Page 1

R

User's Reference Manual

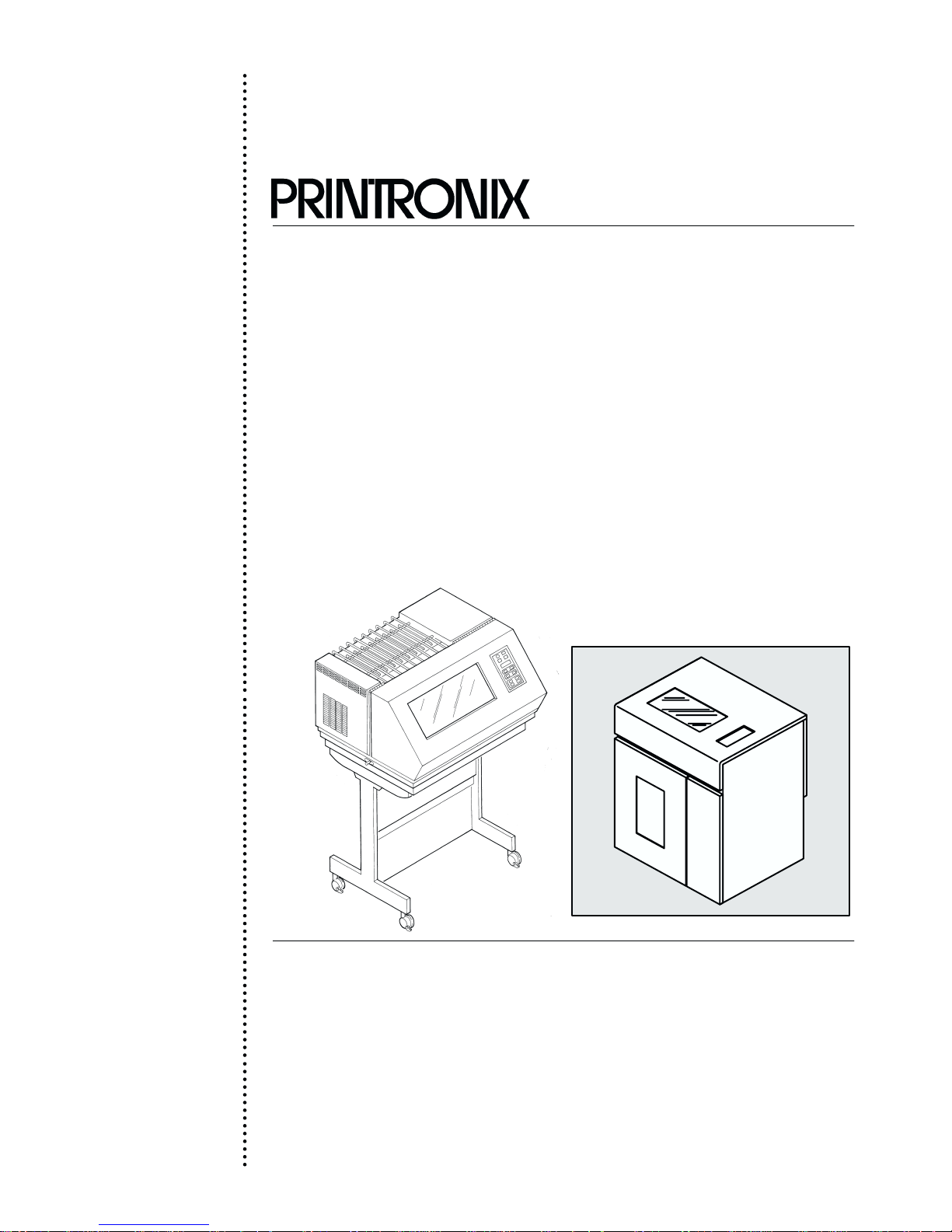

P600L/P6200L Line Printers

Page 2

Page 3

P6000L/P6200L Line Printers

User's Reference Manual

P/N 140576–001, Rev C

R

Page 4

US and CANADA Radio Interference Note

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

Note:

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission limits. The

manufacturer is not responsible for any radio or television interference caused by using other than recommended

cables and connectors or by unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

The input/output (I/O) cable must be shielded for the printer to comply with FCC rules and regulations Part 15

governing the radiation limits for Class “A” equipment.

This Class A digital apparatus meets all requirements of the Canadian Interference–Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du

Canada.

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

Printronix, Inc. makes no representations or warranties of any kind regarding this material, including, but not limited to,

implied warranties of merchantability and fitness for a particular purpose. Printronix, Inc. shall not be held responsible

for errors contained herein or any omissions from this material or for any damages, whether direct, indirect, incidental

or consequential, in connection with the furnishing, distribution, performance or use of this material. The information in

this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No part of this document may be reproduced,

copied, translated or incorporated in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of Printronix, Inc.

All rights reserved. Revision C. January 1996.

Trademark Acknowledgements

The following trademarks are hereby acknowledged:

IBM is a registered trademark of International Business Machines.

QMS is a registered trademark of Quality Micro Systems, Inc.

Epson is a registered trademark of Epson America, Inc.

Printronix is a registered trademark of Printronix, Inc.

IGP is a trademark of Printronix, Inc.

RibbonMinder is a trademark of Printronix, Inc.

17500 Cartwright Road, P.O. Box 19559

Irvine, California 92713

Telephone (714) 863–1900 FAX (714) 660–8682

Technical Support (714) 221–2686

COPYRIGHT 1988, 1989, 1996, PRINTRONIX, INC.

Page 5

TABLE OF CONTENTS

Chapter

1 Overview

Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional F

Character F

Dot Matrix Line P

P

rint R

Plot R

eatures 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormation 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinting 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ate 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ate 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Operation

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ower Switch

P

L

ocking/Unlocking P

Control P

aper A

P

L

oading P

Unloading P

Setting T

aper Stacking - Floor Cabinet Models

P

Selecting P

L

oading the Ribbon

Setting F

Setting Line Spacing

Hex Code Printout 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P

rinter R

unning the Self-T

R

anel 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment Controls

aper 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

aper 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

op-of-Form 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint Mode

orms L

eset 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinter Configuration

ength 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

est 2-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Configuration

Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L

ocking/Unlocking P

Configuration Menus

Configuration P

Set/Save/Load Configuration Values 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set V

alues 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saved Values 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load Values 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Configuration Values 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration P

Hardware Jumper Configuration

P6000L/P6200L User's Reference Manual i

rinter Configuration

rocedure 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rintout 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Side P

anel R

emoval - Floor Cabinet Model 3-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

3 Configuration (continued)

Removing

Control P

Level I - P

Level II - Main Configuration Menus 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Level III - Configuration Menu Parameters 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the PCBA - Floor Cabinet Model

anel Configuration Diagram

rint F

ormat 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Graphics

Introduction 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Matrix Compatible Bit Image Graphics

Plotting a Bit Image P

Bit Image Density

Bit Image P

P-Series Compatible Plot Mode

Plot Density

Plot Data Line F

Plot Data Byte F

Plotting the Data

Combining Graphics and T

rogramming F

attern 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormat 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormat 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormat 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ext 4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Vertical Format Units

Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAVFU 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General DA

Start L

Channel Assignment

End L

Using The D

Clearing The DAVFU Memory

DAVFU/IGP Execute F

DA

VFU Line Slewing

P-Series EVFU

General P-Series EVFU P

P-Series EVFU Command and Channel Codes

P-Series EVFU F

Serial Emulation VFU

Executing V

V

ertical T

VFU P

rogramming 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

oad Code - 6E Hex 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

oad Code - 6F Hex 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AVFU 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

orm Mode

rogramming Information

orm Definition P

ertical T

ab P

abs 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ositions 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rogram 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii P6000L/P6200L User's Reference Manual

Page 7

Chapter

6 Programming

Introduction 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overstrike Mode 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Code F

Special F

A

ttribute Set and R

Control Code R

Backspace 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bell 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Image Mode, Single Density

Bit Image Mode, Double Density

Bit Image Mode, Double Density Double Speed

Bit Image Mode, Quadruple Density

Bold P

rint 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bold P

rint R

Cancel 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carriage R

Character Set Select (Control Codes)

Character Set Select (P

Condensed P

Condensed P

Elongated (Double High) P

Emphasized P

Emphasized P

EVFU Commands (P-Series)

Expanded (Double W

Expanded (Double W

Extended Character Set

Extended Character Set Cancel

(P

rimary Character Set Select)

F

orm F

eed 6-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F

orms L

F

orms L

Horizontal T

Horizontal T

International Character Set Select

Line F

Line F

Line Spacing 1/6 Inch

Line Spacing 1/8 Inch (8 lpi)

Line Spacing 8 lpi (One Line Only)

Line Spacing 7/72 Inch

Line Spacing n/72 Inch (Asserted)

Line Spacing n/72 Inch (Stored)

ength Set (Inches)

ength Set (Lines)

eed 6-33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eed n/216 Inch (one line only)

unctions 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

unction Code - Control Code Header

eset Codes

eference Index

eset 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

eturn 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rintable Symbols)

rint 6-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint R

eset 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint 6-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint R

eset 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ide) P

rint 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ide) P

rint (One Line Only)

ab 6-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ab Set

Page

6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6000L/P6200L User's Reference Manual iii

Page 8

Chapter

6 Programming (continued)

Line

Spacing n/216 Inch

Overscoring 6-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plot, Even Dot (P-Series High Density Graphics)

Plot, Odd Dot (P-Series Normal Density Graphics)

P

rinter Deselect

P

rinter R

P

rinter Select

P

rint Mode/P

RibbonMinder, Enable/Disable

RibbonMinder, Set Job R

RibbonMinder, When W

Skip-Over Perforation 6-52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Skip-Over P

Superscript/Subscript P

Superscript/Subscript P

Underline 6-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ertical T

V

V

ertical T

eset 6-46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

itch Selection

ate 6-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

orn A

ction 6-51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erforation Cancel

rinting 6-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinting R

ab 6-57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ab Set (Serial Matrix)

eset 6-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

6-41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Interfaces

Introduction 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dataproducts P

Dataproducts Interface Signals

arallel Interface Configuration

P

Centronics P

Centronics Interface Signals

arallel Interface Configuration

P

RS-232 Serial Interface

RS-232 Interface Signals

Serial Interface P

Serial Interface Configuration

Alternate T

Floor Cabinet Model

Pedestal Model 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Jumper Platform

arallel Interface

arallel Interface

rotocols 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erminating R

esistors 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Maintenance

Introduction 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Cleaning 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior Cleaning

Interior Cleaning

7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv P6000L/P6200L User's Reference Manual

Page 9

Chapter

8 Maintenance (continued)

Page

Cleaning

rinter Self-T

P

unning the Self-T

R

Hex Code Printout 8-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Messages 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the P

aper Motion Detector

ests 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ests 8-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 RibbonMinder

Introduction 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analyzing a Job

unning a Job

R

Multiple Jobs on the Same Ribbon

Changing a Ribbon Early

Host Interface

Application Hints

10 Installation

Introduction 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ower R

P

Site R

Floor Cabinet Model Installation

P

Shipping R

Platen R

F

Side Shock Mount R

P

edestal Model Installation

P

Table T

Shipping Restraint R

Cable Connections

reliminary T

P

equirements 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

equirements 10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

aper Stacking Chain Assembly Installation

estraints R

estraints R

ront Shock Mount R

edestal Assembly

op Mounting

est 10-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval 10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

estraint Screw R

estraint Screw R

emoval - Pedestal Model 10-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval 10-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Standard ASCII Character Set and Equivalents

Appendix B

Serial

Emulation Mode Character Set #1

Serial Emulation Mode Character Set #2

P6000L/P6200L User's Reference Manual v

A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

Chapter

Appendix B (continued)

Page

P-Series

P-Series Mode Character Set #2

International Characters

Mode Character Set #1

Appendix C

Specifications C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Control

D

Code Cross R

eference D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi P6000L/P6200L User's Reference Manual

Page 11

LIST OF FIGURES

Figure Page

1-1 Typical

1-2

2-1 P

2-2 P

2-3

2-4 P

2-5 P

2-6 F

2-7 V

2-8

2-9 L

2-10 L

2-11

2-12 F

2-13 R

2-14 P

2-15 P

2-16

Dot Matrix Line P

ower Switch - Floor Cabinet Model

ower Switch - P

Control P

aper A

aper A

orms Thickness A

ertical P

Horizontal A

eft P

oading P

Setting T

ront P

ear P

aper T

aper Stacking - Floor Cabinet Models

Ribbon R

Character F

anel 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment Controls - Floor Cabinet Model

djustment Controls - P

osition Knob

aper T

ractor 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

aper 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

op-Of-Form 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

aper F

aper F

ent Installation - Floor Cabinet Models

eplacement 2-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ormation 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinting 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

edestal Model 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

edestal Model 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

djustment L

djustment Knob

ence Installation - Floor Cabinet Models

ence Installation - Floor Cabinet Models

ever 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3-2

3-3

3-4

3-5

3-6

4-1

4-2 V

4-3

4-4

4-5

4-6

4-7

4-8

4-9

P6000L/P6200L User's Reference Manual vii

Sample Configuration P

Side P

anel R

emoval - Floor Cabinet Model 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCBA R

PCBA R

Control P

Control P

Binary Data Byte

ertical Data Byte P

Bit Image P

Bit Image P

Sample Single Density Bit Image Graphics

Normal Density Plot

High Density Plot

Plot Data Line F

P-Series Plot Data Byte F

emoval - Floor Cabinet Model Printer 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval - P

anel Configuration Diagram Symbols

anel Overview 3-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

attern from an A

attern Plan

ormat 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rintout 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

edestal Model P

attern 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCII Character

ormat 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rinter 3-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 12

Figure Page

4-10

4-11

4-12 T

5-1

5-2

5-3

6-1

7-1

7-2

7-3

8-1

8-2

10-1

10-2

10-3

10-4

10-5

10-6 F

10-7

10-8 L

10-9

10-10 P

10-11 R

10-12 P

10-13 Table T

10-14

10-15

10-16

Odd Dot Plot P

Sample Odd Dot Plot

runcated Character Line

Sample DAVFU F

Sample P-Series EVFU F

Sample Serial Matrix V

Overstrike/Underlining Example

Alternate T

Alternate T

Interface Jumper Platform Orientation

Interior Cleaning

Cleaning the P

Site R

Site R

Chain Assembly Installation - Floor Cabinet Model

Shipping R

Platen R

ront Shock Mount R

Side P

owering the Card Cage - Floor Cabinet Model

Side Shock Mount R

edestal L

ubber F

edestal Mounting - P

Shipping Restraint R

Cable Connections - Floor Cabinet Model

Cable Connections - P

attern Plan

orm Design

orm Definition P

ertical T

erminating R

erminating R

aper Motion Detector

equirements - Floor Cabinet Model

equirements - P

estraint L

estraint R

anel R

emoval - Floor Cabinet Model 10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

egs Installation - P

eet R

emoval - Pedestal Model 10-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

op Mounting Specifications - P

edestal Model 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ocations - Floor Cabinet Model

emoval - Floor Cabinet Model 10-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

estraint Screw R

estraint Screw R

edestal Model 10-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

emoval - Pedestal Model 10-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

edestal Model 10-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ab P

ositions 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

esistor L

esistor L

ocation - Floor Cabinet Model

ocation - P

edestal Model 10-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rogram 5-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

edestal Model 7-11. . . . . . . . . . . . . . . . . . . . . . . . . .

emoval - Floor Cabinet Model 10-7. . . . . . . . . . . . . . . . .

emoval - Floor Cabinet Model 10-10. . . . . . . . . . . . . . . . . .

edestal Model 10-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-9. . . . . . . . . . . . . . . . . . . . .

7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

viii P6000L/P6200L User's Reference Manual

Page 13

LIST OF TABLES

Table Page

1-1 P

1-2

3-1 P

3-2

4-1

4-2

5-1 DA

5-3 DA

5-5

5-7

6-1

7-1

7-2

7-3

7-4

rint R

Plot R

rintronix Default Configuration V

Hardware Jumper Configuration

Example Bit Image P

Plot Data Byte Dot P

P-Series EVFU Codes - PI Line Enabled

Example P-Series EVFU Channel F

Character P

Connector P

Centronics Interface Connector P

Serial Interface P

Interface Jumper Configuration

ate 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ate 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

attern Decimal V

atterns 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VFU Channel Assignment

VFU Channel Instruction

itches A

in Assignments for Dataproducts Interface with AMP Connector

vailable by P

in Assignments

alues 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

unctions 5-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rint Mode

in Assignments

3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. . . . . . . . . . .

7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1 Fault Messages 8-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6000L/P6200L User's Reference Manual ix

Page 14

ABOUT THIS MANUAL

This

manual has been written and formatted in a way to make it easy for you to use. The follow

is some general information about this User's R

ing

What This Manual Contains

This manual is divided into chapters that contain all the information required to use the

printer.

data, Vertical Format Unit data, programming information, maintenance procedures, interĆ

face

This manual is written for the advanced level systems engineer or experienced programmer

who will interface this printer with the host computer or who will prepare software for host

computer use to drive the printer. Background information covering fundamental programĆ

ming

Warnings, Cautions, and Notes

Chapters provide introductory

descriptions, and appendices of supplemental information.

concepts is not provided in this documentation.

Ć

eference Manual.

information, complete operating information, graphics

Additional

CAUTION, IMPORTANT, and NOTE. WARNINGs provide information about conditions

that

the printer; IMPORTANT provides information that should be stressed. NOTEs, printed in

italics,

information

could lead to injury; CA

provide supplemental information that could affect printer operation or use.

Switches and Indicators

Throughout this manual, switches, indicators, and possible switch settings or positions are

printed

located

in UPPERCASE TYPE. This allows you to easily identify within the text items that are

on the printer.

requiring special attention is provided under the headings

UTIONs provide information about conditions that could damage

WARNING,

x P6000L/P6200L User's Reference Manual

Page 15

Introduction

The information in this manual applies to both P6000L and P6200L Series printers. The

P6000L

The

line

simply the printer, unless specifically noted otherwise.

The Printronix P6000L/P6200L Series printers are quiet, full-featured, multifunction line

printers. Along with the basic P-Series functions, the P6000L/P6200L include CorresponĆ

dence

and character-by-character attributes (Dynamic Character Generation) for wider applicaĆ

tion

This chapter presents an overview of the printer:

Series is the pedestal

P6040L and the P6240L are 400 line

per minute printers. All models will be identified throughout as P6000L/P6200L Series or

quality print for

compatibility.

n Features

n

n

n

n P

n

Near L

Optional F

Character F

eatures

ormation

Dot Matrix Line P

rint R

ate

Plot R

ate

CHAPTER 1

OVERVIEW

model printer and the P6200L is the floor cabinet model printer.

per minute printers; the P6080L and P6280L are 800

etter Quality (NLQ) printing requirements, high speed printing,

rinting

Refer to the Installation chapter for information on power and site requirements, and printer

installation.

Features

P6000L/P6200L

Series printers provide the following standard features:

n

Quiet Operation

D

The floor cabinet models feature extra quiet operation

n

P-Series and Serial Matrix (IBMr Graphic P

n

P-Series Plot and Bit Image Graphics

n

Dynamic Character Generation

D

Selectable pitch

D

Elongated print

D

Shadow print

D

Expanded print

rinter) emulation protocols

1-1Overview

Page 16

D A

utomatic underline

D A

utomatic overscore

D

Superscript printing

D

Subscript printing

n

Selectable F

n

Electronic V

D

Standard

D

12 channel direct access vertical format unit (D

n R

esident International Character Sets

n RibbonMinderT ribbon

n Built-in Self-T

n

Configuration P

n

Data Stream Hex Code P

n R

esident Serial and P

Tw o

separate graphics capabilities have been included in the printer:

orms L

ertical F

Printronix

ength

ormatting

electronic vertical format unit (EVFU)

est and Diagnostics

rintout

rintout

arallel Interfaces

AVFU)

life monitor

standard P-Series oddeven dot Plot Mode graphics and Bit Image graphics standard on Printronix MVP, P3000, and

P9000 Series printers and many other serial matrix printers. Intelligent graphics capabilities

available by using the

are

Printronix

IGP-10 option.

Serial matrix compatibility makes the printer emulate the most common style of printer for

personal computers, but at much higher speeds. The user may select industry standard

Printronix

P-Series or Serial Matrix compatibility from the control panel.

The programmable Vertical Format Unit provides rapid paper advance to specified lines for

printing repetitive and continuous forms. When P-Series compatible protocol is used, either

the P-Series compatible EVFU (Electronic Vertical Format Unit) or Dataproducts compatĆ

DAVFU (Direct A

ible

an 8 channel serial vertical format unit is available.

col,

Optional Features

P6000L/P6200L

F

tions.

or more information, contact an authorized

n Intelligent

generate logos, bar codes, expanded characters, and other graphics. Forms can be

created with a variety of graphic components and overlayed with alphanumeric and

code data in a single pass. The IGP may be ordered with either P

bar

commands or QMSR

n IBM Interfaces - Includes PI-5225 (Twinax) and PI-3287 (Coax) protocol conĆ

verters to provide compatibility to IBM mainframe and mid-range computers.

Available

n Character

set requirements with field

ter

the

standard

printer.

ccess V

Series printer capabilities and versatility can be

Graphics P

ertical F

ormat Unit) may be selected. In the Serial Matrix proto

Printronix

rocessor (IGPT)

- Allows the user

protocol compatibility. A

enhanced by the following op

representative.

vailable as a field installable option.

as a field installable option.

Set Options

- A

ccommodates various printable symbol or special

installable and changed socket mounted PROMs. All

Printronix

character sets for the P-Series printers are available for

Additionally, custom character sets can be ordered.

to create and store forms,

rintronix graphic

charac

the

Ć

Ć

Ć

Overview1-2

Page 17

n 240 vac Conversion Kit - Changes the printer power source requirement from 120

to 240 vac. A

vac

n Quick

n Pedestal - A stand designed for the printer. The pedestal includes locking casters,

Access Configuration

model

printers allows easy access

bottom feed paper path and accepts the optional paper stacker. Available as a field

installable

n Quietized

supply paper and reduced acoustical rating. Includes locking casters, bottom feed

paper path, and accepts optional paper stacker. Available as a field installable opĆ

tion.

n Paper Stacker - is provided for use with the pedestal model printers. Collects and

properly stacks the printed output. Can be used with the optional pedestal and acts

a caddy to transport the paper. A

as

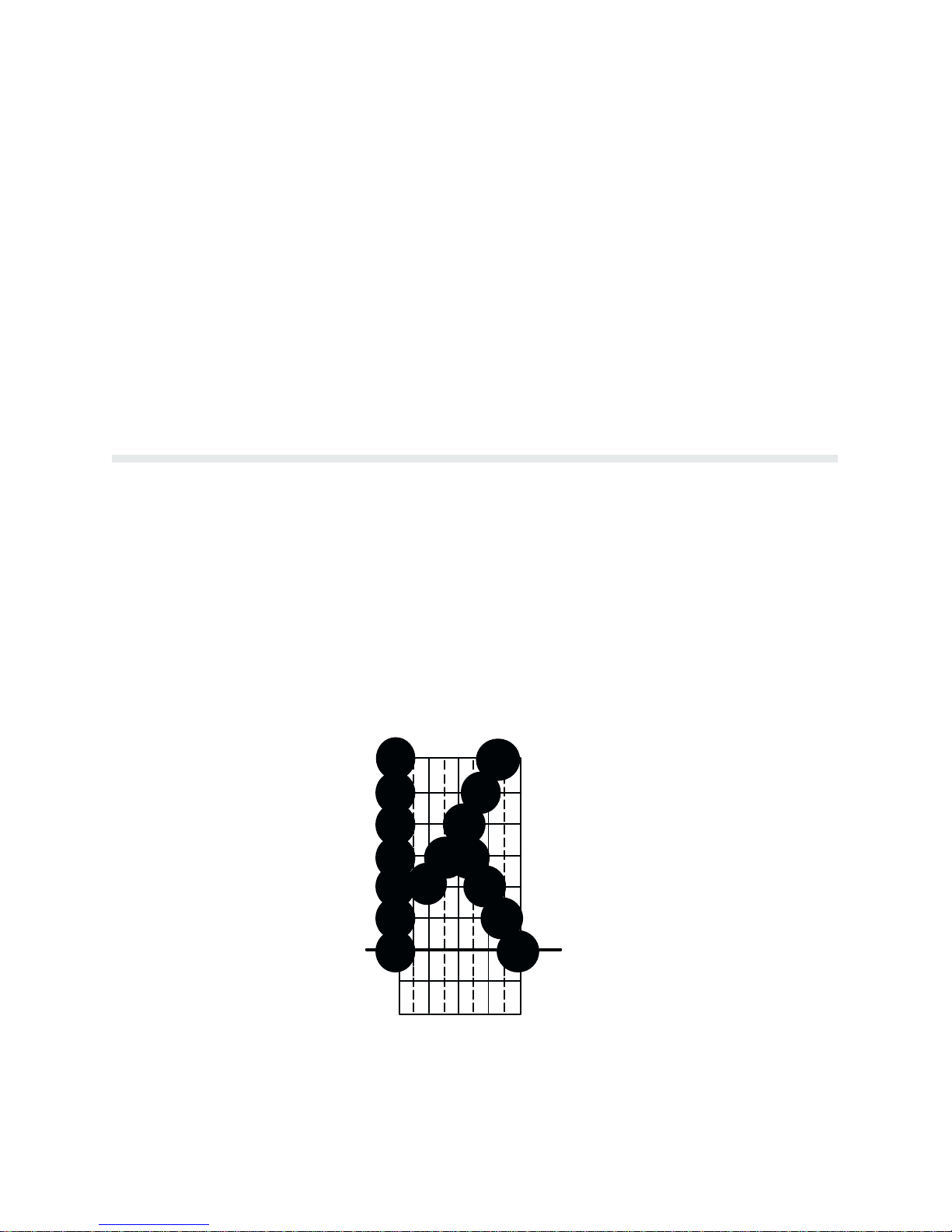

Character Formation

The

P6000L/P6200L

Dots are overlapped to produce a solid appearing character of uniform density as shown in

ces.

Figure 1-1. Dot impressions are made by a row of hammers installed on a moving shuttle. The

400

lines per minute

models

have 66 hammers. The hammers impact the

zontal shuttle movement and vertical paper advancement combine for precise dot printing to

the character matrix.

form

vailable as a field installable option.

- This optional cabinet and down tractors for

pedestal

to labels and forms without lifting the front cover.

option.

Enclosed P

edestal -

A stand for the pedestal models with an enclosure for

vailable as a field installable option.

Series printers generate characters by assembling groups of dots in matri

Ć

models have 44 hammers mounted on the shuttle; the 800 lines per minute

paper through a moving ink ribbon. Hori

Ć

Figure 1-1. T

ypical Character F

ormation

1-3Overview

Page 18

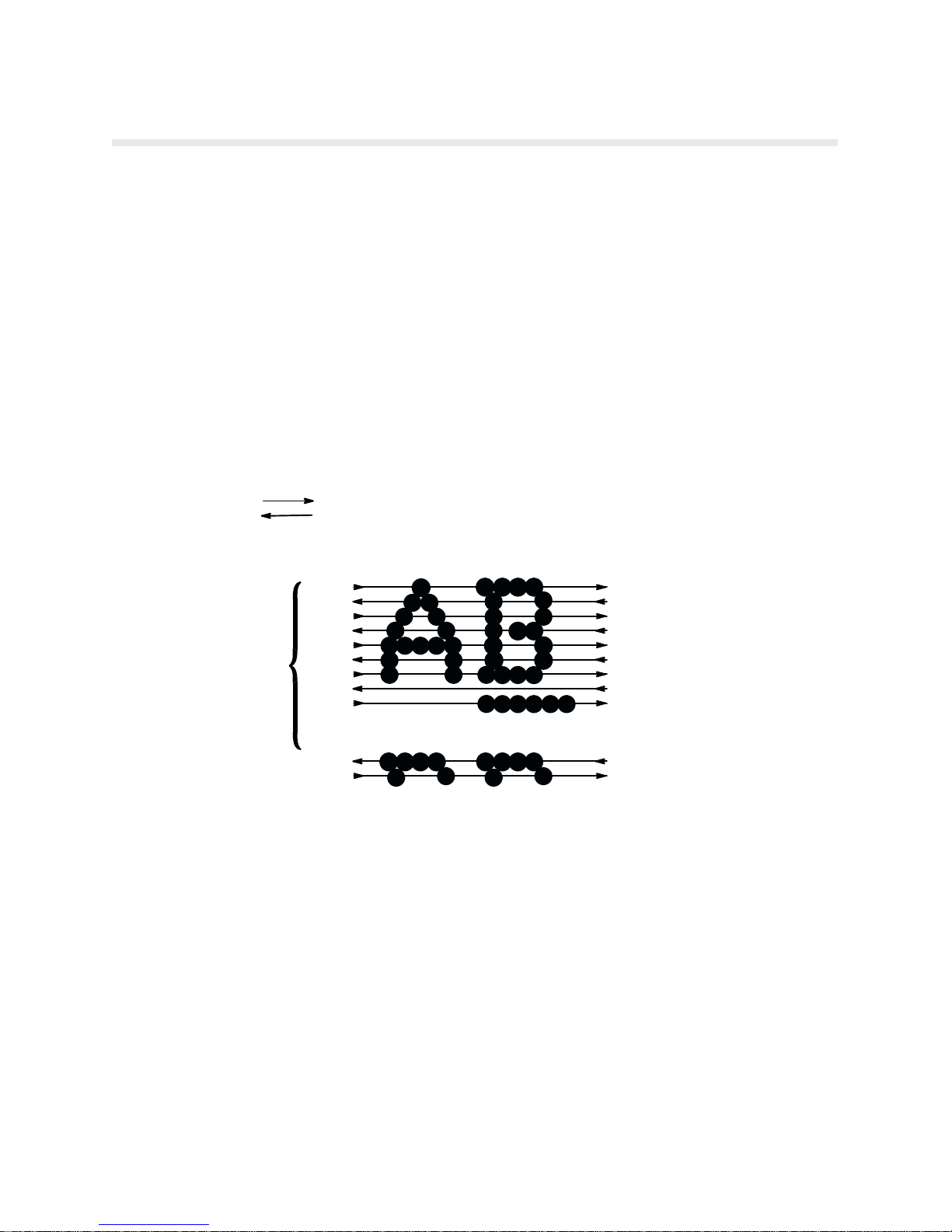

Dot Matrix Line Printing

Unlike single head dot matrix printing, the Printronix P6000L/P6200L Series creates graphics

and characters by printing an entire dot row at one time. As shown in Figure 1-2, dots are

printed in both directions of shuttle travel. In the 400 line per minute printers, the shuttle

sweeps through three tenths (3/10) of an inch. In the 800 line per minute printers, the shuttle

through two tenths (2/10) of an inch. P

sweeps

and

the next row of dots is printed.

During

each sweep of the shuttle, hammers are activated to print dots at selected positions in a

single dot row. When the shuttle reaches the end of a sweep, it reverses direction, paper adĆ

one dot row, and the hammers print the next row of dots.

vances

After

an entire line of characters is printed, hammer

the

first dot row of the next print line. This creates a series of blank rows between lines of char

acters. The number of rows allowed for line separation depends on the line spacing selected.

spacing may be selected from the control panel or the host computer.

Line

INDICATES DIRECTION OF SHUTTLE MOVEMENT

aper is advanced as the

shuttle reverses direction

activity ceases and the paper advances to

Ć

DOT

ROW START

1

2

3

4

ONE

CHARACTER

ROW

5

6

7

8

*

9

**

10

11

12

0

SPACE

1

2

USED FOR LOWERCASE DESCENDER ONLY

*

USED FOR UNDERLINE AND LOWERCASE DESCENDER

**

NOTE: 400 lpm models sweep through three character positions

800 lpm models sweep through two character positions

Figure 1-2. Dot Matrix Line P

rinting

PAPER

ADVANCES

PAPER

FEED

PAPER

ADVANCES

Overview1-4

Page 19

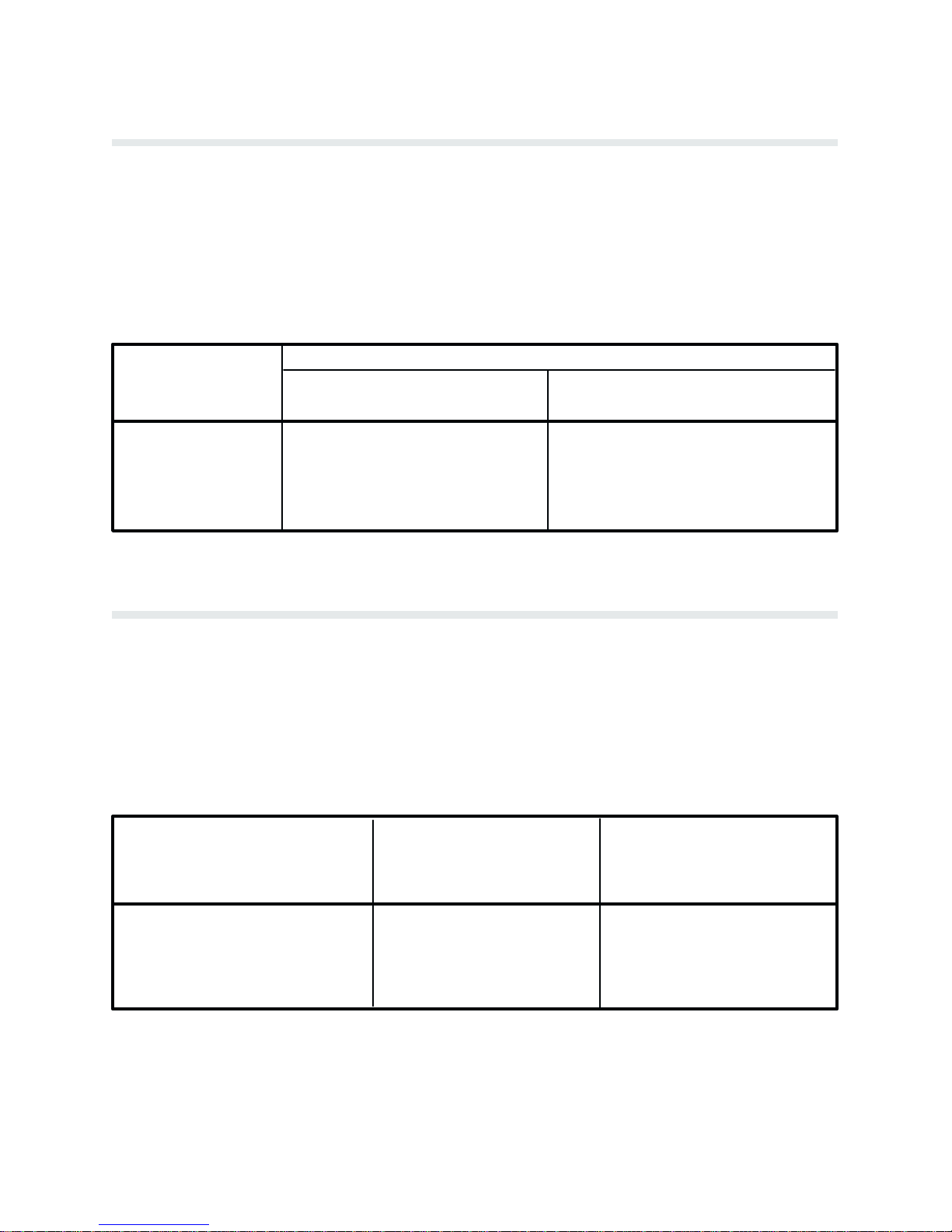

Print Rate

The print rate, in lines per minute (lpm), is a function of the number of dot rows required to

produce the character line regardless of the number of characters in the line. For example,

more dot rows are required to print lowercase characters with descenders and consequently,

those characters are printed at a slower rate. Table 1-1 describes the print rate according to

of character printed and print mode. Complete printing specifications are provided in the

type

Appendix.

PRINT MODE

Table 1-1. Print Rate

PRINT RATE (lpm)

UPPERCASE ONLY UPPER/LOWERCASE

P6040L/P6240L P6080L/P6280L

P6040L/P6240L P6080L/P6280L

Correspondence

Data Processing

High Speed

Plot Rate

As

well as character printing, the printer is capable of dot addressable graphic plotting. Based

on the protocol selected, either P-Series Plot Mode or Serial Matrix Bit Image Graphics is

used; the plot rate specifications apply to both P-Series and Serial Matrix types of graphic

plotting. The plot rate (in inches per minute, ipm) is described in Table 1-2 according to the

dot density (in dots per inch, dpi). Complete plotting specifications are provided in Appendix

C.

DENSITY (dpi)

ă89

300

400

177

600

800

Table 1-2.

P6040L/ P6080L/

P6240L P6280L

Plot Rate

PLOT RATE (ipm)

ă77

240

342

PLOT RATE (ipm)

Unidirectional

P6040L/ P6080L/

P6240L P6280L

154

480

685

60 Horz x 144 Vert (NLQ mode)

60 Horz x 72 Vert (DP mode)

60 Horz x 48 Vert (High Speed) 50 100

16.8

33

33.6

66

8.4

16.6

25 50

16.8

33

1-5Overview

Page 20

Overview1-6

Page 21

Introduction

This

chapter describes basic P6000L/P6200L Series controls and operating procedures. Opera

information and cleaning practices are also provided in the Operator's Guide. R

tion

Installation

P6000L/P6200L Series printers function either online or offline. When online, the printer is

capable

indicates the printer is online and the current print mode. When offline,

pended between the printer and the host computer and the message OFFLINE READY apĆ

pears

of receiving data and control commands from the

on the display. Set the printer offline to perform the following tasks:

n

n

n Run the Self-Test

n

n P

n

n L

n A

n

n A

n A

n Cleaning/R

CHAPTER 2

OPERATION

efer to the

chapter for information on power and site requirements, and printer installation.

host computer. The message display

communication is sus

Select Configuration V

Configure the P

Set T

op-of-Form

erform a Hex Dump

Set Line Spacing

oad P

aper and Ribbon

dvance F

Change P

djust P

dvance P

orms

rint Modes

aper T

ractors

aper

outine Maintenance

alues

rinter

Ć

Ć

P6000L/P6200L Series printers respond to two different command sets or protocol modes:

n

P-Series emulation mode

n

Serial Matrix emulation mode

The

selected protocol determines which programming standard is used by the host computer to

communicate with the printer. Either protocol can be selected as required by the application.

P-Series emulation mode generates characters and graphics by

The

P-Series

control code protocol. The Serial Matrix emulation mode allows printing of charac

ters and graphics utilizing control codes similar to many serial matrix printers used with perĆ

computers. The command protocol is selected

sonal

menu

in

the control panel. R

Series and Serial Matrix protocols and control code definitions.

There are two basic modes of operation: character printing (alphanumeric text) and graphics.

Character

printing is the default mode of operation;

efer to the P

using

Printronix

standard

via the P6000L/P6200L Series application

rogramming chapter for detailed information on P-

graphics, either Serial Matrix compatible

Ć

2-1Operation

Page 22

Bit

Image graphics or P-Series compatible Plot Mode, is programmed on a line-by-line ba

sis.

chapter will discuss the following procedures:

This

n P

ower Switch

n Lock/Unlock F

n

Control P

n P

aper A

n L

oading P

n

Unloading P

n

Setting T

n P

aper Stacking - Floor Cabinet Models

n

Selecting P

n

Setting F

n L

oading the Ribbon

n

Setting Line Spacing

n Hex Code Printout

n P

rinter R

n R

unning the Self-T

unction Switches

anel

djustment Controls

aper

aper

op-of-Form

rint Mode

orms L

ength

eset

est

Ć

or information on the RibbonMinder feature, refer to the RibbonMinder chapter.

F

Power Switch

The printer must be connected to the proper power source, 120/240 V 50/60 Hz, as shown on

the rear panel label. Applying an incorrect power source will damage the printer. Complete

requirement information is provided in the Installation chapter.

power

On floor cabinet models, the printer ac power switch is located on the lower left corner of the

panel as shown in Figure 2-1. On pedestal models, the printer ac power switch is located

rear

on

the lower left side panel

switch

to the ON position.

as shown in Figure 2-2. T

o turn the printer power on, set the power

Operation2-2

Page 23

Figure 2-1. P

ower Switch - Floor Cabinet Model

Figure 2-2. P

ower Switch - P

edestal Model

2-3Operation

Page 24

Locking/Unlocking Printer Configuration

To

prevent accidental reconfiguration, the printer configuration (the parameter settings of the

printer) is normally locked. Before any new parameter settings are selected through the use of

the RUN/STOP TEST switch, the printer configuration must be unlocked. Simultaneously

pressing RUN/STOP TEST and CONFIG MENU, while the printer is OFFLINE READY,

alternately unlocks and locks the printer configuration. Resetting the printer or turning the

off and on will also lock the printer configuration.

power

NOTE: While DATA IN BUFFER is present, the printer configuration will remain

Press P

locked.

buffers and remove the DATA IN BUFFER condition.

er's

APER ADV

ANCE

, TOP-OF-FORM, or

Control Panel

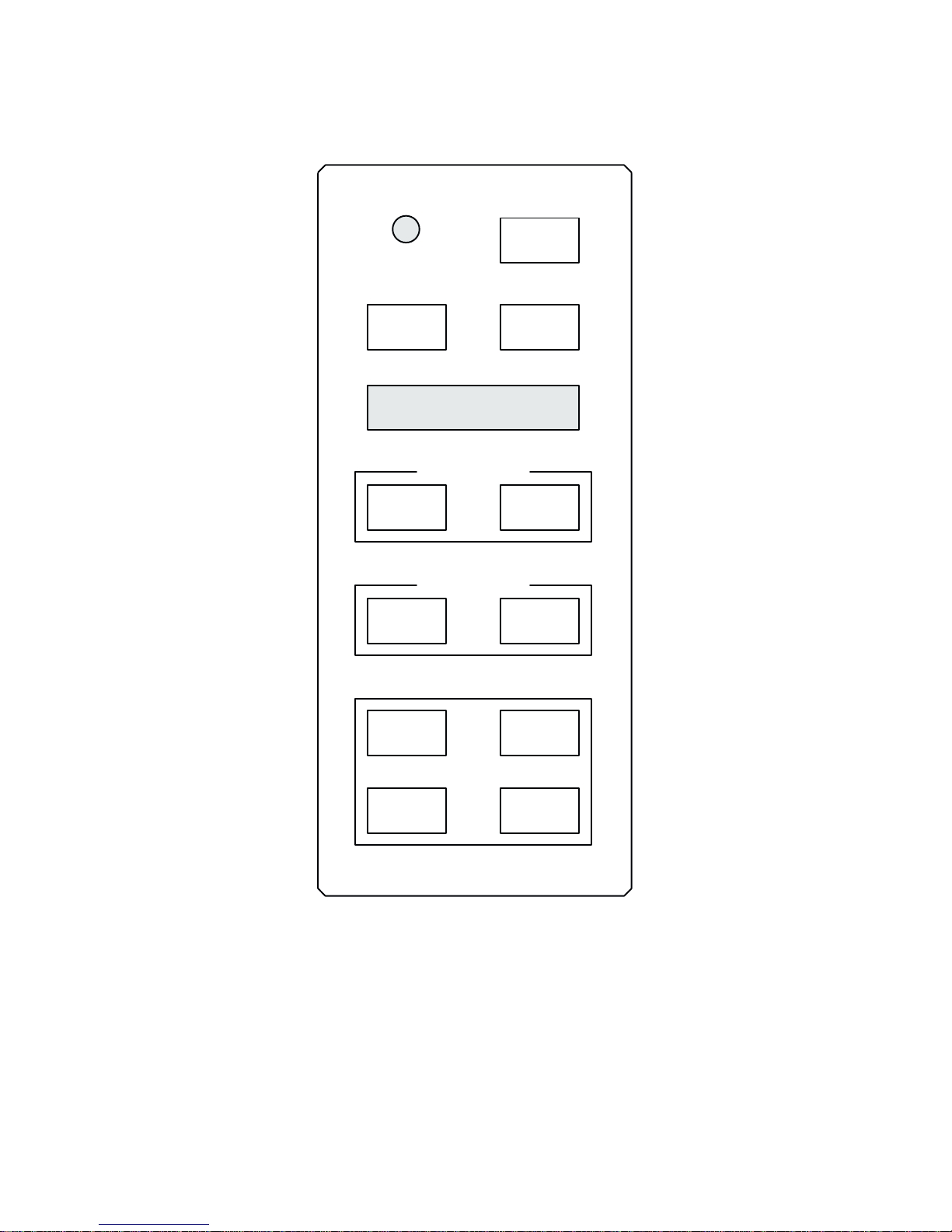

The printer control panel contains eleven switches, a power-on indicator, and a 32 character

alphanumeric

ing pages.

Power Indicator - This indicator lights when the ac POWER switch is ON. On floor cabinet

models, the POWER switch is located on the lower left corner of the rear panel. On pedestal

models,

Message Display as shown in Figure 2-3. Each switch is described on the follow

the POWER switch is located on the bottom left side of the printer.

ONLINE to empty the print

Ć

Ć

ON LINE - Press this switch once to place the printer online or offline. The printer must be

online to print. When online, the display will indicate the current print mode and none of the

other control panel switches will function. When offline, the display will indicate OFFLINE

READY and the printer cannot communicate with the host computer. The printer will go ofĆ

automatically when a malfunction occurs and must be offline to change printing format or

fline

configuration.

P

APER ADVANCE -

hold

the switch to advance the paper continuously. This switch functions only when the

is offline.

OF FORM - Press this switch once to advance one forms length (one page) to

TOP

the

next form. This switch functions only when the printer is offline.

Momentarily press this switch to advance the paper one line or press and

printer

the top of

Operation2-4

Page 25

CONTROL PANEL

POWER

ON LINE

PAPER

ADVANCE

MESSAGE

DISPLAY

FORMS SET UP

FORMS

LENGTH

PRINT FORMAT

LINE

SPACING

CONFIG

MENU

TOP OF

FORM

SET

T O F

PRINT

MODE

CONFIG

VALUE

PRINT MODE - Press this switch to display the current print mode. Subsequently pressing

this switch changes the print mode and updates the display through all of the available print

modes listed below. Each print mode has a variety of pitch selections ranging from 10 to 17

characters per inch (cpi). Print mode is a line-by-line attribute; different print modes (and

pitch) can be used for different lines of the form but you cannot mix print modes on one

related

RUN/STOP

TEST

Figure 2-3. Control P

CLEAR

FAULT

anel

2-5Operation

Page 26

individual

must

line. This switch functions

only when the printer is offline. The printer configuration

be unlocked to select a new print mode.

Data P

rocessing (DP) at 10, 12, 13, 15, and 17 cpi.

Correspondence (NLQ) at 10, 12, 13, 15, and 17 cpi.

High Speed at 10, 12, and 13 cpi.

NOTE:

pitch

Print mode control from the host computer will override the

and print attributes can be selected using control codes.

switch setting. Other

Alphanumeric Message Display - The display presents printer status and error condition

messages.

the display

The display has two rows with sixteen characters

indicates the online status and the current print mode (and pitch) selection. When

per row. During normal operation,

offline, the display indicates offline ready.

FORMS

pressing the switch changes the form length and updates the display through all possible

LENG

TH - Press this switch to display the current forms

(page) length. Subsequently

form

length settings from 1.0 to 24.0 inches in 0.5 inch increments. This switch functions only when

printer is offline. The printer configuration

the

NOTE: Forms length control from the host computer will override the switch setting. Us

control codes, forms length in increments other than 0.5 inch can be selected.

ing

SET

TOF

- Press this switch to set the TOF (top-of-form) position. If this switch is pressed

must be unlocked to select a new forms length.

Ć

when the paper is not properly positioned for the required top-of-form, normal operation

and top-of-form function can be affected. Refer to the Setting Top-of-Form section for

complete

instructions. This switch functions only when the printer is offline.

LINE SPACING - Press this switch to display the current line spacing in lines per inch (lpi).

Subsequently

line

spacing settings (6 and 8 lpi). Line spacing is a line-by-line attribute; different line spac

can be used for different lines of the form but you

ing

pressing this switch changes the line spacing and

cannot mix line spacing on one individual

updates the display through all

line. This switch functions only when the printer is offline.The printer configuration does not

have

to be unlocked to change this setting.

Ć

NOTE: Line spacing control from the host computer will override the switch setting.

Control

codes from the host computer can select line spacing other than the 6 or 8 lpi.

CONFIGURATION MENU - Configuration Menu (CONFIG MENU) is used to display/seĆ

lect configuration parameter main menus and certain submenus. Pressing CONFIG MENU

simultaneously

with RUN/STOP TEST alternately locks and unlocks the printer configuration

(the printer must be offline). Repeatedly pressing CONFIG MENU displays the following

menus:

D Ribbon Life

D

Character Set

D

Application Compatibility

D P

aper F

ormat

D

Host Interface

D L

oad P

arameters

D Save Parameters

Operation2-6

Page 27

D Diagnostics

After the required menu is displayed, individual parameters

VA L

UE switch as shown on the Control P

anel Switch F

are displayed using the CONFIG

unction Diagram in the Configuration

chapter.

CONFIGURATION

configuration parameters and the current value from within the main menus.

vidual

NOTE:

allows

Alternately and/or

the display of the configuration parameters as shown on the Control P

VALUE - Press Configuration V

repeatedly pressing CONFIG MENU and CONFIG V

alue (CONFIG VALUE) to display indi

anel Switch

Function Diagram in the Configuration chapter. The CONFIG MENU and CONFIG

VA LU E

menu,

RUN/STOP TEST -

n Press RUN/STOP TEST simultaneously with CONFIG MENU to alternately unĆ

n Press RUN/STOP TEST to select a configuration parameter, forms length, or print

switches when pressed simultaneously

forms length, and print mode selections.

The RUN/STOP TEST switch performs the following functions:

and lock the printer configuration..

lock

An asterisk (*) will appear to the right of the value to indicate that it has been

mode.

step backward through the configuration

selected.

n Press

n If a self-test is selected and shown on the display, press RUN/STOP TEST to start

RUN/STOP TEST simultaneously with CLEAR F

AUL

T to reset the printer.

the test and press it again to stop the test.

n If the CONFIGURATION PRINTOUT message is selected and shown on the disĆ

press RUN/STOP TEST to print a list of the current configuration. P

play,

STOP

TEST again to return to OFFLINE READ

Y.

Ć

ALUE

ress RUN/

CLEAR FAULT - Press this switch to reset the printer after a fault condition has been corĆ

rected. Fault conditions are indicated on the display. After pressing CLEAR FAULT the disĆ

will indicate the printer is offline if the fault was corrected.

play

In addition, the CLEAR F

n P

ress CLEAR F

n Press

menu

CLEAR F

parameter

AUL

AUL

AUL

selection or to offline. R

Diagram in the Configuration chapter.

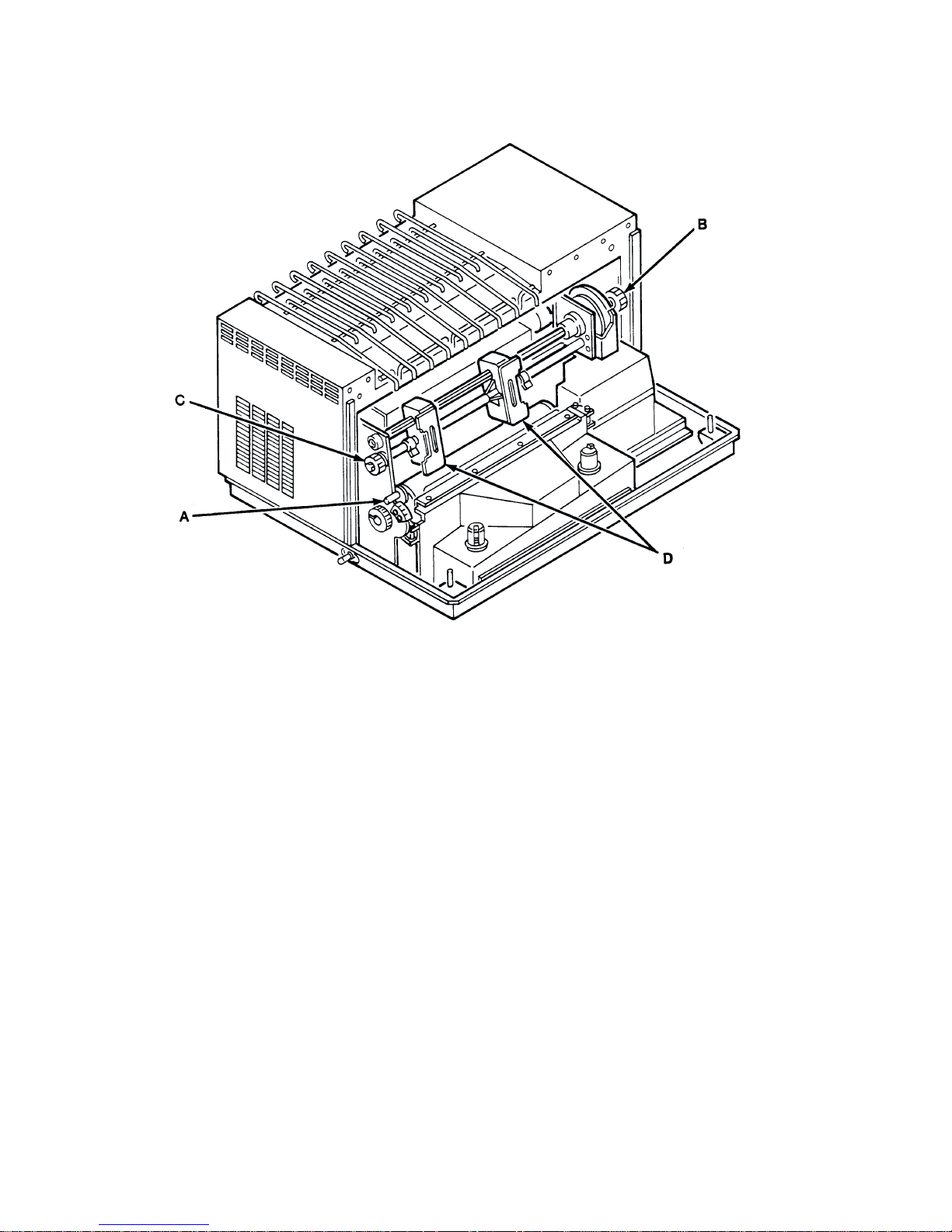

Paper Adjustment Controls

The printer paper loading controls for the floor cabinet model are shown in Figure 2-4. The

printer paper loading controls for the pedestal model are shown in Figure 2-5. The controls

the F

are

Adjustment

trol

orms Thickness A

Knob (C), and the paper tractors (D). The P

panel is also used during the paper loading procedure.

djustment L

T switch performs two special functions:

T simultaneously with RUN/STOP TEST to reset the printer.

T when one of the parameter values is displayed to move up one

ever (A),

efer to the Control P

the V

ertical P

osition Knob (B), the Horizontal

APER ADVANCE switch on the con

anel Switch F

unction

Ć

2-7Operation

Page 28

Figure 2-4. P

aper Adjustment Controls - Floor Cabinet Model

Operation2-8

Page 29

Figure 2-5. P

aper Adjustment Controls - P

edestal Model

Forms Thickness Adjustment Lever - The Forms Thickness Adjustment Lever, shown in

Figure 2-6,

closes

controls

the platen to adjust

the platen gap. R

aising the lever opens the platen and lowering the lever

for various paper thicknesses. The scale indicates approximate posi

tioning to correspond with paper thickness (1 to 6 part forms). Generally, set the lever for a

slight friction on the paper as it moves past the hammer bank. If the F

ment Lever is

of

vertical lines (called poor phasing). When fully

and ribbon replacement; a platen open message is shown on the display. After lowering the

ing

set incorrectly, the print hammer flight timing can be upset, resulting in waviness

raised, the platen is open to allow paper load

orms Thickness A

djustĆ

lever to the appropriate operating position, press CLEAR FAULT on the Control Panel to

the platen open condition.

clear

Ć

Ć

2-9Operation

Page 30

Figure 2-6. Forms Thickness Adjustment Lever

Vertical Position Knob - The Vertical Position Knob, shown in Figure 2-7, moves the paper

or down. The platen must be open (F

up

this

control.

orms Thickness A

djustment L

ever fully raised) to use

Figure 2-7. V

ertical P

osition Knob

Operation2-10

Page 31

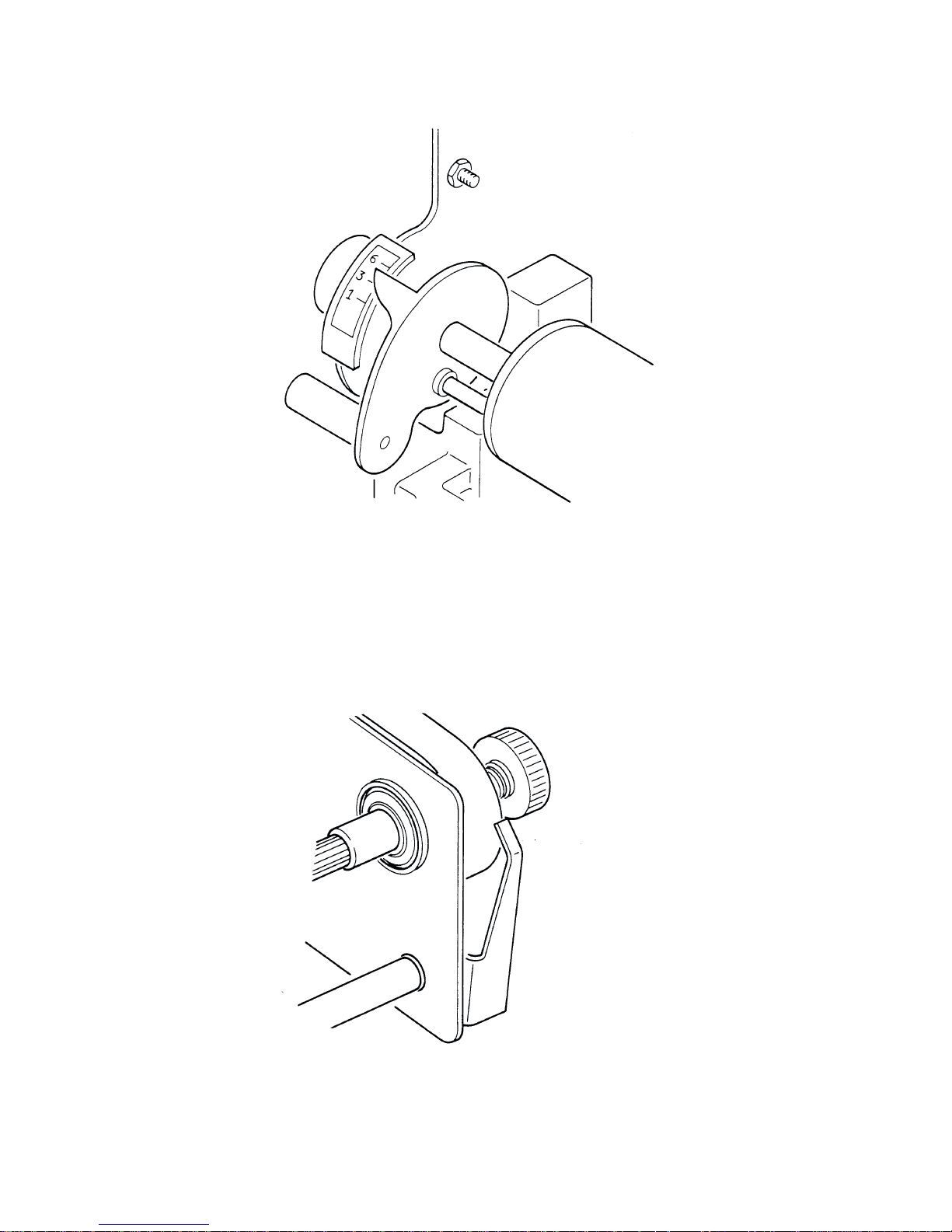

Horizontal Adjustment Knob - The Horizontal Adjustment Knob, shown in Figure 2-8,

shifts the paper left or right up to approximately !/3 inch. This control is used to make fine

adjustments

to the left margin. Once adjusted, further adjustments are usually not required.

Figure 2-8. Horizontal Adjustment Knob

Tractors

- The paper tractors feed the paper through the printer. The position of the left trac

tor, shown in Figure 2-9, establishes the left paper margin. Normally, the left tractor is posiĆ

for the left print margin (first character position) to align with character column 1 on the

tioned

paper scale (on top of the ribbon deck cover). Once properly positioned, further adjustments

are not required unless a change is made to the left print margin. Margins can also be estabĆ

by control codes from the host computer. R

lished

tractor

position is adjusted to compensate for various paper widths. Both tractors are locked in

efer to the P

rogramming chapter. The right

position during normal operation and must be unlocked to make any position adjustment. To

unlock the tractor, simply raise or lower the tractor lock to the center position and slide the

as necessary. If the tractor has screw-type locks, simply rotate the knobs to lock/unlock

tractor

the

tractor. Once in position, be sure to lock the tractor again.

Ć

2-11Operation

Page 32

Loading Paper

P6000L/P6200L Series printers use standard fanfold paper from 3 to 16 inches wide and 15 to

lb bond (0.025 inches thick maximum). T

100

to Figure 2-10.

1.

Place the printer offline and raise the top cover.

2. F

ully raise the F

3.

Open both tractor gates (B) by swinging them out.

4. On floor cabinet models, open the front cover and feed the paper up through the paper

(C) from below.

slot

the pedestal or table from below. On both models, push the paper up until it appears

above

5. Load the paper on the tractor sprockets (E); close the tractor gates (B). If necessary to

the right tractor to remove paper slack or to adjust for various paper widths, release

slide

the right tractor lock (F) by raising or lowering it to the center; slide the tractor into

After positioning the tractor, lock it in place.

tion.

Figure 2-9. Left P

orms Thickness A

On pedestal models, feed the paper up through the paper slot (C) in

the ribbon mask (D). If the paper snags, fold the top edge down before feeding.

djustment L

aper T

ractor

o load paper, perform the following steps and refer

ever (A).

posi

Ć

NOTE: The left tractor should remain locked in alignment with the number 1" on the

paper scale to set the left margin with the first character space.

Operation2-12

Page 33

6. Press TOP OF FORM or PAPER ADVANCE to further advance paper into the paper

stacking area. V

erify unobstructed paper feeding.

7. Set

8. P

9.

10.

11. On

the F

parts).

If closed too tightly, the shuttle may smear or tear the paper.

ress CLEAR F

Set the top-of-form as described in the Setting T

Close the printer cover.

floor cabinet models, perform the P

properly.

ing

Unloading Paper

1. Place

2. Tear off the paper below the paper guide. On pedestal model printers, this will be at the

3. F

4.

5. Gently

the printer offline.

bottom