Prastel UNIK2E, UNIK2ESK User Manual

ISUNIK2Ev2_GB_02_09.doc

ELECTRONIC CONTROL UNIT FOR

TWO 12VDC MOTOR

UNIK2E _ V2

(COMPLETE)

UNIK2ESK

(WITHOUT BOX AND TRANSFORMER)

_ V2

BOX IP 54

TECHNICAL INSTALLATION MANUAL

FOR

Before installing, thoroughly read this manual that is an integral part of this

Kit. Prastel S.p.A. declines any responsibility in the event current standards

in the country of installation are not complied with

The symbol CE conforms with European Directive R&TTE 99/05/CE

AUTOMATIC GATES

WARNING!

UNIK2E V2

ENGLISH

ISUNIK2Ev2_GB_02_09.doc

1. INTRODUCTION ...........................................................................................3

2. MAIN FEATURES .........................................................................................3

3. TECHNICAL SPECIFICATIONS...................................................................3

4. CONNECTION AND SET UP OF THE CONTROL UNIT..............................4

4.1 GENERAL DIAGRAM OF SETTINGS AND CONNECTIONS..................................5

4.2 SIMPLIFIED LEARNING PROCEDURE (also see pages 8-10)..............................6

4.3 PROFESSIONAL LEARNING PROCEDURE (see also pages 8-10)......................7

5. CONTROL UNIT OPERATING LOGIC (ANALYTIC EXAM)........................8

5.1 PROGRAMMING AND CANCELLATION OF THE REMOTE CONTROLS.............8

5.2 OPERATION OF THE SAFETY DEVICES ...............................................................8

5.3 MOTOR SPEED - TRIMMER “FOR”.......................................................................9

5.4 DELAY BETWEEN MOTORS - TRIMMER “DEL” ..................................................9

5.5 “OPENING AND CLOSING” OPERATING MODE ..................................................9

5.6 “PEDESTRIAN OPENING” FUNCTION.................................................................11

5.7 “OBSTACLE SENSITIVITY” DETECTION - TRIMMER “OBS”.............................11

5.8 FLASHING LIGHT ..................................................................................................11

5.9 GATE OPEN WARNING LIGHT.............................................................................11

5.10 SLOW-DOWN.........................................................................................................11

5.11 ELECTRIC LOCK ...................................................................................................11

5.12 COURTESY LIGHT.................................................................................................12

5.13 BUFFER BATTERY – SOLAR PANEL MANAGEMENT .......................................12

5.14 LOGICAL STOP (STP INPUT)................................................................................12

5.15 CONTROL UNIT MEMORY FAULT........................................................................12

6. SIGNALLING LED.......................................................................................12

7. PROGRAMMING THROUGH GTSYSTEM.................................................13

8. ACCESSORIES ABSORPTION CHECK INFORMATION..........................13

9. TROUBLESHOOTING ................................................................................14

SAFETY WARNINGS FOR INSTALLATION AND USE ...................................................15

2

UNIK2E V2

ENGLISH

ISUNIK2Ev2_GB_02_09.doc

1. INTRODUCTION

The universal self-learning UNIK2E control unit has been designed for the automation of an access with 1 or 2

12VDC (24VDC)* motors with or without limit switches. Its innovative self-learning procedure makes for

quick and easy installation and its three trimmers permit fine adjustment of all main parameters: force

(or speed), pause time, obstacle detection sensitivity and closing delay between the two leaves of the

gate when two motors are used.

The following are available:

- simplified programming, thanks to which the unit automatically performs a learning operation to acquire

running time and determine slow-down setting at ninety percent of opening and closing runs;

- A professional programming in which the installer can determine the instant in which the gate starts to

slow-down, the enabling of the pedestrian opening via radio, the safety device trigger mode.

2. MAIN FEATURES

• Manageme nt and control of 12 VDC (or 24 VDC)* powered, 1 or 2 motor-driven automated accesses

• Motors closing offset adjus table from 0 to 15 seconds using trimmers

• Double limit switch input open close

• Motor force (speed) a djustable from 50-100%.using a trimmer.

• Customisable partial opening (for pedestrian transit)

• Softstart (slow motor start)

• 1 to 60” stand-by time adju stment via trimmer.

• 0.1 to 3.0” obstacl e dete ction trigge ring time adjustment via trimmer.

• Initial settings using dip-switches

• Signalling LEDs (8)

• Expansion for electri c lock 12V 15W ma x (optional board ELU)

• Expansion for courtesy light 230VAC 500W max (optional board LCU)

• Built in battery charger with solar panel management

• Box predispo sed for optional 12V 1.2Ah battery for emergency manoeuvres (max connectable battery 7Ah)

• Built-in 433MHz rolling-code receiver with 180 memorisable codes

• Flash microp rocessor re-programmable on-board via serial interface.

• Programming and control of the control unit using a portable terminal GTSYSTEM (optional)

• Built to European refere nce Directive Standards (R&TTE 99/05/CE)

DECLARATION OF CONFORMITY

Prastel S.p.A. declares that UNIK2E IS IN ACCORDANCE with the 99/05/EC (R&TTE) direcitve

The complete declaration of conformity is available in Prastel or to the internet address www.prastel.it

3. TECHNICAL SPECIFICATIONS

Transformer power supply: 230VAC

Control unit power: 12VAC (20VAC)*

Motor output: 12 VDC max 2 x 50Watt (24VDC max 2 x 60W)*

Max current peak of motor: 10 Amperes

Accessories power: 12 VDC - 250 mA protected by fuse (see info page 13)

Environmental operating temperature : -20°C / + 55°C

Programming parameters: memorised in EEPROM

BOX IP rating: IP54

(*)When using 24VDC motors, replace the supplied transformer with a 230/20VAC transformer with at least

20VA more power than the motor. The maximum power of the 24VDC motor driven by the control unit is 120W.

Only 12V batteries can be connected to the control unit, so when there is no mains power 24VDC motors will be

powered at 12VDC.

3

UNIK2E V2

ENGLISH

ISUNIK2Ev2_GB_02_09.doc

4. CONNECTION AND SET UP OF THE CONTROL UNIT

a) Before installing the UNIK2E control unit, read the “General safety warnings and notes” (page 13).

b) Fix the box using the special fixing holes.

c) Mount a differential thermo-magnetic circuit breaker 6A (IC=30mA) on the mains supply as specified in

the current reference standards (IC = differential current).

d) Place the supplied cable-ways and insert the cables keeping the power and supply cables separate from

each other.

e) Connect the external accessories making sure that the total of the average absorption of all the

connected accessories is less than the maximum current available (see info page 11).

f) ATTENTION: Connect the limit switches if present; otherwise do not jump inputs FC1, FC2, FO1

and FO2 in the terminal board.

g) ATTENTION: if there are no electrical limit switches and no mechanical stop in opening, proceed

as follows to define the manoeuvre times during learning:

• Press pushbutton 1 of the remote control or pushbutton P1/SET to stop the gate in the desired position.

• Press pushbutton 2 of the remote control or pushbutton P2/SET to stop the gate in the desired position.

h) Check the correct connection and operation of all the accessories connected to the terminal board.

NOTES:

INITIAL FACTORY SETTINGS

If there is no programming, the control unit will operate as follows:

• Step-step mode with automatic closing disabled.

• No slow-down

• Closing safety present

• No opening safety

• Obstacle detection trigger time (OBS) 1 second

• 3 second opening and closing time of the motors

• Safety test disabled

• Kick-back disabled

• Pushbutton 1 of transmitters enabled

• Rapid re-closing disabled

INITIAL SETTING OF THE TYPE OF OPERATOR

Check that the control unit is set for the application requested. When switched on, the red “RAD” LED flashes

for the number of times set in the control unit.

To modify the setting proceed as follows:

1. press the P2/RAD pushbutton until the corresponding red “RAD” LED lights up

2. press the P1/SET pushbutton, the control unit switches to another application

3. press the P2/RAD pushbutton again to exit the programming

4. The red “RAD” LED switches off to confirm that programming has been exited.

MOTOR POWER SUPPLY

The control unit adapts itself to run with motors of 12 or 24VDC according to the voltage with which it is

powered.

The UNIK2E control unit is fitted with a toroidal transformer with a 12VAC secondary.

NUMBER OF FLASHES APPLICATIONS

1 Linear actuators

2 Operators with variable lever

(Variable absorption)

4

UNIK2E V2

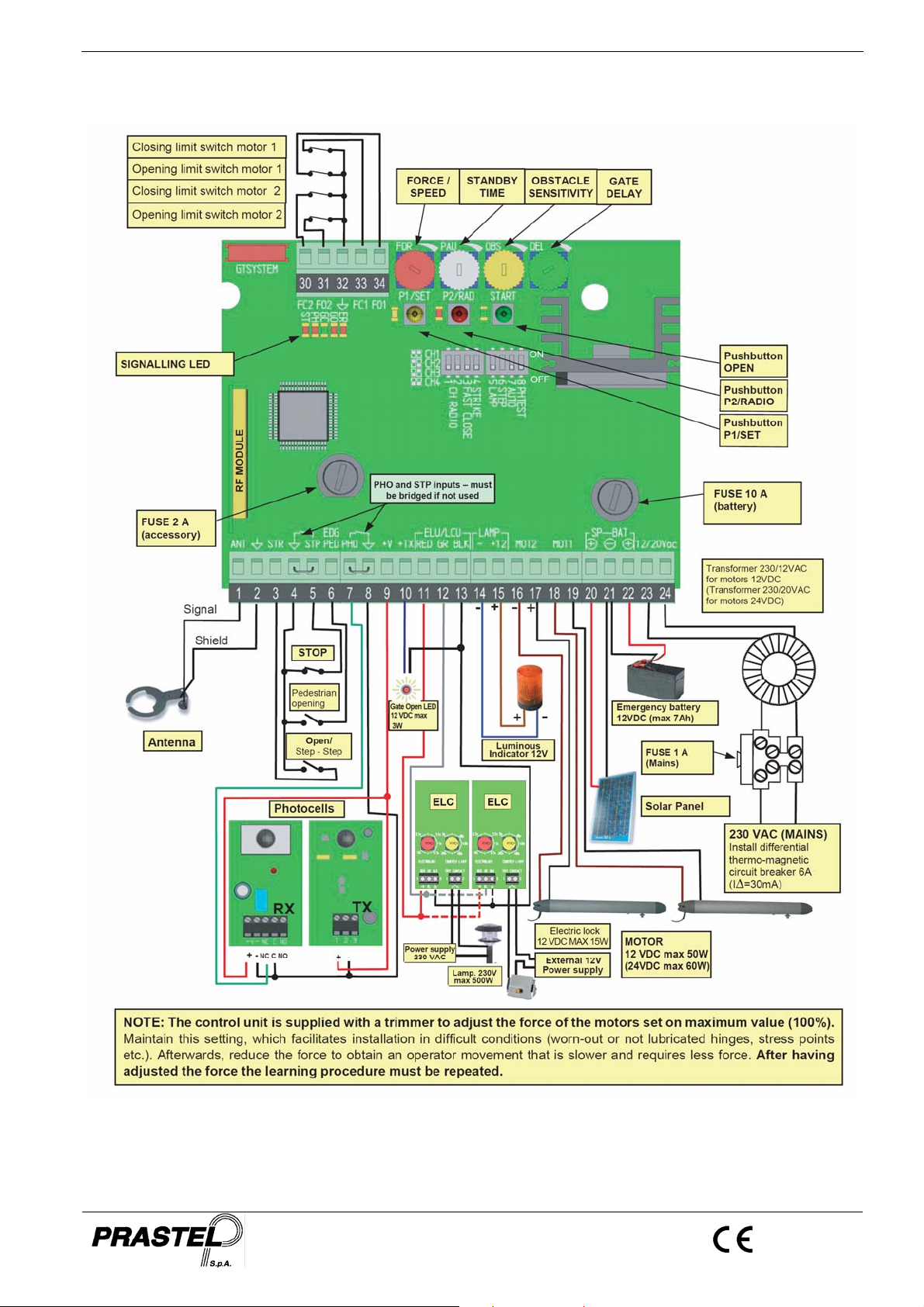

4.1 GENERAL DIAGRAM OF SETTINGS AND CONNECTIONS

ENGLISH

ISUNIK2Ev2_GB_02_09.doc

5

Loading...

Loading...