Page 1

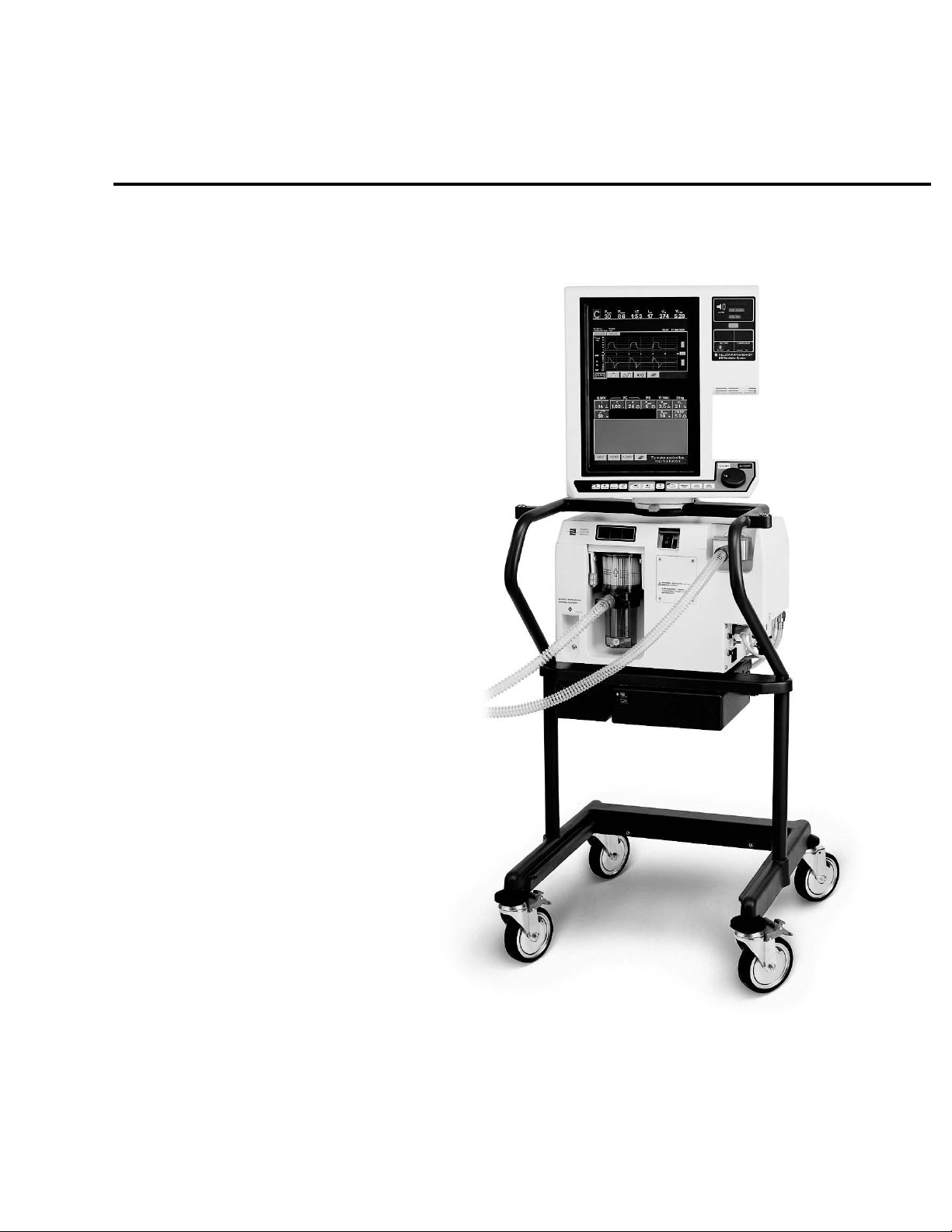

840

Ve nt i l at or Sys t e m

Service Manual

4-070496-00 Rev A

August, 2003

anual 4-070089-00 Rev. B (10/02)

Page 2

Page 3

Copyright information

Copyright 2003 Puritan-Bennett Corporation. All rights reserved. The 840TM Ventilator System is manufactured in

accordance with Puritan Bennett proprietary information, covered by one or more of the following U.S. Patents and

foreign equivalents: 4,954,799; 5,161,525; 5,271,389; 5,301,921; 5,319,540; 5,339,807; 5,368,019; and 5,390,666.

840, 800 Series, DualView, SandBox, SmartAlert, Flow-by, and are trademarks of Puritan-Bennett Corporation.

The information contained in this manual is the sole property of Puritan-Bennett Corporation and may not be

duplicated without permission. This manual may be revised or replaced by Puritan Bennett at any time and without

notice. You should ensure that you have the most current applicable version of this manual; if in doubt, contact the

Technical Support Department of Puritan-Bennett Corp. or your local representative. While the information set forth

herein is believed to be accurate, it is not a substitute for the exercise of professional judgment.

The ventilator should be operated and serviced only by trained professionals. Puritan Bennett’s sole responsibility

with respect to the ventilator, and its use, is as stated in the limited warranty provided.

Nothing in this manual shall limit or restrict in any way Puritan Bennett’s right to revise or otherwise change or

modify the equipment (including its software) described herein, without notice. In the absence of an express, written

agreement to the contrary, Puritan Bennett has no obligation to furnish any such revisions, changes, or

modifications to the owner or user of the equipment (including its software) described herein.

Manufacturer: Authorized Representative:

Puritan-Bennett Corporation Tyco Healthcare UK Limited

4280 Hacienda Drive 154 Fareham Road

Pleasanton, CA 94588-2719 Gosport

USA PO13 0AS

UK

Phone: +800.255.6774

Page 4

Preface

Definitions

This manual uses three special indicators to convey information of a specific nature.

They include:

Warning

Indicates a condition that can endanger the patient or the ventilator operator.

Caution

Indicates a condition that can damage the equipment.

NOTE:

Indicates points of particular interest that make operation of the ventilator more efficient or

convenient.

Warnings, cautions, and notes

Please take the time to familiarize yourself with the following caveats as they cover safety

considerations, special handling requirements, and regulations that govern the use of the 840

Ventilator System.

• To ensure proper servicing and avoid the possibility of physical injury, only qualified

personnel should attempt to service or make authorized modifications to the ventilator.

The user of this product shall have sole responsibility for any ventilator malfunction

due to operation or maintenance performed by anyone not trained by Puritan Bennett

staff.

• To avoid an electrical shock hazard while servicing the ventilator, be sure to remove all

power to the ventilator by disconnecting the power source and turning off all ventilator

power switches.

• To avoid a fire hazard, keep matches, lighted cigarettes, and all other sources of ignition

(e.g., flammable anesthetics and/or heaters) away from the 840 Ventilator System and

oxygen hoses.

Do not use oxygen hoses that are worn, frayed, or contaminated by combustible materials

such as grease or oils. (Textiles, oils, and other combustibles are easily ignited and burn

with great intensity in air enriched with oxygen.)

In case of fire or a burning smell, immediately disconnect the ventilator from the oxygen

supply, facility power, and BPS.

• When handling any part of the 840 Ventilator System, always follow your hospital

infection control guidelines for handling infectious material.

Puritan Bennett recognizes that cleaning, sterilization, sanitation, and disinfection

practices vary widely among healthcare institutions. It is not possible for Puritan Bennett

to specify or require specific practices that will meet all needs, or to be responsible for the

effectiveness of cleaning, sterilization, and other practices carried out in the patient care

setting.

i 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual Rev. A (08/03)

Page 5

Preface

Puritan Bennett does recommend that users of its products that require cleaning and

sterilization/disinfection consider the National Standards and Recommended Practices for

Sterilization published by the Association for the Advancement of Medical

Instrumentation (AAMI), as well as the following Center for Disease Control (CDC)

publications: Guidelines for Maintenance of In-use Respiratory Therapy Equipment and

Guidelines for Prevention of Nosocomial Pneumonia.

• Patients on life-support equipment should be appropriately monitored by competent

medical personnel and suitable monitoring devices.

•The 840 Ventilator System is not intended to be a comprehensive monitoring device and

does not activate alarms for all types of dangerous conditions for patients on life-support

equipment.

• For a thorough understanding of ventilator operations, be sure to thoroughly read the 840

Ventilator System Operator's and Technical Reference Manual before attempting to use the

system.

• Before activating any part of the ventilator, be sure to check the equipment for proper

operation and, if appropriate, run SST (Short Self Test).

• Do not use sharp objects to make selections on the graphical user interface (GUI) display

or keyboard.

• Federal law (U.S.) restricts the sale of this device to, or by the order of, any physician.

• Check the ventilator periodically as outlined in this manual; do not use if defective.

Immediately replace parts that are broken, missing, obviously worn, distorted, or

contaminated.

• An alternative source of ventilation should always be available when using the 840

Ventilator System.

•The 840 Ventilator System is a member of the 800 Series™ family of products. Any

accessory whose model number is 80x (for example, the 802 Backup Power Source or 806

Compressor Unit) operates with all 800 Series ventilators. An accessory whose model

number is 84x operates only with a model 840 Ventilator System.

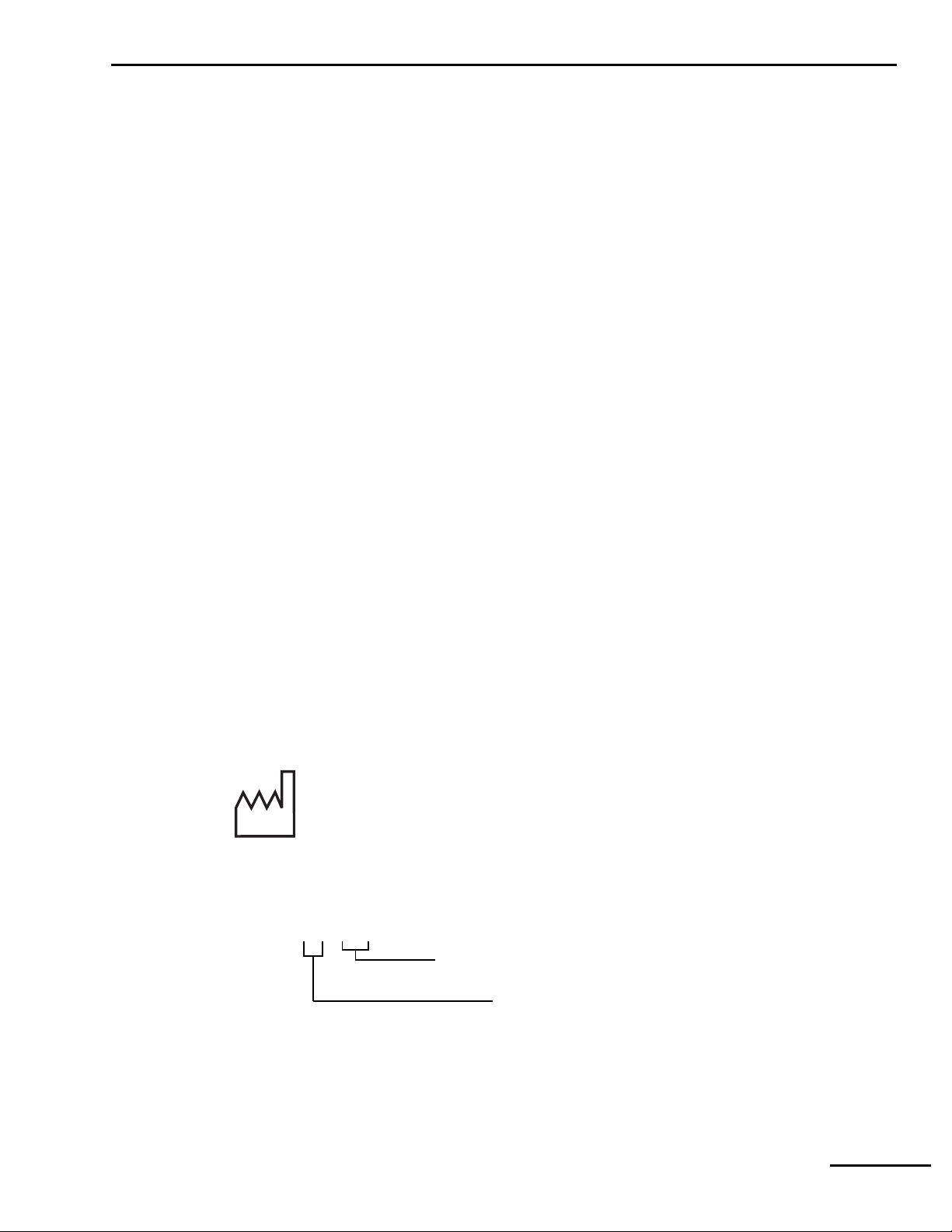

Year of man ufact ure

The year of manufacture for ventilators whose serial numbers begin with 4200 is indicated on

the rear panel of the BDU as shown here. The two digit number following the year indicates

the month of manufacture.

2003 – 10

For ventilators whose serial numbers begin with 3510, the year of manufacture is indicated by

the serial number’s 5th and 6th digits. In the example below, a ventilator with serial number

3510021223 was the 1223rd unit built in 2002.

3510 02 1223

Sequential number

Year of manufacture

840 Ventilator System Service Manual 4-070496-00 Rev. A (08/03) ii

Page 6

Preface

Electromagnetic susceptibility

The 840 Ventilator System complies with the requirements of IEC 601-1-2 (EMC Collateral

Standard), including the E-field susceptibility requirements at a level of 10 volts per meter, at

frequencies from 26 MHz to 1 GHz, and the ESD requirements of this standard. However, even at

this level of device immunity, certain transmitting devices (cellular phones, walkie-talkies,

cordless phones, paging transmitters, etc.) emit radio frequencies that could interrupt

ventilator operation if located in a range too close to the ventilator. It is difficult to determine

when the field strength of these devices becomes excessive. Practitioners should be aware that

radio frequency emissions are additive, and that the ventilator must be located a sufficient

distance from transmitting devices to avoid interruption. Do not operate the ventilator in a

magnetic resonance imaging (MRI) environment. Section 7 describes possible ventilator

alarms and what to do if they occur. Consult with your institution’s biomedical engineering

department in case of interrupted ventilator operation and before relocating any life support

equipment.

Customer assistance

For further assistance contact Puritan-Bennett Corporation at 1.800.255.6774 or your local

Puritan Bennett representative.

About this manual

This manual provides information needed to service the Puritan Bennett 840 Ventilator

System. This manual is intended for use by certified biomedical engineering technicians or

personnel with equivalent experience and training in servicing this type of equipment. It is

recommended that the user complete the Puritan Bennett training class geared specifically to

the 840 Ventilator System.

While this manual covers the ventilator configurations currently supported by Puritan

Bennett, it may not be all-inclusive and may not be applicable to your ventilator. Within the

USA, contact Puritan Bennett at 1.800.255.6774 for questions regarding the applicability of

the information.

iii 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual Rev. A (08/03)

Page 7

1 General information

1.1 How to use this manual...............................................................................................1-1

1.2 General product description ........................................................................................1-1

1.3 Configuration information...........................................................................................1-2

1.4 Accessories ..................................................................................................................1-2

1.5 Specifications ..............................................................................................................1-3

1.6 Compliance and approvals ..........................................................................................1-7

1.7 Technical information..................................................................................................1-8

1.8 Range, resolution, accuracy, and new patient/default settings ..................................1-10

1.9 Tools, equipment, and service materials ....................................................................1-19

1.10 Periodic maintenance ..............................................................................................1-22

1.11 Service kits ..............................................................................................................1-24

1.12 Controls and indicators .........................................................................................1-24

1.13 Onscreen symbols and abbreviations.......................................................................1-41

1.14 Ventilator serial numbers and software version ........................................................1-41

1.15 Service philosophy...................................................................................................1-41

SECTION

CONTENTS

2 Theory of operation

2.1 Major ventilator subassemblies ....................................................................................2-1

2.1.1 Breath delivery unit (BDU)................................................................................... 2-2

2.1.2 Graphic user interface (GUI) ................................................................................2-2

2.1.3 806 Compressor Unit ..........................................................................................2-3

2.1.4 802 Backup Power Source (BPS)..........................................................................2-4

2.1.5 Cart.....................................................................................................................2-4

2.1.6 Patient system .....................................................................................................2-5

2.2 Operational overview ..................................................................................................2-6

2.3 Pneumatic system ....................................................................................................... 2-9

2.3.1 Inspiratory module ............................................................................................2-14

2.3.1.1 Gas supply conditioning subsystem.........................................................2-15

2.3.1.2 Flow control subsystem ........................................................................... 2-20

2.3.1.3 Safety valve and inspiration monitoring subsystem..................................2-23

2.3.1.4 Inspiratory module operation ..................................................................2-28

2.3.2 Patient System................................................................................................... 2-31

2.3.2.1 Patient system components.....................................................................2-32

2.3.2.2 Patient system operation .........................................................................2-33

2.3.3 Exhalation module.............................................................................................2-33

2.3.3.1 Exhalation module components ..............................................................2-34

2.3.3.2 Exhalation module operation...................................................................2-35

840 Ventilator System Service Manual 4-070496-00 Rev. A (08/03)

vii

Page 8

Contents

2.3.4 806 Compressor Unit........................................................................................ 2-38

2.3.4.1 806 Compressor unit components .......................................................... 2-38

2.3.4.2 806 Compressor unit operation............................................................... 2-41

2.4.1 Summary of electrical components ................................................................... 2-42

2.4.2 Overview of electrical system operation ............................................................ 2-47

2.4.3 ac distribution components............................................................................... 2-50

2.4.3.1 Power cord ............................................................................................. 2-50

2.4.3.2 ac panel .................................................................................................. 2-50

2.4.3.3 Power switch........................................................................................... 2-53

2.4.4 Power supply .................................................................................................... 2-54

2.4.5 BPS ................................................................................................................... 2-56

2.4.6 Card Cage ........................................................................................................ 2-58

2.4.6.1 Motherboard PCB ................................................................................... 2-60

2.4.6.2 BDU CPU PCB ......................................................................................... 2-63

2.4.6.3 Analog interface (AI) PCB ........................................................................ 2-67

2.4.7 Data key subsystem .......................................................................................... 2-69

2.4.8 GUI................................................................................................................... 2-69

2.4.8.1 GUI CPU PCB ......................................................................................... 2-69

2.4.8.2 Touch frame PCB .................................................................................... 2-75

2.4.8.3 Keyboard assembly with knob................................................................. 2-76

2.4.8.4 GUI LED PCB........................................................................................... 2-78

2.4.8.5Backlight inverter PCB and LCD lamps ........................................................ 2-79

2.4.8.6 GUI alarm assembly ................................................................................ 2-80

2.4.9 BDU LED PCB ................................................................................................... 2-81

2.4.10 Inspiratory electronics PCB.............................................................................. 2-81

2.4.11 Exhalation transducer PCB .............................................................................. 2-83

2.4.11.1BD (continuous-tone) alarm assembly....................................................... 2-85

2.4.12 806 Compressor unit ...................................................................................... 2-85

2.4.12.1806 compressor unit ac power distribution components and motor.......... 2-86

2.4.12.2 806 compressor PCB............................................................................... 2-86

2.4.12.3806 Compressor unit operation ................................................................ 2-90

2.5 Breath delivery.......................................................................................................... 2-92

2.5.1 Inspiration......................................................................................................... 2-92

2.5.1.1Pressure triggering...................................................................................... 2-94

2.5.1.2 Flow triggering ....................................................................................... 2-94

2.5.1.3 Time-cycling method .............................................................................. 2-94

2.5.1.4 Operator triggering................................................................................. 2-94

2.5.2 Exhalation......................................................................................................... 2-94

2.5.2.1Time-cycling method.................................................................................. 2-95

2.5.2.2 End-inspiratory flow method................................................................... 2-95

2.5.2.3 Airway pressure method.......................................................................... 2-95

2.5.2.4 Time limit................................................................................................ 2-95

2.5.2.5 High circuit pressure limit........................................................................ 2-95

2.5.2.6 High ventilator pressure limit .................................................................. 2-95

viii 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual

Page 9

3Self tests

Contents

2.6 Other hardware operations ....................................................................................... 2-97

2.6.1 Gas supply and control......................................................................................2-97

2.6.2 Data monitoring................................................................................................2-97

2.6.3 Pressure transducer autozero.............................................................................2-98

2.6.4 Power monitoring and power fail handling...................................................... 2-100

2.6.4.1 Loss of power source ............................................................................. 2-100

2.6.4.2 Supply voltage monitoring ....................................................................2-101

2.7.1 Safety valve open (SVO) state..........................................................................2-101

2.7.2 Occlusion handling .........................................................................................2-103

2.7.2.1 When the ventilator declares an occlusion .............................................2-103

2.7.2.2 Occlusion detection and handling .........................................................2-103

3.1 Introduction ................................................................................................................3-1

3.2 How to enter Service Mode .........................................................................................3-1

3.3 Self tests and background checks ................................................................................3-1

3.3.1 POST...................................................................................................................3-1

3.3.2 SST......................................................................................................................3-1

3.3.3 EST .....................................................................................................................3-2

3.3.4 Background checks.............................................................................................. 3-2

3.3.5 When self tests are run ........................................................................................ 3-2

3.4 Power on self test (POST) ............................................................................................3-3

3.4.1 Safety .................................................................................................................3-7

3.4.2 POST characteristics ............................................................................................3-7

3.4.3 POST following power interruptions....................................................................3-8

3.4.4 POST user interface .............................................................................................3-8

3.4.5 Structure of POST................................................................................................3-9

3.5 SST (short self test)....................................................................................................3-11

3.5.1 When to run......................................................................................................3-11

3.5.2 Hardware requirements .....................................................................................3-12

3.5.3 Running SST......................................................................................................3-13

3.6 EST (extended self test) .............................................................................................3-17

3.6.1 Description........................................................................................................3-17

3.6.2 When to run......................................................................................................3-17

3.6.3 Hardware requirements .....................................................................................3-18

3.6.4 Running EST......................................................................................................3-18

4 Service mode

4.1 Accessing service mode ...............................................................................................4-1

4.2 Service mode functions ...............................................................................................4-3

4.2.1 SST RESULT: Displaying SST results......................................................................4-5

4.2.2 DIAG LOG: Displaying error and status logs.........................................................4-5

4.2.3 Alarm log: Displaying the alarm history ............................................................... 4-7

4.2.4 VENT CONFIG: Displaying software revisions and serial numbers ........................4-7

4.2.5 OPERATION TIME: Displaying ventilator and compressor elapsed hours .............. 4-7

4.2.6 TEST SUMMARY: Displaying results from EST and SST .........................................4-7

4.2.7 EST: Extended self test.........................................................................................4-7

4.2.8 DATE/TIME: Adjusting date and time...................................................................4-7

4.2.9 EXIT: Exiting service mode...................................................................................4-7

840 Ventilator System Service Manual 4-070496-00 Rev. A (08/03) ix

Page 10

Contents

4.2.10 Other screens.................................................................................................... 4-8

4.2.11 Service Mode Setup .......................................................................................... 4-8

4.2.12 External Test Control: Performing remote ventilator testing .............................. 4-8

4.2.13 Exp Valve Calibration ........................................................................................ 4-9

4.2.13.1 Running Exp Valve Calibration .................................................................. 4-9

4.2.14 Vent Inop Test ............................................................................................... 4-11

4.2.14.1 Running the Vent Inop Test..................................................................... 4-11

4.2.14.2 Flow Sensor Calibration........................................................................... 4-12

4.2.15 Running Flow Sensor Calibration .................................................................... 4-13

4.2.15.1 Atmospheric Pressure Transducer ............................................................ 4-13

4.2.16 Automatically executed service mode functions .............................................. 4-14

4.2.16.1 Initialize Flow Sensor............................................................................... 4-14

4.2.16.2 Cal Info Duplication ................................................................................ 4-14

4.2.17 Serial number setup ....................................................................................... 4-15

4.2.17.1 Running Serial Number Setup ................................................................. 4-15

4.2.18 Datakey Update .............................................................................................. 4-16

4.2.19 Serial Loopback Test ....................................................................................... 4-17

5 Performance verification

5.1 Tools, test equipment, and service materials ............................................................... 5-1

5.2 When to run ............................................................................................................... 5-1

5.3 Preliminary ventilator cleaning and inspection ............................................................ 5-4

5.4 Preliminary ventilator setup......................................................................................... 5-5

5.5 Preliminary calibrations and tests ................................................................................ 5-5

5.6 Performance verification guidelines............................................................................. 5-7

5.7 Performance verification tests...................................................................................... 5-7

5.7.1 Electrical safety test ............................................................................................ 5-8

5.7.2 Ground isolation check ....................................................................................... 5-8

5.7.3 Extended self test (EST)....................................................................................... 5-9

5.7.4 Regulator setting verification............................................................................... 5-9

5.7.5 Serial loopback test (10.4-inch GUI only) .......................................................... 5-10

5.7.6 Performance verification using PTS 2000 Performance

Test System and BreathLab 840 VTS software ................................................... 5-10

5.7.7 Manual ventilator check using equipment other than

PTS 2000 Performance Test System................................................................... 5-10

6 Diagnostic codes

6.1 Introduction................................................................................................................ 6-1

6.2 Reference Tables ......................................................................................................... 6-1

6.3 Troubleshooting.......................................................................................................... 6-2

6.4 POST fault handling ................................................................................................... 6-2

6.5 Diagnostic CPU LED arrays.......................................................................................... 6-3

6.6 Diagnostic codes......................................................................................................... 6-4

6.6.1 How to interpret diagnostic codes ...................................................................... 6-4

6.7 Organization of diagnostic codes table ....................................................................... 6-5

6.8 System Diagnostic Log and BDU POST analog devices test ....................................... 6-54

x 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual

Page 11

6.9 Diagnostic codes for POST faults ...............................................................................6-55

6.9.1 POST interrupt errors and test failures ...............................................................6-64

6.10 SST and EST test sequences and diagnostic codes.................................................... 6-66

6.10.1 How to troubleshoot LCD inverter PCB faults (UT0002).................................6-102

7 Alarm handling

7.1 Alarm classifications.....................................................................................................7-1

7.2 Responding to alarms..................................................................................................7-2

8 Service and repair

8.1 How to use this section................................................................................................8-1

8.2 General repair safety....................................................................................................8-1

8.3 General repair guidelines.............................................................................................8-2

8.4 Repair-related cleaning................................................................................................ 8-2

8.5 Electrical cables and pneumatic tubing........................................................................8-3

8.6 Adhesive use................................................................................................................8-3

8.7 Leak testing.................................................................................................................8-3

8.8 Electrostatic discharge control .....................................................................................8-4

8.8.1 ESD procedures and precautions .........................................................................8-4

8.9 Replacement part ordering.......................................................................................... 8-4

8.10 Testing, calibration, and other post-service procedures..............................................8-4

8.11 Patient system and accessories...................................................................................8-6

8.12 Graphic user interface (GUI) ......................................................................................8-6

8.13 Repairing the 10.4-inch GUI ......................................................................................8-8

8.13.1 Removing or installing the 10.4-inch GUI ..........................................................8-8

8.13.2 Removing the 10.4-inch GUI cable assembly .....................................................8-9

8.13.3 Replacing the 10.4-inch GUI cable assembly......................................................8-9

8.13.4 Removing 10.4-inch GUI rear housing...............................................................8-9

8.13.5 Replacing 10.4-inch GUI rear housing .............................................................8-10

8.13.6 Removing the 10.4-inch CPU shield ................................................................8-11

8.13.7 Removing the 10.4-inch GUI backlight inverter PCBs.......................................8-11

8.13.8 Removing the 10.4-inch GUI CPU PCB ............................................................ 8-12

8.13.9 10.4-inch GUI support bracket ........................................................................8-14

8.13.9.1 Removing the 10.4-inch GUI support bracket..........................................8-14

8.13.10 10.4-inch LCD panels ...................................................................................8-15

8.13.10.1Removing the 10.4-inch LCD panels........................................................8-15

8.13.11 10.4-inch touchframe PCB (MKG Touch)...................................................... 8-15

8.13.11.1Removing the 10.4-inch touchframe PCB................................................8-15

8.13.12 Replacing the 10.4-inch touchframe PCB.......................................................8-16

8.13.13 10.4-inch GUI LED PCB .................................................................................8-16

8.13.13.1Removing the 10.4-inch GUI LED PCB..................................................... 8-16

8.13.13.2Replacing the 10.4-inch GUI LED PCB .....................................................8-16

8.13.14 10.4-inch GUI alarm assembly.......................................................................8-17

8.13.14.1Removing the 10.4-inch GUI alarm assembly...........................................8-17

8.13.14.2Replacing the 10.4-inch GUI alarm assembly...........................................8-17

8.13.15 10.4-inch GUI keyboard assembly .................................................................8-18

8.13.15.1Replacing the 10.4-inch GUI keyboard assembly .....................................8-18

Contents

840 Ventilator System Service Manual 4-070496-00 Rev. A (08/03) xi

Page 12

Contents

8.13.16 10.4-inch GUI front housing ......................................................................... 8-18

8.13.16.1Replacing the 10.4-inch front housing .................................................... 8-18

8.13.17 10.4-inch rotor housing ................................................................................ 8-19

8.13.17.1Replacing the 10.4-inch rotor housing.................................................... 8-19

8.14 Repairing the 9.4-inch GUI...................................................................................... 8-20

8.14.1 Removing the 9.4-inch GUI touch screen bezel............................................... 8-20

8.14.2 9.4-inch GUI window...................................................................................... 8-21

8.14.3 Installing the 9.4-inch bezel ............................................................................ 8-22

8.14.4 The 9.4-inch keyboard assembly ..................................................................... 8-22

8.14.4.1 Removing 9.4-inch keyboard assembly.................................................... 8-22

8.14.4.2 Installing the 9.4-inch keyboard assembly ............................................... 8-24

8.14.5 Removing or installing the 9.4-inch GUI.......................................................... 8-24

8.14.6 9.4-inch GUI rear housing............................................................................... 8-25

8.14.6.1 Removing 9.4-inch GUI rear housing....................................................... 8-25

8.14.6.2 Installing 9.4-inch GUI rear housing ........................................................ 8-26

8.14.7 9.4-inch GUI alarm assembly .......................................................................... 8-27

8.14.7.1 Removing 9.4-inch GUI alarm assembly .................................................. 8-27

8.14.7.2 Installing 9.4-inch GUI alarm assembly.................................................... 8-28

8.14.8 9.4-inch GUI backlight inverter PCB and GUI LED PCB.................................... 8-28

8.14.8.1 Removing 9.4-inch GUI backlight inverter PCB........................................ 8-28

8.14.8.2Installing 9.4-inch GUI backlight inverter PCB ........................................... 8-29

8.14.8.3 Removing 9.4-inch GUI LED PCB............................................................. 8-29

8.14.8.4 Installing 9.4-inch GUI LED PCB .............................................................. 8-29

8.14.9 GUI EMI shield ................................................................................................ 8-30

8.14.9.1 Removing the GUI EMI shield.................................................................. 8-30

8.14.9.2 Installing the 9.4-inch GUI EMI shield...................................................... 8-30

8.14.10 9.4-inch video controller and VGA LCD controller PCBs ................................ 8-30

8.14.10.1Removing 9.4-inch VGA LCD controller PCBs (older CPU PCB)................ 8-31

8.14.10.2Installing 9.4-inch VGA LCD controller PCBs (older CPU PCB)................. 8-31

8.14.11 9.4-inch GUI CPU PCB .................................................................................. 8-32

8.14.11.1Removing the 9.4-inch GUI CPU PCB...................................................... 8-32

8.14.11.2Installing the 9.4-inch GUI CPU PCB ....................................................... 8-32

8.14.12 9.4-inch touchframe PCB (Carroll Touch)...................................................... 8-33

8.14.12.1Removing the 9.4-inch touchframe PCB.................................................. 8-33

8.14.12.2Reinstalling the 9.4-inch touchframe PCB................................................ 8-34

8.14.13 9.4-inch backlight panels and LCD panels .................................................... 8-36

8.14.13.1Removing a 9.4-inch backlight panel and LCD pane............................... 8-36

8.14.13.2Reinstalling a backlight panel and LCD panel .......................................... 8-36

8.14.14 9.4-inch GUI cooling vent filters.................................................................... 8-38

8.14.15 9.4-inch rotor housing .................................................................................. 8-39

8.14.15.1Removing the 9.4-inch rotor housing...................................................... 8-39

8.14.15.2Installing the 9.4-inch rotor housing ....................................................... 8-39

8.15 Breath delivery unit (BDU) ...................................................................................... 8-40

8.15.1 Removing BDU ............................................................................................... 8-43

8.15.2 BDU power cord and retainer.......................................................................... 8-44

8.15.3 Installing BDU................................................................................................. 8-44

8.15.4 Analog interface (AI) PCB and breath delivery (BD) CPU PCB .......................... 8-45

8.15.4.1 Removing AI PCB or BD CPU PCB ........................................................... 8-46

8.15.4.2 Installing AI PCB or BD CPU PCB ............................................................. 8-47

xii 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual

Page 13

Contents

8.15.5 Power supply assembly....................................................................................8-48

8.15.5.1 Removing power supply assembly ...........................................................8-48

8.15.5.2 Installing power supply assembly.............................................................8-48

8.15.6 Power switch (S1)............................................................................................8-49

8.15.6.1 Removing power switch (S1)...................................................................8-49

8.15.6.2 Installing power switch (S1).....................................................................8-49

8.15.7 Humidifier receptacle (100 – 120 V models only) ............................................8-50

8.15.7.1 Removing humidifier receptacle...............................................................8-50

8.15.7.2 Installing humidifier receptacle ................................................................8-50

8.15.7.3 ac panel...................................................................................................8-51

8.15.8 Inspiratory module ..........................................................................................8-52

8.15.8.1 Inspiratory module modifications.............................................................8-52

8.15.8.2 Additional noise suppression (ferrite cores)..............................................8-52

8.15.8.3 Inspiratory module O-rings......................................................................8-53

8.15.8.4 Air inlet filter (F2).....................................................................................8-53

8.15.8.5 Fascia panel.............................................................................................8-54

8.15.8.6 Oxygen and air pressure switches (PS1 and PS2) .....................................8-56

8.15.8.7 PSOL cartridge ........................................................................................ 8-57

8.15.8.8 Removing inspiratory module..................................................................8-58

8.15.8.9 Leak testing inspiratory module ............................................................... 8-58

8.15.8.10Installing inspiratory module ...................................................................8-59

8.15.8.11Oxygen sensor (OS) ................................................................................ 8-59

8.15.8.12Inspiratory check valve (CV3) ..................................................................8-62

8.15.8.13Right-side plate .......................................................................................8-62

8.15.8.14Inspiratory electronics PCB ...................................................................... 8-64

8.15.8.15Left-side plate..........................................................................................8-64

8.15.8.16PSOL manifold ........................................................................................8-65

8.15.8.17Oxygen and air flow sensors (Q1 and Q2)...............................................8-67

8.15.8.18Safety valve .............................................................................................8-68

8.15.8.19Check valve assembly, regulator assembly, and flow sensor manifold ......8-70

8.15.8.20Oxygen and air regulators (REG1 and REG2) ........................................... 8-72

8.15.8.21Inspiratory pressure transducer autozero solenoid (SOL1)........................8-73

8.15.8.22Inspiratory floor assembly........................................................................8-73

8.15.9 Exhalation module...........................................................................................8-74

8.15.9.1 Exhalation collector vial (ECV) and expiratory filter (F9)...........................8-74

8.15.9.2 Removing exhalation module cover......................................................... 8-74

8.15.9.3 Removing exhalation module ..................................................................8-76

8.15.9.4 Installing exhalation module....................................................................8-76

8.15.9.5 Exhalation valve (EV) ...............................................................................8-77

8.15.9.6 Exhalation flow sensor (Q3).....................................................................8-80

8.15.9.7 Exhalation transducer PCB....................................................................... 8-81

8.15.9.8 Expiratory pressure transducer autozero solenoid (SOL2).........................8-82

8.15.9.9 Exhalation heater (EXH HTR) and check valve (CV5) ................................8-83

8.15.10 BDU housing................................................................................................. 8-84

8.15.10.1Removing BDU housing...........................................................................8-84

8.15.10.2Installing BDU housing............................................................................8-86

8.15.10.3Motherboard PCB ...................................................................................8-86

8.15.10.4BDU alarm assembly................................................................................8-87

840 Ventilator System Service Manual 4-070496-00 Rev. A (08/03) xiii

Page 14

Contents

8.15.11 Power indicator............................................................................................. 8-88

8.15.11.1Removing power indicator...................................................................... 8-88

8.15.11.2Installing power indicator........................................................................ 8-89

8.15.11.3Alarm blindmate cable............................................................................ 8-89

8.15.11.4Inspiratory blindmate cable..................................................................... 8-90

8.15.11.5dc power supply blindmate cable ........................................................... 8-91

8.15.11.6ac power supply blindmate harness ........................................................ 8-92

8.15.12 Release handle .............................................................................................. 8-94

8.15.12.1Removing release handle ........................................................................ 8-94

8.15.12.2Installing release handle.......................................................................... 8-94

8.16 806 compressor unit............................................................................................... 8-94

8.17 Servicing the 806 compressor ................................................................................. 8-95

8.17.1 Compressor inlet filter..................................................................................... 8-95

8.17.2 Removing and installing the compressor inlet filter ......................................... 8-95

8.17.3 Removing compressor from cart ..................................................................... 8-95

8.17.3.1 Disconnecting compressor from BDU...................................................... 8-95

8.17.3.2 Removing compressor from cart.............................................................. 8-96

8.17.4 Removing top cover........................................................................................ 8-96

8.17.5 Installing top cover ......................................................................................... 8-97

8.17.6 Cooling fans.................................................................................................... 8-97

8.17.6.1 Removing a cooling fan........................................................................... 8-97

8.17.6.2 Installing a fan......................................................................................... 8-98

8.17.7 Removing the back panel................................................................................ 8-98

8.17.8 Reinstalling the back panel.............................................................................. 8-98

8.17.9 Replacing an accumulator fitting and O-ring................................................... 8-99

8.17.10 Pneumatic hoses ........................................................................................... 8-99

8.17.11 Plenum assembly ........................................................................................ 8-100

8.17.11.1Removing the plenum assembly............................................................ 8-101

8.17.12 Heat exchanger (HE)................................................................................... 8-102

8.17.12.1Replacing the heat exchanger............................................................... 8-102

8.17.13 Removing and replacing the ac power cord................................................ 8-102

8.17.14 Removing and replacing the data cable ...................................................... 8-102

8.17.15 Compressor PCB ......................................................................................... 8-103

8.17.15.1Removing and replacing the compressor PCB ....................................... 8-103

8.17.16 Air dryer (dryer) and solenoid valve assembly.............................................. 8-103

8.17.16.1Removing and reinstalling the air dryer

and solenoid valve assembly and replacing filters8-104

8.17.17 Compressor assembly ................................................................................. 8-105

8.17.17.1Removing the compressor assembly...................................................... 8-105

8.17.17.2Replacing the coalescing filter element ................................................. 8-106

8.17.18 Replacing the compressor panels ................................................................ 8-107

8.17.19 Reinstalling the plenum assembly................................................................ 8-108

8.17.20 Reconnecting electrical cables.................................................................... 8-108

8.17.21 Replacing the Tinnerman clips .................................................................... 8-108

8.17.22 Reinstalling the back panel/accumulator assembly...................................... 8-108

8.17.23 Replacing the main inlet filter and reinstalling the top................................. 8-109

8.17.24 Reinstalling the compressor module............................................................ 8-109

8.17.25 Running performance verification test......................................................... 8-109

xiv 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual

Page 15

9 Parts list

Contents

8.18 Backup power source (BPS) ................................................................................... 8-110

8.18.1 Removing BPS ...............................................................................................8-110

8.18.2 Installing BPS.................................................................................................8-111

8.18.3 Battery pack .................................................................................................. 8-111

8.18.3.1 Removing battery pack..........................................................................8-111

8.18.3.2 Installing battery pack ...........................................................................8-112

8.18.4 BPS PCB ........................................................................................................8-113

8.18.4.1 Removing BPS PCB................................................................................ 8-113

8.18.4.2 Installing BPS PCB..................................................................................8-113

8.19 Cart....................................................................................................................... 8-113

8.19.1 Casters ..........................................................................................................8-113

8.19.1.1 Removing casters...................................................................................8-113

8.19.1.2 Installing casters ....................................................................................8-114

8.19.2 Removing/installing GUI mount ....................................................................8-114

8.19.3 Removing/installing flex arm inserts ..............................................................8-115

9.1 How to use this parts list..............................................................................................9-1

9.2 840 Ventilator System patient system and accessories ................................................9-3

9.2.1 840 Ventilator System NeoMode patient system and accessories ........................9-6

9.3 Flex arm assembly .....................................................................................................9-8

9.3.1 Oxygen hose assemblies ...................................................................................9-10

9.3.2 Air hose assemblies ...........................................................................................9-12

9.3.3 Power cords .....................................................................................................9-14

9.4 Ventilator major assemblies ...................................................................................... 9-16

9.4.1 Label kits ..........................................................................................................9-18

9.4.2 10.4-inch GUI (graphic user interface) assembly ...............................................9-26

9.4.3 10.4-inch GUI (graphic user interface) handle ..................................................9-28

9.4.4 10.4-inch graphic user interface (GUI) rotor assembly ......................................9-30

9.4.5 10.4-inch GUI keyboards and speaker assembly ................................................9-32

9.4.6 9.4-inch graphic user interface (GUI) ................................................................ 9-35

9.4.6.19.4-inch GUI front housing assembly...........................................................9-38

9.4.6.29.4-inch GUI rear housing assembly ............................................................9-40

9.4.7 Breath delivery unit (BDU) ................................................................................ 9-42

9.4.7.1Exhalation module.......................................................................................9-46

9.4.7.2Inspiratory module ......................................................................................9-49

9.4.7.3BDU cover...................................................................................................9-58

9.4.7.4BDU chassis assembly.................................................................................. 9-60

9.4.7.5BDU chassis kit ............................................................................................9-62

9.4.8 806 compressor unit ........................................................................................9-64

9.4.8.1806 compressor base assembly.................................................................... 9-66

9.4.8.2806 compressor unit enclosure assembly.....................................................9-68

9.4.8.3806 compressor unit plenum assembly........................................................9-70

9.4.9 Backup power source (BPS) .............................................................................. 9-72

9.4.10 Cart assembly .................................................................................................9-74

840 Ventilator System Service Manual 4-070496-00 Rev. A (08/03) xv

Page 16

Contents

This page intentionally blank.

xvi 4-070496-00 Rev. A (08/03) 840 Ventilator System Service Manual

Page 17

SECTION

FIGURES

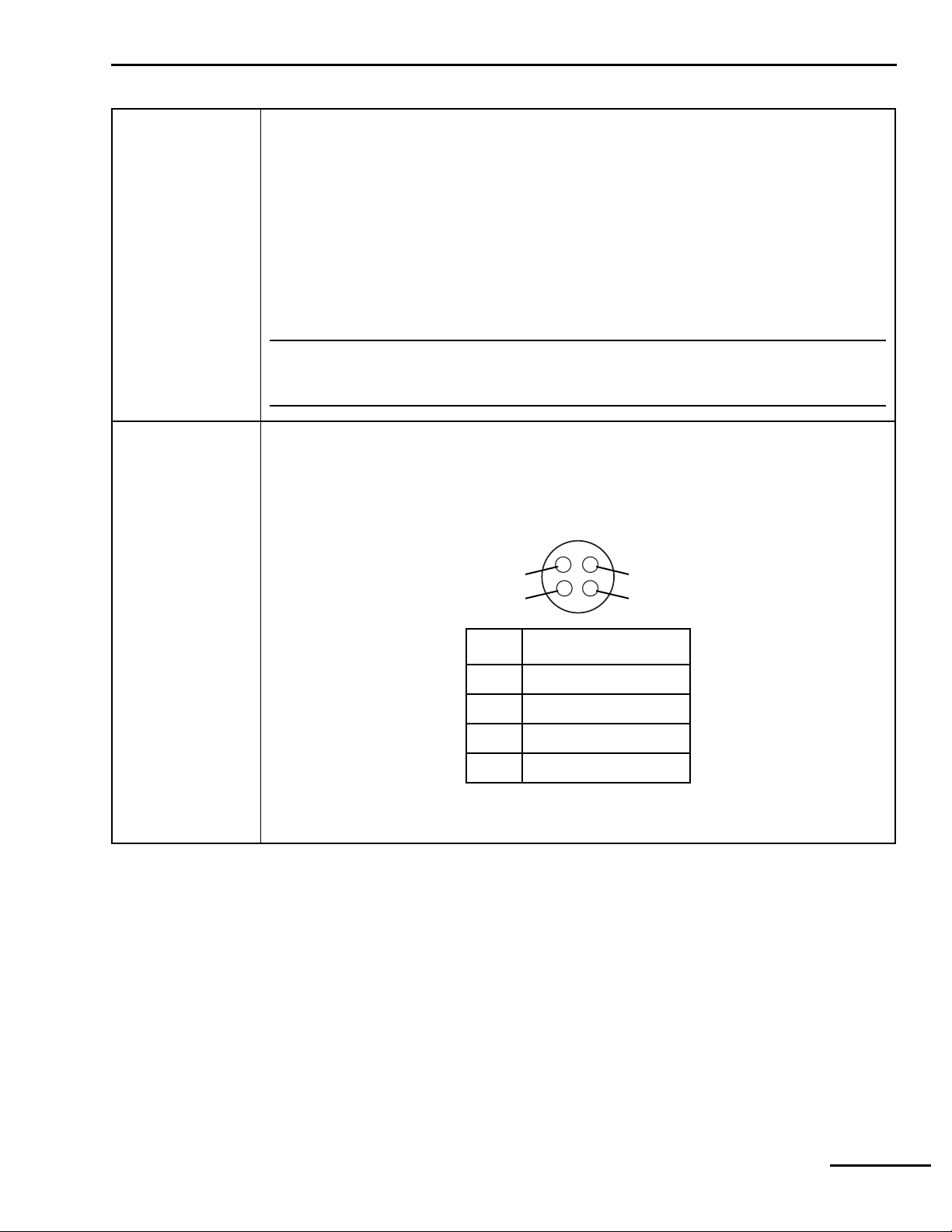

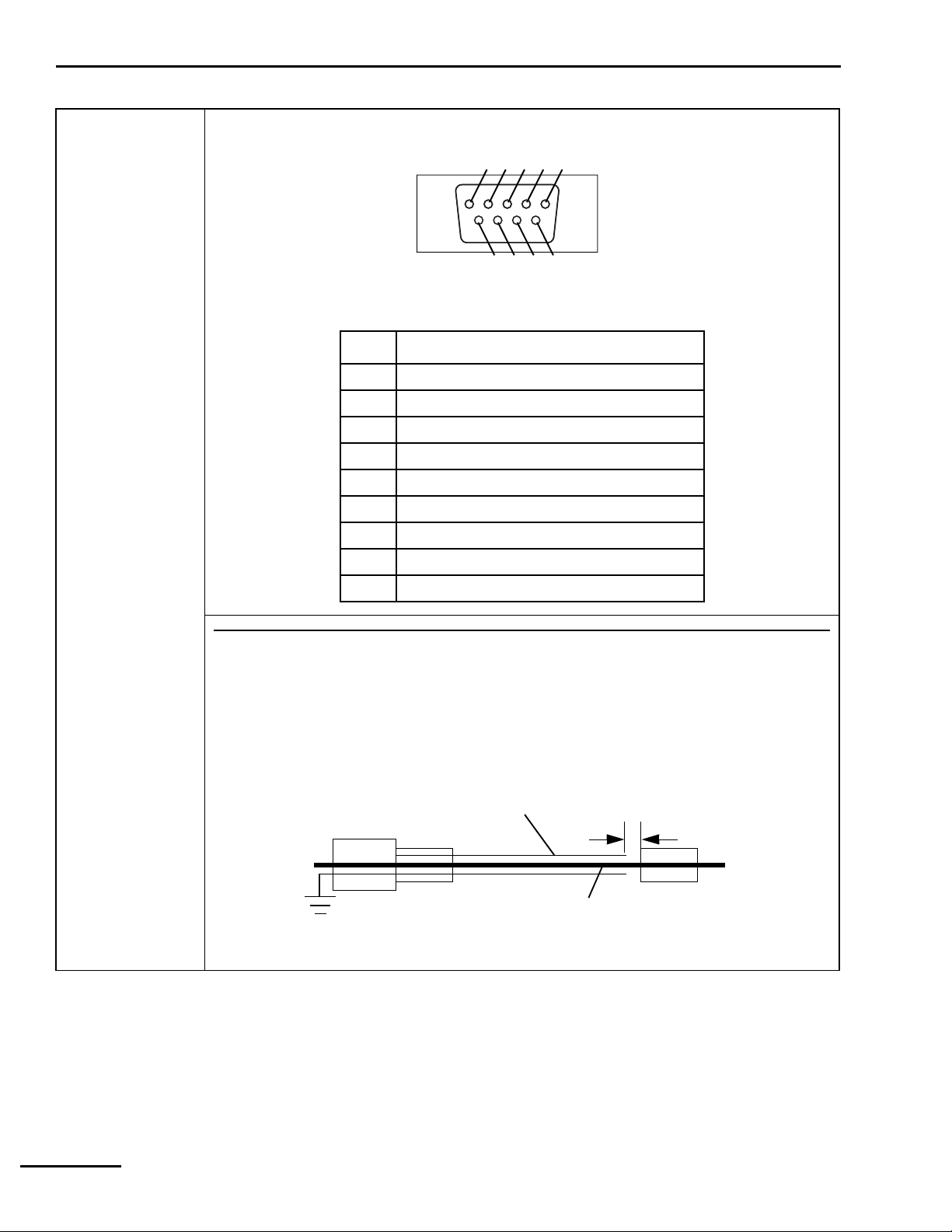

Figure 1-1. Remote alarm (nurse’s call) port pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 1-2. 840 Ventilator System RS-232 serial port pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Figure 1-3. Monochrome GUI front view (showing all keys) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Figure 1-4. 10.4-inch GUI rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-31

Figure 1-5. BDU front view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Figure 1-6. BDU I/O panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Figure 1-7. BDU right-side panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-37

Figure 1-8. BDU rear view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-38

Figure 1-9. GUI rear view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-39

Figure 1-10. BPS controls and indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-40

Figure 2-1. 840 Ventilator System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Figure 2-2. BDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3. 10.4-inch GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4. Compressor unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-5. BPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-6. Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-7. Patient system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-8. NeoMode patient system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-9. 840 Ventilator System block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Figure 2-10. Pneumatic system block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Figure 2-11. Pneumatic system diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-12. Inspiratory module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-13. Inspiratory module in ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-14. Inspiratory module gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-15. Gas supply conditioning subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-16. Gas supply conditioning subsystem gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-17. Gas supply conditioning subsystem components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-18. Flow control subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Figure 2-19. Flow control subsystem gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-20. Hot film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-21. Flow control subsystem components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Figure 2-22. Safety valve and inspiration monitoring subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-23. Inspiration monitoring subsystem gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Figure 2-24. Safety valve and inspiration monitoring subsystem components . . . . . . . . . . . . . . . . . . . 2-25

Figure 2-25. Safety valve open gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

Figure 2-26. Air flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Figure 2-27. Oxygen flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Figure 2-28. Patient system (minus exhalation collector vial and expiratory filter) . . . . . . . . . . . . . . . . 2-31

Figure 2-29. Patient system flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Figure 2-30. Exhalation module (removed from BDU). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Figure 2-31. Exhalation module flow diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

840 Ventilatory System Service Manual 4-070496-00 Rev. A (08/03)

xvii

Page 18

Figures

Figure 2-32. Exhalation module components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Figure 2-33. 806 compressor on cart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Figure 2-34. 806 Compressor Pneumatic diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

Figure 2-35. 806 components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Figure 2-36. Heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Figure 2-37. 806 water trap assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Figure 2-38. Air dryer assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Figure 2-39. 806 back panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Figure 2-40. 806 cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Figure 2-41. Electrical system block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Figure 2-42. ac panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

Figure 2-43. 840 Ventilator System interconnect diagram – ac panel . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Figure 2-44. Power switch (S1) and indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Figure 2-45. Power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Figure 2-46. 840 Ventilator System interconnect diagram – Power distribution . . . . . . . . . . . . . . . . . 2-55

Figure 2-47. BPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

Figure 2-48. BPS battery pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

Figure 2-49. BPS PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

Figure 2-50. Card cage with all PCBs installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Figure 2-51. 840 Ventilator System interconnect diagram – Card cage . . . . . . . . . . . . . . . . . . . . . . . . 2-59

Figure 2-52. Motherboard PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Figure 2-53. Motherboard PCB in place. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

Figure 2-54. Motherboard PCB block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

Figure 2-55. BD CPU PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-64

Figure 2-56. AI PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-67

Figure 2-57. Data key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-69

Figure 2-58. 10.4” GUI CPU PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Figure 2-59. 9.4” GUI CPU PCB and backlight inverter PCB in place . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Figure 2-60. 840 Ventilator System interconnect diagram – GUI 10.4-inch LCD panels . . . . . . . . . . . . 2-72

Figure 2-61. 840 Ventilator System interconnect diagram – GUI 9.4-inch LCD panels . . . . . . . . . . . . . 2-74

Figure 2-62. Touch Frame PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

Figure 2-63. Keyboard assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-77

Figure 2-64. GUI LED PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

Figure 2-65. 10.4” GUI LCD panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-79

Figure 2-66. 9.4-inch LCD panels and backlight tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

Figure 2-67. GUI alarm assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-80

Figure 2-68. BDU LED PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

Figure 2-69. Inspiratory electronics PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-81

Figure 2-70. 840 Ventilator System interconnect diagram – Inspiratory module . . . . . . . . . . . . . . . . . 2-82

Figure 2-71. Exhalation transducer PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-83

Figure 2-72. 840 Ventilator System interconnect diagram – Exhalation module . . . . . . . . . . . . . . . . . 2-84

Figure 2-73. BD alarm assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

Figure 2-74. 806 compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-85

Figure 2-75. 806 Compressor fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

Figure 2-76. 806 compressor PCBA installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

Figure 2-77. 806 compressor PCB block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-88

Figure 2-78. 840 Ventilator System interconnect diagram – Compressor unit . . . . . . . . . . . . . . . . . . . 2-89

Figure 2-79. Compressor operational sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-91

Figure 2-80. Compressor unit start-up sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-92

xviii 4-070496-00 Rev. A (08/03) 840 Ventilatory System Service Manual

Page 19

Figures

Figure 2-81. Inspiration gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-93

Figure 2-82. Exhalation gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-96

Figure 2-83. Pressure transducer autozero mode gas flow diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 2-99

Figure 2-84. Power loss sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-100

Figure 2-85. Safety valve open diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-102

Figure 2-86. Pressure release, patient circuit occluded diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-104

Figure 3-1. Patient circuit setup for SST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Figure 3-2. EST setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Figure 3-3. EST screens during testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Figure 4-1. SERVICE MODE screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-2. Service mode functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-3. System Information Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-4. EST/SST Diagnostic Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 6-1. Location of BD LED array. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Figure 7-1. Alarm message format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Figure 7-2. Alarm log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Figure 8-1. GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Figure 8-2. 10.4-inch GUI front and back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Figure 8-3. 10.4-inch GUI mounting platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Figure 8-4. Removing and replacing 10.4-inch GUI cable assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Figure 8-5. Removing 10.4-inch GUI rear housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Figure 8-6. 10.4-inch GUI rear warning label and serial number tag . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Figure 8-7. Removing the 10.4-inch CPU shield and GUI PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Figure 8-8. Removal of a 10.4-inch backlight inverter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Figure 8-9. RS-232 shield and flex circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Figure 8-10. GUI CPU PCB touch panel jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Figure 8-11. 10.4-inch LCD panels and LCD shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

Figure 8-12. 10.4-inch GUI touchframe PCB and GUI LED PCB locations. . . . . . . . . . . . . . . . . . . . . . . 8-15

Figure 8-13. Removal of the 10.4" GUI LED PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

Figure 8-14. Removing the 10.4-inch GUI alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

Figure 8-15. 10.4-inch GUI rotor housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Figure 8-16. 9.4-inch touch screen bezel and window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Figure 8-17. 9.4-inch GUI tilt positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Figure 8-18. Replacing the 9.4-inch keyboard assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Figure 8-19. 9.4-inch GUI mounting platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Figure 8-20. Removing 9.4-inch GUI handle assembly and interface cable . . . . . . . . . . . . . . . . . . . . . 8-25

Figure 8-21. Replacing 9.4-inch GUI rear housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Figure 8-22. 9.4" GUI interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Figure 8-23. Replacing the 9.4-inch GUI alarm assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Figure 8-24. Replacing 9.4-inch backlight inverter and GUI LED PCBs. . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Figure 8-25. Removing 9.4-inch GUI EMI shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Figure 8-26. Removing 9.4-inch video controller PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

Figure 8-27. GUI CPU PCB touch panel jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Figure 8-28. Replacing the 9.4-inch touchframe PCB and LCD panel assembly . . . . . . . . . . . . . . . . . 8-34

Figure 8-29. Routing the backlight extender cable assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-35

840 Ventilatory System Service Manual 4-070496-00 Rev. A (08/03) xix

Page 20

Figures

Figure 8-30. LCD panel and backlight panel assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Figure 8-31. Replacing the 9.4-inch GUI cooling vent filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

Figure 8-32. 9.4-inch rotor housing assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

Figure 8-33. BDU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Figure 8-34. BDU connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-43

Figure 8-35. Sure-Lock™ retainer and power cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

Figure 8-36. BDU release handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

Figure 8-37. BD CPU PCB and AI PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

Figure 8-38. BD card cage and PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-46

Figure 8-39. BDU I/O panel connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-47

Figure 8-40. Replacing power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48

Figure 8-41. Replacing power switch (S1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

Figure 8-42. Replacing humidifier receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-50