Page 1

Sentry Plus Series

Hipot Testers

Instruction Manual

Form 150697/A4

QuadTech, Inc., 2003

5 Clock Tower Place, 210 East

Maynard, Massachusetts, U.S.A. 01754

January 2005

Telephone: 978-461-2100

Sales: 800-253-1230

Facsimile: 978-461-4295

Website: www.quadtech.com

The material in this manual is for informational purposes only and is subject to change, without notice.

QuadTech assumes no responsibility for any error or for consequential damages that may result from the

misinterpretation of any procedures in this publication.

WARNING

Potentially dangerous voltages may be present on front and rear panel terminals. Follow all warnings in

this manual when operating or servicing this instrument. Dangerous levels of energy may be stored in

capacitive devices tested by this unit. Always make sure the high voltage indicator is not on when

connecting or disconnecting the device under test.

!

Product will be marked with this symbol (ISO#3864) when it is necessary for the user to refer to

the instruction manual in order to prevent injury or equipment damage.

Product marked with this symbol (IEC417) indicates presence of direct current.

Product will be marked with this symbol (ISO#3864) when voltages in excess of 1000V are

present.

Page 2

Page 2 of 85

Page 3

Contents

Warranty ............................................................................................................5

Specifications ............................................................................................................7

Accessories ............................................................................................................11

Safety Precautions....................................................................................................13

Condensed Operating Instructions ........................................................................15

Introduction - Section 1

1.1 Unpacking and Inspection..............................................................................21

1.2 Product Overview ..........................................................................................21

1.3 Controls and Indicators..................................................................................22

1.3.1 Front Panel Controls and Indicators .................................................22

1.3.2 Rear Panel Controls and Connectors ................................................23

1.4 Installation .....................................................................................................24

1.4.1 Dimensions ........................................................................................24

1.4.2 Instrument Positioning.......................................................................24

1.4.3 Power Requirements..........................................................................24

1.4.4 Safety Inspection................................................................................25

Operation - Section 2

2.1 Terms and Conventions.................................................................................27

2.2 Start-Up..........................................................................................................31

2.3 Programming Electrical Safety Tests.............................................................31

2.4 Programming a Ground Continuity Test .......................................................35

2.5 Programming an AC Hipot Test....................................................................37

2.6 Programming a DC Hipot Test......................................................................39

2.7 Programming an Insulation Resistance (IR) Test .........................................41

2.8 Programming a Pause (PA) in Test Sequence ..............................................43

2.9 Storing a Test Setup ......................................................................................45

2.10 Programming a Multi-Step Test.....................................................................47

2.11 PRESET Test Parameters .............................................................................48

2.11.1 AC-V FREQ ......................................................................................48

2.11.2 Software AGC ...................................................................................48

2.11.3 WV AUTO RANGE .........................................................................48

2.11.4 IR AUTO RANGE ............................................................................49

2.11.5 GFI ....................................................................................................49

2.11.6 FAIL RESTART ...............................................................................49

2.12 Instrument Offset ..........................................................................................50

2.13 Connection To Device Under Test ................................................................53

2.14 Measurement Procedure.................................................................................54

Page 3 of 85

Page 4

Contents (Continued)

2.15 MENU Parameters ........................................................................................56

2.15.1 MEMORY Function .........................................................................57

2.15.2 SYSTEM Function ............................................................................59

2.15.2.1 CONTRAST ...................................................................59

2.15.2.2 BUZZER VOLUME .......................................................59

2.15.2.3 EN 50191 ........................................................................59

2.15.2.4 DC 50V AGC ..................................................................60

2.15.3 OPTION Function .............................................................................60

2.15.4 CALIBRATION Function ................................................................60

2.15.5 KEY LOCK Function .......................................................................61

2.15.6 CHANGE PASSWORD Function ....................................................63

2.15.7 ERROR LOG Function .....................................................................65

2.15.8 ABOUT Function ..............................................................................65

Interface - Section 3

3.1 Remote ..........................................................................................................67

3.2 G16 International Power Strip.......................................................................70

3.3 S07 Power Entry Adapter Cable ...................................................................71

3.4 S03 Corded Product Adapter ........................................................................72

3.5 S05 Foot Switch ............................................................................................73

3.6 S08 Gun Probe ..............................................................................................74

3.7 S50 Plus Ground Bond Tester .......................................................................75

Service & Calibration - Section 4

4.1 General...........................................................................................................77

4.2 Instrument Return ..........................................................................................77

4.3 Calibration......................................................................................................77

4.3.1 Calibration Parameters.......................................................................78

4.3.2 Enable Calibration ............................................................................79

4.3.3 AC Voltage Calibration .....................................................................80

4.3.4 DC Voltage Calibration .....................................................................80

4.3.5 IR Voltage Calibration.......................................................................81

4.3.6 AC Current Calibration......................................................................82

4.3.7 DC Current Calibration......................................................................83

4.3.8 ARC Calibration ................................................................................84

4.3.9 IR Resistor Calibration .....................................................................84

4.3.10 Ground Continuity Calibration .........................................................85

4.3.11 Contrast Calibration ..........................................................................85

4.3.12 Finalize Calibration ...........................................................................85

Page 4 of 85

Page 5

Warranty

QuadTech warrants that Products are free from d efects in material and workmanship and, when

properly used, will perform in accordance with QuadTech’s applicable published specifications.

If within one (1) year after original shipment it is found not to meet this standard, it will be

repaired, or at the option of QuadTech, replaced at no charge when returned to a QuadTech

service facility.

Changes in the Product not approved by QuadTech shall void this warranty.

QuadTech shall not be liable for any indirect, special or consequential damages, even if

notice has been given of the possibility of such damages.

This warranty is in lieu of all other warranties, expressed or implied, including, but not

limited to any implied warranty or merchantability of fitness for a particular purpose.

SERVICE POLICY

QuadTech’s service policy is to maintain product repair capability for a period of at least five (5)

years after original shipment and to make this capability available at the then prevailing schedule

of charges.

Page 5 of 85

Page 6

Page 6 of 85

Page 7

Specifications

Dielectric Strength

Sentry 10, 20, & 30 Plus

AC Output Voltage: Range: 0.05 to 5kV AC, in 1V steps

Regulation: ± (1% of setting +5V)

Frequency: 50/60Hz selectable

Voltage Display: Accuracy: ± (1% of reading +5V)

Resolution: 1Volt

AC Current Display: Range: 0.001mA to 20mA AC, in 1µA steps

Accuracy: ± (1.5% of reading + 5 counts) (Total)

Sentry 20 & 30 Plus

DC Output Voltage: Range: 0.05 to 6kV DC, in 1V steps

Voltage Display: Accuracy: ± (1% of reading +5V)

Resolution: 1Volt

DC Current Display: Range: 0.0001mA to 5mA DC

Resolution: 0.1µA

Accuracy: ± (1.5% of reading + 5 counts)

Insulation Resistance

Sentry 30 Plus

Insulation Resistance: Voltage: 50 - 1000V DC in 1V steps

Accuracy: ± (1% of reading + 5V)

Range: 0.1MΩ - 50GΩ (voltage dependent)

Accuracy: 0.1MΩ - 1GΩ, ± (10% + 5counts) < 100V

0.1MΩ - 1GΩ, ± (7% + 5counts) < 500V

1MΩ - 1GΩ, ± (4% + 5counts) ≥ 500V

1GΩ - 10GΩ, ± (7% + 5counts) ≥ 500V

10GΩ - 50GΩ, ± (12% + 5counts) ≥ 500V

Page 7 of 85

Page 8

Specifications (Continued)

Safety Features

Ground

Continuity Test: Programmable: 0.1Ω to 5.0Ω ±0.2Ω Accuracy, or OFF

Ground Fault

Interrupt (GFI): Shutdown of current imbalance when I > 0.5mA ±0.25mA, or OFF

In-Rush Current: DC Mode: Set detection limit: 0.5uA – 5mA in 0.0001mA increments

The programmable range for In-Rush current is dependent on the

programmed High Limit:

Range: High Limit: In-Rush:

1 0.1µA – 300µA 0.5µA – 300µA

2 0.301mA – 3.000mA 5µA – 3.000mA

3 3.01mA – 5.0mA 50µA – 5.0mA

Fast Output Cutoff: HV output voltage terminated <0.4mS after NG (Fail) result

Fast Discharge: <0.2s (Typical) Discharge of DUT upon termination of HV.

ARC Detection: Detection Current: Range: 1mA – 20mA AC and 5mA DC

Pulse Width: Minimum: 10µs

General Features

Time: Test*: 0.1sec – 999 sec, Continuous

Ramp: 0.1sec – 999 sec, OFF

Dwell: 0.1sec – 999 sec, OFF (DC & IR Mode only)

Fall: 0.1sec – 999 sec, OFF

* Te st Time is limited ≤ 60seconds when the voltage and high c urrent limit > 100VA.

* Test Time for IR is 0.3sec – 999sec, Continuous

Limits: HI/LO programmable during Test Time

LO can be set to OFF during Hipot Test

HI can be set to OFF during IR Test

Indication: Pass/fail LEDs, audible alarm

Remote Control: Inputs: START, STOP

Characteristics: 24V active low, Pulse width ≅20ms

Outputs: PASS, FAIL, UNDER TEST

Characteristics: Dry contact relay, Closed if true

115V, <100mA

Connector: 9 pin male D-series & Terminal Strip

Page 8 of 85

Page 9

Specifications (Continued)

General Features

Setup Storage: 60 Memory Locations, 10 steps each

Standard

Interfaces: Remote I/O

Connectors: Front and Rear Connection

HV OUTPUT: Custom Banana Socket

RTN/LOW: Banana Socket

GC (Rear Only): Binding Post/ Banana Socket

Front Panel 10 Digit Password with or without setup recall

Lockout: LED Display: LOCK

Mechanical: Bench Mount

Dimensions:(w x h x d): 10.50 x 4.50 x 14.25 inches

262.5 x 112.5 x 356.25 mm

Weight: 25.0 lbs (11.5 kg) net, 28 lbs (13.0 kg) shipping

Environmental: Specifications: 18°C to 28°C, 70% RH

Operating: 0°C to + 40oC, 80% RH

Storage: -10°C to + 60oC, 80% RH

Warm-up Time: 15 minutes

Power:

Supplied:

Safety Agency: CE, TUV

Ordering Description Catalog No.

Information: AC Hipot Tester Sentry 10 Plus

AC/DC Hipot Tester Sentry 20 Plus

AC/DC/IR Hipot Tester Sentry 30 Plus

•

90 - 130V AC

•

200 - 250V AC

•

Instruction Manual

•

Calibration Certificate

•

Ground Continuity Lead

•

50 or 60Hz

•

300W max

•

Power Cable

•

S02 Test Leads

Page 9 of 85

Page 10

Page 10 of 85

Page 11

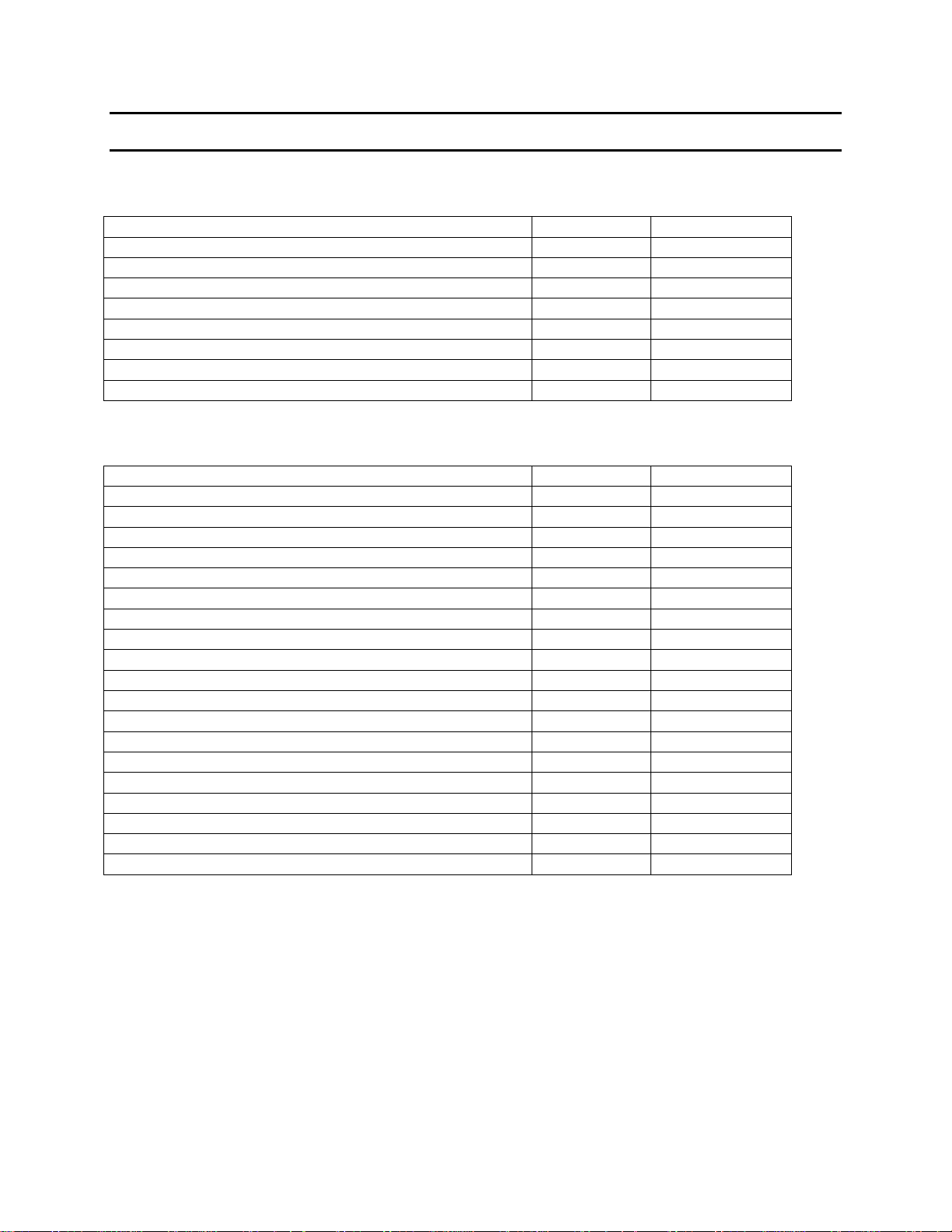

Accessories

Accessories Included

Item Quantity QuadTech P/N

AC Power Cord 1 4200-0300

Power Line Fuse 3.15A 250V SB 1 520072

Power Line Fuse 1.6A 250V SB 1 520074

High Voltage Lead Set, 1m with alligator clips 1 S02

Ground Continuity Lead 1 700100

Instruction Manual 1 150697

Calibration Certificate 1 N/A

Accessories/Options Available

Item Quantity QuadTech P/N

High Voltage Lead Set, high & low, 1m (std. with unit) 1 S02

Corded Product Adaptor, 115V 1 S03

High Voltage Lead Set, high & low, 2m 1 S04

Foot Switch 1 S05

High Voltage Probe 1 S06

Power Entry Adaptor Cable 1 S07

Gun Probe 1 S08

High Voltage Lead, 1m, unterminated 1 S09

High Voltage Lead, 2m, unterminated 1 S10

Gun Probe with Remote Start 1 S11

Load Box, resistive 1 S12

Load Box, custom resistors 1 S14

Interconnection Cable to Sentry 50 Ground Bond Tester 1 S15

Ground Continuity Lead (standard with unit) 1 700100

International Power Strip 1 G16

Corded Product Adaptor, 240V 1 G25

Page 11 of 85

Page 12

Page 12 of 85

Page 13

Safety Precautions

WARNING

The Sentry Plus Series Hipot Tester can provide an output voltage as high as 6000V DC (5000V

AC) to the external device under test (DUT). Although the Sentry Plus unit is designed with full

attention to operator safety, serious hazards could occur if the instrument is used improperly and

these safety instructions are not followed.

1. The Sentry Plus unit is designed for operation with its chassis connected to earth ground.

The instrument is shipped with a three-prong power cord to provide this connection to

ground. This power cord should only be plugged in to a receptacle that provides earth

ground. Serious injury can result if the Sentry Plus is not connected to earth ground.

2. Tightly connect cable(s) to the (blue) RTN/LOW terminal. If this is not done, the

DUT’s casing can be charged to the high voltage t est level and serious injur y or electri cal

shock hazards could result if the DUT is touched.

3. Never touch the metal of the High Volta ge probe directl y. Touch only the insulated parts

of the lead(s).

4. Never touch the test leads, test fixture or DUT in any manner (this includes insulation on

all wires and clips) when the high voltage is applied and the red DANGER light is ON.

5. Before turning on the Sentry Plus unit, make sure there is no device (DUT) or fixture

connected to the test leads.

6. After each test, press the [STOP] (red) button for safety if there is an y concern that HV

may still be applied to the output terminals.

7. When the red DANGER LED is lit or flashing, NEVER touch the device under test, the

lead wires or the output terminals.

8. Before touching the test lead wires or output terminals make sure:

a) The red [STOP] button has been pressed

b) The red DANGER LED is OFF.

9. In the case of an emergency, turn OFF the POWER switch using a “hot stick” and

disconnect the AC power cord from the wall. DO NOT TOUCH THE Sentry Plus

INSTRUMENT.

10. If the DANGER LED does not go off when the [STOP] button is pressed, immediately

stop using the tester. It is possible that the output voltage is still being delivered

regardless of the TEST ON/OFF control signal.

11. When the Sentry Plus instrument is used in remote control mode, be extremel y careful.

The High Voltage Output is being turned on and off with an external signal.

Page 13 of 85

Page 14

Page 14 of 85

Page 15

Condensed Operating Instructions

WARNING

High Voltage is applied to the white HV Output Terminal anytime the red DANGER LED is ON

or flashing. Always make sure the DANGER LED i s OFF when connecting or disconnecting

the device under test (DUT).

General Information

The Sentry Plus Series Hipot Tester is a measuring instrument for direct readout of hipot output

voltage and leakage current and insulation resistance. The voltage applied to the device under

test is adjustable from 50V to 5kV AC and 50V to 6kV DC. The trip current limit is

programmable from 1uA to 20mA AC in 1uA steps and from 0.1uA to 5mA DC in 0.1uA steps.

The output voltage for Insulation Resistance tests is 50V to 1000V DC over a measurement

range of 100kΩ to 50GΩ.

Start-Up

The Sentry Plus Series unit can be operated from a power source betw een 90 and 250VAC at a

power line frequency of 50 or 60Hz. The standard Sentry Plus Series unit is shipped from

QuadTech with a 3.15A fuse in place for AC 90 -130V operation. (A 1.6A fuse is included for

200-250V operation). The Sentry Plus unit is shipped with the line voltage selector set for 120V.

Refer to paragraph 1.4.3 for instructions on changing the fuse or line voltage selector.

Connect the Sentry Plus Series unit AC power cord to the source of p roper voltage. Operate the

Sentry Plus Series instrument with its chassis connected to earth ground. The Sentry Plus

instrument is shipped with a three-prong power cord to provide this connection to ground. This

power cord should only be plugged into a receptacle that provides earth ground. Serious injur y

may result if the Sentry Plus Series instrument is not connected to earth ground.

Press the [POWER] button on the front panel to apply power. To switch the powe r off, press the

[POWER] button again or if measurements are to be made proceed with the Test Parameter

Setup in Table COI-1. The Sentry Plus Series instrument should warm up for 15 minutes prior to

use.

NOTE

Please read this instruction manual in its entirety before operating this instrument.

These condensed operating instructions are not a substitute for all the information provided in the

remainder of this manual.

NOTE

Refer to paragraphs 2.3 through 2.9 for a full description of programming test parameters and

instruction on how to store the test setup. Test parameters must be set before the Sentry Plus

Series instrument can be zeroed.

Page 15 of 85

Page 16

Condensed Operating Instructions (Continued )

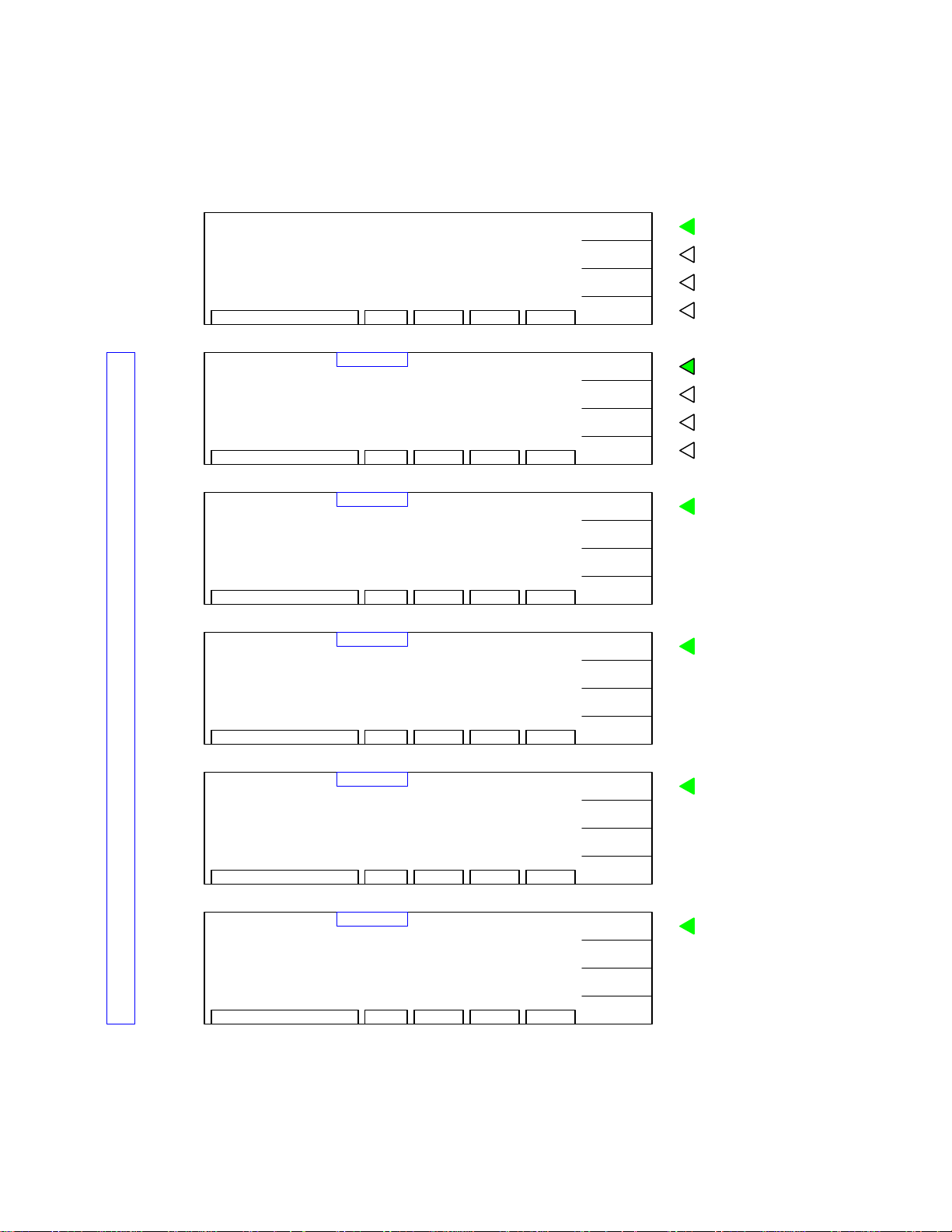

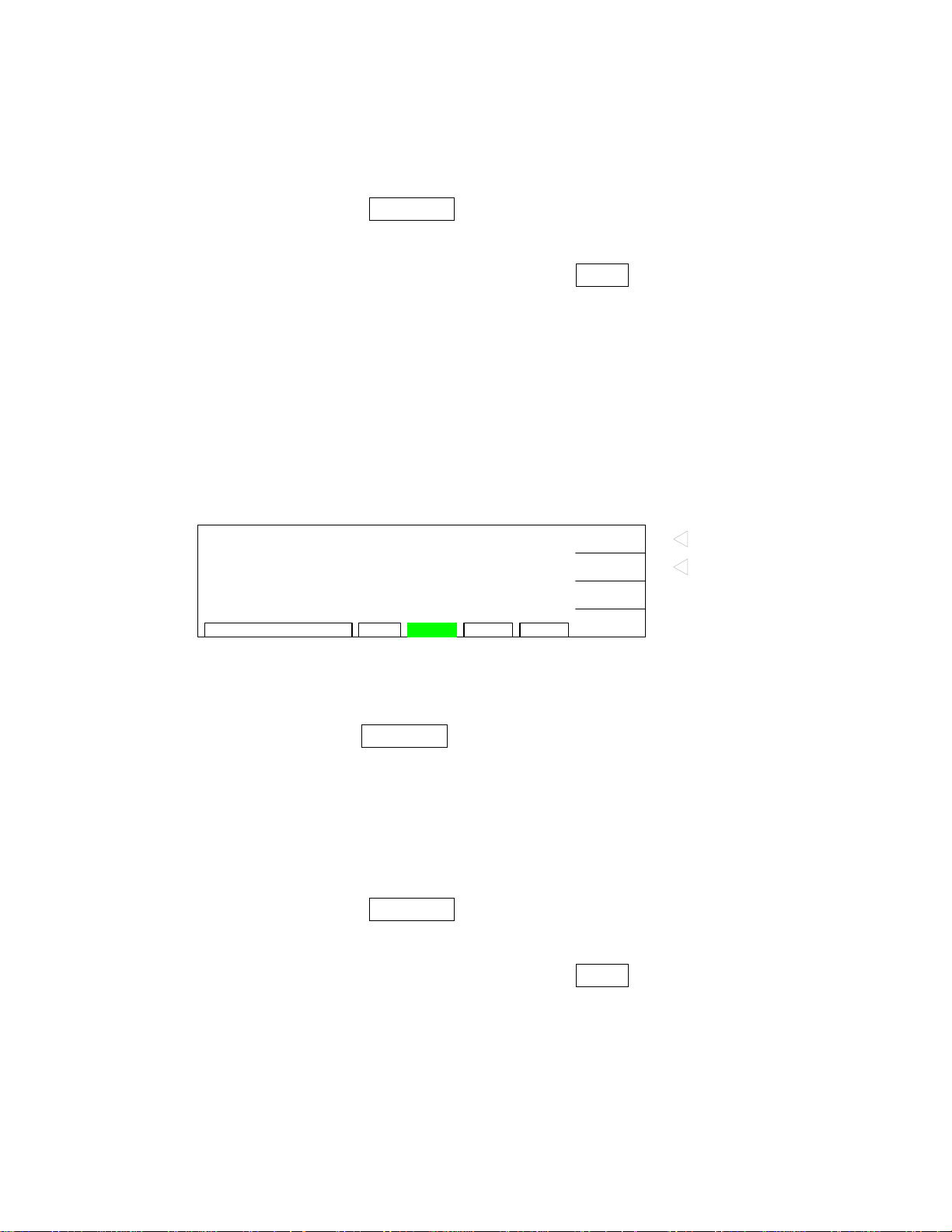

There are numerous menus within the Sentry Plus Series instruments. Familiarize yourself with

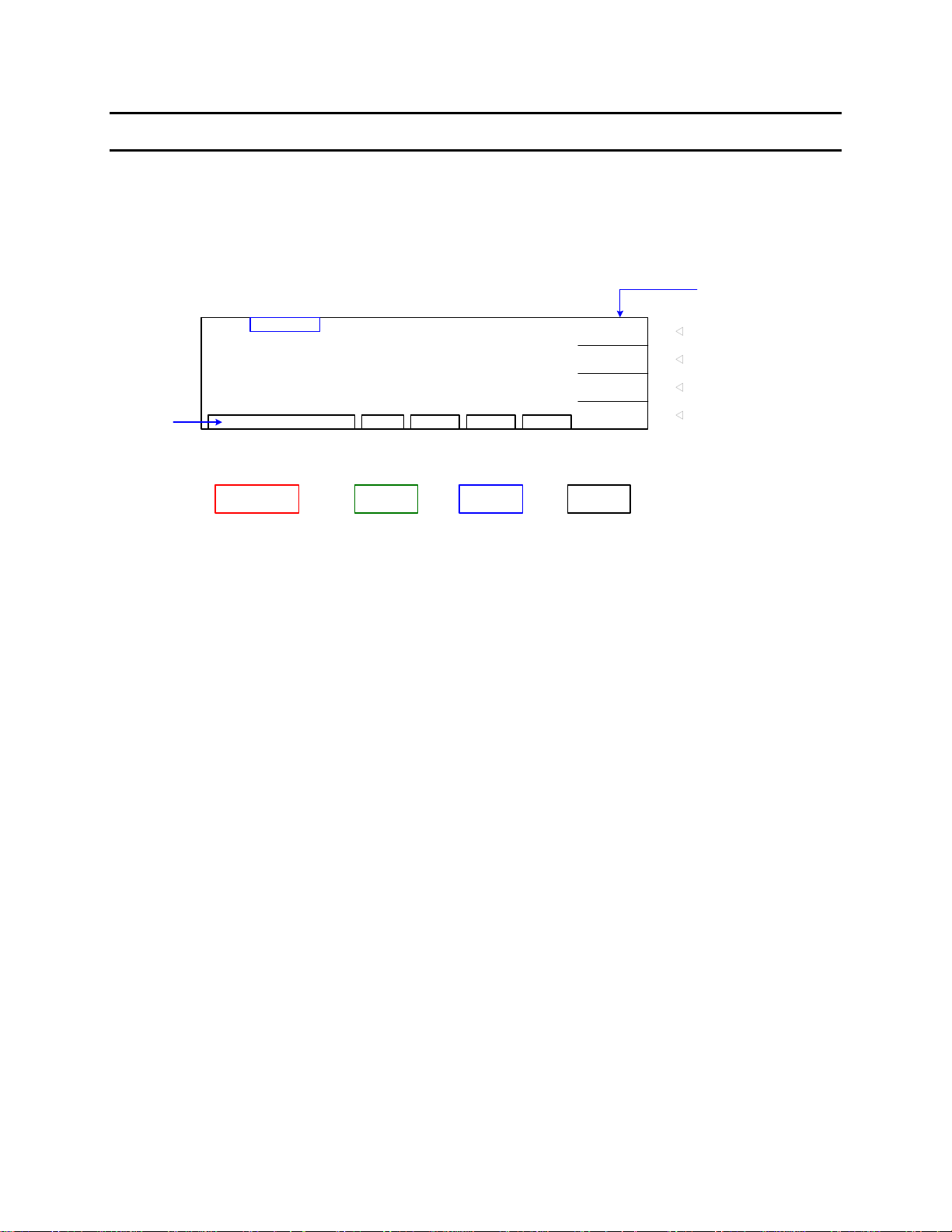

these menus prior to programming a test. Figure COI-1 illustrates the STAND BY display and

lists the functions that can be accessed by pressing the [F1] through [F4] keys.

"STAND BY" or "Power-Up" Display

Function of F1 - F4 Keys

Instrument

Status

M1

STEP 1/1

1.250kV

15.00mA

3.0s

RMT ERROFSTLOCKSTAND BY

PROGRAM MOREMENUPRESET

MORE..

Insert

Delete

NEXT

STEP: 1-10

MODE: AC/DC/IR/GC/PA

Voltage

High Limit

Test Time

Low Limit

ARC Limit

Ramp Time

Dwell Time

Fall Time

In Rush Current

(DC, IR)

(DC)

AC-V Freq. Memory

Soft AGC.

WV Auto Range

IR Auto Range

GFI

FAIL Restart

Figure COI-1: Sentry Plus Series Menus

LOWAC

ARC

RAMP

FALL

: OFF

: OFF

: OFF

: OFF

F3 F4F2F1

Recall

Delete

System

Contrast

Buzzer Volume

EN 50191

DC 50V AGC

Option

Multi-Link

Calibration

(Need password to enter)

Key Lock

(Need password to enter)

Change Password

(Need password to enter)

Error Log

About

Manufacturer

Software version

PROGRAM

PRESET

MENU

MORE..

View Test Steps (Tabular Format)

OffsetStore

To enter programming mode.

F1

To view/change preset (initial) settings.

F2

To view/change: memory, system, option,

F3

cal., key lock, pw, error & about.

To view the programmed test setups and

F4

access offset function.

Page 16 of 85

Page 17

Condensed Operating Instructions (Continued )

With the Sentry Plus Series instrument in “STAND BY” (or power-up display) status, follow the

steps in Table COI-1 to program an AC, DC, IR or GC test or insert a Pause in the test sequence.

"STAND BY"

DISPLAY

0.000kV

0.500mA

3.0s

LOWACSTEP 1/1

ARC

RAMP

FALL

RMT ERROFSTLOCKSTAND BY

OFF

:

OFF

:

OFF

:

OFF

:

PROGRAM

PRESET

MENU

MORE..

To enter programming mode.

F1

To view/change preset (initial)

F2

test parameters.

To view/change system parameters:

F3

memory, system, option, calibration, key

lock, password, error, & about.

To view the programmed test setups and

F4

access offset function.

PROGRAM MODE DISPLAYS

AC

Display

DC

Display

IR

Display

GC

Display

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

LOW

TIME

CURR

HIGH

DWELL

0.000kV

:

0.500mA

:

3.0s

:

0.000kV

:

0.500mA

:

3.0s

:

:

0.000kV

1.0M

::3.0s

: 0.0A

:

1.0

:

3.0s

LOWACSTEP 1/1

ARC

RAMP

FALL

RMT ERROFSTLOCKSELECT MODE

LOWDCSTEP 1/1

ARC

RAMP

FALL

I-RUS

RMT ERROFSTLOCKSELECT MODE

HIGHIRSTEP 1/1

RAMP

DWELL : OFF

Ω

FALL

RMT ERROFSTLOCKSELECT MODE

GCSTEP 1/1

Ω

LOW

OFF

:

OFF

:

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

OFF

:

OFF

:

:

OFFDWELL

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

UP

DOWN

NEXT

To change value in highlighted box.

F1

To toggle choices of highlighted box.

F2

To move highlighted box around

F3

display to select parameter to change

To exit programming mode.

F4

F1

To select test mode: AC/DC/IR/GC/PA

F2

F3

F4

To select test mode: AC/DC/IR/GC/PA

F1

F2

F3

F4

F1

To select test mode: AC/DC/IR/GC/PA

F2

F3

F4

F1

To select test mode: AC/DC/IR/GC/PA

F2

F3

F4

PA

Display

PAUSE

UNDER TEST SIGNAL

PAUSE MODE

::OFF

RMT ERROFSTLOCKSELECT MODE

PASTEP 1/1

EXIT

UP

DOWN

NEXT

RMT ERROFSTLOCKSELECT MODE

EXIT

Figure COI-2: “STAND BY” and PROGRAM Displays

Page 17 of 85

Page 18

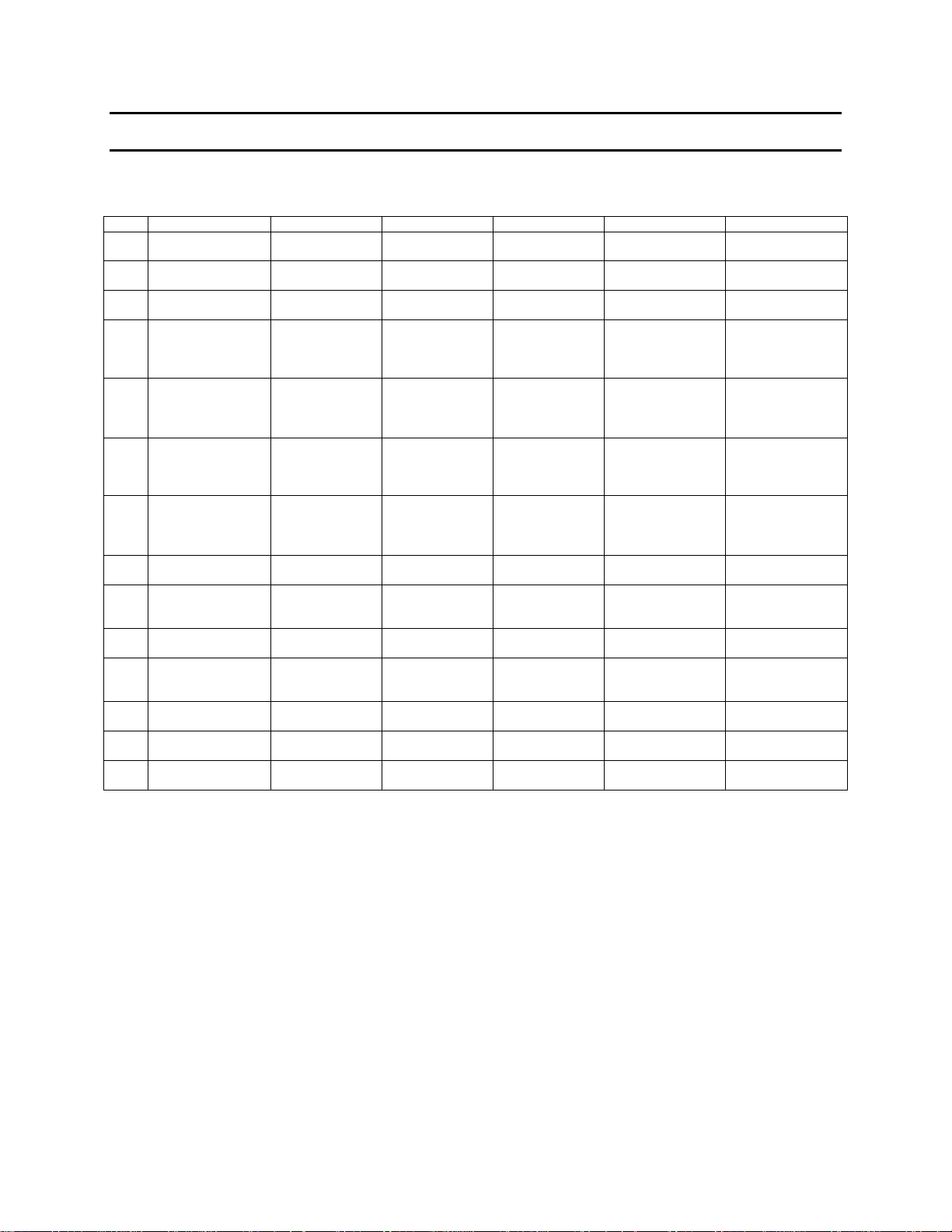

Condensed Operating Instructions (Continued )

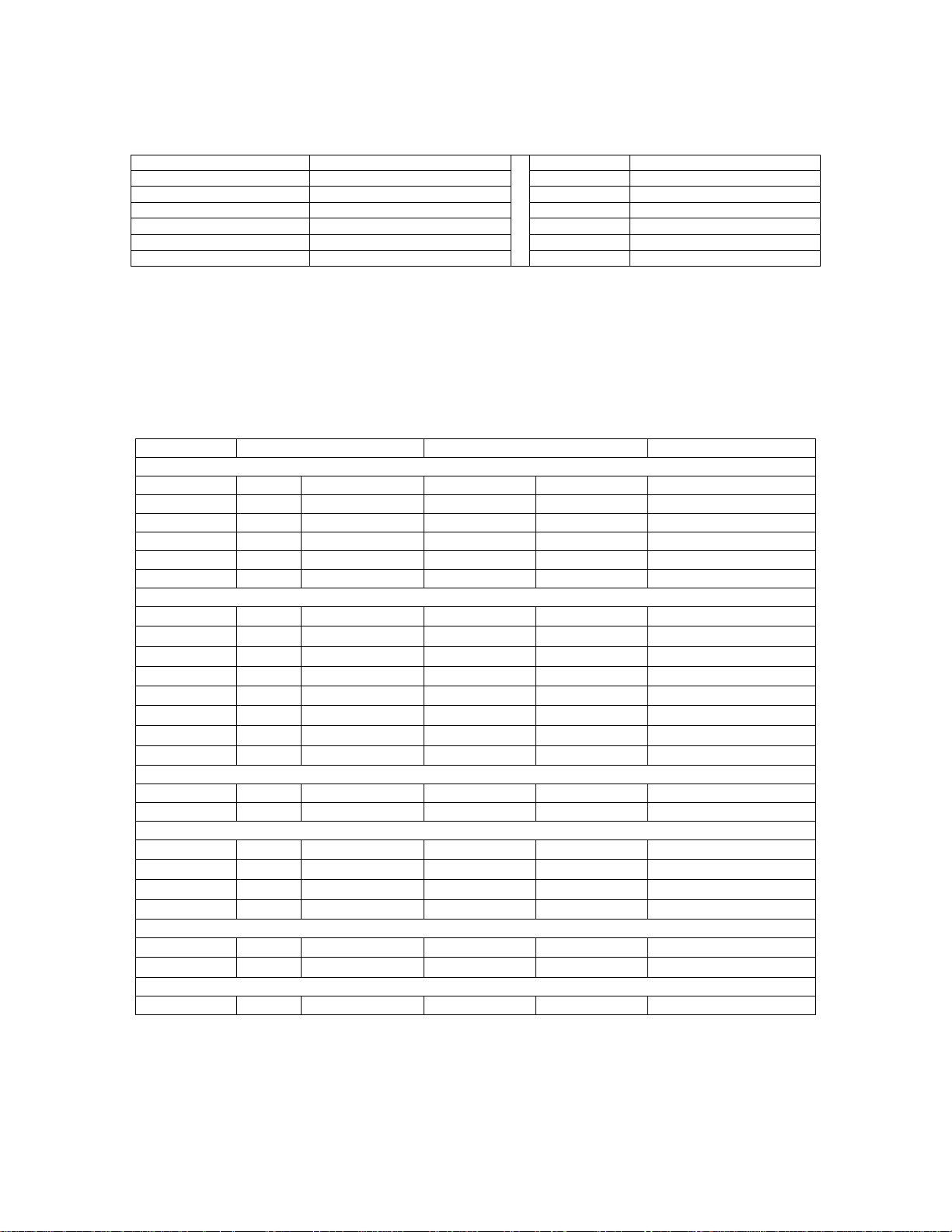

Table COI-1: Test Parameter Setup

Step Test Para meter AC Hipot DC Hipot IR GC Range

1 To enter

programming mode

2 Select Test Step [F1] = UP

3 Select Test Mode [F1] = UP

4 Set Test Voltage

Set Current (GC)

5 Set High Limit *

Set Low Limit (IR)

6 Set Test Time

Set Dwell (GC) ***

7 Set Low Limit **

Set High Limit (IR)

8 Set ARC Limit [F1] = INC.

9 Set Ramp Time [F1] = INC.

10 Set Dwell Time*** [F1] = INC.

11 Set Fall Time [F1] = INC.

12 Set In-Rush Current [F1] = INC.

13a To program next test

step OR

13b To exit

programming mode

* High limit decision is made throughout test time.

** Unit will make low limit decision at the end of test.

* ** Limits will be checked at end of dwell time.

[F1] =

PROGRAM

[F3] = NEXT

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F3] = NEXT

[F3] = NEXT

[F3] = NEXT

[F1] = NEW

OR

[F4] = EXIT [F4] = EXIT [F4] = EXIT Exit programm i ng

[F1] =

PROGRAM

[F1] = UP

[F3] = NEXT

[F1] = UP

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F3] = NEXT

[F1] = NEW

OR

[F1] =

PROGRAM

[F1] = UP

[F3] = NEXT

[F1] = UP

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

1-20mA AC

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

0, 0.5uA-5mA DC

[F1] = NEW

OR

[F1] = PROGRAM

[F1] = UP

[F3] = NEXT

[F1] = UP

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

[F1] = INC.

[F3] = NEXT

0-999s AC

0-999s DC

0-999s AC

[F1] = NEW

OR

1-10

AC, DC, IR, GC, PA

0.05-5kV AC

0.05-6kV DC

0.05-1kV IR

0.1A GC

0.001-20mA AC

0.0001-5mA DC

0.1-50000MΩ IR

0, 0.1-5Ω GC

0, 0.1-999s AC

0, 0.1-999s DC

0, 0.1-999s I R

0.1-1s GC

0-20mA AC

0-5mA DC

0-50GΩ IR

0-5Ω GC

1-5mA DC

0-999s DC

0-999s IR

0-999s IR

0-999s DC

0-999s IR

Program next step

OR

Page 18 of 85

Page 19

Condensed Operating Instructions (Continued )

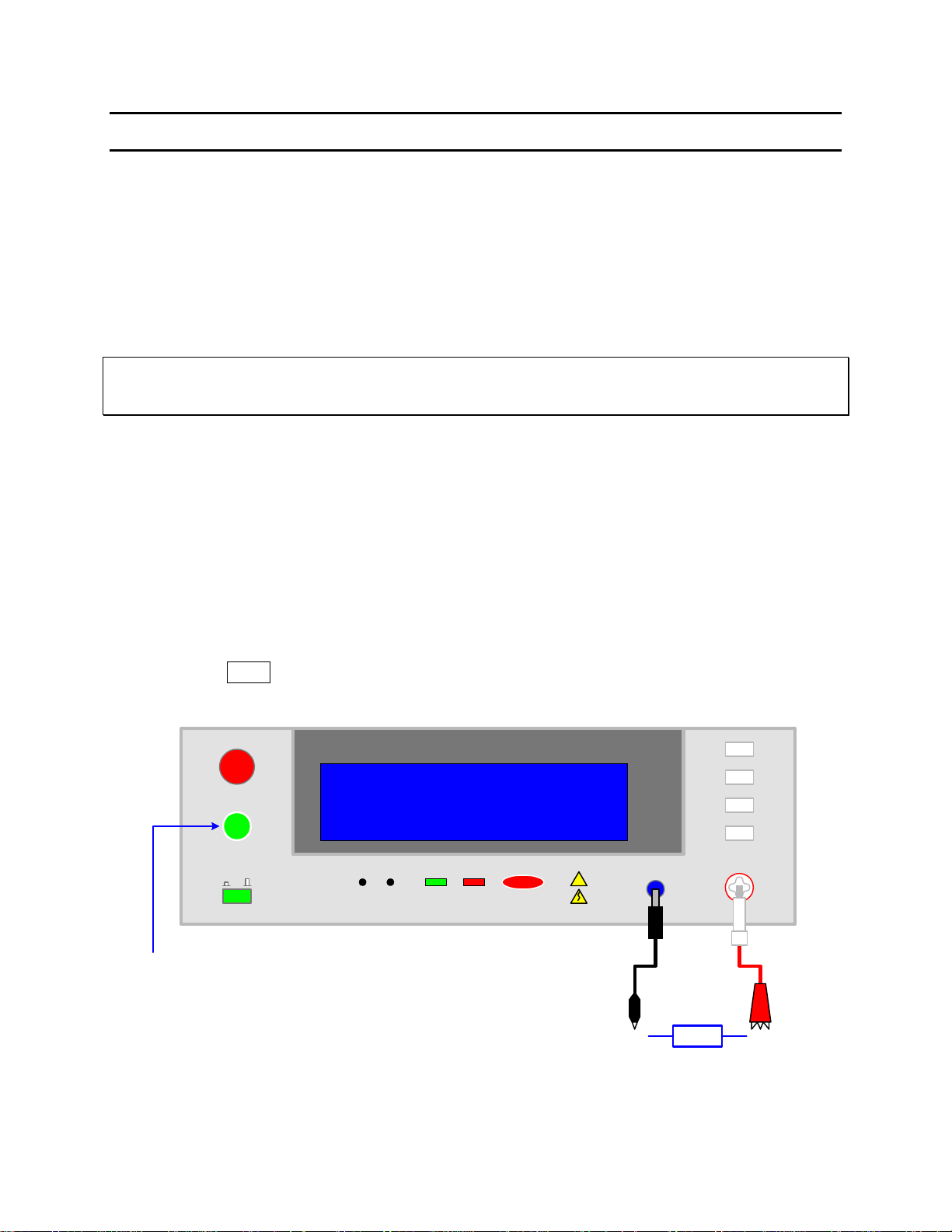

Offset

After setting your test parameters, zero the Sentry Plus Series instrument by using the automatic

offset. With no device connected, connect the appropriate cable (or other fixture) into the

OUTPUT connectors. Refer to paragraph 2.13 cable connections based on test to be performed.

Return and HV test leads should not be connected together (open circuit) for AC and DC hipot

tests. Return and GC test leads should be connected (short circuit) for a GC test. There is no

offset in an IR test.

NOTE:

If Ground Continuity (GC) is turned ON when performing an offset, the continuity lead must be connected to the

return (RTN/LOW) terminal, otherwise turn the continuity test OFF.

Prior to performing the OFFSET function:

• Allow the instrument to warm up for 15 minutes.

• Connect the Test cables (or fixture) to the front panel OUTPUT and RTN/LOW connectors.

• Program the test steps.

With the instrument in STAND BY status:

• Press [F4] = MORE

• Press [F3] = OFFSET

• Follow instructions on display: i.e.: connect OPEN across OUTPUT terminal.

• Press green [START] button.

• Wait while instrument gets OFFSET value.

• The OFST block at the bottom of the display is now highlighted (back lit).

• Press [F4] = MORE to return to STAND BY status.

STOP

START

01

When ready, press [START] to get offset values

Q

uadTech

1.

2.

Figure COI-3: Zero/Offset OPEN Configuration

Sentry 30 Plus AC/DC/IR Hipot Tester

Please open the HV output terminal

No offset in IR mode.

PRESS START KEY TO G ET OFFSET..

CAL UPDATE

DANGERPASS FAIL

!

CAUTION

Max 5kVAC

6kVDC

F1

F2

F3

F4

RTN/LOW

OPEN

F1

F2

F3

F4

OUTPUT

+-

Page 19 of 85

Page 20

Condensed Operating Instructions (Continued )

Connection to Device under Test (DUT)

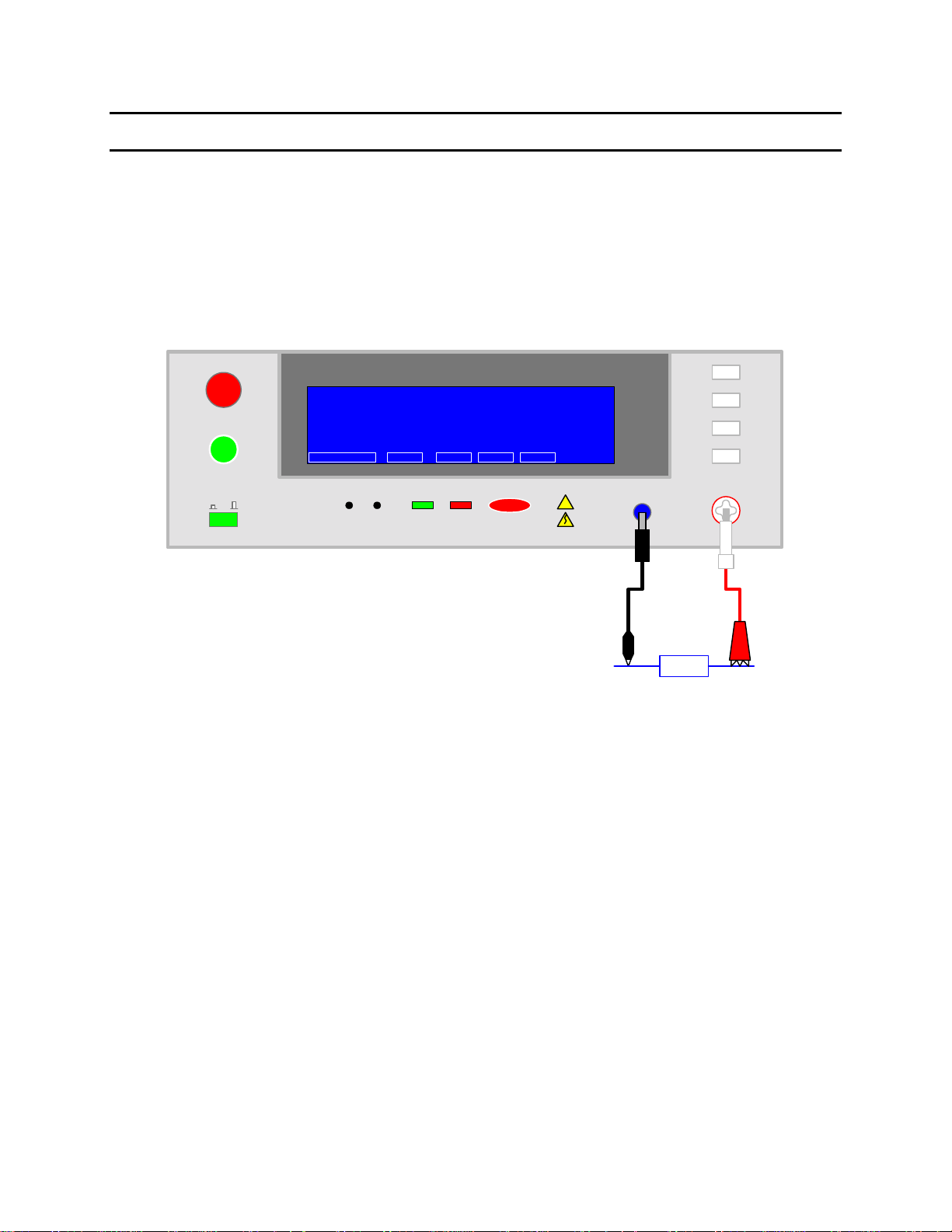

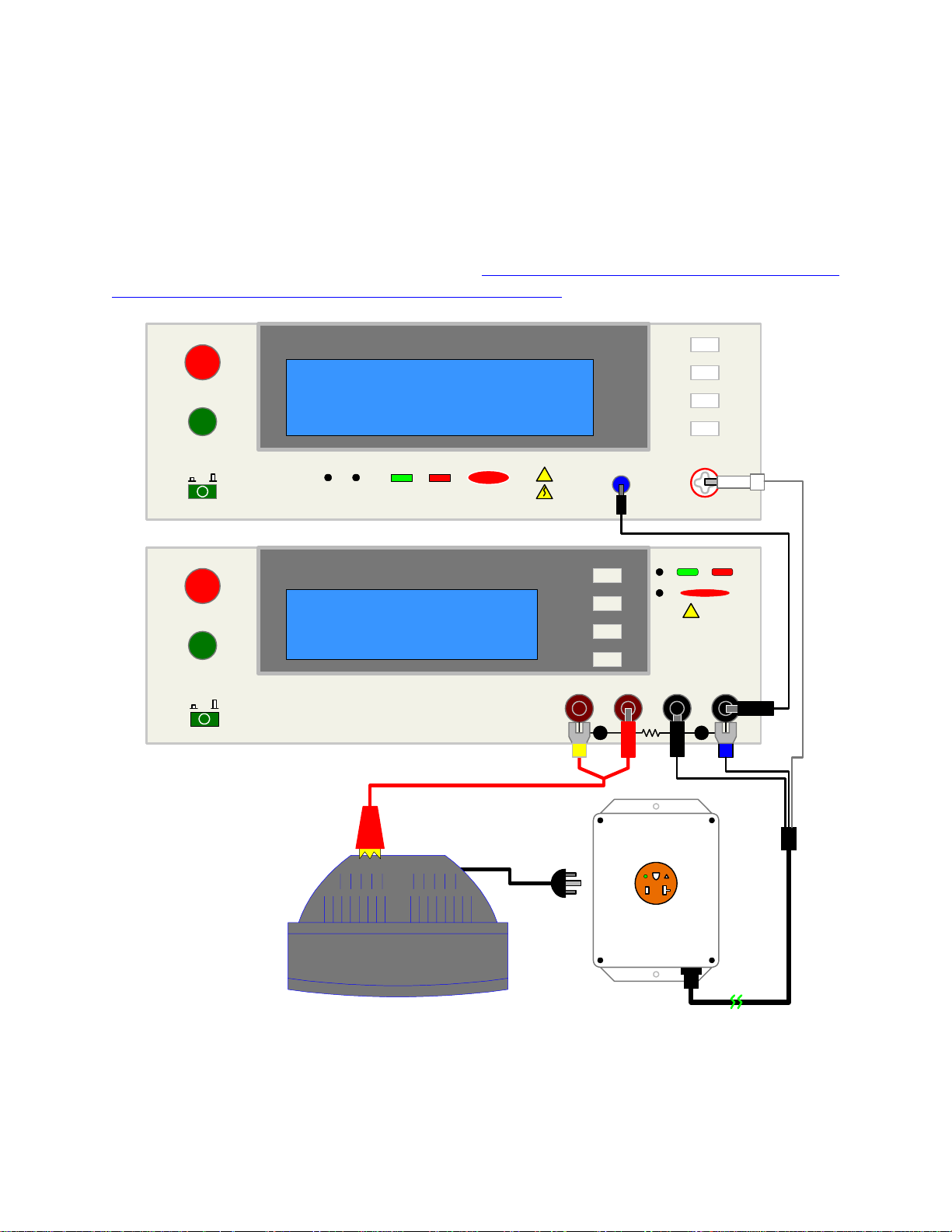

Figure COI-4 illustrates the connection of the Sentry Plus Series unit to a single DUT using the

S02 1-meter HV cable set that comes standard with the instrument. The custom white banana

plug/red alligator clip is connected between the OUTPUT terminal on the Sentry Plus Series unit

and the high side of the device under test. The black banana plug/alligator clip is connected

between the RTN/LOW terminal on the Sentry Plus Series unit to the low side of the DUT.

STOP

START

Q

uadTech

M1

1.250kV

0.500mA

3.0s

STAND BY OFST

01

Sentry 30 Plus AC/DC/IR Hipot Tester

STEP 1/5

CAL UPDATE

AC

RMT LOCK ERR

LOW: OFF

ARC: OFF

RAMP: OFF

FALL: OFF

CAUTION

6kVDC

F1

F2

F3

F4

RTN/LOW

S02

Cable

Set

DUT

PROGRAM

PRESET

MENU

MORE..

DANGERPASS FAIL

!

Max 5kVAC

COI-4: Connection to Device under Test

Measurement Mode

1. Turn [POWER] ON.

Allow Sentry Plus Series instrument a 15-minute warm up time.

2.

3. Connect S02 Black ground cable to Sentry Plus Series unit RTN/LOW terminal

4. Connect S02 White/red HV cable to Sentry Plus Series unit OUTPUT terminal.

5.

Press [F1] = PROGRAM and enter test parameters. When finished programming, press

[F4] = EXIT to return to STAND BY status.

Press [F4] = MORE to access Offset function. Press [F3] = OFFSET. Follow Offset

6.

instructions. When Offset is complete, press [F4] = MORE to return to STAND BY.

7. Connect device under test (DUT) to test leads.

8.

Press [START].

9. Record measurement.

Press [STOP].

10.

F1

F2

F3

F4

OUTPUT

+-

Page 20 of 85

Page 21

Section 1: Introduction

1.1 Unpacking and Inspection

Inspect the shipping carton before opening. If damaged, contact the carrier agent immediately.

Inspect the Sentry Plus Series instrument for an y damage. If the inst rument appears dam aged or

fails to meet specifications notify QuadTech (refer to instruction manual front cover) or its local

representative. Retain t he original shipping carton and packing mat erial for future use such as

returning the instrument for recalibration or service.

1.2 Product Overview

The Sentry Plus Series is available in three models, the 10, 20 and 30, all of which provide AC

Hipot testing capability. Additionally, the Sentry 20 & 30 Plus instruments provide DC Hipot

testing. The Sentry 30 Plus unit provides Insulation Resistance testing. The hipot test can be

programmed over a voltage range of 0.05 to 5kV AC and 0.05 to 6kV DC with a min/max

leakage current detection range of 0.001 to 20mA AC and 0.0001 to 5mA DC. Insulation

resistance measurements are possible to 50GΩ at programmable DC test voltages between 50

and 1000V. Each instrument comes standard with programmable ground continuity, internal

storage containing 60 memory locations (10 steps each) and a remote interface with start/stop

inputs & pass/fail outputs.

Figure 1-1: Sentry 30 Plus AC/DC/IR Hipot Tester

UL Requirements

The Sentry Plus Series instruments meet the requirements outlined by U L for Hipot Testers. The

Sentry Plus indicates the test potential (test voltage), has both visual and audible indication of

failure and the STOP switch must be manually pressed prior to another measurement being

made. The Sentry Plus Series instrument has a 100VA output [(5000V * 20mA) = 100VA]. The

Sentry Plus Series instrument also measures and displays the output voltage directly at the output

terminals during the test.

Introduction Page 21 of 85

Page 22

1.3 Controls and Indicators

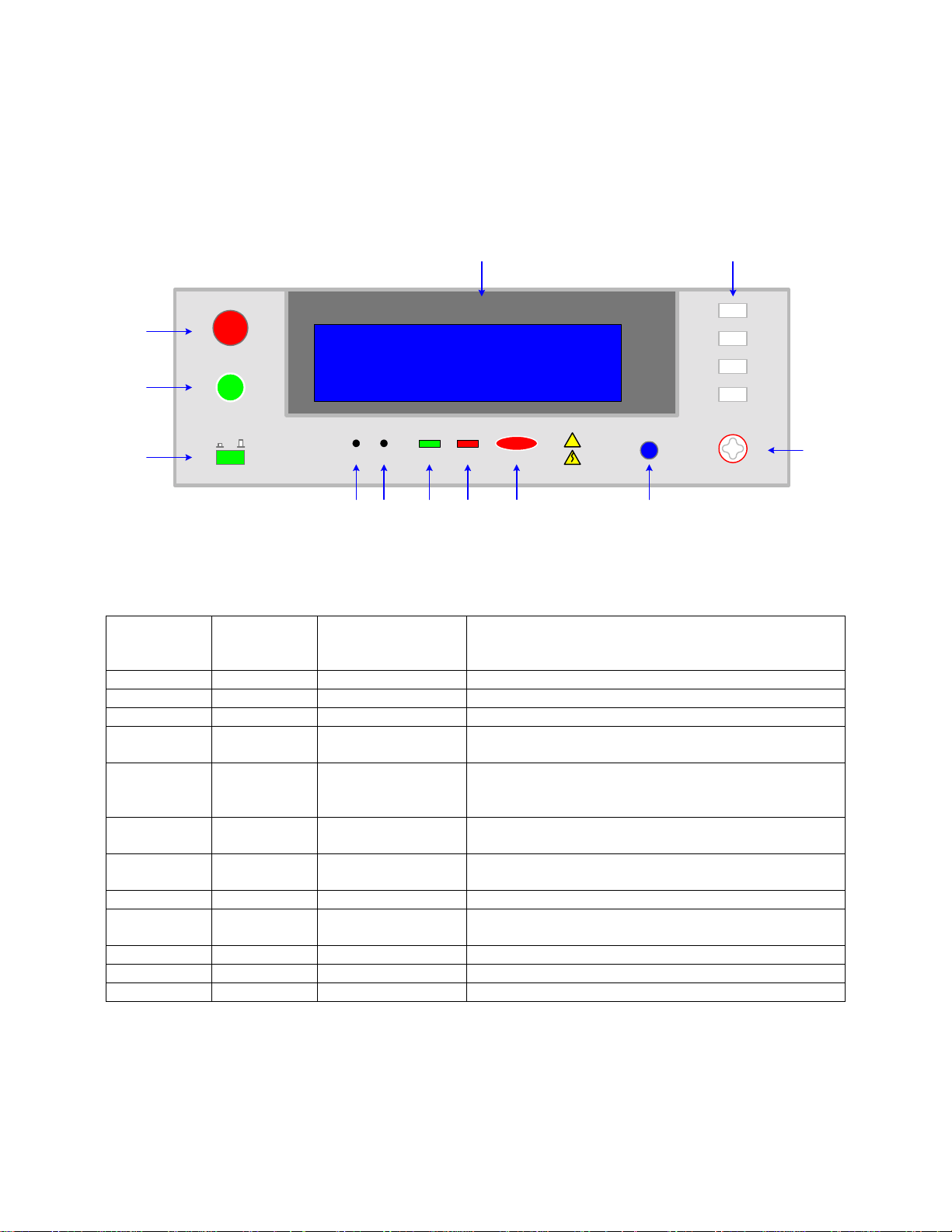

1.3.1 Front Panel Controls and Indicators

Figure 1-2 illustrates the controls and indicators on the front panel of the Sentry Plus Series

AC/DC/IR Hipot Tester. Table 1-1 identifies them with description and function.

54

STOP

Q

uadTech

3

START

2

01

1

Sentry 30 Plus AC/DC/IR Hipot Tester

CAL UPDATE

12

11 10 9

F1

F2

F3

F4

DANGERPASS FAIL

!

CAUTION

Max 5kVAC

8

RTN/LOW

6kVDC

7

F1

F2

F3

F4

OUTPUT

Figure 1-2: Sentry 30 Plus Front Panel Controls & Indicators

Table 1-1: Sentry 30 Plus Front Panel Controls & Indicators

Reference

Number

Figure 1-2

1 Power Green Push Button Apply AC Power: 1=ON, 0=OFF

2 START Green Push Button Initiate Test: HV applied to OUTPUT terminal

3 STOP Red Push Button Stop Test: HV terminated at OUTPUT terminal

4 Display LCD Pro gram Menu, Test Setup, Measurement Results,

5 F1, F2, F3

6 OUTPUT White Custom

7 RTN/LOW Blue Banana Socket RTN: Low voltage reference terminal

8 DANGER Red LED When lit, high voltage is present at OUTPUT terminals

9 FAIL Red LED When lit, DUT judged as FAIL. Output voltage is

10 PASS Green LED When lit, DUT judged as PASS

11 UPDATE Recessed P-B Qualified Service Personnel Only

12 CAL Recessed P-B Enable/Disable Instrument Calibration

Name Type Function

Memory Contents, Calibration

Gray Push Buttons Select Instru men t Functions

and F4

Keys perform different functions under different menus.

Right side of display shows corresponding key function.

High Voltage (Potential) Terminal

Banana Socket

LOW: Common ground reference terminal

immediately cut off. Press [STOP] to disable FAIL LED

6

Page 22 of 85 Introduction

Page 23

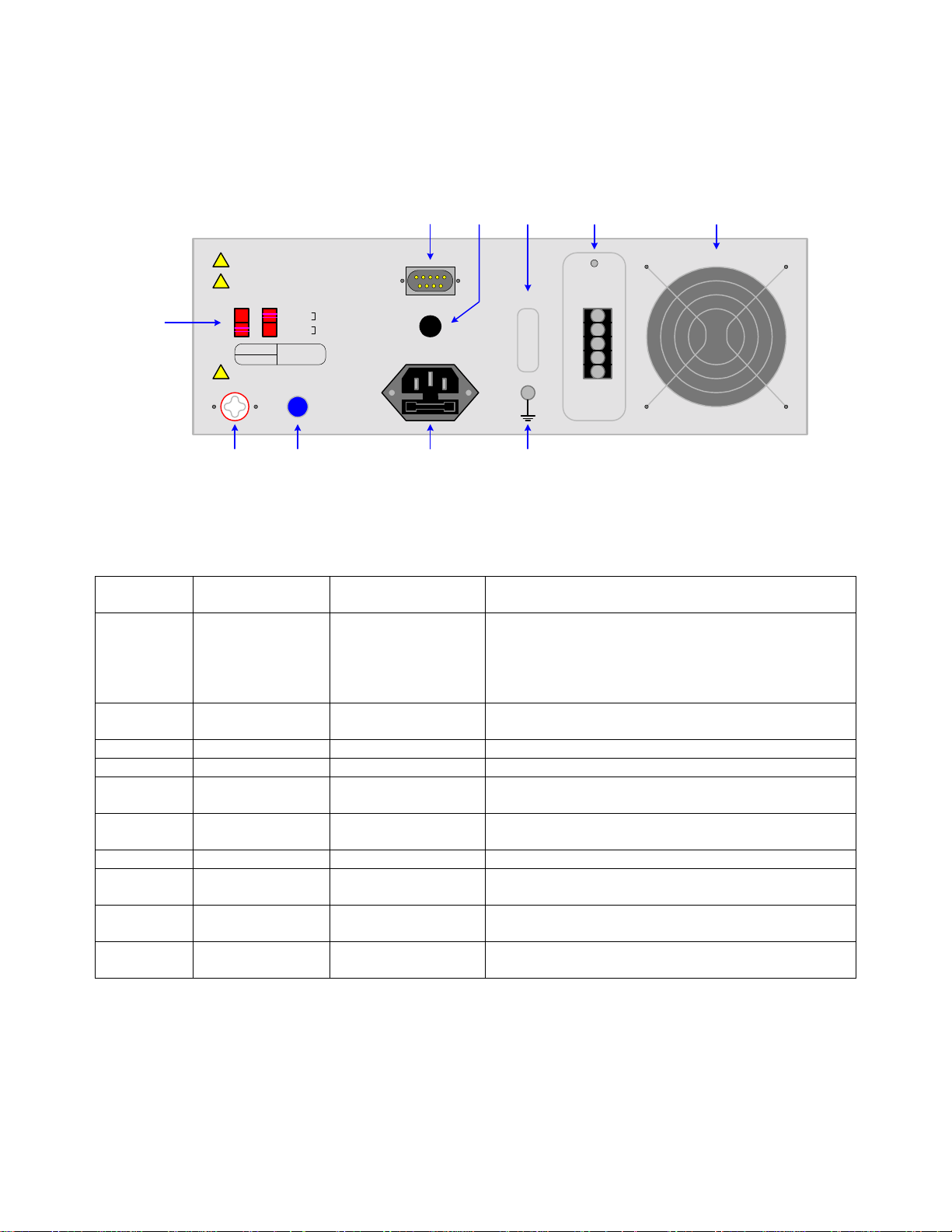

1.3.2 Rear Panel Controls and Connectors

Figure 1-3 illustrates the controls and connectors on the rear panel of the Sentry Plus Series

AC/DC/IR Hipot Tester. Table 1-2 identifies them with description and function.

3254

WARNING: FOR CONTINUED PROTECTION

AGAINST FIRE HAZARD, REPLACE ONLY WITH

THE SAME TYPE AND RATING OF FUSE AS

!

SPECIFIED FOR THE LINE VOLTAGE BEING

UTILIZED.

CAUTION: NO O PERATOR SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED

!

PERSONNEL.

POLLUTION DEGREE 2

INSTALL ATION CATEGORY II

VOLTAGE SELECTOR

1

MODEL NO.

SERIAL NO.

HIGH VOLTAGE

Max 5kVAC/6kVDC

HV OUTPUT

90V - 110V ~

108V - 132V ~

198V - 242V ~

216V - 250V ~

RTN/LOW

3.15AT

250V

1.6AT

250V

15

69

CONT. CHECK OPTION

100V/120V/220V/240V~

50/60Hz 300W MAX

START

RESET

COM

INTER

LOCK

6

FAN 50o C AUTO ON/OFF

10 9

78

Figure 1-3: Rear Panel Sentry Plus Series Instrument

Table 1-2: Sentry Plus Series Rear Panel Controls & Connectors

Reference #

Figure 1-3

1 VOLTAGE

2 Remote Silver 9-pin

3 CONT CHK OPT. Black banana plug Connection for Ground Continuity Check

4 TUV CE Sticker Instrument Safety Agency Listing

5 Remote Black 5-screw

6 Fan SF11580AT

7 Ground Silver Banana Plug Instrument Chassis Ground Connection

8 AC Line Input Black 3-wire inlet

9 RTN/LOW Blue Banana Socket RTN: Low voltage reference terminal

10 HV OUTPUT White Custom

Name Type Function

SELECTOR

2 Red 2-position

Slide Switches

Select Voltage Level corresponding to AC Source

90V – 110V: 3.15A 250V Slow Blow

110V – 130V: 3.15A 250V Slow Blow

200V – 240V: 1.6A 250V Slow Blow

220V – 250V: 1.6A 250V Slow Blow

Remote Connection: Inputs: Start, Reset

D-Type Connector

Outputs: Pass, Fail, Und e r Test

Remote Connection: Start, Reset, Com, Interlock

Terminal Strip

Cool Unit: T≥50°C = ON, T<45°C = OFF

115V 50/60Hz 0.10A

Connection to AC power source

module & fuse holder

Fuse Drawer: 3.15A 250V or 1.6A 250V (see #1)

LOW: Common ground reference terminal

Rear panel High Voltage (Potential) Terminal

Banana Socket

Introduction Page 23 of 85

Page 24

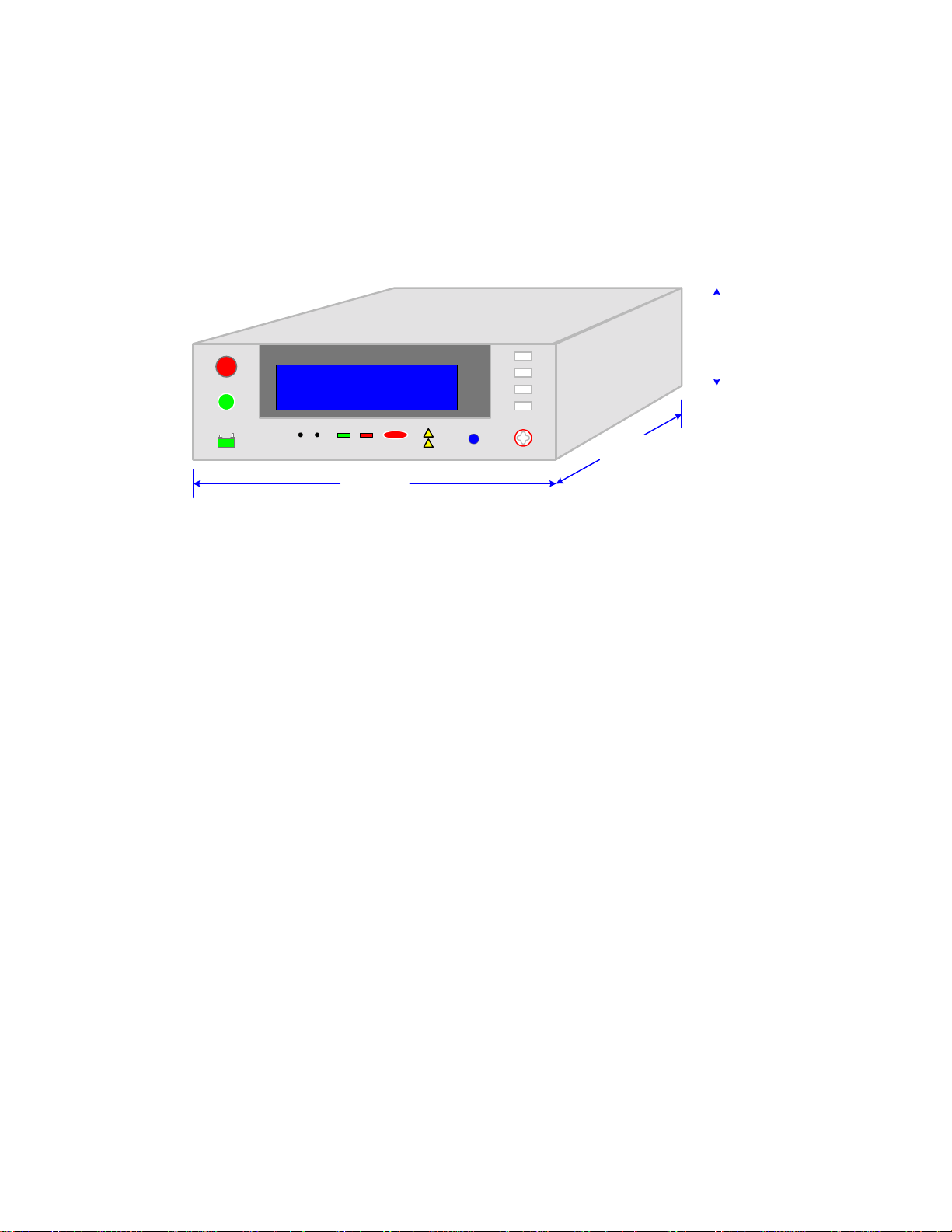

1.4 Installation

1.4.1 Dimensions

The Sentry Plus series unit is supplied in a bench configuration, i.e., in a cabinet with resilient

feet for placement on a table. Flip feet are provided under the front f eet so that the Sentry Plus

instrument can be tilted up for convenient operator viewing.

4.50"

STOP

START

01

Sentry 30 Plus AC/DC/IR Hipot Tester

QuadTech

CAL UPDATE

10.50"

262.5mm

F1

F2

F3

F4

DANGERPASS FAIL

CAUTION

Max 5kVAC

RTN/LOW

6kVDC

F1

F2

F3

F4

OUTPUT

14.25"

356.25mm

112.50mm

Figure 1-4: Sentry Plus Series Instrument Dimensions

1.4.2 Instrument Positioning

The Sentry Plus unit contains a graphic display for direct readout of measured parameters. The

optimum angle for viewing is slightly down and about 10 degrees either side of center. For

bench operation the front flip feet should always be used to angle the instrument up. In bench or

rack mount applications the instrument should be positioned with consideration for ample air

flow around the rear panel fan ventilation hole. An open space of at least 3 inches (75mm) is

recommended behind the rear panel. Testing should be performed on a non-conductive surface.

An ESD mat is not a recommended test platform.

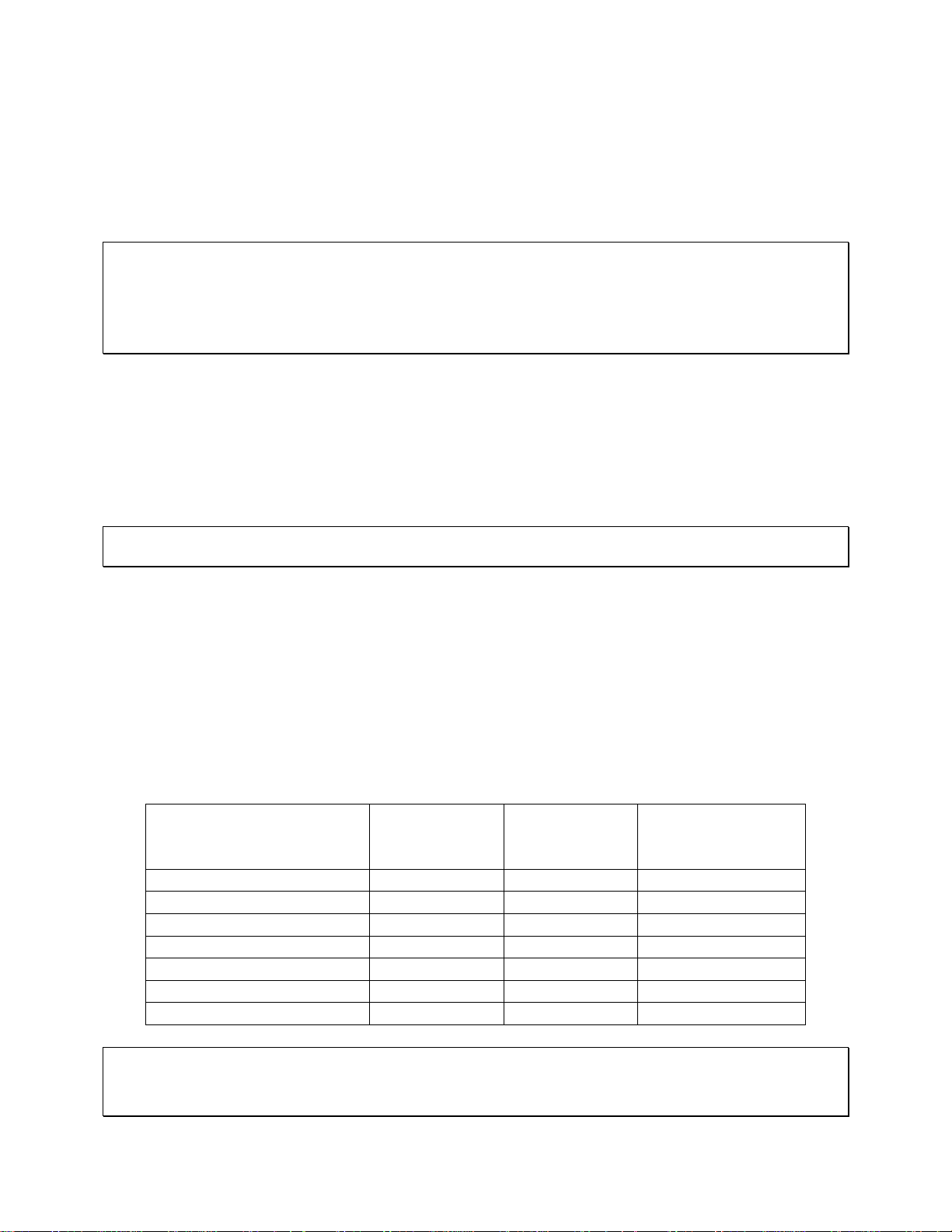

1.4.3 Power Requirements

The Sentry Plus instrument can be operated from a power source of 90 to 132V AC or 198 to

250V AC. Power connection is via the rear panel through a standard receptacle. Before

connecting the 3-wire power cord between the unit and AC power sour ce, make sure the voltage

selection switches on the rear panel (Fi gure 1-5) are in accordance with the power sour ce being

used. For a 90-132V source, use a 3.15A 250V fuse. For a 198-250V so urce, use a 1.6A 250V

fuse. Always use an outlet that has a properly connected protection ground.

Page 24 of 85 Introduction

Page 25

WARNING

MAKE SURE THE UNIT HAS BEEN DISCONNECTED FROM ITS AC POWER SOURCE

FOR AT LEAST FIVE MINUTES BEFORE PROCEEDING.

Procedure For Changing A Sentry Plus Series Fuse

Remove the fuse drawer, by pressing the black tab located at the center of the extended

fuse drawer, just below the 3-prong receptacle, and pull outward.

Once the fuse drawer has been removed from the instrument slide out the fuse from the holder

and replace. Make sure the new fuse is of the proper rating. Note that the fuse drawer can also

be used to store a spare fuse.

Install the fuse drawer back in the inlet module by pushing in until it locks securely in place.

VOLTAGE SELECTOR

90V - 110V ~

108V - 132V ~

198V - 242V ~

216V - 250V ~

3.15AT

250V

1.6AT

250V

100V/120V/220V/240V~

50/60Hz 300W MAX

FUSE Drawer

Figure 1-5: Close-Up of Sentry Plus Series Rear Panel

1.4.4 Safety Inspection

Before operating the instrument inspect the power inlet module on the rear of the Sentry Plus to

ensure that the properly rated fuse i s in place, otherwise damage to the unit is possible. M ake

sure that the voltage selector swit ches are set in accordance with the power source in use. R efer

to paragraph 1.4.3 and Figure 1-5.

The Sentry Plus instrument is shipped with a standard U.S. power cord, QuadTech P/N 42000300 (with Belden SPH-386 socket or equivalent, and a 3-wire plug conforming to IEC 320).

Make sure the instrument is only used with these cables (or other approved international cord

set) to ensure that the instrument is provided with connection to protective earth ground.

The surrounding environment should be free from excessive dust to prevent contamination of

electronic circuits. The surrounding environment should also be free from excessive vibration.

Do not expose the Sentry Plus instrument to direct sunlight, extreme temperature or humidity

variations, or corrosive chemicals.

Introduction Page 25 of 85

Page 26

Page 27

Section 2: Operation

2.1 Terms and Conventions

Table 2-1: Measurement Unit Prefixes

Multiple Scientific Engineering Symbol

1000000000000000 1015 Peta P

1000000000000 1012 Tera T

1000000000 109 Giga G

1000000 106 Mega M

1000 103 Kilo k

.001 10-3 milli m

.000001 10-6 micro u

.000000001 10-9 nano n

.000000000001 10

.000000000000001 10

ARCing: Sparking or ‘flashing over’ caused by a breakdown of electrical

Current:

AC: Alternating Current. AC is an electrical current that has one

DC: Direct Current. Non-reversing polarity. The movement of charge

Charging Current: An insulated product exhibits the basic characteristics of a

-12

pico p

-15

insulation.

polarity during part of the cycle and the opposing polarity during

the other part of the cycle. Residential electricity is AC.

is in one direction. Used to describe both current and voltage.

Batteries supply direct current (DC).

capacitor. Application of a voltage across the insulation causes a

current to flow as the capacitor charges. This current

instantaneously rises to a high value as voltage is applied then

exponentially decays to zero as the DUT becomes fully charged.

Charging current decays to zero much faster than dielectric

absorption.

femto f

Operation Page 27 of 85

Page 28

Dielectric Absorption: The physical phenomenon in which insulation appears to absorb

and retain an electrical c harge slowly over time. Apply a voltage

to a capacitor for an extended period of time. Then quickly

discharge it to zero voltage. Leave the capacitor open circuited

for a period of time then connect a voltmeter to it and measure the

residual voltage. The residual voltage is caused by the dielectric

absorption of the capacitor.

Dielectric Strength: The ratio between the voltage at which breakdown of the insulating

material occurs and the distance between the two poi nts subject to

the applied voltage.

Dielectric Withstand Test: This is t he most common electrical safety test perform ed. A high

voltage (either AC or DC) is applied to determine if a breakdown

will occur in the insulation of the DUT. Dielectric Withstand is

also referred to as a hipot (high potential) test.

Discharge: The act of draining off an electrical charge to gro und. Devices that

retain charge should be discharged after an IR test or DC hipot test.

DUT: Device Under Test. (i.e. the product being tested).

Frequency: The rate at which current or voltage reverses polarity and then

back again completing a full cycle, measured in Hertz (Hz) or

cycles/second. AC Line Frequency = 50/60 Hz.

Ground:

Ground: The base reference from which voltages are measured, nominall y

the same potential as the earth. Ground is also the side of a circuit

that is at the same potential as the base reference.

Ground Bond Test: Test to verify that all conductive parts of a product that are

exposed to user contact are connected to the power line ground.

The ground bond test verifies the integrity of the ground

connection using a high current AC signal with current level as

high as 30Amps. Ground bond provides a better simulation of how

a product will perform under an actual fault condition.

Ground Continuity: Test to verify that all conductive parts of a product that are

exposed to user contact are connected to the power line ground.

GC Test normally performed with a low current DC signal that

checks to ensure the ground connection has a resistance of <1Ω.

Page 28 of 85 Operation

Page 29

Insulation Resistance: Measures the total resistance between any two points separated by

electrical insulation. The IR test determines how effective the

dielectric (insulation) is in resisting the flow of electrical current.

Interface:

IEEE-488: General Purpose Interface Bus (GPIB). GPIB is an industry

standard definition of a Parallel bus connection for the purpose of

communicating data between devices.

RS232: An industry standard definition for a Serial line communication

link or port.

Scanner: An electronic device designed to switch or matrix signals.

Leakage Current (LC):

Leakage Current: The residual flow of current that flows through the insulation after

a high voltage has been applied for a period of time. The leaka ge

current is equal to the applied voltage divided by the insulation

resistance. Leakage current is the main measured value for AC

hipot and DC hipot.

Applied Part LC Test: A line leakage current test that measures the current that would

flow from, to or between applied parts such as sensor and patient

leads. This test is the most complicated and time-consuming line

leakage test.

Earth LC Test: The most important and most common of the line leakage tests.

Earth leakage current is basically the current flowing back through

the ground conductor on the power cord. It is measured by

opening the ground conductor, inserting a circuit with the

simulated impedance of the human body then measuring the

voltage across part of the circuit with a true RMS voltmeter.

Enclosure LC Test: A line leakage test that measures t he cu rrent t hat flows throu gh the

human body if the body had touched the enclosure of the DUT.

Line LC Test: A line voltage leakage current test simulates the effect of a person

touching exposed metal parts of a product and detects whether or

not the leakage current that flows through the person’s body

remains below a safe level. Apply power to the product being

tested, then measure the leakage current from any exposed metal

on the chassis of the product under a fault condit ions such as “no

ground”. A special circuit is used to simulate the impedance of the

human body.

Operation Page 29 of 85

Page 30

Limits:

High Limit: The upper value for a test to be conside red a pass. If the measured

value is higher than the high limit the test is considered a fail. In

hipot, leakage current and ground bond test modes a high limit is

required.

Low Limit: The lower value for a test to be considered a pass. If the measured

value is lower than the low limit the test is considered a fail. In

insulation resistance test mode a low limit is required. In an AC or

DC Hipot test, the low limit FAIL decision occurs at the end of the

programmed test time.

Mode: The test to be performed such as: AC Hipot (AC), DC Hipot (DC),

Insulation Resistance (IR), Ground Continuity (GC) or Pause (PA).

Step: The order in which the tests will be performed. For example if

step 1 is a ground continuity test, step 2 an AC hipot and step 3 an

insulation resistance measurement then when the START but ton is

pressed, the Sentry will perform a GC test followed by an AC test

then an IR test.

Test Time:

Ramp: The period of time for the voltage to climb to programmed level.

Dwell: The period of time for the voltage to settle at programmed level.

Test: The period of time that the voltage is applied to the DUT.

Fall: The period of time for the voltage to decrease back to 0.

Test Current:

Real Current: The resistive current component of the device under test. The

resistive component is attributed to the resistance of the device’s

insulation.

Total Current: A measure of the resistive and reactive current components of the

device under test. The reactive component is attributed to the

capacitive or inductive components of the circuit

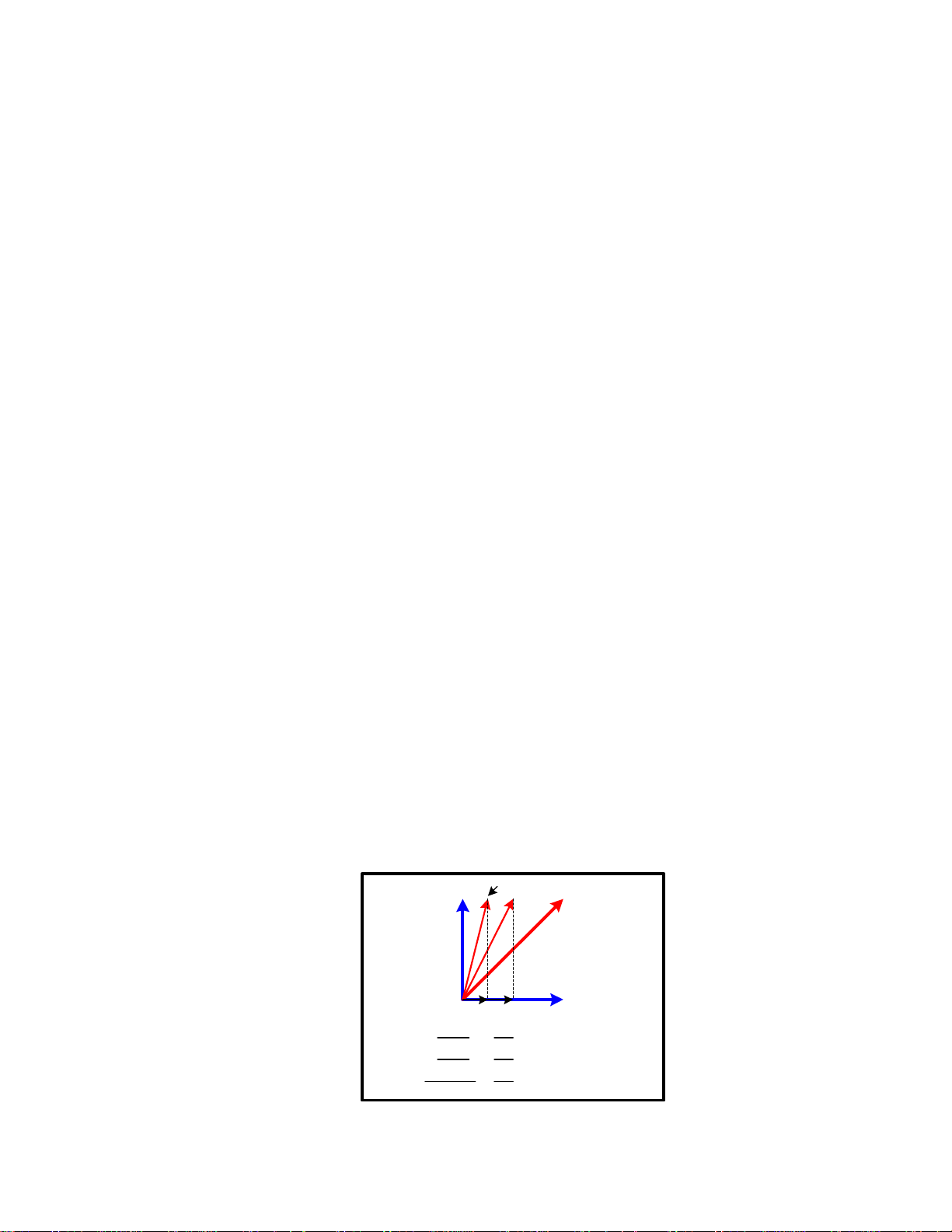

Total Current "A"

"A" "B"

=

=

=

Total Current "B"

200

> 100% Change

100

101

> 1% Change

100

100

>

100

Total Current

Real

(Resistive)

Current

Component

0% Change

Reactive

(Capacitive)

Current

Component

Real "B"

Real "A"

Total "B"

Total "A"

Reactive "B"

Reactive "A"

Page 30 of 85 Operation

Page 31

2.2 Startup

Check to make sure the Red Voltage Selector Switches on the rear panel agree with the power

source available. Depending on the power source the switch positions should be in the up or

down positions as shown in Figure 1-5 (Close-Up of Sentry Plus Series Rear Panel).

WARNING

NEVER TOUCH THE TEST LEADS IN ANY MANNER (this includes insulation on all wires and clips) when

HIGH VOLTAGE IS APPLIED and red DANGER LED is ON.

USE ALL PRECAUTIONS NECESSARY TO AVOID TOUCHING THE DEVICE UNDER TEST WH EN THE

RED DANGER LED IS ON OR FLASHING.

Connect the instrument power cord to the source of proper voltage. The instrumen t is to be

used only with three-wire grounded outlets.

Power is applied to the Sentry Plus Series instrument by pressing the green [POW ER] switch on

the front panel to the ON (1 position). The Sentr y Plus Series unit should warm up for a period

of at least 15 minutes prior to use.

WARNING

DO NOT TURN INSTRUMENT POWER ON OR OFF WITH TEST DEVICES CONNECTED.

2.3 Programming Electrical Safety Tests

The Sentry Plus Series instrument is capable of performing the tests listed in Table 2-2. A

single-step test can be performed on a device and is programmed as described in paragraphs 2.4

– 2.8. When the device under test requires a multi-step test the order of test precedence is

important. Refer to paragraph 2.9 for test setup store/re call instructions and to paragraph 2.10 fo r

instructions on programming a multi-step test.

Table 2-2: Sentry Plus Series Electrical Safety Tests

Test Software

Designation

Programming

Instructions

Sentry Plus Series

Instrument

Paragraph

Ground Continuity GC 2.4 10, 20, 30

AC Hipot AC 2.5 10, 20, 30

DC Hipot DC 2.6 20, 30

Insulation Resistance IR 2.7 30

Pause PA 2.8 10, 20, 30

Storing a Test Setup 2.9 10, 20, 30

Multi-Step 2.10 10, 20, 30

NOTE:

This manual is set up so if you follow the instructions in paragraphs 2.4 through 2.9 and you will

have programmed a 5-step test setup and stored it to memory location 1.

Operation Page 31 of 85

Page 32

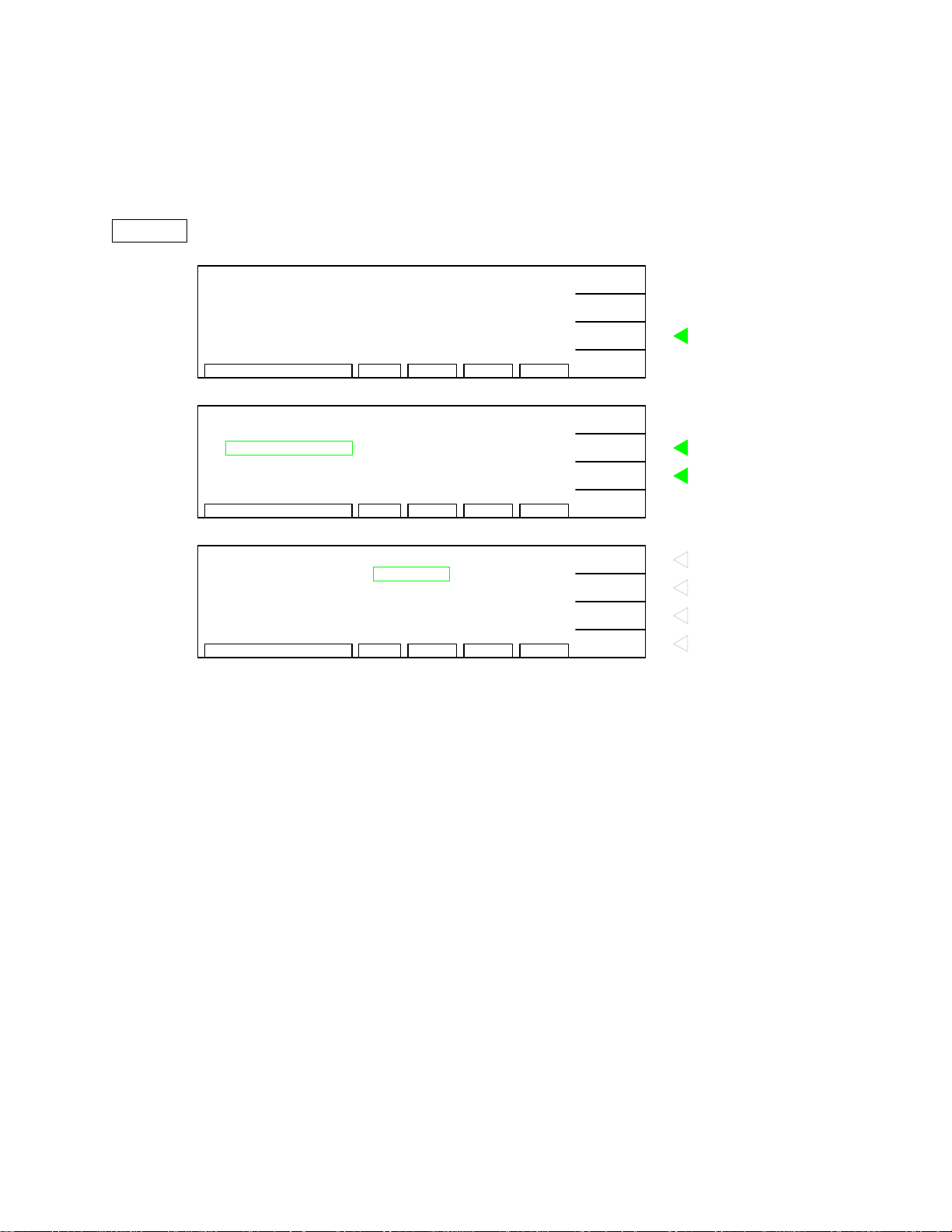

Function keys of the STAND BY Display

The function keys on the right hand side of the displa y allow the operator to access the numerous

menus imbedded within the Sentry Plus Series instrument software. Familiarize yourself with

these menus prior to programming a test. Figure 2-1 illustrates the STAND BY display and lists

the functions that can be accessed by pressing the [F1] through [F4] keys.

"STAND BY" or "Power-Up" Display

Function of F1 - F4 Keys

Instrument

Status

M1

STEP 1/1

1.250kV

15.00mA

3.0s

RMT ERROFSTLOCKSTAND BY

PROGRAM MOREMENUPRESET

MORE..

Insert

Delete

NEXT

STEP: 1-10

MODE: AC/DC/IR/GC/PA

Voltage

High Limit

Test Time

Low Limit

ARC Limit

Ramp Time

Dwell Time

Fall Time

In Rush Current

(DC, IR)

(DC)

AC-V Freq. Memory

Soft AGC.

WV Auto Range

IR Auto Range

GFI

FAIL Restart

Figure 2-1: STAND BY Function Key Menus

LOWAC

ARC

RAMP

FALL

: OFF

: OFF

: OFF

: OFF

F3 F4F2F1

Recall

Delete

System

Contrast

Buzzer Volume

EN 50191

DC 50V AGC

Option

Multi-Link

Calibration

(Need password to enter)

Key Lock

(Need password to enter)

Change Password

(Need password to enter)

Error Log

About

Manufacturer

Software version

PROGRAM

PRESET

MENU

MORE..

View Test Steps (Tabular Format)

OffsetStore

To enter programming mode.

F1

To view/change preset (initial) settings.

F2

To view/change: memory, system, option,

F3

cal., key lock, pw, error & about.

To view the programmed test setups and

F4

access offset function.

Page 32 of 85 Operation

Page 33

POWER UP and STAND BY Displays

The Sentry Plus Series instruments have multiple menus or displays that may seem confusing at

first glance. In an attempt to clarify the numerous functions of the software, this instruction

manual will illustrate these displays in a (hopefully) logical format. The function keys (F1, F2,

F3 & F4) perform different tasks depending upon the menu currently shown on the display.

Figure 2-2 illustrates the instrument display when the instrument is initially turned on.

Function of F1 - F4 KeysSoftware

F1

F2

F3

EXIT

F4

Memory

Calibration

Line Frequency

Model #

SENTRY PLUS 30 VERSION X.XX

DATA MEMORY CHECK

CALIBRATION DATA

AC LINE FREQUENCY

:

:

:

RMT ERROFSTLOCKWAIT 3s

PASS

PASS

60 Hz

Power Up Display: Instrument Initialization

Figure 2-2: Power-Up Display

After 3 seconds, the instrument display reverts to the STAND BY display as illustrated in Figure

2-3. The box in the lower left hand corner denotes the instrument status.

Test Voltage (kV)

Test Current (mA)

Test Time (sec)

Memory

Location Mx

x = 1-60

M1

1.250kV

15.00mA

Test Step 1/x

3.0s

x = 1-10

STEP 1/1

Test Mode

AC, DC, IR,

GC or PA

RMT ERROFSTLOCKSTAND BY

Test

Settings

LOW : OFFAC

ARC : OFF

RAMP: OFF

FALL: OFF

Function

of

F1 - F4 Keys

PROGRAM

PRESET

MENU

MORE..

To enter programming mode.

F1

To view/change preset (initial)

F2

test parameters.

To view/change system parameters:

memory, system, option, calibration, key

F3

lock, password, error, & about.

To view the programmed test setups and

F4

access offset function.

Instrument Status

STAND BY

When box is highlighted (back lit),

the function is

ON.

Remote

Status

On/Off

Front

Panel

Lock Out

Status

On/Off

Offset

Status

On/Off

Error

Status

On/Off

Figure 2-3: STAND BY Display

To access the programming function of the Sentry Plus Series instrument in the STAND BY

menu, press the [F1] key (PROGRAM). Once in the PROGRAM di splay, select the test step

then the test mode (AC, DC, IR, GC or PA). Paragraphs 2.4 - 2.8 illustrate how to program the

specific parameters of each of the 5 tests.

NOTE

This manual is set up so if you follow the instructions in paragraphs 2.4-2.9 you will have programmed a 5-step test

(GC, AC, DC, IR and PA) and saved to memory location 1.

Operation Page 33 of 85

Page 34

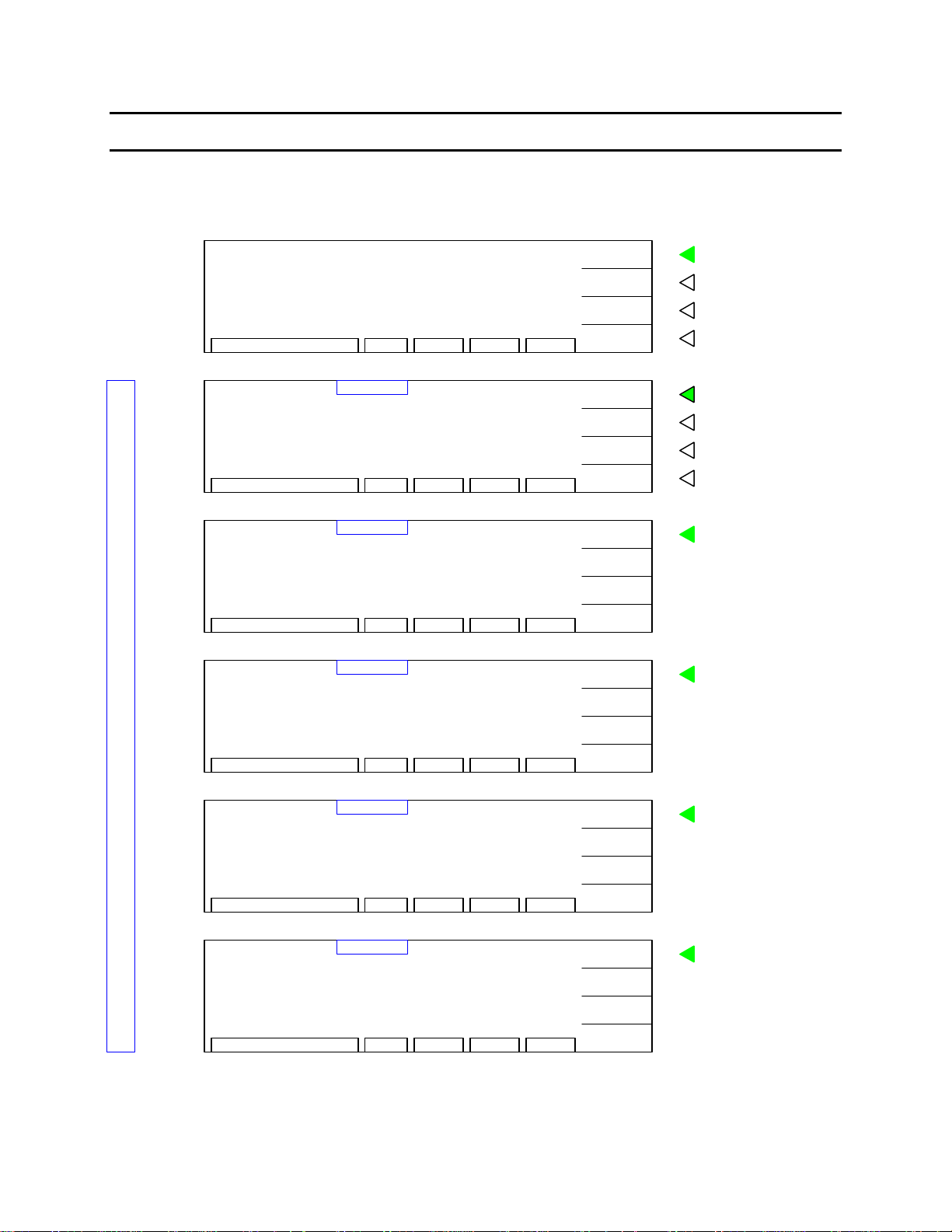

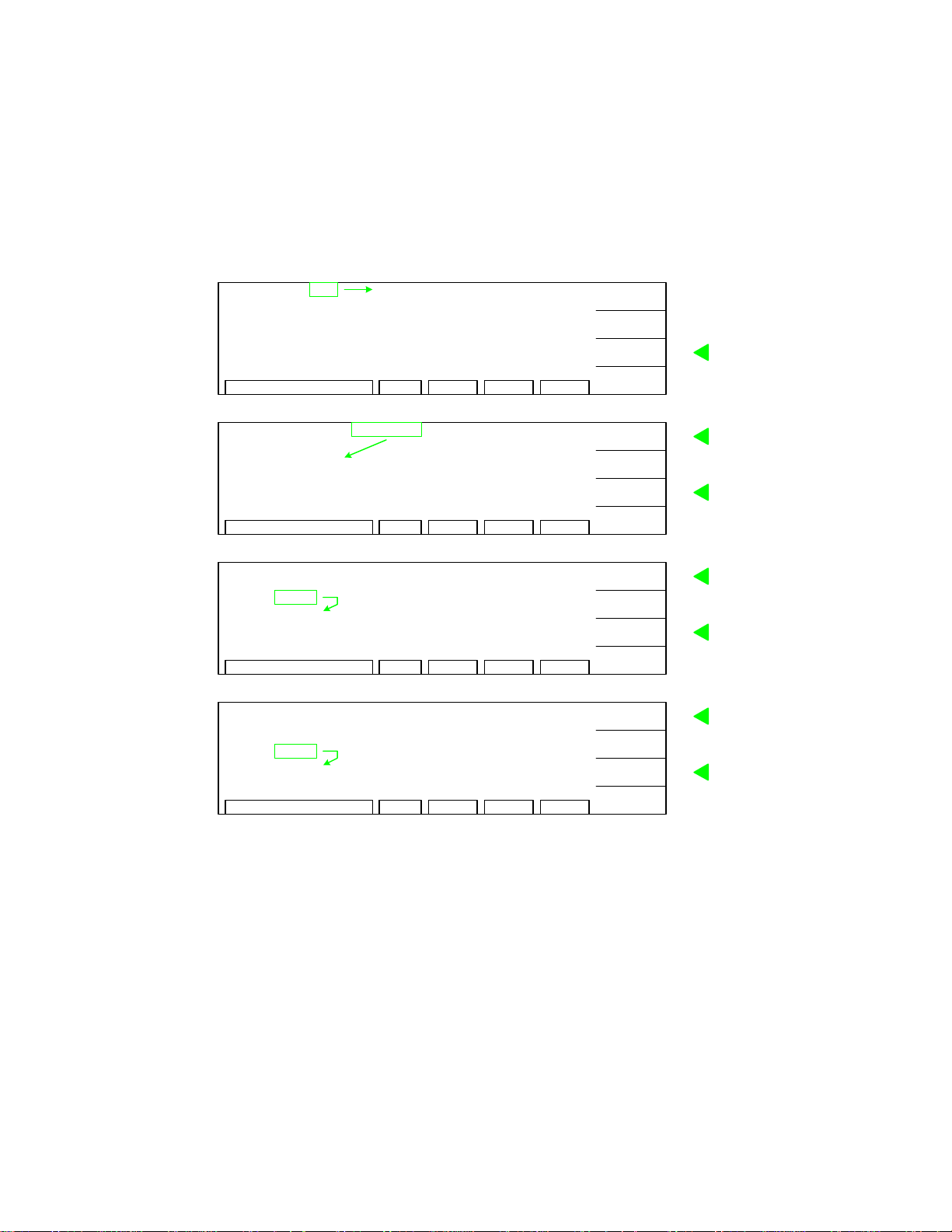

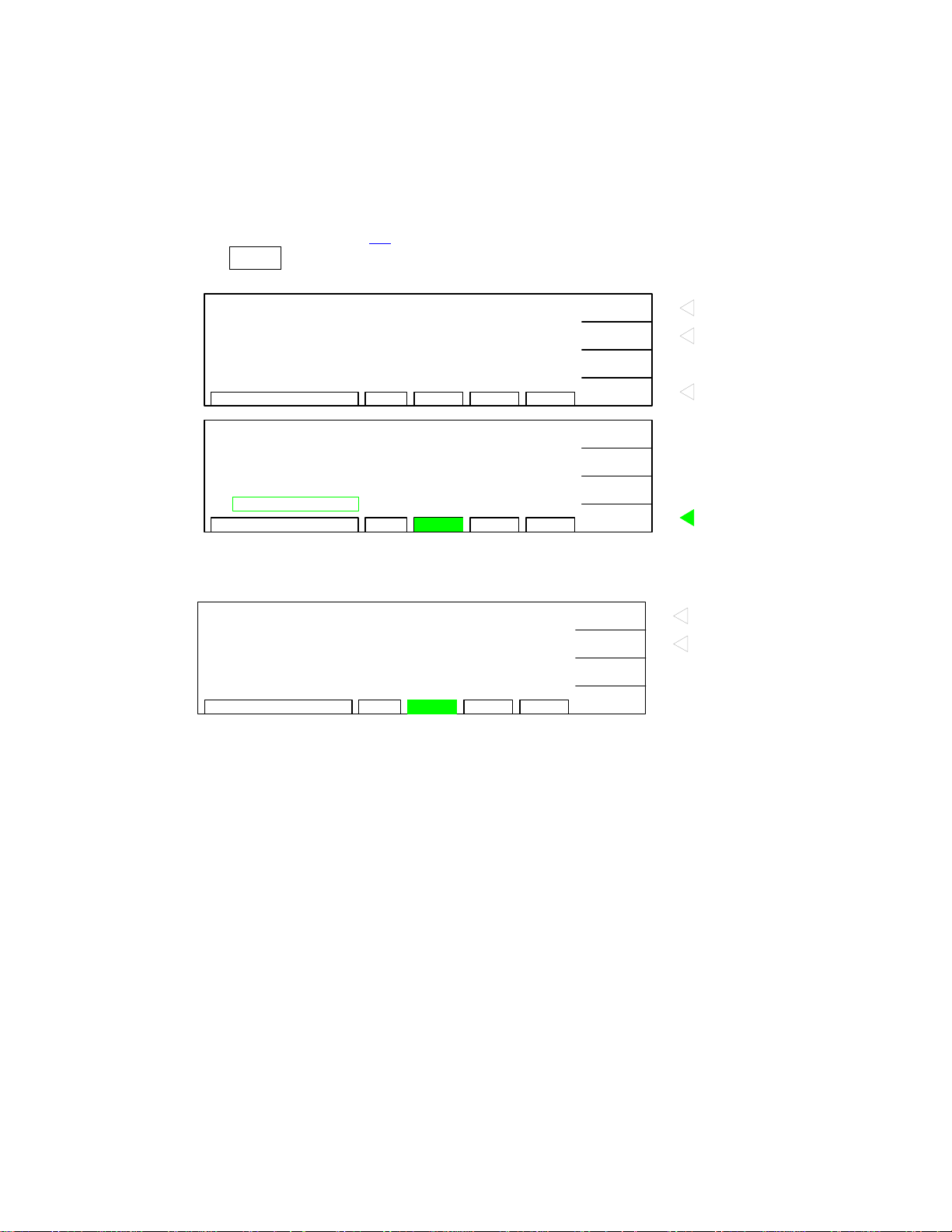

PROGRAM Mode Displays

Figure 2-4 illustrates each program mode display for quick reference. The box in the lower left

hand corner denotes the instrument status. For clarity, a green arrow (!) is used to denote

which function key (F1 – F4) is pressed to get to the next display screen.

"STAND BY"

DISPLAY

AC

Display

DC

Display

IR

Display

0.000kV

0.500mA

3.0s

VOLT

:

HIGH

:

TIME

:

VOLT

:

HIGH

:

TIME

:

VOLT

:

LOW

TIME

::3.0s

0.000kV

0.500mA

3.0s

0.000kV

0.500mA

3.0s

0.000kV

1.0M

Ω

LOWACSTEP 1/1

ARC

RAMP

FALL

RMT ERROFSTLOCKSTAND BY

LOWACSTEP 1/1

ARC

RAMP

FALL

RMT ERROFSTLOCKSELECT MODE

LOWDCSTEP 1/1

ARC

RAMP

FALL

I-RUS

RMT ERROFSTLOCKSELECT MODE

HIGHIRSTEP 1/1

RAMP

DWELL : OFF

FALL

OFF

:

OFF

:

OFF

:

OFF

:

PROGRAM

PRESET

MENU

MORE..

OFF

:

OFF

:

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

OFF

:

OFF

:

:

OFFDWELL

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

OFF

:

OFF

:

UP

DOWN

NEXT

To enter programming mode.

F1

To view/change preset (initial)

F2

test parameters.

To view/change system parameters:

F3

memory, system, option, calibration, key

lock, password, error, & about.

To view the programmed test setups and

F4

access offset function.

To change value in highlighted box.

F1

To toggle choices of highlighted box.

F2

To move highlighted box around

F3

display to select parameter to change

To exit programming mode.

F4

F1

To select test mode: AC/DC/IR/GC/PA

F2

F3

F4

To select test mode: AC/DC/IR/GC/PA

F1

F2

F3

F4

F1

To select test mode: AC/DC/IR/GC/PA

F2

F3

F4

F1

To select test mode: AC/DC/IR/GC/PA

F2

F3

F4

PROGRAM MODE DISPLAYS

GC

Display

PA

Display

CURR

: 0.0A

HIGH

DWELL

PAUSE

UNDER TEST SIGNAL

Ω

:

1.0

:

3.0s

PAUSE MODE

::OFF

RMT ERROFSTLOCKSELECT MODE

GCSTEP 1/1

LOW

OFF

:

EXIT

UP

DOWN

NEXT

RMT ERROFSTLOCKSELECT MODE

PASTEP 1/1

EXIT

UP

DOWN

NEXT

RMT ERROFSTLOCKSELECT MODE

EXIT

Figure 2-4: STAND BY & PROGRAM Mode Displays

Page 34 of 85 Operation

Page 35

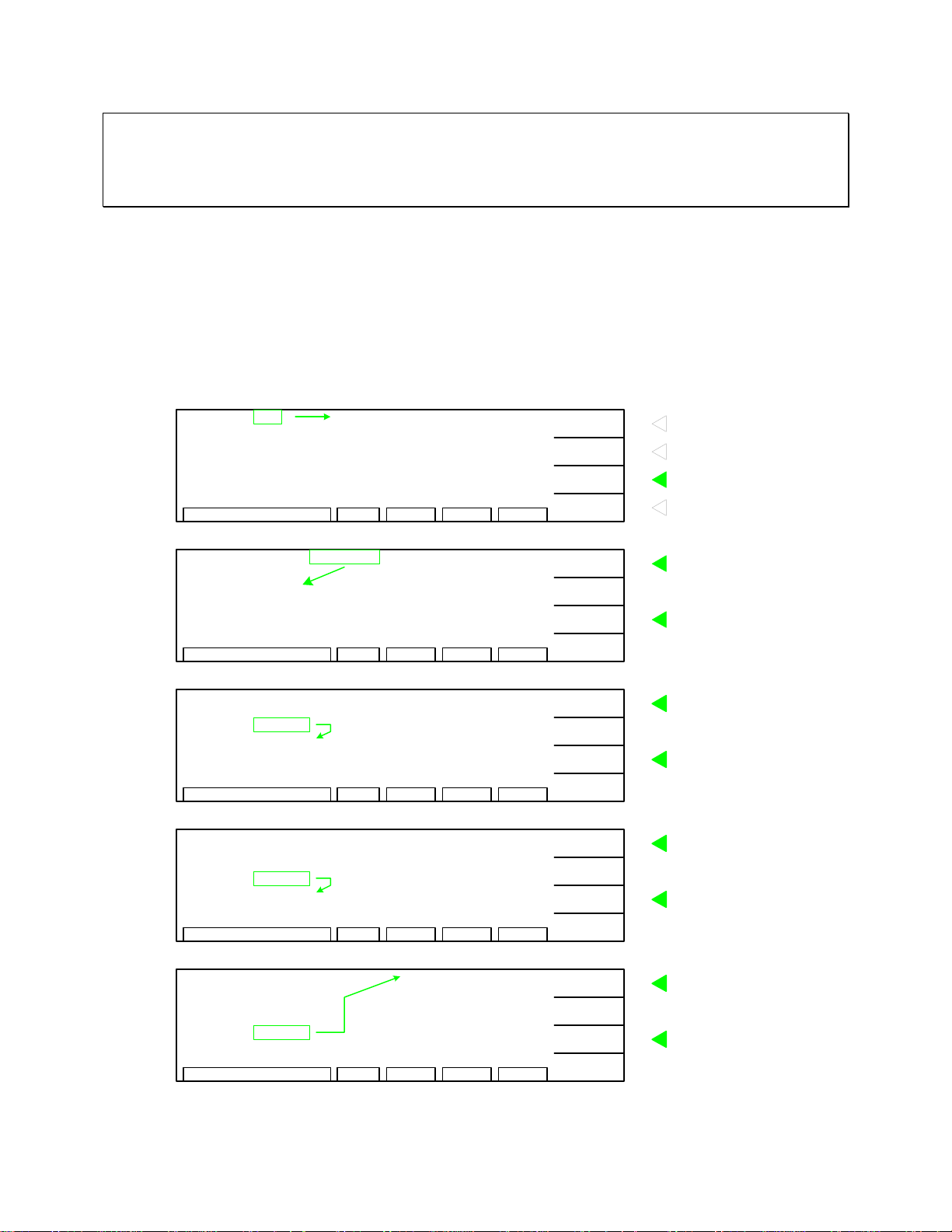

2.4 Programming a Ground Continuity Test

This test is applicable to the Sentry 10, 20 and 30 Plus instruments. A Ground Continuity (GC)

test is usually done first to verify the ground connection before high voltage is applied in the AC

& DC Hipot tests. With the instrument in ‘stand-by’ status, press [F1] = PROGRAM. The AC

test mode programming screen is displayed. Follow the green arrows (!) on the right side of

this diagram to program the individual GC test parameters.

VOLT:

In STAND BY:

Press [F1] =

PROGRAM

Select

GC

Mode

Set

Current

Set

HIGH

Resistance Limit

HIGH:

TIME:

CURR:

HIGH:

DWELL:

CURR:

HIGH:

DWELL:

CURR:

HIGH:

DWELL:

0.000 kV

0.500 mA

Ω

Continue on Next Page.

3.0 s

0.0 A

1.0

0.3 s

0.0A

1.0

0.3s

0.1A

1.0

0.3s

1/1

LOWACSTEP:

ARC

RAMP

FALL

RMT ERROFSTLOCKVoltage is 0

LOWGCSTEP 1/1

Ω

RMT ERROFSTLOCKSelect Mode

LOWGCSTEP 1/1

Ω

RMT ERROFSTLOCK0.1A

LOWGCSTEP 1/1

Ω

RMT ERROFSTLOCK0.1 - 5

OFF

:

OFF

:

OFF

:

OFF

:

MORE..

NEXT

EXIT

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

INC.

DEC.

NEXT

EXIT

OFF

:

INC.

DEC.

NEXT

EXIT

F1

F2

To move highlighted box to AC.

F3

F4

F1

To select Mode = GC

F2

F3

To move highlighted box to CURR.

F4

F1

To set current to 0.1A

F2

F3

To move highlighted box to HIGH.

F4

To set High resistance limit:

F1

0.1 - 5Ω in 0.1Ω increments.

F2

To move highlighted box to DWELL.

F3

F4

Operation Page 35 of 85

Page 36

Programming a GC Test (continued):

Set

DWELL

Time

Set

LOW

Resistance Limit

[F1]

: Program Step 2

[F4] : Exit Program Mode

or

CURR:

HIGH:

DWELL:

CURR:

HIGH:

DWELL:

CURR:

HIGH:

DWELL:

LOWGCSTEP 1/1

0.1A

Ω

1.2

0.3s

RMT ERROFSTLOCK0.1 - 1s

LOWGCSTEP 1/1

0.1A

1.2

Ω

0.5s

Ω

0.1A

1.2

Ω

0.5s

RMT ERROFSTLOCK0 - 5

LOWGCSTEP:

RMT ERROFSTLOCK1 - 10

OFF:

INC.

DEC.

NEXT

EXIT

OFF

:

INC.

DEC.

NEXT

EXIT

0.3

Ω

:1/1

NEW

MORE..

NEXT

EXIT

To set Dwell time:

F1

0.1 - 1s in 0.1s increments

F2

F3

To move highlighted box to LOW.

F4

To set Low resistance limit:

F1

0 - 5Ω in 0.1Ω increments.

F2

F3

To move highlighted box to STEP.

F4

To go to Step 2.

F1

F2

F3

To

exit

F4

programming mode and return

to STAND BY status.

END GC Test Programming. After selecting the LOW resistance limit, one can either press

[F1] = NEW to change the step number in the highlighted box (1-10) and start programming

STEP 2-10 OR one can press [F4] = EXIT to exit programming function and return to STAND

BY status.

For this example, press [F1] = NEW and proceed to program step 2 as an AC Hipot Test (¶ 2.5).

Page 36 of 85 Operation

Page 37

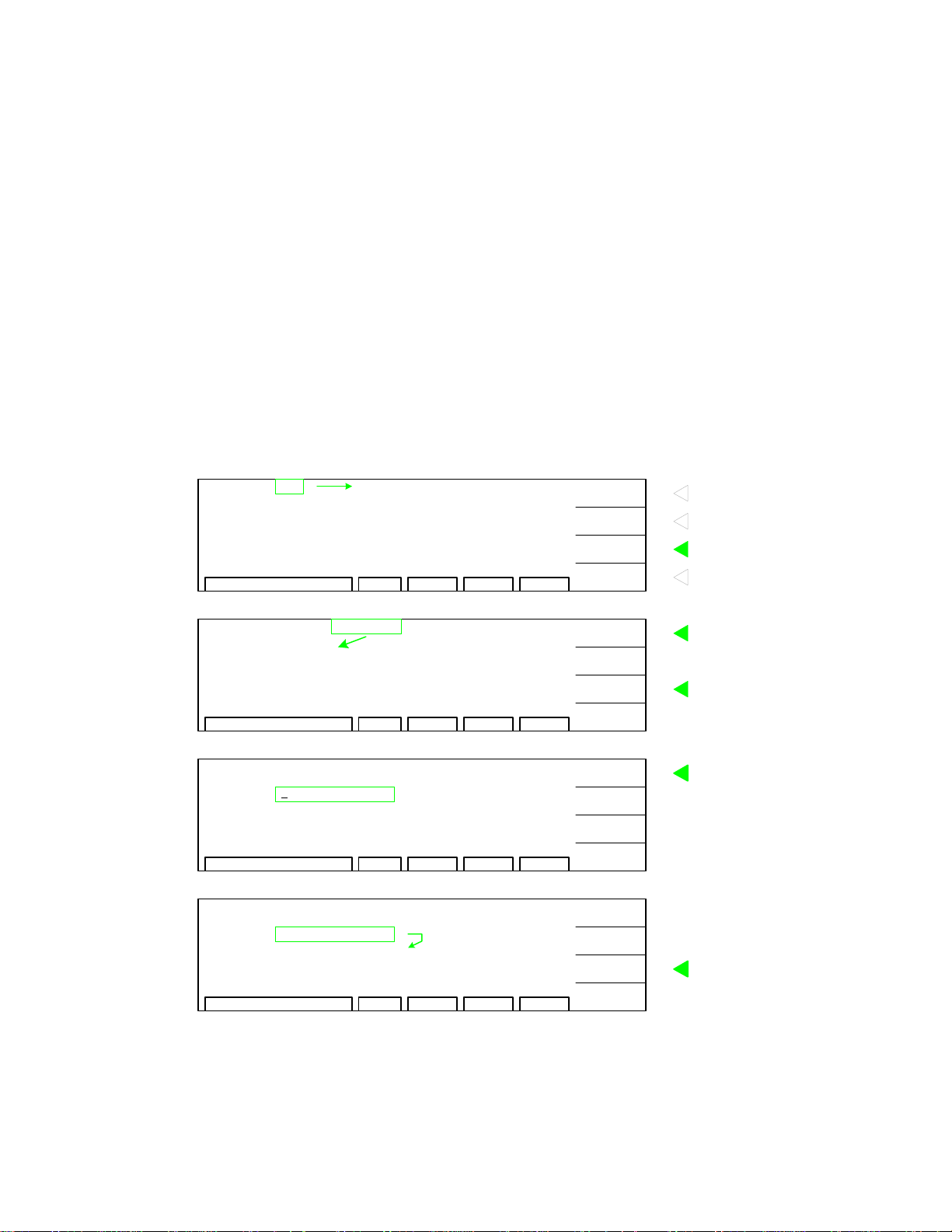

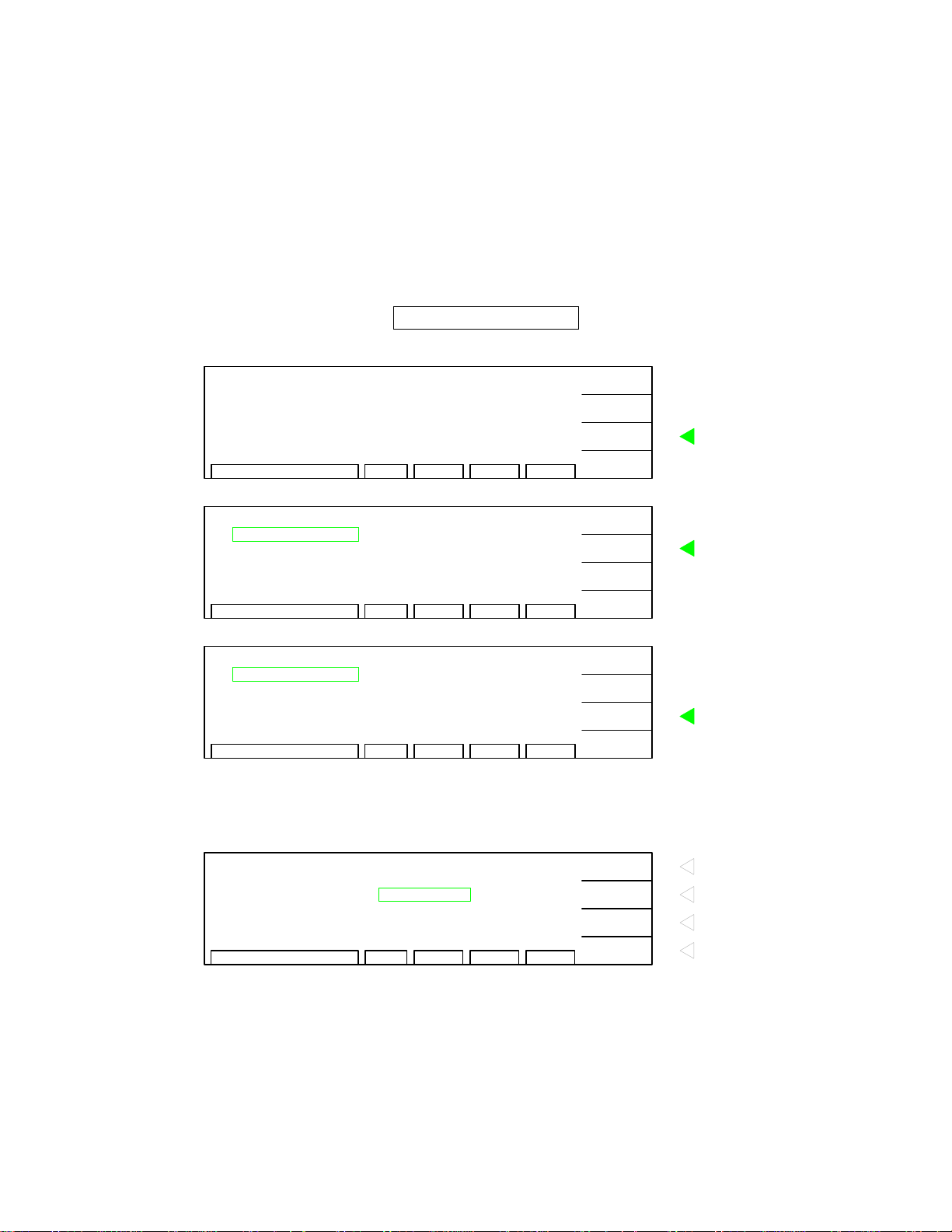

2.5 Programming an AC Hipot Test

This test is applicable to the Sentry 10, 20 and 30 Plus instruments. With the instrument in

‘stand-by’ status, press [F1] = PROGRAM. If continuing the 5-step example from ¶2.4, you are

already in program mode and on the AC test mode page. Follow the green arrows (!) on the

right side of this diagram to program the individual AC hipot test parameters.

[F1] = New

Program

Step 2 = AC

Select

AC

Test Mode

Set

Test Voltage

Set

High Current

Limit

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

0.000kV:

:

0.500mA

:

3.0s

:

0.000kV

:

0.500mA

:

3.0s

0.000kV:

: 0.500mA

:

3.0s

:

2.750kV

:

0.500mA

:

3.0s

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCKVoltage is 0

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCKSelect Mode

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK0.05 - 5kV

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK0.001 - 20mA

OFF

:

OFF

:

OFF

:

OFF

:

FIRST

MORE..

NEXT

EXIT

OFF

:

OFF

:

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

OFF

:

OFF

:

OFF

:

INC.

DEC.

NEXT

EXIT

OFF

:

OFF

:

OFF

:

OFF

:

INC.

DEC.

NEXT

EXIT

To change value in highlighted box.

F1

To delete or insert a test step.

F2

To move highlighted box around

F3

display to select parameter to change

To exit programming mode.

F4

Set MODE = AC

F1

F2

To move highlighted box to VOLT

F3

F4

To set test voltage:

F1

0.05 - 5kV in .001kV increments

F2

F3

To move highlighted box to HIGH.

F4

To set high current limit:

F1

0.001 - 20mA in .001mA increments

F2

To move highlighted box to TIME.

F3

F4

Set

Test Time

Test time = 0

then continuous

voltage until STOP

is pressed.

Set

Low Current

Limit

VOLT

HIGH

TIME

VOLT

HIGH

TIME

:

:

:

:

:

:

2.750kV

15.00mA

3.0s

2.750kV

15.00mA

10.0s

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK0, 0.1 - 999s

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK0 - 20mA 0 = OFF

OFF

:

OFF

:

OFF

:

OFF

:

INC.

DEC.

ENTER

EXIT

OFF

:

OFF

:

OFF

:

OFF

:

INC.

DEC.

NEXT

EXIT

To set test time:

F1

0, 0.1 - 999s in 0.1s increments

F2

F3

To move highlighted box to LOW.

F4

To set low current limit:

F1

0 - 20mA in 0.01mA increments

F2

F3

To move highlighted box to ARC.

F4

Continue on next page.

Operation Page 37 of 85

Page 38

Programming an AC Hipot Test (continued)

Set

Arc Limit

Set

Ramp Time

Set

Fall Time

Set

Next

Test Step

[F1]

: Program Step 3

or

[F4] : Exit Program Mode

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

:

2.750kV

:

15.00mA

:

10.0s

:

2.750kV

:

15.00mA

:

10.0s

:

2.750kV

15.00mA

::10.0s

2.750kV

:

:

15.00mA

:

10.0s

2/2

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK1 - 20mA 0 = OFF

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK0 - 999s 0 = OFF

LOWACSTEP 2/2

ARC

RAMP

FALL

RMT ERROFSTLOCK0 - 999s 0 = OFF

LOWACSTEP

ARC

RAMP

FALL

RMT ERROFSTLOCK1 - 10

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

3.00mA

OFF

OFF

OFF

3.00mA

OFF

OFF

OFF

3.00mA

OFF

3.0s

OFF

3.00mA

OFF

3.0s

3.0s

INC.

DEC.

NEXT

EXIT

INC.

DEC.

NEXT

EXIT

INC.

DEC.

NEXT

EXIT

NEW

MORE..

NEXT

EXIT

Set arc current limit:

F1

1-20mA in 0.1mA increments

F2

To move highlighted box to RAMP.

F3

F4

To set Ramp Time:

F1

0 - 999s in 0.1s increments

F2

F3

To move highlighted box to FALL.

F4

To set Fall Time:

F1

0 - 999s in 0.1s increments

F2

F3

To move highlighted box to STEP.

F4

F1

To set next test step = 3

F2

F3

To

exit

F4

programming mode and return

to STAND BY status.

END AC Hipot Test Programming. After selecting the FALL Time, one can either press [F1]

= NEW to change the step number in the highlighted box (1-10) and start programming STEP 310, OR

one can press [F4] = EXIT to exit programming function and return to STAND BY

status.

For this example, press [F1] = NEW and proceed to program step 3 as a DC Hipot Test (¶ 2.6).

Page 38 of 85 Operation

Page 39

2.6 Programming a DC Hipot Test

This test is applicable to the Sentry 20 and 30 Plus instruments. With the instrument in ‘standby’ status, press [F1] = PROGRAM. If continuing the 5-step example from ¶2.5, you are already

in program mode and on the AC test mode page. The example illustrated herein shows a GC test

as Step 1, an AC test as Step 2 and how to program a DC test in Step 3. Follow the green arrows

(!) on the right side of this diagram to program the individual DC hipot test parameters.

[F1] = New

Program

Step 3 = DC

VOLT

HIGH

TIME

:

:

0.000kV:

0.500mA

3.0s

LOWACSTEP 3/3

ARC

RAMP

FALL

RMT ERROFSTLOCKVoltage is 0

OFF

:

OFF

:

OFF

:

OFF

:

FIRST

MORE..

NEXT

EXIT

To change value in highlighted box.

F1

To delete or insert a test step.

F2

To move highlighted box around

F3

display to select parameter to change

To exit programming mode.

F4

Select

DC

Test Mode

Set

Test Voltage

Set

High Current

Limit

Set

Test Time

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

:

0.000kV

:

0.500mA

:

3.0s

0.000kV:

: 0.500mA

:

3.0s

:

2.500kV

:

0.500mA

:

3.0s

:

2.500kV

:

2.999mA

:

3.0s

LOWACSTEP 3/3

ARC

RAMP

FALL

RMT ERROFSTLOCKSelect Mode

LOWDCSTEP 3/3

ARC

RAMP

FALL

RMT ERROFSTLOCK0.05 - 6kV

LOWDCSTEP 3/3

ARC

RAMP

DWELL :

FALL

I-RUS

RMT ERROFSTLOCK0.0001 - 5mA

LOWDCSTEP 3/3

ARC

RAMP

FALL

I-RUS

RMT ERROFSTLOCK0, 0.1 - 999s

OFF

:

OFF

:

OFF

:

OFF

:

UP

DOWN

NEXT

EXIT

OFF

:

OFF

:

OFF

:

: OFFDWELL

OFF

:

OFF:I-RUS

INC.

DEC.

NEXT

EXIT

OFF

:

OFF

:

OFF

:

OFF

:

OFF

:

OFF

INC.

DEC.

NEXT

EXIT

OFF

:

OFF

:

OFF

:

OFFDWELL

:

OFF

OFF

:

INC.

DEC.

ENTER

EXIT

Set MODE = DC

F1

F2

To move highlighted box to VOLT

F3

F4

To set test voltage:

F1

0.05 - 6kV in .001kV increments

F2

F3

To move highlighted box to HIGH.

F4

To set high current limit:

F1

0.0001 - 5mA in .001mA increments

F2

To move highlighted box to TIME.

F3

F4

To set test time:

F1

0, 0.1 - 999s in 0.1s increments

F2

F3

To move highlighted box to LOW.

F4

Set

Low Current

Limit

VOLT

HIGH

TEST

:

:

:

2.500kV

2.999mA

5.0s

LOWDCSTEP 3/3

ARC

RAMP

DWELL :

FALL

I-RUS :

RMT ERROFSTLOCK0 - 5mA 0 = OFF

OFF

:

OFF

:

OFF

:

OFF

:

OFF

OFF

INC.

DEC.

NEXT

EXIT

To set low current limit:

F1

0 - 5mA in 0.001mA increments

F2

F3

To move highlighted box to ARC.

F4

Continue on next page.

Operation Page 39 of 85

Page 40

Programming an DC Hipot Test (Continued)

LOWDCSTEP 3/3

ARC

Set

Arc Limit

VOLT

HIGH

TIME

:

:

2.500kV

2.999mA

5.0s

RMT ERROFSTLOCK1 - 5mA 0 = OFF

RAMP

DWELL ::OFF

FALL

0.015mA

:

OFF

:

OFF:

:

OFF

:

:I-RUS OFF

INC.

DEC.

NEXT

EXIT

Set arc current limit:

F1

1-5mA in 0.1mA increments

F2

F3

To move highlighted box to RAMP.

F4

Set

Ramp Time

Set

Dwell Time

Set

Fall Time

Set

I-Rus Limit

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

VOLT

HIGH

TIME

:

2.500kV

:

2.999mA

:

5.0s

:

2.500kV

:

2.999mA

:

5.0s

:

2.500kV

2.999mA

::5.0s

2.500kV

:

2.999mA

:

5.0s

LOWDCSTEP 3/3

ARC

RAMP

DWELL

FALL

RMT ERROFSTLOCK0 - 999s 0 = OFF

LOWDCSTEP 3/3

ARC

RAMP

DWELL

FALL

RMT ERROFSTLOCK0 - 999s 0 = OFF

LOWDCSTEP 3/3

ARC

RAMP

DWELL 3.0s

FALL

RMT ERROFSTLOCK0 - 999s 0 = OFF

LOWDCSTEP 3/3

ARC

RAMP

DWELL 3.0s

FALL

I-RUS

RMT ERROFSTLOCK0, 0.5uA-5mA 0 = OFF

0.015mA

:

OFF

:

OFF

:

:

OFF

OFF

:

OFFI-RUS

:

0.015mA

:

OFF

:

:

3.0s

OFF

:

OFF

OFFI-RUS :

0.015mA

:

OFF

:

3.0s

:

:

:

OFF

:I-RUS OFF

0.015mA

:

OFF

:

3.0s:

:

:

3.0s

:

:

OFF

INC.

DEC.

NEXT

EXIT

INC.

DEC.

NEXT

EXIT

INC.

DEC.

NEXT

EXIT

INC.

DEC.

NEXT

EXIT

To set Ramp Time:

F1

0 - 999s in 0.1s increments

F2

F3

To move highlighted box to DWELL.

F4

To set Dwell Time:

F1

0 - 999s in 0.1s increments

F2

F3

To move highlighted box to FALL.

F4

To set Fall Time:

F1

0 - 999s in 0.1s increments

F2

F3

To move highlighted box to I-RUS.

F4

Set in-rush current limit:

0, 0.5uA -5mA

F1

in 0.001mA increments

F2

To move highlighted box to STEP.

F3

F4

Set

Next

Test Step

[F1]

: Program Step 4

[F4] : Exit Program Mode

or

VOLT

HIGH

TIME

:

:

:

3/3

2.500kV

2.999mA

5.0s

LOWDCSTEP

ARC

RAMP

FALL

I-RUS : OFF