Page 1

Series 685 and 1085

Auxiliary Battery

Cabinets

350

9

Installation

Manual

164201408 Rev. P00

Page 2

IMPORTANT SAFETY INSTRUCTIONS

Instructions Importantes Concernant La Sécurité

SAVE THESE INSTRUCTIONS

Conserver Ces Instructions

This manual contains important instructions for your battery

system. You should follow these instructions during the

installation and maintenance of the battery cabinets.

Cette notice contient des instructions importantes

concernant la sécurité.

The installation of battery cabinets should be performed or supervised by

personnel knowledgeable of batteries and their associated precautions. Keep

unauthorized personnel away from battery cabinets.

Observe these precautions when working on or around battery cabinets:

• Remove watches, rings, or other metal objects.

• Use tools with insulated handles.

• Wear rubber gloves and boots.

• Do not lay tools or metal parts on top of batteries or battery cabinets.

• Disconnect the charging source prior to connecting or disconnecting terminals.

• The battery cabinet frame is not referenced to the DC circuit.

• When replacing batteries, use the same number and type of sealed, lead-acid

batteries.

• Refer to local codes for proper disposal requirements for used batteries.

CAUTION:

Do not dispose of battery or batteries in a fire.

The battery may ex plode.

CAUTION:

Do not open or mutilate the battery or batteries.

Released electroly te is ha rmful to the skin and eyes, and may be toxic.

CAUTION:

A battery can cause electrical shock, burn from high short-circuit current, or fire.

Observe proper precautions.

ii

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 3

ATTENTION:

Une batterie peut prêsenter un risque de choc êlectrique, de brulure, ou d’incendie. Suivre les précautions qui s’imposent.

• Pourleremplacement,utiliserlemêmenombreetmodéledesbatteries.

• L’élimination des batteries est règlementée. Consulter les codes locaux à cet

effet.

General Notes About Installing Battery Cabinets

Each battery cabinet is packed and crated separately for shipping. You should

unpack and inspect each cabinet, roll it to its final position, and join it to the UPS

or other cabinets (refer to Chapter 3 or Chaper 4) before installing wiring.

These general installation notes apply to either the Series 685 Battery Cabinet

or the Series 1085 Battery Cabinet:

• Do not tilt battery cabinets more than 10˚ during installation.

• The recommended minimum clearance over each battery cabinet is

305 mm (12 in.).

• The conduit landing plates are removable to add conduit landing holes as

required. The conduit landing plates should be removed when holes are added

to keep metal particles from falling inside the battery cabinet. Plate material is

16 gauge steel (1.5 mm, 0.06 in. thick).

• Low voltage signal wiring must be installed in a separate conduit from the

power wiring.

• Each battery cabinet can be installed as a stand-alone unit or as part of a

redundant joined system.

• The instantaneous trip circuit breakers for the Series 685 and Series 1085

Battery Cabinets must remain set at minimum (full counterclockwise).

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

iii

Page 4

UPS Systems Using Series 685 and Series 1085 Battery Cabinets

• Powerware 9350 (30 kVA---80 kVA)

• Powerware9350(100kVA---160kVA)

Conventions Used in This Manual

The text in this manual uses these conventions:

• Bold type highlights important concepts in discussions and key terms in

procedures.

• Italic type highlights notes and new terms where they are defined.

• Rectangular boxes containing bold type are warnings or cautions that pertain to

the battery system or its electrical connections.

In this manual, the term UPS refers only to the UPS cabinet and its internal

elements. The term UPS system refers to your entire power protection system—the

UPS cabinet plus battery cabinets that you have installed.

Read through each installation procedure before you begin it. Perform only those

procedures that apply to the battery system you are installing.

NOTE: The term “Separate” refers to battery cabinets that are not physically

attached to the UPS, are wired with external contractor supplied wiring, and

use a single overcurent protection and disconnect device located near the

batteries.

The term “Integral” refers to battery cabinets that are physically attached to

the UPS and the wiring between them is internal. The power wiring is

supplied with the system, and they use the UPS battery switch as the battery

isolation device.

iv

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 5

Table of Contents

1 Introduction 1............................................

Typical Battery Cabinets 1.......................................

Identification of Your Battery System 2.............................

For More Information 4..........................................

Getting Help 4..................................................

2 Unpacking Your Battery Cabinet 5.........................

Preparing Your Site 5............................................

Environmental Considerations 5..................................

Preparing for Wiring the Battery Cabinet 5.........................

Inspecting and Unpacking Each Cabinet 6.........................

Unloading the Battery Cabinet from the Pallet 7.....................

Creating an Installation Plan 9....................................

NOTES: 10.................................................

3 Connecting to Powerware 9350 30 thru 160 11...............

The Powerware 9350 UPS with Integral Battery Cabinets 11...........

Powerware 9350 UPS with Separately Located Battery Cabinets 20....

Separate Installation of Series 685 Battery Cabinets 21...............

Separate Installation of Series 1085 Battery Cabinets 23..............

Completing the Installation Checklist 27............................

Installation Checklist for Powerware 9350 30 through 160 27..........

4 Connecting to Powerware 9350 ---80 and 160 29..............

The Powerware 9350---80 or 160 with Separate Battery Cabinets 30....

Completing the Installation Checklist 31............................

Installation Checklist for Powerware 9350--- 80 or 160 32..............

5 Installing a Remote Battery Disconnect 33..................

Appendix A — Customer Information A---1.......................

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

v

Page 6

dddddddddddddddddddddddddddddddddddddddddddddddddddddddddddddddddddddd

ddddddddddddddddddddddddddddddddddddddddddddddddddddddd

List of

Figures

Figure 1. Typical Battery Cabinets 1.........................................

Figure 2. UPS with Lineup and Match Battery Cabinet 2........................

Figure 3. UPS with Separate Battery Cabinets (Attached to Each Other) 3........

Figure 4. Cabinet as Shipped, with Outer Packaging and Pallet 6................

Figure 5. Removing Front and Rear Supports 8...............................

Figure 6. UPS with Integral Battery Cabinet 11.................................

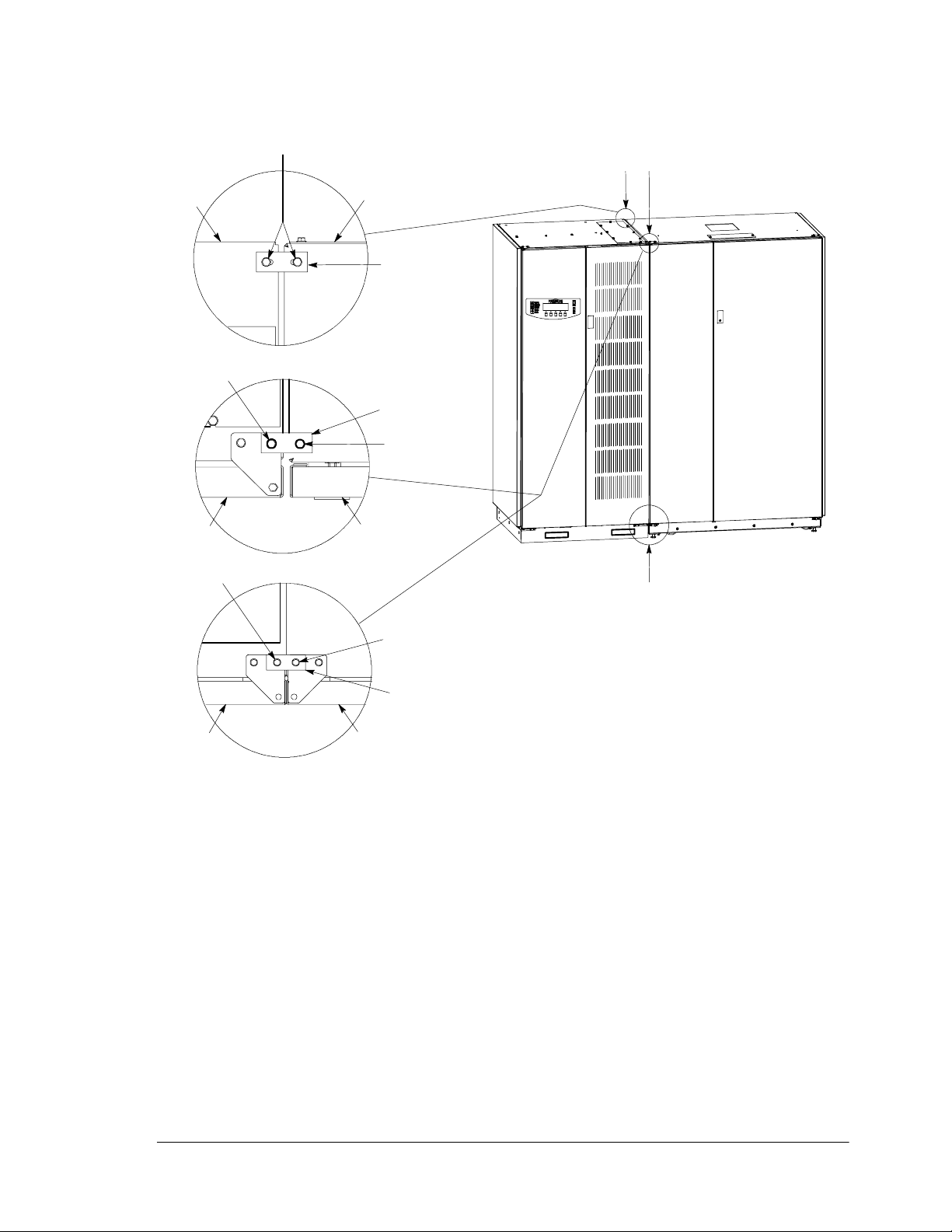

Figure 7. Placement of Attaching Brackets, UPS to Battery Cabinet 13............

Figure 8. Attaching UPS Base to Series 1085 Base 14..........................

Figure 9. Attaching UPS Base to Series 685 Base 15............................

Figure 10. Series 685 Battery Cabinet Wiring Detail 17..........................

Figure 11. Series 685 and 1085 Battery Cabinet Hanger Brackets 18..............

Figure 12. Series 1085 Battery Cabinet Wiring Detail 19.........................

Figure 13. UPS with Separately Located Battery Cabinets 20.....................

Figure 14. Placement of Joining Brackets

(Two or More Series 685 Battery Cabinets) 21.........................

Figure 15. Connecting Two Series 685 Bases 22...............................

Figure 16. Placement of Joining Brackets

(Two or More Series 1085 Battery Cabinets) 23........................

Figure 17. Connecting Two Series 1085 Bases 24..............................

Figure 18. Battery Connections for a Powerware 9350---80 29....................

Figure 19. Battery Connections for a Powerware 9350---160 30...................

Figure 20. Remote Battery Disconnect Enclosure 33............................

Figure 21. Knockout Pattern for Remote Battery Disconnect 35...................

vi

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 7

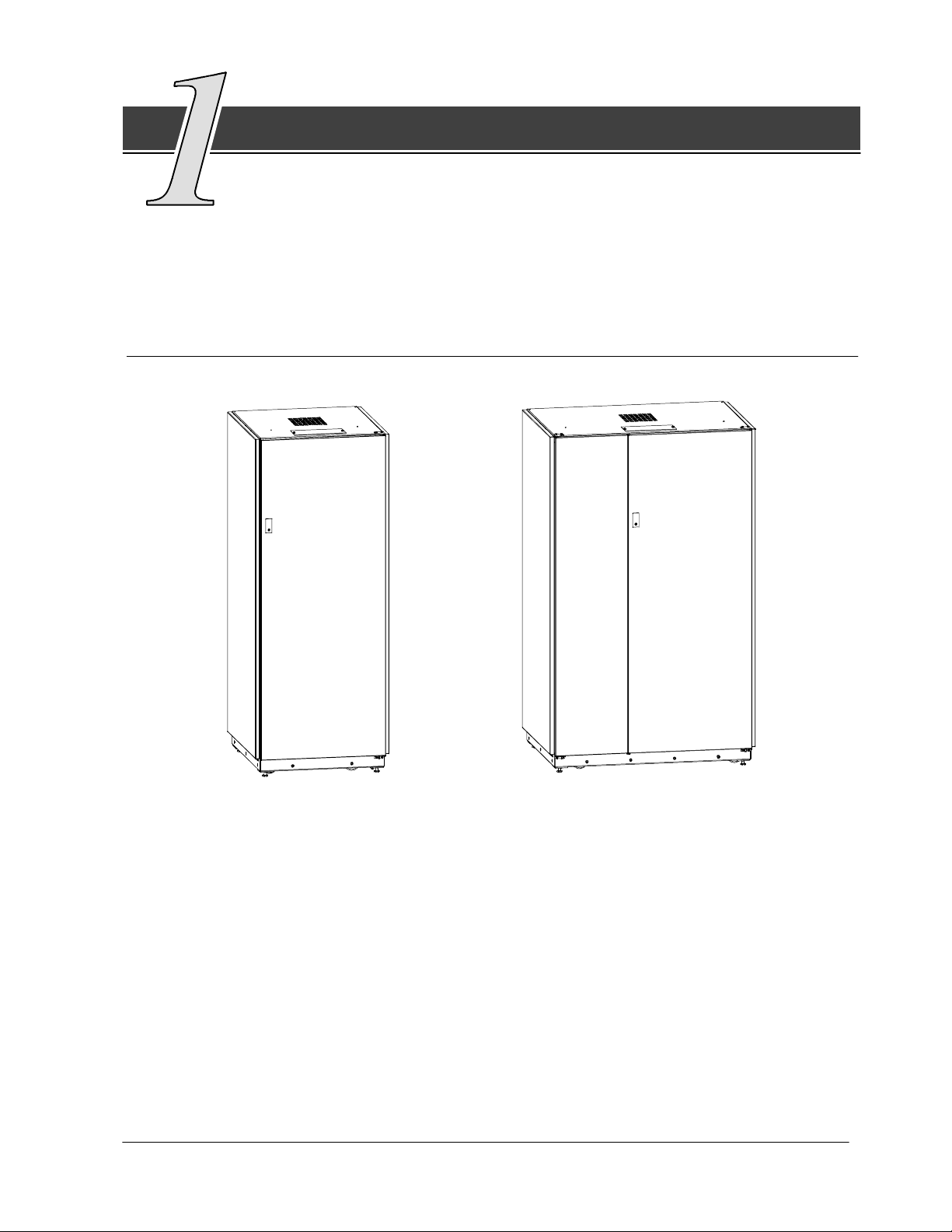

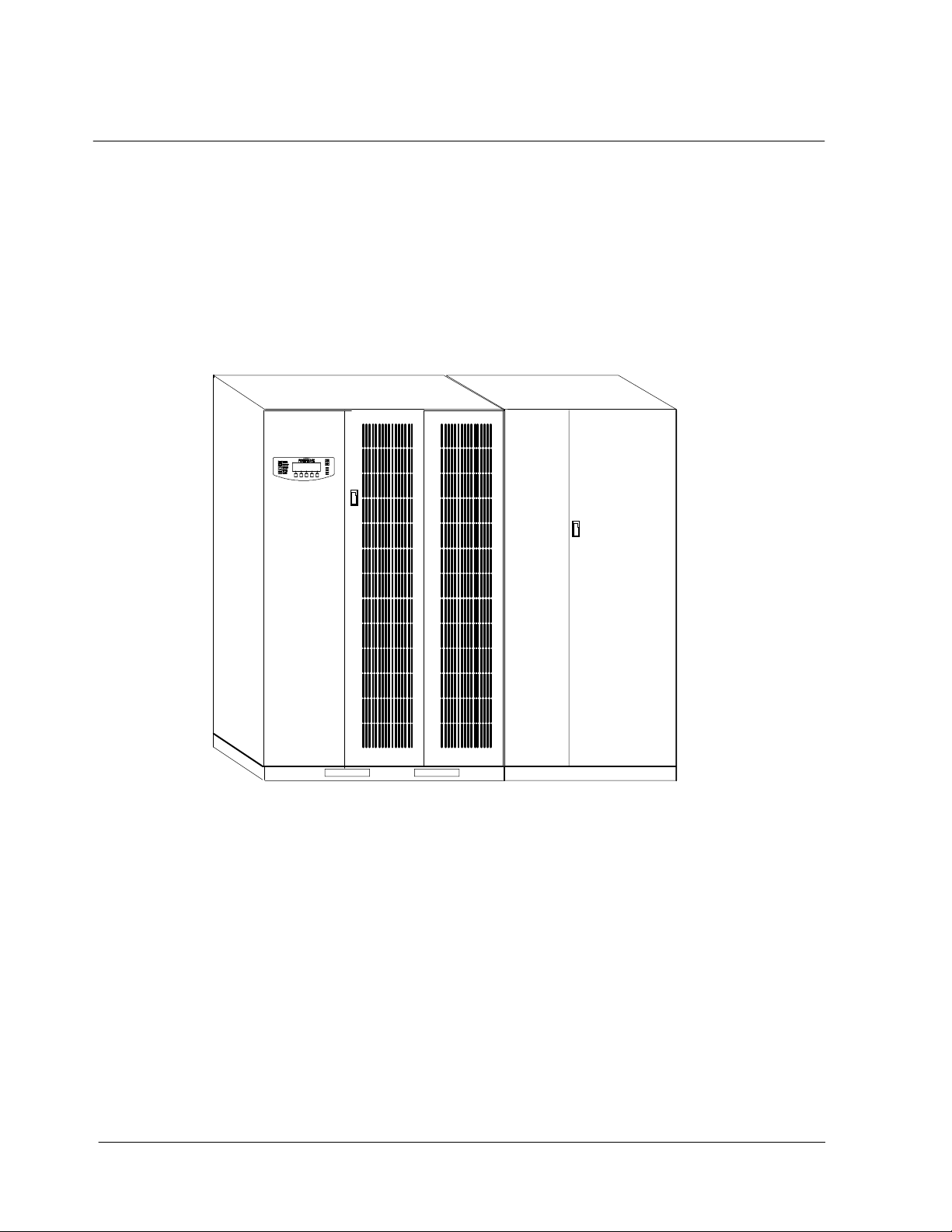

This manual describes how to install the Powerware 9350 Series 685 or

Series 1085 Battery Cabinet (see Figure 1). It contains instructions for

unpacking and inspecting the battery cabinet, locating the battery cabinet with

respect to the UPS, and electrically connecting the battery cabinet to the UPS. The

informationyouwillusedependsonthetypeofUPSandseriesofbatterycabinet

that you purchased.

Typical Battery Cabinets

Introduction

Series 685 Battery Cabinet Series 1085 Battery Cabinet

Figure 1. Typical Battery Cabinets

Two basic battery cabinet configurations are possible:

• The UPS and one or more battery cabinets in an integral configuration

(see Figure 2).

• The UPS and one or more battery cabinets separately installed (see Figure 3).

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

1

Page 8

Identification of Yo ur Battery System

Refer only to the parts of this manual that apply specifically to your system

configuration. See Figures 2 and 3 to determine where to find your system

installation instructions in this manual.

UPS Battery Cabinet

Figure 2. UPS with Lineup and Match Battery Cabinet

For installation instructions, refer to “The Powerware 9350 UPS with Integral Battery

Cabinets” section of Chapter 3. Refer to Chapter 2, “Unpacking Your Battery Cabinet”

for unpacking instructions.

2

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 9

UPS Battery Cabinets

Figure 3. UPS with Separate Battery Cabinets (Attached to Each Other)

For installation instructions, refer to “The Powerware 9350 UPS with Separate Battery

Cabinets” section of Chapter 3 or Chapter 4. Refer to Chapter 2, “Unpacking Your

Battery Cabinet” for unpacking instructions.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

3

Page 10

For More Information

This manual describes how to install your battery cabinet. For more information

about the operation and communications capabilities of your UPS system, refer to

the following:

164201407 Powerware

Describes the UPS installation procedure; discusses optional

accessories, environmental considerations, weight and point

loading, connection diagrams, and information on other optional

cabinets.

Also describes the UPS Cabinet Control Panel and Monitor

Panel, and explains the functions of the UPS; discusses the

standard features of the UPS and optional accessories;

provides procedures for starting and stopping the UPS, and

information about maintenance and responding to system

events.

Contact your local Powerware Corporation Field Service office for information

about how to obtain copies of these manuals.

Getting Help

r

9350 (100 kVA---160 kVA) UPS Installation

If you have a question about any of the information in this manual, or if you have

a question this manual does not answer, please call the Powerware Corporation

Field Service office:

United States 1-800-843-9433

Canada 1-800-461-9166

Outside the U.S. Call your local representative

4

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 11

Unpacking Your Battery Cabinet

Each Powerware 9350 Series 685 or Series 1085 Battery Cabinet is shipped

on a separate pallet. Use a forklift or pallet jack to move the packaged cabinets

to the installation site, or as close as possible to the site, before you unload them

from the pallets.

Battery cabinets must be installed in accordance with all applicable codes and

regulations, including the National Electrical Code (NEC), Article 480.

NOTE: Startup and operational checks should be performed only by authorized

service personnel. This service is offered as part of the sales contract for

your battery system.

Preparing Your Site

The basic environmental requirements for the battery system are:

Ambient Temperature Range: 10 --- 4 0 ˚C (5 0 --- 1 04 ˚F)

Recommended Operating Range: 20 --- 25 ˚C ( 68 --- 77˚F)

Maximum Relative Humidity: 95% noncondensing

The Series 685 or Series 1085 Battery Cabinets use convection cooling to regulate

internal component temperature. Air inlets are in the bottom and top of the

cabinets. You must allow a minimum clearance of 305 mm (12 in.) above each

cabinet for proper air circulation. Additionally, a clearance of 915 mm (36 in.) must

be provided in front of the cabinet for component removal and maintenance .

Maintaining this clearance provides adequate airflow to the front of the cabinet.

Environmental Considerations

The life of the battery system is adversely affected if the installation does not meet

these guidelines:

• The battery cabinet must be installed on a sealed concrete pad

or a sealed concrete floor, or on a raised computer room floor.

• The battery cabinet must be installed in a dust-free, nonconductive

environment.

• The battery cabinet must be installed in a humidity-controlled environment.

Preparing for Wiring the Battery Cabinet

For external wiring requirements, including the minimum AWG size of external

wiring, refer to Appendix A, Table C.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

5

Page 12

Inspecting and Unpacking Each Cabinet

The first task in preparing for installation is inspecting and unpacking each cabinet.

Cabinets arrive covered with protective packaging material, as shown in Figure 4.

P LY --- F OA M C U S HI ON S

Figure 4. Cabinet as Shipped, with Outer Packaging and Pallet

OUTER

PACK A GI N G

6

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 13

1. Carefully inspect the outer packaging for evidence of damage during transit.

CAUTION:

DO NOT INSTALL A DAMAGED CABINET. REPORT ANY DAMAGE TO THE

CARRIER. CONTACT YOUR LOCAL SALES OR SERVICE OFFICE IMMEDIATELY.

2. Use appropriate material handling equipment to move the cabinet to a

convenient unpacking area. Space is provided between the pallets to insert

pallet jack blades on the bottom of the unit.

DANGER:

RISK OF INSTABILITY. DO NOT TILT CABINETS MORE THAN 10 DEGREES

FROM VERTICAL OR THE CABINET MAY TIP OVER.

3. Set each pallet on a firm, level surface, allowing a minimum clearance of 4.6m

(15 ft) on each side for removing the cabinets from the pallets.

4. Cut and remove the steel bands around each cabinet.

5. Remove the protective cardboard covering from the cabinets by vertically cutting

one corner, using a knife blade no longer than 25 mm (1 in.).

6. Remove the corrugated corner protectors, box, plastic bag, and discard or

recycle them in a responsible manner.

CAUTION:

IF YOU CAN SEE DAMAGE IN OR ON A CABINET, DO NOT INSTALL IT.

REPORT ANY DAMAGE TO THE CARRIER. CONTACT YOUR LOCAL SALES OR

SERVICE OFFICE IMMEDIATELY.

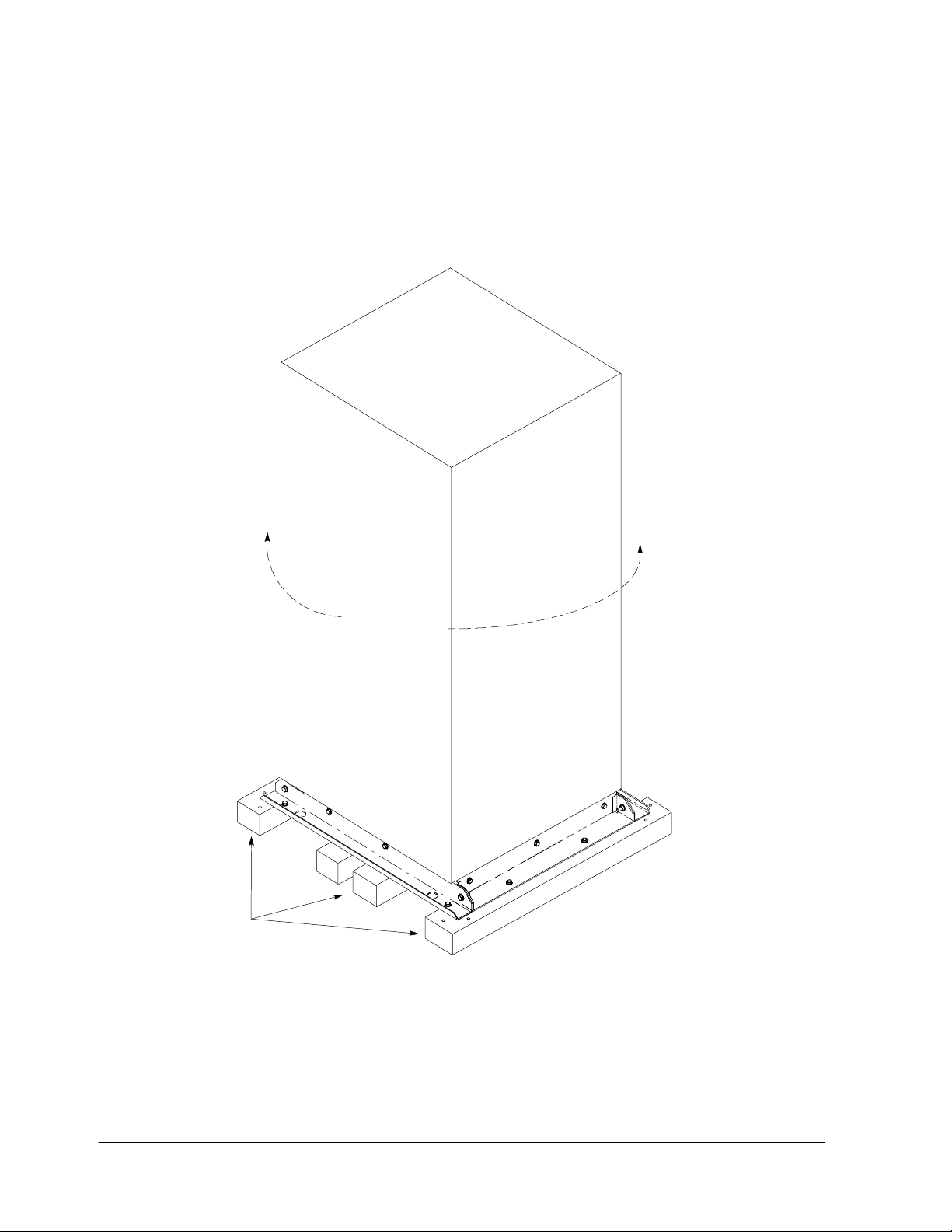

Unloading the Battery Cabinet from the Pallet

The battery cabinet is bolted to a pallet consisting of four angle metal supports

secured to laminated plywood/foam cushions. The foam cushions act as shock

absorbers for the cabinet during shipment.

1. Remove the doors. Remove the retaining screw located inside each door at the

bottom hinge pivot point, then lift the door off. Save the retaining screws for

reinstallation of the doors.

2. Locate the field kit (packed inside of the cabinet). Locate the four 1/2 in. jacking

bolts and install them in the threaded holes in the front and rear supports.

Place a floor protector underneath each jacking bolt, and screw the bolts down

against them. The floor protectors protect the floor from being marred by the

jacking bolts.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

7

Page 14

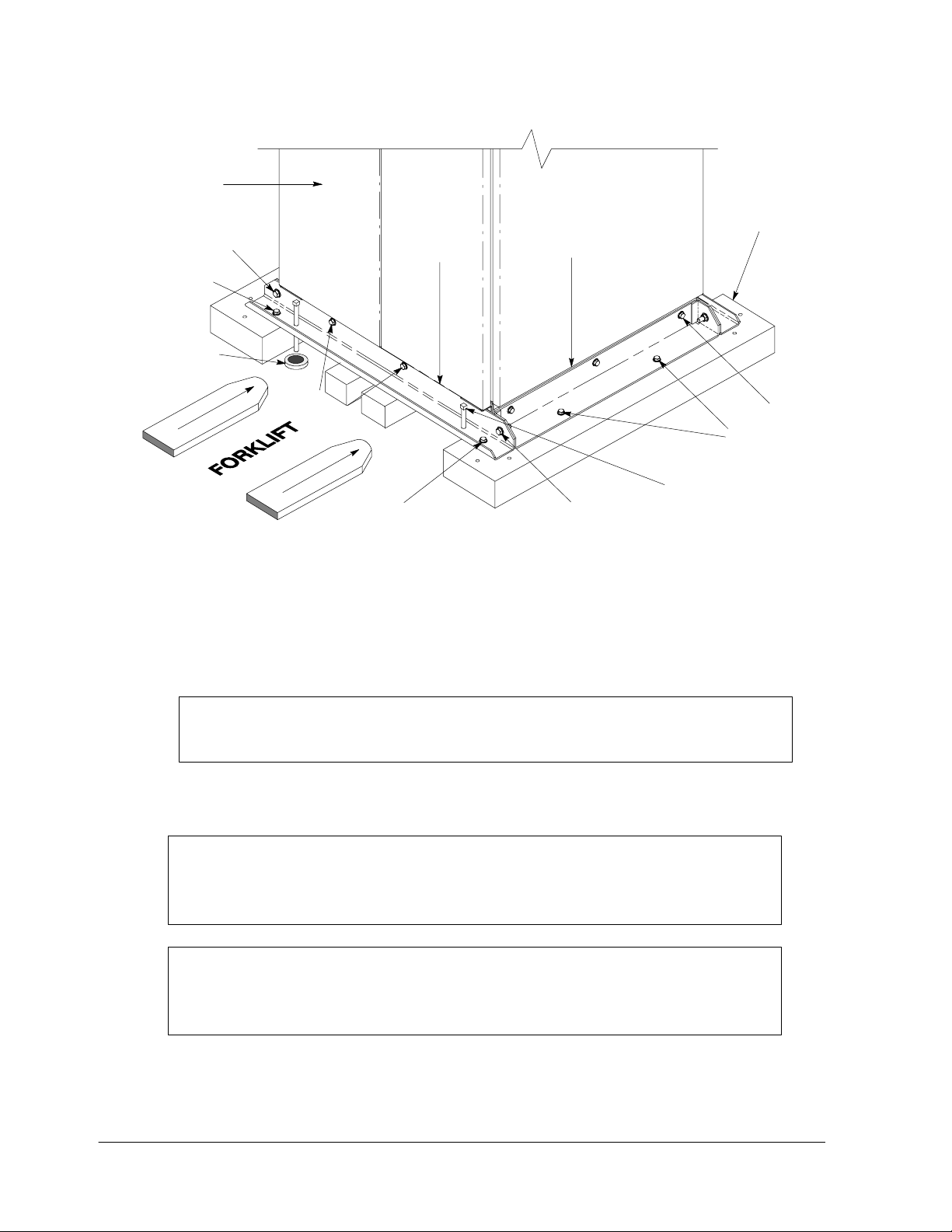

LEFT HAND

DOOR

(Step 1)

1

FLOOR

PROTECTOR

(Step 2)

2

2

2

Figure 5. Removing Front and Rear Supports

FRONT

SUPPORT

1

(Step 3)

SIDE

SUPPORT

2

(Step 8)

JACKING

(Step 2)

FOAM

CUSHION

2

1

BOLT

3. Loosen, but do not remove, the hardware holding the foam cushions to the front

and rear supports (labeled “1” in Figure 5).

WARNING: SERIOUS INJURY MAY OCCUR!

BATTERY CABINETS ARE EXTREMELY HEAVY. IF UNLOADING INSTRUCTIONS

ARE NOT CLOSELY FOLLOWED, CABINET MAY TIP.

4. Turn each jacking bolt consecutively, two full turns, until the foam cushions clear

the floor by approximately 3 mm (1/8 in.).

DANGER: RISK OF INSTABILITY!

TURNING THE JACKING BOLTS UNEVENLY MAY CAUSE THE CABINET TO

BECOME UNBALANCED. TO PREVENT TIPPING THE CABINET, RAISE AND

LOWER THE JACKING BOLTS EVENLY.

DANGER: CABINET MAY TIP!

THE BATTERY CABINET SHOULD ONLY BE RAISED APPROXIMATELY 3 mm

(1/8 in.) ABOVE THE FLOOR (JUST ENOUGH TO ALLOW REMOVAL OF THE

FOAM CUSHIONS).

5. After the foam cushions clear the floor, remove the hardware loosened in Step 3.

Pull the foam cushions out from under the battery cabinet. Please discard or

recycle them in a responsible manner.

8

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 15

DANGER: CABINET MAY FALL!

DONOTLOOSENTHEHARDWAREATTACHINGTHESIDEORFRONT

SUPPORTS TO THE CABINET BASE, OR THE FRONT AND SIDE SUPPORTS

TO EACH OTHER, AT THIS TIME.

THE CABINET MUST BE LOWERED BY THE JACKING BOLTS BEFORE THE

SUPPORTS CAN BE REMOVED.

6. Carefully and evenly lower the cabinet by turning each jacking bolt consecutively

two full turns (maximum)

no longer supported by the jacking bolts.

until the supports contact the floor, and the cabinet is

7. After the battery cabinet is resting on the floor, remove the jacking bolts and

discard or recycle them in a responsible manner.

8. Remove the hardware, labeled “2” in Figure 5, holding the front, rear and side

supports to the cabinet base. Discard or recycle the hardware and support

brackets in a responsible manner.

9. Replace the doors that were removed in Step 1. The battery cabinet is now

readytoberolledtoitsfinallocation.

10. Repeat Steps 1 through 9 for each cabinet you are preparing to install.

Creating an Installation Plan

Before beginning to install your battery cabinet, you should be sure that you

understand the portions of this manual that apply to your system. Use the

procedures and illustrations in the following sections to create a logical plan for

installing the battery cabinet you purchased. Refer to Chapter 3, “Connecting to

Powerware 9350 30 --- 160” to help plan your installation.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

9

Page 16

NOTES:

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

10

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 17

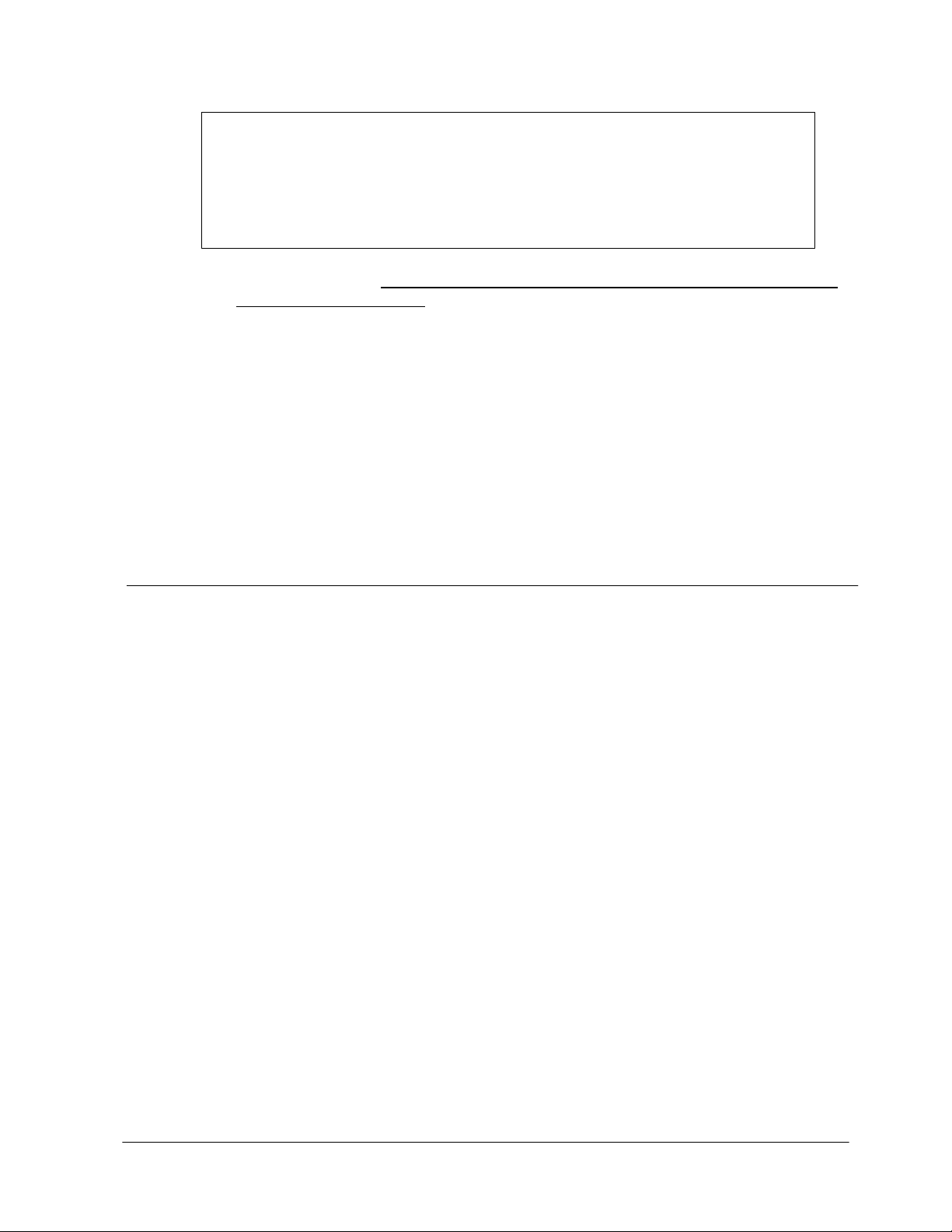

Connecting to Powerware 9350 30 ---160

The method you use to install your battery cabinets depends on which

UPS you have. For the purpose of discussion, this chapter uses the term UPS

to refer to the UPS cabinet, and the term battery cabinet to refer to any battery

cabinet. There are two different sizes of battery cabinets, but the procedure for

connecting the cabinets to your UPS system is the same.

• Joining one or more battery cabinets to the UPS

• One or more battery cabinets separately located from the UPS.

The Powerware 9350 UPS with Integral Battery Cabinets

Use this procedure to attach a Powerware 9350 Series 685 or Series 1085 Battery

Cabinet to any Powerware 9350 UPS cabinet (see Figure 6).

Figure 6. UPS with Integral Battery Cabinet

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

11

Page 18

1. Make sure that the UPS is properly installed and secured with its leveling feet.

2. Roll the battery cabinet to a spot near the right-hand side of the UPS, as

showninFigure7.

3. Thefieldkitisattachedwithcabletiestotheframeinsidethedoor. Remove

and retain the field kit for later use.

4. If necessary, remove the cosmetic covers and hanger brackets from the

right-hand side of the UPS. Save covers, screws, and brackets for later reuse.

5. Push the battery cabinet toward the UPS cabinet until the doors are flush with

each other.

6. Three cabinet attachment brackets are provided for securing each cabinet at

the top and bottom. Two flat brackets join the tops of the cabinets, one at the

frontandoneattheback. Alargerflatbracketjoinsthecabinetsatthe

bottom. Attach the flat brackets to the cabinet tops first.

7. For Series 685 Battery Cabinets, remove the right-hand screw from the top

right door hinge of the UPS cabinet. Align the hole in one flat bracket over this

screw hole, and the other hole over the hole in the top of the battery cabinet.

Replace the screw in the hinge, and attach the other end of the bracket to the

top of the battery cabinet using an M4×10 hex screw from the field kit (see

Figure 7).

8. For Series 1085 Battery Cabinets, remove the right-hand screw from the top

right door hinge of the UPS cabinet, and the right-hand screw from the top left

door hinge of the battery cabinet. Align the holes in the flat bracket over these

screw holes and then replace the screws in the hinges (see Figure 7).

9. Align the holes in the other small flat bracket with the two holes in the top rear

of the UPS and the battery cabinet. Attach each end to its mating hole using

an M4×10hexscrewfromthefieldkit(seeFigure7).

NOTE: Perform Steps 10 through 13 for the Series 1085 Battery Cabinet.

Perform Steps 14 through 18 for the Series 685 Battery Cabinet.

10. Locate the large flat bracket from the field kit. Place one end of the bracket

over the stud on the bottom side of the UPS cabinet lower right-hand hinge,

and the other end over the stud on the bottom side of the lower right-hand

hinge on the Series 1085 Battery Cabinet (see Figure 8).

11. Attach the bracket to the hinges with two M8 self-locking nuts from the field kit.

12

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 19

Screw from kit

Back

of UPS

Existing Screw

Two sm al l br ackets go her e

(see detail at left)

Back of 685 and 1085

Battery Cabinet

Bracket from kit

Bracket from kit

Screw from kit

Front of

UPS

Existing Screw

Front of

UPS

Front of 685

Battery Cabinet

UPS

Cabinet

Battery

Cabinet

Large bracket goes here

(see Figure 8 for Series 1085)

Existing Screw

Bracket from kit

Front of 1085

Battery Cabinet

NOTE: When cabinets are properly aligned,

all cabinet doors will be flush with each other.

Figure 7. Placement of Attaching Brackets, UPS to Battery Cabinet

(see Figure 9 for Series 685)

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

13

Page 20

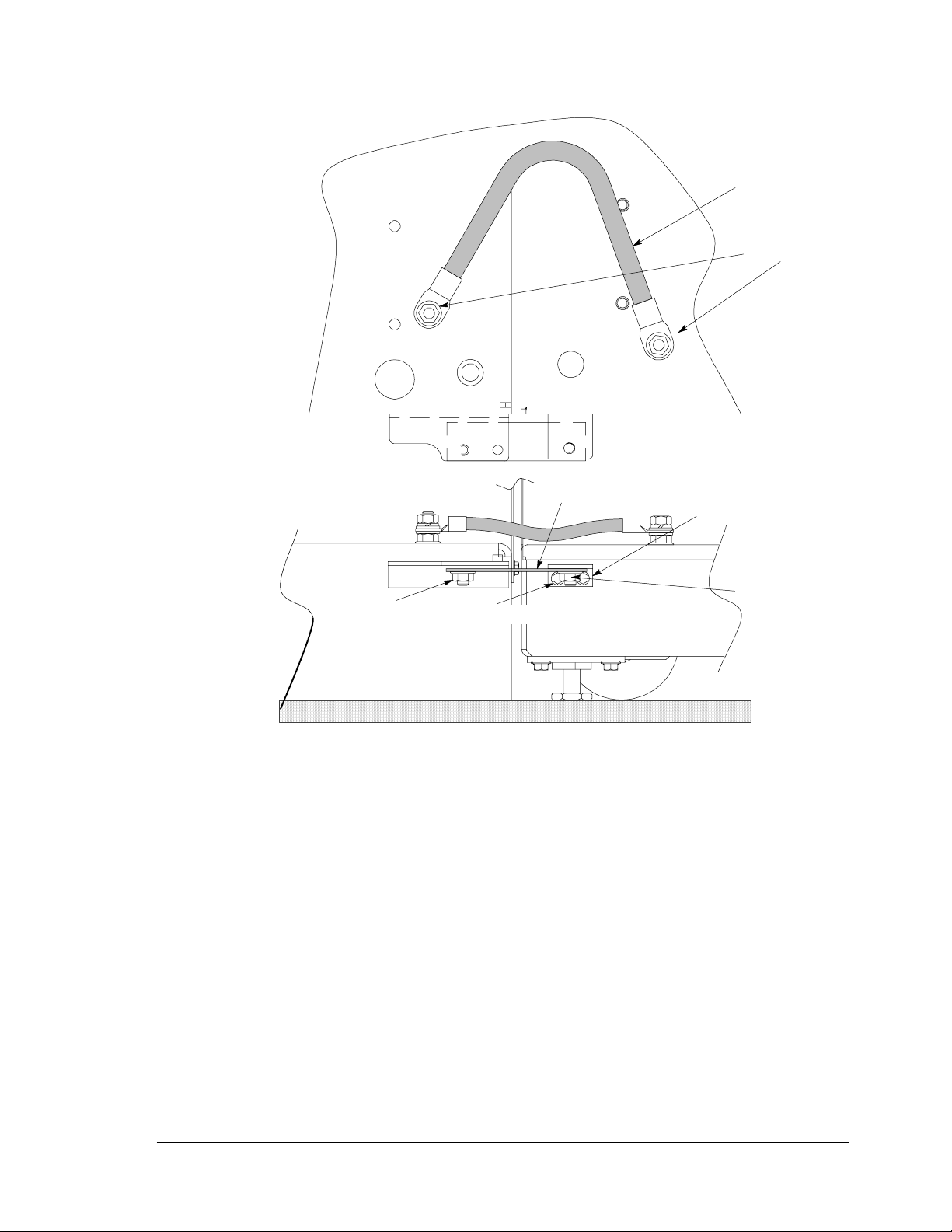

TOP VIEW

Ground Wire

Ground Stud

Bracket from kit

Existing hinge

FRONT VIEW

Nut from kit

Front of

UPS

Figure 8. Attaching UPS Base to Series 1085 Base

Nut from kit

Front of 1085

Battery Cabinet

12. Route the ground wire (from the field kit) from the customer ground stud in the

battery cabinet, under the lower right-hand battery tray, through the access

hole in the side panel of the U PS, and attach to customer ground stud in the

UPS cabinet. Hardware is provided on each ground stud.

13. Repeat Steps 2 through 12 to attach additional Series 1085 Battery Cabinets to

the other side of the first battery cabinet. Level the cabinets with the leveling

screws.

14. Locate the cabinet connecting bracket from the field kit. Attach the bracket to

the lower right-hand side of the Series 685 base using 2 M4 screws.

15. Locate the large flat bracket from the field kit. Place one end of the bracket

over the stud on the bottom side of the UPS cabinet lower right-hand hinge,

and the other end over the stud on the bottom side of the lower right-hand

hinge on the Series 685 Battery Cabinet (see Figure 9).

16. Attach the bracket to the hinges with two M8 self-locking nuts from the field kit.

14

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 21

TOP VIEW

Ground Wire

Ground Stud

FRONT VIEW

Nut from kit

Front of

Bracket from kit

Screw from kit

UPS

Figure 9. Attaching UPS Base to Series 685 Base

Front of 685

Battery Cabinet

Bracket from kit

Nut from kit

17. Locate the ground wire from the field kit. Route the ground wire from the

customer ground stud in the battery cabinet, under the lower right-hand battery

tray,throughtheaccessholeinthesidepaneloftheUPS,andattachto

customer ground stud in the UPS cabinet. Hardware is provided on each

ground stud.

18. Repeat Steps 2 through 17 to attach additional Series 685 Battery Cabinets to

the other side of the first battery cabinet. Level the cabinets with the leveling

screws.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

15

Page 22

To Electrically Connect Integral Battery Cabinets Together and to the UPS:

1.

All battery cabinets will arrive at your site with each battery connection string

electrically disconnected. If you are installing more than one battery cabinet,

perform Steps 2 through 6 for each cabinet. The battery cabinet adjacent to

the UPS will be the only cabinet directly connected to the UPS.

WARNING:

LETHAL VOLTAGE WILL BE PRESENT WHEN PERFORMING THE REMAINING

STEPS IN THIS SECTION AND SUBSEQUENT SECTIONS.

2. After making sure that all battery breakers are in the OFF position, connect the

string of battery trays together by mating the loose red connector from each

tray to the fixed black connector mounted on the front edge of the tray above it

(see Figure 10 for Series 685 and Figure 13 for Series 1085).

3. Find the red (positive) and black (negative) cables supplied coiled inside the

cabinet. These cables are provided half-stripped to facilitate attaching to the

lugs in the cabinet. Use double pole compression lugs to secure the wires to

the unit terminal blocks.

4. Wire the UPS to the Battery cabinet by attaching the provided cable from

E 4( + ) t o “ DC + ” and E 5( --- ) t o “ D C --- ” p ow e r i n ter c on n ec t i on c a bl e s p r o vi d ed .

The provided red(+) and black(---) cables are already cut to length.

5. Remove the cable tie securing the battery breaker sensing cable.

6. Locate the battery breaker sensing cable in the right-hand Battery cabinet.

Route this connector into the cabinet to the immediate left and mate with the

matching connector in the bottom of that cabinet. Connect all battery cabinets

together this way.

7. Locate control harness with semi-stripped ends in Battery cabinet. Connect

this to the CUSTTB terminal strip in the UPS. Route the battery cable to the

immediate right and mate with the matching connector in the bottom of the

UPS cabinet.

8. Repeat Steps 2 through 7 for each battery cabinet to be joined.

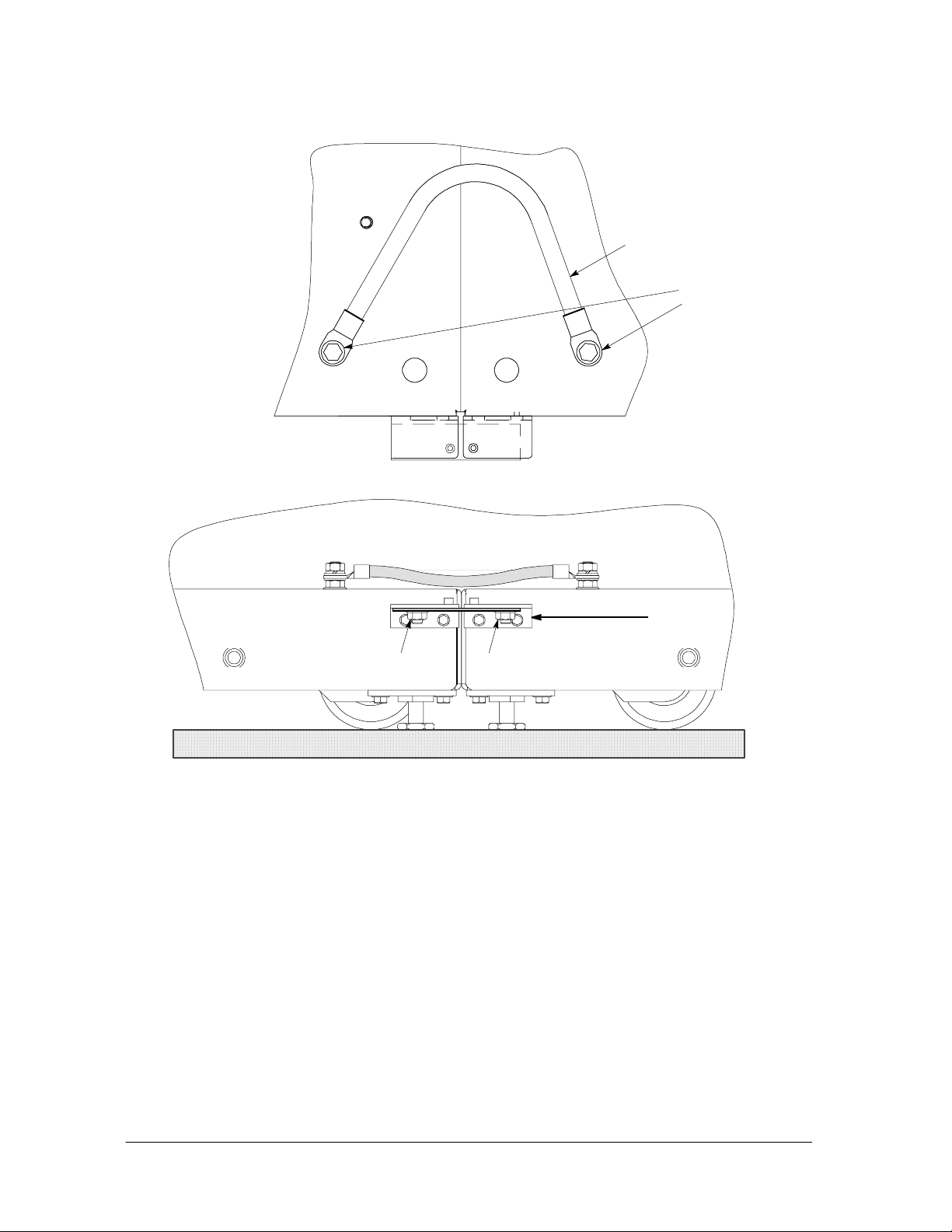

9. Mount the side panel to the side of the right-hand battery cabinet:

a. Mount the hanger brackets to the top side of the right-hand battery

cabinet using M4 screws (see Figure 11).

b. Hangthesidepanelonthehangerbracketsandalignwiththefront

and rear of the battery cabinet.

c. Secure the side panel at the bottom using M4 hex head screws.

10. Secure all battery cabinets by closing and latching the doors.

11. Secure the UPS by reinstalling safety shields and closing and latching the

doors.

16

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 23

GROUNDING STUD

LOCATION (2X)

BATTERY

BREAKER

FIXED RIGHT BATTERY

POWER CONNECTOR

(BLACK)

STRING

CONNECTORS

(RED)

CONNECTION FOR

REMOTE

MONITORING

CUSTOMER CONNECTION

CABINET GROUNDING

(REMOTE INSTALLATION)

CABINET TO CABINET

TERMINAL (+) (LEFT)

CABINET TO CABINET

TERMINAL ( --- ) (RIGHT)

GROUNDING STUD

LOCATION (2X)

CABLE ACCESS LOCATION

LEVELING FEET

Figure 10. Series 685 Battery Cabinet Wiring Detail

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

17

Page 24

HANGER BRACKET LOCATION

(SECURED WITH SCREWS)

Series 685 Cabinet Series 1085 Cabinet

CABINET TO CABINET

CABLE ACCESS AREA

(EACH SIDE)

Figure 11. Series 685 and 1085 Battery Cabinet Hanger Brackets

18

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 25

BATTERY

BREAKER

FIXED RIGHT BATTERY

POWER CONNECTOR

(BLACK)

STRING

CONNECTORS

(RED)

CONNECTION FOR

REMOTE

MONITORING

CUSTOMER CONNECTION

CABINET GROUNDING

(REMOTE INSTALLATION)

CABINET TO CABINET

T E R M I N A L ( --- )

NOTE: COMPRESSION LUGS

SHOWN ARE USED FOR

REMOTE INSTALLATION

ONLY

CABINET TO CABINET

TERMINAL (+)

CABLE ACCESS LOCATION

LEVELING FEET

Figure 12. Series 1085 Battery Cabinet Wiring Detail

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

GROUNDING STUD

LOCATION (2X)

19

Page 26

Powerware 9350 UPS with Separately Located Battery Cabinets

Use this procedure to wire a separately located Series 685 or Series 1085 Battery

Cabinet to any Powerware 9350 UPS cabinet (see Figure 14).

20

In this situation, the Battery cabinets are remotely loacted

fromtheUPSandarelineupandmatchwitheachother.

Figure 13. UPS with Separately Located Battery Cabinets

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 27

Back of

Battery Cabinet #1

Back of

Battery Cabinet #2

Screw from kitScrew from kit

Bracket from kit

Two sm al l br ackets go her e

(see detail at left)

Existing Screw

Front of

Battery Cabinet #1

Battery Cabinet #2

Screw from kit

Bracket from kit

Front of

BATTERY

CABINET #1

Large bracket goes here

(see Figure 15)

NOTE: When cabinets are properly aligned, all cabinet doors

willbeflushwitheachother.

Figure 14. Placement of Joining Brackets ( Two or More Series 685 Battery Cabinets)

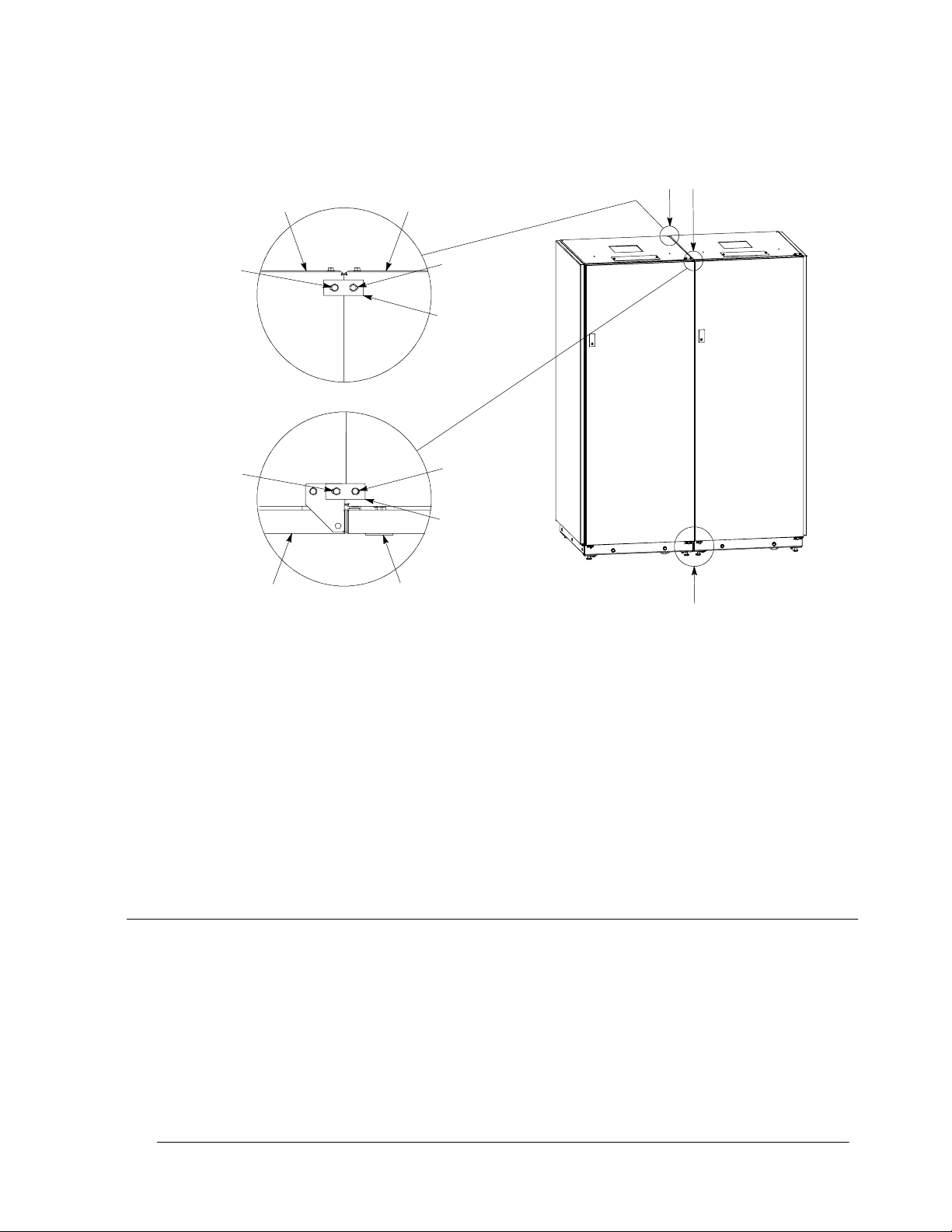

Separate Installation of Series 685 Battery Cabinets

BATTERY

CABINET #2

1. Remove the right-hand screw from the top door hinge of battery cabinet #1.

Align the hole in one flat bracket over this screw hole, and the other hole over

the hole in the top of battery cabinet #2. Replace the screw in the hinge, and

attach the other end of the bracket by using an M4×10 hex screw from the

field kit (see Figure 14).

2. Align the holes in the other small flat bracket with the two holes in the top rear

of battery cabinets #1 and #2. Attach each end to its mating hole using an

M4×10hexscrewfromthefieldkit(seeFigure14).

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

21

Page 28

Grounding cable

Ground

Studs

Existing hinge

Nut from kit

Front of

Battery Cabinet #1

Figure 15. Connecting Two Series 685 Bases

Bracket from kit

Bracket from kit

Nut from kit

Screw from kit

Front of

Battery Cabinet #2

3. Locate the cabinet connecting bracket and two M4×10 hex head screws from

the field kit. Attach the bracket to the lower right-hand side of battery cabinet

#2 using the two screws (see Figure 15).

4. Locate the large flat bracket from the field kit. Place the bracket over the stud

on the bottom side of battery cabinet #1 lower hinge, and over the stud on the

bottom side of the cabinet connecting bracket on battery cabinet #2. Attach

the bracket with two M8 self-locking nuts from the field kit (see Figure 15).

5. Locate the ground wire from the field kit. Route the ground wire from the

customer ground stud in battery cabinet #1, under the lower right-hand battery

tray, into the cable access area in battery cabinet #2, and attach to customer

ground stud. Hardware is provided on each ground stud.

6. Repeat Steps 1 through 5 to jo in additional Series 685 Battery Cabinets

together.

22

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 29

Back of

Battery Cabinet #1

Back of

Battery Cabinet #2

Two sm al l br ackets go her e

(see detail at left)

Screw from kit

Existing Screw

Front of

Battery Cabinet #1

Screw from kit

Bracket from kit

Existing Screw

Bracket from kit

Front of

Battery Cabinet #2

NOTE: When cabinets are properly aligned, all cabinet doors

willbeflushwitheachother.

BATTERY

CABINET #1

Large bracket goes here

(see Figure 17)

BATTERY

CABINET #2

Figure 16. Placement of Joining Brackets ( Two or More Series 1085 Battery Cabinets)

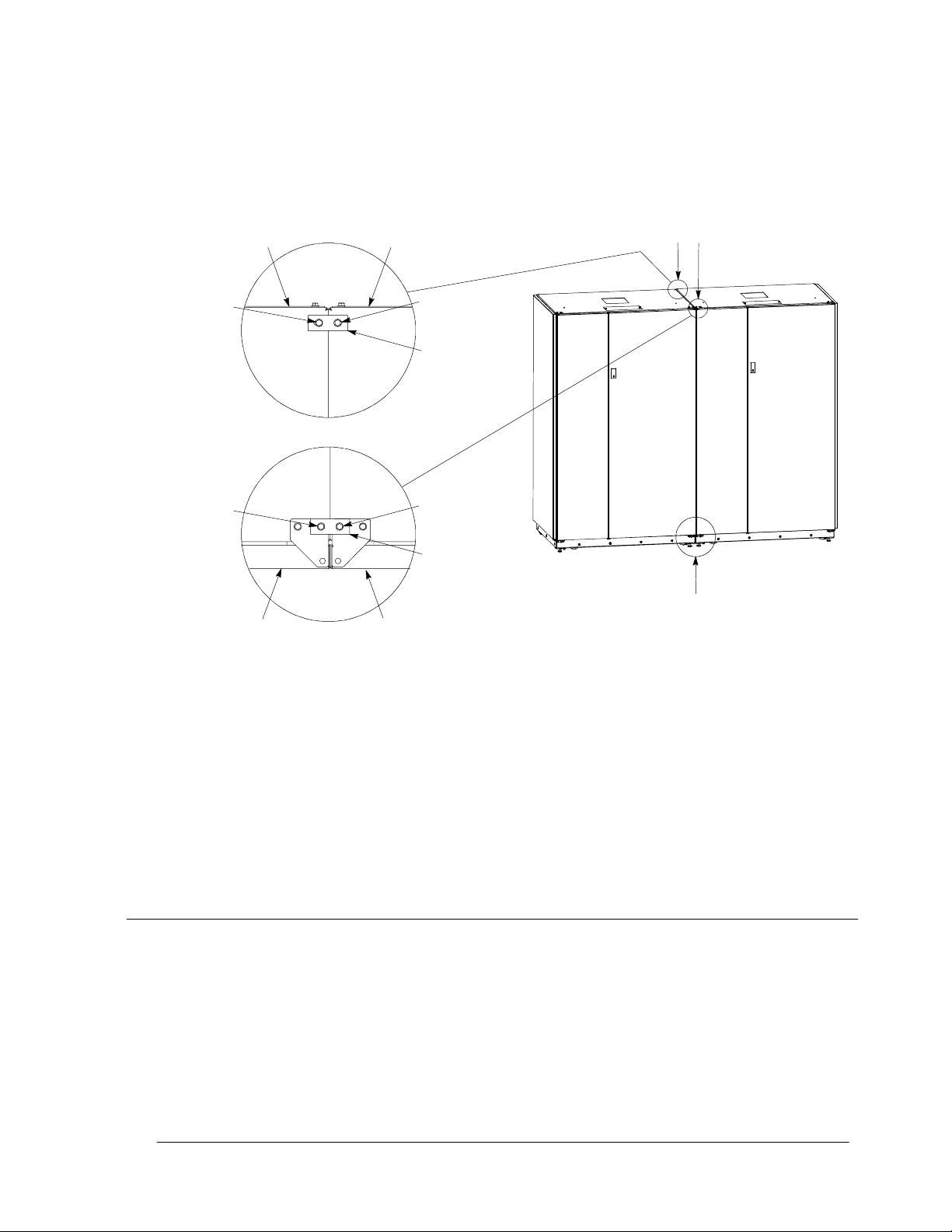

Separate Installation of Series 1085 Battery Cabinets

1. Remove the right-hand screw from the top door hinge of battery cabinet #1.

Align the hole in one flat bracket over this screw hole, and the other hole over

the hole in the top of battery cabinet #2. Replace the screw in the hinge, and

attach the other end of the bracket by using an M4×10 hex screw from the

field kit (see Figure 16).

2. Align the holes in the other small flat bracket with the two holes in the top rear

of battery cabinets #1 and #2. Attach each end to its mating hole using an

M4×10hexscrewfromthefieldkit(seeFigure16).

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

23

Page 30

Bracket from kit

Ground

Wire

Ground

Studs

Existing

hinge

Front of

Battery Cabinet #1

Nut from kit Nut from kit

Figure 17. Connecting Two Series 1085 Bases

Front of

Battery Cabinet #2

3. Locate the large flat bracket from the field kit. Place the bracket over the stud

on the bottom side of battery cabinet #1 lower hinge, and over the stud on the

bottom side of battery cabinet #1 lower hinge. Attach the bracket with two M8

self-locking nuts from the field kit (see Figure 17).

4. Locate the ground wire from the field kit. Route the ground wire from the

customer ground stud in battery cabinet #1, under the lower right-hand battery

tray, into the cable access area in battery cabinet #2, and attach to customer

ground stud. Hardware is provided on each ground stud.

5. Repeat Steps 1 through 4 to jo in additional Series 1085 Battery Cabinets

together.

24

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 31

To Electrically Connect Separate B attery Cabinets to the UPS:

1.

All battery cabinets will arrive at your site with each battery connection string

electrically disconnected. If you are installing more than one battery cabinet,

perform Steps 2 through 6 for each cabinet. Battery cabinet #1 (the left-hand

cabinet) will be the only cabinet directly connected to the UPS.

WARNING:

LETHAL VOLTAGE WILL BE PRESENT WHEN PERFORMING THE REMAINING

STEPS IN THIS SECTION AND SUBSEQUENT SECTIONS.

2. After making sure that all battery breakers are in the OFF position, connect the

string of battery trays together by mating the loose red connector from each

tray to the fixed black connector mounted on the front edge of the tray above it

(see Figure 10 for Series 685 and Figure 13 for Series 1085 for location of all

items discussed in this section).

3. Find the red (positive) and black (negative) cables supplied coiled inside the

cabinet. These cables are provided half-stripped to facilitate attaching to the

lugs in the cabinet. Use double pole compression lugs to secure the wires to

the unit terminal blocks.

4. Remove the cable tie securing the battery breaker sensing cable.

5. Locate the battery breaker sensing cable in the right-hand battery cabinet.

Route this connector into the cabinet to the immediate left and mate with the

matching connector in the bottom of that cabinet. Connect all battery cabinets

together this way.

6. Repeat Steps 2 through 5 for each battery cabinet to be joined.

7. Route cables from positive (+) and negative (---) terminals in the bottom of

battery cabinet #1 through conduit (top or bottom entry) to terminals E4 and

E5oftheUPScabinet. SeeFigure10orFigure12forlocationofpositive(+)

and negative ( ---) terminals.

a. Refer to Appendix A, Table C to size wire for connecting the battery

cabinets to the remotely located UPS cabinet.

b. See Drawing 164201408---1 in Appendix A for Series 685 Battery

Cabinet top or bottom conduit landing locations.

c. See Drawing 164201408---2 in Appendix A for Series 1085 Battery

Cabinet top or bottom conduit landing locations.

d. See Installation Manual 164200253 for Powerware 9350 30---80 kVA top

or bottom conduit landing locations.

e. See Installation Manual 164200292 for Powerware 9350 100---160 kVA

top or bottom conduit landing locations. The conduit landing plates are

removable to add conduit landing holes as required. The conduit

landing plates should be removed when holes are added to keep metal

particles from falling inside the battery cabinet.

f. Refer to Chapter 5, Table C for remote battery disconnect circuit

breaker information.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

25

Page 32

8. Mount the side panels to the sides of the first and last battery cabinets:

a. Mount the hanger brackets to the top side of the battery cabinets using

M4 screws (see Figure 11).

b. Hangthesidepanelonthehangerbracketsandalignitwiththefront

and rear of the battery cabinet.

c. Secure the side panel at the bottom using M4 hex head screws.

9. Secure all battery cabinets by closing and latching the doors.

10. Secure the UPS by reinstalling safety shields and closing and latching the

doors.

26

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 33

Completing the Installation Checklist

The final step in installing your battery cabinet is to complete the Installation

Checklist. This checklist ensures that you have installed all hardware, cables,

and other equipment. Completing all items on the checklist will ensure a smooth

installation. Make a copy of the Installation Checklist before filling it out, and retain

the original.

After completing your installation, a service representative will be able to verify the

operation of your battery cabinet, and commission it to support your critical load.

The service representative cannot perform any installation tasks other than verifying

that the battery cabinet has been correctly installed. Service personnel may request

a copy of the completed Installation Checklist to be sure you have completed all

applicable equipment installation requirements.

NOTE:

The Installation Checklist MUST be completed prior to starting up the UPS system

for the first time.

Installation Checklist for Powerware 9350 30 through 160

-All packing materials and restraints have been removed from each cabinet.

-Each cabinet in the battery system is placed in its correct location.

-All cabinets are bolted together.

-A ground wire is installed between all cabinets that are bolted together.

-All conduits and cables are properly routed to the battery cabinets.

-A ground conductor is properly installed.

-Battery cables and harness are terminated on the K2 battery contactor E4 and E5 in

the UPS cabinet.

-Internal battery cabinet connections have been completed (bus bars, plugs, etc.)

-Air conditioning equipment is installed and operating correctly.

-The area around the installed battery system is clean and dust-free.

(It is recommended that the battery cabinet be installed on a sealed concrete pad or a

sealed concrete floor.)

-Adequate working area exists around the battery cabinet and other cabinets.

-Adequate lighting is provided around all battery cabinet equipment.

-A remote battery disconnect control is mounted in its installed location and its wiring is

terminated inside the battery cabinet (OPTIONAL).

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

27

Page 34

This Page Intentionally Left Blank.

28

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 35

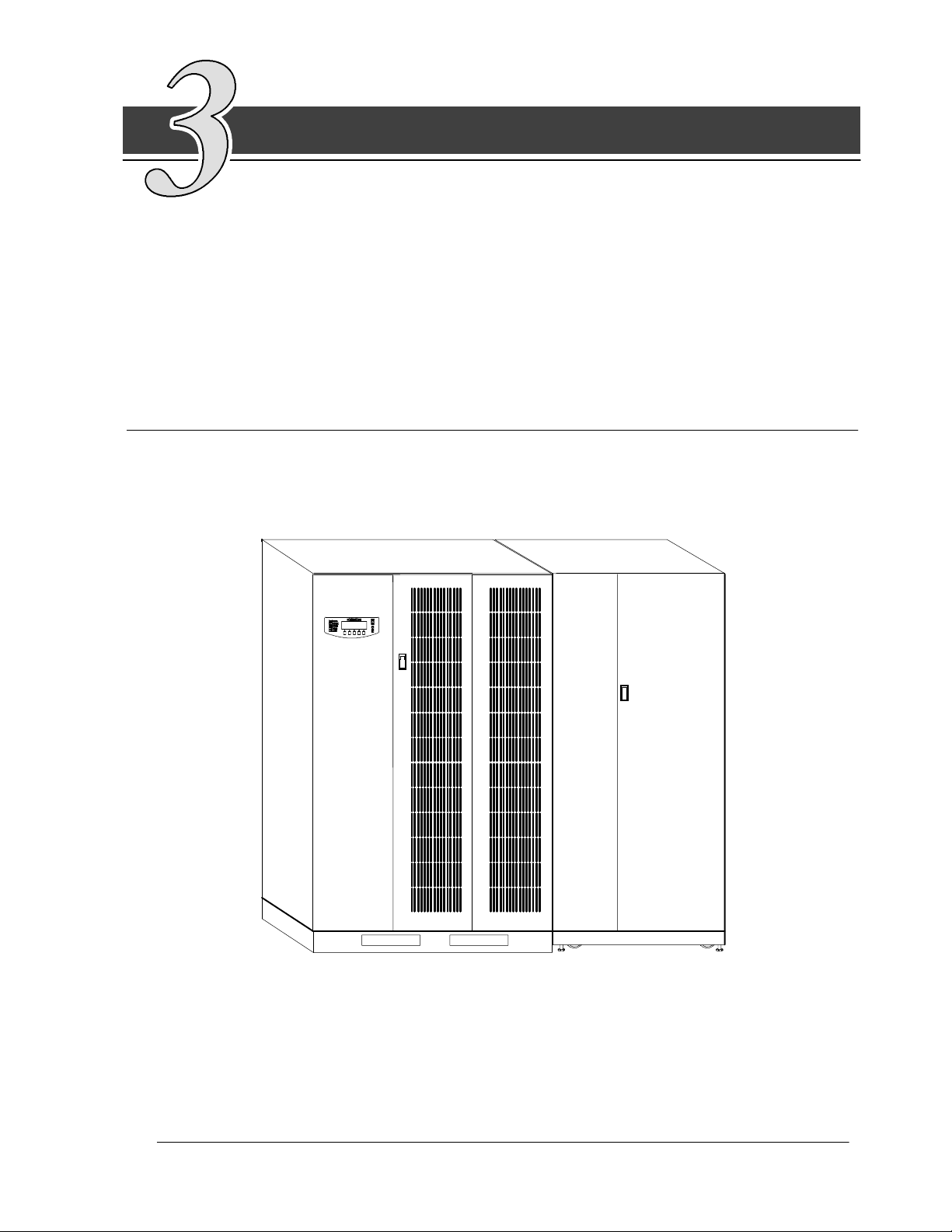

Connecting to

Powerware 9350 ---80 and 160

This chapter will explain how to electrically connect your battery cabinets to

your Powerware 9350---80 or 160 UPS.

Figure 18 details the Battery cabinet DC connections and control wiring connection

point in a Powerware 9350---80 UPS. Figure 19 details the same connections in a

Powerware 9350---160 UPS.

NOTE: See Table C in Appendix A for sizing wire for separate battery configurations.

There are no battery cabinet-to-UPS mechanical attachment requirements for this

type of system. However, individual battery cabinets should be attached and

grounded to each other. Please refer to later sections of this chapter for

instructions on these procedures.

CUSTTB terminal block

for control wiring.

Mounted to inside top of

cabinet.

DC INPUT

from battery

to UPS

(E4, E5)

Figure 18. Battery Connections for a Powerware 9350 ---80

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

29

Page 36

Powerware 9350---80 or 160 with Separate Battery Cabinets

1. Make sure that the UPS is properly installed and secured.

2. Roll the battery cabinets to their permanent location.

3. Attach and connect the battery cabinets to each other (refer to “The

Powerware 9350 UPS with S eparate Battery Cabinets” section of Chapter 3).

4. If necessary, remove the cosmetic covers and doors from the UPS. Save

covers, screws, and brackets for later reuse.

5. Each battery cabinet in your system will have to be individually connected to

terminals E4 and E5.

6. Route cables from positive (+) and negative (---) terminals in the bottom of

each battery cabinet through conduit (top or bottom entry) to terminals E4

and E5 of the UPS cabinet. See Figure 18 or 19 for location of terminals E4

and E5. Refer to Chapter 3, Figure 11 or Figure 13 for location of battery

cabinet positive (+) and negative (---) terminals.

CUSTTB terminal block

for control wiring.

Mounted to inside top of

cabinet.

DC INPUT

from battery

to UPS

(E4, E5)

30

Figure 19. Battery Connections for a Powerware 9350 ---160

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 37

7. Mount the side panels to the sides of the first and last battery cabinets:

a. Mount the hanger brackets to the top side of the battery cabinets using

M4 screws (refer to Chapter 3, Figure 11 for location).

b. Hangthesidepanelonthehangerbracketsandalignitwiththefront

and rear of the battery cabinet.

c. Secure the side panel at the bottom using M4 hex head screws.

8. Secure all battery cabinets by closing and latching the doors.

9. Secure the UPS by reinstalling safety shields and closing and latching the

doors.

WARNING:

Initial closing of the battery cabinet breakers or the external battery disconnect

should be performed only in the presence of authorized service personnel.

Completing the Installation Checklist

The final step in installing your battery cabinet is to complete the Installation

Checklist. This checklist ensures that you have installed all hardware, cables, and

other equipment. Completing all items on the checklist will ensure a smooth

installation. Make a copy of the Installation Checklist before filling it out, and retain

the original.

After completing your installation, a service representative will be able to verify the

operation of your battery cabinet, and commission it to support your critical load.

The service representative cannot perform any installation tasks other than verifying

that the battery cabinet has been correctly installed. Service personnel may

request a copy of the completed Installation Checklist to be sure you have

completed all applicable equipment installation requirements.

NOTE:

The Installation Checklist MUST be completed prior to starting up the UPS system

for the first time.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

31

Page 38

Installation Checklist for Powerware 9350---160

-All packing materials and restraints have been removed from each cabinet.

-Each cabinet in the battery system is placed in its correct location.

-All battery cabinets are bolted together.

-A ground wire is installed between all cabinets that are bolted together.

-All conduits and cables are properly routed to the battery cabinets.

-A ground conductor is properly installed.

-Battery cables and harness are terminated on the battery terminals E4 and E5 in the

UPS cabinet.

-Internal battery cabinet connections have been completed (bus bars, plugs, etc.)

-Air conditioning equipment is installed and operating correctly.

-The area around the installed battery system is clean and dust-free.

(It is recommended that the battery cabinet be installed on a sealed concrete pad or a

sealed concrete floor.)

-Adequate working area exists around the battery cabinet and other cabinets.

-Adequate lighting is provided around all battery cabinet equipment.

-A remote battery disconnect control is mounted in its installed location and its wiring is

terminated inside the battery cabinet (OPTIONAL).

32

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 39

Installing a Remote Battery Disconnect

The remote battery disconnect is crated separately for shipping. It is enclosed

in a box and is designed to be wall mounted on a surface that can support the

weight and bolt pattern described in this chapter. You can install a remote battery

disconnect anywhere between the remote DC supply and the UPS, according to

national and local codes. Figure 20 shows the remote battery disconnect

enclosure.

FRONTSIDE

ON

OFF

Figure 20. Remote Battery Disconnect Enclosure

The breaker switch on the remote battery disconnect should be set to ON for

normal UPS operation when DC power is available at the UPS. When service

personnel are performing maintenance on the UPS or battery cabinet, the switch

should be OFF.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

33

Page 40

You should read and understand these general notes before beginning installation:

• The material and labor for external wiring requirements is to be supplied by

others.

• Power cables and control wiring must be installed in separate conduit.

• The ground conductor is to be sized per NEC Article 250 and local electrical

code requirements.

• The maximum current listed is at the minimum DC operating voltage.

• Nominal voltages listed in this chapter are for a lead-acid battery plant rated per

NEC at 2.00 VDC per cell.

• Battery cabinets must be installed in accordance with all applicable codes and

regulations, including the National Electrical Code (NEC), Article 480.

• The UPS to battery cable should be sized for a total maximum voltage drop of

1% nominal DC link voltage at maximum current.

• The external wiring specifications are outlined in Table C of Appendix A. Tables

A and B in this chapter detail the power cable terminations.

• The remote battery disconnect weighs approximately 11.4 kg (25 lb) and has an

ampere interrupting capacity of 10,000 at 500 VDC.

• Tightening Torque: 28.7 --- 31.1 N-M (255 --- 275 lb-in.)

Internal Drive Hex Size: 5/16 in.

• The knockout pattern for conduit is shown in Figure 21. If a larger size conduit

is required, the contractor may enlarge knockouts at your site during

installation.

34

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 41

E

T

E

A

T

A

A

EE

TT

Figure 21. Knockout Pattern for Remote Battery Disconnect

T

T

A

T

EE

T

A

A

Table A. Remote Battery Disconnect Power Terminations

Ter mi nal Size of Pressure Termination Terminal Function

E4 (+)

E 5 ( --- )

Breaker (+)

B re a ke r ( --- )

Breaker (jumper)

Battery Cabinet (+)

Battery Cabinet (---)

See Table C (Appendix A)

See Table C (Appendix A)

1 --- # 8 --- 3 /0

1 --- # 8 --- 3 /0

1 --- # 4 --- 3 00 k cm i l

1 --- # 4 --- 3 00 k cm i l

1 --- # 4 --- 3 00 k cm i l

UPS Battery Contactor K2 (+)

UPS Battery Contactor K2 (---)

Battery Disconnect (+)

Battery Disconnect ( ---)

Battery Disconnect (jumper)

Stand---alone battery cabinet (+)

S ta n d --- a lo n e ba t t er y c ab i ne t ( --- )

Table B. Battery Cabinet Terminations

Battery Cabinet Size of Pressure Termination

Series 685 ( 1) # 2 --- 1 /0 k c mi l [B r ea k e r ( + ) & ( --- ) ]

Series 1085 ( 1) 3 /0 --- 2 50 k c mi l [B r ea k e r ( + ) & ( --- ) ]

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

35

Page 42

Table C. Remote Battery Disconnect Circuit Breaker Ratings

UPS Model Circuit Breaker Rating DC Voltage

9350---40 125 420

9350---50 125 480

9350---65 175 420

9350---80 200 480

9350---125 350 420

9350---130 350 420

9350---150 350 480

9350---160 350 480

9350---200 600 420

9350---225 600 480

9350---250 800 420

9350---300 800 480

9350---300 900 420

9350---400 1200 420

9350---400 1000 480

9350---500 1200 480

36

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 43

Appendix A --- Customer Information

The information in the appendix will help you plan for and install your battery

system. The appendix contains these drawings:

164201408---1 Series 685 Battery Cabinet

164201408---2 Series 1085 Battery Cabinet

164201408---3 Remote Interface Connections

164201408---4 Series 685 / 1085 Configurations

NOTE: Outline diagrams and oneline diagrams for the various UPS models are

available in their respective manuals. See this manual for more information.

164201407 Powerwarer 9350 (100 kVA--- 160 kVA) UPS Installation

and Operation Manual

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

A --- 1

Page 44

1. The output of the UPS is a separately derived source. Output neutral is bonded

to equipment ground through the main bonding jumper. Refer to NEC Article

250 and local codes for proper grounding practices.

2. Your battery cabinet operating environment must meet the size and weight

requirements shown in Table A:

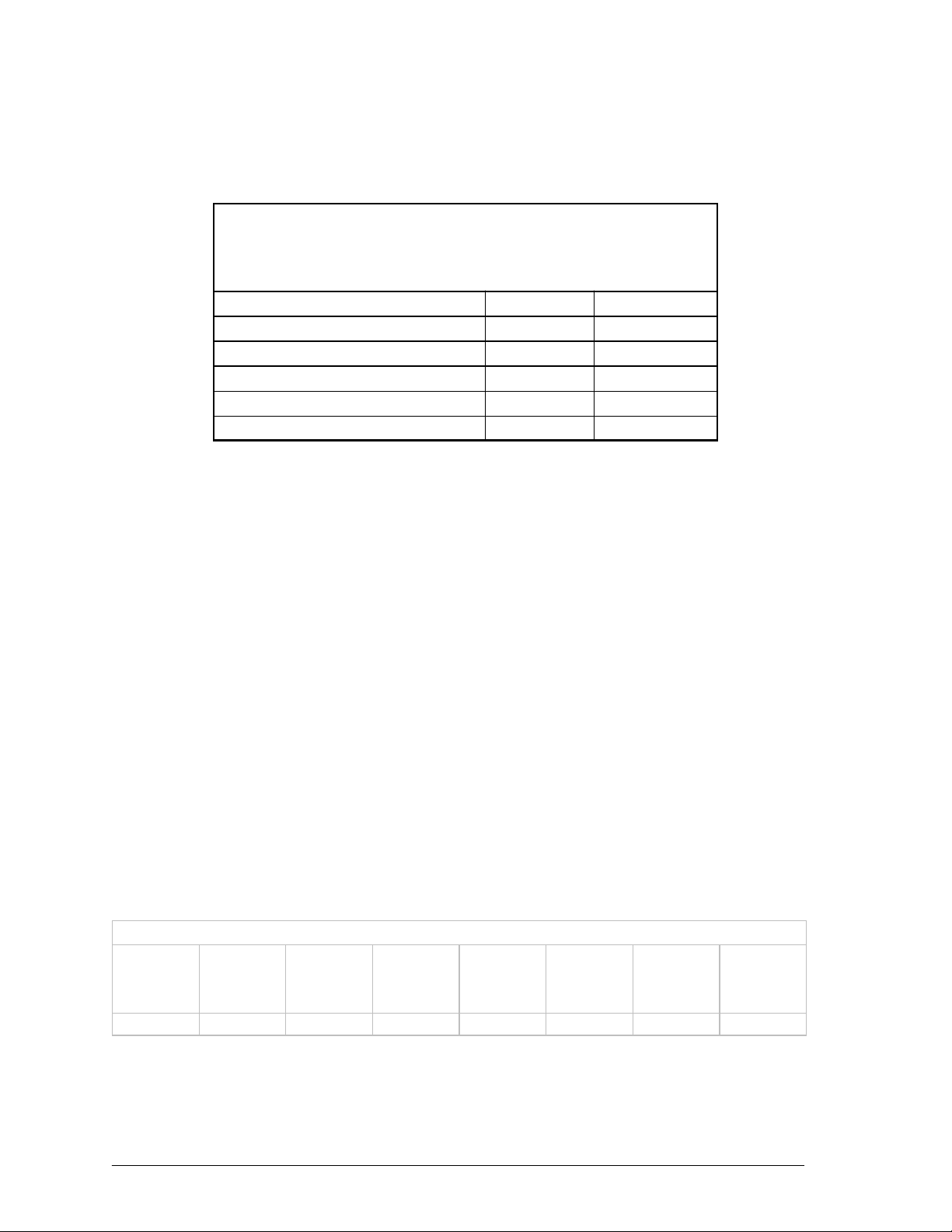

Table A. Equipment Weight and Point Loading (on casters)

(4 leveling feet are provided)

Weight Point Loading

Component Kg(lb) Kg(lb)

Series 685-J14 869 (1915) 4 at 217 (479)

Series 685-J17 1111 (2450) 4 at 278 (613)

Series 1085-J27 1429 (3150) 8 at 179 (394)

Series 1085-J31 1588 (3500) 8 at 199 (438)

Series 1085-J37 1708 (3765) 8 at 214 (471)

Series 1085-J47 2178 (4800) 8 at 272 (600)

3. The basic environmental requirements for operation of the battery system are:

Ambient Temperature Range: 1 0 --- 40˚C ( 50 --- 1 04 ˚F)

Recommended Operating Range: 20 --- 25 ˚C ( 68 --- 77˚F)

Maximum Relative Humidity: 95% noncondensing

4. Use Class 1 wiring methods (as defined by the NEC) for control wiring. Install

the control wiring in separate conduit from the power wiring. The wire should

be rated at 24 volts, 1 amp minimum.

5. Battery voltage is computed at 2 volts per cell as defined by Article 480 of the

NEC. Rated battery current is computed at 1.8 volts per cell.

6. The battery wiring used between the battery and the UPS should not allow a

voltage drop of more than 1% of nominal DC voltage at rated battery current.

7. A battery disconnect switch is recommended, and may be required by NEC or

local codes when batteries are separately located. The battery disconnect

switch may be supplied as an accessory, and should be installed between the

battery and the UPS.

8. If the conductors used for DC input from the battery cabinet(s) to the UPS are

those provided by the UPS manufacturer, and the UPS and battery cabinet are

manufactured by the same supplier, then it is acceptable if they do not meet the

noted minimum conductor sizes.

Table B. External Ground Wire Requirements for Battery Cabinets

Integral

UPS

Model

all 685 or 1085 all all all 1/0 7/16I slot 5.6 (50)

Battery

Series

Battery

Typ e

#of

Cabinets

or

Separate

Battery

Wire Size

Battery

Tool Size

Battery

Cabinet

Tor q ue

(lb-in)

N-M

A --- 2

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 45

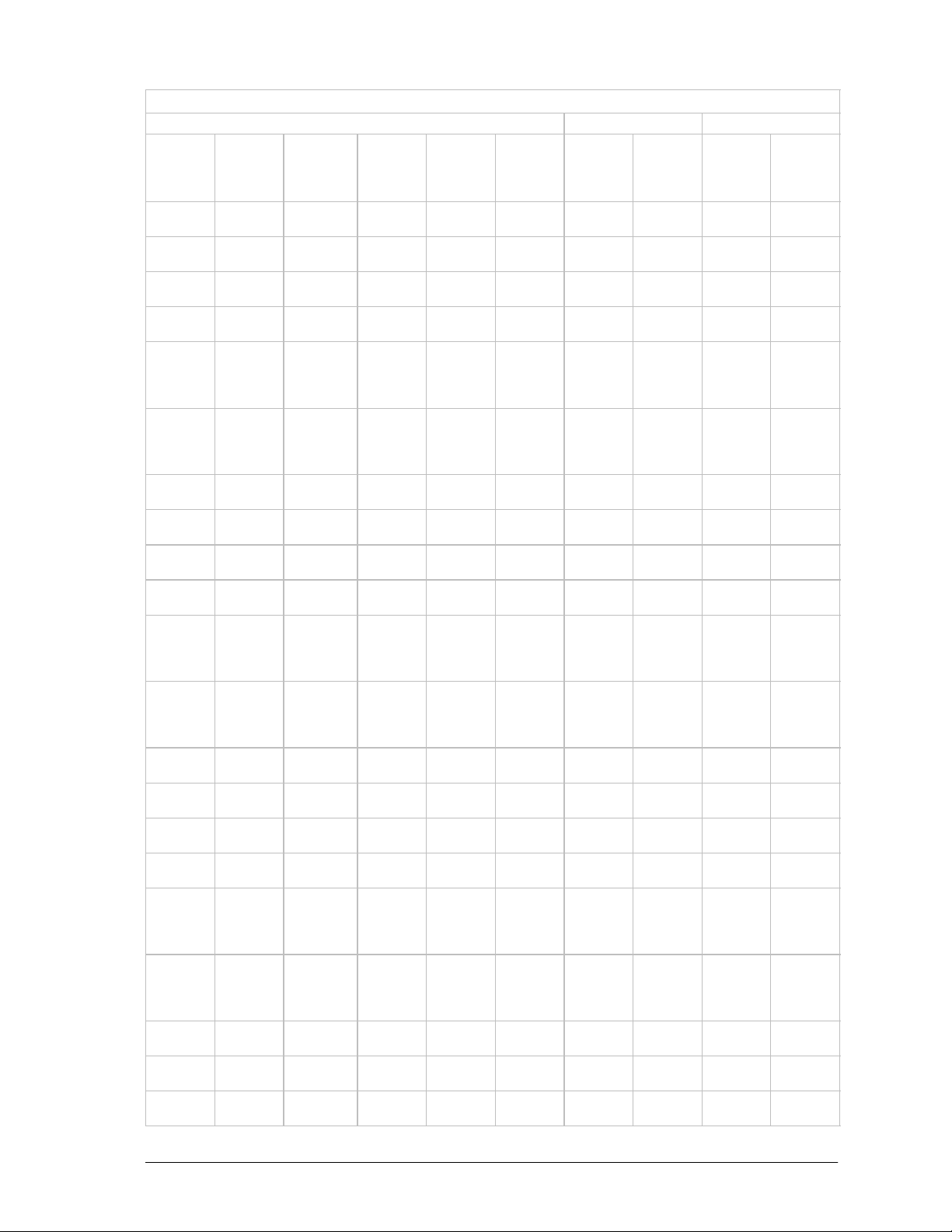

Table C. External Wiring Requirements (UPS-to-Battery or Remote Disconnect-to-Battery)

NOTE: All specified wire sizes are 90_C rated copper minimum Battery Cabinet UPS Cabinet

UPS

Series/

Model

50/30 685

50/30 685

50/30 1085R B10

50/30 1085R B10

50/30 1085

50/30 1085

50/40 685

50/40 685

50/40 1085R B10

50/40 1085R B10

50/40 1085

50/40 1085

50/50 685

50/50 685

50/50 1085R B10

50/50 1085R B10

50/50 1085

50/50 1085

80/50 685

80/50 685

80/50 1085R B10

Battery

Cabinet

Series

Battery

Typ e*

B14, B17,

H20

B14, B17,

H20

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B14, B17,

H20

B14, B17,

H20

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B14, B17,

H20

B14, B17,

H20

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B14, B17,

H20

B14, B17,

H20

#of

Cabinets

1or2 Integral Supplied 3/8I hex

1or2 Separate 2/0 3/8I hex

1, 2, 3,

or 4

1, 2, 3,

or 4

1, 2, 3,

or 4

1, 2, 3,

or 4

1or2 Integral Supplied 3/8I hex

1or2 Separate 2/0 3/8I hex

1, 2, 3,

or 4

1, 2, 3,

or 4

1, 2, 3,

or 4

1, 2, 3,

or 4

1or2 Integral Supplied 3/8I hex

1or2 Separate 2/0 3/8I hex

1, 2, 3,

or 4

1, 2, 3,

or 4

1, 2, 3,

or 4

1, 2, 3,

or 4

1or2 Integral Supplied 3/8I hex

1or2 Separate 2/0 3/8I hex

1, 2, 3,

or 4

Integral

or

Separate

Integral Supplied 3/8I hex

Separate 3/0 3/8I hex

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

Integral Supplied 3/8I hex

Separate 3/0 3/8I hex

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

Integral Supplied 3/8I hex

Separate 3/0 3/8I hex

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

Integral Supplied 3/8I hex

Wire

Size

UPS to

Battery

Tool Size

Tor q ue

N-M

(lb-in)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

Tool Size

1/4I hex

1/4I hex

3/8I hex

3/8I hex

1/4I hex

1/4I hex

1/4I hex

1/4I hex

3/8I hex

3/8I hex

1/4I hex

1/4I hex

1/4I hex

1/4I hex

3/8I hex

3/8I hex

1/4I hex

1/4I hex

1/4I hex

1/4I hex

3/8I hex

Tor q ue

N-M

(lb-in)

22.6

(200)

22.6

(200)

42.4

(375)

42.4

(375)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(200)

42.4

(375)

42.4

(375)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(200)

42.4

(375)

42.4

(375)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(200)

42.4

(375)

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

A --- 3

Page 46

Table C. External Wiring Requirements (UPS-to-Battery or Remote Disconnect-to-Battery)

I

l

S

l

ied3/

I

hex

4

2.4

I

hex

2

2.6

S

I

hex

4

2.4

I

hex

2

2.6

NOTE: All specified wire sizes are 90_C rated copper minimum UPS CabinetBattery Cabinet

UPS

Series/

Model

80/50 1085R B10

80/50 1085

80/50 1085

80/60 685

80/60 685

80/60 1085R B10 1 Integral Supplied 3/8I hex

80/60 1085R B10 1 Separate 3/0 3/8I hex

80/60 1085

80/60 1085

80/80 685

80/80 685

80/80 1085

80/80 1085

160/100 685

160/100 685

160/100 1085

160/100 1085

Battery

Cabinet

Series

Battery

Typ e*

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

H20 1

B14, B17 2

H20 1

B14, B17 2

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

H20 1

B14, B17,

H20

H20 1

B14, B17,

H20

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30. H40,

H50

B14, B17,

H20

B14, B17,

H20

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

Cabinets

1, 2, 3,

1, 2, 3,

1, 2, 3,

1, 2, 3,

1, 2, 3,

1, 2, 3,

1, 2, 3,

1, 2, 3,

1, 2, 3,

#of

or 4

or 4

or 4

or 4

or 4

2

2

or 4

or 4

2 Integral Supplied 3/8I hex

2 Separate 3/0 3/8I hex

or 4

or 4

Integral

or

Separate

Separate 3/0 3/8I hex

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

ntegra

eparate 2/0 3/8

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

Integral Supplied 3/8I hex

Separate 2/0 3/8I hex

Integral Supplied 3/8I hex

Separate 3/0 3/8I hex

Wire

Size

UPS to

Battery

upp

Tool Size

8

Tor q ue

N-M

(lb-in)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

Tool Size

3/8I hex

1/4I hex

1/4I hex

1/4

1/4

3/8I hex

3/8I hex

1/4I hex

1/4I hex

1/4I hex

1/4I hex

1/4I hex

1/4I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

Tor q ue

N-M

(lb-in)

42.4

(375)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(2)

42.4

(375)

42.4

(375)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(200)

22.6

(200)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

A --- 4

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 47

Table C. External Wiring Requirements (UPS-to-Battery or Remote Disconnect-to-Battery)

NOTE: All specified wire sizes are 90_C rated copper minimum UPS CabinetBattery Cabinet

UPS

Series/

Model

160/125 685 H20 2 Integral Supplied 3/8I hex

160/125 685 H20 2 Separate

160/125 1085

160/125 1085

160/150 685 H20 2 Integral Supplied 3/8I hex

160/150 685 H20 2 Separate

160/150 1085

160/150 1085

160/160 685 H20 2 Integral Supplied 3/8I hex

160/160 685 H20 2 Separate

160/160 1085

160/160 1085

Battery

Cabinet

Series

Battery

Typ e*

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

B27, B31,

B37, B47,

H30, H40,

H50

* BATTERY TYPE DESIGNATIONS: B = C&D, H = HAWKER

#of

Cabinets

2, 3, or 4 Integral Supplied 3/8I hex

2, 3, or 4 Separate

2, 3, or 4 Integral Supplied 3/8I hex

2, 3, or 4 Separate

1, 2, 3,

or 4

1, 2, 3,

or 4

Integral

or

Separate

Integral Supplied 3/8I hex

Separate

Wire

Size

UPS to

Battery

300

kcmil

300

kcmil

300

kcmil

300

kcmil

300

kcmil

350

kcmil

Tool Size

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

Tor q ue

N-M

(lb-in)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

Tool Size

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

3/8I hex

Tor q ue

N-M

(lb-in)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

42.4

(375)

NOTE: The term “Separate” refers to battery cabinets that are not physically attached to the

UPS, are wired with external contractor supplied wiring, and use a single overcurent

protection and disconnect device located near the batteries.

The term “Integral” refers to battery cabinets that are physically attached to the UPS

and the wiring between them is internal. The power wiring is supplied with the

system, and they use the UPS battery switch as the battery isolation device.

Thewiresizeratingforproductsuptoandincludingthe160/160areforthetotal

battery supply. Since these UPS units can only land one wire per DC connection

point, a common DC collector including an isolation device and overcurrent

protection should be used. Refer to applicable national or local code requirements

foryourinstallation.

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

A --- 5

Page 48

735.8

(28.97)

685

(26.97)

(without decorative panels)

1870.3

(73.6)

Dimensions are in millimeters (inches)

A --- 6

Series 685 Battery Cabinet

DESCRIPTION:

DRAWING NO:

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Series 685 Battery Cabinet (eleva tion)

164201408--1

Installation Manual 164201408 Rev. P00 053002

SHEET:

1of2

Page 49

WALL --- NO BACK ACCESS REQUIRED

80

(3.15)

120

(4.72)

TOP CABLE ENTRY LOCATION

(COVER SECURED WITH SCREWS)

201.1

(7.92)

Series 685 Battery Cabinet

335

(13.19)

TOP VIEW

(2.95)

148

(5.83)

75

135

(5.32)

175

(6.89)

282

(11.1)

613

(24.14)

453

(17.83)

735.8

(28.97)

280.4

(11.04)

226.9

(8.93)

300.4

(11.83)

914.4 (36.00)

MINIMUM CLEARANCE

FOR SUBASSEMBLY

REMOVAL

61.4

(2.42)

141.4

(5.57)

71

(2.80)

151

(5.95)

690

(27.17)

(20.87)

Series 685 Battery Cabinet

530

802.7

(31.6)

BOTTOM VIEW

BOTTOM CABLE ENTRY LOCATION

(COVER SECURED WITH SCREWS)

DESCRIPTION:

Dimensions are in millimeters (inches)

DRAWING NO:

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Series 685 Battery Cabinet (p lan)

164201408--1

SHEET:

2of2

A --- 7

Page 50

1870.3

(73.6)

1135.8

(44.72)

1085

(42.72)

(without decorative panels)

A --- 8

Series 1085 Battery Cabinet

DESCRIPTION:

DRAWING NO:

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Series 1085 Battery Cabinet (elevation)

164201408--2

Installation Manual 164201408 Rev. P00 053002

SHEET:Dimensions are in millimeters (inches)

1of2

Page 51

Series 1085 Battery Cabinet

(TOP VIEW)

WALL --- NO BACK ACCESS REQUIRED

201.1

(7.92)

335

(13.19)

120

(4.72)

80

(3.15)

480.4

(18.91)

426.9

(16.81)

61.4

(2.42)

141.4

(5.57)

442.9

(17.44)

(16.79)

426.5

(11.1)

250

(9.84)

175

(6.89)

282

1135.8

(44.72)

TOP CABLE ENTRY LOCATION

(COVER SECURED WITH SCREWS)

426.5

(16.79)

1013

(39.88)

914.4 (36.00)

MINIMUM CLEARANCE

FOR SUBASSEMBLY

REMOVAL

88.9

(3.5)

151

(5.95)

102

(4.02)

265

(10.43)

802.7

(31.6)

265

(10.43)

Series 1085 Battery Cabinet

(BOTTOM VIEW)

Dimensions are in millimeters (inches)

BOTTOM CABLE ENTRY LOCATION

(COVER SECURED WITH SCREWS)

DESCRIPTION:

DRAWING NO:

Series 1085 Battery Cabinet ( pl an)

164201408--2

71

(2.80)

229.1

(9.02)

690

(27.27)

151

(5.95)

265

(10.43)

265

(10.43)

SHEET:

2of2

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

A --- 9

Page 52

1

23456789 1110 12

CB1 ST (--) C11

CB1 ST (+) C12

Note 1

CB1 ST (--)

Note 1

TB1

CB1 ST (+)

CB1 AUXILIARY SWITCH (N/C)

CB1 AUXILIARY SWITCH (N/O)

CB1 AUXILIARY SWITCH (N/C)

CB1 AUXILIARY SWITCH (COMM)

Note 2,3,4 Note 2,3,4

Notes:

1. Shunt trip requires 24V (150 VA instantaneous) to activate (supplied by user).

2. Auxiliary switches are rated as follows:

240 VAC @ 15A

125 VDC @ 0.3A

250 VDC @ 0.15A

3. Wiring shall be s uitable for Class 1, 600V wiring methods.

All wiring shall be #10-22 AWG, 75 deg. C minimum.

4. Torque screw terminals to 20 in.-lb.

DESCRIPTION:

DRAWING NO:

Remote Interface Connections

164201408--3

CB1 AUXILIARY SWITCH (N/O)

CB1 AUXILIARY SWITCH (COMM)

SHEET:

1of1

A --- 1 0

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Page 53

(E4)

(E5)

4 Cabinets Maximum

UPS

CABINET

Powerware 9350 30 through 160

Battery Cabinets integral to UPS

and connected using Manufacturer supplied wiring

CONTRACTOR

WIRING (1)

(E4)

(E5)

UPS

CABINET

Powerware 9350 30 through 160

Battery Cabinets located separately

BATTERY

CABINET

BATTERY

DISCONNECT

from the UPS

BATTERY

CABINET

CONTRACTOR

WIRING (2)

4 Cabinets Maximum

BATTERY

CABINET

BATTERY

CABINET

NOTE: The term “Separate” refers to battery cabinets that are not physically attached

to the UPS, are wired with external contractor supplied wiring, and use a single

overcurent protection and disconnect device located near the batteries.

The term “Integral” refers to battery cabinets that are physically attached to the

UPS and the wiring between them is internal. The power wiring is supplied

with the system, and they use the UPS battery switch as the battery isolation

device.

Thewiresizeratingforproductsuptoandincludingthe160/160areforthe

total battery supply. Since these UPS units can only land one wire per DC

connection point, a common DC collector including an isolation device and

overcurrent protection should be used. Refer to applicable national or local

code requirements for your installation.

Contractor Wiring (1): Refer to UPS manual to size wiring

Contractor Wiring (2): See

Table C of Appendix A to size

Contractor Supplied wiring

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

DESCRIPTION:

DRAWING NO:

Series 685 / 1085 Configurations

164201408--4

SHEET:

1of1

A---11

Page 54

This Page Intentionally Left Blank.

A --- 1 2

Powerware 9350 Series 685 and 1085 Auxiliary Battery Cabinets

Installation Manual 164201408 Rev. P00 053002

Loading...

Loading...