Presto 01745 Instruction Manual

Pressure Canner

and Cooker

Visit us on the web at www.GoPresto.com

Instructions and Recipes

♥2009 by National Presto Industries, Inc.

Table of Contents

Important Safeguards . . . . . . . . . . . . . . . . . |

. |

. |

|

. 3. . . . . . . . |

Getting Acquainted . . . . . . . . . . . . . . . . . . |

. |

. |

. |

4. . . . . . . . . |

Before Using the Canner for the First Time . . . . . |

. |

. . |

.8 . . |

|

Pressure Canning .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

.. |

.. |

|

9 |

How to Pressure Can Foods . . . . . . . . . . . . . . |

. . .11. . . . . . . |

|||

Care and Maintenance . . . . . . . . . . . . . . . . . . . |

16. . . . . . . . . |

|||

Pressure Canning Fruits and Tomatoes . . . . . . . |

. . . 20. . . . |

|||

Pressure Canning Vegetables . . . . . . . . . . . . . . . . 26. . . . . . . |

||||

Pressure Canning Meat . . . . . . . . . . . . . . . . . . .32. . . . . . . . |

||||

Pressure Canning Poultry . . . . . . . . . . . . . . . |

. |

. |

34. . . . . . . . |

|

Pressure Canning Fish and Seafood . . . . . . . . . |

. |

. |

. 36. . . . . |

|

Pressure Canning Soups . . . . . . . . . . . . . . . |

. |

. |

. 38. . . . . . . . |

|

Helpful Hints For Pressure Canning . . . . . . . . . |

. |

. |

39. . . . . |

|

How To Can Foods Using Boiling Water Method . . |

. . |

.41. |

||

How to Pressure Cook Foods in Your Pressure Canner |

|

. . |

44 |

|

Important Safety Information . . . . . . . . . . . . . . . |

47. . . . . . . |

|||

Helpful Hints for Pressure Cooking .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. |

.. |

.. |

50 |

|

Pressure Cooking Meat . . . . . . . . . . . . . . . . |

. |

. |

.51. . . . . . . . |

|

Pressure Cooking Entrees . . . . . . . . . . . . . . . |

. |

. |

57. . . . . . . . |

|

Pressure Cooking Poultry . . . . . . . . . . . . . . . |

. |

. |

61. . . . . . . . |

|

Pressure Cooking Dry Beans and Peas . . . . . . . . |

. . .64. . . . |

|||

Pressure Cooking Soups . . . . . . . . . . . . . . . . . . .67. . . . . . . . |

||||

Pressure Cooking Desserts . . . . . . . . . . . . . . . . . |

69. . . . . . . . |

|||

Recipe Index . . . . . . . . . . . . . . . . . . . . . . |

. |

. |

.73. . . . . . . . . |

|

Service and Parts Information . . . . . . . . . . . . |

. |

. |

.75. . . . . . |

|

Warranty . . . . . . . . . . . . . . . . . . . . . .Back. . . cover. . . . . . .

This is a  Listed appliance. The following Important Safeguards are recommended by most portable appliance manufacturers.

Listed appliance. The following Important Safeguards are recommended by most portable appliance manufacturers.

IMPORTANT SAFEGUARDS

To reduce the risk of personal injury or property damage, basic safety precautions should always be followed, including the following:

1.Read all instructions. Improper use may result in bodily injury or property damage.

2.Always check the vent pipe before use. Hold cover up to light and look through vent pipe to be certain it is clear.

3.Always check the air vent/cover lock to be sure it moves freely before use.

4.Do not fill pressure canner over 2⁄3 full when using for pressure cooking. For soup, rice, and dried vegetables which expand during cooking, do not fill canner over 1⁄2 full. Overfilling may cause a risk of clogging the vent pipe and developing excess pressure. See food preparation instructions.

5.Do not pressure cook applesauce, cranberries, rhubarb, pearl barley, cereals, pastas, grains, split peas, or soup mixes containing dry beans or peas. These foods tend to foam, froth, and sputter and may block the vent pipe, overpressure plug, and air vent/cover lock.

6.This appliance cooks under pressure. Improper use may result in scalding injury. Make certain pressure canner is properly closed before operating; cover handles must be directly above the body handles. See “How To Use” instructions.

7.Do not place the pressure canner or attempt to pressure can or cook in a heated oven.

8.Caution: Do not use pressure canner on an outdoor LP gas burner or gas range over 12,000 BTU’s..

9.Extreme caution must be used when moving a pressure canner containing hot liquids. Do not touch hot surfaces. Use handles or knobs.

10.Do not open canner until internal pressure has been completely reduced, air vent/cover lock has dropped, and no steam escapes when the pressure regulator is removed. See “How To Use” instructions.

11.Caution: To ensure safe operation and satisfactory performance, replace the overpressure plug every time you replace the sealing ring or sooner if it becomes hard, deformed, cracked, worn, or pitted. It is recommended

. . that the sealing ring and overpressure plug be replaced at least every three years.

12.Close supervision is necessary when the pressure canner is used near children. It is not recommended that children use the pressure canner.

3

13.When normal operating pressure is reached, the pressure regulator will begin to rock. Gradually lower the heat as necessary to maintain the pressure. If the pressure regulator is allowed to rock vigorously, excess steam will escape, liquid will be evaporated, and food may scorch.

14.Do not use this pressure canner for other than intended use.

15.Do not use this pressure canner for pressure frying with oil.

SAVE THESE INSTRUCTIONS

This product is for household use only.

Getting Acquainted

Your canner is a special, large capacity pressure vessel designed for home canning a wide variety of fruits, vegetables, meats, and poultry. The canner may also be used to fast cook many of your favorite foods in larger quantities than can be prepared in a conventional size pressure cooker.

The canner uses pressure to achieve the high temperatures required for safely processing foods while canning. The United States Department of Agriculture recommends the pressure canner as the only safe method for canning low-acid foods—vegetables, meats, and poultry.

The canner will also cook many foods in one-third to one-tenth the time required by conventional methods. Pressure cooking preserves flavor and nutrients and tenderizes tougher cuts of meat. Information for pressure cooking begins on page 44.

It is necessary to follow a few special rules in using and caring for your Pressure Canner. Become familiar with the various parts as shown in Fig. A on page 5.

7 |

4 |

3 |

2 |

1 |

6 |

5 |

Fig.. A

Note: The Pressure Regulator can be found in the top foam filler of the carton.. It is in a bag identified with the words

“Pressure Regulator Enclosed”.

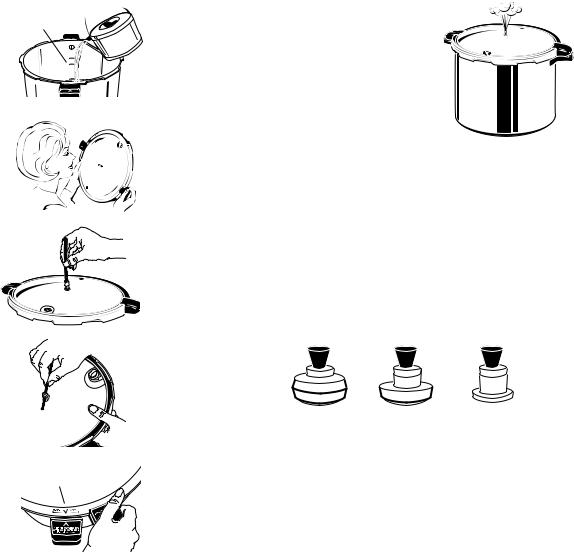

1.. THREE-PIECE PRESSURE REGULATOR

The pressure regulator controls and maintains the correct pressure in the canner. The correct pressure is obtained when the pressure regulator begins a gentle rocking motion.

The regulator can be adjusted to maintain any of three pressure levels (5 pounds, 10 pounds, or 15 pounds). Completely assembled, the regulator will maintain 15 pounds of pressure.

When it is desirable to use another pressure level (see recipe section), the regulator can be adjusted by removing the appropriate number of weight rings (Fig. B, page 6). When one ring is removed, the regulator will maintain 10 pounds of pressure. With both rings removed, 5 pounds of pressure will be maintained.

4 |

5 |

15 pounds |

10 pounds pressure |

5 pounds |

pressure |

|

pressure |

Fig.. B

To remove weight rings, hold the complete regulator between the first two fingers of the hand with the thumb on top of the knob. Press down on the knob to force weight rings over the lock ring. Replace weight rings by pushing them down over the lock ring at the top of the regulator body.

|

2.. VENT PIPE |

|

The vent pipe is the primary pressure relief |

|

valve and will release pressure in excess of |

|

the desired pressure. The pressure regula- |

|

tor sits loosely on the vent pipe. |

Small Gasket |

3.. AIR VENT/COVER LOCK |

|

|

|

The air vent/cover lock automatically |

|

“vents” or exhausts air from the canner |

|

and acts as a visual indication of pressure |

|

in the canner. The small gasket must be |

|

in place for the air vent/cover lock to seal |

|

completely. |

|

4.. LOCKING BRACKET |

|

The locking bracket on the inside of the |

|

canner body engages with the air vent/ |

|

cover lock to prevent the cover from be- |

|

ing opened when there is pressure in the |

|

unit. |

5.. SEALING RING

The sealing ring fits into the canner cover and forms a pressure-tight seal between the cover and body during canning and cooking.

6.. OVERPRESSURE PLUG

The black, rubber overpressure plug is located in the canner cover. It will automatically pop out and release steam in case the vent pipe becomes blocked and/or clogged and pressure cannot be released normally through the vent pipe.

7.. CANNING-COOKING RACK

The canning-cooking rack is placed in the

bottom of the canner to hold jars off the

bottom of the unit while canning. When

cooking, the rack is used for steaming foods. It can also be used to hold foods such as vegetables out of the cooking liquid which allows several foods

cooking, the rack is used for steaming foods. It can also be used to hold foods such as vegetables out of the cooking liquid which allows several foods

to be cooked at the same time without an intermingling of flavors. When it is desirable to blend flavors, do not use the canningcooking rack. The canning-cooking rack must always be used when canning.

REPLACEMENT PARTS

PRESTO Canner parts are available at most hardware stores or they can be ordered directly from Presto; see service and parts information on page 75.

When ordering parts, please specify the seven digit model number found stamped on the side of the canner body.

6 |

7 |

BEFORE USING THE CANNER

FOR THE FIRST TIME

1.Remove the sealing ring by simply pulling it from the sealing ring groove.

2.Wash the cover, body, and sealing ring with hot, sudsy water to remove any manufacturing oils. Rinse all parts with warm water and dry.

3.Replace the sealing ring in the sealing ring groove, making certain to fit the ring under the stop tab located on the inside rim of the cover (Fig. C).

4.The sealing ring is prelubricated. If necessary, to help make the cover easier to open and close, a very light coating of cooking oil may be applied to the sealing ring and underside of the body lugs (Fig. D). The cover should open and close easily when following the instructions on page 12.

Fig.. D |

Cover |

Body Lug |

Stop Tab |

|

Apply |

Fig.. C |

Cooking |

|

Oil Here |

|

Apply

Cooking

Oil Here

Sealing Ring in

Sealing Ring

Groove

HELPFUL HINT: To help yourself understand the operation of the pressure canner, pour 4 cups of water into the canner and follow the step-by-step instructions beginning with step 5 on page 12. For actual usage of the canner, follow the complete instructions beginning on page 11 for pressure canning and on page 44 for pressure cooking.

PRESSURE CANNING

The United States Department of Agriculture recommends the pressure canner as being the only safe method for canning low acid foods—vegetables, meats, and poultry.

There are invisible microorganisms present all around us. Fruits, vegetables, and meat contain these microorganisms naturally, and yet, they are not a problem unless food is left to sit for extended periods of time, causing food spoilage. This is nature’s way of telling us when food is no longer fit to eat.

There are four basic agents of food spoilage—enzymes, mold, yeast, and bacteria. Canning interrupts the natural spoilage cycle so food can be preserved safely. Molds, yeast, and enzymes are destroyed at temperatures below 212°F, the temperature at which water boils (except in mountainous regions). Therefore, boiling water processing is sufficient to destroy those agents.

Bacteria, however, are not as easily destroyed. The bacteria, Clostridium botulinum produces a spore that makes a poisonous toxin which causes botulism. This spore is not destroyed at 212°F. In addition, the bacteria thrive on low acid foods in the absence of air. For a safe food product, low acid foods need to be processed at 240°F, which can be achieved only with a pressure canner.

In pressure canning, some of the water in the pressure canner is converted to steam, which creates pressure within the canner. As pressure increases, temperature increases, 5 pounds pressure— 228°F, 10 pounds pressure—240°F, 15 pounds pressure—250°F.

8 |

9 |

This pressurized heat destroys the potentially harmful bacterial spores. As the jars cool, a vacuum is formed, sealing the food within and preventing any new microorganisms from entering and spoiling the food.

As a safeguard against using canned foods which may be affected with spoilage that is not readily detected, boil all low acid foods and tomatoes for 10 minutes at altitudes below 1,000 feet. Extend the boiling time by 1 minute for each 1,000 foot increase in altitude.

Many times odors that cannot be detected in the cold product will become evident by this method. If, after boiling, food does not smell or look right, discard it without tasting..

MASON JARS: While there are many styles and shapes of glass jars on the market, only Mason jars are recommended for home canning. Mason jars are available in ½ pint, pint, and quart capacities with threads on which a cap may be screwed. See the chart below for the jar capacity of your canner. Additional information may be obtained from the manufacturers of Mason jars.

CLOSURES FOR MASON JARS: The two-piece vacuum cap consists of a flat metal lid held in place with a screw band. A rubber compound on the underside of the lid forms a seal during processing. Follow the closure manufacturer’s directions for using the two-piece cap and for testing for a proper seal. If the closure has not sealed, completely reprocess or use the food immediately. Refer to the closure manufacturer’s directions for additional information.

Maximum JAR CAPACITIES

Regular jars |

Wide mouth jars |

||

|

|

|

|

12 |

half-pints |

8 |

half-pints |

10 |

pints |

8 |

pints |

7 |

quarts* |

7 |

quarts* |

*Do not use the boiling water method with quart jars.

HOW TO PRESSURE

CAN FOODS

IMPORTANT: Read carefully.. Do not attempt to use your canner before reading these instructions..

Follow these step-by-step instructions for pressure canning in your canner. Prepare food according to the directions in specific recipe.

1.Be sure your canner is thoroughly cleaned and working properly. Before each canning season, check the sealing ring, overpressure plug, and the small white gasket of the air vent/cover lock. Replace these parts when they become hard, deformed, cracked, worn, pitted, or unusually soft.

2.Check Mason jars for nicks, cracks, and sharp edges. Check screw bands for dents or rust. Use only jars, lids, and bands in perfect condition so an airtight seal may be obtained.

Wash and rinse jars, lids, and bands. Pour hot water into jars and set aside until needed. Follow closure manufacturer’s directions for bands and lids.

3.Select fresh firm food. Sort food according to size. Clean food thoroughly. Prepare according to recipe. Fill hot Mason jars promptly with food and liquid to recommended level. Allow ½-inch headspace for fruits. Most vegetables and meats require 1-inch headspace due to expansion during processing.

Work out air bubbles with a clean, nonmetallic spatula. Wipe sealing edge clean with a damp cloth.

Adjust bands according to closure manufacturer’s directions.

10 |

11 |

4.Place 3 quarts of boiling water, canning rack, and jars in canner (Fig. E). To prevent water stains on jars, add 2 tablespoons white vinegar to water in canner. Always use canning rack. Jars may break if set directly on bottom of canner.

5.Hold the cover up to the light and look through the vent pipe (Fig. F) to be certain it is open before placing the cover on the canner. If it is clear, proceed to step 6. If it is blocked or partially blocked, clean the vent pipe with a small brush or pipe cleaner (Fig. G). Also clean the vent pipe nut as shown (Fig. H).

6.Place cover on canner, aligning the V mark on the cover

with the V mark on the body handle (Fig. I). Press down on the cover handles to compress the sealing ring and turn the cover in the direction indicated to close (clockwise) until the cover handles are centered directly above the body handles. Do not rotate the cover beyond this point.

Fig.. E

3-quart water line (lowest mark in canner)

Fig.. F

Fig.. G

Fig.. H

Align the V mark on the cover with the V mark on the body handle.

Fig.. I

7. Position canner on a level

burner and range only. Use on a tilted burner or range may interfere with the operation

of the pressure regulator. To prevent damage to the pres-

sure canner, do not use on an outdoor LP gas burner or gas range over 12,000 BTU’s. Using a relatively high heat setting, heat the pressure canner until a steady flow of steam

can be seen, heard, or felt coming from the vent pipe (Fig. J). Exhaust air from the canner for 10 minutes by allowing steam to flow from the vent pipe. Reduce heat, if necessary, to maintain a steady, moderate flow of steam.

8.Assemble pressure regulator (Fig. K) to register the desired canning pressure (see pages 5 and 6 for assembly instructions). See specific canning recipe to determine how many pounds of pressure to use.

15 pounds |

10 pounds pressure |

5 pounds |

|

pressure |

pressure |

Fig.. K

9.Place pressure regulator on vent pipe. If heat was reduced for exhausting, adjust to a relatively high setting and heat canner. As pressure develops in the canner the air vent/cover lock will lift and lock the cover on the canner. The air vent/cover lock is a visual indicator of the presence of pressure. When in the

12 |

13 |

up position pressure is in the unit, when in the down position there is no pressure in canner (Fig. L). Continue heating until the pressure regulator begins to rock. Adjust heat to maintain a slow, steady rocking motion.

Fig.. L |

UNLOCKED |

LOCKED |

Air Vent/Cover Lock |

Air Vent/Cover |

in DOWN Position. |

Lock in UP Position. |

No Pressure in Unit. |

Pressure in Unit. |

10.Processing time begins when the pressure regulator begins to rock gently. Adjust heat to maintain a slow steady rocking motion.

11.At end of processing time, turn burner to “OFF” and remove canner from heat source. Note: Lift pressure canner to remove it from burner. Sliding cookware can leave scratches on stovetops.

12.Let pressure drop of its own accord. Do not attempt to speed the cooling of the canner, which can cause jar breakage, liquid loss from the jars and other problems. Pressure is completely reduced when the air vent/cover lock and overpressure plug have dropped and no steam escapes when the pressure regulator is lifted.

13.When pressure has been completely reduced, remove pressure regulator from vent pipe and let canner cool for 10 minutes. Do not remove the pressure regulator until pressure is completely reduced and the air vent/cover lock has dropped. Always remove pressure regulator before opening the cover.

14.To remove cover, turn counterclockwise until cover hits stop (Fig. M). Cover handles will be beyond the body handles. If cover seems to stick or is hard to turn, do not force it open. Sticking may indicate that there is still pressure inside the canner. If in doubt about pressure being completely reduced, let the canner stand until cool before removing the cover.

15.Lift canner cover toward you to keep steam away from you when opening (Fig. N).

16.Remove jars from canner. Set jars upright on board or cloth, away from draft to cool. When jars are cold, test seal, remove bands, wipe jars, label, date, and store in a cool, dry place.

Fig.. M

Fig.. N

14 |

15 |

CARE AND MAINTENANCE

1.The outside surface may be kept bright and shiny by cleaning with a good silver polish or simply by washing with soap and water. Iron and various minerals in water and foods may darken the inside of the canner but this discoloration will in no way affect food cooked. These stains may be removed by using a solution of water and cream of tartar. For each quart of water, use one tablespoon cream of tartar. Pour enough solution into the canner to cover the discoloration (do not fill over 2⁄3 full), then close cover securely. Place regulator on vent pipe and heat until 15 pounds pressure is reached. Remove canner from heat; allow canner to stand two to three hours. Remove regulator, open canner, and empty contents. Scour thoroughly with a soap impregnated steel wool cleaning pad; wash, rinse, and dry.

Due to the acidic nature of the water supply in some areas, deterioration of the interior surface of the canner body may occur. To minimize this effect, thoroughly scour the inside of the canner body with an abrasive cleanser at least once a year.

2.Each time the canner is washed, remove the sealing ring and wash in warm, sudsy water, rinse, dry, and replace in cover.

3. The air vent/cover lock may |

|

Fig.. O |

be removed for occasional |

|

|

|

Cover |

|

cleaning or for replacing |

|

|

|

|

|

the small gasket. To remove |

|

|

the air vent/cover lock, |

|

Cup |

grasp and hold secure the |

Pin |

Small |

cup portion on the under- |

Gasket |

|

|

|

|

side of the cover with your |

|

|

fingers (Fig. O). Using the |

|

|

fingers of your other hand, |

|

Threaded |

turn the pin portion of the |

|

shaft |

air vent/cover lock on the |

|

|

top side of the cover counterclockwise until the pin is free of the cup portion. Lift the pin out of the cover and remove the cup from under the cover. Carefully pull the small gasket off the threaded shaft on the cup portion. Wash all parts in warm, sudsy water. Use a soft cloth or small nylon brush to clean the cover hole.

4.To reassemble the air vent cover lock, place the small gasket over the threaded shaft of the cup portion. Reinsert the cup portion by pushing the threaded shaft through the air vent/ cover lock opening from the underside of the cover (Fig. O). Screw the pin portion clockwise onto the threaded shaft until it is not possible to tighten it any further.

5.The overpressure plug can be removed for cleaning by pushing it out of its opening from the top of the cover. After cleaning, reinsert the plug by pushing the domed side of the plug into the opening from the underside of the cover, until the bottom edge is fully and evenly seated against the underside of the cover. When the overpressure plug is properly installed, the word (TOP) will be visible on the overpressure plug when viewing the outside of the cover (Fig. P).

Fig.. P |

Cover |

Overpressure Plug |

|

||

|

|

Top |

|

|

Indented Portion |

If the overpressure plug is ever forced out of its cover opening due to excess pressure while cooking or canning, it is important to call the Test Kitchen at 1-800-368-2194. Do not attempt to use the released overpressure plug..

6.Pouring water into a dry overheated canner may crack the metal.

7.Do not strike the rim of the canner body with any cooking utensil as this will cause nicks which may damage the rim and allow steam to escape.

16 |

17 |

8.When your pressure canner is not in use, invert the cover on the canner body and store in a dry place. Storing the canner with the cover locked on may cause unpleasant odors and deform the sealing ring.

9.To ensure safe operation and satisfactory performance, replace the overpressure plug every time you replace the sealing ring or sooner if it becomes hard, deformed, cracked, worn, or pitted. Replace the sealing ring and overpressure plug at least every three years. Failure to follow these instructions could result in bodily injury or property damage.

10.If the canner body or cover handles become loose, tighten them with a screwdriver.

11.If leakage of moisture or steam develops while using your canner, check the following possible causes:

The formation of a small amount of moisture under the pressure regulator is normal when canning or cooking first begins. This condensation is a result of the temperature of the pressure regulator being lower than the rest of the canner. If excess condensation continues, the vent pipe may be loose and should be tightened with an adjustable wrench.

Leakage between the cover and body is usually caused by shrinkage of the sealing ring after prolonged use. Replace the sealing ring and overpressure plug.

A slight amount of leakage around the air vent/cover lock is normal when canning or cooking first begins. If leakage continues, the cover handles may not be fully aligned with the body handles and, therefore, the cover lock cannot engage (see page 12, step 6). Clean the air vent/cover lock occasionally to assure that it operates correctly (see page 16, step 3). Replace the small gasket if cracked or nicked.

A small amount of steam or moisture may be visible around

the overpressure plug when canning or cooking begins. This will stop when the overpressure plug seals. If leakage continues, clean or replace the overpressure plug (see page 17, step 5).

Do not operate your pressure canner with continual leakage. If the preceding steps do not correct the problem, return the entire unit to the Presto Factory Service Department (see page 75).

12.If the pressure canner becomes difficult to open or close, replace the sealing ring.

13.IMPORTANT: The sealing ring, overpressure plug, and rubber gasket of the air vent/cover lock may shrink, become hard, deformed, cracked, worn, or pitted with normal use. Exposure to high heat, such as a warm burner or oven top, will cause these parts to deteriorate rapidly. When this happens, replace the sealing ring, overpressure plug, and small rubber gasket of the air vent/cover lock. Replace the sealing ring and overpressure plug at least every three years.

Before inserting a new sealing ring, clean the sealing ring groove with a brush.

Any maintenance required for this product, other than normal household care and cleaning, should be performed by the Presto Factory Service Department (see page 75).

18 |

19 |

Pressure CANNING

FRUITS AND TOMATOES

Fruits and tomatoes may be processed using pressure canning or boiling water canning. The pressure processing method for fruits and tomatoes gives a heat treatment equivalent to the much longer processing time required with the boiling water method.

Select firm, fully-ripened but not soft fruit or tomatoes. Do not can overripe foods. Some fruits tend to darken while they are being prepared. To prevent the darkening, place fruit in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) or use ascorbic acid or citric acid mixtures according to package instructions.

Although fruit has better color, shape, and flavor when it is canned with sugar, it may be canned unsweetened if desired. White sugar is preferable to brown sugar for canning. Light corn syrup or honey may be used to replace up to one-half the sugar.

The amount of sugar desirable to use in preparing syrups will depend upon the tartness of the fruit and on family preference. It should be remembered that fruit, when heated, releases some of its juices which will dilute the syrup in proportion to the juiciness of the fruit.

SYRUPS FOR CANNING FRUITS

|

SUGAR PER |

YIELD OF |

|

SYRUP |

QUART OF LIQUID |

SYRUP |

|

Very Light |

1 |

cup |

4½ cups |

Light |

2 |

cups |

5 cups |

Medium |

3 |

cups |

5½ cups |

Heavy |

4¾ |

cups |

6½ cups |

Heat sugar with water or juice until sugar is dissolved. Add fruit and cook until heated through. Pack fruit into clean Mason jars to within ½-inch of top of jar. Cover with hot liquid leaving ½-inch headspace. The liquid may be syrup, fruit juice, or plain water. For steps on boiling water canning, refer to page 41.

Altitude Adjustments

The processing times for pressure canning given in the specific fruit and tomato recipes are for altitudes of 1,000 feet or less. When pressure canning fruit above 1,000 feet, process at 10 pounds of pressure. When pressure canning tomatoes above 1,000 feet, process at 15 pounds of pressure. Processing time is the same at all altitudes.

The processing times for boiling water canning given in the specific fruit and tomato recipes are for altitudes of 1,000 feet or less. When processing at higher altitudes, process according to the chart below.

Altitude |

Processing Time for Pints |

1,001 – 3,000 ft. |

increase processing time 5 minutes |

3,001 – 6,000 ft. |

increase processing time 10 minutes |

6,001 – 8,000 ft. |

increase processing time 15 minutes |

CANNING RECIPES: FRUITS AND TOMATOES

APPLES

Wash, peel, and cut apples into pieces. Place apples in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening during preparation. Drain well. Boil apples in a light syrup or water for 5 minutes. Pack hot apples in clean, hot Mason jars, leaving ½-inch headspace. Cover apples with hot syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 8 minutes.

Boiling water canning: Process pints 20 minutes.

APPLESAUCE

Wash, peel, and core apples. If desired, slice apples into ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening. Drain well. Place slices in a pan. Add ½ cup water. Cook until apples are tender. Press through food mill or sieve. Sweeten to taste. Reheat sauce to boiling. Pack into clean, hot Mason jars, leaving ½-inch headspace. Adjust jar lids.

20 |

21 |

Pressure canning: Process at 5 pounds pressure, pints 8 minutes and quarts 10 minutes.

Boiling water canning: Process pints 15 minutes.

APRICOTS

Wash well-ripened, firm apricots. If peeled apricots are desired, dip 1 minute in boiling water, then in cold water, and peel. Cut apricots in halves and remove pits. Place apricots in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening during preparation. Drain well. Heat apricots through in a very light, light, or medium syrup or water (see page 20). Pack hot apricots, cut side down, in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

BERRIES (EXCEPT STRAWBERRIES)

Wash firm berries carefully, removing caps and stems. Heat berries in boiling water for 30 seconds and drain. Pack hot berries in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 8 minutes.

Boiling water canning: Process pints 15 minutes.

CHERRIES

Wash cherries and remove stems. Remove pits, if desired. If canning whole cherries, prick each cherry with a clean needle to prevent splitting. Heat cherries with ½ cup water or syrup to each quart of cherries. Cover pan and bring to a boil. Pack hot cherries and cooking liquid in clean, hot Mason jars, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints 8 minutes and quarts 10 minutes.

Boiling water canning: Process pints 15 minutes.

PEACHES

Wash fully-ripened but not soft peaches. Loosen skins by dipping peaches 1 minute in boiling water, then in cold water. Peel. Cut peaches in half and remove pits. Slice if desired. Place peaches in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening during preparation. Drain well. Heat peaches through in very light, light, or medium syrup or water (see page 20). Pack hot peaches, cut side down, in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

PEARS

Wash pears. Peel, cut in half lengthwise, and core. Slice pears, if desired. Place pears in an ascorbic acid solution (1 teaspoon ascorbic acid to 1 gallon water) to prevent darkening during preparation. Drain well. Boil pears 5 minutes in very light, light, or medium syrup or water (see page 20). Pack hot pears in clean, hot Mason jars, leaving ½-inch headspace. Cover with boiling syrup or water, leaving ½-inch headspace. Adjust jar lids.

Pressure canning: Process at 5 pounds pressure, pints and quarts 10 minutes.

Boiling water canning: Process pints 20 minutes.

PLUMS

Wash firm, ripe plums. Remove stems. If plums are to be canned whole, prick each side with a fork. Freestone varieties may be cut in halves and pitted. Heat plums to boiling in very light, light, or medium

22 |

23 |

Loading...

Loading...