User’s Manual

© 2019 All rights reserved.

For the most recent version of this manual please visit

http://www.primera.com/customer-support

2

Notices: The information in this document is subject to change without notice. NO WARRANTY OF ANY KIND IS MADE

WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. No liability is assumed for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material. This document contains

proprietary information that is protected by copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated into another language without prior written consent.

Trademark Acknowledgments: Primera and Primera LX610 are registered trademarks of Primera Technology, Inc.

Windows is a registered trademark of Microsoft Corporation. All other trademarks are the property of their respective

owners.

Revision History

Edition 1.0, Copyright 2019, All rights reserved.

FCC Compliance Statement: This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

For Users in the United States: This product is intended to be supplied by a UL listed Direct Plug-In Power Supply

marked "Class 2"or a UL listed ITE Power Supply marked "LPS" with output rated 12VDC, 5A or higher. This equipment

has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. In

a domestic environment this product may cause radio interference, in which case the user may be required to take

adequate measures. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

Re-orient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Use of shielded cables is required to comply with the Class A limits of Part 15 of the FCC Rules. You are cautioned that

any changes or modifications not expressly approved in this manual could void your authority to operate and/or obtain

warranty service for this equipment.

For Users in Canada: This digital apparatus does not exceed the Class A limits for radio noise for digital apparatus set

out on the Radio Interference Regulations of the Canadian Department of Communications. Le present appareil

numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques de la class

A prescrites dans le Reglement sur le brouillage radioelectrique edicte par le ministere des Communications du Canada.

122019

3

4

Table of Contents

Section 1: Getting Started ..................................................................................................................................... 6

1A Choosing a Good Location ........................................................................................................................... 6

1B Unpacking and Inspection ........................................................................................................................... 7

1C Installing the Roll Holders ............................................................................................................................ 8

1D Identifying the Parts .................................................................................................................................. 12

Section 2: Media, Cartridges and Knives ............................................................................................................ 14

2A Label and Roll Specifications ..................................................................................................................... 15

2B Installing Digital Die-Cutting Label Stock ................................................................................................... 18

2C Installing Pre Die-Cut Label Stock .............................................................................................................. 21

2D Replacing the Digital Die Cutting Knife holder .......................................................................................... 25

2E Replacing the Cutting Knife ........................................................................................................................ 27

2F Replacing Ink Cartridges ............................................................................................................................. 28

2G Adjusting the Gap Sensor Position (Pre Die-Cut Labels Only) ................................................................... 30

Section 3 Primera PrintHub ................................................................................................................................ 32

3A Adjusting Knife Pressure and Stretch Factor ............................................................................................. 33

3B Using the Cost Estimator ........................................................................................................................... 35

3C Set the Gap Sensor Mode (Pre Die-Cut Labels Only) ................................................................................. 36

3D Set the Present/Cut Mode......................................................................................................................... 38

3E Adjusting Print Alignment .......................................................................................................................... 40

3F PrintHub Settings ....................................................................................................................................... 42

3G PrintHub Printer Settings .......................................................................................................................... 44

3G1. Multiple Printer Support .................................................................................................................... 45

Section 4 Printing and Cutting with PTCreate .................................................................................................... 46

4A Overview (Standard version vs Pro version) ............................................................................................. 46

4B PTCreate Software Activation .................................................................................................................... 49

4C Software Deactivation ............................................................................................................................... 51

4D Tutorial How to setup a Print and Cut in PTCreate Standard .................................................................... 52

4D.1 Choosing a Label Size (Page Layout) ................................................................................................... 52

4D.2 Import a flat Image (JPG, BMP, PNG, TIF, GIF) ................................................................................... 53

4D.3 Add a Cut file ...................................................................................................................................... 55

4D.4 Print. ................................................................................................................................................... 58

4E: Tutorial: How to Setup a Print and Cut using PTCreate Pro – Vector File Cut .......................................... 59

5

4E.1 Choosing a Label Size (Page Layout) ................................................................................................... 59

4E.2 Import a flat Image (JPG, BMP, PNG, TIF, GIF) .................................................................................... 60

4E.3 Working with Layers in an Imported Vector File ................................................................................ 63

4F Tutorial: How to Setup a Print and Cut using PTCreate Pro – Contour Cut ............................................... 65

4F.1 Choosing a Label Size (Page Layout) ................................................................................................... 65

4F.2 Import an Image. ................................................................................................................................. 66

4F.3 Trace Image and create Cut Line ......................................................................................................... 68

4F.4 Offset a Cut Path ................................................................................................................................. 72

4G Setup multiple identical cuts (Duplicate and Array) ................................................................................. 74

4H Print Preview ............................................................................................................................................. 79

4I Vector File Specifications for Designer ....................................................................................................... 80

Section 5: Printing only to Pre Die-Cut labels ..................................................................................................... 81

5A Using BarTender for Pre Die-Cut Printing .................................................................................................. 81

5B Add Text, Barcodes and Graphics to a BarTender Label ........................................................................... 88

5C Printing from Other Programs ................................................................................................................... 89

5D Creating a Full Bleed Print ......................................................................................................................... 90

5E Printer Driver Settings ................................................................................................................................ 92

Section 6: Troubleshooting ................................................................................................................................. 95

6A Solving Pre Die-Cut Print Alignment Problems .......................................................................................... 95

6B Maintenance .............................................................................................................................................. 97

6C Poor Print Quality – Cleaning the Cartridge .............................................................................................. 98

6D Technical Support. ................................................................................................................................... 101

Section 7: Technical Specifications ................................................................................................................... 102

6

Section 1: Getting Started

THANK YOU…

...for choosing an LX610 Color Label Printer. The LX610 Printer will print razor-sharp text and

barcodes, vibrant colors, and even stunning photo-realistic photographs directly onto rolls of labels,

card stock and a variety of other approved media. AND with the built in digital die cutter you can

cut and create your labels in any size or shape you choose.

This User's Manual is your complete step-by-step guide to quickly and easily setting up and printing

with your new Color Label Printer!

1A Choosing a Good Location

Place the printer on a flat surface in a location with adequate air circulation to prevent

internal heat buildup.

Do not place the printer near heat sources such as radiators or air ducts, or in a place subject

to direct sun light, excessive dust, mechanical vibration or shock.

Allow for adequate clearance in front of the printer to accommodate the printed label stock

as it is leaving the printer to avoid the possibility of binding or jamming of the label stock.

Allow for 6” of clearance behind the printer to accommodate loop creation during cutting

operations. The area directly behind the printer must also not be obstructed by USB or

power cables connected to the printer.

Allow for adequate overhead clearance for opening the top cover to allow easy access to the

labels tock and ink cartridge. The printer will require 7 inches (17.78 cm) of additional space

on the top side to completely open the cover (Total = 16.5" or 41.91 cm).

7

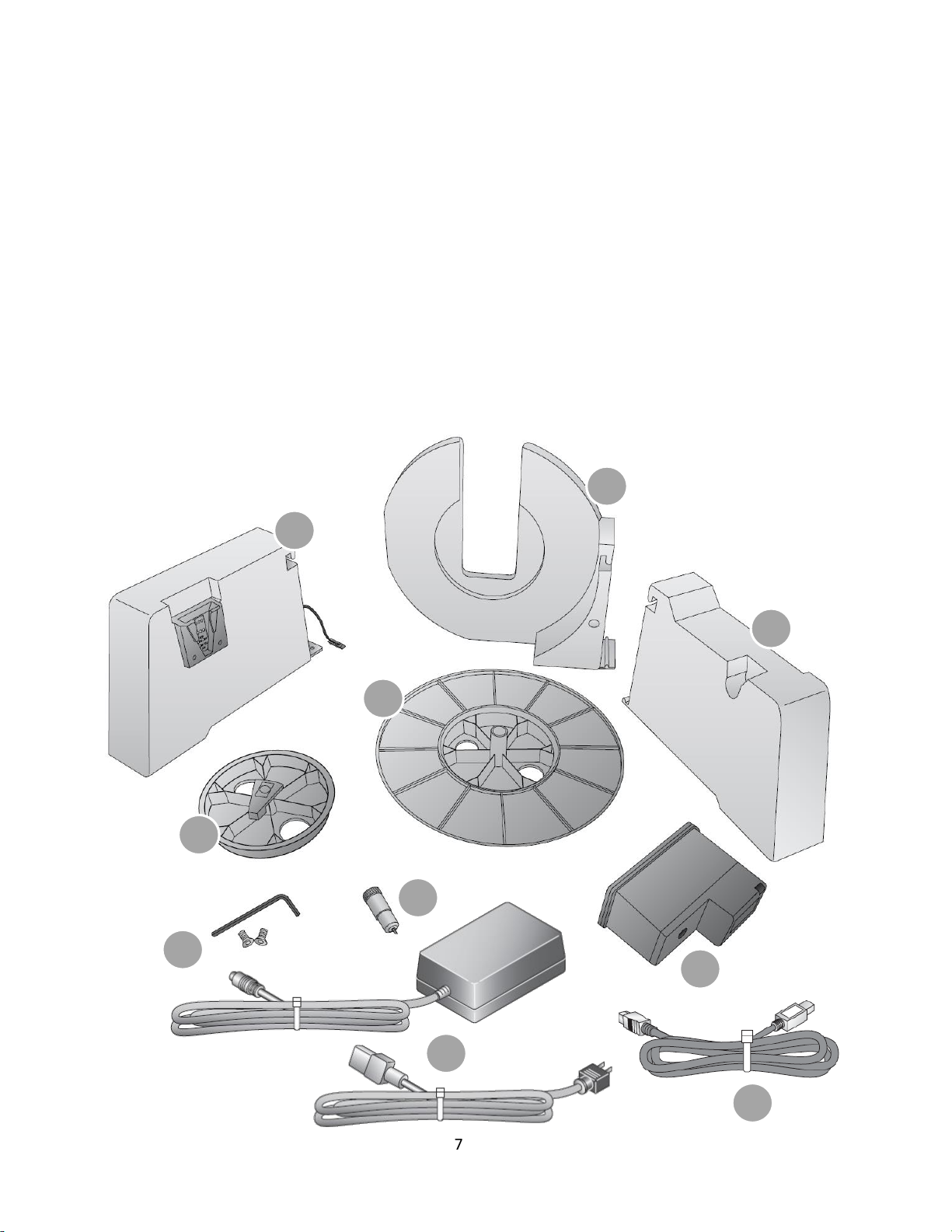

1B Unpacking and Inspection

While unpacking your printer, inspect the carton to ensure that no damage has occurred during

shipping. Make sure that all supplied accessories are included with your unit. The following items

are included in the supply box:

1. Power Adapter and Cord

2. 6’ USB Cable (If other USB cable is used, it must be 6’ (2 M) or less)

3. Color Dye Ink Cartridge Part Number 53496 (Pigment is also available – Part Number: 53491)

4. Die Cutting Knife Holder with knife preinstalled

5. Label roll holders (Assembly required – section 1C)

6. Large Roll Hub

7. Small Roll Hub

8. T8 Allen Key and two screws

9. Printed documentation

2

1

4 5 6

7 8 5

5

8

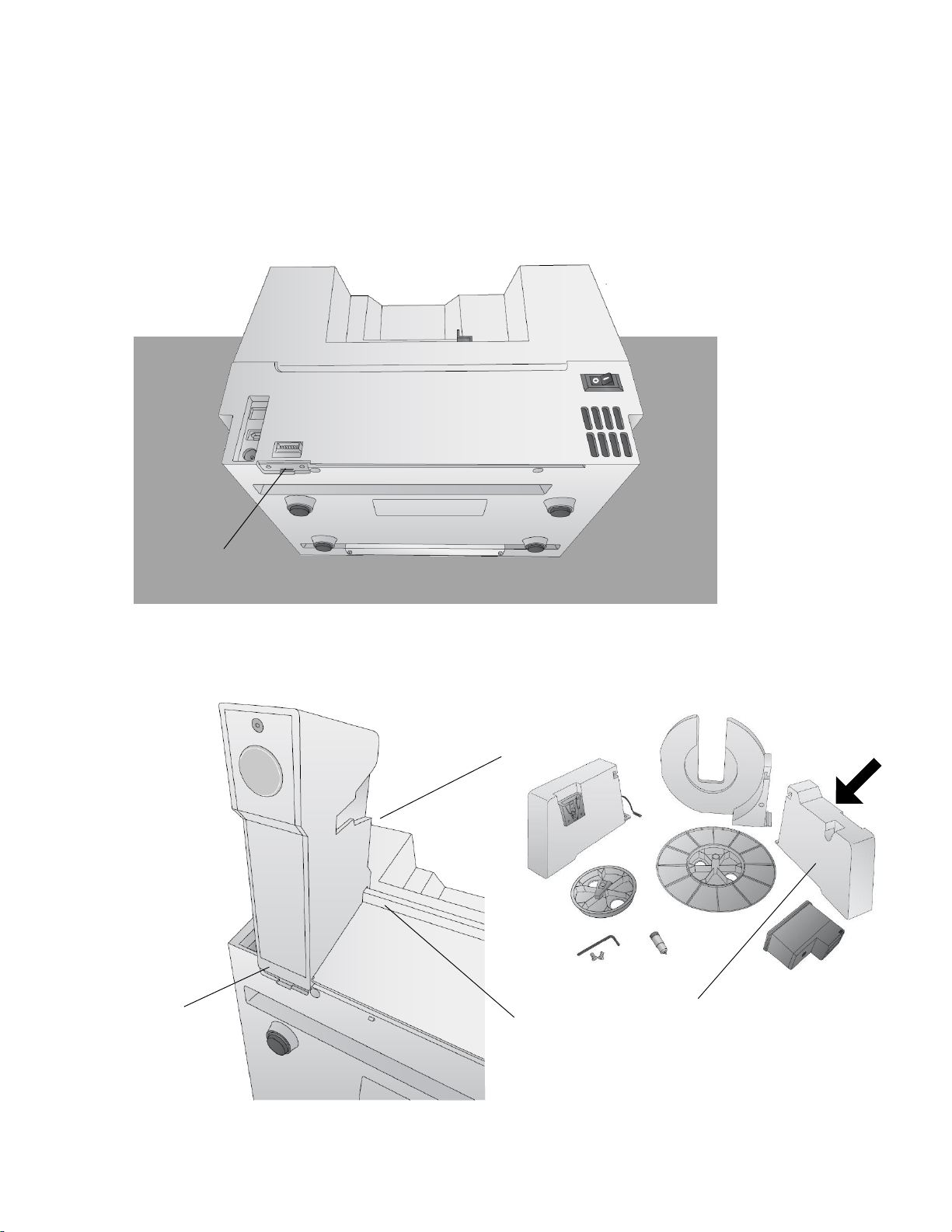

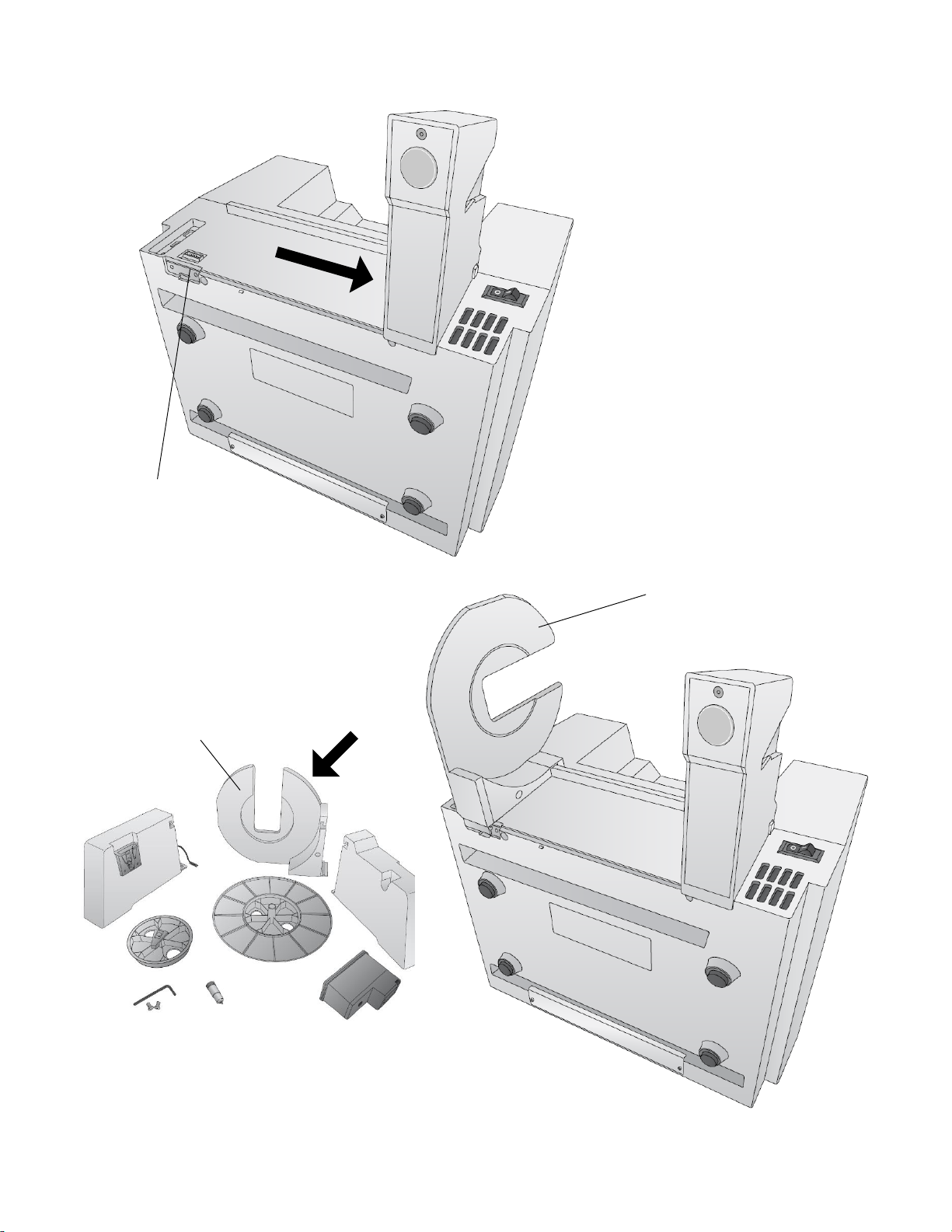

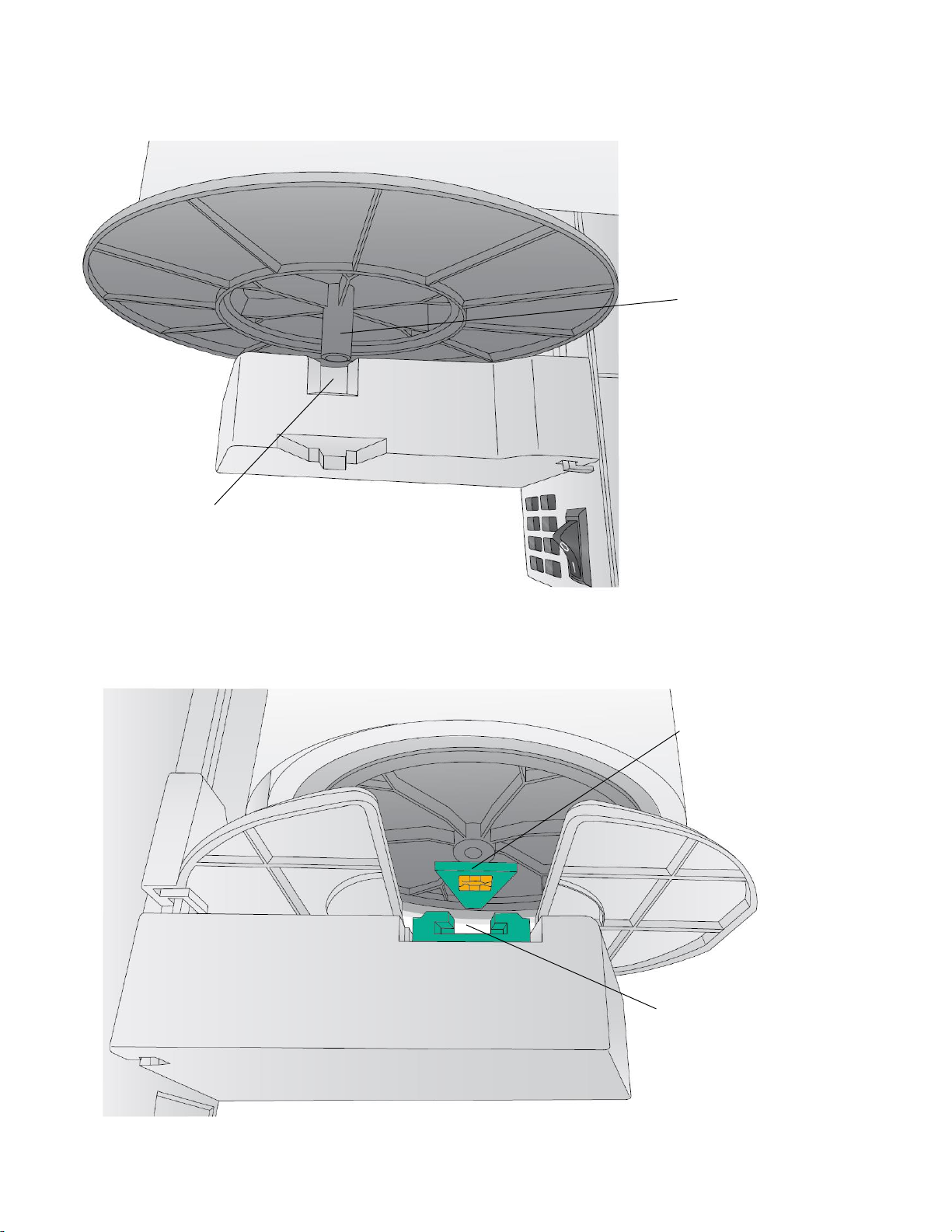

1C Installing the Roll Holders

Some light assembly is required before operating the printer. Follow these instructions to install the

roll holders.

1. Set the printer on its front so the bottom is facing you.

2. Install the movable label roll holder by attaching the hooked end on the rail. The bottom of

the holder will fit in the notch on the printer.

Rail

Notch

Tab

Movable Roll Holder

Movable Roll Holder

9

3. Slide the Roll Holder to the far right.

4. Install the roll guide by attaching

the hooked end on the rail. The

bottom of the holder will fit in the

notch on the printer.

Notch

Roll Guide

Roll Guide

10

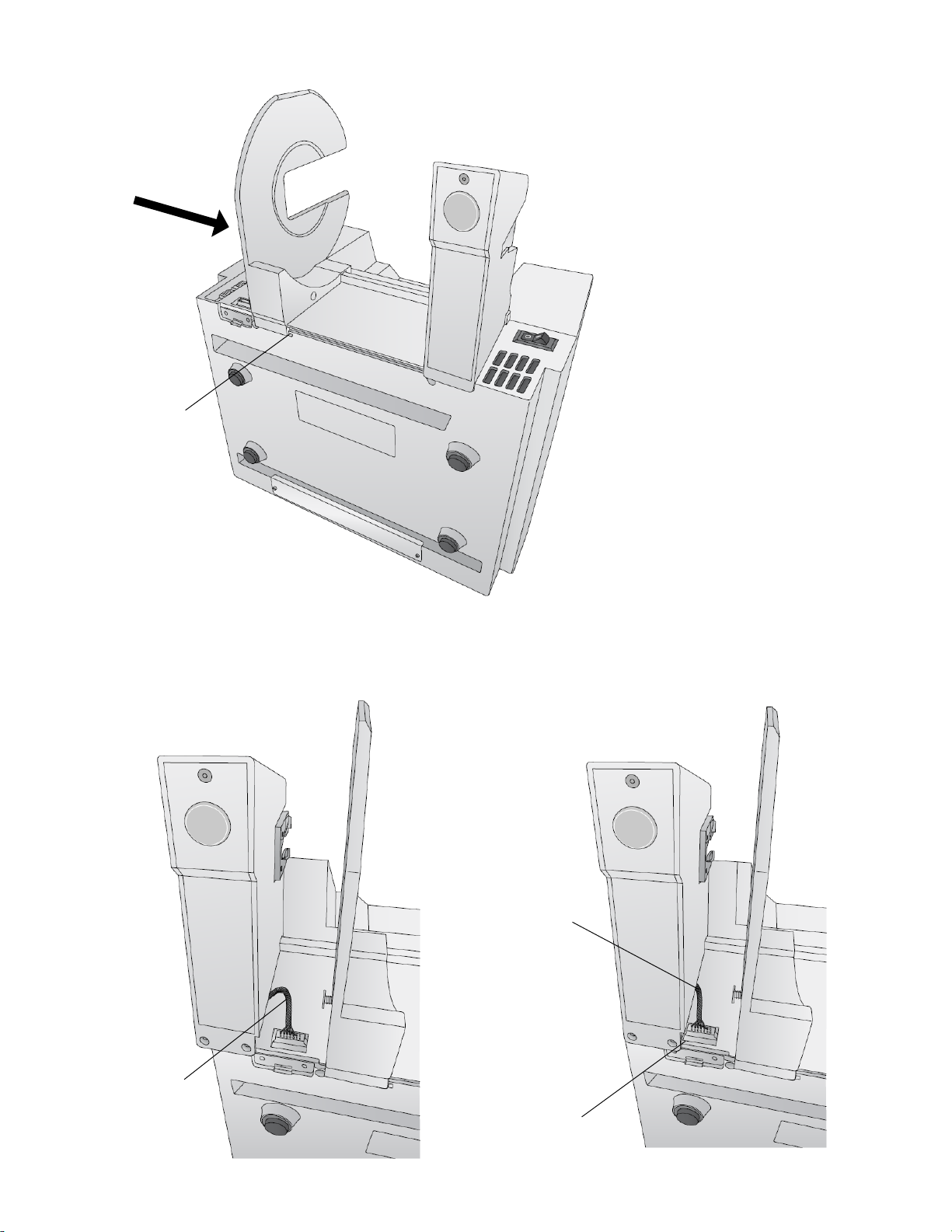

5. Slide the Guide to the stop.

6. Locate the remaining roll holder with the protruding wire. Connect the wire to the port on

the printer. Tuck the wire inside the cavity.

Stop

Wire

Push the wire

into the cavity

as you move the

holder closer to

the notch

Notch

11

7. Snap the holder in place so the two screw holes line up with the holes on the printer.

8. Install the T8 screws using the INCLUDED Allen key or a Torx T8 screwdriver.

9. Rotate the printer back on its feet.

12

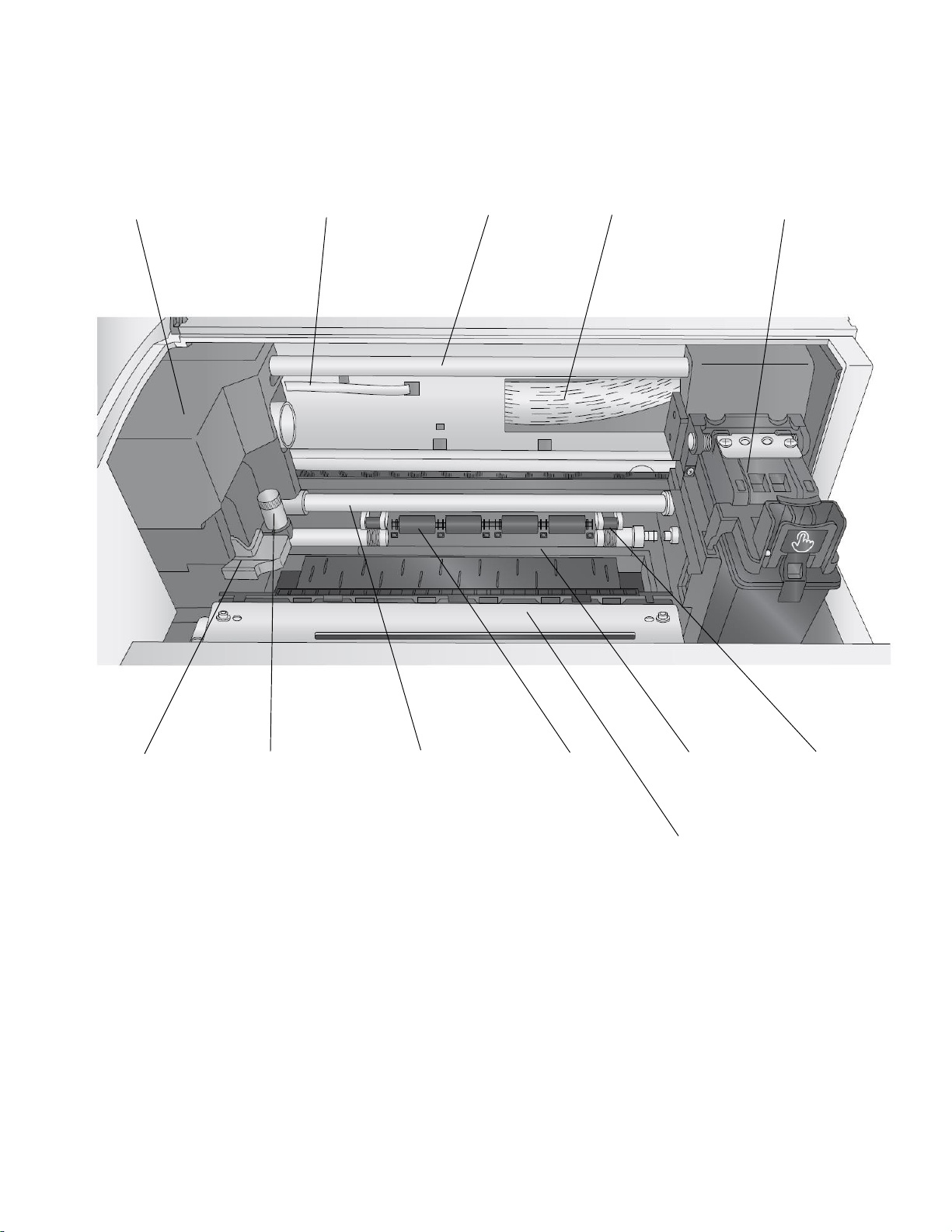

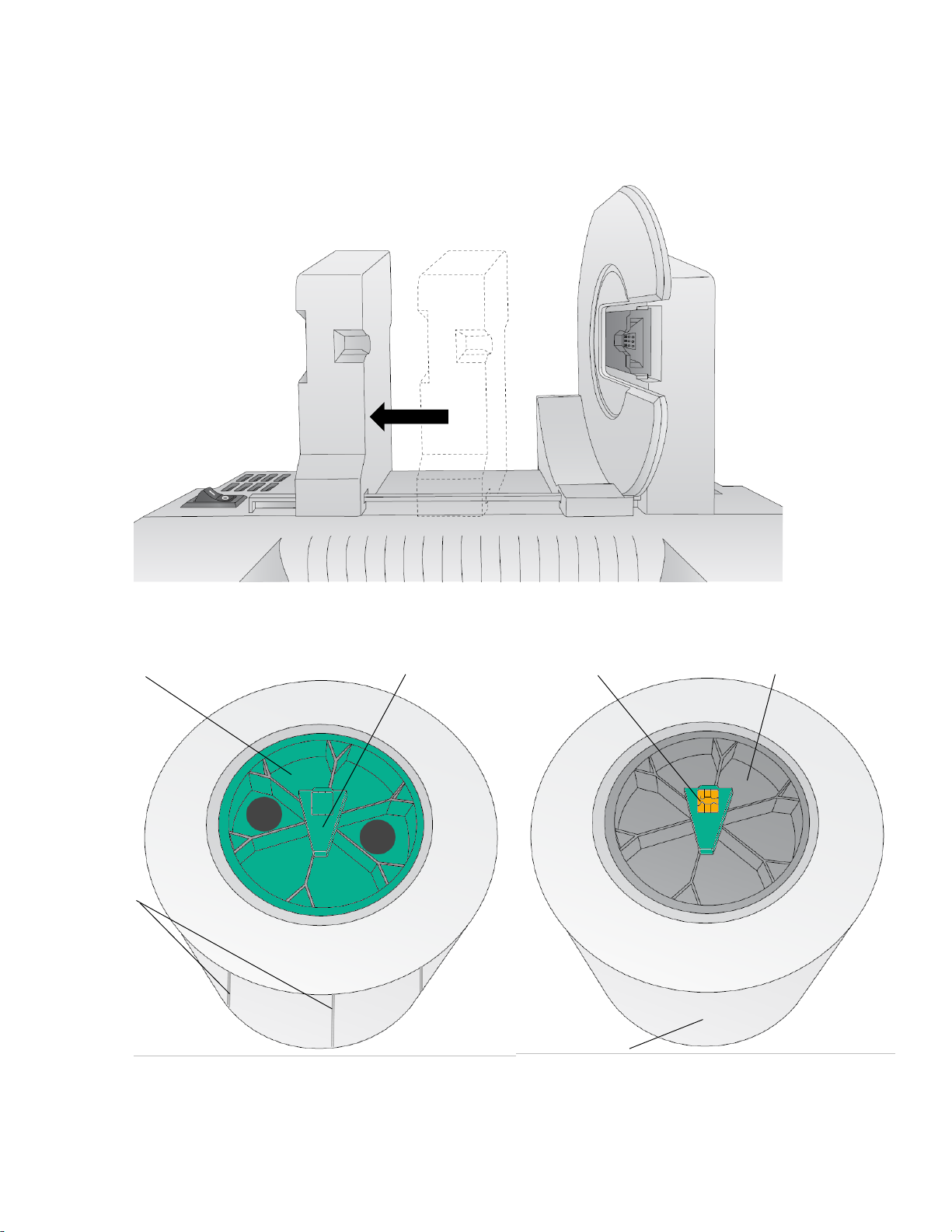

1D Identifying the Parts

These illustration shows the printer from various angles so all important parts can be identified.

The Power LED indicates that the printer is on and ready to receive print jobs.

The Ink LED will illuminate when a cartridge has 10% or less of its ink remaining.

The Pause Button is pressed to pause a job to allow for loading of label stock and ink cartridges. The

printer pauses after the printing of the current label has finished.

The Feed Button is pressed in order to load label stock if the printer does not automatically detect

the stock. When stock is loaded each press of the button will cause one label or a few inches to be

fed through the printer.

The Unload Button is pressed to unload label stock after you receive an End of Roll message in

PrintHub. The printer will reverse the label stock through the feed area.

Front Cover

Control Panel

13

Interior

Die Cutting

Carriage

Die Cutter

Ribbon Cable

Upper Guide

Shaft

Print Carrier

Ribbon Cable

Print Carrier

Knife Collar

Handle

Die Cutting

Knife

Lower Guide

Shaft

Pre die-cut

rollers

Die Cutting

Pinch Rollers

Cutter Wheel

Mechanism

Wear Strip

14

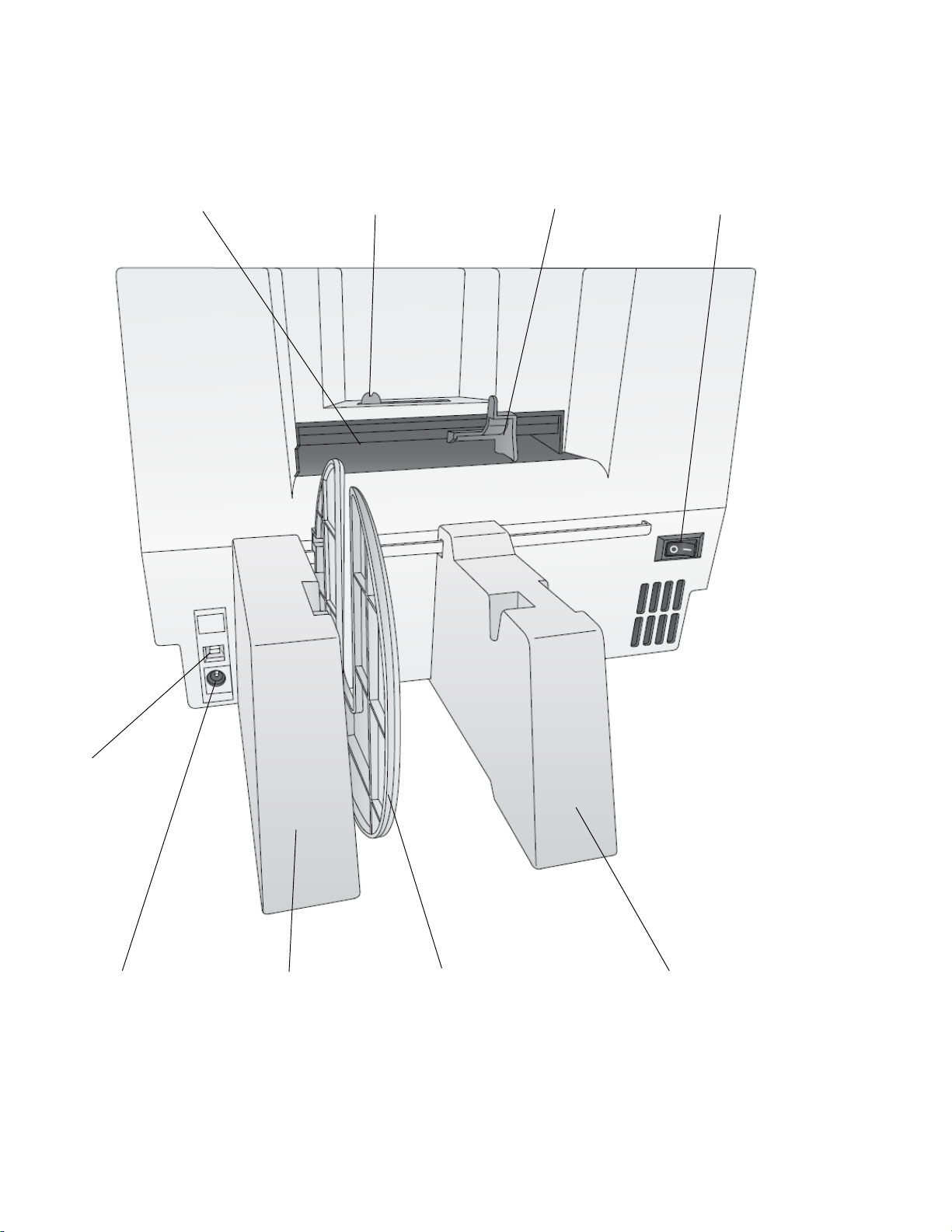

Back

Section 2: Media, Cartridges and Knives

Infeed Area

Gap Sensor

Adjustment

Power Switch

Movable

Throat Guide

USB

Power

Fixed Roller

Holder w/

Chip Reader

Fixed Guide

Movable Roll

Holder

15

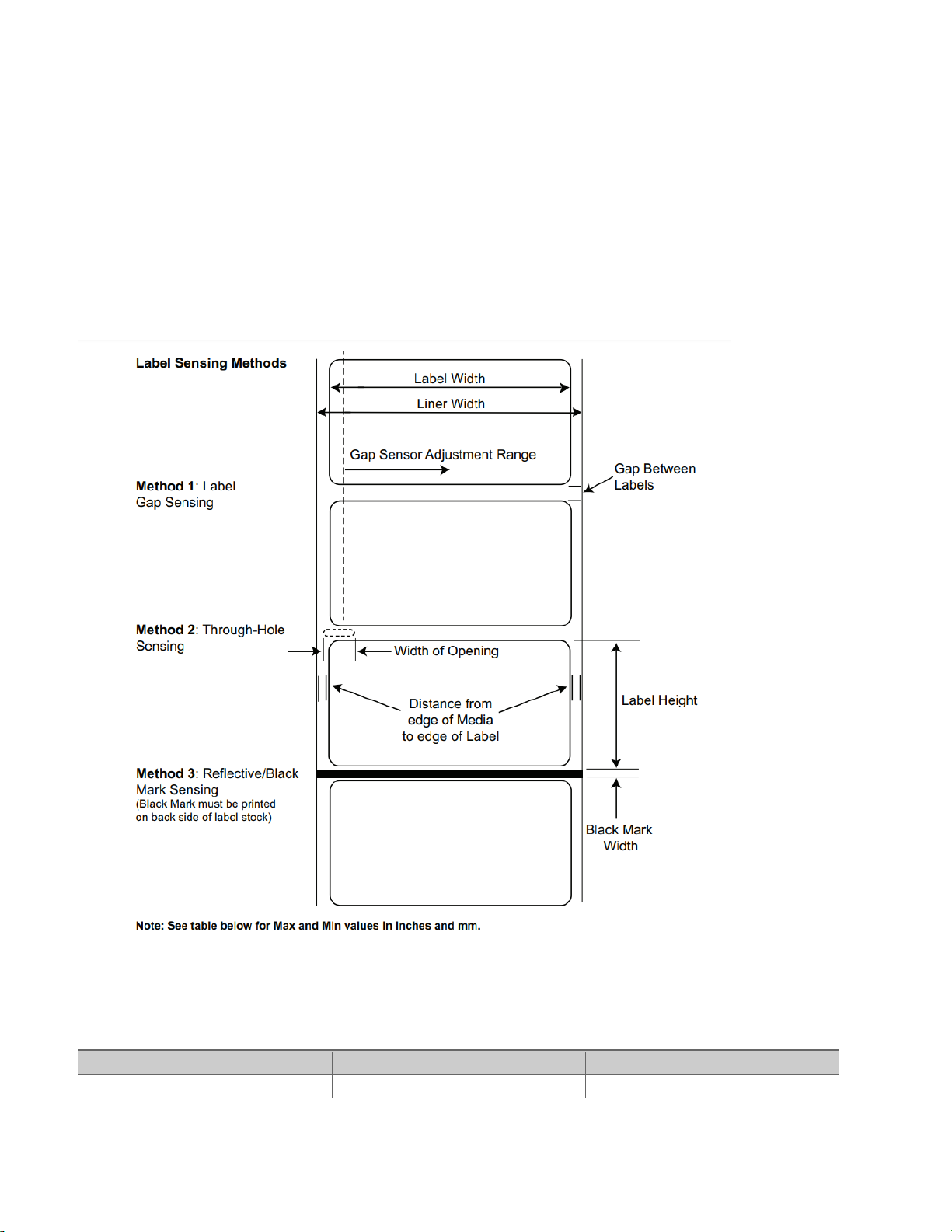

2A Label and Roll Specifications

Pre Die-Cut Labels. A wide variety of pre die-cut label stock can be used in the printer. Refer to the

specifications and settings in the following sections before ordering custom stock from Primera or

any stock from another company.

Digital Die-Cut Labels. If you are using the printer to digitally die-cut your own shapes and sizes only

Primera label stock can be used.

Important! Test all custom made label stock with the intended printer before ordering large quantities!

Primera will only assume responsibility for custom label stock ordered from Primera.

Max

Min

Label width

5” (127mm)

0.5" (13mm)

Liner/media width

5.125 (130.17mm)

2" (50.8mm)

16

Label height/length

12” (305mm)

0.5" (13mm)

Gap between labels

10" (253mm)

0.10" (2.5mm)

Width of through-hole

0.5" (12.65mm)

0.25" (6.325mm)

Gap Sensor Adjustment

Range (from left edge)

2.05" (52mm)

0.40" (10.16mm)

Reflective/Black Mark Width*

N/A

0.1" (2.54mm)

Max Outer Diameter (OD)

6.0"(152.4mm)

N/A

Inner Core Diameter (ID)

3.0" (76.2mm)

3.0" (76.2mm)

Recommended Total

Thickness

(Liner + Label)**

.0010” (10 mil)

Distance from edge of media

to edge of label

Printer assumes 2mm (1/16”) gap. However, this is adjustable

via the left margin offset.

* The Reflective/Black Mark should be opaque to infrared light. The mark should be between the

labels. The end of the mark should correspond with the beginning of the label.

** This is the recommended maximum. There are two factors that determine whether the printer

will accept any particular stock thickness.

1. The ability for the printer to pull the paper through the print area.

2. The ability for the sensor to read through the backing if the sensor is set to die-cut.

If you are printing in continuous or reflective label sensing mode number 2 does not apply. The fact

that the printer must read through the backing in die-cut mode will limit the thickness much more

than the printer's ability to pull the paper through the print area. However, if you adjust opacity

level of the liner enough to allow the label to be seen by the stock sensor, the thickness will only be

limited by the printer's ability to pull it through the printer area. For these reasons the weight or

thickness of the liner is a variable that cannot easily be defined. Primera recommends and uses 40#

liner with all Pre Die-Cut label stock.

It is important to test all label stock with the intended printer before ordering large quantities!

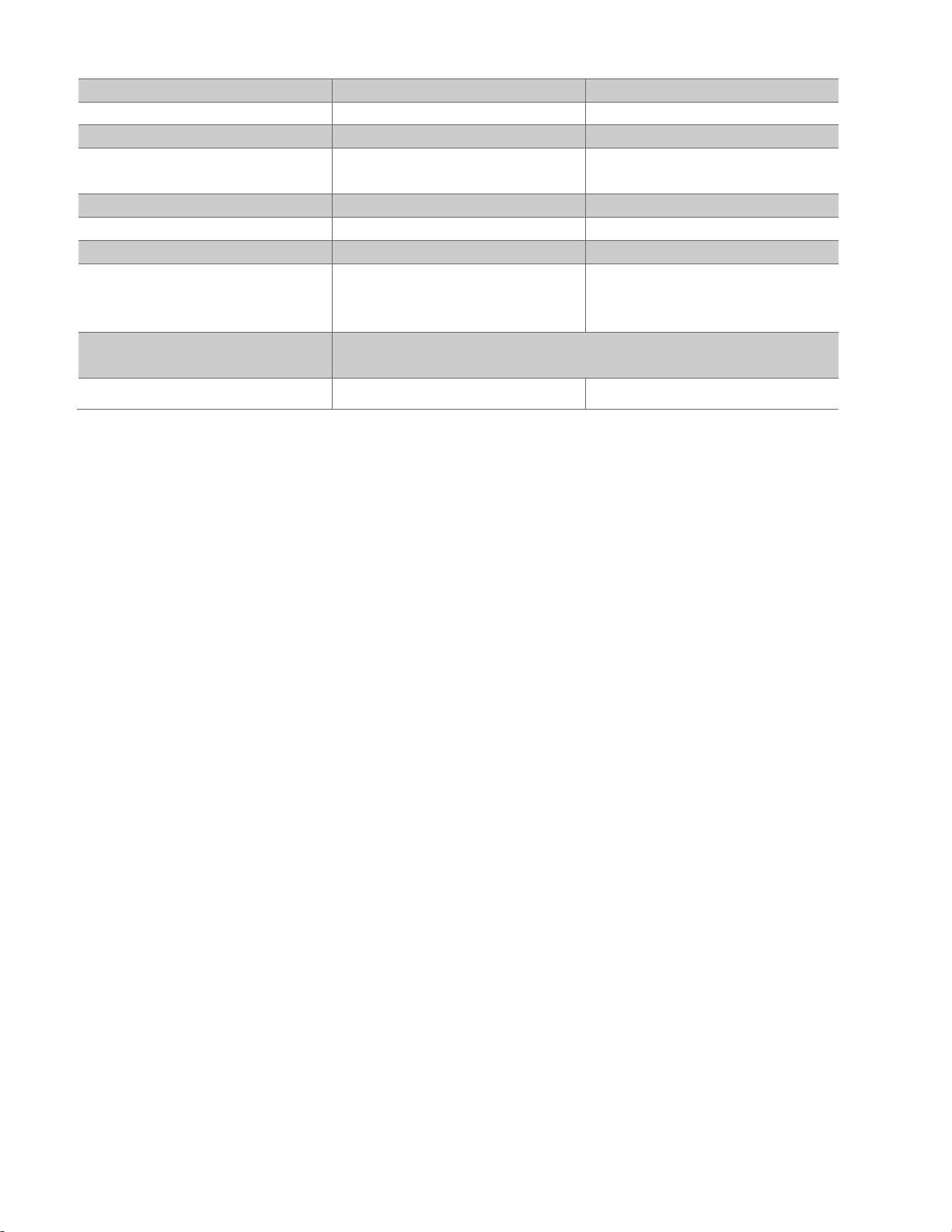

Roll Specifications:

17

Note on Label Orientation: If you are using an applicator to apply your labels, be sure to order label

stock with the correct orientation for your applicator. For example, most applicators will apply the

side of the label first, so you will want to print the labels sideways.

18

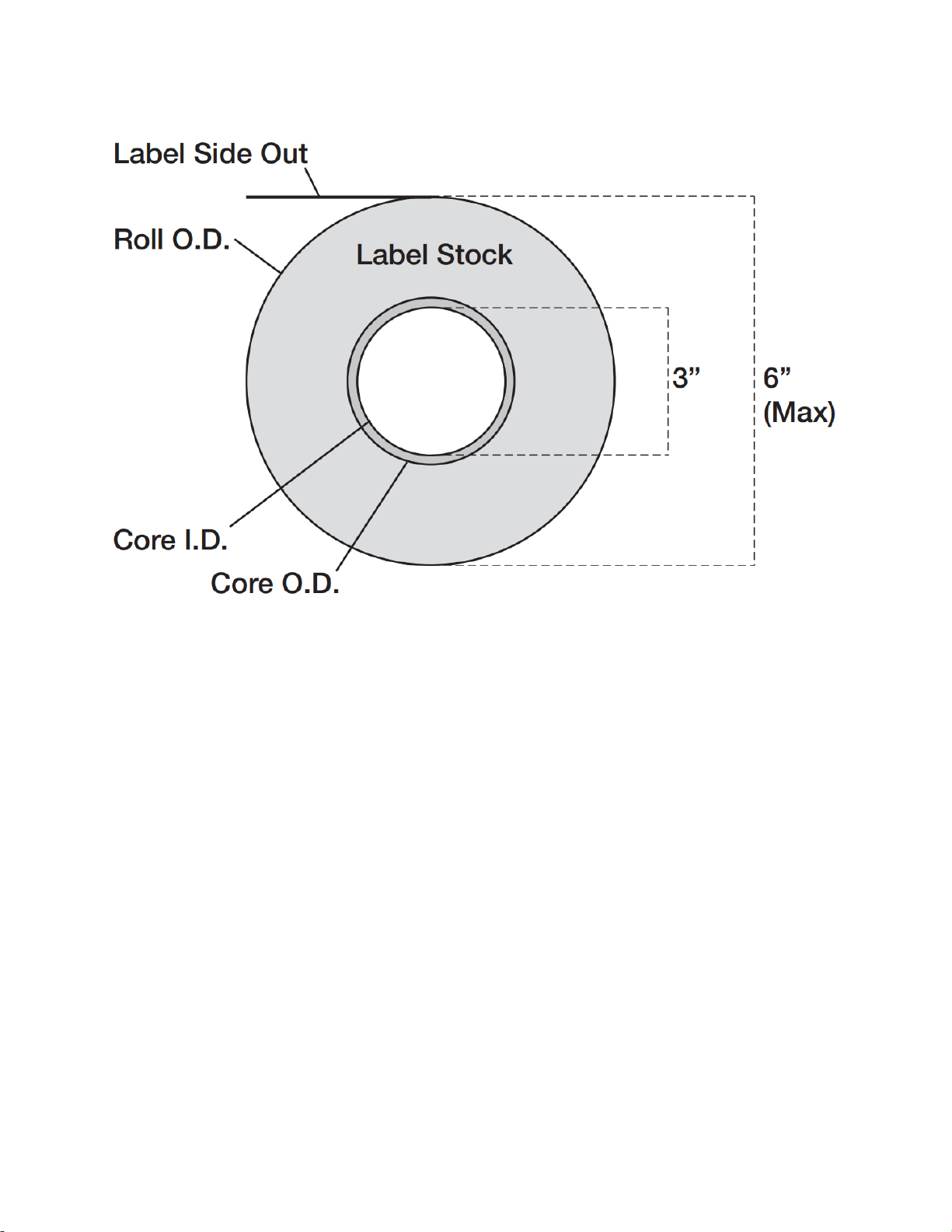

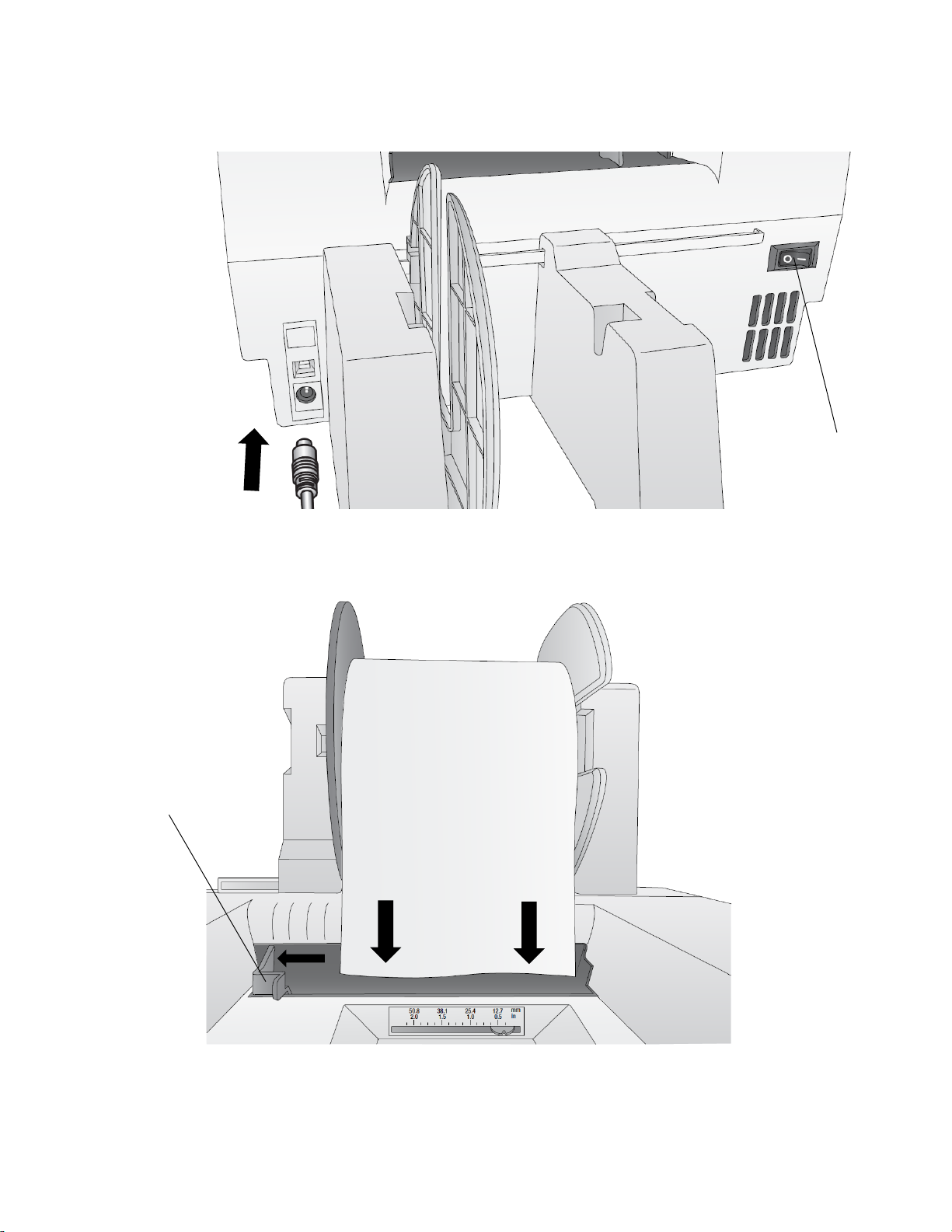

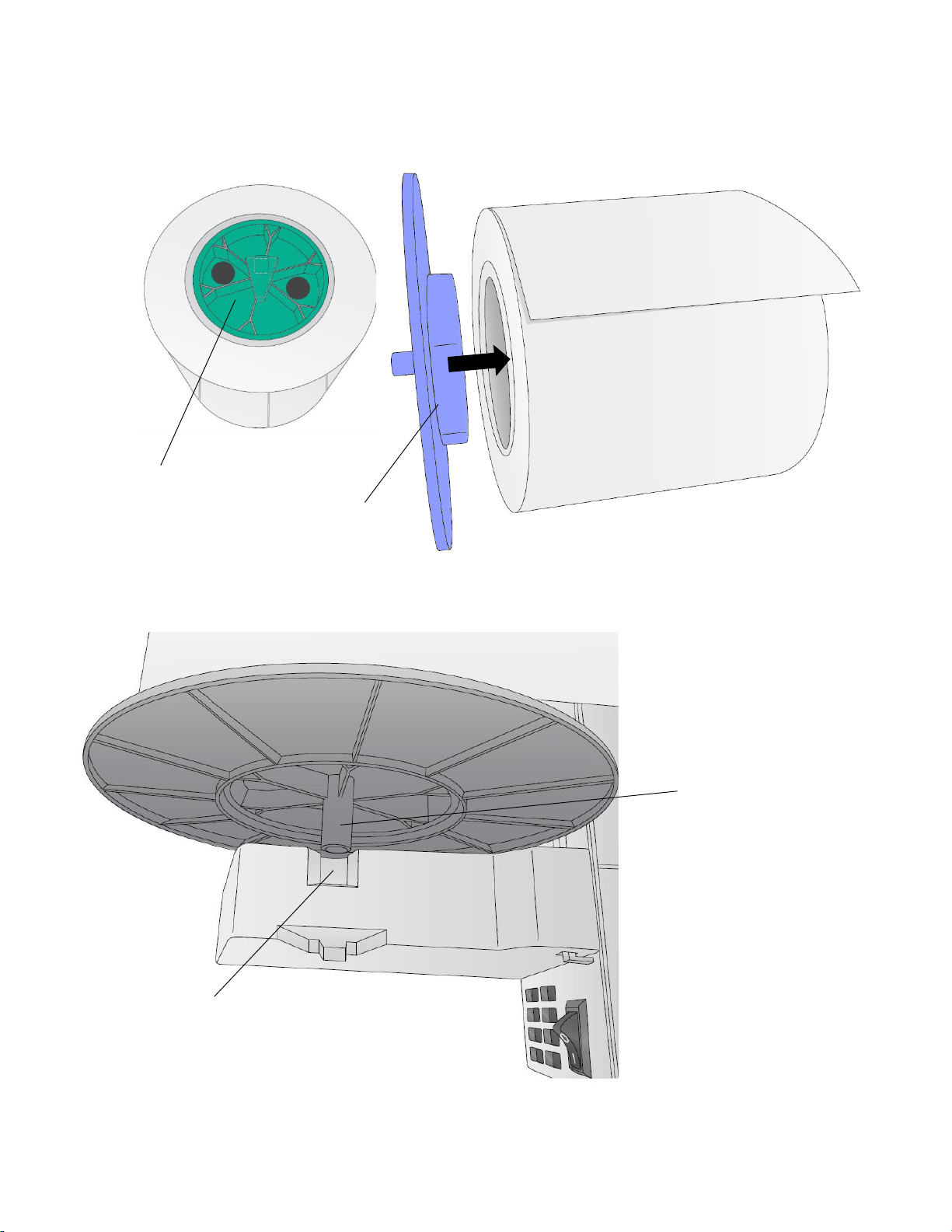

2B Installing Digital Die-Cutting Label Stock

1. Move the roll holder to the preset position for on demand digital die-cutting (3rd mark from

the left – 1.25”)

2. Install the Blue Hub on the open side of the digital die-cutting media.

Move to third

mark from Left

Digital Die Cutting

Media comes with

black hub with green

chip.

Blue Hub

Note: The green hub is not needed for

digital die-cutting and can be stored in

the notch on the movable holder.

19

3. Set the roll in place so that the blue pin sits in the notch on the roll holder.

4. Make sure the green chip holder fits in the corresponding green slot on the roll holder.

Blue Pin

Notch

Notch

Green Chip

Holder

20

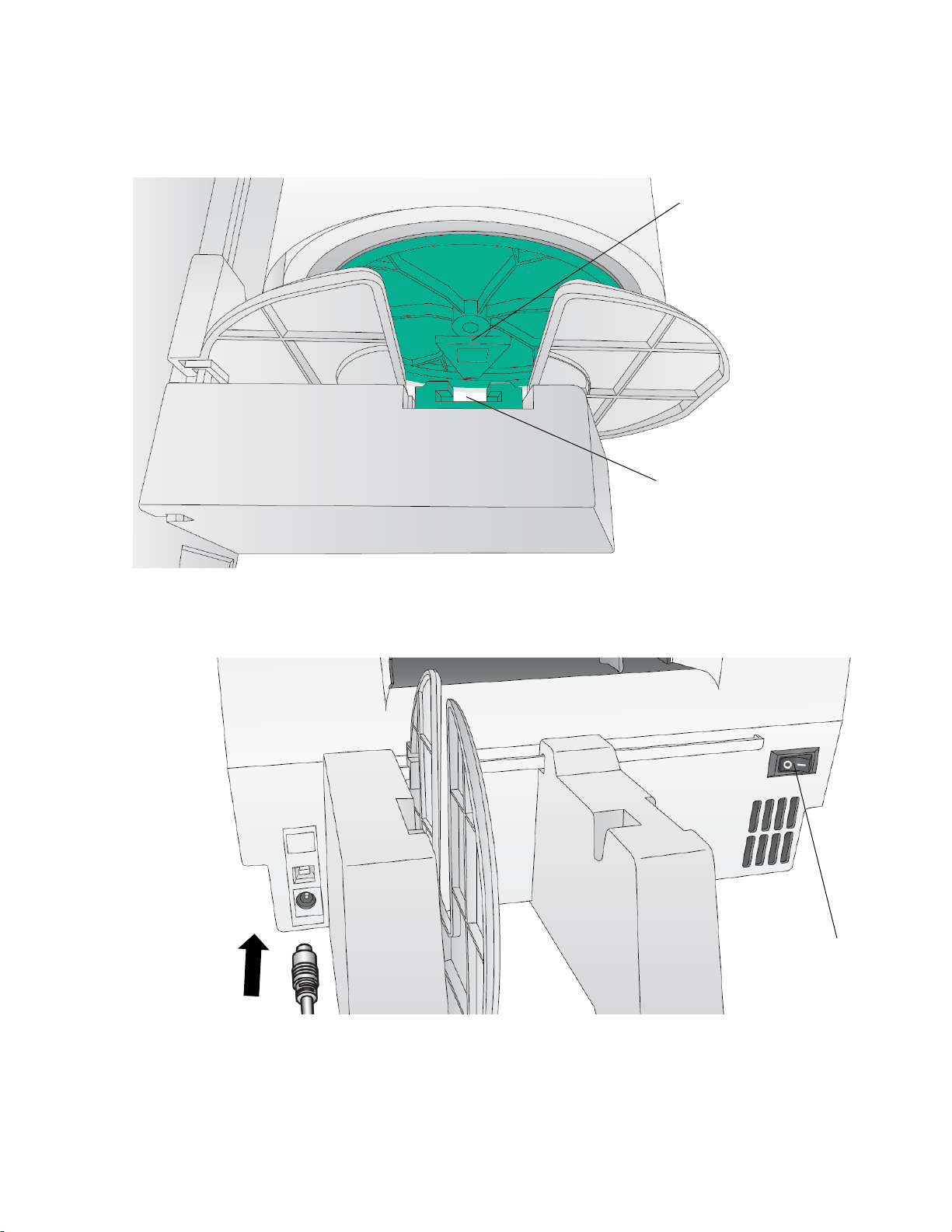

5. Before feeding the stock you must plug in power and switch on the printer.

6. Guide the leading edge of the roll into the feed area. Move the blue guide to the far side.

7. Push until the printer detects the stock, grabs it and pulls it through the printer.

Power Cable

Power Switch

Blue Guide

21

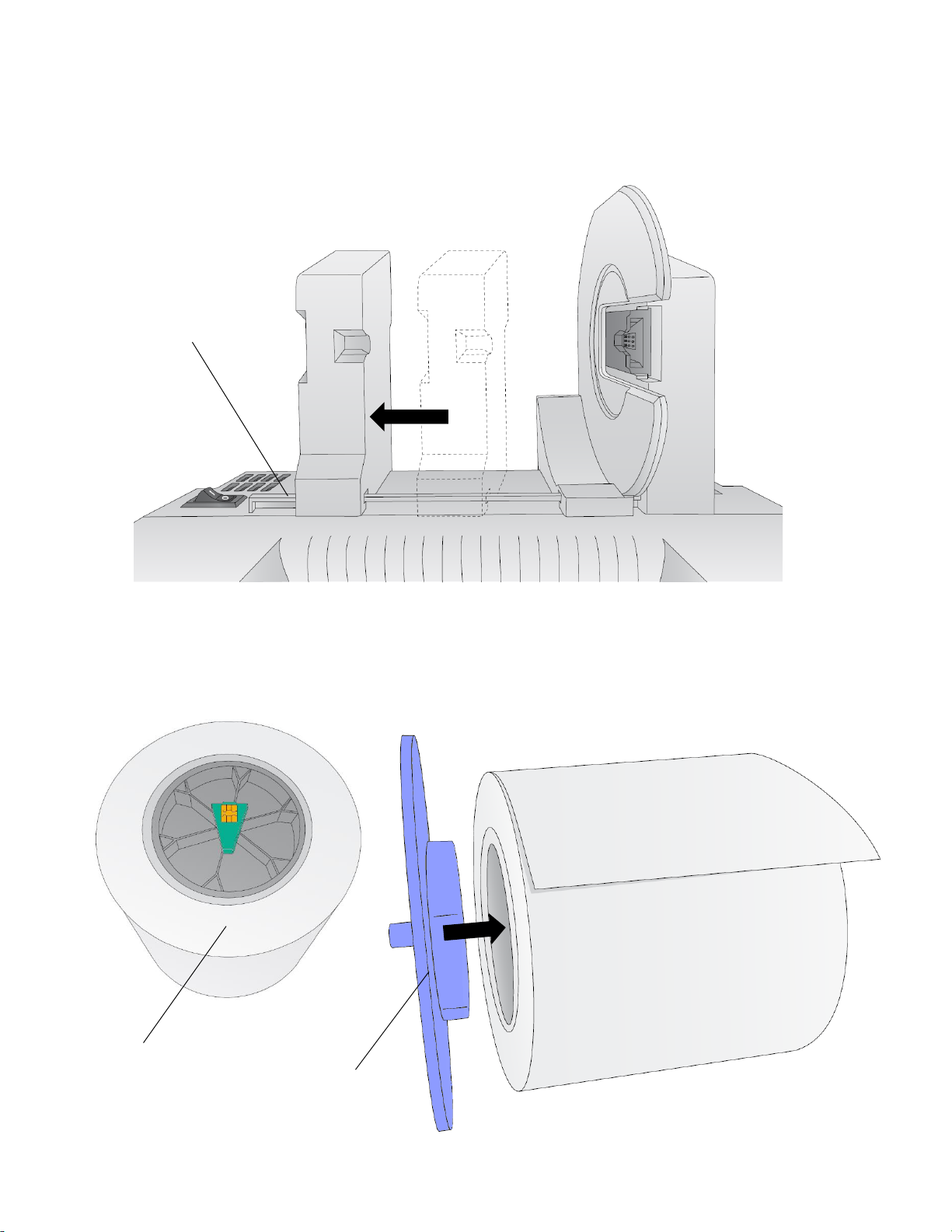

2C Installing Pre Die-Cut Label Stock

1. Move the roll holder to the approximate position which matches the width of the stock you

are installing. You can always fine tune this later.

2. Install the Green Hub on the right side of the pre die-cut media.

Green Hub

Die Cuts

Blank Chip Holder

Pre Die-Cut Roll

Digital Die-Cut Roll

Smart Chip

Black Hub

Continuous Media

(User must install Green Hub)

22

3. Install the Blue Hub on the left side of the digital die cutting media.

4. Set the roll in place so that the blue pin sits in the notch on the roll holder.

Pre Die-Cut Media

Blue Hub

Blue Pin

Notch

(Hub/Chip comes preinstalled)

23

5. Make sure the green blank chip holder fits in the corresponding green slot on the roll holder.

Before feeding the stock you must plug in power and switch on the printer.

Notch

Blank Chip

Holder

Power Cable

Power Switch

24

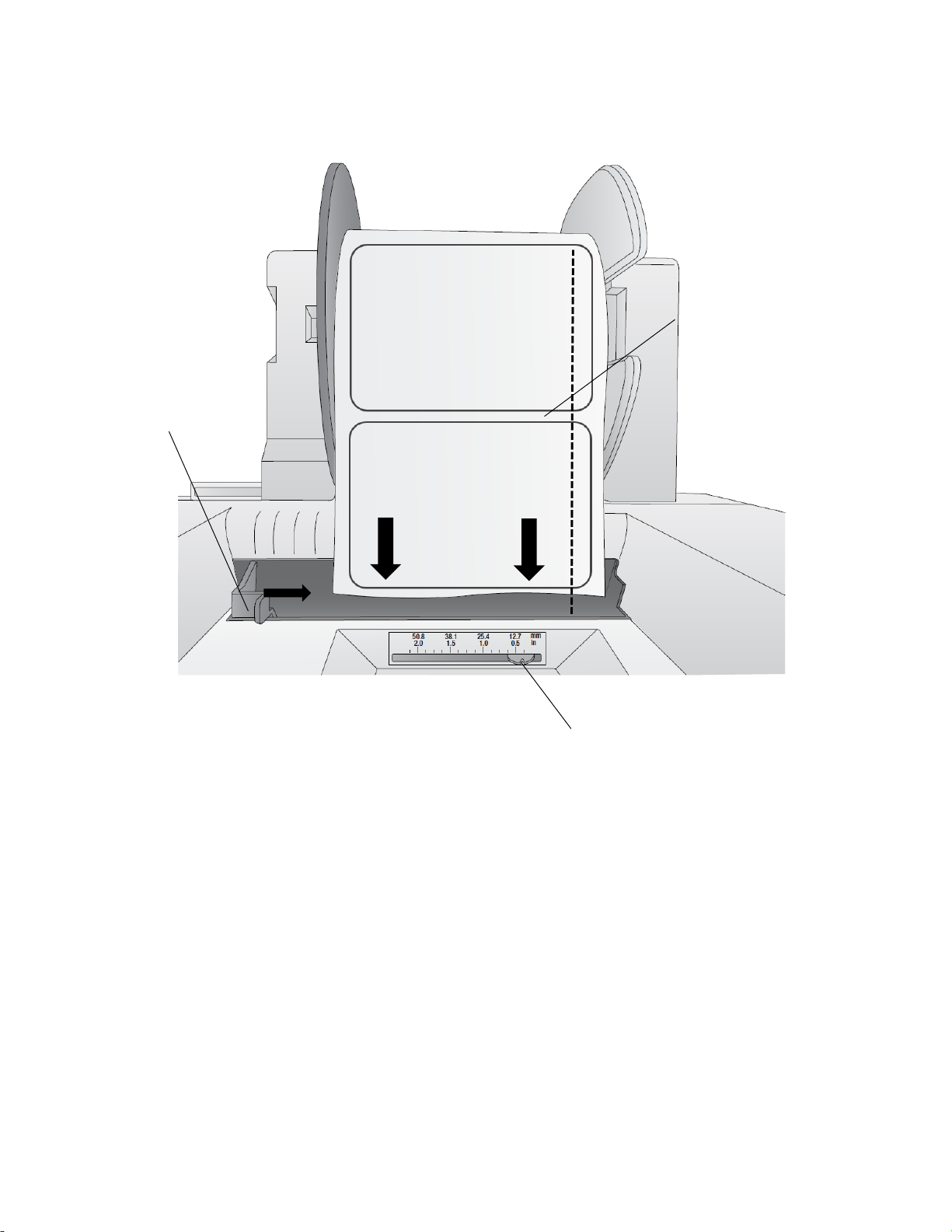

6. Guide the leading edge of the roll into the feed area. Move the blue guide so that it touches

the label stock.

7. Push until the printer detects the stock, grabs it and pulls it through the printer.

Blue Guide

Gap Sensor Position

Indicator from right

edge of media

Gap sensor

should intersect

the gap between

labels

Note the positon of the label sensor. Slide

the sensor position indicator so that it

intersects with the gaps between your labels.

For most label stock you will not need to

move this.

25

2D Replacing the Digital Die Cutting Knife holder

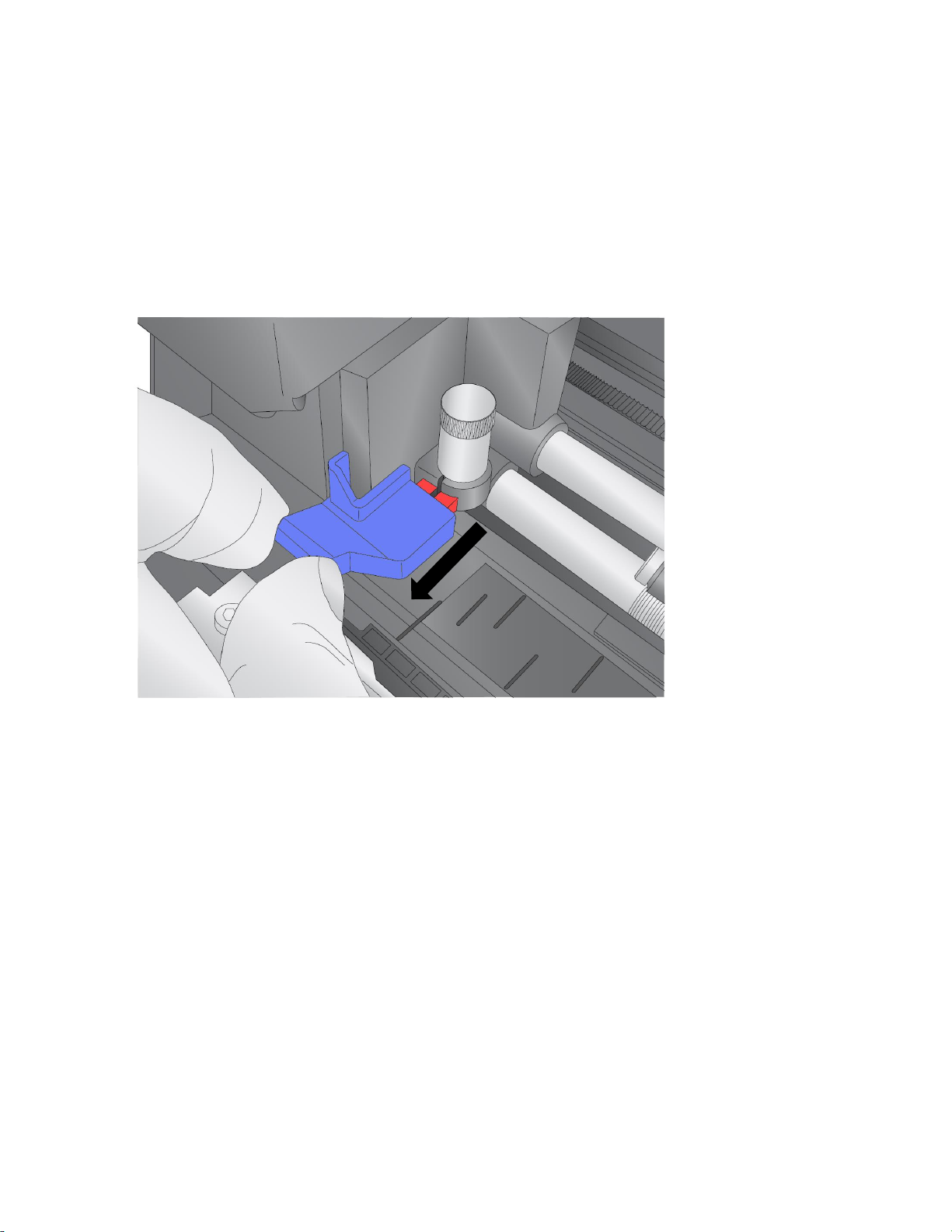

Install the included die cutting knife shown here.

1. Open the Cover

2. Pull out on the blue handle to loosen the knife collar.

26

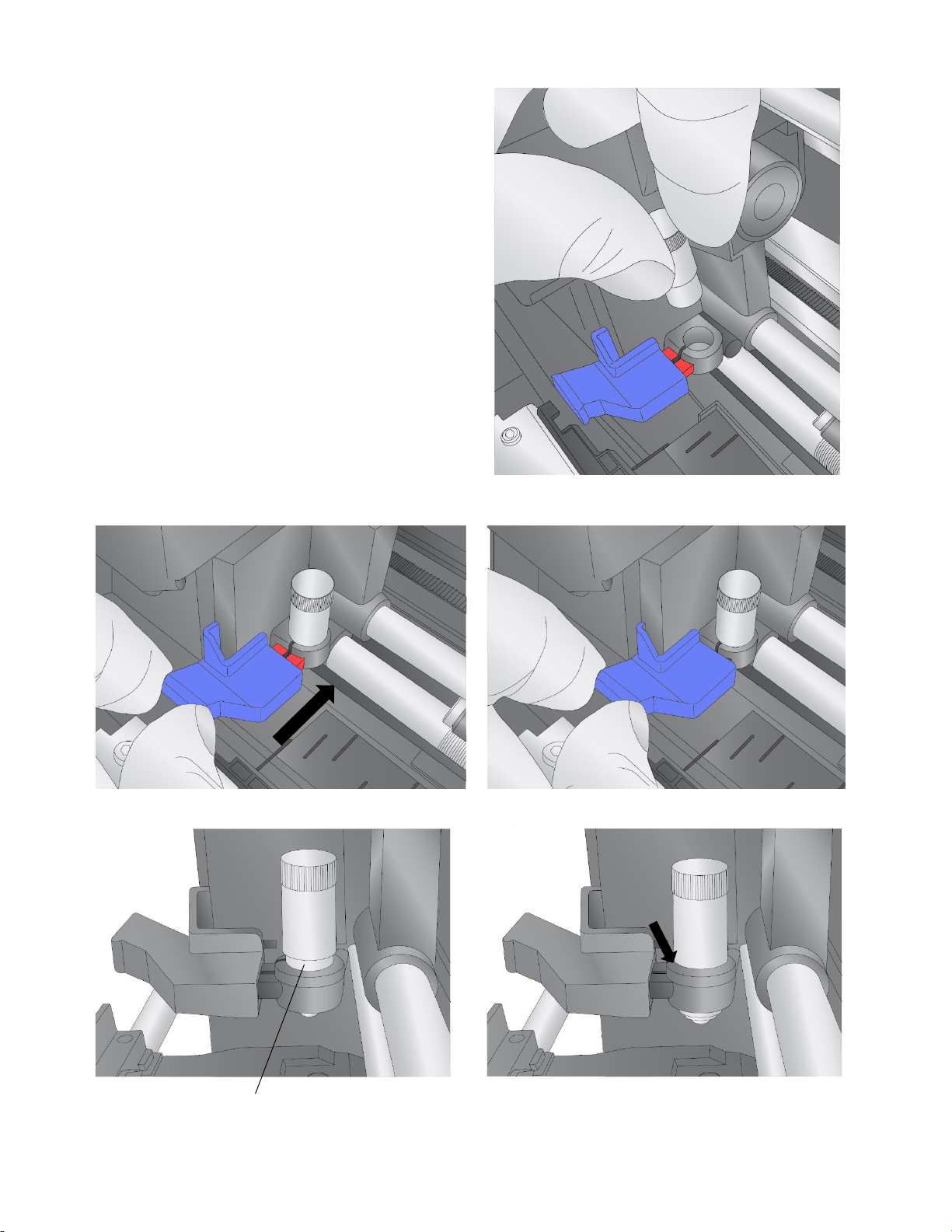

3. Install the knife holder.

4. Push on the knife so it goes all the way down

before pushing the collar in.

5. Push the collar to tighten the knife holder

and allow it to cut.

Incorrect

Correct

27

2E Replacing the Cutting Knife

When a knife is dull it will no longer cut through the label at maximum pressure. You will start to

see ragged cuts or cuts that do not cut all the way through the label material. You can attempt to

increase the pressure but you’ll probably need to replace the knife.

If a knife cuts through the liner and contacts the wear strip it may break the tip of the knife. This

can be seen under 10x magnification using a loupe or magnifying glass. If the tip is broken the knife

must be replaced.

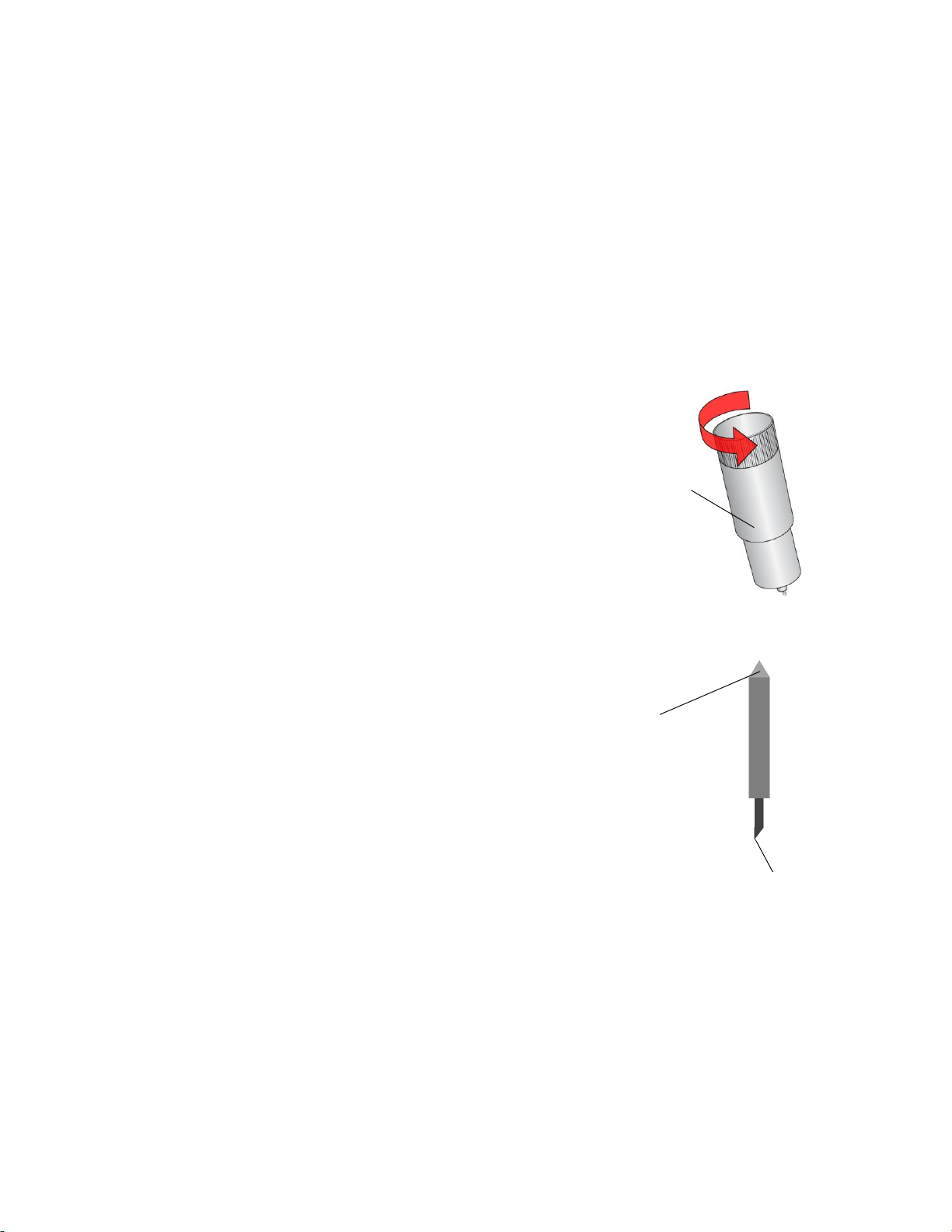

If your knife needs replacement, follow this procedure:

1. Remove the knife holder from the carrier using the instructions from

section 2D.

2. Rotate the cap of the knife holder counter clockwise.

3. Remove the knife from the holder. You can tap the holder on a hard

surface to free the knife from the holder.

4. Locate a new knife. Remove the molded plastic cover from the knife. The plastic cap covers

the cutting end of the knife. However, both sides are sharp! The cutting end has an angled

carbide tip. The top end comes to a point so it can be easily centered in

the receiving divot on the knife holder cap.

5. Insert the cutting end into the knife holder.

6. Using the knife holder cover center the back end of the knife in the

holder. You may need to screw down the cover and reverse it several

times until the knife has been centered. Do not force the cap on the holder. The

carbide tip will break. A very light amount of force is necessary to secure the

knife holder cap.

Replacement Cutter Knife 5 pack Part Number: 074332

Replacement Knife Holder Part Number: 074548

Knife Holder

Carbide Tip

(Cutting End)

Centering

Point

Knife

28

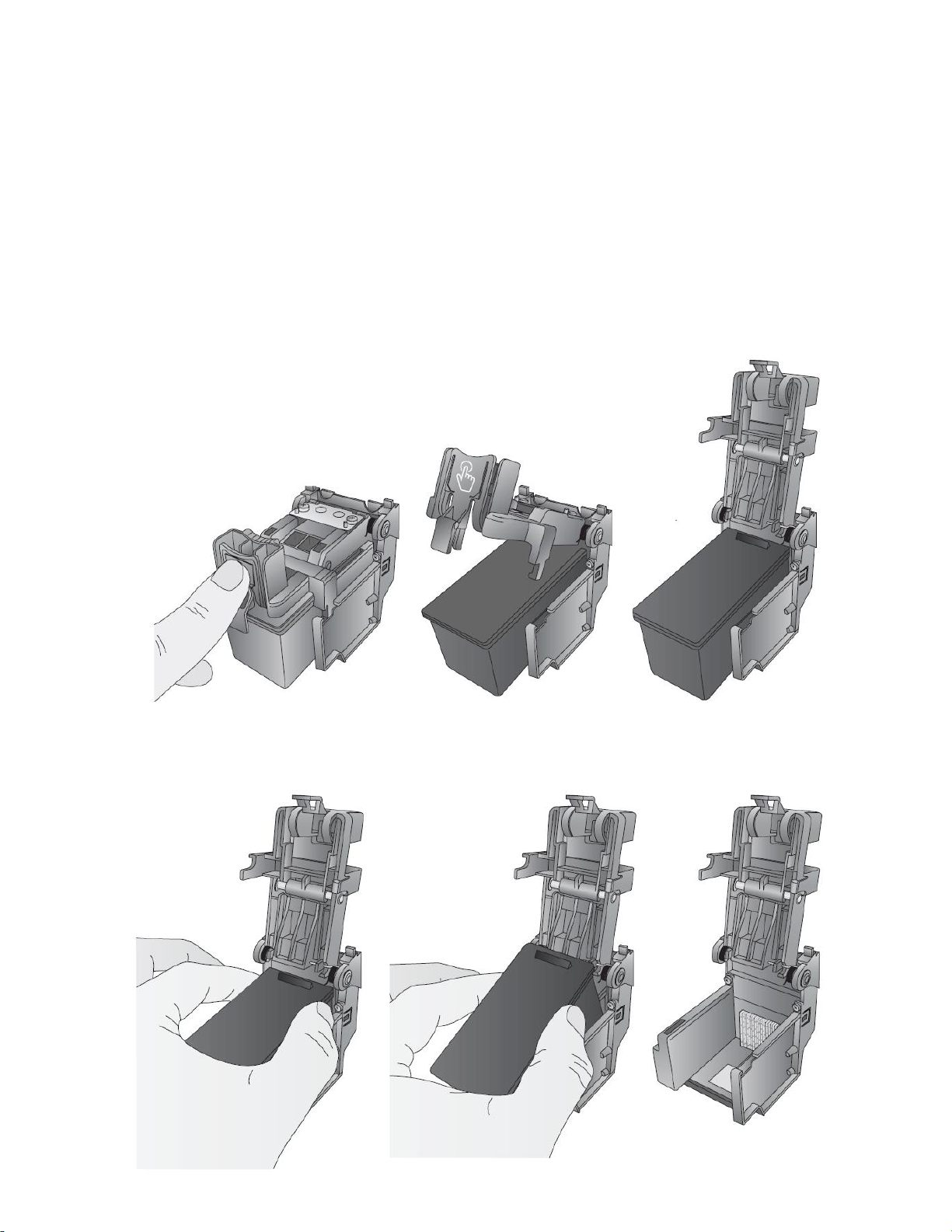

2F Replacing Ink Cartridges

You can replace cartridges at any time or wait for the Low Ink Warning to prompt you to replace

cartridges. You will receive low ink warnings at 10% and 0%. Press the Load/Feed button to continue

printing after you receive this warning.

To change a cartridge, follow this procedure:

1. Open the front cover. That cartridge will automatically move to the right side if it is not

already there.

2. Press or pinch the tab on the front of the cartridge holder.

3. Remove the cartridge.

29

4. Locate a new cartridge and remove it from its packaging. Remove the foil outer package and

the tape covering the nozzles.

5. Place the new cartridge into the empty carriage. Note: When installing the cartridge, tilt the

cartridge at a slight backward angle of approximately 30 degrees.

6. Make sure the cartridge is pushed back far enough so the ridge on the cartridge is behind

the spring-loaded pusher on the lid. Push down on the cartridge. Close the lid on the

cartridge by lightly pressing down from the top until you hear a click.

PUSH DOWN

30

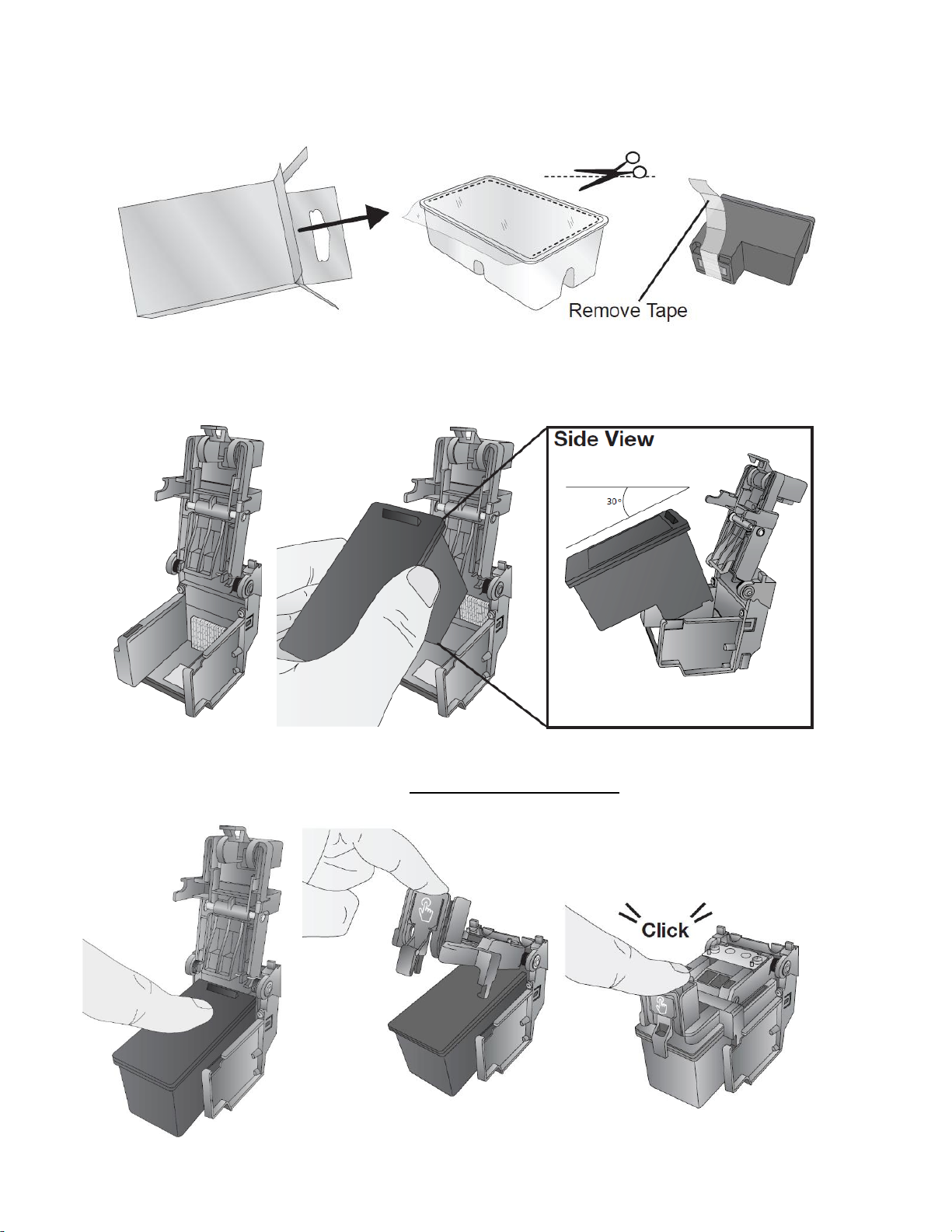

2G Adjusting the Gap Sensor Position (Pre Die-Cut Labels Only)

If you are using label stock other than standard square / rectangular die-cut labels such as circular

die-cut labels or through-hole stock use the instructions below to adjust the position of the label

stock gap sensor. The sensor can be adjusted using the slide bar on the back of the printer. Below

the slide bar is a measurement which represents the distance between the edge of the label stock

and the sensor. Measure the distance from the edge of the label stock to the correct position on the

stock. Set the sensor so the side of the slide bar lines up to this measurement. See dashed line in the

illustration below.

Circular Labels

If you are using Circular Labels you must adjust the stock sensor to correspond with the very top of

the label where the circles are closest together. If the sensor is too far to the right or the left the

printer will still sense the label but the image may be offset downward because the printer will start

printing at the wrong position. If you are using stock that has multiple labels across, make sure the

sensor corresponds to a place on the stock that has a label and not a vertical gap

Important Note: You must adjust the stock sensor

before loading nonstandard label stock.

31

The sensor can only be moved a maximum of 2 inches from the left side of the printable area. This

means that the maximum diameter circular label that can be printed is 4 inches. For circular labels

larger than 4 inches in diameter, you must have a black mark printed on the back of the label stock.

This means that you must change the Stock Sensor Mode to Reflective. The printer will now look for

the black mark representing the beginning of the next label instead of the die-cut. For more

information on changing the Stock Sensor Mode see section 3C.

32

Section 3 Primera PrintHub

Primera PrintHub is used to interact with the printer for gathering ink levels, maintenance,

alignment, cost calculation and several other functions. You can use it to manage these functions on

multiple LX610 printers and other Primera label printer models. PrintHub automatically installs with

your printer driver and can be accessed through the printer driver preferences or as a program on

your Windows start menu.

1. Connect the printer via USB and turn on the power. The PrintHub accesses most of the

information it uses from the printer itself so the printer must be turned on and

communicating for the program to be useful.

2. Go to Start - Programs - Primera Technology - Primera PrintHub.

A. Adjust alignment, sensor mode, output mode and advanced settings.

B. If you have multiple Primera printers connected, they will be listed here.

C. Past jobs will show the last 5 jobs along with cost information. Click the document icon to

view a cost report.

D. Application Settings

E. Print Queue shows the currently printing job.

F. Order Link

G. Frequent Activities

H. Current Ink Levels (Ink is displayed in 10% increments. Example 100% to 90% to 80% etc.)

I. Digital Die Cutting Media Status and Remaining Amount (If installed)

33

3A Adjusting Knife Pressure and Stretch Factor

Knife Pressure and Stretch Factor settings can be found in Primera Print Hub on the Printer Settings

Tab for the LX610. Click the Advanced Settings button to view these settings.

Pressure affects how deep into the media the

knife will cut. Ideally you want to cut deep

enough to cut through the label layer on the

top but not so deep that you cut through the

backing paper. When you cut through the

backing paper your label will not peel cleaning

off the backing paper. You will also score the

wear strip under the cutting knife. It will then

need to be replaced more often.

By default, the cutter is calibrated to work with

High Gloss Paper Media. However, other

media types will need more or less cut pressure

to cut properly.

Each roll of media will have a recommended

value to add or subtract from the default

baseline value used for High Gloss media. The

default value is zero. For Magnetic media,

34

stretch factor will need to be adjusted to compensate for the thicker material and different feed

speed.

Adjusting Knife Pressure over time.

Eventually, the knife blade will begin to wear and require more cut pressure to cut at the same

depth as when it was brand new and sharper. Therefore, you may need to add cut pressure when

cutting any media even the High Gloss Paper.

To determine if cut pressure needs to be increased or decreased, follow these steps.

1. Print and Cut 1 copy and then attempt to peel the label from the liner.

2. Check for tear. If the label tears when you remove it, you will need to increase the cut

pressure. Increase pressure in small increments to avoid over compensating and cutting

through the liner.

3. Check the liner. Once you peel up the label, check the liner. If it has been cut through,

decrease pressure.

4. Continue increasing or decreasing pressure until the label no longer tears when

removed or the liner is not cut through.

35

3B Using the Cost Estimator

The cost estimator is found under the queue section on the first tab of the PrintHub. The last five

job costs are stored in the list. Each job will show the cost per label based on the cost per cartridge

entered below the list. Enter the actual cost of the cartridge you paid. Prints remaining on the

currently installed cartridge and total prints on new cartridge are both displayed.

To see a printable/savable report click on the document icon next to the job you want to see. A

report will display the information. You can print or save the report from this screen. You can also

change the currency using the drop down, change the job name or adjust the cost from this screen.

36

3C Set the Gap Sensor Mode (Pre Die-Cut Labels Only)

The stock sensor mode refers to the method the printer will use to detect the print starting position

for each label. To adjust the stock sensor mode, open the PrintHub. In most cases you will NOT need

to change this setting. By default, it is set to sense standard Pre die-cut labels. It is only necessary to

change this setting if you are using clear labels or any label with a black sensing mark on the back.

When you install Digital Die-Cutting Label Stock this setting will automatically be set for you.

1. Connect the printer via USB and turn on the power. The Stock Sensor Mode setting is stored

in the printer's internal memory so you will not be able to access it unless the printer is

turned on and properly communicating with the computer.

2. Go to Start - Programs - Primera Technology - Primera PrintHub.

3. Click on the Label Feed (3rd tab from left).

4. Select the Stock Sensor Mode by clicking on the graphic that most closely corresponds to the

stock you intend to install.

5. Load the label stock after you have set the sensor mode

There are three sensor modes:

Die-Cut (Default). If you are using standard die-cut labels that look similar to the graphic, use this

setting regardless of the size of the label. Also, use this setting for Through-hole label material

where a hole is punched through each label or a notch is cut in the side.

Reflective. Use Reflective for label material where a black pre-printed line (black mark) on the back

of the label stock indicates the break between labels. Black marks are required on clear label stock

rolls, or label where the label waste matrix (waste) is left on the liner. Black marks can also be used

37

for irregular shaped labels, circles larger than 4 inches or on any stock where the print starting

position cannot be sensed using the label itself.

Continuous. (Sensor off) If you have continuous stock with no die-cut, reflective mark or holes, set

the sensor type to Continuous. This will turn off the stock sensor. In this mode there is no way to set

the print starting position. The printer will simply start printing the first label and print each

subsequent label immediately after that previous one. To produce a gap between prints simply add

the desired amount of white space to the end of the label being printed. The printer will

automatically switch to this setting when Digital Die Cutting Label Stock is installed.

Important Note: You must also set the Stock Sensor Position (Section 2G)

38

3D Set the Present/Cut Mode

Use the Present/Cut Mode to adjust how the printer presents labels after they are printed or

if/when they are cut after printing. To adjust the Present/Cut Mode, open the PrintHub program.

1. Connect the printer via USB and turn on the power. The Output/Cut Mode Setting is stored

on the printer main board so you will not be able to access it unless the printer is turned on

and properly communicating with the computer.

2. Go to Start - Programs - Primera Technology - Primera PrintHub.

3. Click on the Label Feed Tab.

4. Click on the Output/Cut Mode button. There are different options available which change if

the Cutter is enabled or disabled. If the Cutter is disabled, the label present options will be

available. If the Cutter is enabled the present options are no longer available but cut options

become available.

Cutter Options

Cut after button press. This setting will cut after you press the Load/Feed button on the printer.

This can be used after one label or an entire job. This feature is useful if you will not be present at

the end of the print to catch the cut label.

Cut after label count. This option will cut after the number of labels specified in the toggle box that

appears when this option is selected. This is useful if you have front/back labels or sets of labels.

Cut after no activity. This setting will cut at the end of a print job if the printer does not receive

another print job within one second of the last print job in the queue. You can use this feature to

cut at the end of multi-copy job, multi-page job or multiple individual jobs in the queue.

Cut every label. This setting will cut after every label.

39

Present Options

Do not present. In this mode the label stock does not move after the last label is printed. This

means that part of the last label printed is still in the printer. This should be used only if you have a

label rewinder attached.

Present after no activity. This setting will present (feed all printed labels past the front opening) at

the end of a print job if the printer does not receive another print job within one second of the last

print job in the queue. You can use this feature to present at the end of a multi-copy job, a multipage job or multiple individual jobs in the queue.

40

3E Adjusting Print Alignment

If your previous experience with printing is limited to printing letters and cards to 8.5 inch by 11

inch paper you probably are not familiar with an essential part of a label printing - Print Alignment.

Standard printers feed a sheet and start printing based on the start of the sheet. They also prohibit

printing to the edge of the sheet. This is to avoid any need for alignment.

The LX610 senses the beginning of the label with an optical sensor and is capable of printing to top,

bottom, left and right edge. Because of this it is necessary to align the printer to work with specific

types of label stock.

The LX610 comes factory calibrated to print exactly to the edge of Primera label stock. However,

due to variations in the left margins and other variables it may be necessary to fine tune these

settings at the beginning of each roll. This is especially true for other non-Primera brand label stock.

Adjust print alignment using the PrintHub. Go to the Print Alignment Tab (second tab).

41

Click on Test Alignment to print the alignment shown to the right.

Look at the print to determine how much white space is visible on

the edges. The black lines should print right on the leading edge

and left edge. In this example the Top of Form needs

approximately - 10.

1. Left Margin Offset. This value moves the printed label left

or right. Add to the current value to move the printed label

to the right. Subtract from the current value to move the

printed label to the left.

2. Top of Form (TOF). This value moves the print start position

up or down on the label. Add to the current value to move

the printed label down or toward the printer. Subtract from the current value to move the

printed label up or away from the printer. The value is automatically saved as soon as you

set it. You may have to make several adjustments to one or more of these values. After each

adjustment you can click the Test Alignment button to print a small test pattern on the label.

This will help you find the proper alignment value.

3. Tear off/Cut Position. This value adjusts the position of the last label printed after it has

been presented. This only applies if the output mode is set to "Present the label." Add to the

current value to move the tear point closer to the printer. Subtract from the current value to

move the tear point away from the printer. The value is automatically saved as soon as you

set it.

Adjust

Top of Form -10

42

3F PrintHub Settings

General application settings that apply to the software and all printers can be found by clicking the

blue “Settings” button in the lower left. Printer specific settings can be found on the “Printer

Settings” Tab. See next section.

Language. Typically, the language is set to match the language setting in the operating system.

However, you can override currency settings on the Language Tab.

Automatic Updates. Automatic Updates will update PrintHub, the printer driver and the printer

firmware. Every 7 days you will be prompted to update the software if there are any newer

versions. You can choose to increase or decrease that automate check. You can also perform a

check for updates immediately by clicking the “Check for Updates” button. Finally, if you would like

to receive beta software check the “Check for Beta updates” box

Printing Preferences. You can choose to close PrintHub after printing completes by checking the

“Close this application after printing completes” box. PrintHub automatically opens whenever you

send a print job to the printer. If you do not want PrintHub to open in front of other programs, you

can check the “Launch minimized during print” option.

Support. Click the “Generate Support Report” button to generate a zip file on your desktop

containing all recent log files. Send this to tech support so they can help solve any printing

problems.

43

Advanced. Check the “Generate Printer Status XML” box to create an XML at

"C:\ProgramData\PTI\PrintHub\PrinterStatus.xml".

Software developers can use this file to display status information such as error messages and ink

levels in 3rd party applications.

44

3G PrintHub Printer Settings

Printer settings can be found in Primera Print Hub on the Printer Settings Tab for the LX610.

Information. This section displays all current driver, software and firmware versions.

Advanced Setting Button. Click the Advanced Settings button to view the following settings.

45

General Settings

3G1. Multiple Printer Support.

You can install multiple printers to the same computer and use them simultaneously. To do so you

will need to change the USB serial number identifier of one of the two printers, two of three

printers, three of four printers etc. To change serial numbers:

1. Connect each new printer one at a time. The current USB Serial Number will be displayed.

2. Click Generate. It will find the next available USB Serial Number based on the currently

connected printers. For the first one it should set it to 2 and for the next printer 3 and so on.

3. Click Set. You will hear the printer reset and the settings window will turn gray. After it

resets you will be able to see the settings window again. Keep the printer connected.

4. Now you can connect the next printer. Windows will automatically install a new driver for

that new printer and name it Color Label 610 (Copy 1). You can rename it later by editing the

printer properties in the Windows printer list.

5. You will now see a second printer appear in the left column – Color Label 610 (Copy 1). Click

on it to display information about this printer. If this is the last printer, you will connect you

are done. If you wish to connect additional printers follow through steps 2-4.

Restore Factory Defaults. This will set all Print alignment and other calibration settings back to

factory defaults.

Cartridge Settings. Here you can adjust the frequency of certain maintenance operations. Increasing

the value of “Seconds between Maintenance Spits” will decrease ink usage but could also cause

poor quality printing.

Increasing or Pages between Maintenance Wipes will speed up printing but could also cause poor

quality printing.

Check the Suppress Alignment message to prevent the window from appearing which prompts you

to align the cartridge every time a new cartridge is installed. Skipping the alignment is faster but can

result in poor print quality.

Stock Feed Settings.

Adjust these settings only if directed to do so by Tech Support.

Calibrate the paper sensor if you are receiving TOF errors. The calibration process will prompt you

to remove all paper/stock from the printer before calibrating.

46

Section 4 Printing and Cutting with PTCreate

PTCreate is everything you will need to layout your prints and cuts for your LX610. It can be used to

print only or Print and Cut. Every object that you place in your layout, can be set to print only, cut

only or Print and Cut. There are two different versions. The Standard version comes with the

printer. The Professional version can be purchased. Both require an activation code. The activation

code for the Standard version that came with your printer can be found on a label attached to the

bottom of your printer and with the printed documentation that comes with your printer.

4A Overview (Standard version vs Pro version)

47

1. Layers. (Pro Version Only) Layers allows you to see and manipulate layers of imported

SVG files or elements added within PTCreate. SVG files can be created in programs like

Adobe Illustrator.

2. Import and Trace. Import allows you to flat files (Pro and Standard) and vector files (Pro

Only) which can be a graphic you would like to print, a cut file or both in the same file.

Trace allows you to create a cut file be tracing a JPG, BMP or TIF or other flat file that you

have imported. This is a great option for creating complex cut files without needing

another expensive and complex design program.

3. Advanced Design Tools. (Pro Version Only) Advanced design tools such as Gradient, Eye

Dropper, Eraser, Freehand drawing and the Shape Node Tool allow you to create your

own design in PTCreate.

4. Document, Position and Size, Fill and Stroke, Style, Text. These tabs all manipulate

existing objects on the page. Document controls the artboard or page size. Position and

size allow you to precisely move objects on the page. Fill and stroke allows you to change

the color of lines. Style allows you to change whether a particular object should be cut,

printed or both. Text allows you the change font and size of text objects.

a. Document. Use this tab to adjust the page size after it has already been setup.

Sometimes you may need to increase the height the page to accommodate a

bleed or multiple rows.

b. Position and Size. You will use this tab to move both the cut line and the image

on the page. It is much easier than trying to drag and drop images manually.

48

c. Fill and Stroke. Use this to change the line style of the cut. For the most part you

should leave these settings at their defaults. If you are having trouble seeing your

cut line, you can change the color of it here.

d. Style. Here you can designate whether any object should be Print, Cut or both.

By default all images imported using the import icon will be set to Print. Also, all

objects drawn using the rectangle or circle tool will be set to Cut. However, this

tab will allow you to adjust this if necessary.

e. Text. The text tab allows you to adjust the font, size and other properties of text.

Text can be added using the Text tool from the left side tool bar.

5. Library. The library contains some preset

shapes that you can apply to your

document as cut objects or print

objects.

6. Page Layout. This area shows your

actual image. You can move objects

here by clicking and dragging. You

can also see where the cut will be

made in relation to your print. In the

example above the cut line is

highlighted red and inset (overbled)

slightly so there will unprinted area on the

label

49

4B PTCreate Software Activation

You will need to activate either the Standard or Pro versions of your PTCreate software.

If you purchase the Pro Version you will be sent an activation code in your purchase confirmation.

If you use the Standard Version you will find your activation code on a card in printed material that

came with your printer -OR- on a label placed on the bottom of your printer.

To Activate follow the activation prompt that appears when you open the software or go to the

Help Menu - Activate

An activation windows will appear. Enter your 30 digit activation with the dashes included. Click OK.

50

The software is now activated on this computer.

Important Note: Activation requires internet access!

51

4C Software Deactivation

To move the activation to another computer you will need first remove the activation from this

computer.

To remove activation, go the Help Menu – Deactivate…

A confirmation prompt will appear.

Important Note: Deactivation requires internet access!

If you are unable to deactivate because of a computer crash, please contact tech support to receive

another activation code. If you have the Pro version, please have your order number ready to

speed up the process.

52

4D Tutorial How to setup a Print and Cut in PTCreate Standard

This tutorial will walk you through the basic steps to print and cut a label.

4D.1 Choosing a Label Size (Page Layout)

After you activate your software you will be prompted to open or create a new project.

1. Choose New Project…

2. Set your page size. Since all die cutting media is 4.25” wide the standard maximum width is

automatically set to 4.25. In this example we have set the size to 4.25 x 3 to accommodate

approximately a 4” x 3” label.

Tip! Set your page larger than the

label size to be cut. This will allow

you to create a bleed around the

label so that you always cut inside

your print and get perfect cut every

time.

53

3. To set the page height or width to a custom size type the size in the W: and H: boxes or

toggle the size up or down with the arrows.

4D.2 Import a flat Image (JPG, BMP, PNG, TIF, GIF)

PTCreate Standard allows you to import flat files for printing only. You can import the following

image formats: JPG, BMP, PNG, TIF, GIF.

Important Note: Primera recommends imported images are at least 300 DPI. The software is

optimized for this size. Larger DPI images can be manually resized. Smaller DPI images will not

utilize the maximum quality of the printer and may appear pixelated. Images downloaded from

websites are typically made to display only onscreen load quickly so they are typically only 72 DPI.

To import an image for printing follow these steps.

1. Go to the File Menu or shortcut bar, choose Import.

54

2. Browse to the file you would like to use and choose Open.

3. The file will appear on your page layout.

4. You can manually move it on your page or increase the size. However, a better option is to

use the Position and Size window. Set the size to match the size of the page layout. In this

case set the width to 3.25” and check the Keep Proportions box.

55

5. Center the image horizontally and vertically to the Page.

4D.3 Add a Cut file

In PTCreate Standard you can either draw a box in the approximate location of the cut file or use

one of the preset size from the library. If you have a rectangular label or you would like to add a

corner radius to your cut it is preferable to draw the cut line. Corner radius make it easier to

remove your label from the liner. In this example we will draw the cut line.

1. RIGHT CLICK on the

rectangle icon and choose

Rounded Rectangle.

56

2. Before you start to draw the cut line, adjust the corner radius. You will not be able to

change this after you draw your cut line. The corner radius is the amount of curve around

the corners. .125 in (1/8 Inch) is the standard corner radius.

3. Draw the cut line by hovering your mouse over the top left corner of your design. When you

are ready to start, left click and hold to start the rounded rectangle box. Keep holding the

left mouse button and move to the lower right corner of your design. Let go of the mouse

button when your box is the approximate size you would like it. We will adjust the exact size

and position in the next step but to maintain a proper corner radius it is important to get as

close as possible in this step.

57

4. Once the cut line is in place you can adjust its size and positon. Whatever size you choose

will be the exact size of final cut label. A typical overbleed is 1/16”. This will ensure that the

cut is completely within the printed label every time so you have no white space around the

edges.

a. First select the cut line using the arrow tool. TIP: If you are having trouble selecting

the object, first select any object and then press the TAB key to move the selection

from object to object.

b. Then change the size. Adjust the size to 1/16 (.0625”) less than the height and width

of the print. In this example the cut file would be 3.937 x 2.937. You may have to

uncheck the Keep Proportions box.

c. Finally adjust the position by centering horizontal and vertical alignment to Page.

58

4D.4 Print.

To print go to the File Menu and choose Print or click the Print Icon on the shortcut bar. The print

dialog will appear. Make sure Print+Cut is selected. Click the Properties button to access the printer

settings such as Print Quality, Saturation and Color Matching. For a full explanation of printer driver

settings see section 5E

Note: Before printing we recommend

clicking the print Preview Button

described in section 4H

59

4E: Tutorial: How to Setup a Print and Cut using PTCreate Pro – Vector File Cut

If you have a designer that is able to use an advanced program like Adobe Illustrator or Corel Draw,

you can save your print file and cut file together as a multi-layer vector file in AI, EPS, or SVG format.

You can then import them into PTCreate and designate which layer will be the cut and which will be

the print. This will allow you to create complex cuts in exactly the right shape and exactly the right

position. This method is the best way to get the highest quality print and cut. While tracing the

image using the steps in the previous section will allow you to create the same shapes, you can save

time and create a smoother cut file using this

method.

Important Note: Before you start with PTCreate, your

designer should create the print and cut line together

and save them as two separate layers in the same

file. You’ll be able to see these layers when you

import the file into PTCreate.

4E.1 Choosing a Label Size (Page Layout)

After you activate your software you will be prompted to open or create a new project.

1. Choose New Project…

2. Set your page size. Since all die cutting media is 4.25” wide the standard maximum width is

automatically set to 4.25. In this example we have set the size to 4.25 x 6 to accommodate

approximately a 4” x 6” label.

Cut Layer

Print Layer

60

3. To set the page height or width to a custom size type the size in the W: and H: boxes or

toggle the size up or down with the arrows.

4E.2 Import a flat Image (JPG, BMP, PNG, TIF, GIF)

PTCreate Pro allows you to import vector files for printing and cutting. You can import the following

vector image formats: PDF, AI, EPS, SVG

To import an image for printing follow these steps.

6. Go to the File Menu or shortcut bar, choose Import.

Tip! Set your page larger than the

label size to be cut. This will allow

you to create a bleed around the

label so that you always cut inside

your print and get perfect cut every

time.

61

7. Browse to the file you would like to use and choose Open.

62

8. The file will appear on your page layout. You can manually move it on your page or increase

the size. However, a better option is to use the Position and Size window. Set the size to

match the size of the page layout. In this case center the image to the page.

63

Outline

4E.3 Working with Layers in an Imported Vector File

Once you have imported the vector file you view the layers in the layers window.

The cut file must separated from the design at the top level. It cannot be buried

under other layers that will be printed. In this example the cut line layer is setup

in Illustrator as an Outline instead of a Fill. Either will work but Outline is

preferable.

9. To view the sublayers and find the cut line click on the arrow to open up the group.

Click Arrow to open layer groups

Note: Before printing we recommend clicking the print

Preview Button described in section 4H

64

10. Once you find the cut line, select that layer and click the style tab above.

A. Choose Cut Only!

B. Set Style to Blackout.

11. Now select the Print layer, click on the stye tab above and choose Print Only!

12. To print go to the File Menu and choose Print or click the Print Icon on the shortcut bar. The

print dialog will appear. Make sure Print+Cut is selected. Click the Properties button to

access the printer settings such as Print Quality, Saturation and Color Matching. For a full

explanation of printer driver settings see section 5F.

Layer to be Printed

Layer to be Cut

65

4F Tutorial: How to Setup a Print and Cut using PTCreate Pro – Contour Cut

This tutorial will walk you through the basic steps to print and cut a label using the trace image /

contour cut feature found in the Professional version of PTCreate.

4F.1 Choosing a Label Size (Page Layout)

After you activate your software you will be prompted to open or create a new project.

1. Choose New Project…

2. Set your page size. Since all die cutting media is 4.25” wide the standard maximum width is

automatically set to 4.25. In this example we have set the size to 4.25 x 4.25 to

accommodate approximately a 4” x 4” label.

Tip! Set your page larger than the

label size to be cut. This will allow

you to create a bleed around the

label so that you always cut inside

your print and get perfect cut every

time.

66

3. To set the page height or width to a custom size type the size in the W: and H: boxes or

toggle the size up or down with the arrows.

4F.2 Import an Image.

PTCreate Pro allows you to import flat files and vector files. You can import the following image

formats: AI, EPS, PDF, SVG, JPG, BMP, PNG, TIF, GIF.

Important Note: Primera recommends imported images are at least 300 DPI. The software is

optimized for this size. Larger DPI images can be manually resized. Smaller DPI images will not

utilize the maximum quality of the printer and may appear pixelated. Images downloaded from

websites are typically made to display only onscreen load quickly so they are typically only 72 DPI.

To import an image for printing follow these steps.

4. Go to the File Menu or shortcut bar, choose Import.

67

5. Browse to the file you would like to use and choose Open.

6. The file will appear on your page layout.

7. You can manually move it on your page or increase the size. However, a better option is to

use the Position and Size window. Set the size to match the size of the page layout. In this

case set the width to 4” and check the Keep Proportions box.

68

8. Center the image horizontally and vertically to the Page.

4F.3 Trace Image and create Cut Line

Tracing the images requires a flat file such as BMP, GIF, JPG or PNG.

9. Select the image object that

you just imported. This is very

important. You’ll know it is

selected when the bounding

box appears around the image.

Now click on the Trace Icon.

69

10. There are many options available in the Trace Image window. However, the most important

option is the Contrast. You should adjust the contrast until the preview shows a single green

highlighted image in the shape you would like to cut.

11. Click Update Preview to show the cut lines and the number of points/nodes in your cut file

(if you check Show Nodes). These nodes are the points on your image to which the knife will

travel to cut the label. Don’t worry if your cut line isn’t exactly in the right position or size.

We’ll adjust that later. At this point you are just looking for smooth lines that represent the

correct shape.

70

12. Note the difference in the preview when you increase and decrease the contrast.

Contrast to High: If contrast is too high you will lose the shape detection

and end up with a rectangle cut.

Contrast to Low: If contrast is too low you will end up with extra cut lines

outside of the main cut and potentially the wrong shape. In this example

the cut line is tracing the wrong part of the image.

71

13. Click OK when you are happy with the shape of your cut line. The cut line will appear on top

of your image as a red outline. You’ll see a trace layer appear in the layer window.

72

4F.4 Offset a Cut Path

14. Now you’ll need to offset the cut line inside your image so that you’ll have a bleed. With the

cut line selected go to the Path Menu and select Offset.

15. On the Path Offset Window, check the Inset Offset box and adjust the amount of offset. For

this image we chose 0.040 inches. You’ll see a preview of the new position of the cut line in

black.

73

16. Click OK to change the Offset. The new cut line will appear.

17. To print go to the File Menu and choose Print or click the Print Icon on the shortcut bar. The

print dialog will appear. Make sure Print+Cut is selected. Click the Properties button to

access the printer settings such as Print Quality, Saturation and Color Matching. For a full

explanation of printer driver settings see section 5F.

Note: Before printing we recommend

clicking the print Preview Button

described in section 4H

74

4G Setup multiple identical cuts (Duplicate and Array)

If you intend to print and cut a smaller label such a 2” circle you may want to duplicate that image

and cut line across the page so that you don’t waste material. No matter what your label size is

your page size for die cutting is always 4.25”. It makes sense to fill up that page with as many labels

across as you can. Follow these steps to Duplicate images and cut across the page.

1. Create your page size. In this example we chose 4.25” x 4.25”. You can choose a custom size

to fit your labels. In this case we wanted to choose a height that was able to accommodate 2

rows and two columns of 2.125 x 2.125 cut to 2” x 2”.

2. Import your image using the import Icon.

75

3. Set the Size and Position. In this example we are setting the size to 2.125 x 2.125. Center the

image horizontally and vertically.

4. Create your cut line using the shape tool on the left size tool bar. Right click on the rectangle

icon and choose the circle tool.

5. Draw the circle close to the size of the images. You

don’t have to be accurate on this step since we will

be changing the size and position in the next step.

6. Set the size to correspond to the actual cut label

size you would like. In this case we set the size to

2” x 2 so that we have a standard 1/16” bleed

around the label. Uncheck the Keep Proportions

box. This will make sure that no labels have any

white unprinted areas around the edges.

76

7. Center the cut line horizontally to the page

8. Using the arrow tool select both image and the cut line by drawing a box around them.

77

9. Group them together by going to the Object Menu – Group. This will ensure that cut says

with the image and in the correct relative location while we move and duplicate the image in

the next steps.

10. Align the group image and cut line to the upper left corner.

78

11. Now go to the Object Menu and click Duplicate. Make sure the image and cut line are still

selected otherwise the Duplicate item will not be available.

12. Set the number of rows and columns.

13. Set the gap between the rows and columns.

In this case we are setting the gaps to zero.

We already created a bleed so the cuts will

not intersect or be too close to each other

with zero gap between prints.

14. To print go to the File Menu and choose

Print or click the Print Icon on the shortcut

bar. The print dialog will appear. Make sure

Print+Cut is selected. Click the Properties

button to access the printer settings such as

Print Quality, Saturation and Color

Matching. For a full explanation of printer

driver settings see section 5F.

79

4H Print Preview

Before you print you can click the Preview button to verify what objects will cut and what objects

will print. Check either Show Cut Lines or Show Printable to see what will print or cut.

80

4I Vector File Specifications for Designer

When importing files using the methods described in section 4 <> please make sure the imported file follows

the specifications below:

81

Section 5: Printing only to Pre Die-Cut labels

If you don’t need to cut custom shapes, the LX610 is an extremely capable Pre Die-Cut Label printer.

While PTCreate can print only to the LX610 other dedicated printing programs offer some

advantages.

5A Using BarTender for Pre Die-Cut Printing

Primera recommends BarTender for printing only. A fully functional Free Edition can be

downloaded from the BarTender website.

https://www.bartendersoftware.com/free-edition-download/

When you open BarTender you will be given the choice to select an existing label or create a new

one using a wizard. Use the following instructions as a guide through the wizard setup process.

1. Choose "Start a new BarTender document..."

82

2. Select "Blank Template". Click "Next".

3. Select "Color Label 610". Click "Next".

83

4. Select "Specify Custom Settings". Click "Next".

5. Set the page size, width and height to match labels installed in the printer. Click "Next".

Important: Measure the label stock if you are unsure about the size.

84

6. Select your label shape. This is typically "Rounded Rectangle" for standard labels from

Primera. Click Next.

7. Set all of the margins to zero. (You can adjusted the left margin and Top of Form in the Label

Alignment Section). Click Next.

85

8. Set Rows and Columns to 1 for a standard label. Click Next.

9. Set Template Size to be the same as the label size. Click Next.

86

10. Check the "Picture" box to add a background photo or graphic to your label. Click "Next". If

you click "Finish", the remaining default wizard options will be set and no picture will be

added.

11. Select "Embedded Picture". Click the "File" Button to browse to the location of your

photo/graphic file. Set the Size Method to "Stretch". Note the preview to the right. Click

"Next" if you are satisfied with the layout of the photo or graphic. Otherwise you may try

one of the other Size Methods in the drop down menu.

87

12. Review the label setup summary. If it is correct, click "Finish". Your blank label or label with

background will be displayed.

You can edit any of these initial settings by going to the File Menu and selecting "Page

Setup". Basic and advanced settings are available on the various tabs.

88

5B Add Text, Barcodes and Graphics to a BarTender Label

Once you have created your label size you will be able to add text, a barcode and/or graphics. This

can be done using one of the buttons on the button bar at the top of the screen.

Add Text. Click the Text button. Now

click anywhere on your label.

"Sample Text" will appear. Edit the

text on screen or double click it to

open up text settings to change font,

size and other settings.

Add Graphic. Click the Image button.

Now click anywhere on your label.

An Image icon will appear. Doubleclick it to open up image settings

and browse to the image/graphic

that you would like to insert.

Add Barcode. Click the Barcode

button. Now click anywhere on your

label. A barcode settings window

will appear. Here you can choose

any type of barcode and enter the

value.

Page Setup. Click the Page Setup

button to change your label size,

adjust corner radius or change the

shape.

Tip! Double-click any object to open settings for that object.

Tip! Go to the Help menu to access the BarTender Manual and Tutorials.

89

5C Printing from Other Programs

Since this printer uses a standard Windows printer driver you can print from any application you

would like. There are just a few things to remember that will make it much easier.

1. Set the Page/Label Size in the Driver. BarTender automatically prompts you for the size of

the label that you are using. When printing from any other program you must do this

manually. Before you print, simply set the custom page size just as you would set print

quality in the printing preferences. In the example below the label size is 4" x 3" so the

custom page size is set to 400 x 4300 (displayed in .01 inch units).

2. Check the image or document size. The image size or document size set in Illustrator should

match to the Page/Label Size set in the driver. If you have set your page size to 4" x 4" but

your image is actually 5" x 3" the printer driver will automatically shrink your image to fit

inside the 4" x 4" label. The result is that the actual printed label is 4" x 2.4". Avoid this by

setting your document size or image size to match the label size.

3. Choose the right printing program. There are many different applications that are capable of

printing to the LX610. However, there are only a few that are ideal printing applications. For

example, Adobe Illustrator is an excellent design program but is not always the best printing

program. It can be difficult to find the printing preferences or to know the exact size of the

art board. It is best to save as a PDF file and print from Adobe Reader or export as a 300 dpi

JPG and print from BarTender.

90

5D Creating a Full Bleed Print

To create a label that completely fills the space with no white margins, adjust these settings in the

status monitor and printing application (BarTender). This is only necessary if you are printing to PreDie Cut Label stock. If you are printing and cutting using die cutting media, you can adjust the

position of the cut line to accomplish this.

Page Size. Increase the page size width by .03 inches (1mm). Increase the height by .03 inches

(1mm). If you are using BarTender, simply change the size under the File Menu - Page Setup. If you

are using other graphics programs you will need to change the page size in the application and in

the printer driver preferences.

Left Margin Offset. You must decrease the left margin offset to center the over bleed on the label. If

you over bleed by .03" you will need to decrease the Left Margin Offset by 0.4mm. This will center

the page size increase so there is a .03 inch over bleed on both left and right sides. Some additional

adjustment may be necessary if the label was not perfectly aligned to begin with. See Section 4E.

91

TOF. Increase the Top of Form by 0.4mm. This will cause the printer to start printing before the

label and ensure a fully printed label. Some additional adjustment may be necessary if the label was

not perfectly aligned to begin with. See Section 4E.

Note: It is best to over bleed as little as possible to avoid excess ink on the label backing. Also, over

bleeding too much will cause the printer to skip labels. This is because the printer stops printing too

late to sense the next label.

92

5E Printer Driver Settings

Once the printer driver has been successfully installed, you will need to setup the driver with the

appropriate print options. Refer to the following steps to change or verify your default printer driver

preferences. These settings will apply to all new designs created in BarTender or other programs

after the preferences were changed. Existing labels saved in BarTender will not be affected since the

preferences are saved with the label. To change these preferences, you will have to change printer

preferences through BarTender. (File Menu - Printer Settings)

Click the Start button, search for "Printers". Select Printers and Scanners. Select the Color Label 610.

Choose Manage. Select Printing preferences.

93

Note on PC Settings:

Most applications allow you to change these same printer driver options from their "Print" and/or

"Printer Setup" screens. Some applications such as BarTender save your settings with the label,

others use settings only for the current print job just sent to the printer.

Paper Size

If you are using BarTender, this setting is adjusted during the label setup wizard. If you are using a

program other than BarTender you will need to set this to the dimensions of your label. Keep in

mind that the dimensions are always relative to the width and height of the actual label in the

printer. Orientation of an image on the label should not change this setting. See Section 2A for

minimum and maximum label sizes.

Orientation

There are two settings for orientation, Portrait and Landscape. If your text and graphics print left to

right or as shown on the screen, select portrait. If you wish your printing to rotate 90 degrees from

what you see on the screen so it is printing horizontally, select landscape as your orientation.

Remember, this does not change the width and height Paper Size. It is only a tool for viewing a label

upright on screen that will be printed sideways on the printer.

Print Quality

There are 4 levels of print quality in the driver. The lower the quality, the faster the print. Quality 1

provides the fastest print available while Quality 4 provides the best quality. It is recommended that

you experiment with the different levels when designing your label to find a good balance between

print quality and print speed. Quality 2 is the default.

Color Matching

There are several options available depending on which cartridge is installed (Pigment or Dye). The

options will update automatically depending on which cartridge is installed.

Vivid Graphics mode is best used for graphical images where accurate color reproduction is not as

essential. Images printed in this mode will look more vibrant because more ink is being used to

produce them. However, printing images of people may produce skin tones that have a reddish tint.

Vivid Photos mode is best used for photographic images where accurate color reproduction is very

essential. Images printed in this mode will look lighter than those printed in Vivid Graphics mode.

Skin tones especially will look more natural in this mode.

ICC Gloss Paper, ICC Gloss Polyester and ICC Matte Bopp are all ICC calibrated color matching

options. Select the setting that corresponds to your installed Primera media of the same type to

produce ICC color matched prints. Note: ICC monitor calibration and additional setup is required for

this option to work.

-NONE- will use no color matching.

94

Ink Saturation

This option controls the amount of ink used when printing an image. The default setting is 100%,

which will provide the most accurate color matching. If the ink is not drying fast enough or

"bleeding", you can decrease the Ink Saturation to lessen the amount of ink that is applied to the

label.

Rotate 180 Degrees

Set this setting to Yes to print with the labels right side up as they exit the printer.

Enable Bi-di

Set to "Yes" for fastest print speed. Requires an alignment print after every cartridge change. Set to

"No" for better quality print (in some cases).

Launch PrintHub

This setting will open the Primera PrintHub application.

Details

Select this setting to see current firmware and driver version information and other printer settings.

95

Section 6: Troubleshooting

6A Solving Pre Die-Cut Print Alignment Problems

Image is Vertically Offset (White space can be seen on the top or bottom of the label) The LX610

decides where to start printing by detecting the start of a die-cut label, detecting a black mark on

the back or detecting a thru-hole that corresponds to the start of the label. The following items can