Qasair EAS120L2B, EAS120LT2, WCV1300L3B, WCV1300L3T, WES120L2B Installation and Operation Guide

...

UNDERCUPBOARD

INSTALLATION & USER

INSTRUCTIONS

Qasair Rangehoods Installation Instructions2

Important Information

4

Cutout Dimensions

Duct Direction Change Instructions

Instructions for Models

MT / MC

Instructions for Models

FA

Instructions for Models

CON / NDCH / LIS / ETN

Instructions for Models

WCV

Instructions for Models

WES / EAS

6

7

8

11

13

23

27

Remote Switching Specications

Ducting Pieces

Installation Ideas

Operation Details, Rangehood Cleaning, Filter Cleaning

Appliance Guarantee

Guarantee Exclusions

Standard Warranty / Extended Warranty

31

34

46

51

52

53

54

Qasair Rangehoods Installation Instructions

3

IMPORTANT INFORMATION

The installation of QASAIR Rangehoods must comply with the information in this booklet. QASAIR Rangehoods are

designed and made to work efciently over all domestic cookware available on the Australian market.

Clearance from cooktop to Rangehood

For electric hot plate cooktops

As there are no regulations for Rangehoods over an electric hot plate, please follow the manufacturers Instructions /

Recommendations.

For Induction cooktops

Induction cooktops may present problems with condensation on lters of Rangehoods.

All Qasair Rangehoods installed above an induction cooktop must be installed no less than 750mm between the

induction cooktop and the Rangehood, with the exception of the Eastmore (EAS) Rangehood which can be installed

no less than 600mm. Undermount (NDCH) and Conley (CON) Rangehoods are not suitable for induction cooktops.

For gas cooktops

All Qasair Rangehood installations over a gas appliance must comply with (AS/NZS 5601.1).

The Regulations for the installation of Gas Appliances (AS/NZS 5601.1) states that the clearance between the

highest part of the burner of a gas cooking appliance and a Rangehood be no less than 600mm. If the gas

appliance is designed for use without a cooking vessel like an indoor barbecue or open ame grill, then the

clearance from the cooking surface to the Rangehood shall be no less than 1200mm.

All Qasair Rangehoods installed above a gas cooktop must be installed no less than 600mm between the highest

part of the burner and the Rangehood.

The recommendation for Qasair Wallmount Rangehoods is that they be installed between 700 to 800mm above the

highest part of the burner. When the Rangehood is installed in a galley or partially enclosed kitchen the Rangehood

can be installed between 900 to 1000mm above the highest part of the burner.

Qasair Island Rangehoods should not be installed any higher than 800mm above the highest part of the burner as

any movement around the bench will result in fumes being drawn out from the catchment area of the Rangehood

with the exception of the Thermidor and Liverpool which for aesthetic reasons is installed ush with the ceiling.

Ducting

1. Every QASAIR Rangehood must be ducted to the outside atmosphere by the use of zinc-alume duct or

non-porous and non-ammable materials. Do not use of any type of exible ducting or plastic PVC piping.

Rangehoods must not be vented into a wall cavity or a ceiling space. Externally ducting the rangehood prevents

a build up of grease, which can be a re risk. Ensure the external outlet vent does not restrict the airow in any

way, as this may result in reduced performance.

2. QASAIR Rangehoods must be ducted in duct work equivalent to the outlet of the rangehood ie: The cross

sectional area of the rangehood outlet and the duct work must be equal. Do not reduce the duct size or have

sharp bends. Enlarge the duct size if the duct is to run 6 metres or longer. Advice from CONDARI is available to

ensure optimum performance. Always use nonammable materials to minimise the risk of re in the duct.

3. Ensure all ducting pieces are correctly tted and sealed with either duct tape or silicone to ensure that fumes

do not escape into the ceiling space and seep into living areas through vents or light ttings.

Qasair Rangehoods Installation Instructions4

Other Important Information

1. Always adequately ventilate the room when the rangehood is in use at the same time as appliances

burning gas or other fuels.

2. WARNING: Incorrect venting will result in additional noise and a reduction in efciency. Exhaust air must not be

discharged into any chimney or ue, which may carry combustible products from other sources.

a) Do not discharge the air-ow from the rangehood into a ue used for exhausting fumes

from burning gas or fuel;

b) For cleaning purposes please refer to page 51 of installation instructions for stainless steel;

c) If cleaning is not carried out in accordance with the instructions as listed on page 51, there may be an

increased risk of re;

d) Some parts of the rangehood may become hot when cooking;

e) This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

3. The installation and tting of the rangehood should be done in such a way that will allow the unit to be removed

if service is required. Additional costs incurred in the removal of wall tiles, damage to walls or bench tops are not

covered by warranty.

4. To reduce the risk of xing screws coming in contact with live parts, do not drill or screw into the rangehood.

Live wires are encapsulated where possible to prevent user contact. If necessary drill from the inside out and

only through single sheet material.

5. NOTE: CONDARI recommend an air movement of between 1000 to 1400 cubic metres per hour over an indoor

barbecue, depending on the length of the duct run. Ensure a twin motor unit is installed over indoor barbecues

for optimum results. Barbecues should be positioned under the centre of the hood where the fans are mounted

and not near the outer edges where leakage may occur.

6. The lights in the rangehoods are LED and come with a night light except for D400L-1 and SEN400L-1.

7. If the supply cord is damaged, an authorised service centre or licensed electrician must replace it.

8. Do not ambé under the rangehood.

9. QASAIR domestic rangehoods must not to be used over barbecues approved for outdoor use only,

CONDARI make a range of hoods specically for outdoor barbecues in alfresco areas under the CONDOR

name.

10. CONDARI can manufacture rangehoods to be used over commercial cookers in domestic applications.

12. NOTE: Ensure all requirements are met with gas and electrical regulations and or state authorities.

Qasair Rangehoods Installation Instructions

5

INSTALLATION INSTRUCTIONS

EXECUTIVE / FLINDERS RANGE

CUTOUT DIMENSIONS

MODEL HOOD SIZE BASE SIZE

CON 60L 243 x 580 280 x 600 258 x 585 280 x 600

CON 80L

NDCH 90L 243 x 880 280 x 900 258 x 885 280 x 900

NDCH 100L 243 x 980 280 x 1000 258 x 985 280 x 1000

NDCH 120L 243 x 1180 280 x 1200 258 x 1185 280 x 1200

LIS 500L 390 x 480 430 x 500 400 x 485 430 x 500

LIS 800L 390 x 780 430 x 800 400 x 785 430 x 800

LIS 900L 390 x 870 430 x 900 400 x 885 430 x 900

LIS 1000L 390 x 980 430 x 1000 400 x 985 430 x 1000

LIS 1200L 390 x 1180 430 x 1200 400 x 1185 430 x 1200

LIS 1500L 390 x 1480 430 x 1500 400 x 1485 430 x 1500

WES 60L / EAS 60L 290 x 565 330 x 600 300 x 570 330 x 600

WES 80L / EAS 80L 290 x 780 330 x 800 300 x 785 330 x 800

243 x 780 280 x 800 258 x 785 280 x 800

PROUD MOUNT

CUT OUT DIMENSION

FLUSH MOUNT

CUT OUT DIMENSION

WES 90L / EAS 90L 290 x 880 330 x 900 300 x 885 330 x 900

WES 100L / EAS 100L 290 x 980 330 x 1000 300 x 985 330 x 1000

WES 120L / EAS 120L 290 x 1180 330 x 1200 300 x 1185 330 x 1200

WCV 1000L 560 x 980 600 x 1000 570 x 985 600 x 1000

WCV 1300L 560 x 1280 600 x 1300 570 x 1285 600 x 1300

WCV 1600L 560 x 1580 600 x 1600 570 x 1585 600 x 1600

WCV 1800L 560 x 1780 600 x 1800 570 x 1785 600 x 1800

ETN 600L 340 x 580 380 x 600 355 x 585 380 x 600

ETN 900L 340 x 880 380 x 900 355 x 885 380 x 900

ETN 1200L 340 x 1180 380 x 1200 355 x 1185 380 x 1200

Qasair Rangehoods Installation Instructions6

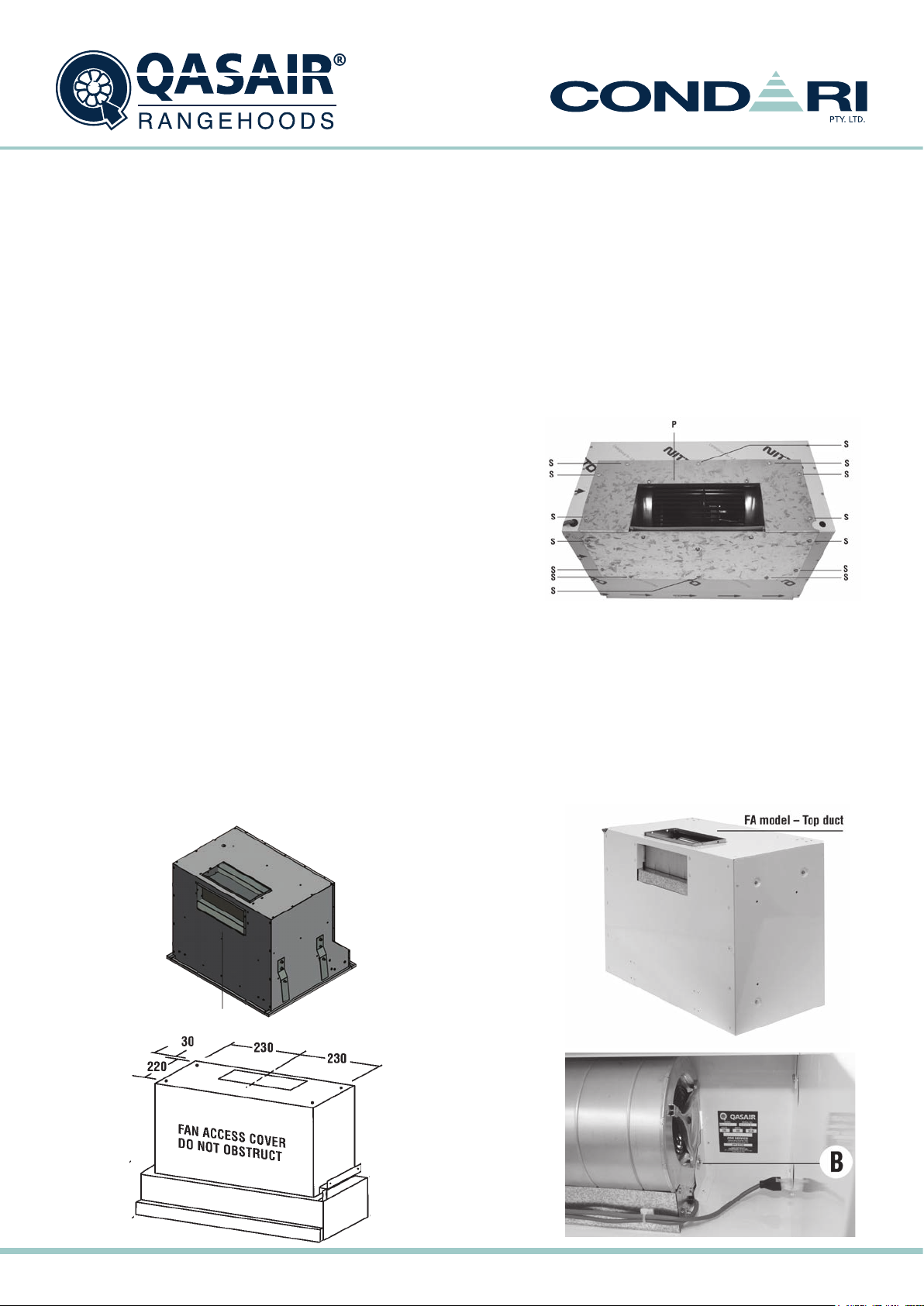

DUCT DIRECTION CHANGE INSTRUCTIONS

Before installing your rangehood check whether it has the fan mounted for back or top ducting.

For top ducting, the unit will have the air outlet at the top, and for back ducting, the unit will have the air outlet at the

back.

To change from top to back or back to top, proceed as follows:

Duct direction for ETN, NDCH and CON models

The motor shown is fitted to the back plate (P) and this plate is attached to the hood by screws (S). To change from

top to back, remove the filters, unplug fan(s). Undo all the screw (S), carefully remove the plate and turn it around so

the motor points out the way required. Fit and reconnect the fan(s), and fit all the screws again and tighten.

Duct direction for LIS / FA / MT / MC / EAS and WES

To change the duct direction, proceed as follows:

1. Remove the screws from the fan access panel and remove access panel (for MT and MC models only).

2. Disconnect fan(s).

3. Unscrew the 2 x 7mm screws (B) fixing the fan to the hood. Remove fan entirely. Repeat for each fan.

4. Rotate the fan assembly and re-install so that the air outlet meets with the rangehood outlet hole through which

you are going to vent (top or back).

5. Replace the 2 x 7mm screws holding each fan.

6. Reconnect the fan(s)

7. Refit the fan access panel (for MT, EAS and WES models only).

LIS model – Rear duct

Qasair Rangehoods Installation Instructions

7

INSTALLATION INSTRUCTIONS

• MT

Installation must be carried out by the procedure outlined.

Failure to do so may void the guarantee.

Electrical: Wiring to the appliance must comply with State and local Regulations.

Connection to be carried out by a registered electrician.

• MC

1. Fit a shelf at 410mm from the base of the cupboard.

2. Note hinge location prior to drilling.

3. Work from the centre line mark and drill 4 x M5 to M8 holes.

4. For top ducted models, cut out hole for the ducting allow 20mm clearance.

5. Fix left and right hand mounting brackets (supplied) 145mm from the base of the cupboard flush with the rear

of the unit. Notch to the back.

6. Lift rangehood onto mounting brackets by holding either end. DO NOT use the slide mechanism as this may

cause damage.

7. Insert the 4 x 50mm pan head screws supplied through the shelf and into the rangehood. Turn clockwise to level

the rangehood.

8. Fix the rangehood position by inserting 2 x no 8 1/2 inch screws through the left and right hand brackets.

9. Fit doors.

10. Minor adjustments may be required on the rangehood handle. Loosen the screws on the rear of the handle and

adjust handle position and re- tighten. The rangehood handle can be replaced.

11. All of the rangehoods shown on pages 1 and 8 are supplied with a 10AMP plug and lead for connection

to a 10AMP GPO, which must be in an accessible position.

12. The handle can be removed and replaced with one made by the cabinet maker to fit in with the kitchen cabinets.

The MT 90 has 3 screws and the MT 60 has 2 screws. These can be accessed by sliding the facia out and

un-screwing the front from underneath and behind the facia. The handle will come off by tilting it forward from

the top.

Qasair Rangehoods Installation Instructions8

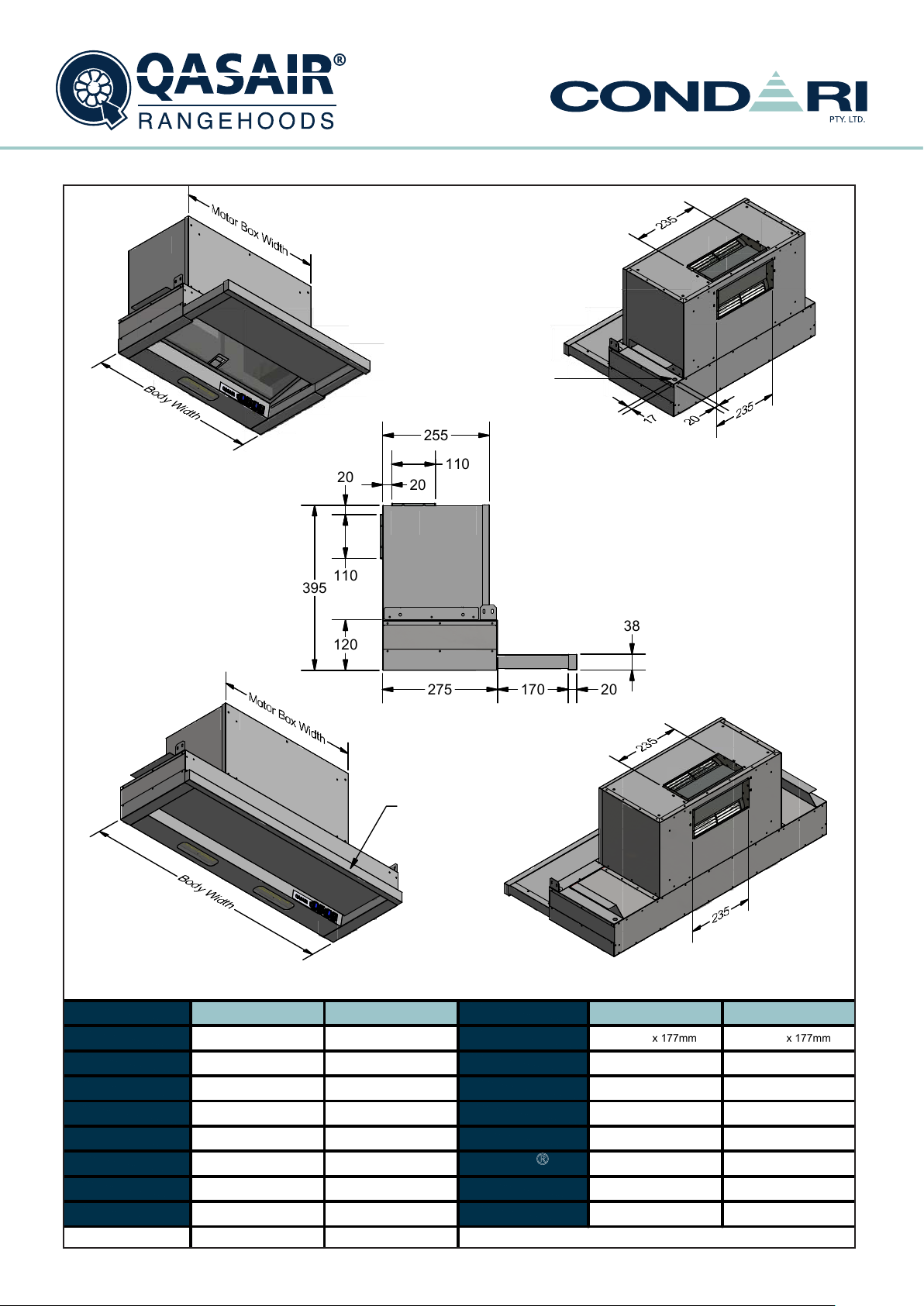

Mini Trim

Technical Specification Sheet

MT Slide Out

Page 1 of 1Condari Pty Ltd.

Version: B 03/12/2014F

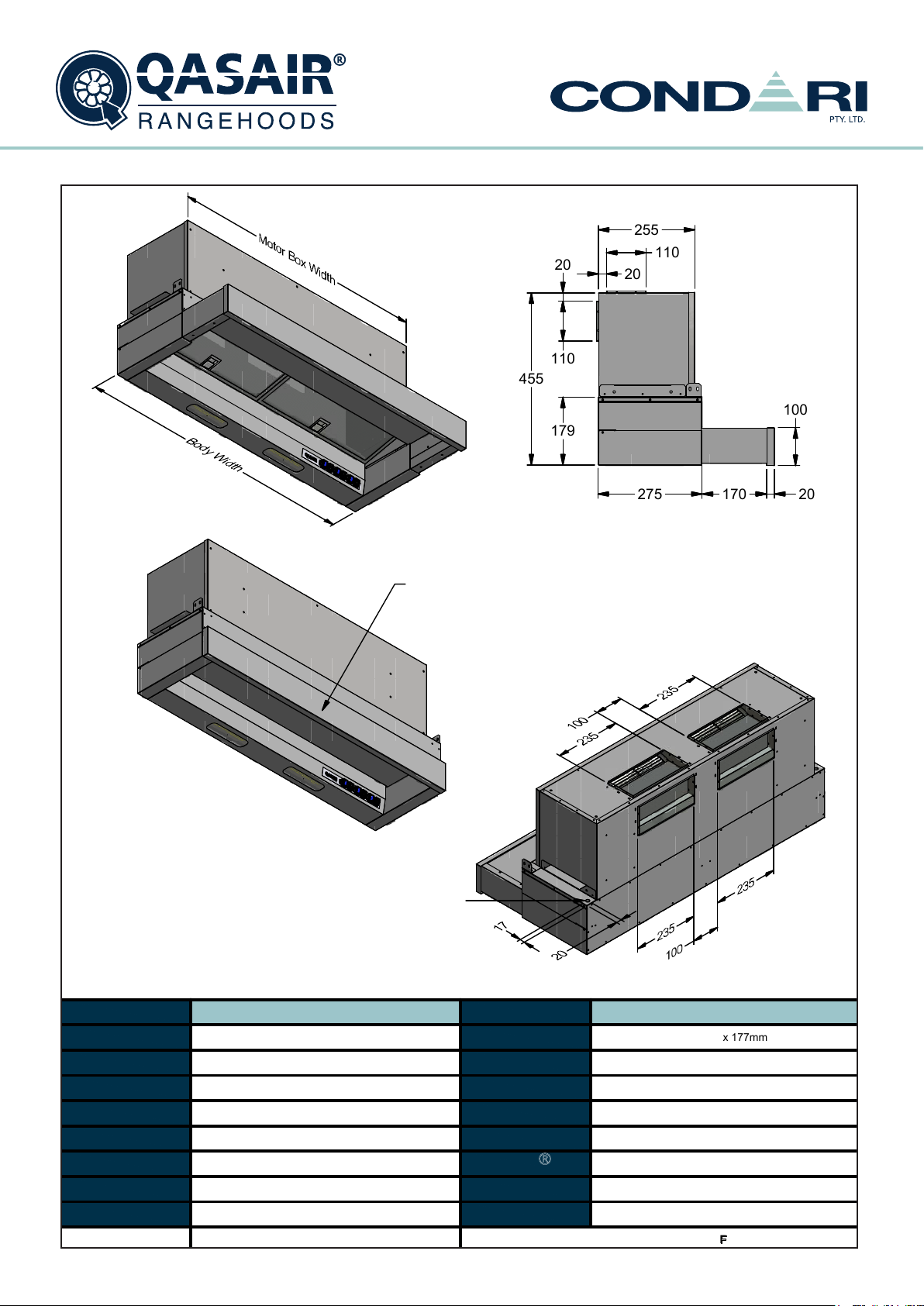

MINI TRIM - MT

Power entry location

is the same for all

MT models.

255

395

110

120

2

0

2

0

3

8

2

275

170

0

This view is shown

with slide out trim

in closed position.

110

Model Model MT 60L-1

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

MT 60L-1

600mm

518mm

1

Cool

YES

1

N/A

1

MT 90L-1

900mm

518mm

1

Cool

YES

2

320mm

2

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

514mm

10 Amp Lead

Square

Qasair Rangehoods Installation Instructions

x 177mm

YES

N/A

N/A

N/A

N/A

MT 90L-1

x 177mm

407mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

9

Condari Pty Ltd. Page 1 of 1

Version: B 03/12/2014

Marcel

Technical Specification Sheet

MC Slide Out

MARCEL - MC

2

110

455

179

255

0

110

2

0

100

This view is shown

with slide out trim

in closed position.

Power Entry

275

170

2

0

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

1000mm

918mm

2

Cool

YES

2

320mm

2

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

MC 1000L-2MC 1000L-2

x 177mm

457mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

F

Qasair Rangehoods Installation Instructions10

INSTALLATION INSTRUCTIONS

• FA

1. The rangehood is designed to be fitted within joinery and can be installed by inserting screws in the three holes

provided on each side, or to the top or back by drilling your own mounting holes as required.

2. When installed, cover the access holes to the side fixing screws with the plastic plugs supplied.

3. Fit filters.

4. Install front panel to suit as per your kitchen design.

Installation must be carried out by the procedure outlined.

Failure to do so may void the guarantee.

Electrical: Wiring to the appliance must comply with State and local Regulations.

Connection to be carried out by a registered electrician.

Qasair Rangehoods Installation Instructions

11

Condari Pty Ltd. Page 1 of 1

Version: B 03/12/2014F

m

m

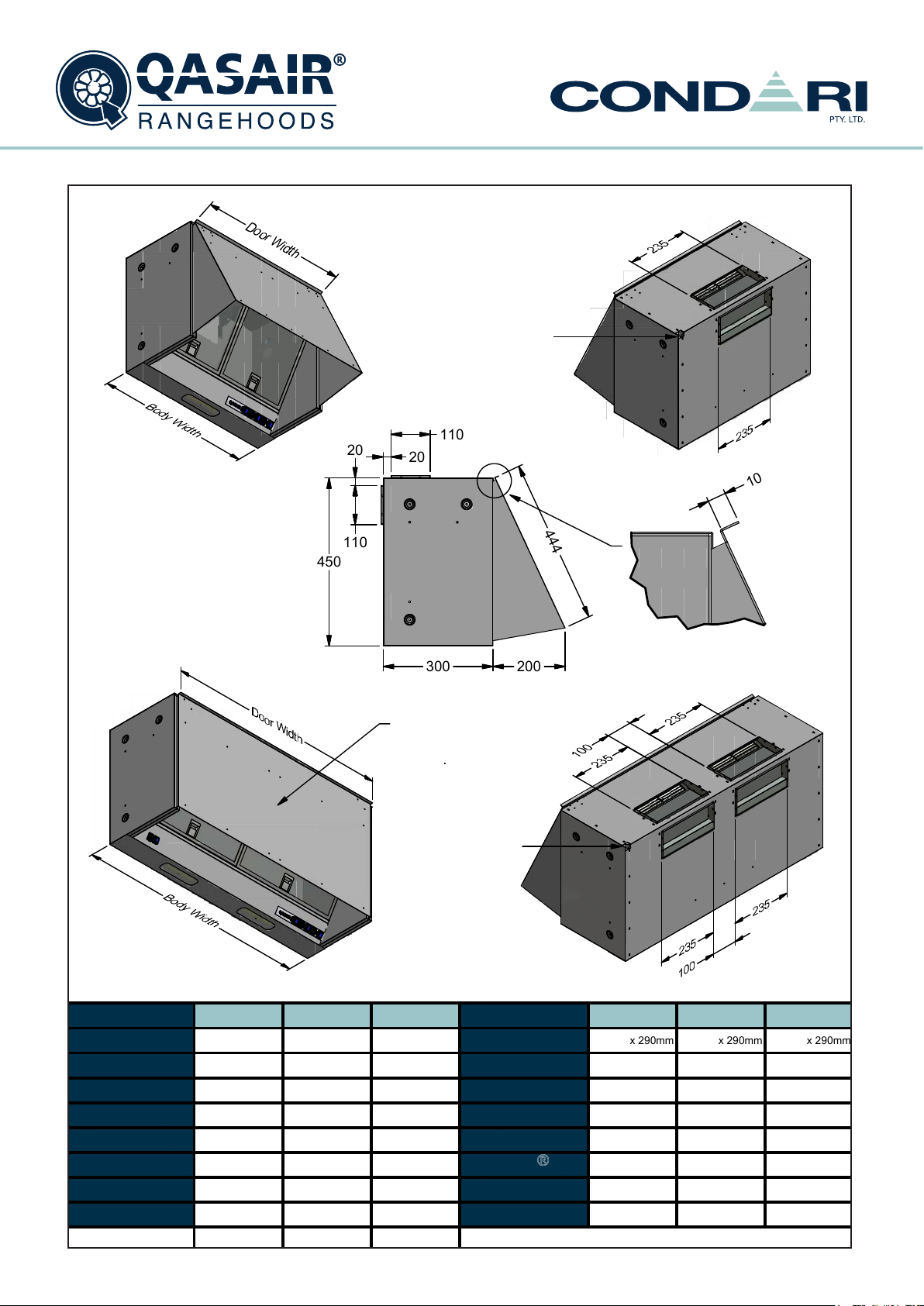

Foldaway

Technical Specification Sheet

FA

Undercupboard

FOLDAWAY - FA

450

110

Power Entry

110

2

0

2

0

300

0

1

4

4

4

200

Model

Body Width

Door Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

FA 60L-1 FA 90L-2FA 90L-1FA 60L-1FA 90L-2FA 90L-1

598mm

573.4mm

1

Cool

YES

1

Centre

2

898mm

873.4mm

1

Cool

YES

2

350mm

2

This view is shown

with door in closed

.

position

Power Entry

Model

898mm

873.4mm

2

Cool

YES

2

350mm

2

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

x 290mm

274mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

x 290mm

424mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

x 290

424mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

Qasair Rangehoods Installation Instructions12

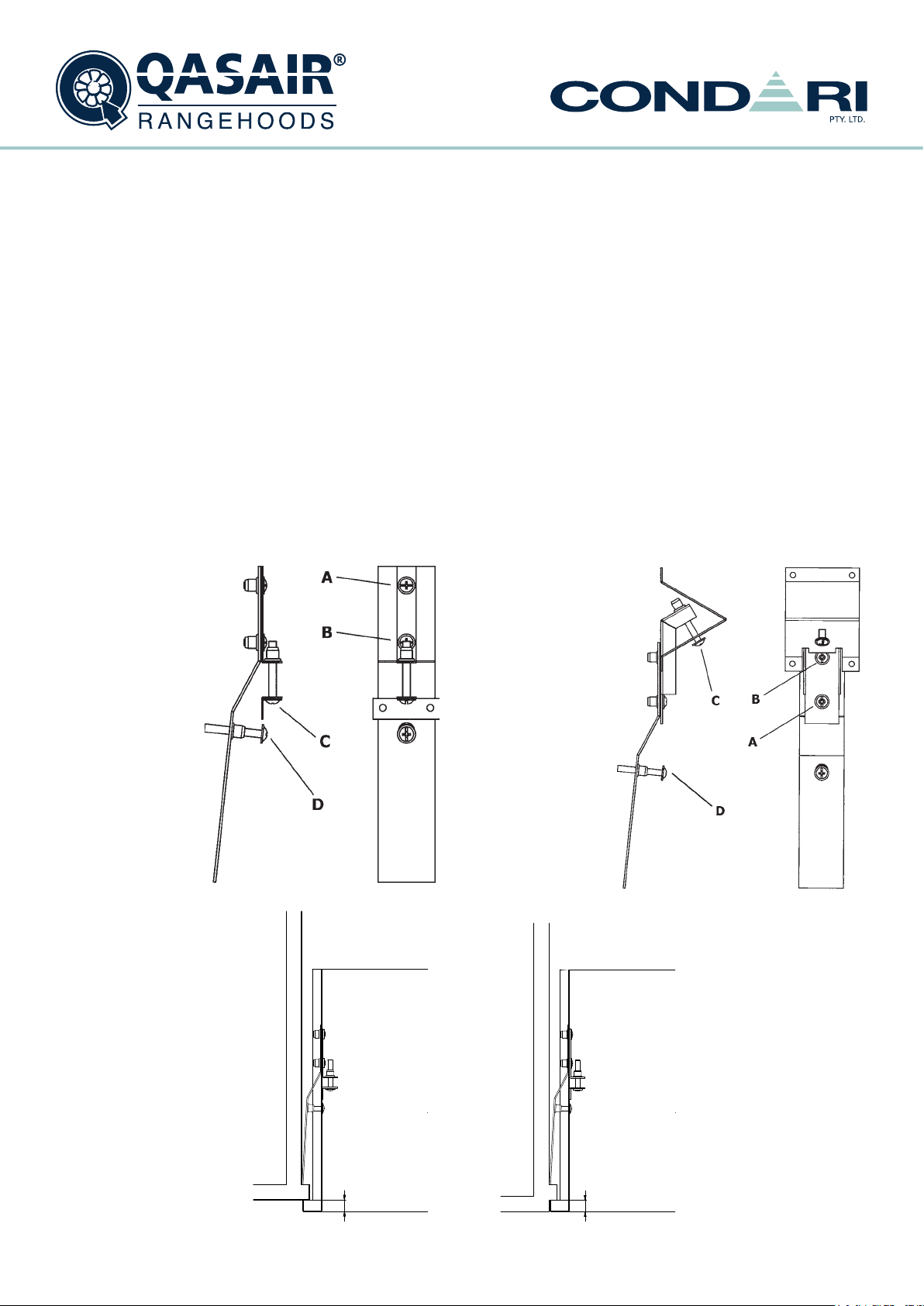

INSTALLATION INSTRUCTIONS

Flush Mount ( 1 : 4 )Proud Mount ( 1 : 4 )

AAB B

• CON

Installation must be carried out by the procedure outlined.

Failure to do so may void the guarantee.

Electrical: Wiring to the appliance must comply with State and local Regulations.

Connection to be carried out by a registered electrician.

• NDCH

• LIS

• ETN

1. Loosen screws A and B by turning anti-clockwise.

2. Turn screw ‘D’ anti-clockwise to extend the outer spring bracket.

3. Insert rangehood into cut out and turn screw ‘C’ clockwise to align rangehood with cupboard base.

4. Do not over tighten.

5. Tighten screw ‘A’ by turning clockwise to lock xing bracket.

6. Fit off ductwork as required.

7. To remove rangehood, turn screw ‘D’ clockwise.

RANGEHOOD SPRING BRACKETS

Models: LIS

CON

MOUNTING POSITION

Models: ETN

NDCH

Cupboard

PROUD MOUNT

Qasair Rangehoods Installation Instructions

Front of Rangehood

12

Front of Rangehood

12

Cupboard

FLUSH MOUNT

13

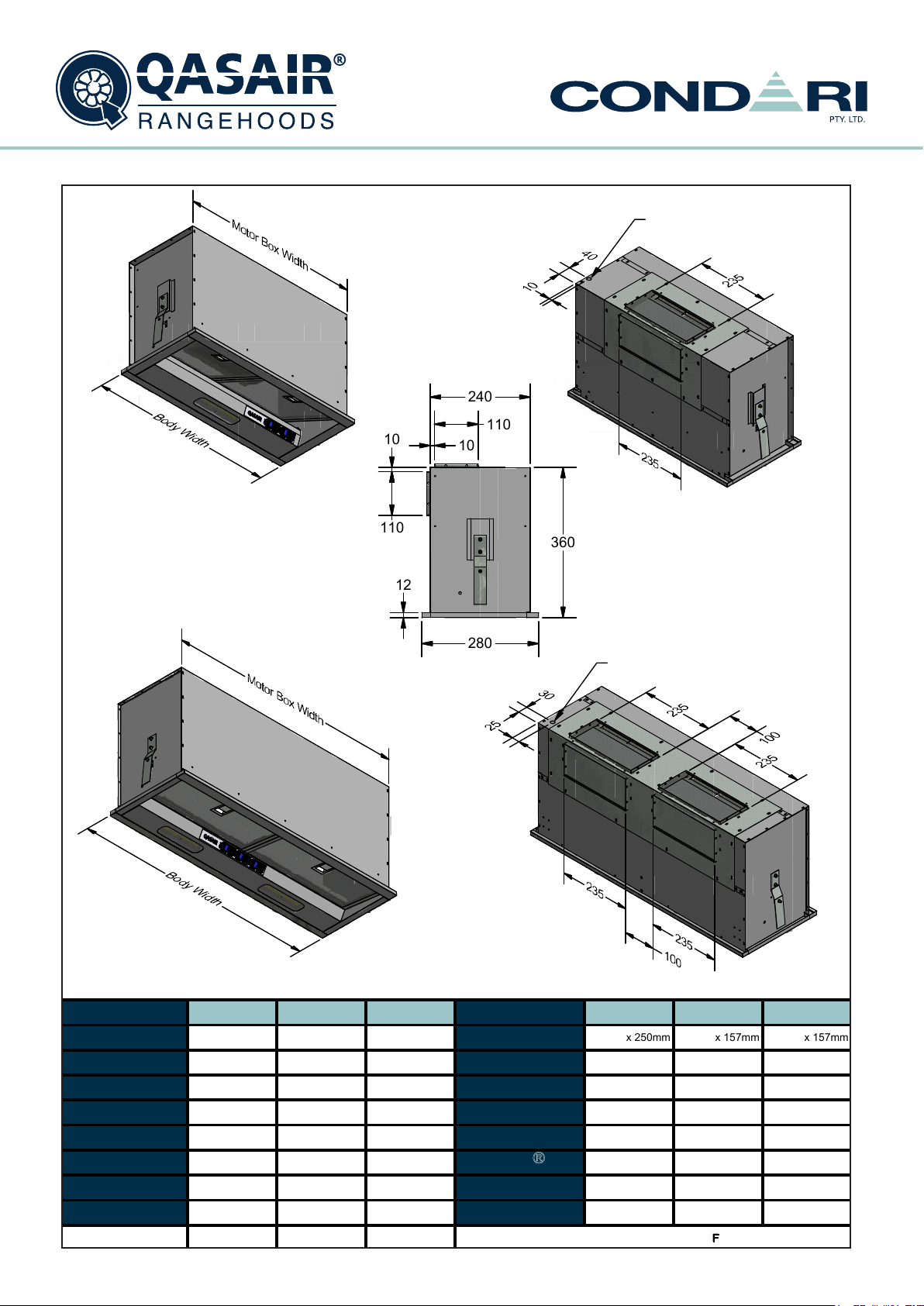

m

m

Conley

Technical Specification Sheet

CON

Undercupboard

CONLEY - CON

1

0

110

1

Power Entry

240

110

1

0

360

2

280

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

CON 60L-1 CON 80L-2CON 80L-1CON 60L-1CON 80L-2CON 80L-1

600mm

580mm

1

Cool

YES

1

Centre

2

800mm

780mm

1

Cool

YES

2

379mm

2

800mm

780mm

2

Cool

YES

2

379mm

2

Power Entry

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

Condari Pty Ltd. Page 1 of 1

x 250mm

269mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

Version: A 01/07/2014

379mm

10 Amp Lead

x 157mm

YES

N/A

N/A

N/A

N/A

Square

F

x 157

379mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

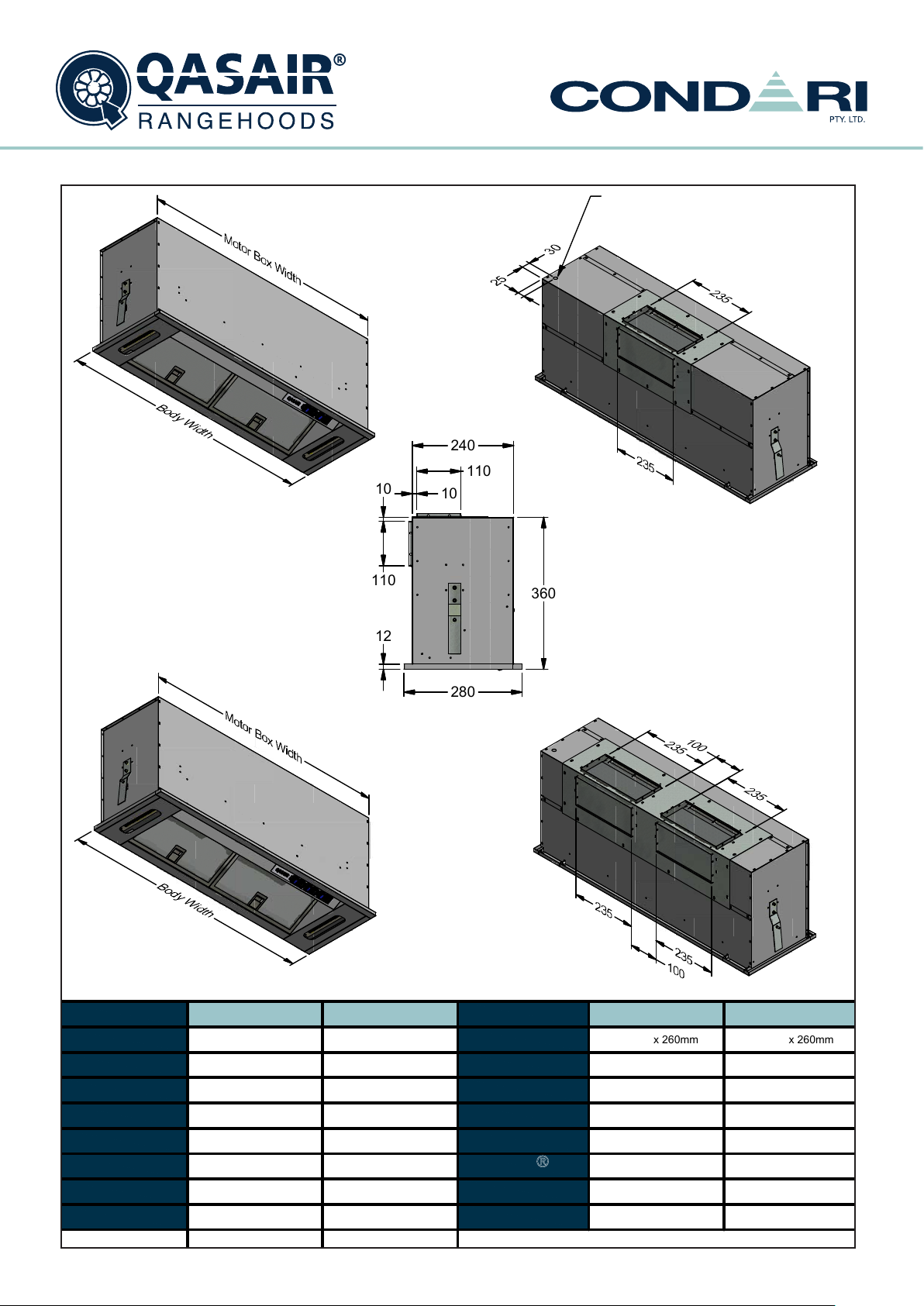

Qasair Rangehoods Installation Instructions14

Undermount

Technical Specification Sheet

NDCH

Undercupboard

Page 1 of 2

Condari Pty Ltd.

Version: B 19/12/2014F

Power entry location

UNDERMOUNT - NDCH

1

0

110

1

2

is the same for all

NDCH models.

240

110

1

0

360

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

NDCH 90L-1

900mm

880mm

1

Cool

YES

2

770mm

2

NDCH 90L-2

900mm

880mm

2

Cool

YES

2

770mm

2

280

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

NDCH 90L-1 NDCH 90L-2

x 260mm

340mm

YES

10 Amp Lead

N/A

N/A

N/A

Square

x 260mm

340mm

YES

10 Amp Lead

N/A

N/A

N/A

N/AN/A

Square

Qasair Rangehoods Installation Instructions

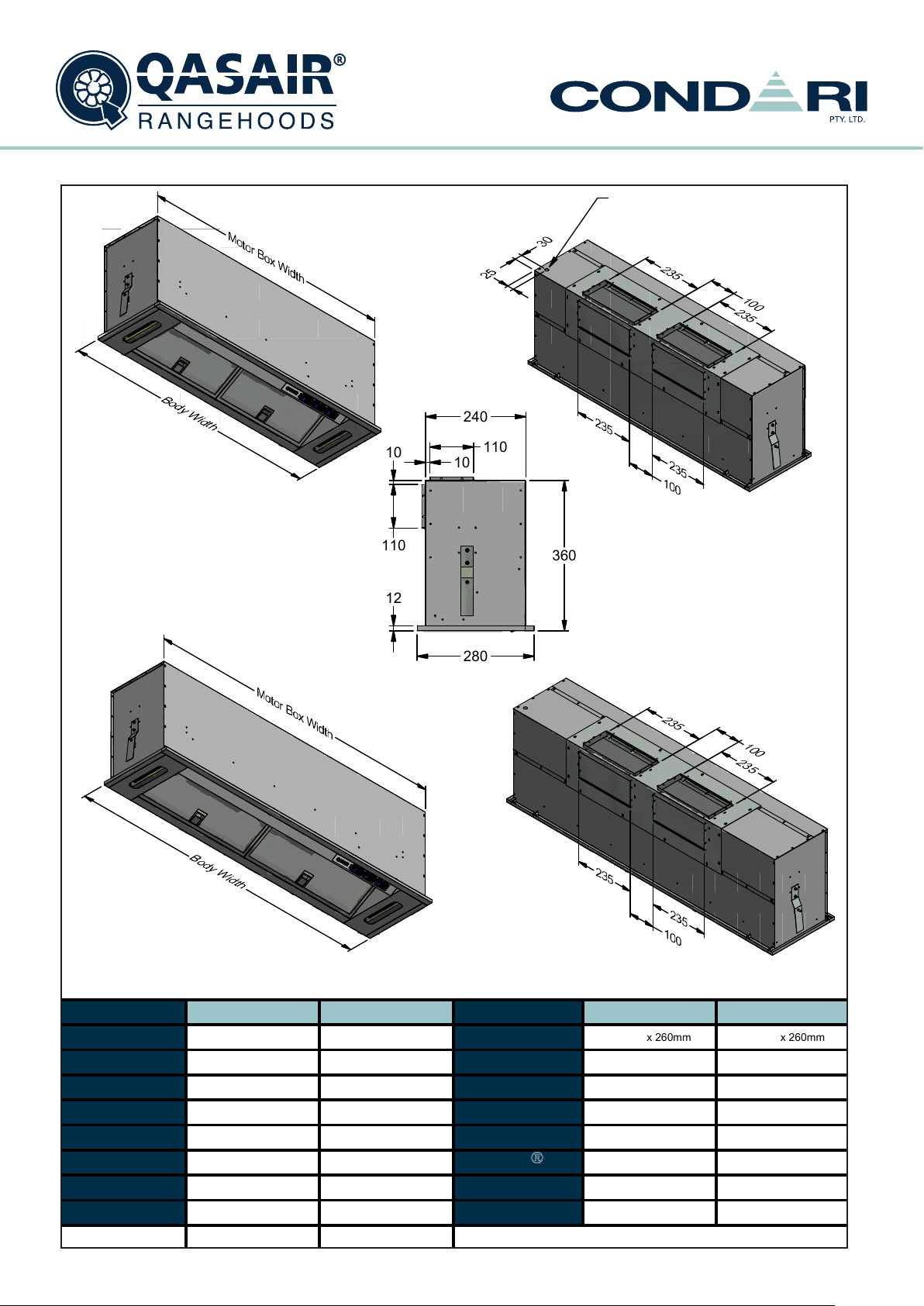

15

Undermount

Technical Specification Sheet

NDCH

Undercupboard

UNDERMOUNT - NDCH

240

Power entry location

is the same for all

NDCH models.

110

1

0

110

1

0

360

1

2

280

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

NDCH 100L-2

1000mm 1200mm Filter Size

980mm

2

Cool

YES

2

860mm

2

NDCH 120L-2

1180mm

2

Cool

YES

2

1060mm

2

Model

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

Condari Pty Ltd.

NDCH 100L-2

x 260mm

379mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A N/A

Square

Version: B 19/12/2014F

Qasair Rangehoods Installation Instructions16

NDCH 120L-2

479mm

YES

10 Amp Lead

Square

Page 2 of 2

x 260mm

N/A

N/A

N/A

m

m

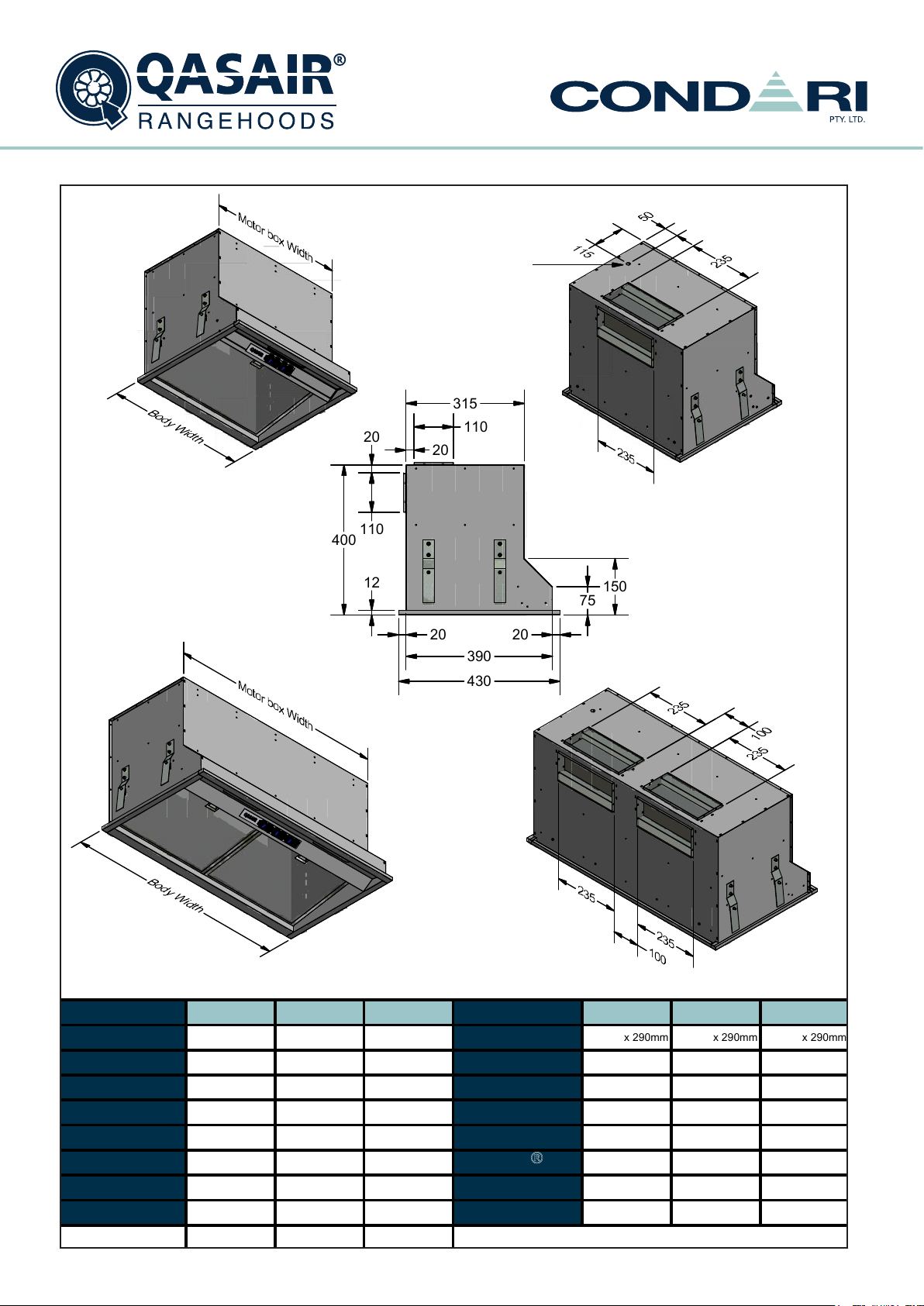

Lismore

Technical Specification Sheet

LIS

Undercupboard

LISMORE - LIS

400

Power entry location

is the same for all

2

110

1

0

2

2

0

2

0

LIS models.

315

110

390

430

150

7

5

2

0

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

LIS 500L-1 LIS 800L-2LIS 800L-1LIS 500L-1LIS 800L-2LIS 800L-1

500mm

480mm

1

Cool

YES

1

Centre

1

800mm

780mm

Cool

YES

380mm

Qasair Rangehoods Installation Instructions

Model

800mm

780mm

1

2

2

2

Cool

YES

2

380mm

2

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

Condari Pty Ltd. Page 1 of 3

x 290mm

459mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

Version: B 03/12/2014F

379mm

10 Amp Lead

x 290mm

YES

N/A

N/A

N/A

N/A

Square

x 290

379mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

17

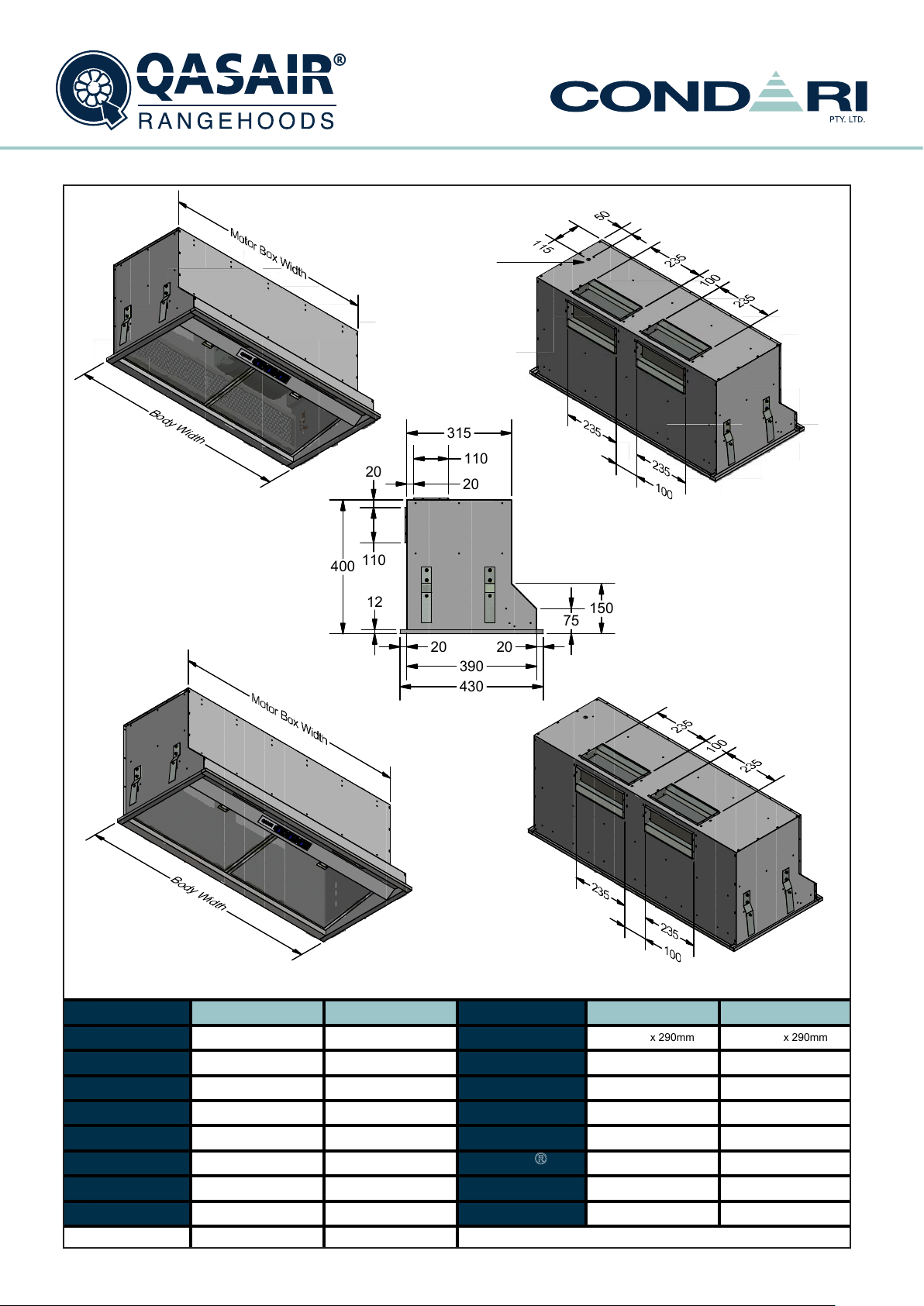

Lismore

Technical Specification Sheet

LIS

Undercupboard

Motor Box /

Flue Width

Body Width

Light Centres

LED Light

Light Qty

Motor Qty

Filter Qty

2

424mm

Model Model LIS 900L-2

2

480mm

Nightlight

N/A

Minimum Height

(H =)

Page 2 of 3Condari Pty Ltd.

All-thread

Fixing Centres

PowderKote

Available

Maximum Height

(H =)

Corner Type

Conversion

Top/Back Back/Top

Electrical Connection

YES

N/A

10 Amp Lead

N/A

Square

N/A

Version: B 03/12/2014F

N/A

424mm

x

290mm

2

LIS 1000L-2

2

Cool

YES

LIS 900L-2

900mm

870mm

2

10 Amp Lead

YES

479mm

x

290mm

LIS 1000L-2

N/A

Square

Cool

YES

980mm

1000mm

2

Filter Size

N/A

N/A

Power entry location

is the same for all

LIS models.

430

2

0

2

0

400

2

0

110

2

0

110

315

390

7

5

1

2

150

LISMORE - LIS

Qasair Rangehoods Installation Instructions18

Page 3 of 3

Version: B 03/12/2014F

Condari Pty Ltd.

m

m

Lismore

Technical Specification Sheet

LIS

Undercupboard

LISMORE - LIS

Power entry location

is the same for all

LIS models.

2

0

110

400

1

2

2

0

315

110

2

390

430

0

150

7

5

2

0

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

LIS 1200L-2

1200mm

1180mm

2

Cool Cool

2

580mm

4

LIS 1200L-3

1200mm

1180mm

YES

580mm

Qasair Rangehoods Installation Instructions

LIS 1500L-3

1500mm

1480mm

3

2

4

3

Cool

YESYES

3

452mm

4

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

LIS 1200L-2

x 290mm

290mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A

Square

LIS 1200L-3

290mm

YES

N/A

N/A

N/A

N/A

Square

x 290mm

LIS 1500L-3

365mm

YES

10 Amp Lead10 Amp Lead

N/A

N/A

N/A

N/A

Square

x 290

19

Eaton

Technical Specification Sheet

ETN

Undercupboard

EATON - ETN

Power entry location

is the same for

M

o

t

o

r

B

o

x

W

i

d

t

h

B

o

d

y

W

i

d

t

h

340

10

110

10

110

7

1

2

290

all ECH models.

3

5

2

0

2

3

5

12

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

380

M

o

t

o

r

B

o

d

y

W

i

d

t

h

B

o

d

y

W

i

d

t

h

ETN 600L-1

600mm

580mm

520mm

1

Cool

YES

2

1

ETN 900L-1

900mm

880mm

1

Cool

YES

2

800mm

2

Model

Filter Size

Conversion

Top/Back Back/Top

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type Square

Condari Pty Ltd.

2

3

5

ETN 600L-1 ETN 900L-1

479mm x 290mm

YES

10 Amp Lead

N/A

N/A

N/A

Version: C 2/6/2016F

2

3

5

379mm x 290mm

10 Amp Lead

Page 1 of 2

YES

N/A

N/A

N/A

N/AN/A

Square

Qasair Rangehoods Installation Instructions20

Eaton

Technical Specification Sheet

ETN

Undercupboard

2

Light Centres

Filter Qty

800mm

Motor Box /

Flue Width

Body Width

Motor Qty

Nightlight

Light Qty

LED Light

1060mm

Cool

ETN 1200L-2

1180mm

YES

2

ETN 900L-2

Cool

880mm

Model

2

All-thread

Fixing Centres

Page 2 of 2

Version: C 2/6/2016F

Condari Pty Ltd.

3

Corner Type

Maximum Height

(H =)

2

900mm 1200mm

Filter Size

Electrical Connection

Minimum Height

(H =)

Square

N/A

N/A N/A

Square

Model

PowderKote

Available

N/A

N/A

10 Amp Lead

N/A

N/A

YES

340mm

x 290mm

N/A

ETN 900L-2

YES

ETN 1200L-2

10 Amp Lead

379mm

x 290mm

YES

2

Conversion

Top/Back Back/Top

Power entry location

is the same for

all ECH models.

2

0

1

7

1

0

0

2

3

5

2

3

5

2

3

5

1

0

0

2

3

5

110

10

110

10

340

290

12

380

M

o

t

o

r

B

o

x

W

i

d

t

h

B

od

y

W

i

d

t

h

M

o

t

o

r

B

o

x

W

i

d

t

h

B

o

d

y

W

i

d

t

h

1

0

0

2

3

5

2

3

5

1

0

0

2

3

5

2

3

5

EATON - ETN

Qasair Rangehoods Installation Instructions

21

INSTALLATION INSTRUCTIONS

Installation Instructions

WCV1000L-2 WCV1300L-3

WCV1600L-3 WCV1800L-3

Cutout Dimensions -

WCV1000L-2 985 x 568

WCV1300L-3 1285 x 568

WCV1600L-3 1585 x 568

WCV1800L-3 1785 x 568

Flush Mount ( 1 : 4 )Proud Mount ( 1 : 4 )

AAB B

• WCV

Installation must be carried out by the procedure outlined.

Failure to do so may void the guarantee.

Electrical: Wiring to the appliance must comply with State and local Regulations.

Connection to be carried out by a registered electrician.

All the rangehoods are supplied as Top ducted and can be Side or Back ducted through separate ducting pieces.

Side ducting can be either Left or Right.

When being installed over a gas cooker with an open flame griller the filters must be 1200 mm above the cooking

surface. In these cases, it may be necessary to have remote switching as the switches on the rangehood may be

out of reach.

Please refer to Gas Installation Code AG 601 – 2002.

1. Unplug power cable ‘A’ and fan cables.

2. Remove screws ‘B’ and remove inner section of rangehood.

3. Loosen screws ‘C’ & ‘D’ by turning anti-clockwise.

4. Turn screw ‘F’ anti-clockwise to extend the spring bracket.

5. Insert outer shell of rangehood into cutout and turn screw ‘E’ clockwise to align rangehood with cupboard base. Be

sure that the spring bracket has engaged with the cabinet panel before tightening ‘E’.

6. Do not over tighten.

7. Tighten screw ‘C’ by turning clockwise to lock xing bracket.

8. Ret inner section of rangehood with screws ‘B’.

9. Plug power cable ‘A’ into it’s socket and in in fan cables.

10. Fit off ductwork as required.

11. To remove rangehood repeat points 1 & 2 loosen screw ‘C’, turn screw ‘F’ clockwise.

MOUNTING POSITION

Front of Rangehood

Cupboard

12

Cupboard

Front of Rangehood

12

C

D

E

F

B

A

22

PROUD MOUNT

FLUSH MOUNT

Qasair Rangehoods Installation Instructions

COBAR

Technical Specification Sheet

WCV

Undercupboard

COBAR - WCV

500

Power entry location

is the same for all

Cobar models.

340

3

0

2

0

1

2

110

280

560

600

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

WCV 1000L-2

1000mm

980mm

2

Cool

YES

4

580mm

3

Qasair Rangehoods Installation Instructions

WCV 1300L-3

1300mm

1280mm

3

Cool

YES

4

580mm

4

Model WCV 1300L-3

Filter Size

Top Ducted

Conversion: Back , Side

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

Condari Pty Ltd.

WCV 1000L-2

x 422mm

290mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A N/A

Square

Version: A 13/11/2014F

290mm

10 Amp Lead

Square

Page 1 of 3

x 422mm

YES

N/A

N/A

N/A

23

Version: A 13/11/2014F

Undercupboard

COBAR

Technical Specification Sheet

WCV

COBAR - WCV

Power entry location

is the same for all

Cobar models.

340

110

500

3

0

2

0

Model

Body Width

Motor Box /

Flue Width

Motor Qty

LED Light

Nightlight

Light Qty

Light Centres

Filter Qty

WCV 1600L-3

1600mm

1580mm

3

Cool

YES

4

872mm

5

1

2

WCV 1800L-3

1800mm

1780mm

3

Cool

YES

4

816mm

6

560

600

Model

Filter Size

Top Ducted

Conversion: Back , Side

Electrical Connection

Minimum Height

(H =)

Maximum Height

(H =)

PowderKote

Available

All-thread

Fixing Centres

Corner Type

Condari Pty Ltd.

280

WCV 1600L-3

x 422mm

290mm

YES

10 Amp Lead

N/A

N/A

N/A

N/A N/A

Square

WCV 1800L-3

272mm

10 Amp Lead

Square

Page 2 of 3

x 422mm

YES

N/A

N/A

N/A

Qasair Rangehoods Installation Instructions24

COBAR

Technical Specification Sheet

Undercupboard

WCV

COBAR - WCV

WCV B2

150

BACK DUCTED PIECES

WCV B3

2

4

110

138

1

110

2

5

5

WCV S2

SIDE DUCTED PIECES

WCV S3

W

C

V S3T

Qasair Rangehoods Installation Instructions

25

INSTALLATION INSTRUCTIONS

Flush Mount ( 1 : 4 )Proud Mount ( 1 : 4 )

AAB B

• WES

Installation must be carried out by the procedure outlined.

Failure to do so may void the guarantee.

Electrical: Wiring to the appliance must comply with State and local Regulations.

Connection to be carried out by a registered electrician.

• EAS

1. Loosen screws A and B by turning anti-clockwise.

2. Turn ‘D’ anti-clockwise to extend the outer spring bracket.

3. Insert rangehood into cut out and turn screw ‘C’ clockwise to align rangehood with cupboard base.

4. Do not over tighten.

5. Tighten screw ‘A’ by turning clockwise to lock xing bracket.

6. Fit off ductwork as required.

7. To remove rangehood, turn screw ‘D’ clockwise.

The Westmore (WES) rangehood must be installed at a minimum of 750mm over induction cooktops

The Eastmore (EAS) rangehood can be installed at a minimum of 600mm over induction cooktops

RANGEHOOD SPRING BRACKETS

Model: WES Model: EAS

A

B

MOUNTING POSITION

D

C

B

A

C

D

26

Cupboard

PROUD MOUNT

Front of Rangehood

12

Front of Rangehood

12

Cupboard

FLUSH MOUNT

Qasair Rangehoods Installation Instructions

Eastmore

Technical Specification Sheet

EAS

Undercupboard

Motor Qty

LED Light

Nightlight

Model

Body Width

Motor Box /

Flue Width

Light Qty

Light Centres

Filter Qty

Cool

YES

1

565mm

600mm

EAS 60L-1

2

Page 1 of 2

All-thread

Fixing Centres

Condari Pty Ltd.

PowderKote

}

Available

2

380mm

EAS 80L-2

2

300mm

780mm

Minimum Height

(H =)

Model

Maximum Height

(H =)

Corner Type Square

N/AN/A

Version: C 30/05/2017F

Square

Electrical Connection

N/A

N/A

272mm x 272mm

YES

EAS 60L-1 EAS 80L-2

Cool

YES

800mm

2

2

10 Amp Lead

YES

379mm x 260mm

10 Amp Lead

N/A

Filter Size

Conversion

Top/Back Back/Top

N/A

N/A

N/A

Power entry location

is the same for all

EAS models.

Motor Access

Panel

Motor Access

Panel

330

12

FILTER

330

110

20

20 110

290

FILTER

225

570

EASTMORE - EAS

Qasair Rangehoods Installation Instructions

27

Eastmore

Technical Specification Sheet

EAS

Undercupboard

N/A

10 Amp Lead

N/A

YES

N/A

479mm x 260mm

N/A

Square

N/A

N/A N/A

N/A N/A

SquareSquare

PowderKote

}

Available

Condari Pty Ltd.

Maximum Height

(H =)

EAS 100L-2

2

900mm 1200mm

680mm

3

2

1160mm

1000mm

2

480mm

2

YES

Cool

980mm

YES

2

Cool

Minimum Height

(H =)

N/A

10 Amp Lead

YES

379mm x 260mm

N/A

10 Amp Lead

EAS 90L-2

YES

Cool

2

880mm

2

Motor Qty

Model

429mm x 260mm

N/A

YES

2

430mm

Light Centres

Filter Size

ModelEAS 120L-2 EAS 90L-2

Corner Type

All-thread

Fixing Centres

Electrical Connection

Conversion

Top/Back Back/Top

EAS 100L-2 EAS 120L-2

Filter Qty

Nightlight

Light Qty

LED Light

Body Width

Motor Box /

Flue Width

Version: C 30/05/2017F

Page 2 of 2

Power entry location

is the same for all

EAS models.

Motor Access

Panel

Motor Access

Panel

330

12

110

20

20 110

290

570

FILTER

330

FILTER

225

EASTMORE - EAS

Qasair Rangehoods Installation Instructions28

Westmore

Technical Specification Sheet

WES

Undercupboard

Motor Qty

LED Light

Nightlight

Model

Body Width

Motor Box /

Flue Width

Light Qty

Light Centres

Filter Qty

Cool

YES

1

565mm

600mm

WES 60L-1

2

Page 1 of 2

All-thread

Fixing Centres

Condari Pty Ltd.

PowderKote

}

Available

2

380mm

WES 80L-2

2

300mm

780mm

Minimum Height

(H =)

Model

Maximum Height

(H =)

Corner Type Square

N/AN/A

Version: C 30/05/2017F

Square

Electrical Connection

N/A

N/A

272mm x 272mm

YES

WES 60L-1 WES 80L-2

Cool

YES

800mm

2

2

10 Amp Lead

YES

379mm x 260mm

10 Amp Lead

N/A

Filter Size

Conversion

Top/Back Back/Top

N/A

N/A

N/A

Power entry location

is the same for all

WES models.

Motor Access

Panel

Motor Access

Panel

330

12

FILTER

145

450

110

20

20 110

290

FILTER

60

WESTMORE - WES

Qasair Rangehoods Installation Instructions

29

Westmore

Technical Specification Sheet

WES

Undercupboard

N/A

N/A

mm x mm

N/A

N/A

N/A

Square

N/A

479mm x 260mm

N/A

10 Amp Lead

YES

10 Amp Lead

YES

N/A

379mm x 260mm

YES

N/A

N/A

10 Amp lead

Model

Conversion

Top/Back Back/Top

2

3

2

Corner Type Square

1160mm

1200mm

YES

WES 120L-2

680mm

2

Cool

YES

Cool

480mm

2

2

980mm

1000mm

2

Cool

880mm

430mm

2

Light Qty

2

YES

Electrical Connection

Maximum Height

(H =)

Minimum Height

(H =)

Filter Size

PowderKote

}

Available

N/A

N/A

429mm x 260mm

WES 100L-2

900mm

All-thread

Fixing Centres

Condari Pty Ltd.

WES 90L-2 WES 120L-2WES 90L-2 WES 100L-2

Motor Qty

Nightlight

Filter Qty

Motor Box /

Flue Width

Model

Body Width

Light Centres

LED Light

Version: C 30/05/2017F

Page 2 of 2

Power entry location

is the same for all

WES models.

Motor Access

Panel

Motor Access

Panel

FILTER

60

290

11020

20

110

450

FILTER

145

12

330

WESTMORE - WES

30

Qasair Rangehoods Installation Instructions

REMOTE SWITCHING SPECIFICATIONS

3 FAN (no lights)

1. Wiring to the appliance must comply with State and local regulations.

2. Switching is not provided with this unit. - The order was for the controls to be separate from the unit.

3. You may use any switching to connect the rangehood (e.g. Clipsal switches).

4. All fans must be controlled by at least one ON/OFF and one HI/LO switch.

(i.e. single or twin motor models).

5. Please refer to Wiring Diagram below for detailed wiring information.

WIRING DIAGRAM

-------------------- CABLES TO REMOTE SWITCHES --------------------

NOTES:-

ALL FANS MUST BE CONTROLLED

1. IT IS NECESSARY TO PROVIDE

BY AT LEAST ONE ON/OFF AND

AN ON/OFF AND A HIGH/LOW

ONE HI/LO SWITCH.

SWITCH FOR EACH FAN.

2. THE WIRING FOR THE FANS ARE 4 CORE LOW SPEED - BROWN

HIGH SPEED - WHITE

NEUTRAL - BLUE

EARTH - GREEN

BLUE

WHITE

BROWN

GREEN

BLUE

WHITE

BROWN

GREEN

BLUE

GREEN

WHITE

JUNCTION

BOXES

BLUE

BROWN BROWN

BLACK

BLUE

BROWN

BLACK

JUNCTION

BOXES

BLUE

BROWN

BLACK

NOTE: This diagram is for reference only. A qualied elecrician must connect remote

switching to rangehood.

Reected in this drawing is the most common method of connecting the rangehood.

Be aware that Active voltage must NOT be applied to both the ‘White- High’ or

‘Brown-Low’ wires at the same time. This will cause the fan to fail.

Qasair Rangehoods Installation Instructions

31

REMOTE SWITCHING SPECIFICATIONS

‘Brown-Low’ wires at the same time. This will cause the fan to fail.

3 FAN, LED and NIGHTLIGHT

1. Wiring to the appliance must comply with State and local regulations.

2. Switching is not provided with this unit. - The order was for the controls to be separate from the unit.

3. You may use any switching to connect the rangehood (e.g. Clipsal switches).

4. All fans must be controlled by at least one ON/OFF and one HI/LO switch.

(i.e. single or twin motor models).

5. Please refer to Wiring Diagram below for detailed wiring information.

WIRING DIAGRAM

ALL FANS MUST BE CONTROLLED

BY AT LEAST ONE ON/OFF AND

ONE HI/LO SWITCH.

NOTE: This diagram is for reference only. A qualied elecrician must connect remote

switching to rangehood.

Reected in this drawing is the most common method of connecting the rangehood.

Be aware that Active voltage must NOT be applied to both the ‘White- High’ or

Qasair Rangehoods Installation Instructions32

REMOTE SWITCHING SPECIFICATIONS

22/08/2013

3 FAN with LED

1. Wiring to the appliance must comply with State and local regulations.

2. Switching is not provided with this unit. - The order was for the controls to be separate from the unit.

3. You may use any switching to connect the rangehood (e.g. Clipsal switches).

4. All fans must be controlled by at least one ON/OFF and one HI/LO switch.

(i.e. single or twin motor models).

5. Please refer to Wiring Diagram below for detailed wiring information.

WIRING DIAGRAM

-------------------- CABLES TO REMOTE SWITCHES --------------------

GREEN

WHITE

BROWN

BLUE

BLACK

BROWN

BLUE

CIRCUIT DIAGRAM

AC1 AC2

LED

BLUE

BLUE

BLUE

BLUE

BROWN

BROWN

BROWN

BROWN

BLUE

JUNCTION

BROWN

BLUE

BOXES

GREEN

WHITE

BROWN

BLUE

JUNCTION

BOXES

BROWN

BLACK

BLUE

AC1

AC2

LED

GREEN

WHITE

BROWN

BLUE

JUNCTION

BLACK

BROWN

BLUE

CONDARI PTY LTD

8 Argent Place, Ringwood VIC 3134

Ph: (03) 9873 5877 / Fx: (03) 9873 5748

BOXES

NOTE: This diagram is for reference only. A qualied elecrician must connect remote

switching to rangehood.

Reected in this drawing is the most common method of connecting the rangehood.

Be aware that Active voltage must NOT be applied to both the ‘White- High’ or

‘Brown-Low’ wires at the same time. This will cause the fan to fail.

NOTES:-

1. IT IS NECESSARY TO PROVIDE

ALL FANS MUST BE CONTROLLED BY

AN ON/OFF AND A HIGH/LOW

AT LEAST ONE ON/OFF AND ONE

SWITCH FOR EACH FAN.

HI/LO SWITCH.

2. THE WIRING FOR THE FANS ARE 4 CORE LOW SPEED - BROWN

HIGH SPEED - WHITE

NEUTRAL - BLUE

EARTH - GREEN

3. THE WIRING FOR THE LIGHTS IS 2 CORE ACTIVE - BROWN

NEUTRAL - BLUE

DESIGNER

M. Brewin

CHECKED

M. Malesevic REVISION

DATE

A

Qasair Rangehoods Installation Instructions

33

SINGLE MOTOR DUCTING

NOTE:

This Zinc Alume Strip is provided to join some duct pieces together.

It will be clearly shown on the drawing of the piece it is supplied with.

I/I: Inside to Inside Measurement

101. DL-1 Single Motor Duct Length 1200mm

DL-1 CB Single Motor Duct

Back Draft Wall Vent Single Motor Horizontal

1200mm Colourbond

Horizontal Bend Single Motor 90º

102. HB-1

105. BD/WV-H-1 SS

445M2 Stainless Steel

Length

Single Motor Duct Length 300mm

Horizontal Bend Single Motor 45º

Vertical Bend Single Motor 90º

101. DL-1 A

103. HB-1/45

106. VB-1

Single Motor Duct Length Extension

Back Draft Wall Vent Single Motor Horizontal

See alternative Duct Piece No. 145

Vertical Bend Single Motor 45º

101. DL-1 E

104. BD/WV-H-1

107. VB-1/45

Back Draft Wall Vent Single Motor

108. BD/WV-V-1

Vertical

Back Draft Wall Vent Single Motor Vertical

109. BD/WV-V-1 SS

445M2 Stainless Steel

Duct Director Single Motor Horizontal Left

110. DD-1H L

Qasair Rangehoods Installation Instructions34

SINGLE MOTOR DUCTING

Duct Director Single Motor Horizontal

111. DD-1H R

Right

114. CD-920

Cavity Duct Extendible

117. DR-200

Duct Length 200Ø

Twisted Transition Single Motor

Duct Length 200Ø Colourbond

112. TT-1

115. CD-920 TO DL-1

Cavity Duct to DL-1

118. DR-200 CB

113. DLE-DLE

Flue Joiner Single Motor

Single Motor Transition DL-1 to 200Ø

116. TR-1

119. DR-200/45

200Ø Bend 45º

120. DR-200/90

200Ø Bend 90º

123. CH-200

Chairman’s Hat 200Ø

Qasair Rangehoods Installation Instructions

Back Draft Wall Vent Rear Register Kit to

121. BD-6/7/9-WV-R/R

Suit 6/7/900H

Chairman’s Hat 200Ø Colourbond

124. CH-200 CB

122. BD/WV-200Ø

Back Draft Wall Vent

Back Draft Roof Cowl Single Motor

125. BD/RC-1

35

SINGLE MOTOR DUCTING

Back Draft Roof Cowl Single Motor

Wall Vent Cover Single Motor Horizontal

126. BD/RC-1 CB

Colourbond

Back Draft Damper Single Motor

129. BD/M-1

132. WVC-H-1 SS

445M2 Stainless Steel

Back Draft Roof Cowl Single Motor 200Ø

Wall Vent Cover Single Motor Vertical

127. BD/SQ-RC 200

130. CF 6/7/900H

Ceiling Flange to Suit 6/7/900H

133. WVC-V-1

Stainless Steel Flue Cap to Suit DLE

Wall Vent Cover Single Motor Horizontal

Wall Vent Cover Single Motor Vertical

128. DLE-S/S CAP

131. WVC-H-1

See alternative Duct Piece No. 145

134. WVC-V-1 SS

445M2 Stainless Steel

135. 6/7/900H-SC

Spiggot Cap to Suit 6/7/900H

Roof Cap 200Ø 445M2 Stainless Steel

138. RCP 200 SS

136. EV/DL-1

Eave Vent to Suit DL-1

Roof Cowl 200Ø 445M2 Stainless Steel

139. RC 200 SS

Wall Vent Cover to Suit Rear Register Kit

137. WVC-6/7/9H-R/R

for 6/7/900H

140. RC 200

Roof Cowl 200Ø

Qasair Rangehoods Installation Instructions36

Roof Cowl Single Motor 445M2 Stainless Steel

400

75

250

141. RC 1 SS

WALL VENT

144. FRWV-V-1 SS

Fire Rated Wall Vent Vertical

445M2 Stainless Steel

142. FRC 200 SS

Fire Rated 200Ø Roof Cowl

445M2 Stainless Steel

I

/

I

2

4

2

4

8

WALL VENT

0

/

I

3

1

7

7

5

I

/

I

3

1

8

2

5

0

0

5

1

Back Draft Wall Vent & Cover Single Motor

Horizontal kit assembled as one piece

145. BD/WV/K-H-1

WALL VENT

143. FRWV-H-1 SS

Fire Rated Wall Vent Horizontal

445M2 Stainless Steel

0

1

1

I

ROOF COWLS, WALL VENTS

AND WALL VENT COVERS

All the above ducting pieces

are all made in stainless

steel type 445M2 which

has a chromium content of

22% which is far greater

than marine grade stainless

steel and provides better

protection.

This is stated on the

description of each piece in

the ducting brochure.

WALL VENT COVERS SPECIFICATIONS

FIRE RATED APPROVED

The wall vent covers have

stainless steel screening

type 316 and meets the

requirements for stainless

steel screening under the

Australian Standard.

Qasair Rangehoods Installation Instructions

AS 3959-2009 Construction

of Buildings in Bushfire

prone areas.

37

TWIN MOTOR DUCTING

NOTE:

This Zinc Alume Strip is provided to join some duct

pieces together. It will be clearly shown on the drawing

of the piece it is supplied with.

I/I: Inside to Inside Measurement

201. TMT

Twin Motor Transition

Horizontal Bend Twin Motor 45º

204. HB-2/45

Vertical Bend Twin Motor 90º

207. VB-2

Twin Motor Duct Length 1200mm

Back Draft Wall Vent Twin Motor

Vertical Bend Twin Motor 45º

202. DL-2

205. BD/WV-H-2

Horizontal

208. VB-2/45

Horizontal Bend Twin Motor 90º

Back Draft Wall Vent Twin Motor Horizontal

203. HB-2

206. BD/WV-H-2 SS

445M2 Stainless Steel

Back Draft Wall Vent Twin Motor Vertical

209. BD/WV-V-2

Back Draft Wall Vent Twin Motor Vertical

210. BD/WV-V-2 SS

445M2 Stainlerss Steel

Twisted Transition Twin Motor

211. TT-2

212. DLE-2 TO DLE-2

Flue Joiner Twin Motor

Qasair Rangehoods Installation Instructions38

TWIN MOTOR DUCTING

213. BD-10/12/15-WV-R/R

Back Draft Wall Vent 10/12/1500H

216. DR-300

Duct Length 300Ø

219. DR-300/90

300Ø Bend 90º

Twin Motor Transition to 300Ø

Duct Length 300Ø Colourbond

Twin Motor Transition DL-2 to 250SQ

214. TMT-300

217. DR-300 CB

220. DL-2/250SQ

Twin Motor Transition from DL-2 to 300Ø

Twin Motor Transition 250SQ to 300Ø

215. TR-2

218. DR-300/45

300Ø Bend 45º

221. TMT-250/300

Twin Motor Transition to 250SQ

222. TMT-250

225. HB-250/45

Horizontal Bend 250SQ 45º

Qasair Rangehoods Installation Instructions

223. DL-250

Duct Length 250SQ

226. TMT-250/90 L

Duct Deflector 250SQ Left

224. HB-250

Horizontal Bend 250SQ 90º

227. TMT-250/90 R

Duct Deflector 250SQ Right

39

TWIN MOTOR DUCTING

228. BD/WV-250 SQ

Back Draft Wall Vent 250SQ

231. BD/RC-2 CB

Back Draft Roof Cowl Twin Motor

Colourbond

234. BD/SQ-RC 300

Back Draft Roof Cowl 300Ø

229. BD/WV-250 SQ SS

Back Draft Wall 250SQ 445M2 Stainless

Back Draft Roof Cowl 250SQ

Steel

232. CH-300

Chairman’s Hat 300Ø

235. BD/RC-250 SQ

Back Draft Roof Cowl Twin Motor

Chairman’s Hat 300Ø Colourbond

Stainless Steel Flue Cap to Suit DLE-2

230 BD/RC-2

233. CH-300 CB

236. DLE-2-S/S CAP

237. CF 10/12/1500H

Ceiling Flange to Suit 10/12/1500H

240. CF 4F-900-2

Ceiling Flange to Suit 4F 900-2

238. CF 3F-900-2

Ceiling Flange to Suit 3F 900-2

241. CF 4F-1200-2

Ceiling Flange to suit 4F 1200-2

239. CF 3F-1200-2

Ceiling Flange tp suit 3F 1200-2

Wall Vent Cover Twin Motor Horizontal

242. WVC-H-2

Qasair Rangehoods Installation Instructions40

TWIN MOTOR DUCTING

Wall Vent Cover Twin Motor Horizontal

243.WVC-H-2 SS

445M2 Stainless Steel

246. WVC-250 SQ

Wall Vent Cover 250SQ

249. 10/12/15H-SC

Spiggot Cap to Suit 10/12/1500H

Wall Vent Cover Twin Motor Vertical

Wall Vent Cover 250SQ 445M2 Stainless

Duct Director Twin Motor Horizontal Left

244. WVC-V-2

247. WVC-250 SQ SS

Steel

250. DD-2H-L

Wall Vent Cover Twin Motor Vertical

Wall Vent Cover to suit 10/12/1500H

Duct Director Twin Motor Horizontal Right

245. WVC-V-2 SS

445M2 Stainless Steel

248. WVC-10/12/15H-R/R

251. DD-2H-R

Duct Director Twin Motor Vertical Left

Back Draft Damper Twin Motor 250SQ

252. DD-2V-L

255. BD/M-250SQ

Qasair Rangehoods Installation Instructions

Duct Director Twin Motor Vertical Right

253. DD-2V-R

256. BD/WV-300Ø

Back Draft Wall Vent

254. EV/DL-2

Eave Vent to Suit DL-2

257. BD/WVC-SBS

Twin Motor Wall Vent Deflector

41

TWIN MOTOR DUCTING

75

400

250

EXTENDED

250

75

400

EXTENDED

6

7

5

258. CF 3F-1500-2

Ceiling Flange to Suit 3F 1500-2

Roof Cowl 300Ø 445M2 Stainless Steel

Fire Rated Wall Vent Twin Motor Horizontal

I

/

I

6

5

Kit assembled as one piece. Two Single Motor

261. RC 300 SS

264. FRWV-H-2 SS

445M2 Stainless Steel

5

2

5

3

9

5

2

5

0

0

267. BD/WV/K-H-2

Back Draft Wall Vent Horizontal

with telescopic length & cover

I

/

I

0

4

2

I

/

I

0

1

1

2

4

8

Roof Cap 300Ø 445M2 Stainless Steel

Roof Cowl Twin Motor 445M2 Stainless

259. RCP 300 SS

262. RC 2 SS

Steel

WALL VENTWALL VENT

Fire Rated Wall Vent Twin Motor Vertical

I

/

I

7

5

Kit assembled as one piece. Fire rated Two

Single Motor Back Draft Wall Vent Horizontal

265. FRWV-V-2 SS

445M2 Stainless Steel

6

5

2

6

5

3

2

5

0

0

5

268. FRWV/K-H-2

with telescopic length & cover

9

5

I

/

I

0

4

2

I

/

I

0

1

1

2

4

8

WALL VENTWALL VENT

Roof Ventilation Cowl 300Ø 445M2

260. RV 300 SS

Stainless Steel

263. FRC 300 SS

Fire Rated Roof Cowl 300Ø

445M2 Stainless Steel

WALL VENT

Fire Rated Wall Vent Twin Motor 250SQ

266. FRWV-250 SQ SS

445M2 Stainless Steel

ROOF COWLS, WALL VENTS

AND WALL VENT COVERS

All the above ducting pieces

are all made in stainless

steel type 445M2 which

has a chromium content of

22% which is far greater

than marine grade stainless

steel and provides better

protection.

This is stated on the

description of each piece in

the ducting brochure.

WALL VENT COVERS SPECIFICATIONS

FIRE RATED APPROVED

The wall vent covers have

stainless steel screening

type 316 and meets the

requirements for stainless

steel screening under the

Australian Standard.

AS 3959-2009 Construction

of Buildings in Bushfire

prone areas.

Qasair Rangehoods Installation Instructions42

TRIPLE MOTOR DUCTING

NOTE:

This Zinc Alume Strip is provided to join some duct pieces together.

It will be clearly shown on the drawing of the piece it is supplied with.

I/I: Inside to Inside Measurement

301. 3MT-DL-3

Three Motor Transition to DL-3

Horizontal Bend Triple Motor 45º

Triple Motor Twisted Transition

304. HB-3/45

307. TT-3

302. DL-3

Triple Motor Duct Length

Vertical Bend Triple Motor 90º

Triple Motor Transition DL-3 to 350Ø

305. VB-3

308. TMT-400x200/350

Horizontal Bend Triple Motor 90º

Vertical Bend Triple Motor 45º

Triple Motor Transition to 350Ø

303. HB-3

306. VB-3/45

309. TR-3

310. DR-350

Duct Length 350Ø

Qasair Rangehoods Installation Instructions

311. DR-350 CB

Duct Length 350Ø Colourbond

312. DR-350/45

350Ø Bend 45º

43

TRIPLE MOTOR DUCTING

313. DR-350/90

350Ø Bend 90º

Back Draft Roof Cowl Triple Motor 350SQ

316. BD/SQ-RC 350

319. CH-350 CB

Chairmans Hat 350Ø Colurbond

Back Draft Roof Cowl Triple Motor

Back Draft Wall Vent Triple Motor Horizontal

314. BD/RC-3

317. BD/SQ-RC 350 SS

Back Draft Roof Cowl 350Ø

445M2 Stainless Steel

320. BD/WV-H-3

315. BD/RC-3 SS

Back Draft Roof Cowl Triple Motor

445M2 Stainless Steel

318. CH-350

Chairmans Hat 350Ø

Back Draft Wall Vent Triple Motor Horizontal

321. BD/WV-H-3 SS

445M2 Stainless Steel

Back Draft Wall Vent Triple Motor Vertical

Wall Vent Cover Triple Motor Horizontal

322. BD/WV-V-3

325.WVC-H-3 SS

445M2 Stainless Steel

Back Draft Wall Vent Triple Motor Vertical

Wall Vent Cover Triple Motor Vertical

323. BD/WV-V-3 SS

445M2Stainless Steel

326. WVC-V-3

Wall Vent Cover Triple Motor Horizontal

Wall Vent Cover Triple Motor Vertical

324. WVC-H-3

327. WVC-V-3 SS

445M2 Stainless Steel

Qasair Rangehoods Installation Instructions44

TRIPLE MOTOR DUCTING

0

75

EXTENDED

9

I

1

EXTENDED

9

5

I

Duct Director Triple Motor Vertical Left

328. DD-3V-L

WALL VENT

331. FRWV-H-3 SS

Fire Rated Wall Vent Triple Motor

/

I

9

8

8

7

5

Kit assembled as one piece. Three Single

Motor Back Draft Wall Vent Horizontal

with telescopic length & cover

Horizontal

8

7

9

5

0

334. BD/WV/K-H-3

9

5

I

/

I

0

4

2

I

/

I

0

1

1

2

4

8

2

5

0

WALL VENT WALL VENT

Duct Director Triple Motor Vertical Right

329. DD-3V-R

WALL VENT

Fire Rated Wall Vent Triple Motor Vertical

/

I

7

Kit assembled as one piece. Fire rated Three

Single Motor Back Draft Wall Vent Horizontal

332. FRWV-V-3 SS

8

7

9

8

8

5

9

0

5

335. FRWV/K-H-3

with telescopic length & cover

5

9

5

I

/

I

0

4

2

/

I

1

1

2

4

8

2

5

0

330. BD/WV-350Ø

Back Draft Wall Vent

Fire Rated Roof Cowl 350Ø 445M2

I

333. FRC 350 SS

Stainless Steel

ROOF COWLS, WALL VENTS

AND WALL VENT COVERS

All the above ducting pieces

are all made in stainless

steel type 445M2 which

has a chromium content of

22% which is far greater

than marine grade stainless

steel and provides better

protection.

This is stated on the

description of each piece in

the ducting brochure.

WALL VENT COVERS SPECIFICATIONS

FIRE RATED APPROVED

The wall vent covers have

stainless steel screening

type 316 and meets the

requirements for stainless

steel screening under the

Australian Standard.

AS 3959-2009 Construction

of Buildings in Bushfire

prone areas.

Qasair Rangehoods Installation Instructions

45

INSTALLATION IDEAS

Condari recommends Qasair and Condor Rangehoods be installed using ducting that is:

• rigid

• non-ammable

• correctly sized

to ensure maximum air movement and minimum noise levels.

Ducting incorrectly with exible or smaller diameter ducting will dramatically reduce the air movement

and increase the noise level of the rangehood and will void the manufacturer’s warranty.

The Installation Ideas below will give you some guidelines on how to correctly duct your Qasair and

Condor Rangehood using Qasair and Condor ducting pieces.

FA 60L-1 T

Rangehood

3. FA 60L-1 T 4. FA 60L-1 T

FA 60L-1 T

Rangehood

5. FA 60L-1 T

6. FA 60L-1 T / FA 60L-1 B

FA 60L-1 T

Rangehood

FA 60L-1 T

FA 60L-1 B

Rangehood

Qasair Rangehoods Installation Instructions46

FA 90L-2 T

Rangehood

FA 90L-2 T

Rangehood

7. FA 90L-2 T 8. FA 90L-2 T

FA 90L-2 B

Rangehood

FA 90L-2 T

Rangehood

9. FA 90L-2 T 10. FA 90L-2 B

FA 90L-2 T

Rangehood

11. FA 90L-2 T 12. FA 90L-2 T

Qasair Rangehoods Installation Instructions

FA 90L-2 T

Rangehood

47

600HL-1 T / 700HL-1 T / 900HL-1 T

Rangehood

13. 600HL-1 T / 700HL-1 T / 900HL-1 T 14. 600HL-1 T

600HL-1 T Rangehood

CON 60L-1 T Rangehood

15. CON 60L-1 T 16. CON 80L-1 T

17. CON 60L-1 T 18. CON 80L-2 T

CON 80L-1 T Rangehood

CON 80L-2 T RangehoodCON 60L-1 T Rangehood

Qasair Rangehoods Installation Instructions48

1200HL-2 T

Rangehood

19. 1200HL-2 T 20. LIS 800L-2 T

LIS 800L-2 T

Rangehood

21. LIS 1000L-2 T 22. 3F 900L-2 T / 1200L-2 T

LIS 500L-1 T

Rangehood

23. LIS 500L-1 T 24. LIS 800L-1 T

Qasair Rangehoods Installation Instructions

LIS 1000L-2 T

Rangehood

3F 900L-2 T / 1200L-2 T

Rangehood

LIS 800L-1 T

Rangehood

49

LIS 1200L-2 B

Rangehood

CON 80L-1 T

Rangehood

FA-90L-1 T

Rangehood

LIS 1000L-2 T

Rangehood

25. CON 80L-1 T / LIS 1000-2 T 26. LIS 1200L-2 B

FA-60L-1 B

Rangehood

1. FA 60L-1 B2. FA 90L-1 T

Qasair Rangehoods Installation Instructions50

OPERATION DETAILS

Light ON and OFF

Light High and Low

Fan Left Side ON and OFF

Fan Left Side High and Low

Right Side Fan/s ON and OFF

Right Side Fan/s High and Low

RANGEHOOD CLEANING

Qasair Rangehoods are made from stainless steel, either type 304 or type 316.

* Type 304 is classied as 18/8 stainless steel

* Type 316 is classied as 18/10 stainless steel

This means that the stainless steel is made of 18% nickel and either 8% or 10% of chromium respectively.

Stainless steel gets its protective coating from the chromium oxidising in the air to form a protective surface

of chromium oxide. This can be attacked by different substances, such as salt water or sea air. The stainless

steel will start to show pit marks which are referred to in the industry as tea staining. This will happen to

marine grade stainless steel type 316 in the same way it will happen to stainless steel type 304, it will just

take longer to happen.

The way to overcome this is to clean the stainless steel with warm soapy water and then polish it with a cloth

so that the chromium will oxidise again.

When exposed to sea water or sea side conditions this is only a stop gap measure as the attack will start

again.

With stainless steel rangehoods exposed in Alfresco areas we recommend spraying the hood with vegetable

oil and rubbing it all over the rangehood, if it is going to be unused over a period of time.

FILTER CLEANING

For the best results, please clean filters regularly.

Condari recommends cleaning filters once per month, or immediately after heavy use.

You can do this by hand washing in warm soapy water, or by placing filters in the top rack of the

dishwasher using a detergent of pH 8 or less.

Note: Washing the filters in the dishwasher may cause discolouration of the filters.

We recommend washing filters in the dishwasher without detergent or use one of the powder

detergent.

Ensure the filters are completely dry before placing them back.

Do not operate the rangehood without the filters installed.

Condari does not recommend the use of corrosive, caustic or acidic products, particulary industrial

or citric products.

Condari has experienced problems with many of the dishwashing detergents now on the market.

Particularly with the tablet type detergents as many come from overseas, which are made for a hard

water environment. We have found that these detergents have a deleterious effect on the filters and

the result is that the filters last for about 50 to 60 washes.

This is equivalent to about 5 to 6 years life.

Qasair Rangehoods Installation Instructions

51

CONDARI PTY LTD APPLIANCE GUARANTEE

The benefits conferred by this warranty are in addition to all other rights and remedies in respect of the product

which the consumer has under the Competition and Consumer Act 2010 and similar state and territory laws.

Condari P/L in Melbourne (and by their agency in Country Areas and other States) warrants that the appliance

will be free from defects in materials and workmanship for a period of 36 months from the date of purchase of

the appliance to the consumer.

If there is a breach of this warranty, Condari will rectify, free of charge, at it’s nearest service centre or

authorised service agency any fault caused by faulty workmanship or material at the time of manufacture

occurring in the appliance within 36 months from the date of purchase of the appliance to the customer.

This warranty is conditional upon the appliance being used only for personal, domestic and household purposes

and installed and operated in accordance with QASAIR Instructions and does not apply to articles which by their

nature are consumable.

If a defect is caused by neglect, misuse, or failure to follow operating instructions where special precautions are

detailed for user attention then a charge shall be made for the service call.

For example:

With the filters the user is specifically requested:

• To clean filter regularly by handwashing or placing in a dishwasher at least once a month.

• To turn rangehood off after each use.

• Note: Warranty under filter cleaning on page 51

Where a claim is made under warranty, CONDARI reserves the right to determine whether or not the fault is

caused by faulty workmanship or material or that the part is defective.

The consumer shall be fully responsible for all expenses whatsoever incidental to the removal of parts from

the unit or to their replacement. Amongst other things, such responsibility shall extend to damaged walls, tiles,

fixtures and fittings whether or not the unit has been built into a cupboard and irrespective of the stage either of

its installation or the fitting of any other item whatsoever in its vicinity.

No other person, or firm or corporation is authorised by Condari to offer or give on its behalf any other greater

warranty than that given by Condari under this warranty.

Condari Pty Ltd provides to all QASAIR Rangehoods a 10 year motor replacement warranty. This is a change

over warranty.

The installation of the rangehood must comply with the information in this guide. Failure to follow the instructions

may result in loss of the warranty.

We do point out that incorrect installation such as the ducting being the incorrect size or the duct run being too

long will result in the motor failing and possible burning out.

The change over will be carried out by a authorized technician and will be charged at the rates applicable at

time of the change over.

Qasair Rangehoods Installation Instructions52

EXCLUSIONS

There are some exclusions from the Condari Pty Ltd Guarantee. (on previous page)

CONDOR Rangehoods are designed to be used over all domestic barbecues available

in AUSTRALIA.

QASAIR Rangehoods are not to be used over barbecues approved for outdoor use only.

Outdoor barbecues will have a rating plate on them specifying that they are approved for outdoor use only and

also a mega joule rating per burner or a total mega joule rating.

In practice any barbecue or outdoor cooking appliance over 50 mega joule will need a specially made

rangehood with an air movement exceeding 2000 cubic meters per hour.

QASAIR have hoods to go over domestic cookers such as VIKING, WOLF and CAPITAL cooking appliances.

These brands have a mega joule rating of up to 95 mj and therefore special hoods are required for the

appliances.

CONDARI will manufacture special rangehoods to go over commercial cooking appliances situated in domestic

kitchens.

Once the heat output is over 50 mega joule a special rangehood is required.

Qasair Rangehoods Installation Instructions

53

STANDARD

WARRANTY

Date purchased

Purchased from

Model

Serial No

The purchaser must fill in the above information and keep this with the original purchase document.

This form must be produced if and when

a claim is made under this warranty.

QASAIR Rangehoods are made in Ringwood, Australia.

Tel: +61 3 9482 7088

Fax: +61 3 9482 7011

Email: sales@condari.com.au

Pleae Note that the Warranty is from the date of installation and the service technician will need to see proof of

purchase so he can provide service under the guarantee.

If no proof of purchase then the service call will be charged at standard rates and if proof provided later,

reimbursement will be made.

Qasair Rangehoods Installation Instructions54

EXTENDED

WARRANTY

Condari Pty Ltd provides an extended warranty from 36 months to 72 months if installed by an authorised

Qasair installer and the below form is completed.

The authorised installer also offers a warranty on their workmanship for the same period of 72 months with a

guarantee that the installation is in compliance with

‘Qasair installation instructions’.

Customer Name:

Model Number: Serial Number:

Purchased from:

Purchased Date: Installed Date:

Installer Name:

Installer Signature:

Condari Pty Ltd authorised installer stamp:

(This is required for validity of extended warranty)

Pleae note: The installation warranty does not cover the ageing process in a building or any problems due to

storm damage.

Qasair Rangehoods Installation Instructions

55

NOTES

Qasair Rangehoods Installation Instructions56

NOTES

Qasair Rangehoods Installation Instructions

57

NOTES

Qasair Rangehoods Installation Instructions58

NOTES

Qasair Rangehoods Installation Instructions

59

DISTRIBUTED IN AUSTRALIA BY CONDARI PTY LTD

www.condari.com.au

Tel: 1300 360 563

HEAD OFFICE

VIC Tel: 03 9482 7088 Fax: 03 9482 7011

Email: sales@condari.com.au

Website: www.condari.com.au

YOUR DISTRIBUTORS

NSW/ACT Tel: 02 9316 4599 Fax: 02 9316 9299 Email: salesnsw@qasair.com.au

QLD Tel: 07 3423 3503 Fax: 07 3282 9122 Email: salesqld@qasair.com.au

WA Tel: 08 9242 5387 Fax: 08 9201 0887 Email: saleswa@qasair.com.au

SA/NT Tel: 1300 360 563 Fax: 03 9482 7011 Email: salessa@qasair.com.au

TAS Tel: 03 9482 7088 Fax: 03 9482 7011 Email: sales@qasair.com.au

New Zealand

Kouzina Appliances Email: sales@kouzina.co.nz

Singapore

Eldric Marketing Pte Ltd Email: enquiry@eldric.sg

CONDARI RESERVES THE RIGHT TO CHANGE SPECIFICATION WITHOUT NOTICE

QASAIR RANGEHOODS MADE IN RINGWOOD 3134

rev. 150318

Loading...

Loading...