Proheat X45 User Manual

INSTALLATION AND SE R V I C E M A N U A L

PROHEAT X45

Rev. H

CONTENTS

A. SAFETY .

B. INTRODUCTION .

..................................................................................... A-1

........................................................................ B-1

C. MODEL DESCRIPTIONS............................................................ C-1

1.0 TECHNICAL SPECIFICATIONS ................................................. 1-1

1.1 PHYSICAL – X45 ..................................................................... 1-2

1.2 ELECTRICAL – X45 .................................................................. 1-4

1.3 TORQUE SPECIFICATIONS ........................................................ 1-6

2.0 OPERATING YOUR PROHEAT HEATER..................................... 2-1

3.0 INSTALLATION .......................................................................... 3-1

3.1 LOCATING THE HEATER ........................................................... 3-2

3.1.1 Select Your Location ...................................................... 3-2

3.1.2 General considerations................................................... 3-2

3.1.3 Mounting the Proheat Heater in an Enclosure................... 3-3

3.2 MOUNTING THE HEATER .......................................................... 3-4

3.2.1 Option A – Heater With Enclosure .................................... 3-4

3.2.1 Option B – Heater Without Enclosure ............................... 3-5

3.3 EXHAUST PIPE CONNECTION.................................................... 3-6

3.4 PLUMBING THE SYSTEM.......................................................... 3-7

3.4.1 General Considerations .................................................. 3-7

3.4.2 Option A – Engine Heat or Supplemental Heat .................. 3-8

3.4.3 Option B – Engine and Sleeper Heat ................................ 3-9

3.5 WIRING & ELECTRICAL CONNECTIONS.................................... 3-10

3.5.1 General Considerations ................................................ 3-10

3.5.2 Power Connection to Batteries ...................................... 3-11

3.5.3 Timer Connections (Optional) ........................................ 3-12

3.5.4 On/Off Switch Connections ........................................... 3-13

3.5.5 Sleeper Fan Model Heater Wiring Details ....................... 3-14

3.5.6 Option A – OEM Heater & Proheat Thermostat ................ 3-14

3.5.7 Option B – OEM Heater & Thermostat............................ 3-15

3.5.8 Option C – Auxiliary Sleeper Heater................................ 3-16

3.5.9 Option D – Auxiliary Sleeper Heater Current Limited ........ 3-17

3.5.10 Auxiliary Input Model Heater Wiring Details................... 3-18

3.5.11 Option A –

3.5.12 Option B –

3.5.13 Option C – Standard Mode & Supplemental Mode .........3-20

3.6 FUEL SYSTEM ....................................................................... 3-22

3.6.1 General Considerations ................................................ 3-22

3.6.2 Option A – 1/4" or 1/2" NPT Port ................................. 3-23

3.6.3 Option B – Existing Blank Fuel Sender Cover Plate .......... 3-24

3.6.4 Option C – Hole Drilled into Fuel Tank ............................ 3-24

3.6.5 Installation .................................................................. 3-25

3.7 FIRST TIME STARTUP............................................................. 3-26

Preheat Mode Supplemental Mode Operation

Preheat and Supplemental Mode

................... 3-20

... 3-19

4.0 PRINCIPLES OF OPERATION ................................................... 4-1

4-1 GENERAL DESCRIPTION ........................................................... 4-1

4-2 MODES OF OPERATION ............................................................ 4-5

4.2.1 Standard Mode – All Models ........................................... 4-5

4.2.2 Preheat Mode – Aux Input Models Only ............................ 4-6

4.2.3 Supplemental Mode – Aux Input Models Only ................... 4-7

i

5.0 TROUBLESHOOTING & REPAIR .

5.0.1 Troubleshooting a Problem........................................ 5-1

.0.2 Example Proheat Behavior Error – Code 01................. 5-2

5

5-1 OPERATION INDICATORS, FUNCTION & COMPONENT

IAGNOSTICS ................................................................... 5-3

D

5.1.1 Operation Indicators ................................................. 5-4

5.1.2 Function Diagnostics ................................................ 5-5

1 Start ................................................................... 5-5

0

02 Flame Out ......................................................... 5-15

03 Coolant Flow ..................................................... 5-16

04 Overheat ........................................................... 5-17

05 Voltage ............................................................. 5-18

5.1.3 Component Diagnostics................................................ 5-19

06 Flame Sensor.................................................... 5-19

07 Temp Sensor .................................................... 5-21

08 Fuel Pump......................................................... 5-23

09 Compressor ...................................................... 5-23

10 Ignition Coil....................................................... 5-25

11 Coolant Pump ................................................... 5-27

12 Blower .............................................................. 5-30

13 Sleeper Fan ...................................................... 5-32

14 Hour Meter (Auxiliary Output).............................. 5-33

5-2 COMPONENT MECHANICAL OR ELECTRICAL PROBLEMS ........... 5-34

5.2.1 Fuel Nozzle .................................................................. 5-34

5.2.2 Fuel Regulator.............................................................. 5-34

5.2.3 Air Compressor ............................................................ 5-34

5.2.4 Fuel Pump ................................................................... 5-34

5.2.5 Ignition Electrode ......................................................... 5-34

5.2.6 Coolant Pump .............................................................. 5-34

5.2.7 Blower ......................................................................... 5-34

5.2.8 Fuse ........................................................................... 5-35

5-3 OPERATIONAL PROBLEMS ...................................................... 5-37

5.3.1 Smoking exhaust ......................................................... 5-37

5.3.2 Low heat output ........................................................... 5-37

5.3.3 Engine temperature gauge reads low ............................. 5-37

5.3.4 Backfiring .................................................................... 5-37

.............................................. 5-1

6.0 MAINTENANCE.......................................................................... 6-1

6-1 WEEKLY MAINTENANCE ........................................................... 6-1

6-2 ANNUAL MAINTENANCE ........................................................... 6-1

6.2.1 Clean Heater Enclosure and Air Intake ............................. 6-2

6.2.2 Check Exhaust System ................................................... 6-3

6.2.3 Check Heat Exchanger.................................................... 6-3

6.2.4 Clean Flame Sensor ....................................................... 6-4

6.2.5 Check Cooling System .................................................... 6-4

6.2.6 Check Batteries ............................................................. 6-4

6.2.7 Check Fuel System......................................................... 6-5

6.2.8 Check Fuel Filter ............................................................ 6-5

6.2.9 Clean Nozzle.................................................................. 6-6

6.2.10 Replace Compressor Air Filter ....................................... 6-6

6.2.11 Check Electrical System ............................................... 6-7

6.2.12 Check Air Pressure ....................................................... 6-8

6.2.13 Check

Modes of Operation – Switch, Timer or OEM Signals

.. 6-8

7.0 APPENDICES ............................................................................ 7-1

Bulletins 951528, 967329, SB0003, PB0034, SB0062

8.0 WARRANTY ............................................................................... 8-1

ii

PROHEAT INSTALLATION & SERVICE

A.

SAFETY

Throughout this manual, you will see notes labeled DANGER, WARNING,

CAUTION and NOTICE to alert you to special instructions or precautions

concerning a particular procedure that would be hazardous if performed

incorrectly or carelessly.

Observe them carefully!

These safety alerts alone cannot eliminate all hazards. Strict compliance

with these special instructions and common sense are major accident

prevention measures.

DANGER

Immediate hazards that will result

in severe injury or death.

WARNING

Hazards or unsafe practices that

could result in severe personal

injury or death.

CAUTION

Hazards or unsafe practices that

could result in minor injury or

product or property damage.

NOTICE

Information that is important to

proper installation or maintenance,

but is not hazard-related.

SECTION A. SAFETY

A-1

SAFETY CONSIDERATIONS

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Exhaust

Inhalation of exhaust gas (containing carbon monoxide) may cause severe personal

injury and/or death. Anyone suspected of suffering from CO inhalation should be

removed from the hazardous area and given medical assistance immediately.

Explosion Hazard

Do not operate heater where combustible fumes or airborne particles, such as sawdust, are present.

Fuel

Exercise extreme caution when working near fuel or fuel-filled equipment. Do not

operate heater during fueling operations. In addition, do not smoke or handle open

flame equipment, such as a blowtorch, around fuel.

Fire Hazard

Do not place any flammable items around the heater and exhaust pipe.

Batteries

Wear hand and eye protection when working near batteries. Do not smoke or use open

flames near batteries.

Electrical

Electric shock can cause severe personal injury, burns, and death. Before working on

any unit, disconnect the batteries. Use only approved materials and methods when

working on the electrical system and follow local electrical codes. Never work with

electricity in wet conditions or when you are feeling fatigued.

WARNING

WARNING

WARNING

DANGER

Poisons/Toxins

Fuel and coolant are toxic and in some cases, carcinogenic. Wear eye and hand

protection at all times. Remove contaminated clothing immediately and wash

contaminated skin. Do not breathe in vapors.

Moving/Hot Parts

Moving/hot parts can cause severe injury and or death. Before working on any unit,

shut it off. Do not operate any unit until protective covers have been replaced. Always

ensure bolts and clamps are correctly torqued and secured. Inspect mechanical components periodically for damage and corrosion.

Coolant

Never remove the filler cap when the engine is hot – escaping steam or scalding water

could cause serious personal injury. The coolant level in the expansion tank should be

checked at least weekly (more frequently in high mileage or arduous conditions). Always

check the level when the system is cold. Unscrew the filler cap slowly, allowing the

pressure to escape before removing completely. Never run the engine without coolant.

Prevent anti-freeze coming in contact with the skin or eyes. If this occurs, rinse

immediately with plenty of water. Anti-freeze will damage painted surfaces.

Never top-up with salt water. Even when travelling in territories where the water supply

contains salt, always ensure you carry a supply of fresh (rain or distilled) water.

California Proposition 65 Warning

Do not operate heater in garages or in other closed or unventilated areas.

Diesel exhaust and some of its constituents are known to the State of California to

cause cancer, birth defects, and other reproductive harm.

Electrical components in this product may contain lead, a chemical known to the

State of California to cause cancer and birth defects and other reproductive harm.

A-2

PROHEAT INSTALLATION & SERVICE

INTRODUCTIONB.

PROHEAT Model X45

This manual is provided to assist an authorized PROHEAT

dealer to install and service a PROHEAT heater. Although

trucks have been used in the examples, applications for

PROHEAT are by no means limited to trucks. PROHEAT

heaters are designed to be used on any diesel equipped

vehicle including: trucks, buses (school, transit and coach),

construction equipment, off road equipment, military

equipment and cargo.

PROHEAT heaters are used in the following applications:

(1) Engine Block Heat – PROHEAT will preheat an engine

block to ensure reliable starting in cold weather. At

the same time it may be used throughout the year to

reduce the wear associated with cold starts.

(2)

Cab or Sleeper Heat (engine off) – PROHEAT will supply

heat to the cab or sleeper. Drivers can sleep in comfort

not only in the cold of winter but also in the spring

and fall when the weather is miserable. Substantial

savings through reduced fuel consumption and engine

wear can be obtained by not idling the engine.

(3)

Supplemental Heat (engine running) – as the efficiency

of modern diesel engines are improved there is no

longer adequate reject heat available to heat the

vehicle’s interior. This is particularly true for buses.

PROHEAT can be used while the vehicle is operating

to provide supplemental heat for the interior.

(4) Cargo Heat – PROHEAT can be used to provide heat to

protect valuable cargo such as produce or beverages

from damage due to freezing.

(5) Marine – Marine applications typically involve the

engineering and installation of a complete hot-water

heating system of which PROHEAT is only one

component. Proheat recommends that only an

expert in marine hot-water heating systems install a

PROHEAT on a boat. It is the installer’s responsibility

to ensure that the installation complies with all

applicable regulations.

SECTION B. INTRODUCTION

B-1

B-2

PROHEAT INSTALLATION & SERVICE

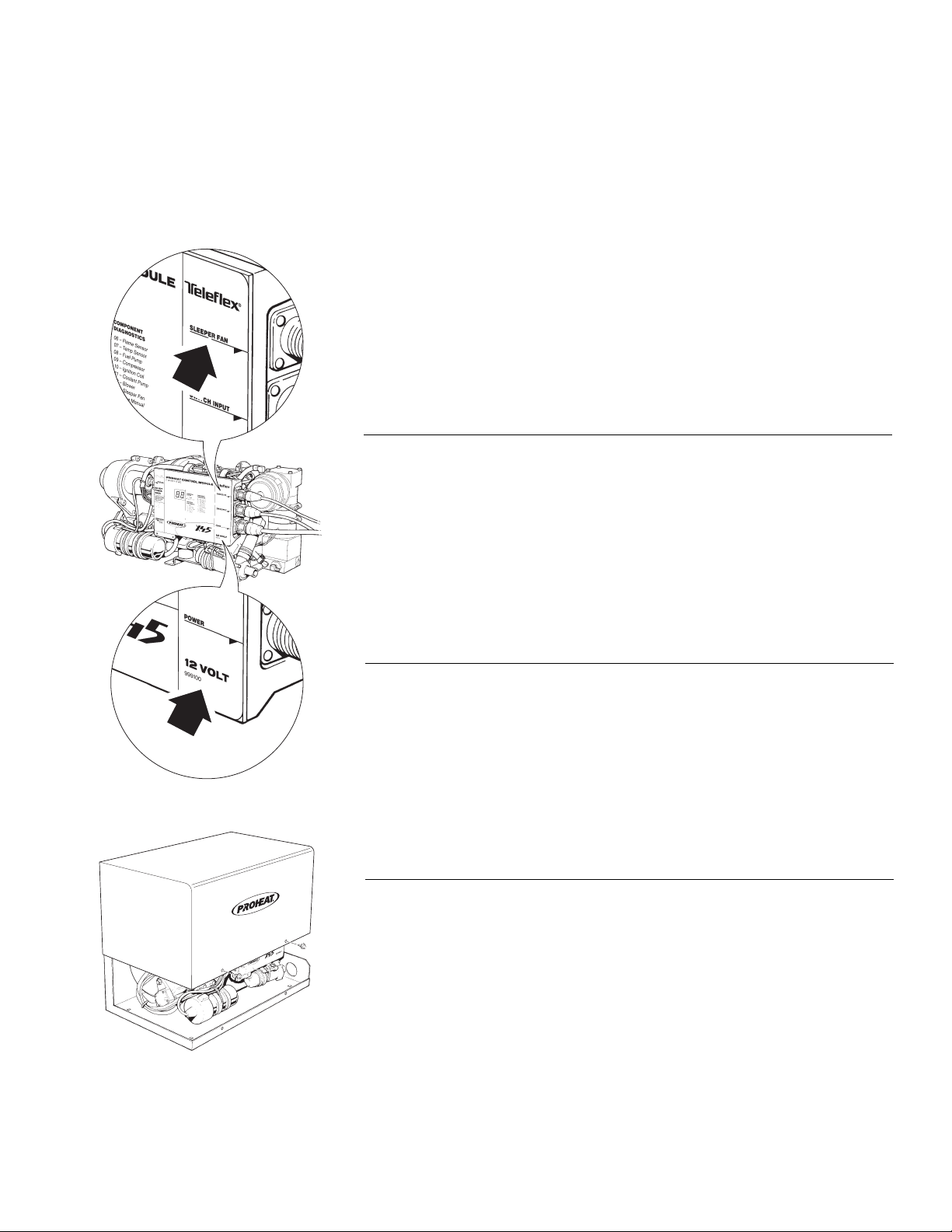

C.

Sleeper Fan Output or Auxiliary Input

Identification.

MODEL DESCRIPTIONS

This manual covers all models of PROHEAT X45. Please refer to the X45 Parts

Book at www.proheat.com for detailed part descriptions and part numbers.

Included in the parts book are optional features such as a timer, sleeper fan

ontrol kit, impact switch (for school bus applications) and associated

c

installation and maintenance tools.

The following information describes the three general characteristics of X45

models covered in this manual: voltage, enclosure and Proheat Control Module

(PCM) options.

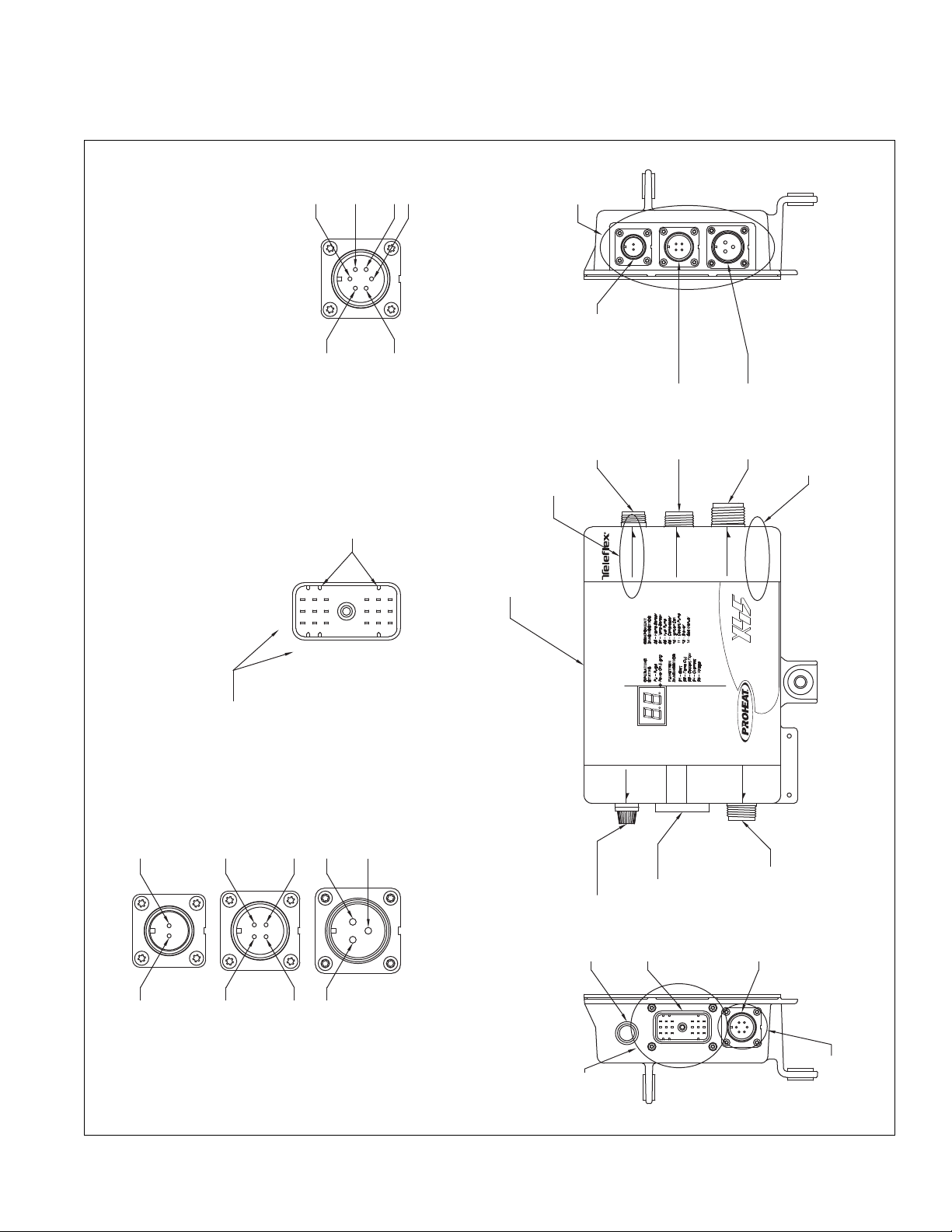

PROHEAT CONTROL MODULE (PCM): SLEEPER FAN

OUTPUT OR AUXILIARY INPUT

The PCM comes in either a sleeper fan output or auxiliary input model. The

sleeper fan model is limited to a 3 amp output and is generally installed on

trucks that require sleeper fan power (it is only available on 12 V models).

The

Auxiliary

Mode and Supplemental Mode. This operation is typically used for transit and

coach installation. Refer to page 4-2 for more information.

Input model uses two special input pins that allow for a Preheat

Voltage Identification.

VOLTAGE CONFIGURATION: 12 V OR 24 V

The X45 is available in either a 12 V or 24 V models.

ENCLOSURE

An optional enclosure provides environmental protection.

SECTION C. MODEL DESCRIPTIONS

C-1

C-2

PROHEAT INSTALLATION & SERVICE

1.0

TECHNICAL

SPECIFICATIONS

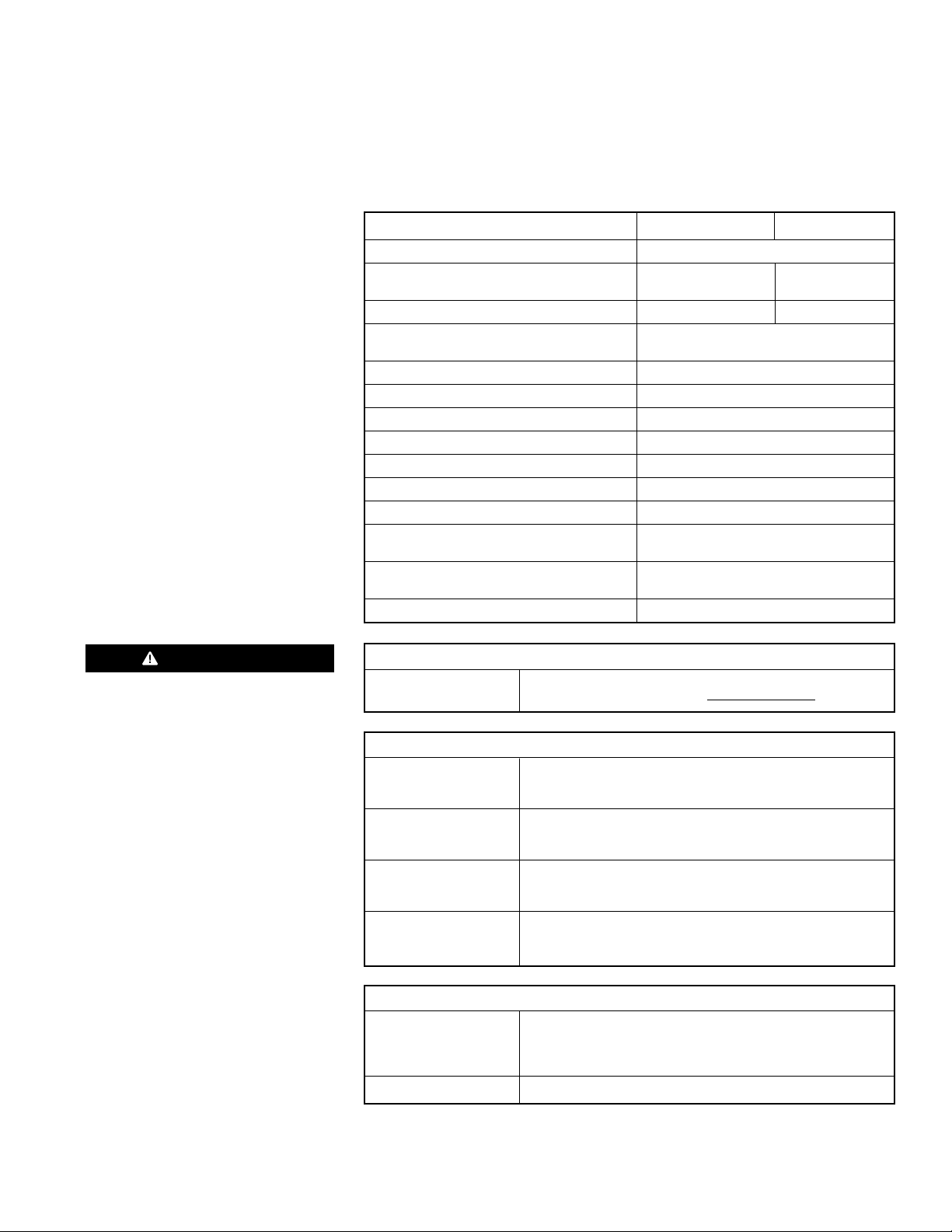

X45 12V X45 24V

RATING 45,000 BTU (13 kW)

YSTEM VOLTAGE 10 –15 VDC 20 – 30 VDC

S

ominal Voltage Range

N

CURRENT DRAW 7.5 Amps 3.75 Amps

FUEL CONSUMPTION

(Average to Maximum) 0.1 – 0.45 gal/hr. (0.4 – 1.7 L/hr.)

COOLANT FLOW 8.0 gal/min. (30 L/min.)

COOLANT TEMPERATURE (at Heater) 150°F to 185°F (65°C to 85°C)

OPERATING TEMPERATURE RANGE -40°F to +122°F (-40°C to +50°C)

IGNITION TYPE Electronic Spark Ignition

HEAT EXCHANGER CAPACITY 1 quart (0.95 L)

WEIGHT Heater ONLY 40 lbs (18 Kg)

WEIGHT Heater with Enclosure 55 lbs (25 Kg)

DIMENSIONS – HEATER (L x W x H) 18.9 x 11.2 x 10.6 inches

DIMENSIONS – ENCLOSURE (L x W x H) 20.2 x 12.3 x 10.5 inches

WARRANTY Two years parts and labor

(520 x 320 x 280 mm)

(513 x 313 x 267 mm)

DANGER

DO NOT use gasoline.

FUEL TYPES

COMPATIBLE Diesel (ULSD, #1, #2, Arctic), JP8, Jet A1

Bio Fuels – Contact Proheat www.proheat.com

SYSTEM OUTPUTS

HOUR METER Same as System Voltage

(AUXILIARY OUTPUT) Maximum 1 Amp draw (over-load shut-off protection)

High-side switched

SWITCH/TIMER Same as System Voltage

POWER Maximum 1 Amp draw (over-load shut-off protection)

High-side switched

SLEEPER FAN Same as System Voltage

(Certain Models Only) Maximum 3 Amp draw (over-load shut-off protection)

High-side switched

INDICATOR LIGHT Same as System Voltage

Maximum 1 Amp draw (over-load shut-off protection)

High-side switched

SYSTEM INPUTS

SWITCH 10 – 15 VDC (12V X45) | 20 – 30 VDC (24V X45)

Standard Run Mode

Preheat Run Mode (Certain Models Only)

Supplemental (Certain Models Only)

POWER 12 VDC or 24 VDC

SECTION 1. TECHNICAL SPECIFICATIONS

1-1

O

A

L

I

T

T

R

L

L

D

N

A

L

E

I

,

E

R

E

S

O

T

N

R

HEATERMODELNo:..........

SERIALNo:

MadeinCanadabyTeleexCanada Ltd Richmond B.C.

OPERATINGVOLTAGE:...10-16VOLTS

HEATOUTPUT:.............

PRESSURE:..............

MAX.OPERATING

FUELTYPE:...................

******

915822

9.0kW(KBTU)

2BAR(29PSI)

DIESELFUEL

X-4512V

POWER

G-IIISOFT START

PROHEATCONTROL MODULE

FUSE15A

SWITCHINPUT

SLEEPERFAN

ThisProductMeets

FHWABusHeater

Requirements

DieselFueledVechicle

CoolentHeater

ApprovedforUsein

BusApplications

12VOLT

999100

COMMINICATION

RS232&

CANBus

DONOT

POWER

WASH

ProtectedbyUSPatents

5,878,950and6,082,625

1.5 I.D.

C EXHAUST

PORT

L

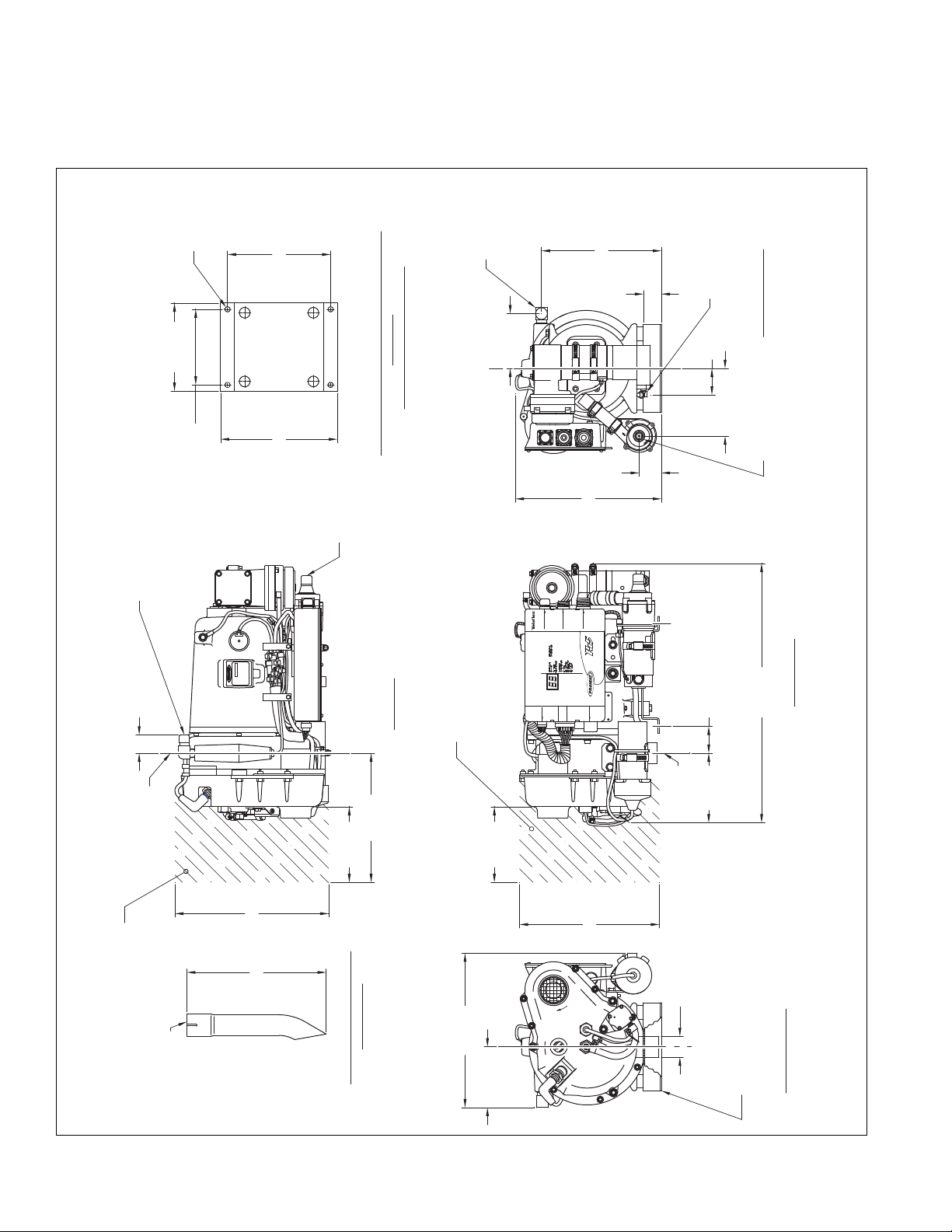

Ø1.5" [38]

4.9" [125]

1.9" [49]

8.7" [222]

1.3" [33]

1.6" [41]

10.6" [270]

4.0" [101]

1.3" [34]

10.1" [258]

11.2" [285]

4.4" [112]

4X 0.38" [10]

MOUNTING HOLES

STANDARD EXHAUST PIPE

SEE NOTE 1

5.5" [140]

9.4" [239]

COOLANT OUTLET

TOP VIEW

COOLANT INLET

C EXHAUST

PORT

L

NOTES:

1/ REFER TO X45 PARTS BOOK SL9070 FOR PART

NUMBER IDENTIFICATION

2/ DIMENSIONS ARE FOR REFERENCE PURPOSES ONLY

AND SUBJECT TO CHANGE WITHOUT NOTICE

AUXILIARY MOUNTING PLATE

SEE NOTE 1

18.9" [479]

C EXHAUST

PORT

L

5.1" [129]

C EXHAUST

PORT

L

COOLANT OUTLET

CONNECTION3/4" [19]

ID HOSE1/2" NPT

HOSE FITTINGSEE

NOTE 1

FUEL SUPPLY

CONNECTION

3/16" [48] ID HOSE

SEE NOTE 1

COOLANT INLET

CONNECTION

3/4" [19] ID HOSE

LEFT SIDE VIEW

FRONT VIEW

RIGHT SIDE VIEW

AUXILIARY MOUNTING PLATE - SEE NOTE 1

TOP VIEW

MOUNT HOLE DIMENSIONS

2X 5.5" [140]

2X 7.5" [191]8.50" [216]

6.40" [163]

THIS SPACE

IS REQUIRED FOR

COMBUSTION TUBE REMOVAL

11.2" [284]

10.2" [259]

5.5" [140]

THIS SPACE

IS REQUIRED FOR

COMBUSTION TUBE REMOVAL

2.0" [50]

1.1

PHYSICAL – X45

X45 HEATER1.1.1

Figure 1-1 Heater Dimensions – X45

1-2

PROHEAT INSTALLATION & SERVICE

POWER

G-IIISOFT START

PROHEATCONTROL MODULE

FUSE15A

SWITCHINPUT

SLEEPERFAN

ThisProductMeets

FHWABusHeater

Requirements

DieselFueledVechicle

CoolentHeater

ApprovedforUsein

BusApplications

12VOLT

999100

COMMINICATION

RS232&

CANBus

DONOT

POWER

WASH

ProtectedbyUSPatents

5,878,950and6,082,625

O

A

L

I

T

T

R

L

L

D

N

A

L

E

I

E

R

E

S

O

T

N

R

HEATERMODELNo:..........

SERIALNo:

MadeinCanadabyTeleexCanadaLtd Richmond B.C.

OPERATINGVOLTAGE:...XX-XXVOLTS

HEATOUTPUT:.............

PRESSURE:..............

MAX.OPERATING

FUELTYPE:...................

******

XXXXXX

9.0kW(KBTU)

2BAR(29PSI)

DIESELFUEL

X-45XXV

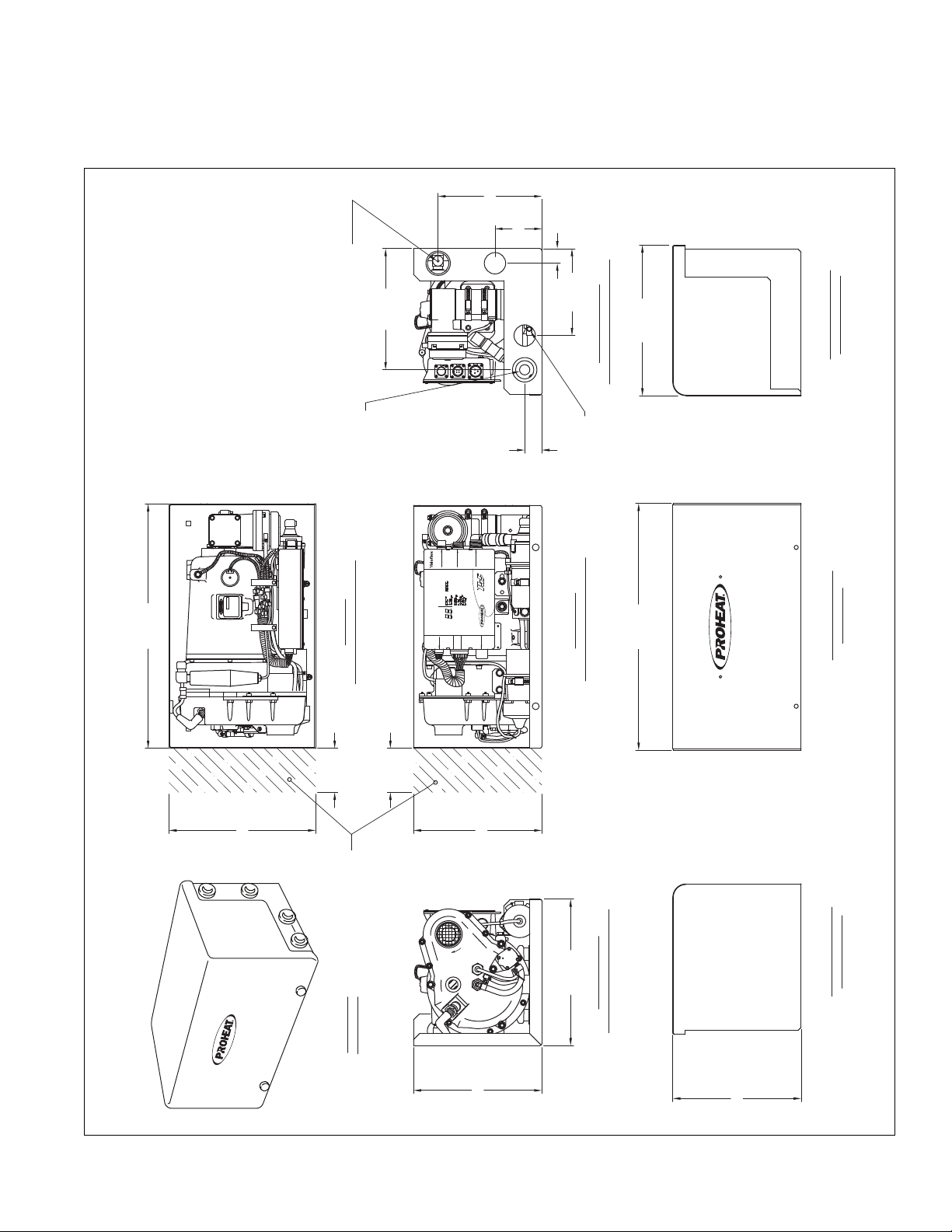

COOLANT INLET

CONNECTION

3/4" [19] ID HOSE

COOLANT OUTLET CONNECTION

3/4" [19] ID HOSE

1/2" NPT HOSE FITTING

SEE NOTE 1

TOP VIEW

ENCLOSURE LID REMOVED

FUEL SUPPLY

CONNECTION

1/4" [48] ID HOSE

SEE NOTE 1

9.9" [252]

2X 1.4" [36]

FRONT VIEW

ENCLOSURE LID REMOVED

LEFT SIDE VIEW

ENCLOSURE LID REMOVED

RIGHT SIDE VIEW

ENCLOSURE LID REMOVED

ENCLOSURE COVER

FRONT VIEW

ENCLOSURE COVER

LEFT SIDE VIEW

20.2" [513]

10.5" [267]

20.0" [508]

10.5" [267]

12.0" [305]

8.5" [216]

ENCLOSURE COVER

RIGHT SIDE VIEW

12.3" [313]

3.8" [97]

2X 1.20" [30]

7.1" [181]

12.0" [305]

10.5" [267]

3.6" [92]

3.6" [92]

THIS SPACE

IS REQUIRED FOR

COMBUSTION

TUBE REMOVAL

ASSEMBLED

ENCLOSURE

NOTES:

1/ REFER TO X45 PARTS BOOK SL9070 FOR PART

NUMBER IDENTIFICATION

2/ DIMENSIONS ARE FOR REFERENCE PURPOSES ONLY

AND SUBJECT TO CHANGE WITHOUT NOTICE

X45 WITH ENCLOSURE1.1.2

Figure 1-2 Heater Dimensions including Enclosure – X45

SECTION 1. TECHNICAL SPECIFICATIONS

1-3

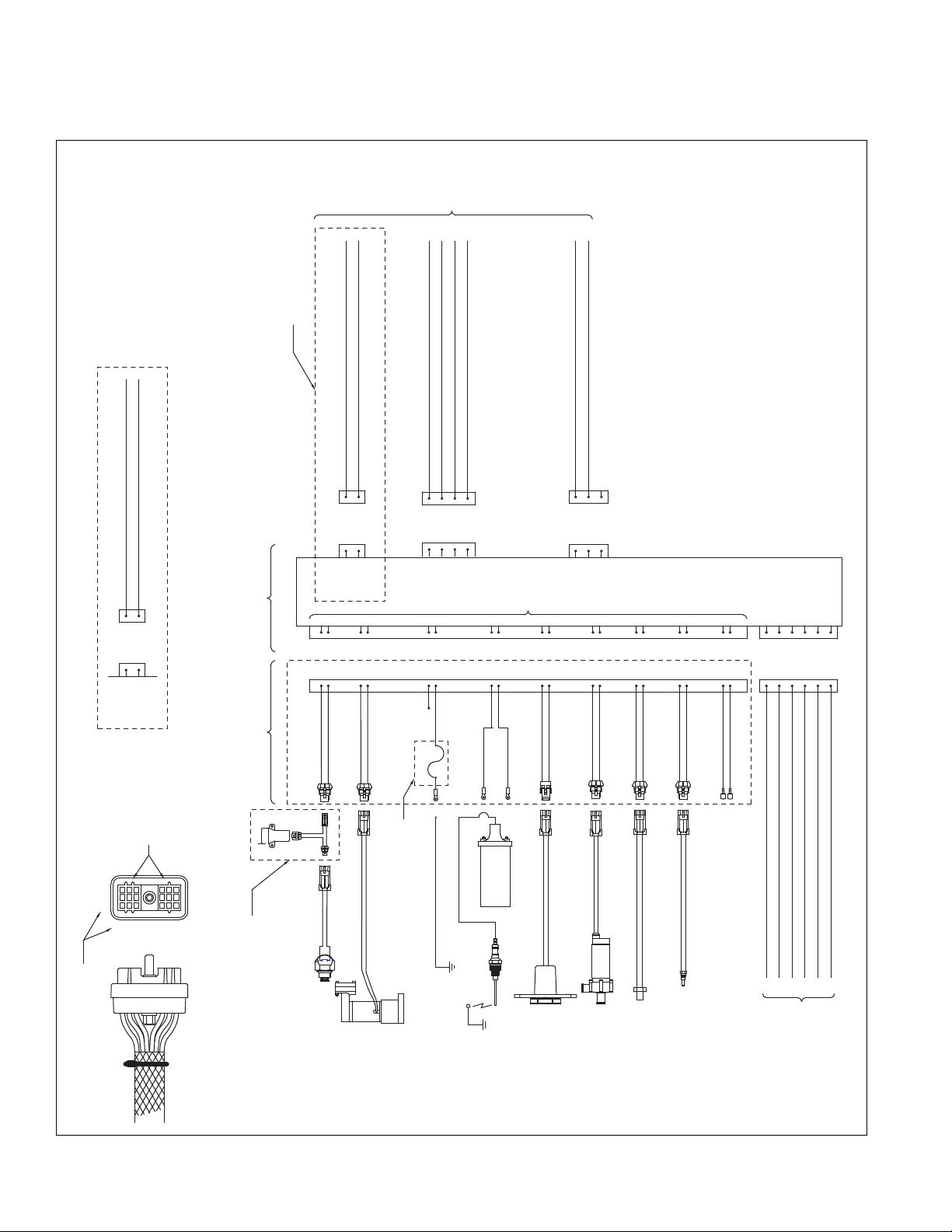

FUEL PUMP

COMPRESSOR

ELECTRODE

IGNITION

BLOWER

PUMP

FLAME

TEMPERATURE

SENSOR

SENSOR

COOLANT

B (-)BLACK/BLUE

HOUR METER (AUXILIARY OUTPUT)

12V/24V 1A MAX.

P5

COMMUNICATION

CANBUS AND

RS232

E

F

E

F

(+)RED/WHITE

(-)GREEN/WHITE

A

B

BCA

D

BCA

D

E1

F1

(-)BROWN

(-)BLACK/WHITE

(+)GRAYA

A

B

B

(+)WHITE

B

A

B

A

F3

E3

F2

E2

P1

POWER

C

C

A

B

B

A

HEATER CHASIS GROUND LUG

(GROUND VIA

COMBUSTION TUBE)

IGNITION

COIL

OVERHEAT SENSOR

D1

(-)BLACK

(+)PURPLE

(-)BLACK/PURPLE

B

(+)BLUE

B

A

A

A

B

A

B2

A2

B3

A3

(+)RED

D2

C3

P5

HEATER

INTERNAL

HARNESS

P2

SWITCH

C

C

D

D

B

A

A

B

(-)BLACK/ORANGE

(+)ORANGE

A

B

B

A

(-)PINK

(+)PINK

B

A

A

B

PLUGGED

C1

A1

B1

C2

D3

P3

SLEEPER

FAN

A

A

B

B

CONNECTOR TERMINAL

DESIGNATORS

NOTE ORIENTATION

OF CONNECTOR LUGS

(+) RED - BATTERY POSITIVE 12V/24V

(-) BLACK - BATTERY NEGATIVE

PLUGGED - NOT USED

(+) RED - POWER 12V/24V OUTPUT

(-) BLACK - GROUND

GREEN - ON SIGNAL STANDARD MODE 12V/24V INPUT

(+) WHITE - INDICATOR LAMP 12V/24V OUTPUT

(+) RED - POWER 12V/24V (3 AMP LIMIT) OUTPUT

(-) BLACK - GROUND

CAN - H

RS232 - GROUND

CAN - SHIELD

RS232 - TRANSMIT

CAN - L

RS232 - RECEIVE

E1

F1

F3

E3

F2

E2

A2

B3

D1

B2

A3

D2

C2

D3

A1

B1

C1

C3

NOTES:

1/ REFER TO X45 PART BOOK SL9070 FOR PART

NUMBER IDENTIFICATION

(+)PINK

A

B

(-)PINK

(+)ORANGE

A

(-)BLACK/ORANGE

B

(+)

(-)

(+)PURPLEA

(-)BLACK/PURPLE

B

(+)BLUEA

(-)BLACK/BLUEB

(+)BROWNA

(-)BROWNB

(+)WHITEA

(-)BLACK/WHITEB

P3

AUXILIARY

INPUT

A

B

ON SIGNAL PREHEAT MODE 12V/24V INPUT

ON SIGNAL SUPPLEMENTAL MODE 12V/24V INPUT

A

B

SEE DETAIL A FOR

AUXILIARY INPUT OPTION

DETAIL A

AUXILIARY INPUT OPTION

SEE NOTE 1

OPTIONAL IMPACT SWITCH

SEE NOTE 1

A

B

A

B

C

SEE NOTE 1

FOR HARNESS

PART NUMBERS

SEE NOTE 1

FOR HARNESS

PART NUMBERS

OPTIONAL GROUND FUSE

SEE NOTE 1

(-)BLACK/GREEN

SLEEPER FAN PCM SHOWN

SEE NOTE 1

HEATER INTERNAL HARNESS

SEE NOTE 1

10 A

1 2 3

A

BCD

E

F

A

B

C

D

E

F

HEATER INTERNAL HARNESS

18 PIN CONNECTOR PIN OUT DETAIL

1.2

ELECTRICAL – X45

Figure 1-3 Wiring Diagram – X45

1-4

PROHEAT INSTALLATION & SERVICE

PROHEAT CONTROL MODULE

G-III SOFT START

5,878,950and 6,082,625

Protectedby US Patents

WASH

POWER

DO NOT

COMMINICATION

BusApplications

ApprovedforUse in

CoolentHeater

DieselFueledVechicle

Requirements

FHWABus Heater

ThisProduct Meets

CANBus

RS232&

FUSE 15A

999100

SLEEPER FAN

12 VOLT

SWITCHINPUT

POWER

P1 - POWER

3 PIN

P2 - SWITCH

4 PIN

P3 - SLEEPER FAN OUTPUT

OR AUXILIARY INPUT

2 PIN

SEE NOTE 1

P4 - COMMUNICATION

CANBUS AND

RS232 6 PIN

FUSE 15 A

SEE NOTE 1

P5 - HEATER

INTERNAL

HARNESS

18 PIN

PROHEAT CONTROL MODULE (PCM)

SEE NOTE 1 FOR PART NUMBER OPTIONS

1A

1B

1C

2A

2B2C

2D

3A3B

DETAIL B

DETAIL B

P1 - P3 CONNECTOR PIN OUT DETAIL

DETAIL C

2

3

1

CONNECTOR TERMINAL

DESIGNATORS

NOTE ORIENTATION

OF CONNECTOR LUGS

DETAIL C

P5 CONNECTOR PIN OUT DETAIL

ABC

DFE

CONTROLLER VOLTAGE AND

PART NUMBER IDENTIFICATION

SEE NOTE 1

SLEEPER FAN OR AUX INPUT MODEL

IDENTIFICATION - SEE NOTE 1

4A

4B

4C

4D

4E

4F

DETAIL D

DETAIL D

P4 CONNECTOR PIN OUT DETAIL

NOTES:

1/ REFER TO X45 PART BOOK SL9070 FOR PART

NUMBER IDENTIFICATION

Figure 1-4 PCM Electrical Connections – X45

SECTION 1. TECHNICAL SPECIFICATIONS

1-5

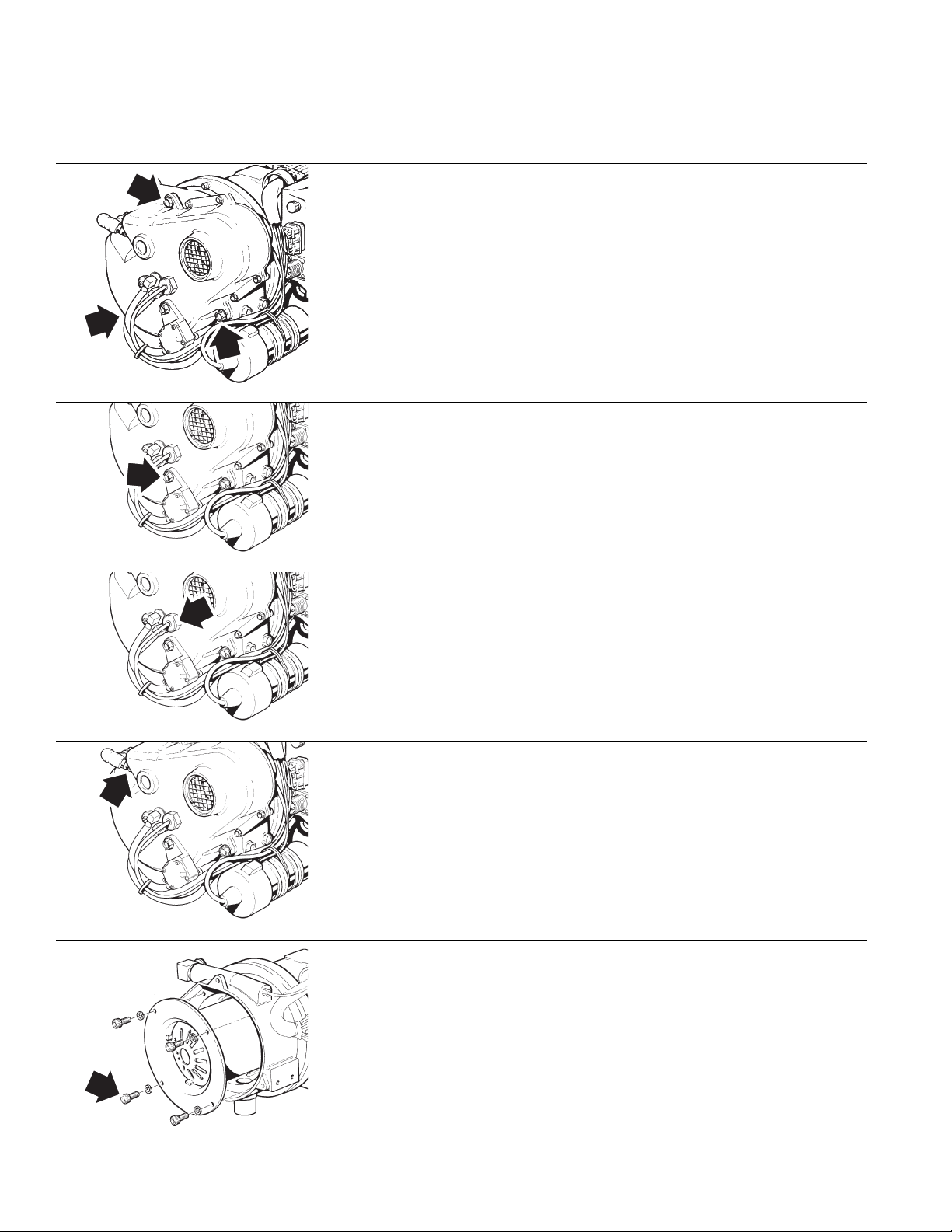

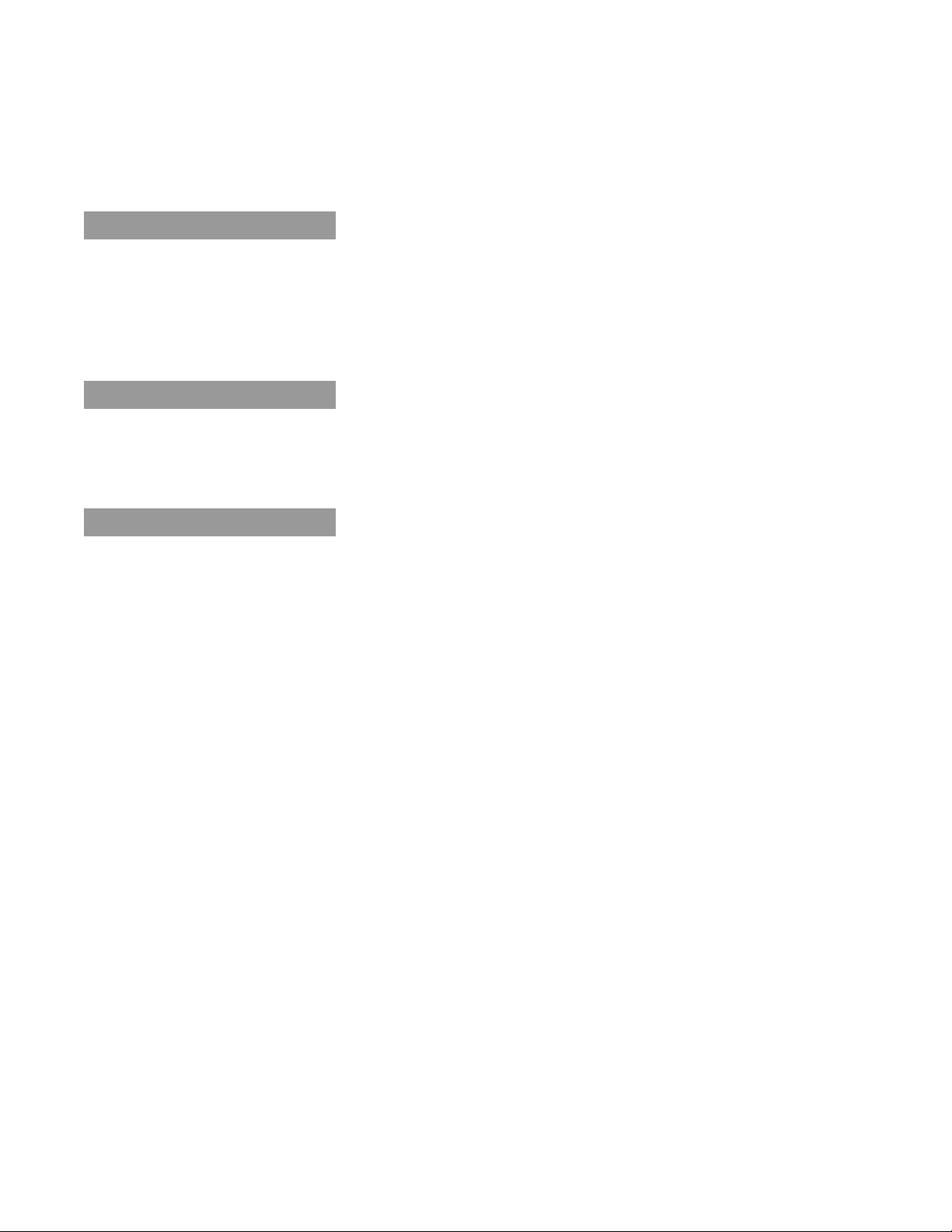

TORQUE SPECIFICATIONS1.3

FAN END CASTING

Apply anti-seize to bolts (3)

•

• Torque bolts (3) to 75±5 in/lbs (8.5±0.5 Nm)

REGULATOR

• Apply anti-seize to cap screw

• Torque cap screw to 94±6 in/lbs (10.6±0.7 Nm)

FLAME SENSOR

• Torque sensor to 25±3 in/lbs (2.8±0.3 Nm)

IGNITER

• Apply anti-seize to igniter threads

• Ensure gasket is present before installing

• Torque igniter to 50±5 in/lbs (5.6±0.6 Nm)

COMBUSTION TUBE

• Apply anti-seize to cap screws

• Torque cap screws (4) to 25±3 in/lbs (2.8±0.3 Nm)

1-6

PROHEAT INSTALLATION & SERVICE

OVERHEAT SENSOR

• Lubricate o-ring with o-ring lubricant

• Torque senor to 500±50 in/lbs (56±5.6 Nm)

TEMPERATURE SENSOR

• Lubricate o-ring with o-ring lubricant

• Torque senor to 25±3 in/lbs (2.8±0.3 Nm)

AIR FILTER

• Torque cap screw to 50±5 in/lbs (5.6±0.6 Nm)

SECTION 1. TECHNICAL SPECIFICATIONS

BLOWER ASSEMBLY

• Apply anti-seize to bolts (4)

• Torque bolts (4) to 25±3 in/lbs (2.8±0.3 Nm)

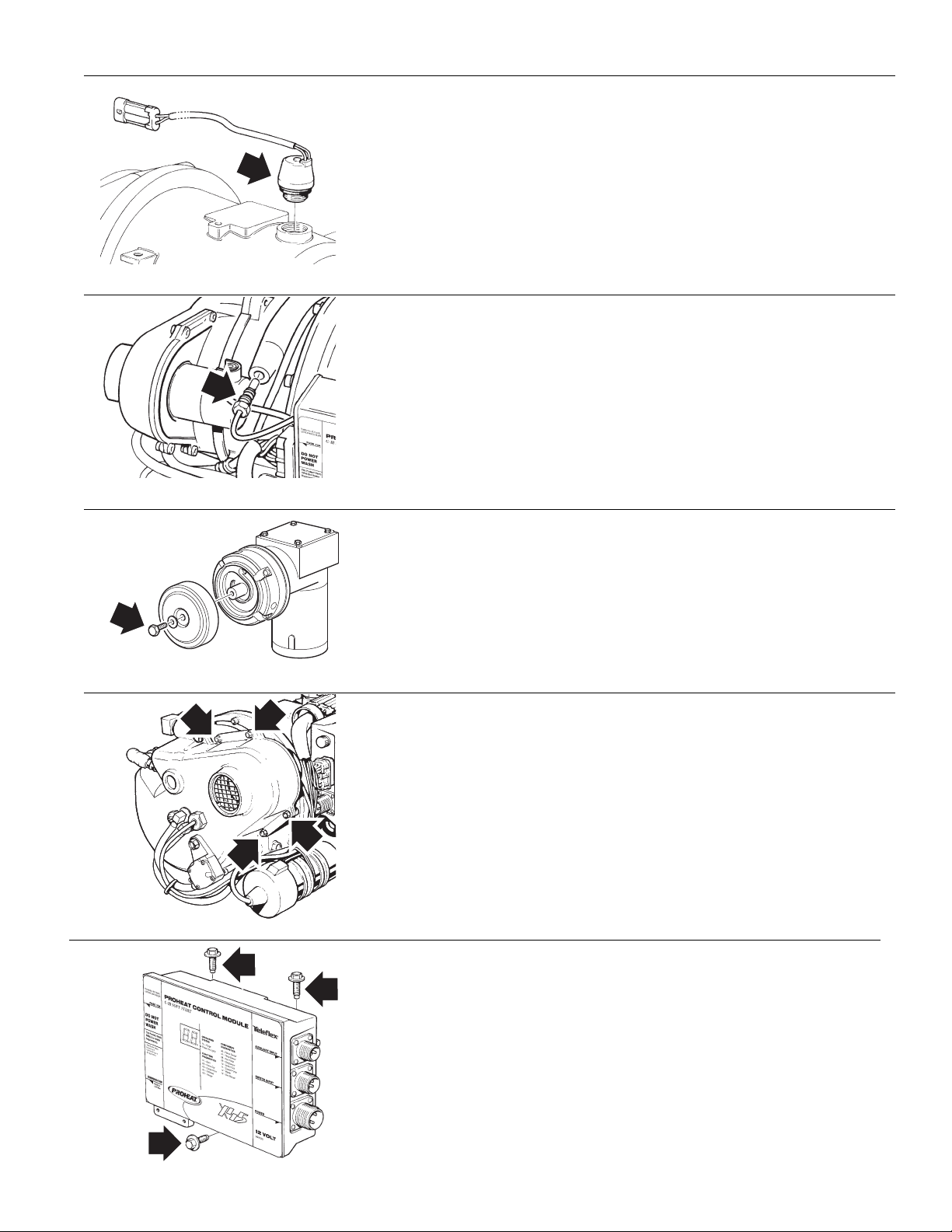

PROHEAT CONTROL MODULE (PCM)

• Apply anti-seize to bolts (3)

• Torque bolts (3) to 75±7 in/lbs (8.5±0.8 Nm)

1-7

MAIN INTERNAL HARNESS

• Torque bolt (1) to 10±2 in/lbs (1.1 +/- 0.2)

NOZZLE TO FAN END

• Lubricate o-ring on nozzle with diesel

• Torque nozzle to 150±10 in/lbs (17±1.1 Nm)

NOZZLE REASSEMBLY

• Torque nozzle (1) to 30±3 in/lbs (3.4±0.3 Nm)

BAND CLAMPS

• Torque clamps (4) to 25±3 in/lbs (2.8±0.3 Nm)

ENCLOSURE LID (Optional)

• Anti-seize recommended on bolts

• Torque clamps (2) to 30±3 in/lbs (3.4±3.4 Nm)

1-8

PROHEAT INSTALLATION & SERVICE

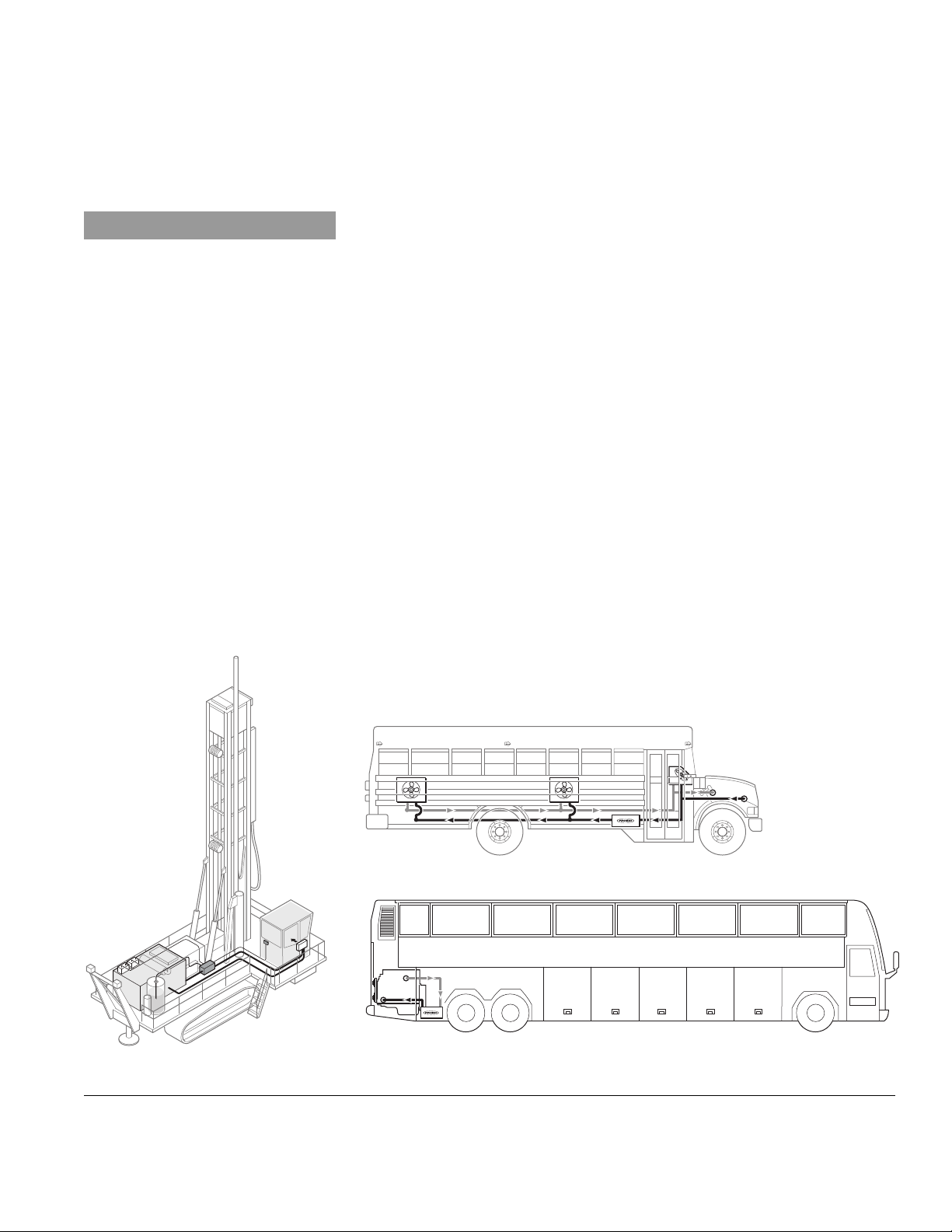

HARNESS GROUND LUG

A

B

C

• Apply anti-seize to bolt

• Torque bolt (1) to 75±5 in/lbs (8.5±0.5 Nm)

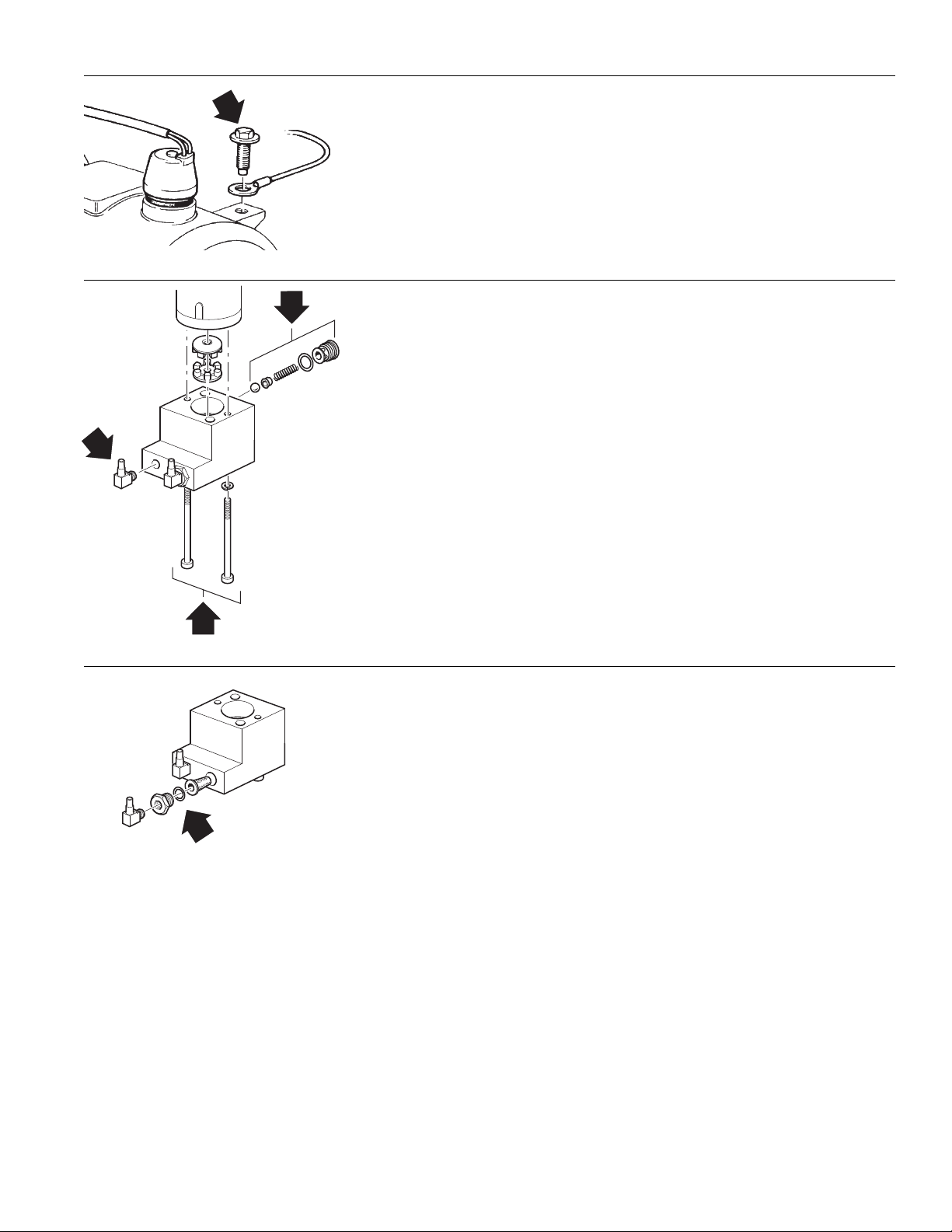

FUEL PUMP ASSEMBLY

A

• Apply Loctite 242 to threads

• Torque bolts (2) to 25±3 in/lbs (2.8±0.3 Nm).

B

• Lubricate o-ring with diesel fuel

• Torque relief valve to 22±2 in/lbs (2.5±0.2 Nm).

C

• Apply Loctite 59241 sealant to threads

• Torque elbow (1) to 55±5 in/lbs (6.2±0.5 Nm) minimum or until

elbow is at correct orientation

FUEL FILTER

• Lubricate o-ring with diesel fuel

• Torque nut (1) to 150±10 in/lbs (17±1.1 Nm)

SECTION 1. TECHNICAL SPECIFICATIONS

1-9

1-10

PROHEAT INSTALLATION & SERVICE

2.0

OPERATING YOUR

PROHEAT HEATER

NOTICE

These instructions cover Standard

Mode operation that are normally

installed on trucks. To operate your

heater in Preheat or Supplemental,

refer to page 3-18 to page 3-20 and

page 4-6 to page 4-7.

NOTICE

Regular use of your PROHEAT

throughout the year will improve

its reliability. Weekly operation is

recommended.

NOTICE

The PROHEAT heater can be

operated by either using a toggle

switch or a 7 day timer.

Refer to page 3-10 for WIRING &

ELECTRICAL CONNECTIONS.

ENGINE HEAT ONLY

1. Switch the ON/OFF switch located in the vehicle dash to “ON.”

The switch will light and the heater will cycle on. It will continue to operate until

the coolant reaches 185˚F (85˚C) at the heater outlet and then cycle “OFF.”

When the coolant temperature falls below 150˚F (65˚C) at the heater

outlet, it will refire and repeat the cycle.

It will continue to cycle until:

a) the heater is switched “OFF,”

b) the heater runs out of fuel,

c) the vehicle battery voltage drops below 10.0 Volts, or

d) an error occurs and the switch light flashes

(See Troubleshooting & Repair, Section 5)

NOTE: The PROHEAT may be operated if the engine is running or not running.

2. When engine preheat is no longer required, switch the PROHEAT heater

“OFF.”

ENGINE AND SLEEPER HEAT

1. Switch the ON/OFF switch located in the vehicle dash to “ON.”

The switch will light and the heater will cycle on. It will continue to operate until

the coolant reaches 185˚F (85˚C) at the heater outlet and then cycle “OFF.”

When the coolant temperature falls below 150˚F (65˚C) at the heater

outlet, it will refire and repeat the cycle.

It will continue to cycle until:

a) the heater is switched “OFF,”

b) the heater runs out of fuel,

c) the vehicle battery voltage drops below 10.0 Volts, or

d) an error occurs and the switch light flashes

(See Troubleshooting & Repair, Section 5)

SECTION 2. OPERATING YOUR PROHEAT HEATER

NOTE: The PROHEAT may be operated if the engine is running or not running.

2. For sleeper heat – set the thermostat in the sleeper to the desired

temperature. If the set temperature is higher than the temperature in the

sleeper the fan will cycle “ON.” When the air reaches the set temperature

the fan will cycle “OFF.” The fan will cycle “ON” and “OFF” to maintain the

set temperature.

3. When engine and/or sleeper preheat is no longer required, switch the

PROHEAT heater “OFF.”

2-1

2-2

PROHEAT INSTALLATION & SERVICE

3.0

®

®

INSTALLATION

NOTICE

If additional installation information is

required

Dealer regarding your specific

application.

For more technical information,

please contact PROHEAT Product

Support at www.proheat.com

please contact your PROHEAT

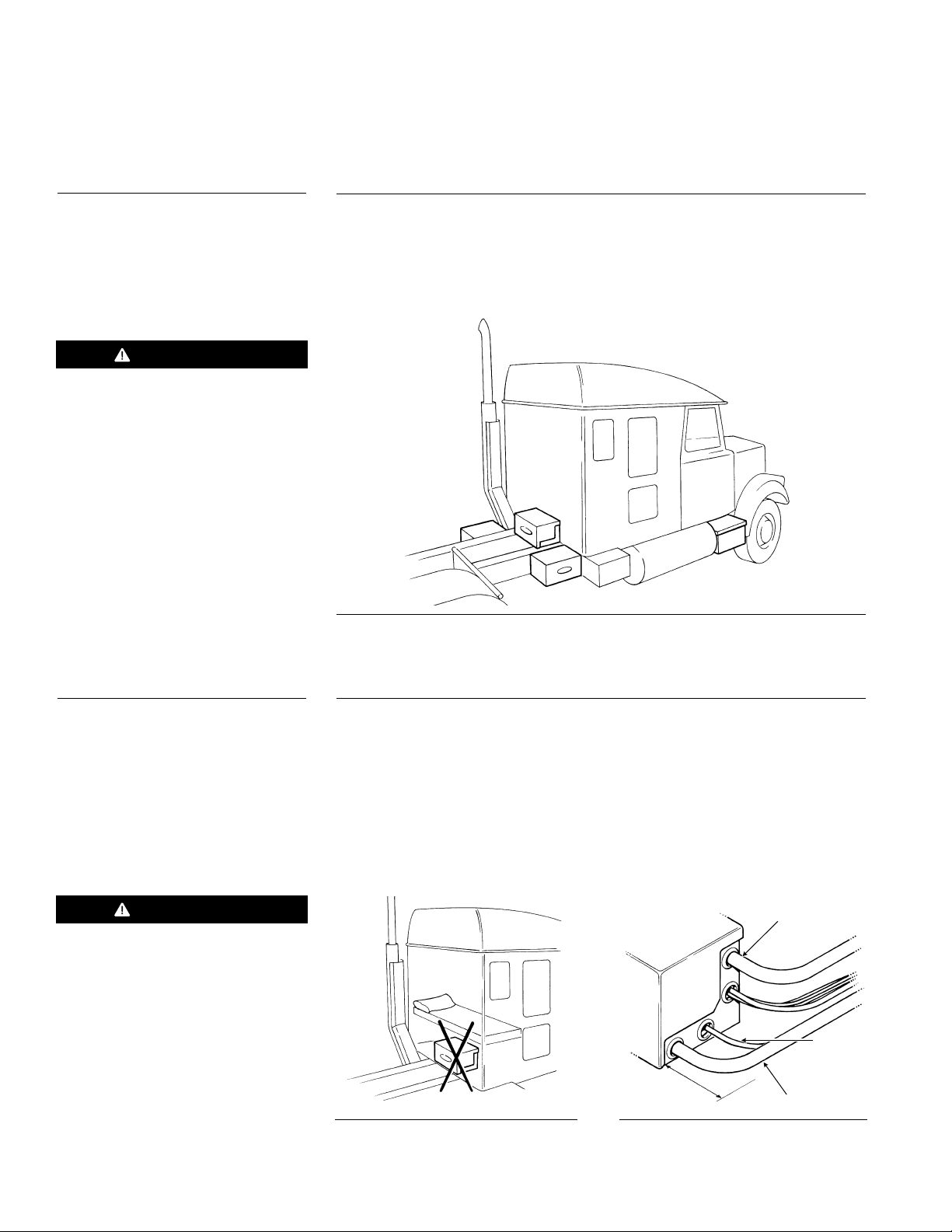

The installation details described in this manual focuses on truck applications

and does not cover all of the possible installations. As seen in the figures

below, the PROHEAT X45 is installed on a variety of equipment including

trucks, school buses, coaches, drill rigs, mine dump trucks and excavators.

In these cases the manual should be used as a guideline only.

There are seven major steps that must be completed to successfully install

the PROHEAT heater.

3.1 LOCATING THE HEATER......................................................... page 3-2

3.2 MOUNTING THE HEATER ....................................................... page 3-4

3.3 EXHAUST PIPE CONNECTION ................................................. page 3-6

3.4 PLUMBING THE SYSTEM....................................................... page 3-7

3.5 WIRING & ELECTRICAL CONNECTIONS ................................. page 3-10

3.6 FUEL SYSTEM .................................................................... page 3-22

3.7 FIRST TIME STARTUP.......................................................... page 3-26

Prior to the installation of your PROHEAT, consult your engine owner’s manual

or engine manufacturer for any restrictions or changes that may apply to

plumbing into the engine coolant system.

Figure 3-1 Other Applications.

SECTION 3. INSTALLATION

3-1

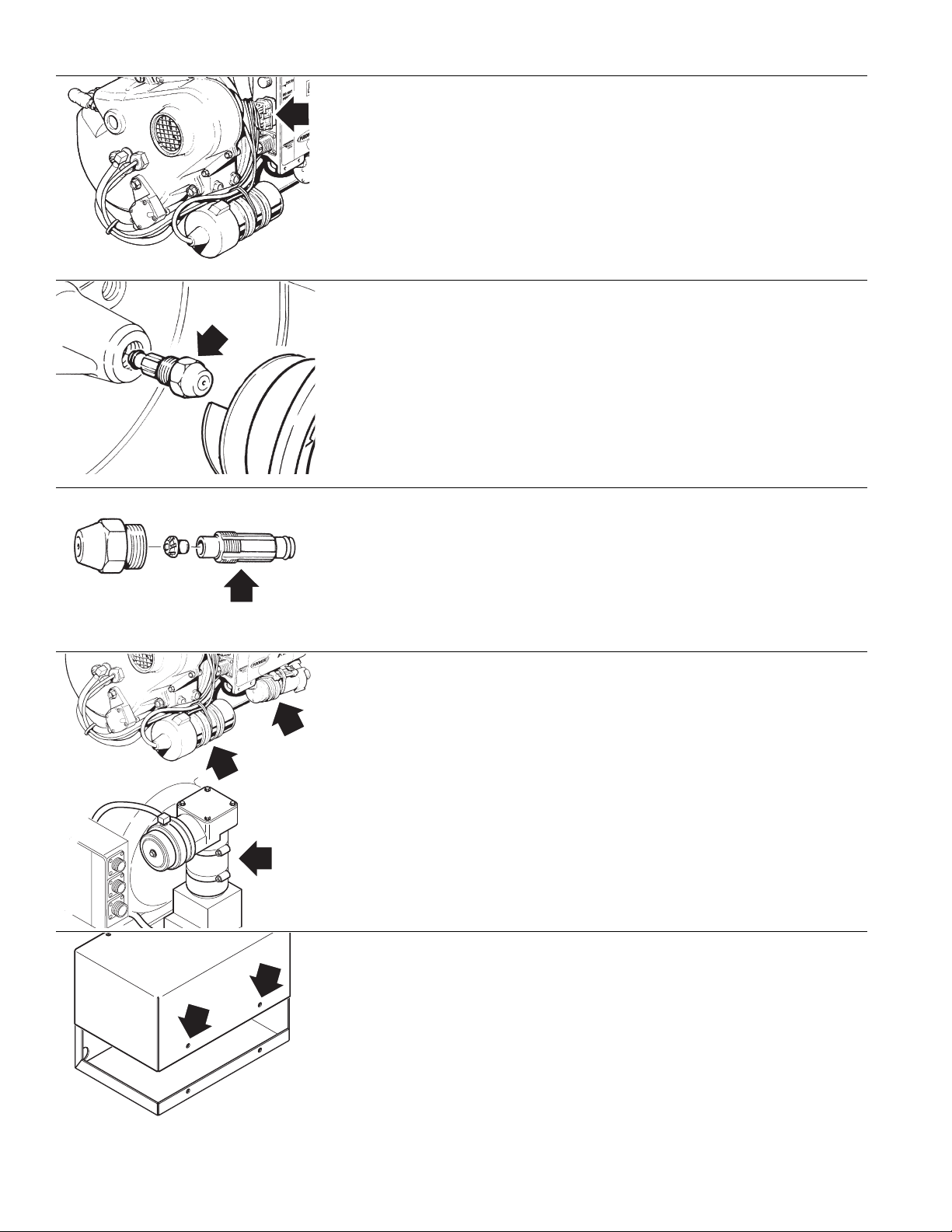

3.1

LOCATING THE HEATER

3.1.1

You Choose

CAUTION

Do not weld PROHEAT heater

mounting brackets to the

vehicle frame.

If repairs to the vehicle require

welding, disconnect the PROHEAT

power cable at the PCM. This will

prevent damage to the PROHEAT

electronics.

SELECT YOUR LOCATION

The most suitable location for mounting the heater will vary depending

on the type of vehicle. Recommended mounting locations are:

• Behind the cab across the frame rails (1).

• On either side of the frame rails (2).

• In an existing enclosure on the vehicle (step or toolbox) (3).

1

2

3

2

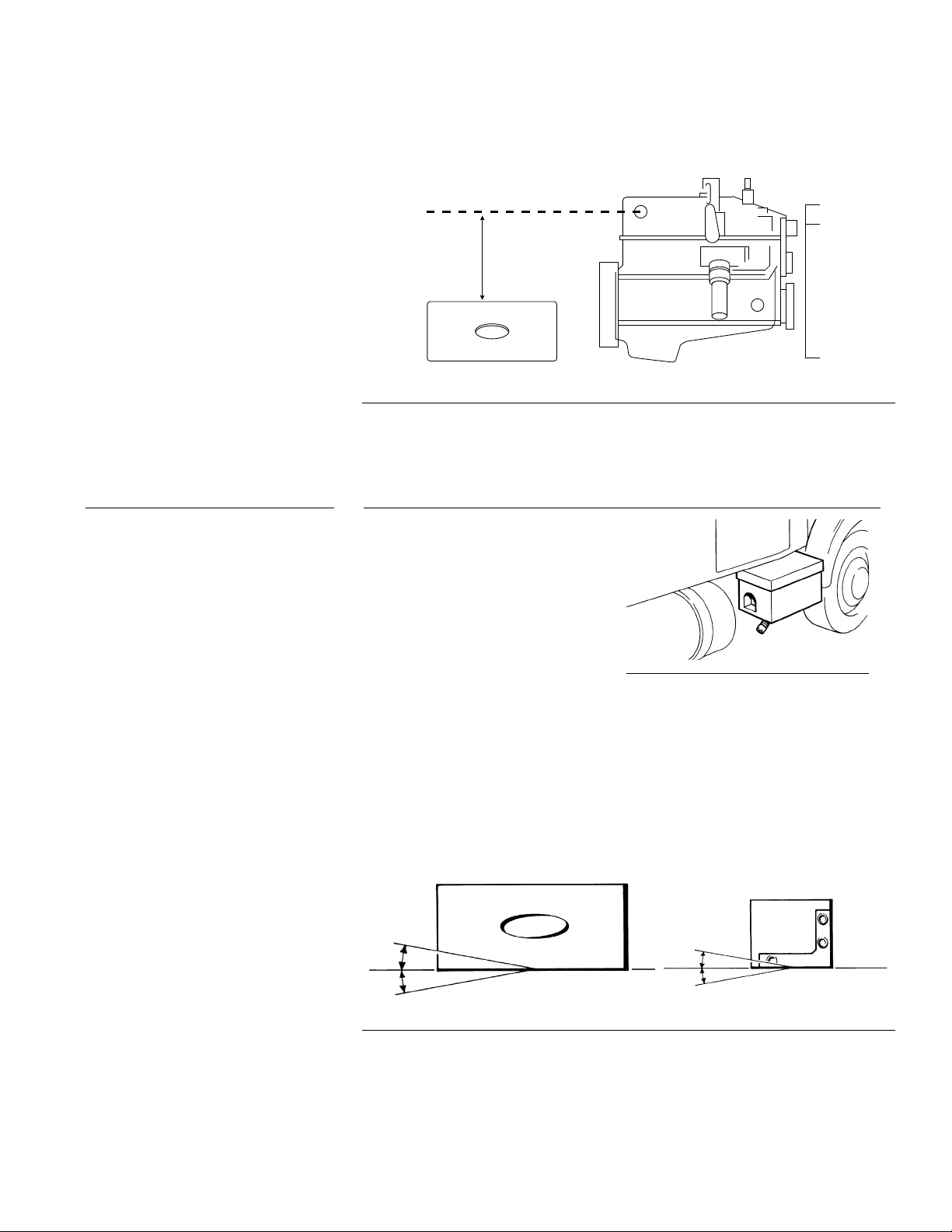

Figure 3-2 Recommended Mounting Positions

3.1.2

WARNING

Never locate the heater inside

the vehicle cab. (See Figure 3-3)

GENERAL CONSIDERATIONS

• Never mount the heater to two separate parts of the vehicle.

• Avoid mounting the heater in areas of excessive vibration.

• Do not mount the heater directly to the engine.

• Do not mount the heater beneath a wood floor without a proper fire wall

above the heater.

• Avoid mounting the heater in areas of excessive dust, dirt and moisture

accumulation.

• The heater must be easily accessed for service.

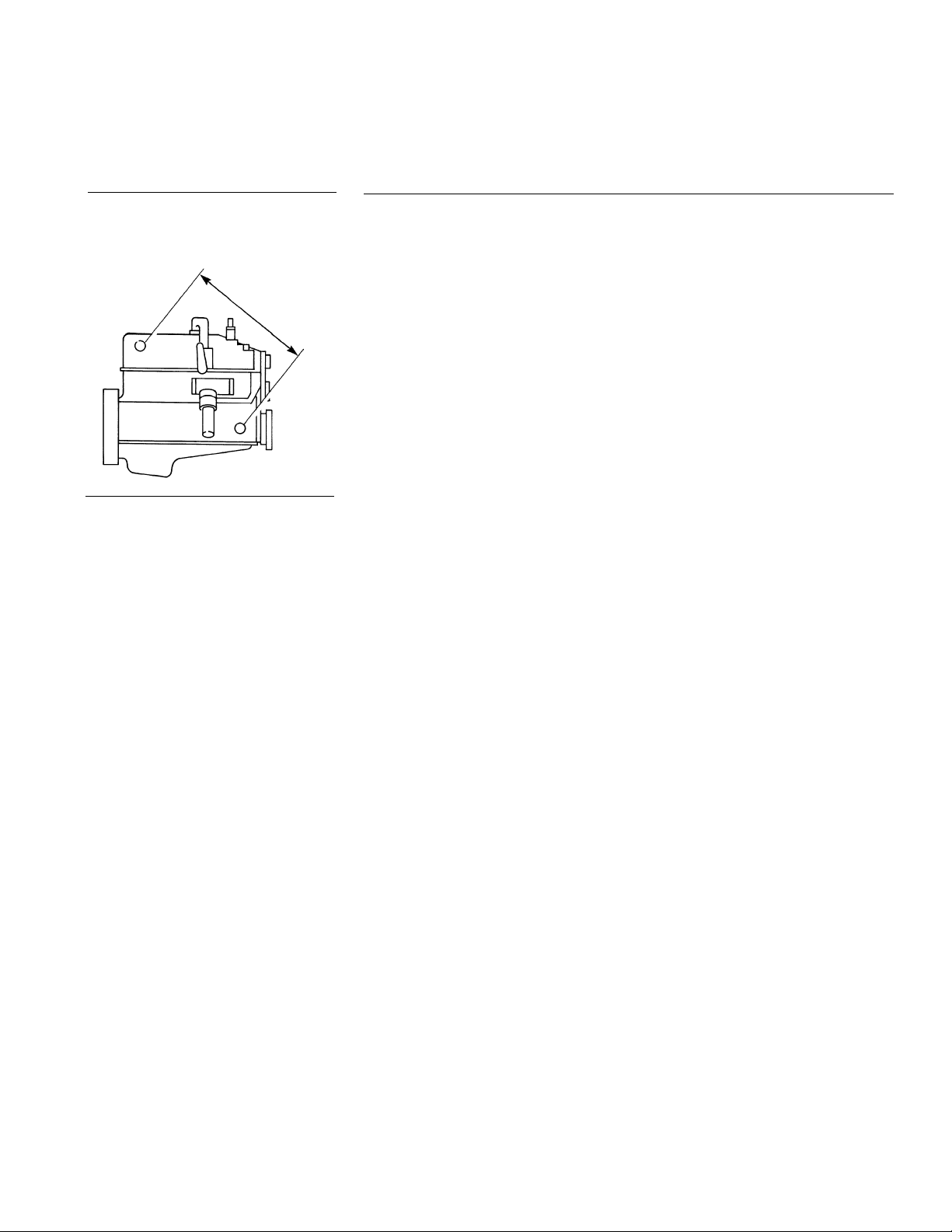

COOLANT OUT

FUEL IN

Figure 3-3

MINIMUM

CLEARANCE 6"

Figure 3-4 Allow minimum 6" clearance

for hose connections.

COOLANT IN

3-2

PROHEAT INSTALLATION & SERVICE

Heater must be mounted below the highest point in the cooling system. An

expansion tank may be added to the coolant system above the heater if this

is not possible.

HIGHEST POINT IN

COOLING SYSTEM

HEATER MUST

BE MOUNTED

BELOW

HIGHEST POINT

PROHEAT ENGINE OR RADIATOR

Figure 3-5 Height Requirement

3.1.3

MOUNTING THE PROHEAT HEATER IN AN ENCLOSURE

Do not locate the heater in an

airtight enclosure. If the heater is to

be mounted in an enclosure other

than the PROHEAT enclosure,

adequate air flow must be provided

to ensure proper combustion. The

enclosure must also be adequately

ventilated so that the ambient

temperature inside the enclosure

does not exceed 185 °F (85 °C).

The openings must be positioned to prevent moisture dirt and snow from

accumulating in the enclosure. The heater enclosure must be easily

accessed for servicing of the heater.

Heater must be mounted within 5˚ of horizontal, as shown.

Figure 3-6 Adequate Air Flow

SECTION 3. INSTALLATION

5˚

5˚

Figure 3-7 Mounting Angle

5˚

5˚

3-3

3.2

MOUNTING THE HEATER

Select Your Mounting Option

Figure 3-8 Mounting Tray

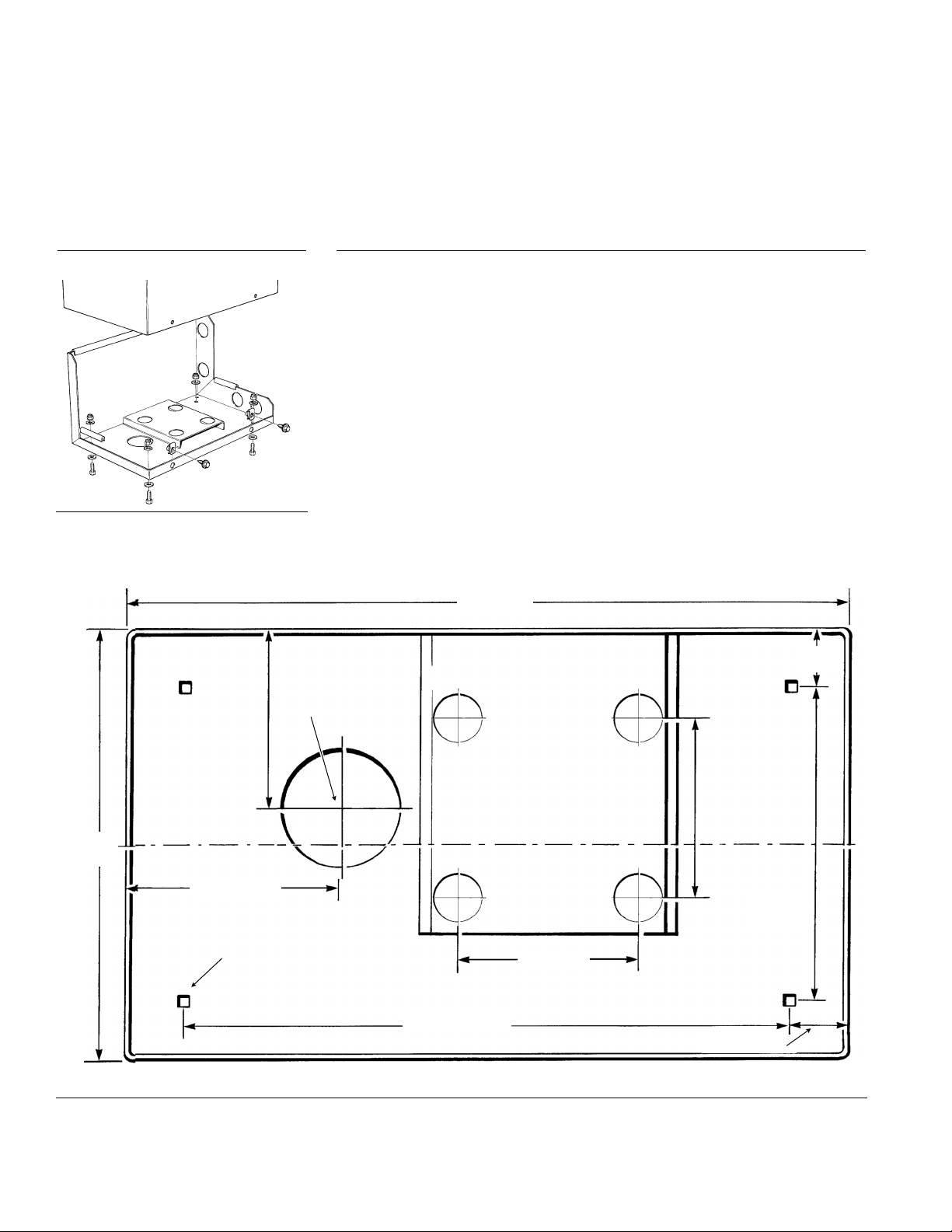

3.2.1

OPTION A

1. Remove the enclosure cover.

2. Drill the (4) mounting holes and exhaust pipe clearance hole.

3. Using the bolts supplied, fasten the enclosure to the mounting

tray or brackets.

4. Ensure that the combustion tube can be removed for service.

See Figure 1-2 on page 1-3 for service space requirements.

– Heater With Enclosure

20" (508 mm)

1 5/8"

(45 mm)

3" (76 mm) Dia.

5" (127 mm)

12"

(306 mm)

5 3/4" (146 mm)

3/4" (20 mm) MOUNTING HOLES

(4 REQUIRED)

Figure 3-9 X45 Enclosure Base Dimensions

5" (127 mm)

CENTERLINE OF ENCLOSURE

8 13/16"

(223 mm)

5" (127 mm)

16 11/16" (427 mm)

1 5/8" (45 mm)

3-4

PROHEAT INSTALLATION & SERVICE

NOTICE

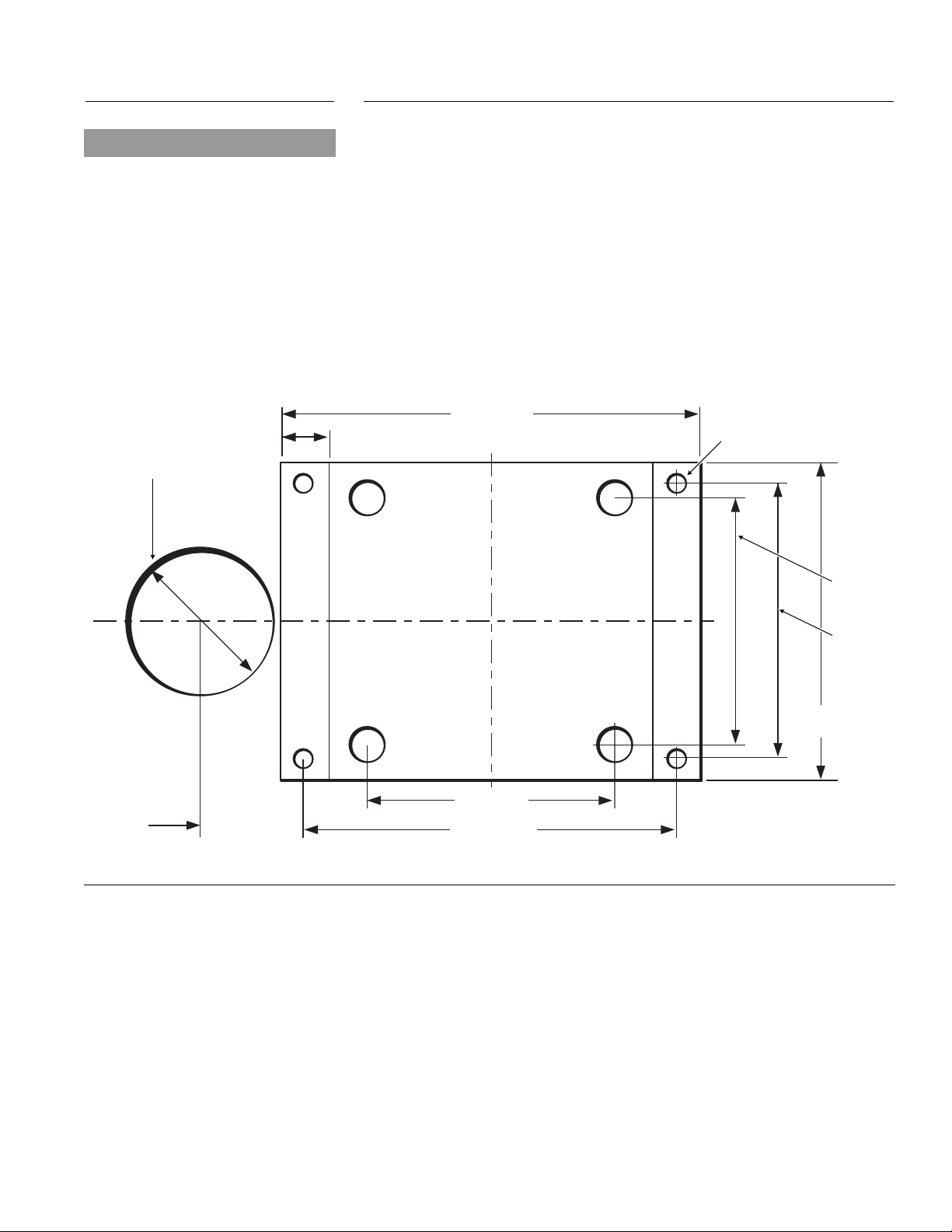

3.2.2

OPTION B

– Heater Without Enclosure

Heater supplied without an enclosure (mount in an existing enclosure on the

vehicle ie. tool box). Heater supplied with an auxiliary mounting plate.

Use anti-seize compound on fasteners

to prevent galling and corrosion.

3" (76 mm) Dia.

. Ensure that the proposed enclosure is big enough for the heater.

1

2

1

⁄2W x 11H x 201⁄2L inches (318 x 280 x 521 mm)

12

. Using the indicated dimensions, drill the (4) mounting holes

and exhaust pipe clearance hole.

3. Ensure that the combustion tube can be removed for service.

See Figure 1-2 on page 1-3 for service space requirements.

8.5" (216 mm)

1.0" (25 mm)

4 X .38" (10MM)

MOUNTING HOLES

5"

(127 mm)

2.02"

(51 mm)

Figure 3-10 X45 Mounting Plate Dimensions & Exhaust Hole

5.5"

(140 mm)

6.4"

(163mm)

5" (127 mm)

7.5" (191 mm)

SECTION 3. INSTALLATION

3-5

3.3

NOTICE

If additional information is required,

please contact your PROHEAT Dealer

regarding your specific application.

Alternatively, please contact PROHEAT

Product Support at www.proheat.com.

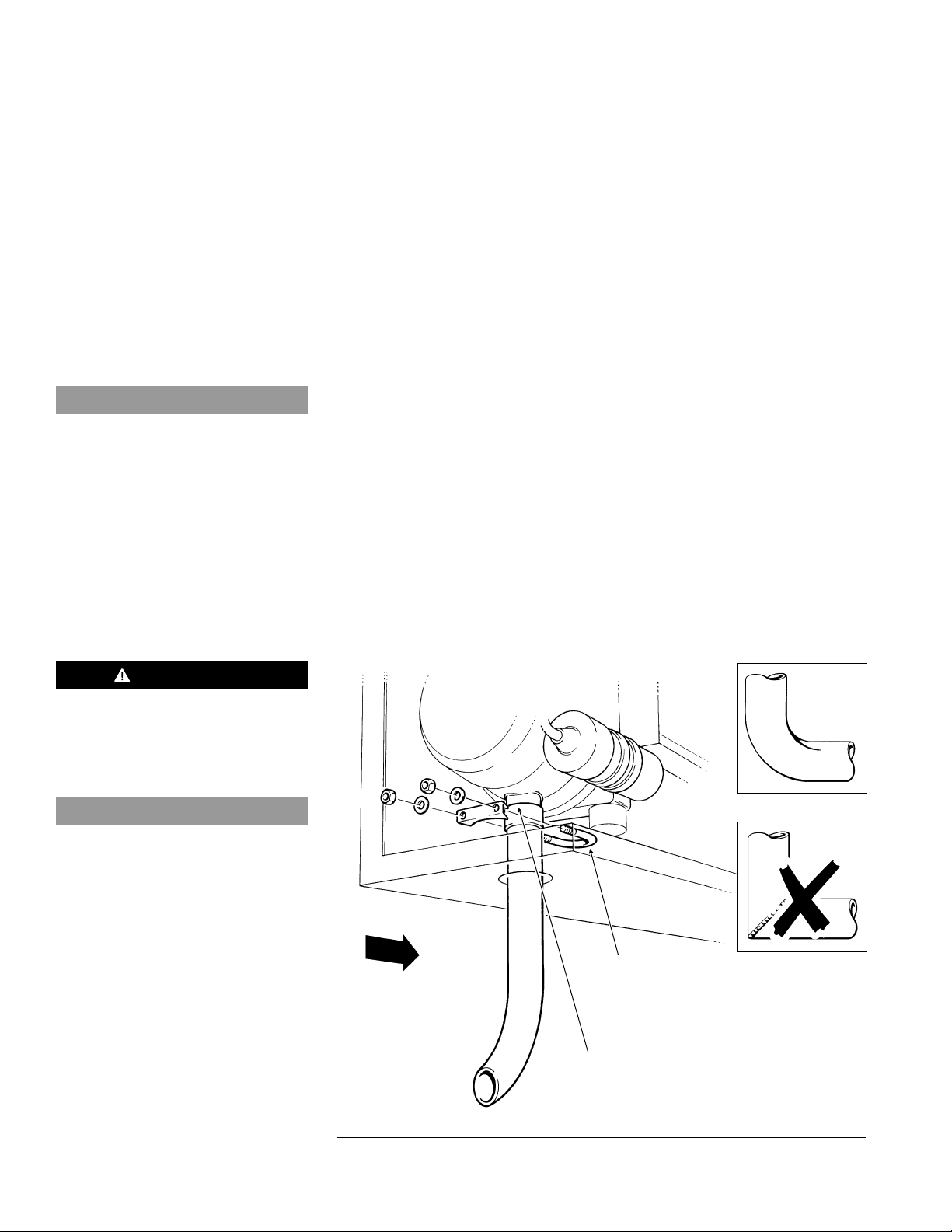

EXHAUST PIPE CONNECTION

1. Push the exhaust pipe through the hole in the enclosure and onto the

exhaust outlet port of the heater. Ensure that the pipe is pushed onto

the spigot at least 11⁄2" (38 mm).

2. Route the exhaust pipe such that:

• exhaust gasses do not enter the passenger compartment.

• exhaust gasses do not enter the heater's combustion air inlet

• exhaust system does not rest against or be directed toward any parts

of the vehicle that may be damaged by heat (i.e. brake lines, seals, wires

rubber hoses or bumpers). The exhaust pipe may be have to be insulated

if it's within 6" of combustible materials or composite body parts

• the exhaust outlet does not face the same direction as vehicle travel

• debris and snow will not plug the outlet

• the exhaust pipe is protected from curb damage

• the exhaust system should have a downwards slope for condensation

to drain. If needed a 3/8" hole should be drilled into the exhaust pipe

at the lowest point so that the condensation will drain.

3. Disassemble the exhaust pipe clamp and apply anti-seize compound to

the threads.

4. Assemble the exhaust clamp over the exhaust pipe (clamp goes inside

the enclosure) and tighten the nuts.

,

WARNING

Exhaust gases must not enter

the vehicle interior. Direct

exhaust pipe away from vehicle.

NOTICE

Use of muffler or other restrictions in the

exhaust system is not recommended.

NOTE: 11⁄2" exhaust pipe should not exceed 5 ft and have no more than

180 degrees of bends. The bends must be formed for best results.

Do not use 90 degree welded pipe to turn corners.

Use formed elbows.

Do not use welded

90˚ elbows.

DIRECTION

OF VEHICLE

TRAVEL

EXHAUST CLAMP

U BOLT (APPLY

ANTI-SEIZE

COMPOUND

TO THREADS)

3-6

ENSURE THERE ARE

NO AIR LEAKS AROUND

THE CONNECTION

Figure 3-11 Exhaust Pipe

PROHEAT INSTALLATION & SERVICE

3.4

PLUMBING THE SYSTEM

MA

X

I

MUM

C

ROS

S

-

F

Figure 3-12 Maximum cross-flow

3.4.1

L

OW

GENERAL CONSIDERATIONS

Coolant flow must be maintained throughout the coolant system

nder all conditions.

u

• Keep the engine inlet and outlet ports as far apart as possible to maximize

cross-flow through engine.

• Coolant pump and engine water pump must flow in the same direction.

• Ensure that no sharp kinks or bends exist in the hoses which may restrict

coolant flow.

• Avoid high points in the hose routing to prevent air traps.

• For systems requiring more than 50 feet of coolant line, contact Proheat

Product Support at www.proheat.com for coolant pump recommendations.

For plumbing the system use:

1

⁄2" NPT pipe fittings or bigger.

3

⁄4" ID heater hose.

NOTE: Use of silicone hose requires special hose clamps.

Shut-off valves are not required at the engine inlet and outlet connections but

may be used if desired. They should be left open at all times so that the heater

can be operated throughout the year.

You Choose

Select Your Plumbing Option

Option A:

Engine heat or supplemental heat.

The PROHEAT heats the engine block only.

NOTE: When the engine block is preheated you will have nearly

instant heat from the dash heat exchanger.

Option B: Engine and sleeper heat.

The PROHEAT heats the engine block and the sleeper.

NOTE: Plumbing the PROHEAT through the dash fan is not

recommended.

SECTION 3. INSTALLATION

3-7

Instructions for Options A and B

®®

WARNING

Opening the radiator cap when

the engine is hot may cause

serious injury.

3.4.2

1. Remove the radiator cap to release the system pressure.

2. Drain the coolant system.

3. Plumb the system as per Figure 3-13 or Figure 3-15

. Add engine coolant to the system as per the specific engine

4

manufacturer’s recommendations and re-install the radiator cap.

NOTE: Plumbing the PROHEAT through the dash fan is not recommended.

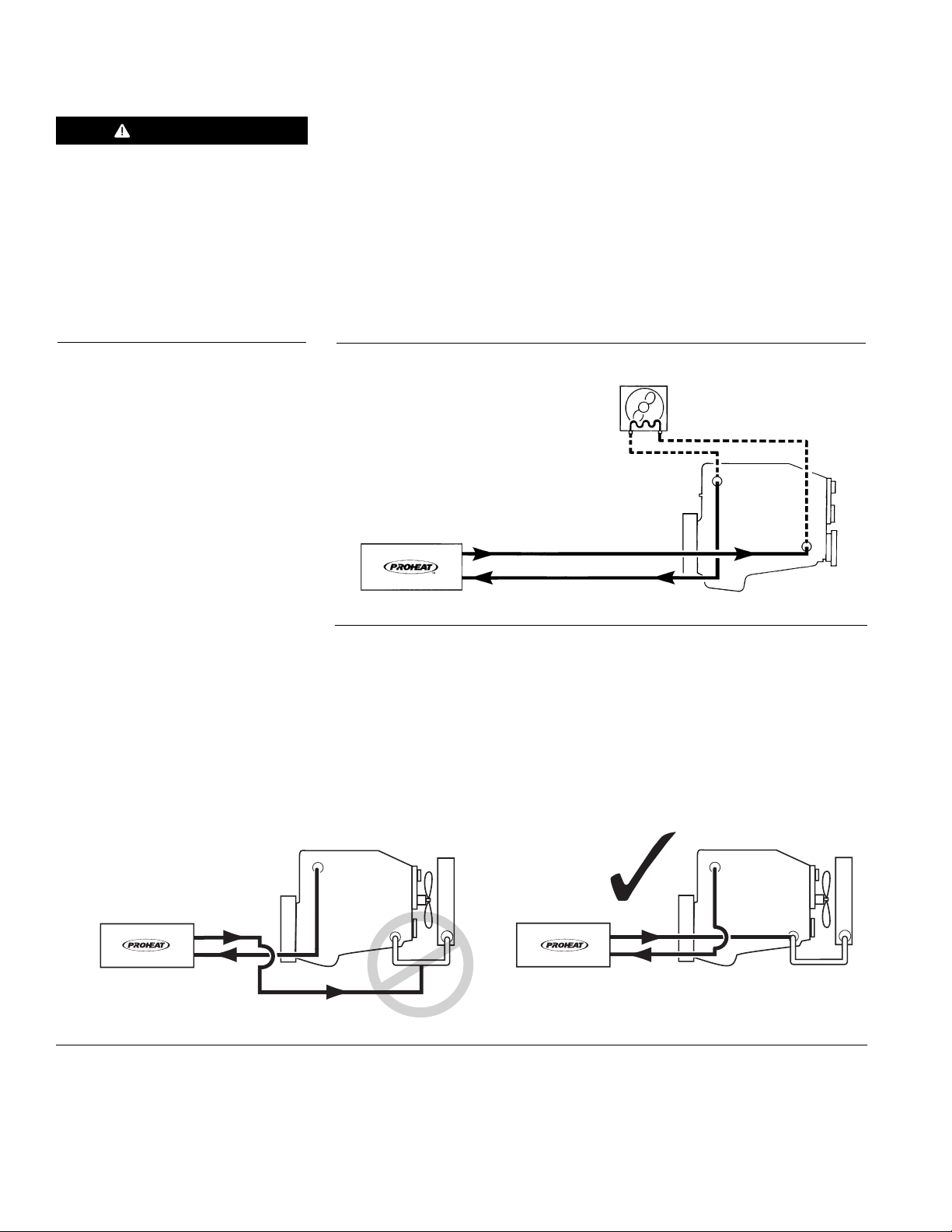

OPTION A – Engine Heat or Supplemental Heat

DASH HEATER

RETURN TO ENGINE

RETURN TO ENGINE

SUPPLY TO PROHEAT

SUPPLY TO PROHEAT

Figure 3-13 Engine Heat or Supplemental Heat

ENGINE

NOTE: On coolant systems where the return from the PROHEAT is plumbed to

the bottom of the main coolant supply line from the radiator to engine

pump, the return line must be moved to avoid loss of heat through the

radiator.

ENGINE

RETURN TO ENGINE

SUPPLY TO PROHEAT

ENGINE

Figure 3-14 Correct Return Line Plumbing

3-8

PROHEAT INSTALLATION & SERVICE

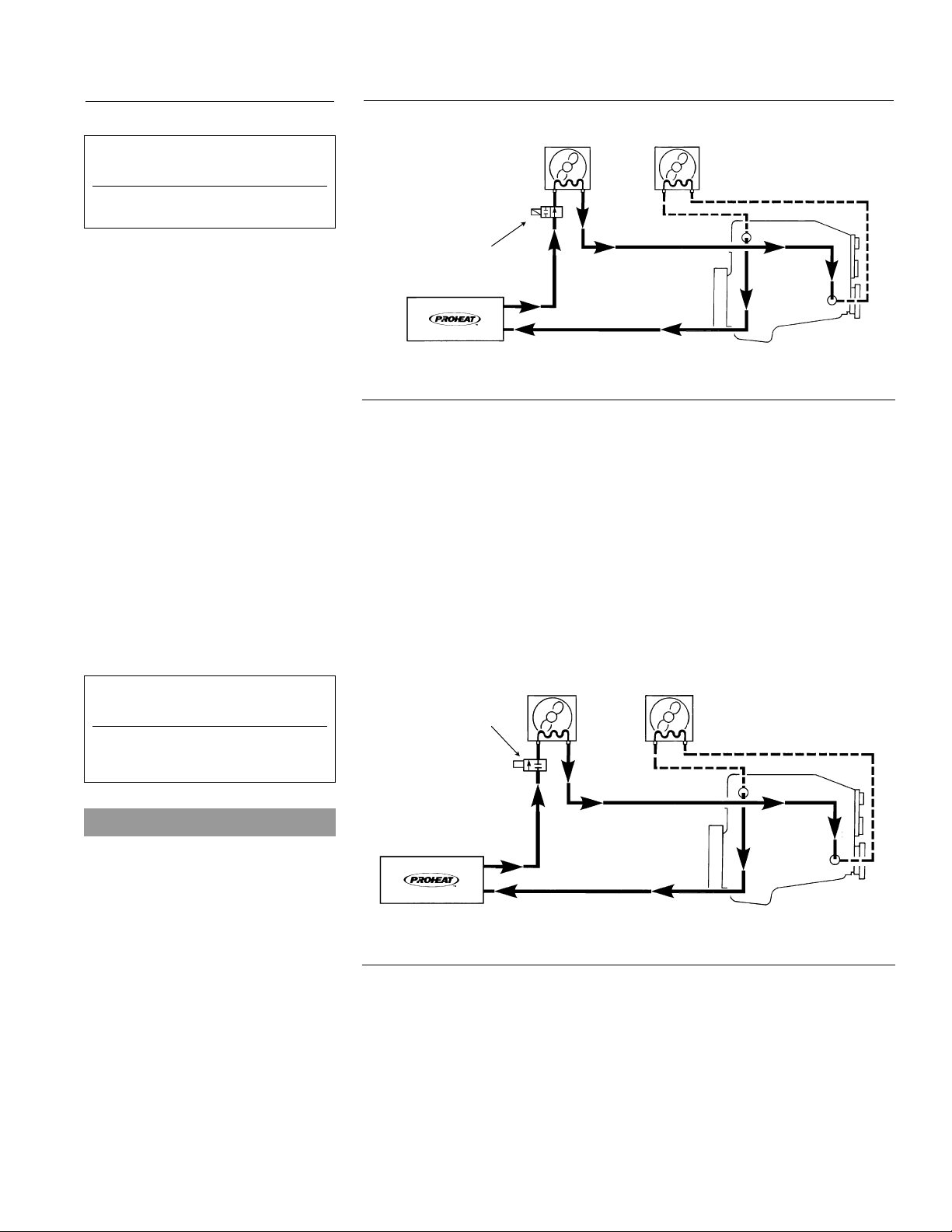

3.4.3

or best results these vehicles

F

should use an auxiliary heater.

International with single heater

OPTION B – Engine and Sleeper Heat

OEM OR AUXILIARY

SLEEPER HEATER

DASH HEATER

For vehicles with solenoid valves

in the normally closed position.

Western Star

SOLENOID VALVE

OEM COMBO HEATERS

ONLY (NORMALLY OPEN)

SUPPLY TO PROHEAT

Figure 3-15 Engine and Sleeper Heat

RETURN TO ENGINE

ENGINE

NOTE: Vehicles equipped with a combination heater/air-conditioner will have

a solenoid operated shut-off valve in the heater unit. Typically this valve

is normally open with the truck engine turned off and the key removed.

(See Figure 3-16 for plumbing)

Due to the many options available in vehicle heating and air

conditioning systems, the installer should be looking for any

restrictions that may affect coolant flow, with vehicle ignition in the

“OFF” position.

SLEEPER HEATER

SOLENOID VALVE

(NORMALLY CLOSED)

DASH HEATER

NOTICE

The PROHEAT PCM sleeper fan circuit

has a one minute delay during ignition.

Power to open a sleeper fan coolant

valve must be taken from another

source such as the wire for the hour

meter (auxiliary output). (See PROHEAT

Wiring Diagram on page 1-4.)

SECTION 3. INSTALLATION

SUPPLY TO PROHEAT

Figure 3-16 Engine and Sleeper Heat

RETURN TO ENGINE

ENGINE

3-9

Loading...

Loading...