Page 1

Powerware Modbus Card

®®

User’s Guide

Page 2

Class A EMC Statements

FCC Part 15

NOTE This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

ICES-003

This Class A Interference Causing Equipment meets all requirements of the Canadian Interference Causing

Equipment Regulations ICES-003.

Cet appareil numérique de la classe A respecte toutes les exigences du Reglement sur le matériel brouilleur du

Canada.

EN 50091-2

Some configurations are classified under EN 50091-2 as “Class-A UPS for Unrestricted Sales Distribution.” For

these configurations, the following applies:

WARNING This is a Class A-UPS Product. In a domestic environment, this product may cause radio interference, in

which case, the user may be required to take additional measures.

Requesting a Declaration of Conformity

Units that are labeled with a CE mark comply with the following harmonized standards and EU directives:

S Harmonized Standards: EN 50091-1-1 and EN 50091-2; EC 60950 Third Edition

S EU Directives: 73/23/EEC, Council Directive on equipment designed for use within certain voltage limits

The EC Declaration of Conformity is available upon request for products with a CE mark. For copies of the EC

Declaration of Conformity, contact:

Eaton Power Quality Oy

Koskelontie 13

FIN-02920 Espoo

Finland

Phone: +358 -9-452 661

Fax: +358-9-452 665 68

93/68/EEC, Amending Directive 73/23/EEC

89/336/EEC, Council Directive relating to electromagnetic compatibility

92/31/EEC, Amending Directive 89/336/EEC relating to EMC

Eaton, Powerware, and X-Slot are registered trademarks of Eaton Corporation or its subsidiaries and affiliates.

Modbus is a registered trademark of Schneider Electric. Wonderware is a registered trademark of Wonderware

Corporation. HyperTerminal is a registered trademark of Hilgraeve. Microsoft and Windows are registered

trademarks of Microsoft Corporation.

ECopyright 2002–2008 Eaton Corporation, Raleigh, NC, USA. All rights reserved. No part of this document may be

reproduced in any way without the express written approval of Eaton Corporation.

Page 3

Table of Contents

1 Introduction 1.........................................................

2 Installing the Modbus Card 3.............................................

Inspecting the Equipment 3................................................................

Four-Wire Communication 4...............................................................

Installing the Modbus Card into an X-Slot 6....................................................

3 Wiring the Modbus Card 7...............................................

Two-Wire Networks 7...................................................................

Four-Wire Networks 8...................................................................

RS-485 Terminal Strip 8..................................................................

RS-485 Modbus Port 9...................................................................

Termination 10.........................................................................

Biasing Resistors 11...................................................................

RS-232 Modbus Port 12...................................................................

4 Modbus Card Configuration 13.............................................

Configuring the Modbus Card 13.............................................................

5 Integrating the UPS 17...................................................

Generating Modbus Data 17................................................................

Example Modbus Profiler Output Files 18.......................................................

6 Troubleshooting 23......................................................

Service and Support 25...................................................................

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

i

Page 4

TABLE OF CONTENTS

ii

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 5

Chapter 1 Introduction

The Eaton®Powerware®Modbus®Card is an X-Slot®connectivity device

that allows you to continuously and reliably monitor the UPSs in your

Building Management System (BMS). The card uses the Modbus

protocol to integrate data from the UPS into your building management

software, such as Wonderware

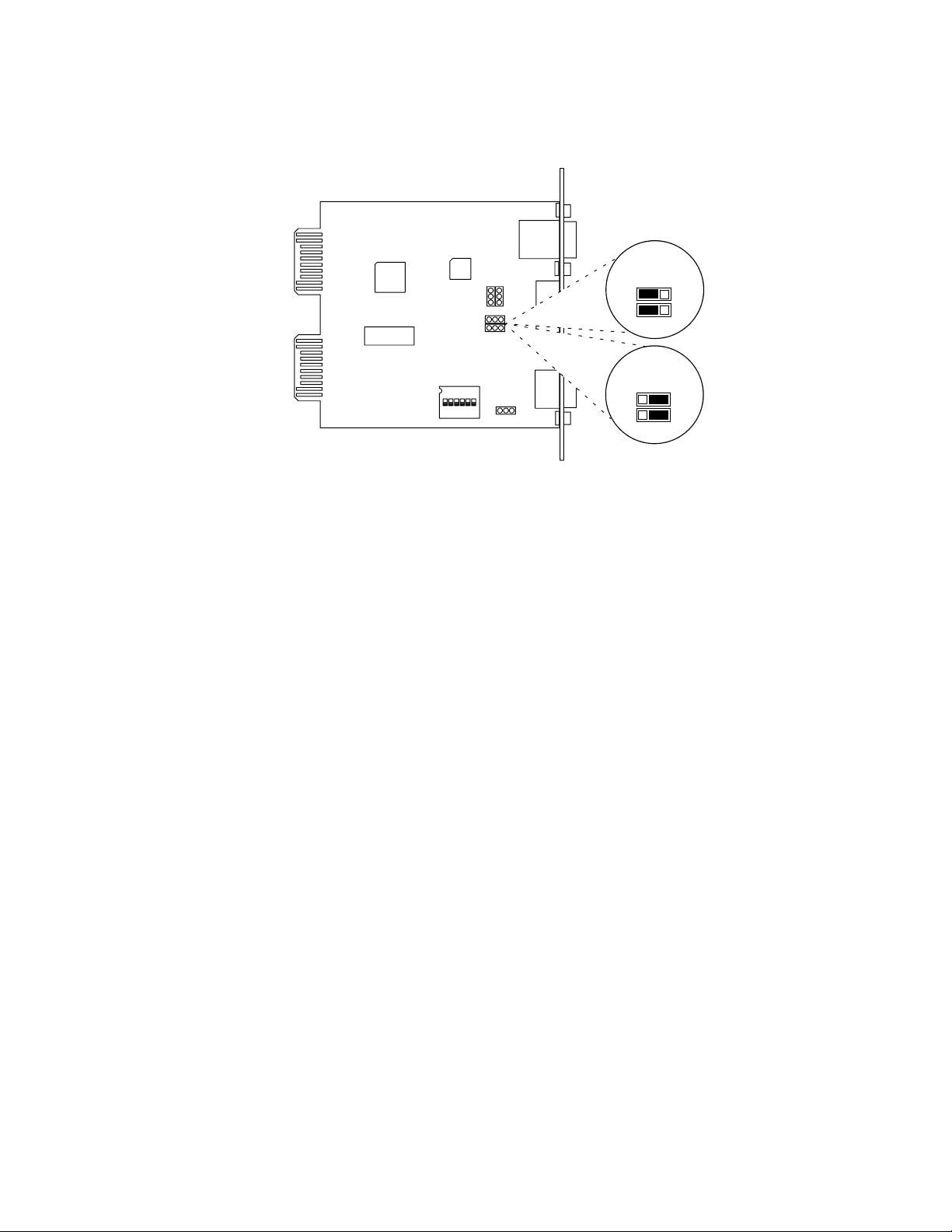

The Modbus Card, shown in Figure 1, has the following features:

S RS-485 communication through an isolated DB-9 port or isolated

terminal strip

S Selectable termination and polarity resistance

S RS-232 communication through a DB-9 port

S Supports Modbus READ INPUT STATUS and READ INPUT REGISTER

commands

S Two-wire or four-wire communication topology

S LEDs showing communication activity

S The Modbus Profiler tool can generate a Modbus register map for

easy integration into your building management software (see

page 17)

R

.

S X-Slot design for UPSs with an internal X-Slot or installed in a

Powerware Expansion Chassis for UPSs that do not have internal

X-Slots

Configuration PortCommunication LEDs

(use either the DB-9 port or terminal strip)

RS-485 Modbus

Figure 1. The Modbus Card

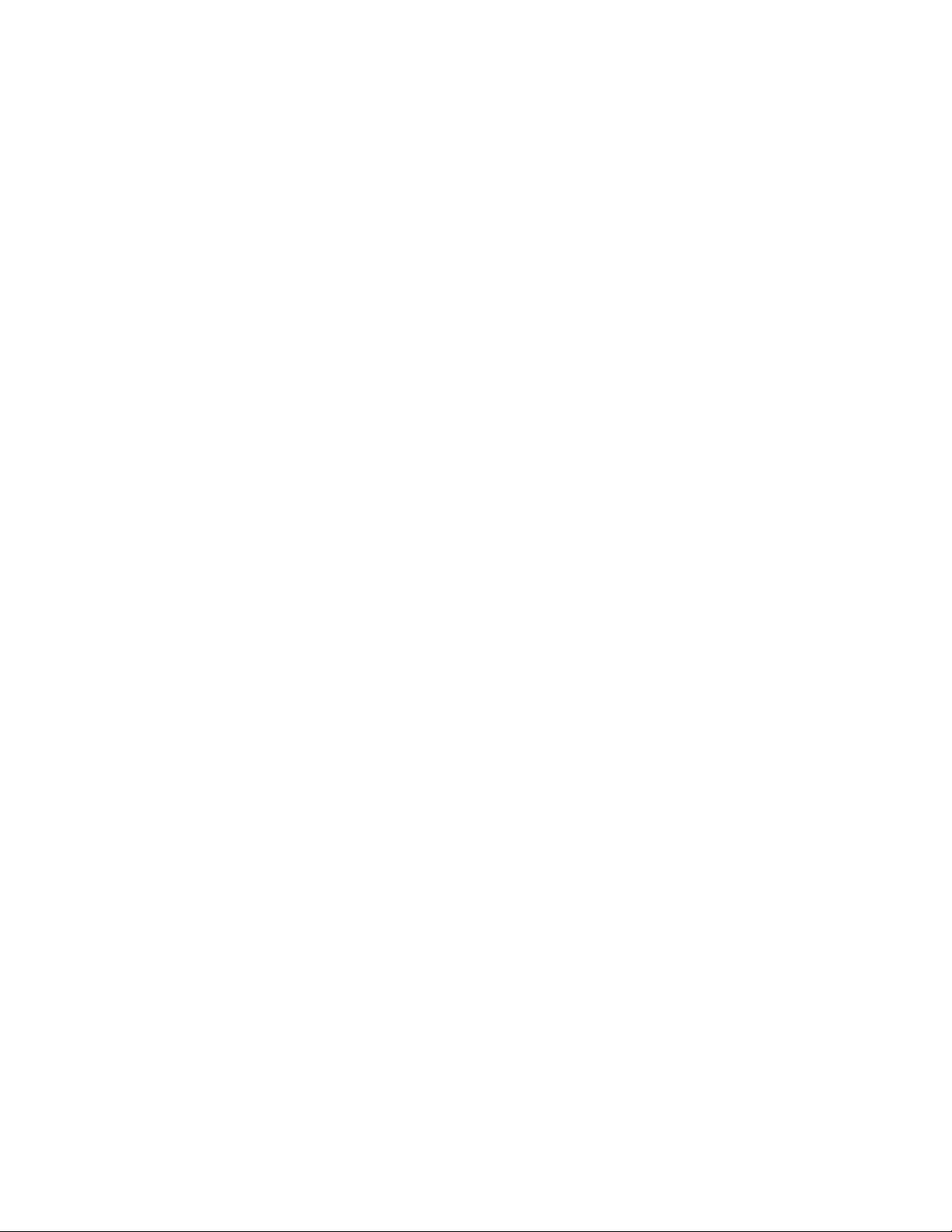

Figure 2 shows a Powerware UPS added to an existing network by

connecting the terminal strip on the Modbus Card to the RS-485

terminals on another device.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

RS-232 Modbus DB-9 Port

1

Page 6

INTRODUCTION

Building Management Software

Ethernet

Ethernet Gateway

RS-485 Network

-270.6 -270.6

Power Meter

PLC

Figure 2. UPS Integrated with RS-485 Network

UPS with Modbus Card

2

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 7

Chapter 2 Installing the Modbus Card

The Modbus Card is available:

S as a separate card for use with UPSs that have an X-Slot

S factory-installed in a Powerware Expansion Chassis

Use the following sequence for installing the Modbus Card:

1. For four-wire networks only, change the jumpers on the Modbus

Card (see “Four-Wire Communication” on page 4).

2. If the Modbus Card will be the last device installed in the network

chain or the length of the network cable is excessive, termination

needs to be enabled (see “Termination” on page 10).

3. Install the card with the UPS (see the Powerware Expansion

Chassis User’s Guide or “Installing the Modbus Card into an X-Slot”

on page 6).

4. Wire the card to your network (see Chapter 3, “Wiring the Modbus

Card”onpage7).

5. Configure the card (see Chapter 4, “Modbus Card Configuration”

on page 13).

6. Run the Modbus Profiler tool to integrate the UPS data with the

building management software (see Chapter 5, “Integrating the

UPS” on page 17).

Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping

cartons and packing materials for the carrier or place of purchase and file

a claim for shipping damage. If you discover damage after acceptance,

file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with

the carrier within 15 days of receipt of the equipment; 2) Send a copy of

the damage claim within 15 days to your service representative.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

3

Page 8

INSTALLING THE MODBUS CARD

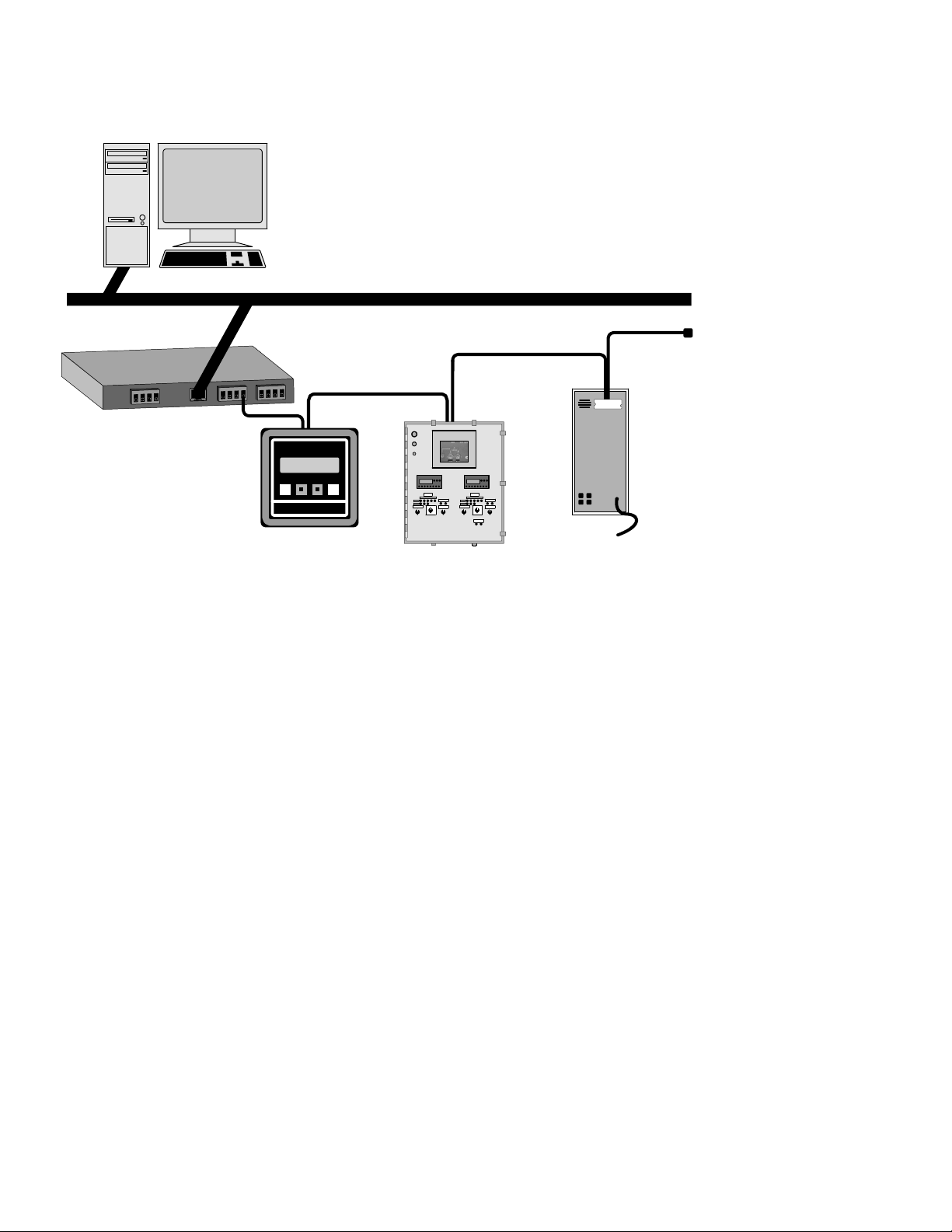

Four-Wire Communication

The factory-default setting for the Modbus Card is for two-wire

communication. To change the default setting, adjust the jumpers on the

Modbus Card.

To prevent electrostatic discharge (ESD), place one hand on an unpainted metal surface such

as the UPS rear panel.

1. If you are installing the Modbus Card into an X-Slot, complete

Step 3 only.

If you are installing the Powerware Expansion Chassis with your

UPS, complete Steps 2 through 4.

2. Remove the card from the slot on the Powerware Expansion

Chassis rear panel. Retain the screws (see Figure 3).

CAUTION

Figure 3. Removing the Modbus Card

4

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 9

INSTALLING THE MODBUS CARD

3. Change the J9 and J10 jumpers to the desired setting as shown in

Figure 4.

Two-Wire

(Default)

J7 J8

J10

J9

1

ON

S2

1

23456

J11

J10

1

1

J9

Four-Wire

J10

1

1

J9

Figure 4. Modbus Card Jumpers

4. Reinstall the Modbus Card into the Powerware Expansion Chassis.

Align the Modbus Card with the slot guides and slide the card into

the slot until it is firmly seated.

Secure the Modbus Card with the screws removed in Step 2.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

5

Page 10

INSTALLING THE MODBUS CARD

Installing the Modbus Card into an X-Slot

To prevent electrostatic discharge (ESD), place one hand on an unpainted metal surface such

as the UPS rear panel.

1. Remove the X-Slot cover (or existing X-Slot module) on the UPS

rear panel. Retain the screws (see Figure 5).

NOTE Some UPSs may have another X-Slot module already installed (such as the

Powerware 9125 UPS). If there is a communication cable attached to this module, disconnect

the cable and then remove the X-Slot module.

CAUTION

Figure 5. Removing the Single-Port Module

2. Install the Modbus Card into the X-Slot on the UPS.

Align the Modbus Card with the slot guides and slide the card into

the slot until it is firmly seated.

Secure the Modbus Card with the screws removed in Step 1.

6

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 11

Chapter 3 Wiring the Modbus Card

The Modbus Card provides an easy path for integrating a Powerware

UPS into an RS-485 Modbus network and also provides isolation of the

communication between the UPS and the RS-485 Modbus network.

You can use the DB-9 port or terminal strip on the Modbus Card to wire

into a two-wire or four-wire network.

Two-Wire Networks

The Modbus Card’s default configuration is for two-wire, half-duplex,

RS-485 networks. Figure 6 shows a detailed view of two-wire

connections using the Modbus Card terminal strip.

Slave Device #1

Slave Device #2

UPS with

Modbus Card

RxD+ RxD–

RT*

Master Device

T-R-T+

R+

Gnd

T-- R+T+ GndR--

RT*

T-- R+T+ GndR--

*See Note

Figure 6. Two-Wire RS-485 Modbus Network

NOTE Only one transmission pair is used. It is not necessary to jumper the unused pair

together (this connection is made internally). Belden 9841 or equivalent cabling (a single

twisted-pair shielded cable with ground) is recommended.

NOTE If the Modbus Card is the last device installed in the network chain or the length of

the network cable is excessive, termination needs to be enabled (see page 10).

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

7

Page 12

WIRING THE MODBUS CARD

Four-Wire Networks

The Modbus Card also supports four-wire, half-duplex, RS-485 networks.

Figure 7 shows a detailed view of four-wire connections using the

Modbus Card terminal strip.

Slave Device #1

Master Device

RT*

T-R-T+

R+

Gnd

Slave Device #2

T--R+ T+Gnd R-- T--R+ T+Gnd R--

UPS with

Modbus Card

RxD+ RxD–TxD+ TxD–

RT*

RT*

RT*

NOTE Belden 9842 or equivalent cabling (a dual twisted-pair shielded cable with ground)

is recommended.

NOTE If the Modbus Card is the last device installed in the network chain or the length of

the network cable is excessive, termination needs to be enabled (see page 10).

RS-485 Terminal Strip

The RS-485 five-position terminal strip provides an alternate interface to

attach the RS-485 transmission lines. This connector also allows external

resistors to be applied to terminate the network.

Before connecting the RS-485 network to the Modbus Card, remove the

detachable plug from the 5-pin terminal strip connector. The RS-485

signal names are shown just above the connector (see Figure 8).

For two-wire networks. Connect the RS-485 network signal TxD(+) to the

RxD(+) input signal on the Modbus Card terminal strip. Connect the

RS-485 network signal TxD(–) to the RxD(–) input signal on the Modbus

Card terminal strip. The Modbus Card factory-default jumper setting for

J9 and J10 is two-wire communication.

*See Note

Figure 7. Four-Wire RS-485 Modbus Network

8

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 13

WIRING THE MODBUS CARD

For four-wire networks. All four RS-485 network signals including TxD(+),

RxD(+), TxD(–), and RxD(–) must be connected to the terminal strip as

illustrated in Table 1. Verify that the Modbus Card J9 and J10 jumpers

are set to the four-wire option (see “Four-Wire Communication” on

page 4).

TxD+ RxD+ TxD– RxD– GND

12345

Figure 8. RS-485 Terminal Strip

Table 1. RS-485 Terminal Strip Pin Assignments

Pin Number Modbus Card Signal Name

1 TxD(+) RxD(+)

2 RxD(+) TxD(+)

3 TxD(–) RxD(–)

4 RxD(–) TxD(–)

5 Signal common Signal common

RS-485 Network Signals

Master Signal Name

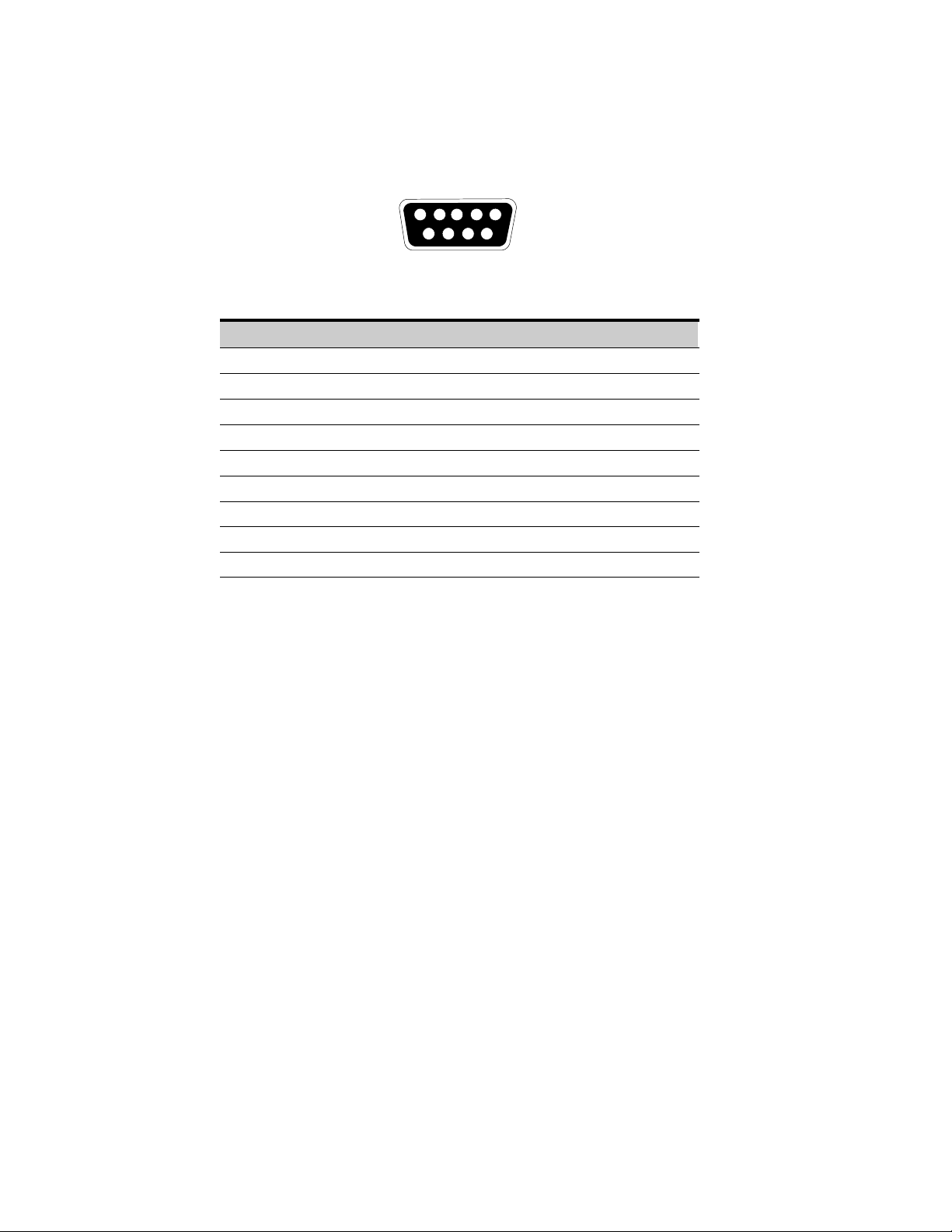

RS-485 Modbus Port

For two-wire networks. Connect the RS-485 network signal TxD(+) to the

Modbus RxD(+) input signal (DB-9 Pin 1). Connect the RS-485 network

signal TxD(–) to the Modbus RxD(–) input signal (DB-9 Pin 6). The

Modbus Card factory-default jumper setting for J9 and J10 is two-wire

communication.

For four-wire networks. All four RS-485 network signals including TxD(+),

RxD(+), TxD(–), and RxD(–) must be connected to the pin assignments

on the DB-9 connector as illustrated in Table 2. Verify that the Modbus

Card J9 and J10 jumpers are set to the four-wire option (see “Four-Wire

Communication” on page 4).

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

9

Page 14

WIRING THE MODBUS CARD

3

245

1

9

8

7

6

Figure 9. RS-485 DB-9 Pin Numbers

Table 2. RS-485 DB-9 Pin Assignments

Pin Number Modbus Card Signal Name

1 RxD(+) TxD(+)

2 TxD(+) RxD(+)

3 Signal common Signal common

4 Reserved —

5 Reserved —

6 RxD(–) TxD(–)

7 TxD(–) RxD(–)

8 Reserved —

9 Reserved —

RS-485 Network Signals

Master Signal Name

Termination

10

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

CAUTION

Termination resistors should be placed only at the extreme ends of the RS-485 network. No

more than two termination points should be used in the RS-485 network.

Termination is not required unless the Modbus Card is located at the

end of the RS-485 network or the length of the network cable is

excessive.

If receive termination is required, an on-board 120 ohm termination

resistor may be selected by setting S2-3 to the ON position. A 120 ohm

resistor will be placed in parallel with the RxD(+) and RxD(–) lines (see

Figure 10).

If transmit termination (four-wire networks) is required, an on-board

120 ohm termination resistor may be selected by setting S2-4 to the ON

position. A 120 ohm resistor will be placed in parallel with the TxD(+)

and TxD(–) lines (see Figure 10).

Page 15

WIRING THE MODBUS CARD

Four-Wire

Two-Wire

ON

*OFF

J7 J8

J10

J9

1

S2

J11

123456

*Factory-default = OFF

TxD(–) Pull Down (620Ω)

TxD(+) Pull Up (620Ω)

TxD Terminator (120Ω)

RxD Terminator (120Ω)

RxD(+) Pull Up (620Ω)

RxD(–) Pull Down (620Ω)

Figure 10. S2 Termination Configuration

If a value other than the on-board 120 ohm termination is required, then

S2-3 and S2-4 should be set to the OFF position. The Modbus Card

terminal strip provides easy access to attach external termination

resistors across the TxD(+), TxD(–), RxD(+), and RxD(–) RS-485 network

lines.

Biasing Resistors

CAUTION

Biasing resistors should be used at only one point in the RS-485 network.

Biasing resistors are used to ensure that the idle voltage sensed across

the receiver does not create false data bits. The factory-default for

S2 (1–6) is OFF.

Two on-board 620 ohm biasing resistors may be selected by setting

S2-1 and S2-2 to the ON position. If biasing is set at the master terminal

unit, then S2-1, S2-2, S2-5, and S2-6 should be set to the OFF position.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

11

Page 16

WIRING THE MODBUS CARD

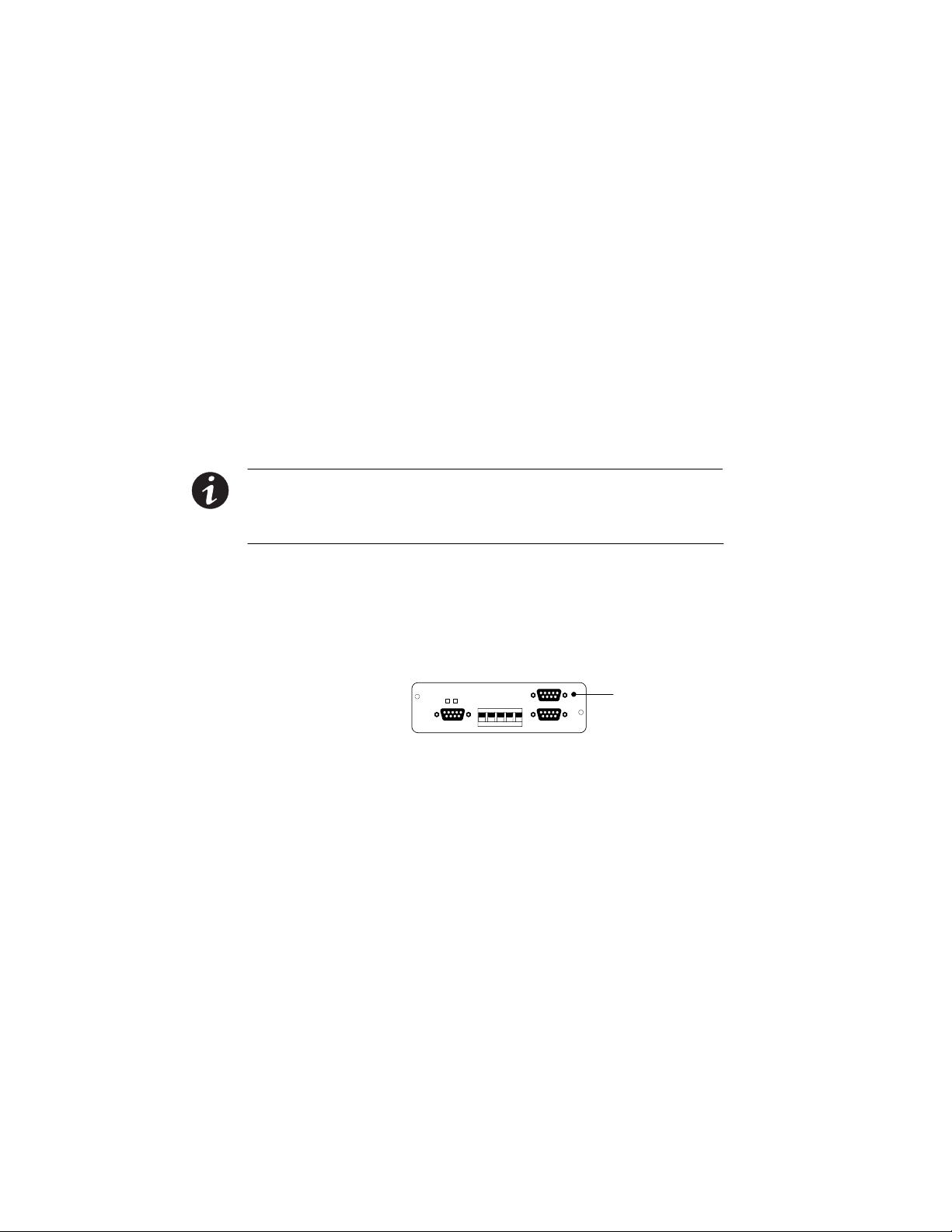

RS-232 Modbus Port

It is also possible to use the RS-232 Modbus port for connecting to your

network.

Table 3. RS-232 DB-9 Pin Assignments

3

245

1

9

8

7

6

Figure 11. RS-232 DB -9 Pin Numbers

Pin Number Function Direction from the Modbus Card

1 No connection —

2 RS-232 transmit data Out

3 RS-232 receive data In

4 No connection —

5 Signal common —

6 No connection —

7 No connection —

8 No connection —

9 No connection —

12

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 17

Chapter 4 Modbus Card Configuration

The Modbus Card has an RS-232 configuration port that you can access

with a terminal or a computer equipped with a terminal emulation

program.

To use the configuration screens for the Modbus Card, you need:

S A serial communication cable (supplied).

S A terminal with a serial communication port, or a computer with a

terminal emulation program such as HyperTerminal

The serial line should be set to 9600 baud, No parity, 8 data bits,

1 stop bit, and no hardware handshaking. The configuration port

always runs at these settings.

Configuring the Modbus Card

NOTE The Modbus Card is already configured for communication at 9600 baud and the

slave address is set to 29. If you do not need to change these settings, continue to Chapter 5,

“Integrating the UPS” on page 17 to integrate the UPS data with your building management

software.

To connect the card to the computer and start the terminal emulation

program:

R

1. Connect the supplied serial cable from the configuration port on the

Modbus Card to an available RS-232 communication port on your

computer (see Figure 12).

Configuration

Port

Figure 12. Configuration Port

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

13

Page 18

MODBUS CARD CONFIGURATION

2. Press [Enter]. The Configuration screen appears (see Figure 13).

Current Configuration:

Baud Rate: 9600

Slave Address: 29

-----------------------------------------------------------------------------

Valid Commands:

AD Change Slave Address, usage AD n,

where n is the new slave address for the card (1 - 247 valid).

BD Change Modbus Baud Rate, usage BD n,

where n is the new baud rate (1200, 2400, 4800, 9600, 19200).

SA Save Configuration

-----------------------------------------------------------------------------

Powerware Modbus Card

Version 1.00 (1-16-02)

Figure 13. Configuration Screen

If the Configuration screen does not appear, press [Enter] one more

time.

14

If you still do not see the Configuration screen, check the following

conditions:

S The communication settings of the terminal should be

9600 baud, No parity, 8 data bits, 1 stop bit, and no hardware

handshaking.

S If the serial configuration is correct, check the cabling to be sure

all connections are secure.

S Verify that your terminal emulation program is on the correct

communication port for serial communication.

S Verify that the UPS has input power and is turned on.

3. To configure the Modbus Card baud rate, type BD followed by a

space and the baud rate (1200, 2400, 4800, 9600, or 19200) and

press [Enter]. The default is 9600 baud. This setting affects both

RS-232 and RS-485 Modbus connections.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 19

MODBUS CARD CONFIGURATION

4. To configure the slave address, type AD followed by a space and

node (1 through 247) and press [Enter]. The default is 29. This

setting affects both RS-232 and RS-485 Modbus connections.

5. To save and exit, type SA and press [Enter] to permanently save the

new configuration changes.

6. The card is now configured. Shut down the terminal emulation

program and disconnect the serial cable from the Modbus Card.

7. Continue to Chapter 5, “Integrating the UPS” on page 17.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

15

Page 20

MODBUS CARD CONFIGURATION

16

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 21

Chapter 5 Integrating the UPS

Powerware provides a software tool named Modbus Profiler that

creates a Modbus register map specifically for your Powerware UPS.

Refer to the Master Modbus Register Map for a complete list of the

Status, Alarm, and Meter data for all Powerware UPS equipment (open

the reg_map.pdf file in the directory where the Modbus Profiler tool is

located).

You need the following system requirements to install the Modbus

Profiler tool:

S Microsoft

S 100 KB of free hard drive space

S 100 KB of free RAM

S An open RS-232 communication port on your computer

S A working Internet connection

Generating Modbus Data

To generate Modbus data that your building management software

needs to poll UPS information:

1. Connect the supplied serial cable from the configuration port on the

Modbus Card to an available RS-232 communication port on your

computer (see Figure 14).

2. Create a directory on your computer for the Modbus Profiler tool,

such as: c:\ModbusProfiler

3. Download the Modbus Profiler tool from the Powerware Web site

at: http://www.powerware.com/software/modbus_profiler.asp

®

Windows®9x, NT, 2000, or XP operating system

Configuration

Port

Figure 14. Configuration Port

4. Unzip the files to the directory created in Step 2.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

17

Page 22

INTEGRATING THE UPS

5. Run profiler from the command prompt or double-click profiler.exe

from Microsoft Windows Explorer.

By default, Modbus Profiler uses the communication port specified

in the [Connection] section of the profiler.ini file. If profiler fails to

connect using this communication port, you are prompted with a

list of alternate communication ports. You may also edit the Port=

value in the [Connection] section of the profiler.ini file to change the

default value.

6. Modbus Profiler creates an output file named profiler.csv in the

directory where the Modbus Profiler tool is located.

Before the program exits, you are prompted to view the data.

The comma delimited file can be easily imported into Microsoft

Excel for viewing of the Modbus data. This data is used to create

the necessary template files on your Building Management System

for polling the desired UPS information.

NOTE Modbus Profiler does not provide Modbus data for the Powerware 9315 Series UPS.

Powerware 9315 configuration-specific profiles are available in the directory where the

Modbus Profiler tool is located (refer to the 950*.pdf files).

Example Modbus Profiler Output Files

The following tables are sample Modbus Profiler output files for a

Powerware 9315 Reverse Transfer (RT) Single Module UPS. Refer to the

Master Modbus Register Map for a complete list of the Status, Alarm,

and Meter data for all Powerware UPS equipment (open the

reg_map.pdf file in the directory where the Modbus Profiler tool is

located).

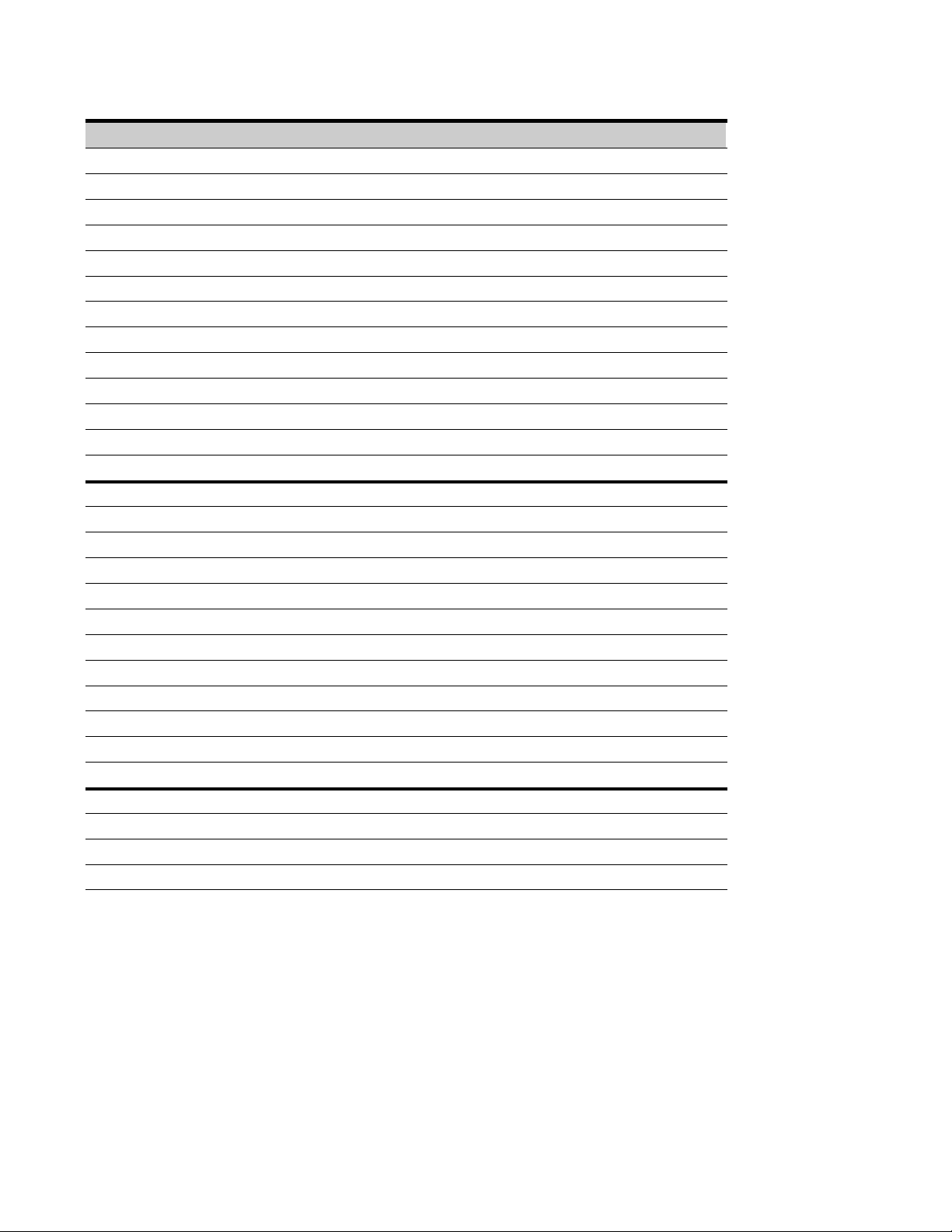

Table 4. Read Input Status - Modbus Function Code 02 (Inputs Start at 10000)

Register Name Value Format Unit

1 On Battery 0 BOOL Status

10 On Bypass 1 BOOL Status

11 System Normal 0 BOOL Status

16 UPS Off 0 BOOL Status

NOTE Registers 1–16 are mutually exclusive.

112 Rectifier Status 1 BOOL Status

18

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 23

INTEGRATING THE UPS

UnitFormatValueNameRegister

113 Rectifier Input Status 1 BOOL Status

114 Bypass Status 0 BOOL Status

115 Bypass Input Status 1 BOOL Status

116 Input Circuit Breaker Status (CB1) 1 BOOL Status

117 Battery Disconnect Status 1 BOOL Status

118 Inverter Disconnect Status 1 BOOL Status

119 Inverter Status 1 BOOL Status

120 UPM Normal 0 BOOL Status

121 UPM On Battery 0 BOOL Status

122 UPM Bypass (Off Line) 0 BOOL Status

123 UPM Notice 0 BOOL Status

124 UPM Alarm 0 BOOL Status

125 UPM Standby 0 BOOL Status

144 Inverter AC over voltage 0 BOOL Status

145 Inverter AC under voltage 0 BOOL Status

146 Inverter under or over frequency 0 BOOL Status

147 Bypass AC over voltage 0 BOOL Status

148 Bypass AC under voltage 0 BOOL Status

149 Bypass under or over frequency 0 BOOL Status

150 Input AC over voltage 0 BOOL Status

151 Input AC under voltage 0 BOOL Status

152 Input under or over frequency 0 BOOL Status

153 Output AC over voltage 0 BOOL Status

154 Output AC under voltage 0 BOOL Status

155 Output under or over frequency 0 BOOL Status

158 Building Alarm 6 0 BOOL Status

159 Building Alarm 5 0 BOOL Status

160 Building Alarm 4 0 BOOL Status

161 Building Alarm 3 0 BOOL Status

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

19

Page 24

INTEGRATING THE UPS

162 Building Alarm 2 1 BOOL Status

163 Building Alarm 1 0 BOOL Status

169 Output overload 0 BOOL Status

172 DC link over voltage 0 BOOL Status

173 DC link under voltage 0 BOOL Status

174 Rectifier failed 0 BOOL Status

176 Battery contactor fail 0 BOOL Status

177 Bypass breaker fail 0 BOOL Status

191 Battery current limit 0 BOOL Status

194 Output current over 100% 0 BOOL Status

199 Shutdown imminent 0 BOOL Status

200 Battery low 0 Status

212 Battery DC over voltage 0 BOOL Status

214 Power supply failure 0 BOOL Status

229 Network not responding 0 BOOL Status

241 Emergency shutdown command 0 BOOL Status

249 Bypass not available 0 BOOL Status

251 Battery contactor open 0 BOOL Status

252 Inverter contactor open 0 BOOL Status

270 Battery totally discharged 0 BOOL Status

295 Battery not charged 0 BOOL Status

312 UPS On Battery 0 BOOL Status

313 UPS On Bypass 1 BOOL Status

314 Load Dumped (Load Power Off) 0 BOOL Status

337 Fan Failure 0 BOOL Status

345 Transformer Over Temperature 0 BOOL Status

361 Input Breaker Failed 0 BOOL Status

UnitFormatValueNameRegister

20

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 25

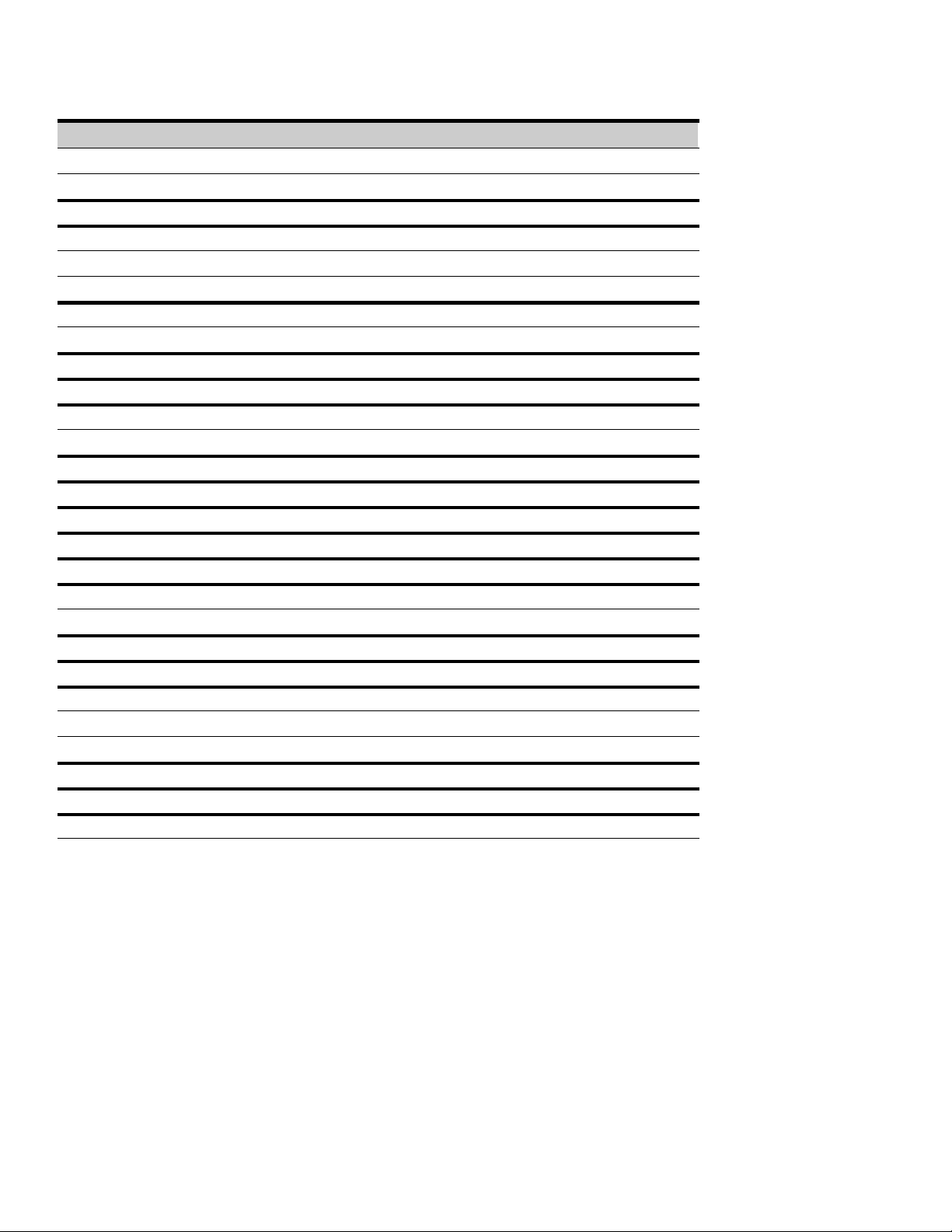

Table 5. Read Input Registers - Modbus Function Code 04 (Input Registers Start at 30000)

Register Meter Name Scale Unit

1 OUTPUT VOLTS AB /10 Volts

2 OUTPUT VOLTS BC /10 Volts

3 OUTPUT VOLTS CA /10 Volts

4 INPUT VOLTS AB /10 Volts

5 INPUT VOLTS BC /10 Volts

6 INPUT VOLTS CA /10 Volts

10 BYPASS VOLTS AB /10 Volts

11 BYPASS VOLTS BC /10 Volts

12 BYPASS VOLTS CA /10 Volts

19 INPUT CURRENT PHASE A /10 Amps

20 INPUT CURRENT PHASE B /10 Amps

21 INPUT CURRENT PHASE C /10 Amps

22 OUTPUT TRUE POWER /10 kW

23 INPUT TRUE POWER /10 kW

24 OUTPUT APPARENT POWER /10 kVA

25 INPUT APPARENT POWER /10 kVA

26 OUTPUT POWER FACTOR /100 —

27 INPUT POWER FACTOR /100 —

28 OUTPUT FREQUENCY /10 Hz

29 INPUT FREQUENCY /10 Hz

30 INVERTER FREQUENCY /10 Hz

31 BYPASS FREQUENCY /10 Hz

33 BATTERY CURRENT /10 Amps

34 BATTERY VOLTAGE /10 Volts

35 % BATTERY LEFT /10 %

36 BATTERY TIME REMAINING /10 Minutes

60 INVERTER VOLTS PHASE A /10 Volts

61 INVERTER VOLTS PHASE B /10 Volts

INTEGRATING THE UPS

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

21

Page 26

INTEGRATING THE UPS

62 INVERTER VOLTS PHASE C /10 Volts

66 LOAD CURRENT PHASE A /10 Amps

67 LOAD CURRENT PHASE B /10 Amps

68 LOAD CURRENT PHASE C /10 Amps

69 LOAD CURRENT PHASE A BAR CHART /10 Amps

70 LOAD CURRENT PHASE B BAR CHART /10 Amps

71 LOAD CURRENT PHASE C BAR CHART /10 Amps

72 OUTPUT VA BAR CHART /10 kVA

79 OUTPUT VOLTS A /10 Volts

80 OUTPUT VOLTS B /10 Volts

81 OUTPUT VOLTS C /10 Volts

UnitScaleMeter NameRegister

22

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 27

Chapter 6 Troubleshooting

g

Problem Possible Cause Corrective Action

The Modbus Profiler

tool does not

generate the

profiler.csv file

Communication

doesn’t work

The wrong communication port number was

entered in the profiler comX command.

The serial cable is not connected.

Incorrect communication parameters. Verify that the communication parameters are

RS-485 communication lines are reversed. For two-wire networks. Verify that the

Verify the correct port number on your

computer that is connected to the Modbus

Card.

Verify that the serial cable connections are

secure.

set to the desired baud rate, No parity, 8 data

bits, 1 stop bit, and no hardware handshaking.

master RS-485 network signal TxD(+) is

connected to the Modbus Card RxD(+) input

signal and the RS-485 network signal TxD(–)

is connected to the Modbus Card RxD(–) input

signal.

For four-wire networks. Verify that all four

RS-485 network signals are connected to the

terminal strip or DB-9 connector as illustrated

in Table 1 on page 9 or Table 2 on page 10,

respectively.

See Chapter 3, “Wiring the Modbus Card” on

page 7 for more information.

If the Modbus Card is the last device installed

in the network chain or the length of the

network cable is excessive, termination

needs to be enabled.

J9 and J10 jumpers could be in the incorrect

position for your configuration.

The polling rate in the Building Management

Software (BMS) application or Modbus

software is set below 500 mS.

Verify the termination settings (see

“Termination” on page 10 for the correct

settings).

Verify the jumpers are in the correct position

(see Figure 4 on page 5).

The Modbus Card updates the status of the

Eaton equipment every 1000 mS. Configure

the BMS/Modbus application polling rate to

500 mS or greater to ensure proper operation.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

23

Page 28

TROUBLESHOOTING

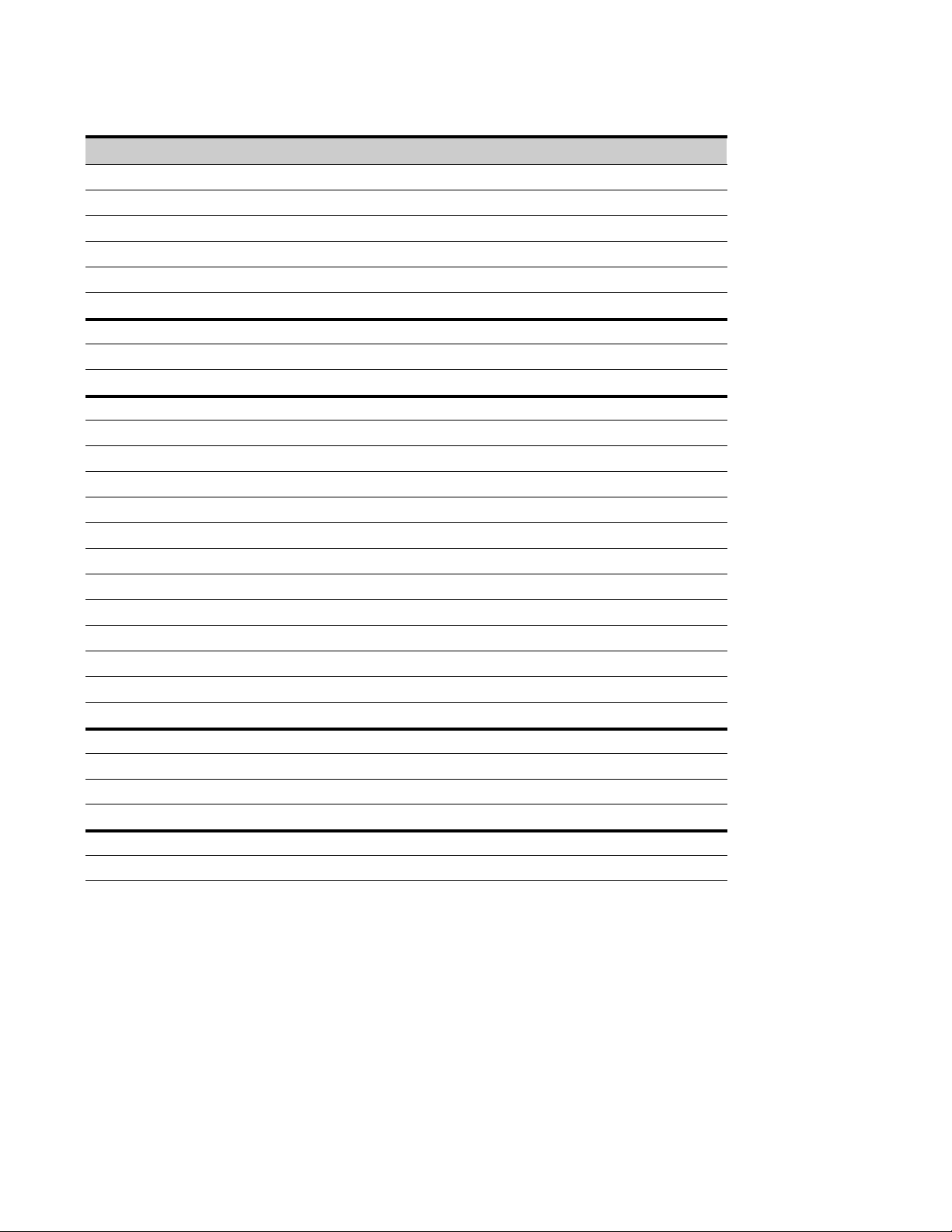

J7 J8

DCE

(Default)

11

J10

J9

1

ON

S2

Termination

(Default ”OFF”)

S2

213456

J11

J11

Half Duplex

(Default)

1

Full-Duplex

1

Figure 15. Modbus Card Default Jumper Settings

J7 J8

DCE/DTE

Two-Wire

(Default)

J10

1

1

J9

Two-Wire/Four-Wire

24

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 29

Service and Support

If you have any questions or problems with the Modbus Card, call your

Local Distributor or the Help Desk at one of the following telephone

numbers and ask for a Modbus Card technical representative.

TROUBLESHOOTING

United States:

1-800-356-5737 or 1-919-870-3149

Canada: 1-800-461-9166 ext 260

All other countries: Call your local service representative

Please have the following information ready when you call the Help

Desk:

S Model number

S Date of failure or problem

S Symptoms of failure or problem

S Customer return address and contact information

If repair is required, you will be given a Returned Material Authorization

(RMA) Number. This number must appear on the outside of the package

and on the Bill Of Lading (if applicable). Use the original packaging or

request packaging from the Help Desk or distributor. Units damaged in

shipment as a result of improper packaging are not covered under

warranty. A replacement or repair unit will be shipped, freight prepaid for

all warrantied units.

NOTE For critical applications, immediate replacement may be available. Call the Help

Desk for the dealer or distributor nearest you.

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

25

Page 30

TROUBLESHOOTING

26

EATON Powerware®Modbus®Card User’s Guide S 164201376 Rev C www.powerware.com

Page 31

Page 32

*164201376C*

164201376 C

Loading...

Loading...