Page 1

Title: Companion 1000 / T Date: February 2008

By: Puritan Bennett division of

Covidian

File = Companion-T.doc

DISCLAIMER: THIS PROCEDURE PROVIDED "AS IS"

AND WITH POSSIBLE FAULTS. USER MUST VERIFY

BEFORE USE. NEITHER PROVIDER NOR WEBSITE

ASSUMES ANY RESPONSIBILITY FOR ITS USE.

1. General

Applies to Puritan Bennett Companion, models T and 1000. See

Appendix for differences.

2. Reference Documents

Companion 1000 / Companion T Technical Manual (English)

P/N: B-701964-00 -orhttp://rcsoxygen.com/Pub%20Docs/puritan1.pdf

3. Tools / Fixtures

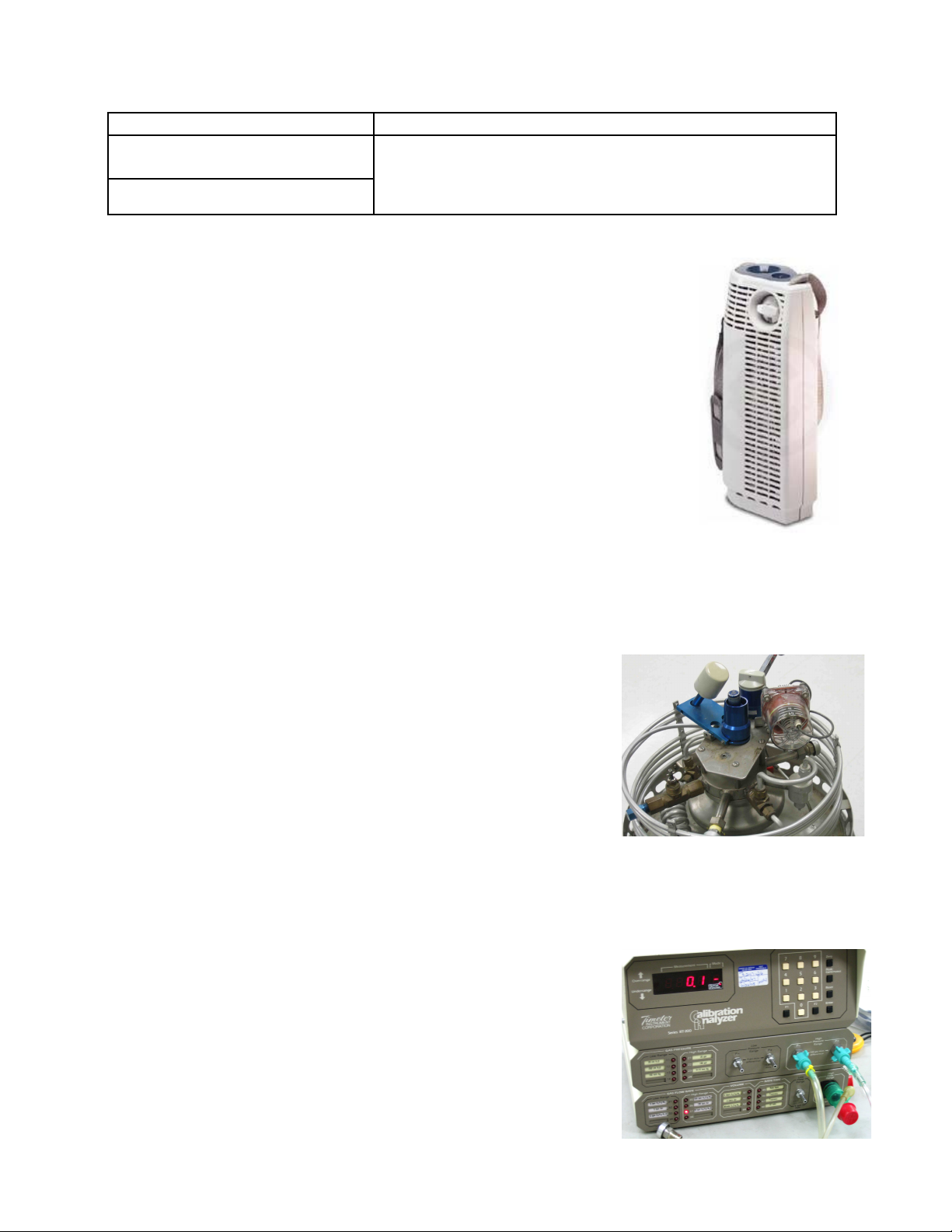

Oxygen Source Tank (The picture shows the Companion Stationary

Unit – which is charged only with gaseous Oxygen for this testing.)

RT-200 Flow/Pressure Analyzer

Setup for the RT200:

a) At E_ _ _, enter 37, <Enter> (sets 20LPM oxygen flow)

b) At 00000, enter 0 0, <Enter> which brings up STP settings; hit “0” sequentially to rotate

thru choices.

c) At StP, hit F2 (brings up P760 -- 760 is sea-level atomospheric pressure)

d) Hit 6, 2, 0 <Enter> 620 mmHg is ATM at 5280 feet.

e) Hit the zero-the- meter button.

f) Assuming use of 100% O2, hit <F1>, enter C100, <Enter>.

4. Basic PM Procedure .

4.1. Physical Inspection.

Replace strap and either or both case halves if necessary.

Note: Be sure to include/order labels if required.

4.2. Safety / Overpressure Valve Check. Connect unit to 22-25 lbs of compressed oxygen (or

air). See photo for typical charging stand. As the unit’s internal pressure approaches

20-22 lbs, this relief valve will be audible. Some other valve designs will actually allow

pressure to overshoot to the charging pressure, but in about 10 – 20 seconds will bleed

down to the 20 –22 lbs target.

4.3. Leak Check (Short Version) -- Connect unit to 22-25 lbs

of compressed oxygen (or air). See photo for typical

charging stand. With flow control = 0, connect output

of unit to the pressure gage (0 - 20lb) input on the

analyzer. Turn output to 0.5 (lowest selection). The

pressure should not drop by more than 0.1 lb per minute.

Page 2

4.4. Leak Check (Long Version). Charge unit to 20-22 lbs. After four hours, the pressure

should still be above 10 lbs *. If fail, use the “bubble fluid” for a leak check of fittings.

Caution: If opening the tube/fitting to the flow selector, be careful not to lose the very

small screen.

* This value the result of filling with gaseous, not liquid oxygen.

4.5. Flow Check

Note: Easier to check all flows before reassembling, not after. At higher flows (> 5 LPM) it is

usually necessary to place the D.U.T charging on the large oxygen source tank in order to

maintain enough pressure to get acceptable flow readings on the RT200.

Connect unit to the flow input of the analyzer. Slowly and sequentially select flows

starting at 0.5 LPM. The corresponding flow reading limits are in the PB tech manual.

.

4.6. Complete the work order form.

5. Extended PM/Repair Procedure

5.1. Be sure to include rubber

feet and warning labels if a

new case(s) is installed.

Use a “transparent

protector” over the

inspection sticker. Normal

PM schedule for this

device is one year.

5.2. Internal Leak

Troubleshooting. Spray a

light soapy liquid onto all

pneumatic fittings to check

for bubbles and therefore

leak identification.

APPENDIX

The Companion 1000 provides continuous oxygen flow at any one of 11 preset flow rates

up to 6 L/min. The Companion T provides continuous oxygen flow at any one of 11 preset

flow rates up to 15 L/min.

Loading...

Loading...