Page 1

1865 Megohmmeter/IR Tester

Instruction Manual

Form 150073/D4

QuadTech, Inc., 1992

5 Clock Tower Place, 210 East

Maynard, Massachusetts, U.S.A. 01754

September, 2003

Telephone 978-461-2100

Sales 800-253-1230

Facsimile 978-461-4295

Website www.quadtech.com

The material in this manual is for informational purposes only and is subject to change, without

notice. QuadTech assumes no responsibility for any error or for consequential damages that may

result from the misinterpretation of any procedures in this publication.

WARNING

Potentially dangerous voltages may be present on front and rear panel terminals. Follow all

warnings in this manual when operating or servicing this instrument. Dangerous energy levels

may be stored in capacitors tested by this unit. Always make sure the high voltage indicator is

not on when connecting or disconnecting the unknown.

!

Product will be marked with this symbol (ISO#3684) when it is necessary for the user to

refer to the instruction manual in order to prevent injury or equipment damage.

Product marked with this symbol (IEC417) indicates presence of direct current.

Product will be marked with this symbol (ISO#3684) when voltages in excess of 1000V

are present.

Page 2

Page 2 of 87

Page 3

Contents

Warranty ............................................................................................................7

Specifications ............................................................................................................9

Accessories ............................................................................................................11

Safety Precautions ...................................................................................................13

Condensed Operating Instructions ........................................................................15

Introduction - Section 1

1.1 Unpacking and Inspection..............................................................................21

1.2 Product Overview ..........................................................................................21

1.3 Controls and Indicators..................................................................................22

1.3.1 Front Panel Controls and Indicators ..................................................22

1.3.2 Rear Panel Controls and Connectors ................................................24

1.4 Installation......................................................................................................25

1.4.1 Dimensions ........................................................................................25

1.4.2 Instrument Positioning.......................................................................25

1.4.3 Power Requirements..........................................................................25

1.4.4 Safety Inspection................................................................................27

Operation - Section 2

2.1 Terms and Conventions .................................................................................29

2.2 Startup ............................................................................................................29

2.3 Zeroing...........................................................................................................30

2.4 Connection to Device Under Test..................................................................30

2.5 Measurement Procedure.................................................................................32

2.5.1 General...............................................................................................32

2.5.2 Default Measurement Conditions......................................................33

2.5.3 Automatic Measurement Mode..........................................................34

2.5.4 Manual Measurement Mode ..............................................................36

2.6 Menu Functions .............................................................................................36

2.6.1 General...............................................................................................36

2.6.2 Setup Menu........................................................................................37

2.6.2.1 Voltage..................................................................................37

2.6.2.2 Charge Time..........................................................................38

2.6.2.3 Dwell Time ...........................................................................38

2.6.2.4 Measure Time .......................................................................38

2.6.2.5 Discharge Time.....................................................................39

2.6.2.6 Mode.....................................................................................39

2.6.2.7 Range ....................................................................................40

2.6.2.8 Limit......................................................................................43

2.6.2.9 Stop on Pass..........................................................................44

2.6.2.10 # to Average........................................................................44

Page 3 of 87

Page 4

Contents (Continued)

Operation - Section 2 (Continued)

2.6.3 I/O Menu............................................................................................45

2.6.3.1 Display Type.........................................................................45

2.6.3.2 Result Format........................................................................46

2.6.3.3 RS-232 ..................................................................................47

2.6.3.4 IEEE-488...............................................................................48

2.6.3.5 Handler..................................................................................48

2.6.3.6 Results to Floppy ..................................................................48

2.6.4 Utilities Menu ....................................................................................50

2.6.4.1 Save Setup.............................................................................51

2.6.4.2 Recall Setup..........................................................................53

2.6.4.3 Zero.......................................................................................54

2.6.4.4 Lock Out ...............................................................................55

2.6.4.5 Calibration.............................................................................55

2.6.4.6 Set Time/Date .......................................................................56

2.6.4.7 Elapsed Time ........................................................................57

2.6.4.8 Calibration Date....................................................................57

2.6.4.9 Set Contrast...........................................................................58

2.6.4.10 LCD Backlite......................................................................58

2.7 Input/Output Interface....................................................................................58

2.7.1 I/O Interface.......................................................................................58

2.7.2 IEEE-488 Interface.............................................................................60

2.7.3 Sample Program for National Instruments GPIB Card......................65

2.7.4 Sample Program for IO Tech GPIB Card ..........................................66

2.7.5 RS232 Interface..................................................................................67

2.7.6 Sample Program for RS232...............................................................68

2.7.7 Results to Printer................................................................................69

2.8 Error Messages...............................................................................................70

Applications - Section 3

3.1 Insulation Resistance Testing.........................................................................73

3.2 Test Sample Resistivity Measurements.........................................................74

3.3 Capacitor Insulation Resistance.....................................................................74

3.3.1 General...............................................................................................74

3.3.2 Charge Time Constant .......................................................................75

3.3.3 Discharge Time..................................................................................76

3.4 Resistance Measurements..............................................................................76

3.5 Measurement of Voltage Coefficient.............................................................76

3.6 Guarded, 3 Terminal Measurements..............................................................77

Page 4 of 87

Page 5

Contents (Continued)

Theory Section 4

4.1 General...........................................................................................................79

4.2 Instrument Description...................................................................................79

4.2.1 Basic I2000 Instrument Architecture .................................................79

4.2.2 1865 Instrument Modules..................................................................80

4.2.3 I2000 Instrument Options..................................................................81

Maintenance/Calibration - Section 5

5.1 General...........................................................................................................83

5.2 Instrument Return ..........................................................................................83

5.3 Routine Maintenance.....................................................................................83

5.3.1 Battery Replacement..........................................................................84

5.3.2 Resetting of Time and Date ...............................................................85

5.3.3 Loss of Display Contrast....................................................................85

5.3.4 Preventive Maintenance/Cleaning .....................................................86

5.4 Calibration......................................................................................................86

5.4.1 General...............................................................................................86

5.4.2 Calibration Procedure ........................................................................86

Page 5 of 87

Page 6

Page 6 of 87

Page 7

Warranty

echuad

!

QuadTech warrants that Products are free from defects in material and workmanship and,

when properly used, will perform in accordance with QuadTech's applicable published

specifications. If within one (1) year after original shipment it is found not to meet this

standard, it will be repaired, or at the option of QuadTech, replaced at no charge when

returned to a QuadTech service facility.

Changes in the Product not approved by QuadTech shall void this warranty.

QuadTech shall not be liable for any indirect, special or consequential damages,

even if notice has been given of the possibility of such damages.

This warranty is in lieu of all other warranties, expressed or implied, including, but

not limited to any implied warranty or merchantability or fitness for a particular

purpose.

SERVICE POLICY

QuadTech’s service policy is to maintain product repair capability for a period of at least

five (5) years after original shipment and to make this capability available at the then

prevailing schedule of charges.

Page 7 of 87

Page 8

Page 8 of 87

Page 9

Specifications

Resistance Range: 1 x103 to > 1x1014 Ω(dependent on test voltage)

1x106 - >1x10

1x105 - 1x1013 Ω at 100VDC

1x104 - 1x1012 Ω at 10VDC

1x103 - 1x1011 Ω at 1VDC

(7 ranges or auto ranging)

Resistance Accuracy:* ±[0.45% +{(Rx/Vx)(0.0005 FS + 2pA) + 30Ω/Rx}100%]

Rx: Measured resistance in ohms

Vx: Programmed voltage in volts

FS: Full scale current range in amperes

Voltage Range: 1 to 1000, Volts programmable in two ranges

Voltage Accuracy:* 1 - 100V: 1% of setting +1V

25mV resolution

100 - 1000V: 1% of setting +2V

250mV resolution

Output Voltage

Impedance: 1 kΩ ± 5%

Current Limited: < 2mA

Current Measure: 1x10

-13

Current Accuracy:* 1nA to 1mA: ±[0.5% + (0.0005FS + 2pA)]

100pA to 1nA: ±[1% + (0.0005FS + 2pA)]

1pA to 100pA: ±[10% + (0.0005FS + 2pA)]

Input Impedance: 5 kΩ ± 5%

Measure Limits: Pass/Fail (1 limit)

Display: LCD graphic display

Voltage warning indicator

Pass/Fail indicator

* specified at front panel connectors

14 Ω

to 1x10

at 1000VDC

-3

amps

Page 9 of 87

Page 10

Specifications (Continued)

Test Cycle: Manual: Charge, Measure, Discharge

Automatic: Charge time: 0 -300 sec Dwell time: 0 - 300 sec Measure time: 0 - 300 sec (0 – 999 on later units) Discharge time: 0 - 300 sec

I/O Interface: Standard -RS232

I/O Port (w/safety interlock)

Optional -1865-01 - IEEE-488, factory installed at unit purchase

1865-02 - Floppy Drive, 3.5", factory installed only

1865-03 - Rear panel input terminals, factory installed at purchase

1865-70 - IEEE-488, field retrofit

Input Terminals: Four sheathed banana plugs, front or rear mount (optional)

+ unknown (red) - unknown (black)

guard (blue) ground (green)

Dimensions: Bench with tilt back bail

(133.4mm high x 444.5mm wide x 406.4mm deep)

(5 1/4" x 17 1/2" x 16")

Weight: Approximately 8.2 kg (18 lbs) - Net

Approximately 11.8 kg (26 lbs) - Shipping

Environmental: MIL-T-28800D, Type 3, Class 5, Style E & F

Operating: 0°C to 50°C, stated accuracy <45% RH

Storage: -40°C to 71°C

Altitude: <2000m, Installation Category 1, Pollution Degree 1

Power: • 90 - 250V • 47 - 63Hz • 40W max

General: • Fully programmable via menu

• Zeroing

• Stored test conditions and results

• Selected measurement units (engineering or scientific)

Accessories • Instruction Manual • AC Power Cable

Supplied: • Calibration Certificate • 1 MΩ and 100 kΩ Capacitor Adapters

• Interlock Connector

Accessories • 1865-50 Rack Mount Kit • 1865-51 Shielded Lead Set

Available: • 1865-52 Component Test Fixture

Page 10 of 87

Page 11

Accessories

Accessories Included

Item Quantity QuadTech P/N

U.S. AC Power Cable (3-prong) 1 4200-0300

T2.5A 250V 5X20mm Line Fuse 1 520049

1MΩ Capacitor Adaptor 1 800015

100kΩ Capacitor Adaptor 1 800014

Interlock Connector 1 630019

Instruction Manual 1 150073

Calibration Certificate 1 N/A

Accessories/Options Available

Item Quantity QuadTech P/N

IEEE-488 Interface (factory installed) 1 1865-01

3.5” Floppy Drive Option (factory installed) 1 1865-02

Rear Panel Input Option (factory installed) 1 1865-03

Rack Mount Kit 1 1865-50

Shielded Lead Set 1 1865-51

Component Test Fixture 1 1865-52

IEEE-488 Interface (Field Retro-Fit Option) 1 1865-70

Page 11 of 87

Page 12

Page 12 of 87

Page 13

Safety Precautions

The 1865 Megohmmeter/IR Tester can provide an output voltage as high as 1000VDC to the external

device under test (DUT).

Although the 1865 unit is designed with full attention to operator safety, serious hazards could occur

if the instrument is used improperly and these safety instructions are not followed.

1. The 1865 unit is designed to be operated with its chassis connected to earth

ground. The 1865 instrument is shipped with a three-prong power cord to provide

this connection to ground. The power cord should only be plugged in to a

receptacle that provides earth ground. Serious injury can result if the Sentry unit

is not connected to earth ground.

2. Tightly connect cable(s) to the (green) GND terminal. If this is not done, the

DUT’s casing can be charged to the high voltage test level and serious injury or

electrical shock hazards could result if the DUT is touched.

3. Never touch the metal of the High Voltage probe directly. Touch only the

insulated parts of the lead(s).

4. Never touch the test leads, test fixture or DUT in any manner (this includes

insulation on all wires and clips) when the high voltage is applied and the red

CAUTION HIGH VOLTAGE LED is lit.

5. Before turning on the 1865 unit, make sure the AC power cord is plugged into

the proper voltage source and that there is no device (DUT) or fixture connected

to the test leads.

6. After each test, press the [STOP] (red) button for safety. This terminates the high

voltage being applied to the output terminals.

7. When the CAUTION HIGH VOLTAGE LED is lit NEVER touch the device

under test, the lead wires or the output terminals.

8. Before touching the test lead wires or output terminals make sure:

a) The red [STOP] button has been pressed.

b) The CAUTION HIGH VOLTAGE LED is OFF.

c) The output voltage display is 0 (zero).

9. In the case of an emergency, turn OFF the [POWER] switch using a“hot stick”

and disconnect the AC power cord from the wall. DO NOT TOUCH THE 1865

INSTRUMENT.

10. If the CAUTION HIGH VOLTAGE LED does not go off when the [STOP]

button is pressed, immediately stop using the tester. It is possible that the output

voltage is still being delivered regardless of the TEST ON/OFF control signal.

11. When the 1865 instrument is used in remote control mode, be extremely careful.

The High Voltage Output is being turned on and off with an external signal.

Page 13 of 87

Page 14

Page 14 of 87

Page 15

Condensed Operating Instructions

WARNING

High voltage is applied to the measurement terminals of the 1865 any time the

CAUTION HIGH VOLTAGE LED is ON. While the current from the instrument is

limited, the energy stored in a capacitive device connected to the terminals may be lethal.

Always make sure the high voltage indicator is OFF when connecting or disconnecting

the unknown. A flashing CAUTION HIGH VOLTAGE light and/or DANGER on the

display indicates a defective unit with dangerously high voltages possible at the input

terminals. Power the unit down and do not use.

General Information

The 1865 Megohmmeter/IR Tester is a computer controlled measuring instrument for

direct readout of resistance and current. The voltage applied to the device under test

(DUT) is programmable from 1 to 1000 volts. A pass/fail indicator provides a visual

display of test results based on a preset limit. A set of power-up default test conditions

are stored in the unit and are as set by the factory (1V, test times zero) until

reprogrammed by the user.

Start-up

The 1865 can be operated from a power source between 90V and 250V AC at a power

line frequency of 47 to 63 Hz. The standard 1865 is shipped from the factory with a 2.5A

fuse in place for 115V or 220V operation. To change the fuse refer to paragraph 1.4.3.

Connect the instrument power cord to the source of proper voltage.

IMPORTANT

The interlock connector (included with the unit) needs to be installed on the rear

panel I/O Port connector if the interlock function is not being used. When the

3.5" Floppy Drive Option is present ALWAYS MAKE SURE NO DISKS ARE

INSTALLED WHEN THE UNIT IS POWERED UP, otherwise information stored

on the disks could be lost.

Press the [POWER] button on the front panel to apply power. To switch power off press

the [POWER] but ton again or if measurements are to be made proceed with Zeroing the

instrument, discussed in the next paragraph.

Page 15 of 87

Page 16

Condensed Operating Instructions

Zeroing

Before measuring, zero out test lead or fixture measurement errors as follows.

1. If test leads are to be used connect them to the 1865 input terminals, red to +

unknown, black to - unknown, with probes open and spaced some distance apart (or

fixture open).

2. Press [MENU] key to select menu display.

3. Press Right or Left Arrow key to select Utilities menu.

4. Press Up or Down Arrow key to select Zero in the sub menu.

5. Press [ENTER] key to activate the Zero routine and follow instructions on the

instrument display.

Auto Measurement Mode

In automatic mode, once the [START] button is depressed the instrument sequences

automatically through the test cycle phases, charge, dwell, measure and discharge and a

pre-stored set of test conditions are executed. These test conditions can be DEFAULT

(those at power up), set using menus or the operator can recall a previously stored setup.

1. Connect the device under test to the 1865 test leads or other fixture being used.

2. If the desired setup conditions are anything other than DEFAULT, set using menus

or proceed to Recalling Setups below before continuing with step 3.

3. Initiate the auto measurement mode by pressing [START]. The High Voltage

Indicator will remain on as the unit sequences automatically through all four phases

(charge, dwell, measure, discharge) of the test cycle.

4. The measurement can be aborted at any time during the test cycle by pressing

[STOP].

5. Once the High Voltage Indicator goes off the measurement is complete, the final

result remains displayed and the device can be removed.

Page 16 of 87

Page 17

Condensed Operating Instructions

Manual Measurement Mode

In manual measurement mode each phase of a test cycle, charge, measure and discharge is

initiated manually at the users discretion. These test conditions can be DEFAULT (those

at power up), set using menus or the operator can recall a previously stored setup.

1. Connect the device under test to the 1865 test leads or other fixture being used.

2. Press [MENU] key to select menu display.

3. Press Right or Left Arrow key to select Setup menu.

4. Press Up or Down Arrow key to select Mode in the sub menu.

5. Press [ENTER] to activate the selection field.

6. Press Right or Left Arrow key to select Manual and press [ENTER].

7. If the desired setup conditions are anything other than DEFAULT, set using menus

or proceed to Recalling Setups below before continuing with step 8. (Setup

measurement times are ignored in manual mode).

8. Initiate the charge phase by pressing [START] to apply high voltage to the

device. The High Voltage Indicator will remain on as long as a voltage is applied.

The measurement can be aborted at any time during the test cycle by pressing

[STOP].

9. Initiate a single measurement by pressing [START] again, The measured result

will be displayed on the LCD and will be updated each time [START] is pressed.

10. To discharge the device press [STOP].

11. Before removing the device press [STOP] again to end the discharge phase and turn

the High Voltage Indicator off.

Recalling Setups

1. To recall a set of test conditions previously stored:

Press [MENU] key to select menu display.

Press Right or Left Arrow key to select Utilities menu.

Press Up or Down Arrow key to select Recall Setup.

Press [ENTER] key to activate the recall entry field.

Press Up or Down Arrow key to select the desired setup. choices are:

- DEFAULT, if conditions are power up which can be changed by the

user.

- FLOPPY, if setup is to be recalled from the optional floppy drive.

- Setup Name stored in the instrument internal memory or floppy.

Once the desired setup is located press [ENTER] key to finalize recall of the

setup conditions.

Page 17 of 87

Page 18

Condensed Operating Instructions

Saving Setups

1. To save the current set of test conditions as entered (conditions include, voltage, test

times, measurement range, limit, and display modes):

Press [MENU] key to select menu display.

Press Right or Left Arrow key to select Utilities menu.

Press Up or Down Arrow key to select Save Setup.

Press [ENTER] key to activate setup entry field.

Press UP or Down Arrow key to select the desired setup, choices are:

- NEW, if a setup is to be saved in instruments internal memory.

- DEFAULT, if conditions at power up are to be changed and restored.

- FLOPPY, if a new setup is to be stored or existing one changed on the

floppy.

- Setup Name if an existing set of conditions are to be changed in the

instrument internal memory or floppy.

Press [ENTER] key to activate the Save entry field selected above.

If NEW is selected (internal memory or floppy) enter the desired identifying

name, up to 8 characters, under which these set of test conditions will be

stored.

Press [ENTER] key to finalize storage of the setup conditions or if DEFAULT

is selected one must answer Y or N to overwrite.

Changing Test Voltage

1. Set the desired test voltage:

Press [MENU] key to select menu display.

Press Right or Left Arrow key to select Setup menu.

Press Up or Down Arrow key to select Voltage.

Press [ENTER] key to activate the voltage entry field.

Enter desired test voltage (up to 5 digits with decimal) between 1 and 1000V.

Press [ENTER] key to finalize the voltage entry.

Changing Measurement Times

1. To set the desired measurement cycle times, charge, dwell, measure and discharge:

Press [MENU] key to select menu display.

Press Right or Left Arrow key to select Setup Menu.

Press Up or Down Arrow key to select desired time: charge, dwell, measure or

discharge.

Press [ENTER] key to activate the corresponding time entry field.

Enter the desired time between 0 and 300 seconds(measure, 0 – 999 on later units)

Press [ENTER] key to finalize the time entry.

2. Continue to set the other times as desired by repeating step 1.

Page 18 of 87

Page 19

Condensed Operating Instructions

Setting Pass/Fail Limit

1. To enter a single measurement limit for resistance or current (depending on results

display selected):

Press [MENU] key to select menu display.

Press Right or Left Arrow to select Setup menu.

Press Up or Down Arrow key to select Limit in sub menu.

Press [ENTER] key to activate the limit entry field.

Enter the numerical value (up to 4 digits plus decimal point) of the limit

desired, then enter the exponential value after first pressing the e select key

(use minus exponential value for current).

Press [ENTER] key to finalize the limit entry.

Changing Display Type and Units

1. To change displayed measurement results between Resistance, Current or Pass/Fail:

Press [MENU] key to select menu display.

Press Right or Left Arrow key to select I/O Menu.

Press Up or Down Arrow key to select Display.

Press [ENTER] key to activate the selection field.

Press Up or Down Arrow key to select desired measurement results,

Resistance, Current or Pass/Fail if a limit is to be used.

Press [ENTER] key to finalize the entry.

2. To change the measurement results format between Scientific or Engineering units:

Press [MENU] key to select menu display.

Press Right or Left Arrow key to select I/O Menu.

Press Up or Down Arrow key to select Result Format.

Press [ENTER] key to activate the selection field.

Press Right or Left Arrow to select desired results format, Sci for Scientific or

Eng for Engineering.

Press [ENTER] key to finalize the entry.

Page 19 of 87

Page 20

Page 21

Section 1: Introduction

WARNING

High voltage is applied to the measurement terminals of the 1865 anytime the CAUTION HIGH

VOLTAGE LED is ON. While the current from the instrument is limited to a value that is not dangerous

under most conditions, the energy stored in a capacitor connected to the terminals may be lethal. Always

make sure the CAUTION HIGH VOLTAGE LED is OFF when connect i ng or disconnecting the

unknown.

1.1 Unpacking and Inspection

Inspect the shipping carton before opening. If the carton is damaged, contact the carrier

agent immediately. Inspect the 1865 instrument for any damage. If the instrument

appears damaged or fails to meet specifications notify QuadTech (refer to instruction

manual front cover) or its local representative. Retain the shipping carton and packing

materials for future use such as returning for recalibration or service.

1.2 Product Overview

The 1865 Megohmmeter/IR Tester is a general purpose high voltage instrument for

resistance measurements on insulating materials and components. It is designed for easy,

accurate and direct readings of high resistance typically found in synthetic resins,

porcelains, insulating oils, plastics and other similar materials. It is also used for

measurements on capacitors, transformers, switches, cables and connectors. The 1865

provides a direct readout of resistance from 1000Ω to 1000TΩ with fully automatic

ranging. The voltage applied to the unknown is programmable from 1V to 1000V.

The 1865 includes a high resolution graphics display and keypad for ease of use. The test

cycle is fully automatic with programmable charge, dwell, measure and discharge times.

These times, along with other test conditions can be stored in instrument memory and

recalled for later use. A pass/fail indicator provides the operator with a visual indication

based on a preset resistance limit. The unit also contains automatic zeroing at the test

leads as well as built-in self-test routines. Safety features include current limiting to less

than 2mA and a front panel indication when voltage is applied to the test terminals, thus

permitting connections to be made safely.

The 1865 comes standard with I/O Port (handler) and RS232 interface. An IEEE-488

interface is optional for communication with other instrumentation and remote control

operation. A 3 1/2" floppy drive option is also available for storing test conditions and

results. There is a direct reading current measurement mode from 1mA to 1pA.

The unit is available with front or rear panel input connections with guard and ground

terminals to permit measurements of grounded or ungrounded devices.

Introduction Page 21 of 87

Page 22

1.3 Controls and Indicators

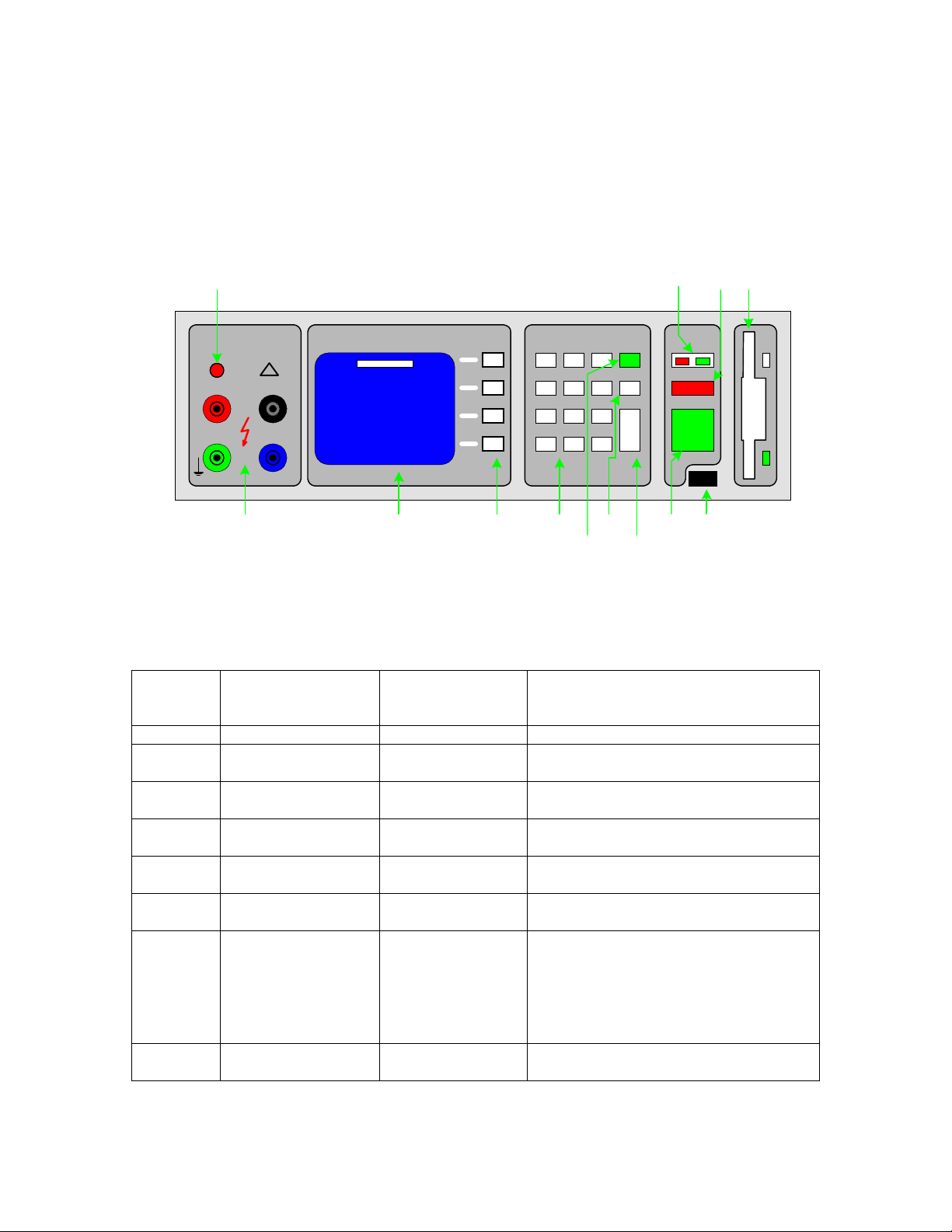

1.3.1 Front Panel Controls and Indicators

Figure 1-1 shows the controls and indicators on the front of the 1865 unit. Table 1-1

identifies them with description and function.

13 12 11 10

QQQQ

uadTech

1865

+

Megohmmeter

IR Tester

!

CAUTION

HIGH VOLTAGE

-

DISPLAY ENTRYSELECT TEST

MENU

RESISTANCE

133.620M

Voltage = 100

Mode = AUTO

Ω

Range = 1uA <A>

321

CNCL

654

987

0

ENTER

.-

STOP

START

GUARD

16

432

10

98

75

Figure 1-1: Front Panel Controls & Indicators

Table 1-1: Front Panel Controls and Indicators

Reference

Number

Figure 1-1

1 Input Panel Connection for device under t est (DUT)

1a GROUND Green Sheathed

1b + Red Sheathed

1c - Black Sheathed

1d GUARD Blue Sheathed

2 Display LCD Graphic Displays measurement results, instrument

3 SELECT 4 Gray Push Buttons Function as indicated on adjacent display

4 Keypad White Push Buttons 12 keys for making numerical entries: 0-9,

Name Type Function

Ground Terminal for jumper of (+) Input

Banana Plug

Terminal or Guard Input to Chassis GND

High Voltage Terminal for connection to

Banana Plug

DUT

Low Voltage Terminal for connection to

Banana Plug

DUT

Guard Terminal for 3-Lead Guarded

Banana Plug

Measurements

status and user interface menus.

From top to bottom: functions as: Up (↑↑↑↑),

Down (↓↓↓↓), Right (→→→→) or Left (←←←←) during

Menu Selection. Other functions include:

measurement units, exponent, Yes or No

and del (delete).

decimal point and minus sign.

Page 22 of 87 Introduction

Page 23

Table 1-1: Front Panel Controls and Indicators (Continued)

5 MENU Green Push Button Press to enter menu display mode or press

to exit sub menu & return to main menu.

6 CNCL Gray Push Button To exit menu mode with no parameter

changes made or to exit current field

7 ENTER Gray Push Button To switch user to entry mode or to accept

menu entry as entered.

8 START Green Push Button To initiate the measurement

9 POWER Black Toggle Switch To apply power to the instrument:

1 = ON, 0 = OFF

10 OPTION 3 ½ “ Floppy Drive To store test setup conditions and

measurement results. High Density (HD:

1.44M) or Low Density (LD: 720k)

compatible floppy drive. Floppies should be

double sided and formatted for DOS

compatibility.

11 STOP Red Push Button To stop the measurement (terminate high

voltage at the output terminals)

12 TEST Indicate P/F Measurement Result based on

preset limit

12a FAIL Red LED

12b PASS Green LED

13 Caution High Voltage Red LED When lit, indicates presence of High

When lit in Resistance Mode, the measured

value is below the set minimum value

(resistance limit).

When lit in Current Mode, the measured

value is above the set maximum value

(current limit).

When lit, in Resistance Mode, the

measured value is above the set minimum

value (resistance limit).

When lit in Current Mode, the measured

value is below the set maximum value

(current limit).

Voltage at the output terminals.

Introduction Page 23 of 87

Page 24

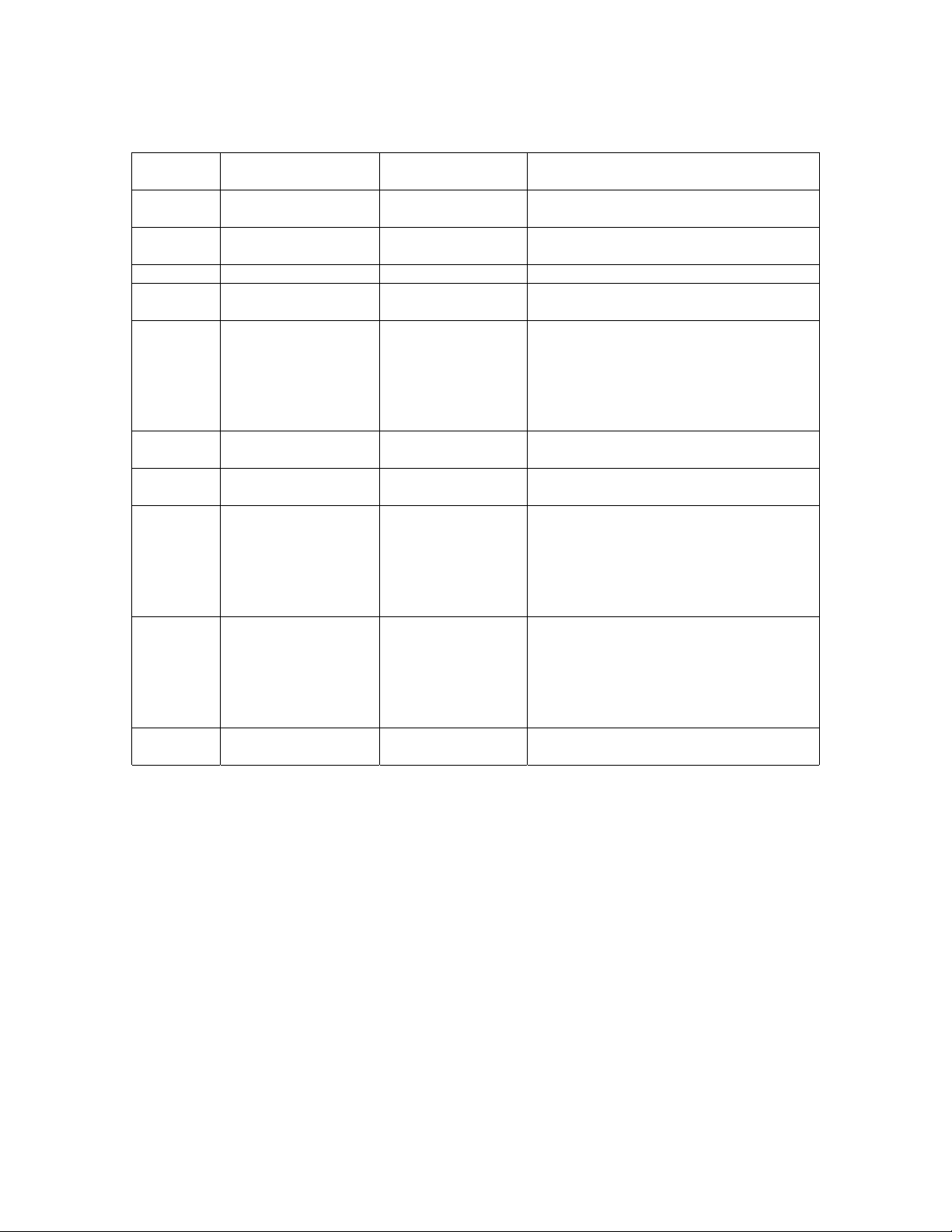

1.3.2 Rear Panel Controls and Connectors

Figure 1-2 illustrates the controls and connectors on the rear panel of the 1865

Megohmmeter/IR Tester. Table 1-2 identifies them with description and function.

8

76

NO USER SERVICEABLE PARTS INSIDE

TO PREVENT ELECTRICAL SHOCK

!

DO NOT OPEN COVERS

REFER TO QUALIFIED PERSON

RS 232 INTERFACEIEEE-488 INTERFACE BATTERY

I/O PORT

PARALLEL PORT

REPLACE WITH

THREE SIZE AA

POSITIVE

TERMINAL OUT

MADE IN USA

543

FUSE 250V

90-250V T2.5A 5x20mm

12

CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD REPLACE ONLY

WITH SAME TYPE AND

RATING OF FUSE

90-250V

47-63Hz

40 WATTS MAX

Figure 1-2: Rear Panel Controls and Connectors

Table 1-2: Rear Panel Connectors and Controls

Reference

Number

Figure 1-2

1 AC Inlet Module Black 3-Prong

2 Vent Rear Panel Portion Instrument ventilation

3 I/O Port 36-pin Male

4 Parallel Port Not Available Not Available

5 Option 1865-03 Rear Panel Input Terminals: Ground, (+), (-

6 Battery 3, AA Size Batteries DC source for System Memory back-up.

7 RS232 Interface 9-pin DB9 Male 9-pin connector for RS232 I/O transfers

8 IEEE-488 Interface 24-pin Male 24-pin connector for IEEE-488 I/O

Name Type Function

3-wire connection for AC power source.

Receptacle & Fuse

90-250V AC: T2.5A 250V 5x20mm Fuse

Drawer

36-Pin Connector for Component Handler.

Amp 552302-1

compatible

Use with Amp 552302-1 plug & 552073-5

strain relief cover or ribbon cable clamp

connector 553600-1 or equivalent(s).

) and Guard for connection to DUT with

High Voltage I ndicator

3 AA batteries need to be replaced yearly.

transfers

Page 24 of 87 Introduction

Page 25

1.4 Installation

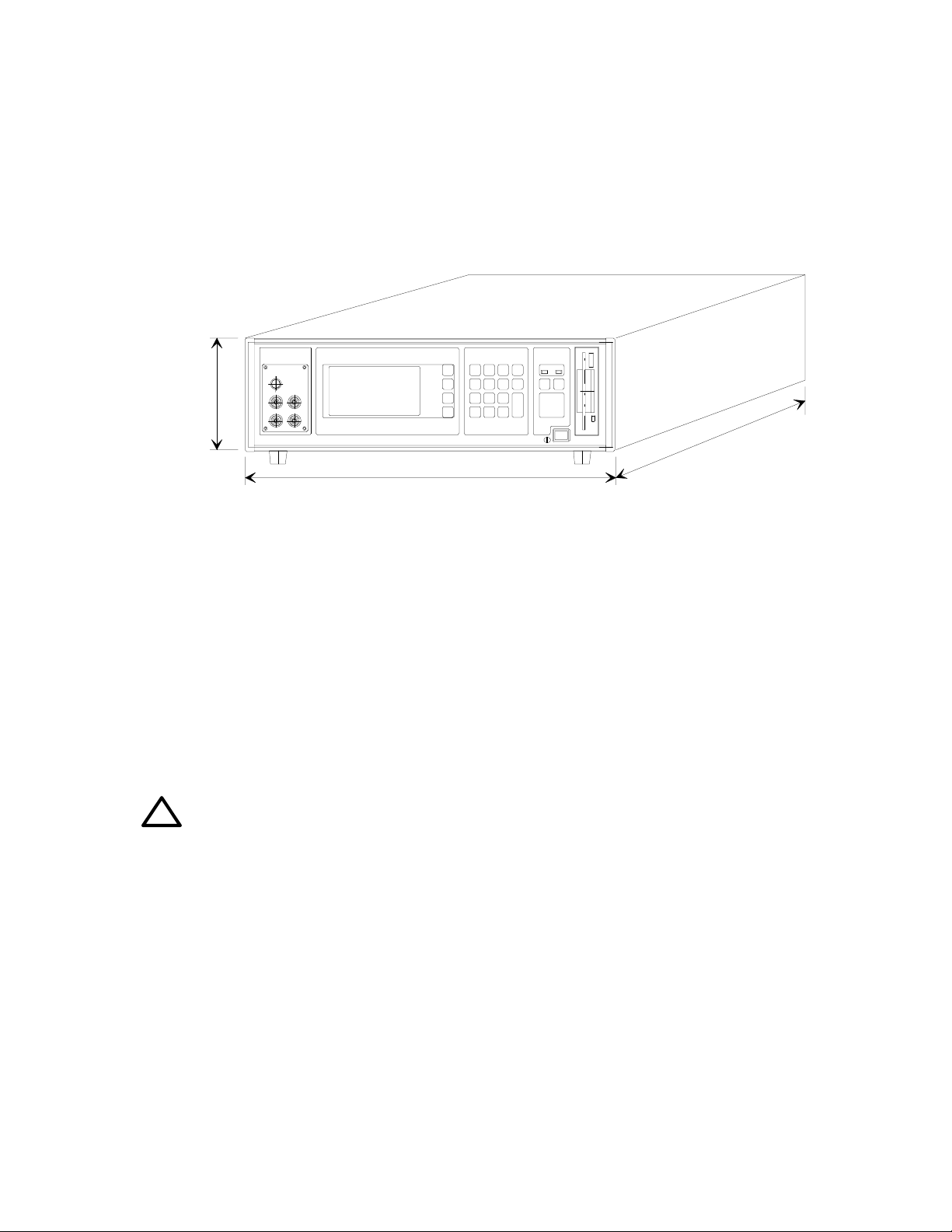

1.4.1 Dimensions

The instrument is supplied in a bench configuration, i.e., in a cabinet with resilient feet

for placement on a table. A bail is provided under the front edge so that the instrument

can be tilted back for convenient operator viewing.

QuadTech

133.4mm

5 1/4"

406.4mm

444.5mm

17.5"

16"

Figure 1-3: 1865 Instrument Dimensions

1.4.2 Instrument Positioning

The 1865 instrument contains a high resolution back lit LCD for convenient viewing.

The optimum angle for viewing is slightly down and about 30° either side of center. This

means that for bench operation the front bail should always be used to angle the

instrument up and for rack installation it should be mounted at eye level or higher.

1.4.3 Power Requirements

!

The 1865 Megohmmeter/IR Tester can be operated from a power source between

90 and 250Vac at a power line frequency of 47 to 63Hz. Power connection to the rear

panel is through an AC inlet module comprised of an AC connector and fuse drawer.

Before connecting the 3-wire power cord between the unit and AC power the fuse should

be in accordance with the power source, T2.5A, 250V, 5x20mm (QuadTech PN 520049)

for 115V or 220V source. Always use an outlet which has a properly connected

protection ground. The standard 1865 is factory shipped with the 2.5A fuse in place.

The instrument can be damaged if the wrong fuse is installed. To change the fuse

proceed as follows:

Introduction Page 25 of 87

Page 26

PROCEDURE FOR CHANGING A FUSE

WARNING

Make sure the unit has been disconnected from its AC power source for at least five

minutes before proceeding.

Fuse drawer with release tab

I/O PORT

RS-232 INTERFACE

BATTERY

90 - 250 V

47 - 63 Hz

40 WATTS MAX

IEEE-488 INTERFACE

PARALLEL PORT

Figure 1-4: 1865 Instrument Fuse Drawer

• Remove the fuse drawer by inserting a small flat head screwdriver behind the small

tab to force the draw outward.

• Once the fuse draw has been completely removed from the instrument now remove

the clear fuse tray from the drawer by lifting upward slightly on the long narrow

locking tab. This will allow the fuse tray to be removed from the fuse draw. This tray

contains the active fuse (secured by holder).

• Remove the fuse from the holder by prying upward using a small flat head

screwdriver. Insert the replacement fuse into the fuse holder.

• Once the fuse has been installed in the holder and spare fuse (if desired) installed in

the right side of the tray insert the tray back into the fuse drawer, push in and lock.

The two silver contacts on the fuse tray should be positioned towards the outside.

• Once the fuse tray has be installed in the draw, reinstall the fuse draw back into the

instrument ac inlet module, push in and lock.

Page 26 of 87 Introduction

Page 27

1.4.4 Safety Inspection

!

Before operating the instrument inspect the AC power inlet module on the rear of

the 1865 instrument to ensure that the properly rated fuse is in place, otherwise damage

to unit is possible. Refer to paragraph 1.4.3.

The 1865 instrument is shipped with a standard U.S. power cord, QuadTech PN 42000300 (with Belden SPH-386 socket or equivalent, and 3 wire plug conforming to IEC

320) and CE units with an approved international cord set. Make sure the instrument is

only used with these cables (or other approved international cord set) which ensures the

instrument is provided with connection to protective earth ground.

When the 1865 instrument is used in a rack installation (using the QuadTech 1865-50

Rack Mount Kit) make sure the unit is secured using the cabinet mounting rai ls and

not securely solely by the front panel angle brackets.

In bench or rack mount applications the instrument should be positioned with

consideration for ample air flow to the rear panel fan ventilation holes. An open space

of at least 3 inches (75mm) is recommend behind the rear panel. The surrounding

environment should be free from excessive dust to prevent contaminati on of electronic

circuits.

WARNING

If this instrument is used in a manner not specified in this manual protection to the

operator and equipment may be impaired.

Read this instruction manual in full before operating this instrument.

Introduction Page 27 of 87

Page 28

Page 29

Section 2 : Operation

2.1 Terms and Conventions

The names of keys in the manual will generally appear in CAPITAL LETTERS.

The MENU key calls up the main menu display and returns to the line previously

selected.

The ">>" symbol on a menu indicates a lower level menu exists.

The select keys generally function as UP, DOWN, LEFT and RIGHT arrow and allow

you to move through a menu or field of choices to make the desired selection or turn a

function ON or OFF.

The ENTER key switches the unit to entry mode and when pressed again initiates the

entry or choice selected on the current screen.

The CNCL key will return the system to main menu display with no changes made.

(From a numeric data field CNCL must be hit twice).

2.2 Startup

Check to make sure the line voltage indicator on the rear panel AC inlet module agrees

with the AC power source available, if not refer to paragraph 1.5.3.

Connect the instrument power cord to the source of proper voltage. The instrument is to

be used only with three wire grounded outlets.

WARNING

A flashing CAUTION HIGH VOLTAGE light and/or DANGER on the display

indicates a defective unit with dangerously high voltages possible at the input terminals.

Power the unit down and do not use.

IMPORTANT

The interlock connector (included with the unit) needs to be installed on the rear panel

I/O Port connector if the interlock function is not being used.

When the 3.5" Floppy Drive Option is present ALWAYS MAKE SURE NO DISKS ARE

INSTALLED WHEN THE UNIT IS POWERED UP, otherwise information stored on the

disks could be lost.

Switching [POWER] OFF and ON quickly may result in error messages. Power should be

off for at least 10 seconds to assure proper power-up.

Operation Page 29 of 87

Page 30

Power is applied to the 1865 by pressing the [POWER] button on the front panel. The

instrument runs a self test and any error messages are displayed accordingly (refer to

paragraph 2.8).

2.3 Zeroing

Before making measurements, the 1865 instrument should be zeroed to correct for test

lead or fixture errors. During the zeroing process corrections are calculated and stored in

instrument memory and applied to ongoing measurements. Generally the unit should be

zeroed at least once per day and each time test leads or fixtures are changed. The zeroing

routine is accessed through the Utilities Menu by selecting [ZERO], instructions are given

on the LCD display. Refer to paragraph 2.6.4.3.

2.4 Connection to Device Under Test

Figure 2-1 illustrates the front panel input terminals and a basic block diagram of their

function.

Range

5k

Select

Zin

Ω

-

+

QQQQ

uadTech

1865

+

Megohmmeter

IR Tester

!

CAUTION

HIGH VOLTAGE

+-

-

GUARD

(Earth)

GUARDGND

Figure 2-1: Input Panel and Block Diagram

An optional shielded lead set is available for use with the 1865 unit, QuadTech part

number 1865-51. How the connection to the DUT is made depends on the device being

measured: if it is a grounded, ungrounded or guarded device. The 1865 instrument is

supplied with two resistor adapters which are recommended for use only when measuring

high value, low leakage capacitors. These are to be added in series with the (-) terminal

lead to eliminate fluctuating test results when measuring this type of device. Refer to

paragraph 3.3.

CAUTION

DO NOT GROUND THE - (negative) UNKNOWN TERMINAL, invalid

measurements will result.

Page 30 of 87 Operation

Page 31

Figures 2-2 through 2-4 illustrate various methods of connection to the device under test

(DUT). Figure 2-2 illustrates the two-wire connection to DUT. The two-wire

ungrounded connection is the recommended connection of ungrounded components or

components that can be connected very close to the 1865 input terminals rather than

through the lead set provided.

High Low

Unknown Unknown

+

GND

+

Unknown and - Unknown are connected to DUT

GUARD

shorted to

DUT

GND

(optional)

-

GRD

Figure 2-2: Two-Wire Ungrounded Connection

The two-wire grounded measurement is a common type of connection to be used on the

1865. This is the recommended connection on grounded components or components that

are some physical distance from the input terminals of the unit. A grounded component

is one in which one of its connections goes to an earth ground, whereas on an ungrounded

component neither connection goes to earth ground. A component being measured with a

lead set is considered to be a physical distance away from the terminals and thus the twowire grounded connection is often recommended.

DUT

+

GND

+

Unknown and - Unknown are connected to DUT

+

Unknown connected to

GND

-

GRD

Figure 2-3: Two-Wire Grounded Connection

Operation Page 31 of 87

Page 32

A three-wire guarded connection is necessary to measure resistance between two points in

the presence of resistance from each of these points to a third point. Refer to paragraph

3.6 for a discussion of guarded measurements. The guarded measurement may require

different grounding techniques depending on the expected impedance of the DUT.

+

GND

DUT

-

GRD

+ -

GND GRD

DUT

DUT UNGROUNDEDDUT GROUNDED

+

Unknown and - Unknown are connected to DUT

GUARD

+

Unknown shorted to

to DUT Guard Point

GND

OR

GUARD

shorted to

GND

Figure 2-4: Three-Wire Guarded Connection (Grounded or Ungrounded)

2.5 Measurement Procedure

2.5.1 General

There are two basic measurement modes of operation, auto and manual. In the automatic

mode the test cycle is sequenced automatically through four phases, charge, dwell,

measure and discharge in accordance with user programmable times. This is the

preferred measurement mode, especially when the approximate resistance value is

unknown, since the 1865 instrument employs an auto ranging technique. The automatic

mode would generally be used in a production environment where measurements are

repetitive and setup conditions have been previously established. For the sake of

reducing measurement time, when making repetitive measurements, a particular range

may be locked in, in place of auto ranging.

Page 32 of 87 Operation

Page 33

In the manual mode the test cycle timing is totally at the users discretion where each of

the three phases, charge, measure or discharge is initiated directly by the user. This mode

would typically be used in an engineering environment or component evaluation where

the measurement results can be observed as test cycle and measurement conditions are

altered.

Whenever the 1865 unit is powered up it is ready to begin measuring at default test

conditions. Initially, these conditions will be set to a factory default (1V, 0 times,

Resistance Display, Auto ranging and Automatic Mode), but can be changed by the user

and stored to overwrite factory default.

2.5.2 Default Measurement Conditions

A set of default measurement conditions are initially established at the factory and stored

in instrument memory. Default conditions are those that determine the instruments status

on power up, thus the instrument is always set to a known state before any testing begins.

These conditions can be changed by the user for tailoring to a specific application. Refer

to paragraph 2.6.4.1 under Save Setup on the Utilities menu.

Factory default measurement conditions are:

Under Setup Menu

Voltage - 1V

Charge, Dwell, Measure and Discharge times – 0

Mode - Auto

Range - Auto (Selected on lower level menu)

Limit - None

Stop on Pass - No

# to Average - None

Under I/O Menu

Display Type - Resistance (selected on lower level menu)

Result Format - Engineering Units

RS-232 - Enable

Handler - On

Under Utilities Menu

Lockout - Off

Backlite - On

Operation Page 33 of 87

Page 34

2.5.3 Automatic Measurement Mode

Measurements in the automatic mode can be initiated after connecting the DUT by simply

pressing [START]. Test conditions are determined by either the power up default

conditions or recalling a previously stored setup from instrument memory. In either case

a test cycle is sequenced automatically (Figure 2-5) once [START] is pressed and results

displayed (Figure 2-6). When a test limit is entered a PASS/FAIL can be displayed in

place of the actual measured value (Figure 2-7).

AUTOMATIC MEASU REMENT

MODE

Charge

Vo ltage

applied

to UUT

Charge t

(0 - 300s)

START

(

High Voltage

Indicator On)

Dwell t

(0 - 300s)

Test Cycle Time (P rogra mmable)

Measure t

(0 - 300s)

or (0 - 999)*

Discharge t

(0 - 300s)

(High Voltage

Indicator Off)

Figure 2-5: Test Cycle Sequence (Automatic)

* on later units

Page 34 of 87 Operation

Page 35

Measurement Value

Measurement Parameter

(Resistance or Current)

RESISTANCE

Measurement Units

(Engineering or Scientific)

Test Cycle Status

(Charge, Dwell,

Measure or Discharge)

1.000M

MEASURE

Charge

Voltage

Measure Mode

(Auto or Manual)

Figure 2-6: Measurement Results Display with Value

VOLTAGE = 1000 LIMIT = 9.0 e +005

MODE = AUTO RANGE = 10 uA (A)

REMOTE

Keypad Disabled

(can indicate REMOTE

or LOCKOUT)

Results Displayed in the "Result Format"

(Scientific or Engineering)

Fullscale Measurement Range

(A) denotes autorange

Pass/Fail Limit

9.0 e +005 ohms

PASS/FAIL

MEASURE

VOLTAGE 1000 LIMIT 9.0 e +005

Operation Page 35 of 87

MODE AUTO RANGE 10uA

REMOTE

Figure 2-7: PASS/FAIL Results Display

Page 36

p

2.5.4 Manual Measurement Mode

The primary difference between automatic and manual mode is that in manual mode the

phases of the test cycle must be initiated manually by the user. Here there are three

phases rather than the four in automatic, the dwell function would be part of the charge

phase. The results would still be displayed in a manner indicated above, the mode would

indicate manual rather than automatic. Default and other stored setups can still be

recalled, the only difference being that the test cycle times are not applicable.

MANUAL MEASUREMENT MODE

Charge

Voltage

applied to

UUT

Charge t Measure t

Test Cycle Time

START

(High Voltage

Indicator On)

Note:

A single measurement will be made in

the measure

START STOP

hase each time START is pressed

(Manually Controlled)

Discharge t

STOP

(High Voltage

Indicator Off)

Figure 2-8: Test Cycle Sequence (Manual)

2.6 Menu Functions

2.6.1 General

All programmable functions of the 1865 are controlled by easy to use menu displays. The

user enters the menu mode by selecting the [MENU] key which calls up three top level

menus, Setup, I/O and Utilities. Each one of these is comprised of a sub menu list whose

functions are described in detail below. Finding ones way around the menu listing is

accomplished in a fashion similar to an Automatic Teller Machine (ATM) using the up,

down, right and left arrow keys as indicated on the adjacent LCD display. A highlighted

menu function can be controlled by selecting the [ENTER] key, making the desired entry

or selection and pressing [ENTER] again to implement.

Page 36 of 87 Operation

Page 37

2.6.2 Setup Menus

Setup I/O Utilities

Voltage

Charge Time

Dwell Time

Measure Time

Discharge Time

Mode Auto Manual

Range > >

Limit

Stop on Pass = 0

#

to Average = 0

= 1000

= 0

= 0

= 0

= 0

= 100 e+ 9

Figure 2-9: Setup Menu

The first of the three main menus is Setup, shown in Figure 2-9. Each function controls a

measurement condition and is described in detail below.

2.6.2.1 Voltage

Setup

Voltage

Charge Time = 10

Dwell Time

Measur e Time

Dis c h a r ge Ti me

Mode Auto Manual

Range > >

Limit

Stop on Pass = 0

#

to Average = 0

I/O Utilities

1000

=

= 10

= 10

= 10

= 100 e+ 9

e

Figure 2-10: Test Voltage Entry

Accepts entry (up to 6 digits and decimal) of a test voltage between 1 and

1000 volts. This is the voltage applied to the unit under test during the test cycle and

present at the DUT connection anytime that the CAUTION HIGH VOLTAGE lamp is

ON. As in the case of many of the menu entries on the 1865 instrument, an "error

message" will be displayed for an invalid entry.

Operation Page 37 of 87

Page 38

2.6.2.2 Charge Time

Setup

I/O Utilities

Voltage = 1000

Charge Time =

Dwell Time

Measure Time

Discharge Time

Mode Auto Manual

Range > >

Limit

Stop on Pass = 0

#

to Average = 0

10

= 10

= 10

= 10

= 100 e+ 9

Figure 2-11: Charge Time Entry

Accepts entry of a charge time between 0 and 300 seconds in 1 second intervals (up to 3

digits). If the selection is out of range an error message will be displayed. This marks the

time when the test voltage is first applied and the unit under test is allowed to charge up

to this voltage. Even if the charge time is entered as zero there is still a small delay

during the charge phase. In this case or even with much longer charge times the

possibility exists that full charge voltage may not be reached at the start of the

measurement phase if the DUT has a long time constant.

NOTE

For low voltage measurements (<5V), a minimum charge time of 2 seconds is

recommended to meet the instruments stated accuracy.

2.6.2.3 Dwell Time

Accepts entry of a dwell time (or electrification time) between 0 and 300 seconds in 1

second intervals. This is a time during which the test voltage is applied to the device

under test and prior to any measurement.

2.6.2.4 Measure Time

Accepts entry of a measure time between 0 and 300 seconds in 1 second intervals (0 –

999 seconds on later units). This is the time during which repeated measurements are

made and results displayed as resistance, current, Pass/Fail or no display depending on

the results format selected. The display is updated each time a measurement is made

during this time phase.

Page 38 of 87 Operation

Page 39

2.6.2.5 Discharge Time

Accepts entry of a discharge time between 0 and 300 seconds in 1 second intervals. This

is the time when the test voltage is removed and the device under test discharged. The

CAUTION HIGH VOLTAGE lamp goes OFF at the end of the programmed interval and

the last measurement result is retained on the display (unless no display is selected).

2.6.2.6 Mode

Setup

I/O Utilities

Voltage = 1000

Charge Time

Dwell Time

Measure Time

Discharge Time

Mode Auto

Range > >

Limit = 100 e+ 9

Stop on Pass =

#

to Average = 0

= 10

= 10

= 10

= 10

Manual

0

Figure 2-12: Measurement Mode Selection

Allows selection from two different modes of operation, Auto or Manual measurement.

In Auto the user presses [START] to initiate the entire test cycle automatically. The first

phase of the cycle is charge time, during which the device initially charges up to the

applied test voltage. The second phase is dwell, or time of electrification, during which

the device is fully charged but prior to a measurement. The third phase is measure time

during which measured results are displayed. The fourth and last phase is discharge time

during which the voltage is removed and the device allowed to discharge.

In Manual, test cycle timing is under complete user control, [START] must be pressed to

initiate the charge and measure phase and [STOP] pressed to discharge the device.

Operation Page 39 of 87

Page 40

2.6.2.7 Range

Setup

Range

Auto

1 mA

100 uA

10 uA

1 uA

100 nA

10 nA

1 nA

I/O Utilities

Figure 2-13: Range Selection

Through a lower level menu (by pressing [ENTER]) allows for selection of Auto or one

of seven different measurement ranges (1mA through 1nA), which is the maximum

current for the selected range. In auto mode the 1865 instrument will automatically select

the optimum range depending on the programmed test voltage and current drawn by the

test device. Any choice other than Auto (1mA through 1nA range) is at the user's

discretion. Determination of the range is governed by the maximum current available to

the DUT for that measurement range and is listed in Table 2-1. To eliminate operator

errors in range setting and ensure specified instrument accuracy the 1865 unit

should generally be left in AUTO. There may be an exception to this when repetitive

measurements are to be made on a known range and there is a desire to reduce test time

by eliminating range switching. When auto ranging is selected the 1865 instrument will

always begin the measurement phase on the highest current range, 1mA and progress

down depending on the current to the device under test. If the current reaches 10% or less

of the maximum for a given range the next lowest range will be switched in.

If a range has been selected and the current exceeds 115% of the maximum for that range

the unit will indicate OVER RANGE on the display. One needs to keep in mind that an

over range does not necessarily mean the incorrect range has been selected, the device

under test could also be defective. Over range should not be confused with an

OVERLOAD display. Overload occurs anytime current to a device attempts to exceed

2mA, this would generally mean a shorted or very low resistance device.

Page 40 of 87 Operation

Page 41

Table 2-1: Range Current

Range Maximum Current

1 1mA

2 100uA

3 10uA

4 1uA

5 100nA

6 10nA

7 1nA

Example:

When measuring an unknown of 200MΩ at 100V, Ohms Law tells us that the device

under test would draw 0.5uA ( I = 100V/200MΩ). Based on the above one would expect

the 1865 instrument to auto range from the 1mA to 1uA range (50% of maximum

current) or the user to select the 1uA range if prior knowledge of the expected results is

known.

NOTE

When measuring in the current mode, in order to calculate the unknown resistance, the

input resistance of the instrument (5kΩ) must be taken into consideration. For further

discussion of this refer to Display Type in ¶ 2.6.3.1

The measurement range capability is represented graphically in Figure 2-14. By locating

the charge voltage on the vertical axis and the measured resi stance, or expect ed measured

resistance, on the horizontal axis one can determine the optimum range. When Auto

range is selected the range switching is done automatically and the specified instrument

accuracy always applies. If a range is selected other than auto and the resistance value for

the given voltage does not fall in the range band shown measurement accuracy as

specified does not necessarily apply.

Operation Page 41 of 87

Page 42

"

)

Measurement Ranges at Specified Voltage

!""./0 !"./0 !./0 !"".10 !".10 !.10!.20

!"""

#

$

!""

%

&

'

(

*

+

!"

,

$

&

'

!

!#""$% "& !#""$% "' !#""$% "( !#""$% ") !#""$% "* !#""$% "+ !#""$% ", !#""$% !" !#""$% !! !#""$% !- !#""$% !& !#""$% !'

1kΩ 1MΩ 1GΩ 1TΩ

Resistance in Ohms

Figure 2-14: Measurement Range Capability

Page 42 of 87 Operation

Page 43

2.6.2.8 Limit

Setup

I/O Utilities

Voltage

Charge Time =

Dwell Time

Measur e Time

Dis c h a r ge Ti me

Mode Auto Manual

Range > >

Limit

Stop on Pass = 0

#

to Average = 0

= 1000

10

= 10

= 10

=

10

=

1 e + 006

e

than R (resistance), the exponent would be

entered as a negative number.

In the case where I (current) is selected rather

Figure 2-15: Limit Value (Resistance or Current)

Allows entry of a single measurement limit in scientific units (up to 4 digits with decimal

and exponent) for resistance or current depending on the results parameter selected. The

exponent must be 3 through 14 for resistance or -3 through -13 for current. This limit

determines the status of the Pass/Fail indicator and Pass/Fail display, when enabled.

When the 1865 instrument is in the resistance mode the limit is a minimum value i.e. any

value above the limit will result in a Pass, whereas a value below the limit will result in a

Fail. The opposite is true when the unit is in the current mode, the limit is a maximum

value, any value below the limit will result in a Pass and a value above the limit will

result in a Fail.

If the display parameter on the I/O Menu is selected as resistance the value entered will

be an R limit, if the display is selected as current the value entered will be an I limit. The

1865's processor will check for consistency between the parameter display selected and

limit entered.

An example of the sequence for entering 1MΩ as a limit would be:

Press [ENTER] or Press [ENTER]

Press [1] Press [1]

Press [e] select key Press [0] (zero), three times

Press [6](exponent multiplier) Press [e] select key

Press [ENTER] Press [3]

Press [ENTER]

Operation Page 43 of 87

Page 44

2.6.2.9 Stop on Pass

Accepts entry of a value between 0 and 300 which is the number of consecutive passing

measurements that must occur to exit the measure loop before the measure time has

passed. This is only active when there is a measure time and limit specified. An entry of

0 disables the stop on pass function.

2.6.2.10 # to Average

Accepts entry of a value between 0 and 400 which is the number of measurements to be

averaged and displayed. If the value is 0 or 1 averaging is disabled and the display is

updated with each measurement, if the value is n (between 2 and 400) the average is

displayed after n measurements. If the measure time has not elapsed after the first

averaged display then a running average of measurements is made until the measure time

is up. For example, if n is 5, the first five measurements are made, averaged and then

displayed. The sixth measurement is averaged with the last four and the first ignored, this

continues until the user specified measurement time is complete.

When Stop on Pass is in effect n measurements are made and averaged.

If the Stop on Pass requirement is met the cycle stops with a Pass even though

the measure time has not passed.

If the measure time has passed and the Stop on Pass requirement not met the

cycle stops with a Fail.

If the Stop on Pass requirement is not met and measure time has not passed

additional measurements are made and averaged. The Stop on Pass and

measure time requirement are tested after each measurement until one or the

other results in an exit from the test cycle.

When the instrument is selected for Manual mode of operation the averaging works very

similar. When the [START] button is pressed to exit charge and start measure, n

measurements are averaged. For each consecutive press of the [START] button one more

measurement is made, the last five averaged and result displayed. The [STOP] button

exits measure to discharge as normal.

Page 44 of 87 Operation

Page 45

2.6.3 I/O Menus

Setup

Display Type

Result Format Sci Eng

RS-232 >>

IEEE >>

Handler Off On

Results to Floppy >>

I/O

Utilities

>>

Figure 2-16: I/O Menu

The second of the three main menus is I/O, shown in Figure 2-16. Each function controls

measurement results or instrument I/O interface and is described in detail in paragraphs

2.6.3.1 through 2.6.3.6.

2.6.3.1 Display Type

Utilities

Setup

I/O

Display

Resistance

Current

Pass / Fail

No Display

Figure 2-17: Measurement Display

Allows selection from four different modes of measurement display, Resistance,

Current, Pass/Fail or No Display. In resistance mode the 1865 instrument will display

the measured value of resistance of the device under test. In current mode the 1865

displays the current to the device under test. In Pass/Fail mode the actual measured value

is displayed in small font along with a pass or fail based on the measurement limit

entered, which could apply to either resistance or current.

Operation Page 45 of 87

Page 46

In No Display only the voltage, mode and range are displayed, with no measured value.

This might be used for security reasons or for the purpose of reducing test time during

remote operation.

When the display is selected as current one needs to keep in mind that the 5kΩ input

impedance and the 1kΩ output volt age source impedance of t he unit are in seri es wit h the

unknown. For low values of resistance (<20MΩ) the measured current would be the

Charge Voltage/(Zin + Z

out

+ R

unknown).

2.6.3.2 Result Format

Setup

I/O

Utilities

Display Type

Result Format

RS-232 >>

IEEE >>

Handler Off On

Results to Floppy >>

Sci

>>

Eng

Figure 2-18: Measurement Results Format

Allows selection from two different measurement result formats SCI and ENG, for

scientific or engineering units. Scientific units are expressed as an exponent and

engineering units are expressed in ohms for resistance and amps for current. For example

e6 in scientific units can be expressed as MΩ in engineering units or e

-6

in scientific units

can be expressed as µA in engineering units, this is strictly user preference and

convenience.

When scientific units is selected the results will always be displayed as 5 digits and an

exponent. The 5 digits will be configured as 1 to the left and 4 to the right of the decimal

point. When engineering units is selected the results will be displayed with a minimum

of 4 and maximum of 6 digits, there is always 3 to the right of the decimal point but to the

left there could be 1, 2, or 3 digits depending on value. For ex ample; when the units is

MΩ and depending on the device being measured the display might show 1.123MΩ,

10.123MΩ or even 100.123MΩ.

Page 46 of 87 Operation

Page 47

A summary of measurement units (scientific and engineering) and their symbols is given

in Table 2-2.

Table 2-2: Measurement Unit Prefixes

Multiple Scientific Engineering Symbol

1000000000000000 1015 Peta P

1000000000000 1012 Tera T

1000000000 109 Giga G

1000000 106 Mega M

1000 103 Kilo k

.001 10-3 milli m

.000001 10-6 micro µ

.000000001 10-9 nano n

.000000000001 10

.000000000000001 10

-12

pico p

-15

femto f

2.6.3.3 RS-232

Setup

Baud

Parity None Even Odd

Data Bits 7 8

Stop Bits 1 2

I/O

RS-232

12 24 48 96

Utilities

Figure 2-19: RS-232 Interface Setup

Allows user setup of standard RS-232 interface formats. Selections include:

Baud Rate: 12, 24, 48 or 96

Parity: None, Even or Odd

Data Bits: 7 or 8

Stop Bits: 1 or 2

When using the RS-232 interface with a printer the IEEE-488 Mode must be set to Talk

and the State to Disable.

Operation Page 47 of 87

Page 48

2.6.3.4 IEEE-488

Setup

Address

Mode Talk Talk/Listen

I/O

Disable EnableState

IEEE

= 4

Utilities

Figure 2-20: IEEE-488 Interface Setup

Allows user setup of IEEE-488 interface operation. Selections include:

Address: 1 through 16

Mode: Talk or Talk/Listen

State: Disable or Enable

The instrument will function as either a Talk or a Talk/Listen device in a system

depending on the choice made by the operator under Mode. Talk is generally suited to a

simple system with no controller or other talkers, for example a printer. Talk/Listen

denotes full programmability and is suited for use in a system that has a controller or

computer to manage data flow. The "handshake" routine assures that the active talker

proceeds slowly enough for the slowest listener.

2.6.3.5 Handler

Allows user to turn Handler Interface function On or Off. When off is selected, input

and output lines on the rear panel I/O interface connector are ignored

2.6.3.6 Results to Floppy

Allows user to store measurement results on floppy disk (if optional drive is present).

When selected, if a results file is not open, the user is prompted for the filename (up to 8

characters) and the file is opened.

To close a results file that is currently open, select Results to Floppy and press [ENTER]

to close. Display indicates “Closing the Results File”.

If a results file is open when a setup is saved, when the setup is later recalled the user will

be prompted for a results file name.

Page 48 of 87 Operation

Page 49

When multiple tests are being conducted the results are stored to floppy periodically

(every 10 measurements) from an internal buffer. To be sure of storing all results

before power is shu t down the file needs to be closed as discussed earlier. It is also

important to note that a file should be closed before changing or recalling a new set of test

conditions, otherwise the stored measurement results would not be consistent with the

setup conditions stored in the file.

NOTE

3 1/2" floppy disks must be formatted for DOS compatibility on a PC or purchased

formatted from the manufacturer, 1.44M high density or 720K low density.

Turning the instrument on with a floppy disk in the drive may cause a loss of data.

The measurement results (one for each complete measurement cycle) are stored as a DOS

text file under its assigned identifying number (up to 8 characters) with an extension of

.65R. The test setup conditions are saved as a header at the beginning of a results file. A

sample file format is shown below. Notice that the results can be stored in either

engineering or scientific terms dependent on what the user has selected for setup

conditions.

100.000000 ;voltage

0.000000 ;charge time

0.000000 ;dwell time

0.000000 ;measure time

0.000000 ;discharge time

0.000000 ;mode (0 = auto, 1 = manual)

0.000000 ;range

1000000.000000 ;limit

0.000000 ;stop on pass

1 ;# to average

0.000000 ;display type

.000000 ;result format

3.000000 ;baud rate (0 = 1200, 1 = 2400, 2 = 4800, 3 = 9600)

0.000000 ;parity

1.000000 ;data bits

0.000000 ;stop bits

4.000000 ;IEEE address

1.000000 ;IEEE mode

0.000000 ;IEEE state

1.000000 ;handler

0.000000 ;result to floppy

1.000000 ;backlite (0 = off, 1 = on)

ENDHEADER

Operation Page 49 of 87

Page 50

1.020 M ohm PASS

1.020 M ohm PASS

1.020 M ohm PASS

1.020 M ohm PASS

1.020 M ohm PASS

1.020 M ohm PASS

or

1.020015E+006 PASS

1.020015E+006 PASS

1.020015E+006 PASS

1.020015E+006 PASS

1.020015E+006 PASS

The number of measurement results that can be stored is dependent on available disk

space and length of the data string. For example; if no limit is set the measurement string

contains no pass/fail result, thus the string is fewer characters. The same is true with

header information, multiple headers (different test conditions) will consume more

memory. Whatever the case, a blank disk is capable of storing thousands of

measurements.

2.6.4 Utilities Menus

Setup

Save Setup

Recall Setup

Zero >>

Lock Out

Calibration

Set Time / Date

Elapsed Time

Calibration Date

Set Contrast

LCD Backlite

I/O

Utilities

Off On

>>

>>

>>

>>

>>

>>

>>

>>

Figure 2-21: Utilities Menu

The last of the three main menus is Utilities, shown in Figure 2-21. Each function is

described in detail in paragraphs 2.6.4.1 through 2.6.4.10.

Page 50 of 87 Operation

Page 51

2.6.4.1 Save Setup

Setup

I/O Utilities

Save

NEW

DEFAULT

FLOPPY

1865-1

1865-2

1865-3

1865-4

page

down

d

e

l

Figure 2-22: Save Setup Test Conditions

Allows a set of test conditions to be stored in instrument memory or on floppy disk (if

optional drive is installed) for later recall. Test conditions are those that are user

programmable in the Setup and I/O menus, refer to paragraphs 2.6.2 and 2.6.3 above.

Stored setup conditions should always be backed up on disk when the floppy drive

option is present or recorded on paper when this option is not present.

NOTE

Setup conditions stored internally or on floppy disk using earlier software are not

compatible with version 2.0 or later.

To store the current set of test conditions as a new set in unit memory one needs to select

[NEW] in the Save Setup menu and enter the identifying name up to 8 characters under

which these conditions will be stored (allowable characters from the keypad include 0

through 9 and minus, characters can also include A through Z when operating from

remote control ). To save the setup under the name selected or to overwrite if the name

already exists one needs to answer Yes or No, Figure 2-23.

Operation Page 51 of 87

Page 52

Setup

I/O

Utilities

>>

Y

SAVE AS XXXXX?

N

Figure 2-23: Save/Overwriting Setup

To make the current set of test conditions the default (at power up) one needs to select

[DEFAULT] in the Save Setup menu and overwrite the conditions currently stored. To

prevent overwriting the default setup by mistake an additional level of safety ex ists where

the operator is required to respond with Yes or No, similar to Figure 2-23.

Selecting [del] will delete a set of test conditions and requires a Yes or No response.

When there are more setups than can fit on th e display the page down key is active. If

there is less than a whole page below, the display wraps around to the previous display.

Continuing to page down will eventually return to the first display of setups. The page