Page 1

Service Manual

UBK13/ UBK13 BASE SERVICE

MANUAL

20039-174 REV A

Vertical Upright & Recumbent Bicycles

PRECOR CUSTOMER SUPPORT

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 1

Page 2

Page 3

Contents

About This Document .............................................................................................. 2

Right, Left, Front, and Back Conventions ..................................................................................................................... 2

Safety...................................................................................................................................................................................... 3

Warning and Caution Statements and General Safety Guidelines....................................................................... 4

General Information ........................................................................................................................................................... 4

Required Tools and Equipment ............................................................................. 5

Preventive Maintenance - Bikes ............................................................................ 6

Regular Preventive Maintenance (Owner) ................................................................................................................. 6

Quarterly Maintenance ........................................................................................................ 7

On-Site Preventive Maintenance (Service Technician) .......................................................................................... 7

Checking the Bicycle Operations ......................................................................... 8

Primary Belt Tension Adjustment .................................................................................................................................. 9

Adjusting the Seat Carriage - RBK Only ..................................................................................................................... 10

RBK13/UBK13 Base Troubleshooting .................................................................. 12

Display does not Illuminate ........................................................................................................................................... 12

No or Incorrect Pedaling Resistance ........................................................................................................................... 13

RBK13/UBK13 Base Replacement Procedures ................................................ 16

Replacing the Covers - UBK13 ....................................................................................................................................... 16

Replacing the Covers - RBK13 ....................................................................................................................................... 21

Replacing a Primary Drive Belt ..................................................................................................................................... 25

Replacing a Crankarm .................................................................................................................................................... 26

Replacing the Primary Pulley ........................................................................................................................................ 28

Replacing the Input Pulley and Axle Assembly ........................................................................................................ 31

Replacing the Idler Pulley .............................................................................................................................................. 36

Replacing a Generator .................................................................................................................................................... 38

Replacing a Battery ........................................................................................................................................................... 41

Replacing the lower PCA ............................................................................................................................................... 42

Replacing the Seat Post Pop-Pin - UBK13 Only ....................................................................................................... 44

Replacing the Seat Post - UBK Only ........................................................................................................................... 46

Replacing a Seat Post Component - UBK Only ....................................................................................................... 48

Replacing All or Part of a Seat Carriage - RBK only ................................................................................................ 51

Wire and Block Diagrams ...................................................................................... 56

Block Diagrams ................................................................................................................................................................. 57

Wire Diagrams ................................................................................................................................................................. 58

Index ............................................................................................................................ 59

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 1

Page 4

General Information ....................................................................................................... 4

Section One

About This Document

In This Section

Right, Left, Front, and Back Conventions.................................................................. 2

Safety ................................................................................................................................. 3

Warning and Caution Statements and General Safety Guidelines ................... 4

Right, Left, Front, and Back

Conventions

In this manual, right, left, front, and back are form the perspective of a user operating the equipment

facing the console.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 2

Page 5

Safety

Safety guidelines you should know and follow include:

♦ Read the owner’s manual and follow all operating instructions.

♦ Operate the equipment on a solid, level surface with the unit properly leveled. The equipment is

properly leveled when the feet are in contact with the floor. Visually check the equipment before

beginning service or maintenance operations. If it is not completely assembled or is damaged in any

way, exercise extreme caution while operating and checking the equipment.

♦ When operating the equipment, do not wear loose clothing. Do not wear shoes with heels or

leather soles. Check the soles of your shoes and remove any embedded stones. Tie long hair back.

♦ Do not rock the unit. Do not stand or climb on the handlebars, display enclosure, or cover.

♦ Do not set anything on the handlebars, display enclosure, or cover. Never place liquids on any part

of the equipment while performing service.

♦ To prevent electrical shock, keep all electrical components away from water and other liquids.

♦ Do not use accessory attachments that are not recommended by the manufacturer-such

attachments might cause injuries.

♦ Units equipped with Personal Viewing Screens will have external power supply and coaxial cable

routed through the bottom of the unit to the top of the display console. Cord management must be

maintained.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 3

Page 6

Warning and Caution

Statements and General Safety

Guidelines

Warning statements indicate a particularly dangerous activity. Warning statements you will find in this

manual include:

♦ Self powered units, it will either be necessary to either equip the unit with the optional external

power supply or have an assistant pedal on the unit while voltage measurements are being taken.

Because of the danger of working on the unit while it is in motion using the optional external power

supply is strongly recommended.

♦ When the unit is used, crank arms are in motion; the generator will operate and produce potentially

hazardous voltages even when the battery is disconnected.

Caution statements are intended to prevent damage to the equipment as a result of the current

activity. Caution statements included in this manual are listed below:

♦ When it is necessary to lift or move the equipment, ensure that the equipment has adequate

support and that you use proper lifting techniques.

♦ To remove power from the equipment, the optional external power supply (when equipped) must

be disconnected from the wall outlet and the red (positive) wire must be disconnected from the

battery. Always ensure that the equipment external power supply is unplugged from the wall outlet

and the red (positive) wire is removed from the battery when you inspect or adjust the equipment,

or when you isolate, remove, or replace an component.

♦ Removing the covers exposes high voltage components and potentially dangerous machinery.

Exercise extreme caution when you perform maintenance procedures with the cover(s) removed.

♦ During service operations you will be very close to moving machinery and voltage bearing

components. When you perform maintenance procedures with the covers removed, remove

jewelry (especially from ears and neck), tie up long hair, remove neck ties, and do not wear loose

clothing.

♦ Exercise caution when touching any wire or electrical component during equipment operation.

General Information

For the latest exploded view, part number and part pricing information, visit the Precor dealer website

at www.precor.com/connection.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 4

Page 7

S ection Two

Required Tools and

Equipment

The following is a summary of the tools and equipment that may be required when you service Precor

Equipment.

Tools

♦ Phillip and flat-head screwdrivers

♦ Metric allen wrench set

♦ Open-end metric wrench set

♦ Metric socket wrench set

♦ Snap ring pliers

♦ Drive belt tension gauge

♦ Park Too CCP-22 crankarm puller or Shimano TL-FC10 Crankarm puller

Equipment

♦ Anti-static kit

♦ Digital multimeter

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 5

Page 8

On-Site Preventive Maintenance (Service Technician) ....................................... 7

Section Three

Preventive Maintenance -

Bikes

In This Section

Regular Preventive Maintenance (Owner) .............................................................. 6

Preventive maintenance measures are either scheduled or unscheduled. Scheduled preventive

maintenance activities are included here so that you are aware of the preventive measures preformed

on a regular basis.

Regular Preventive

Maintenance (Owner)

Cleanliness of the cycle and its operating environment will keep maintenance problems and service

calls to a minimum. Precor recommends that you perform the following preventive maintenance

schedule.

After Each Use

♦ Turn off and, unplug power adapter (if equipped) from the bicycle.

♦ Wipe down the covers, handlebars, seat and pedals with a damp cloth.

Daily Maintenance

♦ Clean the bicycle's frame, covers, seat and pedals using a water damped cloth. Wipe the surface of

the electronic console with a damp sponge or soft cloth. Dry with clean towel.

Weekly Maintenance

♦ Clean underneath the bicycle, following these steps:

1 Turn off the bicycle with the on/off switch, then unplug it from the power adapter (if equipped).

2 Move the bicycle to gain access to the floor directly underneath the bicycle.

3 Vacuum the rug or damp mop the floor.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 6

Page 9

4 Make sure the floor is dry before returning the bicycle to its original position.

Quarterly Maintenance

1 Remove the covers.

2 Thoroughly clean inside the bicycle. Use a vacuum cleaner and damp rag to remove all the dust

particles, etc.

3 Check the belt tension per procedure,

Primary Belt Tension Adjustment

(on page 9).

On-Site Preventive

Maintenance (Service

Technician)

When you are called to service a bicycle perform these preventive maintenance activities:

♦ Perform the software diagnostics. Check LED and keypad functions. Record the odometer reading.

For more information, consult the console service manual equipped with your equipment.

♦ Visually inspect the drive belts for cracks, fraying or excessive wear.

♦ Visually examine all wires and check connectors and wire connections. Secure connections and

replace wiring as necessary.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 7

Page 10

Adjusting the Seat Carriage - RBK Only ................................................................... 10

Section Four

Checking the Bicycle

Operations

In This Section

Primary Belt Tension Adjustment .............................................................................. 9

This section provides you with a quick method of checking operation.

Procedure

1 Start pedaling.

2 With the banner displayed, press QUICK START.

3 The resistance will start at Level 1.

4 Operate the RBK13/UBK13 for 4–5 minutes. As you operate the bike, concentrate on the operating

sounds made by the unit. Be on the alert for unusual rubbing, hitting, grinding, or squeaking noises.

5 Press the RESISTANCE key until you reach Resistance Level 10. Operate the RBK13/UBK13 for

another 2–3 minutes.

6 If the electronic display does not change appropriately, reference per the, Standard Console service

manual.

7 If the resistance does not change or the operation of the bike feels inconsistent compared with

Resistance Level 1, troubleshoot per procedure, No or Incorrect Pedaling Resistance .

8 Press the RESISTANCE key until you reach Resistance Level 20. Operate the bike for another 2–3

minutes.

9 If the resistance of the bike does not change or operation feels inconsistent with Resistance Levels 1

and 20, troubleshoot per procedure, No or Incorrect Pedaling Resistance.

10 Check the LED’s mounted on the upper PCA and the function keys displayed on the electronic

console by performing the diagnostics test in the Standard Console service manual.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 8

Page 11

Figure 1: Belt Gauge

Figure 2: Drive Belt Adjustment

Primary Belt Tension

Adjustment

1 Remove the covers as per Procedure

Covers - RBK13

2 Place the belt tension gauge on the primary drive belt.

3 The correct belt tension is 70 ± 5 pounds. If the belt tension is correct replace the covers. If the belt

tension is incorrect, continue to the next step.

(on page 21).

Replacing the Covers - UBK13

(on page 16) or

Replacing the

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 9

Page 12

4 Slightly loosen the three 4mm idler pulley bracket mounting bolts. The belt tension cannot be

adjusted if the idler pulley bracket mounting bolts are tightened.

5 Loosen the adjustment bolt lock nut.

6 Turn the adjustment bolt clockwise or counter clockwise as required until the gauge is in the range

of 70 ± 5 pounds.

7 Remove and then replace the belt tension gauge on the primary drive belt. If the belt tension is out

range, repeat steps 5 and 6 until the belt tension is in range. If the belt tension is within range,

continue to the next step.

8 Tighten the three 4mm idler pulley bracket bolts. Note: Do not over tighten the bolts, if the bolts

are over tightened it is possible to damage the mounting hole threads of the generator. If by

chance the threads do become damaged, the idler pulley bracket can be removed and flipped

over 360 degrees and reinstalled. Doing this will allow the use of another set of mounting

holes on the generator.

9 Tighten the adjustment bolt lock nut.

10 Replace the covers.

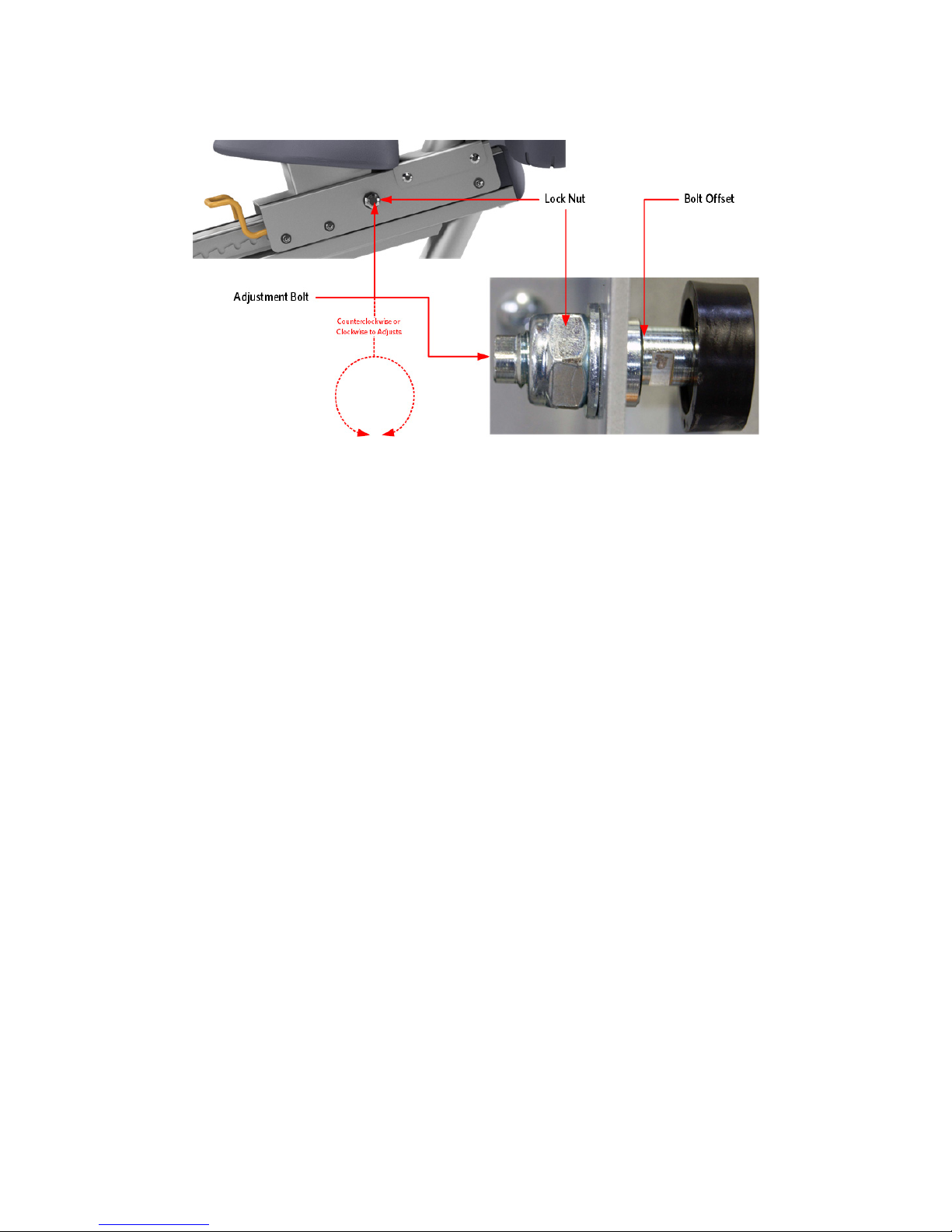

Adjusting the Seat Carriage RBK Only

Perform this procedure if the front to rear movement of the seat is too tight or there is excessive side to

side seat wobble.

1 The end of the adjustment bolts are designed with two flat sides so that an open end wrench can

be used to rotate the bolt. Using a 10mm wrench on the adjust bolt, use a 22mm wrench to loosen

the two lock nuts on the left and right side just enough so the adjust bolt can be turned freely.

2 The seat carriage wheel is mounted on the adjustment bolt, which is offset. The offset bolt enables

the wheel to be tightened or loosened against the seat rail. Perform half of the adjustment using the

right hand adjustment bolt and half of the adjustment using the left hand adjustment bolt. Rotate

the adjust bolt counterclockwise until it just makes contact with the seat rail then turn it an

additional 1⁄8 turn. Hold the 10mm wrench at this position and firmly tighten the lock nut.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 10

Page 13

Figure 3: Seat Carriage Adjustment Bolts

3 When the seat is properly adjusted, the angle of the rotation of both adjustment bolts should be

approximately the same. The seat should not wobble side to side and should move forward and

backward easily. If the seat still wobbles side to side, repeat step 2 but increase from 1⁄8 turn to ¼

Note:Tightening any further may result in accelerated wheel and bearing wear.

turn.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 11

Page 14

No or Incorrect Pedaling Resistance ......................................................................... 13

Section Five

RBK13/UBK13 Base

Troubleshooting

In This Section

Display does not Illuminate ......................................................................................... 12

Display does not Illuminate

Note:

In order to conserve battery power when the cycle is not in use, a time out feature is incorporated in

the cycles software. If the cycle is not used (motion not detected by the speed sensor), when in the

program mode, approximately 15 seconds later, the cycle will “power down” The bike will “power up”

again when pedaling is resumed (motion detected by the speed sensor). In order to measure voltages

in the unit it is necessary to keep the unit powered up. This can be accomplished either by pedaling on

the unit or by installing the optional external power adapter.

1 Attach the anti-static wrist strap to your arm, then connect the ground wire of the wrist strap to

the units frame.

2 Pedal on the cycle for a minimum of 5 seconds. The system monitors one of the three phase

generator windings for AC zero cross. The monitoring system notes every time the generator AC

voltage passes through zero volts. By counting the zero cross rate, the system knows how fast the

generator is turning. The system calculates the user RPM from the generator speed. If the system

does not see a zero cross rate, it assumes the bike is not being used and the display will not

illuminate when the bike is pedaled.

3 Disconnect the generator leads from terminals M3 (Red) and M4 (Black) on the lower PCA.

Connect a AC voltmeter to the leads removed from terminals M3 and M4. Pedal the bike at about

60 RPM (1 rotation per second), the voltmeter should read approximately between 80Vac and 120

Vac. If the voltage reading is absent or extremely low, replace the generator.

voltage will vary depending on the speed the crankarms are rotating. If you are trying to

measure the voltage and rotate the crankarm at the appropriate RPM may be difficult. It is

recommended that you have someone assist with pedaling the bicycle while taking this

voltage measurement. Use extreme caution by staying clear of the bicycles moving parts

while taking the voltage measurement.

Note: The output

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 12

Page 15

Figure 4: Lower PCA Connectors

4 If the voltage reading in step 3 was normal, replace the lower PCA. If the lower PCA did not correct

the problem, continue with step 5.

5 With the unit powered up, measure between test point 24 and test point 37 for approximately 7.5

Vdc. If the measurement is correct, skip to step 8.

6 If the measurement in step 5 is significantly low or high, disconnect the interconnect cable from the

J2 connector and repeat the measurement in step 5.

7 If the measurement in step 5 is still significantly low or high, replace the lower PCA. If replacing the

lower PCA does correct the problem, skip to step 8.

8 Remove the upper display panel and disconnect the interconnect cable form the upper PCA. With

the unit powered up, check the voltage between the outer two pins of the interconnect cable for DC

volts. It should read approximately 7.5 Vdc. Note: The interconnect pins can be difficult to get good

connections with the meter leads. If the voltage is absent or significantly low, troubleshoot the

interconnect cable.

9 If the voltage measurement in step 5 is correct, replace the upper PCA.

If you have performed all of the previous tests and have not been able to locate the trouble, call Precor

customer support.

No or Incorrect Pedaling

Resistance

1 If the display is not illuminated, go to Procedure, Display does not Illuminate.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 13

Page 16

Figure 5: Lower PCA Connectors

2 Enter the "manual" program and set the work level at "level 20". Pedal the cycle and confirm that

there is no resistance or that the resistance is abnormally low.

Note:

The voltage readings in this procedure will vary with the pedaling rate. Pedal the cycle at approximately

60 RPM with the work level set at "10" while taking the voltage readings in this procedure. Resistance

readings must be taken with the power off and the cycle idle.

3 Measure the DC voltage at the terminals M1 and M8 of the lower PCA. The voltage reading should

be approximately 11 Vdc. If the reading is significantly low, or significantly high, skip to step 5.

4 If the reading in step 3 was correct, the pedaling resistance should be correct, skip back to step 2.

5 Disconnect the eddy current magnet wires from terminals M1 and M8 of the lower PCA. Measure

between the eddy current magnet wires with an ohmmeter. It should read approximately 10

Ω (ohms).

6 If the measurement in step 5 was significantly high or low, replace the generator.The eddy current

magnet is furnished with the generator. After replacing the generator, tension the primary belt as

per procedure,

Primary Belt Tension Adjustment

7 If the measurement in step 5 was correct, replace the lower PCA.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 14

(on page 9).

Page 17

Figure 6: Lower PCA Cables

8 It is highly unlikely that the RPM reading could be present but incorrect. If this condition should

occur, replace the lower PCA

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 15

Page 18

Replacing All or Part of a Seat Carriage - RBK only ............................................... 51

Section Six

RBK13/UBK13 Base

Replacement Procedures

In This Section

Replacing the Covers - UBK13 ..................................................................................... 16

Replacing the Covers - RBK13 ..................................................................................... 21

Replacing a Primary Drive Belt .................................................................................... 25

Replacing a Crankarm ................................................................................................... 26

Replacing the Primary Pulley ....................................................................................... 28

Replacing the Input Pulley and Axle Assembly ...................................................... 31

Replacing the Idler Pulley ............................................................................................. 36

Replacing a Generator ................................................................................................... 38

Replacing a Battery ........................................................................................................ 41

Replacing the lower PCA .............................................................................................. 42

Replacing the Seat Post Pop-Pin - UBK13 Only ...................................................... 44

Replacing the Seat Post - UBK Only .......................................................................... 46

Replacing a Seat Post Component - UBK Only ....................................................... 48

Replacing the Covers - UBK13

Top Cover Removal

1 Remove the left side screw and the right side screw that secures the top cover.

2 Lift and remove the top cover.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 16

Page 19

Left Side Cover Removal

3 Move the pedal to its highest position in its rotation.

4 Remove the six screws that secure the left side cover to the frame.

5 Pull and remove the left cover.

Right Cover Removal

6 Move the pedal so that it is at the top of its rotations.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 17

Page 20

7 Remove the five screws that secure the right cover to the frame.

8 Pull and remove the right cover.

Left Side Cover Installation

9 Place the left side cover against the frame and align the cover with the screw holes. Ensure the right

side cover edge is seated in the seat post gasket.

10 Secure the left side cover to the frame with the six screws removed earlier.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 18

Page 21

Right Side Cover Installation

11 Place the right side cover against the frame and align the cover with the left side cover and the

screw holes. Ensure the right side cover edge is seated in the seat post gasket.

12 Secure the right side cover to the frame with the five screws removed earlier.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 19

Page 22

Top Cover Installation

13 Place the top cover on the side covers; align the back of the top cover so that the edge is seated in

the seat post gasket.

14 Secure the left and right side of the top cover with the screws removed earlier.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 20

Page 23

Replacing the Covers - RBK13

Top Cover Removal

1 Remove the left side screw and the right side screw that secures the top cover.

2 Lift and remove the top cover.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 21

Page 24

Figure 7: Top Cover Screw Locations-RBK13

Figure 8: Left Side Cover Screw Locations - RBK13

Left Side Cover Removal

3 Move the pedal to its highest position in its rotation.

4 Remove the four screws that secure the left side cover to the frame.

5 Pull and remove the left cover.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 22

Page 25

Figure 9: Right Side Cover Screw Locations - RBK13

Right Cover Removal

6 Move the pedal so that it is at the top of its rotations.

7 Remove the three screws that secure the right cover to the frame.

8 Pull and remove the right cover.

Right Side Cover Installation

9 Place the right side cover against the frame and align the cover with the left side cover and the

screw holes.

10 Secure the right side cover to the frame with the three screws removed earlier.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 23

Page 26

Figure 10: Right Side Cover Screw Locations - RBK13

Figure 11: Left Side Cover Screw Locations - RBK13

Left Side Cover Installation

11 Place the left side cover against the frame and align the cover with the screw holes.

12 Secure the left side cover to the frame with the four screws removed earlier.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 24

Page 27

Figure 12: Drive Belt Adjustment

Top Cover Installation

13 Replace the top cover.

14 Secure the top cover with the two screw removed earlier.

Replacing a Primary Drive Belt

1 Remove the covers as per procedure,

Covers - RBK13

(on page 21).

Replacing the Covers - UBK13

(on page 16) or

Replacing the

Removing the Primary Drive Belt

2 Slightly loosen the three idler pulley bracket mounting bolts.

3 Loosen the adjustment bolt lock nut.

4 Turn the adjustment bolt counter clockwise as required to remove the tension from the primary

drive belt.

5 Remove the primary drive belt.

Installing the Primary Drive Belt

6 Place the primary drive belt in its mounting position around the input pulley, under the idler pulley

and around the primary pulley.

7 Tension the primary drive belt as per procedure,

8 Replace the covers as per procedure,

Covers - UBK13

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 25

(on page 16).

Primary Belt Tension Adjustment

Replacing the Covers - RBK13

(on page 21) or

(on page 9).

Replacing the

Page 28

Figure 13: Crankarm Removal Tools

Replacing a Crankarm

Removing a Crankarm

1 Using a 15mm open end wrench, remove the pedal from the crankarm being replaced.

2 Using an 8mm allen wrench, remove the crankarm mounting bolt by turning the bolt clockwise.

3 To remove the crankarm, one of the following crankarm removal tools will be required: Shimano

TL-FC10 Crankarm puller or a CCP-22 Crankarm puller; available at most bike repair shops.In this

procedure the Shimano Crankarm Puller will be used.

4 Remove the nut from the crankarm puller. Thread the nut fully into the crankarm.

Note: If the nut is not fully threaded into the crankarm, the crankarm threads may be destroyed when

the crankarm is removed.

5 Thread the crankarm puller into the nut removed from the crankarm puller. When the crankarm

puller is tightened, the crankarm will be extracted from the crankarm axle. Use a opened wrench to

tighten the crankarm puller, continue to tighten the crankarm puller until the crankarm is removed.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 26

Page 29

Figure 14: Crankarm & Crankarm Removal Tool

Figure 15: Crankarm Position

Installing a Crankarm

1 Place the crankarm onto the crankarm axle; ensure the crankarm is positioned 180° opposite the

other crankarm.

2 Thread the crankarm mounting bolt into the crankarm axle and fully tighten.

3 Install the pedal to the crankarm.

4 Pedal the bike for one minute and then re-tighten the crankarm mounting bolt.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 27

Page 30

Figure 16: Crankarm Removal Tools

Replacing the Primary Pulley

1 Remove the covers as per procedure,

Covers - UBK13

2 Remove the left hand crankarm and pedal.

(on page 16).

Replacing the Covers - RBK13

(on page 21) or

Replacing the

Removing a Crankarm

3 Using a 15mm open end wrench, remove the pedal from the crankarm being replaced.

4 Using an 8mm allen wrench, remove the crankarm mounting bolt by turning the bolt clockwise.

5 To remove the crankarm, one of the following crankarm removal tools will be required: Shimano

TL-FC10 Crankarm puller or a CCP-22 Crankarm puller; available at most bike repair shops.In this

procedure the Shimano Crankarm Puller will be used.

6 Remove the nut from the crankarm puller. Thread the nut fully into the crankarm.

Note: If the nut is not fully threaded into the crankarm, the crankarm threads may be destroyed when

the crankarm is removed.

7 Thread the crankarm puller into the nut removed from the crankarm puller. When the crankarm

puller is tightened, the crankarm will be extracted from the crankarm axle. Use a opened wrench to

tighten the crankarm puller, continue to tighten the crankarm puller until the crankarm is removed.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 28

Page 31

Figure 17: Crankarm & Crankarm Removal Tool

Figure 18: Drive Belt Adjustment

Removing the Primary Drive Belt

8 Slightly loosen the three idler pulley bracket mounting bolts.

9 Loosen the adjustment bolt lock nut.

10 Turn the adjustment bolt counter clockwise as required to remove the tension from the primary

drive belt.

11 Remove the primary drive belt.

Removing the Primary Pulley

12 Remove the 32mm retaining nut from the center of the primary pulley while holding the opposite

side crank arm and pedal, turning counterclockwise.

13 Remove the primary pulley.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 29

Page 32

Figure 19: Primary Pulley

Figure 20: Crankarm Axle & Key

Installing the Primary Pulley

14 Slide the primary pulley onto the crankarm axle assembly, ensure the axle key is in place and aligns

with the slot on the primary pulley.

Note: The concaved side of the primary pulley will be facing

the frame.

15 Thread the 32mm retaining nut onto the input axle and fully tighten.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 30

Page 33

Figure 21: Crankarm Position

Installing a Crankarm

16 Place the crankarm onto the crankarm axle; ensure the crankarm is positioned 180° opposite the

other crankarm.

17 Thread the crankarm mounting bolt into the crankarm axle and fully tighten.

18 Install the pedal to the crankarm.

Pedal the bike for one minute and then re-tighten the crankarm mounting

bolt.Installing the Primary Drive Belt

19 Place the primary drive belt in its mounting position around the input pulley, under the idler pulley

and around the primary pulley.

20 Tension the primary drive belt as per procedure,

21 Replace the covers as per procedure,

Covers - RBK13

(on page 21).

Replacing the Covers - UBK13

Primary Belt Tension Adjustment

(on page 16) or

(on page 9).

Replacing the

Replacing the Input Pulley and

Axle Assembly

1 Remove the covers as per procedure,

Covers - UBK13

2 Remove the left hand crankarm and pedal.

(on page 16).

Replacing the Covers - RBK13

(on page 21) or

Replacing the

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 31

Page 34

Figure 22: Crankarm Removal Tools

Removing a Crankarm

3 Using a 15mm open end wrench, remove the pedal from the crankarm being replaced.

4 Using an 8mm allen wrench, remove the crankarm mounting bolt by turning the bolt clockwise.

5 To remove the crankarm, one of the following crankarm removal tools will be required: Shimano

TL-FC10 Crankarm puller or a CCP-22 Crankarm puller; available at most bike repair shops.In this

procedure the Shimano Crankarm Puller will be used.

6 Remove the nut from the crankarm puller. Thread the nut fully into the crankarm.

Note: If the nut is not fully threaded into the crankarm, the crankarm threads may be destroyed when

the crankarm is removed.

7 Thread the crankarm puller into the nut removed from the crankarm puller. When the crankarm

puller is tightened, the crankarm will be extracted from the crankarm axle. Use a opened wrench to

tighten the crankarm puller, continue to tighten the crankarm puller until the crankarm is removed.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 32

Page 35

Figure 23: Crankarm & Crankarm Removal Tool

Figure 24: Drive Belt Adjustment

Removing the Primary Drive Belt

8 Slightly loosen the three idler pulley bracket mounting bolts.

9 Loosen the adjustment bolt lock nut.

10 Turn the adjustment bolt counter clockwise as required to remove the tension from the primary

drive belt.

Remove the primary drive belt.Removing the Primary Pulley

11 Remove the 32mm retaining nut from the center of the primary pulley while holding the opposite

side crank arm and pedal, turning counterclockwise.

12 Remove the primary pulley.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 33

Page 36

Figure 25: Primary Pulley

Figure 26: Crankarm Retainning Screws

13 Remove the right hand crankarm.

Removing the Crankarm Axle Assembly

14 Remove the three 3mm screws and washers that secure the crankarm axle assembly.

15 Pull on the crankarm axle shaft to remove the crankarm axle assembly.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 34

Page 37

Figure 27: Crankarm Axle Assembly Removed

Figure 28: Crankarm Axle & Key

Installing the Crankarm Axle Assembly

16 Slide the crankarm axle assembly into the frame.

17 Secure the crankarm axle assembly into the frame with the three screws and washers, fully tighten.

Installing the Primary Pulley

18 Slide the primary pulley onto the crankarm axle assembly, ensure the axle key is in place and aligns

with the slot on the primary pulley.

the frame.

Note: The concaved side of the primary pulley will be facing

19 Thread the 32mm retaining nut onto the input axle and fully tighten.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 35

Page 38

Figure 29: Crankarm Position

Installing the Primary Drive Belt

20 Place the primary drive belt in its mounting position around the input pulley, under the idler pulley

and around the primary pulley.

21 Tension the primary drive belt as per procedure,

Primary Belt Tension Adjustment

(on page 9).

22 Replace both left and right crankarms.

Installing a Crankarm

23 Place the crankarm onto the crankarm axle; ensure the crankarm is positioned 180° opposite the

other crankarm.

24 Thread the crankarm mounting bolt into the crankarm axle and fully tighten.

25 Install the pedal to the crankarm.

26 Pedal the bike for one minute and then re-tighten the crankarm mounting bolt.

27 Replace the covers as per procedure,

Covers - UBK13

(on page 16).

Replacing the Idler Pulley

1 Remove the covers as per procedure,

Covers - RBK13

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 36

(on page 21).

Replacing the Covers - RBK13

Replacing the Covers - UBK13

(on page 21) or

(on page 16) or

Replacing the

Replacing the

Page 39

Figure 30: Drive Belt Adjustment

Removing the Primary Drive Belt

2 Slightly loosen the three idler pulley bracket mounting bolts.

3 Loosen the adjustment bolt lock nut.

4 Turn the adjustment bolt counter clockwise as required to remove the tension from the primary

drive belt.

5 Remove the primary drive belt.

Removing the Idler Pulley

6 Remove the retaining ring that secures the idler pulley to the axle.

7 Remove the idler pulley.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 37

Page 40

Figure 31: Idler Pulley & Retaining Ring

Installing a Idler Pulley

8 Place the idler pulley onto the axle.

9 Secure the idler pulley to the axle with the retaining ring.

Installing the Primary Drive Belt

10 Place the primary drive belt in its mounting position around the input pulley, under the idler pulley

and around the primary pulley.

11 Tension the primary drive belt as per procedure,

12 Replace the covers as per procedure,

Covers - UBK13

(on page 16).

Replacing the Covers - RBK13

Primary Belt Tension Adjustment

(on page 21) or

(on page 9).

Replacing the

Replacing a Generator

1 Remove the covers as per procedure,

Covers - UBK13

(on page 16).

Removing the Primary Drive Belt

2 Slightly loosen the three idler pulley bracket mounting bolts.

3 Loosen the adjustment bolt lock nut.

4 Turn the adjustment bolt counter clockwise as required to remove the tension from the primary

drive belt.

Replacing the Covers - RBK13

(on page 21) or

Replacing the

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 38

Page 41

Figure 32: Drive Belt Adjustment

Figure 33: Generator Cable Connectons

5 Remove the primary drive belt.

Removing the Generator

6 Fully remove the three Idler pulley mounting bolts that secure idler pulley bracket to the generator.

7 Disconnect the generator cable connectors and the eddy current source magnet. One cable

connector is plugged directly into the generator; the other is connected to a cable extension.

8 Remove the four 5mm mounting bolts, nuts and washers that secure the generator to the frame,

two bolts on each side.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 39

Page 42

Figure 34: Generator Mounting Bolts

Figure 35: Generator Mounting Bolts

Figure 36: Generator Cable Connectons

9 Remove the generator.

Installing a Generator

10 Place the generator on the frame, aligning the generator mounting holes with the frame mounting

holes.

11 Secure the generator to the frame using the four 5mm mounting bolts, nuts and washers; fully

tighten.

12 Connect the two generator connector cables, one directly to the generator and the other to the

cable extension connector.

13 Thread the three mounting bolts through the idler pulley bracket and into the generator, only hand

tighten at this time.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 40

Page 43

Figure 37: Battery

Installing the Primary Drive Belt

14 Place the primary drive belt in its mounting position around the input pulley, under the idler pulley

and around the primary pulley.

15 Tension the primary drive belt as per procedure,

16 Replace the covers as per procedure,

Covers - UBK13

(on page 16).

Replacing the Covers - RBK13

Primary Belt Tension Adjustment

(on page 21) or

(on page 9).

Replacing the

Replacing a Battery

1 Remove the covers as per procedure,

Covers - UBK13

(on page 16).

Removing the Battery

2 Disconnect the cable connectors from the positive (White Wire) and negative (Black Wire)

terminals of the battery.

3 Remove the two screws that secure the battery bracket to the frame, one screw on each side of the

frame.

4 Release the tension from the velcro strap.

Replacing the Covers - RBK13

(on page 21) or

Replacing the

5 Remove the battery.

Installing the battery

6 Place the battery in the battery bracket.

7 Tighten the velcro strap to secure the battery to the battery bracket.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 41

Page 44

Figure 38: Lower PCA Cables

8 Secure the battery bracket to the frame with the two screws and fully tighten.

9 Connect the cable connector with the fuse holder to the positive (White Wire) terminal of the

battery, the positive terminal of the battery will be marked with a red square.

10 Connect the remaining cable connector (Black Wire) to the negative terminal on the battery.

11 Replace the covers as per procedure,

Covers - UBK13

(on page 16).

Replacing the Covers - RBK13

Replacing the lower PCA

1 Remove the covers as per procedure,

Covers - UBK13

(on page 16).

Removing the Lower PCA

2 Disconnect all of the wires from the lower PCA.

Replacing the Covers - RBK13

(on page 21) or

(on page 21) or

Replacing the

Replacing the

3 Remove the two screws that secure the lower PCA mounting bracket to the frame.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 42

Page 45

Figure 39: Lower PCA Mounting Bracket

Figure 40: Lower PCA Mounting Screws

4 Remove the four screws that secure the lower PCA to the mounting bracket.

5 Remove the lower PCA and four stand-offs located underneath the PCA from the bracket .

Installing the Lower PCA

6 Set the lower PCA in the mounting bracket, the data connector should be on the right hand side of

the bracket.

7 Secure the lower PCA to the mounting bracket with the four screws and stand-offs removed earlier.

8 Set the lower PCA bracket in its mounting position and fasten it to the frame with the two screws.

9 Reconnect the wiring to the lower PCA as follows: two red load wires to M1, M8; red generator wire

to M3, white generator wire to M4; generator wire to M5; red battery wire to M6, Black battery

wire to M7; data cable to connector J2.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 43

Page 46

Figure 41: Lower PCA Connectors

10 Replace the covers as per procedure,

Covers - UBK13

(on page 16).

Replacing the Covers - RBK13

(on page 21) or

Replacing the

Replacing the Seat Post Pop-Pin

- UBK13 Only

Removing the Seat Post Pop-Pin

1 Remove the pop-pin knob; turn the knob counter clockwise to remove. Note: Sitting on the seat

while removing the knob will help prevent the pop-pin from rotating.

2 Remove the retaining ring.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 44

Page 47

Figure 42: Seat Post Pop-pin Retaining Ring

Figure 43: Seat Post Pop-Pin Assemble

3 Pull up slightly on the seat post to relieve the pressure off the pop-pin. Pull the pop-pin out of the

frame.

4 The seat post is now unsupported, ease the seat post into its lowest position.

Installing the Seat Post Pop-Pin

5 Assemble the seat post as follows: Starting from the threaded side of the pin, slide on the spring

and bushing; on the non-threaded side of the pin, slide on the rubber insert. See Figure Below.

6 Pull the seat post up until one of the height level holes is aligned with the pop-pin housing on the

frame.

7 Slide the pop-pin assembly into place so the pin locks the seat post into place.

8 Secure the pop-pin assembly in place with the retaining ring.

9 Replace the pop-pin knob.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 45

Page 48

Figure 44: Seat Post Pop-pin Retaining Ring

Replacing the Seat Post - UBK

Only

Removing the Seat Post Pop-Pin

1 Remove the pop-pin knob; turn the knob counter clockwise to remove. Note: Sitting on the seat

while removing the knob will help prevent the pop-pin from rotating.

2 Remove the retaining ring.

3 Pull up slightly on the seat post to relieve the pressure off the pop-pin. Pull the pop-pin out of the

frame.

4 The seat post is now unsupported, ease the seat post into its lowest position.

Removing the Seat Post

5 Lift the seat post until you see the window in the post, than lower the post so that only the top

portion of the window can be seen above the collar. Press on the seat post collar tabs located on

the left and right side of the seat post frame.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 46

Page 49

Figure 45: Seat Post Window & Collar

Figure 46: Seat Post Pop-Pin Assemble

6 Lift and remove the seat post from the bicycle.

Installing the Seat Post

7 Slide the seat post into the bicycle frame until only the top portion of the window can be seen

above the collar and then snap the collar into place.

Installing the Seat Post Pop-Pin

8 Assemble the seat post as follows: Starting from the threaded side of the pin, slide on the spring

and bushing; on the non-threaded side of the pin, slide on the rubber insert. See Figure Below.

9 Pull the seat post up until one of the height level holes is aligned with the pop-pin housing on the

frame.

10 Slide the pop-pin assembly into place so the pin locks the seat post into place.

11 Secure the pop-pin assembly in place with the retaining ring.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 47

Page 50

Figure 47: Seat Post Pop-pin Retaining Ring

12 Replace the pop-pin knob.

Replacing a Seat Post

Component - UBK Only

Removing the Seat Post Pop-Pin

1 Remove the pop-pin knob; turn the knob counter clockwise to remove. Note: Sitting on the seat

while removing the knob will help prevent the pop-pin from rotating.

2 Remove the retaining ring.

3 Pull up slightly on the seat post to relieve the pressure off the pop-pin. Pull the pop-pin out of the

frame.

4 The seat post is now unsupported, ease the seat post into its lowest position.

Removing the Seat Post

5 Lift the seat post until you see the window in the post, than lower the post so that only the top

portion of the window can be seen above the collar. Press on the seat post collar tabs located on

the left and right side of the seat post frame.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 48

Page 51

Figure 48: Seat Post Window & Collar

Figure 49: Seat Post Components

6 Lift and remove the seat post from the bicycle.

Removing Seat Post Components

7 Remove the two screws that secure the seat axle to the seat post. Pull the seat post axle from the

seat post.

8 Compress one side of the compression spring and then pull to release it from the seat axle.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 49

Page 52

Figure 50: Seat Post Pop-Pin Assemble

Remove the location pin from within the compression spring.

Installing Seat Post Components

9 Place the location pin inside the compression spring.

10 Place one side of the compression spring on a tab of the seat axle. Compress the compression

spring and slide the end on the remaining tab of the seat axle.

11 Slide the seat axle into place of the seat post. Secure the seat axle with the two mounting screws.

Installing the Seat Post

12 Slide the seat post into the bicycle frame until only the top portion of the window can be seen

above the collar and then snap the collar into place.

Installing the Seat Post Pop-Pin

13 Assemble the seat post as follows: Starting from the threaded side of the pin, slide on the spring

and bushing; on the non-threaded side of the pin, slide on the rubber insert. See Figure Below.

14 Pull the seat post up until one of the height level holes is aligned with the pop-pin housing on the

frame.

15 Slide the pop-pin assembly into place so the pin locks the seat post into place.

16 Secure the pop-pin assembly in place with the retaining ring.

17 Replace the pop-pin knob.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 50

Page 53

Figure 51: Seat Carriage End Cap

Replacing All or Part of a Seat

Carriage - RBK only

Removing the Seat Carriage

1 There is a heart rate cable that connects the heart rate hand grips in the seat carriage to the heart

rate cable in the seat rail. Care must be taken when removing the seat carriage to avoid damaging

the heart rate cables.

2 Move the seat carriage to its most forward position. Remove the two Philips screws that fasten the

end cap in the seat rail. Remove the end cap.

3 Move the seat carriage to its most back position. Remove the 3mm screw and washer that secures

the water bottle holder to the seat rail. Carefully unsnap the water bottle holder from the rear of the

seat carriage.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 51

Page 54

Figure 52: Water Bottle Mounting Screw

Figure 53: Heart Rate Cable Cover and Connector

4 Move the seat carriage to its most forward position.

5 Remove the two philips screws that secure the cable cover and remove the cable cover.

6 Disconnect the heart rate cables.

7 Carefully slide the seat carriage off the seat rail, ensure the heart rate cable does not get caught on

the rail when removing the carriage.

Removing the Heart Rate Cables

8 On the underside of the seat carriage, remove the cable cover and disconnect the flat ribbon cable

from the cable to the heart rate grips.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 52

Page 55

Figure 54: Cable Cover - Seat Carriage Bottom

9 Remove the flat ribbon cable.

10 Remove the Philips screws from the underside of the heart rate grips on the left handlebar. Lift the

grips from the handlebar and disconnect the wire from both grips. Repeat this procedure on the

right handlebar.

11 Remove the heart rate cable from the seat carriage.

Installing the Heart Rate Cables

12 Feed the replacement heart rate cable into the access hole on the underside of the seat carriage.

13 On both the right and left handlebars, feed the white wire out of the upper heart rate grip access

hole and the black wire out of the lower heart rate grip access hole.

14 On both handlebars, connect the upper heart rate grip to the white wire and the lower handlebar

grip to the black wire. Replace the screws and fully tighten.

15 Connect the flat ribbon cable to the heart rate cable and replace the cable cover.Replace the screw

and fully tighten.

Replacing a Seat Carriage Wheel

1 Remove the 14mm lock nut and washer from the wheel being replaced, remove the 14mm shoulder

bolt and wheel

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 53

Page 56

Figure 55: Seat Carriage Wheel

Figure 56: Seat Carriage Release Handle

2 Set the replacement 14mm shoulder bolt and wheel in its mounting position and fasten it with the

hardware just removed.

Removing the Release Handle Assembly

3 Using a 14mm and 13mm open end wrench, remove the seat carriage wheels located next to the

release handle pivot.

4 Remove the 14mm lock nut that secures the spring and the release handle pivot to the carriage,

remove the release handle.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 54

Page 57

5 Remove the spring assemblies from the release handle pivot.

Installing the Release Handle Assembly

6 Place the springs on the release handle pivot, ensure that the spring arms are closest to the seat

carriage and the spring coil is the farthest from the seat carriage. One spring arm should be sitting

on the seat locking pin.

7 Place the seat carriage wheels underneath the other spring arm and secure the wheel to the

carriage with shoulder bolts and lock nuts.

Installing the Seat Carriage Assembly

8 Slide the seat carriage partially onto the seat rail.

9 Slide the seat carriage fully on the seat rail and all the way forward. Set the seat stop in its position.

10 Connect the flat ribbon cable to the heart rate cable in the seat rail and replace the cable clamp.

Secure the clamp with the screws removed earlier. Fully tighten.

11 Slide the seat carriage fully to back most position. Snap the water bottle holder onto the seat

carriage. Secure the water bottle to the carriage with the screw and washer removed earlier. Fully

tighten.

12 Slide the seat carriage fully to forward most position. Replace the end cap and fasten it to the

carriage with the hardware removed earlier. Fully tighten.

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 55

Page 58

Wire Diagrams ................................................................................................................ 58

Section Seven

Wire and Block Diagrams

In This Section

Block Diagrams ............................................................................................................... 57

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 56

Page 59

Block Diagrams

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 57

Page 60

Wire Diagrams

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 58

Page 61

Index

A

About This Document • 2

Adjusting the Seat Carriage - RBK Only • 10

B

Block Diagrams • 57

C

Checking the Bicycle Operations • 8

D

Display does not Illuminate • 12

G

General Information • 4

N

No or Incorrect Pedaling Resistance • 13

O

Replacing a Seat Post Component - UBK Only • 48

Replacing All or Part of a Seat Carriage - RBK only •

51

Replacing the Covers - RBK13 • 9, 21, 25, 28, 31, 36,

38, 41, 42, 44

Replacing the Covers - UBK13 • 9, 16, 25, 28, 31, 36,

38, 41, 42, 44

Replacing the Idler Pulley • 36

Replacing the Input Pulley and Axle Assembly • 31

Replacing the lower PCA • 42

Replacing the Primary Pulley • 28

Replacing the Seat Post - UBK Only • 46

Replacing the Seat Post Pop-Pin - UBK13 Only • 44

Required Tools and Equipment • 5

Right, Left, Front, and Back Conventions • 2

S

Safety • 3

W

On-Site Preventive Maintenance (Service

Technician) • 7

P

Preventive Maintenance - Bikes • 6

Primary Belt Tension Adjustment • 7, 9, 14, 25, 31,

36, 38, 41

R

RBK13/UBK13 Base Replacement Procedures • 16

RBK13/UBK13 Base Troubleshooting • 12

Regular Preventive Maintenance (Owner) • 6

Replacing a Battery • 41

Replacing a Crankarm • 26

Replacing a Generator • 38

Replacing a Primary Drive Belt • 25

© Precor Incorporated, Unauthorized Reproduction and Distribution Prohibited by Law Page 59

Warning and Caution Statements and General

Safety Guidelines • 4

Wire and Block Diagrams • 56

Wire Diagrams • 58

Loading...

Loading...