Page 1

840

Ventilator System

Part No. 4-075609-00

Rev. G

October 2006

Technical Reference Manual

Operator’s and

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

Page 2

Page 3

Copyright Information

Copyright 2003, 2005, 2006 Puritan-Bennett Corporation. All rights reserved. The

TM

840

Ventilator System is manufactured in accordance with Puritan Bennett

proprietary information, covered by one or more of the following U.S. Patents and

foreign equivalents: 4,954,799; 5,161,525; 5,271,389; 5,301,921; 5,319,540;

5,339,807; 5,368,019; and 5,390,666. 840, 800 Series, DualView, SandBox,

SmartAlert, Flow-by, and PTS 2000 are trademarks of Puritan-Bennett Corporation.

The information contained in this manual is the sole property of Puritan-Bennett

Corporation and may not be duplicated without permission. This manual may be

revised or replaced by Puritan-Bennett Corporation at any time and without

notice. You should ensure that you have the most current applicable version of

this manual; if in doubt, contact Puritan-Bennett Corporation or visit the

Puritan Bennett product manual web page at:

http://www.mallinckrodt.com/respiratory/resp/Serv_Supp/

While the information set forth herein is believed to be accurate, it is not a

substitute for the exercise of professional judgment.

The ventilator should be operated and serviced only by trained professionals.

Puritan Bennett’s sole responsibility with respect to the ventilator, and its use, is as

stated in the limited warranty provided.

Nothing in this manual shall limit or restrict in any way Puritan Bennett’s right to

revise or otherwise change or modify the equipment (including its software)

described herein, without notice. In the absence of an express, written agreement

to the contrary, Puritan Bennett has no obligation to furnish any such revisions,

changes, or modifications to the owner or user of the equipment (including its

software) described herein.

Rx ONLY

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

i

Page 4

Applicability

The information in this manual applies to

ventilator versions

840

manufactured or updated after August 2005. Some of this

information may not apply to earlier versions. Contact your

Puritan Bennett representative if in doubt.

Definitions

This manual uses three special indicators to convey information

of a specific nature. They include:

Warning

Indicates a condition that can endanger the patient or the

ventilator operator.

Caution

Indicates a condition that can damage the equipment.

NOTE:

Indicates points of particular emphasis that make

operation of the ventilator more efficient or

convenient.

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

ii

Page 5

Warnings, cautions, and notes

Please take the time to familiarize yourself with the following

safety considerations, special handling requirements, and

regulations that govern the use of the

• To ensure proper servicing and avoid the possibility of physical

injury, only qualified personnel should attempt to service or

make authorized modifications to the ventilator.

The user of this product shall have sole responsibility for any

ventilator malfunction due to operation or maintenance

performed by anyone not trained by Puritan Bennett.

• To avoid an electrical shock hazard while servicing the

ventilator, be sure to remove all power to the ventilator by

disconnecting the power source and turning off all ventilator

power switches.

• To avoid a fire hazard, keep matches, lighted cigarettes, and all

other sources of ignition (e.g., flammable anesthetics and/or

heaters) away from the

Ventilator System and oxygen

840

hoses.

Do not use oxygen hoses that are worn, frayed, or

contaminated by combustible materials such as grease or oils.

Textiles, oils, and other combustibles are easily ignited and

burn with great intensity in air enriched with oxygen.

Ventilator System.

840

In case of fire or a burning smell, immediately disconnect the

ventilator from the oxygen supply, facility power, and backup

power source.

• When handling any part of the

Ventilator System, always

840

follow your hospital infection control guidelines for handling

infectious material.

Puritan Bennett recognizes that cleaning, sterilization,

sanitation, and disinfection practices vary widely among

health care institutions. It is not possible for Puritan Bennett

to specify or require specific practices that will meet all needs,

or to be responsible for the effectiveness of cleaning,

sterilization, and other practices carried out in the patient care

setting.

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

iii

Page 6

• Patients on life-support equipment should be appropriately

monitored by competent medical personnel and suitable

monitoring devices.

The

Ventilator System is not intended to be a

840

comprehensive monitoring device and does not activate

alarms for all types of dangerous conditions for patients on

life-support equipment.

• For a thorough understanding of ventilator operations, be sure

to thoroughly read this manual before attempting to use the

system.

• Before activating any part of the ventilator, be sure to check

the equipment for proper operation and, if appropriate, run

SST as described in this manual.

• Do not use sharp objects to make selections on the graphic

user interface (GUI) display or keyboard.

• US federal law restricts this device to sale by or on the order of

a physician.

• Check the ventilator periodically as outlined in the

840 Ventilator System Service Manual

; do not use if defective.

Immediately replace parts that are broken, missing, obviously

worn, distorted, or contaminated.

• An alternative source of ventilation should always be available

when using the

Ventilator System.

840

Warranty

The

and workmanship in accordance with Puritan Bennett Medical

Equipment Warranty for 2 years from the time of sale. Keep a

maintenance record to ensure the validity of the warranty.

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

iv

Ventilator System is warranted against defects in material

840

Page 7

Year of manufacture

The graphic user interface (GUI), breath delivery unit (BDU),

backup power source (BPS), and compressor contain a specific

year of manufacture applicable only for that assembly. The year of

manufacture is indicated by the fifth and sixth digits of the serial

number which is located at the back panel of the GUI, BDU, and

BPS, and the side panel of the compressor.

Manufacturer

Puritan-Bennett Corporation

4280 Hacienda Drive

Pleasanton, CA

USA

Electromagnetic susceptibility

The

IEC 60601-1-2:2004 (EMC Collateral Standard), including the Efield susceptibility requirements at a level of 10 volts per meter, at

frequencies from 80 MHz to 2.5 GHz, and the ESD requirements

of this standard.

Ventilator System complies with the requirements of

840

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

v

Page 8

However, even at this level of device immunity, certain

transmitting devices (cellular phones, walkie-talkies, cordless

phones, paging transmitters, etc.) emit radio frequencies that

could interrupt ventilator operation if operated in a range too

close to the ventilator. It is difficult to determine when the field

strength of these devices becomes excessive.

Practitioners should be aware that radio frequency emissions are

additive, and that the ventilator must be located a sufficient

distance from transmitting devices to avoid interruption. Do not

operate the ventilator in a magnetic resonance imaging (MRI)

environment.

Warning

Accessory equipment connected to the power receptacle,

analog, and digital interfaces must be certified according

to IEC 60601-1. Furthermore, all configurations shall

comply with the system standard IEC 60601-1-1. Any

person who connects additional equipment to the power

receptacle, signal input part, or signal output part of the

840 ventilator configures a medical system, and is therefore

responsible for ensuring that the system complies with the

requirements of the system standard IEC 60601-1-1. If in

doubt, consult Puritan Bennett Technical Services at

1.800.255.6774 or your local representative.

This manual describes possible ventilator alarms and what to do if

they occur. Consult with your institution’s biomedical

engineering department in case of interrupted ventilator

operation, and before relocating any life support equipment.

Customer assistance

For further assistance call Puritan Bennett Technical Services at

1.800.255.6774 or contact your local Puritan Bennett

representative.

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

vi

Page 9

Preface

This manual is divided into two parts: the operator’s manual and

the technical reference. The operator’s manual describes how to

operate the Puritan Bennett

provides product specifications and accessory order numbers. The

technical reference includes background information about how

the ventilator functions, including details on its operating modes,

self-tests, and other features. In the table of contents and index,

the prefix OP- identifies page numbers in the operator’s manual,

and the prefix TR- identifies page numbers in the technical

reference.

Any references to the software options

Plus

®

(VV+)

which includes VC+ and VS breath types

Proportional Assist Ventilation

that are made in this manual assume that the option has been

installed on the ventilator. If these options aren’t installed, then

references to their functions do not apply.

While this manual covers the ventilator configurations currently

supported by Puritan Bennett, it may not be all-inclusive and may

not be applicable to your ventilator. Within the USA, contact

Puritan Bennett at 1.800.255.6774 for questions about the

applicability of the information.

Ventilator System. It also

840

®

, Volume Ven t ilation

Tube Compensation (TC)

®

(PAV+),

BiLevel

and

, NeoMode®,

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

vii

Page 10

This page is intentionally blank.

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

viii

Page 11

Contents

Operator’s Manual

1 Introduction OP 1-1

1.1 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . OP 1-3

1.1.1 General background . . . . . . . . . . . . . . . . . . . . . . OP 1-3

1.1.2 Pressure and flow triggering . . . . . . . . . . . . . . . . OP 1-5

1.1.3 Breathing gas mixture. . . . . . . . . . . . . . . . . . . . . OP 1-5

1.1.4 Inspiratory pneumatics . . . . . . . . . . . . . . . . . . . . OP 1-6

1.1.5 Patient circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 1-6

1.1.6 AC mains and backup power system. . . . . . . . . . OP 1-7

1.1.7 Ventilator emergency states . . . . . . . . . . . . . . . . OP 1-8

1.2 Graphic user interface. . . . . . . . . . . . . . . . . . . . . . . . . OP 1-9

1.3 User interface controls and indicators . . . . . . . . . . . . . OP 1-10

1.3.1 Onscreen symbols and abbreviations . . . . . . . . . OP 1-15

1.4 Ventilator system labeling symbols . . . . . . . . . . . . . . . OP 1-22

2 How to set up the 840 ventilator OP 2-1

2.1 How to connect the electrical supply . . . . . . . . . . . . . OP 2-4

2.2 How to connect the air and oxygen supplies. . . . . . . . OP 2-8

2.3 How to connect the patient circuit components . . . . . OP 2-10

2.3.1 How to select and connect a patient circuit . . . . OP 2-11

2.3.2 How to install the expiratory filter and

collector vial . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 2-14

2.3.3 How to install the flex arm . . . . . . . . . . . . . . . . . OP 2-17

2.3.4 How to install the humidifier. . . . . . . . . . . . . . . . OP 2-18

2.3.5 How to use the ventilator cart . . . . . . . . . . . . . . OP 2-20

3 How to run Short Self Test (SST) OP 3-1

3.1 Introduction to SST. . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-1

3.2 When to run SST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-2

3.3 SST components and requirements. . . . . . . . . . . . . . . OP 3-4

3.4 SST Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-5

3.5 SST Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-14

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

ix

Page 12

Contents

3.5.1 How to interpret individual SST test results. . . . . .OP 3-15

3.5.2 SST outcomes . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 3-16

4 How to use the 840 ventilator OP 4-1

4.1 Structure of user interface . . . . . . . . . . . . . . . . . . . . . .OP 4-2

4.2 Patient setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-3

4.2.1 How to ventilate with most recent control

parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-4

4.2.2 How to ventilate with new control parameters . . .OP 4-4

4.2.3 Patient data and current settings . . . . . . . . . . . . .OP 4-7

4.2.4 Ideal Body Weight (IBW) . . . . . . . . . . . . . . . . . . .OP 4-10

4.3 How to change the main ventilator

control parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-13

4.4 Mode, breath type, and other changes . . . . . . . . . . . .OP 4-14

4.5 How to select a constant timing variable during

respiratory rate changes . . . . . . . . . . . . . . . . . . . . . . . .OP 4-15

4.6 How to change apnea ventilation settings . . . . . . . . . .OP 4-17

4.7 How to set alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-18

4.8 How to change other settings . . . . . . . . . . . . . . . . . . .OP 4-19

4.9 Expiratory pause maneuvers. . . . . . . . . . . . . . . . . . . . .OP 4-21

4.10 Inspiratory pause maneuvers . . . . . . . . . . . . . . . . . . .OP 4-22

4.11 How to interpret inspiratory pause maneuver results

for static compliance and resistance. . . . . . . . . . . . . .OP 4-24

4.12 How to use NIV . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-25

4.12.1 NIV intended use . . . . . . . . . . . . . . . . . . . . . . . .OP 4-25

4.12.2 NIV breathing interfaces. . . . . . . . . . . . . . . . . . .OP 4-25

4.12.3 NIV setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-26

4.12.4 High spontaneous inspiratory time limit setting .OP 4-30

4.12.5 Apnea setup. . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-30

4.12.6 Alarm setup . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-31

4.12.7 Changing patient from INVASIVE to NIV

Vent Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-33

4.12.8 Changing patient from NIV to INVASIVE

Vent Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 4-34

4.12.9 NIV patient data. . . . . . . . . . . . . . . . . . . . . . . . .OP 4-34

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

x

Page 13

Contents

5 How to handle alarms OP 5-1

5.1 Ventilator alarm classifications. . . . . . . . . . . . . . . . . . . OP 5-1

5.2 Alarm silence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-2

5.3 Alarm reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-4

5.4 Alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-5

5.5 Alarm volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-6

5.6 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-7

6 How to view graphics OP 6-1

6.1 Graphics display function . . . . . . . . . . . . . . . . . . . . . . OP 6-1

6.2 How to set up a graphics display . . . . . . . . . . . . . . . . OP 6-2

6.3 Graphics display details and calculations. . . . . . . . . . . OP 6-3

6.4 How to adjust displayed graphics . . . . . . . . . . . . . . . . OP 6-4

6.5 The graphics display FREEZE function . . . . . . . . . . . . . OP 6-5

6.6 How to print patient data graphics . . . . . . . . . . . . . . . OP 6-6

6.7 Automatic display of graphics . . . . . . . . . . . . . . . . . . . OP 6-6

6.8 When graphics are not accessible . . . . . . . . . . . . . . . . OP 6-7

7 Preventive maintenance OP 7-1

7.1 How to dispose of used parts . . . . . . . . . . . . . . . . . . . OP 7-1

7.2 How to clean, disinfect and sterilize parts . . . . . . . . . . OP 7-2

7.2.1 How to clean components . . . . . . . . . . . . . . . . . OP 7-6

7.3 Disinfection and sterilization. . . . . . . . . . . . . . . . . . . . OP 7-6

7.4 Preventive maintenance procedures for the operator . OP 7-8

7.4.1 Total operational hours. . . . . . . . . . . . . . . . . . . . OP 7-9

7.4.2 Inspiratory and expiratory bacteria filters . . . . . . OP 7-12

7.4.3 Daily or as required: collector vial and drain bag. OP 7-14

7.4.3.1 How to remove the collector vial . . . . . . . . OP 7-14

7.4.3.2 How to remove the drain bag . . . . . . . . . . . OP 7-15

7.4.4 Daily or as required: in-line water traps. . . . . . . . OP 7-16

7.4.5 Every 250 hours: compressor inlet filter. . . . . . . . OP 7-16

7.4.6 Every year: ventilator inspection . . . . . . . . . . . . . OP 7-17

7.4.7 Every 2 years or as necessary: oxygen sensor. . . . OP 7-17

7.4.7.1 Oxygen sensor replacement procedure. . . . OP 7-18

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

xi

Page 14

Contents

7.5 Additional preventive maintenance procedures . . . . . .OP 7-24

7.6 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP 7-26

7.7 Repacking and shipping. . . . . . . . . . . . . . . . . . . . . . . .OP 7-26

A Specifications OP A-1

A.1 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . .OP A-2

A.2 Environmental requirements . . . . . . . . . . . . . . . . . . . .OP A-4

A.3 Pneumatic specifications . . . . . . . . . . . . . . . . . . . . . . .OP A-4

A.4 Electrical specifications. . . . . . . . . . . . . . . . . . . . . . . . .OP A-6

A.5 Compliance and approvals. . . . . . . . . . . . . . . . . . . . . .OP A-9

A.5.1 Manufacturer’s Declaration . . . . . . . . . . . . . . . . .OP A-10

A.6 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . .OP A-18

A.7 Ranges, resolutions, and accuracies . . . . . . . . . . . . . . .OP A-24

A.7.1 Recommended limits . . . . . . . . . . . . . . . . . . . . . .OP A-24

A.7.2 Software options . . . . . . . . . . . . . . . . . . . . . . . . .OP A-25

B Part numbers OP B-1

C Pneumatic schematic OP C-1

D Alarm and oxygen sensor calibration testing OP D-1

D.1 Alarm test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP D-1

D.2 Oxygen sensor calibration test. . . . . . . . . . . . . . . . . . .OP D-7

E Remote alarm and RS-232 ports OP E-1

E.1 Remote alarm port . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP E-2

E.2 RS-232 port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP E-3

E.3 How to configure the RS-232 ports. . . . . . . . . . . . . . . .OP E-4

E.4 Printers and cables . . . . . . . . . . . . . . . . . . . . . . . . . . . .OP E-5

E.5 RS-232 port commands . . . . . . . . . . . . . . . . . . . . . . . .OP E-6

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

xii

Page 15

Contents

Technical Reference

1 Introduction to breath delivery TR 1-1

2 Detecting and initiating inspiration TR 2-1

2.1 Internally triggered inspiration . . . . . . . . . . . . . . . . . . TR 2-2

2.1.1 Pressure sensitivity . . . . . . . . . . . . . . . . . . . . . . . TR 2-2

2.1.2 Flow sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . TR 2-3

2.1.3 Time-cycled inspiration. . . . . . . . . . . . . . . . . . . . TR 2-5

2.2 Operator-triggered inspiration . . . . . . . . . . . . . . . . . . TR 2-6

3 Detecting and initiating exhalation TR 3-1

3.1 Internally initiated exhalation . . . . . . . . . . . . . . . . . . . TR 3-1

3.1.1 Time-cycled exhalation . . . . . . . . . . . . . . . . . . . . TR 3-1

3.1.2 End-inspiratory flow method. . . . . . . . . . . . . . . . TR 3-2

3.1.3 Airway pressure method . . . . . . . . . . . . . . . . . . . TR 3-2

3.2 Backup limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 3-3

3.2.1 Time limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 3-4

3.2.2 High circuit pressure limit . . . . . . . . . . . . . . . . . . TR 3-4

3.2.3 High ventilator pressure limit . . . . . . . . . . . . . . . TR 3-4

4 Mandatory breath delivery TR 4-1

4.1 Comparison of pressure- and volume-based

mandatory breaths . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 4-1

4.2 Compliance compensation for volume-based

mandatory breaths . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 4-3

4.3 BTPS compensation for volume-based

mandatory breaths . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 4-5

4.4 Manual inspiration . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 4-5

5 Spontaneous breath delivery TR 5-1

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

xiii

Page 16

Contents

6 Assist/control (A/C) mode TR 6-1

6.1 Breath delivery in A/C . . . . . . . . . . . . . . . . . . . . . . . . .TR 6-1

6.2 Rate change during A/C. . . . . . . . . . . . . . . . . . . . . . . .TR 6-3

6.3 Changing to A/C mode . . . . . . . . . . . . . . . . . . . . . . . .TR 6-3

7 Synchronous intermittent mandatory

ventilation (SIMV) TR 7-1

7.1 Breath delivery in SIMV . . . . . . . . . . . . . . . . . . . . . . . .TR 7-2

7.2 Apnea ventilation in SIMV . . . . . . . . . . . . . . . . . . . . . .TR 7-4

7.3 Changing to SIMV mode . . . . . . . . . . . . . . . . . . . . . . .TR 7-5

7.4 Rate change during SIMV. . . . . . . . . . . . . . . . . . . . . . .TR 7-7

8 Spontaneous (SPONT) mode TR 8-1

8.1 Breath delivery in SPONT . . . . . . . . . . . . . . . . . . . . . . .TR 8-1

8.2 Changing to SPONT mode. . . . . . . . . . . . . . . . . . . . . .TR 8-1

9 Apnea ventilation TR 9-1

9.1 Apnea detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 9-1

9.2 Transition to apnea ventilation . . . . . . . . . . . . . . . . . . .TR 9-3

9.3 Key entries during apnea ventilation. . . . . . . . . . . . . . .TR 9-3

9.4 Resetting apnea ventilation . . . . . . . . . . . . . . . . . . . . .TR 9-3

9.4.1 Resetting to A/C. . . . . . . . . . . . . . . . . . . . . . . . . .TR 9-4

9.4.2 Resetting to SIMV. . . . . . . . . . . . . . . . . . . . . . . . .TR 9-4

9.4.3 Resetting to SPONT . . . . . . . . . . . . . . . . . . . . . . .TR 9-4

9.5 Phasing in new apnea intervals. . . . . . . . . . . . . . . . . . .TR 9-5

10 Detecting occlusion and disconnect TR 10-1

10.1 Occlusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 10-1

10.2 Disconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 10-3

10.3 Occlusions and disconnect annunciation . . . . . . . . . .TR 10-5

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

xiv

Page 17

Contents

11 Phasing in setting changes TR 11-1

12 Ventilator settings TR 12-1

12.1 Apnea ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-1

12.2 Circuit type and Ideal Body Weight (IBW) . . . . . . . . TR 12-2

12.3 Disconnect sensitivity (D

12.4 Expiratory sensitivity (E

12.5 Expiratory time (T

) . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-4

E

12.6 Flow pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-4

12.7 Flow sensitivity (V

SENS

12.8 High spontaneous inspiratory time limit (2T

12.9 Humidification type . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-6

12.10 I:E ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-7

12.11 Ideal body weight (IBW) . . . . . . . . . . . . . . . . . . . . . TR 12-7

12.12 Inspiratory pressure (P

12.13 Inspiratory time (T

) . . . . . . . . . . . . . . . . . . . . . . . . TR 12-8

I

12.14 Mode and mandatory breath type . . . . . . . . . . . . . TR 12-8

12.15 O

%. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-11

2

12.16 Peak inspiratory flow (V

12.17 PEEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-12

12.17.1 PEEP restoration . . . . . . . . . . . . . . . . . . . . . . . TR 12-13

12.18 Plateau time (T

) . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-13

PL

12.19 Pressure sensitivity (P

12.20 Pressure support (P

SUPP

12.21 Respiratory rate (f) . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-15

12.22 Rise time %. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-15

12.23 Safety ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-16

12.24 Spontaneous breath type . . . . . . . . . . . . . . . . . . . . TR 12-17

12.25 Tidal volume (V

) . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-18

T

12.26 Vent type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 12-18

) . . . . . . . . . . . . . . . . . . TR 12-3

SENS

) . . . . . . . . . . . . . . . . . . . TR 12-4

SENS

) . . . . . . . . . . . . . . . . . . . . . . . TR 12-5

) . TR 12-6

I SPONT

) . . . . . . . . . . . . . . . . . . . . . TR 12-7

I

) . . . . . . . . . . . . . . . . . TR 12-12

MAX

) . . . . . . . . . . . . . . . . . . . TR 12-14

SENS

) . . . . . . . . . . . . . . . . . . . . . TR 12-14

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

xv

Page 18

Contents

13 Alarms TR 13-1

13.1 Alarm handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-1

13.1.1 Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-3

13.1.2 Alarm summary . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-5

13.2 AC POWER LOSS alarm . . . . . . . . . . . . . . . . . . . . . . .TR 13-23

13.3 APNEA alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-23

13.4 CIRCUIT DISCONNECT alarm. . . . . . . . . . . . . . . . . . .TR 13-24

13.5 DEVICE ALERT alarm. . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-24

13.6 High circuit pressure (

13.7 High delivered O

13.8 High exhaled minute volume (

13.9 High exhaled tidal volume (

13.10 High inspired tidal volume alarm (

↑V

TI SPONT

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-27

13.11 High respiratory rate (

13.12 INSPIRATION TOO LONG alarm . . . . . . . . . . . . . . .TR 13-28

13.13 Low circuit pressure alarm (

13.14 Low delivered O

13.15 Low exhaled mandatory tidal volume

(

↓V

TE MAND

) alarm . . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-30

13.16 Low exhaled spontaneous tidal volume

(

↓

V

TE SPONT

) alarm . . . . . . . . . . . . . . . . . . . . . . . . . .TR 13-30

13.17 Low exhaled total minute volume (

13.18 PROCEDURE ERROR alarm . . . . . . . . . . . . . . . . . . . .TR 13-31

↑

P

) alarm . . . . . . . . . . . . . .TR 13-25

PEAK

% (↑O2%) alarm . . . . . . . . . . . . . .TR 13-26

2

↑

V

↑

VTE) alarm . . . . . . . . . . .TR 13-27

↑f

) alarm. . . . . . . . . . . . . .TR 13-28

TOT

↓P

PEAK

% (↓O2%) alarm . . . . . . . . . . . . . .TR 13-29

2

) alarm . . . . . .TR 13-26

ETOT

↑V

TI

, ↑V

TI MAND

,

). . . . . . . . . . . . . .TR 13-29

↓

) alarm. .TR 13-31

V

E TOT

14 Patient data TR 14-1

14.1 Delivered O2%. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 14-1

14.2 End expiratory pressure (PEEP) . . . . . . . . . . . . . . . . . .TR 14-2

14.3 End inspiratory pressure (P

14.4 Exhaled minute volume (V

14.5 Exhaled tidal volume (V

TE

14.6 I:E ratio (I:E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 14-4

14.7 Intrinsic (auto) PEEP (PEEP

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

xvi

). . . . . . . . . . . . . . . . .TR 14-2

I END

) . . . . . . . . . . . . . . . .TR 14-3

E TOT

) . . . . . . . . . . . . . . . . . . . . .TR 14-4

) and total PEEP (PEEP

I

).TR 14-5

TOT

Page 19

Contents

14.8 Mean circuit pressure (P

14.9 Peak circuit pressure (P

14.10 Plateau pressure (P

) . . . . . . . . . . . . . . . . . . . . . . . TR 14-6

PL

14.11 Spontaneous minute volume (V

14.12 Static compliance and resistance (C

14.13 Total respiratory rate (f

) . . . . . . . . . . . . . . . . . TR 14-5

MEAN

) . . . . . . . . . . . . . . . . . . . TR 14-5

PEAK

E SPONT

). . . . . . . . . . . . . . . . . . . TR 14-13

TOT

) . . . . . . . . . TR 14-6

STAT

and R

) . TR 14-7

STAT

15 Safety net TR 15-1

15.1 Patient problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 15-1

15.2 System faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 15-2

15.3 Ongoing background checks . . . . . . . . . . . . . . . . . . TR 15-3

15.4 Hardware monitoring circuitry . . . . . . . . . . . . . . . . . TR 15-4

15.5 Power on self test (POST) . . . . . . . . . . . . . . . . . . . . . TR 15-5

15.6 Short self test (SST). . . . . . . . . . . . . . . . . . . . . . . . . . TR 15-5

15.7 Extended self test (EST). . . . . . . . . . . . . . . . . . . . . . . TR 15-5

15.8 Oxygen sensor calibration. . . . . . . . . . . . . . . . . . . . . TR 15-6

15.9 Exhalation valve calibration. . . . . . . . . . . . . . . . . . . . TR 15-6

15.10 Ventilator inoperative test. . . . . . . . . . . . . . . . . . . . TR 15-6

15.11 Flow sensor offset calibration . . . . . . . . . . . . . . . . . TR 15-6

15.12 Atmospheric pressure transducer calibration. . . . . . TR 15-6

16 Power on self test (POST) TR 16-1

16.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 16-1

16.2 POST characteristics . . . . . . . . . . . . . . . . . . . . . . . . . TR 16-2

16.3 POST following power interruptions . . . . . . . . . . . . . TR 16-3

16.4 POST fault handling . . . . . . . . . . . . . . . . . . . . . . . . . TR 16-4

16.5 POST system interface . . . . . . . . . . . . . . . . . . . . . . . TR 16-4

16.6 POST user interface. . . . . . . . . . . . . . . . . . . . . . . . . . TR 16-5

17 Short self test (SST) TR 17-1

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

xvii

Page 20

Contents

18 Extended self test (EST) TR 18-1

18.1 EST results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 18-2

18.2 EST failure handling . . . . . . . . . . . . . . . . . . . . . . . . . .TR 18-3

18.3 EST safety considerations . . . . . . . . . . . . . . . . . . . . . .TR 18-3

19 RS-232 commands TR 19-1

19.1 RSET command . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 19-1

19.2 SNDA command . . . . . . . . . . . . . . . . . . . . . . . . . . . .TR 19-1

Glossary

Index

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

xviii

Page 21

Figures

Operator’s Manual

Figure 1-1. 840 Ventilator System block diagram . . . . . . . . . . . . . . . OP 1-4

Figure 1-2. 840 Ventilator System graphic user interface (GUI) . . . . . OP 1-9

Figure 2-1. How to lift the ventilator components . . . . . . . . . . . . . . . OP 2-2

Figure 2-2. How to connect the ventilator power cord . . . . . . . . . . . OP 2-5

Figure 2-3. Ventilator power switch, AC indicator, and AC panel. . . . OP 2-6

Figure 2-4. Power cord storage on the cart . . . . . . . . . . . . . . . . . . . . OP 2-7

Figure 2-5. How to connect the air and oxygen supplies . . . . . . . . . . OP 2-9

Figure 2-6. How to connect the patient circuit . . . . . . . . . . . . . . . . . OP 2-13

Figure 2-7. How to install the expiratory filter and collector vial . . . . OP 2-15

Figure 2-8. How to use the collector vial with or

without the drain bag . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 2-16

Figure 2-9. How to install the flex arm. . . . . . . . . . . . . . . . . . . . . . . . OP 2-17

Figure 2-10. How to install the humidifier

(Fisher & Paykel version shown) . . . . . . . . . . . . . . . . . . . OP 2-19

Figure 2-11. How to lock and unlock the cart’s front wheels . . . . . . . . OP 2-20

Figure 3-1. Test button location . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-6

Figure 4-1. Touch screen user interface . . . . . . . . . . . . . . . . . . . . . . . OP 4-2

Figure 4-2. Ventilator Startup screen . . . . . . . . . . . . . . . . . . . . . . . . . OP 4-3

Figure 4-3. Touch screen appearance during normal ventilation

(shown with alarm silence and

100% O

Figure 4-4.

(or TH) selected as the constant during rate change. . . OP 4-16

T

I

Figure 4-5. Alarm setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 4-19

Figure 4-6. New patient setup screen — NIV. . . . . . . . . . . . . . . . . . . OP 4-27

Figure 4-7. NIV ventilator settings screen . . . . . . . . . . . . . . . . . . . . . OP 4-29

Figure 4-8. New patient default alarm settings . . . . . . . . . . . . . . . . . OP 4-31

Figure 4-9. More patient data screen — NIV . . . . . . . . . . . . . . . . . . . OP 4-35

Figure 5-1. Alarm indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-2

Figure 5-2. Alarm Silence in Progress indicator (lower screen) . . . . . . OP 5-3

Figure 5-3. Alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-5

Figure 5-4. Alarm message format. . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-8

Figure 6-1. Pressure-volume loop . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 6-2

Figure 7-1. How to empty the collector vial and seal the drain bag . . OP 7-15

Figure 7-2. 806 compressor with inlet filter. . . . . . . . . . . . . . . . . . . . OP 7-17

/CAL in progress) . . . . . . . . . . . . . . . . . . . . . . . OP 4-9

2

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

xix

Page 22

Figures

Figure 7-3. Dislodge the O2 sensor access cover . . . . . . . . . . . . . . . . OP 7-20

Figure 7-4. Open O

Figure 7-5. Locate O

Figure A-1. Recommended patient circuit configurations . . . . . . . . . OP A-23

Figure B-1. Ventilator accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . OP B-2

Figure C-1. Pneumatic schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . OP C-1

Figure E-1. Remote alarm and RS-232 ports . . . . . . . . . . . . . . . . . . . OP E-1

Figure E-2. Remote alarm port pinout (view from back of GUI). . . . . OP E-2

Figure E-3. RS-232 serial port pinout . . . . . . . . . . . . . . . . . . . . . . . . OP E-3

Technical Reference

Figure 2-1. Declaring inspiration using pressure sensitivity . . . . . . . . TR 2-3

Figure 2-2. Declaring inspiration using flow sensitivity . . . . . . . . . . . TR 2-4

Figure 2-3. Time-cycled inspiration. . . . . . . . . . . . . . . . . . . . . . . . . . TR 2-6

Figure 3-1. Initiating exhalation using the

end-inspiratory flow method. . . . . . . . . . . . . . . . . . . . . . TR 3-2

Figure 3-2. Initiating exhalation using the airway pressure method. . TR 3-3

Figure 6-1. A/C mode, no patient effort detected. . . . . . . . . . . . . . . TR 6-2

Figure 6-2. A/C mode, patient effort detected . . . . . . . . . . . . . . . . . TR 6-2

Figure 6-3. A/C mode, VIM and PIM breaths . . . . . . . . . . . . . . . . . . TR 6-2

Figure 7-1. SIMV breath cycle

(mandatory and spontaneous intervals) . . . . . . . . . . . . . TR 7-1

Figure 7-2. SIMV breath cycle, PIM delivered within

mandatory interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 7-2

Figure 7-3. SIMV breath cycle, PIM not delivered within

mandatory interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 7-2

Figure 7-4. Apnea ventilation in SIMV. . . . . . . . . . . . . . . . . . . . . . . . TR 7-4

Figure 9-1. Apnea interval equals breath period . . . . . . . . . . . . . . . . TR 9-2

Figure 9-2. Apnea interval greater than breath period. . . . . . . . . . . . TR 9-2

Figure 9-3. Apnea interval less than breath period . . . . . . . . . . . . . . TR 9-2

Figure 12-1. 840 ventilator modes and breath types. . . . . . . . . . . . . . TR 12-10

Figure 13-1. Alarm message format (upper GUI screen) . . . . . . . . . . . TR 13-3

sensor access port . . . . . . . . . . . . . . . . . . . . . . OP 7-21

2

sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 7-22

2

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

xx

Page 23

Tables

Operator’s Manual

Table 1-1. 840 Ventilator System GUI controls and indicators . . . . . . OP 1-10

Table 1-2. BDU indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 1-15

Table 1-3. 840 Ventilator System symbols and abbreviations. . . . . . . OP 1-16

Table 2-1. Patient circuit and IBW values. . . . . . . . . . . . . . . . . . . . . . OP 2-12

Table 3-1. SST test sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-9

Table 3-2. Individual SST test results . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-15

Table 3-3. Overall SST outcomes. . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3-16

Table 4-1. IBW based on patient height . . . . . . . . . . . . . . . . . . . . . . OP 4-11

Table 4-2. Patient circuit and IBW values. . . . . . . . . . . . . . . . . . . . . . OP 4-13

Table 4-3. Monitored ventilator control parameters . . . . . . . . . . . . . OP 4-14

Table 4-5. Automatic settings changes—INVASIVE to NIV . . . . . . . . . OP 4-33

Table 4-6. Automatic settings changes—NIV to INVASIVE . . . . . . . . . OP 4-34

Table 5-1. Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 5-9

Table 7-1. Procedures to clean, disinfect, and sterilize parts. . . . . . . . OP 7-3

Table 7-2. Disinfection and sterilization procedures. . . . . . . . . . . . . . OP 7-7

Table 7-3. Operator preventive maintenance procedures

and frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 7-10

Table 7-4. Service preventive maintenance procedures and intervals. OP 7-25

Table A-1. Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-2

Table A-2. Environmental requirements . . . . . . . . . . . . . . . . . . . . . . . OP A-4

Table A-3. Pneumatic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-4

Table A-4. Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-6

Table A-5. Compliance and approvals . . . . . . . . . . . . . . . . . . . . . . . . OP A-9

Table A-6. Electromagnetic Emissions . . . . . . . . . . . . . . . . . . . . . . . . OP A-11

Table A-7. Electromagnetic Immunity . . . . . . . . . . . . . . . . . . . . . . . . OP A-12

Table A-8. Electromagnetic Immunity – conducted and radiated RF . OP A-14

Table A-9. Recommended separation distances between portable

and mobile RF communications equipment

and the 840 Ventilator System . . . . . . . . . . . . . . . . . . . . . OP A-16

Table A-10. Compliant cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-17

Table A-11. Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-18

Table A-12. Ventilator settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-25

Table A-13. Alarm settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-42

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s and Technical Reference Manual

xxi

Page 24

Tables

Table A-14. Patient data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP A-47

Table A-15. Other Screens — displayed data. . . . . . . . . . . . . . . . . . . . OP A-54

Table B-1. Ventilator parts and accessories . . . . . . . . . . . . . . . . . . . . OP B-3

Technical Reference

Table 4-1. Comparison of pressure- and volume-based

mandatory breaths TR 4-2

Table 4-2. Compliance volume factors . . . . . . . . . . . . . . . . . . . . . . . TR 4-5

Table 5-1. Spontaneous breath delivery characteristics . . . . . . . . . . TR 5-1

Table 12-1. 840 ventilator modes and breath types . . . . . . . . . . . . . . TR 12-9

Table 13-1. Alarm urgency levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 13-2

Table 13-2. Alarm summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 13-5

Table 13-3. Applicability of high inspired tidal volume alarm symbols. TR 13-27

Table 14-1. Inspiratory pause maneuver displays . . . . . . . . . . . . . . . . TR 14-9

Table 19-1. MISCA response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TR 19-3

840 Ventilator System Operator’s and Technical Reference Manual 4-075609-00 Rev. G (10/06)

xxii

Page 25

C

HAPTER

1

Introduction

The intended use of the Puritan Bennett

for acute and subacute care of infant, pediatric, and adult patients.

Software options, available from Puritan Bennett, provide

additional ventilation functions.

The

management, offers selectable modes of breath delivery, and

assists the practitioner in the selection of the most appropriate

ventilator control parameters for the patient. The user interface is

intuitive and easy to operate for those with prior knowledge of

ventilator operation.

The user interface includes

monitored patient data, for easy assessment of the patient’s

condition. The touch screens also display the current ventilator

control parameters.

The

preview the selected ventilator control parameters prior to active

ventilation of the patient.

The

specific information about the cause, and prompts the user with

actions to resolve the reported condition(s).

Ventilator System facilitates work of breathing

840

SandBox

SmartAlert

1

Ventilator System is

840

DualView

™ area on the touch screen allows the practitioner to

™ system intercepts alarms, or events, provides

™ touch screens that display

The breath delivery unit (BDU) comprises the pneumatics and the

patient circuit.

The ventilator uses two independent Central Processing Units

(CPUs):

• Breath delivery unit (BDU) CPU

• Graphic user interface (GUI) CPU

The BDU CPU uses the ventilator control parameters, selected by

the practitioner, to deliver breaths to the patient. The BDU CPU

also runs continuous and extensive operational background

checks to ensure proper operation of the ventilator.

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-1

Page 26

OP 1

Introduction

The GUI CPU monitors the ventilator and the ventilator/patient

interaction. The GUI CPU also monitors the operation of the BDU

CPU and prevents simultaneous failure of control and monitor

functions when a single fault is reported.

The

breaths with a preset level of positive end-expiratory pressure

(PEEP), trigger sensitivity, and oxygen concentration. A

mandatory breath can either be pressure- or volume-controlled,

but it is always pressure-controlled in the optional

spontaneous breath allows patient inspiratory flows of up to

200 L/min, with or without pressure support.

The optional 806 Compressor unit provides compressed air to the

BDU, and can be used in place of wall or bottled air. The

compressor unit is powered through and communicates with the

BDU.

The 802 Backup Power Source (BPS) provides DC power to the

BDU and GUI in the event that AC power is lost. A new, fully

charged BPS runs the ventilator (without a compressor or a

humidifier) for at least 30 minutes, which allows transport of the

patient and the ventilator within the healthcare facility.

This manual tells you how to operate and perform simple

maintenance for the

this manual and accompanying labels before attempting to

operate or maintain the ventilator.

To ensure optimum performance of the

Puritan Bennett strongly recommends that certified biomedical

engineering technicians, or other personnel with equivalent

experience and training in the service of this type of equipment,

perform periodic maintenance on the ventilator. For more

information, contact Puritan Bennett Technical Services in the

U.S. at 1.800.255.6774. Outside of the U.S., contact your local

Puritan Bennett representative.

Ventilator System supplies mandatory or spontaneous

840

BiLevel

Ventilator System. Become familiar with

840

Ventilator System,

840

mode. A

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-2

Page 27

Introduction

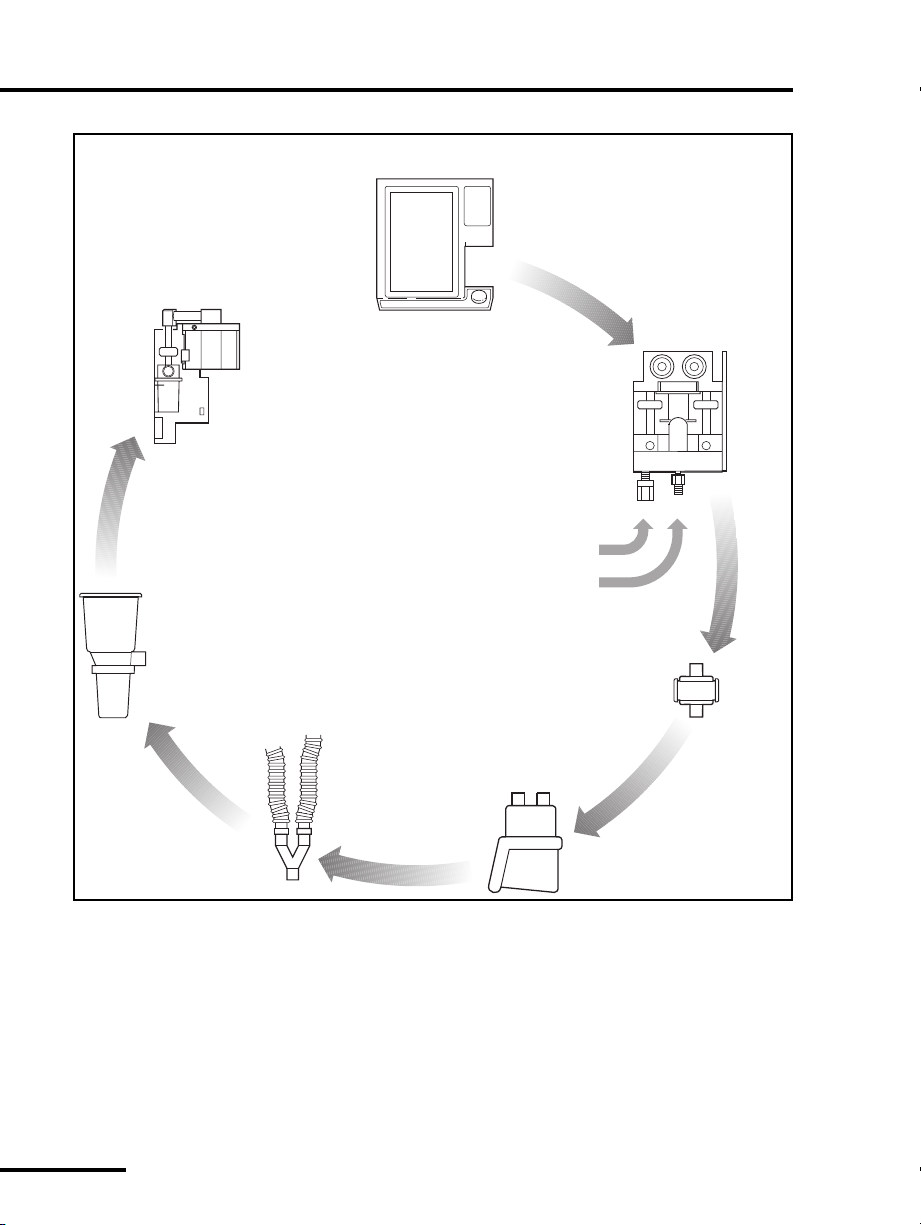

1.1 Technical description

1.1.1 General background

The practitioner uses the GUI touch screens, the off-screen keys,

and GUI knob to select the ventilator control parameters and

input data (see Figure 1-1). The GUI CPU processes this

information and stores it in ventilator memory. The BDU CPU

uses this stored information to control and monitor the flow of

gas to and from the patient. The two CPUs communicate to

transfer and verify any new ventilator control parameters or alarm

limits. Each CPU then performs continuous background

verification of operational and data integrity.

OP 1

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-3

Page 28

OP 1

Graphic user

interface (GUI)

Introduction

Collector

vial

Exhalation

module:

Active exhalation valve

Pressure transducer

Flow sensor

Expiratory

filter

(Expiratory

limb)

(Inspiratory

limb)

regulator

Air

supply

Oxygen

supply

Inspiratory

module:

PSOLs

Safety valve

Oxygen sensor

Pressure transducers

Flow sensors

Air

Oxygen

regulator

Inspiratory

filter

Patient

circuit

Humidification

device

8-00001

Figure 1-1. 840 Ventilator System block diagram

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-4

Page 29

Introduction

OP 1

1.1.2 Pressure and flow triggering

The ventilator uses flow or pressure triggering to recognize patient

effort. When

pressure triggering

pressure in the patient circuit. As the patient draws gas from the

circuit and airway pressure drops by at least the value selected for

pressure sensitivity, the ventilator delivers a breath.

When

flow triggering (Flow-by

monitors the difference between the inspiratory and expiratory

flow sensor measurements. As the patient inhales, the ventilator

measures less exhaled flow while the delivered flow remains

constant. The result is an increase in the difference between the

inspiratory and expiratory flows. When the difference is at least

the operator-selected value for flow sensitivity, the ventilator

delivers a breath.

If the patient is not inhaling, any difference between the delivered

and exhaled flow is due to sensor inaccuracy or leaks in the

patient system. To compensate for leaks in the patient system

which can cause autotriggering, the operator can increase the flow

sensitivity setting.

As a backup method of triggering inspiration, a pressure

sensitivity of 2 cmH

O is also in effect. This setting is the most

2

sensitive setting that is still large enough to avoid autotriggering,

yet will trigger with acceptable patient effort.

is in effect, the ventilator monitors

) is in effect, the ventilator

1.1.3 Breathing gas mixture

Air and oxygen from cylinders, wall supplies, or compressor (air

only) enter the ventilator through hoses and fittings (the fittings

are available in several versions). Once inside the ventilator, air

and oxygen are regulated to pressures appropriate for the

ventilator, then mixed according to the selected O

The ventilator delivers the mixed air and oxygen through the

inspiratory module

and out to the patient. The oxygen

concentration of the delivered gas is monitored here, using a

galvanic oxygen sensor. The galvanic sensor generates a voltage

proportional to the oxygen concentration. The ventilator reports

an alarm if the O

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

sensor is enabled and monitored oxygen

2

%.

2

OP 1-5

Page 30

OP 1

Introduction

concentration is more than seven percent above or below the

O

% setting, or below 18% after the concentration stabilizes.

2

The inspiratory manifold also includes a safety valve to relieve

patient pressure if necessary (for example, if the patient circuit is

kinked or occluded). The inspiratory module also corrects for gas

temperature and humidity, based on the practitioner-set

humidification type.

1.1.4 Inspiratory pneumatics

Ventilator inspiratory pneumatics consist of two parallel circuits:

one for oxygen and one for air. The primary elements of the

inspiratory pneumatics are two proportional solenoid valves

(PSOLs), which control the flow of gas delivered to the patient. Air

and oxygen flow sensors, along with pressure signals from the

patient circuit, provide feedback that the BDU CPU uses to

control the PSOLs.

As a result, the ventilator supplies mixed breathing gas to the

patient, based on the practitioner-set ventilator control

parameters. The mixed air and oxygen passes through the patient

circuit external to the ventilator. The system delivers the

breathing gas mixture to the patient at the patient wye, located in

the external patient circuit.

1.1.5 Patient circuit

The

patient circuit

ventilator that route gas between the ventilator and the patient.

These components include:

•an

• a humidification device (optional) in line with the patient

• the inspiratory and expiratory limbs of the patient circuit that

•a

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-6

inspiratory filter

between the patient and ventilator

circuit

conduct the breathing gas to and from the patient

collector vial

bulk moisture in the exhaled gas

comprises the components external to the

that protects against contamination

that protects the expiratory pneumatics from

Page 31

Introduction

OP 1

•an

expiratory filter

particulates in the patient’s exhaled gas into the room air or

inside the ventilator exhalation pneumatics

The ventilator actively controls the exhalation valve that the

software accurately positions throughout the patient’s inspiration

and exhalation. The exhalation valve allows the ventilator to

deliver aggressive breaths while pressure overshoots are

minimized, PEEP is controlled, and excess patient pressures are

relieved. The exhalation system monitors the exhaled gas leaving

the patient circuit for spirometry.

Throughout the respiratory cycle, pressure transducers monitor

inspiratory, expiratory, and atmospheric pressures. The

temperature of the exhaled gas is heated to a temperature above

its dew point to prevent condensation in the exhalation

compartment. Refer to Appendix C for a detailed diagram of the

ventilator’s pneumatic system and patient circuit.

that limits the escape of microorganisms and

1.1.6 AC mains and backup power system

The ventilator derives its power to operate from the AC mains

(wall) power or the backup power system (BPS). The design of the

BDU integral power supply protects against excessive voltages,

temperatures, or current draws. A power cord retainer prevents

accidental disconnection of the BDU from the AC mains. A power

switch cover on the front face of the BDU protects against spills

and accidental AC power-off.

The ventilator connects to the 802 BPS, which supplies DC power

to the ventilator if AC power is lost. A fully charged BPS operating

under nominal ambient conditions, can power the ventilator for

at least 30 minutes (the BPS does not power the compressor unit

or the humidifier, if present). The GUI indicates when the

ventilator is operating on the BPS, rather than AC mains.

When AC power is connected, it recharges the BPS. The BPS

continues to recharge from the AC power during normal

ventilator operation.

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-7

Page 32

OP 1

Introduction

1.1.7 Ventilator emergency states

Emergency states include

safety valve open (SVO)

always includes the

independent of a

The following describe the two ventilator emergency states:

•

Safety valve open (SVO)

air and oxygen supplies are lost, or an occlusion is detected, or

the ventilator enters the

The safety valve open (

room air unassisted by the ventilator. The ventilator remains

in the

SVO

state is corrected.

When the ventilator enters the

on the front face of the BDU illuminates, and a high-urgency

alarm sounds.

In case of a malfunction that prevents software from opening

the safety valve, there is also an analog circuit that opens the

safety valve if system pressure exceeds 100 to 120 cmH

•

Ventilator inoperative (Vent Inop)

ventilator inoperative condition if a hardware failure or critical

software error occurs that could compromise safe ventilation

of the patient.

Vent I n o p

state until the condition that caused the emergency

ventilator inoperative (Vent Inop)

. When a

state. A

SVO

: The ventilator enters a

Vent Ino p

SVO

condition.

Vent Inop

) state allows the patient to breathe

SVO

condition occurs, it

state can also occur

condition.

state, the

SVO

: The ventilator declares a

SVO

SVO

and

state if both

indicator

O.

2

When a

the front face of the BDU illuminates and the ventilator enters

the

If a

ventilator from use until qualified service personnel evaluate

and correct the

If the ventilator declares a

test (POST) must first verify that power levels to the ventilator

are acceptable and that the functions of the major electronics

systems are satisfactory before normal ventilation can resume.

Qualified service personnel must repair the ventilator to

correct the problem and execute EST successfully before

normal ventilation is allowed.

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-8

Vent Inop

state, which in turns sounds a high-urgency alarm.

SVO

Vent Inop

condition occurs, the

condition occurs, immediately remove the

Vent Ino p

condition.

Vent Inop

Vent I n o p

state, the power on self

indicator on

Page 33

Introduction

1.2 Graphic user interface

This section describes the graphic user interface (GUI), the GUI

keys, the GUI indicators, and the symbols you see on the GUI.

OP 1

Upper screen:

monitored

information

(alarms,

patient data)

Lower screen:

ventilator

control

parameters

The graphic user interface (GUI) of the

comprises the

DualView

touch screens, the off-screen keys located

Ventilator System

840

below the touch screens, and a knob. Use the knob to set a given

ventilator control parameter to its desired value. Press the

ACCEPT

key—the off-screen key above and right of the knob—to enter the

selected value or parameter into memory.

Figure 1-2 identifies the components of the GUI, and the location

of information on the

Vital patient data

Alarms and ventilator status

Assorted patient data,

including graphical displays

Active alarm log, if applicable

Primary patient parameters

Setup of ventilator control

parameters, alarm limits,

breath timing parameters,

and other parameters

Symbol definitions

DualView

touch screens.

Prompt

area

Status

indicators

Off-screen

keys

CLEAR

key

ACCEPT

key

Knob

8-00025

Figure 1-2. 840 Ventilator System graphic user interface (GUI)

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-9

Page 34

OP 1

1.3 User interface controls and indicators

Descriptions of the controls and indicators on the graphic user

interface are given in Table 1-1 below.

Table 1-1: 840 Ventilator System GUI controls and indicators

Control or indicator Function

Screen lock key: When the yellow light on the screen lock key

is lit, the screen or off-screen controls (including the knob and

ACCEPT key) have no effect when touched until you press

the screen lock key again. New alarms automatically unlock

the screen and controls.

The screen lock allows you to clean the touch screen and

prevents inadvertent changes to settings and displays.

Alarm volume key: Allows you to adjust the alarm volume

when you hold down this key while turning the knob. You

cannot turn off the alarm volume.

Alarm silence key: Turns off the audible alarm for two

minutes. The yellow light on the alarm silence key illuminates

during the silence period. An ALARM SILENCE IN PROGRESS

indicator displays on the lower touch screen, along with a

CANCEL button, if there is not a higher-priority alarm display

active. To exit out of the alarm silence, touch the CANCEL

button.

The system automatically exits the alarm silence when the

two-minute interval times out. High-urgency alarms such as

Device Alerts, Safety Valve Open, Occlusion, and loss of either

gas supply cancel the alarm silence.

Each time you press the alarm silence key, the silence period

resets to two minutes. Each time you press the alarm silence

key (whether or not there is an active alarm), the keypress is

recorded in the alarm log.

Introduction

Alarm reset key: Clears active alarms or resets high-urgency

alarms and cancels an active alarm silence. Each time you

press the reset key, it is recorded in the alarm log, if there is an

active alarm. You cannot reset a DEVICE ALERT alarm.

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-10

Page 35

Introduction

OP 1

Table 1-1: 840 Ventilator System GUI controls and indicators (cont)

Control or indicator Function

Information key: Displays basic operating information about

the ventilator. Press the key to display a menu of information

topics, then touch the button corresponding to the desired

topic. Browse topical information using the , ,

, and buttons located in the information header.

GO BACK

Oxygen sensor calibration key: Delivers 100% oxygen (if

available) for two minutes and calibrates the oxygen sensor.

The green light on this key illuminates and a message (100%

Cal in Progress) on the lower touch screen indicates that

O

2

100% O

delivery is active. If you press the O2 key again, the

2

system restarts the two-minute delivery interval. Press

CANCEL to stop the calibration.

Use the procedure in Appendix D.2 to test the oxygen sensor

calibration.

Manual inspiration key: In A/C, SIMV, and SPONT modes,

delivers one manual breath to the patient in accordance with

the current mandatory breath parameters. In BILEVEL mode,

transitions from Low PEEP (PEEP

) to High PEEP (PEEPH) (or

L

vice versa). To avoid breath stacking, a manual inspiration is

not delivered during inspiration or during the restricted phase

of exhalation.

You can use the MANUAL INSP key to supplement minute

volume or to assist measurement of a patient data parameter,

such as peak inspiratory pressure, or to run an INSP PAUSE

maneuver in SPONT mode.

DIAGRAM

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-11

Page 36

OP 1

Introduction

Table 1-1: 840 Ventilator System GUI controls and indicators (cont)

Control or indicator Function

Expiratory pause key: Causes the ventilator to seal the

patient’s breathing circuit when the expiratory phase of a

designated breath, mandatory or spontaneous, is followed by

a time-cycled mandatory inspiration. An expiratory pause is

used to estimate PEEP

The ventilator performs two types of pause maneuver:

automatic, which you initiate by a momentary press of the

EXP PAUSE

continuous press on the key. An automatic pause performs the

maneuver until the pressure stabilizes, then takes its

measurements. The pause lasts at least 0.5 second and does

not exceed 3.0 seconds.

During a manual pause, the ventilator takes its measurements

as soon as the pressure stabilizes or the pause ends. The

ventilator continues the maneuver until you release the

PAU SE key. The pause cannot exceed 20 seconds.

Section 4.9 describes, in detail, how to use the EXP PAUSE

key.

key, and manual, which you control by a

and PEEPI (autoPEEP).

TOT

EXP

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-12

Page 37

Introduction

OP 1

Table 1-1: 840 Ventilator System GUI controls and indicators (cont)

Control or indicator Function

Inspiratory pause key: Causes the ventilator to seal the

patient’s breathing circuit at the conclusion of the gas delivery

phase of a designated, volume- or pressure-based mandatory

inspiration. This inspiratory pause maneuver provides a means

to measure the patient’s static lung-thoracic compliance

), static resistance (R

(C

STAT

The inspiratory pause maneuver maintains the inflated state

of the lungs.

The ventilator performs two types of pause maneuver:

automatic, which is initiated by the momentary press of the

INSP PAUSE

continuous press on the key.

An automatic pause performs the maneuver until the pressure

stabilizes, then the system takes its measurements. The pause

event lasts at least 0.5 second but no longer than

2.0 seconds.

In a manual pause, the maneuver continues until you release

the INSP PAUSE key, but cannot exceed 7 seconds. The

ventilator computes C

and displays the values at the end of the maneuver. P

computed and updated continuously during the plateau, and

its value is frozen at the end of the plateau. Section 4.10

describes, in detail, how to use the INSP PAUSE key.

key, and manual, which you control by a

STAT

), and plateau pressure (PPL).

STAT

and R

at the end of the plateau

STAT

is

PL

Knob: Adjusts the value of a setting. A highlighted button on

a touch screen means that the knob is linked to that setting.

Where applicable, a clockwise turn of the knob increases the

highlighted value, and a counterclockwise turn of the knob

decreases the highlighted value.

Clear: Cancels a proposed ventilator parameter value change.

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-13

Page 38

OP 1

Introduction

Table 1-1: 840 Ventilator System GUI controls and indicators (cont)

Control or indicator Function

Accept: Applies and saves new ventilator parameter value(s).

Red high-urgency alarm indicator ( ! ! ! ): This alarm

indicator blinks rapidly if active; it is steadily lit if autoreset.

Yellow medium-urgency alarm indicator ( ! ! ): This alarm

indicator blinks slowly if active; it turns off if autoreset.

Yellow low-urgency alarm indicator ( ! ): This indicator is

steadily lit if active; it turns off if autoreset.

Green normal ventilator operation indicator: When

ventilation is active and no alarm states exist, this indicator is

steadily lit. This indicator is off if the ventilator is not in a

ventilation mode, for example, during service mode or short

self test (SST).

VENT

INOP

SAFETY

VALVE

OPEN

BATTERY

READY

BATTERY

ON

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-14

Red ventilator inoperative (VENT INOP) indicator: The

ventilator cannot support ventilation and requires service. The

ventilator enters the safe state (safety ventilation) and

discontinues detection of new patient data or alarm

conditions. Qualified service personnel must repair the

ventilator to correct the problem and execute EST successfully

before normal ventilation is allowed. This indicator is

accompanied by an audio signal and cannot be reset.

Red safety valve open (SVO) indicator: The ventilator has

entered its safe state and opened its safety valve to allow the

patient to breathe unassisted from room air.

Green BPS ready indicator: The ventilator senses that the

BPS is installed, operational, and has at least two (2) minutes

of estimated run time.

Battery on power indicator: When the yellow bar to the

right of a lit BPS ready indicator is lit, the ventilator is

operating on BPS, and AC power is insufficient to support

ventilator operation. During BPS operation, power to the

compressor unit and the humidifier outlet is off.

Page 39

Introduction

OP 1

Table 1-1: 840 Ventilator System GUI controls and indicators (cont)

Control or indicator Function

COMPRESSOR

READY

COMPRESSOR

ON

The indicators on the breath delivery unit are shown in Table 1-2.

VENT

INOP

SAFETY

VALV E

OPEN

Green compressor ready indicator: The compressor cable

and air supply hose are connected to the ventilator. The

compressor is up to operating pressure but not supplying gas

to the ventilator. The compressor motor turns on

intermittently to keep the compressor chamber pressurized.

Green compressor operating indicator: When lit,

compressor is supplying air to the ventilator. This indicator

does not light unless the compressor is actually supplying air

to the ventilator.

Table 1- 2: BDU in dicators

Red ventilator inoperative (VENT INOP) indicator: The

ventilator cannot support ventilation and requires service. The

ventilator enters the safe state (safety ventilation) and

discontinues detection of new patient data or alarm

conditions. Qualified service personnel must repair the

ventilator to correct the problem and execute EST successfully

before normal ventilation is allowed. This indicator is

accompanied by an audio signal and cannot be reset.

Red safety valve open (SVO) indicator: The ventilator has

entered its safe state and opened its safety valve to allow the

patient to breathe unassisted from room air.

DISPLAY

(GUI)

INOP

Red loss of GUI indicator: The ventilator has detected a

malfunction that prevents the GUI from reliably displaying or

receiving information.

1.3.1 Onscreen symbols and abbreviations

Touch an onscreen symbol to display its definition in the lower

left corner of the lower screen. Table 1-3 summarizes the symbols

and abbreviations the ventilator uses.

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

OP 1-15

Page 40

OP 1

For example, if you touch:

V

MAX

21.8

The symbol definition area shows this message:

V

MAX

Table 1-3: 840 Ventilator System symbols and abbreviations

L

min

= Peak flow

Introduction

Symbol or

abbreviation

(blinking)

P

%

Definition

Additional alarms that relate to the monitored information are

active. The symbol blinks when there is not enough screen

area to display all active alarms.

The upper alarm limit

The lower alarm limit

Press to access the alarm log

Alarm log contains events that you have not yet viewed

Rise time percent

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

OP 1-16

Page 41

Introduction

OP 1

Table 1-3: 840 Ventilator System symbols and abbreviations (cont)

Symbol or

abbreviation

RAMP SQUARE

Definition

Flow pattern

The value you selected for a ventilator control parameter

exceeds its recommended limit (soft bound) and requires

acknowledgement to continue

or

The value selected exceeds its allowable minimum or

maximum limit (hard bound)

Press to view more patient data

Press to view patient data graphics

Press to view additional screens

X-axis (time or pressure) adjust of patient data graphics

Y-axis (pressure, volume, or flow) adjust of patient data

graphics

Baseline pressure (PEEP) adjust

A/C Assist control ventilation mode

AV Apnea ventilation

C

STAT

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

Static compliance

OP 1-17

Page 42

OP 1

Introduction

Table 1-3: 840 Ventilator System symbols and abbreviations (cont)

Symbol or

abbreviation

E

SENS

Spontaneous expiratory sensitivity percentage

Definition

EST Extended Self Test

f Respiratory rate (ventilator control parameter)

↑ f

f

TOT

TOT

Total respiratory rate (monitored)

High respiratory rate alarm

GUI Graphic user interface

HME Heat-Moisture Exchanger

I:E Inspiratory to expiratory ratio

O

2

O

2

1

O2% High delivered O2% alarm

3

O2%Low delivered O

Monitored oxygen percentage (patient data)

Oxygen percentage (ventilator control parameter)

% alarm

2

PC Pressure control (mandatory breath type)

P

↑P

2 P

3

4

P

MEAN

PEAK

PEAK

P

PEAK

P

PEAK

PEAK

Mean circuit pressure

High circuit pressure alarm

High circuit pressure alarm limit

Low circuit pressure alarm

Low circuit pressure alarm limit

Peak circuit pressure (patient data)

PEEP positive end-expiratory pressure (ventilator control

parameter)

PEEP

H

840 Ventilator System Operator’s Manual 4-075609-00 Rev. G (10/06)

High PEEP (ventilator control parameter, BILEVEL mode only)

OP 1-18

Page 43

Introduction

OP 1

Table 1-3: 840 Ventilator System symbols and abbreviations (cont)

Symbol or

abbreviation

PEEP

I

PEEP

L

PEEP

TOT

PEEP

P

I

P

I END

P

PL

Intrinsic PEEP (patient data)

Low PEEP (ventilator control parameter, BILEVEL mode only)

Total PEEP (patient data)

End expiratory pressure (patient data)

Inspiratory pressure (ventilator control parameter)

End inspiratory pressure (patient data)

Plateau pressure (patient data)

Definition

POST Power on self test

PS Pressure Support (spontaneous breath type)

P

P

P

↑P

SENS

SUPP

-TRIG

VENT

Pressure sensitivity

Pressure support (ventilator control parameter)

Pressure triggering

High internal ventilator pressure alarm

R

STAT

Static resistance

SIMV Synchronous intermittent mandatory ventilation mode

SPONT Spontaneous ventilation mode

SST Short self test

T

A

T

E

T

H

T

I

1

T

I SPONT

4-075609-00 Rev. G (10/06) 840 Ventilator System Operator’s Manual

Apnea interval

Expiratory time

High PEEP time (BILEVEL mode only)

Inspiratory time

High spontaneous inspiration time alarm

OP 1-19

Page 44

OP 1

T

Introduction

Table 1-3: 840 Ventilator System symbols and abbreviations (cont)

Symbol or

abbreviation

2

T

I SPONT

T

L

T

PL

V

E SET

High spontaneous inspiration time alarm limit

Low PEEP time (BILEVEL mode only)

Plateau time

Set minute volume (calculated from ventilator control

Definition

parameters)

V

E SPONT

1

V

3V

E TOT

E TO

Exhaled spontaneous minute volume

High exhaled minute volume alarm

Low exhaled minute volume alarm

VC Volume control (mandatory breath type)

V

MAX

V

SENS

V

1

V

T

TE

V

TE

Peak flow (ventilator control parameter)

Flow sensitivity

Tidal volume (ventilator control parameter)

Exhaled tidal volume

High exhaled tidal volume alarm

3

V

TE MAND

3

V

TE SPONT

1

V

TI

V

TI

Low exhaled mandatory tidal volume alarm

Low exhaled spontaneous tidal volume alarm

Inspired tidal volume

High inspired (mandatory or spontaneous) tidal volume

alarm*

V

TI MAND

1

V

TI MAND

V

TI SPONT

1

V

TI SPONT