Page 1

Puritan-Bennett Corp.

2800 Airwest Blvd.

Plainfield, IN 46168

Customer Service:

1-800-635-5267, press 2

Technical Support:

1-800-255-6774, press 2

TECHNICAL MANUAL

HELiOS™ Liquid Oxygen Reservoirs

(Standard and Universal)

HELiOS™ Liquid Oxygen Portables

Part Number B-701693-00 Rev. C (10/02)

©2002 Puritan-Bennett Corp.

CAUTION: Federal (U.S.A.) laws restricts this

!

device to sale by or on the order of a

physician.

Page 2

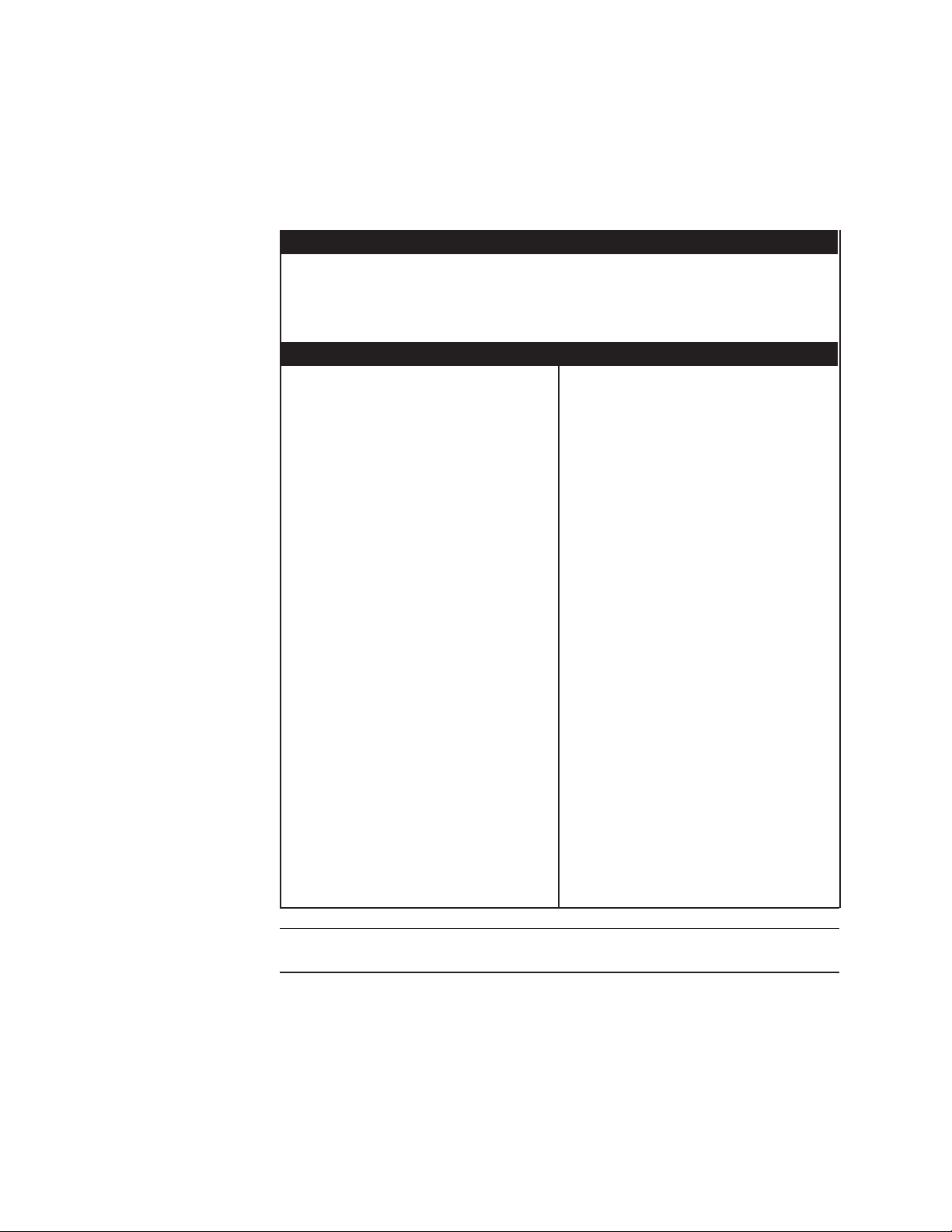

LIST OF EFFECTIVE PAGES

This list of effective pages represents manual P/N B-701693-00, Revision C.

Revision Description Date

A Initial Release 05-00

B Page Information Changes 10-01

C Universal Res. & Parts Illus. Changes 10-02

Effective Pages Revision Effective Pages Revision

Title Page C 11-1 A

ii C 11-2, 11-3 B

iii A 12-1, 12-2 A

iv to x C 12-3 to 12-8 C

1-1 to 1-3 C 12-9, 12-10 A

1-4 to 1-12 A 12-11 to 12-25 C

1-13 to 1-19 B 13-1 to 13-8 C

1-20 to 1-22 A

2-1 to 2-4 C

2-5 B

2-6 to 2-8 C

2-9 B

2-10 to 2-17 C

3-1, 3-2 C

3-3 A

3-4 to 3-15 C

4-1 to 4-13 C

5-1 to 5-3 C

6-1, 6-2 A

6-3 to 6-9 C

6-10 A

6-11 to 6-22 C

7-1 to 7-8 C

8-1 A

8-2, 8-3 B

8-4 to 8-6 A

8-7 to 8-12 B

9-1, 9-2 A

9-3 B

9-4 to 9-7 A

9-8 to 9-14 B

10-1 B

10-2 to 10-10 C

10-11 A

NOTE: SI pressure values expressed in manual are referenced to

atmosphere.

HELiOS™, Companion®, and Teleview™ are trademarks of PURITAN-BENNETT CORP.

SNOOP® is a trademark of the SWAGELOK Co.

Teflon® and Krytox® are trademarks of E. I. DUPONT DE NEMOURS & Co.

Kel-F® and Scotch-Brite™ are trademarks of the 3M Co.

Magnehelic® is a trademark of the DWYER INSTRUMENT Co.

QUICK-GRIP® is a trademark of the AMERICAN TOOL Co.

Sporicidin® is a trademark of SPORICIDIN INTERNATIONAL.

ii

B-701693-00 Rev. C

Page 3

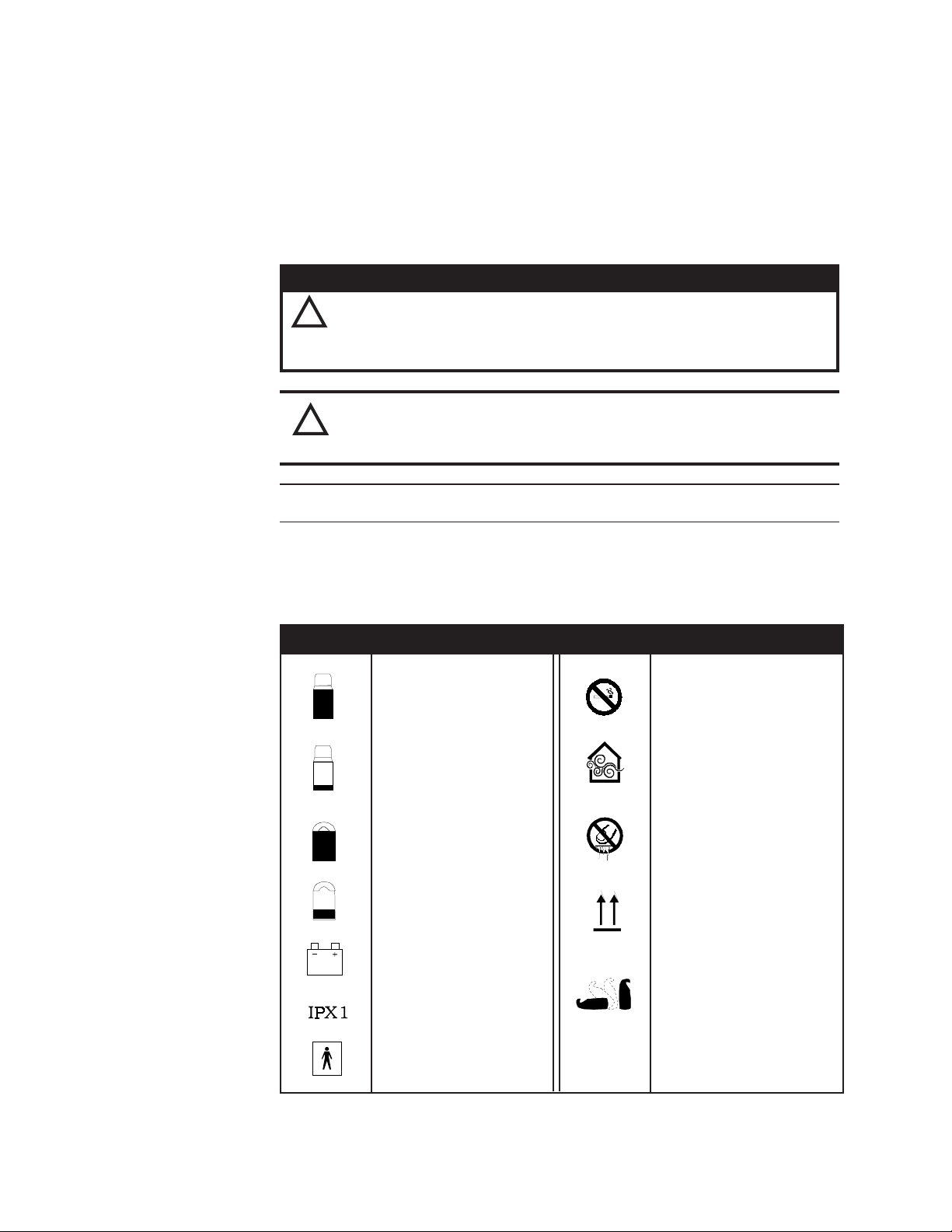

DEFINITION OF STATEMENTS

Statements in this manual preceded by the following words are of special

significance:

!

A warning describes conditions that concern your personal

safety and the safety of others. It includes the actions required to

prevent injury. Ignoring warnings can lead to injury or death.

CAUTION: A caution informs you about conditions that may

!

cause possible damage to the equipment or other property, or

situations that may cause reduced or no oxygen flow.

NOTE: Notes provide important information about using the equipment properly.

WARNING

DEFINITION OF PRODUCT SYMBOLS

SYMBOL DEFINITION SYMBOL DEFINITION

Reservoir Full Do not smoke near unit

Reservoir Empty lated at all times

Portable Full parts

Portable Empty Keep unit in upright

Low Battery (9VDC)

Drip Proof position in between

Keep unit well venti-

Do not touch frosted

position

Keep unit upright,

flat on its back, or any

B-701693-00 Rev. A

Type BF

(Electrical Safety)

iii

Page 4

PREFACE

This manual provides the information needed to service the Puritan Bennett HELiOS

Standard Reservoir, Universal Reservoir, and H300 Portable units. Information in the first

section of this manual covers both the Reservoir and the Portable units. Information in

Sections 2 through 7 covers just the Reservoir unit. Information in Sections 8 through 13

covers just the HELiOS 300 Portable unit. This information is intended for use by

technicians or personnel qualified to repair and service medical liquid oxygen equipment. Do not attempt to fill or repair these units until you read and understand the

information in this manual.

The following document contains additional information useful in servicing this equipment:

• HELiOS Oxygen System Operating Instructions: P/N B-701641-00

For product assistance contact: Puritan-Bennett Corp.

2800 Airwest Blvd.

Plainfield, IN 46168

Customer Service:

1-800-635-5267, press 2

Technical Support:

1-800-255-6774, press 2

www.heliosoxygen.com

NOTE: HELiOS Reservoir and Portable units are intended only for the delivery of

medical grade oxygen as prescribed by a physician.

WARNING

Improper usage hazard. Oxygen supplied from this equipment is

!

for supplemental use and is not intended to be life supporting or

life sustaining. This equipment is not intended for use by patients

who would suffer immediate, permanent, or serious health consequences as a result of an interruption in their oxygen supply.

CAUTION: Consistent with the recommendations of the medical

!

community on the use of conserving devices (which includes the

nasal cannula), it is recommended that the HELiOS system be

qualified on patients in the situations it will be used (rest, exercise,

sleep). Differences in nasal cannula design may vary the ability to

trigger a conserving device.

Information contained in this document, including performance specifications, is subject

to change without notice. Puritan-Benett makes no warranty of any kind with regard to the

material in this manual, including, but not limited to, the implied warranties of salability

and fitness for a particular purpose. Puritan-Bennett shall not be liable for errors contained

herein or for incidental or consequential damages in connection with either providing this

manual or the use of material in this manual. HELiOS is a trademark of Puritan-Bennett

Corp. The information contained in this manual is the sole property of Puritan-Bennett

and may not be reproduced without the permission of the company. Copyright© 2002 by

Puritan-Bennett Corp. All rights reserved.

iv

B-701693-00 Rev. C

Page 5

TABLE OF CONTENTS

Section 1 –Introduction to the HELiOS System

1.1 HELiOS System Description ............................................................................ 1-1

1.2 Serial Number Identification ............................................................................ 1-3

1.3 Safety Precautions ........................................................................................... 1-4

1.3.1 Cold Safety .............................................................................................. 1-4

1.3.2 Expansion Safety ..................................................................................... 1-5

1.3.3 Fire Safety ................................................................................................ 1-5

1.4 Liquid Oxygen Saturation Principles................................................................ 1-7

1.5 Pressure Fittings and Connections.................................................................. 1-9

1.5.1 Compression Fitting Makeup .................................................................. 1-9

1.5.2 Compression Fitting Remake ................................................................... 1-10

1.5.3 Compression Fitting Troubleshooting .................................................... 1-10

1.5.4 Tapered Pipe Thread (NPT) Makeup ....................................................... 1-11

1.5.5 Tapered Pipe Thread Troubleshooting .................................................... 1-12

1.5.6 Flexible Tube Barbed Fitting Makeup ...................................................... 1-12

1.5.7 Flexible Tube Removal from Barbed Fitting ............................................. 1-12

1.6 Recommended Tools, Test Equipment, and Service Materials .........................1-12

1.7 Test Equipment Calibration .............................................................................. 1-17

1.8 Accessories ..................................................................................................... 1-18

Section 2 – Reservoir General Information

2.1 Product Description ......................................................................................... 2-1

2.1.1 HELiOS Standard Reservoir ..................................................................... 2-1

2.1.2 HELiOS Universal Reservoir .................................................................... 2-2

2.2 Performance Specifications .............................................................................. 2-3

2.3 Unpacking, Installation, Repacking ................................................................. 2-4

2.3.1 Unpacking ............................................................................................... 2-4

2.3.2 Installation ............................................................................................... 2-4

2.3.3 Repacking for Return ............................................................................... 2-5

2.4 Controls, Indicators, and Connectors ..............................................................2-5

2.4.1 Fill Connector .......................................................................................... 2-5

2.4.2 Release Button ........................................................................................ 2-5

2.4.3 Vent Valve ................................................................................................ 2-6

2.4.4 Pressure Indicator (Standard Reservoir Only) ......................................... 2-6

2.4.5 Contents Indicator ................................................................................... 2-6

2.4.6 Oxygen Outlet .......................................................................................... 2-6

2.4.7 Moisture Container ..................................................................................2-6

2.5 Filling Instructions ........................................................................................... 2-7

2.5.1 Oxygen Source Requirements .................................................................. 2-7

2.5.2 Transfer Line ........................................................................................... 2-9

2.5.3 Pre-Fill Inspection .................................................................................... 2-10

2.5.4 Filling Procedure ...................................................................................... 2-11

2.5.5 Post-Fill Inspection .................................................................................. 2-14

2.5.6 Checking Saturation Pressure .................................................................. 2-14

2.5.7 Resaturating Liquid Oxygen .................................................................... 2-15

2.6 Operating Procedures ...................................................................................... 2-15

2.7 Maintenance .................................................................................................... 2-16

B-701693-00 Rev. C

v

Page 6

3 – Reservoir Theory of Operation

3.1 Reservoir Components .................................................................................... 3-1

3.1.1Cryogenic Container ................................................................................. 3-1

3.1.2 Fill Connector/Quick Connect ................................................................. 3-2

3.1.3 Vent Valve ................................................................................................ 3-3

3.1.4 Relief/Economizer Valve ........................................................................... 3-3

3.1.5 Secondary Relief Valve ............................................................................ 3-5

3.1.6 Pressure Regulator (Standard Reservoir Only) ........................................ 3-5

3.1.7 Warming Coil ........................................................................................... 3-6

3.1.8 Oxygen Outlet w/Poppet Valve ................................................................ 3-6

3.1.9 Pressure Indicator (Standard Reservoir Only) ......................................... 3-7

3.1.10 Contents Indicator ................................................................................. 3-7

3.2 Reservoir Operation ......................................................................................... 3-8

3.2.1 Filling the Reservoir ................................................................................. 3-8

3.2.2 Fill Termination ........................................................................................ 3-10

3.2.3 Standby ................................................................................................... 3-11

3.2.4 Gaseous Oxygen Use ...............................................................................3-12

3.2.5 HELiOS Reservoir Operation Over 24 Hours ........................................... 3-14

4 – Reservoir Performance Verification

4.1 Equipment Required ........................................................................................ 4-1

4.2 Leak Tests ........................................................................................................ 4-2

4.2.1 Liquid Leak Detector Test ........................................................................ 4-2

4.2.2 Pressure Hold Test (Alternate Leak Test) ................................................ 4-5

4.3 Gaseous Oxygen Functional Tests .................................................................. 4-6

4.3.1 Primary Relief Valve Test ......................................................................... 4-6

4.3.2 Secondary Relief Valve Test .................................................................... 4-7

4.3.3 Pressure Indicator Test (Standard Reservoir Only) ................................. 4-8

4.3.4 Pressure Regulator Test (Standard Reservoir Only) ................................ 4-8

4.3.5 Flow Restrictor Test ................................................................................. 4-9

4.4 Liquid Oxygen Functional Tests ...................................................................... 4-10

4.4.1 Contents Indicator Test ........................................................................... 4-10

4.4.2 Normal Evaporation Rate (NER) Test ....................................................... 4-11

4.4.3 Economizer Test ....................................................................................... 4-12

5 – Reservoir Troubleshooting

6 – Reservoir Service and Repair

6.1 Emptying a Reservoir Unit ............................................................................... 6-1

6.2 Shroud Assembly ............................................................................................ 6-3

6.2.1 Upper Shroud Removal ............................................................................6-3

6.2.2 Upper Shroud Service .............................................................................. 6-3

6.2.3 Upper Shroud Installation ....................................................................... 6-3

6.2.4 Lower Shroud Removal ............................................................................ 6-3

6.2.5 Lower Shroud Installation ....................................................................... 6-4

6.3 Contents Indicator ........................................................................................... 6-5

vi

B-701693-00 Rev. C

Page 7

6.3.1 Removal ................................................................................................... 6-5

6.3.2 Service ..................................................................................................... 6-6

6.3.3 Installation ............................................................................................... 6-6

6.4 Pressure Indicator (Standard Reservoir Only) ................................................. 6-7

6.4.1 Removal ................................................................................................... 6-7

6.4.2 Service ..................................................................................................... 6-7

6.4.3 Installation ............................................................................................... 6-7

6.5 Fill Connector Release Assembly .................................................................... 6-8

6.5.1 Removal ................................................................................................... 6-8

6.5.2 Installation ............................................................................................... 6-8

6.6 Male Fill Connector ......................................................................................... 6-8

6.6.1 Removal ................................................................................................... 6-8

6.6.2 Inspection ................................................................................................ 6-9

6.6.3 Service ..................................................................................................... 6-9

6.6.4 Disassembly ............................................................................................ 6-9

6.6.5 Reassembly ..............................................................................................6-10

6.6.6 Installation ............................................................................................... 6-10

6.7 Vent Valve .......................................................................................................... 6-11

6.7.1 Removal ................................................................................................... 6-11

6.7.2 Inspection ................................................................................................ 6-11

6.7.3 Service ..................................................................................................... 6-11

6.7.4 Disassembly ............................................................................................ 6-11

6.7.5 Reassembly ..............................................................................................6-12

6.7.6 Installation ............................................................................................... 6-12

6.8 Relief/Economizer (R/E) Valve ............................................................................ 6-13

6.8.1 Removal ................................................................................................... 6-13

6.8.2 Installation ............................................................................................... 6-13

6.8.3 R/E Valve Adjustment .............................................................................. 6-14

6.9 Secondary Relief Valve ...................................................................................... 6-16

6.9.1 Removal ................................................................................................... 6-16

6.9.2 Installation ............................................................................................... 6-16

6.10 Warming Coil ................................................................................................... 6-16

6.10.1 Removal ................................................................................................. 6-16

6.10.2 Installation ............................................................................................. 6-17

6.11 Economizer Tube Assembly ............................................................................ 6-17

6.11.1 Removal ................................................................................................. 6-17

6.11.2 Installation ............................................................................................. 6-18

6.12 Pressure Regulator (Standard Reservoir Only) ................................................ 6-18

6.12.1 Removal ................................................................................................. 6-18

6.12.2 Service ................................................................................................... 6-18

6.12.3 Installation ............................................................................................. 6-18

6.12.4 Adjustment ............................................................................................ 6-19

6.13 Oxygen Outlet Block (Universal Reservoir Only) ............................................ 6-20

6.13.1 Removal ................................................................................................. 6-20

6.13.2 Installation ............................................................................................. 6-20

6.14 Cryogenic Container ........................................................................................ 6-20

6.14.1 Removal ................................................................................................. 6-20

6.14.2 Installation ............................................................................................. 6-21

6.15 Purging the Container Liquid Sense Tube ....................................................... 6-21

B-701693-00 Rev. C

vii

Page 8

7 – Reservoir Illustrated Parts List

Figure 7-1, HELiOS Standard Reservoir ........................................................... 7-3

Figure 7-2, HELiOS Standard Reservoir ........................................................... 7-4

Figure 7-3, HELiOS Standard Reservoir ........................................................... 7-5

Figure 7-4, HELiOS Universal Reservoir .......................................................... 7-6

Figure 7-5, HELiOS Universal Reservoir .......................................................... 7-7

Figure 7-6, HELiOS Universal Reservoir .......................................................... 7-8

8 - HELiOS 300 General Information

8.1 Product Description ......................................................................................... 8-1

8.2 Performance Specifications .............................................................................. 8-2

8.3 Unpacking, Installation, and Repacking .......................................................... 8-3

8.3.1 Unpacking ............................................................................................... 8-3

8.3.2 Installation ............................................................................................... 8-3

8.3.3 Repacking for Return ............................................................................... 8-3

8.4 Controls, Indicators, and Connectors ..............................................................8-4

8.4.1 Fill Connector .......................................................................................... 8-4

8.4.2 Vent Valve ................................................................................................ 8-4

8.4.3 Contents Indicator ................................................................................... 8-4

8.4.4 Demand Flow Control .............................................................................. 8-4

8.4.5 Oxygen Supply Tube Quick Connect ...................................................... 8-4

8.4.6 Oxygen Outlet Connector ........................................................................ 8-5

8.4.7 Sense Connector ..................................................................................... 8-5

8.4.8 Dual-Lumen Cannula ............................................................................... 8-5

8.5 Filling Instructions ........................................................................................... 8-5

8.5.1 Pre-Fill Inspection .................................................................................... 8-6

8.5.2 Filling Procedure ...................................................................................... 8-6

8.5.3 Post-Fill Inspection .................................................................................. 8-9

8.6 Operating Procedures ...................................................................................... 8-9

8.7 Maintenance .................................................................................................... 8-11

viii

9 – HELiOS 300 Theory of Operation

9.1 H-300 Portable Components ............................................................................ 9-1

9.1.1 Cryogenic Container ................................................................................ 9-1

9.1.2 Fill Connector/Quick Connect ................................................................. 9-2

9.1.3 Vent Valve ................................................................................................ 9-3

9.1.4 Relief/Economizer Valve ........................................................................... 9-4

9.1.5 Secondary Relief Valve ............................................................................ 9-5

9.1.6 Warming Coils ......................................................................................... 9-6

9.1.7 Demand Flow Control Valve .................................................................... 9-6

9.1.8 Oxygen Supply Tube Quick Connect and Inline Check Valve ................. 9-7

9.1.9 Contents Indicator ................................................................................... 9-8

9.2 H-300 Portable Operation ................................................................................. 9-9

9.2.1 Filling the HELiOS 300 ............................................................................. 9-9

9.2.2 Fill Termination ........................................................................................ 9-10

9.2.3 Standby ................................................................................................... 9-11

9.2.4 Gaseous Oxygen Use – H-300 Filled with Liquid Oxygen ........................ 9-12

9.2.5 Gaseous Oxygen Use – H-300 Connected to Oxygen Supply Tube ........ 9-14

B-701693-00 Rev. C

Page 9

10 – HELiOS 300 Performance Verification

10.1 Equipment Required ........................................................................................ 10-1

10.2 Leak Tests ........................................................................................................ 10-2

10.2.1 Liquid Leak Detector Test ...................................................................... 10-2

10.2.2 Pressure Hold Test (Alternate Leak Test) .............................................. 10-4

10.3 Gaseous Oxygen Functional Tests .................................................................. 10-4

10.3.1 Primary Relief Valve Test ........................................................................ 10-4

10.3.2 Secondary Relief Valve Test ................................................................... 10-5

10.4 Liquid Oxygen Functional Tests ...................................................................... 10-7

10.4.1 Contents Indicator Test ......................................................................... 10-7

10.4.2 Normal Evaporation Rate (NER) Test ..................................................... 10-8

10.4.3 Economizer Test ..................................................................................... 10-8

10.4.4 Demand Flow Control Valve Test ........................................................... 10-10

11 – HELiOS 300 Troubleshooting

12 – HELiOS 300 Service and Repair

12.1 Emptying an H-300 Unit ................................................................................... 12-1

12.2 Side Covers ...................................................................................................... 12-2

12.2.1 Removal ................................................................................................. 12-3

12.2.2 Disassembly – Front Side Cover ............................................................ 12-3

12.2.3 Reassembly – Front Side Cover ............................................................. 12-3

12.2.4 Disassembly – Rear Side Cover ............................................................. 12-4

12.2.5 Reassembly – Rear Side Cover .............................................................. 12-4

12.2.6 Installation ............................................................................................. 12-5

12.3 Contents Indicator ........................................................................................... 12-5

12.3.1 Removal ................................................................................................. 12-5

12.3.2 Inspection .............................................................................................. 12-5

12.3.3 Disassembly and Reassembly ................................................................ 12-5

12.3.4 Installation ............................................................................................. 12-5

12.4 Female Fill Connector and Tube ...................................................................... 12-5

12.4.1 Removal ................................................................................................. 12-6

12.4.2 Inspection .............................................................................................. 12-7

12.4.3 Service ................................................................................................... 12-7

12.4.4 Disassembly ........................................................................................... 12-7

12.4.5 Reassembly ............................................................................................ 12-9

12.4.6 Installation ............................................................................................. 12-11

12.5 Vent Valve and Tube ........................................................................................ 12-11

12.5.1 Removal ................................................................................................. 12-11

12.5.2 Inspection .............................................................................................. 12-12

12.5.3 Service ................................................................................................... 12-13

12.5.4 Disassembly ........................................................................................... 12-13

12.5.5 Reassembly ............................................................................................ 12-14

12.5.6 Installation ............................................................................................. 12-14

12.6 Relief/Economizer Valve ................................................................................... 12-14

12.6.1 Removal ................................................................................................. 12-15

12.6.2 Installation ............................................................................................. 12-15

12.6.3 R/E Valve Adjustment ............................................................................ 12-16

B-701693-00 Rev. C

ix

Page 10

12.7 Secondary Relief Valve ................................................................................. 12-19

12.7.1 Removal .............................................................................................. 12-19

12.7.2 Installation ......................................................................................... 12-19

12.8 Demand Flow Co ntrol Valve ......................................................................... 12-19

12.8.1 Removal .............................................................................................. 12-19

12.8.2 Service ................................................................................................ 12-20

12.8.3 Installation ......................................................................................... 12-20

12.8.4 Sensitivity Adjustment ...................................................................... 12-20

12.9 Warming Coils .............................................................................................. 12-22

12.9.1 Removal – Liquid Withdrawal Warming Coil ...................................... 12-22

12.9.2 Installation – Liquid Withdrawal Warming Coil .................................. 12-23

12.9.3 Removal – Gas Withdrawal Warming Coil .......................................... 12-23

12.9.4 Installation – Gas Withdrawal Warming Coil ...................................... 12-23

12.10 Oxygen Supply Tube Quick Connect & Inline Check Valve ......................... 12-23

12.10.1 Removal – Quick Connect ................................................................ 12-23

12.10.2 Installation – Quick Connect ............................................................ 12-24

12.10.3 Removal – Inline Check Valve .......................................................... 12-24

12.10.4 Installation – Inline Check Valve ...................................................... 12-24

12.11 Cryogenic Container ...................................................................................... 12-24

12.11.1 Removal ............................................................................................ 12-24

12.11.2 Installation ........................................................................................12-25

13 – HELiOS 300 Illustrated Parts List

Figure 13-1, HELiOS 300 Portable ................................................................. 13-3

Figure 13-2, HELiOS 300 Portable ................................................................. 13-4

Figure 13-3, HELiOS 300 Portable ................................................................. 13-5

Figure 13-4, HELiOS 300 Portable ................................................................. 13-6

Figure 13-5, HELiOS 300 Portable ................................................................. 13-7

Figure 13-6, HELiOS 300 Portable ................................................................. 13-8

Technical Bulletins

x

B-701693-00 Rev. C

Page 11

HELiOS Liquid Oxygen System Technical Manual

INTRODUCTION TO THE HELiOS SYSTEM

WARNING

Read Section 1, and any other applicable section, thoroughly

!

before attempting to service or fill a HELiOS Reservoir or Portable.

Failure to do so may result in injury or death.

The HELiOS is an innovative liquid oxygen system where the Reservoir and Portable unit

provide a new level of performance efficiency for oxygen therapy patients. This section

provides introductory information on the HELiOS liquid oxygen system. It includes a brief

system description; serial number identification; safety precautions; liquid oxygen

saturation fundamentals; pressure fittings and connections information; tool, test

equipment, and service material recommendations; test equipment calibration information;

and accessory information.

The information in this section relates to both the Reservoir and the Portable units.

Sections 2 through Section 7 provide technical and service information that is specific to

the HELiOS Standard Reservoir and Universal Reservoir units. Sections 8 through Section

13 provide technical and service information that is specific to the HELiOS 300 Portable

unit.

Section

1

1.1 HELIOS SYSTEM DESCRIPTION

The HELiOS liquid oxygen system provides 24 hour per day reservoir and portable oxygen

therapy for a typical Chronic Obstructive Pulmonary Disease (COPD) patient. HELiOS

uses oxygen conservation and exclusive “no loss” technology to greatly improve

performance efficiency compared to conventional liquid oxygen systems. The HELiOS

Reservoir unit redefines the evaporative loss characteristics of home liquid oxygen

vessels and has features that enhance the safety and usability of the product. Using the

H300 Portable with a Standard HELiOS Reservoir will typically require less than one liquid

oxygen delivery to the patient per month. The HELiOS Universal Reservoir has many of

the same features as the Standard Reservoir plus it permits filling the H300 Portable as well

as the Puritan Bennett Companion 1000, Companion T, and Companion 500 series portables. The HELiOS 300 Portable unit sets a new standard for size, weight, and range that

surpasses existing cylinder or liquid based portables.

B-701693-00 Rev. C

Introduction to the HELiOS System

- 1-1

Page 12

HELiOS Liquid Oxygen System Technical Manual

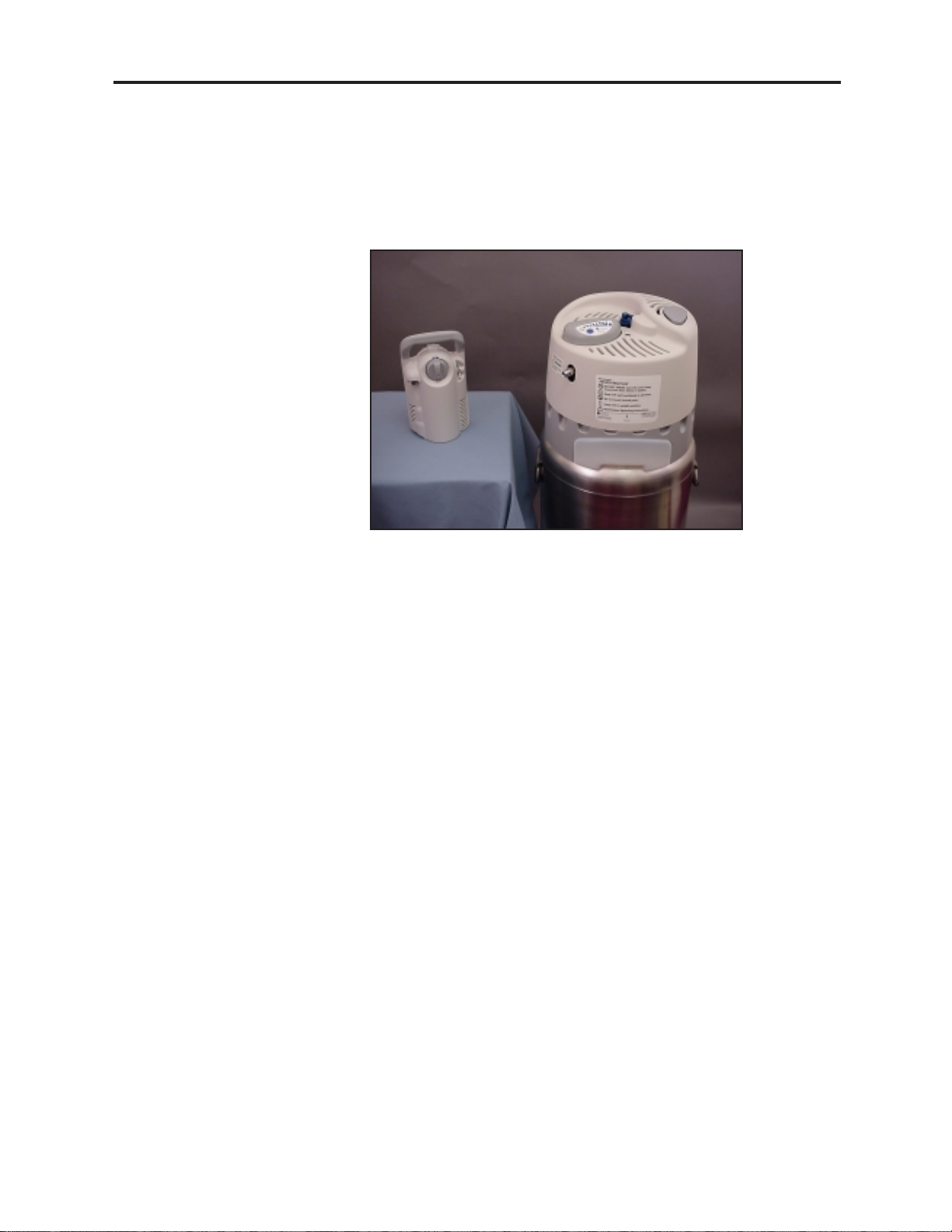

Like today’s liquid oxygen systems, the HELiOS system consists of a Reservoir and a

Portable patient unit (Figure 1-1). However, the system components are capable of

working together rather than separately. The HELiOS 300 Portable fills from the Reservoir

for ambulatory use or connects to the Reservoir with a flexible oxygen supply tube for

home use. This provides the patient with the same familiar interface whether at home or

away.

Figure 1-1: HELiOS Reservoir and Portable

The patient receives oxygen from the H-300 Portable through a dual lumen cannula and a

pneumatic demand flow control system. The H-300 Portable provides 11 different oxygen

flow settings from .12 through 4 . Flow settings from 1 through 4 provide demand flow

oxygen to the patient on each inspiration. No oxygen flows during exhalation. Flow

settings less than 1 provide continuous oxygen flow (L/min) to the patient at the indicated rate. The demand flow control system in a full H-300 Portable can provide a 2 L/min

patient with up to 10 hours of demand flow oxygen. This results in a 4:1 oxygen savings

while still providing adequate oxygen to meet the patient’s needs.

For ambulatory use, the patient fills the H-300 Portable with liquid oxygen from the

Reservoir. When full, it holds slightly less than one pound (454 grams) of liquid oxygen

and weighs a total of 3.6 pounds (1.6 kg). A spring scale type contents indicator shows

the amount of liquid oxygen remaining in the unit.

For oxygen needs in the home, the patient engages the H-300 Portable to a flexible oxygen

supply tube that connects to the oxygen outlet of the Reservoir. The H-300 Portable

provides the patient with the same familiar oxygen delivery interface but the patient now

breathes gaseous oxygen directly from the Reservoir. This makes the H-300 Portable about

one pound (454 grams) lighter since it contains no liquid oxygen. Also, evaporative

oxygen losses from the Reservoir are greatly reduced since the patient breathes the gas

that normally builds pressure and vents through the Reservoir relief valve.

Two HELiOS Reservoir models are available in both 36 liter and 46 liter sizes. The Standard

H-36 and H-46 Reservoirs provide the patient with both a means to fill a HELiOS Portable

with liquid oxygen and a source of regulated 22 psig (152 kPa) gaseous oxygen for

breathing with the H-300 Portable or other external 22 psig (152 kPa) flow-metering device.

The Universal U-36 and U-46 Reservoirs also provide the patient with both a means to fill

a HELiOS Portable with liquid oxygen and a source of 22 psig (152 kPa) gaseous oxygen.

In addition, lower internal pressure in the Universal Reservoir permits the filling of Puritan

1-2 -

Introduction to the HELiOS System

B-701693-00 Rev. C

Page 13

HELiOS Liquid Oxygen System Technical Manual

Bennett Companion portables as well. At the push of a button, an electronic contents

indicator measures and displays the amount of liquid oxygen remaining in the Reservoir.

The H-36 Reservoir, when used with an H-300 Portable, typically yields a four week liquid

oxygen delivery cycle with a 2 L/min patient. The U-36 Reservoir, when used with an H300 Portable, typically yields almost a four week liquid oxygen delivery cycle with a 2 L/

min patient.

The H-46 Reservoir, when used with an H-300 Portable, can yield a six week liquid oxygen

delivery cycle with a 2 L/min patient. The U-46 Reservoir, when used with an H-300

Portable, can yield a five week liquid oxygen delivery cycle with a 2 L/min patient.

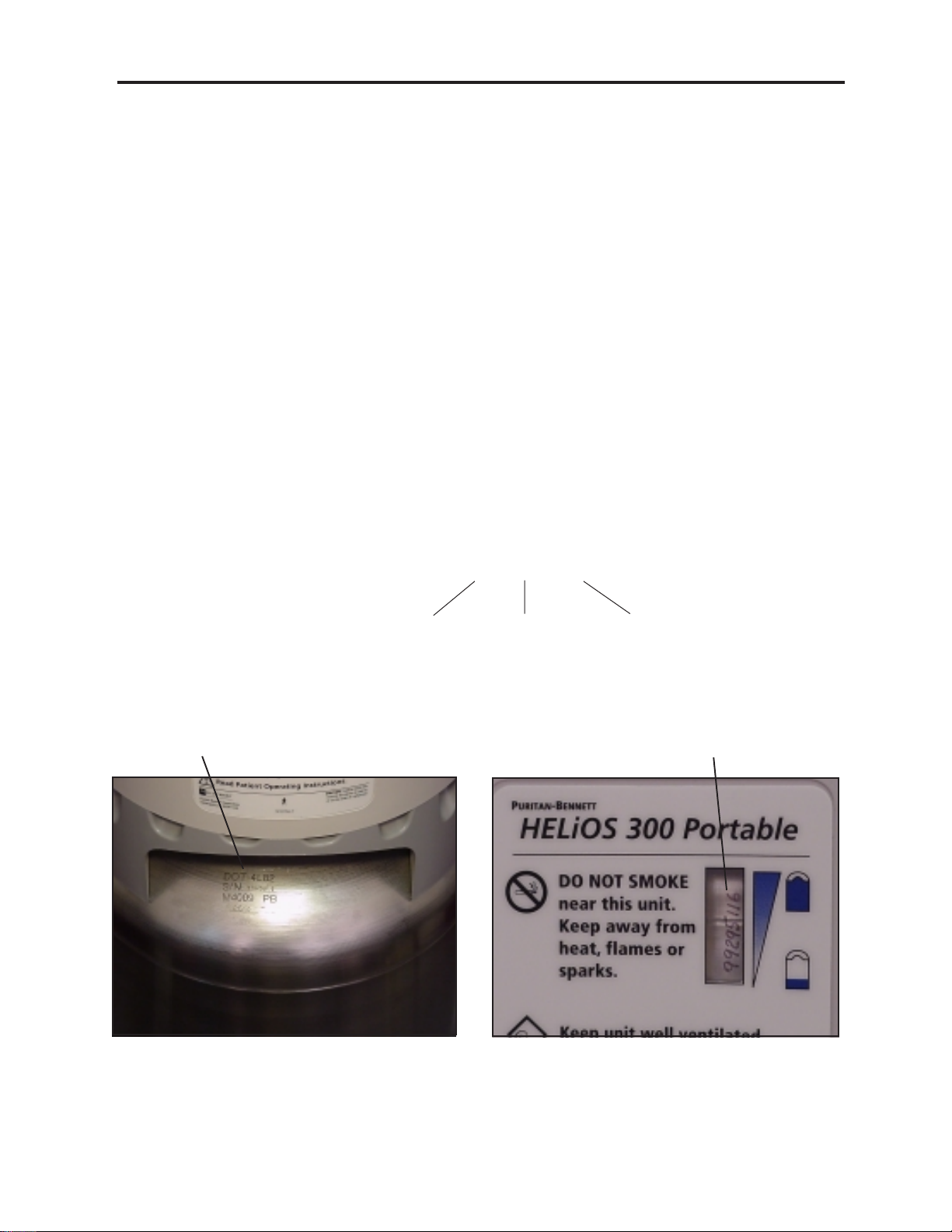

1.2 SERIAL NUMBER IDENTIFICATION

Each HELiOS Reservoir and H-300 Portable are identified by a unique eight-digit serial

number. The number contains the year and calendar day of manufacture, as well as the

unit’s production number for that day (Figure 1-2). The Standard Reservoir serial number

is etched into the upper head of the cryogenic container and is visible when the moisture

container is removed (Figure 1-3). The Universal Reservoir serial number is etched into a

Reservoir handle bracket. The H-300 Portable serial number is etched into the cryogenic

container and is visible through the contents indicator window in the rear side cover

(Figure 1-4).

Serial Number

99 295 116

{

Designates

Year

Figure 1-2: Serial Number Scheme

Designates

Sequential Day of

Year (Jan 1 = 001,

Dec 31 = 365)

{

{

Designates

Number of Specific

Unit Produced

that day

Serial Number

Figure 1-3: Figure 1-4:

Standard Reservoir Serial Number Location H-300 Serial Number Location

B-701693-00 Rev. C

Introduction to the HELiOS System

- 1-3

Page 14

1.3 SAFETY PRECAUTIONS

This section covers precautions and safe practices as they apply to facilities and personnel involved in servicing medical oxygen equipment. These precautions are divided into

three main areas: cold safety, expansion safety, and fire safety. To ensure reliability and

safety, the service techniques, work area, and equipment used in the storage, service, and

handling of this system must be of the highest standard. Refer to the HELiOS Operating

Instructions (B-701641-00) for additional safety precautions regarding the use of this

equipment.

1.3.1 Cold Safety

Extreme cold hazard. Liquid oxygen is extremely cold

!

(-297°F/-183°C) and will freeze skin on contact. Never

touch liquid oxygen or frosted parts.

Extreme cold hazard. Liquid oxygen can spill if the

!

Reservoir is tipped over. Keep the Reservoir upright

at all times. Secure the Reservoir when transporting

to prevent accidental tip-over.

HELiOS Liquid Oxygen System Technical Manual

WARNING

WARNING

WARNING

Extreme cold hazard. Liquid oxygen can spill from the

!

Portable. Always keep the Portable in one of the

following positions; upright, flat on its back or any

position in between.

WARNING

Extreme cold hazard. Forceful discharge of liquid

!

oxygen possible if fill connector freezes open upon

disengagement. Always dry fill connectors with clean,

dry lint free cloth before fill.

Recommended Protective Clothing:

• Heavily insulated gloves (for example, cryogenic or welding gloves). Never use

gloves that are contaminated with grease or oil when working with liquid oxygen.

• Protective face shield and goggles.

• Long sleeve shirt. Wear natural fibers such as cotton or wool. Avoid synthetic

materials such as polyester or rayon.

• Long pants. Never wear pants with cuffs. Liquid oxygen may become trapped and

cause serious burns to skin. Wear natural fibers such as cotton or wool. Avoid

synthetic materials such as polyester or rayon.

• Protective cryogenic or welding apron.

1-4 -

Introduction to the HELiOS System

B-701693-00 Rev. A

Page 15

HELiOS Liquid Oxygen System Technical Manual

Important Facts:

• Direct exposure to liquid oxygen or exposure to its vented gas or components cooled

by liquid oxygen can result in frostbite. If frostbite occurs, seek medical attention

immediately.

1.3.2 Expansion Safety

Explosive hazard. Extreme high pressure can rupture

!

container or plumbing components. Be sure specified

pressure relief devices are present, in the proper

location, and functioning properly.

Important Facts:

• Liquid oxygen at atmospheric pressure expands at a ratio of approximately 860:1 (at 0

psig) when vaporizing into a gas (Figure 1-5). This can occur very rapidly when

exposed to the heat in the atmosphere.

• Ensure that the specified pressure relief devices are present and functioning properly

in any device that will contain liquid oxygen. This includes transfer hose assemblies.

WARNING

LOX

1860

Figure 1-5: Liquid Oxygen Expansion Ratio

1.3.3 Fire Safety

Concentrated Oxygen. Increased risk of fire.

!

• Do not smoke or keep burning tobacco near this equipment.

Death or injury may occur.

• Keep flammable materials away from this equipment. Oils,

grease, including facial creams and petroleum jelly, asphalt, and

synthetic fibers ignite easily and burn rapidly in the presence of concentrated oxygen. If needed, use only specified oxygen compatible

lubricants as directed.

• Keep oxygen equipment away from open flames. Keep Reservoir and Portable units at least five feet away from equipment such as

furnaces, water heaters, and stoves that may contain open flames.

GA S

WARNING

B-701693-00 Rev. A

Introduction to the HELiOS System

- 1-5

Page 16

HELiOS Liquid Oxygen System Technical Manual

WARNING

Concentrated Oxygen. Increased risk of fire.

!

• Keep oxygen equipment away from electrical appliances. Keep

Reservoir and Portable units at least five feet from electrical appliances

that may cause heat or sparks.

• Keep oxygen equipment in a well-ventilated area at all times.

These units periodically release small amounts of oxygen gas that

must be ventilated to prevent buildup. Do not store liquid oxygen

equipment in a car trunk, closet, or other confined area. Do not place

bags, blankets, draperies, or other fabrics over the equipment when it

contains liquid oxygen.

• Do not place the Portable unit under clothing. These units normally

vent oxygen. Placing a Portable unit under clothing may saturate fabrics

with oxygen and cause them to burn rapidly if exposed to sparks or

flame. It may take several hours for oxygen levels in the fabric to return

to normal.

Important Facts:

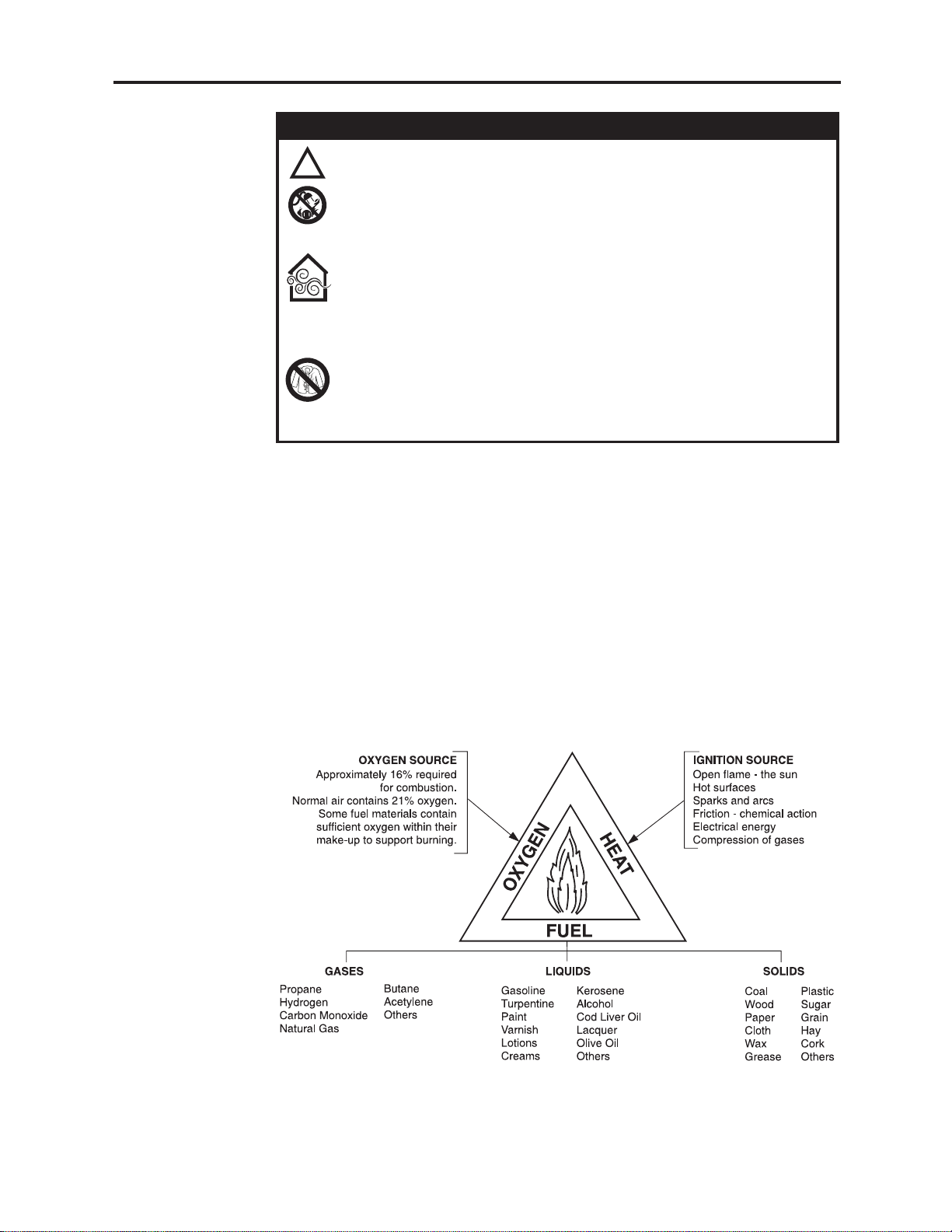

The possibility of fire exists when the combination of a fuel, source of ignition, and oxygen

is present (Figure 1-6). High concentrations of oxygen (air is approximately 21% oxygen)

greatly enhance the possibility of combustion.

• Obtain all replacement parts for medical oxygen equipment from the manufacturer.

• Before servicing, clean all tools that come into contact with the oxygen system.

• Use only recommended oxygen compatible cleaning and leak detection products.

• Keep the Reservoir upright at all times. Secure liquid oxygen equipment when transporting to prevent accidental tipover and spillage.

• If a liquid oxygen spill occurs indoors, open doors and windows to ventilate the area.

Avoid sources of ignition and do not walk on or roll equipment over the affected area.

• Any clothing or porous material that is splashed with liquid oxygen or otherwise absorbs

high concentrations of oxygen should be removed and aired for at least one hour away

from any source of ignition.

1-6 -

Introduction to the HELiOS System

Figure 1-6: Combustion Triangle

B-701693-00 Rev. A

Page 17

HELiOS Liquid Oxygen System Technical Manual

1.4 LIQUID OXYGEN SATURATION PRINCIPLES

Oxygen, in its normal state, is a colorless, tasteless, and odorless gas that is non-flammable, although it greatly accelerates combustion in high concentrations. It constitutes

about 21% of the Earth’s atmosphere by volume. Oxygen in higher concentrations is

medically beneficial to patients suffering from certain respiratory diseases.

Oxygen, like most gases, will condense into a liquid with an increase in pressure or

decrease in temperature. As a liquid, oxygen is pale blue in color and is about 860 times as

dense as its gaseous form. At atmospheric pressure (14.7 psia), oxygen condenses into its

liquid form at a temperature of about -297°F (-184°C). Liquid oxygen (LOX) is an efficient

form of oxygen to meet a patient’s portable, ambulatory oxygen needs. A volume of liquid

oxygen, when vaporized, yields about 860 volumes of gaseous oxygen (Figure 1-5). As

you can see, a relatively small volume of liquid oxygen provides a much larger volume of

gaseous oxygen for a patient to use.

In medical liquid oxygen systems, liquid oxygen, and the gaseous oxygen resulting from

its vaporization or boiling, is stored under pressure. The elevated pressure, typically 22

psig (152 kPa), enables oxygen to flow to the patient at a selected, prescribed rate. To

sustain this oxygen flow to the patient, the liquid oxygen must be in a state that allows

vaporization to readily occur. In other words, the liquid oxygen must be in a state of

saturation. Let’s take a look at what liquid saturation is all about.

A saturated liquid is one that absorbs the maximum amount of heat possible at a given

pressure without vaporizing into a gas. If additional heat is added, the saturated liquid

begins to vaporize (boil) while remaining at a constant temperature until all of the liquid is

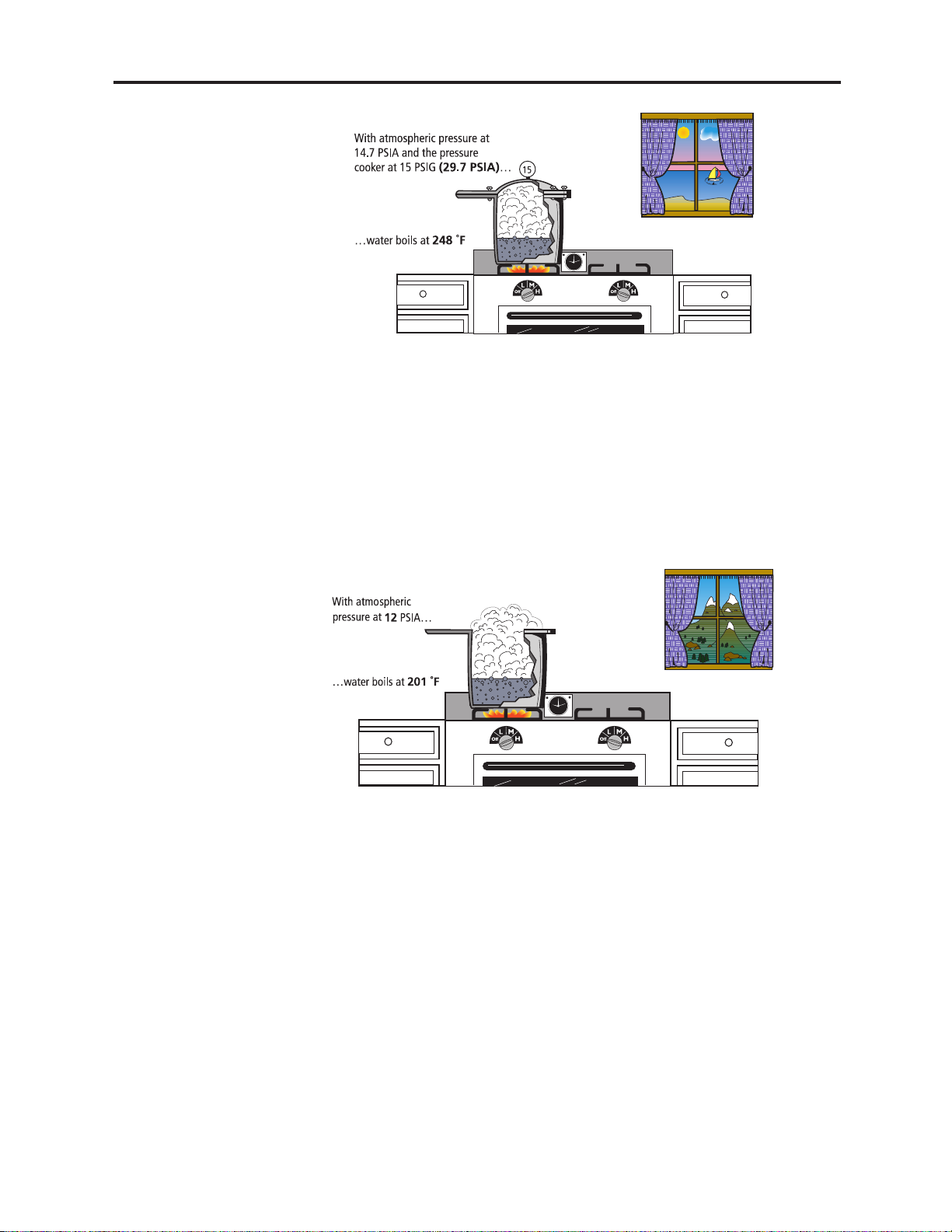

vaporized. A common example of a saturated liquid is water at its boiling point of 212°F

(100°C) at sea level. The constant addition of heat to the boiling water does not cause it to

become hotter, but instead causes part of the liquid water to turn to water vapor

(Figure 1-7).

Figure 1-7: Saturated (Boiling) Water at Sea Level

The saturation (boiling) point of a liquid depends not only on temperature but also on

pressure. If the pressure in a container of saturated liquid increases, the temperature

required for saturation to occur will also increase. This leaves the liquid unsaturated, that

is, capable of accepting more heat before it will boil (Figure 1-8).

B-701693-00 Rev. A

Introduction to the HELiOS System

- 1-7

Page 18

HELiOS Liquid Oxygen System Technical Manual

Figure 1-8: Saturated (Boiling) Water at Higher Pressure

If the pressure in a container of saturated liquid decreases, the temperature required for

saturation to occur will decrease. This leaves the liquid “super saturated” or too warm.

When this occurs, rapid boiling and vaporizing of some of the liquid occurs. The rapid

boiling and evaporation of the liquid dissipates the excessive heat until the remaining

liquid cools down to the new saturation temperature associated with the decreased

pressure (Figure 1-9).

Oxygen, which is normally a gas at atmospheric pressure, changes into liquid form when it

is cooled to about -297°F (-183°C) at atmospheric pressure. It is saturated at this temperature (and pressure) which means it will remain a liquid as long as no additional heat is

added. However, the large quantity of heat present in the atmosphere constantly enters

the liquid oxygen and causes it to boil and vaporize back into a gas. Since it is virtually

impossible to keep all of the heat in the atmosphere from entering the liquid oxygen,

constant boiling and vaporization occurs.

Now when liquid oxygen is placed in a closed container, the vaporizing gas is trapped and

begins to build pressure. As pressure increases above atmospheric pressure, more heat is

needed for boiling to occur at the higher pressure. The heat that is constantly available

from the atmosphere warms the liquid to a higher temperature where boiling again occurs.

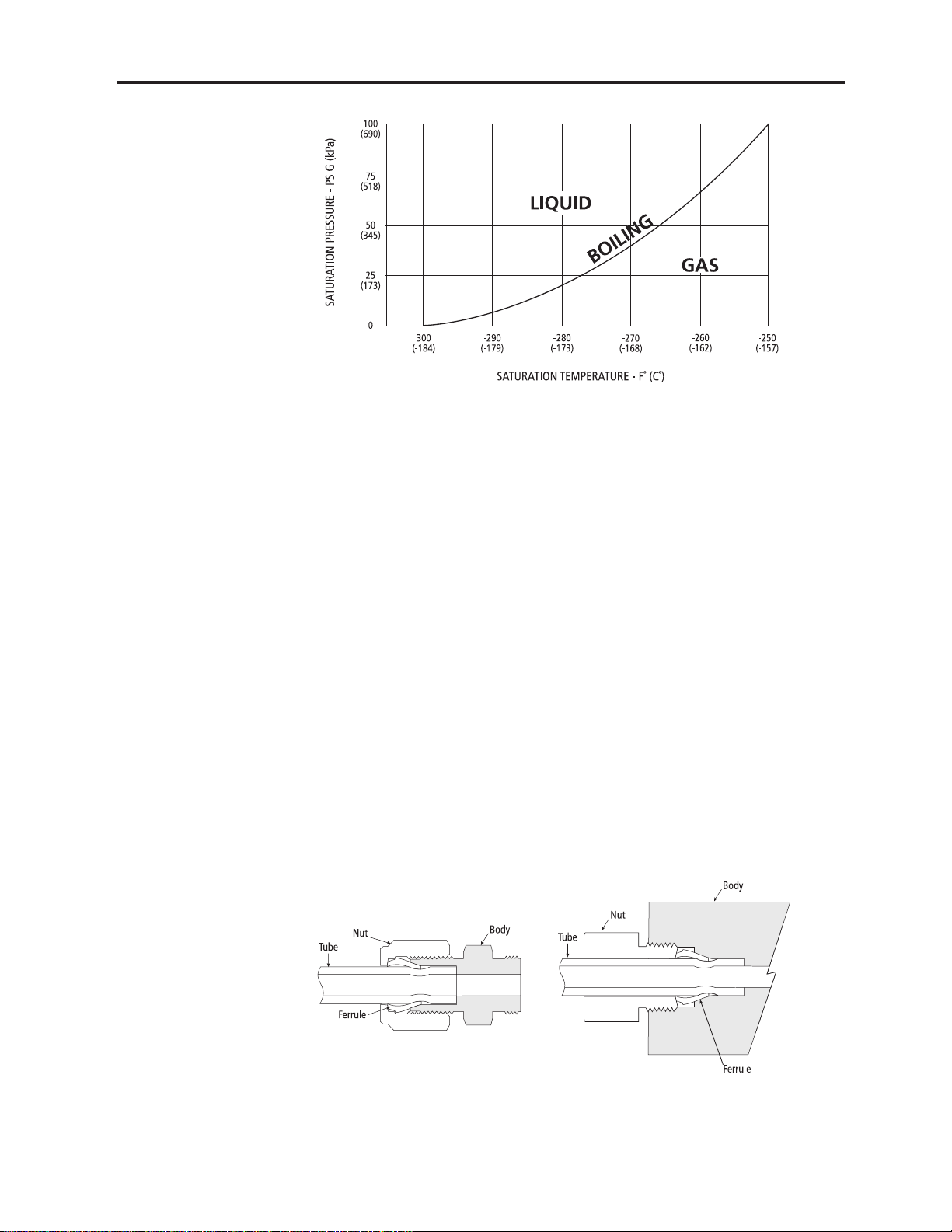

The vaporizing gas builds pressure and the process continues. As the pressure on liquid

oxygen builds, the related saturation temperature of the liquid increases proportionally

(Figure 1-10).

1-8 -

Introduction to the HELiOS System

Figure 1-9: Saturated (Boiling) Water at Lower Pressure

B-701693-00 Rev. A

Page 19

HELiOS Liquid Oxygen System Technical Manual

It is important to maintain liquid oxygen saturation (boiling) at the specified operating

pressure of the HELiOS system. As an oxygen flow demand is put on the system, a slight

decrease in pressure occurs due to oxygen withdrawal. The saturated liquid oxygen in the

system vaporizes enough gaseous oxygen to maintain system operating pressure. This

ensures proper oxygen flow to the patient. If the liquid oxygen saturation temperature is

too low, the corresponding lower saturation pressure causes low oxygen flows to the

patient.

Figure 1-10: Liquid Oxygen Saturation Curve

1.5 PRESSURE FITTINGS AND CONNECTIONS

The HELiOS liquid oxygen system uses aluminum tubing compression fittings, tapered

pipe thread (NPT) fittings, and flexible tube barbed fittings. Proper make-up and service of

these pressure fittings is essential to leak-free operation.

1.5.1 Compression Fitting Makeup

The compression fittings used in the HELiOS system consist of a fitting body, tube,

ferrule, and nut (Figure 1-11). These fittings typically connect the aluminum tubing to

other components in the system. In a properly made-up compression fitting, sealing

occurs at two points: between the ferrule and the fitting body; and between the ferrule

and the tube.

Figure 1-11: Compression Fitting

B-701693-00 Rev. A

Introduction to the HELiOS System

- 1-9

Page 20

HELiOS Liquid Oxygen System Technical Manual

Perform the following steps to make up a new compression fitting:

1. Inspect the tube end. The tube end should be cut square and the outside surface of

the tube should be free of scratches or other marks at least one inch (25 mm) back

from the tube end. Lightly buff the tube end with Scotch-Brite or fine emery paper to

remove any surface marks.

2. Insert the tube and make sure it is aligned squarely in the fitting body.

3. Make sure the tube end is bottomed against the tube stop in the fitting body. This is

necessary to prevent movement of the tube while the nut forces the ferrule to grip the

tube and create a seal.

4. Never permit the fitting body to rotate during make-up; use two wrenches. Always

hold the fitting body with a wrench while tightening the tube nut.

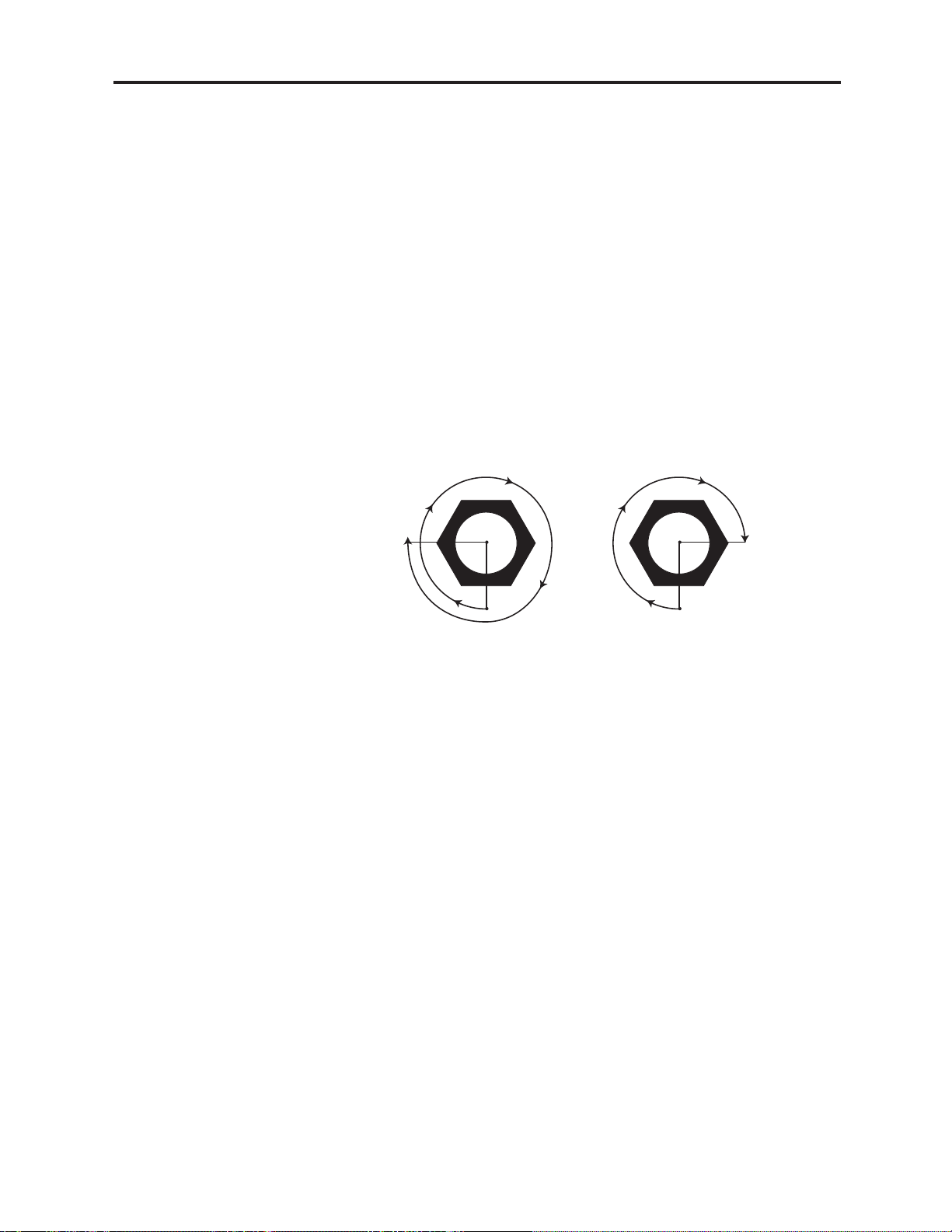

5. Always turn the tube nut the prescribed amount. With the tube against the tube stop

in the fitting body, tighten the tube nut finger-tight (Figure 1-12). For ¼-in. diameter

tubing, tighten the nut an additional 1¼ turns from finger-tight with a wrench. For

1/8-in. diameter tubing, tighten the nut an additional ¾ turn from finger-tight with a

wrench.

1

/

4-in. Tubing

1

/

8-in. Tubing

1

/

1

4 turn from

finger-tight

Figure 1-12: Compression Fitting Makeup

3

/

4 turn from

finger-tight

1.5.2 Compression Fitting Remake

When disassembling a compression fitting, mark the tube nut and the fitting body before

disassembly. To remake the connection, tighten the tube nut until the marks realign. A

slight torque increase indicates the ferrule is being re-sprung into sealing position. After

several remakes, it may become necessary to advance the tube nut slightly past the

original position. This advance need only be 15° to 20° (¼ to 1/3 of a hex flat). In situations where the existing tube with seated ferrule is to be used with a replacement fitting

body, tighten the tube nut until a slight torque increase indicates the ferrule is being resprung into sealing position. Advance the nut an additional 15° to 20°.

1.5.3 Compression Fitting Troubleshooting

Most leaks in compression fittings are the result of improper connections. Typically the

tube is either not aligned squarely in the fitting body before connection or the tube is not

secured against the stop during connection. In addition, overtightening may also result in

a cracked fitting body that will leak.

To check for leaks, pressurize the system and use an oxygen-compatible leak detector

(such as SNOOP) on the fitting. If bubbles form at the back of the nut between the nut and

the tube, you probably did not get a seal between the ferrule and the tube; misalignment

may be the cause. However, check the tube itself for a scratch or seam running along the

tube, allowing a leak to occur.

1-10 -

Introduction to the HELiOS System

B-701693-00 Rev. A

Page 21

HELiOS Liquid Oxygen System Technical Manual

If the leak detector forms bubbles at the front of the nut, between it and the fitting body,

then the leak is probably between the ferrule and the fitting’s tapered seat. Check this area

for imbedded dirt or cracks.

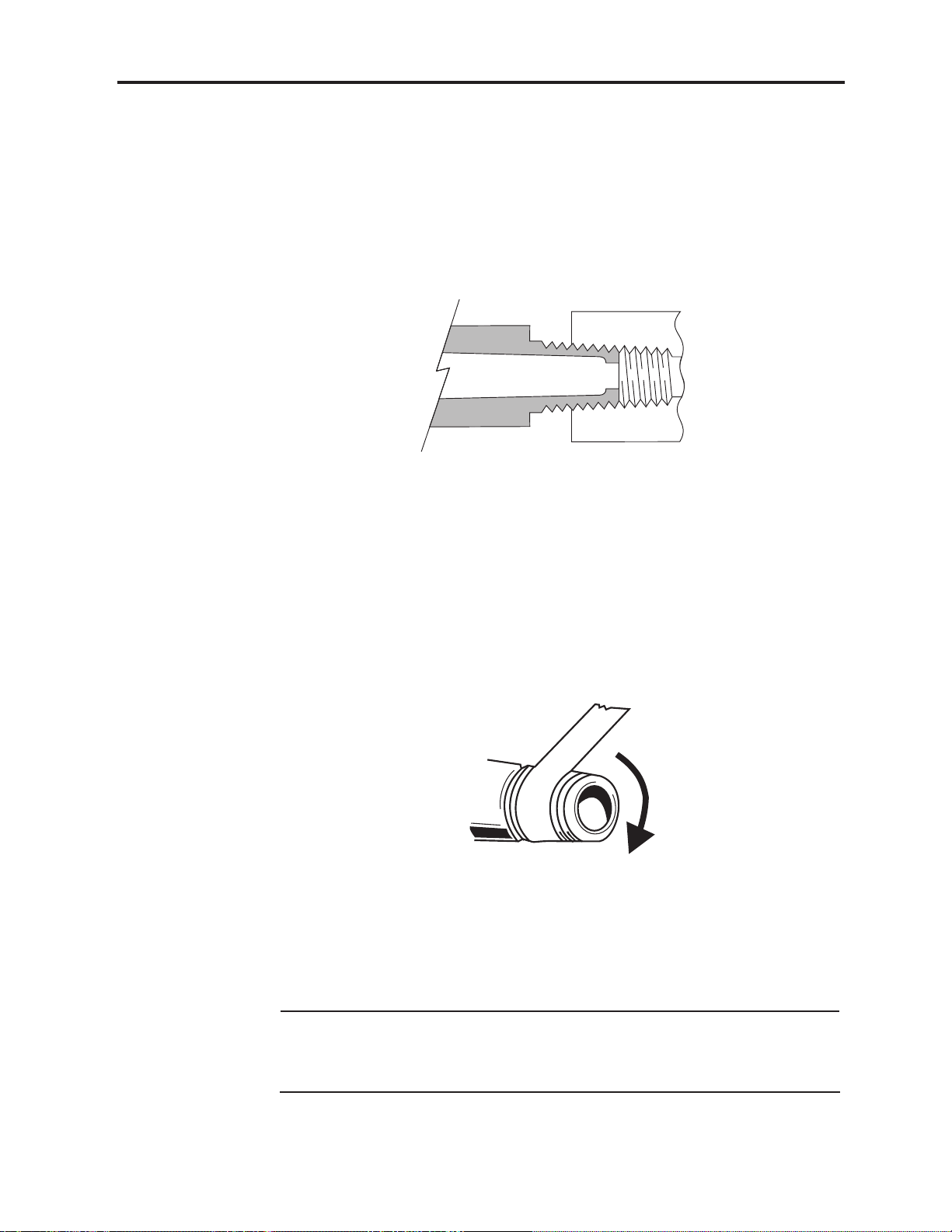

1.5.4 Tapered Pipe Thread (NPT) Makeup

Some components used in the HELiOS system have tapered pipe (NPT) threads (Figure 1-

13). NPT threads create leak-tight connections provided a thread sealant (such as Teflon

tape) is used on the threads.

Figure 1-13: NPT Fittings (National Pipe Tapered)

Perform the following steps when making up a NPT fitting:

1. Remove old thread sealant if present. Use a wire brush to remove sealant or dirt from

male and female threads of NPT fittings. Make sure contaminants do not drop into the

fittings during the cleaning process.

2. Apply thread sealant to the male threads. Apply two to three layers of Teflon tape to

the male threads starting two threads back from the end (Figure 1-14). Wrap the

Teflon tape clockwise (as viewed from thread end of fitting) to prevent unraveling

when installing the fitting.

Figure 1-14: Applying Teflon Tape

3. Assemble the fittings and tighten until snug. Since NPT fittings have tapered threads,

torque requirements increase as the fittings are tightened. Tighten NPT fittings until

you achieve a good seal (usually a minimum of three turns). Do not overtighten NPT

fittings. Overtightening may result in cracked fittings.

Note: Some NPT connections require alignment of one of the fittings in a certain

orientation. Do not back out the fitting if you are unable to achieve the proper

orientation as you tighten the fitting. This will typically result in a leak.

Disassemble and remake the fittings instead.

B-701693-00 Rev. A

Introduction to the HELiOS System

- 1-11

Page 22

HELiOS Liquid Oxygen System Technical Manual

1.5.5 Tapered Pipe Thread Troubleshooting

Leaks at NPT fittings are usually the result of improper application of thread sealant or

loosening of the fittings. To check for leaks, pressurize the system and use an oxygencompatible leak detector (such as SNOOP) on the fitting threads. If bubbles appear,

disassemble the fittings and remake (Section 1.5.4, Tapered Pipe Thread Makeup).

1.5.6 Flexible Tube Barbed Fitting Makeup

Flexible tube barbed fittings are used in the HELiOS system to create leak-tight pressure

connections where flexible tubes connect to components. The outside diameter of the

barb is slightly larger than the inside diameter of the flexible tubing. This creates an

interference fit sufficient to seal and secure the connection.

Perform the following steps to install a flexible tube on a barbed fitting:

1. Inspect the tube end. The tube end should be cut square and should be free of cuts

or tears. If there is an impression of the barb in the tube, cut the end of the tube off (if

the tube length is sufficient) or replace the tube.

2. Where required, install a brass collar on the tube so that the large end of the collar is

toward the barbed fitting.

3. Push the tube squarely onto the barb as far as possible.

4. Push the brass collar (if present) onto the tube end connected to the barbed fitting.

1.5.7 Flexible Tube Removal from Barbed Fitting

Perform the following steps to remove the flexible tube from a

barbed fitting:

1. Use a small flat-blade screwdriver to carefully back the brass collar (when used) off of

the barbed fitting.

2. Work the screwdriver between the end of the tube and the fitting body.

3. Simultaneously pull on the tube and pry the end of the tube back from the barb. Use

care to prevent damage to the barbed fittings.

1.6 RECOMMENDED TOOLS, TEST EQUIPMENT, AND SERVICE MATERIALS

Hand tools, test equipment, and materials used to properly service the HELiOS system

and maintain it in operable condition are listed in Table 1-1. If hand tools, test equipment,

and materials other than those specified in Table 1-1 are used, their functional characteristics such as quality and accuracy must be equal to, or better than, those specified in

the table. Tools, test equipment, and materials should be cleaned for oxygen service.

1-12 -

Introduction to the HELiOS System

B-701693-00 Rev. A

Page 23

HELiOS Liquid Oxygen System Technical Manual

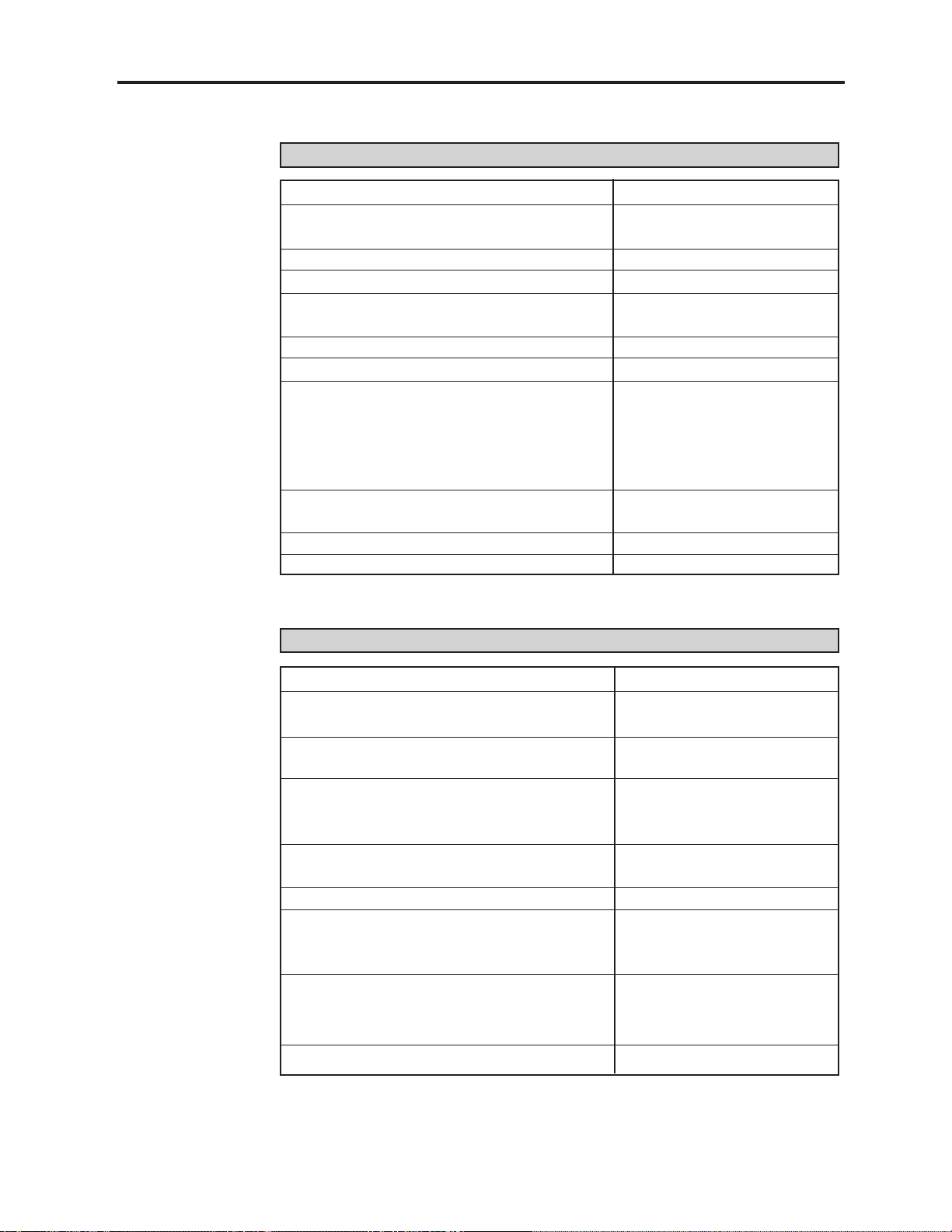

TABLE 1-1. RECOMMENDED TOOLS, TEST EQUIPMENT & SERVICE MATERIALS

Hex Key (Allen) Wrench – 3/32 in., 7/64 in., 5/32 in. Local Source

Open End Wrenches – ¼ in., ½ in., 9/16 in., 5/8 in.,

¾ in., 7/8 in., 1 in. Local Source

Adjustable Wrench – 10 in. Local Source

Pliers – 10 in. arc-joint, needlenose Local Source

Screwdrivers – medium flat blade, small flat blade,

medium Phillips blade, Torx T 10 Local Source

Side Cutters Local Source

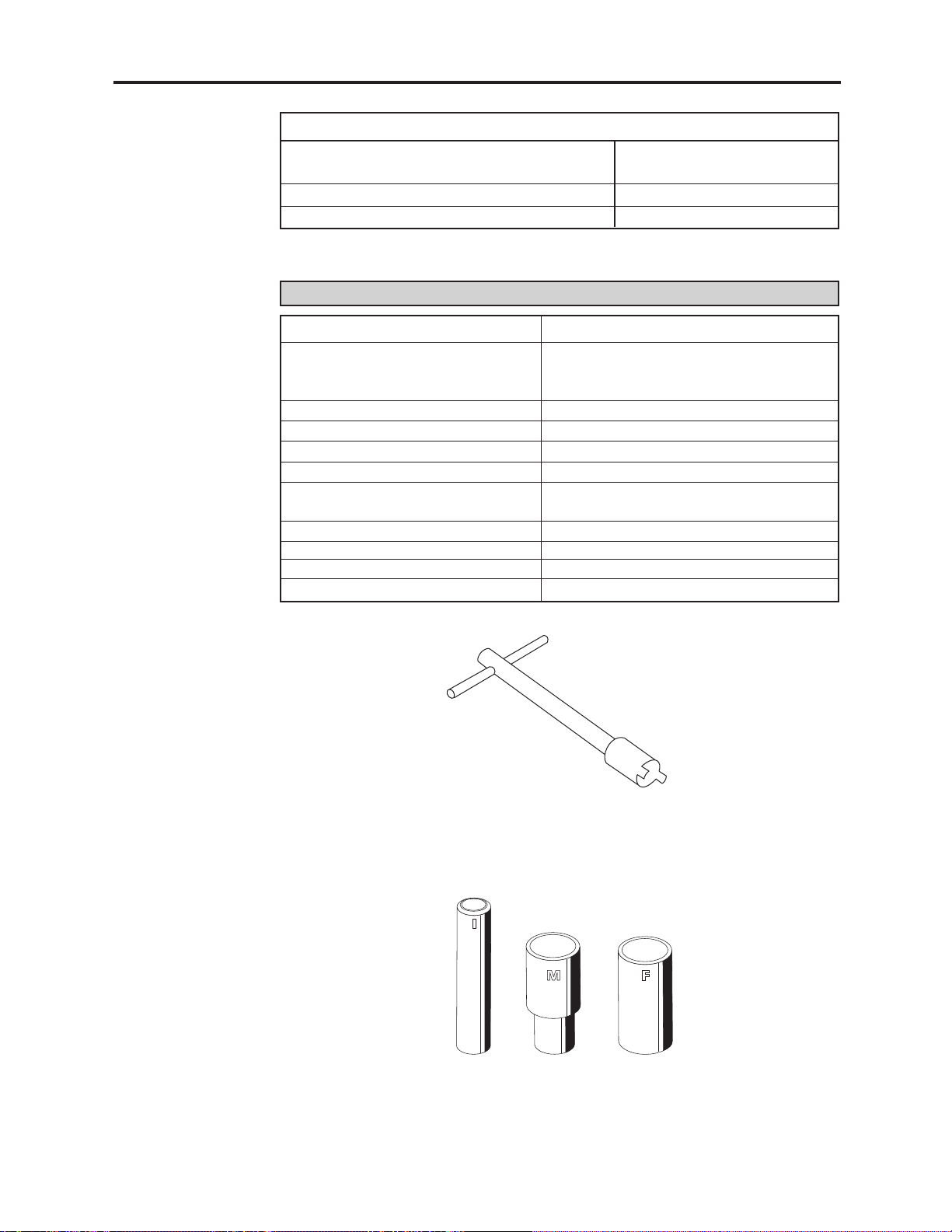

Vent Wrench (Figure 1-15) Puritan-Bennett No. B-775182-00

PB Fill Connector Cartridge Installation

Tools (Figure 1-16)

• Inner Plunger Puritan-Bennett No. B-775392-00

• Male Connector Sleeve Puritan-Bennett No. B-775393-00

• Female Connector Sleeve Puritan-Bennett No. B-775394-00

Micro Bar Clamp American Tool 6-in.

Clamp or Hemostat for 1/16 in. Flexible Tubing Local Source

Dental Pick Local Source

TOOLS

Quick-Grip #53006

TEST EQUIPMENT

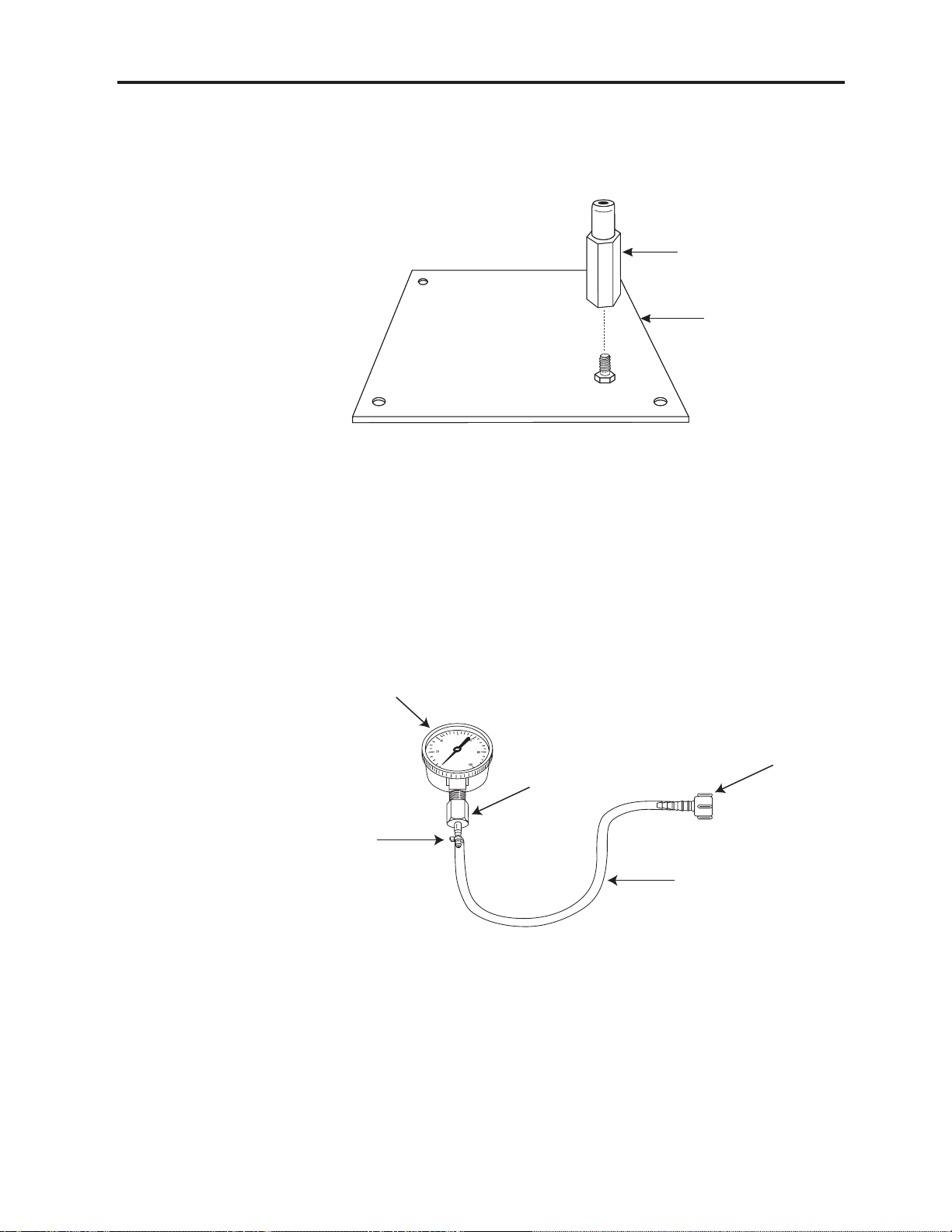

Portable Test Fixture (Figure 1-17) Puritan-Bennett No. B-778202-00

Test Pressure Gauge w/Tubing Adapter –

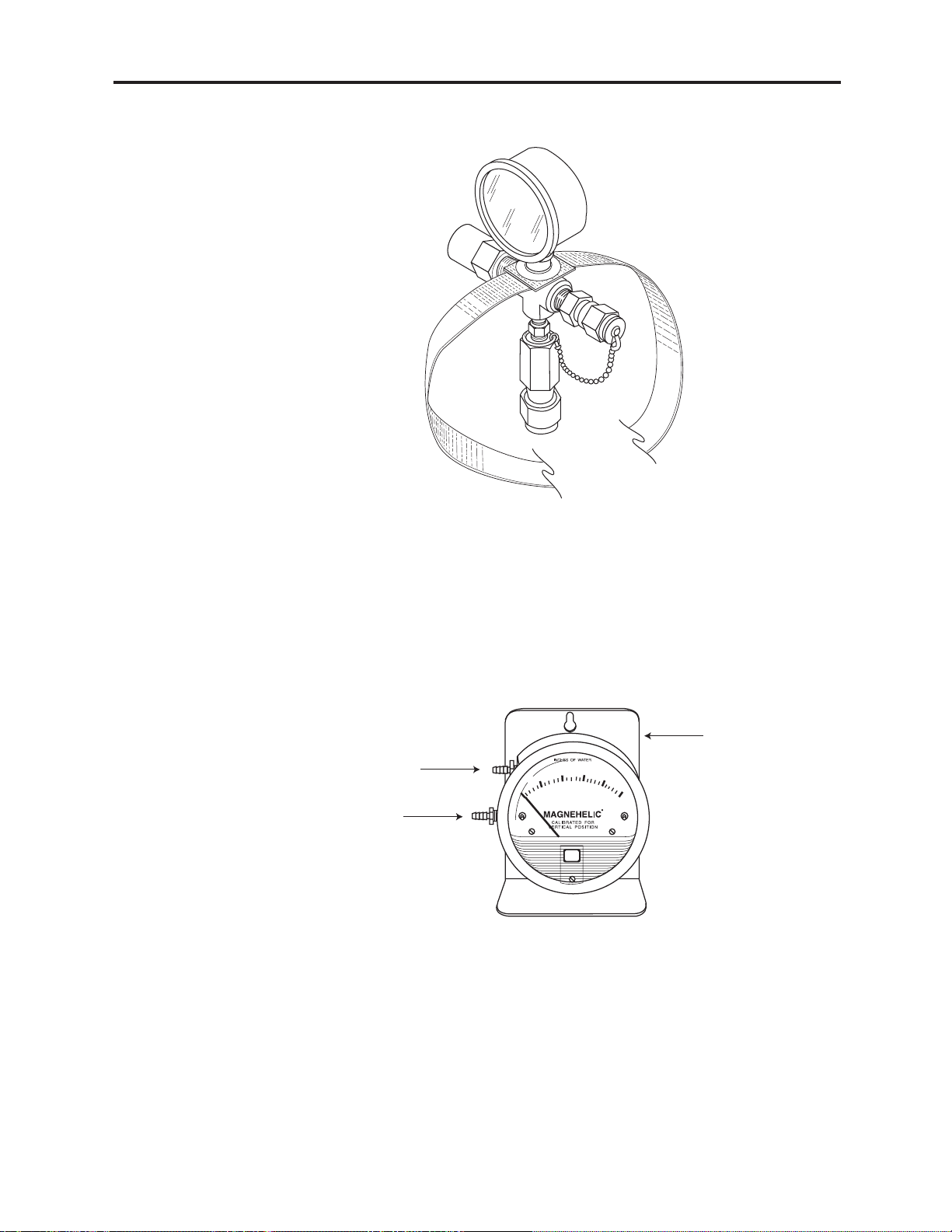

0-100 psig/0-690 kPa (Figure 1-18) Puritan-Bennett No. B-701732-00

Reservoir Pressurizing Fixture –

0-100 psig/0-690 kPa (Figure 1-19) Puritan-Bennett No. B-701731-00

HELiOS Reservoir Unit w/Liquid Oxygen Puritan-Bennett No. B-701652-00

Saturation at 24 psig (166 kPa) minimum or

(for Portable testing) Puritan-Bennett No. B-701653-00

Adjustable 0-100 psig (0-690 kPa)

gaseous oxygen source Local Source

Oxygen Compatible Leak Detector (Snoop) Puritan-Bennett No. B-775272-00

Calibrated Weight Scale – 0-200 lbs (0-91 kg)

with .02 lb (9.1 g) maximum graduation, accuracy, A&D Engineering Model FW

and repeatability 100-KA1 ( or equivalent)

Calibrated Test Flowmeters Brooks Instrument Division,

• 0-3 L/min oxygen, 1% full scale Emerson Electric Co.,

• 0-40 L/min oxygen, 1% full scale Hatfield, PA

0-10 L/min, 22 psig external flow control valve Puritan-Bennett No. B-701655-00

B-701693-00 Rev. B

Introduction to the HELiOS System

- 1-13

Page 24

HELiOS Liquid Oxygen System Technical Manual

OPTIONAL (PORTABLE ONLY)

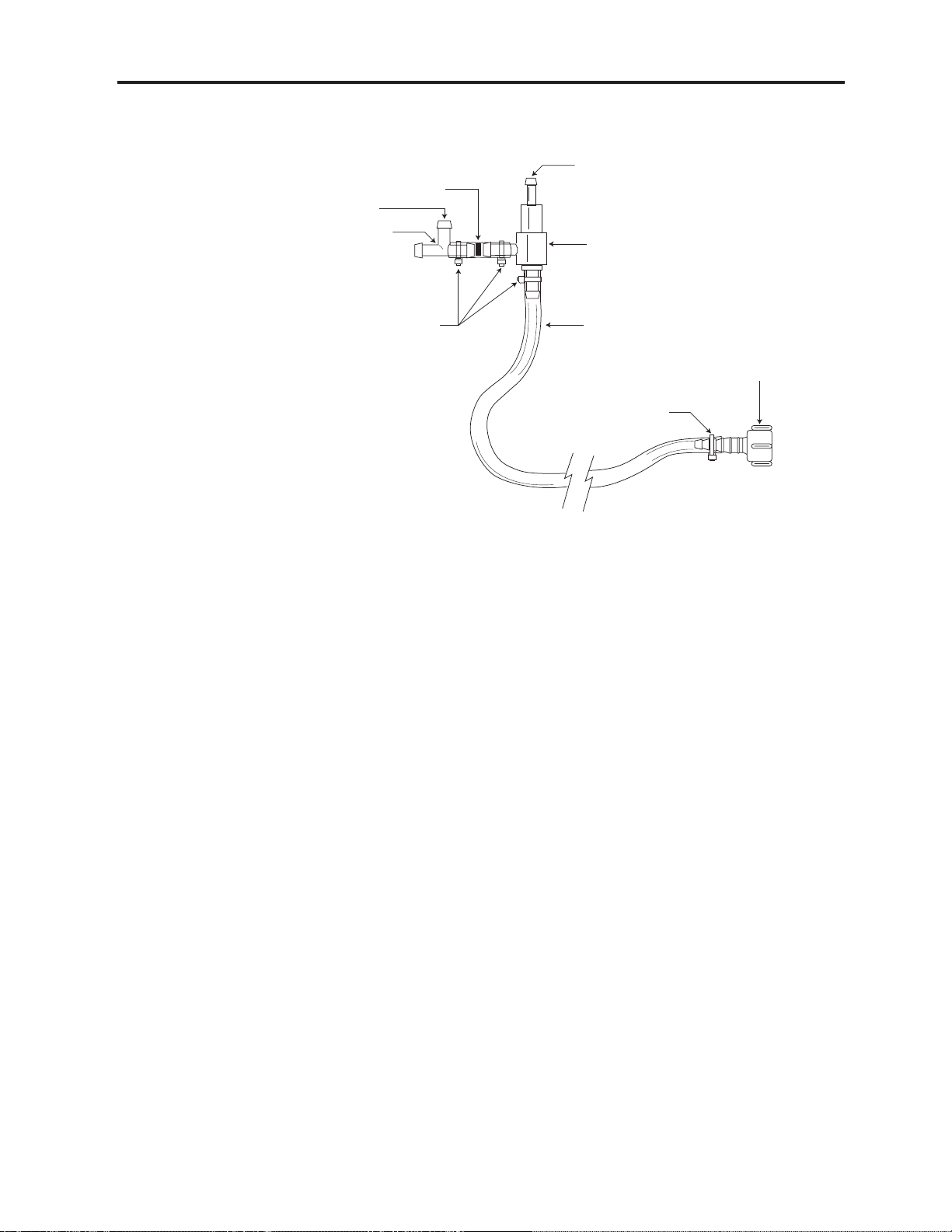

Magnehelic Gauge Assembly – 0-25 in. H2O

(Figure 1-20) Puritan-Bennett No. B-778208-00

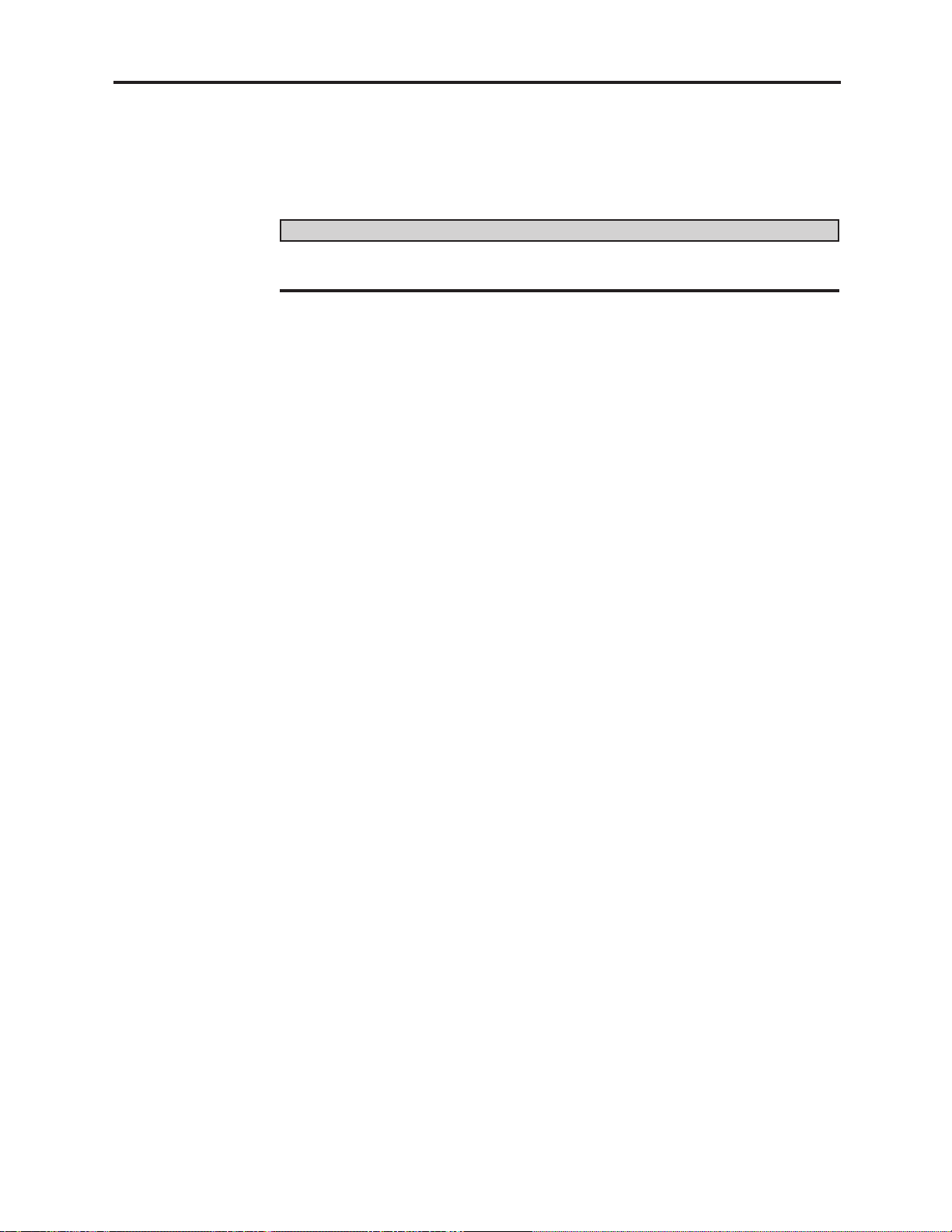

Jet/Venturi Assembly (Figure 1-21) Puritan-Bennett No. B-778210-00

Jet/Venturi Puritan-Bennett No. B-778213-00

SERVICE MATERIALS

Dual Lumen Cannula (Portable) Puritan-Bennett No. B-778057-00 (7 ft./2.1 m)

Oxygen DISS Wye Outlet Adapter w/ Bay Corp., Westlake, OH-Part No. YO-124DV;

Demand Check Valve Outlets Precision Medical, Inc., Northhampton, PA-

Part No. 7211

Size 00 Rubber Stopper VWR Scientific, Batavia, IL-Part No. 59590-084

Tee Connector – 3/16 in. I.D. Tubing Puritan-Bennett No. B-778211-00

3/16 in. (5 mm) I.D. Oxygen Tubing Puritan-Bennett No. B-778214-00 (4 ft./1.2 m)

Tie Wrap, 4-in./10 cm Puritan-Bennett No. B-775091-00

Lubricant - Krytox 240 AC

Fluorinated Grease (DuPont) Puritan-Bennett No. B-775239-00

Isopropyl Alcohol Local Source

Thread Sealant – 3/16 in. Teflon Tape Local Source

Cloth – Lint Free Local Source

HELiOS Oxygen Supply Tube Coupler Puritan-Bennett No. B-701686-00

1-14 -

Introduction to the HELiOS System

Figure 1-15: Vent Wrench

B-775182-00

Figure 1-16: Fill Connector Cartridge Installation Tools

B-775392-00 (I), B-775393-00 (M), B-775394-00 (F)

B-701693-00 Rev. B

Page 25

HELiOS Liquid Oxygen System Technical Manual

Figure 1-17: Portable Test Fixture

B-778202-00

Portable Adapter

P/N B-778203-00

Baseplate

P/N B-778204-00

100 psig Pressure Gauge

P/N B-776004-00

Small Tie Wrap

P/N B-775091-00

Figure 1-18: Test Pressure Gauge w/Tubing Adapter

P/N B-775269-00

B-701732-00

Tubing Barb Adaptor

Disposable Tubing

Barb Adaptor

P/N B-776945-00

Tubing - 3/16 in. I.D. x 4 ft.

(5 mm I.D. x 1.2 m)

P/N B-778214-00

B-701693-00 Rev. B

Introduction to the HELiOS System

- 1-15

Page 26

High Pressure Port

Bracket

P/N B-776594-00

Low Pressure Port

HELiOS Liquid Oxygen System Technical Manual

Figure 1-19: Reservoir Pressurizing Fixture

B-701731-00

Figure 1-20: Magnehelic Gauge Assembly

B-778208-00

1-16 -

Introduction to the HELiOS System

B-701693-00 Rev. B

Page 27

HELiOS Liquid Oxygen System Technical Manual

Bleed

Port

P/N B-778211-00

Restrictor

.024 in. (.61 mm)

P/N B-778212-00

Tee

Small- Tie Wrap

P/N B-775091-00

Bleed

Port

Jet/Venturi

P/N B-778213-00

Tubing - 3/16 in. I.D. x 4 ft.

(5 mm I.D. x 1.2 mm)

P/N B-778214-00

Small-Tie Wrap

P/N B-775091-00

Figure 1-21: Jet/Venturi Assembly

B-778210-00

Disposable Tubing

Barb Adapter

P/N B-776945-00

1.7 TEST EQUIPMENT CALIBRATION

Periodically calibrate test equipment (pressure gauges, weight scales, flowmeters, etc.) to

ensure the reliable operation of the HELiOS liquid oxygen system. Use your prior experience to determine calibration frequency for test equipment. Using a default six-month

schedule is typically acceptable; however, check test equipment with a high usage rate

once a month. Once you have begun using the piece of test equipment, you may adjust

the calibration schedule. If, for example, you begin calibrating your test pressure gauge

every six months and it is repeatedly out of calibration when you check it, you should test

calibration more frequently. Eventually, you should determine an interval where your

equipment is in calibration each time you check it.

Before using any piece of test equipment that has been dropped or mishandled, always

perform a calibration check. Test instruments that are used to test the performance of

HELiOS equipment can be sent to an accredited calibration lab for calibration testing.

Another option is to keep a calibrated master test instrument (pressure gauge, flowmeter,

etc.) on site as a reference to check your field test instruments. Look in the telephone

yellow pages under Calibration for the location of an accredited calibration lab. An

example of an accredited calibration lab is:

PTS Calibrations LLC, 5603 W. Raymond St., Suite 1, Indianapolis, IN 46241

Telephone: 317-487-2378

Refer to ISO 10012-1 (Quality Assurance Requirements for Measuring Equipment) for

additional information.

B-701693-00 Rev. B

Introduction to the HELiOS System

- 1-17

Page 28

1.8 ACCESSORIES

Accessories for the HELiOS Reservoir and Portable units are listed in Table 1-2.

Table 1-2

Description Part Number Location

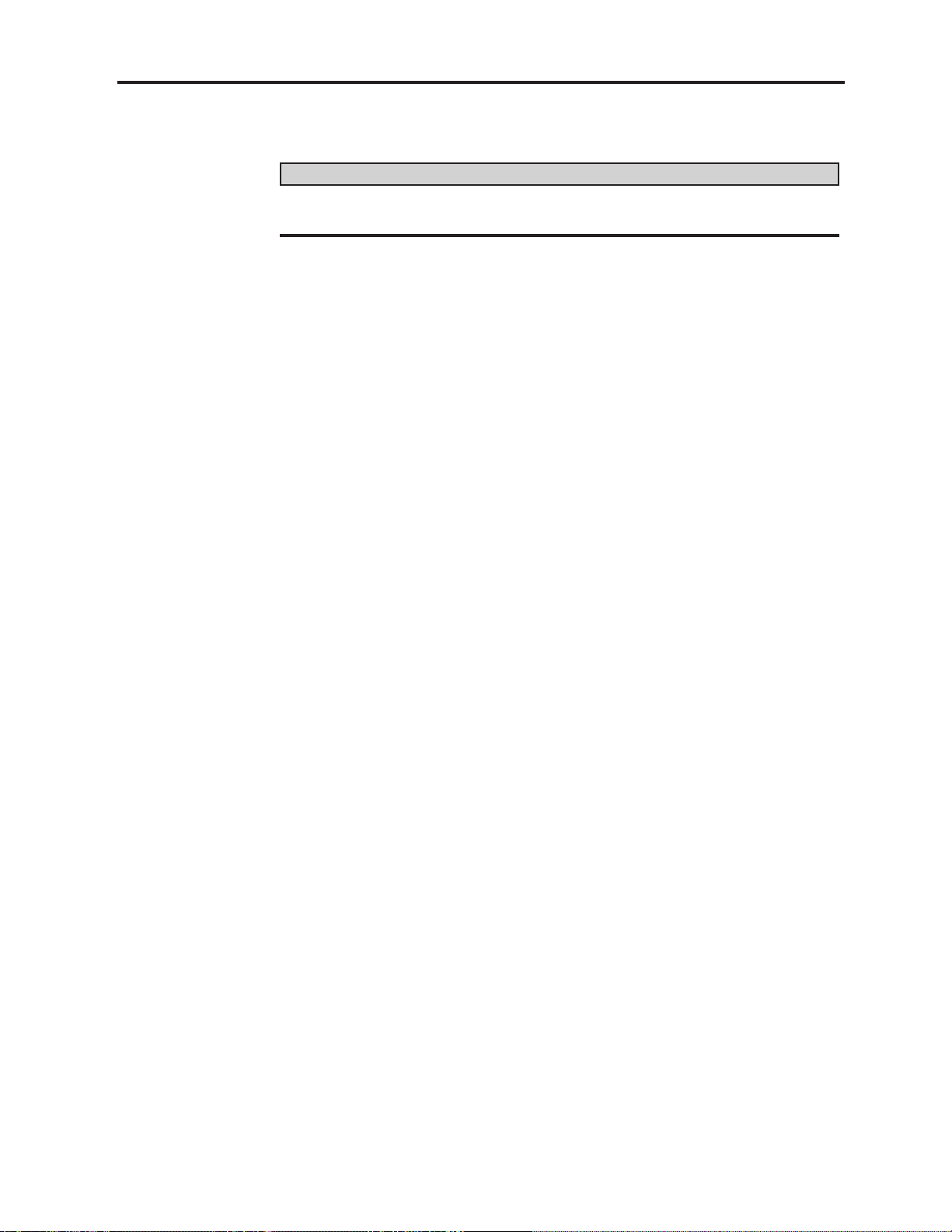

1. Van Companion Assembly (Delivery Cart) B-775462-00 Figure 1-22

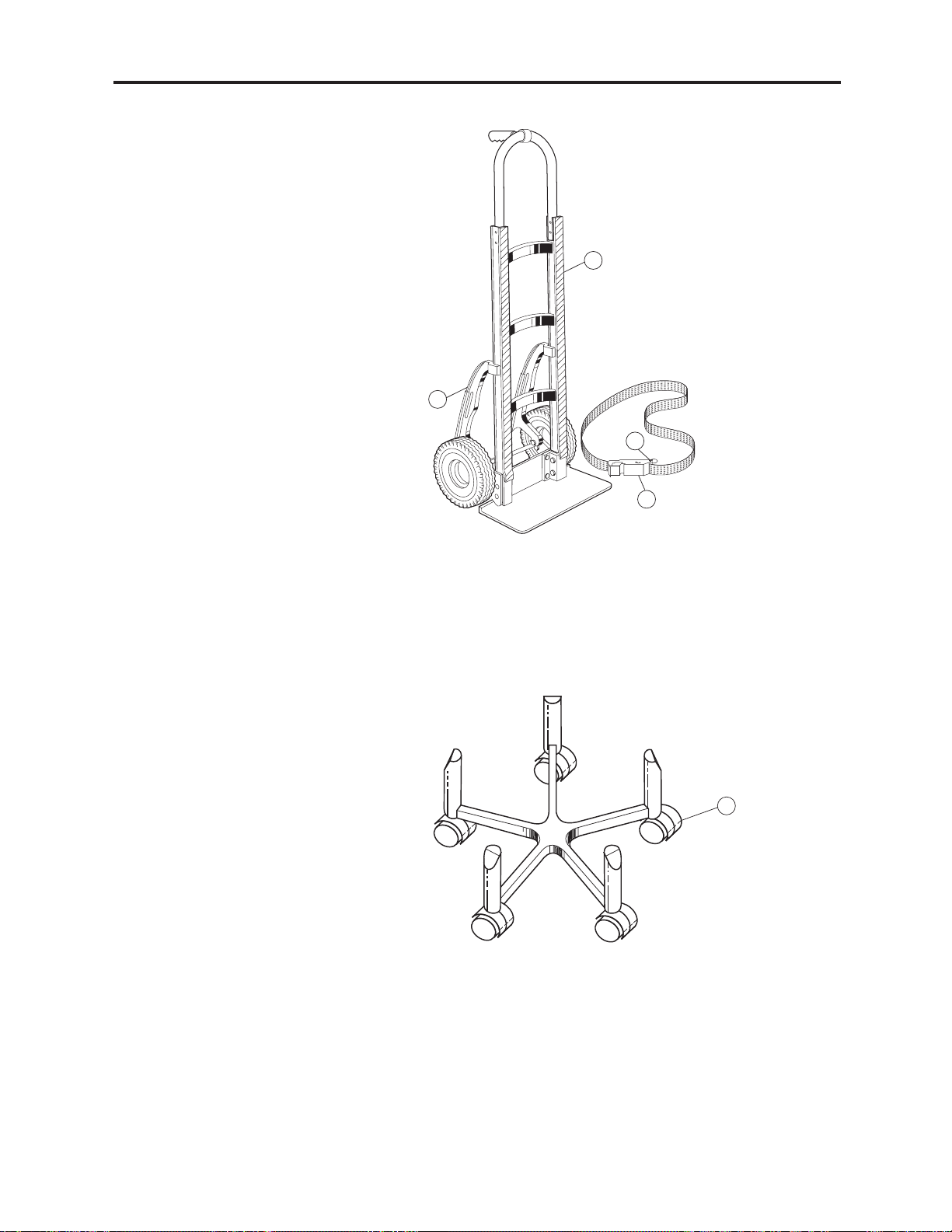

2. Roller base Assembly B-701537-00 Figure 1-23

HELiOS Liquid Oxygen System Technical Manual

HELiOS ACCESSORIES

• Strap and Buckle Assembly B-775477-00 Figure 1-22, #1

• Faspin B-775478-00 Figure 1-22, #2

• Pads (2 Required) B-775476-00 Figure 1-22, #3

• Wear Strips (2 Required) B-776169-00 Figure 1-22, #4

• Caster (5 Required) B-701536-00 Figure 1-23, #1

3. Transfer Line Assembly (6 ft./1.8 m) B-775288-00 Figure 1-24

Transfer Line Assembly (10 ft./3 m) B-775289-00 Figure 1-24

• Transfer Hose (6 ft./1.8 m) B-775280-00 Figure 1-24, #1

• Transfer Hose (10 ft./3 m) B-775281-00 Figure 1-24, #1

• Source Adapter Assembly B-775279-00 Figure 1-24, #2

• Relief Valve (150 psi/1035 kPa) B-775273-00 Figure 1-24, #3

• Source Adapter B-775313-00 Figure 1-24, #4

• Fill Adapter Assembly B-775278-00 Figure 1-24, #5

• Fill Adapter B-775312-00 Figure 1-24, #6

• Fill Adapter Seal B-775262-00 Figure 1-24, #7

• Female Fill Connector B-775264-00 Figure 1-24, #8

• Union, 5/8-in. Flare (2/Transfer Line) B-775277-00 Figure 1-24, #9

4. Universal Adapter Kit B-775461-00 Figure 1-25

• Male Flare Adapter B-775342-00 Figure 1-25, #1

• Female Flare Adapter B-775418-00 Figure 1-25, #2

• PB Fill Connector/Tee Assembly B-775276-00 Figure 1-25, #3

1-18 -

Introduction to the HELiOS System

B-701693-00 Rev. B

Page 29

HELiOS Liquid Oxygen System Technical Manual

Table 1-2 (cont.)

Description Part Number Location

5. Shipping Carton, HELiOS 36 B-701690-00 Not Shown

• Corner Post (4 Required) B-702011-00 Not Shown

Shipping Carton, HELiOS 46 B-701691-00 Not Shown

• Corner Post (4 Required) B-702011-00 Not Shown

Shipping Carton, HELiOS 300 Portable B-701688-00 Not Shown

• Insert (1 Required) B-701689-00 Not Shown

6. Dual Lumen Cannula (7 ft./2.1 m) B-778057-00 Figure 1-26

(Sense and delivery in both nostrils)

Dual Lumen Cannula (5 ft./1.5 m) 6-778058-00 Figure 1-26

(Sense and delivery in both nostrils)

HELiOS ACCESSORIES

Dual Lumen Cannula (3 ft./0.9 m) B-701511-00 Figure 1-26

(Sense and delivery in both nostrils)

Dual Lumen Cannula (7 ft./2.1 m) B-701930-00 Figure 1-26

(Sense and delivery in separate nostrils)

Dual Lumen Cannula (4 ft./1.2 m) B-701931-00 Figure 1-26

(Sense and delivery in separate nostrils)

7. Oxygen Supply Tube Assy. (50 ft./15.2 m) B-701656-00 Figure 1-27

8. Oxygen Supply Extension Tube

(50 ft./15.2 m) B-701432-00 Not Shown

9. Reservoir Fill Connector Cover B-777095-00 Figure 1-28

10. H-300 Portable Belt Pack B-701654-00 Not Shown

11. HELiOS Operating Instructions B-701641-00 Not Shown

12. 0-10 L/min Flow Control Valve, B-701655-00 Not Shown

22 PSI (152 kPa)

B-701693-00 Rev. B

Introduction to the HELiOS System

- 1-19

Page 30

HELiOS Liquid Oxygen System Technical Manual

3

4

2

1

Figure 1-22: Van Companion Delivery Cart

Figure 1-23: Roller Base

1

1-20 -

Introduction to the HELiOS System

B-701693-00 Rev. A

Page 31

HELiOS Liquid Oxygen System Technical Manual

2

Figure 1-24: Transfer Line Assembly

NOTE: Install the universal adapter kit on the transfer line assembly to allow the

filling of both Puritan-Bennett and liquid oxygen units with side-fill connectors

with the same transfer line. (Installs between the side-fill adapter and the

transfer hose.)

Figure 1-25: Universal Adapter Kit

B-701693-00 Rev. A

Introduction to the HELiOS System

- 1-21

Page 32

HELiOS Liquid Oxygen System Technical Manual

Figure 1-26: Dual Lumen Cannula

1-22 -

Introduction to the HELiOS System

Figure 1-27: Oxygen Supply Tube

Figure 1-28: Reservoir Fill Connector Cover

B-701693-00 Rev. A

Page 33

HELiOS Liquid Oxygen System Technical Manual

Section

RESERVOIR GENERAL INFORMATION

This section provides general information on the HELiOS Reservoir liquid oxygen system

(Figure 2-1). This information includes a product description; performance specifications;

unpacking, installation, and repacking procedures; description of controls, indicators, and

connectors; filling instructions; operating procedures; and maintenance.

2

2.1 PRODUCT DESCRIPTION

2.1.1 HELiOS Standard Reservoir

The HELiOS Standard Reservoir is part of an innovative liquid oxygen system that

provides 24 hour per day home oxygen therapy with typically less than one liquid oxygen

delivery per month. The Reservoir provides the patient with a source of liquid oxygen to

fill any HELiOS Portable for ambulatory use and a source of gaseous oxygen to power the

HELiOS 300 Portable at home. The unique design of the Reservoir virtually eliminates

oxygen evaporative losses both in standby mode and when supplying gaseous oxygen to

a patient. The Reservoir is available in two models that are nearly identical with the

exception of the liquid oxygen storage capacity. The H-36 holds 36 liters (85 lbs/38.6 kg) of

liquid oxygen while the H-46 holds 46 liters (110 lbs/49.9 kg) of liquid oxygen.

The Reservoir uses the popular Puritan Bennett top fill connector and is compatible with

Puritan Bennett Companion filling equipment (vent wrench, transfer hose assembly,

source tank). The Reservoir requires a minimum 24 psig (166 kPa) saturated liquid oxygen

to operate and may be filled using standard or fast fill techniques. A standard integral

pressure indicator on the unit helps the filling technician maintain proper liquid oxygen

saturation pressure during the fill. An electronic contents indicator uses reliable, differential pressure based level sensing technology to provide accurate and easy to read liquid

oxygen contents indication. The 9-volt battery powered contents indicator incorporates

H-46, U-46

Figure 2-1: HELiOS Reservoir Units

H-36, U-36

B-701693-00 Rev. C

Reservoir General Information

- 2-1

Page 34

HELiOS Liquid Oxygen System Technical Manual

high visibility LEDs for indicating liquid oxygen contents. LEDs also warn of low battery

and low contents conditions.

The Reservoir provides 22 psig (152 kPa) gaseous oxygen at up to 10 L/min continuous

flow through a Diameter Index Safety System (DISS) connection. Oxygen outlet pressure

is regulated at 22 psig (152 kPa) since the unique design of the Reservoir allows internal

pressure to climb as high as 45 psig (311 kPa) in standby. A flexible oxygen supply tube,

attached to the outlet connector, provides gaseous oxygen to power the H-300 Portable.

To fill a HELiOS Portable with liquid oxygen, the patient merely engages the quick connect

couplings on the Portable and Reservoir. The patient then opens the Portable vent valve

to begin filling and closes the vent valve a short time later to terminate the fill. Reservoir

pressure transfers slightly less than one pound of liquid oxygen into an H-300 Portable.

Depressing a release button disengages the Portable from the Reservoir. Due to different

operational specifications, Puritan Bennett Companion system portables cannot be filled

from the HELiOS Standard Reservoir.

For a more technical description of how the Reservoir operates, refer to Section 3, Theory

of Operation.

2.1.2 HELiOS Universal Reservoir

The HELiOS Universal Reservoir retains many of the features of the Standard Reservoir

while being compatible with Companion portable units. The Reservoir provides the patient

with a source of liquid oxygen to fill any Companion portable or H300 Portable for

ambulatory use and provides a source of gaseous oxygen to power the HELiOS 300

Portable at home. The unique design of the Reservoir minimizes oxygen evaporative

losses both in standby mode and when supplying gaseous oxygen to a patient. The

Reservoir is available in two models that are nearly identical with the exception of the

liquid oxygen storage capacity. The U-36 holds 36 liters (85 lbs/38.6 kg) of liquid oxygen

while the U-46 holds 46 liters (110 lbs/49.9 kg) of liquid oxygen.

The Reservoir uses the popular Puritan Bennett top fill connector and is compatible with