Page 1

1855

Capacitor Leakage Current/IR Meter

Instruction Manual

Form 150767/A4

©QuadTech, Inc., 2004

5 Clock Tower Place, 210 East

Maynard, Massachusetts, U.S.A. 01754

October 2006

Telephone 978-461-2100

Sales 800-253-1230

Facsimile 978-461-4295

Website www.quadtech.com

The material in this manual is for informational purposes only and is subject to change, without notice.

QuadTech assumes no responsibility for any error or for consequential damages that may result from the

misinterpretation of any procedures in this publication.

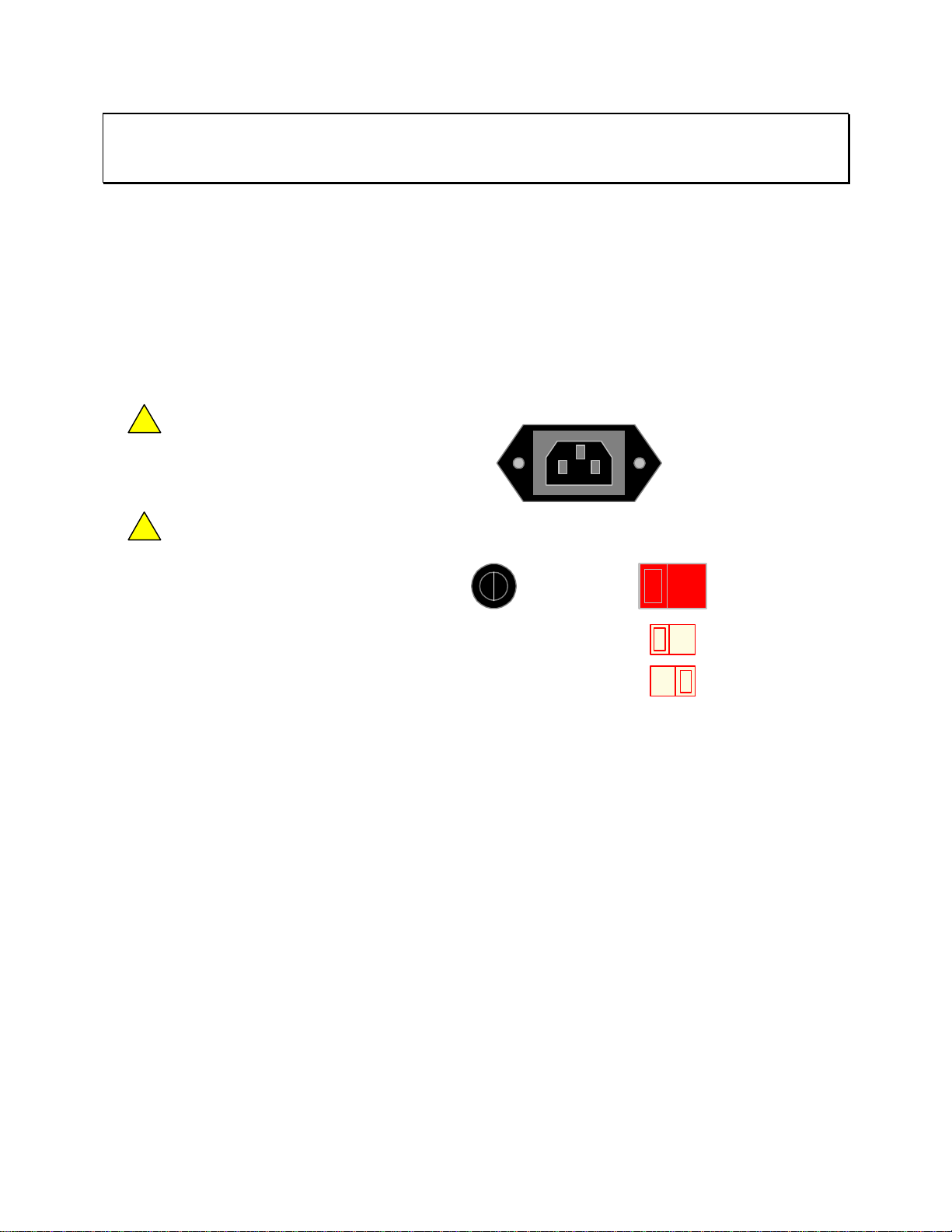

CAUTION

Voltage may be present on front and rear panel terminals. Follow all warnings in this manual when

operating or servicing this instrument. Substantial levels of energy may be stored in capacitive devices

tested by this unit.

!

Product will be marked with this symbol (ISO#3864) when it is necessary for the user to refer to

the instruction manual in order to prevent injury or equipment damage.

Product marked with this symbol (IEC417) indicates presence of direct current.

Product will be marked with this symbol (ISO#3864) when voltages in excess of 1000V are

present.

Page 2

Page 2 of 76

Page 3

Contents

Warranty ....................................................................................................................5

Specifications ....................................................................................................................7

Accessories ....................................................................................................................11

Safety Precautions...............................................................................................................13

Condensed Operating Instructions....................................................................................15

Introduction - Section 1

1.1 Unpacking and Inspection........................................................................................ 19

1.2 Product Overview .................................................................................................... 19

1.3 Controls and Indicators............................................................................................ 20

1.3.1 Front Panel Controls and Indicators .......................................................... 20

1.3.2 Rear Panel Controls and Connectors .........................................................21

1.4 Installation .............................................................................................................. 22

1.4.1 Dimensions ................................................................................................. 22

1.4.2 Instrument Positioning................................................................................ 22

1.4.3 Power Requirements ................................................................................... 22

1.4.4 Safety Inspection......................................................................................... 23

Operation - Section 2

2.1 Terms and Conventions ........................................................................................... 25

2.2 Start-Up.................................................................................................................... 27

2.3 SYSTEM SETUP ...................................................................................................27

2.3.1 Calibration ................................................................................................. 27

2.3.2 Memory Manage ........................................................................................ 27

2.3.3 System Configuration ................................................................................28

2.3.3.1 Test Parameter ........................................................................... 29

2.3.3.2 Beeper ........................................................................................ 29

2.3.3.3 Sound Mode ............................................................................... 29

2.3.3.4 Alarm Mode ............................................................................... 30

2.3.3.5 Trig Delay .................................................................................. 30

2.3.3.6 Trig Edge ................................................................................... 30

2.3.3.7 Handler Mode ............................................................................ 31

2.3.3.8 Contrast ...................................................................................... 31

2.3.3.9 GPIB Address ............................................................................ 31

2.3.3.10 RS232 Baud Rate ...................................................................... 32

2.3.3.11 Key Lock ................................................................................... 32

2.3.3.12 Line Frequency .......................................................................... 33

2.3.3.13 Charge Time .............................................................................. 33

2.3.3.14 Range Dwell .............................................................................. 33

2.3.3.15 Average ...................................................................................... 34

2.3.3.16 EXT Vm Display ....................................................................... 34

Page 3 of 76

Page 4

Contents

Operation - Section 2 – Continued

2.4 MAIN INDEX ........................................................................................................ 35

2.4.1 Sequence Test ............................................................................................35

2.4.2 Step Test .................................................................................................... 36

2.4.3 Null ............................................................................................................36

2.4.4 W.V. Test ................................................................................................... 38

2.4.5 Compare .....................................................................................................39

2.5 MEAS DISPLAY .................................................................................................... 41

2.5.1 Test Voltage ............................................................................................... 42

2.5.2 Constant Current ........................................................................................42

2.5.3 Range .........................................................................................................43

2.5.4 Charge Time ............................................................................................... 44

2.5.5 Dwell Time ................................................................................................. 44

2.5.6 Speed...........................................................................................................45

2.5.7 Trigger .......................................................................................................45

2.5.8 Rated Withstand Voltage (Vf) ................................................................... 46

2.5.9 Measurement Time (Tend) ........................................................................ 46

2.5.10 Maximum Charge Time (CHG Tend) ........................................................ 47

2.6 Connection to Device under Test............................................................................. 48

2.7 Measurement Procedure........................................................................................... 49

Interface - Section 3

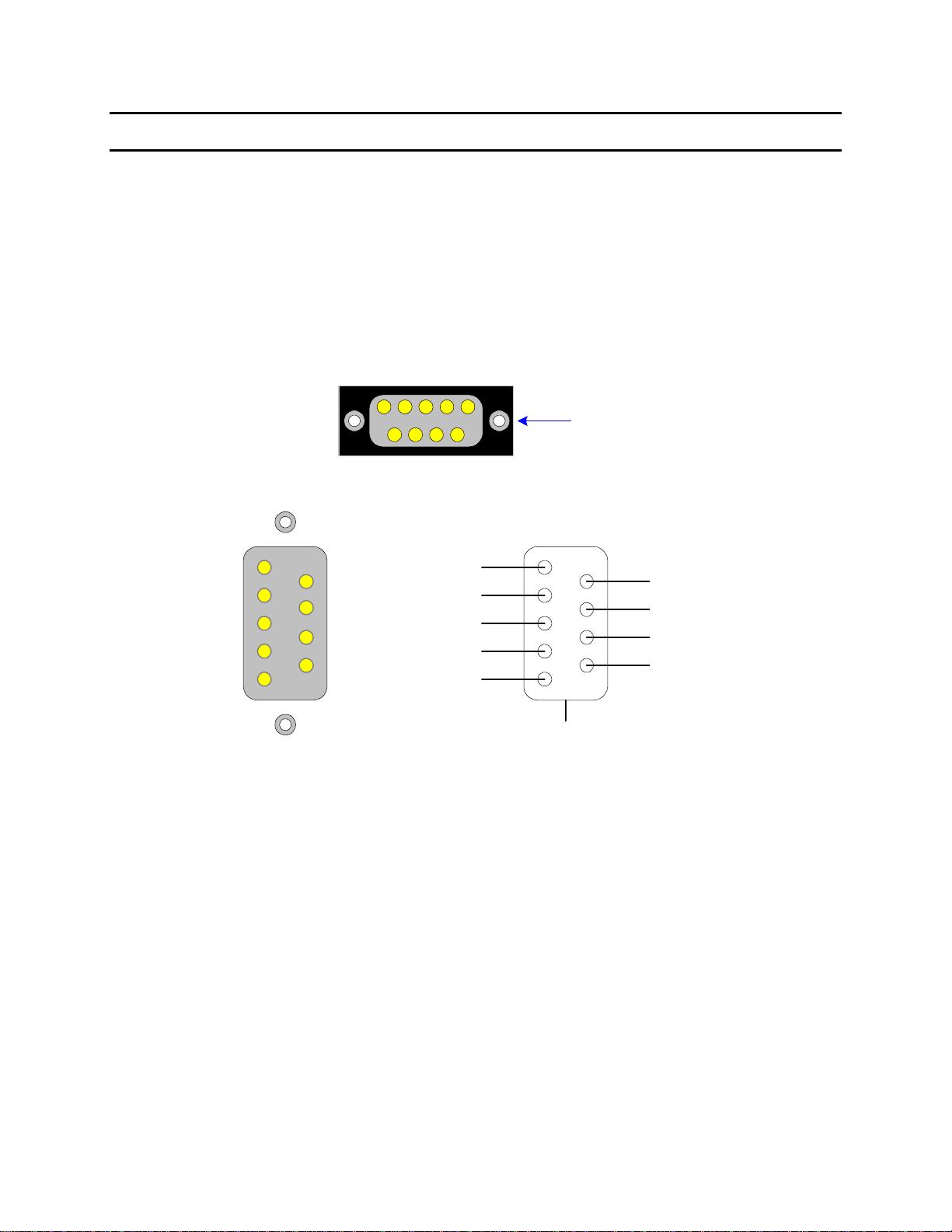

3.1 RS-232 Interface ..................................................................................................... 51

3.1.1 RS232 Pin Configuration ........................................................................... 51

3.1.2 RS232 Specifications ................................................................................. 51

3.1.3 RS232 Commands .....................................................................................52

3.2 IEEE-488 Interface .................................................................................................. 53

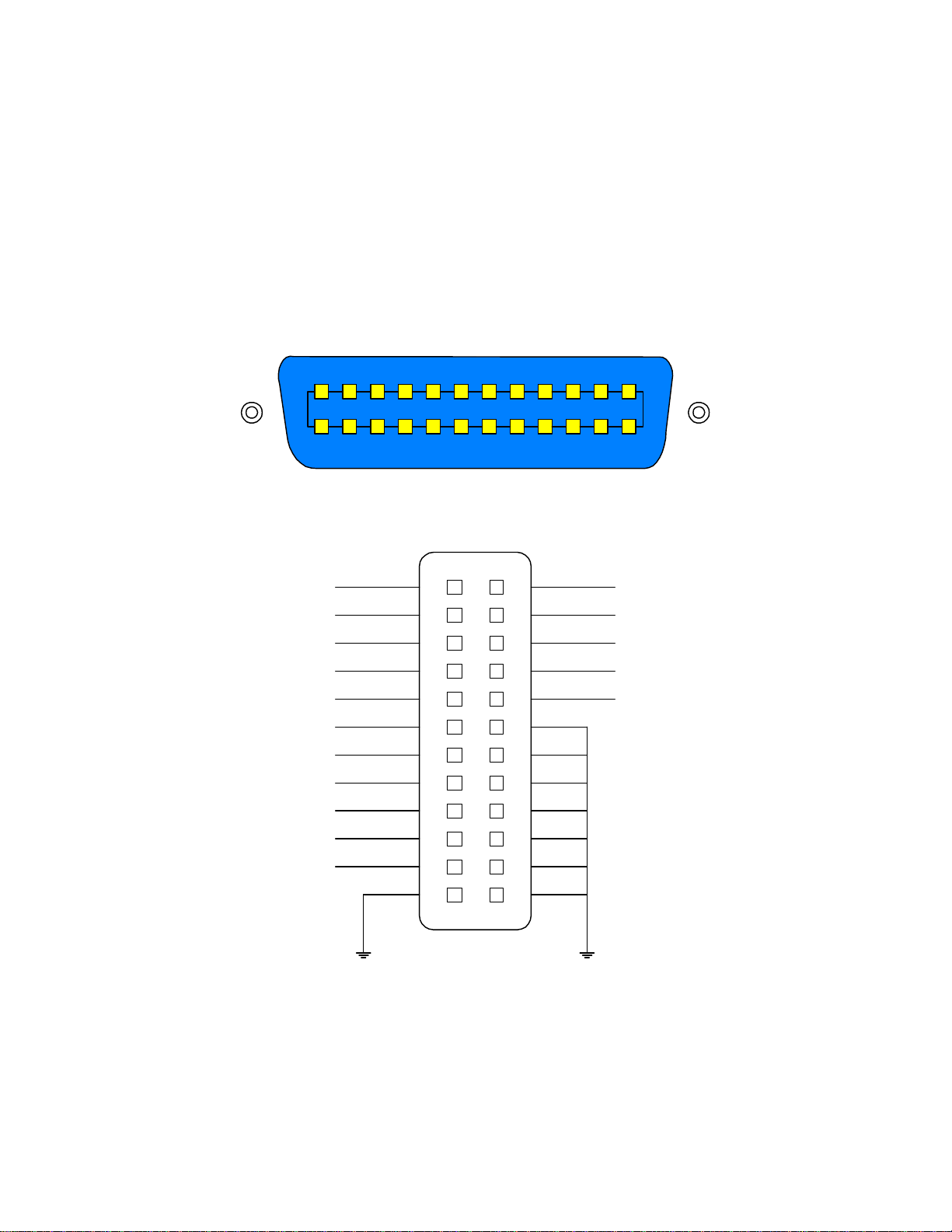

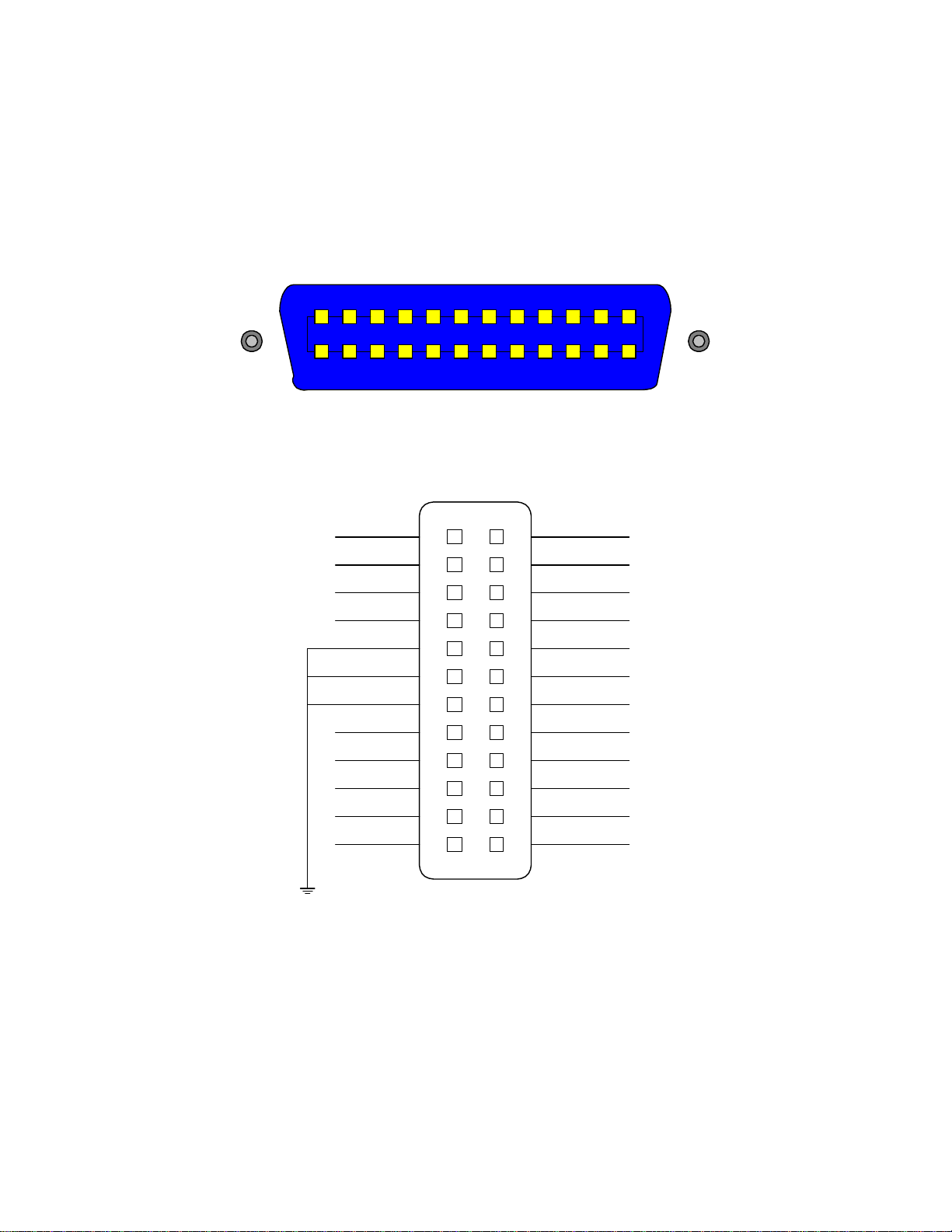

3.2.1 Pin Configuration........................................................................................ 53

3.2.2 IEEE-488 Interface Function Codes and Messages.................................... 55

3.2.3 IEEE-488 Interface Commands .................................................................. 57

3.2.4 IEEE-488 Command Format .....................................................................59

3.2.5 IEEE-488 Commands - Detailed ............................................................... 60

3.2.6 Error Messages .......................................................................................... 71

3.3 Handler Interface .................................................................................................... 72

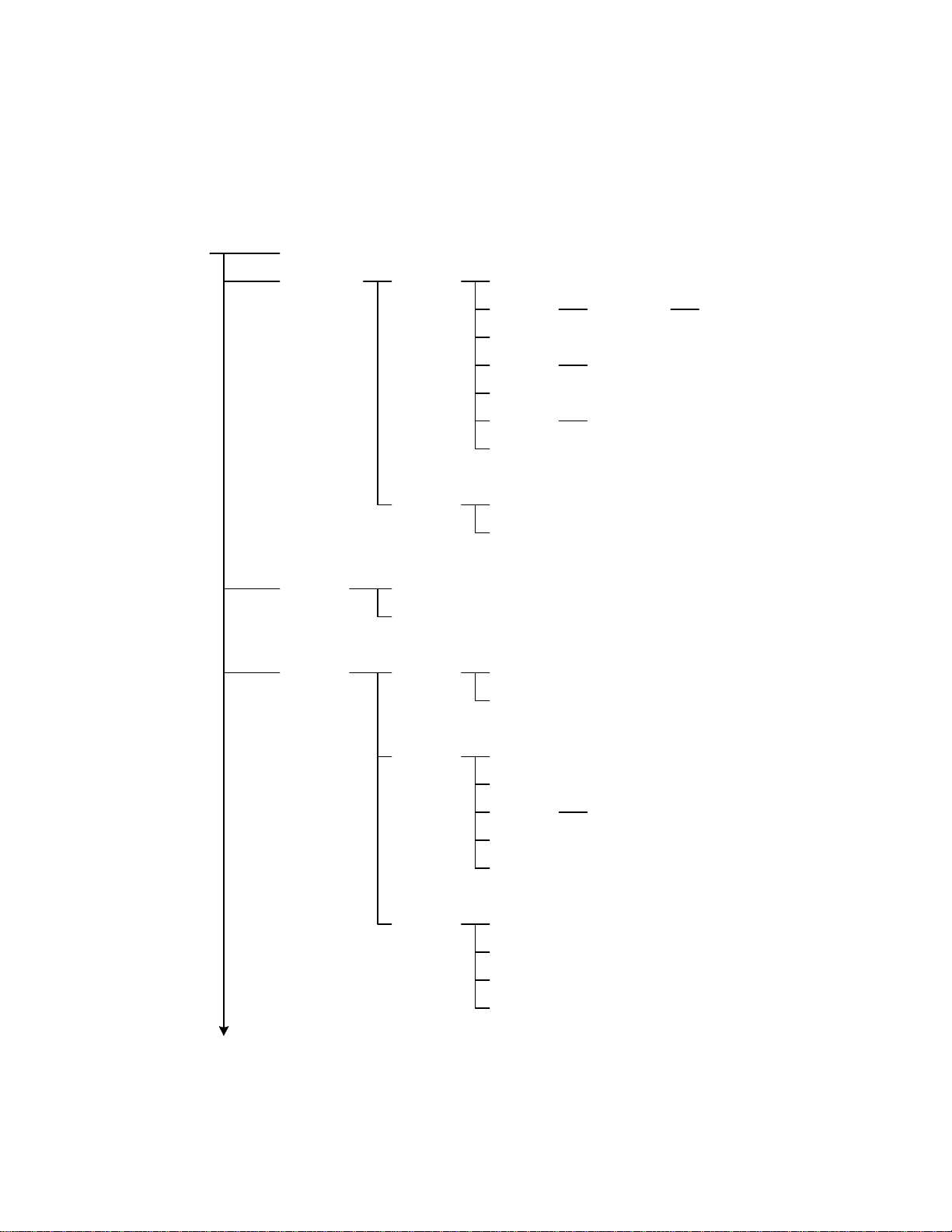

3.3.1 Trigger ....................................................................................................... 73

3.3.2 Handler Pin Assignments for Compare Operation .................................... 74

Service & Calibration - Section 4

4.1 General ................................................................................................................... 75

4.2 Instrument Return .................................................................................................... 75

4.3 Calibration ............................................................................................................... 75

4.3.1 1855 Verification Procedure ...................................................................... 76

4.3.2 1855 Verification Data Sheet ..................................................................... 76

Page 4 of 76

Page 5

Warranty

QuadTech warrants that Products are free from defects in material and workmanship and, when

properly used, will perform in accordance with QuadTech’s applicable published specifications.

If within one (1) year after original shipment it is found not to meet this standard, it will be

repaired, or at the option of QuadTech, replaced at no charge when returned to a QuadTech

service facility.

Changes in the Product not approved by QuadTech shall void this warranty.

QuadTech shall not be liable for any indirect, special or consequential damages, even if

notice has been given of the possibility of such damages.

This warranty is in lieu of all other warranties, expressed or implied, including, but not

limited to any implied warranty or merchantability of fitness for a particular purpose.

SERVICE POLICY

QuadTech’s service policy is to maintain product repair capability for a period of at least five (5)

years after original shipment and to make this capability available at the then prevailing schedule

of charges.

Page 5 of 76

Page 6

Page 6 of 76

Page 7

Specifications

Leakage Current Test:

Leakage Current: 0.001uA – 20.0mA

Accuracy: ±(0.3% + 0.005uA)

Test Voltage: 1.0V – 650V DC, 0.1V/Step

Voltage Accuracy: ±(0.5% + 0.2V)

Test Current: 0.5mA – 500mA, 0.5mA/Step for DCV ≤ 100V

0.5mA – 150mA, 0.5mA/Step for DCV > 100V

Charge Current Accuracy: ±(3% + 0.05mA)

Insulation Resistance Test:

Insulation Resistance: 10Ω – 99.99GΩ

IR Accuracy:

20V

+

++ +0.6

Vm

0.5uA

Im

Where Vm and Im are measured voltage & current for a giv en load.

Test Voltage: 1.0V – 650V DC, 0.1V/Step

Voltage Accuracy: ±(0.5% + 0.2V)

Test Current: 0.5mA – 500mA, 0.5mA/Step for DCV ≤ 100V

0.5mA – 150mA, 0.5mA/Step for DCV > 100V

Charge Current Accuracy: ±(3% + 0.05mA)

Withstand Voltage Test:

Rise Time (Tr): 0.05s – 120s

Withstand Voltage (Vf): 1.0V – 650V DC, 0.1V/Step

Test Current: 0.5mA – 150mA, 0.5mA/Step

Charge Current Accuracy: ±(3% + 0.05mA)

Measure Time: 30s – 600s

MAX Charge Time: 5s – 600s

0.005uA

1

Im

%

Page 7 of 76

Page 8

Specifications (Continued)

General Features

Test Types: Automatic Sequence Test

Manual Step Test

Null: Correction for Lead Leakage

Monitored Voltage (Vm): 1.0V – 650V DC (Voltage across DUT)

Charge Time: 0 – 999seconds in 1s/10s increments <100s; 100s increments >100s

Delay Time: 0.2 – 999seconds in 0.1s increments <100s; 10s increments>100s

Discharge: 65 Watt Discharge Circuit

Trigger: Delay: 0 – 9.995 seconds in 0.1s increments

Edge: Falling or Rising

Measurement Mode: Continuous or Trigger (INT, EXT or Manual)

Measurement Rate: Fast: 18 measurements/second

Medium: 14 measurements/second

Slow: 7 measurements/second

Ranging: Automatic or Hold

Averaging: 1-8 measurements

Compare: Set Upper & Lower Limits for LC and IR Tests

Display: 240 x 64 LCD Graphic display

Indication: Audible alarm programmable HI, LOW or OFF for Pass or Fail

Standard Interface: RS232

Optional Interfaces: IEEE-488 & Handler

Connectors: 1 BNC terminal: Input

2 Banana terminals: HV (+), HV (-)

1 Banana Socket: Chassis Ground

Front Panel Lockout: Keypad Lock

Page 8 of 76

Page 9

Specifications (Continued)

Mechanical: Bench Mount

Dimensions: (w x h x d): 12.50 x 4.00 x 13.50 inches

317.2 x 101.5 x 342.6 mm

Weight: 18 lbs (8.2kg) net, 22 lbs (10kg) shipping

Environmental: Operating: 10°C to 40

Storage: -10°C to 50

Humidity: <90%

Pollution Degree 2

Installation Category I

Power: • 90-125VAC • 190-250VAC

• 50 or 60Hz • 400W max

Supplied: • Instruction Manual • Power Cable

• Calibration Certificate • Lead Set

Ordering Information: Description Catalog No.

Capacitor Leakage Current/IR Meter 1855

o

C

o

C

Page 9 of 76

Page 10

Page 10 of 76

Page 11

Accessories

Accessories Included

Item Quantity QuadTech P/N

AC Power Cord 1 4200-0300

Power Line Fuse: 4A 250V SB for 115V operation 1 520149

Power Line Fuse: 2A 250V SB for 230V operation 1 520148

Test Leads: Banana to Alligator Clip & BNC to Alligator Clip 1 1855-01

Instruction Manual 1 150767

Calibration Certificate 1 N/A

Accessories/Options Available

Item Quantity QuadTech P/N

IEEE-488 & Handler Interface 1 700171

RS-232 Cable 1 630157

Resistivity Test Cell for Surface & Volume Resistivity Msmts 1 1855-11

Page 11 of 76

Page 12

Page 12 of 76

Page 13

Safety Precautions

CAUTION

The 1855 Capacitor Leakage Current/IR Meter can provide an output voltage of 650V DC to the

device under test (DUT). Although the 1855 unit is a low voltage instrument, some devices

(especially capacitors) can store charge when tested. If not discharged properly, these devices

may cause serious hazards. Follow these safety instructions.

1. Operate the 1855 unit with its chassis connected to earth ground. The instrument is

shipped with a three-prong power cord to provide this connection to ground. This power

cord should only be plugged in to a receptacle that provides earth ground. Serious injury

can result if the 1855 unit is not connected to earth ground.

2. Tightly connect BNC cable to the silver INPUT terminal. If this is not done, the DUT’s

casing can be charged to the high voltage test level and injury or electrical shock hazards

could result if the DUT is touched.

3. Never touch the test leads, test fixture or DUT in any manner (this includes insulation on

all wires and clips) when [TRIGGER] has been pressed and the output is applied.

4. Before turning on the 1855 instrument, make sure there is no device (DUT) or fixture

connected to the test leads.

5. Make sure any capacitive device has been discharged fully before touching the test lead

wires or output terminals.

6. In the case of an emergency, turn OFF the POWER switch using a “hot stick” and

disconnect the AC power cord from the wall. Do not touch the 1855 instrument.

7. Be wary when the 1855 instrument is used in remote control mode. The voltage/current

output is being turned on and off with an external signal.]

8. Do not exceed the 1A Maximum Input Current.

Page 13 of 76

Page 14

Page 14 of 76

Page 15

Condensed Operating Instructions

General Information

The 1855 Capacitor Leakage Current/IR Meter is an instrument for measuring the parameters of

leakage current (LC), insulation resistance (IR), withstand voltage (WV) and rise time (Tr). The

1855 instrument functions mainly as a leakage current and withstand voltage tester for aluminum

foil electrolytic capacitors and high dielectric ceramic capacitors. The 1855 instrument is useful

in testing any components for which leakage current is a major factor including Zener diodes,

absorbers, etc. For production testing, the 1855 instrument has a Compare function and Pass/Fail

indication. Connection to device under test is through BNC/Banana terminals on the front panel.

Start-Up

The 1855 Capacitor Leakage Current/IR Meter can be operated from a power source between 90125V or 190-250V AC at a power line frequency of 50 or 60Hz. The standard 1855 unit is

shipped from QuadTech with a 4A fuse in place for AC 90-125V operation. (A 2A fuse is

included for AC 190-250V operation). The 1855 unit is shipped with the line voltage selector set

for 115V. Refer to paragraph 1.4.3 for instructions on changing the fuse or line voltage selector.

Connect the 1855 Capacitor Leakage Current/IR Meter’s AC power cord to the source of proper

voltage. Operate the 1855 instrument with its chassis connected to earth ground. The 1855

instrument is shipped with a three-prong power cord to provide this connection to ground. This

power cord should only be plugged into a receptacle that provides earth ground. Serious injury

may result if the 1855 instrument is not connected to earth ground.

To turn the 1855 instrument ON, press the power button on the front panel. To switch the power

OFF, press the button again or if measurements are to be made proceed with the Test Parameter

Setup in Table COI-1. The 1855 instrument should warm up for 15 minutes prior to use.

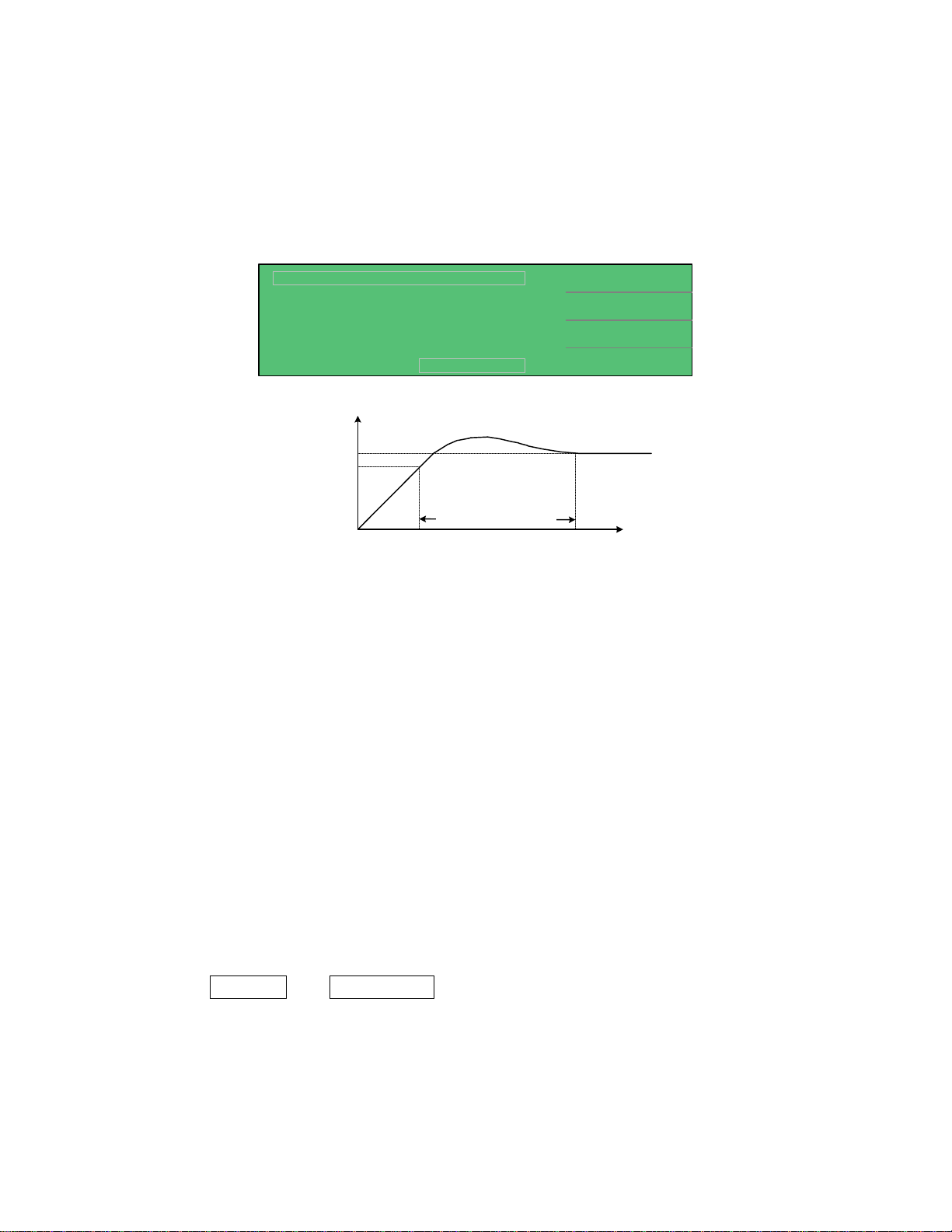

Table COI-1: Test Parameter Setup

Test LC/IR WV/Tr

Parameter

Test V 1.0V – 650V DC N/A

C.C. 0.5mA – 500mA N/A

Range 2uA-20uA-200uA-2mA-20mA N/A

CHG T 0s – 999s N/A

DWELL T 0.2s – 999s N/A

Speed Fast – Medium – Slow N/A

Vf N/A 1.0 – 650V DC

C.C. N/A 0.5mA – 150mA

Tend N/A 30s – 600s

CHG Tend N/A 5s – 600s

NOTE

Refer to paragraphs 2.3.3 through 2.4 for a full description of programming test parameters. Test parameters must

be set before the 1855 instrument can be zeroed.

Page 15 of 76

Page 16

Condensed Operating Instructions (Continued)

There are three main menus within the 1855 instrument software. Familiarize yourself with

these menus prior to programming a test. Figure COI-1 illustrates the MEAS DISPLAY screen

and lists the functions that can be accessed by pressing the [MAIN INDEX] and [SYSTEM

SETUP] keys.

Function of F1 - F4 Keys

MEAS DISPLAY

MAIN

< MEAS DISPLAY: SEQ. TEST >

TEST V.

1.0V

:

F1

MEAS

DISPLAY

INDEX

SYSTEM

SETUP

Lc :

Vm = 0.0V

MEAS

DISPLAY

SEQ. STEP

Test Voltage

Constant Current

Range

NEXT PAGE 1/2

Charge Time

Dwell Time

Speed

NEXT PAGE 2/2

Test Voltage

Constant Current

Range

NEXT PAGE 1/2

Trigger

Speed

NEXT PAGE 2/2

-1.2 A

DISCHARGECHARGE TEST

Sequence Test

Step Test

Null

W.V. Test

Compare

MAIN

INDEX

Test Voltage

Constant Current

Range

Charge Time

Dwell Time

Speed

Test Voltage

Constant Current

Range

Trigger

Speed

Foil Voltage

Constant Current

End Time

Charge End Time

C.C.

RANGE

NEXT PAGE 1/2

:

0.5mA

:

2uA

A

SYSTEM

SETUP

CALIBRATION

Need Password*

MEMORY MANAGE

Need Paasword*

SYSTEM CONFIGURATION

Test Parameter

Beeper

Sound Mode

Alarm Mode

Trigger Delay

Trigger Edge

Handler Mode

Contrast

GPIB Address

RS232 Baud Rate

Key Lock

Line Frequency

Charge Time

Range Dwell

Average

EXT Vm Display

* Qualified Service Personnel Only

Instrument Calibration & Verification

F2

CHARG E/TEST DISCHARGE

F3

F4

TRIGGER

Figure COI-1: 1855 Instrument Menus

NOTE:

The function keys [F1 – F4] are used to select the parameter to change and in some menus to

change the value of that selected parameter.

The function of UP/DOWN depends on the menu. In some menus, the LEFT/RIGHT keys are

used to select a digit by moving the underscored cursor left or right.

Page 16 of 76

Page 17

Condensed Operating Instructions (Continued)

1. Set Test Parameters

• Press [POWER] ON.

• Allow the instrument to warm up for 15 minutes.

• Press [MEAS DISPLAY]

• Set test parameters (voltage, current, range, etc.) using the function & arrow keys.

2. Null

After setting your test parameters, use the Null function of the 1855 instrument to zero the

test leads. With no device connected, connect the appropriate cable to the front panel

BNC/Banana connectors. Refer to paragraph 2.6 for cable connections.

With the instrument in MEAS DISPLAY status:

1. Press [MAIN INDEX]

2. Press [F3] = NULL

3. Press [TRIGGER] button.

4. Wait while instrument cycles through NULL test.

5. Press [MAIN INDEX] to return to MEAS DISPLAY status.

6. Choose Test: [SEQ Test], [STEP Test] or [Next Page] to select [WV Test]

QuadTech

<MEAS. DISPLAY: NULL>

LC : mA

Press TRIGGER to start ...

CHARGE TEST DISCHARGE

01

l

1855 Capacitor Leakage Current /IR Meter

HV

+

OPEN No DUT Connected for NUL L function

-

MAIN

INDEX

TRIGGER

SYSTEM

SETUP

F1

F2

F3

F4

(-)(+)INPUT

F1

F2

F3

F4

MEAS

DISPLAY

CHARGE/TEST DISCHARGE

Figure COI-2: NULL OPEN Configuration

Page 17 of 76

Page 18

Condensed Operating Instructions (Continued)

3. Connection to Device under Test (DUT)

Figure COI-3 illustrates the connection of the 1855 instrument to a DUT using the 1855-01 Lead

Set. For Leakage Current, Insulation Resistance and Withstand Voltage Tests, the red alligator

clip/BNC cable is connected between the silver INPUT terminal on the 1855 unit and the high

side of the device under test. The black alligator clip/banana cable is connected between the

white HV (-) terminal on the 1855 unit and the low side of the DUT.

QuadTech

<MEAS. DISPLAY: SEQ. TEST>

LC :

CHARGE TEST DISCHARGE

01

l

1855 Capacitor Leakage Current /IR Meter

1.5 mA

TEST V

C.C

RANGE

NEXT PAGE 1/2

+

DUT

1.0

:

0.5

:

2

A

:

HV

-

MAIN

INDEX

TRIGGER

SYSTEM

SETUP

V

F1

mA

F2

F3

uA

F4

(-)(+)INPUT

F1

F2

F3

F4

MEAS

DISPLAY

CHARGE/TEST DISCHARGE

COI-3: Connection to DUT for LC Test

4. Make a Measurement

1. Press [MEAS DISPLAY]

2. Connect device under test (DUT) to test leads.

3. Press [TRIGGER].

4. Record measurement.

NOTE

Please read this instruction manual in its entirety before operating this instrument.

These condensed operating instructions are not a substitute for all the information provided in the

remainder of this manual.

Page 18 of 76

Page 19

Section 1: Introduction

1.1 Unpacking and Inspection

Inspect the shipping carton before opening. If damaged, contact the carrier agent immediately.

Inspect the 1855 Capacitor Leakage Current/IR Meter for any damage. If the instrument appears

damaged or fails to meet specifications notify QuadTech (refer to instruction manual front cover)

or its local representative. Retain the original shipping carton and packing material for future use

such as returning the instrument for recalibration or service.

1.2 Product Overview

The 1855 Capacitor Leakage Current/IR Meter is a compact yet powerful LC Tester and IR

meter for production or laboratory testing of aluminum electrolytic capacitors, resistors and other

passive components. The 1855 instrument measures 4 parameters: Leakage Current (LC),

Insulation Resistance (IR), Rise Time (Tr) and Withstand Voltage (Vf) and displays two

simultaneously. Basic accuracy is ±0.3%. From 1-8 measurements can be made, averaged and

the result displayed with the Averaging function. Ranging is automatic or user selectable.

Measurement rate is also selectable (Slow, Medium or Fast) with rates up to 18 measurements

per second. Measurements can be made continuously or triggered with a programmable delay

time up to 10 seconds. The 1855 comes standard with an RS-232 interface. An optional IEEE488 and Handler interface is also available. Voltage across the DUT can be monitored and

displayed. Zero the effects of stray leakage in the test leads with the Null function. The Compare

function on the 1855 instrument has programmable upper and lower limits and displays Pass/Fail

in addition to the measurement value. Connection to the device under test is through 1 BNC

INPUT terminal and 2 Banana HV terminals on the front panel.

QuadTech

<MEAS. DISPLAY: SEQ. TEST>

LC :

CHARGE TEST DISCHARGE

01

l

1855 Capacitor Leakage Current /IR Meter

:

1.0

:

0.5

:

2

A

HV

+

-

1.5 mA

TEST V

C.C

RANGE

NEXT PAGE 1/2

MEAS

MAIN

V

F1

mA

F2

F3

uA

F4

(-)(+)INPUT

F1

F2

F3

F4

DISPLAY

CHARGE/TEST DISCHARGE

INDEX

TRIGGER

SYSTEM

SETUP

Figure 1-1: 1855 Capacitor Leakage Current/IR Meter

Introduction Page 19 of 76

Page 20

1.3 Controls and Indicators

1.3.1 Front Panel Controls and Indicators

Figure 1-2 illustrates the controls and indicators on the front panel of the 1855 Capacitor

Leakage Current/IR Meter instrument. Table 1-1 identifies them with description and function.

10 9 811

QuadTech

<MEAS. DISPLAY: SEQ. TEST>

LC :

CHARGE TEST DISCHARGE

01

l

1 423 56

1855 Capacitor Leakage Current /IR Meter

1.5 mA

TEST V

C.C

RANGE

NEXT PAGE 1/2

+

1.0

:

0.5

:

2

A

:

HV

-

MEAS

MAIN

V

F1

mA

F2

F3

uA

F4

(-)(+)INPUT

F1

F2

F3

F4

DISPLAY

CHARGE/TEST DISCHARGE

INDEX

TRIGGER

SYSTEM

SETUP

7

Figure 1-2: 1855 Front Panel Controls & Indicators

Table 1-1: 1855 Front Panel Controls & Indicators

Reference #

Figure 1-2

1 Green Push Button Apply AC POWER: 1=ON, 0=OFF

2 Silver Banana Jack Chassis ground connection

3a INPUT Silver BNC terminal Current Drive Terminal, High (+)

3b HV (+) Red Banana Jack Voltage Sense Terminal, High (+)

3c HV (-) White Banana Jack Voltage Sense Terminal, Low (-)

4 F1, F2, F3 and

5 ◄, ▼, ►, ▲ 4 gray push buttons Move backlit box around display to choose parameter

6 TRIGGER Gray push button Initiate measurement

7 DISCHARGE STOP measurement in progress & initiate discharge time

8 SYSTEM

9 MAIN

10 MEAS

11 240 x 64 LCD

Name Type Function

4 gray push buttons Select Instrument Functions

F4

Keys perform different functions under different menus.

Right side of display shows corresponding key function.

Change parameter value (increase/decrease)

Gray push button View, Select or Change System Parameters:

SETUP

Parameter, Beeper, Sound, Alarm, Trigger, Handler,

Contrast, GPIB, RS-232, Key Lock, Line Frequency,

Charge, Dwell, Average & EXT Vm Display

Gray push button View, Select or Change Setup & Result Parameters:

INDEX

Sequence, Step, Null, WV Test & Compare

Gray push button View, Select or Change Measurement Parameters:

DISPLAY

Voltage, Current, Range, Charge, Dwell, Speed & Trigger

Show measurement results as value or pass/fail.

display

Show programming instructions

Page 20 of 76 Introduction

Page 21

1.3.2 Rear Panel Controls and Connectors

Figure 1-3 illustrates the controls and connectors on the rear panel of the 1855 Capacitor Leakage

Current/IR Meter instrument. Table 1-2 identifies them with description and function.

56

115V ~/230V~

RS232

WARNING:

!

!

IEEE-488 INTERFACEHANDLER INTERFACE

FOR CONTI NUED PROTECTION

AGAINST FIRE HAZARD, REPLACE ONLY

WITH THE SAME TYPE AND RATING OF FUSE

AS SPECIFIED FOR THE LINE VOLTAGE

BEING UTILIZED.

CAUTION:

NO OPERATO R SERVICEABLE

PARTS INSIDE. REFER SERVICING TO

QUALIFIED PERSONNEL.

POLLUTION DEGREE 2

INSTALLATION CATEGORY I

MODEL NO.

SERIAL NO.

50/60Hz 400VA MAX

FUSE LINE VOLTAGE

SELECTED

115V

230V

115V

90V - 125V~

T4.0AL 250V

190V - 250V~

T2.0AL 250V

1

234

Figure 1-3: Rear Panel 1855 Instrument

Table 1-2: 1855 Rear Panel Controls & Connectors

Reference #

Figure 1-3

1 HANDLER

2 IEEE-488

3 FUSE Black screw cap fuse

4 LINE VOLTAGE

5 AC Line Input Black 3-wire inlet

6 RS-232

Name Type Function

Blue 24-pin

INTERFACE

connector

Blue 24-pin

INTERFACE

connector

holder

2 Red 2-position

SELECTED

Slide Switches

module

Black 9-pin RS-232 interface for serial communication

INTERFACE

Handler Interface connector for remote operation

IEEE-488 Interface connector for data transfer

Short circuit protection

T 4A 250V fuse for 115V operation

T 2A 250V fuse for 230V operation

Select Voltage Level corresponding to AC Source

90V – 125V: T4.0A 250V fuse

190V – 250V: T 2A 250V fuse

Connection to AC power source

Introduction Page 21 of 76

Page 22

1.4 Installation

1.4.1 Dimensions

The 1855 Capacitor Leakage Current/IR Meter unit is supplied in a bench configuration, i.e., in a

cabinet with resilient feet for placement on a table. Flip feet are attached under the front feet so

that the 1855 instrument can be tilted up for convenient operator viewing.

4.0"

101.6mm

QuadTech

01

l

1855 Capacitor Leakage Cur rent/IR Meter

<MEAS. DISPLAY: SEQ. TEST>

Lc : 1.5 mA

TEST V.

C.C

RANGE

NEXT PAGE 1/ 2

HV

0.5mA

MEAS

MAIN

F1

F1

1.0V

F2

F3

2uA

F4

(-)(+)INPUT

DISPLAY

F2

F3

F4

SYSTEM

INDEX

SETUP

TRIGGER

13.5"

342.9mm

14.0"

355.6mm

including

front and

rear

12.50"

connectors

317.50mm

Figure 1-4: 1855 Instrument Dimensions

1.4.2 Instrument Positioning

The 1855 instrument contains one (1) graphic display for direct readout of measured parameters.

The optimum angle for viewing is slightly down and about 10 degrees either side of center. For

bench operation the front flip feet should always be used to angle the instrument up. In bench or

rack mount applications the instrument should be positioned with consideration for ample air

flow around the rear panel fan ventilation hole. An open space of at least 3 inches (75mm) is

recommended behind the rear panel. Testing should be performed on a non-conductive surface.

An ESD mat is not a recommended test platform.

1.4.3 Power Requirements

The 1855 can be operated from a power source of 90 to 125V AC or 190 to 250V AC. Power

connection is via the rear panel through a standard receptacle. Before connecting the 3-wire

power cord between the unit and AC power source, make sure the voltage selection switches on

the rear panel (Figure 1-5) are in accordance with the power source being used. For a 90-125V

source, use a 4A 250V fuse. For a 190-250V source, use a 2A 250V fuse. Always use an outlet

that has a properly connected protection ground.

4.5"

114.3mm

including

feet

Page 22 of 76 Introduction

Page 23

CAUTION

Make sure the unit has been disconnected from its AC power source for at least five minutes

before proceeding.

Procedure for Changing an 1855 Instrument Fuse

Unscrew the fuse cap on the rear panel of the 1855 and pull fuse holder outward.

Once the fuse holder has been removed from the instrument snap the fuse from the holder and

replace. Make sure the new fuse is of the proper rating.

Install the fuse back into the cap holder by pushing in until it locks securely in place.

115V ~/230V~

WARNING:

!

AGAINST FIRE HAZARD, REPLACE ONLY WITH

THE SAME TYPE AND RATING OF FUSE AS

SPECIFIED FOR THE LINE VOLTAGE BEING

UTILIZED.

FOR CONTINUED PROTECTION

50/60Hz 400VA MAX

CAUTION:

!

PARTS INSIDE. REFER SERVICING TO

QUALIFIED PERSONNEL.

POLLUTION DEGREE 2

INSTALLATION CATEGORY I

NO OPERATOR SERVICEABLE

FUSE

LINE VOLTAGE

SELECTED

115V

115V

230V

90V-125V~

T4.0AL 250V

190V-250V~

T2.0AL 250V

Figure 1-5: Close-Up of 1855 Rear Panel

1.4.4 Safety Inspection

Before operating the instrument inspect the fuse holder on the rear of the 1855 instrument to

ensure that the properly rated fuse is in place, otherwise damage to the unit is possible. Make

sure that the voltage selector switches are set in accordance with the power source in use. Refer

to paragraph 1.4.3 and Figure 1-5.

The 1855 instrument is shipped with a standard U.S. power cord, QuadTech P/N 4200-0300

(with Belden SPH-386 socket or equivalent, and a 3-wire plug conforming to IEC 320). Make

sure the instrument is only used with these cables (or other approved international cord set) to

ensure that the instrument is provided with connection to protective earth ground.

The surrounding environment should be free from excessive dust to prevent contamination of

electronic circuits. The surrounding environment should also be free from excessive vibration.

Do not expose the 1855 instrument to direct sunlight, extreme temperature or humidity

variations, or corrosive chemicals.

Introduction Page 23 of 76

Page 24

Page 25

Section 2: Operation

2.1 Terms and Conventions

Table 2-1: Measurement Unit Prefixes

Multiple Scientific Engineering Symbol

1000000000000000 1015 Peta P

1000000000000 1012 Tera T

1000000000 109 Giga G

1000000 106 Mega M

1000 103 Kilo k

.001 10-3 milli m

.000001 10

.000000001 10-9 nano n

.000000000001 10

.000000000000001 10

Capacitor: Abbreviated C. A capacitor is passive component comprised of two conductors

Capacitance: The measure of the ratio of charge on either plate of a capacitor to the potential

Compare: Procedure for sorting components by comparing the measured value against a

DC: Direct Current. Non-reversing polarity. The movement of charge is in one

Dielectric: A material which is an electrical insulator or in which an electric field can be

Dielectric Absorption: The physical phenomenon of insulation appearing to absorb and retain an

Dielectric Constant: Abbreviated K, relative dielectric constant. The dielectric constant of a material

Discharge: The act of draining off an electrical charge to ground. Devices that retain charge

-6

micro µ

-12

pico p

-15

separated by a dielectric. A capacitor stores charge blocks DC flow and allows

AC flow based on frequency and capacitor design.

difference (voltage) across the plates. Unit of measure is the Farad (F).

known standard.

direction. Used to describe both current and voltage. Batteries supply direct

current (DC).

sustained with a minimum dissipation of power.

electrical charge slowly over time. Apply a voltage to a capacitor for an

extended period of time and then quickly discharge it to zero voltage. Leave the

capacitor open circuited for a period of time then connect a voltmeter and

measure the residual voltage. The residual voltage is caused by the dielectric

absorption of the capacitor.

is the ratio of the capacitance of a capacitor filled with a given dielectric to that

same capacitor having only a vacuum as a dielectric.

should be discharged after an IR test or DC hipot test.

femto f

Interface Page 25 of 76

Page 26

DUT: Device Under Test. (i.e. the product being tested).

Ground: The base reference from which voltages are measured, nominally the same

potential as the earth. Ground is also the side of a circuit that is at the same

potential as the base reference.

Insulation Resistance: Measures the total resistance between any two points separated by electrical

insulation. The IR test determines how effective the dielectric (insulation) is in

resisting the flow of electrical current.

Interface:

Handler: Device for remote control of test instrument in component handling operations.

IEEE-488: General Purpose Interface Bus (GPIB). GPIB is an industry standard definition

of a Parallel bus connection for the purpose of communicating data between

devices.

RS232: An industry standard definition for a Serial line communication link or port.

Range: The resistance ranges the instrument uses for reference in making the

measurement.

Speed: The rate at which the instrument makes a measurement in measurements per

second. Speed is inversely proportional to accuracy.

Trigger: The device for initiating the test (applying the voltage or current).

External: The test is initiated via an external source such as a computer with an IEEE-488

or Handler interface. One measurement is made each time the external trigger is

asserted on the handler.

Internal: The instrument continuously makes measurements.

Manual: The operator initiates the test by pressing the [START] button. One

measurement is made each time the trigger is pressed.

Withstand Voltage: Voltage at which the product’s insulation begins to break down. There are many

definitions for Withstand Voltage. This manual uses the terminology from the

EIAJ RC-2364A standard, “Test Methods of Electrode Foils for Aluminum

Electrolytic Capacitors”.

Term Symbol Definition

Formation Voltage Vfe The final applied voltage

Standard Dielectric

Withstand Voltage

Rise Time Tr The time between when the current is applied and

Withstand Voltage Vt

Rated Voltage WV Rated working voltage of a capacitor

Vf The withstand voltage of formed foil

the voltage reaches 90% of the rated withstand

voltage, Vf.

Tr + 3minutes ±10seconds (formed foils)

Tr + 1minute ±10seconds (unformed foils)

Page 26 of 76 Interface

Page 27

2.2 Startup

Check to make sure the red Line Voltage Selector switch on the rear panel agrees with the power

source available. Depending on the power source the switch position should be in the up or down

position as shown in Figure 1-5 (Close-Up of 1855 Rear Panel).

CAUTION

USE ALL PRECAUTIONS NECESSARY TO AVOID TOUCHING THE DEVICE UNDER TEST WHEN THE

TRIGGER BUTTON HAS BEEN PRESSED.

Connect the instrument power cord to the source of proper voltage. The instrument is to be

used only with three-wire grounded outlets.

Power is applied to the 1855 instrument by pressing the green power switch on the front panel to

the ON (1 position). The 1855 unit should warm up for a period of at least 15 minutes prior to

measurements being made.

2.3 SYSTEM SETUP

System Setup contains the 1855 instrument setup functions: Calibration, Memory Manage and

System Configuration. Press [SYSTEM SETUP] to access these functions.

F1

< SYSTEM SETUP > CALIBRATION

MEM MANAGE

Enter Calibration

F2

Enter Memory Manage

F3

SYSTEM CONFIG

Enter System Configuration

Figure: 2-1: System Setup

2.3.1 Calibration

The Calibration menu is to be accessed by Qualified Service Personnel Only. Altering the 1855

instrument calibration will void the instrument warranty. The Calibration function is used to

verify the resistance measurement ranges. To access the calibration function, press [SYSTEM

SETUP] then press [F1] = [CALIBRATION]. Enter the password. [▲] [▼] [►] [◄]

[TRIGGER]. Select cal range 20V or 200V. Refer to paragraph 4.3 Calibration for procedure.

2.3.2 Memory Manage

The Memory Manage menu is to be accessed by Qualified Service Personnel Only. Altering the

1855 instrument memory will void the instrument warranty. The memory manage function is

used to verify the setup of the 1855 unit with a Function Test and a Handler Test. To access the

memory manage function, press [SYSTEM SETUP] then press [F2] = [MEM MANAGE]. Enter

the password. [▲] [▼] [►] [◄] [TRIGGER].

Interface Page 27 of 76

Page 28

2.3.3 System Configuration

Prior to programming a test or measuring a device, set up the system controls of the 1855

instrument. To access the system controls, press [SYSTEM SETUP] then press [F3] = [SYSTEM

CONFIG]. Table 2-2 lists the contents of SYSTEM CONFIG.

F1

< SYSTEM SETUP > CALIBRATION

MEM MANAGE

SYSTEM CONFIG

Enter Calibration

F2

Enter Memory Manage

F3

Enter System Configuration

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

< SYSTEM CONFIG >

AVERAGE :

EXT Vm DISPLAY :

L.C.

LOW

:

FAIL

:

PULSE

:

0000 mS

:

FALLING

:

CLEAR

07

:

17

:

19200

:

OFF

:

60Hz

:

Vm = Vs

0.0 S

1

OFF

I.R.

L.C.

DIGIT UP

DIGIT DOWN

DIGIT UP

DIGIT DOWN

F1

Set Test Parameter to IR

F2

Set Test Parameter to LC

F3

F4

F1

Increase brightness: 00 - 15

F2

Decrease brightness: 15 - 00

F3

F4

F1

Increase # to Average: 1 - 8

F2

Decrease # to Average: 8 - 1

F3

F4

Figure 2-2: System Configuration

Table 2-2: SYSTEM CONFIG

Parameter Function Range

Test Parameter Set the parameter to be tested LC, IR

Beeper Set beeper loudness OFF, LOW or HIGH

Sound Mode Set when the buzzer to sounds PASS/FAIL

Alarm Mode Set type of alarm signal PULSE/CONTINUOUS

Trigger Delay Set external trigger time 0000 – 9999 ms

Trigger Edge Set trigger mode FALLING/RISING

Handler Mode Set handler interface mode CLEAR/HOLD

Contrast Set display contrast 00 – 15

GPIB Address Code Set interface address 00 – 30

RS-232 Baud Rate Set baud rate 600, 1200, 4800, 9600, 19200, 28800

Key Lock Lock out front panel programming OFF/ON

Line Frequency Set line input frequency 50Hz/60Hz

Charge Time Set time for unit to charge DUT 0 – 999seconds

Range Dwell Set time for unit to stabilize at test level 0.2 – 999seconds

Average Time Set measurement average 1 – 8

EXT VM Display Display output voltage OFF/ON

Page 28 of 76 Interface

Page 29

2.3.3.1 Test Parameter

The 1855 Capacitor Leakage Current/IR Meter can function as a Leakage Current tester or as an

Insulation Resistance meter. The instrument default setting is L.C. To change the function of the

1855 Capacitor Leakage Current/IR Meter press [SYSTEM SETUP] then [SYSTEM CONFIG]

The box next to TEST PARAMETER is highlighted. Press [F1] = I.R. to select an Insulation

Resistance test or press [F2] = L.C. to select the Leakage Current test.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

:

LOW

:

FAIL

:

PULSE

:

0000 mS

:

FALLING

CLEAR

I.R.

L.C.

F1

Set Test Parameter to IR

F2

Set Test Parameter to LC

F3

F4

2.3.3.2 Beeper

The volume of the beeper or audible alarm can be set to OFF, LOW or HIGH. The instrument

default setting is LOW. To change the beeper loudness press [SYSTEM SETUP], [SYSTEM

CONFIG] and the down arrow [⇓] until the box next to BEEPER is highlighted, then press [F1]

= OFF, [F2] = LOW or [F3] = HIGH.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

LOW

:

FAIL

:

PULSE

:

0000 mS

:

FALLING

:

CLEAR

OFF

LOW

HIGH

F1

Turn Beeper OFF

F2

Set Beeper to Low

F3

Set Beeper to High

F4

2.3.3.3 Sound Mode

The audible alarm can be set to sound on PASS or to sound on FAIL under high or low limit

judgment in the measure display. The instrument default setting is FAIL. To change the sound

mode press [SYSTEM SETUP], [SYSTEM CONFIG] and the down arrow [⇓] until the box next

to SOUND MODE is highlighted, then press [F1] = PASS for the alarm to sound on a pass result

or [F2] = FAIL for the alarm to sound on a fail result.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

:

LOW

FAIL

:

PULSE

:

0000 mS

:

FALLING

:

CLEAR

PASS

FAIL

F1

Alarm will sound on PASS

F2

Alarm will sound on FAIL

F3

F4

Interface Page 29 of 76

Page 30

2.3.3.4 Alarm Mode

The type of audible alarm can be set to PULSE or CONTINUOUS during judgment in the

measure display. The instrument default setting is PULSE. To change the alarm mode press

[SYSTEM SETUP], [SYSTEM CONFIG] and the down arrow [⇓] until the box next to ALARM

MODE is highlighted, then press [F1] = PULSE for the alarm to sound in a pulse tone or [F2] =

CONTINUOUS for the alarm to sound continuously.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

:

LOW

:

FAIL

:

PULSE

:

0000 mS

:

FALLING

CLEAR

PULSE

CONTINUOUS

F1

Alarm will Pulse*

F2

Alarm will Continuously sound*

*(Until Discharge is pressed)

2.3.3.5 Trigger Delay

The trigger delay is the amount of time between the activation of a trigger (via IEEE, Handler or

front panel) and the 1855 making the measurement. The delay time can be programmed from

0000 to 9995 seconds. The instrument default value is 0000 seconds. To change the TRIGGER

DELAY press [SYSTEM SETUP], [SYSTEM CONFIG] and the down arrow [⇓] until the box

next to TRIGGER DELAY is highlighted, then press [F1] = DIGIT UP to increase the delay

time, [F2] = DIGIT DOWN to decrease the delay time or [F3] = DIGIT to move over a decimal

place.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

:

LOW

:

FAIL

:

PULSE

0000 mS

:

FALLING

:

CLEAR

DIGIT UP

DIGIT DOWN

DIGIT

F1

0 - 9995 mS

F2

9995 - 0 mS

F3

Move cursor to next digit

F4

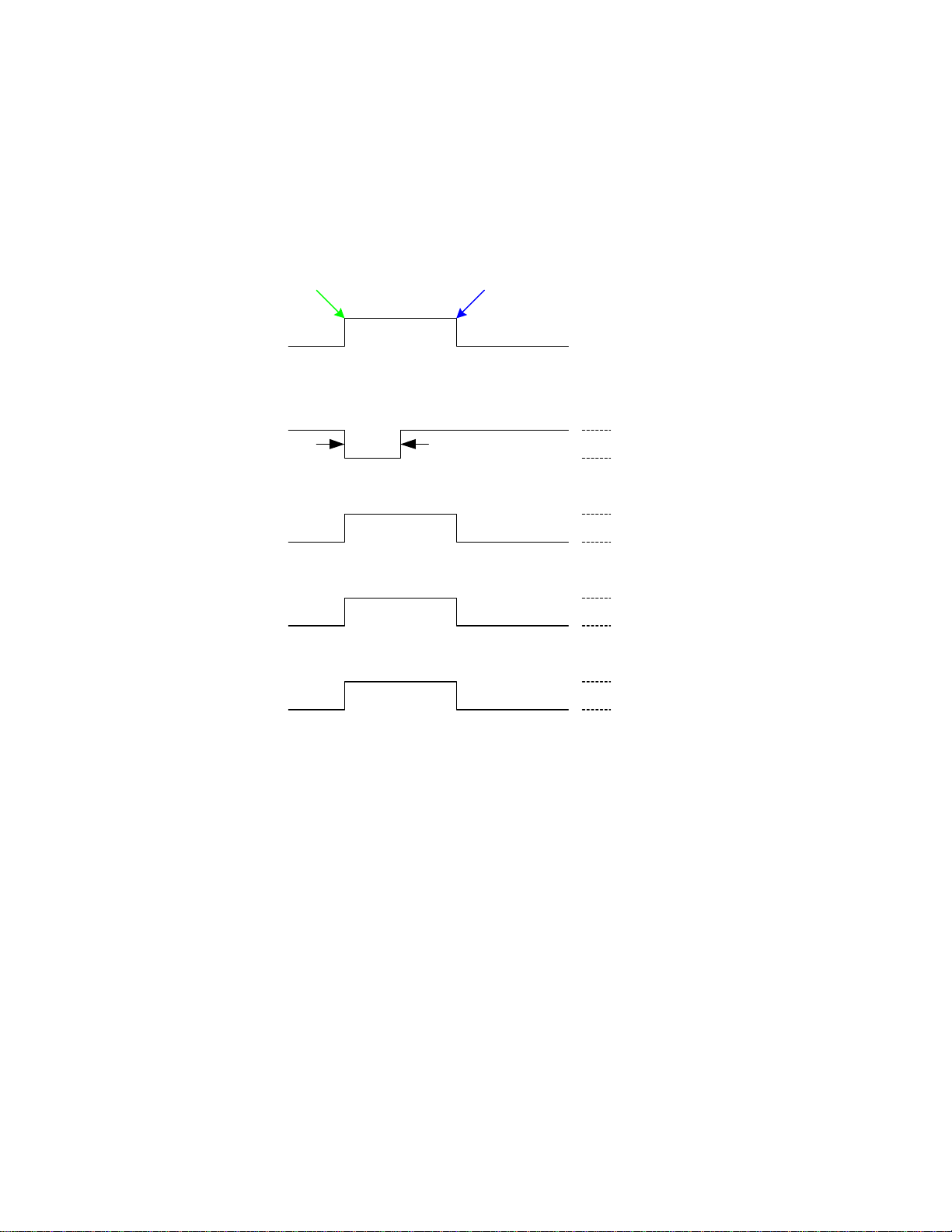

2.3.3.6 Trigger Edge

Select on which edge the measurement is triggered: FALLING or RISING. The instrument

default setting is FALLING. To change the TRIGGER EDGE press [SYSTEM SETUP],

[SYSTEM CONFIG] and the down arrow [⇓] until the box next to TRIGGER EDGE is

highlighted, then press [F1] = FALLING or [F2] = RISING.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

:

LOW

:

FAIL

:

PULSE

:

0000 mS

FALLING

:

CLEAR

FALLING

RISING

F1

Initiate Trigger on Falling Edge

F2

Initiate Trigger on Rising Edge

F3

F4

Page 30 of 76 Interface

Page 31

2.3.3.7 Handler Mode

The handler interface mode can be set to CLEAR or HOLD. The instrument default setting is

CLEAR. When set to CLEAR, the handler interface will clear the last test result prior to each

subsequent measurement. When set to HOLD, the handler interface will hold the last test result

until the next measurement is made and displayed. To change the handler mode press

[SYSTEM SETUP], [SYSTEM CONFIG] and the down arrow [⇓] until the box next to

HANDLER MODE is highlighted, then press [F1] = CLEAR or [F2] = HOLD.

< SYSTEM CONFIG >

TEST PARAMETER :

BEEPER

SOUND MODE

ALARM MODE

TRIG DELAY

TRIG EDGE

HANDLER MODE :

L.C.

:

LOW

:

FAIL

:

PULSE

:

0000 mS

:

FALLING

CLEAR

CLEAR

HOLD

F1

Clear Test Results

F2

Hold Test Results

F3

F4

2.3.3.8 Contrast

The display contrast can be set from 00 to 15. The instrument default setting is 07. The darkest

contrast is 00 the brightest is 15. To change the display contrast press [SYSTEM SETUP],

[SYSTEM CONFIG] and the down arrow [⇓] until the box next to CONTRAST is highlighted,

then press [F1] = DIGIT UP to brighten the contrast or [F2] = DIGIT DOWN to darken the

contrast.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

07

:

17

:

19200

:

OFF

:

60Hz

:

Vm = Vs

0.0 S

DIGIT UP

DIGIT DOWN

F1

Increase brightness: 00 - 16

F2

Decrease brightness: 16 - 00

F3

F4

2.3.3.9 GPIB Address Code

The IEEE-488 interface address can be programmed from 00 to 30. The instrument default

setting is 17. To change the GPIB ADDRESS press [SYSTEM SETUP], [SYSTEM CONFIG]

and the down arrow [⇓] until the box next to GPIB ADDRESS is highlighted, then press [F1] =

DIGIT UP to increase the address, or [F2] = DIGIT DOWN to decrease the address.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

07

17

:

19200

:

OFF

:

60Hz

:

Vm = Vs

:

0.0 S

DIGIT UP

DIGIT DOWN

F1

Increase address: 00 - 30

F2

Decrease address: 30 - 00

F3

F4

Interface Page 31 of 76

Page 32

2.3.3.10 RS-232 Baud Rate

The baud rate of the RS-232 interface can be programmed from 600 to 28800 bps. The

instrument default setting is 9600bps. To change the RS-232 BAUD RATE press [SYSTEM

SETUP], [SYSTEM CONFIG] and the down arrow [⇓] until the box next to RS-232 BAUD

RATE is highlighted, then press [F1] = 600, [F2] = [1200], [F3] = 4800, [F4] = NEXT to go to

the next page and select [F1] = 9600, [F2] = 19200, [F3] = 28800 or [F4] = NEXT to return to

first RS232 baud rate selection page.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

:0717

:

19200

:

OFF

:

60Hz

:

Vm = Vs

0.0 S

600

1200

4800

NEXT PAGE 1/2

F1

F2

F3

F4

Select 600 bps

Select 1200 bps

Select 4800 bps

ND

Go to 2

RS232 page

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

:0717

:

19200

:

OFF

:

60Hz

:

Vm = Vs

0.0 S

9600

19200

28800

NEXT PAGE 2/2

F1

F2

F3

F4

Select 9600 bps

Select 19200 bps

Select 28800 bps

Go back to 1

ST

RS232 page

2.3.3.11 Key Lock

To lock out the front panel operations with the exception of the [TRIGGER] key, set the key lock

function to ON. Press [SYSTEM SETUP], [SYSTEM CONFIG], [⇓] until OFF is highlighted

next to KEY LOCK, then press [F1] = ON. The backlit LOCK block will appear in the top right

hand corner of the measure display. To turn the key lock function OFF: press [F1], [F4] and then

[SYSTEM SETUP]. Key lock can be set ON or OFF. The instrument default setting is OFF.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

< MEAS DISPLAY: SEQ. TEST >

:0717

:

19200

OFF

:

60Hz

:

Vm = Vs

:

0.0 S

ON

OFF

TEST V.

LOCK

:

1.0V

F1

ON= Front panel locked out

F2

OFF = Front panel operational

F3

F4

Lc :

Vm = 0.0V

3.65 mA

DISCHARGECHARGE TEST

C.C.

RANGE

NEXT PAGE 1/2

:

:

0.5mA

A

2uA

NOTE: Key Lock is disabled when the 1855 instrument is shut down.

Page 32 of 76 Interface

Page 33

2.3.3.12 Line Frequency

In accordance with the AC power source, the frequency of the line voltage can be set to 50Hz or

60Hz. The instrument default setting is 60Hz. To change the line frequency press [SYSTEM

SETUP], [SYSTEM CONFIG] and the down arrow [⇓] until the box next to LINE

FREQUENCY is highlighted, then press [F1] = 50Hz or [F2] = 60Hz.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

:0717

:

19200

:

OFF

:

60Hz

:

Vm = Vs

0.0 S

60Hz

50Hz

F1

Line Frequency = 60Hz

F2

Line Frequency = 50Hz

F3

F4

2.3.3.13 Charge Time

Charge Time is defined as when the 1855 instrument will start charging the device under test.

Select Vm = Vs to have the 1855 instrument start charging when monitored voltage reaches the

set (programmed) voltage. Select Vm = 0V to have the instrument start charging the device

when the [TRIGGER] button is pressed. The instrument default value is Vm = Vs. To change

the CHARGE TIME press [SYSTEM SETUP], [SYSTEM CONFIG] and the down arrow [⇓]

until the box next to CHARGE TIME is highlighted, then press [F1] = Vm=Vs or [F2] =

Vm=0V.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

:0717

:

19200

:

OFF

:

60Hz

Vm = Vs

:

0.0 S

Vm = Vs

Vm = 0V

Start Charge Time when

F1

V

monitored

Start Charge Time when

F2

[TRIGGER] is pressed

F3

F4

= V

set

2.3.3.14 Range Dwell

The range dwell is the amount of time the instrument holds at the programmed test voltage

before the 1855 makes the measurement. The range dwell is in addition to, and occurs after, the

charge time. The range dwell can be programmed from 0 to 9.9 seconds. The instrument default

value is 0 seconds. To change the RANGE DWELL press [SYSTEM SETUP], [SYSTEM

CONFIG] and the down arrow [⇓] until the box next to RANGE DWELL is highlighted, then

press [F1] = DIGIT UP to increase the delay time, [F2] = DIGIT DOWN to decrease the delay

time or [F3] = DIGIT to move over a decimal place.

< SYSTEM CONFIG >

CONTRAST :

GPIB ADDRESS

RS232 BAUD RATE

KEY LOCK

LINE FREQUENCY

CHARGE TIME

RANGE DWELL :

:0717

:

19200

:

OFF

:

60Hz

:

Vm = Vs

0.0 S

DIGIT UP

DIGIT DOWN

F1

Increase dwell time 0.0 - 9.9S

F2

Decrease dwell time 9.9 - 0.0S

F3

F4

Note: Refer to paragraph 2.5.5 to program Dwell Time in a Sequence Test.

Interface Page 33 of 76

Page 34

2.3.3.15 Average

The 1855 instrument can make many measurements then display the average based on what

average number was selected. The range is 1 – 8 and the instrument default setting is 1. To

change the number to average press [SYSTEM SETUP], [SYSTEM CONFIG] and the down

arrow [⇓] until the box next to AVERAGE is highlighted, then press [F1] = DIGIT UP to

increase then number of measurements to take before displaying the average or [F2] = DIGIT

DOWN to decrease the number.

< SYSTEM CONFIG >

AVERAGE :

EXT Vm DISPLAY :

1

OFF

DIGIT UP

DIGIT DOWN

F1

Increase # to Average: 1 - 8

F2

Decrease # to Average: 8 - 1

F3

F4

2.3.3.16 EXT VM Display

The voltage across the DUT can be displayed along with the measured value when EXT Vm

DISPLAY is set to ON. EXT Vm DISPLAY can be selected OFF/ON. The instrument default

setting is OFF. To change the EXT Vm Display press [SYSTEM SETUP], [SYSTEM CONFIG]

and the down arrow [⇓] until the box next to EXT Vm DISPLAY is highlighted, then press [F1]

= ON to display the voltage across the DUT, or [F2] = OFF.

< SYSTEM CONFIG >

AVERAGE :

EXT Vm DISPLAY :

< MEAS DISPLAY: SEQ. TEST >

1

OFF

Lc :

Vm = 0.996V

DISCHARGECHARGE TEST

3.65 mA

ON

OFF

TEST V.

C.C.

RANGE

NEXT PAGE 1/2

:

:

:

0.5mA

A

1.0V

2uA

F1

Display Voltage across DUT

F2

Do not display Vm

F3

F4

When selected ON, the measured voltage (Vm) will be displayed in the bottom left-hand corner

of the display.

Note:

For Faster test speed during production testing, EXT Vm should be set to OFF.

Page 34 of 76 Interface

Page 35

2.4 MAIN INDEX

Within the 1855 instrument’s MAIN INDEX are the Sequence Test, Step Test, Null, Withstand

Voltage Test and Compare functions. To access these functions, press [MAIN INDEX] and the

display should look as shown in Figure 2-3.

< MAIN INDEX >

SEQ. TEST

STEP TEST

NULL

NEXT PAGE 1/2

< MAIN INDEX >

W.V. TEST

COMPARE

NEXT PAGE 2/2

Figure 2-3: MAIN INDEX

2.4.1 Sequence Test

The Sequence Test automatically cycles through the test when [TRIGGER] is pressed. To

access the Sequence Test, press [MAIN INDEX] and [F1] = SEQ. TEST. The MEAS DISPLAY

menu will appear. Program the Test Voltage, Constant Current, Range, Charge Time, Dwell

Time and Speed. Refer to paragraphs 2.5.1 through 2.5.6 for programming details.

< MEAS DISPLAY: SEQ. TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

TEST V.

A

C.C.

RANGE

NEXT PAGE 1/2

:

:

:

0.5mA

A

1.0V

2uA

< MEAS DISPLAY: SEQ. TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

CHG T.

A

DWELL T

SPEED

NEXT PAGE 2/2

:

:

0.2 S

:

MEDIUM

0 S

Figure 2-4: Sequence Test Parameters

Interface Page 35 of 76

Page 36

2.4.2 Step Test

The Step Test manually cycles through the test when [TRIGGER] is pressed. To access the Step

Test, press [MAIN INDEX] and [F2] = STEP TEST. The MEAS DISPLAY menu will appear.

Program the Test Voltage, Constant Current, Range, Trigger and Speed. Refer to paragraphs

2.5.1 through 2.5.7 for programming details.

< MEAS DISPLAY: STEP TEST >

TEST V.

1.0V

:

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

< MEAS DISPLAY: STEP TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

A

A

C.C.

RANGE

NEXT PAGE 1/2

TRIGGER

SPEED::

NEXT PAGE 2/2

:

0.5mA

A

:

2uA

INT

MEDIUM

Figure 2-5: Step Test Parameters

2.4.3 Null

During the 1855 instrument Null process a correction is made (subtracted out) as the result of

lead leakage current and stored in instrument memory to be applied to ongoing measurements.

For maximum measurement accuracy it is recommended that the NULL function be performed

on the 1855 instrument after power up, any time the test parameters are changed and any time the

test leads or fixture is changed.

Using the output voltage set in the SEQ or STEP test, the Null function measures the leakage

current of each range (20mA – 2mA – 200uA – 20uA – 2uA) under open circuit conditions.

After setting test parameters in the SEQ or STEP tests, connect the test leads to the 1855 output

connectors. Do not connect the device under test. Press [MAIN INDEX] and [F3] = NULL

TEST. There are no settings for NULL TEST. Press [TRIGGER] and the 1855 instrument will

complete the null function.

Page 36 of 76 Interface

Page 37

Connection of test leads for Null function:

QuadTech

<MEAS. DISPLAY: NULL>

LC : mA

Press TRIGGER to start ...

CHARGE TEST DISCHARGE

01

l

1855 Capacitor Leakage Current /IR Meter

HV

+

-

MEAS

MAIN

F1

F2

F3

F4

F1

F2

F3

F4

DISPLAY

CHARGE/TEST DISCHARGE

INDEX

TRIGGER

SYSTEM

SETUP

(-)(+)INPUT

OPEN No DUT Connected for NUL L function

Figure 2-6: Null Connection

Interface Page 37 of 76

Page 38

2.4.4 Withstand Voltage Test

To access the Withstand Voltage Test, press [MAIN INDEX] and [F4] = NEXT PAGE 1/2 and

then press [F1] = W.V. TEST. The MEAS DISPLAY menu will appear. Program the Test

Voltage, Constant Current, Measurement Time and maximum Charge Time. Refer to paragraphs

2.5.8 through 2.5.10 for programming details.

< MEAS DISPLAY: W.V. TEST >

Vf

:

50.0V

Tr :

Vt : V

Vm = 0.0V

Vt

Vf

0

0.15

58.00

(V)

S

58.0V/30.15S

DISCHARGECHARGE TEST

Withs tand Voltage Time

C.C.

Tend

CHG Tend

TendTr0

:

:

(t)

2.0mA

30S

5S:

Figure 2-7: Withstand Voltage Parameters

Withstand Voltage is the voltage at which the product’s insulation begins to break down. There

are however many definitions for Withstand Voltage. The 1855 instrument and this manual use

the WV terminology from the EIAJ RC-2364A standard, “Test Methods of Electrode Foils for

Aluminum Electrolytic Capacitors”.

Vf: The standard dielectric withstand voltage

CC: The constant charge current for the WV test

Tend: The measurement time for the WV test. Tend = Tr+ the programmed test time.

CHG. Tend: The maximum charge time for the WV test.

Tr: The time between the start of the current application and the voltage reaching

90% of rated withstand voltage (Vf).

Vt: The measured voltage at the end of the WV test.

Figure 2-7 illustrates a Withstand Voltage test. The following parameters were set: Vf=50V,

CC=2mA, Tend=30seconds and CHG Tend=5seconds. After [TRIGGER] is pressed, the results

shown in Figure 2-7 are Rise Time (Tr) = 0.15seconds and Measured Voltage (Vt) = 58.00V. In

the bottom left-hand corner above the test status boxes (CHARGE – TEST – DISCHARGE) are

two results: Vm=0.0V and 58.0V/30.15S. The Vm=0.0V box is the monitor of the output

voltage during the test. The 58.0V/30.15S box is the last measured voltage and time when the

test ended.

Page 38 of 76 Interface

Page 39

2.4.5 Compare

The Compare function provides the capability to set an upper and/or lower limit for a leakage

current or insulation resistance test and to display Pass/Fail with the measured result. To access

the Compare function, press [MAIN INDEX] and [F4] = NEXT PAGE 1/2 then press [F2] =

COMPARE. Select the Parameter (L.C. or IR) and program the Upper and Lower limits.

The Upper Limit is the high limit or upper value for a test to be considered a pass. If the

measured value is higher than the upper limit the test is considered a fail. The Lower Limit is

the lower value for a test to be considered a pass. If the measured value is lower than the low

limit the test is considered a fail.

In an LC test, the range for Upper Limit is 0.000uA – 999.999mA and the Lower Limit range is

0.000uA to the Upper Limit. In an IR test, the range of the Upper Limit is 0.01kΩ – 99.99GΩ

and the Lower Limit is 0.01kΩ – the Upper Limit.

< MAIN INDEX >

SEQ. TEST

STEP TEST

NULL

NEXT PAGE 1/2

< MAIN INDEX >

< MEAS INDEX: COMPARE >

:

L.C.

UPPER (+)

LOWER (-)::

< MEAS INDEX: COMPARE >

UPPER (+)

LOWER (-)::

000.000mA

- - - - - -

:L.C.

0.000mA

02

- - - - - -

W.V. TEST

COMPARE

NEXT PAGE 2/2

COMPARE : ONPARAMETER

EXIT

DIGIT UP

DIGIT DOWNPARAMETER

DIGIT

LIMIT OFF

Select

F2

Compare

Function

Turn

Compare

F2

ON

F1

Increase value of underscored digit

F2

Decrease value of underscored digit

F3

Move underscore cursor to next digit

F4

Turn Upper or Lower Limit Off

Figure 2-8: Compare Function

Interface Page 39 of 76

Page 40

To set up and display PASS/FAIL on the MEAS DISPLAY screen, use the COMPARE function.

Example: Parameter = Leakage Current. Upper Limit = 15mA, Lower Limit = 0.

< MAIN INDEX >

SEQ. TEST

STEP TEST

NULL

NEXT PAGE 1/2

Select:

Upper (+)

Select:

Lower (-)

PRESS

MEAS

DISPLAY

< MAIN INDEX >

< MEAS INDEX: COMPARE >

L.C.

:

UPPER (+)

LOWER (-)::

000.000mA

- - - - - -

< MEAS INDEX: COMPARE >

:L.C.

UPPER (+)

LOWER (-)::

0.000mA

02

- - - - - -

< MEAS INDEX: COMPARE >

:L.C.

UPPER (+)

LOWER (-)::

015.000mA

- - - - - -

< MEAS DISPLAY: STEP TEST >

W.V. TEST

COMPARE

NEXT PAGE 2/2

COMPARE : ONPARAMETER

EXIT

DIGIT UP

DIGIT DOWNPARAMETER

DIGIT

LIMIT OFF

DIGIT UP

DIGIT DOWNPARAMETER

DIGIT

LIMIT OFF

TEST V.

:

20V

Select

F2

Compare

Function

Turn

Compare

F2

ON

F1

Increase value of underscored digit

F2

Decrease value of underscored digit

F3

Move underscore cursor to next digit

F4

F1

F2

F3

F4

Turn Lower Limit Off

:

A

:

:

:

:

A

0.5mA

20mA

20V

0.5mA

2uA

PRESS

TRIGGER

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

< MEAS DISPLAY: STEP TEST >

Lc :

0.750

PASS

Vm = 20.0 V

DISCHARGECHARGE TEST

mA

A

C.C.

RANGE

NEXT PAGE 1/2

TEST V.

C.C.

RANGE

NEXT PAGE 1/2

Figure 2-9: Compare Example

Page 40 of 76 Interface

Page 41

2.5 MEAS DISPLAY

The 1855 instrument’s stand-by display is the MEAS DISPLAY. After power has been applied

to the instrument and it cycles quickly through the information screen, the instrument reverts to

the MAIN INDEX. Once [SEQ. TEST] or [STEP TEST] is selected the instrument enters the

MEAS DISPLAY. To view the instrument information screen as illustrated in Figure 2.10,

press [SYSTEM SETUP] then [⇐].

QUADTECH 1855

LEAKAGE CURRENT/IR METER

Copyright (c) AUGUST 2003

VERSION 1.02 BETA .09.02 CPLD:1855

TEL 1-800-253-1230 FAX 1-978-461-4295

Figure 2.10: Instrument Information Screen

< MEAS DISPLAY: SEQ. TEST >

TEST V.

1.0V

:

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

< MEAS DISPLAY: SEQ. TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

A

A

C.C.

RANGE

NEXT PAGE 1/2

CHG T.

DWELL T

SPEED

NEXT PAGE 2/2

0.5mA

:

2uA

A

:

:

0.2 S

:

MEDIUM

:

0 S

Figure 2.11: MEAS DISPLAY- SEQUENCE TEST

< MEAS DISPLAY: STEP TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

< MEAS DISPLAY: STEP TEST >

Lc :

TEST V.

A

A

C.C.

RANGE

NEXT PAGE 1/2

TRIGGER

SPEED::

1.0V

:

0.5mA

:

2uA

:

A

INT

MEDIUM

Vm = 0.0V

DISCHARGECHARGE TEST

NEXT PAGE 2/2

Figure 2-12: MEAS DISPLAY – STEP TEST

Interface Page 41 of 76

Page 42

Figure 2.11 illustrates the two pages of parameters that can be programmed within the MEAS

DISPLAY for a SEQUENCE TEST. Figure 2.12 illustrates the two pages of parameters that can

be programmed within the MEAS DISPLAY for a STEP TEST. The two tests have the similar

programmable parameters with the exception of Charge Time, Range Dwell and Trigger. All

programmable parameters are explained in Paragraphs 2.5.1 through 2.5.8.

2.5.1 Test Voltage

The test voltage can be programmed from 1.00V to 650V. In MEAS DISPLAY press [F1] =

TEST V so that the 1.00 V box is highlighted. Use the up arrow or down arrow keys to

in/decrease the voltage in multi-V increments. The left and right arrows will increase/decrease

the voltage in 1V increments. The instrument default setting is 1.00V.

UP arrow [⇑] key: 6.3 → 10.0 → 16.0 → 25.0 → 35.0 → 50.0 → 63.0 → 100.0 → 160.0 →

200.0 → 250.0 → 350.0 → 400.0 → 450.0 → 500.0 → 550.0 → 600.0 → 630.0.

DOWN arrow [⇓] key: 630.0 → 600.0 → 550.0 → 500.0 → 450.0 → 400.0 → 350.0 → 250.0

→ 200.0 → 160.0 → 100.0 → 63.0 → 50.0 → 35.0 → 25.0 → 16.0 → 10.0 → 6.3.

RIGHT arrow [⇒] key: increase voltage in 1V increments.

LEFT arrow [⇐] key: decrease voltage in 1V increments.

F1

< MEAS DISPLAY: SEQ. TEST >

TEST V.

1.0

:

V

Select Test V

Lc :

Vm = 0.0V

A

DISCHARGECHARGE TEST

C.C.

RANGE

NEXT PAGE 1/2

:

:

0.5mA

2uA

1.0, 6.3 - 630V

630V - 6.3V

630V - 650V

6.3 - 1.0V

2.5.2 Constant Charge Current

The test current can be programmed from 0.5mA to 500mA. In MEAS DISPLAY press [F2] =

C.C so that the 0.5 mA box is highlighted. Use the up arrow [⇑] key to increase the current or

use the down arrow [⇓] key to decrease the current in 5/50mA increments. The left and right

arrows will increase/decrease the current in 1mA increments. The instrument default setting is

0.5mA.

< MEAS DISPLAY: SEQ. TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

A

TEST V.

C.C.

RANGE

NEXT PAGE 1/2

:

:

:

1.0 V

0.5 mA

2uA

F2

0.5 - 450.5mA

450.5 - 0.5mA

450.5 - 500.0mA

500.0mA - 450.5

NOTE:

For the WV test, the range of C.C. is from 0.5mA to 150mA.

Page 42 of 76 Interface

Page 43

UP arrow [⇑] key: increase current by 5mA from 0.5mA to 100mA then by 50mA from 100mA

to 500mA

DOWN arrow [⇓] key: decrease current by 50mA from 500mA to 100mA then by 5mA from

100mA to 0.5mA

RIGHT arrow [⇒] key: increase current in 1mA increments.

LEFT arrow [⇐] key: decrease current in 1mA increments.

2.5.3 Range

The 1855 instrument’s measurement range can be selected as AUTO or HOLD. The instrument

current measurement ranges are 20mA, 2mA, 200uA, 20uA and 2uA. In MEAS DISPLAY, press

[F3] = RANGE so that the A box is highlighted*. The instrument default setting is A (Auto

Range).

* Use the up arrow [⇑] key to toggle between A (Auto) and H (Hold).

V

< MEAS DISPLAY: SEQ. TEST >

TEST V.

1.0

:

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

< MEAS DISPLAY: SEQ. TEST >

Lc :

Vm = 0.0V

DISCHARGECHARGE TEST

A

A

C.C.

RANGE

NEXT PAGE 1/2

TEST V.

C.C.

RANGE

NEXT PAGE 1/2

:

:

:

:

:

0.5mA

A

1.0

0.5mA

2uA

2uAA

Toggle between:

F3

A = Auto

H = Hold

V

2uA - 20uA - 200uA - 2mA - 20mA

20mA - 2mA - 200uA - 20uA - 2uA

Press [F3] = RANGE a second time to select the value of the range.

UP arrow [⇑] key: increase range: 2uA → 20uA → 200uA → 2mA → 20mA

DOWN arrow [⇓] key: decrease range: 20mA → 2mA → 200uA → 20uA → 2uA

Interface Page 43 of 76

Page 44

2.5.4 Charge Time

The charge time can be programmed from 0 to 999seconds. In MEAS DISPLAY press [F4] =

NEXT PAGE 1/2. Press [F1] = CHG T so that the 0 s box is highlighted. Use the up or down

arrow keys to in/decrease the charge time by base-10 second increments. The left and right

arrows will increase/decrease the time in 1second increments. The instrument default setting is

0s.

< MEAS DISPLAY: SEQ. TEST >

CHG T.

0

:

F1

s

Lc :

Vm = 0.0V

A

DISCHARGECHARGE TEST

DWELL T

SPEED

NEXT PAGE 2/2

:

0.2 S

:

MEDIUM

0 - 900s

by base-10

900 - 999s

by base-1

UP arrow [⇑] key: 0 → 10 → 20 → 30 → 40 → 50 → 60 → 70 → 80 → 90 → 100 → 200 →

300 → 400 → 500 → 600 → 700 → 800 → 900.

RIGHT arrow [⇒] key: increase charge time in 1 second increments. (example: 900 to 999)

DOWN arrow [⇓] key: 999 → 899 → 799 → 699 → 599 → 499 → 399 → 299 → 199 → 99 →

89 → 79 → 69 → 59 → 49 → 39 → 29 → 19 → 9.

LEFT arrow [⇐] key: decrease charge time in 1 second increments. (example: 9 to 0)

2.5.5 Dwell Time

The dwell time can be programmed from 0.2 to 999seconds. In MEAS DISPLAY press [F4] =

NEXT PAGE 1/2. Press [F2] = DWELL T so that the 0.2 s box is highlighted. Use the up or

down arrow keys to in/decrease the dwell time by base-10 second increments. The left and right