Page 1

1689/1689M Precision

RLC Digibridge(R)

Instruction Manual

Foml1689-0120-06/D2

(C)QuadTech, Inc., 1992

5 Clock Tower Place, 210 East

Maynard, Massachusetts, U.S.A. 01754

March, 2000

Telephone 978-461-2100

Sales 800-253-1230

Facsimile 978-461-4295

Website www.quadtech.com

The material in this manual is for informational purposes only and is subject to change, without notice. QuadTech

assumes no responsibility for any error or for consequential damages that may result from the misinterpretation of any

procedures in this publication.

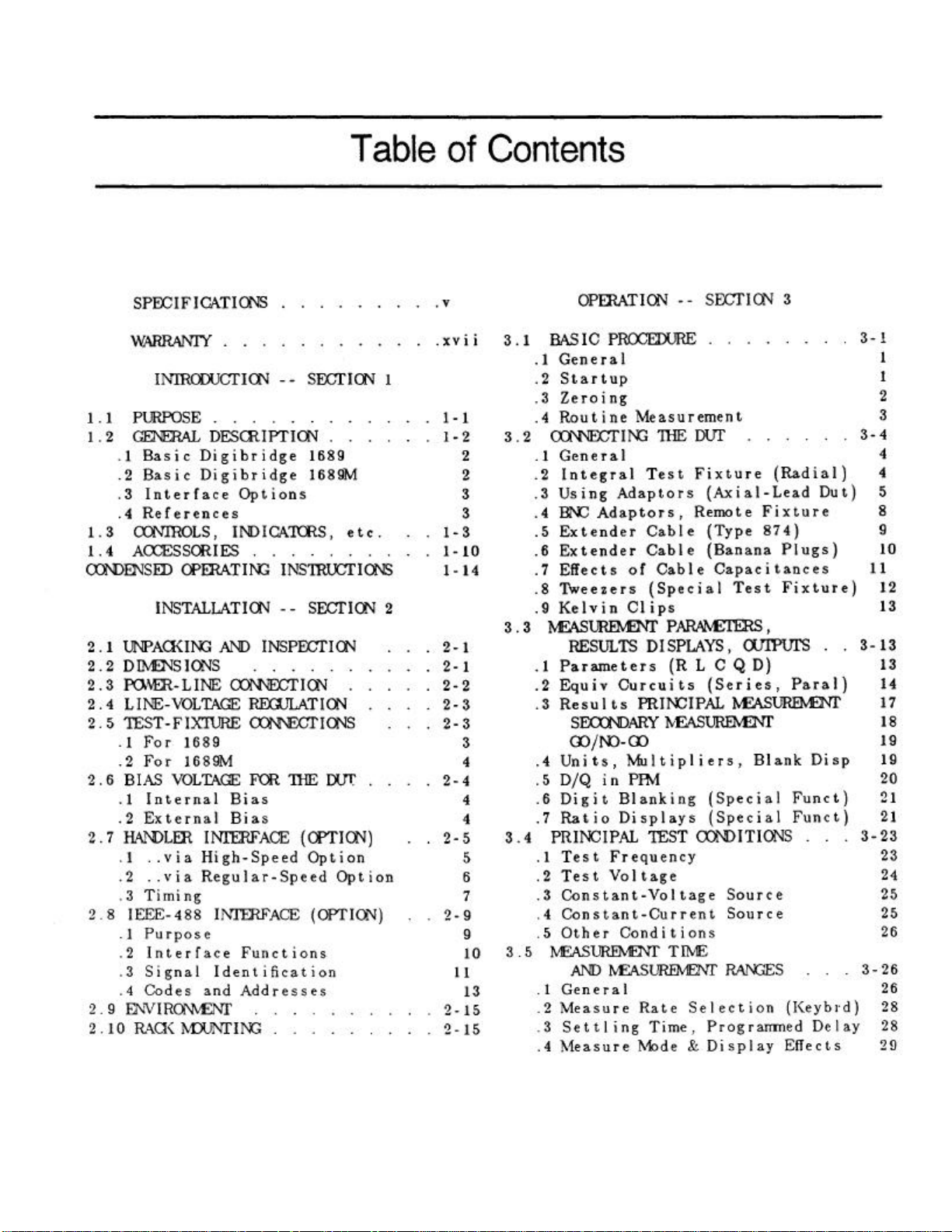

Contents

Specifications

Warranty

Introduction -Section 1

Installation - Section 2

Operation -Section 3

Theory -Section 4

Service and Maintenance -Section 5

Parts Lists and Diagrams -Section 6

Page 2

Page 3

Page 4

Page 5

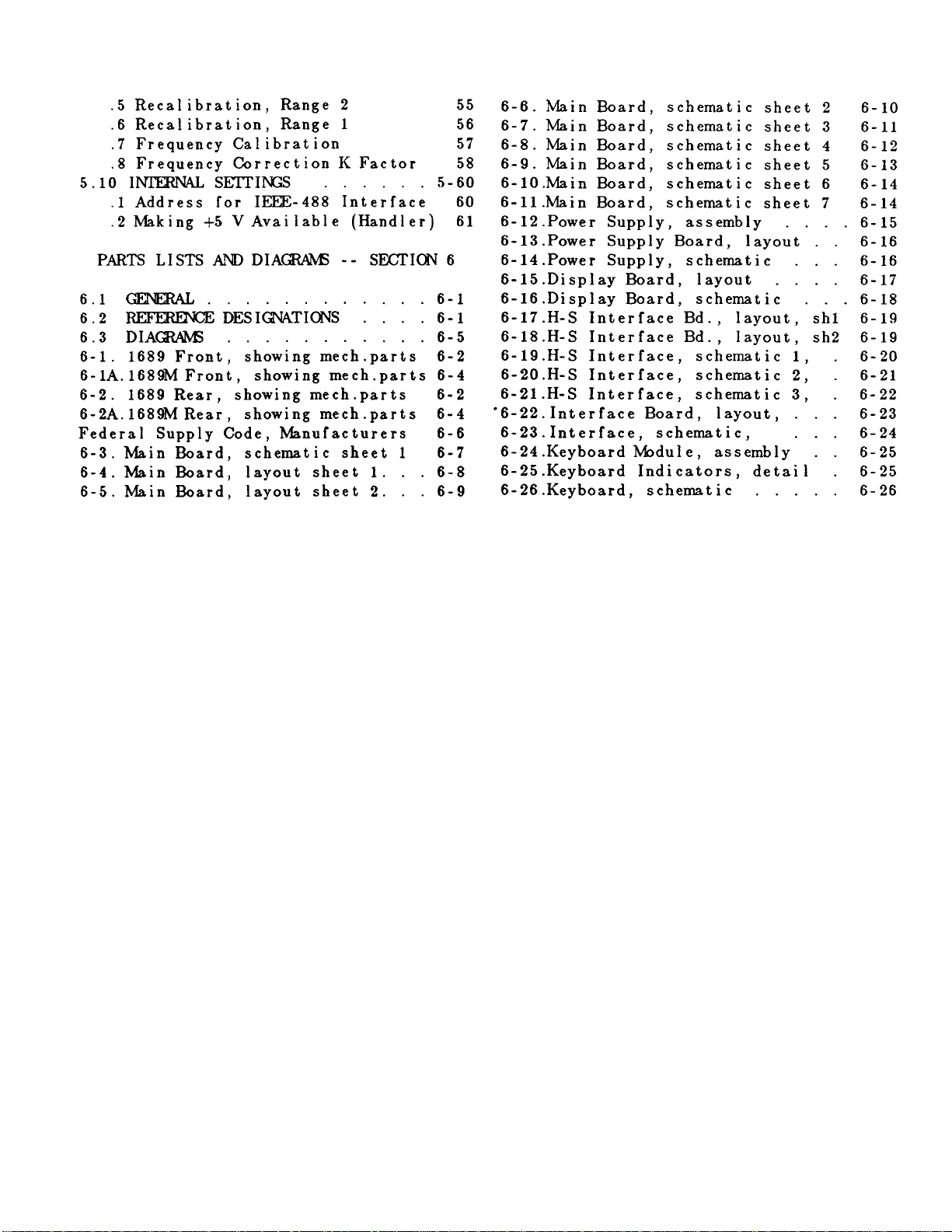

Instruction Manual Changes (continued)

Page 5-41 -Table 5-7, Capacitance Accuracy Checks

1000 nF 600 ppm

.QDR Display Max column corrected as follows:

Nominal

Value QDR Max

10 pF 6100 ppm

100 pF 2500 ppm

1500 pF 700 ppm

1500 pF 1000 ppm

1500 pF 1700 ppm

6400 pF 500 ppm

10 nF 500 ppm

25 nF 500 ppm

25 nF 800 ppm

25 nF 1500 ppm

100 nF 500 ppm

200 nF 600 ppm

400 nF 600 ppm

400 nF 900 ppm

400 nF 1600 ppm

Page 6-2 -Figure 6-2, 1689 Rear View

Rear view should show new power supply assembly (PN 700011) without line

voltage switch.

Page 6-3 -Mechanical Parts List for 1689, Rear

Items 4 through 7 (power connector, fuse extractor post and line voltage switch and

cover) deleted on new power supply assembly.

Page 6-4 -Figure 6-2(A), 1689M Rear View

Rear view should show new power supply assembly (pN 700011) without line

voltage switch.

Page 6-5 -Mechanical Parts List for 1689M, Rear

Items 3 through 6 (power connector, fuse extractor post, line voltage switch and

cover) deleted on new power supply assembly.

Page 6-15 & Page 6-16 -Parts Lists and Diagrams

Power Supply Assembly shown, PN 1689-2005, has been replaced by Power

Supply Assembly, PN 700011. The 700011 Assembly must be repaired by module

exchange.

Page 6-19, 6-20, 6-21, & 6-22 -Parts Lists and Diagrams

High-speed interface board shown, PN 1689-4720, has been replaced by PN 1689

4620. See instructions supplied with the 1689-9630.

Page 6

ii

Page 7

iv

Page 8

Page 9

Displays

GO/NO-GO lights are also provided and these are active with all modes of measurement display as long as test limits have

vii

Measurement results may be displayed in four ways as selected by the keyboard: 1) VALUE, 2) % difference, 3)

RLC difference, and 4) BIN NO.

1) The VALUE display can be one of four pairs of measured quantities Land Q, C and D, C and R, or Rand Q. The primary

display (L, C, or R) has five digi~ of resolution and the secondary display D, Q, or R with C) has four digits of resolution.

2) The % difference display indicates the percent deviation of the measured L, C, or R value from a stored NOMINAL

VALUE. The sign of this deviation is indicated.

3) The RLC difference is similar to the % difference except that the deviation is displayed in appropriate units (ohms, henries,

etc.)

4) The BIN NO. display is the number of the bin (0 through 14) into which the component should be sorted. The testing limits

for these bins are set up by the user in the ENTER mode. These test limi~ may be symmetrical or non-symmetrical about the

NOMINAL VALUE. One bin is used for D or Q rejects and one is used for RLC rejects (outside all limits). The sum of the

number of componen~ sorted into each bin may be displayed (99999 max).

Also displayed during entry or upon interrogation are: test frequency, test voltage, number of measurcments

averaged, delay time, nominal value, bin limi~ and bin sum and codes for SPECIAL FUNCTIONS.

been set.

Ranges

Primary Disp/ay:*

C: .00001 pF to 99999 uF

R:

L:

% difference (C, R, or L): .0001% to 99999%; RLC difference: same as R, L, or C.

.000010 to 99999 kO

.00001 nH to 99999 H

If any of these quantities is negative, the NEG RLC indicator light is lit.

Page 10

Page 11

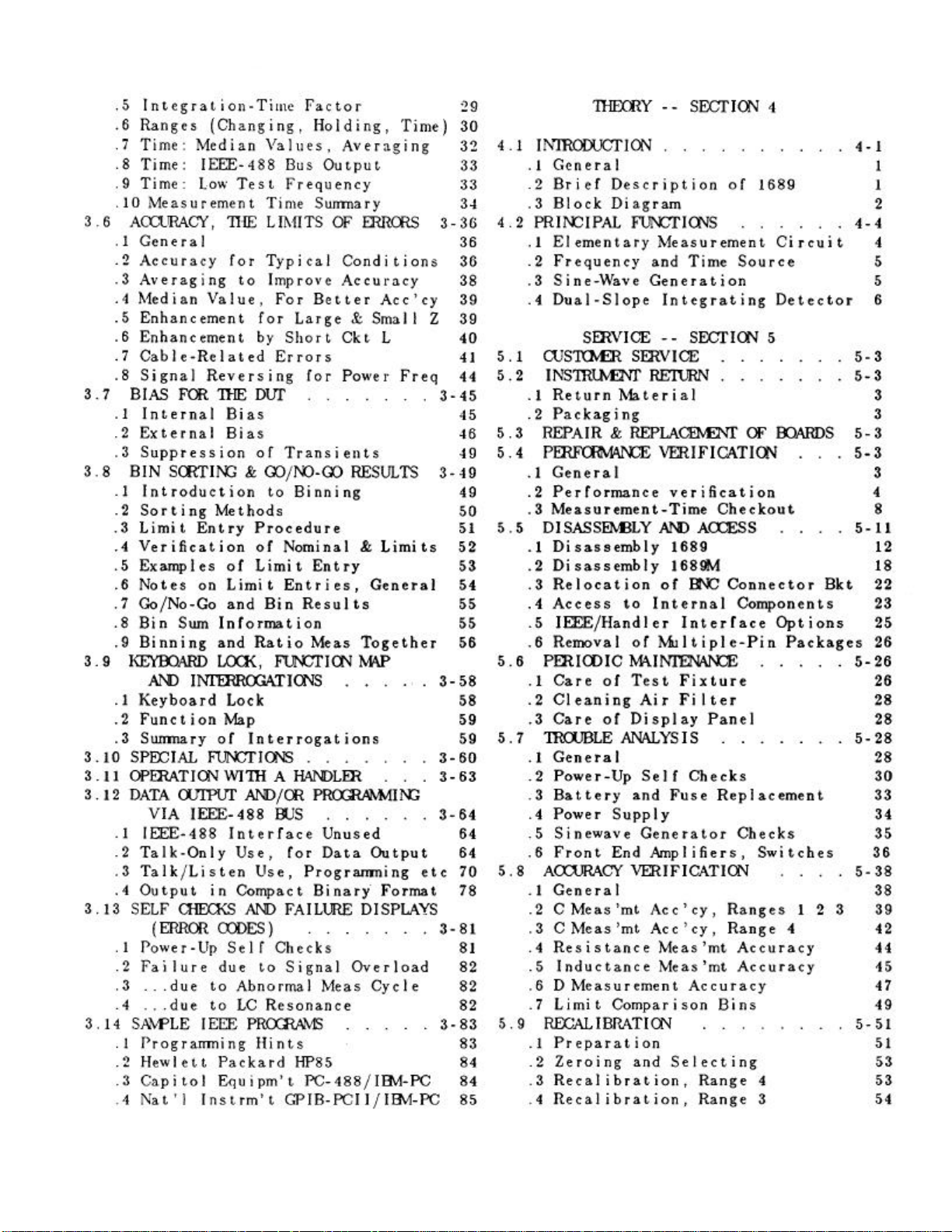

TABLE A

Test connections can be broken (handler indexing can begin) as soon as data acquisition is complete (ACQ

line low on handler interface). See Note 4 in tables.

i

x

GR1689 MEASUREMENT RATE

TEST FREQUENCY

MEASUREMENT

RATE 12 Hz 100 Hz 120Hz 1 kHz 10 kHz 100 kHz

SLOW 875 ms 940 ms 940 ms 970 ms 930 ms 930 ms

MEDIUM 670 ms 130 ms 185 ms 200 ms 190 ms 190 ms

FAST 670 ms 125 ms 110 ms 80 ms 75 ms 70 ms

MAX IMUM 670 ms 110 ms* 100 ms* 40 ms 34 ms 33 ms

Notes:1. If the high-speed option is not used, add 19 ms for MAXIMUM, or 38 ms

for SLOW, NEDIUM or FAST measurement.

2. If the display is value, delta%, or deltaRLC, add 6 to 10 ms.

3. If data is output via the IEEE Bus., add 6 to 12 ms.

4. For ACQ, subtract 22 ms for SLOW, MEDIUM or FAST and 12 ms for MAXIMUM.

TABLE B

GR1689M MEASUREMENT RATE

TEST FREQUENCY

MEASUREMENT

RATE 12 Hz 100 Hz 120 Hz 1 kHz 10 kHz 100 kHz

SLOW 875 ms 920 ms 920 ms 950 ms 920 ms 920 ms

MEDIUM 670 ms 120 ms 170 ms 180 ms 170 ms 170 ms

FAST 670 ms 105 ms 90 ms 65 ms 55 ms 55 ms

MAXIMUM 660 ms 101 ms* 86 ms* 32 ms 22 ms 22 ms

Notes: 1. If the high-speed option is not used, add 12 ms for MAXIMUM,

or 24 ms for SLOW, MEDIUM or FAST measurement.

2. If the display is value, delta% or deltaRLC, add 3 to 5 ms.

3. If data is output via the IEEE Bus, add 3 to 6 ms.

4. For ACQ, subtract 11 ms for SLOW, MEDIUM or FAST and 6 ms for MAXIMUM.

* These times can be shortened by 14 ms with reduced accuracy using the quick acquisition routine.

The measurement times are obtained with use of the high-speed measurement option, continuous

measurement mode, bin number display/handler output, and without IEEE-Bus data output. For other

conditions, refer to the table notes.

If the measurement mode is triggered, programmed delay (settling time), if any, should be added.

Normal power up conditions included a programmed delay of 7/f to 12/f ms depending upon

measurement rate. This delay can be programmed to zero or to any value up to 100 sec.

Page 12

Measurement

Modes

x

Two test modes are available: CONTINUOUS and TRIGGERED.

The CONTINUOUS mode makes successive measurements continuously, updating the display after each

measurement.

TRIGGERED measurements are initiated by the START button, or remotely from the IEEE bus or from the

Handler Interface, and the measurement result is displayed until the next measurement is started.

Average

The AVERAGE of any number of measurements from 1 to 255 may be made as desired in either of the two

MEASURE MODES. In the TRIGGERED mode, the running average is displayed and the final value held until the

START button is again depressed. In the CONTINUOUS mode, only the final value is displayed.

Test Voltage

The RMS test voltage is selectable from 5 mV to 1.275 V in 5 mV steps. The accuracy is: (5% + 2 mV) (1 + .001 f 2) where f

= frequency in kHz.

This voltage may be applied behind a source impedance (which depends on the range) in which case the selected voltage is

the maximum that will be applied and the voltage will be less at the low impedance end of each range. The voltage may be

applied also behind 25 ohms using the CONSTANT VOLTAGE function in which case the applied voltage will be constant

except when low impedances are measured.

Delay

A delay of from 1 to 99999 ms may be added to allow for settling of external switches and to permit a wider selection

of measurement rates.

DC Bias

An internal bias of 2 V may be applied to capacitors under test by means of the INT BIAS key.

An external bias of up to 60 VDC may be applied to capacitors under test using a panel switch. The applied

current should be limited to 200 mA.

The instrument is protected from damage from charged capacitors with a stored energy up to 1 joule at 60 volts or less.

Protection from higher voltages may be provided by external components.

Zeroing

Open: A simple OPEN operation removes the effects of stray capacitance and conductance of the internal test fixture or

any other test fixture or cable.

Short: A similar SHORT zeroing operation removes the effects of series resistance and inductance.

DUT Connections

The 1689 has a built-in test fixture that will accept radial or axial components. The 1689M has BNC

connectors for attachment to a wide variety of measurement accessories. Four terminal (Kelvin) connections are made to

the device under test. The instrument ground is guard for three-terminal measurements.

Page 13

Keyboard Lock

Xl

A combination of keyboard entries makes the keyboard inactive.

Special Functions

Several special features may bl;: :selected. These include:

Direct range setting

Range extension

Choice of integration time

Blanking of lesser digits

Signal Reversal to reduce hum pickup effects

Selection of the median value of three measurements

A routine that reduces transient delays when bias is applied

Automatic parameter selection

Quick acquisition routine

IEEE-488 Bus/Handler Interface Card (1658-9620)

IEEE-488 Bus (J2 on rear panel with option)

All front panel functions are programmable from the bus. All RLC, DQ, and bin data are available as output

to the bus. Output data format: ASCII or Binary.

The following functions, per IEEE-488, have been implemented:

AHI Acceptor Handshake (Listener)

SHI Source Handshake (Talker).

T5 Talker with normal and talk-only modes (for systems without a controller),

switch selectable on rear panel.

L4 Listener.

SRI Service Request (to request service when measurement is complete and the

instrument is not addressed to talk).

RL2 Remote/Local (no local lockout, no return-to-local switch).

PPO No par all e 1 po 11 .

OC1 Device clear.

DT1 Device Trigger (to start measurement).

CO No controller functions.

Handler Connections (JI rear panel with option)

1. Outputs, Active low: (Open collector drivers rated at 30 V max. Each will sink 16 mA at 0.4 V. External power and pull-up

resistors required).

Bin 0 through bin 9 (10 lines) -Sorting outputs.

ACQ OVER (1 line)-indicates end of data acquisition. Component may be removed (see TEST TIME).

EOT (1 line)-indicates end of test. Bin No. is valid.

2. Input, Active low:

(0 V < VI < 0.4 V, + 2.5 V < Vh < + 5 V)

Start (1 line)-Initiates new measurement.

Page 14

High-Speed Measurement/Interface Option 1689-9820)

Same as above option but also with high-speed capability to increase measurement rate and five more sorting bins (15

Primary Readout C, R, or L

xi

lines, open collector drives rated at 15 V max. Each will sink 24 mA at 0.5 V). See Measurement Rate specification, above.

Environment

Operating: O to 50 degrees C, 0 to 85% relative humidity.

Storage: -40 to 74degrees C.

When the high-speed option is used, the operating temperature range is O to 40 degrees C.

Temperature Effects (typical)

R, L or C: +/- 5 ppm/degree C.

Q or D: +/- [2 ppm/degree C + (3 ppm/degree C) x (frequency in kHz)]

All specifications refer to 23degree C (calibration temperature).

Power

90 to 125 V or 180 to 250 V AC, 50 to 60 Hz.

Voltage selected by rear panel switch; 50 watts maximum, 40 watts typical. When the high-speed option is

used, the maximum power is 60 watts.

Mechanical

DIMENSIONS (W x H x D):

1689 14.781 x 4.40 x 13.50 in. (375.4 x 111.8 x 342.9 mm) WEIGHT: 13 lbs. (5.9 kg.)

1689M 17.25 x 5.625 x 15.160 in. (438.15 x 142.87 x 385.06 mm) WEIGHT: 17 lbs. (7.71 kg.)

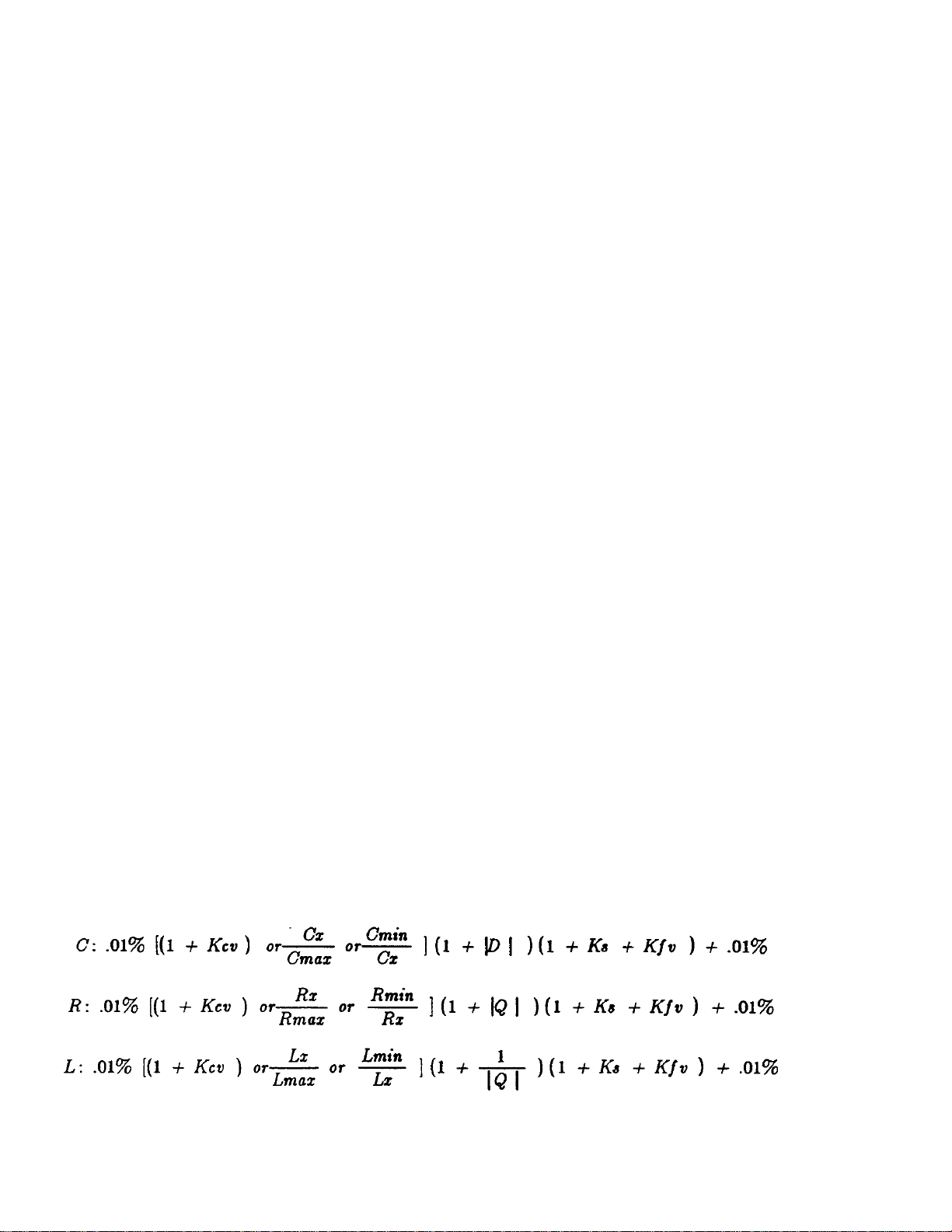

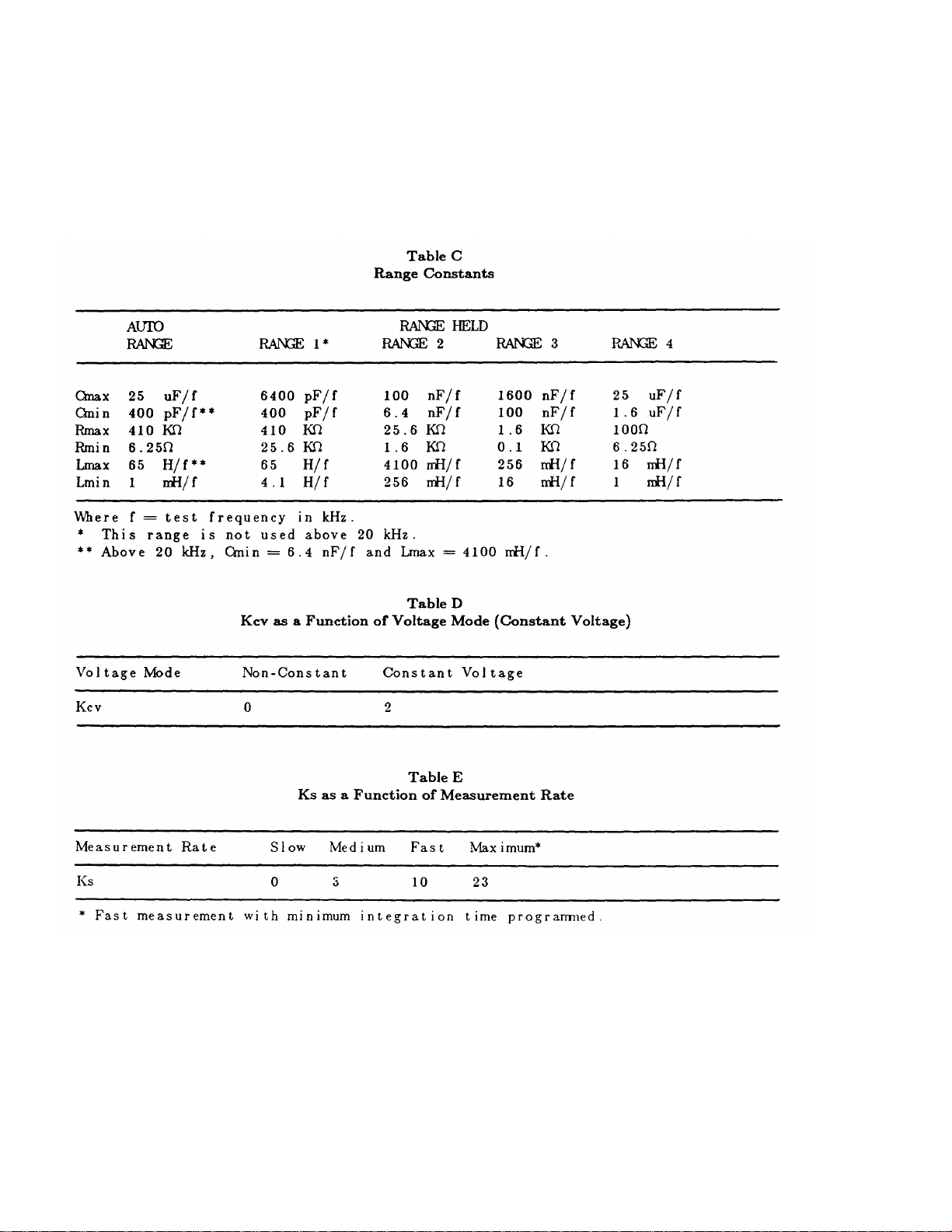

Limit or Error (Accuracy)

Page 15

NOTES:

xiii

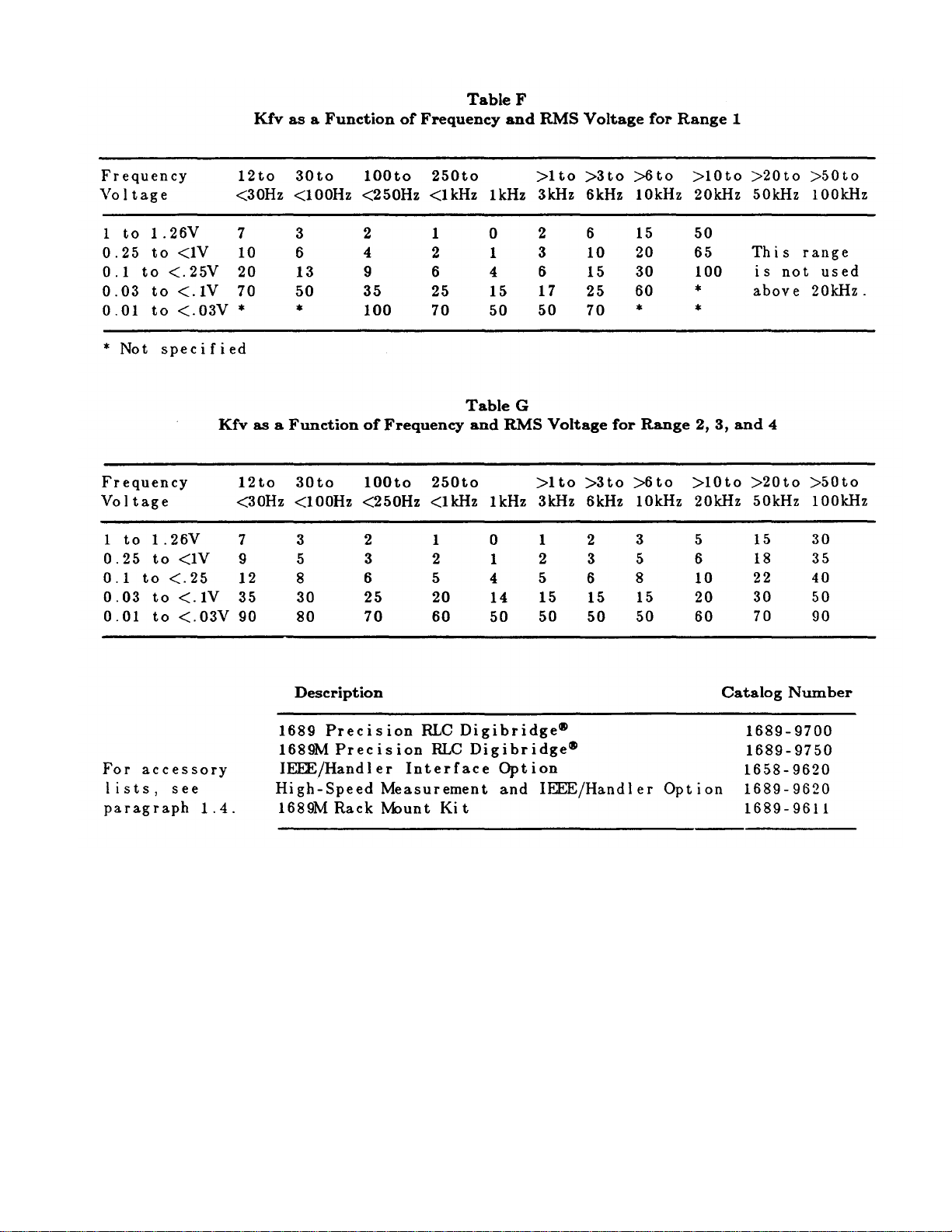

1. The limit of error is a percent of the reading and may be positive or negative.

2. The largest term of the first bracketed factor should be used.

3. CX, RJc, and Lx are the values of the components being tested, and Cmax, Cmin, Rmax, etc., are range constants

given in Table C.

4. The values of Ks, Kfv, and Kcv are all zero for measurements made at 1 kHz, with the SLOW measurement rate and using a

non-CONSTANT 1 V signal. For other test conditions, these constants may be evaluated using Tables D through G.

5. These specifications assume proper OPEN and SHORT zeroing calibrations made at 1 kHz. Much better accuracy is

possible at extreme impedance values if these zeroing calibrations are recent and made at the test frequency to be used. For

example, the SLOW MEASUREMENT rate typically will give 1 % accuracy when measuring 100 Mohm at 30 Hz, 0.lF at 120

Hz, 0.1 pF at 10 kHz, or 0.1 uH at 100 kHz. Even better accuracy is possible if several measurements are averaged.

6. Although L measurements on the 1689 should be capable of the accuracy stated above, calibrations by the National Bureau

of Standards are specified to .02%; this amount should be added to the 1689 specification for inductance measurements if they

are to be used in any manner involving legal certification.

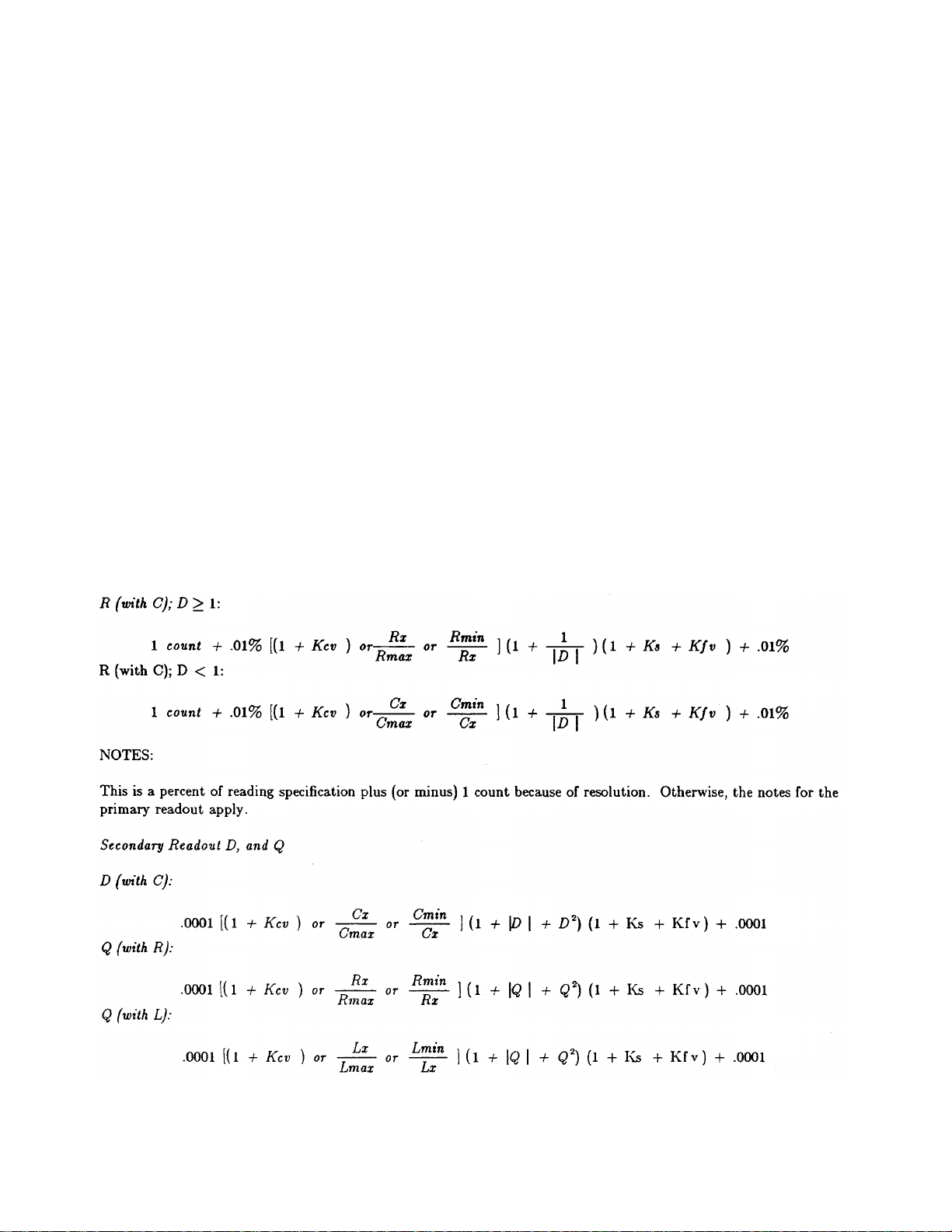

Secondary Readout R with C

Page 16

NOTES:

Otherwise, the notes for the primary readout apply. When using DQ in PPM, the final term of .0001 should be removed.

xiv

This is not a percent error but rather the amount, posiu've or negative, by which the D or Q reading may be in error.

Page 17

xv

Page 18

SERVICE POLICY

QuadTech policy is to maintain product repair capability for a period of five (5) years

after original shipment and to make this capability available at the then prevailing

schedule of charges.

Page 19

1.1 PURPOSE

INTRODUCTION 1-1

The two Digibridge(R) precision RLC testers, GR1689 and GR1689M, are microprocessor-controlled,

automatic, programmable RLC measuring instruments that provide high accuracy, convenience, speed,

and reliability at low cost. Limit comparison, binning, and internal bias are provided; both test frequency

and voltage are selectable. With an interface option, each Digibridge tester can communicate with other

equipment and respond to remote control.

The versatile, adaptable test fixture, lighted keyboard, and informative display panel make

these Digibridge testers convenient to use. Measurement results are clearly shown with decimal points

and units, which are automatically presented to assure correctness. Display resolution is 5 full digits for

R, L, and C (4 full digits for D, Q, Rs with Cs, and Rp with Cs). Notice that Rs is also known as ESR

(equivalent series resistance).

The basic accuracy is 0.02%. Long-term accuracy and reliability are assured by the

measurement system, which makes these accurate analog measurements over many decades of

impedance without any critical internal adjustments. Calibration to ..ccount for any change of testfixture parameters is semiautomatic; the operator needs to provide only open-circuit and short-circuit

conditions in the procedure. The Digibridge tester normally autoranges and automatically identifies the

principal measurement parameter.

The test fixture, with a pair of plug-in adaptors, receives any common component part (axiallead or radial-lead), so easily that insertion of the device under test (DUT) is a one-hand operation. True

4-terminal connections are made automatically. Extender cables are available for measurements at a

moderate distance from the instrument. They are optional for the 1689 (which has a built-in test fixture,

but requires extension typically for bulky components or parts in an automatic handler). They are

necessary for the 1689M, which has no built-in test fixture.

Limit comparisons facilitate sorting into 13 GO and 2 NO-GO bins.

Programmable test conditions include:

Page 20

Test frequencies from 12 Hz to 100 kHz

The essential front-panel features of the 1689 are provided on the vertical front of the model 1689M. These include the keypad,

1-2 INTRODUCTION

Test voltages from 5 mV to 1.275 V; bias (2 V)

Delay (before data acquisition) from zero to 99999 ms

Measurement speeds up to 45 per second (with 1689M) or 30 per second (with 1689)

Multi-measurement routines with automatic averaging and/or median taking of

2 to 765 measurements.

Displays: measured values, percentages, differences, ratios, GO/NO-GO, binning

Automatic output of value, bin number, bin summary and other results via IEEE-488

bus

Bias can be applied to capacitors being measured, either by programming the selection of an internal

supply (2 V) or by sliding a switch to connect an external voltage source (up to 60 V).

A choice between two interface options provides full "talker/listener" and "talker only" capabilities consistent with the

standard IEEE-488 bus. (Refer to the IEEE Standard 488-1978, Standard Digital Interface for Programmable Instrumentation. See

paragraph 2.8, in Section 2.) A separate connector also interfaces with component handling and sorting equipment.

1.2 GENERAL DESCRIPTION

1.2.1 Basic 1689 Digibridge

Convenience is enhanced by the arrangement of test fixture and controls on the front ledge, with all

controls for manual operation arranged on a lighted keyboard. Above and behind them, the display panel is inclined and recessed to

enhance visibility of digital readouts and indicators. These indicators and those at the keyboard serve to inform and guide the operator in

manipulating the simple controls, or to indicate that remote control is in effect.

The 1689 instrument stands on a table or bench top. The sturdy metal cabinet is durably finished, in keeping with the longlife circuitry inside. Glass-epoxy circuit boards interconnect and support high-quality components to assure years of dependable

performance. Although intended for bench-top use, this model can be rack mounted, using a type of mount that slides forward for

convenience.

Adaptability to any common ac power line is assured by the removable power cord and the convenient line-voltage switch.

Safety is enhanced by the fused, isolating power transformer and the 3-wire connection.

1.2.2 Basic 1689M Digibridge

display, and the power ON/OFF button. The set of four BNC connectors for connection to the test fixture is supplied on the front panel, but

can be relocated to the rear if that is preferred. The displaypanel and keyboard indicators serve to inform and guide the operator in

manipulating the simple controls, or to indicate that remote control is in effect.

The 1689M instrument also stands on a table or bench, where the bail provided under its front edge can be used to tilt it back

for operator convenience. This model goes particularly well in a rack, with its vertical front pane] and cable connection (from either front or

rear) to a suitable test fixture. The sturdy metal cabinet is durably finished, in keeping with the long-life circuitry inside. Glass-epoxy circuit

boards interconnect and support high-quality components to assure years of dependable performance.

Safety is enhanced by the fused, isolating power transformer and the 3-wire connection

Adaptability to any common ac power line is assured by the remo\rable power cord and the convenient line-voltage switch.

Page 21

1.2.3 Interface Options

INTRODUCTION 1-3

Either of the two interface options adds I/O capabilities to the instrument, enabling it to control and

respond to parts handling/sorting equipment. Also (via separate connector) either option can be connected in a measurement system using the

IEEE-488 bus. Either "talker/listener" or "talker only" roles can be performed by the Digibridge, by switch selection.

One of the interface options enables the Digibridge to measure at a higher speed than it does without an option. The high-speed

option provides outputs to 15 bins for sorting; the other option, to 10 bins.

1.2.4 References

Electrical and physical characteristics are listed in Specifications at the front of this manual. Interface connections and

instrument dimensions are given in Installation, Section 2. Controls are described below in Section 1; their use, in Operation, Section 3. A

functional description is given in Theory, Section 4.

1.3 CONTROLS, INDICATORS, AND CONNECTORS

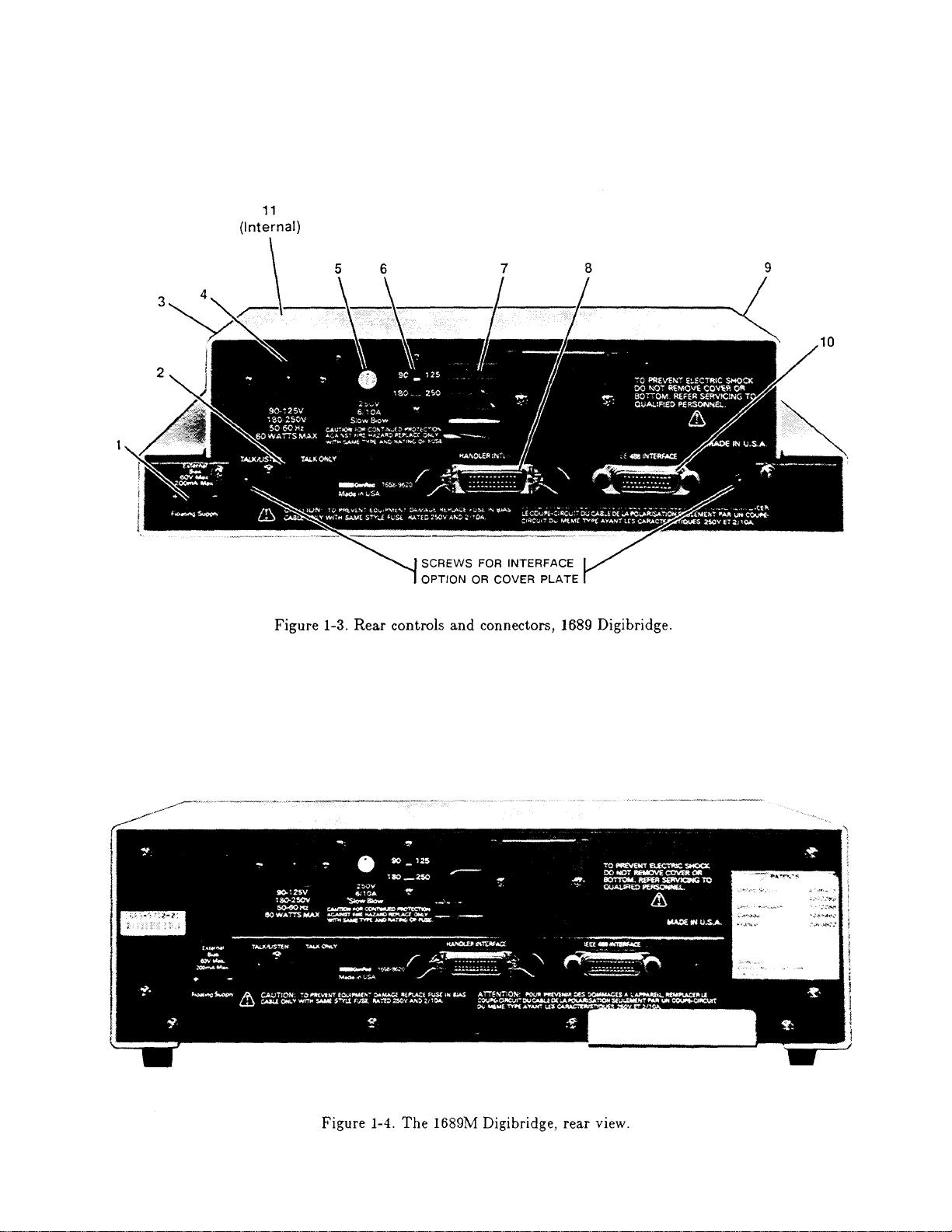

Figure 1-2 shows the controls and indicators on the front of the 1689 instrument. Table 1-1 identifies them with descriptions

and functions. Figure 1-1 shows the front of the 1689M model, which is functionally similar.

Similarly, Figure 1-3 shows the controls and connectors on the rear of the 1689; and Table 1-2 identifies them. Figure 1-4

shows the rear of the 1689M model, which is functionally similar.

Page 22

1-4 INTRODUCTION

Figure 1-2. Front controls and displays. Upper illustration: 1689 Digibridge tester, overall. Lower

illustration: keyboard detail.

Page 23

Table 1-1

Front Panel Controls and Indicators

Fig. 1-2

Ref No. Name Description Function

1 RLC display Digital display, Display of principal measured value.

5 numerals with If function is MEASURE and display

decimal points selection is VALUE, number indicates

R, L, or C. If display selection is delta% or deltaRLC, indicates

percentage difference (respectively) of R, 1, or C compared to

stored nominal value. If display selection is BIN NO., indicates

bin assignment of measured DUT. If function is ENTER,

displays are indications of programned entries,

special functions, bin sum, status in calibration sequences, etc.

2 Units and Light-spot (LED) Indicates measurement units associ~ted with

multipliers indicators RLC display and secondary display if it is

R. Indicates "%" if display selection

is delta%. None of these indicators

are lit if measurement display is "ratio".

3 "NEG" Light-spot (LED) NEG RLC and Nill Q)R indicate negative signs

indicators indicators associated with RLC and QDR displays.

(For explanations see paragraph 3.3.)

4 QDR display Digital display, If function is MEASURE, display of

4 numerals with secondary measured value or (i f display

decimal points is BIN NO.) blank. If function is ENTER,

RLC and Q)R displays together indicate

programned entries, special functions,

status in calibration sequences, etc.

5 POWER switch Pushbutton (push Switches the Digibridge ON (button in) and

again to release) OFF (button out). OFF position breaks both

sides of power circuit.

6 Other display- Light-spot (LED) RANGE HELD indicates that autoranging is

panel indicators disabled. CONST VOLT indicates that measure

indicators ment source resistance is fixed at a low

value. DQ, in PPM indicates that the D or Q

display is in parts per mi II ion.

7 Test fixture Pair of special Receives radial-lead DUT, making 4-ter

connector; each minal connection automatically. Adaptors

[Not on 1689M] axial-lead DUT. Extension cables

makes dual contact (supplied) make similar connection with

(5-terminal) are available.

Page 24

8 Reference card Captive pull-out Handy reference inforamtion for basic

1-6

INTRODUCTION

card operation: zeroing, making measurements,

[Not on1689M.] programming test conditions, limit entry,

and bin sorting.

9 Keyboard Group of keys, Manual programming and control. Refer to

indicators, and items 10 through 22 for more detai I,

2 other switches

10 Prograrmling Set of 16 keys, Multipurpose input of programning

keys labeled white and instructions, selections, and data,

yellow for 1689, Dual purposes of keys are indicated by

black and gray for color: White or black labels apply norm

1689M ally. Yellow or gray labels apply immed

iately after you press and release the

[SHIFT] key,

11 thru 14, Each key has Make selection by pressing key repeatedly

20, and 22 associated LED unti I the desired condition is indicated

(See below.) indicators at right of the key.

11 [FUNCTION] key Indicators MEASURE Selection of function. MEASURE enables

and ENTER. measurements and some routines that cannot

be done in ENTER, such as "zero" calibrations, keyboard lock or unlock, and

part

of full recalibration, ENTER enables programming of all special

functions, frequency, voltage, averaging, delay,

nominal value, and binning instructions, (Either function allows selection

of hold range, constant voltage, DQ in ppm, internal bias, parameter,

equivalent circuit, measure mode, measure rate, and

d i s play.)

12 [DISPLAY] key Indicators: VALUE, Selection of displays for MEASURE function;

13 [MEASURE RATE] Indicators: SLOW, Selection of measurernent speed as

delta%, BIN NO. refer to items 1, 2, and 4 for description

of displays. Two indicators are Lit

simultaneously for deltaRLC. This key

has no effect on ENTER function displays

key MED, FAST. i n d i cat e d. Spee d is also affectcd by

many other choices described in paragraph

3.5. Use SLOW for better accurac y, use

FAST for speed

Page 25

14 [MEASURE MODE] Indicators: CONT, Mode selection: CONT, continuously

Selection of principal measurement parameter

INTRODUCTION 1-7

key TRIGGERED repeating measurements; TRIGGERED,

single measurement initiated by START

button or input signal.

15 BIAS ON LED indicator Indicates that internal bias is on, or the

indi cator EXTERNAL BIAS swi tch is ON.

16 EXTERNAL BIAS Slide switch, 2 To connect and disconnect the external bias

switch positions: ON, circuit (rear connector, cable supplied).

OFF

17 GO/NO-GO Pair of LED GO means measured value is acceptable,

indicators indicators based on the limits previously stored.

(See paragraph 3.8.) NO-GO means RLC or QDR value or both are

unacceptable. Indicator remains lighted during next

me as u r erne n t .

18 START button Pushbutton switch. Starts measurement sequence (aborting any

measurernent that may be in process). Normally used in

TRIGGERED measure mode.

19 REMOTE OONTROL LED indicator Indicates when remote control is

indicator established by external command.

(Functions only if an interface option

is installed.)

20 EQUIVALENT Indicators: SERIES Selection of equivalent circuit. Measured

21 SHIFT key Key labeled SHIFT Pressing this shi fts the role of any

22 Parameter Set of 3 keys,

CIRCUIT key and PARALLEL principal R, L, C and secondary R values

(not D or Q) depend on this selection.

key labeled with both white and yellow

(or black and gray) F~ the white 1U yellow or black to gray. Do NOT hold

the the [SHIFT] key down; press it first,

then the other key.

keys labeled: R/Q, L/Q, --R, L, or C --and (for C only) secondary

C/D, and C/R, with parameter D or R. Repeated pushing of any

subscripts sand P one parameter key changes range in sequence

1 234 1 ...and hence measurement units.

Page 26

Page 27

1 EXTERNAL BIAS Connector, 2 pins, Receives cable (1658-2450, supplied) for

connector labeled 60 V max, external bias supply. Observe the voltage

200 rnA max, + -. and current limits and polarity.

2 TALK switch* Toggle switch. Selection of mode for IEEE-488 interface:

TALK/LISTEN or TALK ONLY, as labeled.

3 Air filter Porous plastic To prevent dirt from entering inlet vent.

sponge

4 Power connector Shrouded 3-wire AC power input. Use appropriate power cord,

labeled plug, conCorming with Belden SPH-386 socket or equivalent.

90-125 V, to International The GenRad 4200-0300 power cord (supplied)

180-250 V, Electrotechnical is rated Cor 125 V.

50-60 Hz, etc. Commission 320.

5 Fuse (labeled Fuse in Short circuit protection. Use Bussman

250 V, 1/2 A, extraction post type MDL or equivalent fuse, 1/2 A,

SLOW BLOW) holder 250 V rating.

6 Line-voltage Slide switch. Adapts power supply to line-voltage ranges,

switch Upper position: as indicated. To operate, use a small

90 to 125 V; screw driver, not a sharp object.

lower position,

180 to 250 V.

7 Vent Air passage Venti lation

8 HANDLER Socket, 24-pin; Connections to component handler (outputs

INTERFACE receives Amphenol are bin numbers and status; input is a

connector* "Microribbon" plug "start" signal).

P/N 5i-30240

(or equiv).

9 Vent Air passage Ventilation

10 IEEE-488 Socket, 24-pin. Input/output connections according to IEEE

INTERFACE Receives IEEE-488 Std 488-1978. Functions: complete remote

connector* interface cable. control. Output of selected resul ts, with

(See paragraph or without controller.

2 .8) .

Page 28

11 Fuse (1/4 A) Plug-in type,subs - Protects instrument circuitry from

information.

1-10 INTRODUCTION

miniature, quick- damage by charged capacitors.

acting. Manufactesr

Part No.273.250

by LITTLEFUSE, Inc.,

800 E.Northwest Hwy,

Des Plaines IL 60016

* TALK switch and 24-pin connectors are supplied with the interface option only.

1.4 ACCESSORIES

GenRad makes several accessories that enhance the usefulness of each Digibridge. The axiallead adaptors (provided) convert the test fixture to a configuration well suited for axial-lead

components. A choice of extender cables facilitates making connection to a parts handler or to any DUT

that does not readily fit the test fixture. Extender cables are available with your choice of banana plugs,

BNC, or type 874 connectors. Each cable branches into 4 parts, for true 4-terminal connections (and

guard) to the device being measured, without appreciable reduction in measurement accuracy. A remote

test fixture is available to receive hand-inserted components at a distance from the Digibridge.

Other useful accessories are offered. Refer to Tables 1-3, 1-4 and inquire at the nearest

Digibridge Technical Support Center. (Refer to the back of this manual.)

NOTE

The GenRad line of Digibridge test

fixtures, adaptors, and other accessories

does continue to be improved and

expanded. Inquire periodically at your

local GenRad sales office for the latest

Page 29

1 supplied Power cord, 200 cm (6.5 ft) long, 3-wire, AWG No.18, 4200-0300

with molded connector bodies. One end, with Belden

SPH-386 socket, fits instrument. Other end conforms

to ANSI standard C73.11-1966 (125 V max).

2 supplied Test-fixture adaptors, for axial-lead parts. 1657-5995

Replacements available: set of 4 adaptors

1 supplied Bias cable, with built-in fuse, to connect external 1658-2450

bias supply and switching circuit.

1 recornnended High-speed measurement and lEEE-488/handl er 1689-9620

interface option retrofit (plug-in).

OR

1 recornnended IEEE-488/handler interface option retrofit (plug-in). 1658-9620

1 recornnended Tweezers, for handl ing and measuring chip components 1689-9603

with terminals on opposite (aces. BNC connectors;

127-cm (50-inch) cable. Use with adaptor 1689-9601.

1 recornnended Kelvin CI ip Cable, (or measuring large, low 1689-9606

impedance components. Use with adaptor 1689-9601.

1 recornnended Extender cable for connection to parts handler, 1657-9600

large or remote DOT, custom test fixture, etc.

Length 100 cm (40 in). One end fits test fixture

of Digibridge; other end terminates in 5 stackable

banana plugs.

1 recornnended Test-fixture adaptor, for BNC cable. 1689-9601

1 recomnended B~ cable assembly, 4 color coded cables with known 1689-9602

"stray" parameters, 90 cm (36 in.) long.

1 recomnended Remote test fixture (I ike the fixture on t.he 1689-9600

Digibridge, adaptable in many ways), with BNC

connectors. (Use 1689-9601 adaptor and 1689-9602

cable.)

Page 30

1 recommended Remote test fixture (like the 1689-9600); also has 1689-9605

of America, 1 Panasonic Way, Secaucus, N.J. 07094).

(Supplied with BNC-to-banana-plug adaptors.)

1-12

INTRODUCTION

START bar, GO/NO-GO lights, which function only if

the Digibridge has an interface option. Use

1689-9601 adaptor and 1689-9602 cable (as well as the 1689-2400 cable,

included with this fixture).

1 available Extender cable for connection to standards, large 1688-9600

1 available Rack mount kit (slides forward for complete access). 1657-9000

1 recommended Calibration kit, contains six Kelvin-connected 1689-9604

1 replacement Battery (Note: shelf life, 10 years; I ife in 8410-3480*

*Use the following battery if available: Panasonic part number BR-2/3A-F1 (Matsushita Electric Corp.

or remote DUT, custom t est fix t u r e, dielectric

measurement cell, etc. Length 30 cm (12 in). One

end fits test fixture of Digibridge, other end

terminates in four type 874 coaxial connectors.

references (four precision resistances, open, and

short), that plug into the built-in or 1689-9600/9605

test fixture.

instrument is 5 to 10 years. Refer to paragraph

3.13. )

1 supplied Power cord, 200 cm (6.5 ft) long, 3-wire, 4200-0300

1 supplied Bias cable, with built-in fuse, to connect 1658-2450

1 supplied BNC cable assembly, 4 color coded cables with 1689-9602

AWG No. 18, with molded connector bodies. One

end, with Belden SPH-386 socket, fits instrument.

Other end conforms to ANSI standard C73.11-1966

(125 V max).

external bias supply and switching circuit.

known "stray" parameters, 90 cm (36 in.) long.

Page 31

1 recommended Tweezers, for handl ing and measuring chip 1689-9603

INTRODUCTION 1-13

components with terminals on opposite faces.

BNC connectors; 127 -cm (50 -inch) cable. (No

adaptor needed.)

1 recommended High-speed measurement and IEEE-488/handler 1689-9620

interface option retrofit (plug-in).

OR

1 recommended IEEE-488/handler interface option retrofit 1658-9620

(plug- in).

1 recommended Rack mount kit. (Digibridge front panel is always 1689-9611

accessible; the BNC connectors for cable to test

fixture can be mounted on either front or rear

pan e I .)

1 recommended Remote test fixture (like the 1689-9600); also has 1689-9605

START bar, GO/NO-GO I ights, which function only if Digibridge has an interface option. Use cables

1689-9602 (supplied with 1689M) and 1689-2400

(included with this fixture).

1 available Remote test fixture for radial-lead DUTs (I ike 1689-9600

test fixture on 1689 Digibridge), with BNC

connectors. Use 1689-9602 cable (supplied with

1689M). Use axial-lead adaptors (supplied) if

appropriate. Accepts other accessories, like

extender cables 1657-9600, 1688-9600. (See

Table 1-3).

2 (suppl ied Test-fixture adaptors, for axial-lead parts. 1657-5995

with fixture) Replacements available: set of 4 adaptors.

1 recommended Cal ibration kit, contains six Kelvin-connected 1689-9601

1 replacement Battery (Refer to information in preceding table.) 8410-3480

1 recommended Kelvin CI ip Cable, for measuring large, low 1689-9606

references (fuur precision resistances, open,

and short), that plug into the 1689-9605 or the

1689-9600 test fixture.

impedance components.

Page 32

1-14

INTRODUCTION

Page 33

INSTr\J,LATION :2-1

2.1 UNPACKING AND INSPECTION

If the shipping carton is damaged, ask that the carrier's agent be present when the instrument, is

unpacked. Inspect the instrument for damage (scratches, dents, broken parts, etc.), If the instrument, is damaged or fails to meet

specifications, notify the carrier and the nearest GenRad field office. (See list at back or this manual.) Retain the shipping carton and the

padding material for the carrier's inspection.

2.2 DIMENSIONS Figure 2-1.

The instrument is supplied in a bench configuration, i.e., in a cabinet with resilient feet for placement on a table. The

overall dimensions are given in the figure. The two cabinet styles differ as follows

keypad horizontal, display tiltcd keypad & display on front (vertical)

instrument does not tilt instrument tilts for convenience

test fixture provided on front test fixture always remote (BNC cables)

bench use primarily (rack possible) multiple use (rack, shelf, bench...)

Page 34

2.3 POWER-LINE CONNECTION Figure 2-2.

2-2 INSTALLATION

The power transformer primary windings can be switched, by means of the line voltage switch on the

rear panel, to accommodate ac line voltages in either of 2 ranges, as labeled, at a frequency of 50 or 60 Hz, nominal. Making sure that the

power cord is disconnected, use a small screwdriver to set this switch to match the measured voltage of your power line.

If your line voltage is in the lower range, connect the 3-wire power cable (P IN 4200-0300) to the power connector on the rear

panel (Figure 1-2) and then to the power line.

The instrument is fitted with a power connector that is in conformance with the International Electrotechnical Commission

publication 320. The 3 flat contacts are surrounded by a cylindrical plastic shroud that reduces the possibility of electrical shock whenever the

power cord is being unplugged from the instrument. In addition, the center ground pin is longer, which means that it mates first and

disconnects last, for user protection. This panel connector is a standard 3-pin grounding-type receptacle, the design of which has been

accepted world wide for electronic instrumentation. The connector is rated for 250 V at 6 A. The receptacle accepts power cords fitted with

the Belden type SPH-386 connector.

The associated power cord for use with that receptacle, for line voltages up to 125 V, is GenRad part no. 4200-0300. It is a 200cm (6.5 ft), 3-wire, 18-gage cable with connector bodies molded integrally with the jacket. The connector at the power-line end conforms to

the "Standard for Grounding Type Attachment Plug Caps and Receptacles", ANSI C73.11-1966, which specifies limits of 125 V and 15 A.

This power cord is listed by Underwriters Laboratories, Inc., for 125 V, 10 A.

If your power line voltage is in the higher range (up to 250 V), be sure to use a power cord that is approved for 250 V. The end

that connects to the Digibridgel8) tester should have a connector of the type that is on the power cord supplied; the other end, an approved

connector to mate with your standard receptacle. A typical configuration for a 250- V, IS-A plug is illustrated in the accompanying figure.

Page 35

Figure 2-2. Configuration of 250-V 15-A plug. Dimensions in mm. This is listed as NEMA 6-15P. Use for example Hubbell

INSTALLATION 2-3

plug number 5666.

2.4 LINE- VOLTAGE REGULATION

The accuracy of measurements accomplished with precision electronic test equipment operated from ac line

sources can often be seriously degraded by fluctuations in primary input power. Line-voltage variations of +/15% are

commonly encountered, even in laboratory environments. Although most modern electronic instruments incorporate some

degree of regulation, possible power-source problems should be considered for every instrumentation setup. The use of linevoltage regulators between power lines and the test equipment is recommended as the only sure way to rule out the effects on

measurement data of variations in line voltage.

2.5 TEST-FIXTURE CONNECTIONS

2.5.1 For the 1689 Digibridge

Because an unusually versatile test fixture is provided on the front shelf of the instrument, external

test-fixture connections are generally NOT required. Simply plug the device to be measured (DUT) into the test fixture, with

or without its adaptors. For details, refer to paragraph 3.2.

Accessory extender cables arc available to connect to a DUT that is multiterminal, physically large, or otherwise

unsuited for the built-in test fixture. Extender cables are needed, similarly, to connect from the Digibridge test fixture to the

DUT socket in a mechanical parts handler. Cables and adaptors are listed in Table 1-3. Connection details are given in

paragraph 3.2.

NOTE

The GenRad line of Digibridge test fixtures,

adaptors, and other accessories does continue

to be improved and expanded. Inquire

periodically at your local GenRad sales office for

the latest information.

Page 36

2.5.2 For the 1689M Digibridge

2-4 INSTALLATION

An external test fixture is always required, because connection from the 1689M Digibridge to the DUT is

provided via BNC cables (from connectors that can be positioned at either front or rear of the instrument, as described in

Section 5). For general purposes, the recommended test fixture, cable, and their connections are as follows. Refer to

paragraphs 1.4 and 3.2 for more information about accessories.

COMMENT: It is important that the n. and PL leads connect to the same end of the DUT (and that PH and IH

connect to the other end). Also, for the 1689 and 1689M Digibridges, connecting IL/PL to the testfixture connectors

labeled "+" (and IH/PH to "-") assures that the test fixture's "+" and "-" labels agree with the bias polarity.

NOTE: In the cable's color code, RED is associated with "hot" leads, which have dc voltage, negative with

respect to ground, when bias is used.

2.6 BIAS VOLTAGE FOR THE DUT

2.6.1 Internal Bias

No external connections are required for the internal 2-volt bias. The circuit is self contained.

2.6.2 External Bias

External bias can be provided by connecting a suitable current-limited, floating dc voltage source, as

follows.

Be sure that the voltage is never more than 60 V, max.

A current limiting voltage supply is recommended; set the limit at 200 mA, max.

Be sure that the bias supply is floating; DO NOT connect either lead to ground.

A well filtered supply is recommended. Bias-supply hum can affect some

measurements, particularly if test frequency is the power frequency.

Generally the external circuit must include switching for both application of bias after

each DUT is in the test fixture and discharge before it is removed.

Connect the external bias voltage supply and switching circuit,

using the 1658-2450 cable, supplied, via the rear-panel EXTERNAL BIAS connector.

Observe polarity marking on the rear panel; connect the

supply accordingly.

Page 37

2.7 HANDLER INTERFACE (OPTIONAL)

2.7.1 Interface via High-Speed Measurement / Interface Option (1689-9620)

If you have the 1689-9620 High-Speed Measurement / IEEE-488 Bus / Handler Interface Option,

connect from the HANDLER INTERFACE on the rear panel to a handler, printer, or other suitable peripheral equipment as

follows. (The presence of the 24-pin connectors shown in Figure 1-3 verifies that you have one of the interface options; see

also paragraph 2.7.2.) Refer to Table 1-2 for the appropriate connector to use in making a cable. Refer to Table 2-1 for the key

to signal names, functions, and pin numbers.

Connect the bin control lines to the handler. See Table 2-1. Notice that the 1689-9620 High-Speed Measurement

Option provides outputs for automatic sorting into 15 bins. (Refer to paragraph 3.8.)

As indicated in the Specifications at the front of this manual, the output signals come from opencollector drivers

that pull each signal line to a low voltage when that signal is active and let it float when inactive. Each external circuit must be

powered by a positive voltage, up to 15 V (max), with sufficient impedance (pull-up resistors) to limit the active-signal (logic

low) current to 24 mA (max).

CAUTION

Provide protection from voltage spikes over 15 V.

The cautionary note above means typically that each relay or other inductive load requires a clamping

diode (rectifier) across it (cathode connected to the power-supply end of the load).

The input signal is also active low and also requires a positive-voltage external circuit, which must pull the signal

line down below 0.4 V, but not less than 0.0 V, i.e., not negative. The logic-low current is 0.4 mA (max). For the inactive state

(logic high), the external circuit must pull the signal line above +2.5 V, but not above +5 V.

NOTE

The "end of test" signal EOT is provided by the

Digibridge only while binning is enabled, by

having a non-zero "nominal value" in memory.

Refer to paragraph 3.8 for details.

Page 38

2.7.2 Interface via IEEE-488 Bus / Handler Interface Option (1658-9620)

2-6 [1\,"STALLATION

panel to a handler, printer, or other suitable peripheral equipment as follows. (The presence of the 24-pin connectors shown in Figure 1-3

verifies that you have one of the interface options; refer to paragraph 2.7.1 ) Refer to Table 1-2 for the appropria.te connector to use in

making a cable. Refer to Table 2-1 for the key to signal names, functions, and pin numbers.

If you have the 1658-9620 interface option, connect from the HANDLER INTERFACE on the rear

Page 39

Connect the bin control lines to the handler. See Table 2-1. Notice that the 1658-9620 IEEE-488 Bus /

INSTALLATION 2-7

Handler Interface Option card provides outputs for automatic sorting into 10 bins. (Refer to paragraph 3.8.)

As indicated in the Specifications at the front of this manual, the output signals come from open

collector drivers that pull each signal line to a low voltage when that signal is active and let it float when inactive. Each

external circuit must be powered by a positive voltage, up to 30 V (max), with sufficient impedance (pull-up resistors) to limit

the active-signal (logic low) current to 16 mA (max).

CAUTION

Provide protection from voltage spikes over 30 V.

The cautionary note above means typically that each relay or other inductive load requir es a clamping

diode (rectifier) across it (cathode connected to the power-supply end of the load).

The input signal is also active low and also requires a positive-voltage external circuit, which must pull the signal

line down below 0.4 V, but not less than 0.0 V, i.e., not negative. The logic-low current is 0.4 mA (max). For the inactive

state (logic high), the external circuit must pull the signal line above +2.5 V, but not above +5 v.

Figure 2-3. Handler interface timing diagram. External circuit must keep a-b > 1 us, and (if START is not "debounced")

a-c < [the settling time or programmed delay]. For single measurements, the DUT can be disconnected after e. The

selected BIN line goes low at f; the other BIN lines stay high. For MEDIAN and/or AVERAGE measurement routines,

ACQ OVER goes low (e) at the end of the last measurement.

2.7.3 Timing Figure 2-3.

(minimum) in each state (high and low). If START is provided by a mechanical switch without debounce circuitry, the

Digibridge will make many false starts; if START does not settle down (low) within the default settling time or the

programmed delay time after the first transition to high, the measurement time may increase substantially. For an explanation

of settling and delay time, refer to paragraph 3.5.3.

Refer to the accompanying figure for timing guidelines. Notice that START must have a duration of 1 us

Page 40

Measurement starts at time d, which is essentially the same as time b or c; measurement is completed at g. (The

2-8 INSTALLATION

START signals are expanded for clarity.) Interval a-e, during which the DUT must remain conllected for data acquisition, is

considerably shorter than the total measurement time a-g. The DUT can be changed after e ("indexing on ACQ", to save time)

or after g ("indexing on EOT", for a simpler test setup), as explained below.

After the calculation interval e-f, measurement results are available for sorting, i.e., one of the BIN lines goes low.

A few micro-seconds later, EOT goes low (can be used to set a latch holding the bin assignment). ACQ OVER, the selected

BIN line, and EOT then stay low until the next start command.

The time required for measurement depends on whether you have the high-speed measurement option, on test

conditions, programmable values, and operating selections. Interval a-e can be less than 15 ms; the cycle ag can be less than 40

ms; refer to paragraph 3.5 for details.

Set up the handler either of two ways: indexing on EOT or indexing on ACQ, as follows. The handler must supply

a signal (here called "start next measurement") when it has completed connection of the DUT to the test fixture.

Indexing on EOT, Set up the handler to respond to the EOT signal from the Digibridge, which occurs at the "end of

test", when the bin assignment is available for sorting. Set up the Digibridge to receive its START signal from the handler's

"start next measurement" signal. This setup is simpler than the one below.

NOTE

The Digibridge requires that a non-zero value

be entered for "nominal value" to enable

generation of the EOT signal and indication

by the GO/NO-GO lights; see paragraphs

3,8.3, 3,8,4.

Indexing on ACQ. Set up the handler to respond to the ACQ OVER signal from the Digibridge, which occurs when

the "data acquisition" is complete, The handler can then remove the DUT from the test fixture and replace it with another DUT,

while the Digibridge is calculating the result,

In addition, set up an interface that provides a START signal to the Digibridge by logical combination of the EOT

signal from the Digibridge AND the "start next measurement" signal from the handler. Indexing on ACQ results in higher

measurement rate than indexing on EOT.

Be sure the TALK switch is set to TALK ONLY, if the IEEE-488 bus is not used.

Page 41

Figure 2-4. Block diagram of a generalized system interconnected by the 16-signal- line bus specified in the IEEE Standard 488.

Reprinted from Electronics, November 14, 1974; copyright McGraw-Hill, Inc., 1974.

2.8 IEEE-488 INTERFACE (OPTION)

2.8.1 Purpose Figure 2-4.

If you have either interface option, you can connect this instrument to a printer or into a system

(containing a number of devices such as instruments, apparatus, peripheral devices, and generally a controller or computer) in which each

component meets IEEE Standard 488-1978, Standard Digital Interface for Programmable Instrumentation. A complete understanding of

this Standard (about 80 pages) is necessary to understand in detail the purposes of the signals at the IEEE-488 INTERFACE connector at

the rear panel of this instrument.

NOTE

For copies of the Standard, order "IEEE Std

1978, IEEE Standard Digital Interface for Programmable

Instrumentation", from IEEE

Department PB-8, 445 Hoes

08854.

To make connection to a single device like a printer, use a IEEE-488 cable, which fits the rear-panel connector labeled IEEE488 INTERFACE. For larger systems, each device is connected to a system bus, in parallel, usually by the use of several stackable cables.

Refer to the figure for a diagram of a hypothetical system. A full set of connections is 24 (16 signals plus shield and ground returns), as

tabulated below and also in the Standard. Suitable cables, stackable at each end, are available from Component Manufacturing Service, Inc.,

West Bridgewater, MA 02379, U.S.A. (Their part number 2024/1 is for a I-meter-Iong cable.)

Service Center,

Lane, Piscataway, N. J.

488-

Page 42

This instrument will function as either a TALK/LISTEN or a TALK ONLY device in the system, depending on the position

identifications below. For example, T5 represents the most complete set of talker capabilities, whereas PPO means the absence of a capability.

2-10 INSTALLATION

of the TALK switch. "TALK/LISTEN" denotes full programmability and is sllited for use in a system that has a controller or computer to

manage the data flow. The "handshake" routine assures that the active talker proceeds slowly enough for the slowest listener that is active,

but is not limited by any inactive (unaddressed) listener. TALK ONLY is suited to a simpler system -e.g. Digibridge and printer --with 110

controller and no other talker. Either mode provides measurement results to the active listeners in the system.

2.8.2 Interface Functions Figure 2-5.

The following functions are implemented. Refer to the Standard for an explanation of the function subsets, represented by the

SHI, source handshake (talker)

AHI, acceptor handshake (listener)

T5, talker (full capability, serial poll)

L4, listener (but not listen-only)

SRI, request by device for service from controller

RL2, remote control (no local lockout, no return-to-local switch)

PP0, no parallel poll

DC1, device clear

DT1, device trigger (typically starts measurement)

C0, no controller functions.

The handshake cycle is the process whereby digital signals effect the transfer of each data byte by means of status and control

signals. The cycle assures, for example, that the data byte has settled and all listeners are ready before the talker signals "data valid".

Similarly, it assures that all listeners have accepted the byte before the talker signals "data not valid" and makes the transition to another byte.

Three signal lines are involved, in addition to the 8 that convey the byte itself. Refer to the accompanying figure.

Page 43

Figure 2-5. The handshake process, illustrated by timing diagrams of the pertinent signals for a system with one talker and

INSTALLATION 2-11

several listeners. For details, refer to the standard.

2.8.3 Signal Identification

Refer to Table 2-2 for a key to signal names, functions, and pin numbers. Further explanation is found in the

Standard. The first three signals listed take part in the "handshake" routine, used for any multiline message via the data bus; the

next five are used to manage the flow of information; the last eight constitute the multiline

message data bus.

Page 44

2-12 INSTALLATION

Page 45

2.8.4 Codes and Addresses

INSTALLA TION 2-13

General. The device-dependent messages, such as instrument programming commands and measurement

data (which the digital interface exists to facilitate), have to be coded in a way that is compatible between talkers and listeners. They have to

use the same language. Addresses have to be assigned, except in the case of a single "talker only" with one or more "listeners" always

listening. The Standard sets ground rules for these codes and addresses.

In this instrument, codes for input and output data have been chosen in accordance with the rules. The

address (for both talker and listener functions) is user selectable, as explained below.

Instrument Program Commands. The set of commands used in remote programming is an input data code to which the

instrument will respond as a "talker/listener", after being set to a remote code and addressed to listen to device-dependent command strings.

The set includes all of the keyboard functions except switching

external bias ON/OFF and full recalibration, which are not remotely programmable.

Refer to paragraph 3.12.3 for a table of the commands used in programming.

Address. The initial setting of address, provided by the factory, is binary 00011. Consequently, the

talk-address command (MTA) is C in ASCII code and, similarly, the listen-address command (MLA) is #. If a different address pair is

desired, set it manually using the following procedure.

WARNING

Because of shock hazard and presence of electronic

devices subject to damage by static electricity (conveyed

by hands or tools), disassembly is strictly a "service"

procedure.

a. Take the Digibridge to a qualified electronic technician who has the necessary equipment for minor disassembly and

adjustment. Have the electronic technician remove the interface option assembly, as described in the 1689 Digibridge Service instructions.

(There is no need to remove the top cover first.)

b. Set the switches in "DIP" switch assembly S2 to the desired address, which is a 5-bit binary number.

(See below.)

c. Replace the interface option assembly in its former place.

Notice that S2 is located at the end of the interface option board, about 3 cm (1 in.) from the TALK

switch SI. If S2 is covered, lift the cover off, exposing the "DIP" switch, which has 6 tiny switches, numbered 1 thru 6. To enter logical 1 's,

depress the side of each switch nearest the end of the board (switch open). To enter logical O's, depress the other side of the switch (switch

closed). The address is read from 5 to 1 (not using 6). Thus, for example, to set up the address 00011, enter O's at positions 5,4,3; enter l's at

positions 2, 1. (This makes the talk address "C" and the listen address "#".) Strictly speaking, the address includes more; S2 determines only

the device-dependent bits of the address. You cannot choose talk and listen addresses separately, only as a pair. The list of possible pairs is

shown in Table 2-3.

Page 46

2-14 INSTALLATION

* Do N:::Yr set the swi tch to 11111, because a talk address of "-" would be confused with an "untalk" comnand, and a

I isten address of "?" with an "unl isten" comnand. (ASCII code for "-" is

1 011 III and for "?" is 0 III Ill.)

Page 47

In the above example, the remote message codes MLA and MTA are X0100011 and X100001 J , respectively. Thus the listen

INSTALLATION 2-15

address and the talk address are distinguished, although they contain the s;\me set of device-dependent bits, which you set into S2.

Data Output. Data (results of measurements) are provided on the DIO1...DI07 lines as serial strings of characters. Each

character is a byte, coded according to the 7-bit ASCII code, as explained above. The alphanumeric characters used are appropriate to the

data, for convenience in reading printouts. The character strings are always provided in the same sequence as that tabulated in paragraph

3.12.3; for example: RLC value, QDR value, bin number --if all 3 were selected (by the X7 command). The carriage-return and line-feed

characters at the end of each string provide a printer (for example) with the basic commands to print each string on a separate line.

For example, if the measurement was 0.54321 uF (1 kHz, range 4 held), the character string for RLC value is:

U(space )C(space )uF(2 spaces )0.54321( CR)(LF).

If the D measurement was .001, the character string for QDR value is:

(2 spaces)D(5 spaces)00.0010(CR)(LF).

If the measurement falls into bin 9, the character string for bin number is:

F(space)BIN(2 spaces)9(CR)(LF).

The character string for RLC value has the length of 17 characters; for QDR value, 17 characters; for

bin number, 10 characters -including spaces, carriage-return, and line-feed characters. Refer to the format tables in paragraph 3.12.2 for

details.

2.9 ENVIRONMENT

The Digibridge can be operated in nearly any environment that is comfortable for the operator. Keep the instrument and all

connections to the parts under test away from electromagnetic fields that may interfere with measurements.

Refer to the Specifications at the front of this manual for temperature and humidity tolerances. To safeguard the instrument

during storage or shipment, use protective packaging. Service personnel refer to Section

When the Digibridge is mounted in a rack or other enclosed location, make sure that the ambient temperature inside the rack

does not exceed the limits specified under "Environment" in the Specifications at the front of this manual, and that air can circulate freely

past all air inlet and outlet vents.

5.

2.10 RACK MOUNTING

1689-9611, For 1689M Digibridge. The 1689M Digibridge is more readily mounted in a rack than the

1689. Use this procedure.

a. If the location of the four BNC connectors (for test-fixture cables) is satisfactory, go on to the next step. Otherwise, the

BNC connector location can be moved from front to rear (or vice versa); this is a SI;:RVICE procedure, described in Section .5, paragraph

5.5.

Page 48

b. Preassemble the instrument with the shelf of the 1689-9611 Rack Mount Kit, as follows. Place the instrument on the shelf so

2-16 INSTALLATION

that its feet drop through the large holes. Lift the shelf up snugly under the instrument and secure them together with a No. 10-32 screw

through the small hole centered at the rear of the shelf, into the corresponding tapped hole in the instrument's rear panel.

NOTE

This screw is important for electrical

grounding, as well as for mechanical security.

c. position this assembly in the rack as desired and fasten the shelf at the front of the rack, using the four dress screws,

supplied. If the rack's mounting holes are tapped with number 10-32 threads, the nuts supplied for these screws can be omitted.

1657-9000, For 1689 Digibridge. The 1689 Digibridge can be mounted in a rack, using hardware that

permits sliding the instrument forward for access. Use this procedure.

a. Obtain the 1657-9000 Slide Rack Mounting Kit, which includes the 1657-3100 sliding shelf assembly,

instructions, and hardware.

b. Mount the shelf and slides in the rack, using the screws provided. Fasten the assembly at the front

and rear of the rack. Slide the shelf forward for access.

c. Remove the four screws from the bottom of the Digibridge and slide the instrument out of its bottom

shell.

d. Remove the four rubber feet from the bottom shell.

e. Place the bottom shell on the slide rack shelf and align it so that four small holes in the shelf appear

centered through the four large holes in the shell. Fasten the shell to the shelf through these four holes using 10-32

screws, provided, as follows. Place a large washer under the head of each screw, which is then run through the hole in the shelf; place lock

washer and nut on the end of the screw and tighten.

f. Slide the instrument into its bottom shell and reinstall the four screws removed in step c. (Large clearance holes are provided

in the shelf for access.) This completes the installation.

Page 49

3.1 BASIC PROCEDURE

3.1.1 General

For initial familiarization with the Digibridge(R) RLC tester, follow this procedure carefully. After that, use this paragraph as a

ready reference and refer to later paragraphs in this section for details. Condensed operating instructions are provided in Section 1.

Users of the 1689 Digibridge (not the 1689M), refer also to the Condensed Operating Instructions, found

stored in a pocket under the instrument. Reach under the front edge and pull the card forward as far as it slides

.easily. After use, slide it back in the pocket for protection.

3.1.2 Startup

CAUTION

Set the line voltage switch properly (rear

panel) before connecting the power cord.

This is the regular startup procedure.

a. After the line-voltage switch has been set to the position that corresponds to your power-line voltage

(which must be in either range: 90 to 125 V or 180 to 250 V ac, nominally 50 or 60 Hz), then connect the power cord as explained below.

Temperature. If the Digibridge tester has been very cold, warm it up in a dry environment, allowing time for the interior to

reach 0 degrees C or above, before applying power. Otherwise, the instrument may be damaged by thermal shock

Power Cord. Connect the power cord to the rear-panel connector, and then to your power receptacle.

Page 50

b. If the Digibridge tester includes an optional IEEE-488 interface, set TALK switch (rear panel) to

3-2 OPERATION

TALK ONLY unless instructions are to be received through the I EEE-488 bus.

c. Switch EXTERNAL BIAS OFF (front panel).

d. Press the POWER button "in", so that it stays in the depressed position. Self-check codes will show

briefly, indicating that the instrument is automatically executing a power-up routine that includes self checks.

(To turn the instrument off, push and release the POWER button and leave it in the "out" position.)

e. Wait until keyboard lights indicate MEASURE, VALUE, SLOW, CONT (or TRIGGERED), SERIES.

If they do not, there are two possible explanations: self-check fault and keyboard lock. If a fault is detected in the self-check,

measurements are blocked and an error code remains displayed. Under some conditions, the block to operation can be bypassed.

(See paragraph 3.13.) If the keyboard is locked, all of those keyboard indicators remain unlit except MEASURE and/or

REMOTE CONTROL --and all previously programmed test conditions, limits, . etc are reestablished. To unlock it, see

paragraph 3.9.

3.1.3 Zeroing

Before measurement, zero the Digibridge as follows. In this process, the instrument automatically measures

stray parameters and retains the data, which it uses to correct measurements so that results represent parameters of the

DUT alone, without (for example) test-fixture or adaptor capacitance.

a. Conditions.

SLOW measure rate, 1 V test voltage (default), RANGE HELD indicator NOT lit.

b. Open Circuit.

Press [FUNCTION] key (if necessary) to select MEASURE function.

Press [MEASURE MODE] key (if necessary) to select TRIGGERED mode.

If any test-fixture adaptors are to be used, install and position them

for use. (See paragraph 3.2.) For the 1689M, connect the remote test

fixture or at least the BNC cables and adaptors that will contact the DUT.

Be sure that the test fixture is open circuited.

If you want this "zero" process to echo a display of 00000,

press the [Cs/D] key. However doing so will disable automatic

parameter selection. (See paragraph 3.1.4, step b.)

Press these keys deliberately: [1] [6] [8] [9] [=] [SHIFT] [OPEN].

Note: the GO indicator being lit and two zeros confirm the previous step.

Watch the GO indicator on the keyboard; not one on any remote test fixture.

Keep hands and objects at least 10 cm (4 in.) from test fixture.

Press the START button. The GO indication disappears.

Wait for the GO indicator to be lit again.

c. Short Circuit.

Short the fixture with a clean copper wire (AWG 18 to 30), length 5 to 8 cm.

Press these keys: [1] [6] [8] [9] [=] [SHIFT] [SHORT].

Note: the GO indicator being lit and two fives confirm the previous step.

Press the START button. The GO indication disappears.

Wait for the GO indicator to be lit again.

Remove the short circuit.

NOTE For best accuracy:

Repeat this procedure daily and after changing test-fixture adaptors or frequency.

Page 51

3.1.4 Routine Measurement

OPERATION 3-3

a. Verify or select measurement conditions as follows (indicated by keyboard lights); press the adjacent

key to change a selection.

Function: MEASURE ([FUNCTION] key), a necessary selection

Display: VALUE ([DISPLAY] key), for normal RLC/QDR results

Measure rate: SLOW ([MEASURE RATE] key), for best accuracy

Measure mode: TRIGGERED ([MEASURE MODE] key), optional

Equivalent circuit: SERIES ([EQUIVALENT CIRCUIT] key) --see paragraph 3.3

If you are in doubt about how to connect the device to be tested with the Digibridge, refer to paragraph

3.2, below.

b. To measure any passive component (without knowing whether it is essentially a resistor, inductor, or capacitor), use

"automatic parameter selection". This feature is provided at power-up and remains enabled as long as you do NOT select any particular

parameter. (Automatic parameter selection can be disabled by pressing the [Cs/D] key, for example. Once disabled, this feature can be

enabled again by selecting the ENTER function and then pressing these keys:

[1][=] [SHIFT] [SPECIAL] [7].)

Place DUT in test fixture. Press START. (See note below.) The RLC display and units indicator show the principal measured value

and the basic parameter, thus identifying the DUT. The QDR display shows the measured Q if the principal units are ohms or

henries; the measured D if they are farads.

NOTE

Use either the Digibridge START button or the start bar

on the 1689-9605 test fixture (if

properly connected).

In steps c, d, e, f, the parameters to be measured are specified by the user.

c. To measure C and D of a Capacitor (C Range .00001 pF to 99999 uF, D range .0001 to 9999): Press

[Cs/D]. Place capacitor in test fixture. Press START. The RLC display shows Cs (series capacitance) and units (uF, nF, pF); the QDR display

shows D (dissipation factor). {If "NEG RLC" is lit, DUT is inductive.}

d. To measure C and R of a Capacitor (C Range .00001 nF to 99999 uF,

R range .0001 ohm to 9999 kilohm): Press [Cs/Rs]. Place capacitor in test fixture. Press START. The RLC display shows Cs (series

capacitance) and units (uF, nF); the QDR display shows Rs (equivalent series resistance) and units (ohms, kilohms). {If "NEG RLC" is lit,

DUT is inductive.}

e. To measure Land Q of an Inductor (1 range .00001 mI-l to 99999 H, Q range .0001 to 9999): Press [Ls/Q]. Place inductor in

test fixture. Press START. The RLC display shows Ls (series inductance) and units (mH, H); the QDR display shows Q (quality factor). {If

"NEG RLC" is lit, DUT is capacitive.}

f. To measure Rand Q of a Resistor (R range .00001 ohm to 99999 kilohms, Q range .0001 to 9999): Press [Rs/Q]. Place

resistor in test fixture. Press START. The RLC display shows Rs (series resistance) and units (ohms, kilohms); the QDR display shows Q

(quality factor). {If "NEG QDR" is lit, DUT is capacitive; if not lit, DUT is inductive.}

Page 52

NOTE: This procedure is basic; there are many alternatives described later. You can select and program for other

3-4 OPERATION

parameters, equivalent circuits, types of results displayed, test conditions, measurement rate, and bin sorting, etc.

3.2 CONNECTING THE DUT

3.2.1 General

Connect the "device under test" (DUT), whose parameters are to be measured.

WARNING

Charged capacitors can be dangerous, even lethal. Never handle their

terminals it they have been charged to more

discharging procedures may not be perfectly dependable.

than 80 V. Routine

NOTE

Clean the leads or the DUT if they are noticeably dirty,

even though the test-fixture contacts will usually bite

through a film ot wax to provide adequate connections.

3.2.2 Using the Integral Test Fixture on the 1689 Digibridge tor Radial-Lead DUTs Figure 3-1.

NOTE: For use of a similar remote test fixture, refer to paragraph 3.2.4.

If the DUT is a radial-lead component or has parallel leads at one side, insert them into the Digibridge

test-fixture slots as described below.

The test fixture provided on the front ledge of the 1689 Digibridge provides convenient, reliable, guarded 4-

terminal connection to any common radial-lead or (with adaptors that are provided) an axial-lead component part.

The slots in the test fixture accommodate wires with diameters from 0.25 mm (.01 in., AWG 30) to 1 mm (.04 in.,

AWG 18), spaced from 4 to 98 mm apart (0.16 to 3.9 in.) or equivalent strip conductors. Each "radial" wire must be at least 4

mm long (0.16 in.). The divider between the test slots contains a shield, at guard potential, with its edges semi-exposed. The

tapped holes (6-32 thread) at the left and right ends of the test fixture are also grounded, to connect the shields of extender

cables.

Page 53

Figure 3-1. A radial-lead DUT is inserted into the test fixture.

OPERATION 3-5

NOTE

If any adaptor(s) , described below, are in place, remove

them before attempting to insert a radiallead DUT.

3.2.3 Using the Test-Fixture Adaptors for Axial-Lead DUTs Figure 3-2.

If the DUT is an axial-lead component or has leads at opposite ends, insert the leads into the test

fixture adaptor's slots as shown in the accompanying figure and described below. NOTE: This description applies to the builtin test fixture of the 1689 Digibridge and also to remote test fixtures 1689-9600 and 1689-9605.

Install the test-fixture adaptors, supplied, as shown; put one in each slot of the test fixture, by pushing

vertically downward. Slide the adaptors together or apart so the body of the DUT will fit easily between them.

Notice that the contacts inside the adaptor are off center; be sure to orient the adaptors so the contacts

are close to the body of the DUT, especially if it has short or fragile leads.

The adaptors accommodate wires with diameters up to 1.5 mm (.06 in., AWG 15). The body of the DUT that will

fit between these adaptors can be 80 mm long and 44 mm diameter (3.1 x 1.7 in.) maximum. Each "axial" wire must be at

least 3 mm long (0.12 in.). The overall length of the DUT, including the axial wires must be at least 22 mm (0.866 in.).

Insert the DUT so that one lead makes connection on the left side of the test fixture, the other lead on the right

side. Insertion and removal are smooth, easy operations and connections are reliable if leads are reasonably clean and straight.

Press the DUT down so that the leads enter the slots in the adaptors as far as they go easily.

Page 54

Be sure to remove any obvious dirt from leads before inserting them. The test-fixture contacts will wipe

Figure 3-2. Use of the adaptors (supplied) for connection of an axial-lead DUT to the Digibridge test fixture.

3-6 OPERATION

through a film of wax, but can become clogged and ineffectual if dirty leads are inserted repeatedly.

Be sure to insert only one thing into each half of the test fixture, at anyone time. (If any object is

inserted into the same slot with a DUT lead, it will probably NOT make true "Kelvin" connections.)

NOTE

For a DUT with very short leads, it is important to

orient each adaptor so that its internal contacts

(which are off center) are clooe to the DUT. To

remove each adaptor, lift with a gentle tilt left or

right (never forward or back).

Page 55

OPERATION 3-7

Page 56

3.2.4 The 1689-9600 or -9605 Remote Test Fixture (with -9602 BNC Cable) Figures 3-3,3-4.

Table 3-1:

3-8 OPERATION

Connection of the DUT at a remote test fixture normally requires:

Remote Test Fixture 1689-9600, 1689-9605, or equivalent special fixture.

BNC Cable Assembly 1689-9602 ---supplied with 1689M Digibridge

BNC Adaptor 1689-9601 -----------------NOT needed with 1689MDigibridge

This remote test fixture functions like the one supplied on the 1689 Digibridge. True "Kelvin" connections are

made at the points of contact with the DUT leads. The recommended cable should be used (rather than any randomly chosen

BNC patch cords) because the known cable parameters enable you to make corrections for best accuracy. Install the remote test

fixture as follows.

a. Remove any adaptors, cables, etc, if present, from the DUT port of the instrument (test fixture of

1689 or BNC connectors of 1689M).

b. If the instrument is a 1689, plug the BNC adaptor into the integral test fixture, with the BNC connectors facing

forward. Lock the connection with the 2 captive thumb screws. (The screws must be seated to complete the ground connection.)

c. Connect the BNC cable assembly to the Digibridge and to the remote test fixture as indicated in Table 3-1. Note

that red designates leads that may be "hot". (When bias is applied, they carry dc negative voltage with respect to ground.)

REMOTE TEST FIXTURE CONNECTIONS VIA BNC CABLE

the 1689-2400 Remote Tester Cable (supplied with the fixture) as follows. Connect'one end to the HANDLER INTERFACE

connector behind the instrument. Connect the other end to a similar connector behind the fixture.

as described in paragraph 3.1.3.

automatically. (See paragraph 3.11 about handlers.) For notes on cable and fixture capacitance and zeroing, see paragraph

3.2.7, below.