Page 1

2000 PSI Pressure Washer

Table Of Contents

Topic Page #

Important Safety

Tips, Precautions, Warnings,

and Usage Instructions

Assembly Instructions 6-8

Operating Instructions 8-11

Detergents 11-13

Clean-up and Storage 13-15

Cleaning Tips 15-16

2-5

Technical Data 16

Troubleshooting Tips 17

Limited Warranty 18- 19

Parts 20- 26

1

Page 2

2000 PSI Pressure Washer

2000 PSI Pressure Washer

IMPORTANT SAFETY PRECAUTIONS

GROUND FAULT CIRCUIT INTERRUPTER

(GFCI)

This pressure washer is provided with a ground fault circuit interrupter (GFCI) built into

the plug of the power supply cord. This device provides additional protection from the

risk of electric shock. Should replacement of the plug or cord become necessary, use

only identical replacement parts that include GFCI protection.

This unit is equipped with a Ground Fault Circuit Interrupter (GFCI). When connecting

the GFCI to the receptacle, the indicator should appear red. If the indicator is not red,

depress the RESET button on the GFCI until the indicator appears red. If the indicator

does not appear red, please see Section titled “Troubleshooting” for more information.

IMPORTANT SAFETY TIPS

Neverpoint the high-pressure nozzle at people or animals.

Neverdrink alcobol or use drugs while operating the pressure washer.

WARNING: When using this product, basic

precautions should always be followed,

including the following:

1. Read all instructions before using the product. Save all

safety instructions.

2. Do not operate the pressure washer when fatigued or under

the influence of alcohol or drugs.

3. Risk of infection or injury – do not direct the high pressure

water stream at any people or animals.

4. Do not allow children to operate the pressure washer at any

time.

5. To redu ce the risk of injury, close supe rvision is ne ce ssa ry

when the pressure washer is used near children.

6. Know how to stop the unit and reduce pressure immediately.

Be completely familiar with the controls.

7. Stay alert – always be aware of where you are directing the

high pressure spray

8. Keep cleaning area clear of all people.

9. Maintain safe footing and balance at all times – do not

overreach or stand on an unstable support.

10. The work area should have adequate drainage to reduce the

possibility of a fall due to slippery surfa ces.

11. Follow the maintenance instructions specified in the manual.

12. To reduce the risk of electrocution, ke ep all connections dry

and off the ground. Do not touch the plug with wet hands.

Neveroperate thepressurewasher whilestanding in water.

Nevertouchthe electrical plug with wet hands.

Never let the electrical connections rest in water.

Neveroperate the pressure washerwithout the water turned on.

Neveruse hot water with this pressure washer.

2

GENERAL SAFETY PRECAUTIONS

1. Intended for outdoor household use only.

2. High-pressure hose can develop leaks from wear, abuse,

kinking etc. Do not use a damaged hose.

3. Do not use the pressure washer in areas near combustible

mate rials, combustible fumes, or dust.

4. Some chemicals or detergents may be harmful if inhaled or

ingested causing severe injury. Use a respirator or mask

whenever there is a chance that vapors may be inhaled.

3

Page 3

2000 PSI Pressure Washer

2000 PSI Pressure Washer

Read all instructions included with the mask so you are certain

the mask will provide the necessary protection against inhaling

harmful vapors.

5. Before starting the pressure washer in cold weather, check all

of the parts of the equipment and be sure that ice has not

formed. Do not store the unit anywhere that the temperature

will fall below 0

6. DO NOT MAKE ANY MODIFICATIONS TO ANY OF THE

COMPONENTS! Units with broken or missing parts, or without

the protective housing or covers should NEVER be operated

7. Keep the high-pressure hose connected to the pressure

washer and the spray gun while the system is pressurized.

Disconnecting the hose while the unit is pressurized is

dangerous, and may cause injury.

8. Do not leave the pressure washer unattended while the power

switch is ON.

9. Keep the water spray away from electrical wiring or fatal electric

shock may result.

°C(32° F).

SERVICING OF A DOUBLE-INSULATED

APPLIANCE

In a double-insulated product, two systems of insulation are provided instead of

grounding. No means of grounding is provided on a double-insulated product, nor

should a means for grounding be added to the product. Servicing a double-insulated

product requires extreme care and knowledge of the system, and should be done

only by qualified service personnel. Replacement parts for a double-insulated product

must be identical to the parts they replace. A double-insulated product is marked with

the words “DOUBLE INSULATION” or “DOUBLE INSULATED”. This symbol may

also be marked on the product.

USE OF EXTENSION CORDS

Use of an extension cord with this product is NOT RECOMMENDED. If you must use an

extension cord, use only extension cords that are intended for outdoor use. These cords

are identified by a mark ing “ACCEPTABLE FOR USE WITH OUTDOOR APPLIANCES, STORE

INDOORS WHILE NOT IN USE.” Use only extension cords having an

electrical rating not less than the rating of theproduct.Examine the extension cord before

use. Do not use damaged extension cords! Do not pull on cord to disconnect from the

receptacle. Always disconnect by pulling on plug. Keep the cord away from heat and

esharp dges. Always disconnect the extension cord from the receptacle before

tdisconnecting he product from the extension cord.

WARNING

– To reduce the risk of electrocution, keep all connections dry and off

the ground. Do not touch the plug with wet hands.

PROPER USE OF THE PRESSURE WASHER

THIS UNIT IS INTENDED FOR USE WITH COLD WATER ONLY!

DO NOT USE HOT WATER IN THIS PRESSURE WASHER.

Operate the pressure washer at no more than the fluid pressure

1.

rated for the pressure washer. Never run the pressure washer

without a water supply. Running the unit without a water supply

will cause irreparable damage to the unit.

2. Make sure that the water supply you use for the pressure

washer is not dirty, sandy, and does not hold any corrosive

chemical products. Using a dirty water supply will compromise

the life of the pressure washer.

3. CAUTION - The pressure washer can be used for a variety of

applications including washing cars, boats, patios, decks,

garages etc. where high pressure is necessary to remove dirt

and debris.

High-pressure water flow can damage the work surface if not

used properly! See the section titled “Operating Instructions” for

more details. Always test the spray in an open area first.

4. NEVERmove the unit by pulling on the high pressure hose. Use

the handle provided on the top of the unit.

5. Always hold the high pressure gun and wand with two hands.

Keep one hand on the gun/trigger, while supporting the wand

with the other hand (see diagram).

6. When dispensing detergent, the pressure washer applies

detergent tothe cleaning area at low pressure only. Once the

detergent has been applied, spray the detergent off of the work

area by using the adjustable nozzle.

4

5

Page 4

2000 PSI Pressure Washer

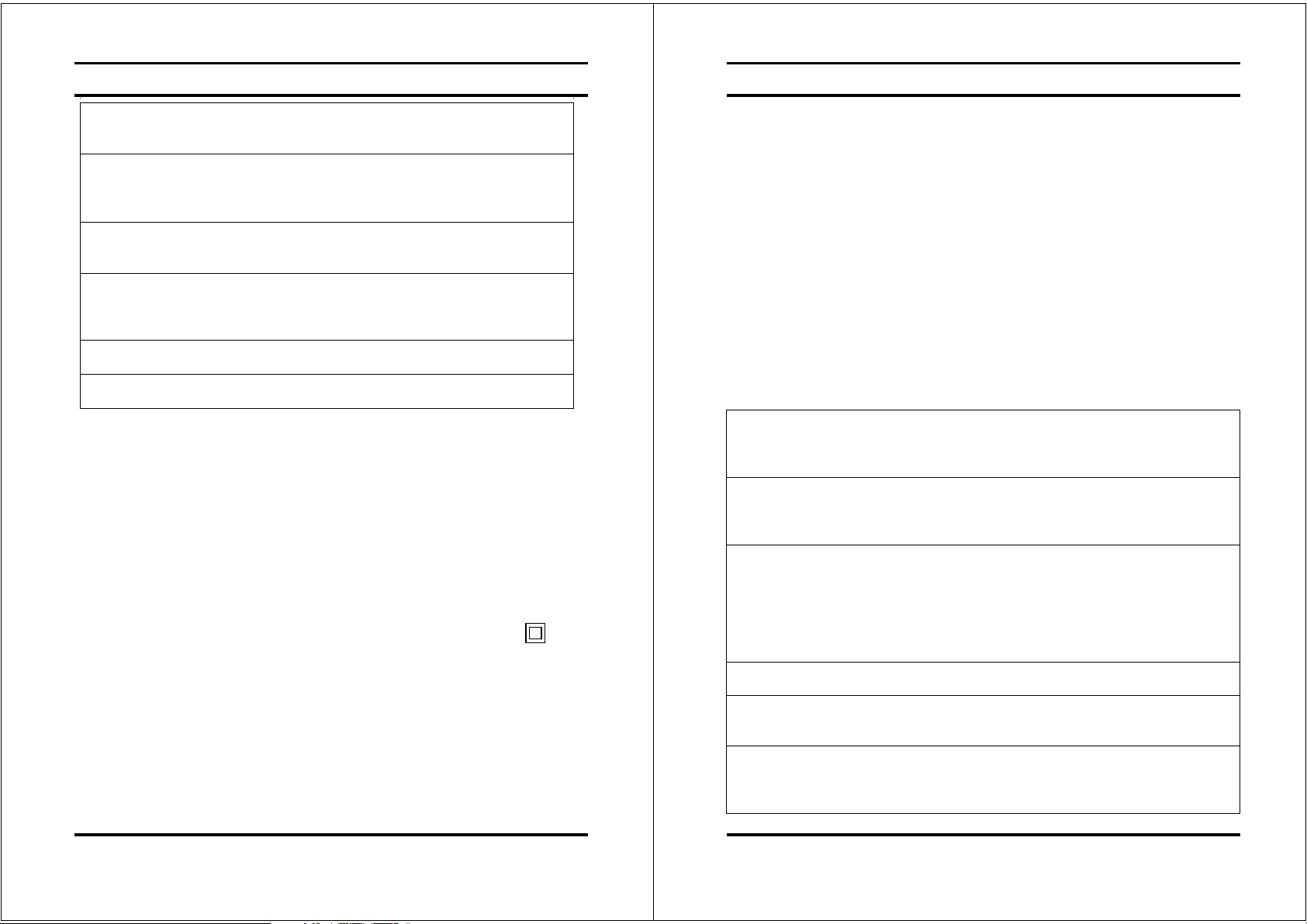

ASSEMBLY INSTRUCTIONS

Unpacking The Carton

After opening the carton, please remove all parts and che ck them against the following

list of components that are included:

2000 PSI Pressure Washer

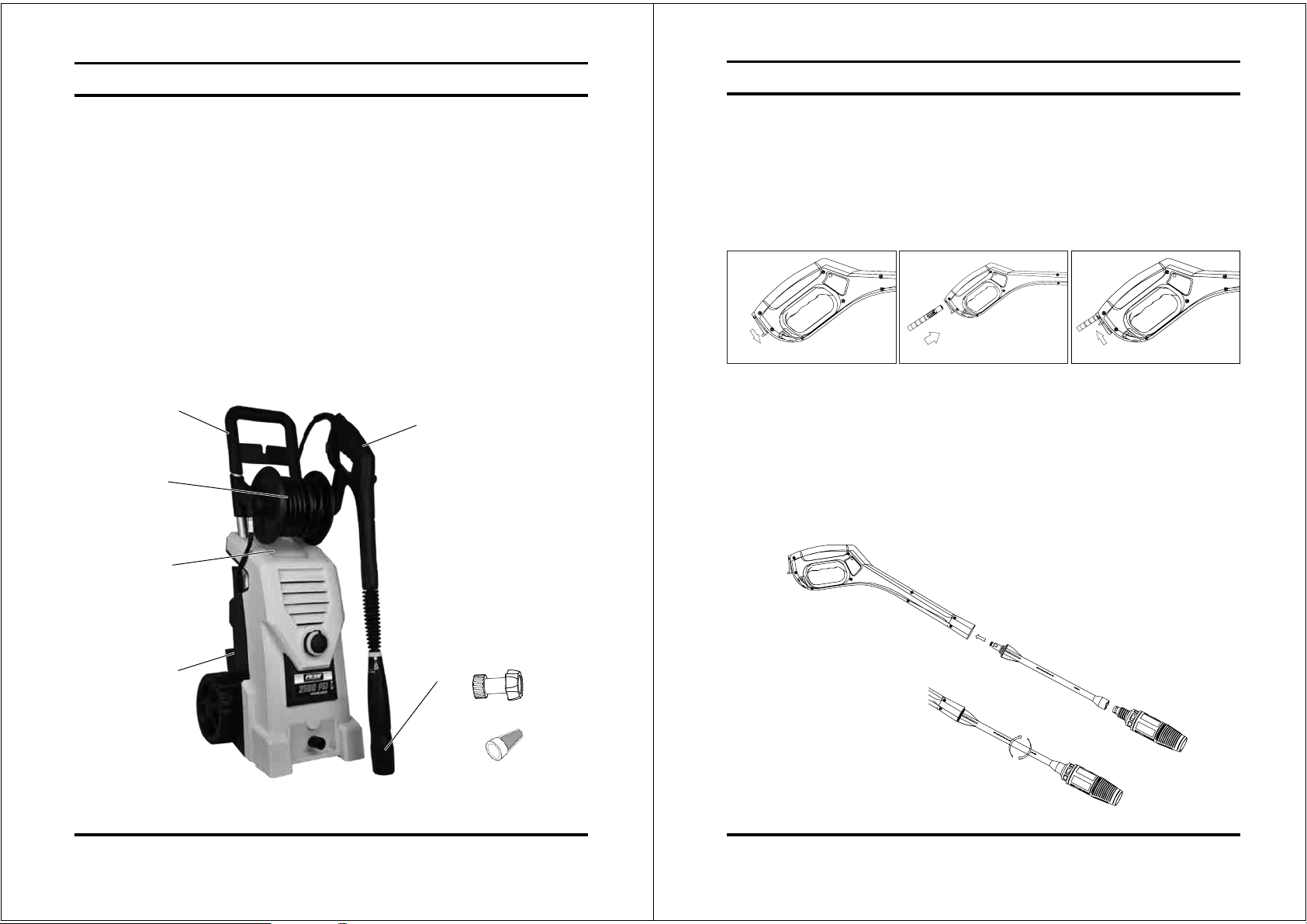

Step 1

Take the hose lock to position A to unlock. Attach the high pressure hose to the gun.

Then push the hose lock to postion B to lock the fitting.

A. High Pressure Washer

B. Gun

C. High Pressure Hose

D. 4 IN 1 Lance Adjustable Nozzle

A

C

G

H

E. Two-wayConnector

F. Water Intake Filter (Pre-Installed)

G. Detergent Bottle

H. Accessories Holder

B

D

E

F

B

A

B

A

Step 2

Insert the adjustable spray nozzle into the gun. Push and turn the adjustable nozzle

clockwise onto the gun until it is hand tight and to lock it in place. When the pieces are

pjoined roperly, you cannot separate the two components by pulling out on the

adjustable nozzle. All attachments must be inserted intothe gun for proper use.

B

D

To assemble the enclosed parts, please refer to the steps that follow:

6

7

Page 5

2000 PSI Pressure Washer

2000 PSI Pressure Washer

Step 3

Attach the hose connector to pressure washer. Before attaching the connector to the male

fitting, remove the plastic cap, which is inserted onto the male fitting on the pressure washer

before shipping. This plastic cap can be discarded once removed. After both components have

been installed, attach the garden hose with connector screw on the pressure washer. Connect

the garden hose to the waterspout.

OPERATING INSTRUCTIONS

THIS UNIT IS INTENDED TO BE USED WITH COLD WATER ONLY!

DO NOT USE HOT WATER IN THIS PRESSURE WASHER!

Starting Up

After connecting the pressure washer to your cold

water supply, proceed as follows:

Make sure that the on/off switch is

-

in the off position.

- Connect the garden hose with a quick

connect to the inlet fitting.

- Attach the hose to the gun as per

assembly instruction step #1.

- Insert the adjustable spray nozzle

into the gun as per assembly step

#2.

- Connect the high pressure hose to

thehighpressureoutletfittingas

per assembly step #3.

- Open the water supply valve completely.

- Before turning the unit on, press the gun trigger to bleed all the

remaining air out of the pump and hose.

- Start the pressure washer by turning the on/off switch to the

on position and squeeze the trigger.

REMIN DER: mThe otor does not run continuously,only when the trigger is sque e zed.

WARNING – Risk injury the unit will start spraying

when trigger is squeezed. When turning the unit off after

use, high pressure still exists inside the hose and unit. Point

the gun in a safe direction and discharge the excess

pressure. NEVER direct the high pressure water stream at

people or animals.

Automatic On / Off

The pressure washer is equipped with an automatic on/off switch.The pressure washer

will only run when the power switch is in the ON position and the trigger on the gun is

squeezed. When you release the trigger to stop spraying water through the gun, the

motor on the pressure washer will automatically shut off. Simply squeeze the trigger

again to resume using the washer. To stop using the pressure washer, release the

trigger and switch the unit to the OFF position. The unit should be turned completely

OFF while not in use or while unattended.

Bleeding The Gun

It is very important to bleed all the air out of the pressure washer before using it.To do this

1. Release trigger lock.

2. Squeeze the trigger before turning the electrical supply on.This removes any air trapped

inside the pressure washer and lance before using the units.

3. Continue holding trigger for approximately one minute to allow any excess air out of the

unit.Water will flow through the gun at low pressure during this procedure.

4. Lock the trigger.

5. Plug the power cord into the electrical outlet.

6. Release the trigger lock.

7. Turn the ON/OFF switch clockwise to the I/ON position.

The pressure washer is ready for operation.

8

9

Page 6

2000 PSI Pressure Washer

2000 PSI Pressure Washer

Gun Safety Lock

This pressure washer is equipped with a gun trigger safety lock. When not using the

pressure washer, use the safety lock to protect from accidentally engaging the high

pressure spray.

Adjustable Spray Nozzle

The 4 IN 1 adjustable nozzle will allow you to use a variety of spray patterns from a

full fan spray to other spray. When using the pressure washer to clean wood decks,

siding, vehicles etc., always start using the fan spray and begin spraying from a

a minimum 36” away to avoid damaging the surface of the material you are cleaning.

Always begin by spraying in a test area free and clear of people and objects.

HIGH

HIGH

HIGH

PRESSURE

JET

STREAM

PRESSURE

OSCILLATING

FANNED TURBO

PRESSURE

WIDE

FAN SPRAY

LOW

PRESSURE

SOAP

Dispensing Detergent

FIGURE A

Low Pressure Setting

High Pressure Setting

FIGURE B

ADJUSTING THE PRESSURE

To adjust the pressure,proceed as follows:

1. Hold the shaft of the lance in one hand.

2. Turn the grey part of the nozzle clockwise

to obtain the high pressure.

3. Turn the grey part of the nozzle anticlockwise

to obtain the low pressure.

Low Pressure Setting

High Pressure Setting

AUTO STOP SYSTEM

The pressure washer is fitted with an automatic stop system to protect the motor when

in use.

W

hen the trigger is released the motor will stop.

When the trigger is squeezed the motor will start up again.

The built-in detergent dispenser will allow you to apply liquid detergent onto the work

surface. Detergent application happens at low-pressure only. Insert the adjustable

nozzle onto the gun, and turn it to “LOW PRESSUER SOAP” so that the pressure washer is

in low-pressure mode (see Figure A below). Remove the cap on the detergent reservoir

and fill with liquid detergent only (see Figure B below). Do not put any water into the

reservoir. The pressure washer will mix water and detergent automatically. When

finished applying the detergent to the work surface, turn it to “HIGH PRESSURE” of the

adjustable nozzle and spray off the detergent by using the high-pressure spray (see

Figure A below). In high-pressure mode, the pressure washer will not dispense detergent.

10

USING DETERGENTS

The pressure washer will dispense detergent only at low pressure.

Use the adjustable spray nozzle to apply detergents and to rinse clean.

Biodegradable detergents are specifically formulated to protect the environment and

your pressure washer. These Detergents will not clog the filter and will protect the

internal parts of the pressure washer for a longer life.

11

Page 7

2000 PSI Pressure Washer

Step 1

Open the cover of the detergent reservoir by twisting it off.

2000 PSI Pressure Washer

Step 2

Fill the detergent reservoir with any approved liguid detergent.

Close the cover.

Step 3

Turn the adjustable nozzle to end of “LOW PRESSURE

SOAP”, put the pressure into

Low Pressure Setting

low-pressure mode.

Step 4

To apply the detergent to your work area. Turn the pressure washer switch

to the ON position. Pull the trigger to operate the unit. The pressure washer will mix

the detergent with water. Do not allow the detergent to dry on the object that you are

cleaning.

WARNING: NEVER USE PRODUCTS WITH BLEACH OR CHLORINE

OR ANY OTHER CORROSIVE MATERIALS, INCL

CONTAINING SOLVENTS (I.E. GAS, OILS ETC), TRI-SODIUM

PHOSPHATE PRODUCTS, AMMONIA, OR ACID-BASED CLEANERS.

THESE CHEMICALS WILL HARM THE UNIT AND CAUSE DAMAGE

TO THE SURFACE BEING CLEANED. ALWAYS READ THE LABEL.

UDING LIQUIDS

High Pressure Setting

CLEAN-UP AND STORAGE

Shutting Down the Pressure Washer

WHEN FINISHED USING THE PRESSURE WASHER,FOLLOW THESE

STEP S TO SHUT DOWN THE UNIT:

Ь Turn the pressure washer to the OFF position.

Ь Turn off the water supply.

Ь Before discon ne cting high-pressure hose conne ction, point the gun in a

safe direction and discharge the high-pressure water.

Ь Disconnect high-pressure hose from the pressure washer and gun.

Ь Disconnect garden hose from the pressure washer.

Ь Remove excess water from the pump by tipping the unit on both sides to

drain any remaining water from the inlet and outlet fittings.

Ь Remove the Water Intake Filter and flush with water to remove dirt or

debris. Return the filter once it is cleaned.

Step 5

To clean the working srea, turn the adjustable nozzle to end of “HIGH PRESSURE”,

return it to high-pressure mode. Spray high-pressure water onto the work area to rinse

off the work area and any remaining detergent.

12

13

Page 8

2000 PSI Pressure Washer

Ь Drain the detergent reservoir and flush with running water.

Ь Wipe away any remaining water on all parts and fittings.

Ь Engage the gun safety lock.

Ь Store the pressure washer, parts, and accessories in an

area with a temperature above 0°C (32°F).

Winterizing and Long-Term Storage

FOLLOW ALL OF THE ABOVE SHUT-DOWN PROCEDURES,ADDING

THE FOLLOWING STEPS….

After disconnecting the water supply, and before disconnecting the

Ь

high-pressure hose, turn the pressure washer on for 2-3 seconds, until any

remaining water in the pump exits. Turn the unit off immediately.

CONTINUED USE OF THE PRESSURE WASHER WITHOUT THE

WATER SUPPLY ATTACHED WILL CAUSE SEVERE DAMAGE TO

THE UNIT!

Always store the pressure washer, parts, and accessories in an area with a

Ь

temperature above 0° C (32° F).

WARNING: FAILURE TO COMPLY WITH THESE STORAGE

INSTRUCTIONS WILL RESULT IN DAMAGE TO THE PUMP

ASSEMBLY

.

Maintenance

Ь This pressure washer is supplied with a closed lubrication system, so no

addition of oil is ne eded.

Ь Check all hoses and accessories for damage prior to use.

Ь Check the water intake filter periodicallyfor deposits. Clean thisfilter

regula rly for maximum pe rformance.

2000 PSI Pressure Washer

CLEANING TIPS

WARNING: ALWAYS TEST THE SPRAY IN AN AREA FREE AND

CLEAR OF PEOPLE AND OBJECTS BEFORE YOU AIMING AT THE

INTENDED CLEANING SURFACE.

Wood and Vinyl Decks

Rinse deck and surrounding area with fresh water. If using detergent, fill the detergent

reservoir and apply to the area being cleaned at low pressure. For optimal results,

reduce your work area to smaller sections and clean each section one at a time. Allow

the detergent to rest on the surface for a few minutes and then rinse at high pressure.

Do not let the cleanser dry. Always clean from left to right and top to bottom for best

results. Rinse at high pressure using the fan spray keeping the tip of the spray nozzle

at least 6-9 inches from the cleaning surface. Maintain a further distance from the

cleaning area when using a direct spray.

Caution: For softer woods, increase the distance from the cleaning area.

Cement Patios, Stone, and Brick

14

Rinse the area with fresh water.If using detergent, fill the detergent reservoir and apply

to the area being cleaned at low pressure. Rinse at high pressure using the fan spray

in a sweeping motion keeping the tip of the spray nozzle at least 3-6 inches from the

cleaning surface. Maintain a further distance from the cleaning area when using a

dire ct spra y.

15

Page 9

2000 PSI Pressure Washer

Cars, Boats, and Motorcycles

Rinse the area with fresh water. If using detergent, fill the detergent reservoir and apply

to the area being cleaned at low pressure. To achieve the best results, clean one side

at a time. Allow the detergent to remain on the surface for a few minutes, but do not

let the detergent dry. Rinse at high pressure using the fan spray in a sweeping motion

keeping the tip of the spray nozzle at least 8 inches from the cleaning surface. Maintain

a greater distance from the cleaning area when using a direct spray.Wipe the surface

dry for a polished finish.

2000 PSI Pressure Washer

TROUBLESHOOTING TIPS

WHEN THE SWITCH IS IN THE “I” POSITION THE MACHINE WILL NOT START

PROBABLE CAUSE

Electrical socket is faulty Check plug, socket, and fuses

Voltage is inadequate Check that the voltage is adequate

GFCI trips Reset / Try another outlet

Powercordisnotpluggedin Pluginpowercord

SOLUTION

Barbecue Grills, Power Equipment, and Garden Tools

Rinse the area with fresh water. If using detergent, fill the detergent reservoir and apply

to the area being cleaned at low pressure. Allow the detergent to remain on the surface

for a few minutes, but do not let the detergent dry. Rinse at high pressure using the fan

spray keeping the tip of the spray nozzle at least 1-3 inches from the cleaning surface.

Maintain a greater distance from the cleaning area when using a direct spray.

TECHNICAL DATA

Main voltage 120 V

Main frequency 60 Hz

Max. operating pressure 2000PSI

Water consumption 1.6 GPM

Max. pressure water supply 40-80PSI

Max. water temperature 40-140F(5-60°C)

Weight 26LBS

WARRANTY

R

efer to the enclosed warranty regarding conditionsfor the terms and conditions of

guarantte.

THE PUMP DOES NOT REACH ADEQUATE PRESSURE OR FLUCTUATES

PROBABLE CAUSE SOLUTION

Water Intake Filter is clogged Remove and clean filter

Pump is drawing air Tighten connections/bleed system

Suction valves are clogged/worn Clean or replace valves

Diameter of garden hose too small Replace to 1” inch garden hose

Water supply is restricted Check hose for kinks or leaks

Insufficient water supply Fully open the water source

THE PRESSURE WASHER HAS OR WILL NOT MAINTAIN PRESSURE

PROBABLE CAUSE SOLUTION

Excessive air in waterline and pump T

THE PRESSURE WASHER MAKES EXCESSIVE NOISE

PROBABLE CAUSE SOLUTION

Intake is blocked Check the intake valves

Valves are worn, dirty, or clogged Check, clean or replace valves

Water Intake Filter is dirty Check, clean, or replace filter

THE MOTOR STOPS RUNNING WHILE IN USE

urn unit and water supply off / and

bleed lines

ENVIRONMENT

Should your machine need replacement after extended use, please do not dispose with

regular wash but dispose of it in an environmentally safe way.

16

PROBABLE CAUSE SOLUTION

Net voltage lower than suggested C

heck to determine that the voltage is

adequate

17

Page 10

2000 PSI Pressure Washer

2000 PSI Pressure Washer

LIMITED WARRANTY

Pulsar Products, Inc.

application (personal, residential or household usage) that all products covered under this

warranty are free from defects in material and workmanship for one year from the date of

purchase. All products covered by this limited warranty which are used in commercial

applications (i.e. income producing) are warranted to be free of defects in material and

workmanship for 90 days from the date of original purchase. Products covered under this

warranty include air compressors, air tools, serivce parts, pressure washers and generators.

Pulsar Products, Inc.

components which have failed within the warranty period. Service will be scheduled

according to the normal work flow and business hours at the service center location, and

the availability of replacement parts. All decisions of Pulsar Products, Inc.with regard to this

limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER(initial User):

To process a warranty claim on this product, DO NOT return item to the retailer. The

product must be evaluated by an Authorized Warranty Service Center.For the location of the

nearest Authorized Warranty Service Center contact the retailer or place purchase.

Retain your original cash sales receipt as proof of purcgase for all warranty work.

Use reasonable care in the operation and maintenance of the product as described in the

Owner’s Manual(s).

warrants to the original purchaser who uses the product in aconsumer

will repair or replace, at Pulsar Products, Inc.’s sole option, products or

LIMITED WARRANTY (cont’d)

THIS WARRANTY DOES NOT COVER:

Merchandise sold as reconditioned, used as rental equipment, or floor or display models.

Merchandise that has become damaged or inoperative because of ordinary wear, misuse,

cold, heat, rain, excessive humidity, freeze damage, use of improper chemicals, negligence,

accident, failure to operate the product in accordance with the instrctions provided in the

Owner’s Manual(s) supplied with the product, improper maintenance, the use of

or attachments not recommended by Pulsar Products, Inc.,or unauthorized

alterations.

Repair and transportation costs of merchandise determined not to be defective.

Costs associated with assembly, required oil, adjustments or other installation and start-up

costs.

Expendable parts or accessories supplied with the product which are expected to become

inoperative or unusable after a resonable period of use.

Merchandise sold by Pulsar Products, Inc. which has been manufactured by and

the product of another company, such as gasonline engines. The product

as

warranty, if any, will apply.

ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT

MAY RESULT FROM ANY DEFECTS, FAILURE OR MALFU

NOT COVERED BY THIS WARRANTY. Some states do not allow this exclusion, so it may

not apply to you.

NCTION OF THE PRODUCT IS

accessories

repair or

identified

manufacturer’s

Deliver or ship the product to the Authorized Warranty Service Center. Freight costs, if any

must be paid by the purchaser.

If the purchaser does not receive satisfactory results from the Authorized Warranty Service

Center, the purchaser should contact

Pulsar Products, Inc.

.

18

IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABLITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL

PURCHASE. Some states do not allow limitations on how long an implied warranty lasts,

so the above limitations may not apply to you.

19

Page 11

2000 PSI Pressure Washer

21

20

2000 PSI Pressure Washer

MPG Assy

Parts No. DESCRIPTION QTY.

Moto Assy

PWE2000-1

PWE2000-2

PWE2000-3

PWE2000-4

Pump Pedestal Assy

PWE2000-5

PWE2000-6

PWE2000-7

PWE2000-8 1

PWE2000-9 Oil Seal

PWE2000-10

PWE2000-11 1

PWE2000-12 1

Thrust Bearing Assy

PWE2000-13 1

PWE2000-14

PWE2000-15

Pistion Body Assy

PWE2000-16

PWE2000-17

PWE2000-18

PWE2000-19

PWE2000-20 1

PWE2000-21

Pilot Sheath Assy

PWE2000-22

PWE2000-23

Pump Body Assy

PWE2000-24

PWE2000-25

PWE2000-26

PWE2000-27 1

PWE2000-28

One-Way Valve Assy

Moto

Hexagon Socket Head Cap Screw

Plain Washer

Deep Groove Ball Bearing

Big Gear

O-Ring 64.77x2.62

Gear Shaft

Pump Pedestal

Deep Groove Ball Bearing

Wobble Plate 11

Wobble Plate Screw ( Left )

Thrust Bearing Thin Board

Thrust Bearing Roller

Thrust Bearing Thick Board

Spring Base

Pistion

Pistion Spring

Shaped-Ring 64.77x2.62

Pistion Body

Oil Seal

Pilot Sheath

Water Seal

Small O-Ring 17x2.0

Big O-Ring 23x2.62

One Way Valve Cover

Pump Body

Hexagon Socket Head Cap Screw M6x55

O

1

4

4

1

1

1

1

1

1

1

1

3

3

3

1

3

3

3

3

3

3

4

2000 PSI Pressure Washer

EXPLODER VIEW

22

Page 12

2000 PSI Pressure Washer

2000 PSI Pressure Washer

MPG Assy

Parts No. DESCRIPTION QTY.

PWE2000-29 6

PWE2000-30

PWE2000-31

PWE2000-32

PWE2000-33

Inlet Assy

PWE2000-34

PWE2000-35

PWE2000-36

PWE2000-37 4

Mainifold Assy

PWE2000-38

PWE2000-39 1

PWE2000-40 4Hexagon Socket Head Cap Screw M5x35

PWE2000-41 4O-Ring 12x2.0

PWE2000-42 1

PWE2000-43

PWE2000-44

PWE2000-45

PWE2000-46

PWE2000-47

PWE2000-48

PWE2000-49

PWE2000-50 1

PWE2000-51

Self-Priming Assy

PWE2000-52

PWE2000-53

PWE2000-54

PWE2000-55

PWE2000-56

PWE2000-57

PWE2000-58 1

PWE2000-59

PWE2000-60 1

One-Way Valve Seat

One-Way Valve Spring

One-Way Valve Door

One-Way Valve Cover

One-Way Valve Cover O-Ring 9x1.8

O-Ring

Inlet Tube

Plain Washer

Hexagon Socket Head Cap Screw M5x16

Slotted Cheese Head Screws

Small O-Ring

Manifold

O-Ring 5x2.0

One-Way Valve Core

One-Way Valve Core Spring

O-Ring 11.4x2.1

Bend Joint

TSS Switch Socket Cover

TSS Switch Cover Sealing Gasket

TSS Switch Socket

Cross Pan Head Self-Tapping Screw SJ3x12

Joint Sleeve

Small O-Ring 5x1.5

Soap Joint

Small O-Ring 3.68x1.78

Steel Ball Ø4.7625

Taper Spring

Big O-Ring 7.65x1.78

Self-Priming Outlet Pipe

O-Ring 11.4x2.1

6

6

6

6

1

1

4

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

MPG Assy

Parts No. DESCRIPTION QTY.

PWE2000-61 1

PWE2000-62 2

TSS Assy

PWE2000-63

PWE2000-64

PWE2000-65

PWE2000-66

PWE2000-67

PWE2000-68

PWE2000-69 1

PWE2000-70

PWE2000-71

Spill Valve Assy

PWE2000-72 1Steel Ball Cover

PWE2000-73 1Steel Ball

PWE2000-75 1

PWE2000-76

PWE2000-77

PWE2000-78

PWE2000-79

PWE2000-80

PWE2000-81

PWE2000-82

PWE2000-83 1

PWE2000-84

PWE2000-85 1Valve Sheath Baffle Ring

PWE2000-86

PWE2000-87

PWE2000-88

PWE2000-89

PWE2000-90

PWE2000-91

Venturi Nozzle Ø1.5

U-Pin

TSS Switch

TSS Round Jacket

Cable Jacket

TSS Lead Wire

Plastic Jacket ( Soft )

Plastic Square Jacket ( Soft )

Plate ( Line )

Receptacle

Lever Sheath

O-Ring 8.75x1.8

Spill Valve Sheel

Valve Core Big Baffle Ring

O-Ring 8.75x1.8

Spill Valve Core

O-Ring 5x1.5

Valve Core Little Baffle Ring

O-Ring 12.42x1.7

Spill Valve Cover

O-Ring 14x1.78

Spill Valve Spring

Lever

Lever Nut

Link Lever

Link Lever Nut

U-Pin

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

4

1

1

1

1

1

1

23

24

Page 13

2000 PSI Pressure Washer

2000 PSI Pressure Washer

Complete Machine

Parts No. DESCRIPTION QTY.

Back Housing Assy

PWE2000-92

PWE2000-93

PWE2000-94

PWE2000-95

PWE2000-96

PWE2000-97

PWE2000-98

Motor Cover Assy

PWE2000-99 1

PWE2000-100

PWE2000-101

PWE2000-102 1

PWE2000-103 1Cap Of Motor Cover

PWE2000-104 2Cross Pan Head Tapping Screw 4x16

Front Housing Assy

PWE2000-105

PWE2000-106

PWE2000-107

PWE2000-108

PWE2000-109 4

Wheel Assy

PWE2000-110

PWE2000-111 2

Hose-Reel Assy

PWE2000-112 1Hexagon Socket Head Cap Screw

PWE2000-113 1

PWE2000-114

PWE2000-115

PWE2000-116

PWE2000-117

PWE2000-118

PWE2000-119 1

PWE2000-120

PWE2000-121 1

Back Housing

Cross Pan Head Tapping Screw ST4.8x19

Back Cover Accessory

Water Gun Rack

Cross Pan Head Tapping Screw 4x16

Hexagon Socket Head Cap Screw 5x30

Cross Pan Head Tapping Screw 4x16

Motor Cover

Main Switch With Shiled

Switch Joint Lever

Switch Cover

Front Palet

Front Housing

Knob Cover

Knob

Cross Pan Head Tapping Screw ST4x12 F

Wheel

Wheel Cover

Hose Reel Holder

Hose Reel Bolt 6x30

Hose Reel Accessory ΙΙ

Hose Reel Big Stents ( Left )

Hose Reel Accessory Ι

Hose Reel

Nut

Cross Pan Head Tapping Screw ST4.8x19

Hose Reel Big Stents ( Right )

1

14

1

1

9

2

2

1

1

1

1

1

1

2

1

1

1

1

2

1

Complete Machine

Parts No. DESCRIPTION QTY.

PWE2000-122 1

PWE2000-123

PWE2000-124

PWE2000-125

PWE2000-126

PWE2000-127

PWE2000-128

Handle Assy

PWE2000-129 6

PWE2000-130 2

PWE2000-131

PWE2000-132

PWE2000-133 2

Cable Assy

PWE2000-134 1Plastic Jacket

PWE2000-135 1

PWE2000-136

PWE2000-137

PWE2000-138

PWE2000-139

PWE2000-140 1

Acc.

PWE2000-142 14 In 1 Lance

PWE2000-143 1P2006 Gun

PWE2000-144 1Nozzle Cleaner

PWE2000-145 1

PWE2000-146

PWE2000-147

PWE2000-148

PWE2000-149

PWE2000-150

PWE2000-151 1

Hose Reel Small Stents ( Right )

Hose Reel Small Stents ( Left )

Cross Pan Head Tapping Screw ST4x16 F

Cross Pan Head Tapping Screw ST4x10 F

High Pressure Joint

U-Pin

Cross Pan Head Tapping Screw ST4x16 C

Cross Pan Head Tapping Screw ST4x16 F

Cross Pan Head Tapping Screw ST4x10 F

Handle ( Front )

Handle ( Back )

Iron Pipe

Plastic Jacket ( Soft )

Cable

Cable Jacket

Plastic Jacket ( Soft )

Receptacle

Cable With GFCI

Cross Pan Head Tapping Screw ST4x12 FPWE2000-141

25’ HP With Long Ring Nut ( Black )

Nipple

O-Ring 5.3x1.6

HP Hose Snap Ring Ø2

Soap Bottle

Soap Bottle Cap

Short HP Hose Assy

1

6

4

1

2

2

1

1

1

1

2

2

2

1

3

1

1

1

25

26

Loading...

Loading...