Page 1

Guardian 5000

AC/DC/IR/GC Safety Analyzer

Instruction Manual

Form 150206/B3

©QuadTech, Inc., 1996

5 Clock Tower Place, 210 East

Maynard, Massachusetts, U.S.A. 01754-2530

November, 1999

Tel. 978-461-2100

800-253-1230 (Sales & Service)

Fax. 978-461-4295

Email: sales@quadtech.com

Web site: http://www.quadtech.com

The material in this manual is for informational purposes only and is subject to change,

without notice. QuadTech assumes no responsibility for any error or for consequential

damages that may result from the misinterpretation of any procedures in this publication.

IEC417

Symbol

information to prevent injury or equipment damage

!

on equipment signifies that the manual contains

Page 2

ii

Page 3

Contents

Warranty ...........................................................................................................v

Specifications ...........................................................................................................vii

Introduction - Section 1

1.1 Unpacking and Inspection.............................................................................1-1

1.1 Product Overview..........................................................................................1-1

1.3 Front Panel Description.................................................................................1-2

1.4 Rear Panel Description..................................................................................1-6

1.5 Accessories Included.....................................................................................1-7

1.6 Accessories/Options Available......................................................................1-7

1.7 Power Requirements......................................................................................1-8

Operation - Section 2

2.1 Startup ...........................................................................................................2-1

2.2 Instrument Zeroing/Offset.............................................................................2-1

2.3 Connection to Device Under Test .................................................................2-3

2.4 Measurement Procedure................................................................................2-6

2.5 Programming Test Modes .............................................................................2-8

2.6 Programming Hipot Test...............................................................................2-10

2.7 Programming Insulation Resistance (IR) Test ..............................................2-12

2.8 Programming Ground Continuity Test..........................................................2-14

2.9 Initial Parameter Setting................................................................................2-16

2.10 Front Panel Lockout......................................................................................2-18

2.11 Software Version Display..............................................................................2-18

2.12 Clear Setup Memory......................................................................................2-18

Input/Output Interfaces - Section 3

3.1 Remote...........................................................................................................3-1

3.2 IEEE-488 Interface........................................................................................3-3

3.2.1 Description ........................................................................................3-3

3.2.2 Interface Commands..........................................................................3-4

3.2.2.1 Listener Functions..............................................................3-5

3.3.2.2 Talker Functions....................................................................3-9

3.2.3 Sample QuickBASIC Program..........................................................3-11

3.3 Scanner Interface...........................................................................................3-14

3.3.1 Scanner Accessories..........................................................................3-14

3.3.2 Scanner Card Installation ..................................................................3-14

3.3.3 Scanner Connections.........................................................................3-15

3.3.4 Scanner Programming.......................................................................3-17

3.4 G16 International Power Strip.......................................................................3-19

iii

Page 4

Contents Continued

Maintenance/Calibration - Section 4

4.1 General ..........................................................................................................4-1

4.2 Instrument Return..........................................................................................4-1

4.3 Calibration.....................................................................................................4-1

4.3.1 Calibration Procedure........................................................................4-2

4.3.2 AC Voltage Calibration.....................................................................4-3

4.3.3 DC Voltage Calibration.....................................................................4-4

4.3.4 IR Voltage Calibration ......................................................................4-4

4.3.5 AC Current Calibration .....................................................................4-5

4.3.6 DC Current Calibration .....................................................................4-6

4.3.7 GC Calibration...................................................................................4-7

4.3.8 Finalize Calibration...........................................................................4-8

iv

Page 5

Warranty

echuad

T

QuadTech warrants that Products are free from defects in material and workmanship and,

when properly used, will perform in accordance with QuadTech's applicable published

specifications. If within one (1) year after original shipment it is found not to meet this

standard, it will be repaired, or at the option of QuadTech, replaced at no charge when

returned to a QuadTech service facility.

Changes in the Product not approved by QuadTech shall void this warranty.

QuadTech shall not be liable for any indirect, special or consequential damages, even if

notice has been given of the possibility of such damages.

This warranty is in lieu of all other warranties, expressed or implied, including, but not

limited to any implied warranty or merchantability or fitness for a particular purpose.

SERVICE POLICY

QuadTech policy is to maintain product repair capability for a period of at least five (5) years

after original shipment and to make this capability available at the then prevailing schedule of

charges.

v

Page 6

Specifications

Dielectric Strength

Output Voltage: Range: • 0.1 to 5 KV AC, in 10V/steps, 50 - 600Hz

Accuracy: +/- (1% of reading + 5 counts)

Regulation: <1% + 5V, rated load

Breakdown: Detection:

Leakage Current: Accuracy: +/- (1.5% + 5 counts), unspecified 0.01 - 0.3mA

Test Time: Ramp: 0.1 to 99.9sec (+/-20ms)

Hold: 0.1 to 999sec (+/-20ms)

Insulation Resistance

Measurements: Range: 10MΩ - 10GΩ

Test Voltage: 100 - 1000V DC

Accuracy: Measurement: +/- 5% ≥ 500V, 10MΩ - 1GΩ

+/- 15% ≥ 500V, 1GΩ - 10GΩ

+/- 10%<500V, 1 - 200MΩ

+/- 15%<200V, 200MΩ - 1GΩ

Voltage: +/- (1% of setting + 5 counts)

Measure Time: 0.1 - 999sec (+/-20ms)

Limit Delay: 0.3 - 99.9sec (+/-20ms)

Voltage

• 0.1 to 6 KV DC, in 10V/steps

• Imax: 0.3 - 40mA AC, 0.3 - 20mA DC

• ∆I: 0.5 to 40mA, ≤ 20µsec

1000V

500V

100V

vi

10M>

20M 50M>>

Specification Range

Resistance

>>>500M 1G 2G

Page 7

Specifications Continued

Ground Continuity

Output Current:Range: 1.0 to 30.0A AC, setting 0.1A/step

Accuracy: +/- (1% of setting + 0.3A)

+/- (1% of reading + 3 counts)

Frequency: 50 or 60Hz, 6 to 15V

Resistance: Range: 0 - 500.0mΩ, 4 digits, Hi Limit

Accuracy: +/- (1% of reading + 3 counts)

Offset Function: 0 to 100mohm offset, user selectable

Test Time: 0.5 - 999sec (+/-20ms)

Current

30A

Specification Range

10A

1A

Resistance

>> >>

100m 150m

500m10m

General

Safety Features: Fast Cutoff (<0.4msec), Fast Discharge, Panel Lock

Setup Storage: 50 Memory Groups

Remote Control: Remote start & reset, Go/NoGo output, IEEE-488 Intf.

Pass/Fail: Display indication & alarm

Mechanical: Bench mount

Dimensions: (w x h x d):17x8.5x22in (430x215x550mm)

Weight: 50 lbs (23kg) net, 60 lbs (27kg) shipping

Environmental: Meets MIL-T-28800E, Type 3, Class 5

Operating: 0 to + 45o C

Humidity: <75%

Storage: - 10 to + 60o C

Power:

• 115 V/230V +/- 10% • 47 - 63Hz • 650W max

Supplied: • Instruction Manual • Power Cable

• Calibration Certificate • Test Leads

Ordering

Information:

Description Catalog No.

AC/DC/IR/GC Safety Analyzer Guardian 5000

vii

Page 8

Page 9

Section 1 Introduction

1.1 Unpacking and Inspection

Inspect the shipping carton before opening, if damaged contact the carriers agent

immediately. Inspect the instrument for any damage. If the instrument appears damaged or

fails to meet specifications notify QuadTech (refer to instruction manual front cover) or its

local representative. Retain the shipping carton and packing material for future use such as

returning for recalibration or service.

1.2 Product Overview

The Guardian 5000 Safety Analyzer combines four critical safety tests into a single

instrument, these being AC hipot, DC hipot, insulation resistance measurements and

ground continuity test. The hipot test can be programmed over a voltage range of 0.1 to

5KV AC and 0.5 to 6KV DC with a min/max leakage current detection range of 300µA to

40mA AC and 20mA DC. Insulation resistance measurements are possible to 10GΩ at

programmable DC test voltages between 100 and 1000V. A ground continuity test to 30A

AC is also possible. The instrument comes standard with internal storage of up to 50 memory

groups and an IEEE-488.2 interface for remote control operation and communication with

other instrumentation.

Figure 1-1

Guardian 5000

Introduction 1-1

Page 10

1.3 Front Panel Description

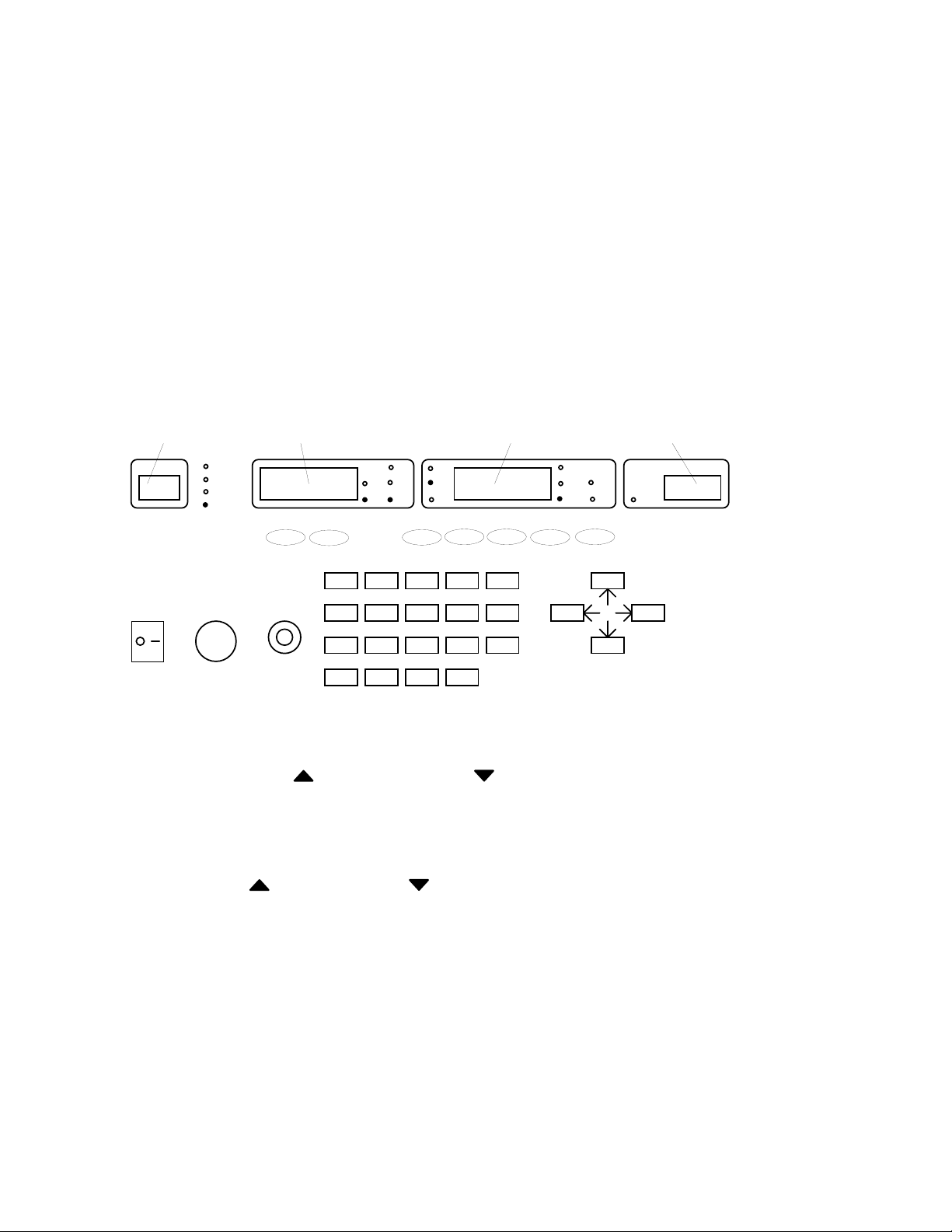

Figure 1-2 shows the controls and indicators on the front panel of the Guardian 5000. Table

1-1 identifies them with descriptions and functions.

12345 678 9 10 11 12 13 14 15 16

Introduction 1-2

Figure 1-2

Front Panel Controls & Indicators

17181920212223242526

Page 11

Table 1-1

Front Panel Controls and Indicators

Fig 1-2

Ref. # Item Function

1 Step Display indicates step number selected in the auto test sequence

(1 to 15). Indicates memory group number (1 to 50) when RCL

(recall) or STO (store) is selected.

2 Mode Light indicates that tester is in Ground Continuity, AC Hipot,

RΩ/W-ACV DC Hipot or Insulation Resistance mode status.

W-DCV/IR

3 RMT Light indicates when instrument is in remote mode.

Indicator

4 Voltage or Display shows voltage/voltage setting value when test is not in

Current process and shows output voltage/current when test is in process.

Display 0.1 - 5KV for AC Hipot, 0.5 - 6KV for DC Hipot,

100 - 1000V for IR, and 1.0 - 30.0A for GC,

5 LOCK Light indicates when instrument front panel keys are locked

Indicator

6 Display Units Indicates the units for the current/voltage display (AC or DC, A,

KV for hipot, V for IR or A for GC)

7 OFFSET Light indicates when instrument offset function is enabled.

Indicator

8 Limit Indicates the function of the limit shown on the Limit Display

Indicator (HI, LO, or ARC)

9 Limit/Measure Display shows limit setting when test is not in process and

shows measured value when test is in process.

10 Result Lights indicate test results based on set limits.

Indicators HI NG - Measured value exceeded high limit

LO NG - Measured value less than low limit

ARC NG - Measured value exceeded arc limit

PASS - Measured value is good based on all set limits

Introduction 1-3

Page 12

Table 1-1

Front Panel Controls and Indicators (continued)

Fig 1-2

Ref. # Item Function

11 Limit/Measure Indicates the units for the entered limits or the measured display

Display Units (mA for hipot, MΩ for IR or mΩ for GC)

12 Timer Indicates when test time shown is RAMP time

Indicator

13 CAL For use by qualified service personnel during instrument

ENABLE calibration.

14 Timer Display shows set time or time countdown when test is in

Display process. A test time of 0 (zero) places the instrument in a

continuous measure mode.

15 TEST ON When indicator light is blinking high voltage is present on the

Indicator output terminals.

16 HIGH High voltage output terminal (Hipot or Insulation Resistance

VOLTAGE tests)

17 LOW SENSE Low potential terminal (SENSE) for Ground Continuity test.

18 LOW Ground reference terminal for all tests

DRIVER

19 HIGH SENSE High potential terminal (SENSE) for Ground Continuity test.

20 HIGH High current terminals (DRIVER) for Ground Continuity test.

DRIVER

21 BUZZER Audible output for pass/fail results.

Introduction 1-4

Page 13

Table 1-1

Front Panel Controls and Indicators (continued)

Fig 1-2

Ref. # Item Function

22 CURSOR Under STOP status:

keys UP or DOWN to examine 1 - 15 steps

Under Hipot test On:

UP or DOWN to increase or decrease test voltage in

continuous mode

Under PROG status:

LEFT or RIGHT to select parameter for programming

UP

23 Data Entry [0] [.] .....[9] Numerical keys to input test parameters

Keys [OFF] For turning off test parameters (limits, arc, etc.)

[PROG] To enter and exit parameter setting status

[DELE] To delete a test step, those below move up

[CLEAR] To cancel parameter number and input again

[ENTER] Press to confirm enter parameter

[RCL] Recalls stored parameters (1 - 50) from memory

[STO] Stores parameter (1 - 50) into memory

[OFFSET] Initiates zeroing offset function

24 START Pressing this button starts a test and applies high voltage/current

button to the test terminals.

25 STOP Pressing this button stops a test in process and must be pressed

button as a reset function before a test can be started (after a failed test

or after test conditions have been reprogrammed).

26 OFF/ON Applies AC power to the tester, 0 is off, 1 is on.

or DOWN to change status status

Introduction 1-5

Page 14

1.4 Rear Panel Description

12 3 456 7

Figure 1-3

Rear Panel View

Table 1-2

Rear Panel Connectors and Controls

Fig 1-3

Ref. # Item Function

1 IEEE Input/output connections according to IEEE

STD-488.2. 24 pin socket for standard

IEEE-488 cable. Refer to paragraph 3.2

2 SCAN Input/output scanner interface for QuadTech 5000-01 or 5000-02

Multiport Scanner Matrix. Refer to Paragraph 3.3.

3 Voltage Switches for selecting range of AC power source

Selector - Set to 100V position for 90 - 100VAC operation

- Set to 120V position for 110 - 130VAC operation

- Set to 220V position for 200 - 240VAC operation

- Set to 240V position for 220 - 250VAC operation

!

4

AC Inlet Fuse drawer and 3-wire connection for AC power source. Module

Contains 7A, 250V, 5x20mm fuse for 90-130V operation or

3.5A, 250V, 5x20mm fuse for 200-250V operation

5 SIGNAL Contact closures for test in process, test results good, and test

OUTPUT results no good. Maximum contact rating is 115V at 0.3A.

6 Ground Chassis ground connection

7 Fan Temperature control fan

- on for > 50oC

- off for < 45oC

Introduction 1-6

Page 15

1.5 Accessories Included

Table 1-3

Item Quantity

Instruction Manual 1

Calibration Certificate 1

Power Cord 1

Power Line Fuse, 7A 2

S02, Test Lead Set, Hipot (1 red, 1 black, with alligator clips) 1

G15, Test Lead Set, GC (1 red, 1 black, with spring clips) 1

G14, Test Lead Set, Hipot (115V Receptacle) 1

1.6 Accessories/Options Available

Table 1-4

Item Part Number

Multiport Scanner Matrix (8 channel high V) 5000-01

Multiport Scanner Matrix (8 channel high V, 4 GC) 5000-02

Multiport Scanner Matrix, rack (8 channel high V) 5000-03

Multiport Scanner Matrix, rack (8 channel high V, 4 GC) 5000-04

High Voltage Lead Set, high & low, 1m (std w/unit) S02

High Voltage Lead Set, high & low, 2m S04

Foot Switch S05

High Voltage Probe S06

Gun Probe S08

High Voltage Lead, 1 meter, unterminated S09

High Voltage Lead, 2 meters, unterminated S10

Gun Probe with remote start S11

Load Box, resistive S12

Load Box custom resistors S14

Corded Product Adaptor G13

Power Entry Adaptor Cable, GC (std w/unit) G14

Ground Continuity Lead Set (std w/unit) G15

International Power Strip G16

Rear Panel Connection (factory installed) G22

Rack Mount Flanges (factory installed) G23

Corded Product Adaptor (240V) G25

RS232 Interface G26

Introduction 1-7

Page 16

1.7 Power Requirements

!

The Guardian 5000 can be operated from a power source of 90 to 130 VAC or 200 to

250 VAC. Power connection is via the rear panel through a standard receptacle. Before

connecting the 3-wire power cord between the unit and AC power source make sure the

voltage selection switches on the rear panel (as indicated) and fuses are in accordance with

the power source being used. 7A, 250V, 5x20mm, for 90-130V source and 3.5A, 250V,

5x20mm, for 200-250V source. Always use an outlet which has a properly connected

protection ground.

To change the fuse proceed as follows:

WARNING

MAKE SURE THE UNIT HAS BEEN DISCONNECTED FROM ITS AC POWER

SOURCE FOR AT LEAST FIVE MINUTES BEFORE PROCEEDING.

Remove the fuse drawer, by inserting a flat head screwdriver behind the small tab located just

below the 3 prong receptacle, and force outward.

Once the fuse drawer has been removed from the instrument snap the fuse from the holder

and replace. Make sure the new fuse is of the proper rating. Note that the fuse drawer can

also be used to store a spare fuse.

Install the fuse drawer back in the inlet module (fuse down) by pushing in until it locks

securely in place.

Introduction 1-8

Page 17

Section 2 Operation

2.1 Startup

Check to make sure the Voltage Selector Switch on the rear panel agrees with the power

source available (Depending on the power source the switch positions should be in the up or

down positions as shown).

WARNING

NEVER TOUCH THE TEST LEADS IN ANY MANNER (this includes insulation on all

wires and clips) WHEN THE HIGH VOLTAGE IS APPLIED AND RED DANGER

LIGHT ON.

USE ALL PRECAUTIONS NECESSARY TO AVOID TOUCHING THE DEVICE

UNDER TEST WHEN THE RED DANGER LIGHT IS ON OR BLINKING.

Connect the instrument power cord to the source of proper voltage. The instrument is to be

used only with three wire grounded outlets.

Power is applied to the Guardian 5000 by pressing the front panel POWER switch to ON (1

position).

WARNING

DO NOT TURN INSTRUMENT POWER ON OR OFF WITH TEST DEVICES CONNECTED.

2.2 Instrument Zeroing/Offset

The Guardian 5000 provides automatic zeroing/offset for lead or fixture effects. During the

zeroing/offset process a correction is made (subtracted out) as the result of lead leakage

current and stored in instrument memory to be applied to ongoing measurements. For

maximum measurement accuracy it is recommended that the unit be zeroed after power-up

and any time the test leads or fixture is changed (the offset is not saved under setup storage, 1

- 50 setups, but is saved on a power down and power back up. The instrument should

warm-up for at least 15 minutes before zeroing.

Operation 2-1

Page 18

Proceed as follows for automatic zeroing/offset:

• Plug the appropriate cable (or other fixture) into the front panel OUTPUT connectors,

with no device connected. Refer to paragraph 2.3 for cable configurations based on test

to be made. Test leads used for an AC Hipot, DC Hipot or Insulation Resistance

measurement should be open and those leads used for the ground continuity measurement

be shorted together before performing the zeroing offset.

• With the instrument in the power-up state (or in any other desired setup, refer to

paragraph 2.4 for recalling setups) press the OFFSET key.

STEP

1

>R

W-ACV

W-DCV

I-R

A

HI

KV

OFSt

RMT LOCK OFFSET HI-NG LO-NG ARC-NG PASS

AC

DC

LO

GEt

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

SEC

5.0

Offset Key

OFF ON

STOP START

7 8 9 PROG

45

1

0

6

23

.

CLEAROFFSET

OFF ENTER

RCL

STODELE

CURSOR

• Display should read OFSt and GEt. Push the START button to initiate the automatic

storage of the offset value for all tests within a sequence.

• The offset will remain on until turned off by pressing the OFFSET key twice. If the

instrument is powered down with the offset on it remains in effect when the unit is again

powered up.

The following formulas apply to the offset function:

For AC offset current < 80µA:

22

−

Display current = current read offset current

()( )

For DC offset or AC offset current ≥ 80µA:

Display current = (current read) - (offset current)

Operation 2-2

Page 19

2.3 Connection to Device Under Test

Before connecting the device for test Press the STOP key and make sure the red DANGER

light is not on.

Depending on the test to be conducted (Hipot, IR or Ground Continuity) connect the test

cables to the front panel OUTPUT connectors. Refer to the following figures to determine the

correct configuration. When using the black cable, with the metal retaining bracket, make

sure it is locked behind the connector to prevent this cable from accidentally coming loose.

WARNING

NEVER TOUCH THE TEST LEADS OR THE DEVICE UNDER TEST WHEN THEY

ARE CONNECTED TO THE INSTRUMENT AND THE RED DANGER LIGHT IS

ON OR BLINKING.

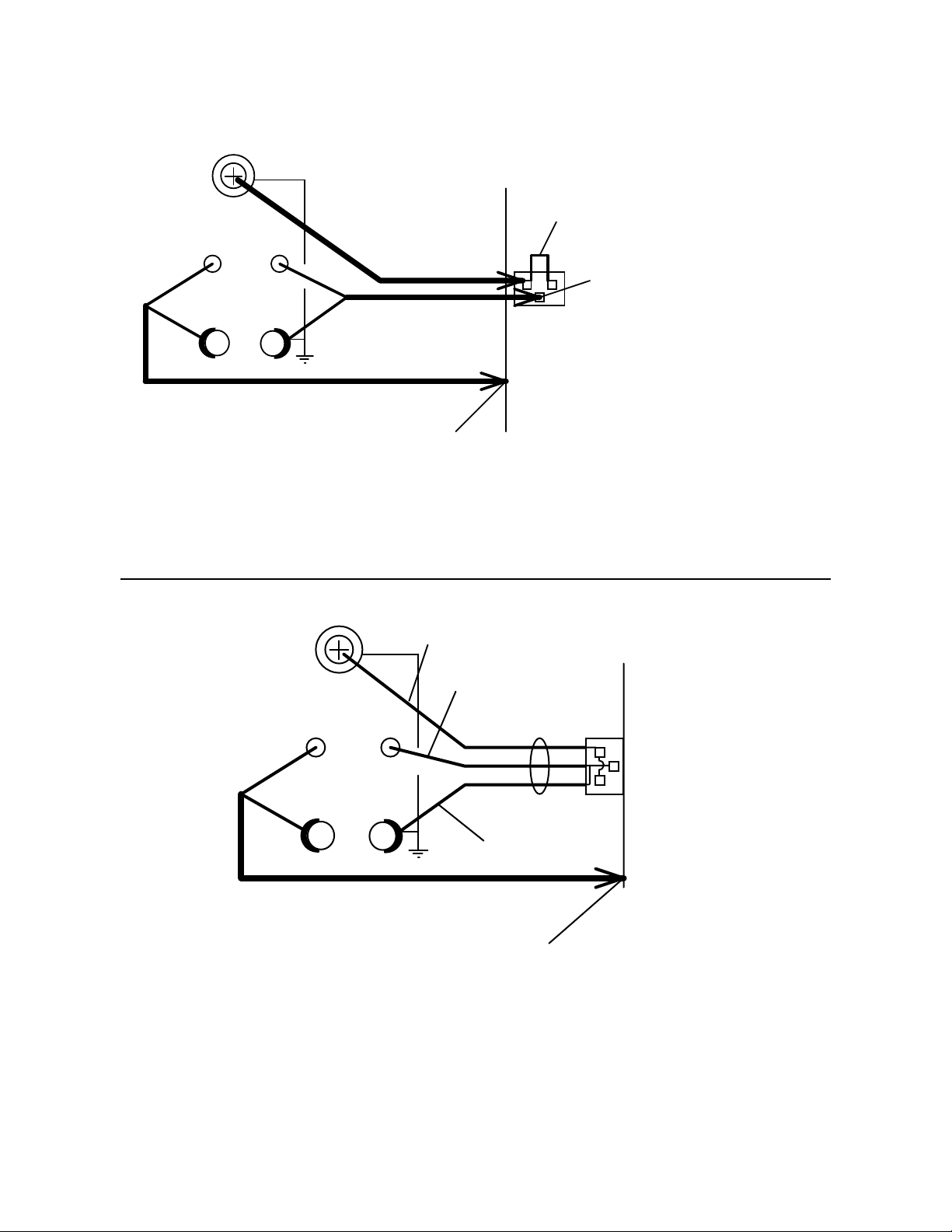

HIGH-VOLTAGE

UNKNOWN

HIGH LOW

SENSE

DRIVER

Connection for Hipot/IR Test

(Using S02 Two Lead Test Set)

Alligator Clip Lead

(Red)

WV

With Retaining Bracket

Alligator Clip Lead

(Black)

Figure 2-1

Shorted

Together

Device Under

Test

(DUT)

Operation 2-3

Page 20

HIGH-VOLTAGE

UNKNOWN

HIGH LOW

SENSE

DRIVER

Large Alligator Clip Lead

Large Alligator Clip Lead

WV

(Red)

Connect to Case

of DUT

Connection for Ground Continuity Test

(Using G15 Two Lead Set, Large Clips)

HIGH-VOLTAGE

(Black)

Figure 2-2

Connect to Power Ground

of DUT

Device Under

Test

(DUT)

Red Lead

UNKNOWN

Black Lead With

Retaining Bracket

HIGH LOW

SENSE

WV

Device Under

Test

(DUT)

DRIVER

Black Lead

With Lug

Figure 2-3

Connection for Hipot Test

(Using G14 Power Entry Cable)

Operation 2-4

Page 21

HIGH-VOLTAGE

UNKNOWN

HIGH LOW

SENSE

DRIVER

Large Alligator Clip Lead

WV

(Red)

Alligator Clip Lead

(Red)

Large Alligator Clip Lead

(Black)

Connect to Case

of DUT

Shorted

Together

Connect to Power Ground

of DUT

Device Under

(DUT)

Test

Figure 2-4

Connection for Hipot and Ground Continuity Test

(Using S02 (HV cable) and G15 Clip Lead Sets)

HIGH-VOLTAGE

Red Lead

UNKNOWN

Black Lead With

Retaining Bracket

HIGH LOW

SENSE

WV

Device Under

Test

DRIVER

Black Lead

With Lug

Large Alligator Clip Lead

(Red)

Connect to Case

of DUT

Figure 2-5

Connection for Hipot and Ground Continuity Test

(Using G15 (one cable) & G14 Power Entry Cable)

(DUT)

Operation 2-5

Page 22

2.4 Measurement Procedure

Once the instrument has been powered up, the offset function implemented and the device

under test connected, testing can begin. The operator has the choice of performing a test at

power-up conditions (test conditions at which the instrument was last powered down), or

recalling one of 50 possible stored setups. Refer to paragraph 2.5 thru 2.8 for instructions to

change the test mode and/or test conditions.

To initiate a test proceed as follows:

• Press STOP (red button) to place the instrument in its standby ready-to-test state.

Test Sep # (1 -15) or

Setup # (1 - 50) entered from keypad in RECALL mode

STEP

1

OFF ON

>R

W-ACV

W-DCV

I-R

STOP START

2.50

RMT LOCK OFFSET HI-NG LO-NG ARC-NG PASS

A

HI

KV

AC

DC

7 8 9 PROG

45

23

1

.

0

LO

ARC

V

6

CLEAROFFSET

OFF ENTER

5.00

RCL

STODELE

>m

uA

M >

CURSOR

TIMER

mA

TEST

>G

RAMP

SEC

5.0

Press to Recall

Setup #

• Press START (green button) to start the test. When this button is pressed the high voltage

is turned on. This is indicated by the DANGER light being on to warn the operator that

high voltage or current is present at the test leads. The step display indicates the step # (1

- 15) within a sequence of tests, voltage/current display will indicate its value, the

measure display will show current or resistance value and the timer will show ramp and

test time countdown.

• Depending on the test conditions, the test voltage or current will cut off if a limit is

exceeded or cut off when the test time has expired. In the case of a FAIL situation the

STOP button must be pressed to stop the buzzer.

• The STOP button can be pressed at any time to stop the test.

Operation 2-6

Page 23

To recall one of the 50 setups proceed as follows:

• Press the RCL key.

• The STEP display shows the current setup # selected. From the front panel keypad type

in the setup number desired (1 - 50).

• Press ENTER to load the stored test conditions and then initiate a test as just described.

Operation 2-7

Page 24

2.5 Programming Tests Mode

Each test can consist of 1 to 15 steps in sequence, for example, a typical three step test might

be an AC hipot test followed by an IR test and followed by a Ground Continuity test. Each

step may be programmed for any available function (ACV, DCV, IR or R-Ω for ground

continuity) with programmed test conditions independent from the other step.

To change the test mode proceed as follows:

• With the instrument in standby status (Stop button previously pressed and no lights

blinking) press the UP

higher. Note the test mode indicator light to the right of the step display, this light

indicates if a particular step selected is AC/DC hipot, an insulation resistance test or

ground continuity test. Press the DOWN key to return to the lower steps. Remember,

up to 15 steps within a single test are possible.

Test Step

cursor one or more times to select or examine steps 2 and

TIMER

mA

TEST

>G

RAMP

SEC

5.0

STEP

1

OFF ON

>R

W-ACV

W-DCV

I-R

2.50

RMT LOCK OFFSET HI-NG LO-NG ARC-NG PASS

STOP START

A

HI

KV

AC

DC

7 8 9 PROG

45

23

1

.

0

LO

ARC

V

6

CLEAROFFSET

OFF ENTER

5.00

RCL

STODELE

>m

uA

M>

CURSOR

For a single step test, the test voltage (or current for a ground continuity test) for

step 2 must be set to 0.00. In a similar fashion, for a two step test the voltage or

current for step 3 must be set to 0.00.

Test Step

STEP

2

>R

W-ACV

W-DCV

I-R

Test Voltage (voltage set to 0 inhibits step 2)

A

HI

KV

0.00

AC

DC

LO

5.00

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

SEC

5.0

Operation 2-8

Page 25

• To change a test mode select the step to be changed (1 to 15) as described above and press

PROG and then ENTER (the VAC/VDC /IR/RΩ light will be blinking).

• Arrow UP or DOWN to the newly desired test mode (VAC/VDC/IR/RΩ) and

press ENTER again.

• Once the desired test mode has been selected refer to paragraph 2.6 for changes to Hipot

test conditions and paragraph 2.7 for changes to IR test conditions and paragraph 2.8 for

changes to Ground Continuity test conditions.

Example of test mode change (step 1 an AC Hipot and step 2 an IR test):

• In standby mode (with no light blinking), arrow UP or arrow DOWN to select

Step 1. Press PROG and then ENTER. UP or arrow DOWN to select W-ACV

for this step and then ENTER.

Starting with test voltage enter the test conditions for step 1 as discussed in paragraph 2.6

for Hipot test conditions. Return to standby mode (with no light blinking) by pressing

PROG key

• In standby mode (with no light blinking), arrow UP or arrow DOWN to select

Step 2. Press PROG and then ENTER. UP or arrow DOWN to select I-R for this

step and then ENTER.

Starting with test voltage enter the test conditions for step 2 as discussed in paragraph 2.7

for IR test conditions. Return to standby mode (with no light blinking) by pressing

PROG key

Operation 2-9

Page 26

2.6 Programming Hipot Test

Test Voltage Leakage Current TimeTest Step

STEP

1

OFF ON

>R

W-ACV

W-DCV

I-R

STOP START

2.50

RMT LOCK OFFSET HI-NG LO-NG ARC-NG PASS

A

HI

KV

AC

DC

7 8 9 PROG

45

23

1

.

0

LO

ARC

V

6

CLEAROFFSET

OFF ENTER

5.00

RCL

STODELE

>m

uA

M>

CURSOR

TIMER

mA

TEST

>G

RAMP

SEC

5.0

With the instrument in standby status (Stop button previously pressed and no lights blinking)

press the arrow UP or arrow DOWN to select the test step # (1 - 15) to be

programmed. If the desired selection is an AC or DC hipot test proceed as described below, if

selection is an IR test refer to paragraph 2.7, if selection is ground continuity refer to

paragraph 2.8.

Press PROG key and ENTER to begin the parameter change. The test mode indicator will

blink, arrow UP or arrow DOWN to select W-ACV (AC Hipot) or W-DCV (DC

Hipot) and press ENTER.

Test Voltage

From the Data Entry Keys type the desired test voltage and then press ENTER. (0.10 to

5.00KV AC and 0.5 to 6.00KV DC are the allowable ranges)

Hi Limit

From the Data Entry Keys type the desired high current limit and then press ENTER. (0.300

to 40.00mA AC, or 20.00mA DC is the allowable range). Any measured value of leakage

current above this will result in a fail decision.

Lo Limit

From the Data Entry Keys type the desired low current limit and then press ENTER. (0.100

to 1/2 the Hi Limit is the allowable range). Any measured value of leakage current below this

will result in a fail decision. An entry of 0 disables the limit detection.

Operation 2-10

Page 27

Arc

From the Data Entry Keys type the desired arc current limit and then press ENTER. (0.500

to 40.00mA AC, or 20.00mA DC is the allowable range). Any measured value of arc current

above this will result in a fail decision. An entry of 0 disables the limit detection.

Test Time

From the Data Entry Keys type the desired test time and then press ENTER. (0.1 to 999s is

the allowable range). A test time of 0 sets the instrument to continuous test mode.

WARNING

EXTREME CAUTION MUST BE USED BY THE OPERATOR, IN CONTINUOUS

MODE, HIGH VOLTAGE IS APPLIED TO THE TEST TERMINALS UNTIL THE

STOP BUTTON IS DEPRESSED OR A LEAKAGE CURRENT BREAKDOWN

OCCURS.

Ramp Time

From the Data Entry Keys type the desired ramp time and then press ENTER. (0.1 to 99.9s

is the allowable range). A test time of 0 for a display of [ - - - - ] sets the ramp time to zero.

After the final test condition entry (ramp time) the instrument returns to the blinking test step

#. Press PROG key to return to standby status in preparation for testing.

OR

If test conditions are to be changed in another step, arrow UP or arrow DOWN to

select the other step:

• if a hipot test, set the test conditions as described in this paragraph.

• if a insulation resistance test refer to paragraph 2.7 for setting test conditions.

• if a ground continuity test refer to paragraph 2.8 for setting test conditions.

Operation 2-11

Page 28

To store the present set of test conditions proceed as follows:

• If the instrument is in programming mode (any lights blinking) press the PROG key.

• Press the STO key.

• From the Data Entry Keys type the setup number desired (1 - 50).

• Press ENTER to store the present test conditions.

2.7 Programming Insulation Resistance (IR) Test

Test Voltage TimeTest Step

Resistance

STEP

OFF ON

>R

W-ACV

W-DCV

I-R

STOP START

7502

RMT LOCK OFFSET HI-NG LO-NG ARC-NG PASS

A

HI

KV

AC

DC

7 8 9 PROG

45

23

1

.

0

LO

ARC

V

6

CLEAROFFSET

OFF ENTER

2.00

RCL

STODELE

>m

uA

M>

CURSOR

TIMER

mA

TEST

>G

RAMP

SEC

5.0

With the instrument in standby status (Stop button previously pressed and no lights blinking)

press the arrow UP

or arrow DOWN to select the test step # (1 - 15) to be

programmed. If the desired selection is an IR test proceed as described below, if selection is a

Hipot test refer to paragraph 2.6, if selection is ground continuity refer to paragraph 2.8.

Press PROG key and ENTER to begin the parameter change. The test mode indicator will

blink, arrow UP or arrow DOWN to select I-R and press ENTER.

Operation 2-12

Page 29

Test Voltage

From the Data Entry Keys type the desired test voltage and then press ENTER. (100 to

1000V DC are the allowable ranges, in 1 steps).

Lo Limit

From the Data Entry Keys type the desired low resistance limit and then press ENTER.

(10MΩ to 9999MΩ is the allowable range). Any measured resistance value below this will

result in a fail decision.

Hi Limit

From the Data Entry Keys type the desired high resistance limit and then press ENTER.

(10MΩ to 9999MΩ is the allowable range and must be above the low limit). Any measured

resistance value above this will result in a fail decision.

Test Time

From the Data Entry Keys type the desired test time and then press ENTER. (0.1 to 999s is

the allowable range). A test time of 0 with display of [ - - - - ] sets the instrument to

continuous test mode.

WARNING

EXTREME CAUTION MUST BE USED BY THE OPERATOR, IN CONTINUOUS

MODE, HIGH VOLTAGE IS APPLIED TO THE TEST TERMINALS UNTIL THE

STOP BUTTON IS DEPRESSED OR A FAILURE RESULTING FROM THE SET

LIMIT OCCURS.

After the final test condition entry (TEST time) the instrument returns to the blinking test step

#. Press PROG key to return to standby status in preparation for testing.

OR

If test conditions are to be changed in another step, arrow UP or arrow DOWN to

select the other step:

• if an insulation resistance test, set the test conditions as described in this paragraph.

• if a hipot test refer to paragraph 2.6 for setting test conditions.

• if a ground continuity test refer to paragraph 2.8 for setting test conditions.

To store the present set of test conditions proceed as follows:

• If the instrument is in programming mode (any lights blinking) press the PROG key.

• Press the STO key.

• From the Data Entry Keys type the setup number desired (1 - 50).

• Press ENTER to store the present test conditions.

Operation 2-13

Page 30

2.8 Programming Ground Continuity Test

Test Current

Resistance

TimeTest Step

STEP

3

OFF ON

>R

W-ACV

W-DCV

I-R

STOP START

25.0

RMT LOCK OFFSET HI-NG LO-NG ARC-NG PASS

A

HI

KV

AC

DC

7 8 9 PROG

45

23

1

.

0

LO

ARC

V

6

CLEAROFFSET

OFF ENTER

300

RCL

STODELE

>m

uA

M>

CURSOR

TIMER

mA

TEST

>G

RAMP

SEC

5.0

With the instrument in standby status (Stop button previously pressed and no lights blinking)

press the arrow UP or arrow DOWN to select the test step # (1 - 15) to be

programmed. If the desired selection is a ground continuity test proceed as described below,

if selection is a Hipot test refer to paragraph 2.6, if selection is insulation resistance refer to

paragraph 2.7.

Press PROG key and ENTER to begin the parameter change. The test mode indicator will

blink, arrow UP or arrow DOWN to select R-Ω and press ENTER.

Test Current

From the Data Entry Keys type the desired test current and then press ENTER. (1.0 to 30.0A

AC are the allowable ranges, in 0.1A steps).

Hi Limit

From the Data Entry Keys type the desired high resistance limit and then press ENTER.

(0.1mΩ to 500mΩ is the allowable range). Any measured resistance value above this will

result in a fail decision.

Test Time

From the Data Entry Keys type the desired test time and then press ENTER. (0.1 to 999s is

the allowable range). A test time of 0 sets the instrument to continuous test mode.

Operation 2-14

Page 31

WARNING

EXTREME CAUTION MUST BE USED BY THE OPERATOR, IN CONTINUOUS

MODE, HIGH CURRENT IS APPLIED TO THE TEST TERMINALS UNTIL THE

STOP BUTTON IS DEPRESSED OR A FAILURE RESULTING FROM THE SET

LIMIT OCCURS.

After the final test condition entry (TEST time) the instrument returns to the blinking test step

#. Press PROG key to return to standby status in preparation for testing.

OR

If test conditions are to be changed in another step, arrow UP or arrow DOWN to

select the other step:

• if a ground continuity test, set the test conditions as described in this paragraph.

• if a hipot test refer to paragraph 2.6 for setting test conditions.

• if an insulation resistance test refer to paragraph 2.7 for setting test conditions.

To store the present set of test conditions proceed as follows:

• If the instrument is in programming mode (any lights blinking) press the PROG key.

• Press the STO key.

• From the Data Entry Keys type the setup number desired (1 - 50).

• Press ENTER to store the present test conditions.

Operation 2-15

Page 32

2.9 Initial Parameter Settings

The Guardian 5000 has a number of parameter setting that seldom require change, the

instrument will power-up with default setting. Each of these parameters are listed in the table

below and can be changed using the following procedure.

Parameter Name

(on Limit display)

St - 1 1 - 30 3 IEEE-488 address

St - 2 50 - 600 60 Hipot VAC freq.

St - 3 50/60 60 GC VAC freq.

St - 4 0.3 - 99.9sec 1 IR test delay

St - 5 0.2- 99.9sec 0.5 PASS hold time

St - 6 0.1- 99.9sec 1 STEP delay time

St - 7 6.0 - 15 volts 15.0 volts GC voltage

St - 8 ON / OFF ON AGC control

St - 9 OFF / 1 / 2 / 3 3 (max) Buzzer

St - A ON / OFF ON PASS hold

ST-b 1 - 8 1 Scanner #

St - C ON / OFF OFF Continue on FAIL

To select initial parameter setting mode:

With the instrument in standby status (Stop button previously pressed and no lights blinking)

press ENTER and then [5] [0] [0] [0]. The limit display will indicate parameter St - 1, and

others (Table 2-1) can be selected by arrow UP or arrow DOWN . Select the St #

desired for change. Once a change is made and the ENTER key pressed the instrument

moves to the next initial setting, if this is not the one desired, arrow UP

to select another. To exit the initial parameter setting mode press PROG.

St - 1 (IEEE-488 Address)

The current address is shown on the Timer display. From the Data Entry Keys type the

address number desired [1 - 30] and ENTER.

St - 2 (AC Hipot test frequency)

The current frequency is shown on the Timer display. From the Data Entry Keys type the

frequency desired [50 - 600] and ENTER.

Selection Range

(on Timer display)

Initial Parameter Setting

Default Value Function

Table 2-1

or arrow DOWN

Operation 2-16

Page 33

St - 3 (Ground Continuity test frequency)

The current frequency is shown on the Timer display. From the Data Entry Keys type the

frequency desired [50 or 60] and ENTER.

St - 4 (IR test delay time)

The current delay time is shown on the Timer display. From the Data Entry Keys type the

time desired [.3 - 999] and ENTER.

St - 5 (Pass indicator hold time)

The current Pass indicator hold time (time in which the Pass indicator remains on after test is

complete) is shown on the Timer display. From the Data Entry Keys type the time desired [.2

- 99.9] and ENTER.

St -6 (step delay)

The current delay time (delay time between steps) is shown on the Timer display. From the

Data Entry Keys type the time desired [.1 - 99.9] and ENTER.

St - 7 (Ground Continuity voltage)

The current ground continuity test voltage is shown on the Timer display. From the Data

Entry Keys type the test voltage desired [6.0 - 15.0] and ENTER.

St - 8 (Hipot automatic gain control)

The current AGC setting (on or off) is shown on the Timer display. From the Data Entry Keys

press the OFF key to toggle the on/off.

St - 9 (Buzzer)

The current Buzzer setting (off or audible levels of 1, 2, or 3) is shown on the Timer display.

From the Data Entry Keys press the OFF or 1, 2, or 3 key and ENTER to turn off or on. 1 is

low volume, 2 is mid-range volume and 3 is high volume.

St - A (Pass indicator hold)

The current Pass indicator hold, on or off (with selection of on Pass indicator remains on until

the next test is initiated) is shown on the Timer display. From the Data Entry Keys press the

OFF key to toggle the on/off.

St - b (# of scanner)

The current # of scanner selected (1 - 8) is shown on the Timer display. From the Data Entry

Keys type the number of scanners to be connected [1 - 8] and ENTER.

St - C (Continue on fail)

The current setting for continue on fail (on or off) is shown on the Timer display. From the

Data Entry Keys press the OFF key to toggle the on/off.

Operation 2-17

Page 34

2.10 Front Panel Lockout

With front panel lock in effect the ability to change test conditions is prohibited. Only the

START and STOP buttons and the setup recall function (RCL) are functional.

To activate the front panel lockout:

• With the instrument in standby status (Stop button previously pressed and no lights

blinking) enter [5] [0] [0] [0] and [OFF] from the data entry keys. The LOCK indicator

light will illuminate indicating the instrument is in the lockout state.

To deactivate the front panel lockout:

• With the instrument in standby status (Stop button previously pressed and no lights

blinking) enter [5] [0] [0] [0] and [OFF] from the data entry keys. The LOCK indicator

light will go out indicating the instrument is no longer in the lockout state.

2.11 Software Version Display

The version of software, installed in the instrument, can be displayed on the front panel.

To display software version:

• Press the front panel POWER switch to ON and immediately press the ENTER key. The

year will be shown in the left display and the month and day in the right display as

illustrated below. This software version display is only held for a couple of seconds.

>m

mA

uA

>G

M >

1997

HI

V

KV

DC

AC

LO

02

ARC

A

15

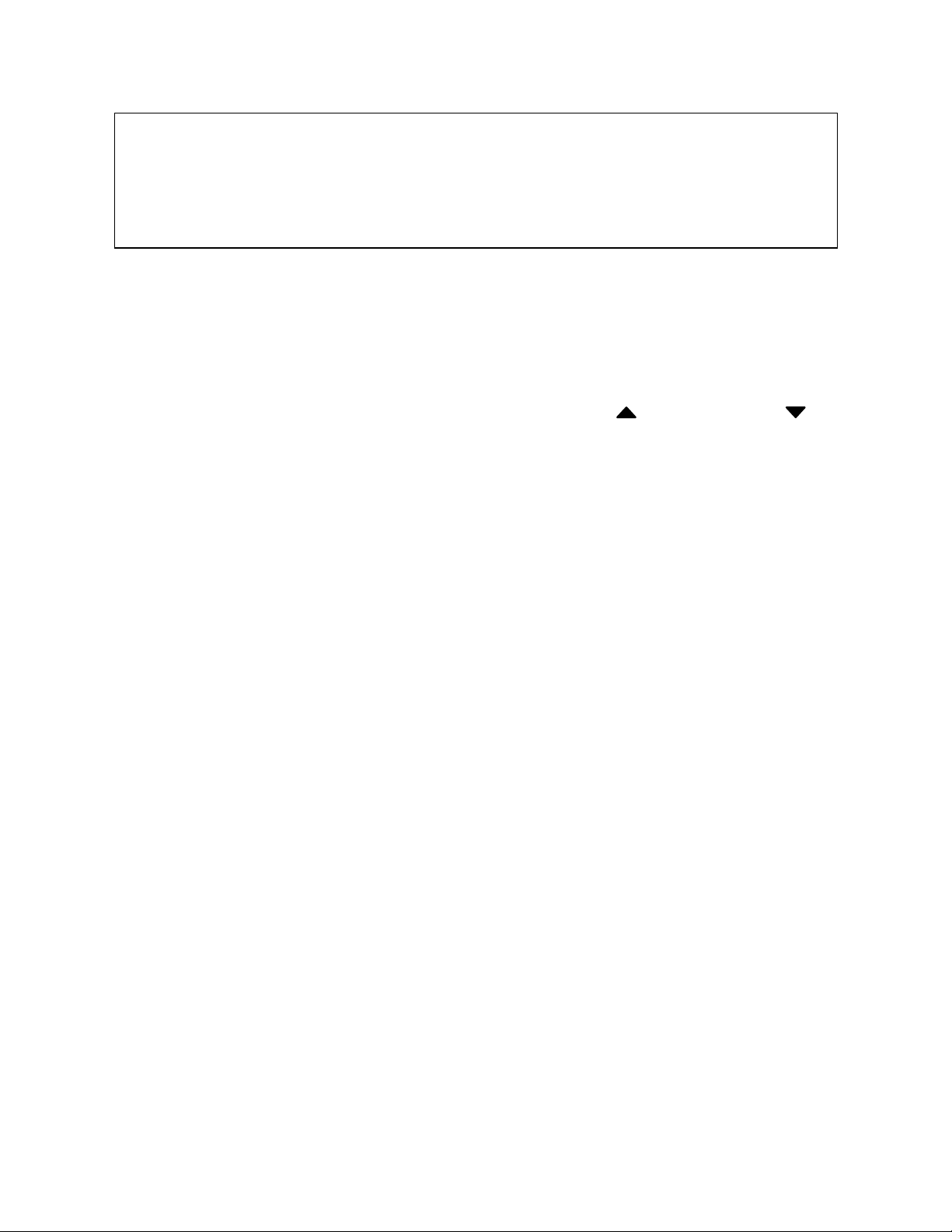

2.12 Clear Setup Memory

All stored test conditions in instrument memory (50 setups) can be cleared with a few key

strokes.

To clear setup memory:

• With the instrument in standby status (Stop button previously pressed and no lights

blinking) press CLEAR and then [5] [0] [0] [0] and CLEAR again.

Operation 2-18

Page 35

Section 3 Input/Output Interfaces

3.1 Remote

A remote control connector is located on the rear panel of the instrument with input

connections for starting and stopping the unit externally and output connections indicating

instrument status and a safety interlock connection.

Inputs require a contact closure and outputs provide a contact closure, as shown in the figure

below.

Before connecting the instrument to its power source the interlock function on the rear panel

remote connector must be properly utilized. This is an important safety feature for the

protection of the operator. Turn on of the instrument's high voltage is inhibited with no

interlock connection and is functional with the interlock jumper in place (as shipped from the

factory).

START

STOP

COM

INPUTS

INTERLOCK

UNDER TEST

PASS

FAIL

Rear Panel

Remote Connector

OUTPUTS

Figure 3-1

Remote Control Connector

Maintenance & Calibration 3-1

Page 36

close

START

open

close

UNDER TEST

open

PASS CONDITION FAIL CONDITION

close

PASS

open

close

FAIL

open

close

STOP

open

close

INTERLOCK

open

215ms 215ms

215ms

215ms

Maintenance & Calibration 3-2

Page 37

3.2 IEEE-488 Interface

3.2.1 Description

The Guardian 5000 includes an IEEE-4888 interface with connection through a connector (24

pin) on the rear panel. This interface can be used to connect to a system containing a number

of instruments and a controller in which each meets IEEE Standard 488.2 (Standard Digital

Interface for Programmable Instrumentation).

The following functions have been implemented:

Code Function

SH1 Source Handshake

AH1 Acceptor Handshake

T4 Basic Talker Function

L4 Basic Listener Function

SR0 No Service Request Function

RL1 All Remote/Local Function

PP0 No Parallel Poll Function

DC1 All Device Clear Function

DT0 Device Trigger Function

C0 No Controller Functions

The address is defined in the INITIAL setting for St-1, refer to paragraph 2.9

The instrument is in a remote control status when the RMT indicator is on.

To switch to Local from Remote press the [PROG] key, disabled by LLO message.

The only controls functional under Remote operation is [PROG], which switches to Local and

STOP which resets the unit.

Intf Message Function Description

GET Ground Execute Trigger Response depends on the *DDT, setting to

START or STOP

GTL Go To Local Switch unit to local

SDC Selected Device Clear Reset the unit

LLO Local Lockout Disables [PROG] switch to local

IFC Interface Clear Reset bus interface

Maintenance & Calibration 3-3

Page 38

3.2.2 Interface Commands

The interface function is controlled by ASCII commands which include:

{[command + parameter] ; [command + parameter] + ending code}

The length of the string is 128 characters. It is not necessary to input any sign or space

between the command and parameter. Any two commands can be connected by "," and

[Ending Code]. Ending Code can be any type of the following.

Ending Code

LF

CR + LF

EOI

LF + EOI

CR + LF + EOI

Maintenance & Calibration 3-4

Page 39

3.2.2.1 Listener Functions

Item Command Parameter Function

1 STOP X stop test

2 TEST X start test

3 SHOW (?) {c} set testing value

4 STEP (?) {n} set Step

5 MODE (?) {n | c} set test mode

6 SOUR (?) {f} set output voltage or current

7 VOLT (?) {f} set output voltage

8 CURR (?) {f} set output current

9 HILI (?) {f | *} set High Limit

10 LOLI (?) {f | *} set Low Limit

11 SARC (?) {f | *} set ARC

12 HICH (?) {n | *} set High Channel

13 LOCH (?) {n | *} set Low Channel

14 TIME (?) {f | *} set the test time

15 RAMP (?) {f | *} set the voltage rise time

16 *SAV {n} save the setting value

17 *RCL {n} read the setting value

18 CLER X clear the memory

19 *IDN (?) X check the unit number

20 *DDT (?) {n | c} set the response to Trigger

21 *TRG X execute Trigger command

22 *RST X reset the unit

where x: no parameter required

n: indicates integer

f: indicates floating

c: indicates memory mark

*: indicates the "*" character of ASCII

Maintenance & Calibration 3-5

Page 40

1. STOP

Stop testing, same as STOP on front panel.

2. TEST

Start testing, same as START on front panel.

3. SHOW (?) {c}

Check the testing value, [STATUS] [STEP] [MODE] [SOURCE] [MEASURE]

[TIMER] [CHAN] [SAVE]

The command can connect each parameter with "|". Each parameter can be

abbreviated. Ex: STA=STATUS, STE=STEP

A delay ≥ 150 msec should be used between commands during measurements.

4. STEP (?) {n}

Step number (1 - 15). Set step number first before setting test conditions for that

step.

5. MODE (?) {n | c}

Set test mode by number or memory sign.

Ground Continuity 0, G or GR

AC Hipot 1, A or WA

DC Hipot 2, D or WD

Insulation Resistance 3, I or IR

If testing mode is changed the test conditions will be cleared to the initial value.

6. SOUR (?) {f}

Set the output voltage of current according to mode selected.

Ground Continuity f = 1 - 30 Amp

AC Hipot f = 0.1 - 5.0 KV

DC Hipot f = 0.5 - 6.0 KV

Insulation Resistance f = 100 - 1000 V

The output voltage for current can be set by SOUR or VOLT or CURR directly.

VOLT or CURR is the recommended method to avoid improper setting

(5 Amp could be interchanged for 5 KV, depending on the MODE selected).

For Ground Continuity the high resistance limit is determined by the current setting.

The maximum high resistance limit is 510mΩ or R = 6.3 V/I (i.e. if the current is 30

Amps the high limit could not exceed 210mΩ.

7. VOLT (?) {f}

Set the output voltage (similar to SOUR). Indicates error 1 if mode is selected for

Ground Continuity.

8. CURR (?) {f}

Set the output current (similar to SOUR). Indicates error 1 if mode is selected for

anything other than Ground Continuity.

Maintenance & Calibration 3-6

Page 41

9. HILI (?) {f | *}

Set the high limit value according to mode selected. * disables the high limit.

Ground Continuity f = 0.1 - 500.0 mΩ

AC Hipot f = 0.01 - 40.00 mA

DC Hipot f = 0.01 - 20.00 mA

Insulation Resistance f = 1 - 9999 MΩ

In Hipot mode if the High Limit/2 is smaller than the Low Limit, the low limit is

disabled.

In IR mode the value can not be smaller than the Low Limit, otherwise error 2 is

indicated.

In Ground Continuity mode the maximum high resistance limit is 510mΩ or

R = 6.3 V/I (i.e. 210mΩ for 30 Amps).

10. LOLI (?) {f | *}

Set the low limit value according to mode selected. * disables the low limit.

Ground Continuity f = 0.1 - 500.0 mΩ

AC Hipot f = 0.01 - 40.00 mA

DC Hipot f = 0.01 - 20.00 mA

Insulation Resistance f = 1 - 9999 MΩ

In Hipot mode the limit is disabled if greater than High Limit/2.

In IR mode the limit is disabled if greater than the High Limit.

In Ground Continuity mode the limit can not be set.

11. SARC (?) {f | *}

Set the arc limit value (Hipot mode only). * disables the limit.

AC Hipot f = 0.01 - 40.00 mA

DC Hipot f = 0.01 - 20.00 mA

12. HICH (?) {n | *}

Set the High Channel from 1 - 8. * disables the limit. More than one channel is

possible (Ex: HICH 1 3 5).

13. LOCH (?) {n | *}

Set the Low Channel from 1 - 8. * disables the limit. More than one channel is

possible (Ex: LOCH 1 3 5). Can not be set in Ground Continuity mode.

14. TIME (?) {f | *}

Set the Test Time from 0.1 - 99.9 sec. * disables the time.

15. RAMP (?) {f | *}

Set the voltage rise time from 0 - 99.9 sec for Hipot mode. * disables the time.

Maintenance & Calibration 3-7

Page 42

16. *SAV {n}

Save the test conditions for later recall (up to 15 steps each) in memory location: 1-

50.

17. *RCL (?) {n}

Recall the test conditions that have been saved (up to 15 steps each) in memory

location 1 - 50.

18. CLER

Resets the instrument from interface control. The address function is till in

effect.

19. *IDN

Checks the instrument for identification.

20. *DDT (?) {n | c}

Determines the response from the interface when the instrument receives TRG or GET

command.

0 or S Stop testing

1 or T Start testing

2 or NS Stops testing after receiving TRG or GET command and

DDT will change to NT.

3 or NT Starts testing after receiving TRG or GET command and

DDT will change to NS.

21. *TRG

Triggers the instrument and functions the same as interface message GET. This is

dependent on the setting of DDT, see above.

22. *RST

Resets the instrument and functions the same as interface message SDC

Maintenance & Calibration 3-8

Page 43

3.2.2.2 Talker Functions

The message of {string + ending code} will be sent when the instrument is assigned as

TALKER. The ending code consists of CR+LF+EOI. The string is dependent on the present

status.

There are several commands with the "?". These commands send the testing value by ASCII

string.

Example:

1. Command : mode WD: mode?

: MODE 2 : With Standing DC voltage test mode.

2. Command : high 1|3|5; high?

:HICH 1|3|5 ; High Channel 1,3,5 is ON

All commands will feed back an error message except *RST, *TRG , show and "?'. If the

error code is not 0 the result will be displayed. Error messages are as follows:

Error Messages

Error 0: Save OK!

Error 1: The command is not valid

Error 2: The parameters are not valid

Error 3: Can not start test

Error 4: Scanner is not connected

Error 5: Channel can not set 0

Error 6: Channel invalid

The TALKER function is completed by SHOW(?) command. The instrument will send back

the testing value for the parameter selected. It may check more than one test value by

connecting the parameters with "|".

Status Messages

Status 0: Presently in STOP status

Status 1: Presently in TEST status

Status 2: Test complete, condition is PASS

Status 3: Test stop, condition is FAIL

Status 4: Test stop, Hipot arc limit FAIL

Status 5: Test stop, Hipot high limit FAIL

Status 6: Test stop, Hipot low limit FAIL

Status 7: Test stop, IR high limit FAIL

Status 8: Test stop, IR low limit FAIL

Status 9: Test stop, GC high limit FAIL

Maintenance & Calibration 3-9

Page 44

1. STATUS

To check the present status, with status code. Output from is:

STATUS_X--8 bytes

note: "_" denotes a space

2. STEP

To check the present step. Output form is STEP_XX--7 bytes

3. MODEL

To check the testing mode. Output form is MODE_X--6 bytes

4. SOURCE

To check the output voltage or current. Output form is:

1) GC Mode AC_XXX>XX_A

2) AC Mode AC_XX>XX_KV

3) DC Mode DC_XX>XX_KV

4) IR Mode DC.XXXX__V

total: 11 bytes

5. MEASURE

To check the tested resistance or current. Output form is:

MEASURE_XXXXX_UU

where XXXXX is the measured value and UU the units

total: 16 bytes

6. TIMER

To check the test time remaining. Output form is:

1) TIME_XX.X

2) RAMP_XX.X

total: 9 bytes

7. CHAN

To check the channel status. Output form is:

HICH_X|X| .....|X, LOCH_X|X|.....|X

total: 13 to 41 bytes

8. SAVE

To save the data of each test. The unit can read the data without the SHOW

parameter.

Example: Write : SHOW Step|save

Read : STEP 1

Read : STEP 1

Write : SHOW mode

Read : MODE 1

Read : STEP 1 shows step by SHOW step|save

SAVE parameter can not be used alone

Example: SHOW SAVE will display Error 2

Maintenance & Calibration 3-10

Page 45

If the instrument is required to display saved item, just use SHOW? command

If the instrument is required to display more than one testing value, no matter

what the order of parameters, the output will display the following.

[STATUS], [STEP],[MODE],[SOURCE],[MESSAGE],[TIMER],[CHAN]

any two parameters separated by a ","

Example: Write: SHOW STEP|STATUS|MODE

Read: STATUS 2, STEP 1, MODE 1

The string length sent by SHOW may not be more than 106 bytes (including

ending code)

3.2.3 Sample QuickBASIC Program

REM $INCLUDE: 'qbdecl.bas'

'declarations

ADAP$ = "GPIB0": G5000$ = "DEV3": V% = 1

W% = 0: C$ = SPACE$(50): d$ = SPACE$(50): C1$ = SPACE$(50): D1$ = SPACE$(50)

STAT$ = SPACE$(50)

'find IEEE card and G5000

CALL IBFIND(ADAP$, GPIB0%)

CALL IBFIND(G5000$, G5000%)

CLS 'clear screen

'read identification from g5000

CALL IBWRT(G5000%, "*IDN")

CALL IBRD(G5000%, D1$)

PRINT D1$

'open a file to store data and status to

20

PRINT "FILE NAME TO STORE RESULT (less than 8 characters)"

INPUT NAME$

IF LEN(NAME$) = 0 THEN NAME$ = "DATA"

IF LEN(NAME$) > 8 THEN GOTO 20

NAME$ = NAME$ + ".TXT"

OPEN NAME$ FOR APPEND AS #1

Maintenance & Calibration 3-11

Page 46

'ask user for mode, voltage, current, ramp and test time

50

PRINT "MODE 1 = AC, 2 = DC"

INPUT MODE$

IF MODE$ = "" OR MODE$ > "2" OR MODE$ < "1" THEN GOTO 50 'check mode is

AC/DC hipot

100

PRINT "INPUT VOLTAGE IN kV"

INPUT VOLT$

IF VOLT$ = "" OR VOLT$ > "5" THEN GOTO 100 'check voltage is in range

200

PRINT "HIGH CURRENT LIMIT IN mA"

INPUT CURR$

IF CURR$ = "" OR CURR$ > "40" THEN GOTO 200 'check current is in range

PRINT "RAMP TIME IN seconds"

INPUT RAMP$

300

PRINT "TEST TIME IN seconds"

INPUT TIM$

IF TIM$ = "" OR TIM$ > "999.9" THEN GOTO 300 'check time is in range

'configure g5000

SET$ = "STEP1;MODE" + MODE$ + ";SOUR " + VOLT$ + ";HILI" + CURR$ + ";RAMP"

+ RAMP$ + ";TIME" + TIM$

CALL IBWRT(G5000%, SET$) 'send string to g5000

REM CALL IBRD(G5000%, C$) 'read status of g5000

'perform a measurement

CALL IBWRT(G5000%, "STOP") 'make sure unit is in stop mode

CALL IBRD(G5000%, C$) 'read status

PRINT C$

CALL IBWRT(G5000%, "TEST") 'start measurement

FOR I = 1 TO 500

NEXT I

CALL IBWRT(G5000%, "SHOW STATUS") 'check status of unit

CALL IBRD(G5000%, STAT$)

WHILE VAL(MID$(STAT$, 8, 1)) = 1 'loop while status is testing

CALL IBWRT(G5000%, "SHOW STATUS")

CALL IBRD(G5000%, STAT$)

PRINT STAT$

WEND

Maintenance & Calibration 3-12

Page 47

'get data from G5000

CALL IBWRT(G5000%, "SHOW SOURCE|MEASURE") 'ask for voltage and current levels

CALL IBRD(G5000%, d$) 'read current and voltage levels

PRINT "DATA IS:"; d$ 'output data to the screen

PRINT #1, d$ + STAT$ + TIME$ + " " + DATE$ 'store data and status to open file

CLOSE #1

END

Maintenance & Calibration 3-13

Page 48

3.3 Scanner Interface

3.3.1 Scanner Accessories

Table 3-1

Guardian 5000 Scanner Accessories

Item Quantity

G17, 25 pin interconnect cable (Guardian 5000 to Scanner) 1

Test Lead Set, Hipot (Guardian Output to Scanner I/P)

G18, HV plug to sheathed banana plug (red) 1

G19, Banana plug(w/retaining bracket) to sheathed banana 1

plug (black)

G21, Scan Clip Leads, Hipot (Scanner front panel outputs to DUT) 8

Sheathed banana (orange) to alligator clip (red)

*G20, Interconnect Cable, GC (Guardian Output to Scanner rear 1

panel GC Input) Banana plug/lug, (red/black) to banana plug/lug

(red/black)

*G15, Scan Clip Lead Set, GC (Scanner rear panel GC outputs to DUT) 4

Large alligator clips (red/black) to banana plug/lug (red/black)

Scan Card for Guardian 5000 1

* Only included with 5000-02 (GC scanner)

3.3.2 Scanner Card Installation

The 5000-01 and 5000-02 Scanners are supplied with an interface card that must be installed

in the Guardian 5000. Proceed as follows:

• Remove the three screws which secure the Guardian 5000 top cover to the rear panel. The

top cover is removed by lifting up and back, out of the front panel groove.

• Remove the 2 screws (to the right of the rear panel SCAN connector hole) and remove the

filler panel.

Maintenance & Calibration 3-14

Page 49

SCANGPIB

Guardian 5000 Rear Panel

remove

2 screws

• Install the scanner card inside the rear panel using the two screws previously removed.

On some of these cards it may be necessary to bend the heatsink up so that it does not

hit the GPIB board (hot glue in the bent position is recommended).

• Plug the scanner card ribbon cable into the plug marked SCAN (adjacent to the GPIB

ribbon cable connector). It will be necessary to first remove the GBIB board ribbon cable,

plug in the scanner card ribbon cable, and then reconnect the GPIB cable Note that the

connectors are keyed with a notch to ensure proper orientation.

• Locate the loose cable (white wires) and plug into the 2-pin connector on the scanner

board.

• Replace the instrument top cover by first sliding into the front panel grove, push down,

and secure with the three screws.

3.3.3 Scanner Connections

Before connecting the scanner to the Guardian 5000 or connecting devices for test Press the

STOP key and make sure the red DANGER light is not on.

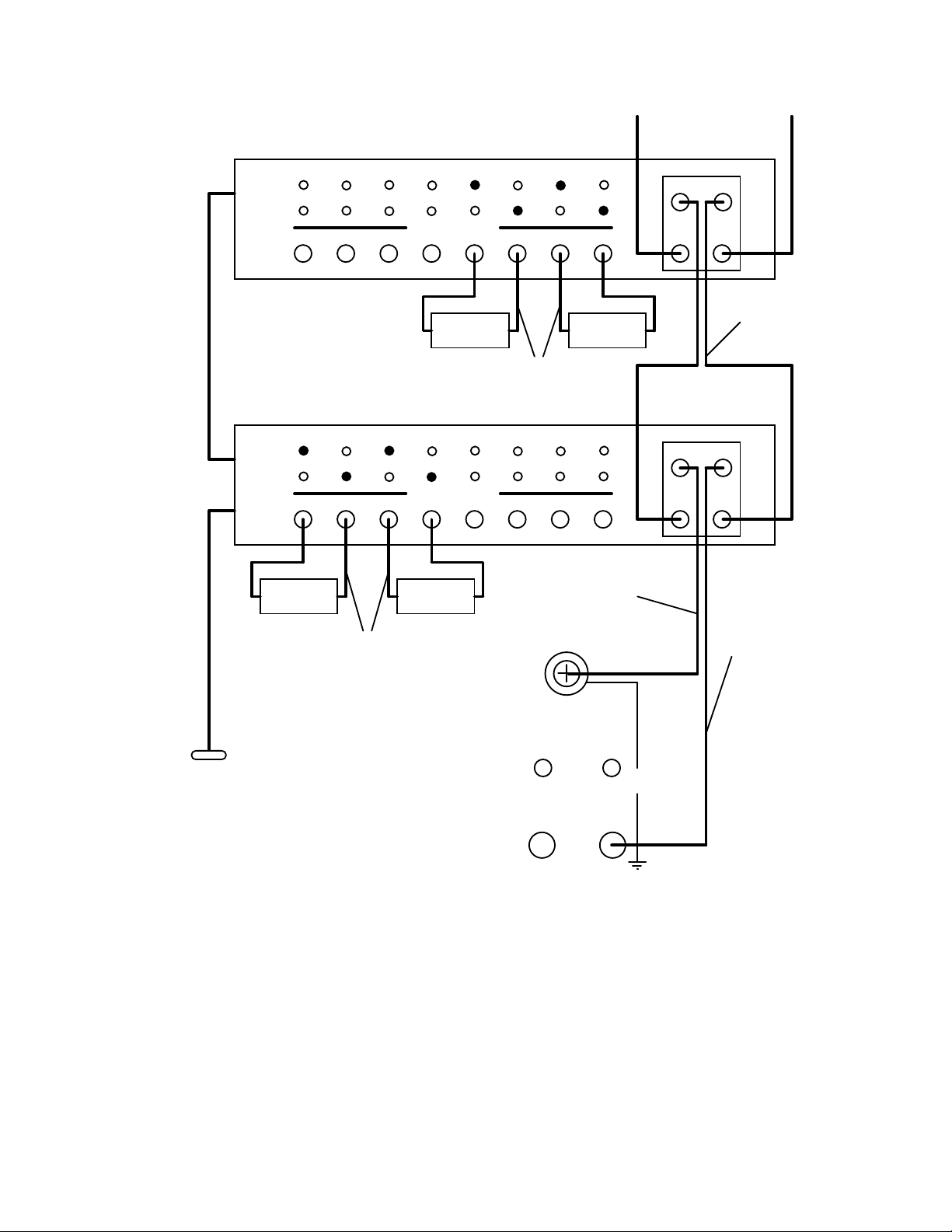

Refer to the diagrams that follow for a typical scanner connection. Figure 3-2 is connection

to the 5000-01 for hipot or insulation resistance (IR) tests. Figure 3-3 is connection to the

5000-02 for ground continuity (GC) testing as well as Hipot or IR testing.

WARNING

THE REAR PANEL GROUND LUGS ON ALL INSTRUMENTS (Guardian 5000 and

Scanners) MUST BE INTERCONNECTED

NEVER TOUCH THE TEST LEADS OR THE DEVICE UNDER TEST WHEN THEY

ARE CONNECTED TO THE INSTRUMENT AND THE RED DANGER LIGHT IS

ON OR BLINKING.

Maintenance & Calibration 3-15

Page 50

To Scanner

3 thru 8

To rear panel

Scan I/P

G17

Control

cable

To rear panel

Scan O/P

To rear panel

Scan I/P

H.V

LOW

H.V

LOW

Under Test

12

12

Device

34

OUTPUT

Device

Under Test

G21,

(orange) to alligator

clip (red)

34

OUTPUT

Device

Under Test

6

5

Sheathed banana plug

5

7

Under Test

6

7

HV plug to sheathed

G18,

banana plug

Device

8

8

(red)

H.VLOW

H.VLOW

I/P

Scanner

#2

O/P

Banana plug cables

Scanner

I/P

#1

O/P

Sheathed banana plug

G21,

G17

Control

cable

To Guardian 5000

rear panel scan

connector

(orange) to alligator

clip (red)

Guardian 5000

Output Connectors

5000-01 Scanner Connection

(one, two or more scanners)

HIGH-VOLTAGE

Figure 3-2

UNKNOWN

HIGH LOW

SENSE

DRIVER

WV

Banana plug (with

G19,

retaining bracket) to

sheathed banana plug

(black)

Maintenance & Calibration 3-16

Page 51

SCAN I/F

GROUNDING

INPUT

Driver

Sense

CHANNEL 1 CHANNEL 2

CHANNEL 3

CHANNEL 4

To front panel

HV I/P

I/P O/P

Device

Under Test

G17

Control cable

G18, HV plug to

sheathed banana (red)

G20

Interconnect cable

banana plug/lug

(red/black)

Device

Under Test

G15, Ground continuity

clip lead set (red/black)

HIGH-VOLTAGE

UNKNOWN

HIGH LOW

SENSE

WV

To Guardian 5000

rear panel scan

connector

DRIVER

Guardian 5000

Output Connectors

Figure 3-3: 5000-02 Scanner Connection

3.3.4 Scanner Programming

There are 16 indicators (8 high, 8 low) on the scanner front panel, during test these indicate

which are programmed for the High Voltage or Low connections. Connections for high

voltage are indicated in red and low in green. When the scanner and Guardian 5000 are

connected (25 pin interconnect cable) the instrument will accept entry of scanner connections.

A Hi or Lo entry (as shown below) is made during the programming process preceding the

entry of a test voltage. It is possible to have one or multiple entries for scanner connections,

i.e. if 1 2 and 3 are entered for the Hi connection all three outputs will be connected to the

High Voltage terminal during the test. When making multiple entries for a scanner

connection up to four will be shown on the Voltage display and those in excess of four shown

on the Limit display.

Maintenance & Calibration 3-17

Page 52

r

Programmed Scanner Connections as Shown in Figure 3-2

When using more than one scanner the initial parameter setting, St-b must be setup for the

number of scanners connected. Refer to paragraph 2.9. Connection of up to 8 scanners

(5000-01 thru 5000-04) for a total of 64 channels, hipot or IR testing or up to 8 scanners

(5000-02 & 5000-04) for a total of 32 channels, ground continuity testing. When

programming scanner connections the scanner number ( 1 thru 8) is shown on the timer

display.

Note

When the scanner is programmed for multiple connections in the same test step the devices

under test are connected in parallel (as shown in Figures 3-3 and 3-3). To test several devices

independent from each other, requires an individual test step (1 to 15) for each. Refer to

paragraph 2.5

Scanner #1

Scanner outputs programmed high

(up to 4)

Scanner outputs programmed high

((those in excess of 4)

STEP

Hi

>R

W-ACV

W-DCV

I-R

13

A

HI

KV

AC

DC

LO

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

Scanner numbe

STEP

Lo 1

>R

W-ACV

W-DCV

I-R

2

4

A

HI

KV

AC

DC

LO

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

Scanner #2

STEP

Hi 2

>R

W-ACV

W-DCV

I-R

57

A

HI

KV

AC

DC

LO

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

STEP

Lo

>R

W-ACV

W-DCV

I-R

68

A

HI

KV

AC

DC

LO

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

Programmed Scanner Connections as Shown in Figure 3-3

STEP

Hi

>R

W-ACV

W-DCV

I-R

14

A

HI

KV

AC

DC

LO

ARC

V

>m

uA

M >

TIMER

mA

TEST

>G

RAMP

SEC

1

SEC

SEC

SEC

2

SEC

1

Maintenance & Calibration 3-18

Page 53

)

3.4 G16 International Power Strip

The G16 International Power Strip allows connection of standard corded products from

several different countries. These being:

Switzerland

Italy

Continental Europe

United States

Denmark

United Kingdom

Australia

Refer to Figure 3-4 for connection of the G16 International Power Strip to the Guardian 5000.

HIGH-VOLTAGE

UNKNOWN

HIGH LOW

SENSE

DRIVER

WV

White

Black

Green

Green/Yellow

(Chassis ground, can also be connected to chassis

ground connector of Guardian 5000 rear panel

G16 International Power Strip

Figure 3-4

G16 International Power Strip Connection

Maintenance & Calibration 3-19

Page 54

Page 55

Section 4 Maintenance & Calibration

4.1 General

Our warranty (at the front of the manual) attests the quality of materials and workmanship in

our products. If malfunction should be suspected, or other information be desired

applications engineers are available for technical assistance. Application assistance is

available in the U.S. by calling 978-461-2100 and asking for Applications Support. For

support outside of the United States please contact your local QuadTech distributor.

4.2 Instrument Return

Before returning an instrument to QuadTech for service please call our Service Department at

800-253-1230 for return material authorization. It will be necessary to include a Purchase

Order Number to insure expedient processing, although units found to be in warranty will be

repaired at no-charge. For any questions on repair costs or shipment instructions please

contact our Service Department at the above number. To safeguard an instrument during

storage and shipping please use packaging that is adequate to protect it from damage, i.e.,

equivalent to the original packaging and mark the box "Delicate Electronic Instrument".

Return material should be sent freight prepaid, to:

QuadTech, Inc.

5 Clock Tower Place, 210 East

Maynard, MA 01754-2530

Attention: Service Department

Shipments sent collect can not be accepted.

4.3 Calibration

Calibration of the Guardian 5000 is recommended on an annual basis. If the unit is returned

to QuadTech for factory calibration refer to paragraph 4.2 for instructions. Using the

calibration procedure below the instrument can be calibrated by a qualified service person if

traceable calibration equipment and standards are available. The instrument should be

powered up for a minimum of 1 hour before calibration to ensure maximum stability.

Maintenance & Calibration 4-1

Page 56

Table 3-1

Equipment for Calibration

Description Requirements

AC/DC Voltmeter Measure range, 0 to 5KV, 0.1%.

AC/DC Current Meter Measure range, 0 to 6KV, 0.1%.

10 MΩ Load Resistor 0.25W

420 kΩ Load Resistor 5W

80 kΩ Load Resistor 25W

50 kΩ Load Resistor 50W

0.1 Ω Load Resistor 100W

0.05 Ω Resistor 5W

4.3.1 Calibration Procedure

The following calibrations procedures are included:

Voltage Calibration

CL 50 OFST ACV ; ACV 50 volts offset

CL 4000 FULL ACV ; ACV 4000 volts full scale

CL 50 OFST DCV ; DCV 50 volts offset

CL 4000 FULL DCV ; DCV 4000 volts full scale

CL 50 OFST IR ; IR 50 volts offset

CL 1000 FULL IR ; IR 1000 volts full scale

Current Calibration

CL OFST 2.99 ACV ; ACV 2.99 mA range offset

CL FULL 2.99 ACV ; ACV 2.99 mA range full scale

CL OFST 30.0 ACV ; ACV 30 mA range offset

CL FULL 30.0 ACV ; ACV 30 mA range full scale

CL OFST 2.99 DCV ; DCV 2.99 mA range offset

CL FULL 2.99 DCV ; DCV 2.99 mA range full scale

CL OFST 15.0 DCV ; DCV 15 mA range offset

CL FULL 15.0 DCV ; DCV 15 mA range full scale

Ground Continuity Calibration

CL 3.0 OFST GrA ; Grounding Current offset

CL 25.00 FULL GrA ; Grounding Current full scale

CL 5.0 OFST GrV ; Grounding Voltage offset

CL 30.0 FULL GrV ; Grounding Voltage full scale

Maintenance & Calibration 4-2

Page 57

To enable calibration:

With the instrument in standby status (Stop button previously pressed and no lights blinking)

remove the front panel calibration seal and push (using pen or pencil point) the recessed

switch through the hole in the front panel (to the in

Press ENTER and then [7] [9] [3] [1]

Display CAL OFF / CAL ON / CAL TEST

CAL OFF : calibration data install zero

CAL ON : calibration finished, in normal operation

CAL TEST : into calibration procedure

Press [OFF] key : to change CAL OFF / CAL ON / CAL TEST

Display CAL TEST : ready to calibrate

Press [PROG] key : ready for calibration

4.3.2 AC Voltage Calibration

Connect the AC voltmeter between the H.V. OUTPUT and the LOW DRIVER terminal.

Press [UP] or [DOWN] key as necessary to display

Display CL 50 OFST ACV

Press [OFF] key to display

Display 1 0.05KV .500mA 0.0 sec

Press [STOP] [START] ; read out the HV meter value

; example 0.062KV

Press [0] [.] [0] [6] [2] [ENTER]

Press [STOP]

Press [DOWN] key to display

Display CL 4000 FULL ACV

Press [OFF] key to display

Display 1 4.00KV .500mA 0.0 sec

Press [STOP] [START] ; read out the HV meter value

; example 4.052KV

Press [4] [.] [0] [5] [2] [ENTER]

Press [STOP] ; stop ACV full scale calibration

position).

Maintenance & Calibration 4-3

Page 58

4.3.3 DC Voltage Calibration

Connect the DC voltmeter between the H.V. OUTPUT and the LOW DRIVER terminal.

Press [UP] or [DOWN] key as necessary to display

Display CL 50 OFST DCV

Press [OFF] key to display

Display 1 0.05KV .500mA 0.0 sec

Press [STOP] [START] ; read out the HV meter value

; example 0.062KV

Press [0] [.] [0] [6] [2] [ENTER]

Press [STOP] ; stop DCV offset calibration

Press [DOWN] key to display

Display CL 4000 FULL DCV

Press [OFF] key to display

Display 1 4.00KV .500mA 0.0 sec

Press [STOP] [START] ; read out the HV meter value

; example 4.052KV

Press [4] [.] [0] [5] [2] [ENTER]

Press [STOP] ; stop DCV full scale calibration

4.3.4 IR Voltage Calibration

Connect the DC voltmeter between the H.V. OUTPUT and the LOW DRIVER terminal.

Press [UP] or [DOWN] key as necessary to display

Display CL 50 OFST IR

Press [OFF] key to display

Display 1 50V 1MΩ 0.0 sec

Press [STOP] [START] ; read out the HV meter value

; example 62V

Press [6] [2] [ENTER]