Quadra-Fire TREKKER-CSB, TREKKER-MBK, TREKKER-PBK, TREKKER-PDB, TREKKER-PMH Installation Manual

...Page 1

Installation Manual

Installation and service of this appliance should be performed by

qualified personnel. Hearth & Home Technologies recommends

HHT Factory Trained or NFI certified professionals.

Installation & Appliance Set-Up

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

NOTICE: DO NOT DISCARD THIS MANUAL

WARNING

TREKKER FREE STANDING PELLET

APPLIANCE

MODEL(S):

TREKKER-CSB

TREKKER-MBK

TREKKER-PBK

TREKKER-PDB

TREKKER-PFT

TREKKER-PMH

CAUTION

Check building codes prior to installation.

• Installation MUST comply with local, regional, state

and national codes and regulations.

• Consult local building, re ocials or authorities

having jurisdiction about restrictions, installation

inspection, and permits.

If the information in these instructions is

not followed exactly, a re could result

causing property damage, personal

injury, or death.

• Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

• Do not over re - If appliance or chimney connector

glows, you are over ring. Over ring will void your

warranty.

• Comply with all minimum clearances to combustibles

as specied. Failure to comply may cause house re.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down. Hot glass will

cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

replace.

• Alert children and adults to hazards of high

temperatures

• High temperatures may ignite clothing or other

ammable materials.

• Keep clothing, furniture, draperies and other

ammable materials away.

CAUTION

Tested and approved for wood pellets only. Burning of

any other type of fuel voids your warranty.

1 September 24, 2018

NOTE

To obtain a French translation of this manual, please contact

your dealer or visit www.quadrare.com

Pour obtenir une traduction française de ce manuel, s’il vous

plaît contacter votre revendeur ou visitez www.quadrare.com

7080-165D

Page 2

TREKKER FS

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Indicates practices which may cause damage to the appliance or to property.

Safety Alert Key:

TABLE OF CONTENTS

1 Important Safety Information ............. 3

A. Appliance Certication........................3

B. BTU & Eciency Specications ................3

C. Glass Specications .........................4

D. Electrical Rating ............................4

E. Mobile Home Approved.......................4

F. Non-Combustible Materials ....................4

G. Combustible Materials .......................4

H. Sleeping Room .............................4

I. California - Prop65 ...........................4

2 Getting Started .................................... 5

A. Design, Installation & Location Considerations .........5

B. Tools And Supplies Needed ...................6

C. Inspect Appliance and Components .............6

D. Removal of Appliance from Shipping Materials.....6

E. Install Checklist .............................7

3 Dimensions and Clearances .............. 8

A. Appliance Dimensions ........................8

B. Clearances to Combustibles (US & Canada) .....10

C. Hearth Pad Requirements (UL & ULC) ..........11

D. Alcove ...................................12

4 Vent Information ................................ 13

A. Venting Termination Minimum Requirements .....13

B. Avoiding Smoke and Odors...................14

C. Negative Pressure..........................15

D. Draft ....................................15

E. Chimney and Exhaust Connection .............15

F. Equivalent Feet of Pipe ......................16

G. Pipe Selection Chart .......................16

5 Venting Systems ............................... 17

A. Through The Wall ..........................17

B. Vertical into Existing Class A Chimney ..........18

C. Through The Wall & Vertical - Exterior ..........18

D. Vertical - Interior - Typical Installation ...........18

E. Masonry..................................19

F. Alternate Masonry ..........................19

6 Appliance Set-Up .............................. 20

A. Leg Leveling System .......................20

B. Outside Air Kit Instructions ...................20

C. Top Vent Adapter Installation..................21

E. Optional Log Set Placement Instructions ........22

F. Installation of User Interface ..................23

G. Power to Appliance and User Interface..........23

H. Location & Mounting User Interface ............23

7 Mobile Home Installation .................. 24

8 Reference Materials .......................... 25

A. Service and Maintenance Log.................25

B. Accessories List............................27

Quadra-Fire is a registered trademark of Hearth & Home Technologies.

2 September 24, 2018

7080-165D

Page 3

1 Important Safety Information

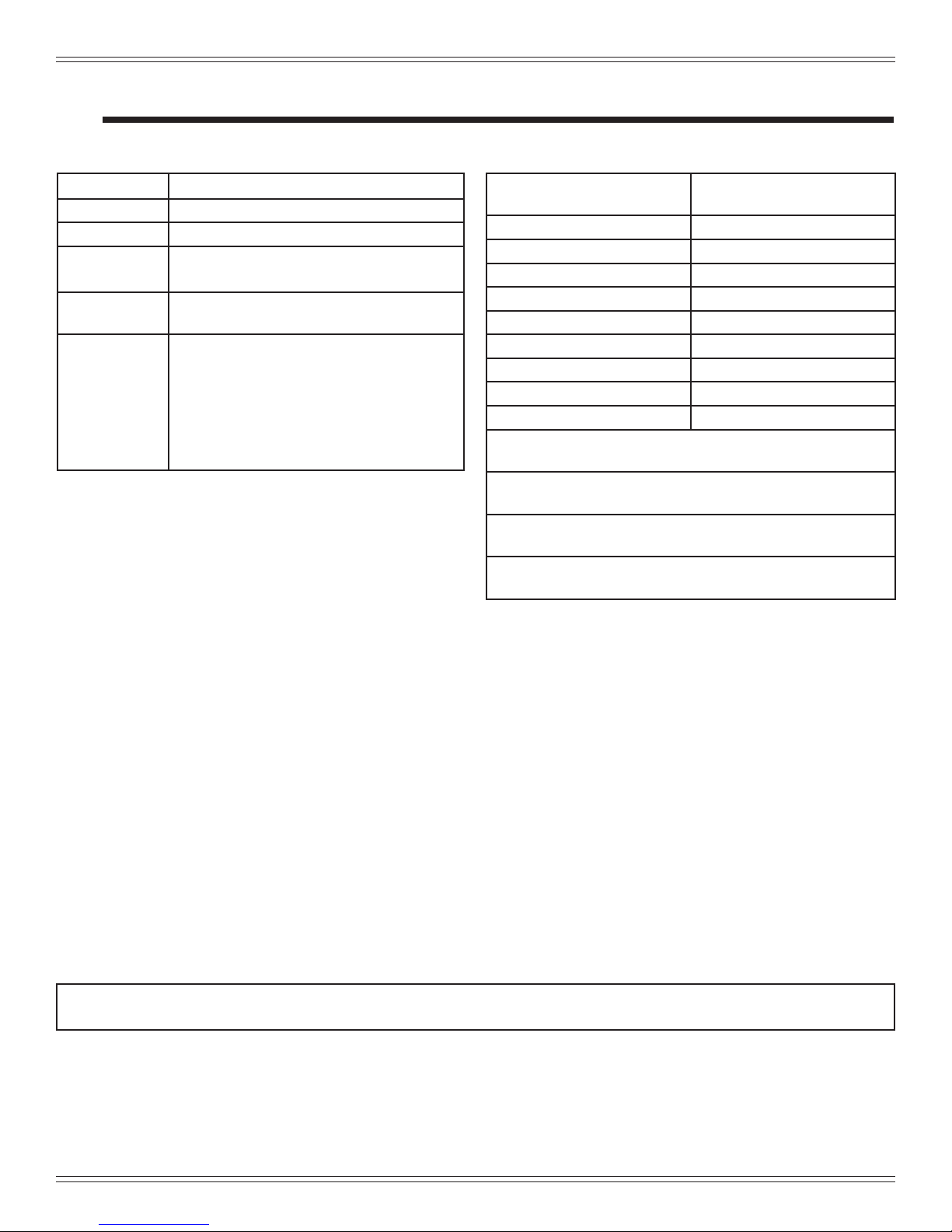

A. Appliance Certication B. BTU & Eciency Specications

TREKKER FS

Model Trekker Pellet Appliance

Laboratory OMNI Test Laboratories, Inc.

Report No. 061-S-83-2

Type

Standard

Solid Fuel Room Appliance, Pellet Fuel

Burning Type

ASTM E1509-12, ULC S627-00 and

(UM) 84-HUD, Mobile Home Approved.

Complies with Part 15 of FCC Rules.

Operation is subject to the following two

conditions: (1) this device may not cause

FCC

harmful interference, and (2) this device

must accept any interference received,

including interference that may cause

undesired operation.

Emissions Report

Number:

EPA Certication #: 98-17

EPA Certied Emissions: 0.74 g/hr

*LHV Tested Eciency: 83.2%

**HHV Tested Eciency: 77.9%

***EPA BTU Output: 12,682 - 39,428 / HR

****BTU Input: 16,396 - 50,775 / HR

Vent Size: 3, 4 or 6 inches, “L” or “PL”

Hopper Capacity: 52 lbs.

* Weighted average LHV eciency using data collected

during EPA emissions test.

**Weighted average HHV eciency using data collected

during EPA emissions test.

***A range of BTU outputs based on HHV and the burn

rates from the low and high EPA tests.

****Maximum BTU input based on the high burn section

of the EPA emissions test.

0061PS094E

Fuel Wood Pellets

NOTICE: This installation must conform with local codes. In the absence of local codes you must comply with the

ASTM E1509-04, ULC S627-00, (UM) 84-HUD and ULC/ORD-C-1482.

This manual describes the installation of the Quadra-Fire, Trekker pellet appliance. This appliance meets the 2020 U.S.

Environmental Protection Agency’s crib wood emission limits for wood heaters sold after May 15, 2020. Under specic test

conditions this appliance has been shown to deliver heat at rates ranging from 12,682 to 39,428 Btu/hr.

This pellet appliance needs periodic inspection and repair for proper operation. It is against federal regulations to operate

this pellet appliance in a manner inconsistent with operating instructions in this manual.

7080-165D

3September 24, 2018

Page 4

TREKKER FS

C. Glass Specications

This appliance is equipped with 5mm ceramic glass.

Replace glass only with 5mm ceramic glass. Please

contact your dealer for replacement glass.

D. Electrical Rating

115 VAC, 60 Hz, Start 2.9 Amps, Run 2.45 Amps

E. Mobile Home Approved

• This appliance is approved for mobile home

installations when not installed in a sleeping room and

when an outside combustion air inlet is provided.

• The structural integrity of the mobile home oor, ceiling,

and walls must be maintained.

• The appliance must be properly grounded to the frame

of the mobile home and use only Listed pellet vent

Class “L” or “PL” connector pipe.

• Outside Air Kit, part OAK-3 must be installed in a

mobile home installation.

F. Non-Combustible Materials

Material which will not ignite and burn, composed of any

combination of the following:

- Steel

- Plaster

- Brick

- Iron

Materials reported as passing ASTM E 136, Standard Test

Method for Behavior of Metals, in a Vertical Tube Furnace

of 750° C.

- Concrete

- Tile

- Glass

- Slate

G. Combustible Materials

Material made of/or surfaced with any of the following

materials:

- Wood

- Compressed Paper

- Plant Fibers

Any material that can ignite and burn: ame proofed or not,

plastered or non-plastered.

- Plastic

- Plywood/OSB

- Sheet Rock (drywall)

H. Sleeping Room

When installed in a sleeping room it is recommended that

3ft of vertical be installed prior to horizontally exiting the

room and a smoke/CO alarm be installed in the bedroom.

The size of the room must be at least 50ft³ per 1,000 Btu/hr

stove input, if the stove exceeds the room size, out air must

be installed.

I. California - Prop65

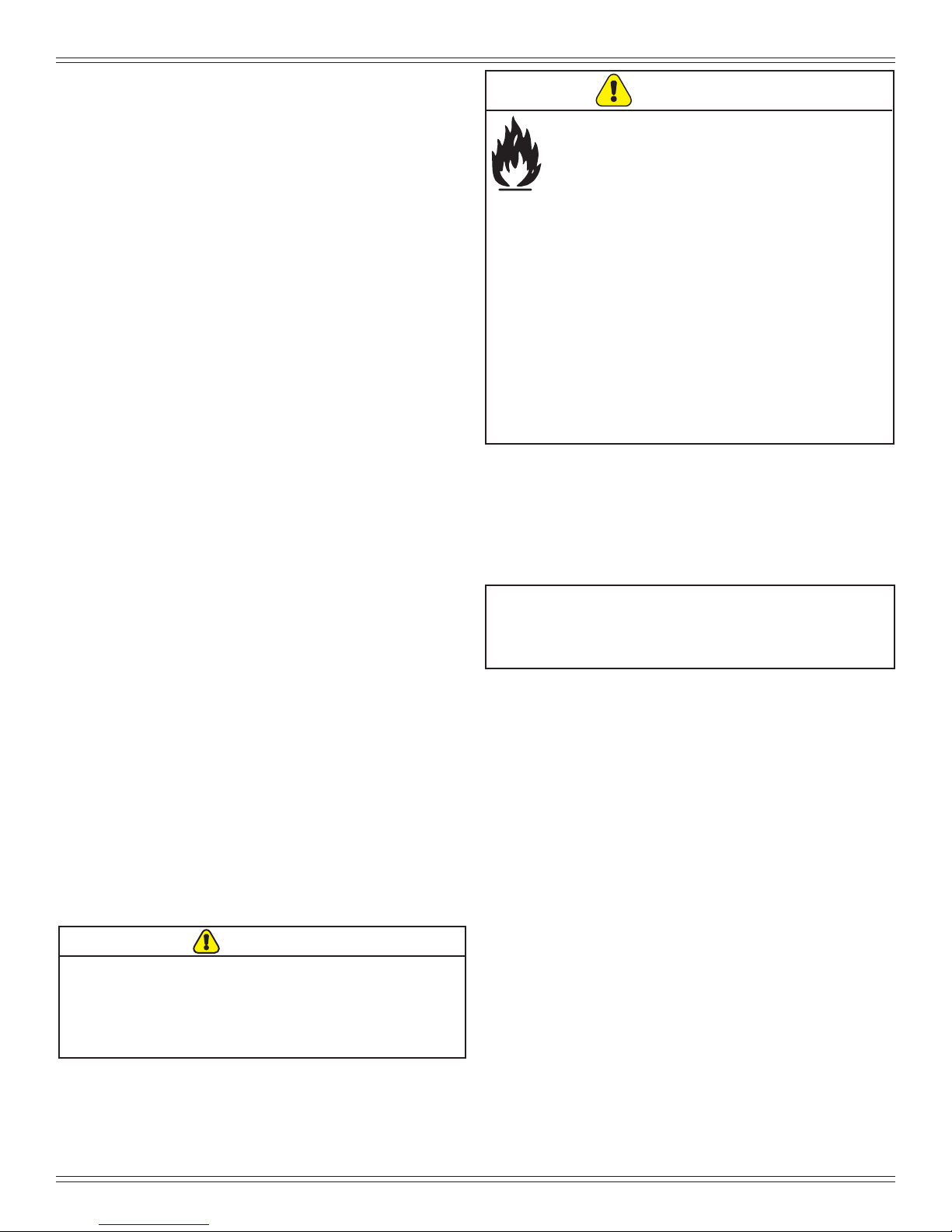

WARNING

Fire Risk

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be voided

by, the following actions:

• Installation and use of any damaged appliance.

• Modication of the appliance.

• Installation other than as instructed by Hearth &

Home Technologies.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

• Operating appliance without fully assembling all

components.

• Operating appliance without legs attached (if

supplied with appliance).

• Do NOT Over re - If appliance or chimney connector

glows, you are over ring.

Any such action that may cause a re hazard.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage.

For assistance or additional information, consult a qualied

installer, service agency or your dealer.

NOTE: Hearth & Home Technologies, manufacturer

of this appliance, reserves the right to alter its

products, their specications and/or price without

notice.

WARNING

This product and the fuels used to operate this product (wood), and

the products of combustion of such fuels, can expose you to

chemicals including carbon black, which is known to the State of

California to cause cancer, and carbon monoxide, which is known to

the State of California to cause birth defects or other reproductive

harm. For more information go to: WWW.P65Warnings.ca.gov

4 September 24, 2018

7080-165D

Page 5

2 Getting Started

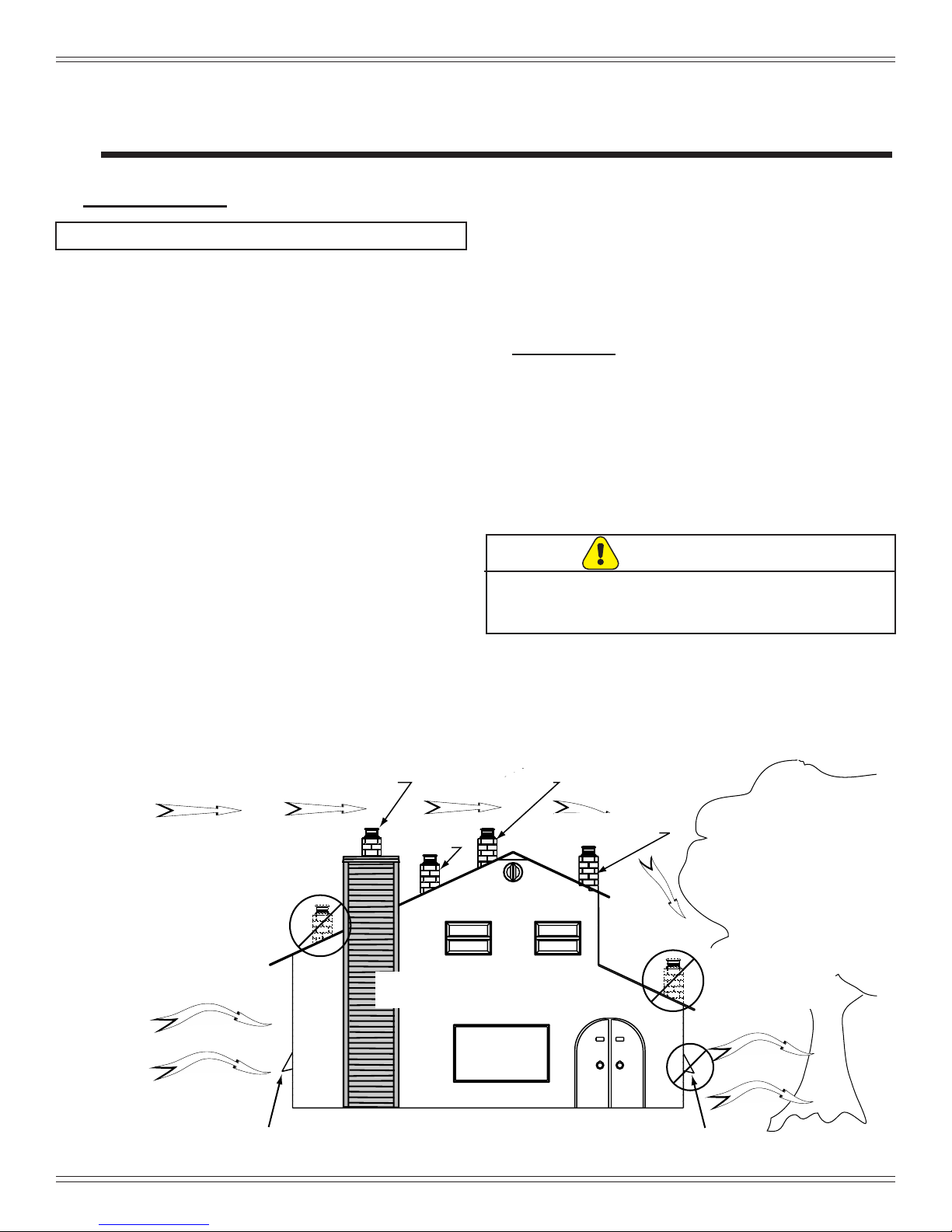

Marginal Location:

• Below peak

Location NOT recommended:

• Not the highest point of the roof

• Wind loading possible

Multi-level Roofs

Windward

Leeward

Recommended:

Outside Air Intake

on windward side

NOT recommended:

Outside Air Intake

on leeward side

Recommended Location:

• Above peak

Recommended:

• Insulated exterior chase

in cooler climates

Recommended Location:

• Above peak

• Inside heated space

Location NOT recommended:

• Too close to tree

• Below adjacent structure

• Lower roof line

• Avoid outside wall

Marginal Location:

• Wind loading possible

TREKKER FS

Install Guide

A. Design, Installation & Location Considerations

1. Appliance Location

Since pellet exhaust can contain ash, soot or sparks, you

must consider the location of:

• Windows

NOTICE: Check building codes prior to installation.

• Air Intakes

• Air Conditioner

• Installation MUST comply with local, regional, state and

national codes and regulations.

• Consult insurance carrier, local building inspector,

• Overhang, sots, porch roofs, adjacent walls

• Landscaping, vegetation

• Horizontal or vertical vent termination

re ocials or authorities having jurisdiction over

restrictions, installation inspection and permits.

2. Floor Support

The supporting oor under the appliance must be able to

It is a good idea to plan your installation on paper, using

exact measurements for clearances and oor protection,

handle the weight of the appliance, fuel load and the weight

of the chimney.

before actually beginning the installation. Location of the

appliance and chimney will aect performance.

Ensure that your oor will support these weights prior to

installation. Add sucient additional support to meet this

Consideration must be given to:

• Safety, convenience, trac ow

• Placement of the chimney and chimney connector and

weight requirement prior to installation. The weight of the

appliance is 426 lbs. with a full load of fuel the max weight

is 473 lbs.

to minimize the use of chimney osets.

• Place the appliance where there will be a clear

passage for a Listed chimney through the ceiling and

roof (vertical) or through exterior wall (horizontal).

• Installing the required outside air kit will aect the

location of the vent termination.

WARNING

Risk of Fire.

Damaged parts could impair safe operation. Do NOT

install damaged, incomplete or substitute components.

When locating vent and venting termination, the ideal

location is to vent above roof line when possible. This

minimizes the aects of wind loading.

Figure 5.1

7080-165D

5September 24, 2018

Page 6

TREKKER FS

WARNING

Risk of Fire!

• Damaged parts could impair safe operation.

• Do NOT install damaged, incomplete or

substitute components.

WARNING

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

• Installation and use of any damaged appliance.

• Modication of the appliance.

• Installation other than as instructed by Hearth &

Home Technologies.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

• Operating appliance without fully assembling all

components.

• Operating appliance without legs attached (if supplied

with appliance).

• Do NOT Over re

Or any such action that may cause a re hazard.

C. Inspect Appliance and Components

• Open the appliance and remove all the parts and

articles packed inside the Component Pack. Inspect all

the parts and glass for shipping damage.

• Report to your dealer any parts damaged in shipment.

• All labels have been removed from the glass door.

• Plated surfaces have been wiped clean with a soft

cloth, if applicable.

• Read all the instructions before starting the

installation. Follow these instructions carefully

during the installation to ensure maximum safety

and benet.

• Follow pipe manufacturer instructions for

installation and air clearance requirements.

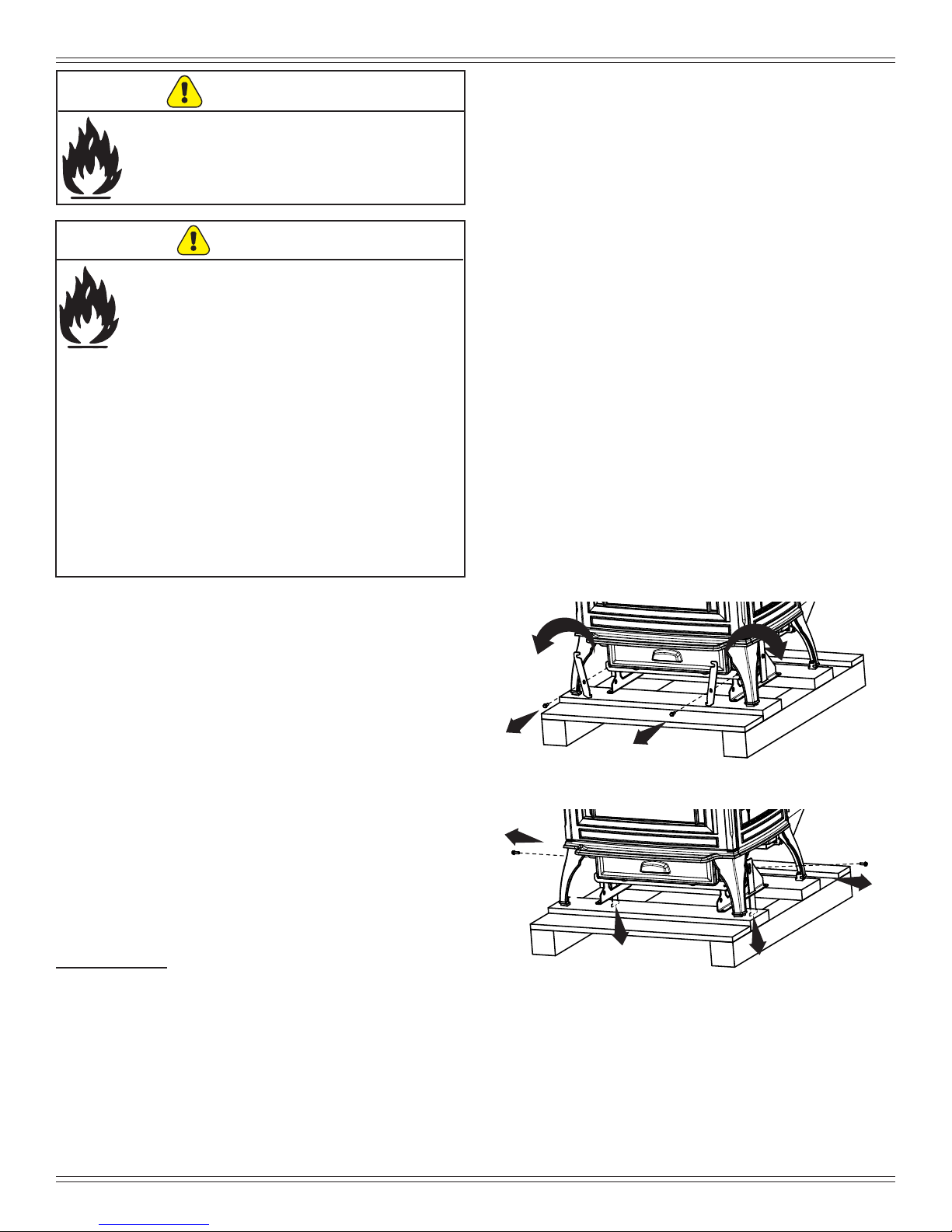

D. Removal of Appliance from Shipping

Materials

1. Remove box and 2x4 structural boards being careful

not to damage product.

2. Using 3/8 socket or wrench remove both front bolts

from pallet mount brackets. Front pallet mount brackets

will slide outwards away from appliance (Figure 6.1).

3. Using 3/8 socket or wrench remove bolts from side

pallet mount brackets. Side pallet mount brackets will

slide downwards from appliance (Figure 6.2).

4. Carefully pull appliance o of pallet and put in desired

location following Hearth Pad and Clearance to

Combustibles on pages 8 & 9.

B. Tools And Supplies Needed

Tools and building supplies normally required for

installation, unless installing into an existing masonry

replace:

• Reciprocating Saw

• Channel Locks

• Hammer

• Phillips Screwdriver

• Tape Measure

• Plumb Line

• 1/4” Self-Tapping Screws

• Framing Material

• Hi-temp Caulking Material

• Gloves

• Safety Glasses

• Framing Square

• Electric Drill & Bits (1/4”)

• Level

May also need:

Vent Support Straps

Venting Paint

Figure 6.1

Figure 6.2

6 September 24, 2018

7080-165D

Page 7

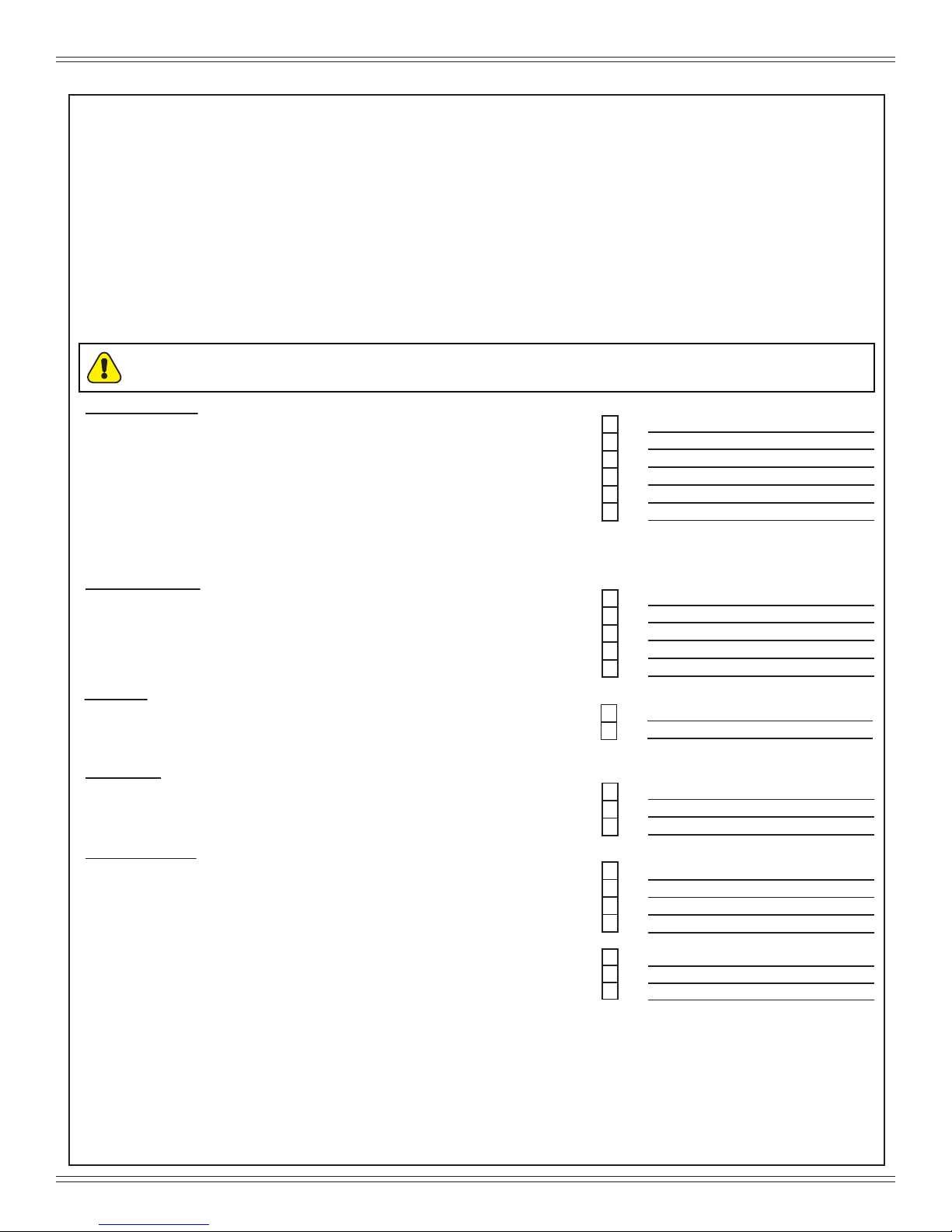

E. Install Checklist

This standard work checklist is to be used by the installer in conjunction with, not instead of, the instructions contained in this installation manual.

TREKKER FS

ATTENTION INSTALLER:

Follow this Standard Work Checklist

Customer:

Date Installed:

Lot/Address:

Location of Appliance:

Installer:

Dealer/Distributor Phone Number:

Serial Number:

Model Name:

WARNING! Risk of Fire or Explosion! Failure to install appliance to these instructions can lead to a fire or

explosion.

Appliance Install

Verified clearance to combustibles.

Appliance is leveled and connector is secured to appliance.

Hearth extension size/height decided.

Outside air kit installed.

Floor protection requirements have been met.

If appliance is connected to a masonry chimney, it should be cleaned and

inspected by a professional. If installed to a factory built metal chimney, the

chimney must be installed according to the manufacturer’s instructions and

clearances.

Venting/Chimney

Chimney configuration complies with diagrams.

Chimney installed, locked and secured in place with proper clearance.

Chimney meets recommended height requirements (5 feet minimum vertical).

Roof flashing installed and sealed.

Terminations installed and sealed.

__________________________________________________________________________

______________________________________________________________________

_______________________________________________________________________

________________________________________________________________

___________________________________________________________________________

________________________________________________________

______________________________________________________________________

_______________________________________________________________________

YES IF NO, WHY?

Electrical

120 VAC unswitched power provided to the appliance.

Check outlet with multi-meter for proper polarity and voltage (115-120 VAC).

Record voltage reading: _____________

Clearances

Verified all clearances meet installation manual requirements.

Mantels and wall projections comply with installation manual requirements.

Floor protection and heart extensions installed per manual requirements.

Appliance Setup

All protective materials removed.

All labels have been removed from the door.

All packaging materials are removed from inside/under appliance.

Manual bag and all of its contents are removed from inside/under the appliance

and given to the party responsible for use and operation.

Started appliance and verified that all motors and blowers operate as they should.

Checked draft using a Manometer. Record readings: ______________________

Checked vacuum using a Manometer. Record readings: ____________________

Hearth & Home Technologies recommends the following:

Photographing the installation and copying this checklist for your file.

That this checklist remain visible at all times on the appliance until the installation is complete.

Comments: Further description of the issues, who is responsible (Installer/Builder/Other Trades, ets.) and corrective action needed:

Comments communicated to party responsible

__________________________ by ______________________ on ____________

(Builder/Gen. Contractor) (Installer) (Date)

7080-165D

7September 24, 2018

Page 8

TREKKER FS

3-3/4 in

(97mm)

4-1/8 in

(104mm)

6-1/8 in

(155mm)

6-1/8 in

(155mm)

14 in (357mm)

qq

5-13/16 in

(147mm)

2-9/16 in

(65mm)

3-13/16 in

(97mm)

14-1/16 in

(357mm)

3-3/4 in

(97mm)

3-3/4 in

(97mm)

4-1/8 in

(104mm)

4-1/8 in

(104mm)

8-1/4 in

(208mm)

8-1/4 in

(208mm)

10-3/8 in

(264mm)

10-3/8 in

(264mm)

28-1/8 in (714mm)

32 in

(813mm)

11-3/4 in

(297mm)

18-1/2 in (469mm)

28-7/16 in (722mm)

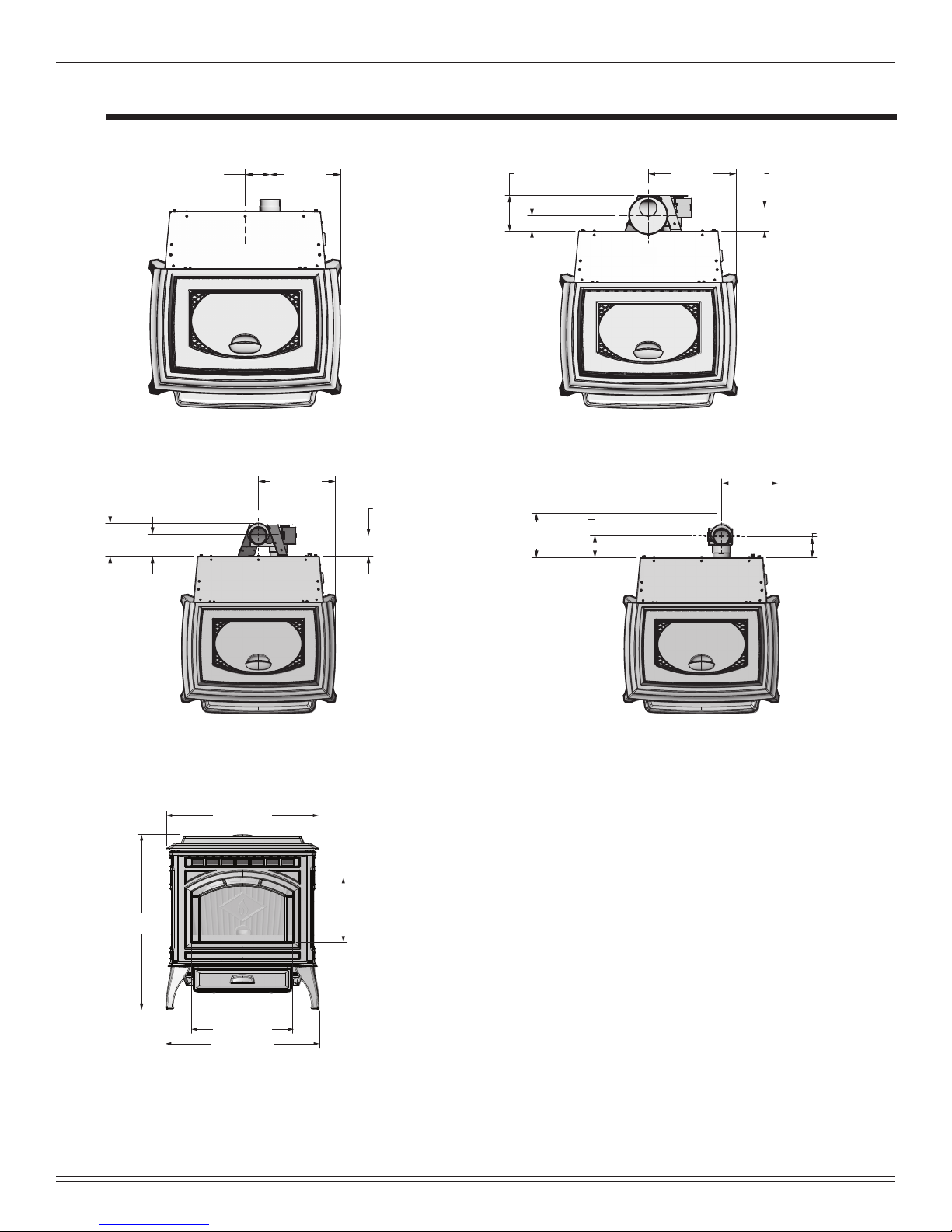

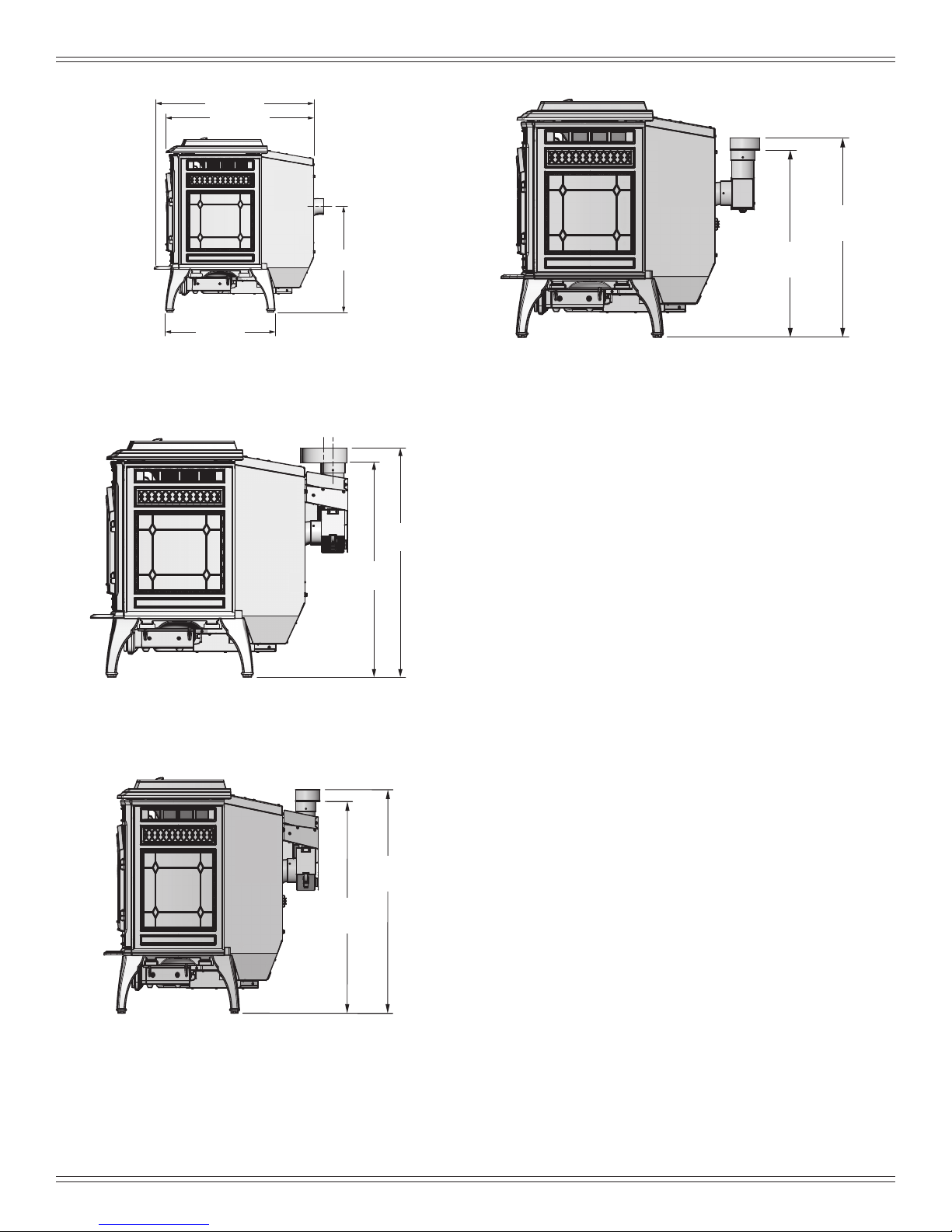

3 Dimensions and Clearances

A. Appliance Dimensions

3-5/8 in

3-5/8 in

(93mm)

(93mm)

qq

Figure 8.1 - Top View Figure 8.4 - Top View with Top Vent Adapter (TPVNT-3) and

10-3/8 in

10-3/8 in

(264mm)

(264mm)

Oset Adapter (812-3570).

Figure 8.2 - Top View with Top Vent Adapter (TPVNT-3) and

Oset Adapter (811-0720).

Figure 8.3 - Front View

Figure 8.5 - Top View with Top Vent Adapter (TPVNT-6) and

Oset Adapter (811-0720).

8 September 24, 2018

7080-165D

Page 9

TREKKER FS

31-1/16 in

(788mm)

29-3/16 in

(741mm)

25-3/8 in

(646mm)

25-3/8 in

(646mm)

27-1/8 in

(688mm)

27-1/8 in

(688mm)

29 in

(738mm)

29 in

(738mm)

30-5/8 in

(779mm)

30-5/8 in

(779mm)

28-3/4 in (730mm)

26-7/8 in (683mm)

19-9/16 in

(497mm)

20 in (508mm)

Figure 9.1 -Side View

Figure 9.2 - Side View with Top Vent Adapter (TPVNT-3) and

Oset Adapter (812-3570).

Figure 9.4 - Side View with Top Vent Adapter (TPVNT-6) and

Oset Adapter (811-0720).

Figure 9.3 - Side View with Top Vent Adapter (TPVNT-3) and

Oset Adapter (811-0720).

7080-165D

9September 24, 2018

Page 10

TREKKER FS

D

E

F

A

B

C

C

G

G

B. Clearances to Combustibles (US & Canada)

Installations with:

TPVNT-3 Top Vent Adapter with Heat Shield and

Clean-out

TPVNT-6 Top Vent Adapter with Clean-out

811-0720 (3” to 4”) Oset Adapter

812-3570 (3” to 6”) Oset Adapter

Horizontal Through the Wall Inches Millimeters

A Back Wall to Appliance 2 51

B Side Wall to Appliance 6 152

Corner Installation Inches Millimeters

C Walls to Appliance 2 51

NOTE:

• Illustrations reect typical installations and are FOR

DESIGN PURPOSES ONLY.

• Illustrations/diagrams are not drawn to scale.

• Actual installation may vary due to individual design

preference.

Vertical Installation Inches Millimeters

D Back Wall to Flue Pipe 3 76

E Side Wall to Appliance 6 152

F Back Wall to Appliance 8 203

Corner Installation Inches Millimeters

G Side Wall to Flue Pipe 3 76

10 September 24, 2018

7080-165D

Page 11

TREKKER FS

32-1/8 in.

minimum

30-1/4 in.

minimum

6 in

(FROM FUEL DOOR

OPENING)

6 in

USA

6 in

FUEL DOOR OPENING

24-1/4 in.

minimum

152mm

from fuel door opening

816mm

minimum

768mm

minimum

CANADA

Must extend 51mm

beyond each side

of pipe (shaded area)

to the wall thimble.

152mm

152mm

FUEL DOOR OPENING

514mm

minimum

44-1/8 in.

22-5/8 in.

24-1/4 in.

39-3/4 in.

6 in.

from the fuel door

opening

1121mm

mm

1010mm

152mm

(front door opening)

C. Hearth Pad Requirements (UL & ULC)

Use a non-combustible oor protector, extending beneath

appliance and to the front, sides and rear as indicated.

Measure front distance “M” from the surface of the glass

door.

USA INSTALLATIONS:

A non-combustible oor protection is recommended

extending beneath the ue pipe when installed with

horizontal venting or under the Top Vent Adapter with

vertical installation.

CANADA INSTALLATIONS:

A non-combustible oor protection extending beneath the

ue pipe is required with horizontal venting or under the

Top Vent Adapter with vertical installation.

WARNING

Fire Risk

Comply with all minimum clearances to

combustibles as specied.

Failure to comply may cause house re.

Figure 11.1

Figure 11.2

Figure 11.3

Figure 11.4

7080-165D

Must extend 51mm

beyond each side

of pipe (shaded area)

to the wall thimble.

616mm

USA

575

CANADA

11September 24, 2018

Page 12

TREKKER FS

D

D. Alcove

Figure 12.1

C

A

B

Figure 12.2

Minimum* Maximum

Inches Millimeters Inches Millimeters

A Height 43 1092 n/a n/a

B Width 40 1016 n/a n/a

C Depth n/a n/a 36 914

D To Side Wall 6 152 n/a n/a

*All minimums listed are to a combustible surface.

NOTE:

• Illustrations reect typical installations and are FOR

DESIGN PURPOSES ONLY.

• Illustrations/diagrams are not drawn to scale.

• Actual installation may vary due to individual design

preference.

12 September 24, 2018

7080-165D

Page 13

4 Vent Information

V

A. Venting Termination Minimum Requirements

D

O

E

V

Inside Corner

G

V

A

TREKKER FS

V

N

Electrical

Service

N

V

N

N

V

H

P

Figure 13.1

L

V

B

C

FIXED

V

CLOSED

F

V

B

V

Termination Cap

OPEN

OPEN

V

V

B

X

Air Supply Inlet

FIXED

CLOSED

B

A

G

G

Gas Meter

M

I

V

Restricted Area

X

J or K

All minimum clearances are listed with an Outside Air Kit (OAK) installed, unless otherwise noted in table below.

12 in.

A

12 in.

B

48 in. no OAK

12 in. Open door or window: above

B

6 in.

C

18 in.

D

36 in. no OAK

12 in. Clearance to unventilated sot

E

12 in. Clearance to outside corner

F

12 in. Clearance to inside corner

G

36 in.

H

36 in. USA

I

72 in. Canada

12 in.

J

48 in. no OAK

10 ft horizontal

K

3 ft vertical

7 ft.

L

12 in.

M

See Note

N

below*

24 in.

O

12 in.

P

Above Finish Grade (the grade surface must

be a non-combustible material

Open door or window: below or to the side

Permanently closed window: above, below or

to the side

Vertical clearance to a ventilated sot located

above the terminal within a horizontal distance

of 2 ft from the center-line of the terminal

Above gas meter/regulator measured from

horizontal center-line of regulator

Clearance to service regulator vent outlet

Clearance to non-mechanical air supply inlet to

the building or the combustions air inlet to any

other appliance

Clearance to mechanical air supply

Above paved sidewalk, paved driveway located

on public property

Under an open veranda, porch, deck or

balcony

Electric service: above, below or to the side

(location must not obstruct or interfere with

access)

Adjacent building, fences and protruding parts

of the structure

Clearance above roof line for vertical

terminations

24 in.

12 in.

36 in. no OAK

12 in. Clearance horizontally from combustible wall

15 in.

6 in. horizontal

12 in. vertical

DO NOT TERMINATE VENT:

• In any location that will allow ue gases or soot from

entering or staining the building

• In any location which could create a nuisance or

hazard

• In any enclosed or semi-enclosed area such as a

carport, garage, attic, crawl space, under a sun deck

or porch, narrow walkway

• Closely fenced area, or any location that can build up

a concentration of fumes such as a stairwell, covered

breezeway, etc.

TERMINATION MUST EXHAUST ABOVE AIR INLET

ELEVATION:

• It is recommended that at least 60 inches (1.52m) of

vertical pipe be installed when appliance is vented

directly through a wall. This will create a natural draft,

which will help prevent the possibility of smoke or

odor venting into the home during a power outage.

Above grass, top of plants, wood or any other

combustible

Clearance from any forced air intake of other appliance

Vented directly through a wall, minimum length of

horizontal pipe

Minimum horizontal or vertical terminations must

protrude from wall

NOTICE

NOTICE

• It will also keep exhaust from causing a nuisance

*NOTE: Consult local building, re ocials or authorities

having jurisdiction. Local codes or regulations

may require dierent clearances.

or hazard by exposing people or shrubs to high

temperatures.

• The safest and preferred venting method is to extend

the vent vertically through the roof or above the roof.

7080-165D

13September 24, 2018

Page 14

TREKKER FS

B. Avoiding Smoke and Odors

Negative Pressure, Shut-Down and Electrical Power

Failure

To reduce the probability of back-drafting or burn-back

in the pellet appliance during power failure or shut down

conditions, it must be able to draft naturally without exhaust

blower operation.

Negative pressure in the house will resist this natural draft if

not accounted for in the pellet appliance installation.

Heat rises in the house and leaks out at upper levels. This

air must be replaced with cold air from outdoors which

ows into lower levels of the house.

Vents and chimneys into basements and lower levels of the

house can become the conduit for air supply and reverse

under these conditions.

Outside Air

An outside air kit (OAK-3) is recommended in all

installations and must be ordered separately.

Per national building codes, consideration must be given

to combustion air supply to all combustion appliances.

Failure to supply adequate combustion air for all appliance

demands may lead to back drafting of those and other

appliances.

Vent Congurations

When installing a pellet appliance with a horizontal vent

conguration the frequency of power outages should be

considered:

• Power outages during operation will cause the

appliance to immediately turn o and may create

conditions where smoke will back draft into the house.

In order to reduce the likelihood of smoke back drafting

into the house during a power outage, Hearth and

Home Technologies strongly suggests:

- Installing the pellet venting with a minimum vertical

run of 5 feet (1.52m).

- Installing the outside air kit at least 4 feet (1.22m)

below the vent termination.

To prevent soot damage to exterior walls of the house and

to prevent re-entry of soot or ash into the house:

• Maintain specied clearances to windows, doors and

air inlets, including air conditioners.

• Vents should not be placed below ventilated sots.

Run the vent above the roof.

• Avoid venting into alcove locations.

• Vents should not terminate under overhangs, decks or

onto covered porches.

• Maintain minimum clearance of 12 inches (305mm)

from the vent termination to the exterior wall. If you

see deposits developing on the wall, you may need to

extend this distance to accommodate your installation

conditions.

When the appliance is roof vented (strongly recommended):

- The air intake is best located on the exterior wall

oriented towards the prevailing wind direction

during the heating season.

When the appliance is side-wall vented:

- The air intake is best located on the same exterior

wall as the exhaust vent outlet and located lower

on the wall than the exhaust vent outlet.

The outside air supply kit can supply most of the demands

of the pellet appliance, but consideration must be given to

the total house demand.

House demand may consume the air needed for the

appliance. It may be necessary to add additional ventilation

to the space in which the pellet appliance is located.

Consult with your local HVAC professional to determine the

ventilation demands for your house.

CAUTION

• DO NOT CONNECT THIS APPLIANCE TO

A CHIMNEY FLUE SERVICING ANOTHER

APPLIANCE.

• DO NOT CONNECT TO ANY AIR DISTRIBUTION

DUCT OR SYSTEM.

14 September 24, 2018

7080-165D

Page 15

TREKKER FS

C. Negative Pressure

WARNING

Risk of Asphyxiation!

Negative pressure can cause spillage of combustion

fumes and soot

Negative pressure results from the imbalance of air

available for the appliance to operate properly. It can be

strongest in lower levels of the house.

Causes include:

• Exhaust fans (kitchen, bath, etc.)

• Range hoods

• Combustion air requirements for furnaces, water

appliances and other combustion appliances

• Clothes dryers

• Location of return-air vents to furnace or air

conditioning

• Imbalances of the HVAC air handling system

• Upper level air leaks such as:

- Recessed lighting

- Attic hatch

- Duct leaks

To minimize the eects of negative air pressure:

• Install the outside air kit with the intake facing prevailing

winds during the heating season

• Ensure adequate outdoor air for all combustion

appliances and exhaust equipment

• Ensure furnace and air conditioning return vents are

not located in the immediate vicinity of the appliance

• Avoid installing the appliance near doors, walkways or

small isolated spaces

• Recessed lighting should be a “sealed can” design

• Attic hatches weather stripped or sealed

• Attic mounted duct work and air handler joints and

seams taped or sealed

D. Draft

Draft is the pressure dierence needed to vent an

appliance successfully. When an appliance is drafting

successfully, all combustion byproducts are exiting the

home through the chimney.

E. Chimney and Exhaust Connection

1. Chimney & Connector: Use 3 or 4 inch (76-102mm)

diameter type “L” or “PL” venting system. It can be

vented vertically or horizontally.

NOTE: The appliance exhaust outlet is designed to

accommodate 3 inch venting. Use of 4 inch

venting requires the use of a 3-to-4 inch exhaust

vent increaser in addition to any other venting

components needed, sold separately.

2. Mobile Home: Approved for all Listed pellet vent. If

using the 3 inch (76mm) vertical Top Vent Adapter

Kit or the 3 to 6 inch (76-152mm) Top Vent Oset

Adapter, use Listed double wall ue connector. A

Quadra-Fire Outside Air Kit (OAK-3) must be used with

manufactured home installations.

3. Residential: The 3 inch (76mm) vertical Top Vent

Adapter Kit and the 3 to 6 inch (76-152mm) Top Vent

Oset Adapter are tested to use 24 gauge single wall

ue connector or Listed double wall ue connector to

Class A Listed metal chimneys, or masonry chimneys

meeting International Residential Code standards for

solid fuel appliances.

4. INSTALL VENT AT CLEARANCE SPECIFIED BY THE

VENT MANUFACTURER.

5. Secure exhaust venting system to the appliance with

at least 3 screws. Also secure all connector pipe joints

with at least 3 screws through each joint.

6. DO NOT INSTALL A FLUE DAMPER IN THE

EXHAUST VENTING SYSTEM OF THIS APPLIANCE.

7. DO NOT CONNECT THIS APPLIANCE TO A

CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

NOTE: All pipe must be welded seam pipe whenever

possible. Seal pipe joints with high temperature

silicone (500°F [260°C] minimum rated only).

WARNING

USE ONLY RECOMMENDED VENTING

COMPONENTS; OTHERWISE MAKESHIFT PARTS

MAY RESULT IN PROPERTY DAMAGE, PERSONAL

INJURY, OR DEATH.

Install through the warm airspace enclosed by the building

envelope. This helps to produce more draft, especially

during lighting and die-down of the re.

Considerations for successful draft include:

• Preventing negative pressure

• Location of appliance and chimney

NOTICE: Hearth & Home Technologies assumes no

responsibility for the improper performance of

the chimney system caused by:

• Inadequate draft due to environmental conditions

• Down drafts

• Tight sealing construction of the structure

• Mechanical exhausting devices

7080-165D

15September 24, 2018

Page 16

TREKKER FS

3 in. or 4 in. (76mm or 102mm) Diameter Pipe

Equivalent Pipe

Length In Feet

ALTITUDE IN THOUSANDS OF FEET

0

20

30

1 2 3 4 5 6 7 8 9 10

4 in. (102mm) Diameter Pipe Only

10

Example 1

Example 2

2 ft.

F. Equivalent Feet of Pipe

The table below can help you calculate the equivalent feet

of pipe which is a method used to determine pellet vent

size (Figure 16.1).

Example of 3 Elbow-Rear Vent Termination Calculation

Pellet

3 ft.

Figure 16.1

2 ft.

2 ft.

Venting

Component

90° Elbow or

Tee

45° Elbow

Horizontal

Pipe

Vertical Pipe

NOTE: This is a generic example and is not intended to represent any specic

fuel type.

Elbows

WARNING

Vent surfaces get HOT, can cause burns

if touched. Non-combustible shielding or

guards may be required.

# of

3 X 5 15

Feet

Multiplied ByEquivalent

of

Feet

Components

Equivalent

Pipe

X 3

7 X 1 7

2 X 0.5 1

Total Equivalent Feet 23

Feet

G. Pipe Selection Chart

The chart will help you in determining proper venting

size according to the equivalent feet of pipe calculated

previously and the altitude above sea level of this

installation (Figure 16.2).

1. Locate the calculated equivalent feet of pipe on the

vertical left side of the chart.

2. Move to the right horizontally on the chart until you

reach your altitude above sea level.

3. If you fall below the diagonal line, 3 or 4 inch (76 to

102mm) pipe may be used.

4. If it is anywhere above the diagonal line, a 4 inch

(102mm) diameter pipe is required.

NOTICE

• A 90° elbow is 5 times as restrictive to the ow of

exhaust gases under positive pressure as 1 foot

(305mm) of horizontal pipe.

• A foot of horizontal pipe is twice as restrictive as a

foot of vertical pipe.

WARNING

16 September 24, 2018

Risk of Fire!

• Only LISTED venting components may be

used.

• NO OTHER vent components may be

used.

• Substitute or damaged vent components

may impair safe operation.

Figure 16.2

Example 1: If the equivalent length of pipe is 23 feet (7m)

with altitude of 8,000 feet (2438m) you must use

4 inch (102mm) diameter type “L” or “PL” vent.

Example 2: If the equivalent length of pipe is 12 feet (3.7m)

with altitude of 6,000 feet (1829m) you may use 3

or 4 inch (76 to 102mm) diameter type “L” or “PL”

vent.

WARNING

Risk of Injury or Property Damage.

• Improper installation, adjustment, alteration,

service or maintenance can cause injury or

property damage.

• Refer to the owner’s information manual

provided with this appliance.

• For assistance or additional information

consult a qualied installer, service agency

or your dealer.

7080-165D

Page 17

Wall

Thimble

Illustration shows venting going in both directions.

Choose which one is best for your installation.

2 in. (51mm)

Minimum

2 in.

(51mm)

Minimum

6 in. (152mm)

Minimum

6 in. (152mm)

Minimum

5 Venting Systems

TREKKER FS

A. Through The Wall

Horizontal termination cap must be a minimum of 6

inches. (152mm) from the wall. Approved for mobile home

installations. Must use 3 or 4 inch (76-102mm) “L” or “PL”

Listed pellet venting or Listed double wall pipe and a

Quadra-Fire Outside Air Kit in mobile homes.

CAUTION

We strongly recommend that you DO NOT DOWNWARD

VENT. The following may occur:

• The appliance will not vent properly

• Smoke spillage in the house

• Excessive sooting

Straight Out

6 in

[152mm]

Min

2 in [51mm] min

NOTE: In Canada, where passage through a wall or

partition of combustible construction is desired,

the installation shall conform to CAN/CSA-B365

NOTICE:

Please note that while the minimum clearance for

the termination cap is 6 inches (152mm) there is the

possibility of soot build-up around the termination area.

If this occurs we suggest to move the termination further

away from the house to prevent it.

Horizontal

Termination

Wall

Thimble

Cap

Figure 17.1

45 Degree

6 in

[152mm]

Min

Non-combustible Hearth Pad

Figure 17.2

7080-165D

17September 24, 2018

Page 18

TREKKER FS

Firestop

Flashing

Rain Cap

6 in

[152mm]

Min

Non-combustible Hearth Pad

3 in [76mm] Min

Clean-out Cover

12 in. [305mm] Min

Ceiling Support

3 to 6 in [76 to 152mm]

Offset Adapter

6 in. [152mm] Class A

Chimney Connector

Adapter

3 to 3 in

[76-76mm]

Top Vent Kit

Non-combustible Hearth Pad

Clean-out

Cover

Tee

Wall Thimble

Support

Bracket

every 60 in

[1524mm]

12 in

[305 mm]

Minimum

Rain

Cap

Flashing

2 in [51mm] min

6 in

[152mm]

Min

B. Vertical into Existing Class A Chimney

Figure 18.1

We recommend a minimum of 60 inches (1524mm) vertical,

however above the eave is preferred.

All three installations are approved for mobile home

installations. Must use 3 or 4 inch (76 to 102mm) “L” or “PL”

Listed pellet venting or Listed double wall pipe and QuadraFire Outside Air Kit in mobile homes. Single wall pipe is

approved for residential installations only.

*NOTE: Clearance to combustibles are for standard

pellet pipe. If pellet pipe manufacturer allows

reduced clearances to their pipe, reduced

clearances are allowed.

NOTE: A chimney connector shall not pass through an

attic or roof space, closet or similar concealed

space, or a oor or ceiling.

C. Through The Wall & Vertical - Exterior

Figure 18.2

18 September 24, 2018

D. Vertical - Interior - Typical Installation

Rain

Cap

12 in

Flashing

Firestop

6 in

[152mm]

Min

Non-combustible Hearth Pad

Figure 18.3

7080-165D

[305 mm]

Minimum

3 in [76mm] Min

3 to 3 in

[76 to 76mm]

Top Vent Kit

Clean-out Cover

Page 19

E. Masonry

Concrete Cap

Non-combustible Hearth Pad

6 in

[152mm]

Min

Airtight clean-out door

Sheathing

1 in [25mm] clearnance

2 in [51mm] min to

combustible material

Flashing

Fireclay Flue Liner

with airspace

1 in [25mm] clearance

with firestop

Concrete Cap

Non-combustible Hearth Pad

6 in

[152mm]

Min

Airtight clean-out door

Sheathing

1 in [25mm] clearnance

Flashing

Fireclay Flue Liner

with airspace

1 in [25mm] clearance

with firestop

3 in [76mm] min to

combustible material

Clean-out cover

TREKKER FS

Figure 19.1

F. Alternate Masonry

Figure 19.2

Fire Risk.

WARNING

Inspection of Chimney:

• Masonry chimney must be in good condition.

• Meets minimum standard of NFPA 211

• Factory-built chimney must be a minimum 6 inch

(152mm) UL103 HT.

7080-165D

19September 24, 2018

Page 20

TREKKER FS

Termination Cap

Wire

Tie

Trim Ring

Wire Tie

Collar

3 inch Aluminum

Flex Pipe

(not included)

6 Appliance Set-Up

A. Leg Leveling System

1. Thread Allen bolts through nuts until ush (Figure

20.1). The

component pack inside the appliance rebox.

2. Slide assembled nuts and bolts into slots on legs with

the nuts on the bottom (Figure 20.2). Use a 5/32 in.

(3.96mm) Allen wrench to adjust legs up and down to

desired level (Figure 20.3).

Figure 20.1

Allen bolts and nuts are included in the

B. Outside Air Kit Instructions

CAUTION

Never draw outside combustion air from:

• Wall, oor or ceiling cavity

• Enclosed space such as an attic or garage

Included in Kit: 2 wire ties, 1 collar assembly,

1 termination cap assembly, 1 trim ring, fasteners.

NOTE: 3 INCH ALUMINUM FLEX PIPE NOT

INCLUDED.

Tools Needed: Phillips head screw driver; wire cutters hole

saw or jig saw.

1. Measure distance from oor to air vent opening in

appliance and mark location on wall.

- Use saw to cut opening in wall. Cut a 3-1/2 to 4

inch (89-102mm) opening on inside wall and a 4

to 4-1/2 inch (102-114mm) opening on outside of

house.

2. Use wire tie to secure ex pipe to collar assembly.

3. Slide trim ring over ex pipe and run pipe through wall.

4. Attach ex pipe (not supplied) to outside termination

cap with second wire tie.

5. Secure termination cap to outside surface.

6. Secure trim ring to interior wall.

Figure 20.2

Figure 20.3 - Bolt fully extended

Figure 20.4 - OAK exploded view

20 September 24, 2018

7080-165D

Page 21

3 in. to 6 in.

Offset Adapter

Silicone Rear

Exhaust Outlet

3 in. to 3 in. Top

Vent Adapter

Clean-Out

Cover

Drill Hole, 1

on each side

C. Top Vent Adapter Installation

Clean-Out Cover

Clean-Out Cover

3 to 3 inch (76-76mm) Top Vent Adapter

3 to 6 inch (76-152mm) Top Vent Oset Adapter

Installing the Top Vent Adapter

1. Put a layer of high temperature silicone on the 3 inch

(76mm) exhaust outlet. Do not put silicone inside of

pipe (Figure 21.1).

2. Slide the top vent adapter onto the rear exhaust outlet

and adjust the assembly to a vertical position until

the top of the ue outlet is centered and is in a level

position (Figure 21.1).

3. Align slot on left of adapter with hole in the back of

the appliance and secure with screw. You may drill out

the hole using #26 drill bit provided but only if needed

(Figure 21.2).

4. Install the 5 mounting screws, 3 on the left and 2 on the

right.

5. Drill 2 holes with #26 drill bit through the rear exhaust

outlet using the 2 holes already in the short horizontal

pipe in the top vent adapter as a guide. Install the

screws.

6. Install the vent pipe into the top vent adapter (be sure

to silicone all joints). To use an existing 6 inch (152mm)

vent system, install the 3 to 6 in (76-152mm) oset

adapter before installing vent pipe.

7. To clean top vent adapter, open clean-out cover and

remove any debris build-up (Figure 21.2).

TREKKER FS

Figure 21.2

D. Rear Vent & Rear Vent to Top Vent Adapter

Figure 21.1

Figure 21.3 - Rear Vent Adapter

Figure 21.4 - Rear to Top Vent Adapter - 90°

1. Put a layer of high temperature silicone on the 3 inch

(76mm) exhaust outlet. Do not put silicone inside of

pipe (Figure 21.1).

2. Slide the adapter onto the rear exhaust outlet and

adjust the assembly to the appropriate position.

3. Install the vent pipe into the adapter (be sure to silicone

all joints)

7080-165D

21September 24, 2018

Page 22

TREKKER FS

E. Optional Log Set Placement Instructions

2 PIECE LOG SET INSTALLATION

1. Place the left log as shown. There are 2 indentations in

the bottom of the log to t over the screw heads in the

rebox (Figures 22.1 and 22.2).

2. Place the right log in front of the 2 screw heads in the

rebox (Figures 22.3 and 22.4).

CAUTION

Logs are FRAGILE. Use extreme care when handling or

cleaning logs.

Left Log

Right Log

Log rests in front of screws

Figure 22.3

Figure 22.1

Figure 22.2

Log fits over screws

Log has indentations on the

bottom to fit over the screw

heads.

Figure 22.4

NOTICE: Due to the abrasive nature of a pellet

appliance re, the logs are not covered under

warranty. Any placement variation other than

shown here can cause excessive heat and

shall void the appliance warranty.

22 September 24, 2018

7080-165D

Page 23

F. Installation of User Interface

Level

Bluetooth Key

Plug the Bluetooth key into the appliance (Figure 23.1)

TREKKER FS

Install battery (Figure 23.4)

Figure 23.3

Figure 23.1

G. Power to Appliance and User Interface

1. Prior to installing the power cord, turn the user interface

to OFF.

2. Make sure the was receptacle has 120vac output.

NOTE: Using a circuit protector can protect the appliance

circuits from power surges.

3. The appliance receptacle is located on its lower, back

right hand corner. Install the cord to the appliance

reception and to the wall (Figure 23.3).

• This will cause the combustion blower to turn on

for approximately 45 seconds and run a systems

check.

NOTE: See user interface manual on how to operate the

user interface.

H. Location & Mounting User Interface

- Make sure you have a reliable bluetooth connection

- Maximum distance of 30 foot radius from appliance

- On an interior wall

- 5 feet from the oor

- Not behind doors, bookcases or other objects

- Away from drafts and direct heat from the

appliance

Mount base plate using screws and anchors provided using

the level as a guide.

If necessary drill 3/16 holes for drywall or drill 7/32 for

plaster.

Figure 23.2

CAUTION

Shock hazard.

• Do NOT remove grounding prong from

plug.

• Plug directly into properly grounded 3

prong receptacle.

• Route cord away from appliance.

• Do NOT route cord under or in front of

appliance.

Figure 23.4

7080-165D

23September 24, 2018

Page 24

TREKKER FS

Spark Arrestor Cap

Roof Flashing

Storm Collar

Joist Shield/Firestop

Approved Class L

or PL Pellet Vent

7 Mobile Home Installation

You must use a Quadra-Fire Outside Air Kit for

installation in a mobile home.

1. An outside air inlet must be provided for the

combustion air and must remain clear of leaves, debris,

ice and/or snow. It must be unrestricted while the

appliance is in use to prevent room air starvation which

causes smoke spillage. Smoke spillage can also set o

smoke alarms.

2. The combustion air duct system must be made of

metal. It must permit zero clearance to combustible

construction and prevent material from dropping into

the inlet or into the area beneath the dwelling and

contain a rodent screen.

3. The appliance must be secured to the mobile home

structure by bolting it to the oor (using lag bolts).

Use the same holes that secured the appliance to the

shipping pallet.

4. The appliance must be grounded with #8 solid copper

grounding wire or equivalent, terminated at each end

with an NEC approved grounding device.

5. Refer to Clearances to Combustibles and oor

protection requirements on page 8 for listings to

combustibles and appropriate chimney systems.

6. Use silicone to create an eective vapor barrier at

the location where the chimney or other component

penetrates to the exterior of the structure.

7. Follow the chimney manufacturer’s instructions when

installing the vent system for use in a mobile home.

8. Installation shall be in accordance with the

Manufacturers Home & Safety Standard (HUD) CFR

3280, Part 24.

CAUTION

THE STRUCTURAL INTEGRITY OF THE MOBILE

HOME FLOOR, WALL AND CEILING/ROOF MUST BE

MAINTAINED

Do NOT cut through:

• Floor joist, wall, studs or ceiling trusses.

• Any supporting material that would aect the

structural integrity.

This appliance is to be connected to a factory-built

chimney conforming to CAN/ULC-S629, Standard for

650°C Factory-Built Chimneys.

For removal of the chimney for mobile home

transportation, contact the proper transportation ocials.

Figure 24.1

Part Number: OAK-3

WARNING

Products of combustion generate carbon monoxide

and dierent fuels generate dierent levels. Carbon

monoxide

• Only use approved fuels in this appliance.

• Always keep door shut during operation. Operating

this appliance with doors open can allow CO to leak

into the home.

CO can kill you before you are aware it is in your home.

At lower levels of exposure, CO causes mild eects that

are often mistaken for the u. These symptoms include

headaches, dizziness, disorientation, nausea and fatigue.

The eects of CO exposure can vary greatly from person

to person depending on age, overall health and the

concentration and length of exposure.

24 September 24, 2018

CAUTION

Never draw outside combustion air from:

• Wall, oor or ceiling cavity

• Enclosed space such as an attic or garage

WARNING

It is critical to have a working smoke detector

installed in the home of appliance operation.

• Smoke alarms that are properly installed and

maintained play a vital role in reducing re deaths

and injuries. Having a working smoke alarm reduces

the chance of re related injuries..

WARNING

NEVER INSTALL IN A SLEEPING ROOM.

7080-165D

Page 25

8 Reference Materials

A. Service and Maintenance Log

Date of Service Performed By Description of Service

TREKKER FS

7080-165D

25September 24, 2018

Page 26

TREKKER FS

Date of Service Performed By Description of Service

26 September 24, 2018

7080-165D

Page 27

B. Accessories List

Service Parts

R

TREKKER

Beginning Manufacturing Date: Jun 2018

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor.

Hearth and Home Technologies does not sell directly to consumers. Provide model number

and serial number when requesting service parts from your dealer or distributor.

Stocked

at Depot

ITEM DESCRIPTION COMMENTS PART NUMBER

Component Pack Assembly

Matte Black SRV7080-066

Porcelain Black SRV7080-069

Porcelain Dark Blue SRV7080-070

Porcelain Frost SRV7080-071

Porcelain Mahogany SRV7080-068

Sienna Bronze SRV7080-067

Cleanout Tool 414-1140 Y

Leveling Assembly 7000-000

Paint Touch-Up

Matte Black 812-0910

Porcelain Black 1-00-0022

Porcelain Dark Blue

1-00-0020

Porcelain Frost 1-00-0021

Porcelain Mahogany

855-1450

Sienna Bronze TOUCHUP-CSB

Power Cord 812-1180 Y

Exhaust Probe SRV7000-669

Heating Element Assembly 18”, 120 VAC, 300 Watt,

(Wood Pellet Fuel Only)

SRV7000-647 Y

Pkg of 10 SRV7000-647/10 Y

Wing Thumb Screw 8-32 X 1/2 Pkg of 24 7000-223/24 Y

Wire Clip Pkg of 10 7000-400/10 Y

ITEM DESCRIPTION COMMENTS PART NUMBER

R

Service Parts

Beginning Manufacturing Date: Jun 2018

Ending Manufacturing Date: Active

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor.

Hearth and Home Technologies does not sell directly to consumers. Provide model number

and serial number when requesting service parts from your dealer or distributor.

ACCESSORIES

Collar, Offset, Top Vent 812-3570

Damper, 3 Inch - Tall Vertical Installs Only PEL-DAMP3 Y

Damper, 4 Inch - Tall Vertical Installs Only PEL-DAMP4

Log Set, (Sold as Set only) 2 Pc LOGS-60-AE-B

Outside Air Kit OAK-3

Top Vent Adapter TPVNT-3

TREKKER FS

TREKKER

Stocked

at Depot

7080-165D

27September 24, 2018

Page 28

CONTACT INFORMATION

Hearth & Home Technologies

352 Mountain House Road

Halifax, PA 17032

Division of HNI INDUSTRIES

Please contact your Quadra-Fire dealer with any questions or concerns.

For the number of your nearest Quadra-Fire dealer

log onto www.quadrafire.com

CAUTION

DO NOT DISCARD THIS MANUAL

• Important operating and

maintenance instructions included.

•

Read, understand and

follow these instructions for safe installation and operation.

•

Leave this manual with

party responsible for use

and operation.

DO NOT

DISCARD

We recommend that you record the following pertinent

information for your heating appliance.

Date purchased/installed:_________________________________________________________________________

Serial Number:____________________________________ Location on appliance:___________________________

Dealership purchased from:________________________________________ Dealer phone:_1(_____)_____-______

Notes:________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

This product may be covered by one or more of the following patents: (United States) 5341794, 5263471, 6688302, 7216645, 7047962

or other U.S. and foreign patents pending.

28 September 24, 2018

7080-165D

Loading...

Loading...