Page 1

Maintenance Bypass

Module

30--160kVA

315

9

Installation/Operation

Manual

164201177 Rev. C

Page 2

------------------------------------------------------------------------

------------------------------------------------------------------------

----------------------------------

IMPORTANT SAFETY INSTRUCTIONS

Instructions Importantes Concernant La Sécurité

SAVE THESE INSTRUCTIONS

Conserver Ces Instructions

This manual contains important instructions for your Uninterruptible Power

Supply (UPS) system. You should follow these instructions during the

installation and maintenance of the UPS, options, accessories, and batteries.

Cette notice contient des instructions importantes

concernant la sécurité.

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

their own expense.

WARNING:

This is a product for restricted sales distribution to informed partners. Installation

restrictions or additional measures may be needed to prevent disturbances.

ii

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 3

Table of Contents

1 Introduction 1............................................

Using This Manual 2............................................

Conventions Used in This Manual 2...............................

For More Information 3..........................................

Getting Help 3..................................................

2 Getting Started 5.........................................

Preparing the Site 6.............................................

Creating an Installation Plan 6....................................

Environmental Considerations 6..................................

Preparing for Wiring the Maintenance Bypass Module 6.............

Inspecting and Unpacking the Maintenance Bypass Module 7........

Unloading the MBM from the Pallet 9..............................

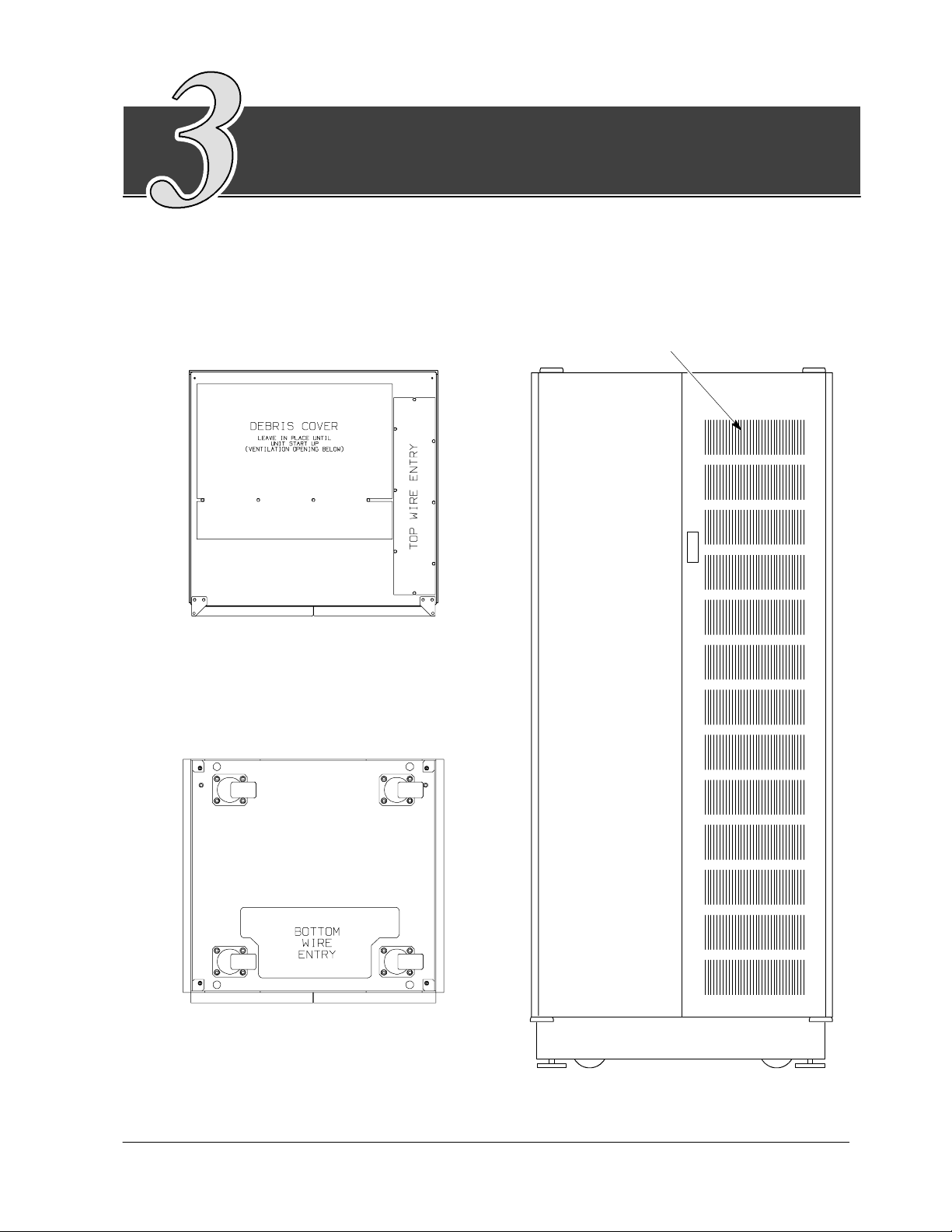

3 Installing and Wiring the Maintenance Bypass Module 11....

LineandLoadWiring 13..........................................

4 Maintenance Bypass Module Operation 15..................

Preliminary Checks and Startup for UPS Equipped with

Maintenance Bypass Module 15................................

Maintenance Bypass Module Operation 15.........................

MBM Operation Without Kirk Key Interlocks 16......................

MBM Operation With Kirk Key Interlocks (Optional) 17................

Kirk Key Solenoid Release Unit (SKRU) 17..........................

MBM Transfer Sequences 17......................................

Maintenance 19.................................................

Short Circuits 19.................................................

Maintenance Bypass Module Diagrams 19..........................

Appendix A A ---1.................................................

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

iii

Page 4

List of Figures

Figure 1. Typical 30--- 160kVA MBM with Isolation Transformer 1........

Figure 2. Front and Side View of Typical Maintenance Bypass

Module on Shipping Pallet (30---160kVA w/XFMR) 5..........

Figure 3. MBM as Shipped, with Outer Packaging and Pallet 7.........

Figure 4. Detail of Shipping Supports 10.............................

Figure 5. Top, Bottom, and Front View of Maintenance Bypass Module

(30---160kVA w/XFMR) 11..................................

Figure 6. Typical Power Wiring Terminations of UPS Module

and Maintenance Bypass Module (30---160kVA) 13............

iv

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 5

Introduction

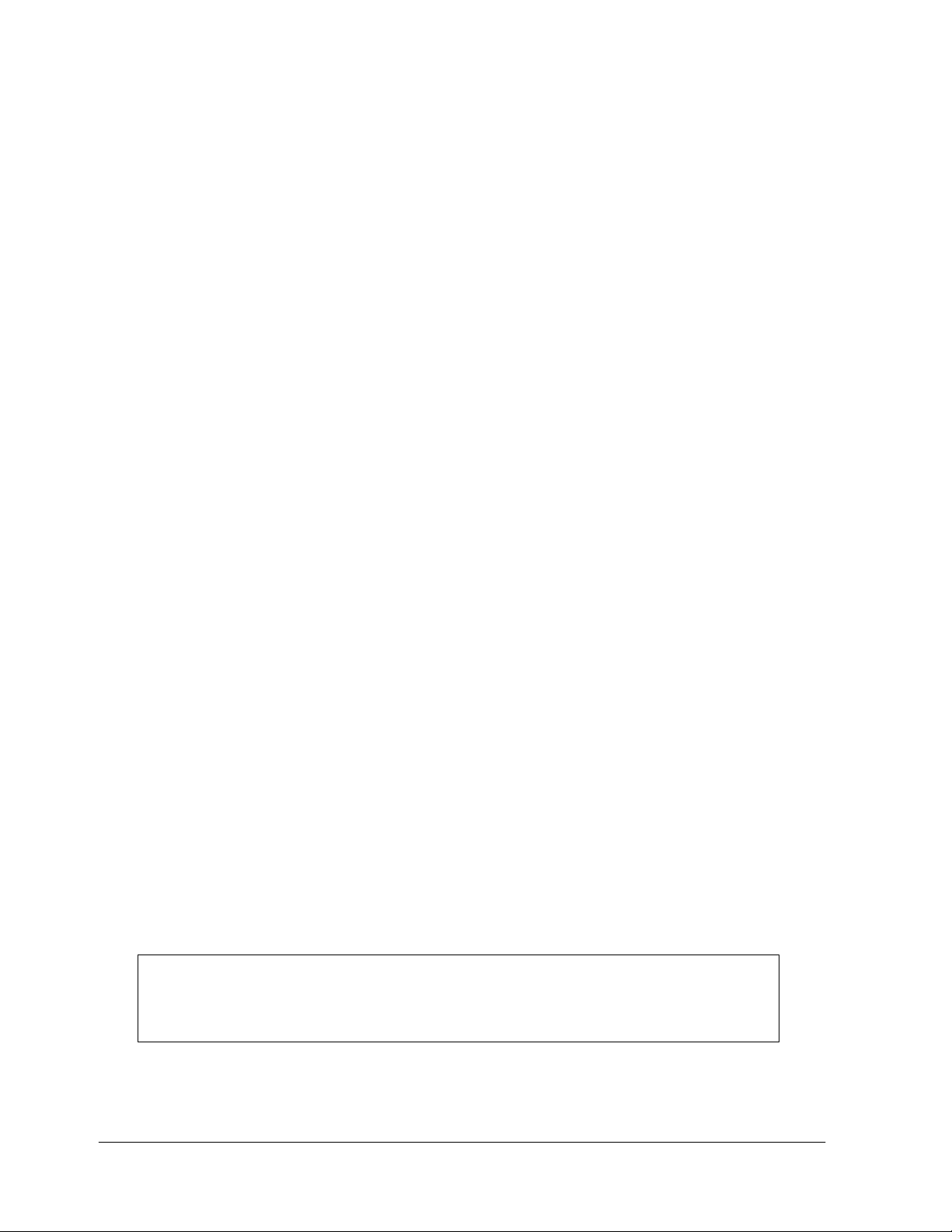

The Powerware 9315 Maintenance Bypass Module (MBM) is a

floor-mounted, enclosed cabinet containing a UPS module, Maintenance

Isolation circuit breaker (MIS), and a maintenance Bypass circuit breakr

(MBP). An optional UPS Module Input Bypass circuit breaker (BIB) is available. The MBM

can be either free-standing or line-up-and-match. Figure 1 shows a typical MBM cabinet

with isolation transformer for a Powerware 9315 30---160kVA UPS and MBM cabinet

without isolation transformer for a Powerware 9315 30 ---160kVA UPS.

The equipment and devices described in this manual are provided for operation with the

specific UPS Modules (model and rating) described in the appendix.

BREAKER ANNUNCIATION

UTILITY INPUT,

IF BIB BREAKER

IS NOT

INSTALLED

MBP

MIS

BIB1

BIB2

CRITICAL LOAD

CONNECTIONS

UPS/PTC OUTPUT

CONNECTION

NEUTRAL

CONNECTIONS

OPTIONAL UPS

BYPASS

INPUT CONNECTIONS

UTILITY INPUT,

IF BIB BREAKER

INSTALLED

Figure 1. Typical 30---160kVA MBM with or without Isolation Transformer.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

1

Page 6

Using This Manual

This manual contains installation and operation procedures for the MBM. Before

installation and operation, read through each procedure.

· Chapter 1 provides an overview of this manual and references for further

information.

· Chapter 2 tells you how to prepare your site for the installation of the MBM.

It discusses equipment environmental requirements, inspecting, and unpacking

cabinets.

· Chapter 3 describes how to install the MBM cabinet.

· Chapter 4 contains operating information for the MBM.

· Appendix A contains important information for planning and installing the MBM,

including wiring data and illustrations of cabinets.

Conventions Used in This Manual

This manual contains installation and operation procedures for the Maintenance

Bypass module.

· Bold type highlights important concepts in discussions, key terms in

procedures, and menu options.

· Italic type highlights notes, references to other system manuals, references

to other sections of this manual, and new terms where they are defined.

· Rectangular boxes containing bold type are warnings or cautions that pertain

to the system or its electrical connections. This important information indicates

possible dangers pertaining to personnel safety, equipment damage, critical

load protection, or operational concerns.

2

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 7

For More Information

For more information on the installation and operation of the UPS system and its

accessories, refer to the following:

164200252 Powerware

Each manual describes the UPS cabinet, Control Panel, and

Monitor Panel, and explains the functions of the UPS; discusses

the s tandard features of the UPS and optional accessories;

provides procedures for starting and stopping the UPS, and

information about maintenance and responding to system events.

T h es e a l so de s c r ib e t h e R S --- 4 8 5 a n d RS --- 2 3 2 s e r i a l

communications capabilities of the UPS system; discuss the two

communications ports on the Customer Interface Panel inside the

UPS and how to connect optional remote accessories to your

UPS system; and provide information about enabling, disabling,

and customizing building alarms.

164200253 Powerware

164200292 Powerware

Each manual contains the following information: how to prepare

the site and plan for installation, detailed step-by-step procedures

for installing each component of your system, how to join

cabinets in a line-up-and-match system, detailed illustrations of

cabinets and optional accessories, including dimensions and

connection points.

9315 30--- 160 kVA UPS Operation

9315 30--- 80 kVA UPS Installation

9315 100--- 160 kVA UPS Installation

Contact the local Powerware Field Service office for information on how to obtain

copies of these manuals.

Getting Help

If you have a question about any of the information in this manual, or if you have a

question this manual does not answer, please call Powerware Field Service:

United States 1-800-843-9433

Canada 1-800-461-9166

Outside the U.S. Call your local representative

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

3

Page 8

This Page Intentionally Left Blank.

4

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 9

Getting Started

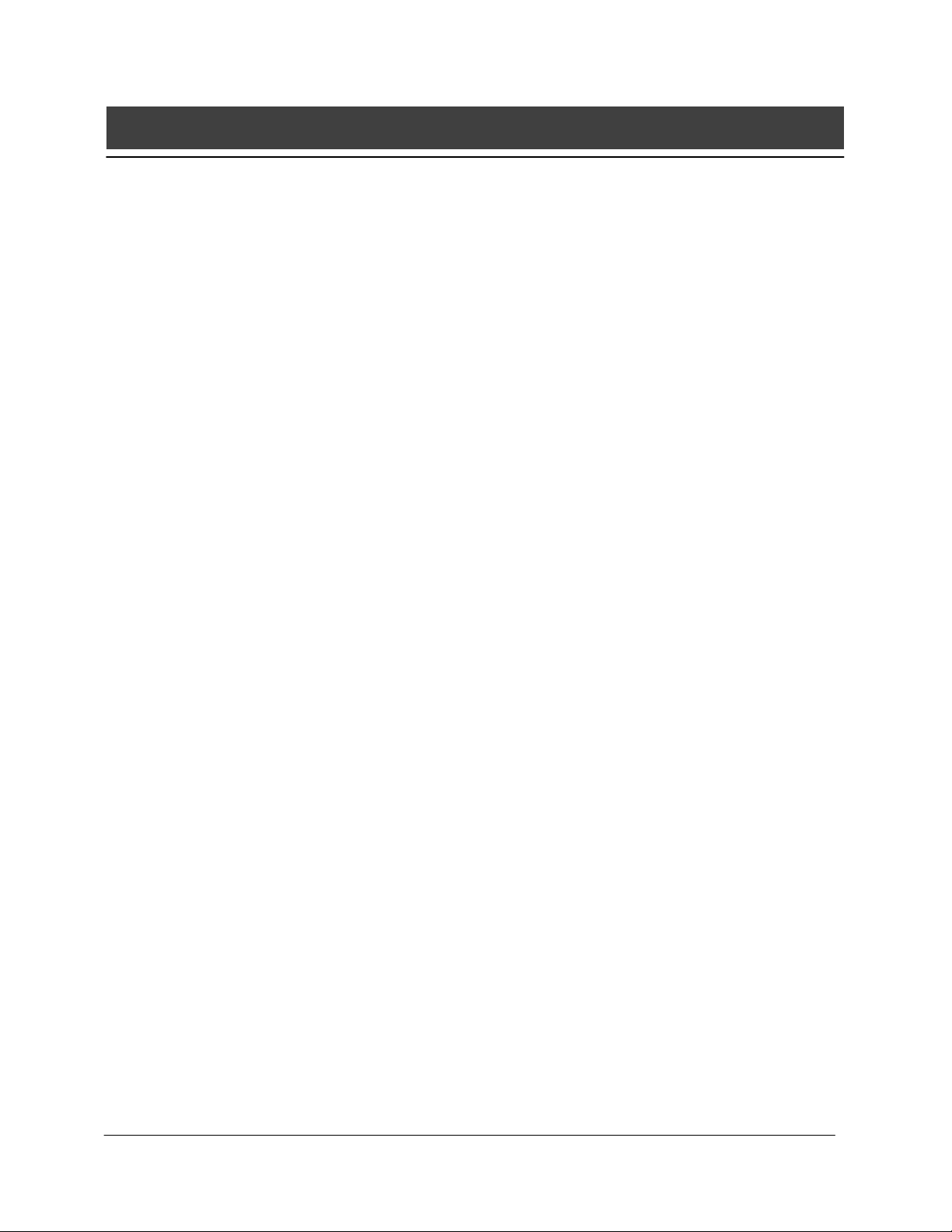

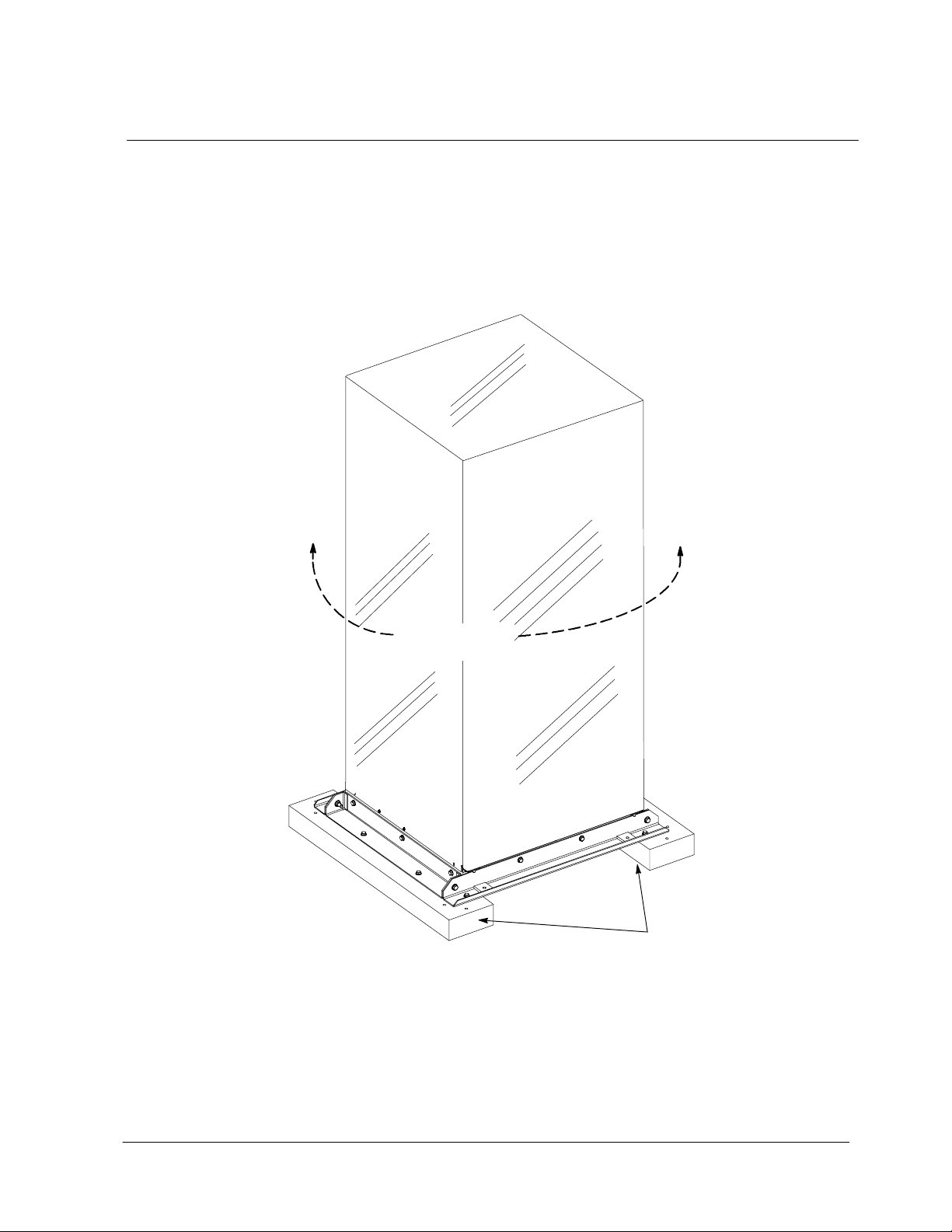

This section describes how to install the Powerware 9315 Maintenance

Bypass Module (MBM). It contains instructions for installing the MBM and

basic site preparation procedures. Figure 2 shows the front and side view of the

MBM with or without transformer for a Powerware 9315 30---160kVA module.

The MBM is shipped as a separate item. Use a forklift or pallet jack to move the

packaged cabinet to the installation site, or as close as possible to the site, before

unloading.

The basic sequence of the installation steps is:

1. Prepare the site for the MBM installation.

2. Inspect, unpack, and unload the MBM.

3. Create an installation plan for wiring the MBM to the UPS system.

4. Prepare for wiring.

5. Complete the installation checklist from the PowerwareR 9315 Installation manual.

6. Have authorized service personnel perform preliminary checks and startup.

NOTE: Startup and operational checks should be performed only by authorized

service personnel. This service is usually offered as part of the sales

contract for your UPS system.

Figure 2. Front and Side View of Typical Maintenance Bypass Module on

Shipping Pallet (30---160kVA with or without XFMR)

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

5

Page 10

Preparing the Site

For the MBM to o perate at peak efficiency, the installation site should meet the

environmental parameters outlined in the PowerwareÒ 9315 Operation manual

provided with the UPS system. The operating environment must meet the size and

weight requirements supplied in the PowerwareÒ 9315 Installation manual provided

with the UPS system. If the MBM is to be operated at an altitude higher than 1500

meters (5000 feet), contact the local sales or service office for important information

about high altitude operation.

The basic environmental requirements for operation of the MBM are:

Ambient Temperature Range 0 --- 4 0 ˚C (32 ---104˚F)

Recommended Operating Range 20---25˚C (68--- 77˚F)

Maximum Relative Humidity 95%

The MBM uses convection cooling to regulate internal component temperature. Air

inlets are in the front of the cabinet, and outlets are in the top. Clearance in front of

and above each cabinet for proper air circulation is essential.

Creating an Installation Plan

Before beginning to install the MBM, read and understand how this manual applies

to the system being installed. It is important to note that UPS module installation

procedures are contained in the PowerwareÒ 9315 Installation manual provided

with the UPS system. It is recommended to first understand how to install the UPS

modules. The information in Chapter 2 of this manual is a guide for installation of

the MBM to the UPS modules.

Environmental Considerations

Thelifeofthemaintenancebypassmoduleisadverselyaffectediftheinstallation

does not meet the following guidelines:

1. The MBM must be installed on a sealed concrete pad or floor.

2. The MBM must be installed in a dust-free environment.

3. The MBM must be installed in a humidity-controlled environment.

Preparing for Wiring the Maintenance Bypass Module

See Tables A-1 through A-6 in Appendix A of this manual for wiring requirements.

The power wiring for this equipment is rated at 90_C. Ifwireisruninanambient

temperature greater than 30_C, higher temperature rating and/or larger size wire

may be necessary. Wiring should be installed through the bottom or top entry of

the module. For UPS external wiring requirements, including minimum AWG size

of external wiring, see the PowerwareÒ 9315 Installation manual provided with the

UPS system.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

6

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 11

Inspecting and Unpacking the Maintenance Bypass Module

The first task in preparing for installation of the MBM is inspecting and unpacking

the unit. The MBM arrives covered with protective packaging material as shown in

Figure 3.

OUTER

PACKAG I N G

LAMINATED PLYWOOD

AND POLYFOAM SKIDS

Figure 3. MBM as Shipped, with Outer Packaging and Pallet

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

7

Page 12

1. Carefully inspect the outer packaging for evidence of damage during transit.

CAUTION:

Do not install a damaged MBM. Report any damage to the carrier and contact

the local sales or service office immediately.

2. Use a forklift or other material handling equipment to move the MBM to a

convenient unpacking area. Insert the forklift jacks between the laminated

plywood/polyfoam skids on the bottom of the unit.

CAUTION:

Do not tilt unit more than 10 degrees from vertical.

3. Set the pallet on a firm, level surface, allowing a minimum clearance of

4.6m (15 ft) on each side for removing the MBM from the pallet.

4. Cut the steel bands around the MBM.

5. Remove the protective cardboard covering from the MBM, cutting where

indicated, using a knife blade no longer than 25 mm (1 in.).

NOTE: Do not discard the packaging material. Instructions for unloading the MBM

from the pallet are printed on the cardboard. Please to refer to them.

6. Remove the plastic bag and foam packing material. Please discard or recycle

them in a responsible manner.

8

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 13

Unloading the MBM from the Pallet

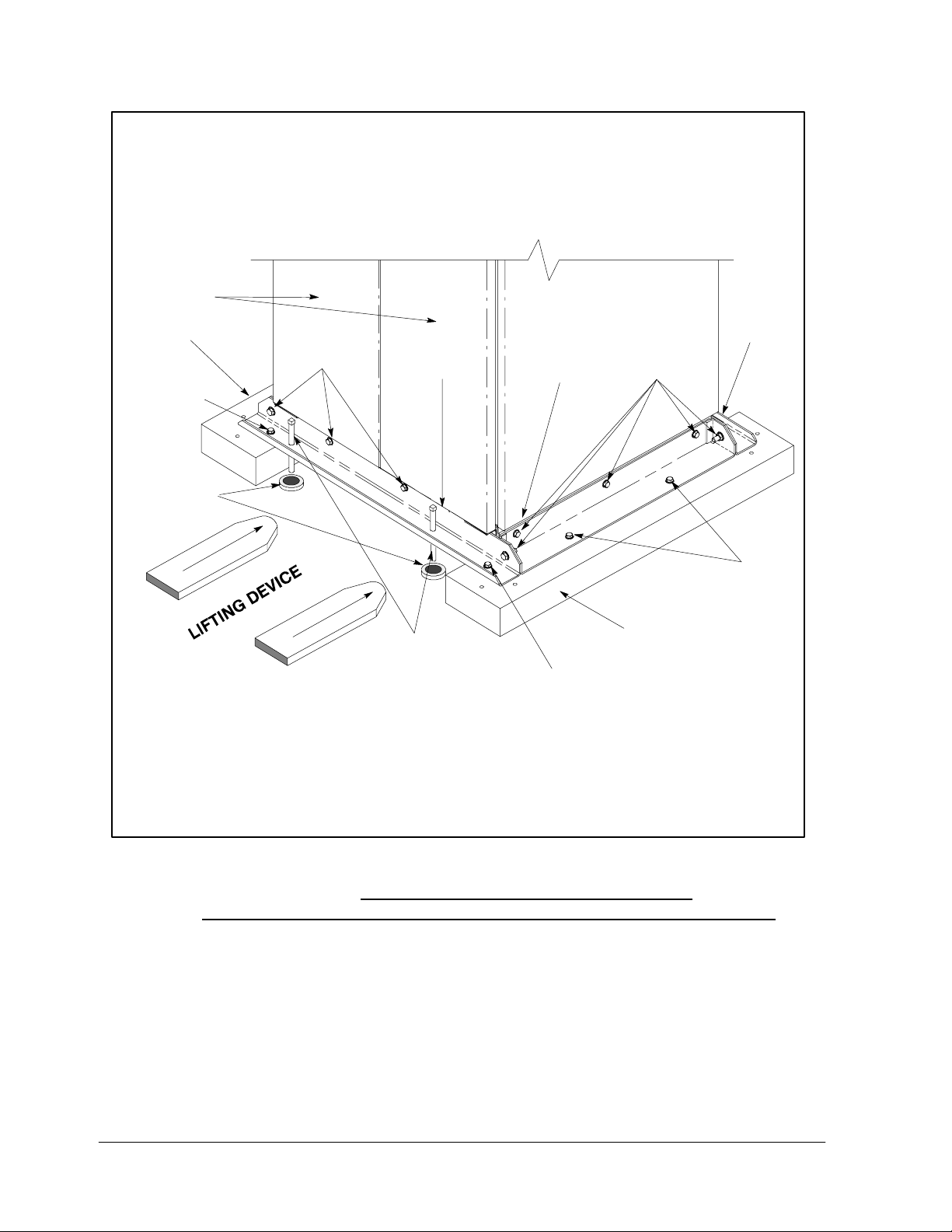

The MBM pallet consists of four metal angle supports secured to plywood /pol y f oam

laminated skids. The skids act as shock absorbers for the MBM during shipment.

WARNING:

Unit is extremely heavy. If unloading instructions are not closely

followed, the unit may tip and cause serious injury.

Turning the jacking bolts unevenly may cause the unit to become

unbalanced. To prevent tipping, raise and lower the jacking bolts

evenly and sequentially. The unit should only be raised approximately

3mm(

1. Remove the doors. Remove the retaining screw located inside each door at

2. Locate the field kit packed inside the unit. Lo cate the four ½-in. jacking bolts

1/8 in.) above the floor (just enough to remove polyfoam skids).

the bottom hinge pivot point, then lift off the door. Save the retaining screws

for reinstallation of the doors.

and install them in the threaded holes in the front and rear supports. Place a

floor protector underneath each jacking bolt, and screw the bolts down until

they contact the floor protectors. The floor protectors prevent the floor from

being damaged by the jacking bolts.

WARNING:

Module may fall. Do not loosen hardware attaching the side or front/rear

shipping supports to the module base. Also, do not loosen the shipping

supports from each other. The module must be lowered using jacking

bolts before the shipping supports can be removed.

3. Loosen, but do not remove the hardware holding the plywood/polyfoam skids

to the front and rear supports (labeled “1” in Figure 4 --- 8 places).

4. Turn each jacking bolt clockwise sequentially, no more than two full turns each,

until the foam cushions clear the floor by approximately 3 mm (

1/8 in.).

5. After the plywood/polyfoam skids clear the floor, remove the hardware

loosened in step 3. Pull the skids out from under the MBM. Discard or recycle

them in a responsible manner.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

9

Page 14

DOOR

POLYFOAM

SKID

1

FLOOR

PROTECTOR

(4 PLACES)

2

(USE FRONT AND REAR)

FRONT SIDE

SUPPORT

JACKING BOLT

SUPPORT

1

REAR

SUPPORT

2

1

POLYFOAM

SKID

10

Figure 4. Detail of Shipping Supports

6. Carefully and evenly lower the MBM by turning each jacking bolt

counterclockwise in sequence no more than two full turns each (maximum)

until the supports contact the floor, and the module is no longer supported by

the jacking bolts.

7. When the module is resting on the floor, remove the jacking bolts. Discard or

recycle them in a responsible manner.

8. Removethehardwarelabeled“2”inFigure4,holdingthefront,rearandside

supports to the module base (14 places). Discard or recycle the hardware and

support brackets in a responsible manner.

9. Install the doors removed in step 1. The MBM is now ready to be rolled to its

final location.

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 15

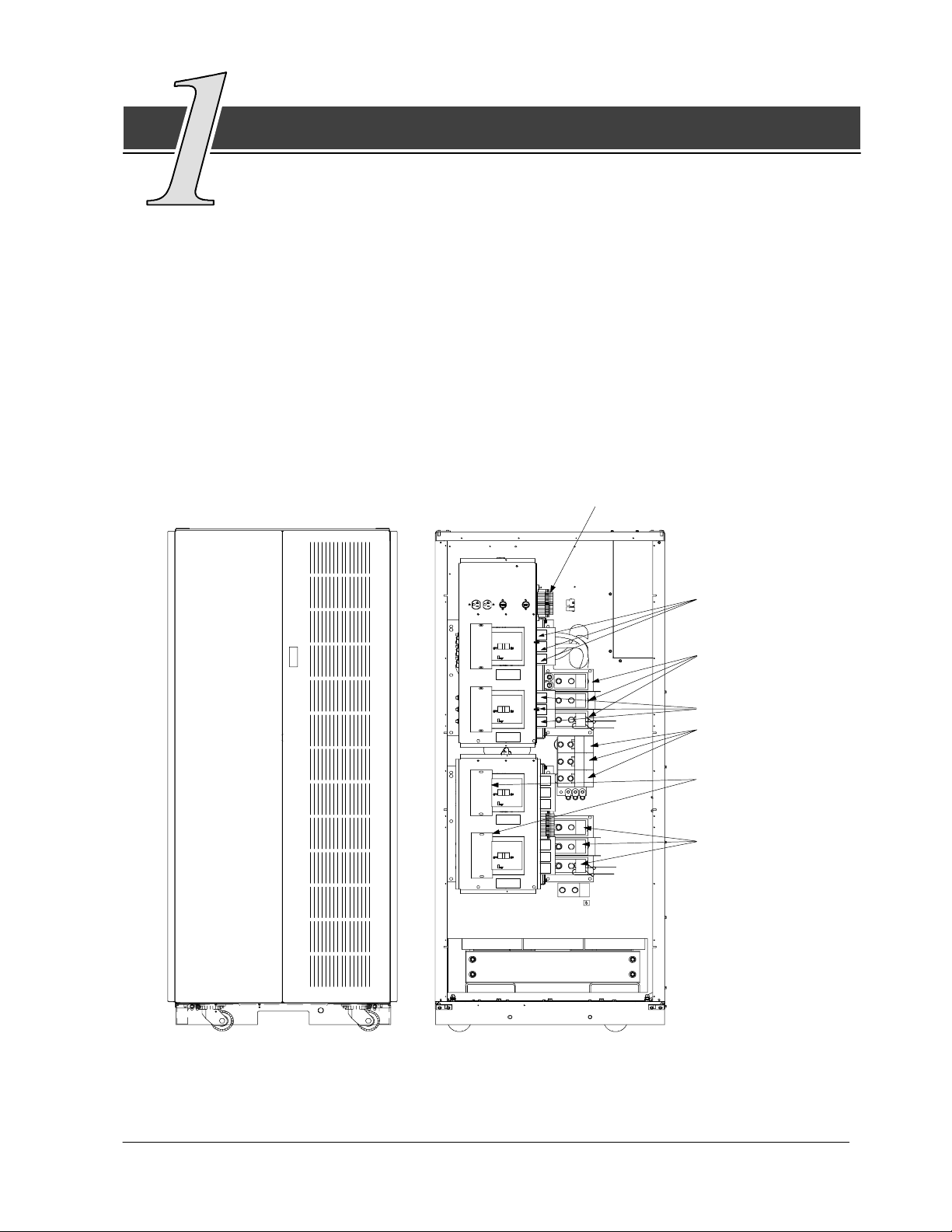

Installing and Wiring the

Maintenance Bypass Module

When the maintenance bypass module (MBM) has been moved to its installed

location, unpacked, and inspected, it is ready for installation. This section

discusses the typical process of installing the MBM in both the line-up and match

and free-standing situations. The MBM is shown in Figure 5.

Cooling Air Inlets

(Front)

Cable Entry, Top Plan View

(Front)

Cable Entry, Bottom Plan View

Figure 5. Top, Bottom, and Front View of Maintenance Bypass Module

(30---160kVA with or without XFMR)

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

11

Page 16

Refer to the following while installing the MBM:

· Dimensions in this manual are in millimeters and (inches).

· Do not tilt the unit more than 10˚ during installation.

· Remove the conduit landing plates to add conduit landing holes as required.

Plate material is 16 gauge steel (0.06 in. thick).

· Terminals are UL and CSA rated at 90˚C. A hex key tool is required to attach

wires to the terminals.

· Details about power wiring are provided in the tables of Appendix A of this

manual.

Figure 6 shows typical power wiring terminations of the UPS module and

Maintenance Bypass Module (30--- 160kVA). Refer to the Powerware 9315

Installation manual provided with the UPS system for location of UPS module

cabinet wiring terminations.

NOTE: Material and labor for external wiring are to be provided by designated

personnel.

BREAKER ANNUNCIATION

RIGHT DOOR

UTILITY INPUT,

IF BIB BREAKER

IS NOT

INSTALLED

REMOVED

FOR

CLARITY

MBP

MIS

BIB1

BIB2

Maintenance Bypass Module

Figure 6. Typical Power Wiring Terminations of UPS Module and

CRITICAL LOAD

CONNECTIONS

UPS/PTC OUTPUT

CONNECTION

NEUTRAL

CONNECTIONS

OPTIONAL UPS

BYPASS

INPUT CONNECTIONS

UTILITY INPUT,

IF BIB BREAKER

INSTALLED

LEFT DOOR

A/C Output

E9, E10, E11

TB1

TB2

UPS MODULE

Maintenance Bypass Module (30 ---160kVA)

Output

Neutral

Connection

(E12)

(30--160kVA UPS Shown)

12

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 17

The recommended location, for the Maintenance Bypass Module, is as close to the

installed UPS module as possible. Refer to the tables in Appendix A for wire rating

and sizing information

The MBM is packaged in a module similar to the UPS modules (same height,

width, depth). The MBM is designed as a standard line-up-and-match accessory

for the 30---160 KVA rated modules.

Wiring harness assemblies for connecting the UPS module bypass input and

output to the MBP are provided in separate shipping containers, if applicable. The

wiring harness assemblies are passed through the 3-inch wiring feed-through hole

located at the lower right side of the MBM cabinet, for connecting to the UPS input

and output terminals. Refer to Appendix A for UPS module to MBM wiring terminal

locations.

Line up and match connection (cables sold separately by Powerware)

· From the UPS to the MBM, the power cables are connected by mechanical

pressure lugs.

· From the UPS to the MBM, the control cables are connected to terminal blocks.

Remote connection (cables, lugs, and hardware supplied by others)

· All cables are terminated to MBM mechanical pressure lugs.

LineandLoadWiring

The Maintenance Bypass Module provides a means to manually transfer the Critical

load from the UPS module via the UPS Module Bypass to a Maintenance Bypass

Module as may be necessary for shutting down the UPS Module for maintenance

or testing. The proper operation of the transfer is accomplished without interrupting

the load power.

The UPS Module Bypass AC Input and the Maintenance Bypass AC Input must be

from the same or synchronized AC sources. The UPS Module Bypass Input is

connected through the MBP cabinet via an optional Bypass Input Breaker (BIB), if

installed. The Maintenance Bypass Breaker (MBP) is placed in the secondary of the

stepdown transformer (480:208 VAC or 600:208 VAC) or connected directly to the

Maintenance Bypass source if the Isolation Transformer is not required.

UPS Module AC output connects through the MBM cabinet via isolation breaker

MIS. Critical L oad terminals are located on the load side of breakers MBP and MIS.

The Critical Load may be transferred in a Make-Before-Break transfer sequence

between the UPS Bypass Source and the Maintenance Bypass source after UPS

output has been transferred from the UPS module and UPS bypass operating

mode. The MBP must first be closed to prevent power interruption and MIS opened

to provide UPS isolation from the Critical Load bus. Refer to the Transfer Sequence

placard affixed to the front of the MBM cabinet.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

13

Page 18

This Page Intentionally Left Blank.

14

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 19

Maintenance Bypass Module Operation

This chapter provides preliminary checks, maintenance operations and a

schematic diagram of the maintenance bypass module.

Preliminary Checks and Startup for UPS Equipped with

Maintenance Bypass Module (MBM)

Installation inspection and startup procedures must be performed only by a

Powerware Corporation authorized service person. The procedure is normally part

of the sales contract for the UPS system.

WARNING:

Attempts to startup the UPS system yourself may damage equipment and/or

your critical load. Such attempts may also invalidate your system warranty.

Maintenance Bypass Module Operation

The MBM is provided for use with the Powerware 9315 (30 ---160kVA) UPS module.

WARNING:

Only persons familiar with the operation of this equipment should transfer loads.

Failure to follow the transfer sequence exactly may cause loss of power to the

critical load or may cause overload protection devices to function.

Operator Note:

MIS is to be OPENED only after MBP is CLOSED

MBP is to be OPENED only after MIS is CLOSED

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

15

Page 20

MBM Operation Without Kirk Key Interlocks

The following transfer sequence is the recommended procedure for the

step-by-step load transfer from and back to the UPS when required. This

information is provided on a label located on the deadfront panel behind

the right front door of the MBM.

From UPS Bypass to Maintenance Bypass:

1. Confirm BIBs, if installed, are closed.

2. Transfer UPS from Normal to Bypass mode (see UPS Operation manual).

NOTE: For Parallel Redundant systems, transfer both UPS modules to

Bypass mode.

3. Close MBP breaker.

CAUTION:

Failure to close MBP breaker results in loss of power to the critical load.

4. Open MIS breaker.

5. Deenergize UPS before servicing unit (see UPS operation manual).

CAUTION:

For UPS electrical isolation, BIB breaker (if applicable) must be opened.

From Maintenance Bypass to UPS Bypass:

1. Confirm BIBs, if installed, are closed.

2. Transfer UPS from Normal to Bypass mode (see UPS Operation manual).

NOTE: For Parallel Redundant systems, transfer both UPS modules to

Bypass mode.

3. Close MIS breaker.

CAUTION:

Failure to close MIS breaker results in loss of power to the critical load.

4. Open MBP breaker.

5. To place UPS in Normal Mode, see UPS operation manual.

NOTE: While the UPS is in Normal Mode and the MIS breaker is closed, the MBP

breaker always trips OFF. Likewise, while the UPS is in Normal Mode and the

MBP is closed, the MIS breaker always trips OFF.

16

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 21

MBM Operation With Kirk Key Interlocks (Optional)

The following transfer sequence is the recommended procedure for the

step-by-step load transfer from and back to the UPS when required. This

information is provided on a label located on the deadfront panel behind

the right front door of the MBM.

Kirk Key Solenoid Release Unit (SKRU)

The 120 VAC operating power for the Kirk Key Solenoid Release Unit (SKRU) is

derived from the Maintenance Bypass source.

The Kirk Key SKRU is provided to prevent access to the key, which is necessary to

initiate the transfer sequence. The operator must observe the instructions on the

Transfer Sequence nameplate mounted on the MBP Panelboard.

Electrical interlocks inhibit key release until UPS is in the Bypass mode.

MBM Transfer Sequences

From UPS Bypass to Maintenance Bypass:

1. Confirm BIBs, if installed, are closed.

2. Transfer UPS from Normal to Bypass mode (see UPS Operation manual).

NOTE: For Parallel Redundant systems, transfer both UPS modules to

Bypass mode.

3. Depress pushbutton on the solenoid key release unit (SKRU). Turn and

remove key “A”. Key “A” may be removed when UPS system is in Bypass

mode as indicated by illuminated pilot light.

4. Insert key “A” into MBP lock, retract bolt, close MBP breaker. Remove key “B”.

CAUTION:

Failure to close MBP breaker results in loss of power to the critical load.

5. Insert key “B’ into MIS lock, open MIS breaker, extend bolt. Remove key “A”.

6. Insert key “A” into solenoid and turn key to LOCK position.

7. Deenergize UPS before servicing (see UPS Operation manual).

CAUTION:

For UPS electrical isolation, BIB breaker (if applicable) must be opened.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

17

Page 22

From Maintenance Bypass to UPS Bypass:

1. Confirm BIBs, if installed, are closed.

2. Transfer UPS to Bypass mode (see UPS Operation manual).

NOTE: For Parallel Redundant systems, transfer both UPS modules to

Bypass mode.

3. Depress pushbutton on the Solenoid Key Release Unit (SKRU). Turn and

remove key “A”.

4. Insert key “A” into MIS lock, retract bolt, close MIS breaker. Remove key “B”.

CAUTION:

Failure to close MBP breaker results in loss of power to the critical load.

5. Insert key “B” into MBP lock, open MBP breaker, extend bolt. Remove key “A”.

6. Insert key “A” into solenoid and turn key to LOCK position.

7. SeeUPSOperationmanualtoplaceUPSinNormalmode.

WARNING:

Dangerous and potentially lethal voltages are present within the UPS enclosure.

When maintenance or repair activities are to be performed, the UPS and the UPS

Bypass power sources should be deenergized and verified with a meter before

working in the required area.

WARNING:

UPS equipment has power feeds that are derived from two or more power

sources.

18

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 23

Maintenance

Maintenance should be scheduled on a periodic basis, recommended not to

exceed one year. More frequent intervals are recommended if the equipment is

subjected to highly repetitive operations.

CAUTION:

Refer to Section 9 -- Maintaining the UPS System of the Powerware 9315

30--160kVA Operation manual, Powerware part number 164200252, before

beginning maintenance or repairs on the UPS equipment.

WARNING:

Dangerous and life-threatening voltages are present when the UPS is

operating. De-energize all equipment before physically touching potentially

live parts.

Periodic inspections of the maintenance bypass module should be made to

determine if components, wiring, and connections exhibit evidence of overheating.

Particular attention should be given to bolted connections. Maintenance

procedures should specify that the bolted connections be retorqued to values

listed on labels posted on the equipment.

CAUTION:

Overtightening of bolted connections containing compression washers

decreases the washer’s ability to maintain compression during heating and

cooling cycles.

Refer to circuit breaker manufacturer’s application and maintenance literature for

recommended maintenance practices and procedures.

Short Circuits

Short circuits are not considered normal phenomena in UPS applications. Tripping

of protective devices due to low impedance short circuits should be thoroughly

investigated for damage to conductors, insulation, and the protective devices in

accordance with the manufacturer’s recommendations.

Maintenance Bypass Module Diagrams

See Appendix A for onelines and system configuration schematics

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

19

Page 24

This Page Intentionally Left Blank.

20

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 25

Appendix A --- Customer Information

The information in this appendix will help you plan for and install your Maintenance Bypass

Module cabinet. This appendix contains the following:

· 164201177 ---1 Installation Notes

· 164201177 ---2 Typical MBM Cabinet --- 30-160kVA with or without XFMR

· 164201177 ---3 Typical UPS System with MBM

· 164201177 ---4 Oneline --- 30-160kVA, Reverse Transfer (RT), 480:480VAC,

600:600VAC, 400:400VAC

· 164201177 ---5 Oneline --- 30-160kVA, Reverse Transfer (RT), 480:208VAC,

600:208VAC

· 164201177 ---6 Oneline --- 30-160kVA, Reverse Transfer (RT), 208:208VAC,

· 164201177 ---7 Oneline --- 30-160kVA, Parallel, 480:480VAC, 600:600VAC,

400:400VAC

· 164201177 ---8 Oneline --- 30-160kVA, Parallel, 480:208VAC, 600:208VAC

· 164201177 ---9 Oneline --- 30-160kVA, Parallel, 208:208VAC

· 164201177 ---10 UPS Module Line Up and Match 1 through 3

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

A --- 1

Page 26

Table A -- 1. Ratings & External Wiring Requirements for Powerware 9315

A

B

C

D

A

B

C

D

M B M 3 0 --- 1 6 0

Rating and External Wiring Requirement

Basic unit rating at

0.8 lagging PF load

UPS Input Voltage/Bypass Input

UPS Output Voltage

AC Input to Maintenance Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Input to UPS Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Output to Critical Load

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

UPS/PTC Output to MBM Cabinet (MIS)

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

E

Control Wiring to UPS

(2) Conductors

kVA, 480:208VAC/600:208VAC

Units Rating 60 Hz

KVA

KW

VOLTS

VOLTS

AMPS 192 153 156 125 120 96 96 77

AWG/MCM

(each)

AMPS 192 153 156 125 120 96 96 77

AWG/MCM

(each)

AMPS 444 444 361 361 278 278 222 222

AWG/MCM

(each)

AMPS 444 444 361 361 278 278 222 222

AWG/MCM

(each)

VOLTS

AMPS

160

128

480

600

208

208

300

300

(1)

(1)

300

300

(1)

(1)

400

400

(2)

(2)

400

400

(2)

(2)

1201120112011201120112011201120

480

208

300

(1)

300

(1)

400

(2)

400

(2)

130

104

600

208

300

(1)

300

(1)

400

(2)

400

(2)

408

208

300

(1)

300

(1)

400

(2)

400

(2)

100

80

600

208

300

(1)1(1)1(1)

300

(1)1(1)1(1)

400

(2)

400

(2)

80

64

480

208

300

(1)

300

(1)

600

208

300

(1)

300

(1)

1

Basic unit rating at

0.8 lagging PF load

UPS Input Voltage/Bypass Input

UPS Output Voltage

AC Input to Maintenance Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Input to UPS Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Output to Critical Load

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

UPS/PTC Output to MBM Cabinet (MIS)

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

E

Note: Callout letters A, B, C, D,and E map to drawing 164201177 ---5 (Reverse Transfer Connection) and

Control Wiring to UPS

(2) Conductors

164201177---8 (Parallel Connection). Read and understand the notes on drawings when planning your installation.

KVA

KW

VOLTS

VOLTS

AMPS 78 63 60 48 48 38 36 29

AWG/MCM

(each)

AMPS 78 63 60 48 48 38 36 29

AWG/MCM

(each)

AMPS 180 180 139 139 111 111 83 83

AWG/MCM

(each)

AMPS 180 180 139 139 111 111 83 83

AWG/MCM

(each)

VOLTS

AMPS

65

52

480

600

208

208

1

(1)1(1)

1

(1)1(1)

300

300

(1)

(1)

300

300

(1)

(1)

1201120112011201120112011201120

50

40

480

208

1

(1)1(1)

1

(1)1(1)

300

(1)

300

(1)

600

208

300

(1)

300

(1)

480

208

1

(1)

1

(1)

300

(1)

300

(1)

40

32

600

208

1

(1)1(1)1(1)

1

(1)1(1)1(1)

300

(1)

300

(1)

480

208

300

(1)

300

(1)

30

24

600

208

300

(1)

300

(1)

1

A --- 2

DESCRIPTION:

DRAWING NO:

REVISION:

INSTALLATION NOTES

164201177--- 1

C

DATE:

SHEET:

041500

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

1of4

Page 27

Table A -- 2. Ratings & External Wiring Requirements for Powereware 9315

A

B

C

D

A

B

C

D

M B M 3 0 --- 1 6 0

Rating and External Wiring Requirement

Basic unit rating at

0.8 lagging PF load

UPS Input Voltage/Bypass Input

UPS Output Voltage

AC Input to Maintenance Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Input to UPS Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Output to Critical Load

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

UPS/PTC Output to MBM Cabinet (MIS)

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

E

Control Wiring to UPS

(2) Conductors

kVA, 480:480VAC/600:600VAC

Units Rating 60 Hz

KVA

KW

VOLTS

VOLTS

AMPS 192 153 156 125 120 96

AWG/MCM

(each)

AMPS 192 153 156 125 120 96

AWG/MCM

(each)

AMPS 192 153 156 125 120 96

AWG/MCM

(each)

AMPS 192 153 156 125 120 96

AWG/MCM

(each)

VOLTS

AMPS

160

128

480

600

480

600

300

300

(1)

300

(1)

300

(1)

300

(1)

12011201120112011201120

(1)

300

(1)

300

(1)

300

(1)

480

480

300

(1)

300

(1)

300

(1)

300

(1)

130

104

600

600

300

(1)

300

(1)

300

(1)

300

(1)

100

80

480

480

300

(1)

300

(1)

300

(1)

300

(1)

600

600

300

(1)

300

(1)

300

(1)

300

(1)

1

Basic unit rating at

0.8 lagging PF load

UPS Input Voltage/Bypass Input

UPS Output Voltage

AC Input to Maintenance Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Input to UPS Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Output to Critical Load

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

UPS/PTC Output to MBM Cabinet (MIS)

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

E

Note: Callout letters A, B, C, D,and E Map to drawing 164201177 ---4 (Reverse Transfer Connection) and

Control Wiring to UPS

(2) Conductors

164201177---7 (Parallel Connection). Read and understand the notes on drawings when planning your installation.

KVA

806465525040403230

KW

VOLTS

VOLTS

AMPS 96 78 60 48 36

AWG/MCM

(each)

AMPS 96 78 60 48 36

AWG/MCM

(each)

AMPS 96 78 60 48 36

AWG/MCM

(each)

AMPS 96 78 60 48 36

AWG/MCM

(each)

VOLTS

AMPS

480

480

1201120112011201120

(1)

(1)

(1)

(1)

480

480

480

1

(1)

1

(1)

1

(1)

1

(1)

480

480

1

(1)1(1)

1

(1)1(1)

1

(1)1(1)

1

(1)1(1)

480

1

1

1

1

1

(1)

1

(1)

1

(1)

1

(1)

24

480

480

1

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

DESCRIPTION:

DRAWING NO:

REVISION:

INSTALLATION NOTES

164201177--- 1

C

DATE:

SHEET:

041500

2of4

A --- 3

Page 28

Table A -- 3. Ratings & External Wiring Requirements for Powerware 9315

A

B

C

D

M B M 3 0 --- 1 6 0

Rating and External Wiring Requirement

Basic unit rating at

0.8 lagging PF load

UPS Input Voltage/Bypass Input

UPS Output Voltage

AC Input to Maintenance Bypass

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

AC Input to UPS Bypass

(3) Phases, (1) Ground

Conductor Size

Number per Phase

AC Output to Critical Load

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

UPS/PTC Output to MBM Cabinet (MIS)

(3) Phases, (1) Neutral, (1) Ground

Conductor Size

Number per Phase

E

Control Wiring to UPS

(2) Conductors

kVA, 208:208VAC

Units Rating 60 Hz

KVA

KW

VOLTS

VOLTS

AMPS 444 361 278 222 180 139 111 83

AWG/MCM

(each)

AMPS 444 361 278 222 180 139 111 83

AWG/MCM

(each)

AMPS 444 361 278 222 180 139 111 83

AWG/MCM

(each)

AMPS 444 361 278 222 180 139 111 83

AWG/MCM

(each)

VOLTS

AMPS

160

128

130

10080806465525040403230

104

208

208

400

400

400

400

1201120112011201120112011201120

(2)

(2)

(2)

(2)

208

208

400

(2)

400

(2)

400

(2)

400

(2)

208

208

400

(2)

400

(2)

400

(2)

400

(2)

208

208

300

(1)

300

(1)

300

(1)

300

(1)

208

208

300

(1)

300

(1)

300

(1)

300

(1)

208

208

300

(1)

300

(1)

300

(1)

300

(1)

208

208

300

(1)

300

(1)

300

(1)

300

(1)

24

208

208

300

(1)

300

(1)

300

(1)

300

(1)

1

Note: Callout letters A, B, C, D,and E map to drawing 164201177 ---6 (Reverse Transfer Connection) and

164201177---9 (Parallel Connection). Read and understand the notes on drawings when planning your installation.

A --- 4

DESCRIPTION:

DRAWING NO:

REVISION:

INSTALLATION NOTES

164201177--- 1

C

DATE:

SHEET:

041500

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

3of4

Page 29

Table A--4. Rating and External Wiring Requirements for Powerware 9315

A

B

C

D

M B M 5 0 --- 1 6 0

RATING AND EXTERNAL WIRING REQUIREMENT UNITS RATING 50/60 HZ

BASIC UNIT RATING AT

0.8 LAGGING PF LOAD

UPS INPUT VOLTAGE

BYPASS INPUT/UPS OUTPUT VOL T AGE

AC INPUT TO MAINTENANCE BYPASS

(3) PHASES, (1) GROUND

CONDUCTOR SIZE

NUMBER PER PHASE

AC INPUT TO UPS BYPASS

(3) PHASES, (1) GROUND

CONDUCTOR SIZE

NUMBER PER PHASE

AC OUTPUT TO CRITICAL LOAD

(3) PHASES, (1) NEUTRAL, (1) GROUND

CONDUCTOR SIZE

NUMBER PER PHASE

UPS/PTC OUTPUT TO MBM CABINET (MIS)

(3) PHASE, (1) NEUTRAL, (1) GROUND

CONDUCTOR SIZE

NUMBER PER PHASE

CONTROL WIRING TO UPS

E

(2) CONDUCTORS

KVA, 380:380VAC, 400:400VAC, 415:415VAC

KVA

KW

VOLTS

VOLTS

AMPS 231 188 146 115 97 74 60 45

AWG/MCM

(each)

AMPS 231 188 146 115 97 74 60 45

AWG/MCM

(each)

AMPS 231 188 146 115 97 74 60 45

AWG/MCM

(each)

AMPS 231 188 146 115 97 74 60 45

AWG/MCM

(each)

VOLTS

AMPS

160

130

128

300

(1)

300

(1)

300

(1)

300

(1)

1201120112011201120112011201120

10080806465

104

300

300

(1)

(1)

300

300

(1)

(1)

300

300

(1)

(1)

300

300

(1)

(1)

52

380/400/415

380/400/415

300

300

(1)

(1)1(1)1(1)

300

300

(1)

(1)1(1)1(1)

300

300

(1)

(1)1(1)1(1)

300

300

(1)

(1)1(1)1(1)

50

40

40

32

30

24

1

(1)

1

(1)

1

(1)

1

(1)

1

Note: Callout letters A, B, C, D,and E map to drawing 164201177 --- 4 (Reverse Transfer Connection) and

164201177---7 (Parallel Connection). Read and understand the notes on drawings when planning your installation.

DESCRIPTION:

DRAWING NO:

REVISION:

INSTALLATION NOTES

164201177--- 1

C

DATE:

041500

SHEET:

4of4

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

A --- 5

Page 30

MBM

FAMIL Y

MBM

30KVA

0KV

A

0KV

A

MBM 50

40KVA

5

MBM 80

5

65KVA

Table B. Circuit Breaker Requirements for Powerware 9315

M B M 3 0 --- 1 6 0

Model No.

MBM 50/30 --- 48/20 480V/208V 36A/83A 100A/40A 150 --- 1200A 250A/100A 375 ---3000A

MBM 50/30 --- 48/48 480V/480V 36A/36A 100A/40A 150 --- 1200A 100A/40A 150---1200A

MBM 50/30 --- 60/20 600V/208V 29A/83A 100A/40A 150 --- 1200A 250A/100A 375 ---3000A

MBM 50/30 --- 20/20 208V/208V 83A/83A 250A/100A 375--- 3000A 250A/100A 375 ---3000A

MBM 50/30 --- 38/38 380V/380V 45A/45A 100A/50A 150 --- 1200A 100A/50A 150---1200A

MBM 50/30 --- 40/40 400V/400V 45A/45A 100A/50A 150 --- 1200A 100A/50A 150---1200A

MBM 50/30 --- 41/41 410V/410V 45A/45A 100A/50A 150 --- 1200A 100A/50A 150---1200A

MBM 50/40 --- 48/20 480V/208V 48A/111A 100A/50A 150---1200A 250A/125A 375--- 3000A

MBM 50/40 --- 48/48 480V/480V 48A/48A 100A/50A 150 --- 1200A 100A/50A 150---1200A

MBM 50/40 --- 60/20 600V/208V 38A/111A 100A/40A 150---1200A 250A/125A 375--- 3000A

MBM 50/40 --- 20/20 208V/208V 111A/111A 250A/125A 375---3000A 250A/125A 375--- 3000A

MBM 50/40 --- 38/38 380V/380V 60A/60A 100A/70A 150 --- 1200A 100A/70A 150---1200A

MBM 50/40 --- 40/40 400V/400V 60A/60A 100A/70A 150 --- 1200A 100A/70A 150---1200A

MBM 50/40 --- 41/41 415V/415V 60A/60A 100A/70A 150 --- 1200A 100A/70A 150---1200A

MBM 50/50 --- 48/20 480V/208V 60A/139A 100A/70A 150---1200A 250A/150A 375--- 3000A

MBM 50/50 --- 48/48 480V/480V 60A/60A 100A/70A 150 --- 1200A 100A/70A 150---1200A

MBM 50/50 --- 60/20 600V/208V 48A/139A 100A/50A 150---1200A 250A/150A 375--- 3000A

MBM 50/50 --- 20/20 208V/208V 139A/139A 250A/150A 375---3000A 250A/150A 375--- 3000A

MBM 80/50 --- 48/20 480V/208V 60A/139A 100A/70A 150---1200A 250A/150A 375--- 3000A

MBM 80/50 --- 48/48 480V/480V 60A/60A 100A/70A 150 --- 1200A 100A/70A 150---1200A

MBM 80/50 --- 60/20 600V/208V 48A/139A 100A/50A 150---1200A 250A/150A 375--- 3000A

MBM 80/50 --- 38/38 380V/380V 74A/74A 100A/80A 150 --- 1200A 100A/80A 150---1200A

MBM 80/50 --- 40/40 400V/400V 74A/74A 100A/80A 150 --- 1200A 100A/80A 150---1200A

MBM 80/50 --- 41/41 415V/415V 74A/74A 100A/80A 150 --- 1200A 100A/80A 150---1200A

MBM 80/50 --- 20/20 208V/208V 139A/139A 250A/150A 375---3000A 250A/150A 375--- 3000A

MBM 80/65 --- 48/20 480V/208V 78A/180A 100A/80A 150---1200A 250A/200A 375--- 3000A

MBM 80/65 --- 48/48 480V/480V 78A/78A 100A/80A 150 --- 1200A 100A/80A 150---1200A

MBM 80/65 --- 60/20 600V/208V 63A/180A 100A/70A 150---1200A 250A/200A 375--- 3000A

MBM 80/65 --- 38/38 380V/380V 97A/97A 250A/100A 375--- 3000A 250A/100A 375 ---3000A

MBM 80/65 --- 40/40 400V/400V 97A/97A 250A/100A 375--- 3000A 250A/100A 375 ---3000A

MBM 80/65 --- 41/41 415V/415V 94A/94A 250A/100A 375--- 3000A 250A/100A 375 ---3000A

MBM 80/65 --- 20/20 208V/208V 180A/180A 250A/200A 375---3000A 250A/200A 375--- 3000A

KVA, 380:380VAC, 400:400VAC, 415:415VAC, 600:600VAC,

480:208

VAC, 600:208VAC, 208:208VAC, 480:480VAC.

BIB1 & BIB2 MBP & MIS

Vin/V

out

Iin/I

out

Frame/T rip

Instantaneous

Trip Ra n ge

Frame/T rip

Instantaneous

Trip Ra n ge

NOTE: See Sheet 2 For Model Number Legend.

DESCRIPTION:

DRAWING NO:

REVISION:

A --- 6

INSTALLATION NOTES

164201177--- 1

C

DATE:

041500

SHEET:

Powerware 9315 Maintenance Bypass Module 30-160kVA

1of2

164201177 Rev. C 041500

Page 31

MBM

FAMIL Y

MBM

80KVA

100KV

A

130KV

A

160KV

A

MBM 80

MBM 160

Table B. Circuit Breaker Requirements for Powerware 9315

M B M 3 0 --- 1 6 0 KVA, 380:380VAC, 400:400VAC, 415:415VAC, 600:600VAC,

480:208VAC, 600:208VAC, 208:208VAC, 480:480VAC.

BIB1 & BIB2 MBP & MIS

Vin/V

Model No.

MBM 80/50 --- 48/20 480V/208V 60A/139A 100A/70A 150--- 1200A 250A/150A 375 ---3000A

MBM 80/80 --- 48/20 480V/208V 96A/222A 100A/100A 150--- 1200A 250A/237A 375 --- 3000A

MBM 80/80 --- 48/48 480V/480V 96A/96A 100A/100A 150---1200A 100A/100A 150--- 1200A

MBM 80/80 --- 60/20 600V/208V 77A/222A 100A/80A 150--- 1200A 250A/237A 375 ---3000A

MBM 80/80 --- 38/38 380V/380V 115A/115A 250A/125A 375--- 3000A 250A/125A 375---3000A

MBM 80/80 --- 40/40 400V/400V 115A/115A 250A/125A 375--- 3000A 250A/125A 375---3000A

MBM 80/80 --- 41/41 415V/415V 115A/115A 250A/125A 375--- 3000A 250A/125A 375---3000A

MBM 80/80 --- 20/20 208V/208V 222A/222A 250A/237A 375--- 3000A 250A/237A 375---3000A

MBM 160/100 --- 48/20 480V/208V 120A/278A 250A/125A 375--- 3000A 600A/300A 900 ---7200A

MBM 160/100 --- 48/48 480V/480V 120A/120A 250A/125A 375--- 3000A 250A/125A 375 ---3000A

MBM 160/100 --- 60/20 600V/208V 96A/278A 250A/100A 375--- 3000A 600A/300A 900 --- 7200A

MBM 160/100 --- 60/60 600V/600V 96A/96A 250A/100A 375 ---3000A 250A/100A 375---3000A

MBM 160/100 --- 38/38 380V/380V 146A/146A 250A/150A 375--- 3000A 250A/150A 375 ---3000A

MBM 160/100 --- 40/40 400V/400A 146A/146A 250A/150A 375 --- 3000A 250A/150A 375 ---3000A

MBM 160/100 --- 41/41 415V/415V 146A/146A 250A/150A 375--- 3000A 250A/150A 375 ---3000A

MBM 160/100 --- 20/20 208V/208A 278A/278A 600A/300A 900 --- 7200A 600A/300A 900 ---7200A

MBM 160/130 --- 48/20 480V/208V 156A/361A 250A/175A 375--- 3000A 600A/420A 900 ---7200A

MBM 160/130 --- 48/48 480V/480V 156A/156A 250A/175A 375--- 3000A 250A/175A 375 ---3000A

MBM 160/130 --- 60/20 600V/208V 125A/361A 250A/150A 375--- 3000A 600A/420A 900 ---7200A

MBM 160/130 --- 60/60 600V/600V 125A/125A 250A/150A 375--- 3000A 250A/150A 375 ---3000A

MBM 160/130 --- 38/38 380V/380V 188A/188A 250A/200A 375--- 3000A 250A/200A 375 ---3000A

MBM 160/130 --- 40/40 400V/400V 188A/188A 250A/200A 375--- 3000A 250A/200A 375 ---3000A

MBM 160/130 --- 41/41 415V/415V 188A/188A 250A/200A 375--- 3000A 250A/200A 375 ---3000A

MBM 160/130 --- 20/20 208V/208V 361A/361A 600A/420A 900--- 7200A 600A/420A 900 ---7200A

MBM 160/160 --- 48/20 480V/208V 192A/444A 250A/200A 375--- 3000A 600A/480A 900 ---7200A

MBM 160/160 --- 48/48 480V/480V 192A/192A 250A/200A 375--- 3000A 250A/200A 375 ---3000A

MBM 160/160 --- 60/20 600V/208V 153A/444A 250A/175A 375--- 3000A 600A/480A 900 ---7200A

MBM 160/160 --- 60/60 600V/600V 153A/153A 250A/175A 375--- 3000A 250A/175A 375 ---3000A

MBM 160/160 --- 38/38 380V/380V 231A/231A 250A/237A 375--- 3000A 250A/237A 375 ---3000A

MBM 160/160 --- 40/40 400V/400V 231A/231A 250A/237A 375--- 3000A 250A/237A 375 ---3000A

MBM 160/160 --- 41/41 415V/415V 231A/231A 250A/237A 375--- 3000A 250A/237A 375 ---3000A

MBM 160/160 --- 20/20 208V/208V 444A/444A 600A/480A 600A/480A 900--- 7200A

out

Iin/I

out

Frame/T rip

Instantaneous

Trip Ra n ge

Frame/T rip

Instantaneous

Trip Ra n ge

NOTE: Model Number Legend

1. MBM 50/30---20/20 means MBM cabinet,

Family 50, 208V (input) and 208V (output),

model 30 (30kVA).

2. All breakers are 100% UL rated with

Interrupting Capacity (IC) of 65kAIC@480VAC.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

DESCRIPTION:

DRAWING NO:

REVISION:

INSTALLATION NOTES

164201177--- 1

C

DATE:

041500

SHEET:

2of2

A --- 7

164201177 Rev. C 041500

Page 32

Terminal

E3Phase

C

,

,

BIB---4

Phase

B

(

(MISbreaker

L

Function

AC Input to

MBM

AC Input to

UPS Bypass

(BIB breaker

Load side)

UPS Output

to MBM

MIS breaker

Line side)

MBM Output

to Critical

oad E15 Phase C

Neutral Lug E12 Neutral

Customer

Ground Lug

Terminal Function

E1,

E2,

E3

B I B --- 2 ,

B I B --- 4

B I B --- 6

M I S --- 1 ,

M I S --- 3 ,

M I S --- 5 Phase C

E13,

E14,

Ground Ground

,

Phase A,

Phase B,

Phase C

Phase A,

Phase B

Phase C

Phase A,

Phase B,

Phase A,

Phase B,

Presure

Terminal

2 --- # 6 - 3 5 0

(Note 2)

2 --- # 6 - 3 5 0

(Note 2)

4 --- # 2 - 6 0 0

(Note 2)

1 --- # 6 - 3 5 0

,

3 --- # 3 / 0 - 4 0 0

1 --- # 6 - 3 5 0

3 --- # 3 / 0 - 4 0 0

2 --- # 6 - 3 5 0

4 --- # 2 - 6 0 0

12---#2-500

2 --- # 6 - 3 5 0

Ta b l e C -- 1 . Pow e r Ca b l e Te r m i n a t i o n s

With Optional BIB Without Optional BIB

Size of

kcmil

kcmil

kcmil

kcmil

kcmil

kcmil

kcmil

kcmil

kcmil

kcmil

kcmil

Tightening

Torqu e

N --- M

( l b --- i n )

31.1 (275) 3/8

31.1 (275) 3/8

56.5 (500) 1/2

31.1 (275) 3/8 N/A N/A N/A

42.4 (375) 5/16 N/A N/A N/A 100--- 160KVA, 20/20

311 (275) 3/8

42.4 (375) 5/16

31.1 (275) 3/8

56.5 (500) 1/2

56.5 (500) 1/2

31.1 (275) 3/8

Int.

Hex

Size

(In.)

Size of

Presure

Terminal

1 --- # 6 - 3 5 0

kcmil

(Note 3)

2 --- # 6 - 3 5 0

kcmil

(Note 2)

3 --- # 3 / 0 - 4 0 0

kcmil

(Note 3)

1 --- # 6 - 3 5 0

kcmil

3 --- # 3 / 0 - 4 0 0

kcmil

2 --- # 6 - 3 5 0

kcmil

4 --- # 2 - 6 0 0

kcmil

12---#2-500

kcmil

2 --- # 6 - 3 5 0

kcmil

Tightening

31.1 (275) 3/8

31.1 (275) 3/8

42.4 (375) 5/16 100---160KVA, 20/20

42.4 (375) 5/16

31.1 (275) 3/8

56.5 (500) 1/2

56.5 (500) 1/2 30 --- 160KVA, all voltages

31.1 (275) 3/8 30 --- 160KVA, all voltages

Torqu e

N --- M

( l b --- i n )

311 (275) 3/8

Int.

Hex

Size

(In.)

Powerware 9315

UPS Model in KVA

(see note below)

30---160KVA,

38/38, 48/48, 60/60

30---80KVA, 20/20

30---160KVA,

48/20, 60/20

30---160KVA,

38/38, 48/48, 60/60, 48/20, 60/20

30---80KVA, 20/20

30---160KVA,

38/38, 48/48, 60/60

30---80KVA,

48/20, 60/20, 20/20

100---160KVA,

48/20, 60/20, 20/20

30---160KVA,

38/38, 48/48, 60/60

30---80KVA,

48/20, 60/20, 20/20

100---160KVA,

48/20, 60/20, 20/20

NOTES: Model Number Legend

1. 38/38: 380VAC in--- 380VAC out; 48/48: 480VAC in --- 480VAC out; 60/60: 600VAC in --- 600VAC out

48/20: 480VAC in --- 208VAC out; 60/20: 600VAC in --- 208VAC out; 20/20: 208VAC in --- 208VAC out

2. AC input wiring is connected to input lugs E1 ---E3. Lugs are located on the right side of BIB breaker.

3 . A C i n p u t w i r i n g i s c o n n e c t e d d i r e c t l y to t h e l i n e si d e o f M B P b r e a k e r ( M B P --- 1 , M B P --- 3 , a n d M B P --- 5 ) .

4. AC input wiring is connected to input lugs E1--- E3.

A --- 8

DESCRIPTION:

DRAWING NO:

REVISION:

Powerware 9315 Maintenance Bypass Module 30-160kVA

INSTALLATION NOTES

164201177--- 1

C

DATE:

SHEET:

1of2

041500

164201177 Rev. C 041500

Page 33

Table C--2. Control Wiring Requirements and Termination Requirement for

V

A

#18#8

#18#8

120VA

C

SeeFig1

#18#8

#18#8

120VA

C

SeeFig2

Connecting Point

in MBM Cabinet

Size of

Pressure

Termination

(lb-in)

Reverse Transfer (RT) System.

Connection

Point in UPS

Size of

Pressure

Termination

(lb-in)

Recommended

Wire Size

Maximum

Voltage and

Current

Remarks

T B 1 --- 1 2

T B 1 --- 1 4

#18---#8

(55)

T B 6 --- 1

T B 6 --- 2

Table C--3. Control Wiring Requirements and Termination Requirement for

Connecting Point

in MBM Cabinet

T B 1 --- 1 2

T B 1 --- 1 3

T B 1 --- 1 3

T B 1 --- 1 4

Size of

Pressure

Termination

(lb-in)

#18---#8

(55)

Connection Point

in UPS

T B 6 --- 1 (U P S 1 )

T B 6 --- 1 (U P S 2 )

T B 6 --- 2 (U P S 1 )

T B 6 --- 2 (U P S 2 )

NOTES FOR TABLES C--2 AND C--3:

· Install the copper wiring in a conduit separate from the power wiring.

· Control wiring is NEC Class 1.

· Control wiring from each UPS Module should be twisted.

#18---#8

(55)

#18--- #14

Parallel Redundant System.

Size of

Pressure

Termination

(lb-in)

#18---#8

(55)

Recommended

Wire Size

#18--- #14

120

1.0A

C See Fig1.

.

(Twisted Pair)

Maximum

Voltage and

Current

Remarks

120VAC See Fig2.

1.0A

(Twisted Pair)

.

UPS

TB6

K3

--- 1 --- 2

BLK WHT

Twist Pa i r

--- 1 2 --- 1 3 --- 1 4

TB1

MBM

Figure 1. (Reverse Transfer)

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

UPS1

TB6

K3

--- 1 --- 2

BLK WHT

BLKWHT

UPS2

TB6

--- 1 --- 2

Twist Pa i r

--- 1 2 --- 1 3 --- 1 4

TB1

MBM

Figure 2. (Parallel Redundant)

DESCRIPTION:

DRAWING NO:

REVISION:

INSTALLATION NOTES

164201177--- 1

C

DATE:

K3

Twist Pa i r

041500

SHEET:

2of2

A --- 9

Page 34

Dimensions are in millimeters (inches)

DESCRIPTION:

DRAWING NO:

REVISION:

TYPICAL MBM CABINET -30-160kVA with or without XFMR

164201177--- 2

A

DATE:

080498

SHEET:

1of3

A --- 1 0

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 35

MBP

MIS

BREAKER ANNUNCIATION

UTILITY INPUT,

IF BIB

BREAKER IS

NOT

INSTALLED

CRITICAL LOAD CONNECTIONS

UPS/PTC OUTPUT

CONNECTION

NEUTRAL CONNECTIONS

OPTIONAL UPS BYPASS

INPUT CONNECTIONS

BIB1

BIB2

DESCRIPTION:

DRAWING NO:

REVISION:

UTILITY INPUT,

IF BIB

BREAKER

INSTALLED

TYPICAL MBM CABINET -30-160kVA with or without XFMR

INTERIOR COMPONENTS

164201177--- 2

A

DATE:

080498

SHEET:

2of3

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

A---11

Page 36

TOP VIEW

Dimensions are in millimeters (inches)

A --- 1 2

BOTTOM VIEW

DESCRIPTION:

DRAWING NO:

REVISION:

Powerware 9315 Maintenance Bypass Module 30-160kVA

TYPICAL MBM CABINET -30-160kVA with or without XFMR

TOP and BOTTOM VIEW

164201177--- 2

A

DATE:

080498

164201177 Rev. C 041500

SHEET:

3of3

Page 37

PDM CABINET

(optional)

MBM CABINET

(optional)

INPUT

TRANSFORMER

CABINET

(optional)

30--- 160kVA UPS System with MBM

UPS

CABINET

BATTERY CABINET

(optional)

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

DESCRIPTION:

DRAWING NO:

REVISION:

TYPICAL UPS SYSTEM WITH MBM

164201177--- 3

A

DATE:

080498

SHEET:

1of1

A---13

Page 38

Read and understand the following notes while planning your installation:

1. Refer to national and local electric codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by others.

3. For external wiring requirement, including the minimum AWG size of external wiring, see the appropriate column

in Table A-2 and A-4. The power wiring for this equipment is rated at 90 degrees Celsius.

4. The output of the UPS is not a separately d erived source. Output neutral is not bonded to equipment ground through the main

bonding jumper. Refer to NEC and local codes for proper grounding practices.

5. The maintenance bypass (MBM) source must contain overcurrent protection with the maximum trip setting of 125% of the full

load input current in Table A-2 and A-4.

6. The Bypass three-phase feeds should be symmetrical about ground.

7. Transfer sequence instructions for the MBM are placed on the breaker access panel behind the cabinet doors.

8. Control wiring must be installed in separate conduit from the power wiring.

9. Electronic interlock is a standard part of the maintenance bypass module cabinet. This electronic interlock can be replaced with

an optional (extra cost) mechanical interlock if required.

10. Refer to UPS Installation Manual for proper Bypass terminating lugs at UPS cabinet or input transformer cabinet.

11. Refer to Table C-2 for control wiring connections.

12. A Maintenance Bypass neutral feeder must be supplied when the MBM output neutral is used. If no Maintenance Bypass

neutral is supplied, the MBM output neutral is not to be used. In neither case shall the MBM output neutral be bonded to ground.

LEGEND

MIS: MAINTENANCE ISOLATION BREAKER

MBP: MAINTENANCE BYPASS BREAKER

BIB: BYPASS INPUT BREAKER

SKRU: SOLENOID KEY RELEASE UNIT

(MECHANICAL INTERLOCK)

RT: REVERSE TRANSFER

110100057 D3

DESCRIPTION:

ONELINE -- 30-160kVA, RT, 480:480VAC,

600:600VAC, 400:400VAC

DRAWING NO:

REVISION:

164201177--- 4

A

DATE:

080498

SHEET:

1of1

A --- 1 4

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 39

Read and understand the following notes while planning your installation:

1. Refer to national and local electric codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by others.

3. For external wiring requirement, including the minimum AWG size of external wiring, see the appropriate column in Table A ---1.

The power wiring for this equipment is rated at 90 degrees Celsius.

4. The output of the UPS is a separately derived source. Output neutral is bonded to equipment ground through the main

bonding jumper. Refer to NEC and local codes for proper grounding practices.

5. The maintenance bypass (MBM) source must contain overcurrent protection with the maximum trip setting of 125% of the full

load input current in Table A --- 1.

6. The Bypass three-phase feeds should be symmetrical about ground.

7. Transfer sequence instructions for the MBM are placed on the breaker access panel behind the cabinet doors.

8. Control wiring must be installed in separate conduit from the power wiring.

9. Electronic interlock is a standard part of the maintenance bypass module cabinet. This electronic interlock can be replaced with

an optional (extra cost) mechanical interlock if required.

10. Refer to UPS Installation Manual for proper Bypass terminating lugs.

11. Refer to Table C-2 for control wiring connections.

LEGEND

MIS: MAINTENANCE ISOLATION BREAKER

MBP: MAINTENANCE BYPASS BREAKER

BIB: BYPASS INPUT BREAKER

SKRU: SOLENOID KEY RELEASE UNIT

(MECHANICAL INTERLOCK)

RT: REVERSE TRANSFER

110100056 D1

DESCRIPTION:

DRAWING NO:

REVISION:

ONELINE -- 30-160kVA, RT,

480:208VAC, 600:208VAC

164201177--- 5

A

DATE:

080498

SHEET:

1of1

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

A---15

Page 40

Read and understand the following notes while planning your installation:

1. Refer to national and local electric codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by others.

3. For external wiring requirement, including the minimum AWG size of external wiring, see the appropriate column in Table A ---3.

The power wiring for this equipment is rated at 90 degrees Celsius.

4. The output of the UPS is not a separately derived source. Output neutral is not bonded to equipment ground through the main

bonding jumper. Refer to NEC and local codes for proper grounding practices.

5. The maintenance bypass (MBM) source must contain overcurrent protection with the maximum trip setting of 125% of the full

load input current in Table A --- 3.

6. The Bypass three-phase feeds should be symmetrical about ground.

7. Transfer sequence instructions for the MBM are placed on the breaker access panel behind the cabinet doors.

8. Control wiring must be installed in separate conduit from the power wiring.

9. Electronic interlock is a standard part of the maintenance bypass module cabinet. This electronic interlock can be replaced with

an optional (extra cost) mechanical interlock if required.

10. Refer to UPS Installation Manual for proper bypass terminating lugs at UPS cabinet or at input transformer cabinet.

11. Refer to Table C-2 for control wiring connections.

LEGEND

MIS: MAINTENANCE ISOLATION BREAKER

MBM: MAINTENANCE BYPASS BREAKER

BIB: BYPASS INPUT BREAKER

SKRU: SOLENOID KEY RELEASE UNIT

(MECHANICAL INTERLOCK)

RT: REVERSE TRANSFER

110100058 D2

DESCRIPTION:

DRAWING NO:

REVISION:

ONELINE -- 30-160kVA, RT, 208:208VAC

164201177--- 6

A

DATE:

080498

SHEET:

1of1

A --- 1 6

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 41

Read and understand the following notes while planning your installation:

1. Refer to national and local electric codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by others.

3. For external wiring requirement, including the minimum AWG size of external wiring, see the appropriate column in Table A ---2

and A--- 4. The power wiring for this equipment is rated at 90 degrees Celsius.

4. The output of the UPS is not a separately derived source. Output neutral is not bonded to equipment ground through the main

bonding jumper. Refer to NEC and local codes for proper grounding practices.

5. The maintenance bypass (MBM) source must contain overcurrent protection with the maximum trip setting of 125% of the full

l o a d i n p u t c u r r e n t i n Ta b l e A --- 2 a n d A --- 4 .

6. The Bypass three-phase feeds should be symmetrical about ground.

7. Transfer sequence instructions for the MBM are placed on the breaker access panel behind the cabinet doors.

8. Control wiring must be installed in separate conduit from the power wiring.

9. Electronic interlock is a standard part of the maintenance bypass module cabinet. This electronic interlock can be replaced with

an optional (extra cost) mechanical interlock if required.

10. Refer to UPS Installation Manual for proper Bypass terminating lugs at UPS cabinet or input transformer cabinet.

11. Refer to Table C ---3 for control wiring connections.

12. Refer to Parallel Redundant System Manual for details.

13. A Maintenance Bypass neutral feeder must be supplied when the MBM output neutral is used. If no Maintenance Bypass

neutral is supplied, the MBM output neutral is not to be used. In neither case shall the MBM output neutral be bonded to ground.

LEGEND

MIS: MAINTENANCE ISOLATION BREAKER

MBM: MAINTENANCE BYPASS BREAKER

BIB: BYPASS INPUT BREAKER

SKRU: SOLENOID KEY RELEASE UNIT

(MECHANICAL INTERLOCK)

PTC: PARALLEL TIE CABINET

RT: REVERSE TRANSFER

110100069

DESCRIPTION:

ONELINE -- 30-160kVA, PARALLEL, 480:480VAC

600:600VAC, 400:400VAC

DRAWING NO:

REVISION:

164201177--- 7

A

DATE:

080498

SHEET:

1of1

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

A---17

Page 42

Read and understand the following notes while planning your installation:

1. Refer to national and local electric codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by others.

3. For external wiring requirement, including the minimum AWG size of external wiring, see the appropriate column in Table A ---1.

The power wiring for this equipment is rated at 90 degrees Celsius.

4. The output of the UPS is a separately derived source. Output neutral is bonded to equipment ground through the main

bonding jumper. Refer to NEC and local codes for proper grounding practices.

5. The maintenance bypass (MBM) source must contain overcurrent protection with the maximum trip setting of 125% of the full

load input current in Table A --- 1.

6 The Bypass three-phase feeds should be symmetrical about ground.

7. Transfer sequence instructions for the MBM are placed on the breaker access panel behind the cabinet doors.

8. Control wiring must be installed in separate conduit from the power wiring.

9. Electronic interlock is a standard part of the maintenance bypass module cabinet. This electronic interlock can be replaced with

an optional (extra cost) mechanical interlock if required.

10. Refer to UPS Installation Manual for proper Bypass terminating lugs.

11. Refer to Table C ---3 for control wiring connections.

12. Refer to Parallel Redundant System Manual for details.

LEGEND

MIS: MAINTENANCE ISOLATION BREAKER

MBP: MAINTENANCE BYPASS BREAKER

BIB: BYPASS INPUT BREAKER

SKRU: SOLENOID KEY RELEASE UNIT

(MECHANICAL INTERLOCK)

PTC: PARALLEL TIE CABINET

RT: REVERSE TRANSFER

110100068

DESCRIPTION:

ONELINE -- 30-160kVA, PARALLEL

480:208VAC, 600:208VAC

DRAWING NO:

REVISION:

164201177--- 8

A

DATE:

SHEET:

080498

1of1

A --- 1 8

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Page 43

Read and understand the following notes while planning your installation:

1. Refer to national and local electric codes for acceptable external wiring practices.

2. Material and labor for external wiring requirements are to be provided by others.

3. For external wiring requirement, including the minimum AWG size of external wiring, see the appropriate column in Table A ---3.

The power wiring for this equipment is rated at 90 degrees Celsius.

4. The output of the UPS is not a separately derived source. Output neutral is not bonded to equipment ground through the main

bonding jumper. Refer to NEC and local codes for proper grounding practices.

5. The maintenance bypass (MBM) source must contain overcurrent protection with the maximum trip setting of 125% of the full

load input current in Table A --- 3.

6. The Bypass three-phase feeds should be symmetrical about ground.

7. Transfer sequence instructions for the MBM are placed on the breaker access panel behind the cabinet doors.

8. Control wiring must be installed in separate conduit from the power wiring.

9. Electronic interlock is a standard part of the maintenance bypass module cabinet. This electronic interlock can be replaced with

an optional (extra cost) mechanical interlock if required.

10. Refer to UPS Installation Manual for proper Bypass terminating lugs at UPS cabinet or at input transformer cabinet.

11. Refer to Table C ---3 for control wiring connections.

12. Refer to Parallel Redundant System Manual for details.

LEGEND

MIS: MAINTENANCE ISOLATION BREAKER

MBM: MAINTENANCE BYPASS BREAKER

BIB: BYPASS INPUT BREAKER

SKRU: SOLENOID KEY RELEASE UNIT

(MECHANICAL INTERLOCK)

PTC: PARALLEL TIE CABINET

RT: REVERSE TRANSFER

110100072

DESCRIPTION:

ONELINE -- 30-160kVA, PARALLEL, 208:208VAC

DRAWING NO:

REVISION:

164201177--- 9

A

DATE:

080498

SHEET:

1of1

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

A---19

Page 44

(NOTE 4)

LINE UP AND MATCH ARRANGEMENT #1

Applicable to POWERWARE 9315 30---160 kVA

UPS modules only. 160kVA UPS is shown.

A --- 2 0

DESCRIPTION:

DRAWING NO:

REVISION:

Powerware 9315 Maintenance Bypass Module 30-160kVA

LINE UP AND MATCH ARRANGEMENT #1

164201177--- 10

A

DATE:

SHEET:

080498

164201177 Rev. C 041500

1of4

Page 45

(NOTE 4)

(NOTE 5)

(NOTE 5)

(NOTE 2)

LINE UP AND MATCH ARRANGEMENT #2

Applicable to POWERWARE 9315 30---160 kVA

UPS modules only. 160kVA UPS is shown.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

DESCRIPTION:

DRAWING NO:

REVISION:

LINE UP AND MATCH ARRANGEMENT #2

164201177--- 10

A

DATE:

SHEET:

080498

2of4

A---21

Page 46

(NOTE 3)

A --- 2 2

(NOTE 4)

LINE UP AND MATCH ARRANGEMENT #3

Applicable to POWERWARE 9315 30---160 kVA

UPS modules only. 160kVA UPS is shown.

DESCRIPTION:

DRAWING NO:

REVISION:

LINE UP AND MATCH ARRANGEMENT #3

164201177--- 10

A

Powerware 9315 Maintenance Bypass Module 30-160kVA

DATE:

(NOTE 4)

SHEET:

3of4

080498

164201177 Rev. C 041500

Page 47

1 Line up and match power and control interconnection wiring from

MBM to UPS/Input Transformer cabinet is applicable for Reverse

Transfer (Single UPS module) connection only and sold separately

by Powerware Corporation.

2 Run power cables underneath the transformer.

3 External wiring is requiredandsuppliedbyothers.

4 The PDM cabinet is applicable IF AND ONLY IF the MBM and UPS

module outputs are 3 phase, 60Hz, 280VAC.

5 Refer to Powerware 9315 UPS module installation manual for

proper terminating lugs.

Powerware 9315 Maintenance Bypass Module 30 --- 160kVA

164201177 Rev. C 041500

DESCRIPTION:

LINE UP AND MATCH ARRANGMENT NOTES

DRAWING NO:

REVISION:

164201177--- 10

A

DATE:

SHEET:

080498

4of4

A---23

Page 48

This Page Intentionally Left Blank.

A --- 2 4

Powerware 9315 Maintenance Bypass Module 30-160kVA

164201177 Rev. C 041500

Loading...

Loading...