Page 1

Powerware Energy Management System (EMS)

®

Upgrade Kit (208/120V, 380/220V, 400/230V, 415/240V)

User’s Guide

Page 2

Requesting a Declaration of Conformity

Units that are labeled with a CE mark comply with the following harmonized standards and EU directives:

S Harmonized Standard: IEC 61010−1:2001−02

S EU Directives: 2006/95/EC, Council Directive on equipment designed for use within certain voltage limits

The EC Declaration of Conformity is available upon request for products with a CE mark. For copies of the EC

Declaration of Conformity, contact:

Eaton Power Quality Oy

Koskelontie 13

FIN−02920 Espoo

Finland

Phone: +358−9−452 661

Fax: +358−9−452 665 68

2004/108/EC, Council Directive relating to electromagnetic compatibility

Eaton, Powerware, Power Xpert, and X−Slot are registered trademarks of Eaton Corporation or its subsidiaries and

affiliates. HyperTerminal is a registered trademark of Hilgraeve. Kirk is a registered trademark of the Kirk Key

Interlock Company. Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States

and/or other countries. Modbus is a registered trademark of Schneider Electric. National Electrical Code and NEC are

registered trademarks of National Fire Protection Association, Inc. Phillips is a registered trademark of Phillips Screw

Company. All other trademarks are property of their respective companies.

ECopyright 2008 Eaton Corporation, Raleigh, NC, USA. All rights reserved. No part of this document may be

reproduced in any way without the express written approval of Eaton Corporation.

Page 3

Special Symbols

The following are examples of symbols used on the UPS or accessories to alert you to important

information:

RISK OF ELECTRIC SHOCK − Observe the warning associated with the risk of electric shock

symbol.

CAUTION: REFER TO OPERATOR’S MANUAL − Refer to your operator’s manual for additional

information, such as important operating and maintenance instructions.

This symbol indicates that you should not discard waste electrical or electronic equipment (WEEE) in

the trash. For proper disposal, contact your local recycling/reuse or hazardous waste center.

Three−phase alternating current

PROTECTIVE CONDUCTOR TERMINAL

Do not apply around or remove from hazardous live conductors.

Page 4

Page 5

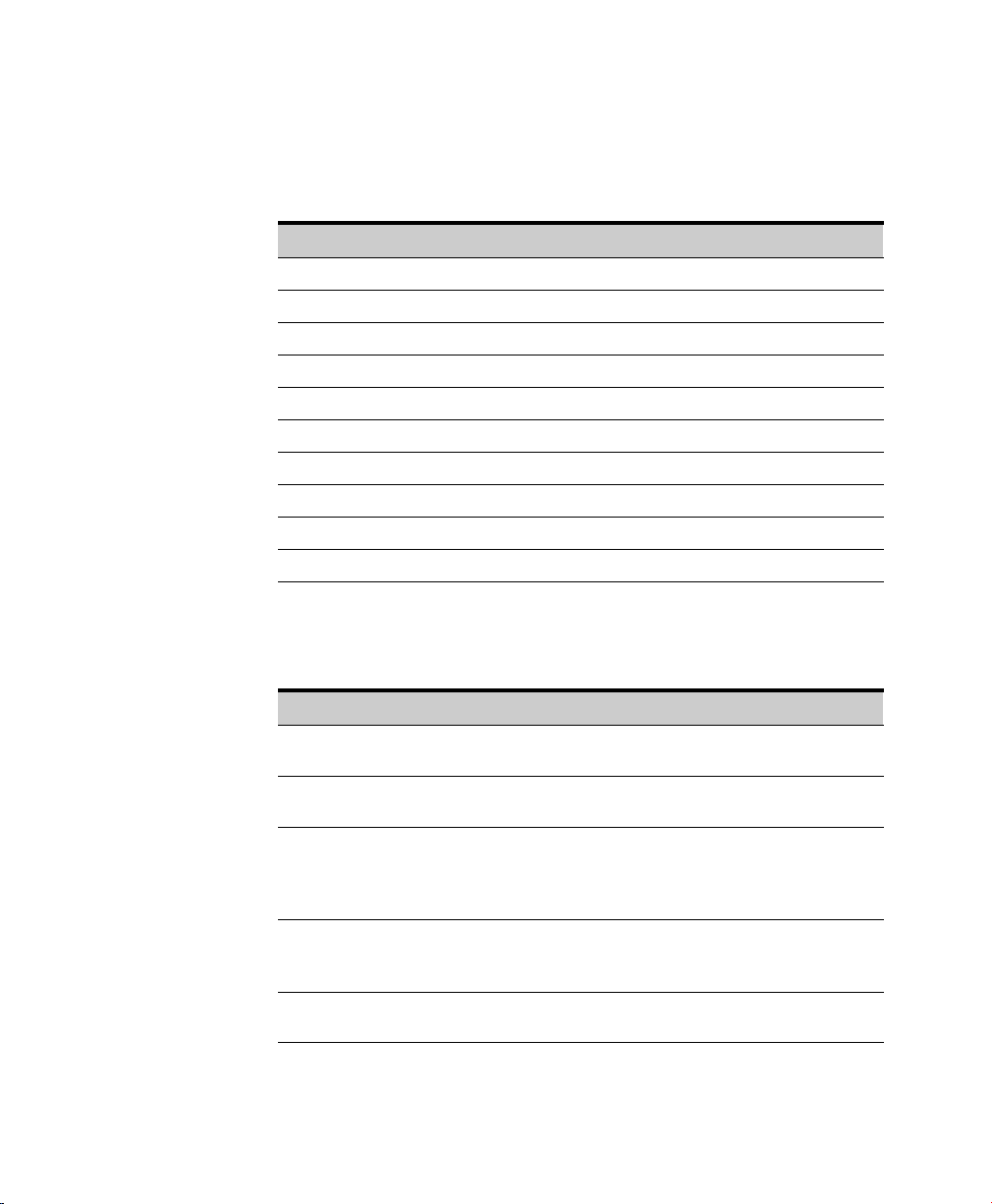

Table of Contents

1 Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Installation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspecting the Equipment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Cabinet 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking the Parts List 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Hardware 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Configuration 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Software Configuration Tool 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial System Configuration 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Panel and Breaker Configuration (Using the Software Configuration Tool) 31. . . . . . . . . . . . . . . . . . . . . .

Initial Panel and Breaker Configuration (Using the Display) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Metering Installation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Operation 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Function 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Breaker Numbering 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Functions 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Functions 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Map 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Options 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Panel Configuration 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Configuration 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Panels Containing Branch Circuit Breakers 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Panels Containing Subfeed Breakers 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Branch Circuit Breakers 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Panel Meters 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Breaker Meters 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

i

Page 6

TABLE OF CONTENTS

4 Communication 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Communication Features 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Options 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Port (Service) 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X−Slot Card 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Terminals 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Output Contacts (Alarm Relay) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programmable Signal Inputs (Building Alarms) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Maintenance 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recycling the Used Equipment 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updating the Firmware 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Power Xpert Gateway Series 1000 Card 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rewiring and Reconfiguring the Installation 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Specifications 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Troubleshooting 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Alarms and Conditions 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service and Support 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Warranty 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limited Factory Warranty 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 7

Chapter 1 Introduction

Eaton’s Powerware® Energy Management System (EMS) Upgrade Kit

(EMS−UGK) is designed to monitor energy usage of existing power

distribution panelboards, remote power panels, or power distribution

units. Providing outstanding performance and reliability, the EMS−UGK’s

unique benefits include the following:

S Monitors up to 42 (single panel) or 84 (dual panel) circuits in a

standard three−phase panelboard. Measures and stores energy

parameters for each of the individual monitored circuits, letting you

manage power with greater precision.

S Functions in a wide variety of applications supporting various data

center loads that may require a power distribution monitoring

solution, especially where power needs are changing and backup

architecture must be scalable.

S Can be mounted on a wall with the included mounting bracket and

customer−supplied fasteners appropriate for the type of wall.

S Choice of voltage sensing installation: connection to an unoccupied

circuit breaker using included transition harnesses or connection to an

occupied circuit breaker using included wire taps.

S Includes a software tool for easy configuring of settings and options.

S All harnesses supplied except for optional external ground.

S No preventive maintenance required other than verifying the

hardware and wiring are clear of debris. The EMS−UGK does not

require an annual calibration.

S Advanced Metering monitoring system, providing communication

options such as network connectivity through the Power Xpert

Gateway Card installed in the X−Slot® communication bay.

S Intended for continuous duty operation.

S Backed by worldwide agency approvals.

®

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

1

Page 8

INTRODUCTION

The following options for the EMS−UGK are available:

S Single panel (42 circuits) or dual panel (84 circuits)

S 208/120V or 380/220V, 400/230V, 415/240V rating

S Liquid crystal display (LCD) for local indication of energy usage

S Conduit box for enhanced harness protection

S Main input monitoring (three phases and one neutral rated to

measure currents up to 400A; up to 100A for input ground)

The following accessories for the EMS−UGK are available:

S Subfeed breaker monitoring, rated to measure currents up to 400A

S 100A branch circuit breaker monitoring

S Temperature and humidity monitoring with the optional

Environmental Monitoring Probe (EMP) that is used with the

Power Xpert Gateway Series 1000 Card installed in the EMS−UGK

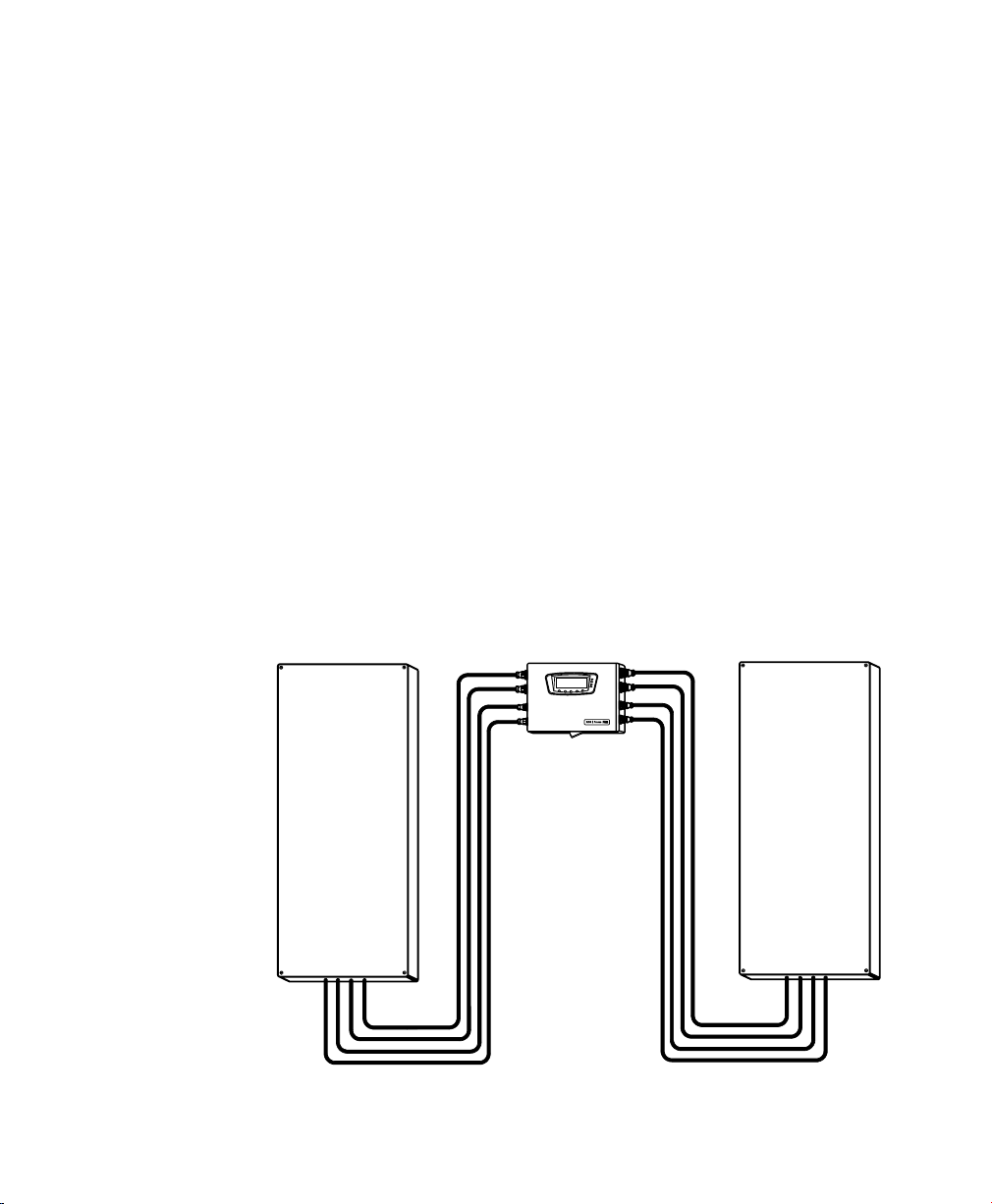

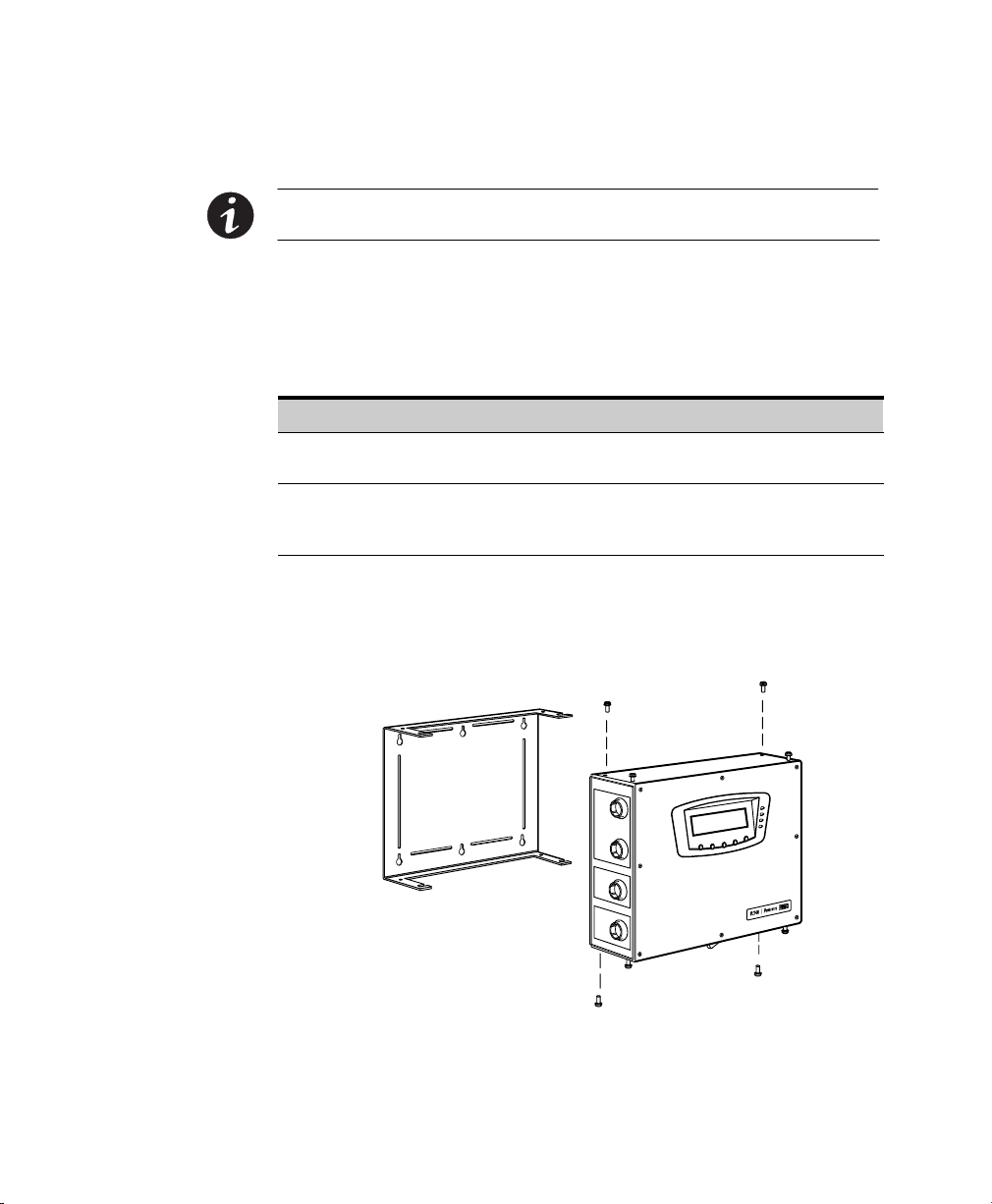

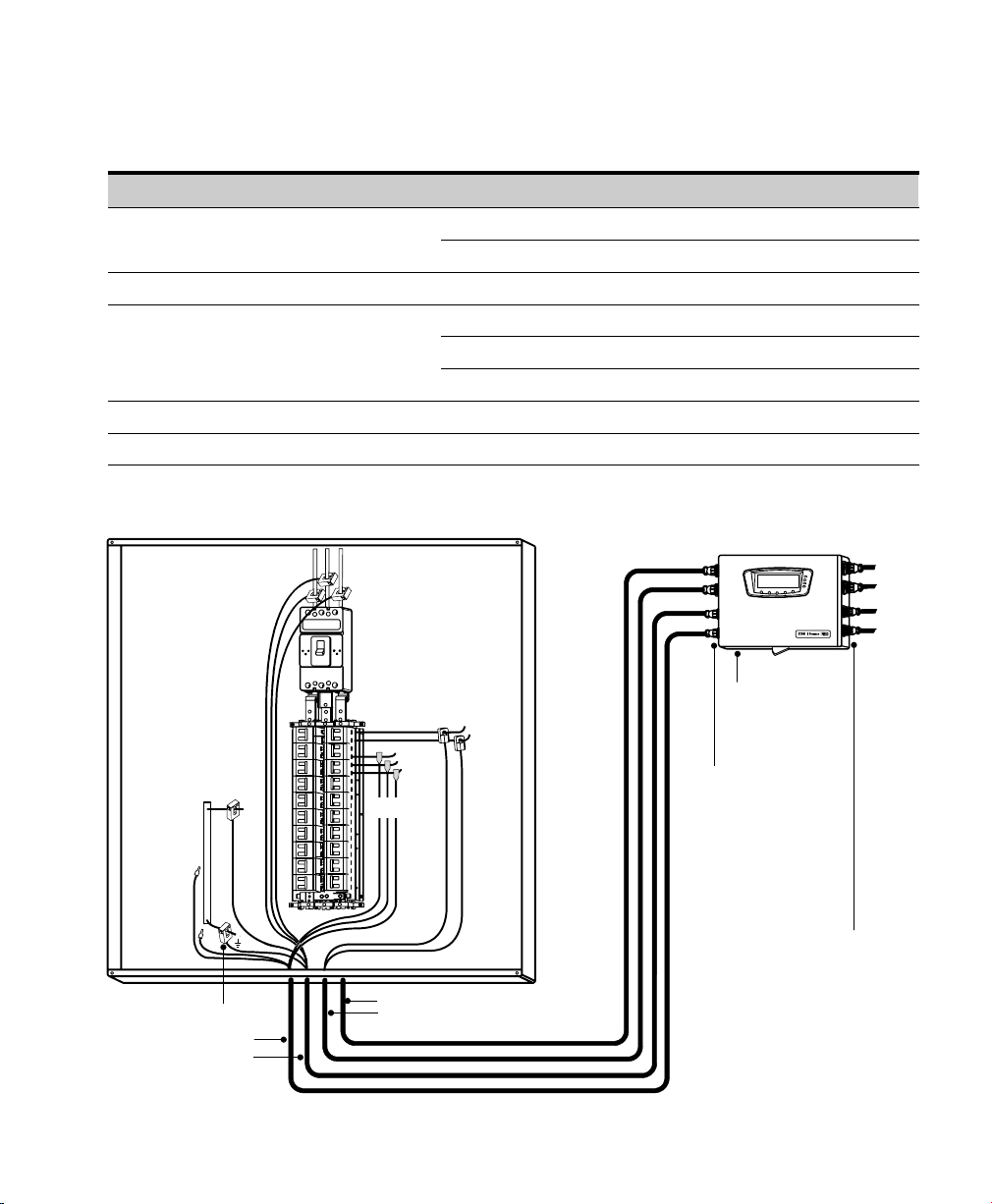

The EMS−UGK includes an externally−mounted enclosure with an

optional display. Current transformers (CTs) provide branch circuit

monitoring of installed panelboards. Figure 1 shows an example

installation of an EMS−UGK.

Figure 1. Typical EMS−UGK Installation (Dual Panel Shown with Optional Display)

2

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 9

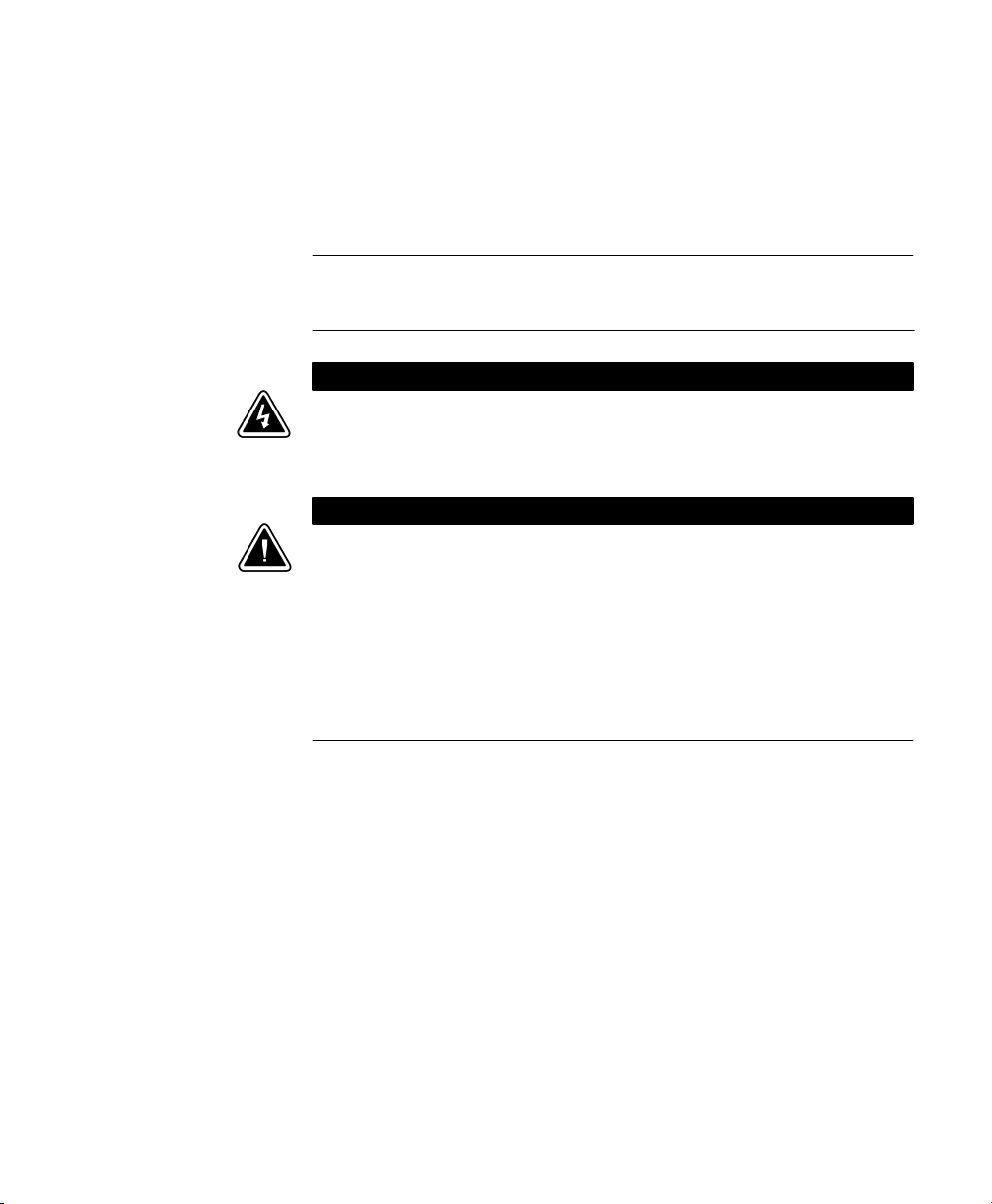

Safety Warnings

INTRODUCTION

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that you should follow during installation and

operation of the EMS−UGK. Please read all instructions before operating the equipment and

save this manual for future reference.

D A N G E R

This EMS−UGK contains LETHAL VOLTAGES. All repairs and service should be performed

by AUTHORIZED SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE

PARTS inside the EMS−UGK.

C A U T I O N

S To reduce the risk of fire or electric shock, install this EMS−UGK in a temperature and

humidity controlled, indoor environment, free of conductive contaminants. Ambient

temperature must not exceed 40°C (104°F). Do not operate near water or excessive

humidity (95% maximum).

S Use the branch circuit breakers to disconnect hazardous voltage from the EMS−UGK. Turn

off the breaker before disconnecting the voltage measuring circuit cables, or hazardous

voltage may be present at the exposed end of the cable.

S Installation or use of the equipment in a manner not specified by the manufacturer may

impair the protection provided by the equipment.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

3

Page 10

INTRODUCTION

Consignes de sécurité

Ce manuel contient des instructions importantes que vous êtes invité à suivre lors de toute

procédure d’installation et de fonctionnement de EMS−UGK. Veuillez consulter entièrement

ces instructions avant de faire fonctionner l’équipement et conserver ce manuel afin de

pouvoir vous y reporter ultérieurement.

Cet EMS−UGK contient des TENSIONS MORTELLES. Toute opération d’entretien et de

réparation doit être EXCLUSIVEMENT CONFIÉE A UN PERSONNEL QUALIFIÉ AGRÉÉ.

AUCUNE PIÈCE RÉPARABLE PAR L’UTILISATEUR ne se trouve dans la EMS−UGK.

S Pour réduire les risques d’incendie et de décharge électrique, installer la EMS−UGK

CONSIGNES DE SÉCURITÉ IMPORTANTES

CONSERVER CES INSTRUCTIONS

D A N G E R !

A T T E N T I O N !

uniquement à l’intérieur, dans un lieu dépourvu de matériaux conducteurs, où la

température et l’humidité ambiantes sont contrôlées. La température ambiante ne doit

pas dépasser 40 °C. Ne pas utiliser à proximité d’eau ou dans une atmosphère

excessivement humide (95 % maximum).

4

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 11

Sicherheitswarnungen

Dieses Handbuch enthält wichtige Hinweise, welche Sie bei der Installation und Wartung

des EMS−UGK beachten sollten. Bitte lesen Sie alle Anweisungen des Handbuches bevor sie

mit dem Gerät arbeiten. Bewaren Sie das Handbuch zum Nachlesen auf.

Die EMS−UGK führt lebensgefährliche Spannungen. Alle Reparatur− und Wartungsarbeiten

sollten nur von Kundendienstfachleuten durchgeführt werden. Die EMS−UGK enthält keine

vom Benutzer zu wartenden Komponenten.

S Um die Brand- oder Elektroschockgefahr zu verringern, diese EMS−UGK nur in Gebäuden

mit kontrollierter Temperatur und Luftfeuchtigkeit installieren, in denen keine leitenden

Schmutzstoffen vorhanden sind. Die Umgebungstemperatur darf 40°C nicht übersteigen.

Die EMS−UGK nicht in der Nähe von Wasser oder in extrem hoher Luftfeuchtigkeit (max.

95 %) betreiben.

INTRODUCTION

WICHTIGE SICHERHEITSANWEISUNGEN

AUFBEWAREN

W A R N U N G

A C H T U N G

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

5

Page 12

INTRODUCTION

Advertencias de Seguridad

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

Este manual contiene instrucciones importantes que debe seguir durante la instalación y el

funcionamiento de la EMS−UGK. Por favor, lea todas las instrucciones antes de poner en

funcionamiento el equipo y guarde este manual para referencia en el futuro.

Este EMS−UGK contiene VOLTAJES MORTALES. Todas las reparaciones y el servicio técnico

deben ser efectuados SOLAMENTE POR PERSONAL DE SERVICIO TÉCNICO AUTORIZADO.

No hay NINGUNA PARTE QUE EL USUARIO PUEDA REPARAR dentro de la EMS−UGK.

S Para reducir el riesgo de incendio o de choque eléctrico, instale este EMS−UGK en un

lugar cubierto, con temperatura y humedad controladas, libre de contaminantes

conductores. La temperatura ambiente no debe exceder los 40°C. No trabaje cerca del

agua o con humedad excesiva (95% máximo).

GUARDE ESTAS INSTRUCCIONES

P E L I G R O

P R E C A U C I Ó N

6

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 13

Chapter 2 Installation

This section explains:

S Equipment inspection

S Unpacking

S Parts list

S Required tools

S Installation and wiring

S Initial configuration

S Advanced Metering installation

Inspecting the Equipment

If any equipment has been damaged during shipment, keep the shipping

cartons and packing materials for the carrier or place of purchase and file

a claim for shipping damage. If you discover damage after acceptance,

file a claim for concealed damage.

To file a claim for shipping damage or concealed damage: 1) File with

the carrier within 15 days of receipt of the equipment; 2) Send a copy of

the damage claim within 15 days to your service representative.

Unpacking the Cabinet

Use care when moving and opening the carton. Leave the components

packaged until ready to install.

To unpack the cabinet:

1. Open the outer carton and remove the items packaged with the

cabinet.

2. Carefully lift the cabinet out of the outer carton.

3. Discard or recycle the packaging in a responsible manner, or store it

for future use.

Place the cabinet in a protected area that has adequate airflow and is

free of humidity, flammable gas, and corrosion.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

7

Page 14

INSTALLATION

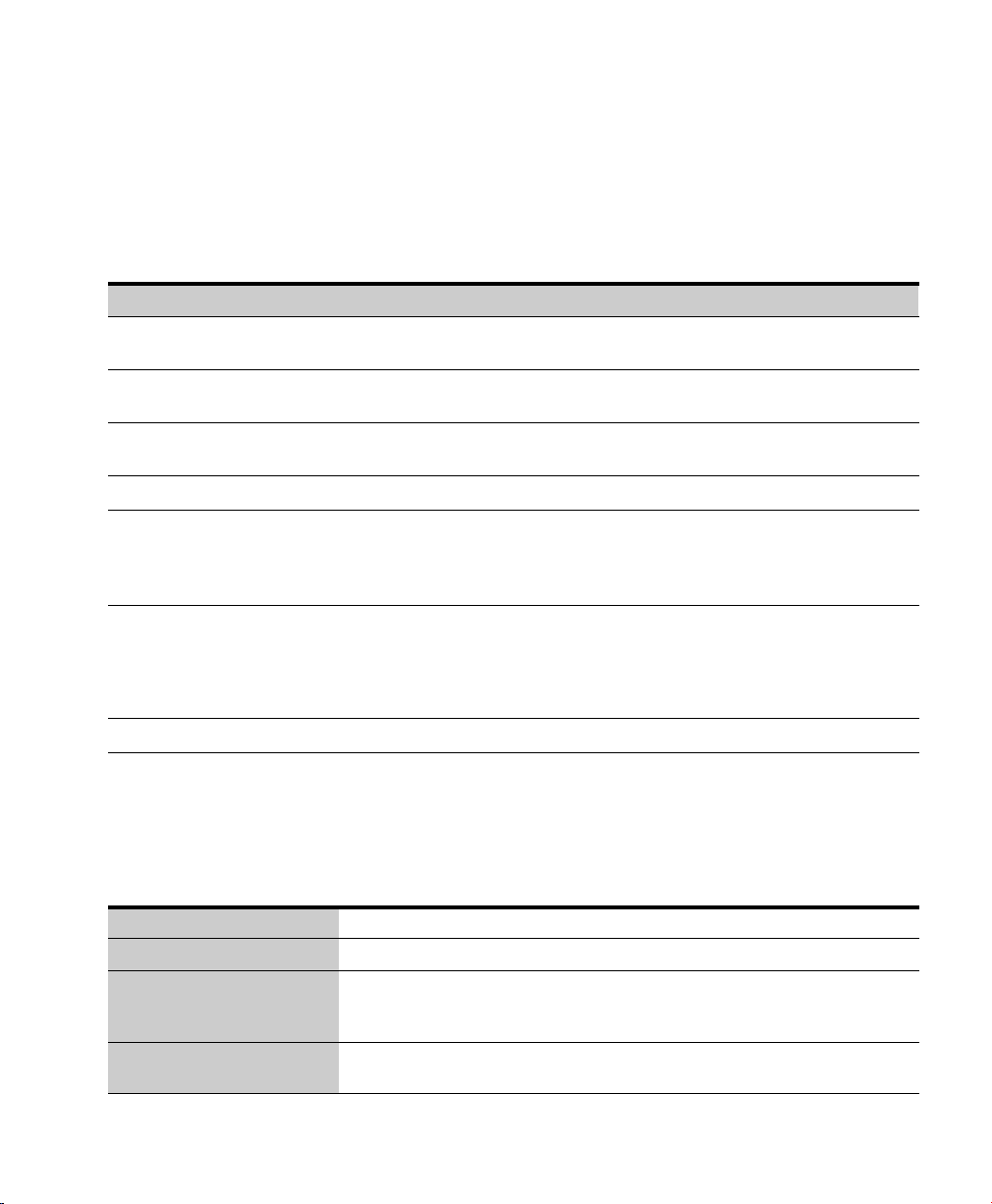

Checking the Parts List

Verify that the following items are included with the EMS−UGK.

All models

Electronics module (display optional)

Mounting bracket (installed on electronics module)

EMS Configuration Tool CD for setup and calibration

EMS configuration cable (DB−9 to RS−232 serial)

This user’s guide

Power Xpert Gateway Series 1000 Card (installed on electronics module)

Card configuration cable (RJ−45 to RS−232 serial)

Ethernet cable

Power Xpert Gateway Series 1000 Card registration card

Power Xpert Gateway Series 1000 Card Quick Start Instructions

NOTE For more detailed information, download the Power Xpert Gateway Series 1000

Card User’s Guide from the Documentation page on the Power Xpert card once the card

is accessible on the user’s network or from www.eaton.com/powerxpert.

All models (for each panel ordered)

(2) Branch circuit harnesses, each with one 28−position circular connector and

21 two−position connector plugs

(44) Branch current transformers (CTs), split−core, 75A, 1V output, with two−position

connector receptacle (includes 2 spares) (optional)

(1) Voltage harness, with one 7−position circular connector, three spade connectors

(A, B, C), and two ferrule connectors (Neutral, Ground)

NOTE Dual panel option only. Voltage harness V2 does NOT include a connector for

Ground.

(10) Wire taps:

− (5) 4.0 mm

− (5) 0.75–2.5 mm

2

(12 AWG), yellow

2

(18–14 AWG), blue

(3) Wire tap transition harnesses, each with a quick disconnect receptacle and a ferrule

connector

8

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 15

INSTALLATION

Main input monitoring option only (one set for each panel if ordered)

(1) Main input harness, with one 28−position circular connector and five 2−position

connector plugs (A, B, C, Ground, Neutral)

(4) Main CTs, split−core, 400A, 1V output, with 2−position connector receptacle

(1) Input ground CT, split−core, 100A, 1V output, with 2−position connector receptacle

Conduit box option only (if ordered)

Conduit box, left side

Conduit box, right side, with installed DB−9 extender cable

Subfeed Accessory Kit only (if ordered)

(3) Subfeed transition harnesses, each with 2 two−position connector plugs

(3) Branch CTs, split−core, 400A, 1V output, with two−position connector receptacle

100A Split−Core CTs Accessory Kit only (if ordered)

(10) Branch CTs, split−core, 100A, 1V output, with two−position connector receptacle

75A Split−Core CTs Accessory Kit only (if ordered)

(5) Branch CTs, split−core, 75A, 1V output, with two−position connector receptacle

NOTE Accessory kits may be shipped in separate cartons.

Tools Required

To assemble the components, the following tools may be needed:

anchors

®

#2 screwdriver

S Phillips

S Pliers or other appropriate tool for installing wire taps

S Drill or other appropriate tool for installing customer−supplied wall

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

9

Page 16

INSTALLATION

Installing the Hardware

NOTE Review the wiring planning requirements in Step 3 on page 14 as an aid to locating

an appropriate site for the EMS−UGK.

To install the EMS−UGK on a wall:

1. Verify that the wall on which the EMS−UGK is to be mounted meets

the recommendations listed in Table 1.

Table 1. Wall Specifications (Customer−Supplied Components)

Component Specification

Wall surface and

wall anchors

Clearance around

electronics module

Sufficient to support the weight of the EMS−UGK and installed

cables (see Table 12 on page 57 for weight specifications)

Above: 102 mm (4") [152 mm (6") recommended]

Below: 102 mm (4")

Sides: 152 mm (6")

2. Loosen the four front screws, and remove the four rear screws.

Remove the mounting bracket from the electronics module. Retain

the bracket and four removed screws. See Figure 2.

M4 10 screws

(8 places)

Figure 2. Mounting Bracket and Electronics Module (with Optional Display)

10

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 17

INSTALLATION

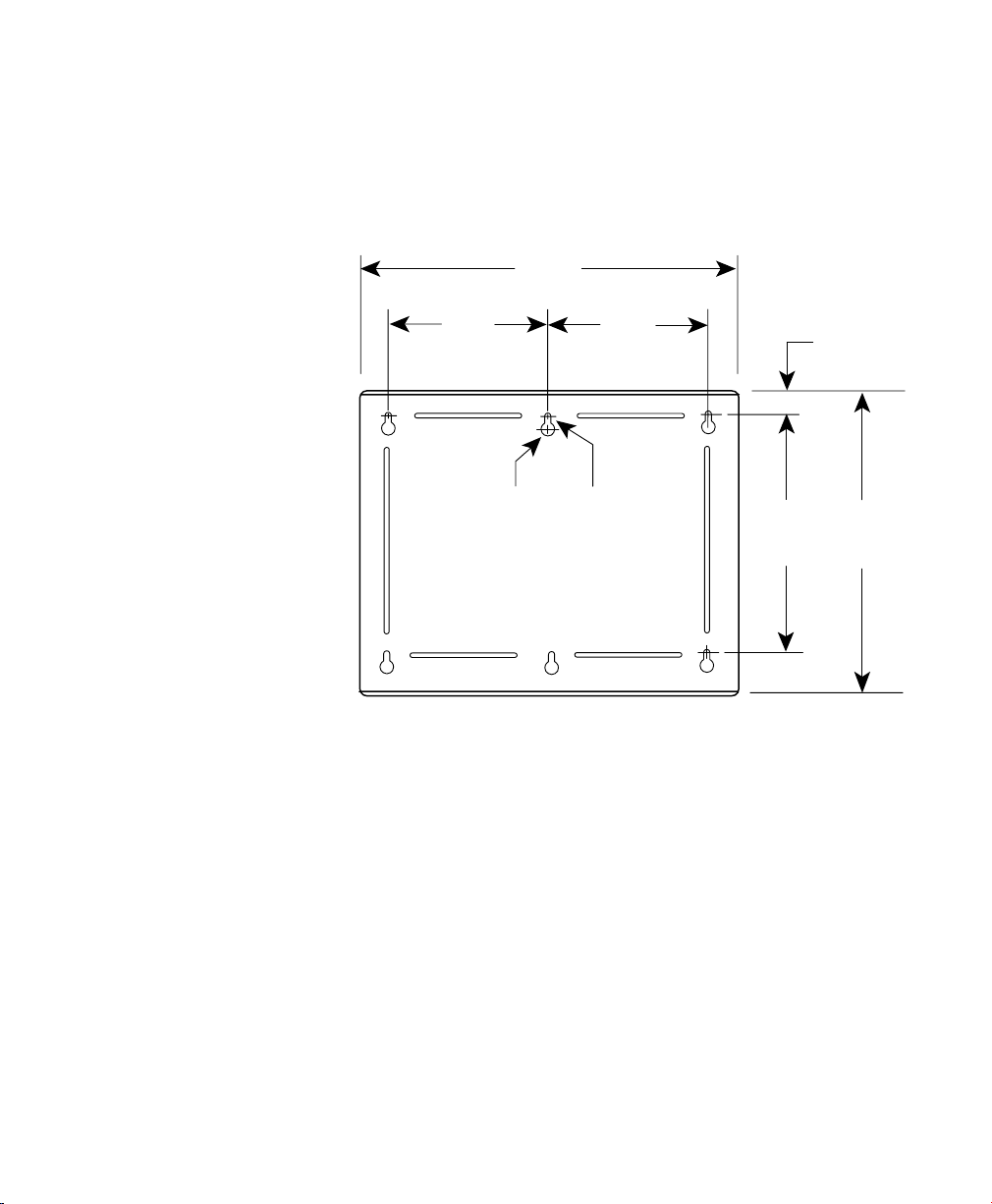

3. Attach the mounting bracket to the wall with appropriate wall

anchors (not supplied). See the mounting template in Figure 3.

Verify that at least two wall anchors attach to studs within the wall.

376.5 mm

(14.82")

152.4 mm

(6.00")

∅ 12.7 mm

(0.50") TYP

152.4 mm

(6.00")

∅ 5.3 mm

(0.21") TYP

226.0 mm

(8.90")

16.8 mm

(0.66")

283.5 mm

(11.16")

Figure 3. Mounting Template

4. Slide the loosened front screws on the electronics module into the

slots on the mounting bracket.

5. Verify all screw holes are aligned. Reinstall the four screws

removed in Step 2, but do not fully tighten. See Figure 2.

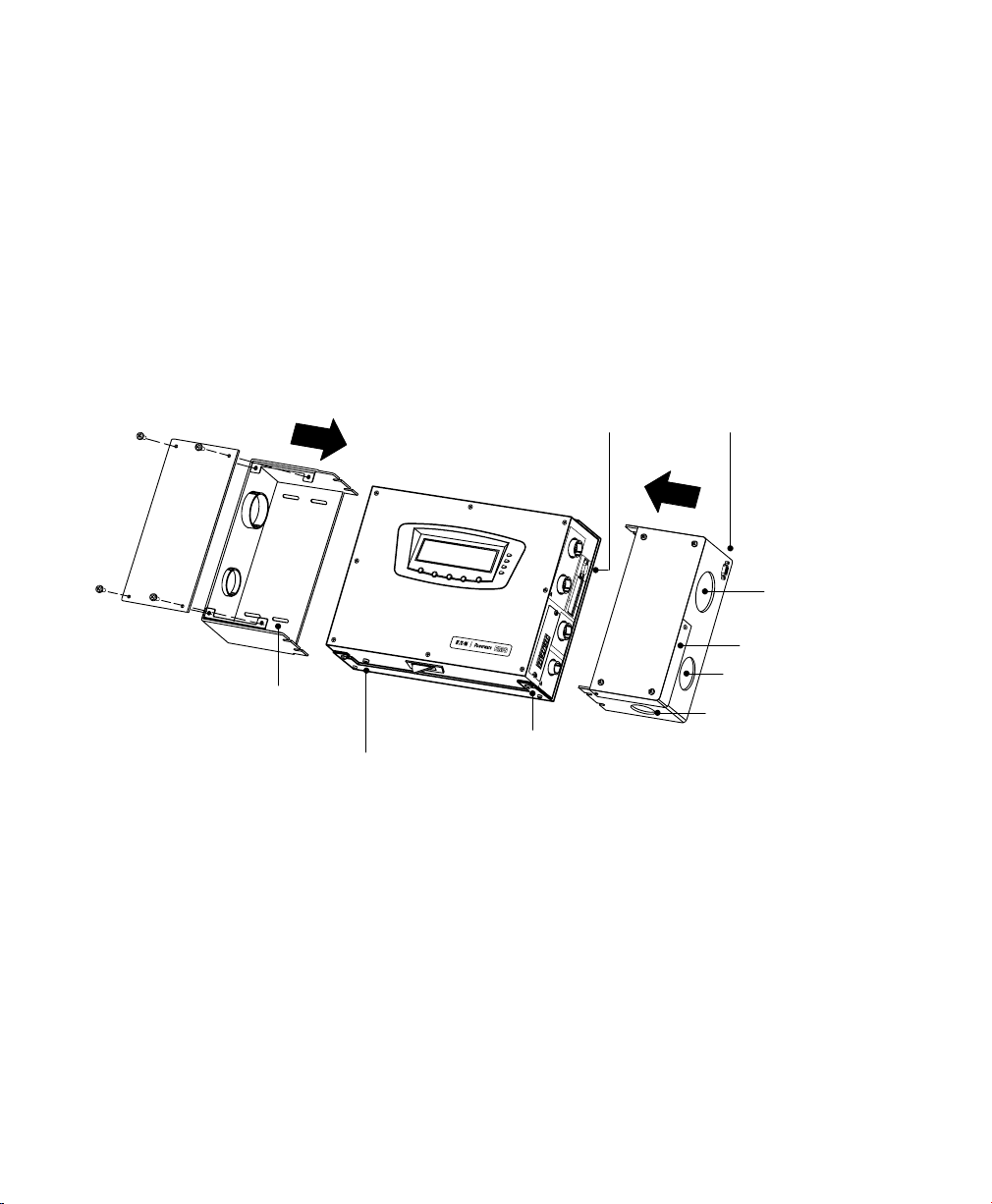

6. If installing the optional conduit box, continue to Step 7. Otherwise,

proceed to Step 11.

7. Remove the front plate from each conduit box. Retain the plates

and screws for later reinstallation. See Figure 4.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

11

Page 18

INSTALLATION

8. If installing a right conduit box, connect the DB−9 extender cable

(installed on the extended serial port on the inside of the right

conduit box) to the serial port (Service) on the electronics module.

Figure 4 shows the location of the two serial ports.

9. Slide the conduit box into place on one side of the electronics

module. Loosen the mounting bracket screws further if needed.

If installing conduit on both panels, repeat for the other conduit box.

Tighten the mounting bracket screws to secure the conduit box(es).

Front

Plate

Left Conduit

Box

Mounting

Slots

(4 places)

Ground Bonding Screw

10. Optional but recommended. Attach the conduit box(es) to the wall

with appropriate wall anchors (not supplied). Use one or more of

the four available mounting slots in each conduit box.

11. Verify that all hardware is mounted and aligned properly, then

tighten all screws. Verify the hardware is attached safely and

securely to the wall.

12. Continue to the following section, Electrical Connections."

Mounting Bracket

Screws (8 places)

Figure 4. Conduit Box Option

Serial Port

(Service)

Front

Plate

Right Conduit Box

Extended

Serial Port

2" Bushing

Card Cover Plate

1.5" Bushing

1" Bushing

12

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 19

Electrical Connections

S Only qualified service personnel (such as a licensed electrician) shall perform the

S Always follow all personal protective equipment (PPE) and other safety rules when

S Use the branch circuit breakers to disconnect hazardous voltage from the EMS−UGK. Turn

S To prevent mechanical damage, coil and secure any excess cable away from the floor.

The EMS−UGK is designed for quick and easy installation. Labels on the

harnesses describe where to connect the CTs and wire taps. Keyed

circular connectors provide a quick and secure installation to the

electronics module.

INSTALLATION

W

A R N I N G

electrical installation. Risk of electrical shock.

working around electricity.

C A U T I O N

off the breaker before disconnecting the voltage measuring circuit cables, or hazardous

voltage may be present at the exposed end of the cable.

To connect the wiring for the EMS−UGK:

C A U T I O N

Before wiring the EMS−UGK, disconnect the load and shut down the host equipment. Refer

to the user’s guide for the host equipment for shutdown instructions.

1. Verify that no circuits on which the EMS−UGK will be installed are

energized. Be absolutely sure there is no power.

2. Optional. Connect the ground cable (not supplied) from the host

equipment to the M5 ground bonding screw on the bottom of the

electronics module. Figure 4 shows the location of the ground

bonding screw.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

13

Page 20

INSTALLATION

3. Plan the wiring route from the electronics module to the monitored

breaker panel(s). See Table 2 through Table 4, Figure 5, and use the

following guidelines.

S Mount the electronics module within 3.05m (10 ft) of a

disconnect device.

S If installing conduit (not supplied), plan for adequate conduit

routing. Follow National Electrical Code

guidelines for conduit length and bending radius. Installed width

of the EMS−UGK with both conduit boxes is 633 mm (24.9").

Remove conduit box hole plugs as needed for conduit.

S Follow NEC and local guidelines for filling wiring space and

maintaining the thermal performance of the equipment.

S Plan the location and installation of the CTs and wire taps to

allow for adequate bending radius of wiring. If necessary,

support the CTs to avoid undue strain on wiring.

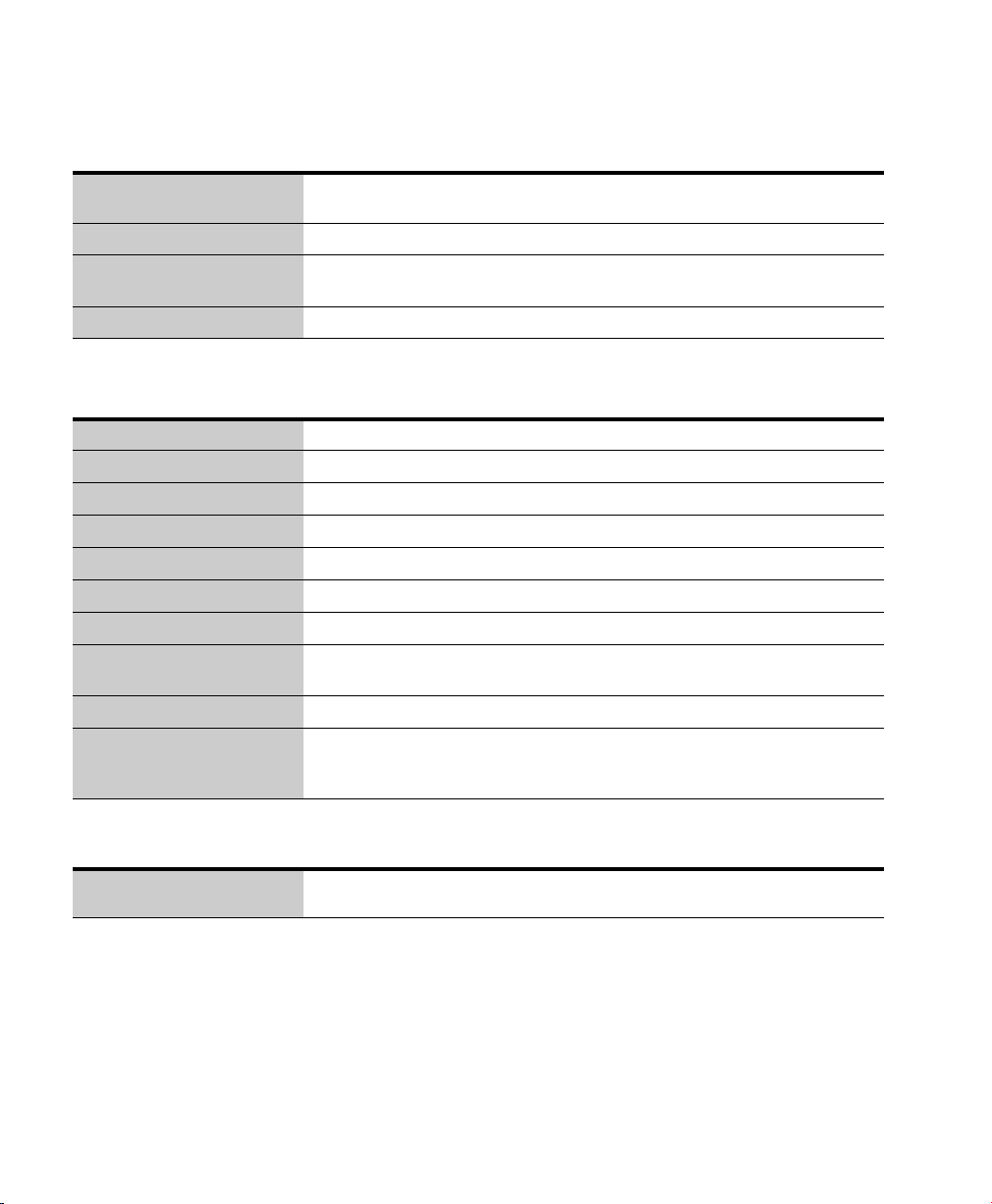

Table 2. Current Transformer Sizing

Type of CT Rating

Branch CT 75A 25.4 38.1 25.4 mm

Branch CT

(separate accessory)

Main CT (phases A,

B, C, and Neutral)

Input Ground CT 100A 66.0 70.0 33.0 mm

Subfeed CT

(separate accessory)

100A 41.0 51.0 30.0 mm

400A 96.0 100.0 46.0 mm

400A 96.0 100.0 46.0 mm

CT Dimensions

H D)

(W

1.5" 1.0")

(1.0"

2.0" 1.2")

(1.6"

3.9" 1.8")

(3.8"

2.8" 1.3")

(2.6"

3.9" 1.8")

(3.8"

®

(NEC®) and local

Lead Length

0.91m (36.0") 10.16 mm (0.40")

1.00m (39.4") 16.00 mm (0.63")

0.91m (36.0") 22.86 mm (0.90")

0.91m (36.0") 15.24 mm (0.60")

0.91m (36.0") 22.86 mm (0.90")

Maximum Wire Insulation

Outside Diameter

Table 3. Wire Tap Sizing

Housing Color Wire Size

Blue 0.75–2.5 mm2 (18–14 AWG)

Yellow 4.0 mm2 (12 AWG)

NOTE Use wire taps ONLY on thermoplastic insulation (PVC).

14

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 21

INSTALLATION

Table 4. Harness Sizing

Harness Bundled Length Connection Lead Length

Voltage 3.05m (10 ft)

Phases (A, B, C) 0.91m (3 ft)

Ground (V1 only), Neutral 1.83m (6 ft)

Main Input 2.74m (9 ft) Phases (A, B, C), Neutral, Ground 304.8 mm (12")

Branch Circuit 2.74m (9 ft)

Circuit Breakers 1/1 – 14/28* 304.8 mm (12")

Circuit Breakers 15/8 – 28/35* 203.2 mm (8")

Circuit Breakers 29/15 – 42/42* 101.6 mm (4")

Wire Tap Transition N/A Three−Phase Circuit Breaker 101.6 mm (4")

Subfeed Transition N/A Subfeed Breaker 50.8 mm (2")

* Circuit breaker numbering: NEMA/Standard (See Breaker Numbering" on page 37.)

NOTE Voltage harness

shown installed with wire

taps on an occupied

Main CTs

(A, B, C)

Electronics Module

branch circuit breaker

(20A maximum).

External Ground

Branch CTs

(optional)

Panel Connections:

Branch CTs (CT1)

Wire Taps

Neutral

Branch CTs (CT2)

Main CTs (CTM)

Voltage (V1)

CT1

CT2

CTM

V2

Panel Connections

and

Communication Features

(see Figure 20 on page 49)

Input Ground CT

Branch Circuit Harnesses

Voltage Harness

Main Harness

Figure 5. Wiring Overview (Example Installation)

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

15

Page 22

INSTALLATION

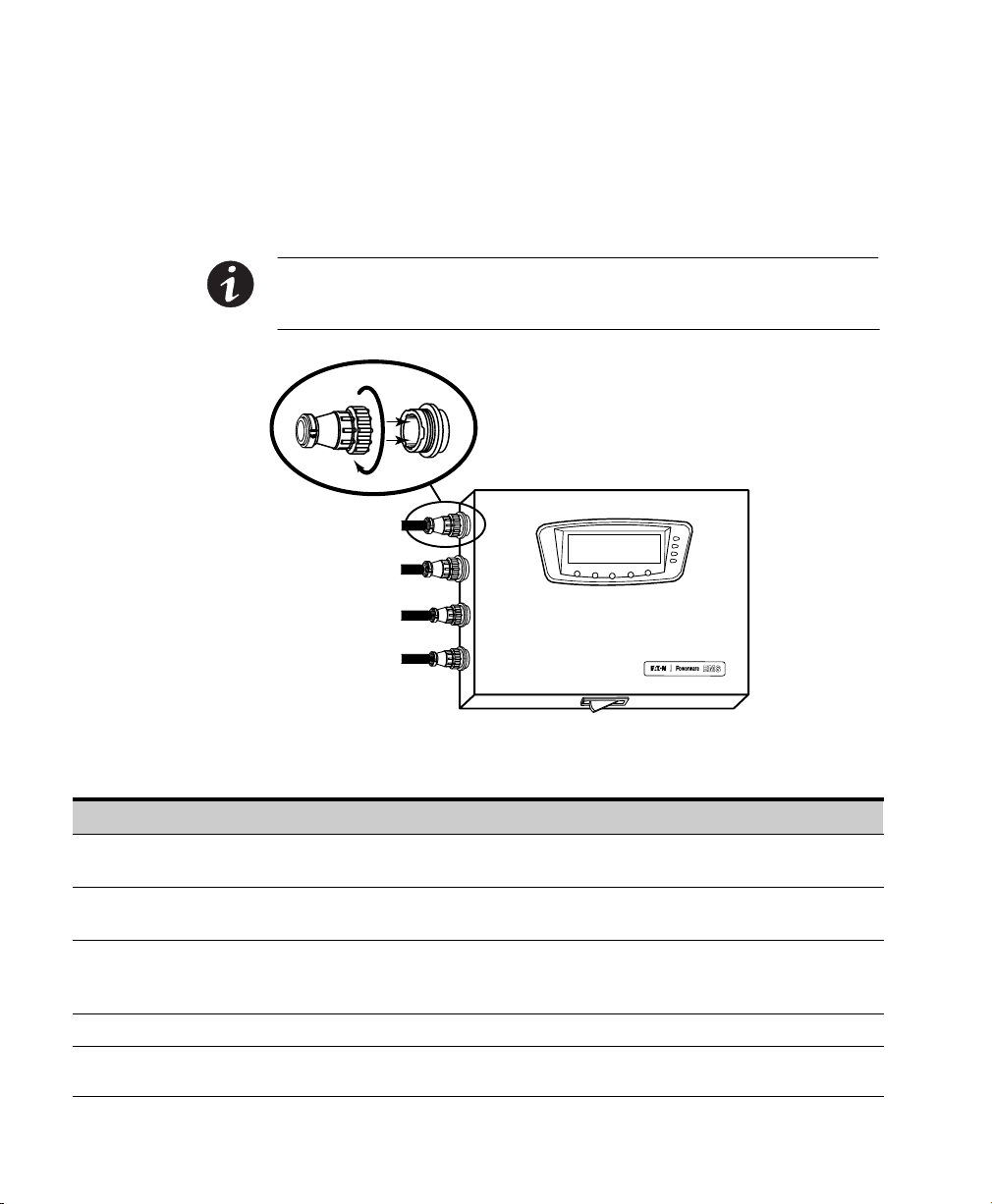

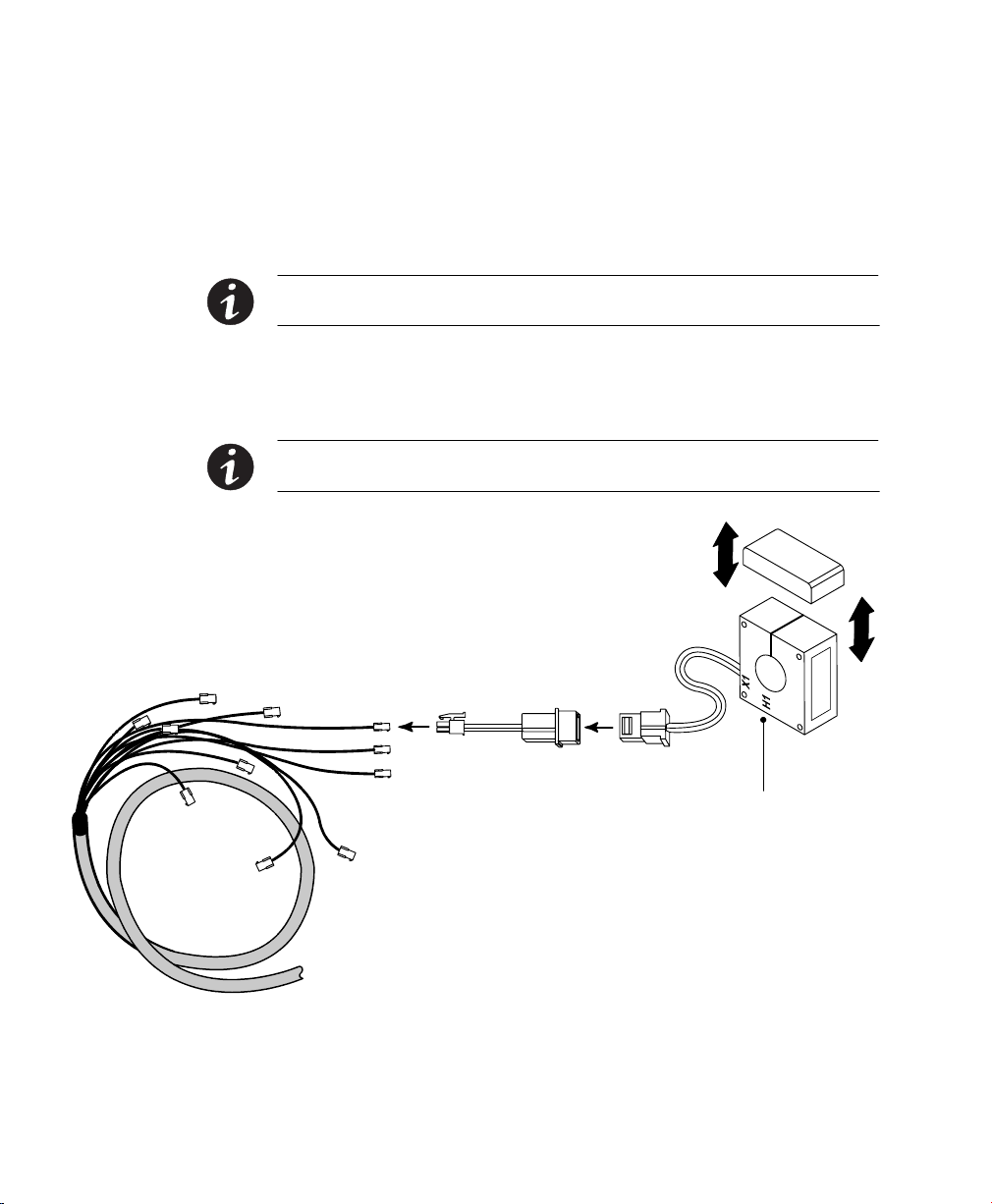

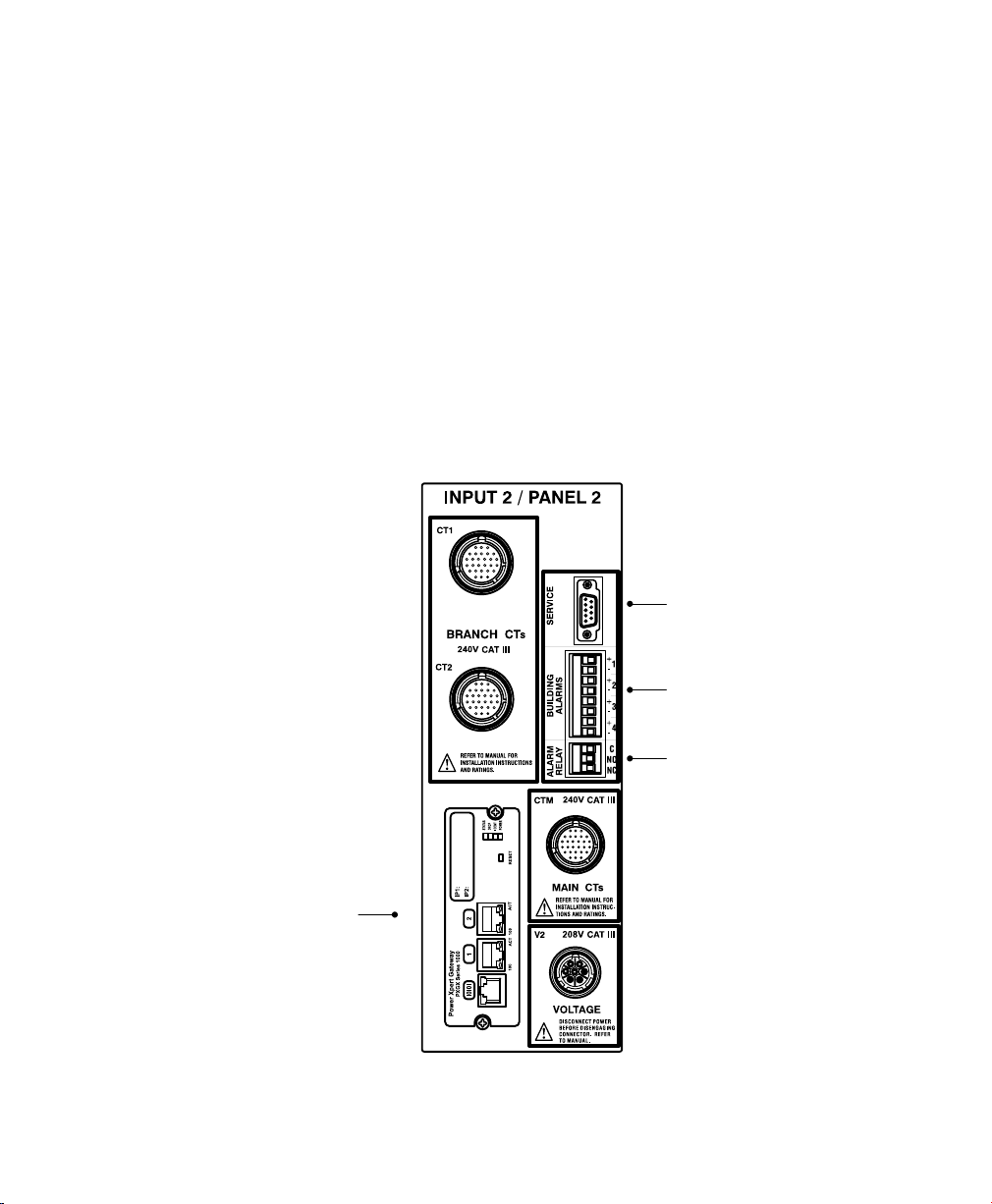

4. Connect the circular connector of each harness to the electronics

module. Verify the harness label matches the connector label on

the electronics module. See Figure 6 and Table 5. Figure 7 shows a

detailed view of both panels.

NOTE To connect a harness to the electronics module, align the polarizing keys and

keyways and insert the plug into the receptacle. Rotate the attached coupling ring clockwise

until it snaps into position.

Branch Circuit Harness CT1

Branch Circuit Harness CT2

Main Input Harness CTM

Voltage Harness V1

CT1

CT2

CTM

V1

Figure 6. Harness Connections at the Electronics Module

Table 5. EMS−UGK Harness Connections

Connection Description

CT1 Branch circuit harness from Panel 1 / Input 1 to Panel 1 breaker poles 1–21.

Dual panel option only. Branch circuit harness from Panel 2 / Input 2 to Panel 2 breaker poles 1–21.

CT2 Branch circuit harness from Panel 1 / Input 1 to Panel 1 breaker poles 22–42.

Dual panel option only. Branch circuit harness from Panel 2 / Input 2 to Panel 2 breaker poles 22–42.

CTM Main input monitoring option only. Main input harness from Panel 1 / Input 1 to Panel 1 main

connections.

Dual panel option only. Main input harness from Panel 2 / Input 2 to Panel 2 main connections.

V1 Voltage harness from Panel 1 / Input 1 to Panel 1 reference voltage connection.

V2 Dual panel option only. Voltage harness from Panel 2 / Input 2 to Panel 2 reference voltage

connection.

CT1

CT2

CTM

V2

16

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 23

INSTALLATION

Figure 7. Panel Detail (EMS−UGK−LV Model with Dual Panel Option Shown)

Single Panel option only. Connections for CT1, CT2, CTM, and V2 on

NOTE

Input 2 / Panel 2 are covered with hole plugs.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

17

Page 24

INSTALLATION

5. Main input monitoring option only. Connect the main input harness to

the breaker panel (see Figure 8):

NOTE If you prefer not to install the Neutral CT, the EMS−UGK software can perform an

approximate calculation of the Neutral CT values.

Install the four 400A main CTs to the breaker panel wiring for A, B,

and C phases, and Neutral. Install the 100A input ground CT to the

breaker panel ground wiring.

NOTE To install a CT, remove the cap, open the body of the CT to insert the wire through

the slit, and reinstall the cap. Install all CTs with the H1" lettering facing the same direction.

Connect each labeled lead on the main input harness (A, B, C,

Neutral, and Ground) to the appropriate installed CT. Coil and secure

any excess cable away from other conductors.

If installing dual panels, repeat Step 5 for the second panel.

NOTE Verify all installed main input monitoring wiring is correct and follows NEC and local

guidelines. Verify all CTs are installed with their H1" lettering facing the same direction.

NOTE The input ground CT will provide valid readings only in an isolated ground system.

A

400A

B

Main CT

H1"

Lettering

Main Input

Harness

Input Ground CT

C

C

Neutral

400A

Ground

100A

Figure 8. Main Input Harness Connections

18

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Cap

Page 25

INSTALLATION

6. 75A or 100A Split−Core Branch CT option only. Connect the two branch

circuit harnesses to the breaker panel (see Figure 9):

NOTE Each connector on the branch circuit harness is labeled with two numbers, such as

1/1" or 5/3." The first number indicates the circuit breaker number according to NEMA

breaker numbering; the second number is Standard breaker numbering. See Breaker

Numbering" on page 37 for an explanation of breaker numbering.

For each circuit breaker to be monitored, find its labeled connector

on the branch circuit harness, connect a 75A or 100A branch CT to

the connector, then install the CT around the output wire connected

to the matching breaker.

For example, for circuit breaker 05 in a NEMA panel, connect a CT

to harness connector 5/3, then install the CT on the output wire for

circuit breaker 05.

Coil and secure any excess cable away from other conductors.

Branch

Circuit

Harness

Branch CT

Breaker 05

5/3

Figure 9. Branch Circuit Harness Connections

7. If installing dual panels, repeat Step 6 for the second panel.

8. Verify all installed branch circuit monitoring wiring is correct and

follows NEC and local guidelines.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

19

Page 26

INSTALLATION

9. Subfeed Accessory only. Locate the Subfeed Accessory Kit (three

subfeed transition harnesses and three 400A CTs). Connect a

subfeed transition harness to each CT. See Figure 10.

Install each CT around the appropriate subfeed breaker wire.

NOTE To install a CT, remove the cap, open the body of the CT to insert the wire through

the slit, and reinstall the cap. Install all CTs with the H1" lettering facing the same direction.

Attach each subfeed transition harness to the appropriate

connection on the branch circuit harness as described in Step 6.

Coil and secure any excess cable away from other conductors.

NOTE Verify all installed subfeed monitoring wiring is correct and follows NEC and local

guidelines. Verify all CTs are installed with their H1" lettering facing the same direction.

Cap

Subfeed Transition Harness

H1"

Lettering

Branch

Circuit

Harness

Figure 10. Subfeed Monitoring Connections

20

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

400A CT

Page 27

INSTALLATION

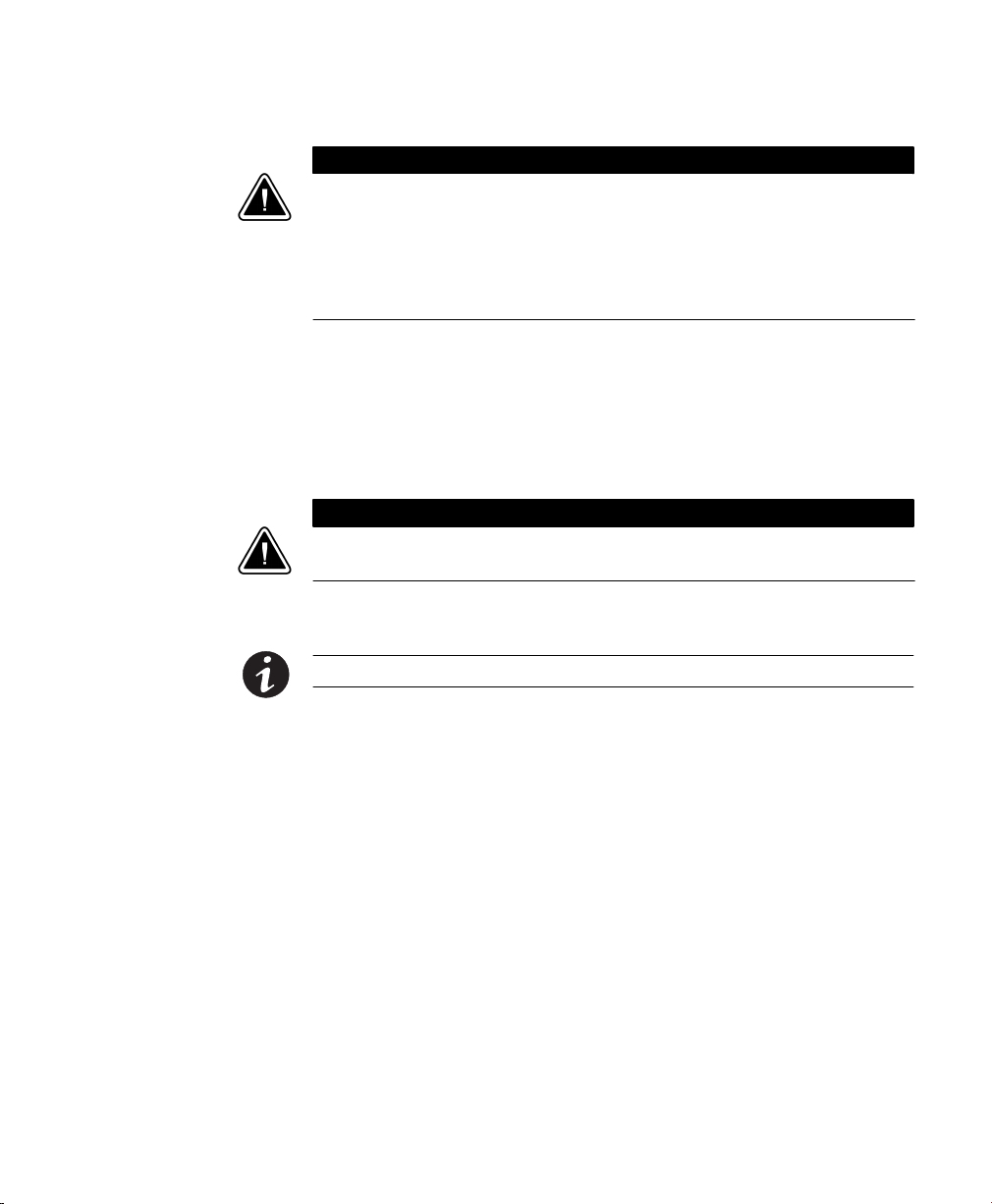

C A U T I O N

S Panel 1 voltage sensing includes a ground wire, but Panel 2 voltage sensing does not. If

installing dual panels, connect the voltage harness V1 for Panel 1 first. When

disconnecting dual panels, disconnect the voltage harness V2 for Panel 2 first.

S Use the branch circuit breakers to disconnect hazardous voltage from the EMS−UGK. Turn

off the breaker before disconnecting the voltage measuring circuit cables, or hazardous

voltage may be present at the exposed end of the cable.

10. On the voltage harness V1 for Panel 1, locate the green and yellow

Ground wire. Attach the Ground ferrule to a ground point within the

panel. See Figure 5 on page 15.

11. Attach the Neutral wire to the Neutral bar in the panel. See Figure 5

on page 15.

C A U T I O N

Before connecting the voltage harness to a branch circuit breaker, shut down the branch

circuit breaker. Risk of electric shock.

12. Choose an option for connecting the phases for voltage sensing:

NOTE Maximum branch circuit breaker size where the voltage sensing is located is 20A.

S Use the supplied wire tap transition harnesses to connect the

voltage harness to an unoccupied three−phase branch circuit

breaker (continue to Step 13).

S Use the supplied wire taps to connect the voltage harness to an

occupied three−phase branch circuit breaker (proceed to Step 14

on page 23).

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

21

Page 28

INSTALLATION

Voltage

Harness

13. Unoccupied three−phase branch circuit breaker connection only. Verify

that the branch circuit breaker is turned off. Be absolutely certain

there is no power.

Attach a wire tap transition harness (supplied) to each of the phase

A, B, and C connectors on the voltage harness.

Connect the wire tap transition harnesses to the appropriate phase

connections of the unoccupied three−phase branch circuit breaker.

Coil and secure any excess cable away from other conductors.

Proceed to Step 15 on page 23.

Wire Tap

Transition Harness

Unoccupied

A, B, C

Phases

Neutral

Ground

Breakers

Breaker

Figure 11. Voltage Harness Connections to Unoccupied Breaker (V1 Harness Shown)

22

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 29

INSTALLATION

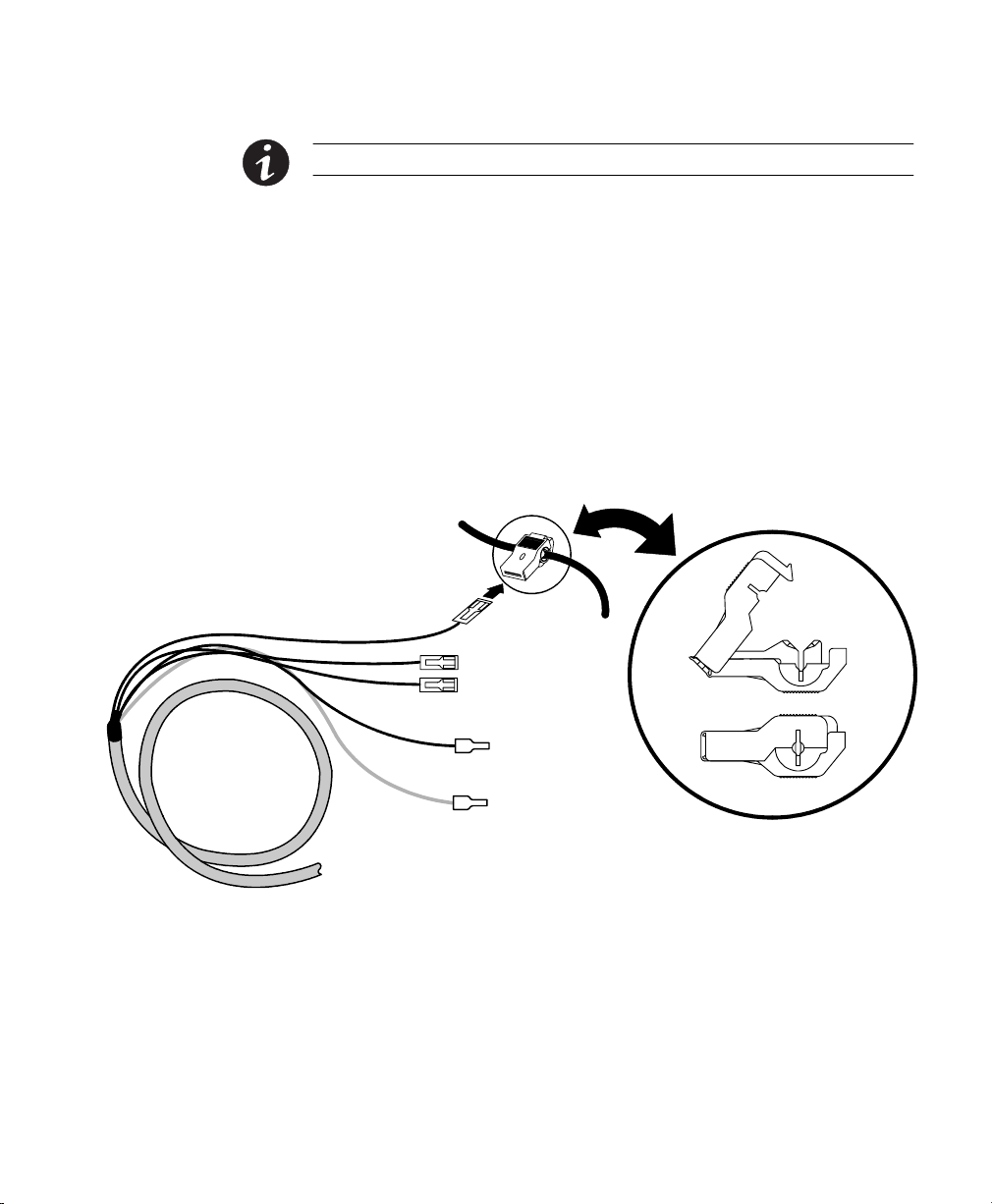

NOTE Use wire taps ONLY on thermoplastic insulation (PVC).

14. Occupied three−phase branch circuit breaker connection only. Verify that

the branch circuit breaker is turned off. Be absolutely certain there

is no power.

Use pliers to carefully install the appropriate size wire taps

(supplied) to phase A, B, and C wiring on the occupied circuit

breaker. See Figure 12. For sizing, see Table 3 on page 14.

Verify the wire taps are completely closed around the wires.

Connect the phase A, B, and C connectors on the voltage harness

to the appropriate installed wire taps. Coil and secure any excess

cable away from other conductors.

Wiring to Occupied Breaker

A, B, C

Phases

Neutral

Voltage

Harness

Ground

Wire Tap

Figure 12. Voltage Harness Connections to Occupied Breaker (V1 Harness Shown)

15. If installing dual panels, repeat Steps 11 through 14 for the voltage

harness V2 and Panel 2 for Neutral, A, B, and C phase connections.

Panel 2 does not have a Ground connection.

16. Verify all installed voltage monitoring wiring is correct and follows

NEC and local guidelines.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

23

Page 30

INSTALLATION

17. If installing communication functions, install the wiring for the Alarm

Relay and Building Alarms connections. For more information, see

Communication" on page 49.

18. Start up the host equipment. Refer to the user’s guide for the host

equipment for startup instructions.

19. Activate the reset switch on the bottom of the electronics module:

hold the switch for 10 seconds or until the display (if installed) turns

off, then release the switch.

20. Verify that the Power LED on the Power Xpert Gateway Series

1000 Card illuminates (see Figure 13).

Display option only. Verify that the display on the front of the

electronics module also activates. Press any button to display the

mimic screen.

Power LED

Figure 13. Power LED on the Power Xpert Gateway Series 1000 Card

21. Conduit Box option only. Reinstall the top plate on the left conduit

box.

22. If installing network connections, proceed to Step 24. Otherwise,

continue to the following step.

23. Conduit Box option only. If a right conduit box is installed, reinstall the

top plate on the right conduit box.

24. Continue to the following section, Initial Configuration."

24

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 31

Initial Configuration

This section describes how to use the supplied software configuration

tool to perform initial configuration and calibration. You can use either

the tool or the optional display (if installed) to configure the panels and

breakers.

After initial configuration, interface with the EMS−UGK using a Web page

interface, the Advanced Metering monitoring system, or (if the optional

display is installed) directly through the display.

Installing the Software Configuration Tool

INSTALLATION

NOTE For best results, install the software configuration tool on a computer running the

Microsoft

®

Windows® XP or Windows 2000 operating system.

To install the software configuration tool:

1. Connect a computer to the service port on the electronics module

using the supplied DB−9 to RS−232 serial cable.

2. Set the computer’s COM port settings to COM1, 19200 baud.

3. Verify that the computer’s settings for the date and time are

correct. The configuration tool uses the computer’s settings to

automatically set the date and time for the EMS−UGK. You can

disable this feature later if needed.

4. Insert the EMS Configuration Tool CD into the computer’s CD drive.

The installation program begins automatically within 10 seconds.

If the installation program does not begin automatically, run the

CD_Menu.exe program on the CD.

5. Follow the installation program instructions to install the tool.

6. Continue to the following section, Initial System Configuration."

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

25

Page 32

INSTALLATION

Initial System Configuration

To configure required and optional system settings:

1. Verify the EMS−UGK is physically connected to all installed CTs.

2. Verify that main voltages are connected and the EMS−UGK is

powered on.

3. Click Start > Programs > EATON > EMS Configuration Tool to open the

configuration tool. The System Status page displays, as shown in

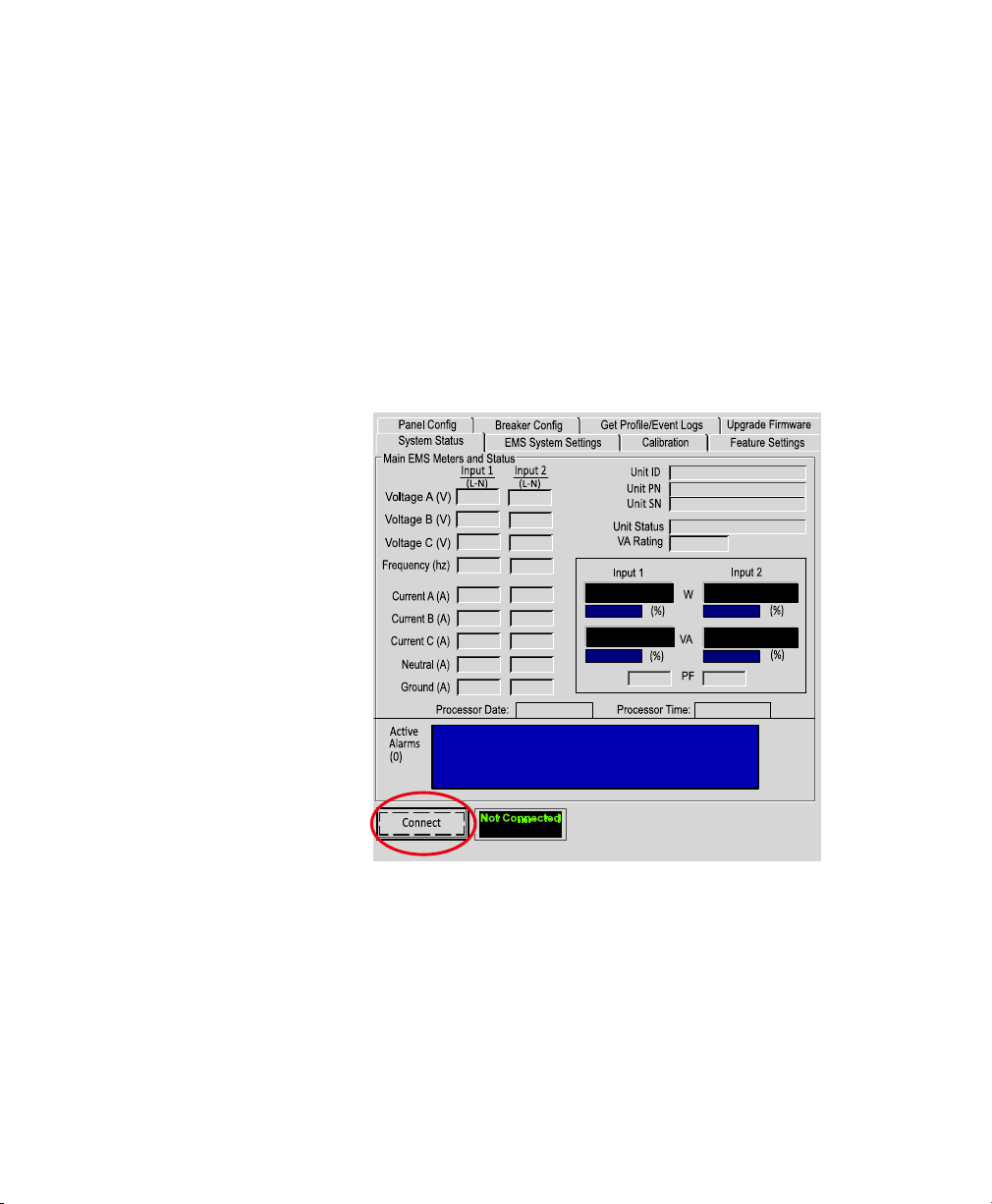

Figure 14.

Figure 14. System Status Page (Not Connected)

4. Click Connect to establish communication with the EMS−UGK.

26

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 33

INSTALLATION

5. Verify that meter and status information from the EMS−UGK

displays on the page, similar to the example shown in Figure 15.

NOTE Because the system is not yet configured, active alarms may appear in the Active

Alarms window upon connection and may be ignored.

If your system is dual input but only one input displays on the

System Status page, click the Feature Settings tab and select the

Enable Dual Input Mode check box. Return to the System Status page

to verify that both inputs display (as shown in Figure 15), then

continue to Step 6.

Figure 15. System Status Page (Connected)

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Active

Alarms

Window

27

Page 34

INSTALLATION

6. Click the EMS System Settings tab to display the Configure Primary

EMS Settings page.

7. Configure the following required settings:

EMS System Setting Description

Nominal Voltage

Settings

Input / Output CT

Settings

System Name and

Rating

LCD Mimic Screen

Display

Verify the nominal input voltage and frequency settings are

correct for your installation. Adjust as needed.

NOTE Specify nominal voltage as Line to Neutral voltage (not

Line to Line voltage).

Main input monitoring option only. Select the type and rating

for the input and neutral CTs installed (400A) and for the input

ground CT installed (100A).

NOTE Configure a CT only if it is installed.

NOTE If the neutral CT is not installed, the software calculates

its approximate values.

(1) Specify a Name for the system:

To change the default name, double−click in the Name field and

type the new name. Press Enter, then click Yes to confirm.

(2) Set the Rating in VA for the installation:

This setting matches the summation of the ratings on your

panels and is the overload level. To calculate the Rating, multiply

the main breaker rating for each panel by the nominal L−N

voltage. For example, for two 225A panels and a 120V nominal

input voltage, the rating is 225

2 120, or 54,000 VA.

NOTE If your breakers are configured, you can select Auto

Calc to have the software automatically calculate the VA rating.

(1) Select the option that best describes the installation:

S For an EMS−UGK, select EMS−UGK.

S For one panel, select 1 In / 1 Out.

S For two panels, select 2 In / 2 Out.

S For Harmonic Distortion transformers, select 1 In / 2 Out.

S For dual input PDUs with Kirk

®

key interlocks, select

2 In / 1 Out.

(2) To display a transformer on the mimic screen, select the

check box for Input Transformer Installed.

NOTE The transformer symbol is not available for all mimic

screen options.

NOTE To revert any changes made on the current page (except System Name) back to

default settings before saving, click

28

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Reload Sys Config.

Page 35

INSTALLATION

8. Optional. To prevent the software configuration tool from

synchronizing with the PC date and time, select Don’t auto update.

9. Click Save Sys Config to save the settings to the EMS−UGK.

Depending on communication speed, updates take effect within

15–20 seconds.

10. Optional. Voltage and current calibration is performed at the factory.

The EMS−UGK does not require calibration. If you choose to

recalibrate, the original calibrated values will be lost.

To recalibrate the settings, click the Calibration tab to display the

EMS System Calibration page.

NOTE For optimal results, verify that the circuits are loaded to nominal load levels prior to

starting calibration. Have qualified service personnel (such as a licensed electrician) obtain

the physical measurements using a multimeter and RMS current probe. For calibration,

measure the L−N voltage (not L−L voltage).

Enter the voltage and current measurements from the installed

panel(s) on the EMS System Calibration page. Blank fields will not

be calibrated.

NOTE To revert any changes made on the current page back to default settings before

saving, click

Reload Cal Data.

Click Save Cal Data to update the voltage calibration data and save

the settings to the EMS−UGK. Depending on communication speed,

updates take effect within 15–20 seconds.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

29

Page 36

INSTALLATION

11. Click the Feature Settings tab to display the EMS Feature Settings

page.

12. Configure the following Miscellaneous Features:

Feature Setting Description

Audible Horn Disabled Select to disable the audible horn. If enabled, the horn

sounds for each new alarm and can be turned off by

pressing any key on the display.

Meter Simulation Mode

Enabled

LCD Displays Input 1 V as L to L

LCD Displays Input 2 V as L to L

Enable THD Alarms Select to enable Total Harmonic Distortion metering

Enable Dual Input Mode Select for dual input models.

Select to enable demonstration mode for use with a

simulator.

Select to display Line to Line voltages on the display.

If unselected, voltages display as Line to Neutral

voltages.

alarms detected by monitor.

NOTE Deselecting this option removes all selections

and displays for the second input.

13. Configure the following Building Alarm Settings:

Feature Setting Description

Set Custom Alarm Name Type a name for Building Alarms 1 through 4.

Contact Type Select if the Building Alarm is connected as

normally−closed.

Action When Active Select the action to occur when the Building Alarm

becomes active.

NOTE To revert any changes made on the current page back to default settings before

saving, click

Reload Config.

14. Click Save Config to save the settings to the EMS−UGK. Depending

on communication speed, updates take effect within 15–20

seconds.

30

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 37

INSTALLATION

15. To configure panels and breakers using the software configuration

tool, continue to the following section, Initial Panel and Breaker

Configuration (Using the Software Configuration Tool)."

To configure panels and breakers using the optional display,

continue to Step 16.

16. Click Disconnect to disconnect from the EMS−UGK. Verify that Not

Connected" displays at the bottom of the page.

17. Close the software configuration tool and remove the configuration

cable.

18. Activate the reset switch on the bottom of the electronics module:

hold the switch for 10 seconds or until the display (if installed) turns

off, then release the switch.

19. Continue to Initial Panel and Breaker Configuration (Using the

Display)" on page 34.

Initial Panel and Breaker Configuration (Using the Software Configuration Tool)

To configure the panels and breakers:

1. Click the Panel Config tab to display the EMS Panel Settings page.

2. Verify that the Number of BCM Panels Installed is correct for your

installation.

If you change the value, click Save Panel Config to save the setting to

the EMS−UGK. Depending on communication speed, updates take

effect within 15–20 seconds.

3. Select the panel number to configure (Panel Selected).

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

31

Page 38

INSTALLATION

4. Configure the following settings for the selected panel:

Panel Setting Description

Panel Rating Specify the panel breaker rating (in amps).

NOTE Setting the panel breaker rating to 0 silences all

main panel breaker alarms and zeroes the panel percent

current levels.

Panel Warn (%) Specify the warning threshold level (in percent load).

Panel Alarm (%) Specify the alarm threshold level (in percent load).

Num Brkr Positions Specify the number of breakers in the panel.

Panel Name Specify a panel name (up to 19 characters).

Panel Serial Number Specify the panel’s serial number (up to 19 characters).

Panel Layout Specify the panel numbering style.

NOTE Changing panel layout erases all branch circuit

breaker configurations.

NOTE To revert any changes made on the current page back to default settings before

saving, click

Reload Panel Config.

5. Click Save Panel Config to save the settings to the EMS−UGK.

Depending on communication speed, updates take effect within

15–20 seconds.

6. Repeat Steps 3 through 5 to configure the remaining panels.

7. Click the Breaker Config tab to display the Breaker Settings page.

The tool automatically updates the default breaker schedule with

the latest information from the EMS−UGK. Depending on

communication speed, updates take effect within 15–20 seconds.

8. Select the Panel Number of the panel containing the breakers to

configure. The tool automatically updates the selected breaker

schedule with the latest information from the EMS−UGK.

Depending on communication speed, updates take effect within

15–20 seconds.

32

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 39

INSTALLATION

9. The selected breaker is highlighted in bold in the schedule. The

breaker’s configuration details display in the right half of the page.

Click the breaker to configure. The breaker number highlights and

its details display at right.

10. Configure the following settings for the selected breaker:

Breaker Setting Description

Num Phases Specify the number of phases (1–3).

Breaker Rating Specify the branch breaker rating (in amps).

Warning Level Specify the warning threshold level (in percent load).

Alarm Level Specify the alarm threshold level (in percent load).

CT Ratio Specify the current transformer ratio (75A).

NOTE The selected ratio converts to the value 71.9.

NOTE To revert any changes made on the current page back to default settings before

saving, click

Reload Breaker Config.

11. Repeat Steps 9 and 10 to configure the remaining breakers in the

panel.

12. Click Save Breaker Config to save the settings to the EMS−UGK.

13. Repeat Steps 8 through 12 to configure the breakers in the

remaining panels.

14. Click Disconnect to disconnect from the EMS−UGK. Verify that Not

Connected" displays at the bottom of the page.

15. Close the software configuration tool and remove the configuration

cable.

16. Activate the reset switch on the bottom of the electronics module:

hold the switch for 10 seconds or until the display (if installed) turns

off, then release the switch.

17. Continue to Advanced Metering Installation" on page 36.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

33

Page 40

INSTALLATION

Initial Panel and Breaker Configuration (Using the Display)

NOTE Use this section only if the optional display is installed.

Configure the panel and breaker data. You can use the following

abbreviated instructions or follow the more detailed steps in Control

Panel Configuration" on page 43.

1. From the setup screen, enter the Level 1 access password (default

password is L1).

2. Select Meters then Panel, highlight the panel to configure, then

select Config.

3. Set the Reset value to Yes and select OK to clear any breaker

configuration settings for the panel.

4. Configure the following settings to match the physical panel:

Phases (always three−phase)

Breakers (the number of breakers in the panel)

Rating (the rating in Amps of the main panel breaker)

Panel Layout (panel numbering style)

5. Highlight the panel number and select Schedule.

6. Highlight the breaker to configure and select Config.

7. Configure the following settings to match the physical breaker:

Phases (number of phases for the breaker)

Rating (breaker rating in Amps)

Warning (alarm warning level in %)

Overload (alarm overload level in %)

CT (the CT ratio – specify 71.9)

8. Configure each installed breaker in the panel.

9. If a second panel is installed, repeat the panel and breaker

configuration for the second panel.

10. Activate the reset switch on the bottom of the electronics module:

hold the switch for 10 seconds or until the display (if installed) turns

off, then release the switch.

34

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 41

INSTALLATION

11. From the setup screen, clear the History Log and Load Profile. For

detailed instructions, see Setup Options on page 42.

12. Continue to the following section, Advanced Metering

Installation."

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

35

Page 42

INSTALLATION

Advanced Metering Installation

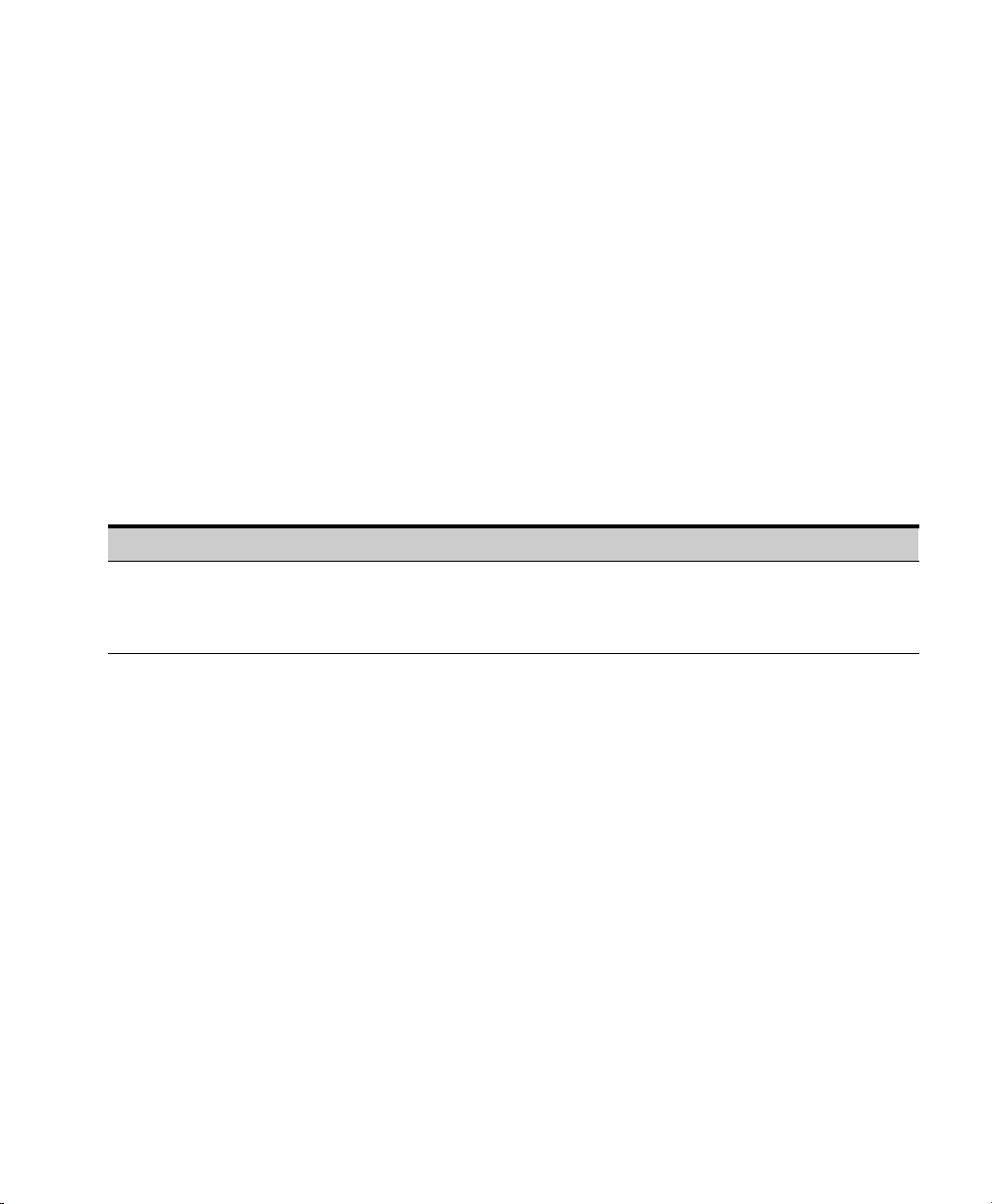

The Power Xpert Gateway Series 1000 Card (shown in Figure 16) is

factory−installed in the X−Slot communication bay on the side of the

EMS−UGK electronics module.

To connect the cables and configure the card:

1. Locate the Power Xpert Gateway Series 1000 Card Quick Start

Instructions included with the EMS−UGK.

2. Perform all the steps in the quick start instructions, ignoring the

initial few steps that describe how to install the card in a PDU.

The quick start instructions direct you to:

S Connect the Ethernet cable

S Connect the configuration (serial) cable

S Configure IP Address assignments

3. For more detailed information about installing the card or using

Advanced Metering, download the Power Xpert Gateway Series

1000 Card user’s guide from the Documentation page on the Power

Xpert card once the card is accessible on your network or from

www.eaton.com/powerxpert.

Configuration

(Serial) Port

Figure 16. Power Xpert Gateway Series 1000 Card

Ethernet

Port 1

Ethernet

Port 2

4. Conduit Box option only. If a right conduit box is installed, reinstall the

top plate on the right conduit box.

36

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 43

Chapter 3 Operation

This chapter describes how to use the Energy Management System

(EMS) Upgrade Kit (EMS−UGK) interface.

Reset Function

The EMS−UGK is intended for continuous duty operation. Cycle power

for the EMS−UGK using the reset switch at the base of the electronics

module: hold the switch for 10 seconds or until the display (if installed)

turns off, then release the switch. The switch is intended for use as a

programming reset function.

NOTE The reset switch controls power to the transformer inside the electronics module.

The reset switch does not remove three−phase sensing voltage from the Universal Control

Board (UCB).

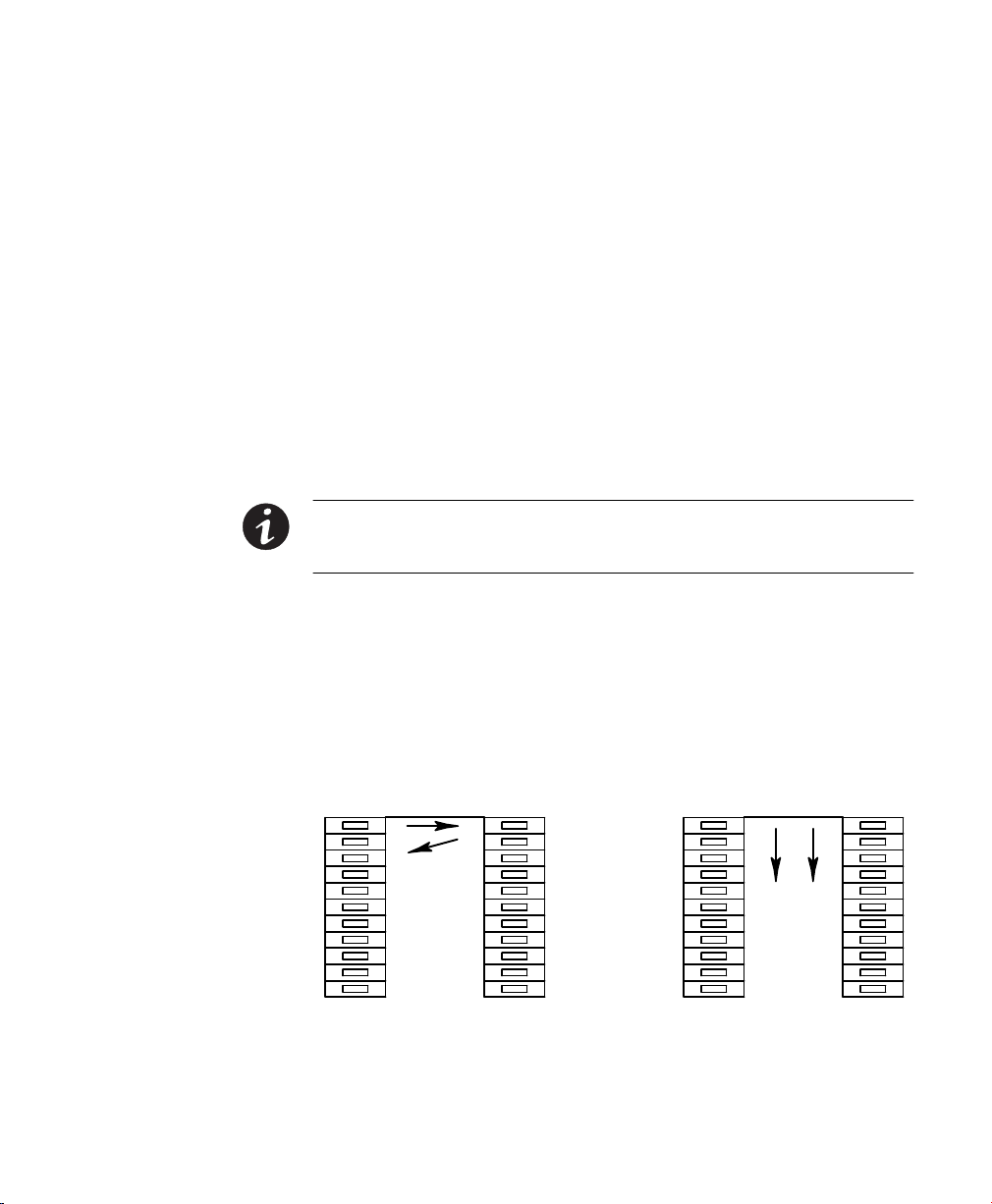

Breaker Numbering

NEMA numbering is left to right in a two−column panel. Odd−numbered

breakers are on the left and even−numbered breakers are on the right.

Standard numbering is top to bottom down the left side of the panel,

then top to bottom down the right side of the panel.

See Figure 17.

01 02

03

05

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

04

06 03

NEMA

Panel

Figure 17. Breaker Numbering

01

02

04 25

Standard

Panel

22

23

24

37

Page 44

OPERATION

Control Panel Functions

NOTE Use this section only if the optional display is installed.

The EMS−UGK has a graphical LCD with backlight, four status LEDs, and

five control buttons (see Figure 18). The display provides useful

information about system events, measurements, and settings.

PRESS ANY KEY TO CONTINUE

Power On (green)

Overload (yellow)

No function (always off)

Alarm (red)

Control Buttons for the LCD Menu Options

Figure 18. EMS−UGK Display

The following table shows the indicator status and description.

Indicator Status Description

ON

Green

O/L

Yellow

OFF Off Not applicable for the EMS−UGK.

AL

Red

38

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

On The product on which the EMS−UGK is installed is

operating normally.

Off The product on which the EMS−UGK is installed is turned

off and will not turn on automatically.

On One or more phases is in overload, or there is an alarm or

warning for neutral overload, ground overload, main panel

breaker overload, or panel breaker overload.

Flashing There is a new or cleared EMS−UGK alarm condition. See

Troubleshooting" on page 61 for additional information.

To silence the horn, press any button.

On An acknowledged alarm condition exists.

Page 45

OPERATION

Display Functions

The LCD displays the Eaton Powerware logo. Press any button to

activate the mimic screen and menu options (see Figure 19). The mimic

screen shows a real−time graphical representation of the operating

status of the system. At the top of the screen, an information line cycles

through displays of information such as the date and time and any active

alarms or events.

To select a menu option, press the button below the option name.

When available:

S Use the and buttons to scroll through a listing of information.

S Use the and buttons to select another item on the screen to

view or change.

S Use the + or — button to increase or decrease a selected value.

S Press the button to return to the previous menu.

NOTE After making configuration changes, you can save your changes immediately by

pressing the Reset button on the Power Xpert Gateway Card installed in the X−Slot

communication bay. The card resets automatically after five minutes.

The backlit LCD automatically dims after a long period of inactivity. Press

any button to restore the screen.

Input 2 / Panel 2Input 1 / Panel 1 Unit Name

EATON EMS−UGK

000.0

000.0

EMS

000.0

METEREVENTS SETUP

EVENT

S

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

METER

Figure 19. EMS−UGK Mimic Screen and Main Menu

PROFILE

PROFILE

000.0

000.0

000.0

SETUP

39

Page 46

OPERATION

Menu Map

The following tables show the basic menu structure.

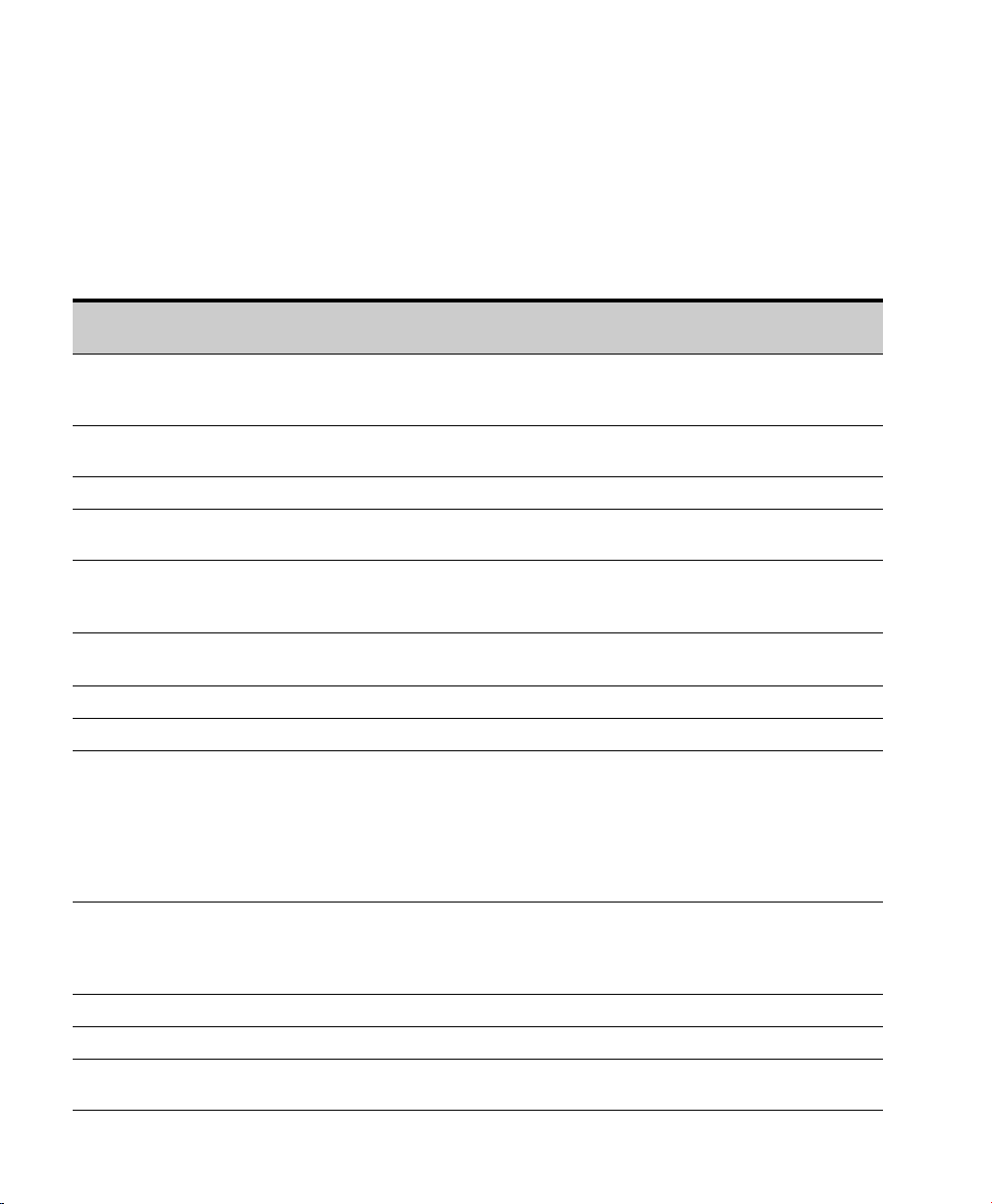

Table 6. Menu Map for Display Functions

Main Menu Submenu Display Information or Menu Function

Events

Active Events Displays list of active system events. As events clear, they are removed from the list.

History Displays historical log of system events. The log stores the most recent 127 events

and alarms.

Meter*

Input 2 Displays Input 2 / Panel 2 performance meters for the system or critical load:

RMS / % / THD / Crest / KWH

Select PANEL to configure or view panel meters (see Table 7 for detail).**

Select PANEL then SCHEDULE to configure or view breaker meters (see Table 8 for

detail).**

Input 1 Displays Input 1 / Panel 1 performance meters for the system or critical load:

RMS / % / THD / Crest / KWH

Select PANEL to configure or view panel meters (see Table 7 for detail).**

Select PANEL then SCHEDULE to configure or view breaker meters (see Table 8 for

detail).**

Profile* Displays load profile for the most recent 24 months. Profile includes highest and

lowest input and output currents, frequencies, power levels, power factors,

AC undervoltage, THD, and exact time each reading occurred. Current month’s profile

reflects real−time values.

Setup* Displays setup options. See Table 9 on page 42 for detail.

* Information displayed depends on product configuration.

** Configuration options are password−protected.

40

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 47

Table 7. Panel Meters

Screen Label Meters Displayed

OPERATION

Panel

(first screen)

Panel

(second screen)

Panel

(third screen)

Panel

(fourth screen)

Panel*

(fifth screen)

ALM

%LOAD

Vavg

Imax

V1, V2, V3

I1, I2, I3

I1%, I2%, I3%

KW

KVA

PF

#BRKS

KWH/m

KWH/y

KWHt

MAX V

MAX I

Alarm status (W for warnings, A for critical alarms)

Ratio (in percent) of present load compared to maximum

Average voltage

Phase with highest current

Voltage per phase

Current per phase

Ratio (in percent) of present current compared to maximum

Total kW of panel breakers

Total kVA of panel breakers

Power factor

Number of breakers

Kilowatt hours per month

Kilowatt hours per year

Total kilowatt hours

Maximum voltage logged

Maximum current logged

* To reset the panel statistics (fifth screen) to zero, select RESET.

Table 8. Breaker Meters

Screen Label Meters Displayed

Panel X Breaker Meters

(first screen)

Panel X Breaker Meters

(second screen)

Panel X Breaker Meters

(third screen)

Panel X Breaker Meters

(fourth screen)

ALM

CURR%

PHASE

Irms

RTNG

W

VA

PF

WARN

OVER

KWH/m

KWH/y

KWHt

Imax

Wmax

VAmax

PFmin

Alarm status

Ratio (in percent) of present current compared to breaker rating

Phase assignment

Current (RMS value)

Breaker rating

Average W

Average VA

Average power factor

Threshold load (in percent) at which a warning alarm is logged

Threshold load (in percent) at which an overage alarm is logged

Kilowatt hours per month

Kilowatt hours per year

Total kilowatt hours

Maximum current logged

Maximum W logged

Maximum VA logged

Minimum power factor logged

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

41

Page 48

OPERATION

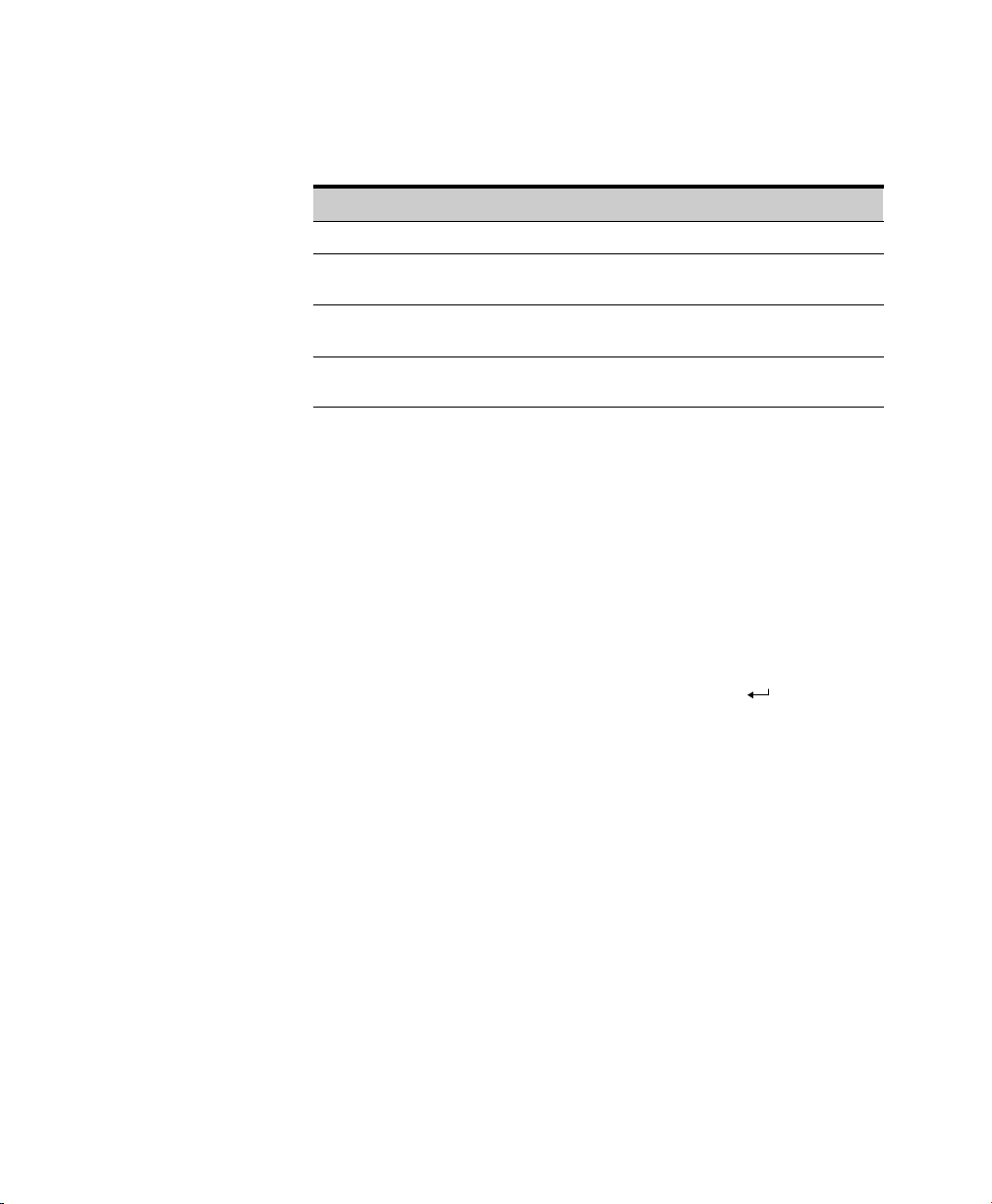

Table 9. Setup Options

Minimum

Level*

Description Available Settings Default Setting

Setup Options

Access to setup options is restricted to three System Setup Levels: 0, 1,

or 2. The higher the level, the more setup options are available. Options

on System Setup Level 0 do not require password access.

0 Enter Password Use the arrow keys to enter the password for the level you

want to access, then select DONE to display the options for

the setup level

0 Versions Read only Current firmware

0 Contrast Adjust Adjust screen contrast with left/right arrow buttons 10%

1 Log Out Exit the Level 1 or Level 2 setup options and display the

Level 0 setup options

1 Change Access

Level Password

1 Set Date and Time Set Month, Date, Year (mm/dd/yyyy)

1 Clear History Clear the History Log None

1 Clear Load Profile Clear the Load Profile None

1 Building Alarm

Setup

(see page 53)

1 THD Alarm Level Set the voltage and current Total Harmonic Distortion for

2 Unit Type Read only: Model / CTO / Serial Factory−set identifiers

2 Unit Name Up to 19 characters (A–Z, 0–9, –, blank) EATON EMS−UGK

2 Reset All Lower

Level Passwords

* Minimum System Setup Level required to access the setup option.

Change the password for the current setup level

Use the arrow keys to enter the new password (A–Z, 0–9, –,

blank,), then select DONE to save the new password.

Set Hour, Minute (Time is a 24−hour clock.)

For Building Alarm 1 through Building Alarm 4:

Name String [up to 19 characters (A–Z, 0–9, –, blank)]

Settings: Contact Normally Open or Closed

Building Alarm Type (REPO, EPO, TVSS/SPD,

Custom)

Notice Level (Log and Alarm options)

Enabled/Disabled

Input 1 and Input 2, and enable or disable this feature:

THD settings

Enabled/Disabled

Reset the Level 1 password to the default setting None

Level 1: L1

Level 2: Contact your

service representative

versions installed

None

None

00/00/0000

00:00

BUILDING ALARM [X]

Open

1 and 2: Custom;

3: REPO; 4: EPO

Log Only

Enabled

5.0

Disabled

42

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 49

Control Panel Configuration

NOTE Use this section only if the optional display is installed.

To set up branch circuit monitoring on your product, configure the panels

and branch circuit breakers. Configuration requires System Setup

Level 1 password access.

Accessing Configuration

To access the configuration options at System Setup Level 1:

1. In the Setup menu, select ENTER PASSWORD.

2. Use the arrow keys to enter the password (default password is L1

for Level 1).

3. Select DONE. The screen displays the setup options.

OPERATION

To change the default password while logged into System Setup Level 1

access:

1. In the Setup menu, select CHANGE ACCESS LEVEL PASSWORD.

2. Use the arrow keys to enter the new password (A–Z, 0–9, –, blank).

3. Select DONE.

Configuring Panels Containing Branch Circuit Breakers

To configure panels containing branch circuit breakers:

1. If not already obtained, access the System Setup Level 1 password

level. See the previous section, Accessing Configuration."

2. From the main menu, select METER then PANEL.

3. On the PANEL screen, select the panel number (PNL) to configure,

and then select CONFIG.

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

43

Page 50

OPERATION

4. On the PANEL CONFIG screen, set the panel’s meter settings:

Default Range Meter Setting Description

3 3 PHASES Number of phases

42 0–42

(even numbers)

100 0–1200 RATING Panel breaker rating (in amps)

STANDARD STANDARD

COLUMN

NOTE 1 Setting the panel breaker rating to 0 silences all main panel breaker

alarms and zeroes the panel percent current levels.

NOTE 2 Changing panel layout erases all branch circuit breaker configurations.

BREAKERS Number of branch circuit

breakers in the panel

(see Note 1)

PNL LAYOUT Panel layout

(see Note 2)

To reset all values on the screen to defaults, set the RESET value to

YES.

5. Select OK.

6. Repeat Steps 3 to 5 for each panel containing branch circuit

breakers to configure.

7. When all panel configuration is complete, select the

button

repeatedly to reach the main menu.

8. If all configuration is complete, save your changes by pressing the

Reset button on the Power Xpert Gateway Card in the X−Slot

communication bay. (The card automatically resets after five

minutes.) Otherwise, continue to Configuring Branch Circuit

Breakers" on page 46.

Configuring Panels Containing Subfeed Breakers

To configure panels containing subfeed breakers (up to 12 per panel):

1. If not already obtained, access the System Setup Level 1 password

level. See Accessing Configuration" on page 43.

2. From the main menu, select METER then PANEL.

3. On the PANEL screen, select the panel number (PNL) to configure,

and then select CONFIG.

44

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

Page 51

OPERATION

4. On the PANEL CONFIG screen, set the panel’s meter settings:

Default Range Meter Setting Description

3 3 PHASES Number of phases

42 0–42

(even numbers)

100 0–1200 RATING Subfeed breaker rating (in amps)

STANDARD STANDARD

COLUMN

* For example, if the panel has 6 subfeed breakers, set the BREAKERS value to 18.

NOTE 1 Setting the panel breaker rating to 0 silences all main panel breaker

alarms and zeroes the panel percent current levels.

NOTE 2 Changing panel layout erases all branch circuit breaker configurations.

BREAKERS* Number of subfeed breakers in

the panel, times 3

(see Note 1)

PNL LAYOUT Panel layout

(see Note 2)

To reset all values on the screen to defaults, set the RESET value to

YES.

5. Select OK, the panel number (PNL), then SCHEDULE.

On the PANEL SCHEDULE screen, each subfeed breaker displays

as a group of three phases.

6. Select the

button to return to the PANEL screen.

7. Repeat Steps 3 to 6 for each panel containing subfeed breakers to

configure.

8. When all panel configuration is complete, select the

button

repeatedly to reach the main menu.

9. If all configuration is complete, save your changes by pressing the

Reset button on the Power Xpert Gateway Card in the X−Slot

communication bay. (The card automatically resets after five

minutes.) Otherwise, continue to the following section,

Configuring Branch Circuit Breakers."

EATON Powerware® Energy Management System (EMS) Upgrade Kit User’s Guide S 164201724 Rev 1 www.powerware.com

45

Page 52

OPERATION

Configuring Branch Circuit Breakers

Follow the appropriate steps to configure, remove, or change the branch

circuit breakers.

To configure the branch circuit breakers (up to 42 per panel):

1. If not already obtained, access the System Setup Level 1 password

level. See Accessing Configuration" on page 43.

2. From the main menu, select METER then PANEL.

3. On the PANEL screen, select the panel number (PNL) to configure,

and then select SCHEDULE.

4. On the PANEL SCHEDULE screen, highlight the individual breaker

to configure and then select BREAKER.

Breakers with blank rating (RTNG) values are not yet configured.

See Breaker Numbering" on page 37 for an explanation of breaker

numbering.

5. On the PANEL X BREAKER METERS screen, select CONFIG and

then configure the individual breaker’s meter settings:

NOTE Configure a breaker only if its CT is installed.

Default Range Meter Setting Description

1 1–3 PHASES Number of phases

20 10–100 RATING Branch breaker rating (in amps)

NOTE Subfeed breaker rating range

is 100–1200.

80 0–100 WARNING Warning threshold level (in percent

load)*

90 0–100 OVERLOAD Alarm threshold level (in percent

load)*

71.9 10–100 CT CT ratio