Page 1

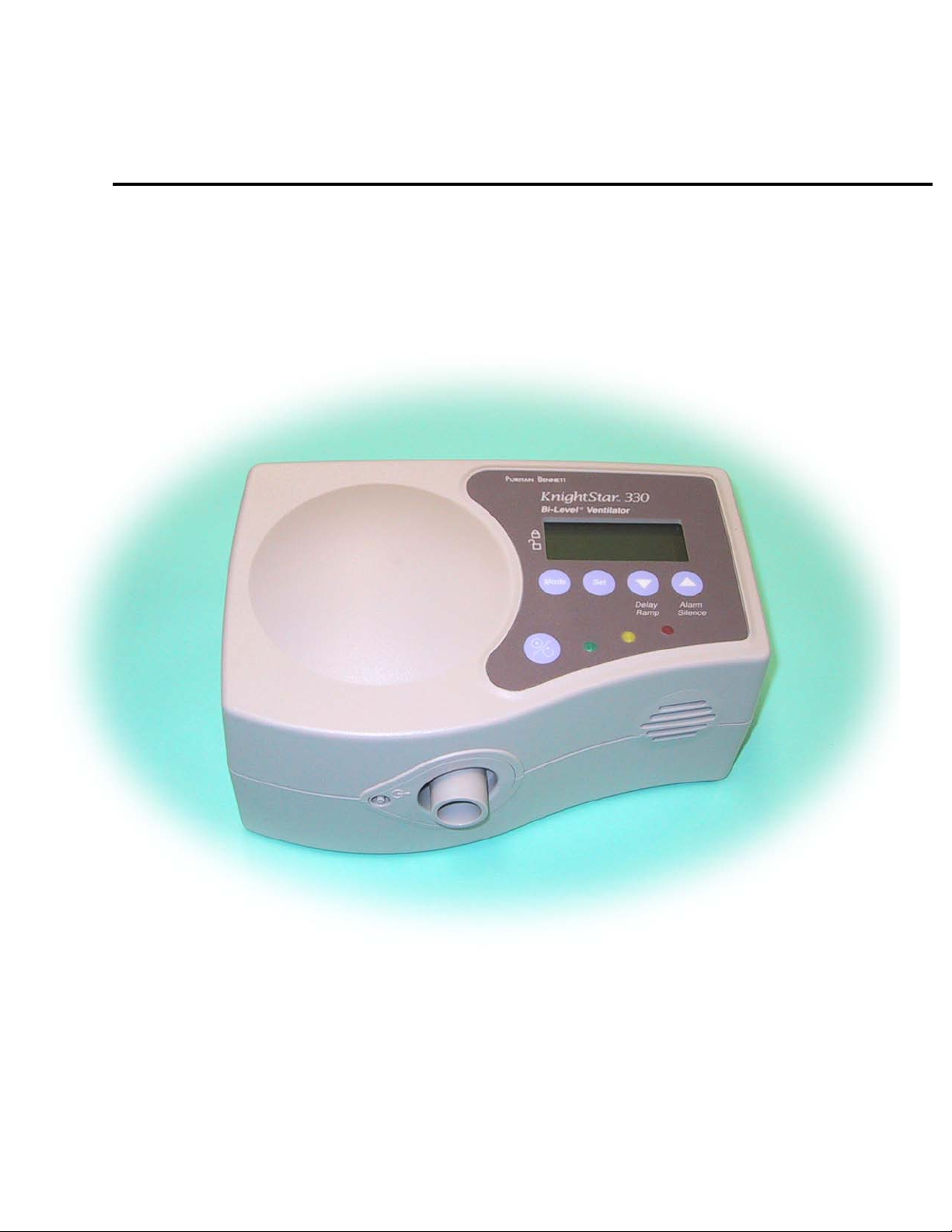

KnightStar

®

330

Bi-Level® Ventilator

Service Manual

Y-102942-00A Rev G

March, 2004

manual 4-070089-00 Rev. B (10/02)

Page 2

© Copyright 2004 Nellcor Puritan Bennett Inc. All rights reserved.

KnightStar, Bi-Level, SoftFit, ADAM, and Breeze are trademarks of Nellcor Puritan Bennett Inc. For more information, contact

your Puritan Bennett representative.

The ventilator should be operated and serviced only by trained professionals. Puritan Bennett’s sole responsibility with respect

to the ventilator, and its use, is as stated in the limited warranty provided.

Nothing in this manual shall limit or restrict in any way Puritan Bennett’s right to revise or otherwise change or modify the

equipment (including its software) described herein, without notice. In the absence of an express, written agreement to the

contrary, Puritan Bennett has no obligation to furnish any such revisions, changes, or modifications to the owner or user of

the equipment (including its software) described herein.

Manufacturer: Authorized Representative:

Puritan-Bennett Corporation Tyco Healthcare UK Limited

4280 Hacienda Drive 154 Fareham Road

Pleasanton, CA 94588 USA Gosport PO13 0AS, U.K.

Toll Free: 1.800.635.5267

Page 3

1

General information

1.1 Safety considerations...................................................................................................1-1

1.2 Electromagnetic susceptibility......................................................................................1-2

1.3 Customer assistance ....................................................................................................1-2

1.4 How to use this manual...............................................................................................1-2

1.5 General product description ........................................................................................1-3

1.6 Configuration information...........................................................................................1-4

1.7 Accessories ..................................................................................................................1-4

1.8 Specifications ..............................................................................................................1-5

1.9 Compliance and approvals ..........................................................................................1-8

1.10 Breathing modes and settings ..................................................................................1-9

1.11 Initial factory settings .............................................................................................1-11

1.12 Controls, indicators, and symbols ............................................................................1-12

1.13 Onscreen symbols and abbreviations.......................................................................1-21

1.14 Ventilator serial numbers and software version ........................................................1-22

1.15 Tools, equipment, and service materials ..................................................................1-22

1.16 Periodic maintenance .............................................................................................1-24

1.17 Spare parts ..............................................................................................................1-24

1.18 Service philosophy ..................................................................................................1-25

SECTION

CONTENTS

1.4.1 Definitions...........................................................................................................1-3

1.4.2 Using the manual to troubleshoot the KnightStar 330..........................................1-3

2

Theory of operation

2.1 Ventilator components ................................................................................................2-1

2.2 Operational overview ..................................................................................................2-2

2.2.1 Operating modes ................................................................................................2-3

2.2.2 Breathing modes .................................................................................................2-4

2.3 Breath delivery ............................................................................................................2-5

2.4 Breath detection..........................................................................................................2-6

2.4.1 Expiratory sensitivity............................................................................................2-6

2.4.2 Inspiratory sensitivity ...........................................................................................2-7

2.4.3 Rise time .............................................................................................................2-7

2.5 External battery operation ...........................................................................................2-8

2.6 Safety features .............................................................................................................2-9

2.6.1 Overcurrent protection........................................................................................2-9

2.6.2 Controls protection .............................................................................................2-9

2.6.3 Power off protection............................................................................................2-9

2.6.4 Maximum pressure..............................................................................................2-9

2.6.5 Audible alarms.....................................................................................................2-9

2.6.5.1 High priority alarm ....................................................................................2-9

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04)

i

Page 4

Contents

2.6.5.2 Medium priority alarm ............................................................................ 2-10

2.6.5.3 Low priority alarm................................................................................... 2-10

2.6.5.4 Alarm control .......................................................................................... 2-10

3

Performance verification

3.1 Initial ventilator cleaning and inspection ..................................................................... 3-1

3.2 System set-up ............................................................................................................. 3-1

3.3 Performance verification tests...................................................................................... 3-3

3.3.1 Functional performance tests .............................................................................. 3-3

3.3.1.1 Self tests.................................................................................................... 3-3

3.3.1.2 Blower test................................................................................................ 3-3

3.3.1.3 Leak alarm test.......................................................................................... 3-4

3.3.1.4 Sensitivity test ........................................................................................... 3-4

3.3.1.5 Pressure test.............................................................................................. 3-5

3.3.1.6 Delay sequence test .................................................................................. 3-5

3.3.1.7 Low pressure alarm test............................................................................. 3-5

3.3.1.8 High pressure alarm test............................................................................ 3-6

3.3.1.9 Power failure indicator test........................................................................ 3-6

3.3.1.10 Autoclear procedure.................................................................................. 3-6

3.4 KnightStar 330 performance verification checklist........................................................ 3-7

4

Troubleshooting

4.1 Alarms ........................................................................................................................ 4-1

4.2 Troubleshooting checklist ........................................................................................... 4-3

4.3 Internal malfunction errors.......................................................................................... 4-7

4.4 Logged errors ........................................................................................................... 4-11

5

Repair

5.1 Tools, test equipment, and service materials ............................................................... 5-1

5.2 Ventilator cleaning and inspection .............................................................................. 5-1

5.3 Ventilator assembly drawing ....................................................................................... 5-1

5.4 Initial ventilator disassembly ....................................................................................... 5-2

5.5 Membrane switch replacement................................................................................... 5-4

5.6 LCD panel replacement............................................................................................... 5-5

5.7 Alarm PCBA replacement ............................................................................................ 5-5

5.8 Cooling fan assembly replacement.............................................................................. 5-9

5.9 Ventilator reassembly ................................................................................................ 5-10

5.10 Post-repair testing................................................................................................... 5-10

6

Warranty and service information

6.1 Limited warranty......................................................................................................... 6-1

6.2 Service information ..................................................................................................... 6-1

ii Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 5

SECTION

SECTION

General information 1

This manual provides information needed to service the Puritan Bennett KnightStar 330® Bi-

®

Level

personnel with equivalent experience and training in servicing this type of equipment.

This section provides introductory information on the KnightStar 330 ventilator including:

1.1 Safety considerations

Please take the time to familiarize yourself with the following caveats as they cover safety

considerations, special handling requirements, and regulations that govern the use of the

KnightStar 330 ventilator.

ventilator and is intended for use by certified biomedical engineering technicians or

• General safety information

• Instructions on how to use the manual

• A description of the ventilator, its accessories, and its controls and indicators

• Detailed specifications and required tools and test equipment used for service and repair

• To ensure proper servicing and avoid the possibility of physical injury, only qualified

personnel (minimum requirement Certification for Biomedical Equipment Technician or

equivalent) should attempt to service or make authorized modifications to the ventilator.

The user of this product shall have sole responsibility for any ventilator malfunction

due to operation or maintenance performed by anyone not trained by Puritan Bennett

staff.

• To avoid an electrical shock hazard while servicing the ventilator, be sure to remove all

power to the ventilator by turning off the ventilator power switch and disconnecting the

power source.

• To avoid a fire hazard, keep matches, lighted cigarettes, and all other sources of ignition

(e.g., flammable anesthetics and/or heaters) away from the KnightStar 330 and oxygen

hoses.

Do not use oxygen hoses that are worn, frayed, or contaminated by combustible materials

such as grease or oils. (Textiles, oils, and other combustibles are easily ignited and burn

with great intensity in air enriched with oxygen.)

In case of fire or a burning smell, immediately disconnect the ventilator from the oxygen

supply, and the power source.

• When handling any part of the KnightStar 330, always follow your hospital infection

control guidelines for handling infectious material.

1

Puritan Bennett recognizes that cleaning, sterilization, sanitation, and disinfection

practices vary widely among healthcare institutions. It is not possible for Puritan Bennett

to specify or require specific practices that will meet all needs, or to be responsible for the

effectiveness of cleaning, sterilization, and other practices carried out in the patient care

setting. Specific cleaning instructions for the KnightStar 330 are given in section 5.2 on

page 1.

Puritan Bennett recommends that users of its products that require cleaning and

sterilization/disinfection consider the Center for Disease Control (CDC) publication:

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04)

1-1

Page 6

1 General information

Guidelines for Prevention of Nosocomial Pneumonia available from the CDC Web site:

http://www.cdc.gov/publications.htm. Refer to the table on page 1-23 for a list of

approved disinfectants and cleaning agents.

• Patients on ventilation equipment should be appropriately monitored by competent

medical personnel and suitable monitoring devices.

• For a thorough understanding of ventilator operations, be sure to thoroughly read this

manual and the KnightStar 330 Clinician’s Manual before operating the device. These

manuals provide service, repair, and technical information concerning the operation and

performance of the ventilator.

• Before patient use, be sure to check the equipment for proper operation.

• Do not use sharp objects to make selections on the keypad.

• Check the ventilator periodically as outlined in this manual; do not use if defective.

Immediately replace parts that are broken, missing, obviously worn, distorted, or

contaminated.

• Federal law (U.S.) restricts this device to sale by or on the order of a physician.

1.2 Electromagnetic susceptibility

The KnightStar 330 equipment has been tested and found to comply with the limits for

medical devices to IEC 60601-1-2:2001 (or Medical Device Directive 93/42/EEC). This testing

shows that the device provides reasonable protection against harmful interference in a typical

medical installation. There is, however, no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to other devices or

is negatively affected by other devices, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Re-orient or relocate the devices

• Increase the separation between the devices

• Connect the equipment to an outlet on a different circuit

• Contact the manufacturer or your local representative for help

1.3 Customer assistance

For further assistance, or for questions regarding the applicability of the information in this

manual, contact Puritan Bennett Technical Support at 1.800.255.6774 (within the USA) or

your local Puritan Bennett representative (outside the USA).

1.4 How to use this manual

While this manual covers the ventilator configurations currently supported by Puritan

Bennett, some product upgrades may be available prior to a corresponding revision of this

manual. The current revision of this manual is available on the Internet at:

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/PBProductManuals.html.

Puritan Bennett recommends that you become familiar with this manual and the KnightStar

330 Clinician’s Manual before attempting to operate or service the ventilator. These manuals

provide service, repair, and technical information concerning the operation and performance

of the Puritan Bennett KnightStar 330 bi-level ventilator.

1-2 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 7

General information 1

1.4.1 Definitions

This manual uses three special indicators to convey information of a specific nature.

They include:

Warning

Indicates a condition that can endanger the patient or the ventilator operator.

Caution

Indicates a condition that can damage the equipment or other property.

NOTE:

Indicates points of particular interest that make operation of the ventilator more efficient or

convenient.

1.4.2 Using the manual to troubleshoot the KnightStar 330

NOTES:

• At a minimum, the repair technician should be a Certified Biomedical Equipment

Technician (CBET) or possess equivalent experience and training before performing

any of the service instructions described in this manual

• Due to specific design interactions between the Main PCBA, blower, and pitot

tube, individual field replacement of any of these parts is not possible. If required,

please return the KnightStar 330 to a Puritan Bennett factory service center for

repair.

1 Refer to Section 4 of this manual to diagnose the problem. Using the troubleshooting

guides in this section, determine if the problem can be corrected without returning the

device to a factory service center.

2 Use Table 1-14 to identify and order the required service parts.

3 Follow instructions in Section 5 to disassemble, repair, and reassemble the KnightStar

330.

4 Perform and document performance verification tests described in Section 3.

1.5 General product description

The Puritan Bennett KnightStar 330 is a continuous, bi-level ventilator that provides

noninvasive ventilation for the treatment of respiratory insufficiency and obstructive sleep

apnea that may occur in the home. It is also indicated for the treatment of respiratory failure

in institutional environments. It is intended to assist the ventilation of spontaneously

breathing patients who are over 30 kg (66 lb) in weight.

The KnightStar 330 is a microprocessor-controlled pressure generator capable of monitoring

the air flow and controlling the pressure delivered to the patient. The following are some of

its operating features:

• Provides three breathing modes, including Continuous Positive Airway Pressure (CPAP),

Inspiratory/Expiratory Positive Airway Pressure (I/E PAP), and Assist Control (A/C).

• Monitors pressure, tidal volume, respiratory rate, air leaks, peak flow, and I:E ratio.

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-3

Page 8

1 General information

• Provides precise respiratory support and patient comfort via adjustable inspiratory and

expiratory trigger sensitivity.

• Uses audible and visual indicators to alert users to power failure, system leaks, and other

conditions that could affect device performance.

• Allows a maximum pressure setting of 30 cmH

for a single-fault condition.

• Compensates for delivered pressure within specification for altitudes from 0 to 8,000 feet

(2438 meters) at 3 to 30 cmH

1.6 Configuration information

The KnightStar 330 is available in six configurations—North American and five international

versions. The major differences between ventilators are listed below:

North American: The North American version has Mode and Settings control panel keys and

some displayed information identified in English, and includes English labels, software, and

manuals. The power cord provided fits a standard 115 V AC outlet. Alarm volume may be set

from 0 (off) to 3 (maximum).

All other versions: All versions of the KnightStar 330 other than North American have

control panel keys and displayed information identified using symbols. Labels, software and

manuals are provided in various language configurations. A power cord with the appropriate

plug end is provided according to the configuration ordered. Alarm volume may be set from

0 (off) to 3 (maximum), except for Japanese. The Japanese KnightStar 330 alarm volume may

be set from 1 (minimum) to 3 (maximum) and cannot be set to “off.”

Figure 1-2 on page 1-12 shows the KnightStar 330’s control panel.

1.7 Accessories

The following accessories are either required or can be used with the KnightStar 330. See

Tab le 1-1 for ordering information.

O, with a pressure limitation of 40 cmH2O

2

O, and compensates for leaks up to 60 liters per minute.

2

Calibration Shell: The calibration shell is required for Performance Verification testing on

the KnightStar 330.

Patient circuit: Puritan Bennett recommends using the KnightStar 330 with 1.8 m (6 ft) or

2.4 m (8 ft) tubing and approved interfaces.

Oxygen Adapter: An optional O

or outlet air filter to enable the use of supplemental oxygen. Refer to the KnightStar 330

Clinician’s Manual for more information.

Humidification device: The KnightStar 330 supports the use of an optional Fisher & Paykel

HC100 Humidifier, or equivalent.

External Battery: The KnightStar 330 may be powered by an external battery. A 32 ampere-

hour or a 7 ampere-hour battery are available. Separate cables are required to connect the

KnightStar 330 to an external battery or to a car or truck cigarette lighter outlet.

Other accessories: A carrying case and rolling stand are also available for the KnightStar 330.

adapter may be connected to the KnightStar 330 outlet port

2

1-4 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 9

General information 1

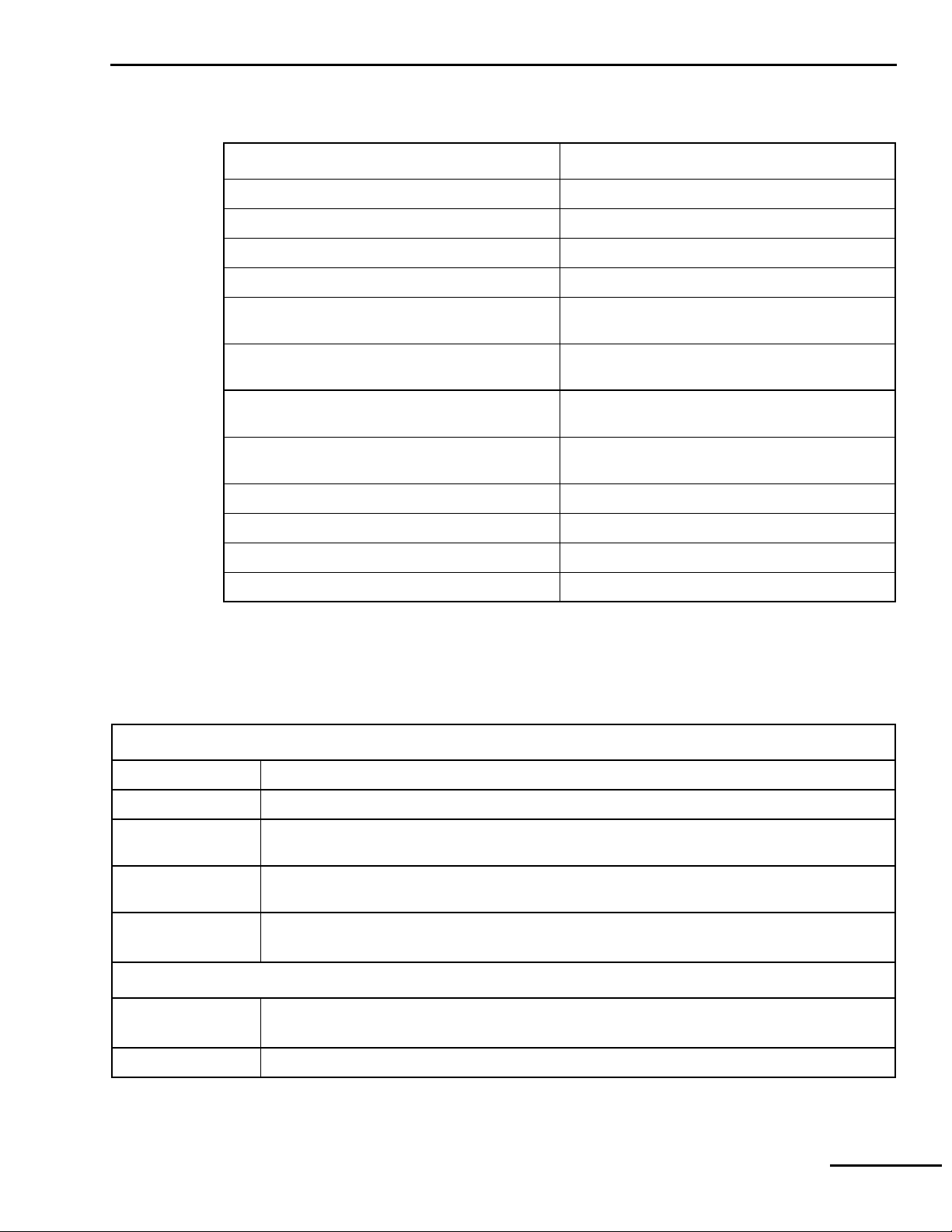

Table 1-1 lists the ordering information for KnightStar 330 accessories.

Table 1-1: KnightStar 330 accessories

Description Part number

Calibration Shell S-231702-00B

KnightStar 330 Patient tube, 6 ft Y-261000-27

KnightStar 330 Patient tube, 8 ft Y-261000-30

Oxygen Adapter Y-616155-03B

Passover humidifier kit (includes 13 in. hose, base,

and reservoir)

Battery Kit, 32 Ampere-hour, Domestic (includes

battery, case, 115 VAC charger, charger cable)

Battery Kit, 32 Ampere-hour, European (includes

battery, case, 220 VAC charger, charger cable)

Battery Kit, 7 Ampere-hour (includes battery, case,

universal charger, charger cable)

Cable, battery adapter Y-102914-00

Cable, cigarette lighter adapter Y-102913-00

Carrying Case, KnightStar 330 Y-213531-01

Rolling Stand, KnightStar 330 902284

1.8 Specifications

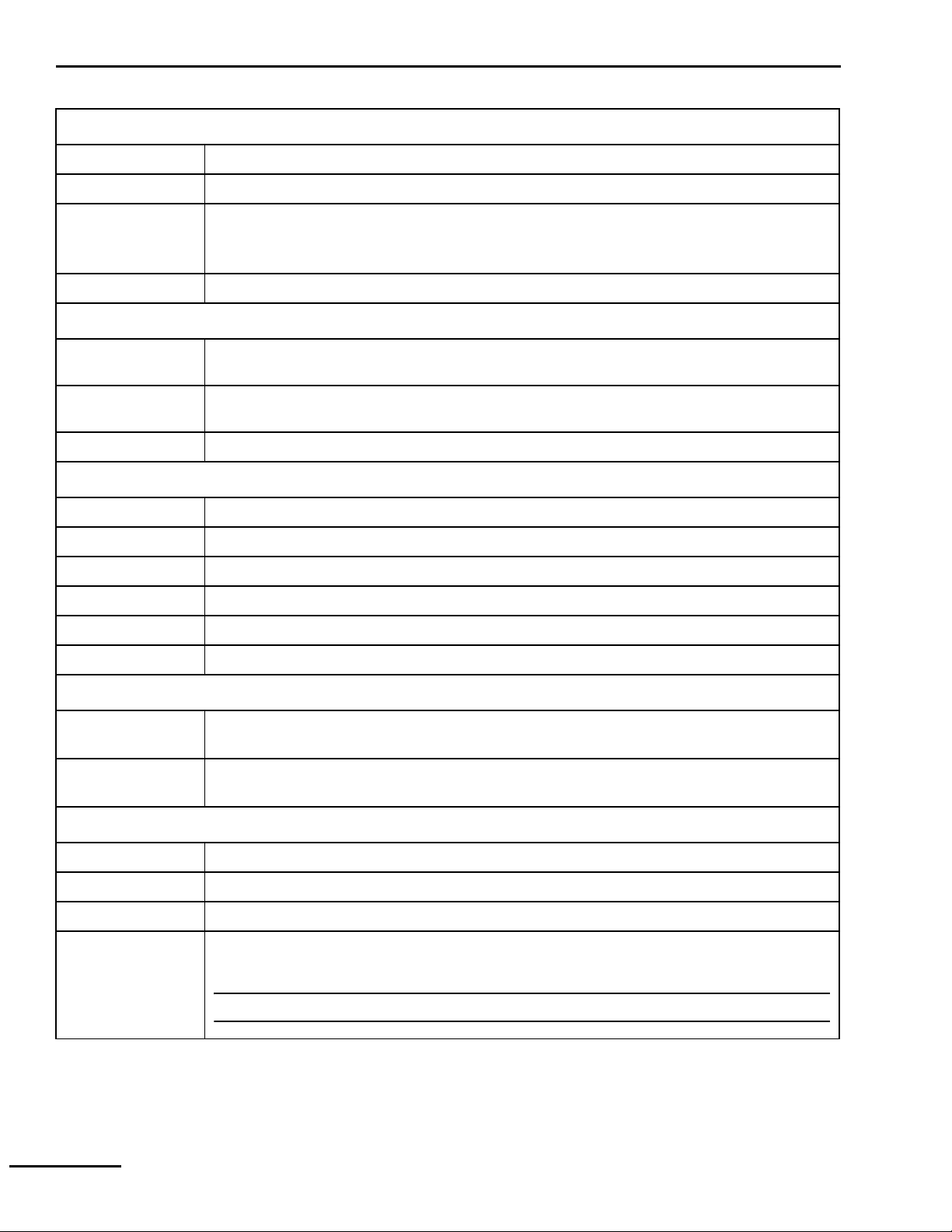

Table 1-2 lists the technical specifications of the KnightStar 330 ventilator.

Physical characteristics

Y-102938-00

Y-C GVPD

Y-C GVPE

Y-CGVP7120

Table 1-2: Ventilator specifications

Weight 1.21 kg (2.7 lb)

Dimensions 9.52 cm x 20.95 cm x 14.27 cm (3.75 in x 8.25 in x 5.62 in)

Air Outlet Port

Connector

Device Airway

Volume

Patient Circuit

Volume

Environmental specifications

Temperature and

Humidity

Altitude Operating: 0 to 2438 m (0 to 8,000 ft)

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-5

Standard 22-mm conical male

65 mL

695 mL (1.8 m/6 ft)

927 mL (2.4 m/8 ft)

Operating: 5 to 40 ° C (41 to 104 ° F) at 15 to 95% relative humidity, noncondensing

Storage: -40 to 70 ° C (-40 to 158 ° F) at 10 to 95% relative humidity, noncondensing

Page 10

1 General information

Table 1-2: Ventilator specifications (continued)

Performance specifications

Working Pressure 3 to 30 cmH2O (1 cmH2O = 0.098 kPa)

Pressure Limit 40 cmH

Static Flow Pressure

Regulation

For flow rates up to 60 L/min:

CPAP ± 0.5 cmH2O for settings from 4 to 20 cmH2O

Bi-level ± 1.0 cmH

Noise ≤ 30 dBA for IPAP/EPAP = 10 cmH

O

2

O for settings from 4 to 30 cmH2O

2

O (measured 1 m in front of device)

2

Electrical specifications

Rated Mains/AC

100 – 240 V AC nominal (85 – 264 V AC operating range)

Input Voltage

Rated Input

50 – 60 Hz

Frequency

Rated Input Power 140 W

Displayed Patient Parameter Accuracy

Tidal Volume (Vt) ± 20 mL +20% of reading (between 50 mL and 2000 mL)

Peak Flow (V) ± 5 LPM +20% of reading (between 1 and 100 LPM)

Leak (L) ± 5 LPM +20% of reading (between 1 and 100 LPM)

Respiratory Rate ± 1 BPM (between 1 and 50 BPM)

I:E Ratio ± 15% of reading (between 1:1 and 1:9.9)

Pressure ± 1 cmH

O + 10% of reading (3 to 35 cmH2O)

2

Circuit Resistance

Inspiratory 0.2 cmH2O at 30 L/min

0.9 cmH

Expiratory 4.1 cmH

5.0 cmH

O at 60 L/min

2

O at 30 L/min

2

O at 60 L/min

2

External Battery Specifications

Rated Input Voltage 12 V DC

Rated Input Current 6.0 A

Rated Input Power 140 W

Operating Time 32 Ampere-hour: approximately 8 hours

7 Ampere-hour: approximately 3 hours

NOTE: Actual usage times depend upon patient’s prescription settings.

1-6 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 11

General information 1

Table 1-2: Ventilator specifications (continued)

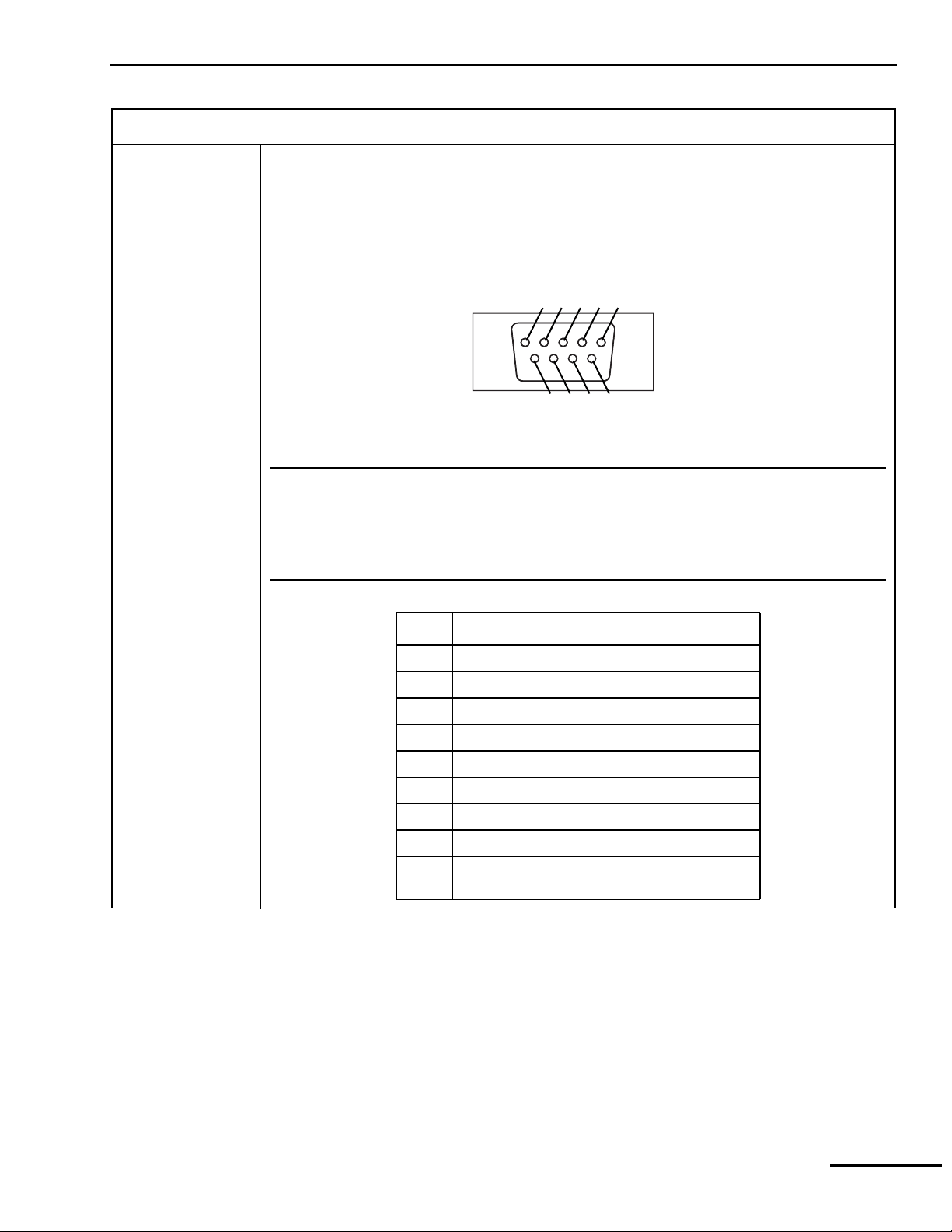

Communication Port Specifications

Communication

capabilities

RS-232 (serial) port (Figure 1-1). A 9-pin female connector provides for RS-232 serial

communications, I/E PAP digital triggering, and calibration EEPROM programming. The RS-232

function operates at signal levels of at least 3 V into a standard load at a data rate of 9.6 kbps and

19.2 kbps. Pin 9 is used for calibration EEPROM programming at the manufacturing and service sites,

and during normal bi-level operation, supplies a 0 or 5-volt signal indicating a respective exhalation

or inhalation trigger. Applying 24 ± 1 V to pin 9 enables the write function of the calibration EEPROM

(U3). Any voltage less than 15 V will not enable the EEPROM write function. The calibration EEPROM

contains calibration constants including those for flow and pressure control.

1 2 3 4 5

8

6

9

7

Figure 1-1. KnightStar 330 RS-232 serial port pinout

NOTES:

• The RS-232 connector on devices manufactured prior to the year 2004 is rotated 180o from

the configuration shown above.

• If you would like to use the KnightStar 330 in a special application requiring serial

communications, contact Puritan Bennett Technical Support at 1.800.255.6774 or your

local Puritan Bennett representative.

Pin Signal

1 Not connected

2 Transmit data (TxD) to PC

3 Receive data (RxD) from PC

4 Not connected

5Ground (GND)

6 Not connected

7 Not connected

8 Not connected

9 Dual use I/E PAP trigger-out and program-

enable input

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-7

Page 12

1 General information

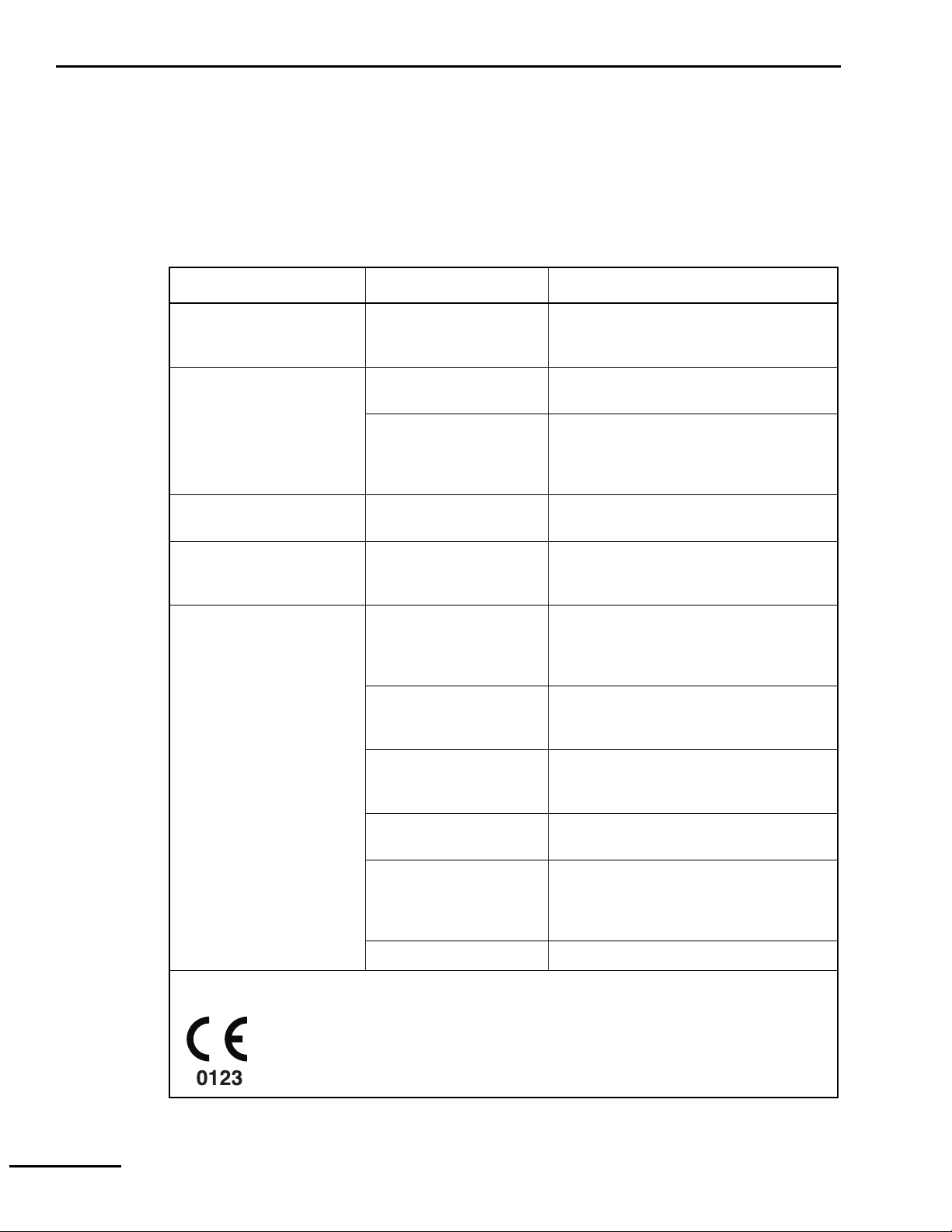

1.9 Compliance and approvals

The KnightStar 330 was developed in accordance with pertinent FDA guidances and North

American and ISO international standards (Table 1-3). The manufacturing facility for this

product is ISO 13485 certified.

The ventilator’s IEC 60601-1/EN 60601-1 classification is Protection class II, Type BF,

externally powered, IPX1 drip-proof equipment.

Table 1-3: Compliance with standards

Standard Type Standard Number Description

Quality system EN ISO 13485:2000 Quality Systems – Medical Devices –

Particular Requirements for the application

of EN ISO 9001:1994

FDA Ventilator Guidance FDA Reviewer Guidance for Ventilators,

Draft (July 1995)

FDA Guidance

FDA Medical Electrical

Safety Guidance

FDA Reviewer Guidance for Pre-market

Notification Submissions, November 1993

draft, Anesthesiology and Respiratory

Devices Branch

Safety, USA UL 2601-1 Medical Electrical Equipment, General

Requirements for Safety, (2

Safety, Canada CAN/CSA C22.2 No.

601.1- M90

EN 60601-1 (compliant

with all applicable

collateral standards and

particular requirements)

EN 60601-1-1 Collateral Standard: Safety Requirements

Safety, Europe &

International

EN 60601-1-2 (compliant

with all applicable tests)

JIST-1001-1 Safety Requirements for Medical Electrical

CISPR 11 EMC Disturbance Characteristics – Limits

EN 475 Electrically generated alarm signals

Safety of Medical Electrical Equipment,

General Requirements (Supplement

1:1994), (A2:1998)

Medical Electrical Equipment, Part 1:

General Requirements for Safety, 1

Edition, 1988. (A1:1993), (A2:1995)

for Medical Electrical Systems, 2

2001

Medical Electrical Equipment, Collateral

Standard: EMC – Requirements and Test,

nd

Edition, 2001

2

Equipment in Japan

and Methods of Measurement, Industrial

Scientific and Medical (ISM) RF Equipment,

Edition 3.1, 1999-08

nd

Edition)

st

nd

Edition,

This device complies with the requirements of Medical Device Directive 93/42/EEC concerning medical

devices.

1-8 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 13

General information 1

1.10 Breathing modes and settings

The KnightStar 330 offers three breathing modes: CPAP, I/E PAP, and A/C. Each breathing

mode enables a different set of system settings. Table 1-4 lists the modes and the adjustable

settings within each mode. Table 1-5 describes each setting, its adjustable range, and how the

setting can be accessed.

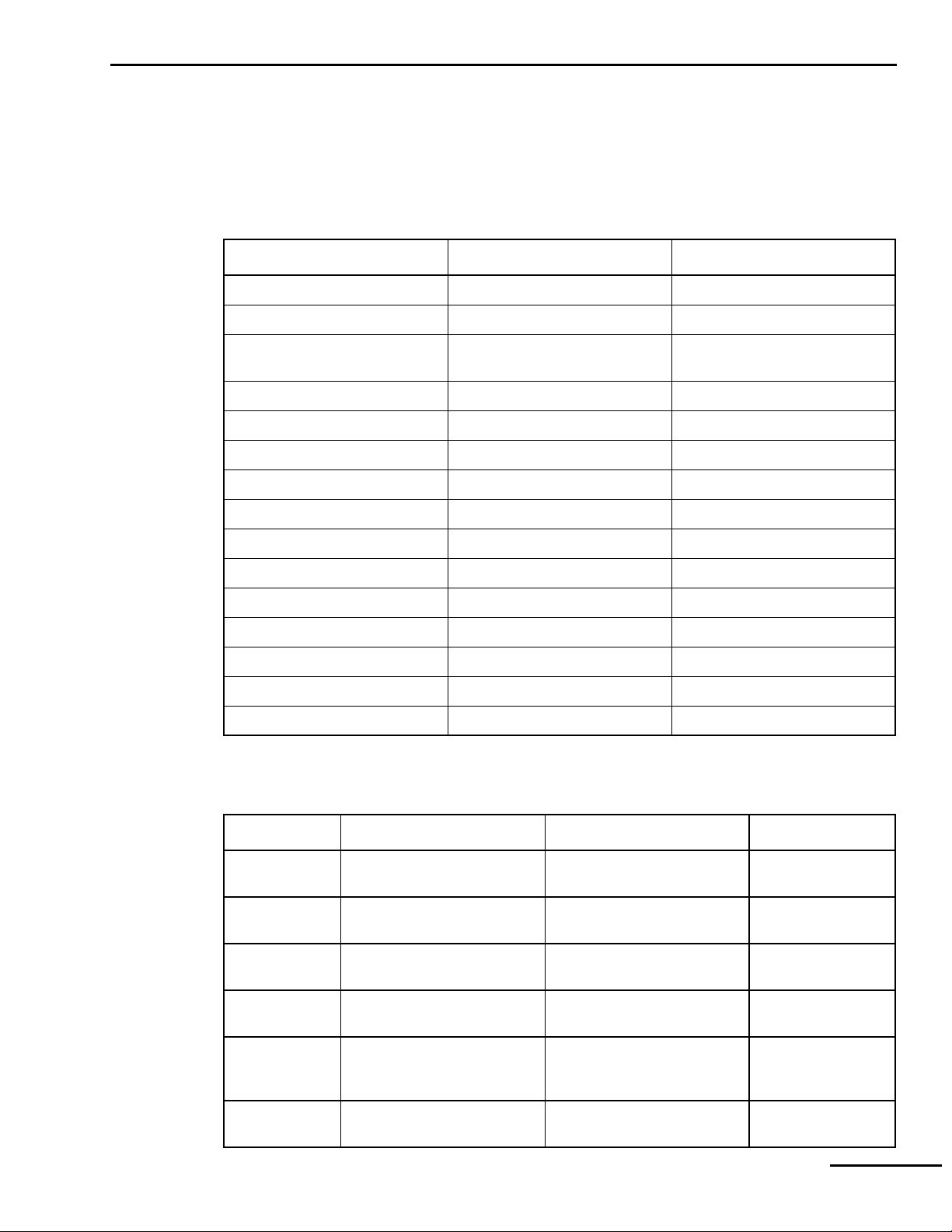

Table 1-4: Adjustable settings in each breathing mode

CPAP I/E PAP A/C

CPAP IPAP IPAP

Alarm volume EPAP EPAP

Leak alarm Inspiratory sensitivity Respiratory rate and backup

respiratory setting (f)

Delay time

Expiratory sensitivity I:E ratio

Ramp duration Rise time Inspiratory sensitivity

Ramp start pressure Alarm volume Expiratory sensitivity

Mask leak Leak alarm Rise time

Low pressure alarm Alarm volume

High pressure alarm Leak alarm

Delay time Low pressure alarm

Ramp duration High pressure alarm

Ramp start pressure Delay time

Mask leak Ramp duration

Ramp start pressure

Mask leak

Table 1-5: KnightStar 330 settings, ranges, and accessibility

Setting Description Range Accessibility

CPAP Level of CPAP pressure 3–20 cmH

1 cmH

IPAP Pressure during inspiration 3–30 cmH

1 cmH

EPAP Pressure during expiration 3–20 cmH

1 cmH

Backup

respiratory rate

I:E ratio Ratio of inhalation time to

Rate of machine-initiated

breaths

exhalation times for backup

3–30 bpm (increments of 1

bpm)

1:1.0 to 1:4.0 (increments

0.5)

O (increments of

2

O)

2

O (increments of

2

O)

2

O (increments of

2

O)

2

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

breath rate

Inspiratory

sensitivity

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-9

Sensitivity at which devices

switches from EPAP to IPAP

1–5 (1 most sensitive; 5 least

sensitive)

Top panel, RS-232

Page 14

1 General information

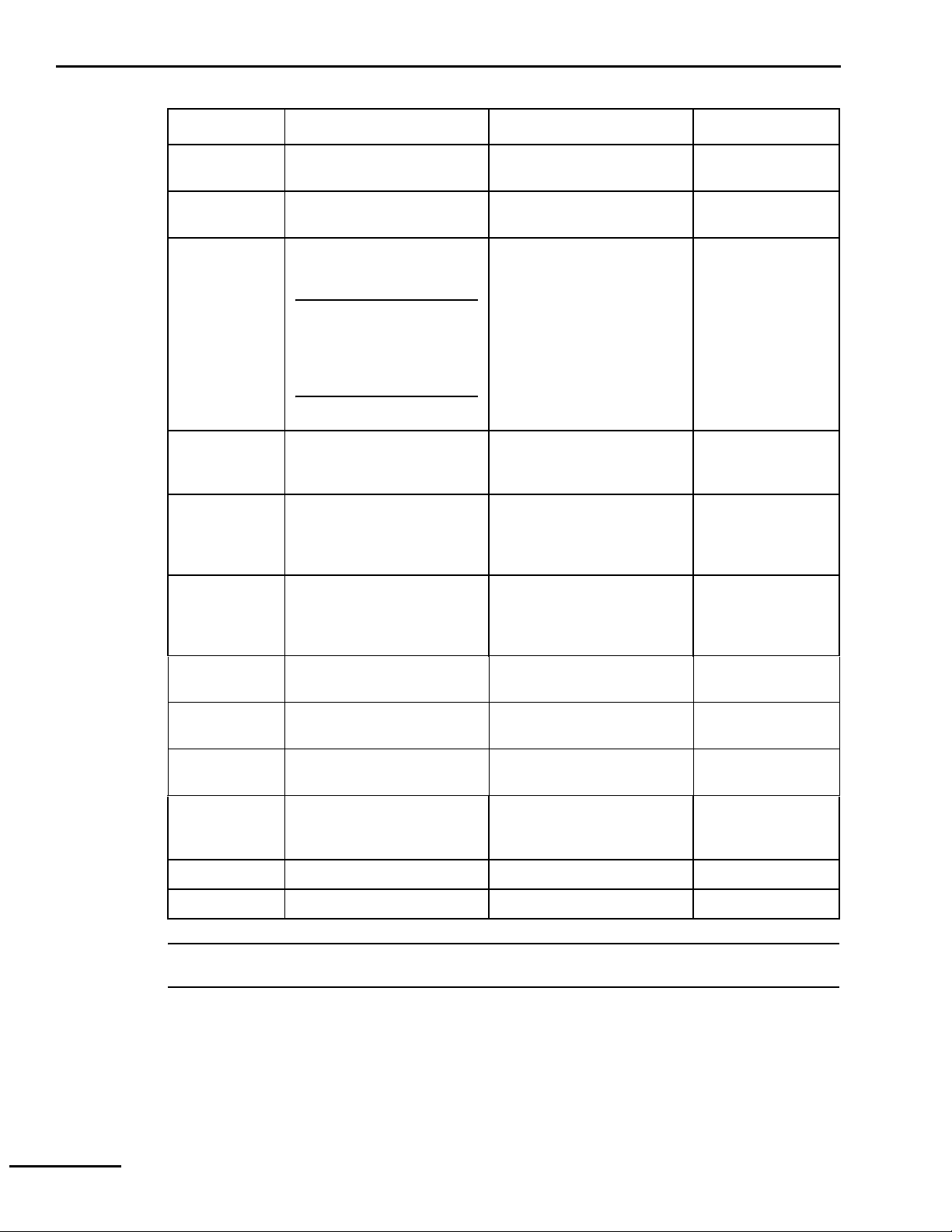

Table 1-5: KnightStar 330 settings, ranges, and accessibility (continued)

Setting Description Range Accessibility

Expiratory

sensitivity

Rise-time Rate of pressure increase 1–5 (1 is the fastest setting; 5

Alarm volume Sets the loudness of the

Leak alarm Rate of air leaking at which

Low pressure

alarm

High pressure

alarm

Sensitivity at which devices

switches from IPAP to EPAP

alarm.

NOTE:

The alarm volume

cannot be turned off

on Japanese versions of

the KnightStar 330.

alarm sounds

Pressure below the prescribed

IPAP setting at which an

alarm will sound

Pressure above the prescribed

IPAP setting at which an

alarm will sound

1–5 (1 most sensitive; 5 least

sensitive)

is the slowest)

0–3 (0=Off, 3=loudest)

Japanese configuration only:

1–3 (1=lowest volume,

3=highest volume)

50–100 liters per minute

(increments of 10 L/min);

0=Off

1 cmH

setting to 1 cmH2O above

EPAP (in increments of 1

cmH

1 cmH

setting to 35 cmH2O (in

increments of 1 cmH2O); 0 =

Off.

O below the IPAP

2

O); 0 = Off.

2

O above the IPAP

2

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Delay time Time delay before device

automatically starts

Ramp duration Time from device start to

prescribed operating pressure

Ramp start

Pressure

Interface

(Mask) leak/

type

Patient ID Unique patient identifier 12 digits RS-232

Internal Clock Clock used by device 24-hour clock RS-232

Pressure at which the device

starts ramp sequence

Patient interface purge hole

leak rate

0–30 minutes (in increments

of 5 minutes)

0–30 minutes (increments of

5 minutes)

3–20 cmH

1 cmH

1–6 (1 is the lowest leak

value, and 6 is the highest)

O (increments of

2

O)

2

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

Top panel, RS-232

NOTE: For information on using the RS-232 port, contact Puritan Bennett Technical

Support at 1.800.255.6774 or your local Puritan Bennett representative.

1-10 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 15

General information 1

1.11 Initial factory settings

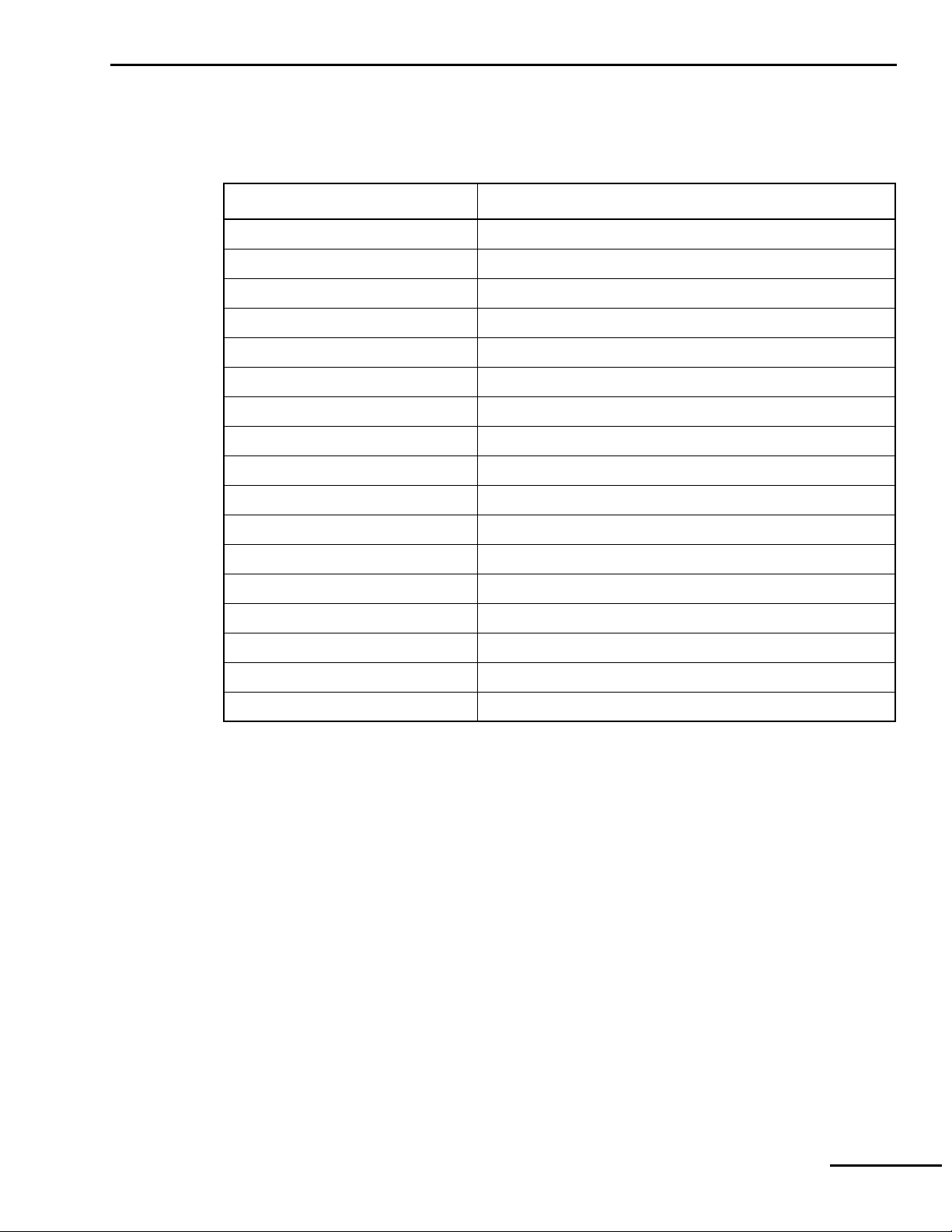

The KnightStar 330’s initial factory settings are listed in Table 1-6.

Table 1-6: Initial factory settings

Setting Value

MODE A/C

IPAP 5 cm H

EPAP 3 cm H

O (same setting for CPAP)

2

O

2

Respiratory rate 10

I:E ratio 1:2.0

I Sensitivity 3

E Sensitivity 3

Rise time 3

Alarm volume 3

Leak alarm 100 L/min

Low pressure alarm 4 cmH

High pressure alarm 6 cmH

O

2

O

2

Delay time 0

Ramp duration 0

Ramp start pressure 3 cm H

O

2

Mask leak 2

Over-pressure alarm 40 cmH

2

O (not adjustable)

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-11

Page 16

1 General information

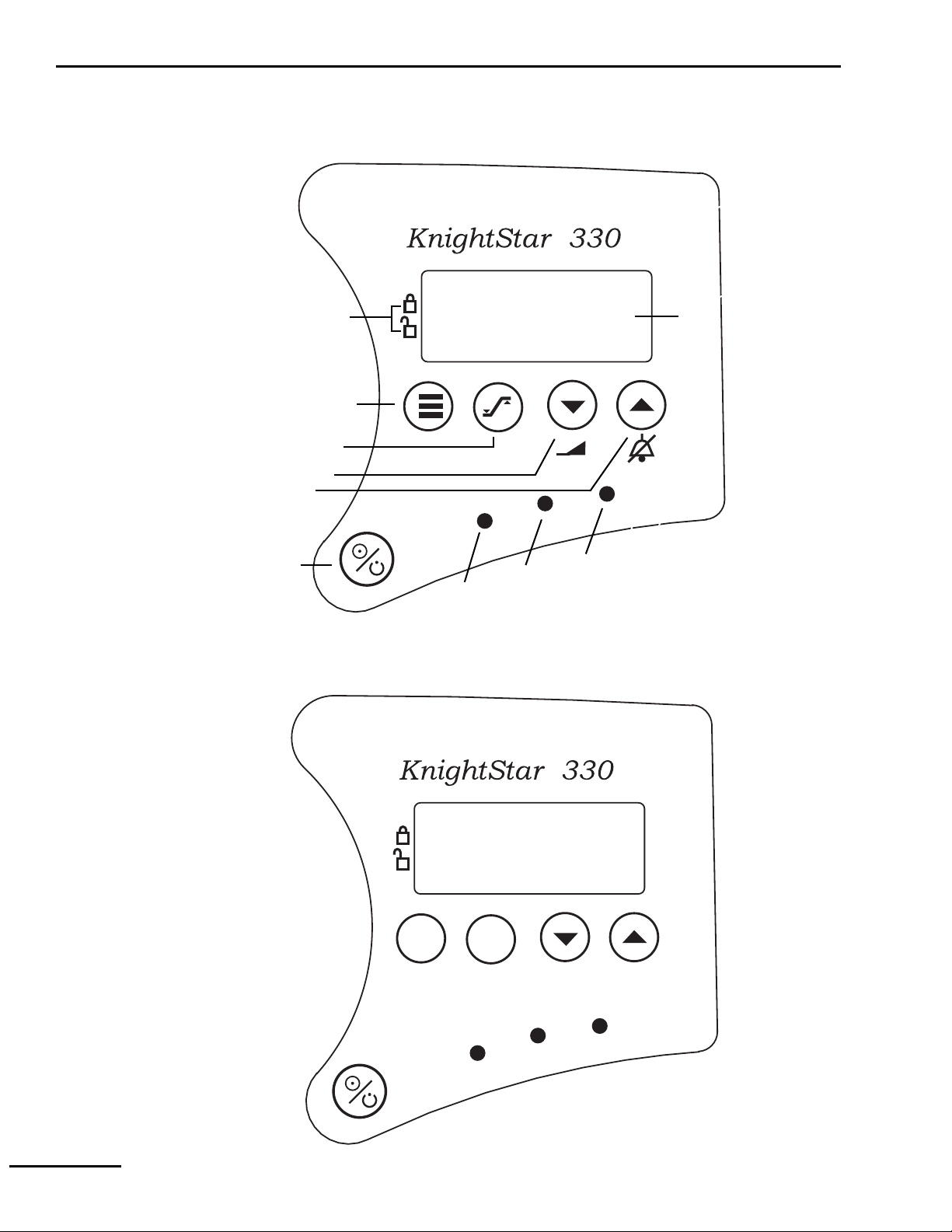

1.12 Controls, indicators, and symbols

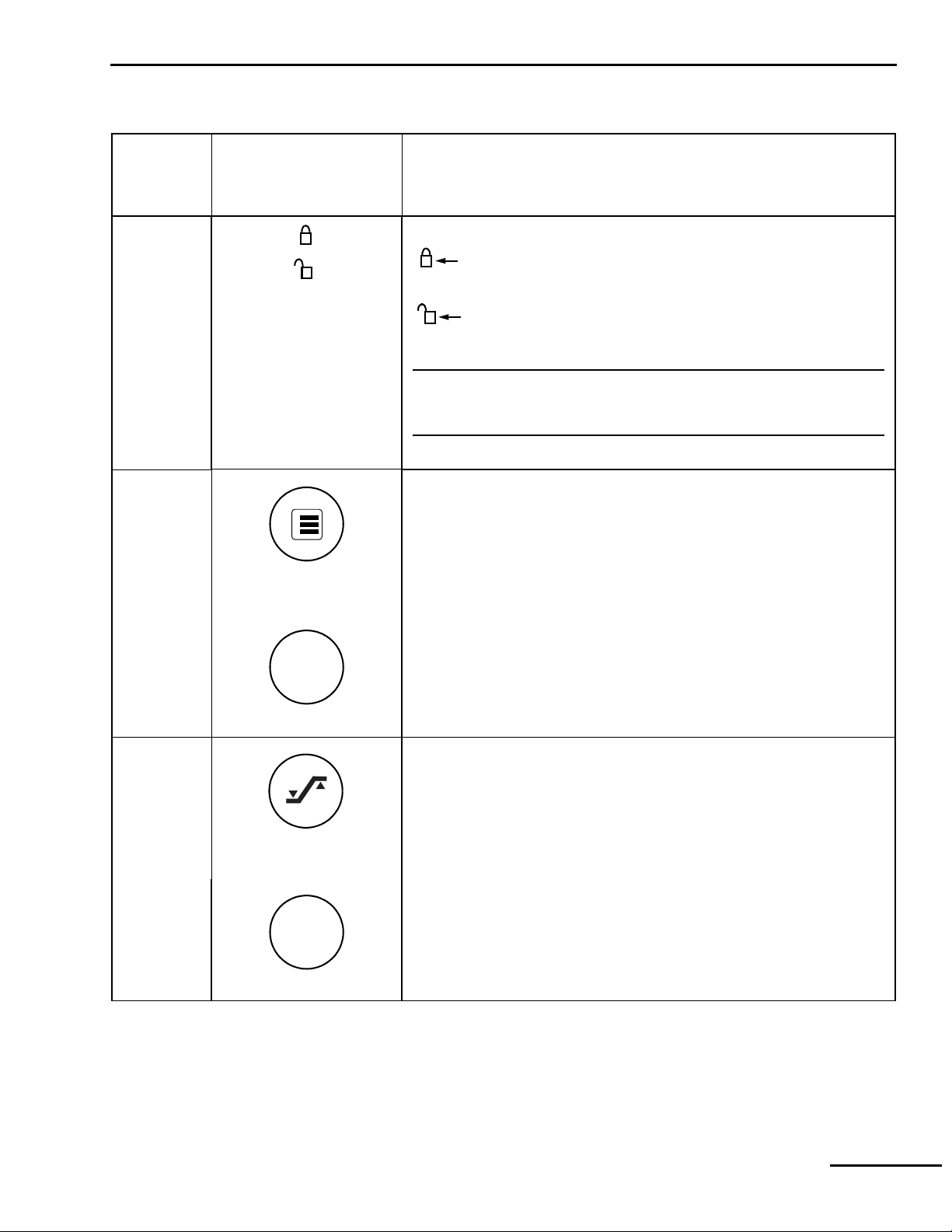

Refer to Figure 1-2 through Figure 1-4 and Table 1-7 through Table 1-10 for ventilator

controls, indicators, and symbols.

P

URITAN BENNETT

TM

Bi-Level âVentilator

1

2

3

4

5

6

1

2

3

8

7

9

10

12

14

13

Figure 1-2. KnightStar 330 Control Panel (International version shown above, North

American version shown below)

P

URITAN BENNETT

TM

Bi-Level âVentilator

Mode

Set

Delay

Ramp

Alarm

Silence

1-12 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 17

General information 1

Table 1-7: KnightStar 330 control panel keys and indicators

Index

(Figure 1-2

on page 1-

12)

1 Lockout Mode Indicator.

Labeling Function

Indicates the KnightStar 330 control panel is locked. In Lockout

mode, the patient can change only the delay time, ramp duration,

and start pressure settings.

Indicates the KnightStar 330 control panel is unlocked. When

Lockout mode is inactive, the clinician may change any ventilator

settings.

NOTE:

To change the Lockout state, press and hold the Mode and Up Arrow

keys simultaneously for approximately 2 seconds.

2

1

2

3

Mode key.

Pressing the Mode key repeatedly allows you to scroll through CPAP, I/E, and

A/C modes. Press the Mode key to leave Settings mode when finished

adjusting settings.

The Mode key does not function when the KnightStar 330 control panel is

International

locked.

or

Mode

North American

3

Settings key.

Press the Settings key repeatedly to scroll through available parameters for

each breathing mode. When the KnightStar 330 control panel is locked, the

Settings key can only be used to change the delay time, ramp duration, and

ramp start pressure.

International version

or

Set

North American version

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-13

Page 18

1 General information

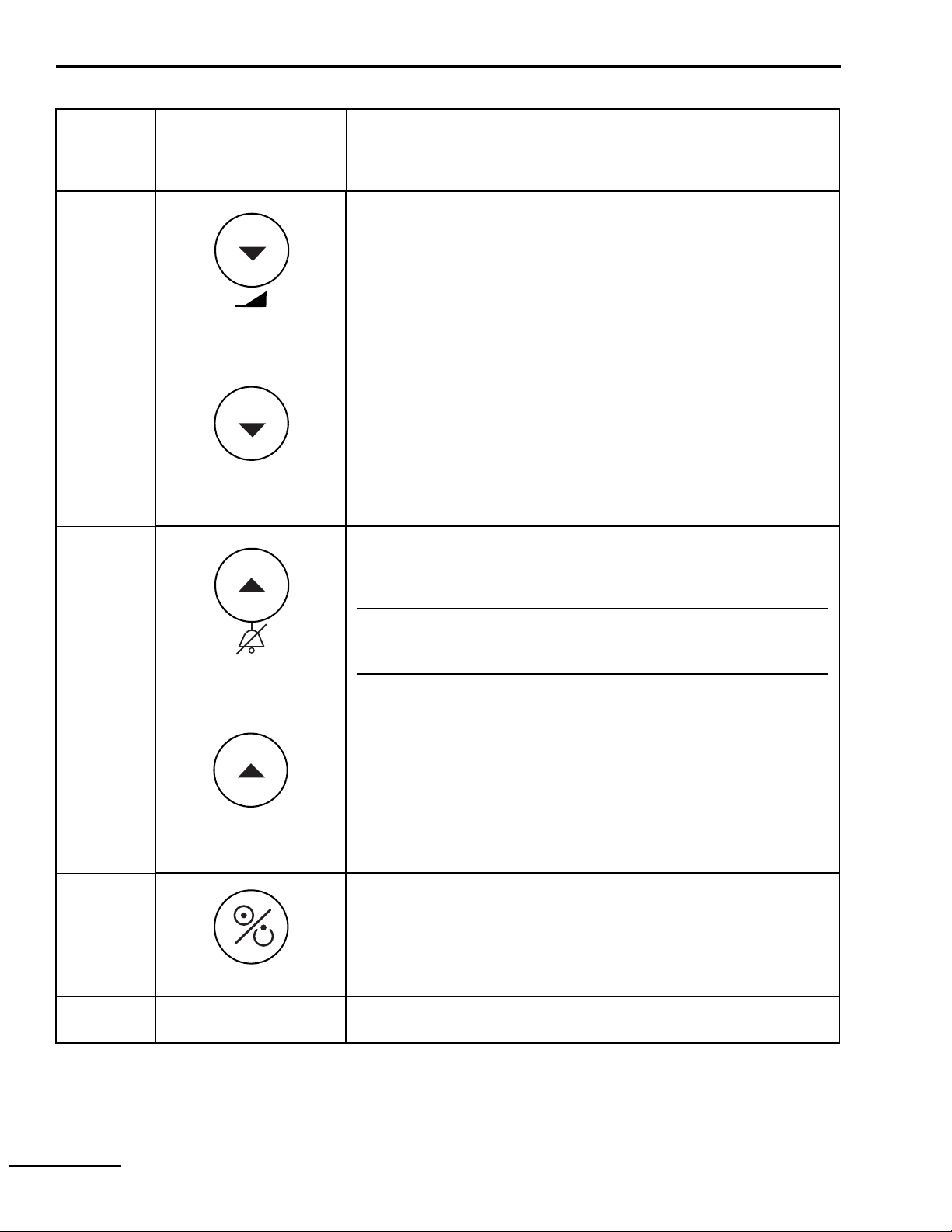

Table 1-7: KnightStar 330 control panel keys and indicators (continued)

Index

(Figure 1-2

on page 1-

12)

Labeling Function

4

International version

or

Delay

Ramp

North American version

5

Down Arrow & Delay/Ramp key.

Use the Down Arrow key to decrease a selected setting value in Settings

mode. If not in Settings mode, use this key to start or stop the Delay/Ramp

function.

Up Arrow & Alarm Silence key.

Use the Up Arrow key to increase a selected setting value in Settings mode. If

not in Settings mode, use this key to mute an active alarm for one minute.

NOTE:

In A/C or I/E mode, when the main display screen is shown, pressing

this key displays V and I:E ratio if there are no active alarms.

International version

or

Alarm

Silence

North American version

6 On/Off key. Turn the KnightStar 330 system on with a quick press and release

action. To turn the device off, press and hold the On/Off key for 3 seconds.

The KnightStar 330 retains in memory the prescription settings last entered.

7 Green LED When illuminated, indicates the presence of power, whether from Mains/AC

or external battery (Stand-by mode).

1-14 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 19

General information 1

Table 1-7: KnightStar 330 control panel keys and indicators (continued)

Index

(Figure 1-2

on page 1-

12)

Labeling Function

8 Yellow LED When steadily illuminated and accompanied by the symbol displayed in

the lower left corner of the LCD panel, indicates a LOW PRIORITY alarm

condition.

When steadily illuminated, with no symbol displayed on the LCD panel,

indicates a full compliance log (see Table 4-4 on page 4-11).

When flashing, indicates a MEDIUM PRIORITY alarm condition accompanied

by an audible alarm signal (3 beeps at intervals of approximately 25

seconds).

Refer to Section 4 for causes and corrections for alarm conditions.

9 Red LED When flashing, indicates a HIGH PRIORITY alarm condition accompanied by

an audible alarm signal (a series of 3 beeps, then 5 beeps, then 2 beeps at

intervals of approximately 6 seconds). Refer to Table 4 for causes and

corrections for alarm conditions.

10 Liquid Crystal Display

(LCD)

The LCD provides an easy-to-read format for mode, settings, and patient

data. A backlight illuminates the display when the Mode, Settings, or Up

arrow key is pressed. The display will remain illuminated for approximately

60 seconds after the last key is pressed.

f

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-15

Page 20

1 General information

1

2

3

1

2

back.eps

3

Figure 1-3. KnightStar 330 rear view

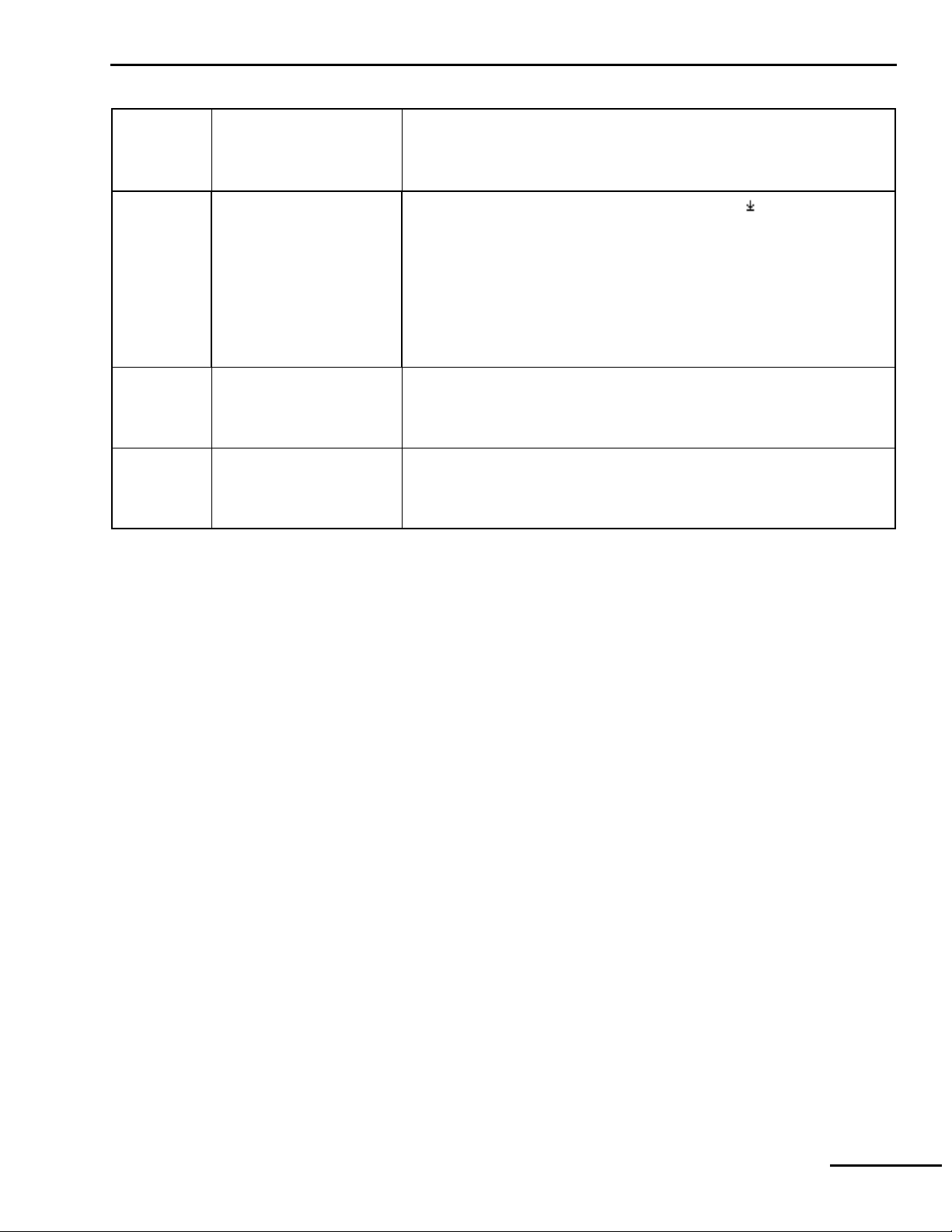

Table 1-8: KnightStar 330 rear view

Index

(Figure 1-3

on page 1-

16)

1 Mains/AC power electrical input connector. The KnightStar 330 operates on

Labeling Function

100V to 240 V AC at 50 or 60 Hz.

1-16 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 21

General information 1

Table 1-8: KnightStar 330 rear view (continued)

Index

(Figure 1-3

on page 1-

16)

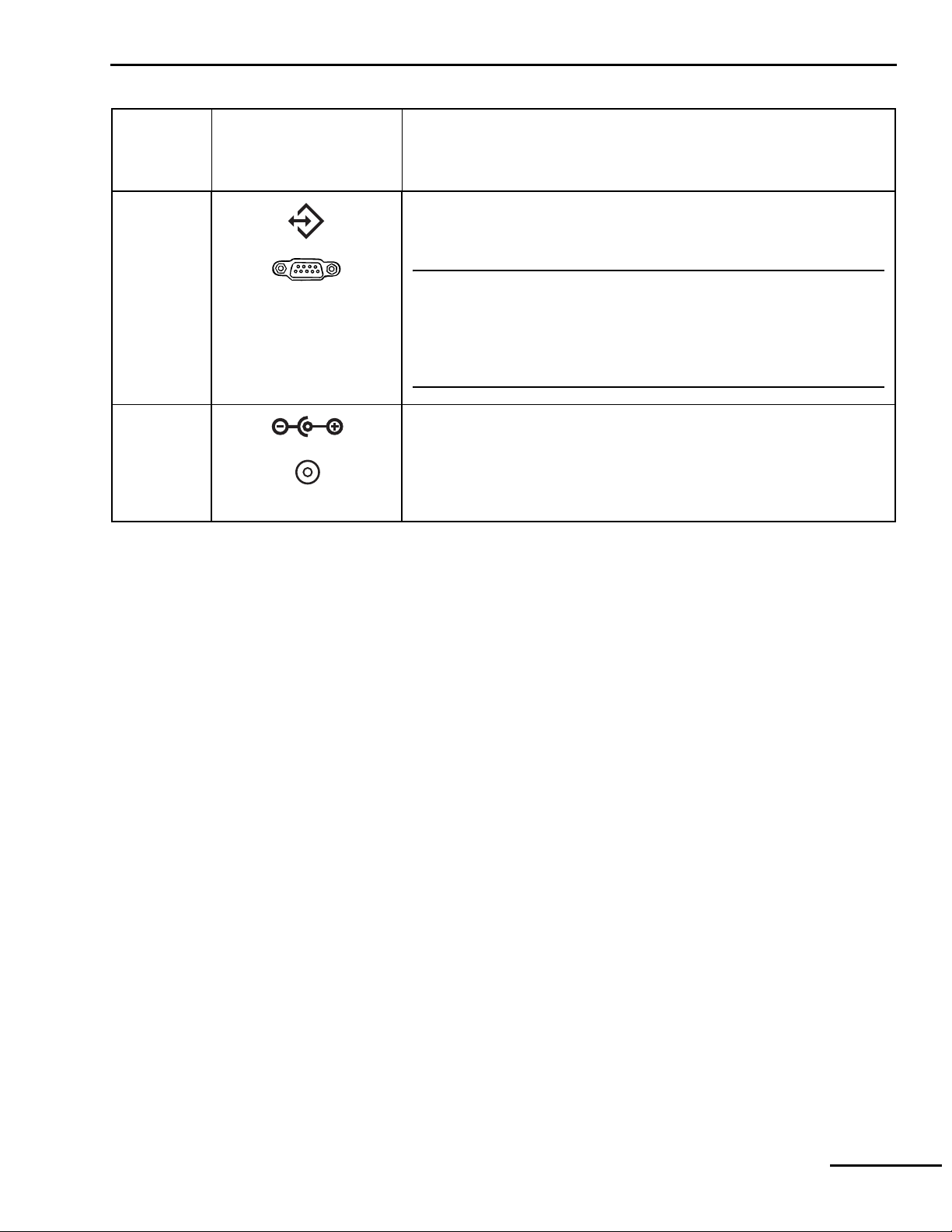

2 RS-232 (serial) port. The KnightStar 330 is capable of serial communications

3 External battery connector. Used for connecting an optional external 12 V

Labeling Function

with other devices such as a personal computer (PC). Contact your Puritan

Bennett representative for more information.

NOTE:

PCs used with the KnightStar 330 must meet regulatory standards for Safety

of Information Technology Equipment (i.e. UL 60950 or EN 60950). Available

from many sources, these standards specify requirements intended to reduce

risks of fire, electrical shock, and injury to the operator or service person who

comes into contact with the equipment.

DC battery, or for use with a 12 V automobile cigarette lighter adapter when

Mains/AC power is not available.

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-17

Page 22

1 General information

2

1

1

2

7

3

6

3

cover.eps

5

8-00197

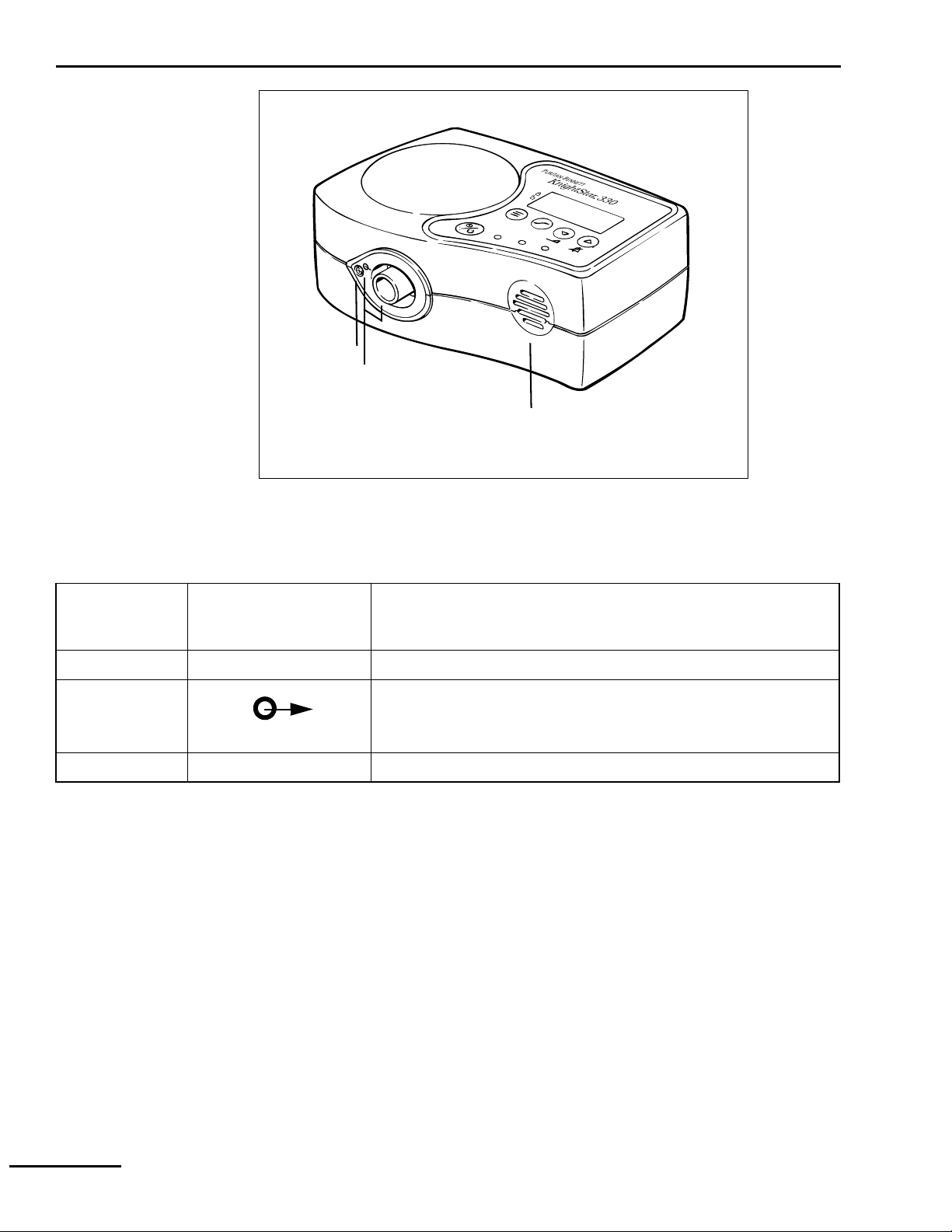

Figure 1-4. KnightStar 330 front view

Table 1-9: KnightStar 330 front view

Index

(Figure 1-4 on

page 1-18)

1 N/A Patient pressure connector.

2 Air outlet connector.

3

Labeling Function

N/A Alarm speaker.

1-18 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 23

General information 1

7

6

5

8

1

2

3

4

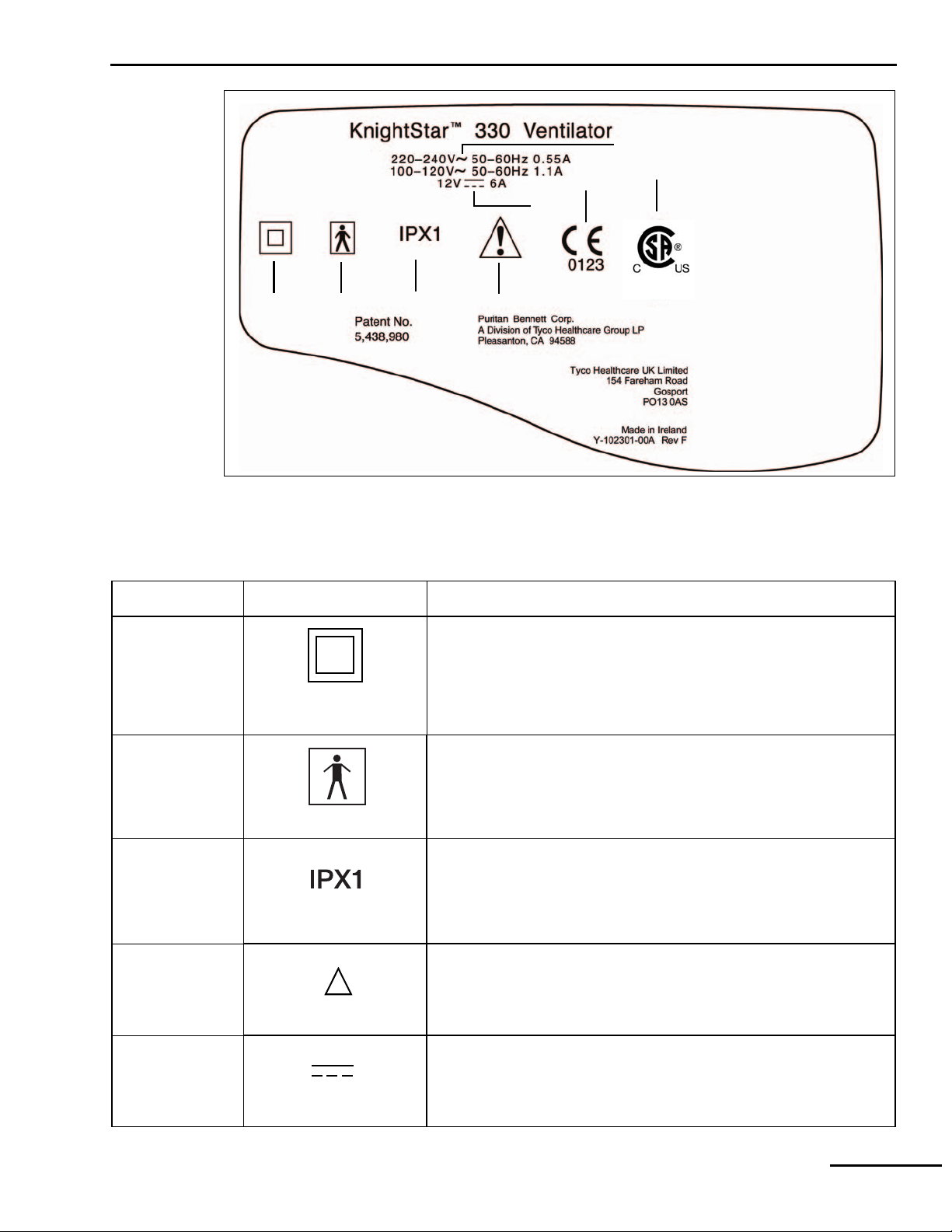

Figure 1-5. KnightStar 330 bottom panel (International version shown)

Table 1-10: Symbols found on the KnightStar 330 bottom panel

Item Labeling Description

1 Class II equipment

(Per IEC 60601-1: Equipment in which protection against electric shock

does not rely on BASIC INSULATION only, but in which additional safety

precautions such as DOUBLE INSULATION or REINFORCED INSULATION

are provided, there being no provision for protective earthing or reliance

upon installation conditions.)

2 Type BF equipment.

bottomlabel.eps

3 Drip proof.

4 Attention! Consult accompanying documents.

!

5 Direct current (battery power).

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-19

Page 24

1 General information

Table 1-10: Symbols found on the KnightStar 330 bottom panel (continued)

Item Labeling Description

6 This device complies with the requirements of Medical Device Directive

93/42/EEC concerning medical devices.

7 Alternating current (Mains/AC power from wall outlet).

8 Authorized to bear the CSA certification mark, signifying the product has

been evaluated to the applicable CSA standards for use in the US and

Canada.

UL2601-1

CAN/CSA C22.2 No. 601.1- M90

1-20 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 25

General information 1

1.13 Onscreen symbols and abbreviations

Table 1-11 lists the symbols that appear on the KnightStar 330 display during operation.

Table 1-11: Display symbols

Symbol

Symbol (Int’l) Description

START-UP DISPLAY SYMBOLS

Total hours of operation ON TIME

Total compliance time (usage in hours) USAGE

SN Serial number SN

Patient identification number (12 digits) ID

MODES

A/C Assist control mode A/C

CPAP Continuous Positive Airway Pressure mode and pressure setting CPAP

(North

America)

I/E Inspiratory/Expiratory PAP mode I/E

MEASURED PARAMETERS

f Respiratory rate f

P Current pressure P

Vt Tidal Volume Vt

LLeak rate L

V Peak inhalation flow V

I:E Ratio of inspiration time to expiration time (also a setting in A/C

mode)

SETTINGS

IPAP Inspiratory pressure IPAP

EPAP Expiratory pressure EPAP

f Backup respiration rate (in A/C mode) BACKUP f

ISENS Inspiratory sensitivity ISENS

ESENS Expiratory sensitivity ESENS

Rise time setting RISE

I:E

Alarm volume level

L

P

P

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-21

Leak alarm setting

Low pressure alarm setting

High pressure alarm setting

Delay time DELAY

VOL

LEAK

LO P

HI P

Page 26

1 General information

Table 1-11: Display symbols (continued)

Symbol (Int’l) Description

Ramp duration RAMP

P

L

ALARMS

P P

P P

L L

f f

#

#

STATUS

Ramp start pressure STRT P

Interface (mask) leak/type (1-6) MASK L

High pressure alarm condition

Low pressure alarm condition

Leak alarm condition

Backup respiratory rate active (apnea)

Malfunction (one or two digit error code, ##, denotes alarm type)

Ramp delay active

Lockout mode active

Lockout mode inactive

Symbol

(North

America)

#

#

Alarm is silenced

1.14 Ventilator serial numbers and software version

The KnightStar 330 serial number and software version is displayed during the Power On Self

Test (POST) that runs immediately after turning the ventilator on. The model number and

serial number are also displayed on the bottom panel of the ventilator.

1.15 Tools, equipment, and service materials

The tools, equipment, and service materials listed in Table 1-12 are used to service the

KnightStar 330.

Table 1-12: Tools, equipment, and service materials

Description

Calibration shell S-231702-00B Performance verification

6 ft. Patient circuit with pressure

feedback

Calibrated manometer

0 to 50 cmH

O resolution, or equivalent

cmH

2

60 cc syringe Local supplier Performance verification

O range, minimum 0.5

2

Manufacturer/model or Puritan

Bennett part number

Y-261000-27 Performance verification

Local supplier Performance verification

Where used

1-22 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 27

General information 1

Table 1-12: Tools, equipment, and service materials (continued)

Description

Manufacturer/model or Puritan

Bennett part number

Where used

Outlet air filter L-006197-000 Performance verification

NOTE:

Replace the outlet air filter at

least once every 2 months.

KnightStar 330 Service

Communications Cable

24 V power supply Local supplier Troubleshooting

Static-dissipative field service kit

(includes wrist strap, static dissipative

mat, and earth (ground) cord)

Anti-static adhesive tape Local supplier General repair

Disinfectant/cleaner The following solutions are acceptable

Y-103086-00A Troubleshooting

4-018149-00 General repair

General cleaning

for disinfecting/cleaning the KnightStar

330:

Mild detergent and water solution

Isopropyl alcohol (70% solution)

Bleach (10% solution)

Glutaraldehyde (e.g. Cidex, 2.4%

solution)

Paper towels or soft cloths Local supplier General cleaning

Tool kit, including the following:

Local supplier General repair

• Screwdriver, #1 Phillips

• Screwdriver, #2 Phillips

®

•Torx

T20 driver

• Torque driver, #1 Phillips set to

5 ± 0.5 in-lb

• Torque driver, Torx

®

T20 bit set to

15 ± 0.5 in-lb

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-23

Page 28

1 General information

1.16 Periodic maintenance

Caution

• To ensure proper operation, perform periodic maintenance and replace components at

recommended intervals, as indicated in Table 1-13.

Pru

The KnightStar 330 and associated test equipment require very little maintenance. Table 1-13

Frequency Part Maintenance

lists the periodic maintenance activities required for the KnightStar 330.

Table 1-13: Schedule of periodic maintenance

As Needed Outer surfaces of the KnightStar 330

ventilator

Weekly KnightStar 330 air inlet filter (see Table 1-14

for ordering information)

Every 2 months Outlet air filter, KnightStar 330 test setup (see

Table 1-14 for ordering information)

1.17 Spare parts

The KnightStar 330 spare parts and their order numbers are listed in Table 1-14. Where

applicable, item numbers from the assembly drawing in Figure 5-2 on page 5-3 are shown for

reference. Parts may be ordered by calling Puritan Bennett at 1.800.635.5267.

Table 1-14: Spare parts list

Assembly

Drawing Item

No.

1 Base, enclosure Y-101618-00A

Description Order No.

Clean surfaces with cloth dampened with

warm soapy water or disinfectant described

in Table 1-12. Wipe dry. Do not let liquid drip

into any openings in the device.

Inspect filter. Replace if damaged.

Use warm, soapy, sterile or distilled water to

wash the filter. Rinse thoroughly with sterile

or distilled water, and let air dry.

Replace.

27-28 Cover, enclosure with membrane switch

(International)

28 Switch, membrane (International)

Switch, membrane (North America)

30 Screws, 4-20 x 0.375, PH, Pan head S-815371-00A

17 Filter, air inlet Y-101922-00A

26 LCD display, 16 x 24 Y-102328-00A

25 Insulator, LCD Y-102837-00A

15 Screw, Torx, hilo 2.2 Y-103095-000

19 Assembly, cooling fan Y-103026-00

18 Adhesive foam, fan base Y-102499-00A

20 Assembly, PCB, Alarm board 066035

1-24 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Y-103027-00A

Y-101614-00A

Y-103115-00A

Page 29

General information 1

Table 1-14: Spare parts list (continued)

Assembly

Drawing Item

No.

34 Shield, alarm Y-102973-00A

N/A Outlet air filter L-006197-000

N/A KnightStar 330 Power cord, NEMA 1-15 Y-500012-00

N/A KnightStar 330 Power cord, CEE 7/16 Y-500013-00

N/A KnightStar 330 Power cord, UK Y-500014-00

Description Order No.

1.18 Service philosophy

Field service of the ventilator is limited to the service activities described in this manual. Any

ventilator requiring replacement of the main PCBA, blower, and/or pitot tube should be sent

to a Puritan Bennett Factory Service Center for repair. For field service, technical support, or

technical information regarding the use of the serial communication functions, call Puritan

Bennett Technical Support at 1.800.255.6774 (within the USA) or contact your Puritan

Bennett representative (outside the USA).

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 1-25

Page 30

1 General information

This page intentionally blank.

1-26 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 31

SECTION

SECTION

Theory of operation 2

This section details the operational theory of the KnightStar 330 and contains the following

information:

• description of ventilator components

• overview of ventilator operation

• information on breath delivery and detection

• description of safety features

2.1 Ventilator components

The following components make up the KnightStar 330 system:

• KnightStar 330 bi-level ventilator

• Patient circuit with proximal pressure line

•Power cord

• Spare inlet air filter

2

• Outlet air/bacteria filter

• KnightStar 330 Clinician’s and User’s Manuals

Puritan Bennett recommends using the KnightStar 330 with 1.8 m (6 ft) or 2.4 m (8 ft) circuit

and any of the following Puritan Bennett interfaces:

• Breeze™ Sleepgear with Dreamseal or Nasal Pillows

• ADAM™ Interface System

•SoftFit

Figure 2-1 shows the KnightStar 330 and its components.

®

Mask System and Ultra Nasal CPAP Mask

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04)

2-1

Page 32

2 Theory of operation

KnightStar 330 bi-level ventilator

Power cord

Patient circuit with proximal

pressure line

Puritan

Bennett

KnightStar 330

Bi-level Ventilator

Spare inlet air filter

Outlet air/bacteria

filter

2.2 Operational overview

The KnightStar 330 uses a micro-controller to control a 2-pole, 3-phase high frequency blower.

The device can be operated using either AC or DC power per the specifications in Section 1.8

Ventilator breathing modes and settings are selected using the keypad and LCD on the top

panel of the ventilator.

NOTE: If you would like to use the KnightStar 330 in a special application that requires

changing the settings via the RS-232 serial communications port, contact Puritan

Bennett Technical Support at 1.800.255.6774 or your local Puritan Bennett

representative for more information.

Once the settings are entered, the KnightStar 330 can be put into Lockout mode, preventing

accidental or unauthorized changes to prescribed settings. In Lockout mode, the user may

only change the ramp duration, delay period prior to the start of ramp, and the ramp start

pressure.

A gross particulate filter provided at the air inlet filters the incoming air. A high efficiency

bacteria filter at the air outlet is provided and recommended for optimal device performance.

A patient circuit with proximal pressure tube provides air delivery to the patient and pressure

feedback to the device.

KnightStar 330 documentation

Figure 2-1. KnightStar 330 Ventilator System

2-2 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 33

Theory of operation 2

2.2.1 Operating modes

The KnightStar 330 operates in four distinct modes:

•Stand-by

•Power On

• Delay/Ramp

•Therapy

Stand-by

When the AC power cord (or battery cable, if running on DC power) is connected, the device

enters Stand-by mode and illuminates the green LED. Although the LCD remains blank, the

device performs a self-test to verify the integrity of the firmware, hardware, and stored data.

These tests include the following:

• Embedded ROM checksum test

• RAM read/write test

• Manufacturing EEPROM checksum test

• Real time clock valid date and time test

• Alarm board processor RAM read/write test

• Stuck switch test

The KnightStar 330 remains in Stand-by mode until the On/Off key is pressed to turn it on.

When the device is running, it may be returned to Stand-by mode by pressing and holding

the On/Off key for three seconds. The KnightStar 330 retains all settings in memory during

periods when it is turned off.

NOTE: The KnightStar 330 consumes battery power in Stand-by mode when connected

to an external battery. To conserve battery power, disconnect the KnightStar 330

from the battery when not in use.

Power on

The device powers on by pressing the On/Off key, then displays copyright notice, company

name, and firmware version. Each time the device is turned on, the device performs the

following internal tests:

• Valid settings test and critical parameter checksum

• Alarm/battery voltage test

•LED test

After these tests are performed, the KnightStar 330 transitions into Delay/Ramp mode (if

active) or Therapy mode.

Delay/Ramp

Upon completion of the power on sequence, the device begins the delay/ramp function if a

delay and/or ramp are set and the function is active, indicated by the

display. The Delay/Ramp mode can be cancelled or restarted by pressing the Delay/Ramp key.

The delay/ramp feature allows the patient to fall asleep during the delay period prior to the

ventilator starting to deliver air flow. The delay period can be set from 0 to 30 minutes. When

the delay is activated, both inspiratory and expiratory pressures will decrease to the ramp

start pressure. After the delay time has elapsed, pressure will increase to the prescription

pressures over the set ramp duration period, and the ventilator will start Therapy mode.

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 2-3

symbol in the

Page 34

2 Theory of operation

Therapy

In Therapy mode, the KnightStar 330 ventilates patients in one of three breathing modes set

by the clinician. The next section describes each mode.

2.2.2 Breathing modes

The KnightStar 330 can ventilate a patient with the following breathing modes:

• CPAP (Continuous Positive Airway Pressure)

• I/E PAP (Inspiratory/Expiratory Positive Airway Pressure)

• A/C (Assist with Control)

CPAP

In the CPAP mode, the system delivers a continuous positive regulated airway pressure

throughout the breath cycle at the prescribed level. The normal operating range is 3 to 20

cmH

O.

2

The KnightStar 330 continuously monitors and displays pressure (

mode.

I/E PAP

P) and leak rate (L) in CPAP

I/E PAP mode provides two pressure levels; an inspiratory pressure level of 3 to 30 cmH2O and

an exhalation pressure level of 3 to 20 cmH

In I/E PAP mode, the KnightStar 330 continuously monitors and displays breath rate (

pressure (

P), tidal volume (Vt), leak rate (L). Pressing the Up Arrow key (with no alarm

conditions present) will display the current peak flow (V), and I:E ratio (

O.

2

f),

I:E) values for five

seconds.

If no inspiration is detected while at the IPAP level for the average inspiration period plus five

seconds, the device enters a DEFAULT condition. During the DEFAULT condition, the device

cycles to the EPAP level and remains at this level until it detects an inspiration trigger. If an

inspiration is not detected while at the EPAP level, the device remains at the EPAP level until

an inspiration is detected. During the DEFAULT condition the rest of the displayed values

become 0, except for the I:E ratio, which becomes 1:0.0.

Upon detecting an inspiration trigger, the device resumes normal I/E PAP mode operation

supporting all detectable spontaneous breathing at the prescribed pressure levels.

A/C

The A/C mode provides the same inspiratory and expiratory pressure levels as I/E PAP mode

and provides an additional backup breath rate feature (normal operating range of 3 to 30

breaths/min) and a settable I:E ratio (normal operating range of 1:1.0 to 1:4.0).

In A/C mode, the KnightStar 330 continuously monitors and displays breath rate (

(

P), tidal volume (Vt), leak rate (L). Pressing the Up Arrow key (with no alarm conditions

present) will display the current peak flow (V), and I:E ratio (

I:E) values for five seconds.

f), pressure

If the device is unable to track breathing efforts, or the patient’s spontaneous respiratory rate

falls to or below the prescribed backup breath rate, the device enters a DEFAULT condition

and will cycle at the prescribed IPAP and EPAP levels, backup respiratory rate, and I:E ratio. If

the backup rate cycles for five (5) continuous breaths, the

symbol will appear at the lower

f

left corner of the display, and the yellow LED will illuminate (indicating a low priority alarm).

The

own. When the back up rate is cycling, the patient data for “

symbol and yellow LED will remain active until the patient breathes on his or her

f

f” and I:E ratio are displayed as

the prescribed values.

2-4 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 35

Theory of operation 2

When the patient’s spontaneous respiratory rate returns to a rate higher than the prescribed

respiratory rate, the device will resume tracking the patient’s spontaneous respiratory rate

and will continue to provide pressure at the prescribed IPAP and EPAP levels.

2.3 Breath delivery

Control of delivered pressure is accomplished by measuring the pressure at the interface

(mask) via a pressure measurement tube and sensor, and increasing or decreasing pressure by

changing the motor speed with the motor/stator directly controlled by the micro-controller.

A low-mass impeller allows for rapid speed (pressure) changes. This control method provides

the ability to compensate pressure due to leaks in the patient circuit and changes in altitude.

The micro-controller also monitors the analog flow and breath trigger signals to determine

tidal volume and leak. Altitude compensation of the flow is accomplished by using an

internal barometer that adjusts the flow value in software. Figure 2-2 shows a system block

diagram with the micro-controller inputs and outputs that control breath delivery.

AC Power

Main 85 to

264 VAC

DC Power

External

Battery

12VDC

Bi-Level Device

power

supply

cooling

fan

LCD

module

keyboard

module

switches &

LEDs

RS-232, IE

trigger

program

enable

data storage

real time

clock and

battery

blower

driver

current

measurement

Micro-Controller

air inlet/filter

blower

Blower Control

current analysis

flow & volume

analysis/

triggering/

patient

compliance/

altitude flow

compensation

pressure analysis/

leak

compensation/

altitude pressure

limitation

program memory

patient

outlet/

flowmeter

flow

sensor

trigger

circuit

data

control

atmospheric

pressure

sensor

proximal

pressure

sensor

audible

alarm

alarm

battery

outlet

air

filter

patient

circuit

proximal

pressure

tube

patient

8-00187

Figure 2-2. System and micro-controller block diagram

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 2-5

Page 36

2 Theory of operation

2.4 Breath detection

When in I/E PAP and A/C modes, the KnightStar 330 monitors the flow to determine if the

patient is inhaling or exhaling. Breath detection is performed using a mass flow sensor

connected to a pitot tube at the blower outlet. The sensor output is then connected to an

analog hardware circuit that sends inhale and exhale triggers to the micro-controller. An

inhalation trigger occurs when the flow exceeds a fixed threshold set by the inspiration

sensitivity. An exhalation trigger occurs when the difference between the instantaneous flow

and the flow from an earlier time is less than the threshold set by the expiratory sensitivity.

When the KnightStar 330 changes from inhalation to exhalation or exhalation to inhalation,

additional flow triggers are ignored for a 340 millisecond time period in order to prevent

autocycling.

NOTE: Autocycling refers to a delivered breath that was not initiated by the patient.

The sensitivity of the breath detection set by the user is adjusted by the micro-controller. Five

settings each for expiratory and inspiratory sensitivity are provided for clinician selection.

2.4.1 Expiratory sensitivity

Of the five levels of expiratory sensitivity available to the clinician, a setting of 1 causes the

KnightStar 330 to cycle into the expiratory phase quickly, and a setting of 5 allows the

inspiratory flow to diminish significantly before cycling into the expiratory phase. Expiratory

sensitivity is set via a digital potentiometer that controls the gain of a signal into an analog

comparator circuit.

The exhalation detection is determined by comparing the high pass (0.015 Hz) and low pass

(7.2 Hz) filtered flow signal with a delayed copy of itself (a 0.93 Hz low pass filter determines

the delay). During an inhalation, the flow signal is more positive than the delayed signal; but

when the flow signal diminishes to a value less than the delayed signal, exhalation is

triggered. The amplitude of the delayed signal, which is determined by the gain setting in

series with the 0.93 Hz filter, sets the threshold.

Figure 2-3 illustrates the effects of changing the expiratory sensitivity on the KnightStar 330.

The longer it takes for the device to cycle into the expiratory phase, the greater the potential

tidal volume delivered to the patient.

2-6 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 37

Theory of operation 2

8-01159

Figure 2-3. Effects of changing expiratory sensitivity

2.4.2 Inspiratory sensitivity

The inspiratory sensitivity is set by a DC voltage derived from a pulse width modulated

(PWM) signal generated by the microcontroller and is partially affected by the signal from the

exhalation stage. An inspiratory sensitivity setting of 1 is the most sensitive inhalation

trigger, and a setting of 5 is the least sensitive. An inspiratory sensitivity adjusted too low may

result in autocycling.

The inhalation detection is determined by comparing the high pass (0.015 Hz) and low pass

(7.2 Hz) filtered flow signal to the delayed signal (from the 0.93 Hz filter) and to a fixed

inhalation threshold. If the delayed signal is greater than the fixed threshold, the inhalation

detection works as just the reverse of the exhalation threshold, triggering an inhalation when

the filtered flow signal goes more positive than the delayed signal. If the delayed signal is less

than the fixed threshold, the flow signal is compared to the fixed threshold.

2.4.3 Rise time

Rise time is the amount of time it takes for the inspiration to reach the set inspiratory

pressure. Five rise time settings are available to the clinician. Figure 2-4 illustrates the relative

time to reach a peak pressure level for rise time settings of 1, 3, and 5. The clinician adjusts

the rise time setting based upon the patient’s inspiratory demands and level of comfort. A

lower rise time setting will enable the target pressure to be reached sooner than a higher rise

time setting.

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 2-7

Page 38

2 Theory of operation

2.5 External battery operation

The KnightStar 330 may be powered by either of two Puritan Bennett-supplied external 12 V

DC batteries using a battery adapter cable, or by a standard 12V DC automobile battery using

the appropriate cigarette lighter adapter cable. Table 1-1 on page 1-5 lists the ordering

information for these parts.

Caution

Connect the KnightStar 330 to only one power source at a time; external battery power or

AC power. Damage to the device can result if connected to both power sources

simultaneously.

When operating on battery power, the KnightStar 330 functions as it does on AC power. The

available 32 ampere-hour battery provides the KnightStar 330 with up to 8 hours of operation,

while the 7 ampere-hour battery powers the device for up to 3 hours.

To switch the KnightStar 330 from Mains/AC power to battery power:

1 Tur n th e KnightStar 330 off and unplug it from the AC power outlet.

8-01159

Figure 2-4. Rise Time

2 Connect the appropriate cable to the battery and to the DC connector at the rear of the

KnightStar 330.

3 Tur n th e KnightStar 330 back on.

2-8 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 39

Theory of operation 2

NOTE: The KnightStar 330 consumes battery power in Stand-by mode when connected

To switch the KnightStar 330 from battery power to Mains/AC power:

1 Tur n th e KnightStar 330 off and disconnect the battery cable from the device.

2 Connect the AC power cord to the rear of the KnightStar 330 and to the Mains/AC outlet.

3 Tur n th e KnightStar 330 back on.

2.6 Safety features

Several features have been designed into the KnightStar 330 to protect the patient and user

from injury following a single fault condition.

2.6.1 Overcurrent protection

Fuses in the Mains/AC inlet lines protect against electrical shock.

2.6.2 Controls protection

The Lockout mode allows the clinician to limit patient access to settings except for comfort

features (delay time, ramp duration, and start pressure).

2.6.3 Power off protection

to an external battery. To conserve battery power, disconnect the KnightStar 330

from the battery when not in use.

The On/Off key must be depressed for three seconds to turn off the device.

2.6.4 Maximum pressure

A software control shuts down the blower if delivered pressure exceeds 40 cmH2O.

2.6.5 Audible alarms

The KnightStar 330 includes an audible alarm capable of an adjustable sound level and can

produce 85 dB(A) sound pressure level at a distance of one meter. An alarm sounds for various

equipment fault conditions and device output conditions which exceed thresholds set by the

clinician. Alarms are categorized into High, Medium, and Low priority.

2.6.5.1 High priority alarm

High priority alarms are indicated by a flashing red LED accompanied by an audible alarm

signal (a series of 3 beeps, then 5 beeps, then 2 beeps at intervals of approximately 6 seconds).

High priority device alarms include:

• Low pressure

•Leak

• Loss of power

• Internal malfunction

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04) 2-9

Page 40

2 Theory of operation

2.6.5.2 Medium priority alarm

A medium priority alarm is indicated by a flashing yellow LED accompanied by an audible

alarm signal (3 beeps at intervals of approximately 25 seconds).

Medium priority device alarms include:

•High pressure

2.6.5.3 Low priority alarm

Low priority alarms are indicated by a steadily illuminated yellow LED and no audible

alarm.

Low priority device alarms include:

•Apnea

Table 4-1 on page 4-2 describes the various alarm conditions, how they are displayed on the

LCD panel, and how to reset them.

2.6.5.4 Alarm control

The audible alarm function is provided on a separate alarm PCBA, which connects to the

main PCBA via a 10-pin double row header. Table 2-1 lists the pin number and corresponding

signal.

Table 2-1: Alarm connector pin-out

Pin No. Signal

1Ground

2 SDA signal of I2C interface

3 SCL signal of I2C interface

4 Red LED (on membrane switch) anode

5 Resistor and base of PNP transistor on main board that drives

yellow LED

6Ground

7 Alarm silence key input

8 +27 V from main board

9 Ground connection on main board for alarm board batteries

10 Ground

The alarm processor takes commands from the main PCBA processor via the I2C interface for

the alarm controls (including sound level). The alarm processor can control its onboard

audible alarm and the red and yellow LEDs on the membrane keypad. It is powered at

maximum volume on the alarm PCBA with +13.5 V nominal with a 5 mA current limit. The

alarm is equipped with a lithium battery power source. This allows the alarm to function

during power outages or failure of the main PCBA.

2-10 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 41

SECTION

SECTION

Performance verification 3

This section describes how to set up the KnightStar 330 and verify the performance of the

ventilator.

3.1 Initial ventilator cleaning and inspection

Prior to verifying the performance of the KnightStar 330 it is important that the ventilator is

clean and that the accessories are in good condition.

Warning

To prevent disease transmission, use personal protective equipment when handling

contaminated bacterial filters or other patient accessories.

Caution

Do not soak any portion of the KnightStar 330 in solvent, alcohol, or any other cleaning

agent. Soaking ventilator components may damage the ventilator.

Clean and inspect the ventilator as follows:

3

1 Clean ventilator exterior using an approved cleaner/disinfectant. (See Table 1-12: Tools,

equipment, and service materials on page 1-22.) After cleaning, ensure that there is no

liquid residue at any of the ventilator openings or enclosure joints.

2 Refer to the assembly drawing shown in Figure 5-2, and Table 5-1 on page 5-3 for ITEM

numbers called out in this step.

Inspect the air inlet filter. To remove the air inlet filter, pull the baffle, ITEM 16, away

from the ventilator and remove the foam filter, ITEM 17. Clean or replace as required.

(See Table 1-13: Schedule of periodic maintenance on page 1-24 for air inlet filter

cleaning instructions.) Re-install the baffle over the foam filter by snapping it into the

base.

3 Visually inspect ventilator exterior for obvious problems such as missing, broken, or

loose parts. Check the power cord for evidence of wear or damage. Repair or replace as

needed.

3.2 System set-up

The following items are required for Performance Verification (see Table 1-12 on page 1-22 for

part numbers):

• Calibration shell with included pressure tubing

• Patient circuit with pressure feedback

• Outlet air filter

•60 cc syringe

• Calibrated manometer

KnightStar 330 Service Manual Y-102942-00A Rev. G (03/04)

3-1

Page 42

3 Performance verification

Test set-up:

1 Set the KnightStar 330 on the test bench, ensuring that it is placed such that there is at

least 2.5 cm (1 in) of clearance at the back of the device.

2 Connect one end of the AC power cord into the rear panel of the KnightStar 330, and the

other end into an AC wall outlet.

3 Attach the patient circuit and outlet air filter to the air outlet.

4 Attach the proximal pressure line to the patient pressure connector on the ventilator.

Refer to Figure 3-1 for connecting the ventilator components.

Air outlet

Patient pressure

connector

Proximal pressure line

from patient circuit

Outlet air filter

Figure 3-1. Connecting KnightStar 330 components

5 Attach calibration shell to the patient circuit and connect the pressure tube between the

manometer and calibration shell pressure ports. See Figure 3-2.

calibrated manometer

calibration shell

with pressure tube

attached to

manometer’s

pressure port

Figure 3-2. KnightStar 330 test set-up

3-2 Y-102942-00A Rev. G (03/04) KnightStar 330 Service Manual

Page 43

Performance verification 3

3.3 Performance verification tests

3.3.1 Functional performance tests

Warning

Be careful when handling the KnightStar 330 during or immediately after use. Under

specified conditions, some surfaces may become hot to the touch. This is a normal

occurrence and is typical of this type of device.

NOTES:

•Because the KnightStar 330 is double-insulated and has a non-grounded AC

power connector, it is not necessary to perform hi-pot, ground continuity, or

leakage current tests.

• If locked, unlock the KnightStar 330 by simultaneously pressing and holding

the Mode and Up Arrow keys for approximately 2 seconds. Verify that the

indicator arrow on the LCD panel has moved from the locked to the

unlocked position.

For the following Performance Verification tests:

• Perform the functional performance tests in the order that they appear.

• Change the breathing mode by repeatedly pressing the Mode key until the

desired mode is displayed on the LCD panel.

• Change a specific setting by pressing the Settings key to scroll to the desired

setting, then using the Up or Down Arrow keys to adjust the value. Exit the

Settings mode by pressing the Mode key.