PVI Industries TRICON 90 L 125 A-PVIF, TRICON 40 L 125 A-PVIF, TRICON 50 L 125 A-PVIF, TRICON 75 L 125 A-PVIF, TRICON 100 L 125 A-PVIF Installation & Maintenance Manual

...

INSTALLATION & MAINTENANCE MANUAL

TRICON

MODELS (40, 50, 75, 90, 100) (L, SS) 125 A-PVIF

MODELS (50, 75, 90, 100) (L, SS) (250, 300) A-PVIF

Installation and service must be performed by a qualified service installer, service agency or the gas supplier.

IMPORTANT: THIS MANUAL CONTAINS INFORMATION REQUIRED FOR INSTALLATION, OPERATION AND

MAINTENANCE OF THIS EQUIPMENT. READ AND FOLLOW THE INFORMATION IN THIS MANUAL AND ALL OTHER

PROVIDED INSTRUCTIONS, LABELS AND MARKINGS BEFORE INSTALLING, OPERATING OR SERVICING THIS UNIT.

WATER HEATER

TO THE INSTALLER: After installation, these instructions must be given to the equipment user or left near the appliance.

SPECIAL INSTRUCTIONS TO THE OWNER: Retain this manual for future reference. These instructions contain

important information that will help you in maintaining and operating this appliance.

PVI INDUSTRIES, LLC - Fort Worth, Texas 76111 - Web www.pvi.com - Phone 1-800-433-5654

1

PV500-45C 06/12

TABLE OF CONTENTS

1. Safety Considerations

2. Standard Features and Equipment

2.1 Performance

2.2 Pressure Vessel

2.3 Heat Exchanger

2.4 Code and Standards

2.5 Burner, Operating Controls & Safeties

2.6 Warranty and Service Policy (see warranty and service policy for details)

2.7 Miscellaneous

3. Product Descriptions

4. Water Heater Installation

4.1 Checking Equipment Before You Install

4.2 Codes

4.3 Electrical Requirements

4.4 Handling and Location

4.5 Service Clearances

4.6 Clearances to Combustible Surfaces

5. General Piping Guidelines

5.1 Inlet and Outlet Connections

5.2 Building Return Piping

6. Condensate Drain, Trap & Disposal

6.1 Condensate Neutralization System (optional)

7. Gas Supply and Piping

7.1 Gas Train and controls Certification

7.2 Gas Control Trains

7.3 Inlet Pressure

7.4 Manifold Pressure

7.5 Gas Piping Size

7.6 Appliance Isolation during Gas Supply Piping Pressure Test

7.7 Gas Connection

8. Combustion and Ventilation Air

8.1 Equipment Located in Confined Spaces

8.2 Maximum Allowed Remote Combustion Air Inlet Length

8.3 Remote Combustion Air Cap

8.4 Vertical or Horizontal Remote Air Duct Termination

8.5 Remote Air Consideration for Combined Remote Air Ducting

9. Venting

9.1 Venting The TriCon

9.2 Maximum Category IV Vent Length

9.3 Vertical or Horizontal Vent Termination

9.4 Combining Category IV Vents

2

PV500-45C 06/12

10. Operating and Safety Controls

10.1 Temperature and Pressure Relief Valve(s)

10.2 Operating Temperature Control

10.3 High Water Temperature Limit Control

10.4 Cathodic Protection

10.5 Electronic Low Water Cut-off (optional)

11. TEMPTRAC Electronic Controller Panel

11.1 Principal of Operation

11.2 Upper LED Readout

11.3 Lower LED Readout

11.4 Control Buttons

11.5 To View the Setpoint

11.6 To Change the Setpoint

11.7 To Change Other Parameters

11.8 LED Display Alarm Messages

12. Remote Connections – Terminal Strip

12.1 Making BMS/BAS Remote Connection for Analog and Binary Signals

12.3 Terminal Functions

13. Sequence of Operation

14. Initial Startup

14.1 Initial Startup Requirements

14.2 Tools and Instrumentation Required

14.3 Resources

14.4 On Site Considerations

14.5 Startup Procedure

15. Troubleshooting Guide

16. Replacement Parts

16.1 Control Panel

16.2 Control Panel Components

16.3 Burner Assembly

16.4 Burner Assembly Components

17. Periodic Maintenance

18. Recommended Maintenance Schedule

Warranty forms ship separately with each product.

3

PV500-45C 06/12

1 SAFETY CONSIDERATIONS

WARNING: If the information in the supplied manual(s) is not followed exactly, a fire, explosion or exposure to

hazardous materials may result, causing property damage, personal injury or loss of life.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electric switch; do not use any phone in your building.

Immediately call your gas supplier from a location away from your building and the smell of gas. Follow the gas

supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

This product contains, or may come to contain materials that have been identified as carcinogenic, or possibly carcinogenic

to humans. Before installing, servicing or removing this product, read and follow the supplied instructions

WARNING: Installation and service must be performed by a qualified installer, service agency or the gas supplier,

who must read and follow the supplied instructions before installing, servicing or removing this appliance. Refer to

the information contained in this manual. Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury, exposure to hazardous materials or loss of life.

WARNING: Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the unit and to replace any part of the control system, all gas contro ls and all other items

affecting safe appliance operation and which has been under water.

WARNING: In an emergency shut the main gas supply valve to the appliance from a location safely away from the

emergency. Failure to follow these instructions can cause property damage, personal injury, and exposure to

hazardous materials or loss of life.

PRODUCT SAFETY INFORMATION

WARNING: This product contains or may come to contain crystalline silica, which has been identified by the

International Agency for Research on Cancer (IARC) as carcinogenic to humans. This product also contains

refractory ceramic fibers, which have been identified by the IARC as possibly carcinogenic to humans. Avoid

breathing fiber particulates and dust.

RISKS:

Air borne fibrous insulation is a possible cancer hazard by inhalation.

Airborne crystalline silica may cause silicosis (lung disease) by inhalation.

May cause temporary irritation to eyes, skin, and respiratory tract.

PRECAUTIONARY MEASURES:

Minimize airborne fibers with engineering controls.

Use NIOSH/MSHA approved respirators as required (see MSDS).

Wear long sleeved, loose-fitting clothing, eye protection and gloves.

FIRST AID MEASURES: (If any of the irritations listed persists, seek medical attention)

Eyes: Flush with water.

Skin: Wash with soap and warm water.

Ingestion: Do not induce vomiting. Get medical attention if gastrointestinal symptoms develop.

Inhalation: Remove to fresh clean air.

WARNING: If you are unfamiliar with the safe handling of refractory ceramic fiber products, or if you wish additional

information prior to beginning any disassembly of the water heater or boiler th at might expose refractory ceramic

fiber materials, contact: Unifrax Corporation, 2351 Whirlpool Street, Niagara Falls, NY 14305-2413, 1-800-322-2293.

IDENTIFICATION OF REFRACTORY CERAMIC FIBER MATERIALS (RCF):

The burner, lower tank and upper and lower flue collector assemblies utilize RCF material. (The RFC materials are located

within the product and not generally exposed except during service, disassembly or assembly.)

REFRACTORY CERAMIC FIBER PRODUCT WITH CRYSTALLINE SILICA

4

PV500-45C 06/12

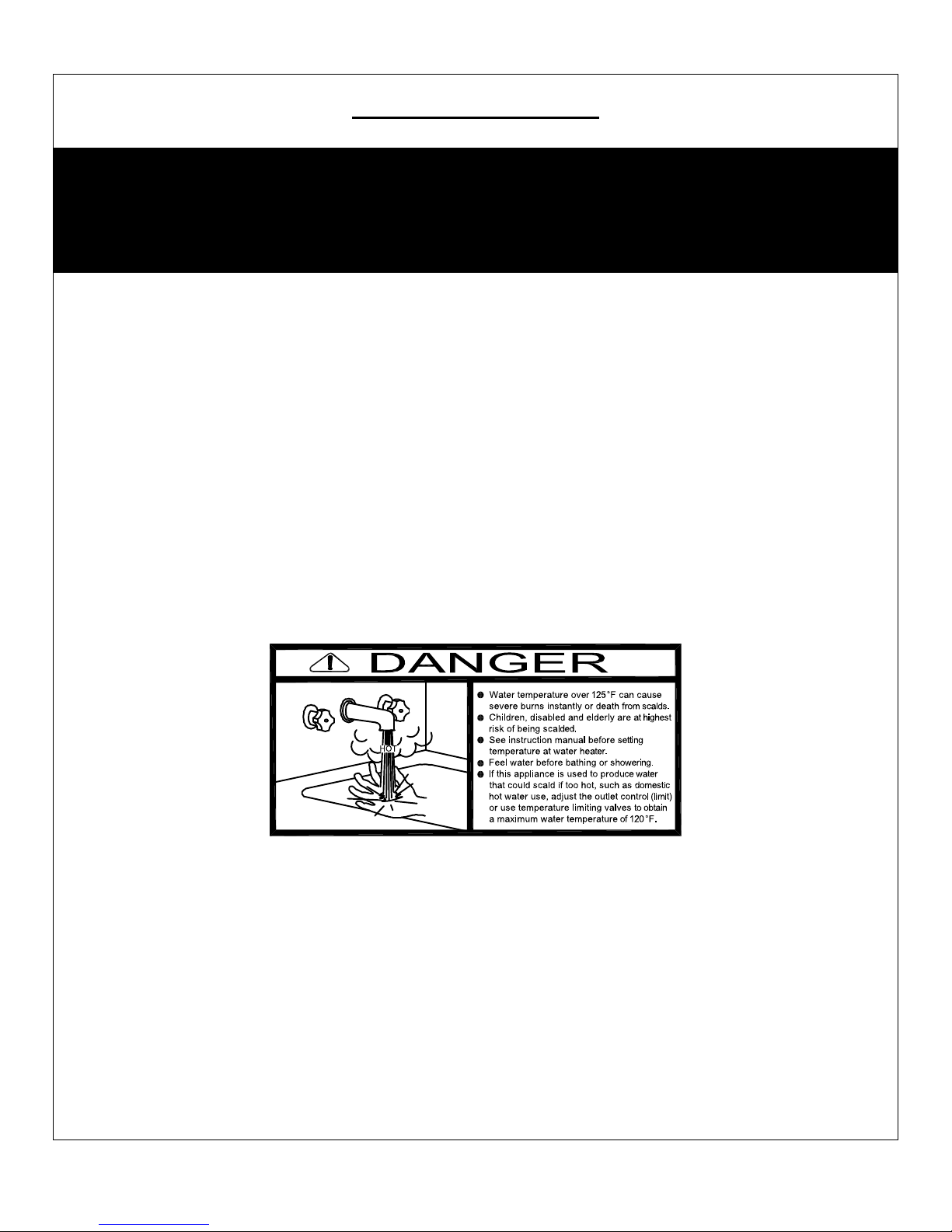

IMPORTANT SAFETY NOTE

It takes only 5 seconds of skin contact with 140°F water to cause a

second degree burn! You must protect against high water temperatures at all

lavatories, tubs, showers and other points of hot water contact.

Accidental scalding from high water temperatures is a greater

risk in some types of installations. Some examples are:

HOMES FOR THE MENTALLY HANDICAPPED

HOMES FOR THE PHYSICALLY HANDICAPPED

HOSPITALS AND NURSING HOMES

ELDER CARE FACILITIES AND REST HOMES

ORPHANAGES AND CHILD CARE FACILITIES

OTHER INSTALLATIONS - WHERE RESPONSE TO CONTACT WITH HOT

WATER MAY BE SLOWER OR WHERE THE DANGER OF HOT WATER

CONTACT IS GREATER

Thermostatically controlled mixing valves must be used in the

design of the potable hot water system.

Potable hot water should be tempered to no more than

110°F when used for bathing or other personal uses.

Good engineering practice mandates the use of thermostatically controlled

mixing valves set at 120°F or less to keep the delivered water temperature

below scalding temperatures.

5

PV500-45C 06/12

2 STANDARD FEATURES AND EQUIPMENT

2.1 Performance

90% thermal efficiency at full fire from 40° to 140°F

Up to 96% thermal efficiency with modulation

< 20 ppm NOx (399 to 900 MBH)

Ducts direct combustion air up to 100 equivalent feet through 6-inch diameter material (requires UL

approved vent cap, see optional equipment list)

Vents up to 100 equivalent feet through 6-inch diameter material

2.2 Pressure Vessel

AquaPLEX

tank (unlined duplex alloy)

Storage tank ASME stamped and National Board registered for 150 psi MAWP

Nonferrous, removable fittings at all tank connections

Hand hole cleanout

Fiberglass insulation

Steel jacket panels with industrial-grade finish

Drain valve

2.3 Heat Exchanger

Three-pass, fire tube design

AquaPLEX

fire tubes

2.4 Codes and Standards

Intertek / ETL listed to US and Canadian safety standards

Intertek / ETL listed for use with stainless steel Category IV vent material

Intertek / ETL certified as low-lead compliant

FM compliant

ASHRAE 90.1 compliant

2.5 Burner, Operating Controls & Safeties

Pre-mix surface burner with self-adjusting, proportionate gas/air ratio

UL 795 compliant gas train

Electronic flame safeguard with pre- and post-purge

Combustion sequence panel lights including lockout

Programmable electronic operating control with digital temperature readouts,

adjustable from 70°F to 180°F

Immersion temperature limiting device (high limit control)

ASME-rated temperature and pressure relief valve

NEMA-1 control enclosure

Terminals for remote on-off

Flame failure audible alarm and indicating light with remote contacts

Seamless VFD modulation with 7-to-1 turndown

2.6 Warranty and Service Policy (see warranty or service policy for details)

10-Year tank warranty (PV 627)

3-Year scale failure warranty (PV 563)

First-year cost-free service policy (PV 551)

10-Year chloride-induced stress corrosion cracking warranty (PV 8083)

2.7 Miscellaneous

Factory authorized startup

Vent termination cap, 6-inch diameter (larger cap optional)

Factory-equipped for connection to direct inlet air (requires UL listed vent termination cap, see options list)

Condensate “P” trap (provided for field installation)

6

PV500-45C 06/12

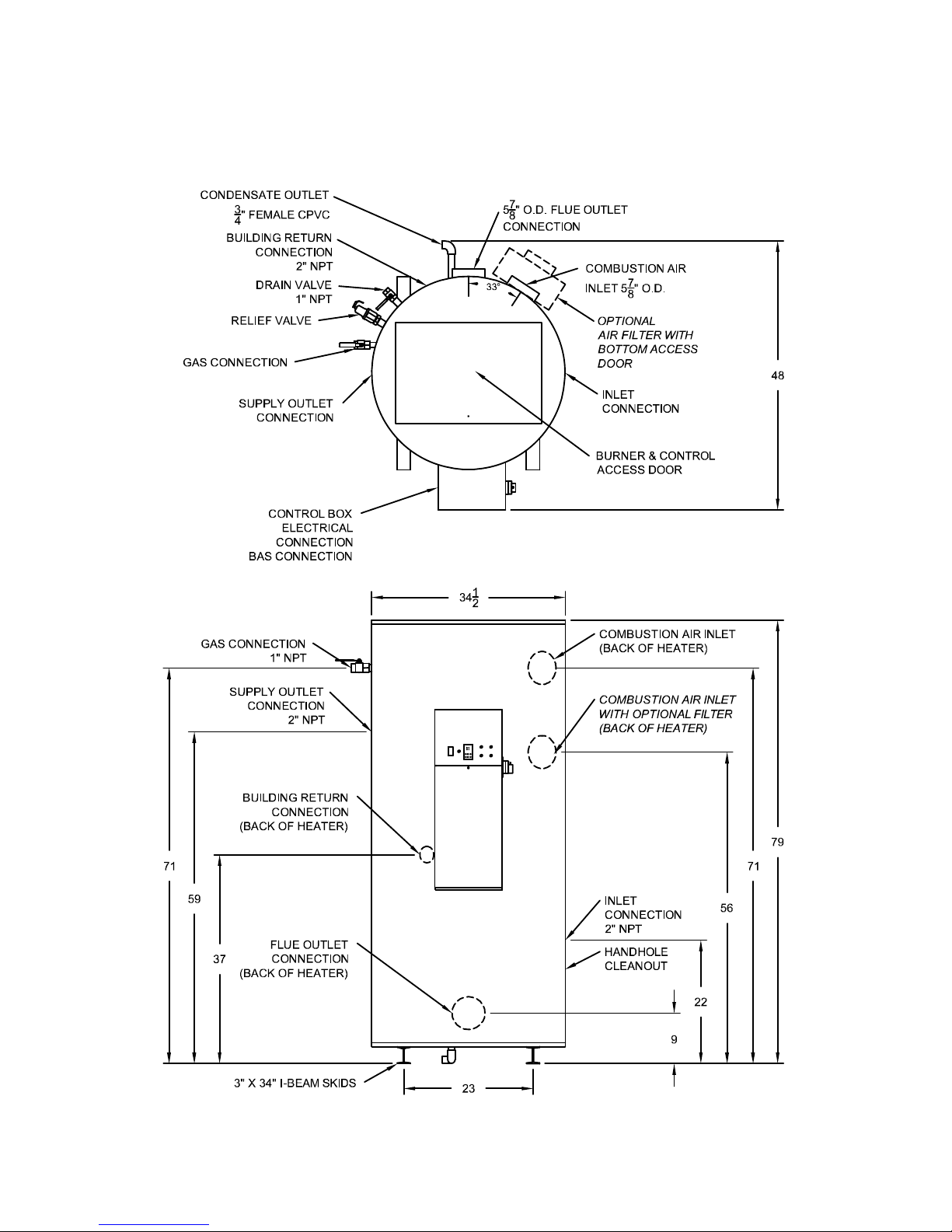

3 PRODUCT DESCRIPTION Component, Controls and Connection Locations

(Locations May Vary)

125 SERIES

7

PV500-45C 06/12

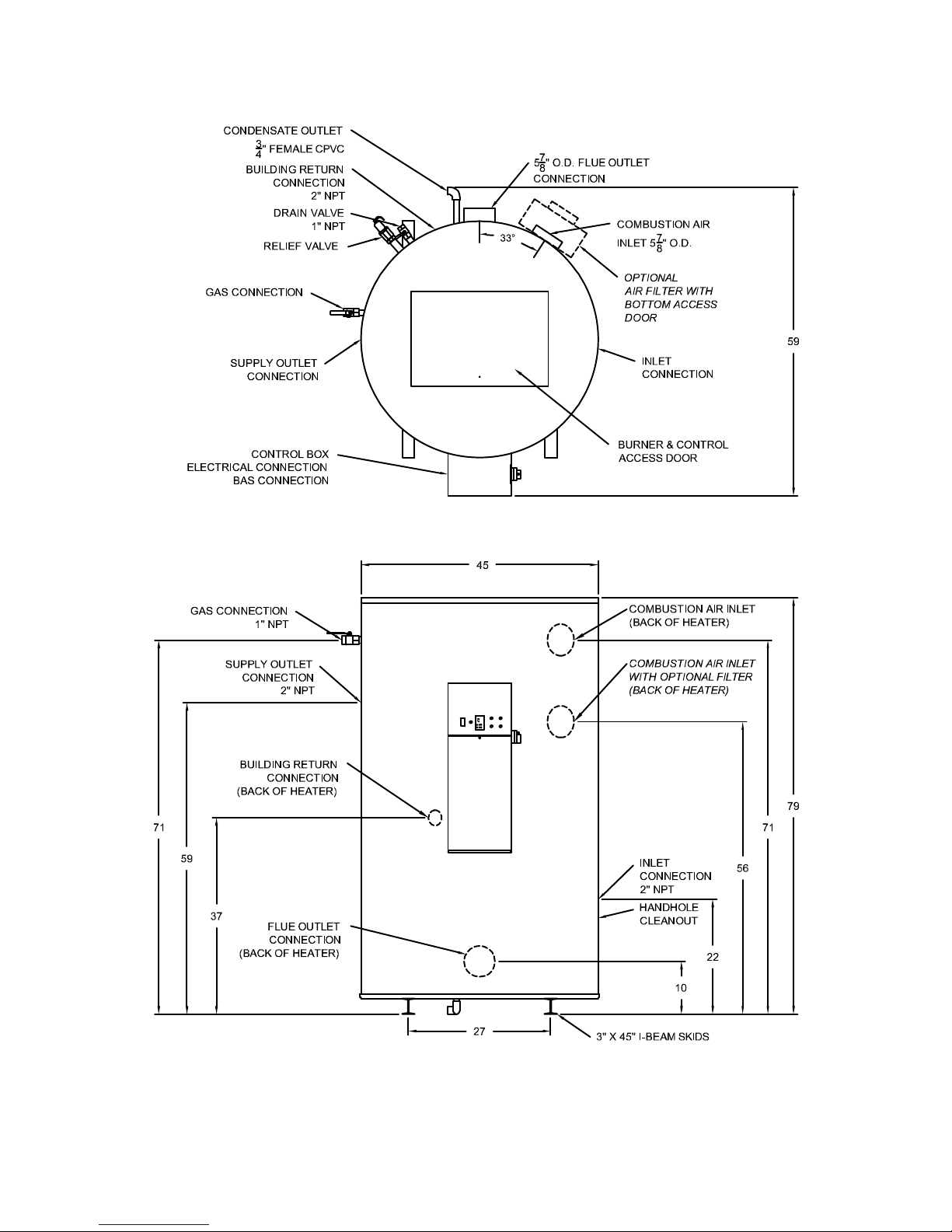

250 SERIES

8

PV500-45C 06/12

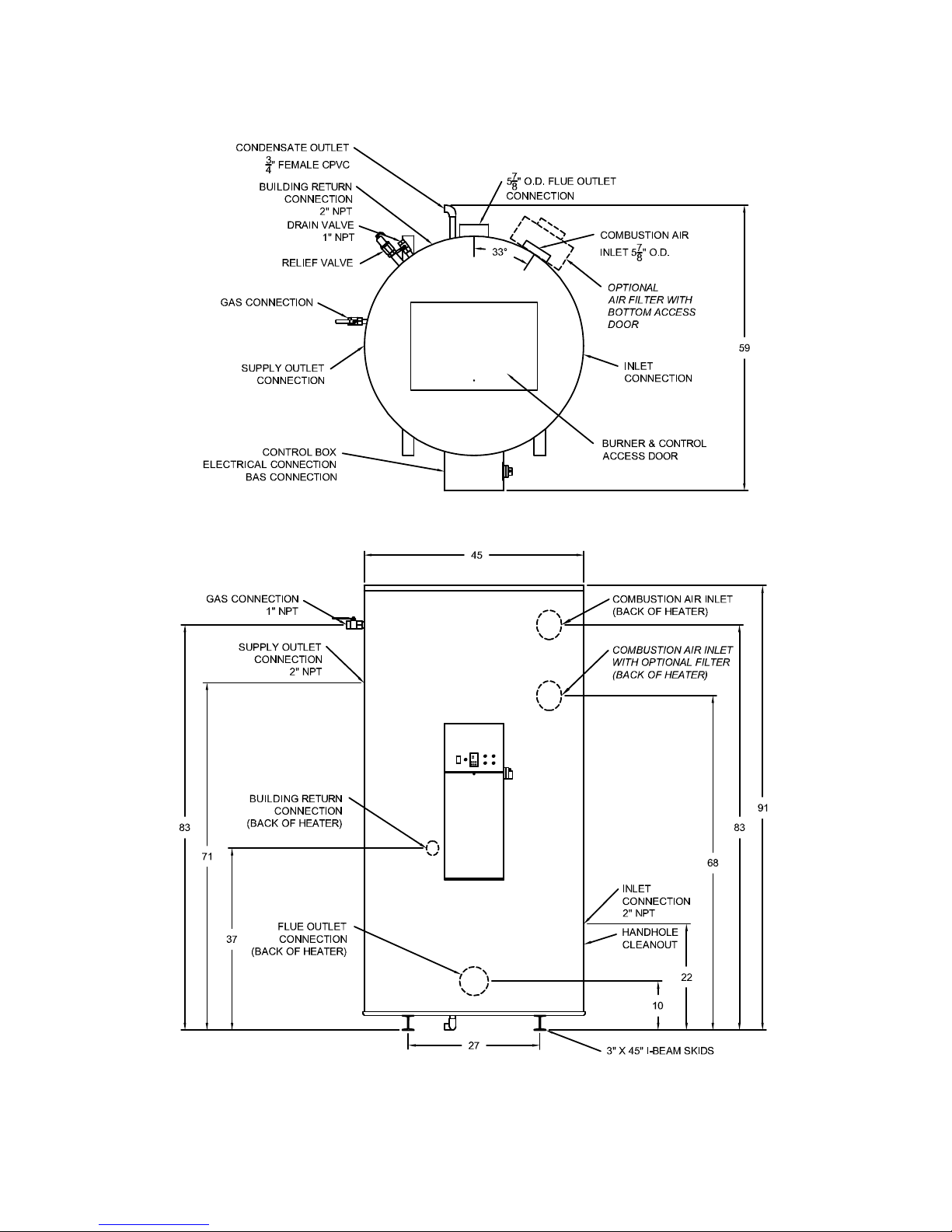

300 SERIES

9

PV500-45C 06/12

4 WATER HEATER INSTALLATION

4.1 Checking Equipment Before You Install

Inspect the unit completely upon receipt from the freight carrier before signing the bill of lading. Inspect the appliance

and all accompanying parts for signs of impact or mishandling. Verify the total number of pieces shown on packing

slips with those actually received. Contact the freight carrier immediately if any damage or shortage is detected.

4.2 Codes

The equipment must be installed in accordance with those installation regulations in force in the local area where the

installation is to be made. Authorities having jurisdiction must be consulted before installation is made. In the

absence of such requirements, the installation shall be in accordance with the instructions in this manual, appliance

markings and supplemental instructions and in compliance with the latest edition of the National Fuel Gas Code,

ANSI Z223.1. Where required by the Canadian authority having jurisdiction, the equipment must be installed in

accordance with the latest edition of the Installation Code for Gas Burner Appliances and Equipment CAN/CSA

B149.1 and/or B149.2 and applicable Provincial Regulations. All appliances conform to the latest edition of the

ASME Boiler and Pressure Vessel Code, Section IV, Part HLW.

4.3 Electrical Requirements

See appliance rating decal for electrical service requirements. The appliance must be electrically supplied and

grounded in accordance with the requirements of the authority having jurisdiction or in the absence of such

requirements, with the latest edition of the National Electrical Code ANSI/NFPA No. 70. In Canada, the electrical

service must conform to local electrical codes and/or CSA C22.1, Canadian Electrical Code, Part 1.

All wiring between the unit and field installed devices must be made with type T copper wire.

Line voltage wire exterior to the appliance must be enclosed in approved conduit or approved metal clad cable.

To avoid serious damage, DO NOT energize the unit until the system and appliance is full of water.

4.4 Handling and Location

WARNING: Use industry standard safe rigging methods, such as including the use straps and spreader bars

and lifting from the water heater base skid assembly, when attempting to lift or move this product. Failure to

follow industry safe rigging methods could result in property damage, serious injury or death.

1 Check the data decal on the appliance. Be sure the electrical, water, oil, or gas supply is adequate for the

installation.

2 Carefully remove all shipping supports and bracing.

3 These units are suitable for indoor installation only.

4. Installing the water heater on a 4 inch to 6 inch housekeeping pad is recommended to ensure proper condensate

drainage.

5. Locate the unit so that if water connections should leak, water damage will not occur. When such locations are

unavoidable, install a suitable drain pan, and plumb pan to ensure adequate drainage in the event of a leak.

Under no circumstances is the manufacturer responsible for water damage in connection with this unit, or any of

its components. The manufacturer’s warranty does not cover water damage.

6. Protect associated electrical components and electrical connections from water (dripping, spraying, rain, etc.)

during appliance operation and service.

7. Place the appliance on a level, non-combustible floor. Concrete over wood is not considered non-combustible.

10

PV500-45C 06/12

8. Do not install on carpet or other combustible floor coverings. If installation over a combustible floor is required,

follow these guidelines:

Use a base of hollow clay tile or concrete blocks from 8" to 12" thick and extending 24" beyond the sides.

Place the blocks in line so that the holes line up horizontally to provide a clear passage through the blocks.

Install 1/2” fireproof millboard with a 20-gage sheet metal cover over the block base.

Center the unit on the base. Also follow this procedure if electrical conduit runs through the floor, and

beneath the appliance. A field-installed base must meet all local fire and safety code requirements.

4.5 Service Clearances

Allow sufficient space to provide adequate clearances on all sides for service and inspection. At least 24” above the

water heater is required for filter replacement (if equipped) and burner/gas control service, 18” at left and right sides

of the appliance. Optional equipment may increase the clearance requirements. Allow sufficient space for installing

and servicing connections such as water, gas, vent, combustion air, electrical, pump and other auxiliary equipment.

4.6 Clearances To Combustible Surfaces

Minimum 1” clearance must be provided from any vent surface to adjacent combustible material. The minimum

clearances to unprotected combustible material are 24” be provided at the front, 8” be provided at the rear and 8” at

top, left and right sides of the appliance.

5 GENERAL PIPING GUIDELINES

5.1 Inlet and Outlet Connections

1. Use only non-ferrous water piping and fittings. Do not use galvanized pipe or fittings. Use of ferrous or

galvanized pipe or fittings can cause rust to form.

2. Install shut-off valves and unions on the inlet and outlet water piping for servicing. Use caution when

threading pipe nipples into tank connections to prevent cross threading, or over-tightening. Always use a

back-up wrench on tank nipples when tightening unions, valves, etc.

3. Insulate hot water and return circulation lines. Insulate cold water supply lines if subject to freezing during

shutdown periods. IMPORTANT: Do not use the plumbing connected to the appliance as a ground for

welding or any other purpose.

4. Pipe the drain valve to a suitable open drain.

5.2 Building Return Piping

To maximize water heater efficiency, connect the building return (≈ 5 gpm) directly to the return fitting located at the

rear of the tank.

11

PV500-45C 06/12

SINGLE WATER PIPING

SINGLE STORAGE WATER HEATER WITH SUPPLEMENTAL STORAGE TANK

12

PV500-45C 06/12

TWO WATER HEATERS WITH REVERSE RETURN PIPING

6 CONDENSATE DRAIN, TRAP & DISPOSAL

The Tricon water heater is designed to produce significant amounts of condensate because of its high efficiency.

Condensate occurs naturally when water vapor in combustion gases is cooled below the dew point. A 3/4” NPT drain

connections is provided. A trap with three inches of standing water below the bottom of the heater (3” above the base

of the I-Beam skids), and no higher than the bottom of the heater must be field installed as part of the condensate

piping.

WARNING: A trap with three inches of standing water as described in these instructions must be included as

part of the condensate piping system. This trap is required to keep hazardous products of combustion from

continually entering the room through the condensate piping. Failure to provide this trap can cause,

personal injury, exposure to hazardous materials or loss of life.

1. Installing the water heater on a 4 inch to 6 inch housekeeping pad is recommended to ensure proper

condensate drainage.

2. Attach a 3/4” CPVC pipe from the heater condensate to a 3” CPVC trap and on to a suitable floor drain or

collection system. Each condensing appliance must drain separately. Do not combine condensate drains from

multiple condensing appliances into a single drain pipe.

3. Each condensate drain must contain a trap or siphon/pigtail to provide at least 3 inches of standing water, to

prevent flue gas flow through the condensate piping. To construct the trap, connect to the 3/4” condensate

drain, route the piping downward until the standing water in the trap is not higher than the bottom of the water

heater.

4. Install the condensate plumbing as shown in the following diagram.

5. All condensate plumbing must be protected from freezing. Do not locate the condensate piping such that an ice

dam of frozen condensate can block the outlet.

13

PV500-45C 06/12

Loading...

Loading...