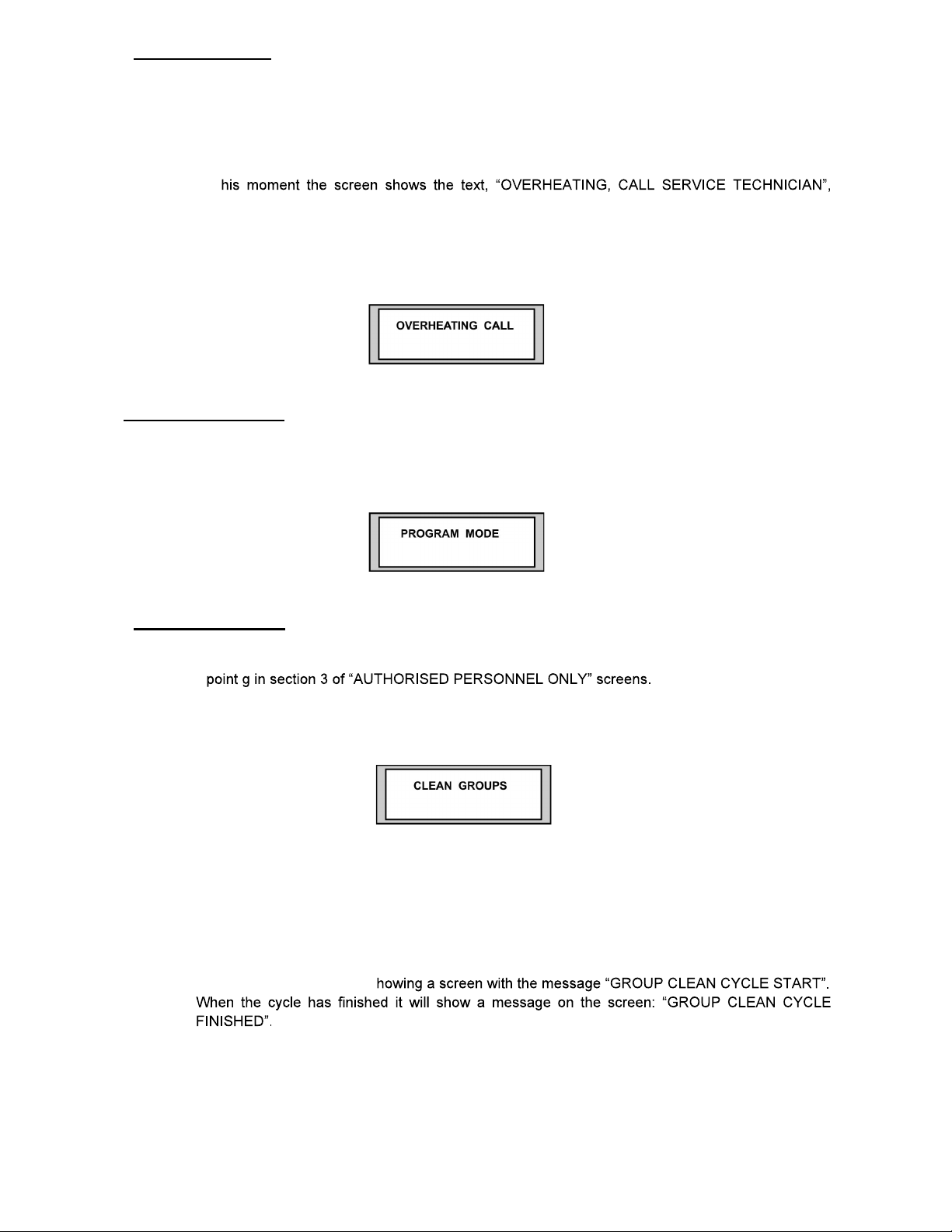

3.8 Overheating

The system has a safety mechanism in case of failure in the temperature control that may cause

the pressure to increase in the boiler.

This safety mechanism is activated when, for whatever reason, the temperature of the boiler

surpasses the maximum temperature by more than two degrees, or when the programmed

temperature is lowered by more than two degrees.

At t

although the machine can continue working, since the system has a parallel control, which will

maintain the machine in controlled working order until the Technical Service carries out the repair.

The screen disappears when the temperature drops to the maximum level and appears again

when the temperature surpasses the maximum temperature by two degrees again.

3.9 Programming

This screen is shown whenever in the portion programming cycle and disappears when leaving

this cycle.

3.10 Clean Groups

This screen appears when the quantity of coffees made reaches the programmed amount (see

This screen will only cease to appear when a cleaning cycle has been carried out and will never

appear if this function has not been authorised.

EQUIPMENT CLEANING CYCLE PROCEDURE

1.- Turn the general switch to the ZERO position

2.- Place a filter holder with a blind filter in each group.

3.- Keeping the key pressed for 2 LARGE coffees of any group, turn on the general switch to position

ONE. The indicator of the above-mentioned key will light up and after about 4 seconds the

cleaning cycle will start up s

4.- To leave the group cleaning cycle and erase the message displayed on the screen, turn the

general switch to the ZERO position.

9

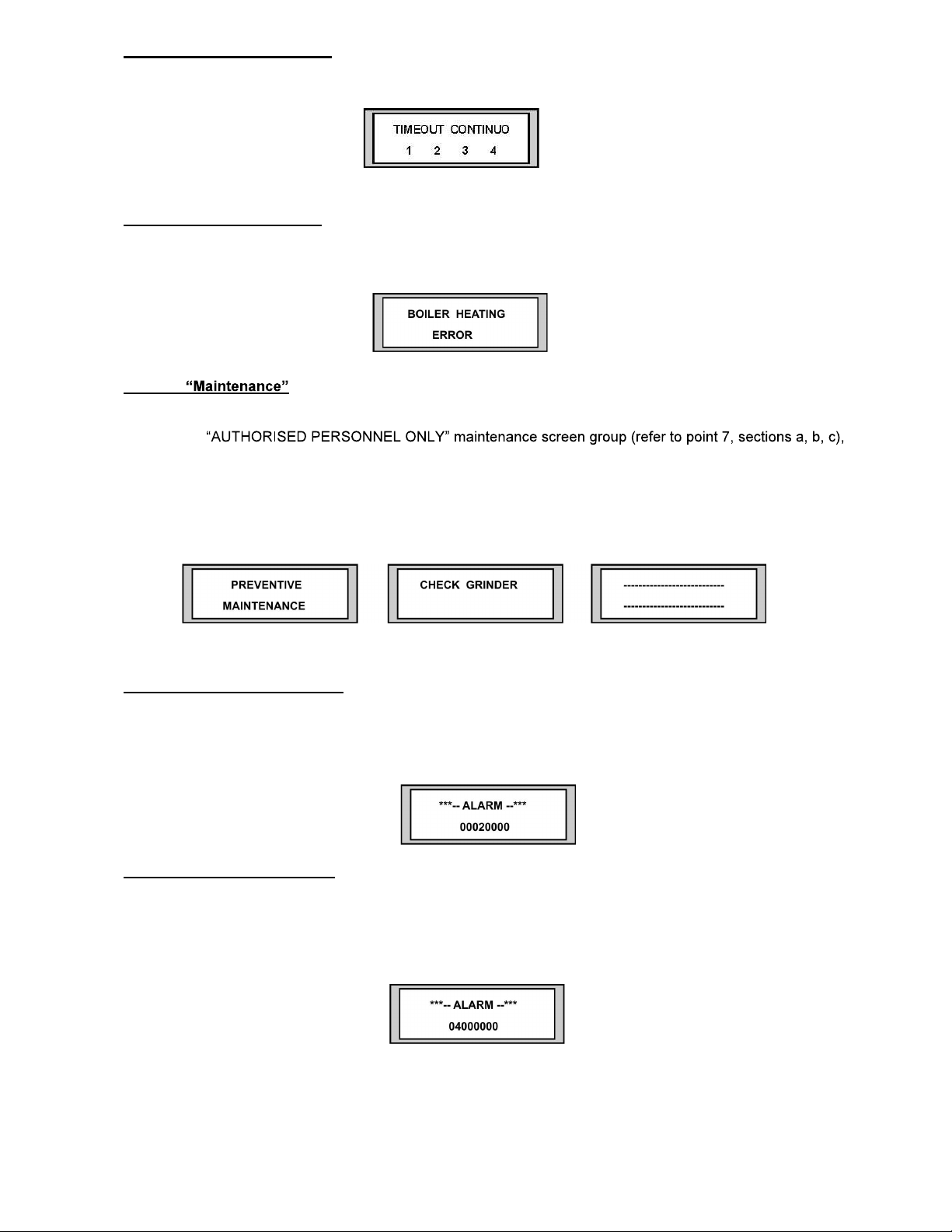

Page 11

3.11 Continuous Timeout

This screen appears when there exists a continuous coffee preparation of for more than 5 minutes

NOTE: The display shows the number of the group which has caused the message to appear.

3.12 Boiler heating error

This screen appears when for any reason the machine detects that the boiler temperature should

increase but it does not happen.

3.13

When the number of coffees prepared is greater than the number of coffees entered in the

the following screens appear.

This happens every time a coffee is made, unless the quantities are reprogrammed or the counters

were disabled.

3.14 Last configuration lost

This screen appears when the last configuration has not been successfully entered and the previous

configuration is used without the latest modifications. The lost of the configuration can be due to

dosing or parameter values changed by the display.

3.15 Relay activation error

This screen appears when there exists an error in the system that activates the relays in the

electronic control of the machine.

(PROGRAMMABLE TEXT)

10

Page 12

11

Page 13

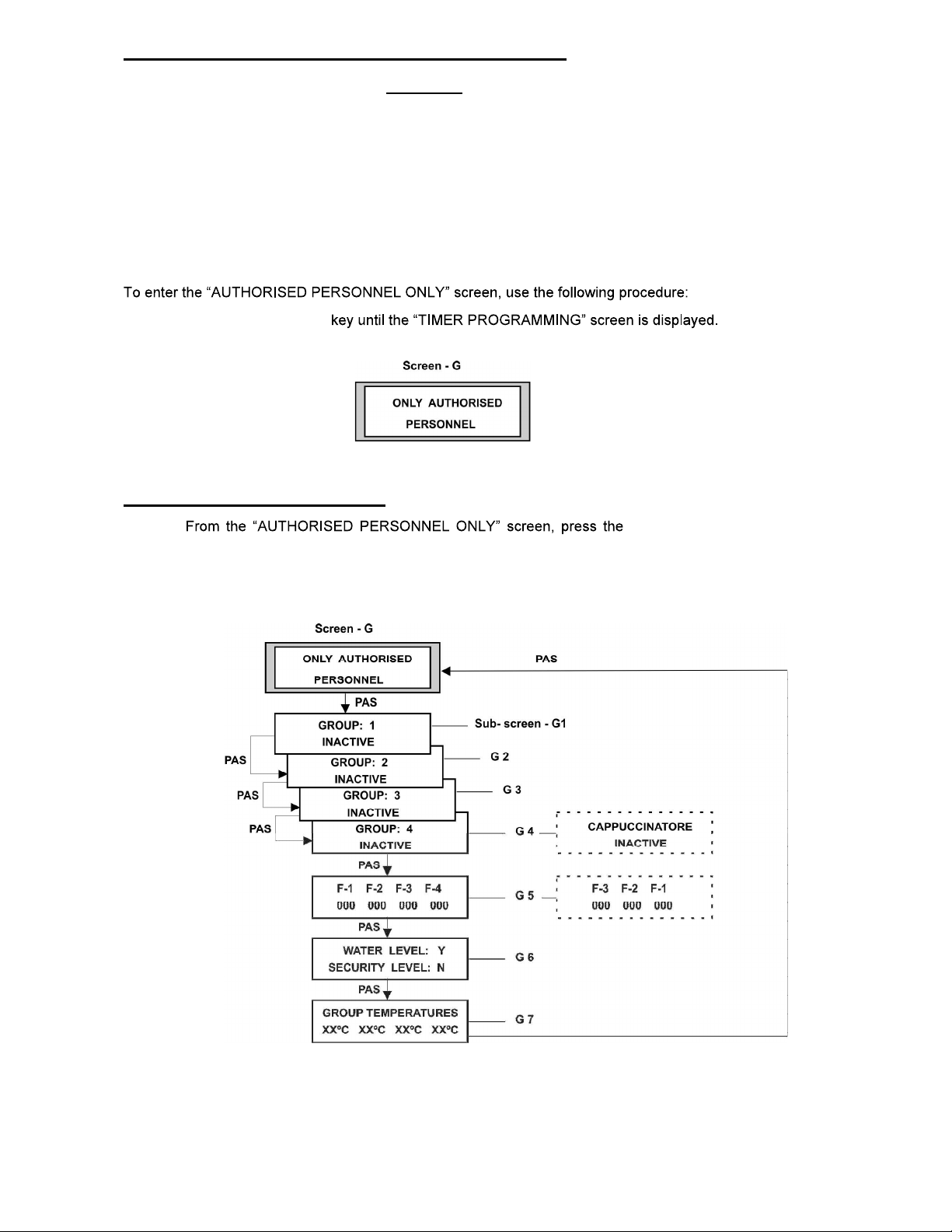

4. SCREENS FOR AUTHORISED PERSONNEL ONLY

Contents

1 Consult state of machine

2 Set up

3 Distribution time

4 Performance record

5 Program publicity

6 Select language

7 Maintenance

1 Press the MOD

2 Keep the CAM key pressed (4 sec.) (Screen -G).

1. Consult state of the machine

necessary until the information required is displayed.

PAS key the number of times

13

Page 14

Sub-screens G1 to G4 show the functioning of the panel buttons corresponding to the group

selected (Sub-screen - G1 corresponds to group 1 and so on).

Sub-screen G5 shows the total number of pulses of each volumetric meter every time a dosage of

coffee is made.

Sub-screen G7 shows the temperature of each one of the distribution groups (depending on the

model).

NOTE: Sub-screen G4 shows the state of the panel corresponding to distribution group 4 in the

conventional machines (fourth position counting from the left) and the state of the panel

corresponding to the cappuccino maker in the machines with automatic cappuccino included.

2. Parameters

1 Pulse = approx. 0.50 cm3

This setup screen (Screen H) leads to a group of sub-screens (from H1 to H11) in which the

operating parameters of the machine are memorised, these being:

a) Boiler temperature (Sub-screen H1)

b) Boiler probe adjustment (Sub-screen H2) adjustable between +/- 9.9

c) Steam temperature (Sub-screen H3) adjust

with adjustable temperature steam nozzle.

d) Steam probe adjustment (Sub-screen H4) adjustable between +/- 9.9

14

Page 15

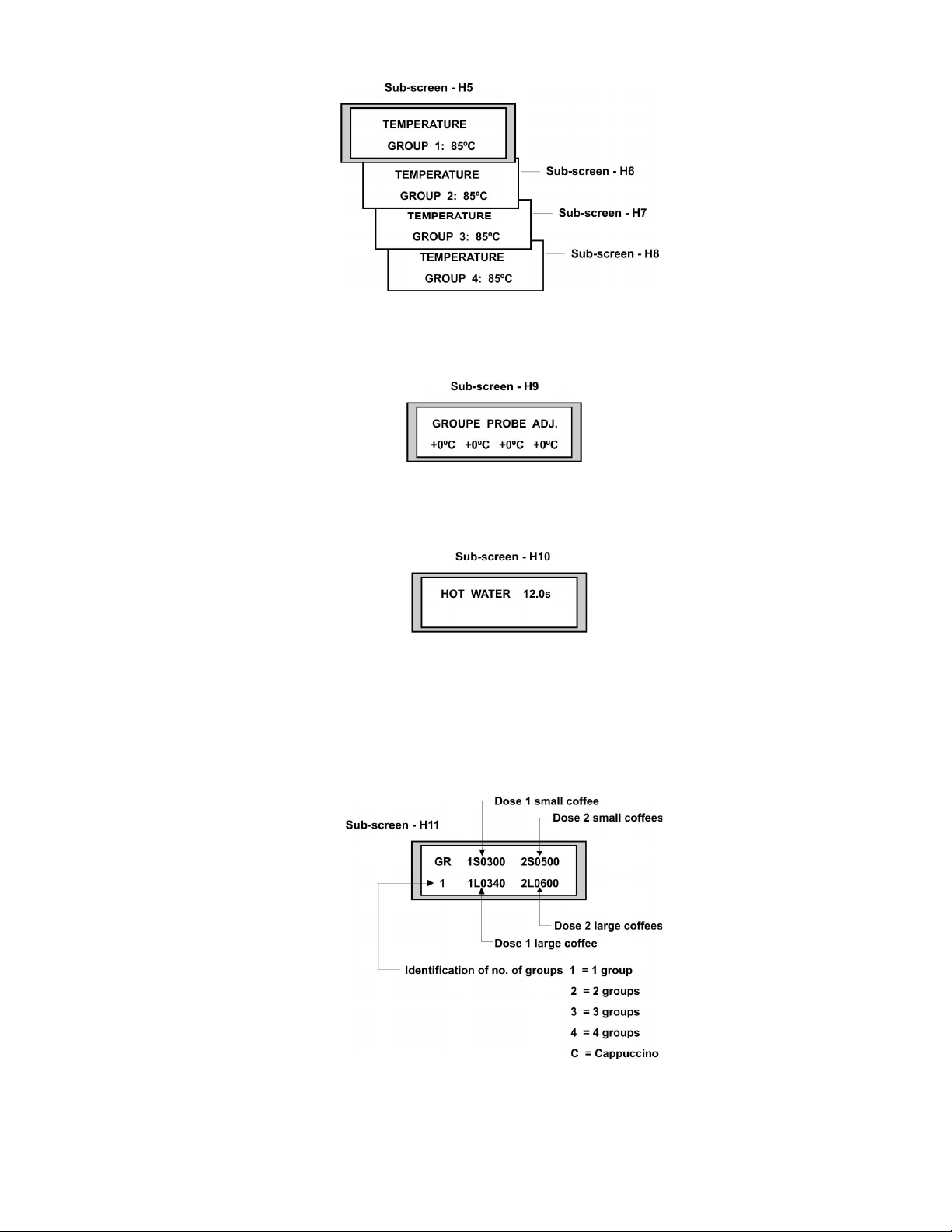

e) Temperature adjustment for each one of the groups can be made on H5, H6, H7, H8 sub-

screens

f) Groups probe adjustment (sub-screen H9) adjusted between -/+ 1 to -/+ 9

g) Hot water dosage time (Sub-screen H10) adjustable from 0 to 30 seconds

h) Flowmeter pulses for coffee dosage (Sub-screens H11, H12, H13 and H14). On each of

these the pulses programmed for each of the dosages in each group is displayed. These

dosages are adjustable from the display to between 1 and 8000 pulses.

15

Page 16

NOTE: In the machines with automatic cappuccino maker, Screen H12 corresponds to

the cappuccino maker panel, and on it is shown the pulses for the doses of coffee and the

dosage time for the milk, as well as the dosage time of milk only.

The pulses for coffee dosage are adjustable between 1 and 4,000 impulses and the milk

dosage times are adjustable between 0 and 180 seconds.

i) Number of coffees before carrying out cleaning of groups (Sub-screen H13) shows the

number of coffees programmed to carry out the cleaning of the groups and the number of

coffees made since the last cleaning process. If the quantity programmed is ZERO the

associated message will never appear.

j) Date of installation of the machine (Sub-screen H14) shows the date of installation of the

machine, according to the data recorded.

MODIFICATION OF THE DATA

information (see example).

1- Press the CAM key. The digits to change blink.

Pressing the CAM key repeatedly the cursor moves around the screen over the positions that

can be modified.

2- The SET key is used to change the blinking data.

Example:

PAS key the number of times necessary to display the required

3- Once the data has been modified on a screen, press the PAS key to confirm the changes

made.

16

Page 17

3 Brewing timer

This screen (Screen I) enables the brewing timer of group 1 to be displayed when programming the

dosage and displays the brew timer of each one of the groups.

3.1 Display of brew time of group one

1.-- From Screen I PAS key. Sub-screen I1 will be shown,

2.- Press the button for the dosage required of group 1 (1S, 1L, 2S, 2L) and the memorised

brew time when the initial programming of the machine was carried out and the brew time

at that moment will be shown.

NOTE: If t

memorised time is 000.

3.2 Displaying the brewing times

1- From Screen I PAS key until Sub-screen I2

BRE

2- Press the CAM key, the word NO will flash intermittently

3- Press the SET key, the word YES will appear

4- Press the PAS key to confirm the change.

From this moment on every time a coffee is made a screen will appear showing the brew time.

NOTE: To stop displaying the brew times, carry out the same procedure as for displaying it.

17

Page 18

4. Performance record

Shows the incidents that have occurred in the machine (errors in flowmeters, level alarm, etc.).

4.1 Consult statistical record.

1. Press the MOD (Screen - J).

2. Press the PAS key the number of times necessary until displaying the required sub-screen.

(Screen - G).

Sub-screens J1 to J4 show the number of incidents detected by the flowmeters.

Sub-screen J5 shows the incidents detected in the normal working level.

Sub-screen J6 shows the incidents due to excess of water in the boiler.

Sub-screen J7 shows the number of regenerations undertaken of the water softener.

Sub-screen J8 shows the group cleaning cycles undertaken.

Sub-screen J9 shows the number of cappuccino maker cleaning cycles undertaken.

Sub-screen J10 shows the number of preventive maintenance operations performed.

Sub-screen J11 shows the number of grinder maintenance operations performed.

18

Page 19

4.2 Setting the incidents to zero

screen required for setting to zero.

1. Press the CAM key (the digits on the display flash).

2. Press the SET key (the meter goes to zero)

3. Press the CAM key (the digits on the display stop flashing)

5. Program message

This screen is programmed at origin according to Screen A.

To program a new text carry out the following procedure:

1. Press the MOD key (Screen-K)

2. Press the PAS key, sub-screen K1 appears with the current text

3. Press the CAM key, the cursor appears, to move the cursor press the CAM key again.

4. Press the SET key to modify the value of the space occupied by the cursor.

5. Repeat steps 1 and 2 until programming the desired text.

6. Press the PAS key to confirm.

screen (Screen - J) press the PAS key until reaching the sub-

(Screen - G)

. Select language

6

Select the display communication language.

1. Press the MOD (Screen- L).

2. Press the PAS key (Sub-screen L1 appears with the language of origin selected).

3. Press the CAM key (the language currently set flashes).

4. Press the SET key to select the language required (Spanish, English, French, Italian,

Portuguese, German, Catalan, Basque and Galician).

5. Press the PAS to confirm.

6. Press the MOD key to return to the main screen.

(Screen - G).

19

Page 20

7. Maintenance

The maintenance screens are those which tell us when the machine needs a maintenance.

The maintenance screen leads us to a group of screens (from M1 to M4).

a) The sub-screen M1 allows us to set a number of coffees. When this number is exceeded, the

NOTE: To enable this function, change the N letter next to the number of coffees to an S letter. To

disable the feature, replace the S with an N.

b) The sub-screen M2 operates like the M1 sub-

NOTE: To enable or disable this feature, act like in the M1 sub-screen.

c) The sub-screen M3 works like the M1 and M2 sub-screens, but the text can be programmed by the user.

NOTE: To enable or disable this feature, act like in the M1 sub-screen.

d) The sub-screen M4 allows programming the M3 sub-screen warning text

20

Page 21

Data Modification.

as many times as needed to view the desired information

(see the example.)

1. Press the CAM key (the unit digit blinks.) By pressing the CAM key we go through the screen fields that

can be changed.

2. Press the SET key to change the blinking data

Example:

3. Once the screen data is modified, press the PAS key to confirm the changes.

21

Loading...

Loading...