Page 1

M-Drive

©2019 Powersoft

DO000184.00 R02

USER GUIDE

Keep this manual

for future reference

Page 2

powersoft_MDrive_UG_EN_R02

Data are subject to change without notice.

For latest update please refer to the

online version available on www.powersoft-audio.com.

Page 3

M-Drive User Guide

Table of contents

1. Important safety instructions iii

2. Importantes instructions de sécurité iv

3. Instrucciones de seguridad importantes v

4. Importanti istruzioni di sicurezza vi

5. Regulatory information vii

6. Electrostatic Discharge (ESD) viii

7. M-Drive 1

7 : 1.Welcome 1

7 : 2.Unpacking & checking for shipping damage 1

7 : 3.Disposal of the packing material 1

7 : 4.Differential Pressure Control 1

7 : 4.1. Pressure mode 1

8. Thermal constrains 2

8 : 1.Heatsink performance 2

8 : 2.Suggested heatsink 2

9. Electromagnetic Compatibility (EMC) & Safety 4

9 : 1.AC MAINS filter 4

9 : 2.Cabling 4

9 : 3.Ferrite cores 4

9 : 4.Chassis shielding 4

11 : 7.PL 21 pinout 9

11 : 8.SO5 pinout 10

12. Hardware protections 12

12 : 1.Thermal Protections and Fan Control 12

12 : 2.Power supply protections 12

12 : 2.1. Primary AC mains overcurrent protection 12

12 : 2.2. Primary AC mains overvoltage protection 12

12 : 2.3. Primar y thermal protection 12

12 : 3.Amplifier protections 12

12 : 3.1. Auxiliary power protections 12

12 : 3.2. Second ar y overcurrent protect ion 12

13. LED chart 13

13 : 2.SIMM board LED chart 13

13 : 1.Interface board LED chart 13

14. Pressure sensor 14

15. Initialization 15

15 : 1.DPC P rogramming System 15

15 : 2.initialization framework 16

15 : 2.1. Initialization workfl ow 16

15 : 2.2. OEM Manufact urer Registr atio n 17

15 : 2.3. Sof twa re installat ion 18

15 : 2.4. Soft war e Activatio n 18

9 : 5.Mains Fuse 4

9 : 6.Earth connection 4

10. Mechanical drawings 5

11. Connections 7

11 : 1.Interface board: bill of connectors 7

11 : 2.RS-485 inter face 7

11 : 3.Control board: bill of connectors 7

11 : 4.Amp module: bill of connectors 8

11 : 5.PL1000 pinout 8

11 : 6.PL22 / PL23 pinout 8

15 : 3.M-drive DSP initialization 19

15 : 3.1. Required tools 19

15 : 3.2. Connec tio n 19

15 : 3.3. Progra mming Cable and Adapter 19

15 : 3.4. DSP initialization as Powersoft model 20

15 : 4.Programming M-Drive DSP 21

15 : 5.Setting M-Drive serial port 21

15 : 5.1. Automatic Dis cover y 21

15 : 5.2. Monitor View 23

15 : 5.3. Advanced View 23

15 : 5.4. Global Se t tings 24

| i

Page 4

15 : 5.5. Pressure Model Op erat ing M ode 25

15 : 5.6. Internal paramet ers 25

15 : 5.7. Metering 27

15 : 5.8. Locking 28

16. Export Custom Presets 28

17. Creating Custom models 29

17 : 1.DPC Custom Model Builder 29

18. Export Custom Model 30

19. Install Custom Model 30

20. Initialize M-Drive DSP as Custom Model 31

20 : 1.Add online Custom Model 32

20 : 2.Add offline Custom Model 32

21. DSP-4 Initialization 33

21 : 1.Required Tools 3 3

21 : 2.Connection 33

21 : 3.DSP-4 initialization as Powersoft model 33

22. Programming DSP-4 35

23. Export Custom Preset 36

24. Creating Custom Model (DSP-4) 37

24 : 1.Custom model builder 37

24 : 2.Export Custom Model 38

24 : 3.Install Cus tom Model 38

25. Initialize DSP-4 as Custom Model 39

25 : 1.Add online Custom model 40

25 : 2.Add offline Custom model 40

26. Appendix 41

26 : 1.How to install jrsoftware 41

27. Support and warranty 42

27 : 1.Service 42

27 : 2.Warranty 42

27 : 2.1. Return of Goo ds 42

27 : 2.2 . Repair or replac ement 42

27 : 2.3. Cost and responsibility of transport 42

27 : 3.Assist ance 42

28. Specifications 43

ii | M-Drive | User guide

Page 5

Important safety instructions

This amplifier module is intended to be installed inside

other devices and must be checked in the final product.

EXPLANATIONS OF GRAPHICAL SYMBOLS

1

CAUTION

RISK OF ELECTRICK SHOCK

DO NOT OPEN

The triangle with the lightning bolt is used to alert the

user to the risk of electric shock.

The triangle with the exclamation point is used to

alert the user to important operating or maintenance

instructions.

The CE-mark indicates the compliance with the low

voltage and electromagnetic compatibility.

Symbol for earth/ground connection.

Symbol for conformity with Directive 2002/96/EC

and Directive 2003/108/EC of the European

Parliament on waste electrical and electronic equipment (WEEE).

Symbol for electrostatic discharge sensitive devices.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this equipment near water.

6. Do not block any ventilation openings. Install in accordance with

Powersoft’s instructions.

7. Do not install near any heat sources such as radiators, heat registers, stover or other apparatus that produce heat.

8. Do not defeat the safety purpose of the polarized or groundingtype plug.

9. Only use attachments/accessories specified by Powersoft.

10. Refer all servicing to qualified service personnel. Servicing is

required when the apparatus has been damaged in any way, such

as power-supply cord or plug is damaged, liquid has been spilled

or objects have fallen into the apparatus, the apparatus has been

exposed to rain or moisture, does not operate normally, or has

been dropped.

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT ATTEMPT

TO OPEN ANY PART OF THE UNIT. NO USER-SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE,

DRIPPING OR SPLASHING LIQUIDS. OBJECTS FILLED WITH

LIQUIDS, SUCH AS VASES, SHOULD NOT BE PLACED ON THIS

APPARATUS.

SPEAKER TERMINALS COULD BE HAZARDOUS LIVE IF

SPEAKER BRIDGE MODE CONNECTION IS USED.

PROPER CONNECTIONS AND INSULATIONS TECHNIQUES

MUST BE ADOPTED WHEN SPEAKER BRIDGE MODE

CONNECTION IS USED.

Important safety instructions | iii

Page 6

Importantes instructions de sécurité

Ce module d’amplification est destiné à être

installé à l’intérieur d’autres dispositifs et doit

donc être contrôlé sur le produit fini.

EXPLICATION DES SYMBOLES GRAPHIQUES

2

AVIS

RISQUES D’ÉLECTROCUTION

NE PAS OUVRIR

La triangle avec le symbol du foudre est employée

pour alerter l’utilisateur au risque de décharge électrique.

Le triangle avec un point d’exclamation est employée

pour alerter l’utilisateur d’instruction importantes

pour lors opérations de maintenance.

Le marquage CE indique la conformité à la directive de

basse tension et la compatibilité électromagnétique.

Symbole pour la connexion à la terre.

Symbole pour la conformité al la Directive 2002/96/

EC et la Directive 2003/108/EC du Parlement

Européen sur les équipements électriques et électroniques (WEEE).

Symbole pour les appareils sensibles aux décharges

électrostatiques.

1. Lisez ces instructions.

2. Gardez ces instructions.

3. Tenez compte de toutes les mises en garde.

4. Suivez toutes les instructions.

5. N’utilisez pas cet amplificateur à proximité de l’eau.

6. Assurez-vous d’une bonne ventilation de l’appareil. Installez en

accord avec les instructions préconisées par Powersoft.

7. N’installez pas l’appareil à proximité de sources de chaleur ou

d’autres appareils produisant de la chaleur.

8. Respectez le dispositif de mise à la terre de la prise secteur.

9. Utilisez uniquement les accroches et accessoires spécifiés par

Powersoft.

10. Confiez toute réparation à un technicien qualifié. L’intervention

d’un technicien est nécessaire dans les cas suivants : le cordon

d’alimentation ou la prise secteur sont endommagés, des corps

étrangers ou du liquide se sont introduits dans l’appareil, l’appareil

a été exposé à la pluie ou à l’humidité, l’appareil montre des

signes de dysfonctionnement ou est tombé.

MISE EN GARDE : AFIN DE RÉDUIRE LES RISQUES DE CHOC

ÉLECTRIQUE, N’ESSAYEZ PAS D’OUVRIR L’UNITÉ, MEME EN

PARTIE. AUCUNE PIÈCE A L’INTERIEUR NE PEUT ETRE CHANGÉE PAR

L’UTILISATEUR. LAISSEZ L’ENTRETIEN A UN PERSONNEL QUALIFIÉ.

iv | M-Drive | User guide

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L’HUMIDITÉ,

AUX GOUTTES OU AUX ÉCLABOUSSURES. LES OBJETS

REMPLIS DE LIQUIDE, TELS QUE LES VASES, NE DOIVENT PAS ETRE

PLACÉS SUR CET APPAREIL.

LES BORNES D’ENCEINTES POURRAIENT ÊTRE DANGEREUX SI

LA CONNEXION DE MODE PONT DU HAUT-PARLEUR EST

UTILISÉ.

ADOPTER DES TECHNIQUES CORRECTES DE CONNEXION ET

D’ISOLEMENT LORSQUE LA CONNEXION EN MODE BRIDGE

HAUT-PARLEUR EST UTILISÉ.

Page 7

Instrucciones de seguridad importantes

Este módulo amplificador está diseñado para ser instalado dentro

de otros dispositivos y debe verificarse en el producto final.

EXPLICACIÓN DE LOS SÍMBOLOS GRÁFICOS

3

PRECAUCIÓN

RIESGO DE CHOQUE ELÉCTRICO

NO ABRA LA UNIDAD

El triángulo con el símbolo de rayo eléctrico es usado para alertar al usuario de el riesgo de un choque

eléctrico.

El triángulo con el signo de admiración es usado

para alertar al usuario de instrucciones importantes

de operación o mantenimiento.

La marca CE indica el cumplimiento de la directiva

de bajo voltaje y de compatibilidad electromagnética.

Símbolo de la conexión a tierra.

Símbolo de conformidad con la Directiva 2002/96/

EC y Directiva 2003/108/EC del Parlamento Europeo

sobre los aparatos eléctricos y electrónicos (WEEE).

Símbolo para los dispositivos sensibles a descargas

electrostáticas.

1. Lea estas instrucciones.

2. Guarde estas instrucciones.

3. Preste atención a todas las advertencias.

4. Siga todas las instrucciones.

5. No use este aparato cerca del agua.

6. No bloquee las aberturas de ventilación. Realice la instalación de

acuerdo con las indicaciones de Powersoft.

7. No instale cerca ninguna fuente de calor como, por ejemplo,

radiadores, rejillas de calefacción, hornos u otros aparatos que

produzcan calor.

8. No elimine el diseño de seguridad del enchufe, ya sea del tipo polarizado o con conexión a tierra.

9. Use exclusivamente los dispositivos/accesorios indicados por

Powersoft.

10. El servicio técnico debe realizarlo siempre personal cualificado. Se

requerirá servicio de asistencia técnica cuando el aparato sufra

algún tipo de daño como, por ejemplo, que el cable de alimentación

o el enchufe estén dañados, que se haya derramado líquido o hayan

caído objetos dentro del aparato, que éste se haya expuesto a la lluvia o humedad, que no funcione normalmente o que se haya caído.

PRECAUCIÓN: PARA REDUCIR EL RIESGO DE DESCARGA

ELÉCTRICA, NO DESMONTE LA TAPA (NI EL PANEL TRASERO).

NO HAY PIEZAS REPARABLES POR EL USUARIO EN EL INTERIOR.

LLÉVELO A REPARAR A PERSONAL DE SERVICIO CUALIFICADO.

NO EXPONGA ESTE UNITAD A LA LLUVIA O LA HUMEDAD,

GOTEO O SALPICADURAS. NO COLOQUE OBJETOS LLENOS DE

LÍQUIDOS, TALES COMO VASIJAS, SOBRE EL APARATO.

TERMINALES DE LOS ALTAVOCES PODRÍA SER PELIGROSO, SI

SU CONEXIÓN SE UTILIZA EL ALTAVOZ MODO PUENTE.

ADOPTAR TÉCNICAS CORRECTAS DE CONEXIÓN Y

AISLAMIENTO CUANDO SE USA CONEXIÓN DE ALTAVOZ MODO

PUENTE.

Instrucciones de seguridad importantes | v

Page 8

Importanti istruzioni di sicurezza

Questo modulo amplificatore è destinato ad essere

installato dentro altri dispositivi e deve quindi

essere controllato nel prodotto finito.

SPIEGAZIONE DEI SIMBOLI GRAFICI

4

ATTENZIONE

RISCHIO DI SCOSSE

ELETTRICHE, NON APRIRE

Il triangolo con il lampo è utilizzato per avvisare

l’utente del rischio di scossa elettrica.

Il triangolo con il punto esclamativo è utilizzato per

avvisare l’utente di importanti istruzioni d’uso e manutenzione.

Il marchio CE indica la conformita’ del prodotto a

tutte le direttive europee applicabili

Simbolo della connessione di terra.

Simbolo di conformità alla Direttiva 2002/96/CE e

alla Direttiva 2003/108/CE del Parlamento Europeo

sulle apparecchiature elettriche ed elettroniche

(RAEE).

Simbolo per le apparecchiature sensibili alle scariche

elettrostatiche

1. Leggere queste istruzioni.

2. Conservare le istruzioni.

3. Tenere conto di tutti gli avvisi.

4. Seguire tutte le istruzioni.

5. Non usare l'apparecchio in prossimità di acqua.

6. Non ostruire le prese di ventilazione. Installare secondo le indicazioni del produttore.

7. Non installare vicino a fonti di calore quali radiatori, bocchette

dell'aria calda, stufe o altri apparecchi (compresi gli amplificatori)

che producono calore.

8. Non compromettere la sicurezza delle spine polarizzate o con

messa a terra.

9. Usare solo accessori specificati dal produttore.

10. Ricorrere a personale qualificato per qualsiasi intervento. Tali

interventi sono necessari in caso di guasti dell'apparecchio

quali danneggiamento del cavo di alimentazione o della spina,

versamento di liquidi o caduta di oggetti nell'apparecchio, esposizione a pioggia o umidità o se l'apparecchio non funziona

normalmente o è caduto.

ATTENZIONE: PER RIDURRE IL RISCHIO DI SCOSSE

ELETTRICHE, NON TENTARE DI APRIRE ALCUNA PARTE

DELL’UNITÀ. NON CI SONO PARTI INTERNE AD USO DELL’UTENTE.

RIVOLGERSI A PERSONALE QUALIFICATO PER L’ASSISTENZA.

vi | M-Drive | User guide

NON ESPORRE QUESTO APPARECCHIO ALLA PIOGGIA,

UMIDITÀ O SOSTANZE LIQUIDE. OGGETTI PIENI DI LIQUIDI,

COME VASI, NON DEVONO ESSERE COLLOCATI SU QUESTO APPARATO.

I TERMINALI DEI DIFFUSORI POTREBBERO ESSERE

PERICOLOSI, SE VIENE UTILIZZATA LA CONNESSIONE IN

MODALITÀ BRIDGE DEGLI ALTOPARLANTI.

ADOTTARE LE CORRETTE TECNICHE DI CONNESSIONE E

ISOLAMENTO QUANDO VIENE UTILIZZATA LA CONNESSIONE

IN MODALITÀ BRIDGE DEGLI ALTOPARLANTI.

Page 9

Regulatory information

5 4

FCC COMPLIANCE NOTICE

This device complies with part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

CAUTION: Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

NOTE: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

EC DECLARATION OF CONFORMITY

Manufacturer:

Powersoft S.p.A.

via E. Conti 5

50018 Scandicci (Fi)

Italy

We declare that under our sole responsibility the products:

Model Name: M-Drive IK

M-Drive IK

Intended use: Professional Audio Amplifier Module

Are in conformity with the provisions of the following EC Directives,

including all amendments, and with national legislation implementing

these directives:

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility Directive

2011/65/EU RoHs Directive

The following harmonized standards are applied:

EN 55103-2: 2009 /IS: 2012

EN 55032: 2012

EN 55035: 2017

EN 60065: 2014 /AC: 2016

EN 61000-3-3: 2013

EN 61000-3-2: 2014

WEEE DIRECTIVE

If the time arises to throw away your product, please recycle all the

possible components.

This symbol indicates that when the end-user wishes

to discard this product, it must be sent to separate collection facilities for recovery and recycling. By separating this product from other household-type waste, the

volume of waste sent to incinerators or land-fills will be

reduced and natural resources will thus be conserved.

The Waste Electrical and Electronic Equipment Directive (WEEE Directive)

aims to minimise the impact of electrical and electronic goods on the environment. Powersoft S.p.A. comply with the Directive 2002/96/EC and

2003/108/EC of the European Parliament on waste electrical finance the

cost of treatment and recovery of electronic equipment (WEEE) in order

to reduce the amount of WEEE that is being disposed of in land-fill site.

All of our products are marked with the WEEE symbol; this indicates that

this product must NOT be disposed of with other waste. Instead it is the

user’s responsibility to dispose of their waste electrical and electronic

equipment by handing it over to an approved reprocessor, or by returning it to Powesoft S.p.A. for reprocessing. For more information about

where you can send your waste equipment for recycling, please contact

Powesoft S.p.A. or one of your local distributors.

Scandicci,

April 2019

Luca Lastrucci

Managing Director

For compliance questions only: compliance@powersoft.it

Regulatory information | vii

Page 10

Electrostatic Discharge (ESD)

Electrostatic discharge (ESD) is one of the most

signicant factors leading to damage and failure of a wide

variety of electronic components.

Poor handling can cause internal damage, which is

invisible. This internal damage can then cause electrical

failure or reliability problems.

It is recommended that all workstations where

Electrostatic Discharge Sensitive devices (ESDS)

and assemblies are handled outside of full static protection

packaging (i.e. within static control areas) should be provided with some form of ground conductive or dissipative

ooring.

6

viii | M-Drive | User guide

Page 11

M-Drive User Guide

7

7 : 1.Welcome

Congratulations on your purchase of the Powersoft

M-Drive module.

We know you are eager to use the M-Drive module, but

please take a moment to read this user’s manual and safety

instructions. In case you have any questions, please do not

hesitate to contact your dealer or Powersoft.

The M-Drive is a one channel amplier modules

specically designed to fully exploit the potential of the

M-Force transducer. M-Drive shows amazing gures

in terms of both output voltage (310 V

capabilities (200 A

The new design of the power supply equipped with PFC,

reduces power consumption while enhancing reliability and

consistency in all operating conditions.

M-Drive can be equipped with any Powersoft or thirdparty DSP solution, and integrates the Powersoft’s patented

Differential Pressure Control technology that optimizes

sonic performances of the amplier+transducer+cabinet+

environment system.

A custom heat sink designed to best t the M-Drive is

available: please refer to the M-Drive IK solution for more

info on this subject.

peak

).

) and current

peak

7 : 2.Unpacking & checking for shipping damage

Your Powersoft product has been completely tested and

inspected before leaving the factory. Carefully inspect the

shipping package before opening it, and then immediately

inspect your new product. If you nd any damage notify the

shipping company immediately.

7 : 3.Disposal of the packing material

The transport and protective packing has been selected

from materials which are environmentally friendly for

disposal and can normally be recycled.

Rather than just throwing these materials away, please

ensure they are offered for recycling.

7 : 4.Differential Pressure Control

The Differential Pressure Control – DPC – is the core

technology of the Integrated Powered Adaptive Loudspeaker

system, also known as IPAL.

DPC makes M-Drive efcient and reactive to

®

DIFFERENTIAL

PRESSURE CONTROL

PATENTED

The differential pressure measurement, senses the

difference of pressure between the front and the rear sides

of the radiating diaphragm and uses this information to

alter the behaviour of the transducer, according to the real

boundary conditions. Thanks to this innovative approach

to full boundary conditions feedback processing, the DPC

dramatically improves the electroacoustic efciency in

terms of high SPL and sonic performance of the sound

reinforcement system.

The DPC system combines a high-efcient transducer

with a high-power switching mode amplier that embed a

fast and effective ZeroLatency™ DSP. The DSP performs

the double operation of both managing the loudspeaker

processing and taking care of the differential pressure

control signal. M-Drive establishes a global feedback

between the electrical and the acoustic domains.

Thanks to the rich graphic user interface – GUI – it is

possible to weight and customize the feedback between the

electrical and the acoustic domains.

7 : 4.1. Pressure mode

The Pressure mode relies on the DPC making it possible

to match a specic target pressure response. Being the SPL

output of any acoustic signal derived from the relationship

between the pressure and the acoustical impedance, it’s

straightforward to use a direct measurement of such a

pressure signal to make the system track a reference

target pressure model. Benets in terms of predictability

of the system response and reduction of sensitivity from

disturbing effects could be substantially appreciated.

the environment condition, overcoming the

physical limitation of traditional sound reinforcement systems.

M-Drive | 1

Page 12

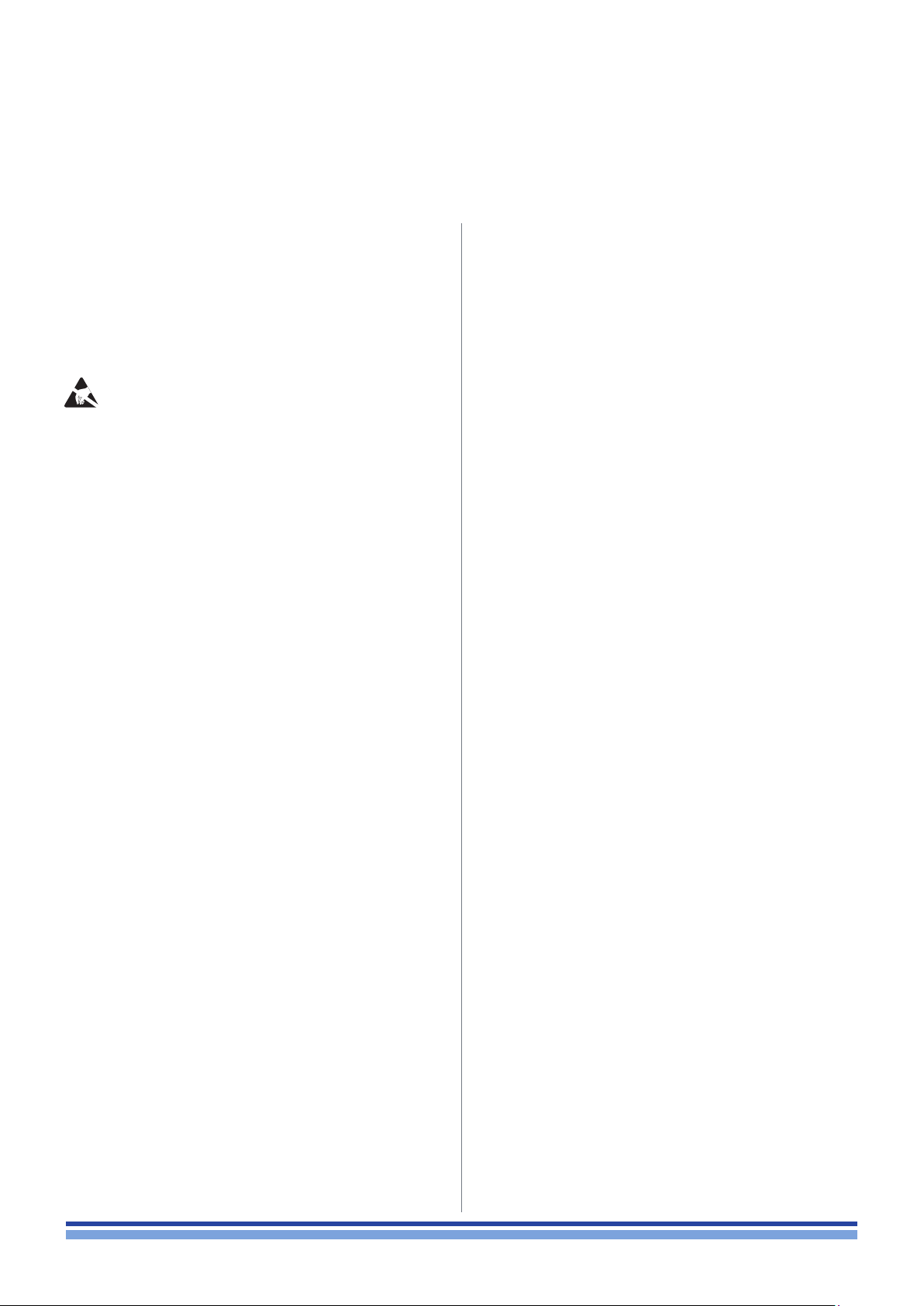

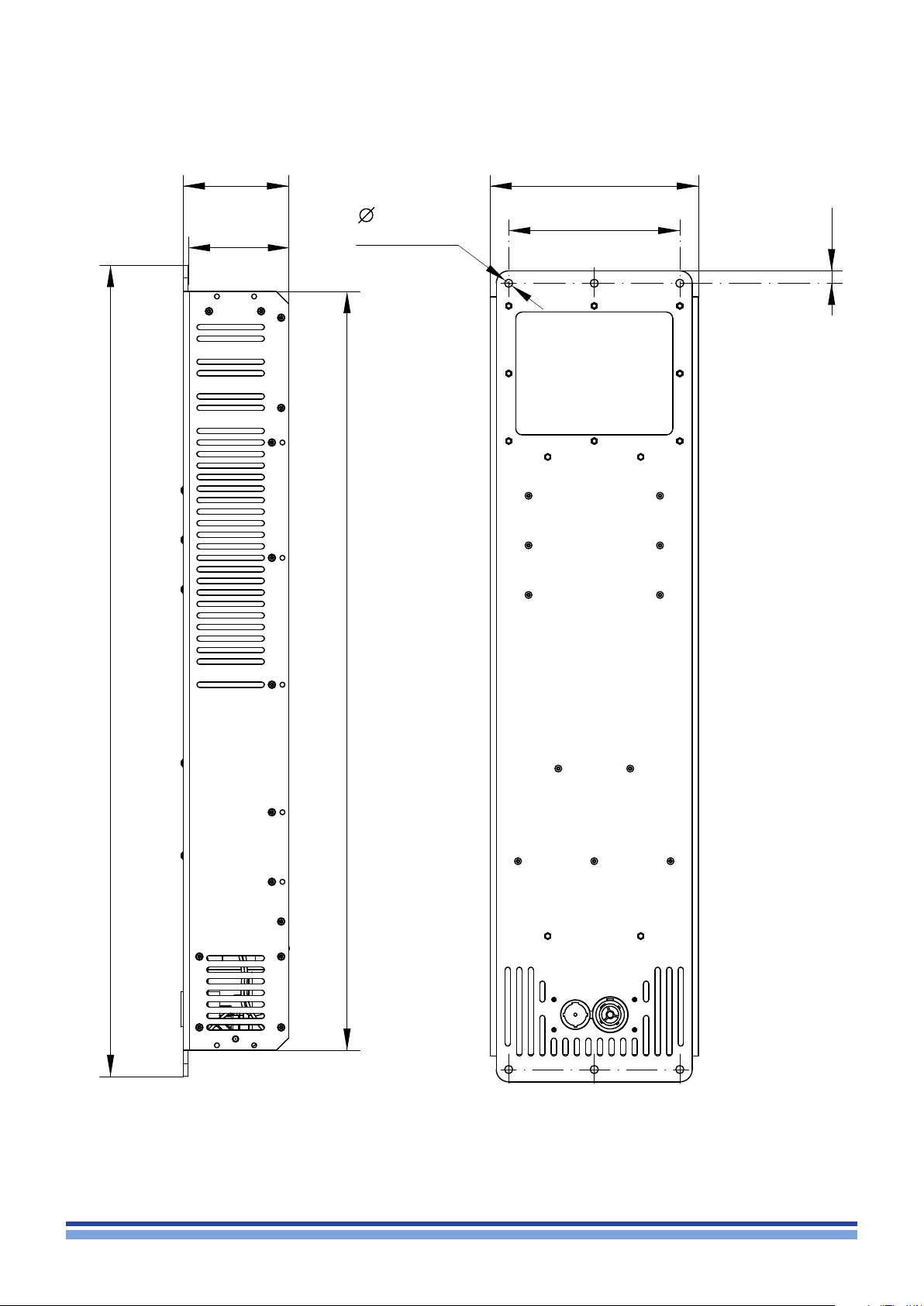

Thermal constrains

100 mm

3.94 inch

MIN.

Fans side

This device must be correctly heatsinked for proper and

reliable operation.

The built-in fans and an appropriate external passive

heat sink guarantee by design thermal efciency and

reliability.

Proper heat sink planarity is strongly suggested to allow

thermal transfer from the module’s bottom plate to the

heatsink; a thermal compound may be used, but it is not

strictly necessary.

In order to ensure proper ventilation of the module,

reasonable spacing of at least 100 mm must be left between

the frame of the unit and any side component or surface of

the enclosure.

The module has been designed to t into a loudspeaker

cabinet: please refer to FIGURE 1 for proper module placing.

IN FIGURE 1 HEATSINK FINS ARE SET HORIZONTALLY

(WRONG!) ONLY FOR DESCRIPTIVE PURPOSE.

We suggest to position the module vertically with respect

the ground in order to take advantage of the chimney effect

for ventilation and heat dissipation.

A custom heat sink designed to best t the M-Drive is

available: please refer to the M-Drive IK solution for more

info on this subject.

8 : 1.Heatsink performance

8

Do not obstruct

air ow

Fans side

FIGURE 1: Cooling solutions (for descriptive

purpose the heatsink fins are set in wrong direc-

tion): module in a separate vented chamber.

lowing formula:

W

(1 - e)

Dissipated power =

The maximum dissipated power can be calculated as:

For example, stating an efciency of 80%, 6 dB crest factor

max

cf

Here we suggest a rule of thumb to calculate the thermal

resistance of the heatsink.

The absolute thermal resistance of the heatsink is

the temperature difference (kelvin or celsius) across it

structure when a unit of heat energy ows through it in

unit time (watt). For seek of simplicity, a heatsink with low

thermal resistance offers high heat dissipation, as well as

a low electric resistance allows high current ow through a

conductive wire.

In order to dene the maximum allowed thermal

resistance for the heatsink let assume the following:

e as the amp module efciency

cf as the crest factor of the audio signal

W

as the peak power delivered by the module

max

T

as the highest ambient temperature

amb

T

as the highest operating temperature

mod

The thermal resistance of the heatsink derives from the fol-

T

- T

mod

Rth =

Dissipated power

amb

3400 (1 - 0.8)

4

and 3400 W peak power, the dissipated heat is:

Considering that thermal protection of the module (T

set at 75°C (167°F) on the bottom aluminium plate and stating an ambient temperature of 45 °C (113°F), the previous

75 - 45

170

example gives:

meaning that the temperature of the bottom plate is always

lower than 75°C if the heatsink has a thermal resistance better than 0.14°C/W (or 0.14 K/W) with ambient temperature

up to 45 °C.

= 170 W

= 0.14°C/W

mod

) is

8 : 2.Suggested heatsink

Powersoft provides a M-Drive compatible heat sink,

specically designed to house the amp module, an input/

output interface and the AC mains connection: please refer

to the M-Drive IK solution for more info on this subject.

2 | M-Drive | User guide

Page 13

85

168

81

6,5

N. 6 HOLES

138

10

654

612

FIGURE 2: M-Drive IK heat sink with powerCON and AC Mains filter.

Thermal constrains | 3

Page 14

Electromagnetic Compatibility (EMC) &

Safety

9

9 : 1.AC MAINS filter

In order to improve the electromagnetic compatibility

an EMC lter must be inserted before the AC MAINS

plugs on the power supply. Powersoft suggests:

Schaffner FN2030-10-06 model.

9 : 2.Cabling

FIGURE 3: Typical electrical schematic of the EMI Filter.

Wiring between the amp module and the load may lead

to radio frequency noise. The following guide lines should

be observed:

reduced cabling length is advisable;

keep cable pairs as close as possible to each other in

order to minimize the antenna effect;

design the cabling path far from RF noise source;

set the cabling for RF noise rejection: shielded or

twisted cables are advisable conguration (ref.

FIGURE 4);

place ferrites as close to the module as possible

Loose pair

Configuration

prone to high

RF noise

Parallel pair

Configuration

prone to RF noise

Twisted pair

Highly immune

to RF noise

RFC-H13 ferrite core, or equivalent.

Wrap both cables around one side of each ferrite so that

it pass through each ferrite twice (ref. FIGURE 3). Install the

ferrite shield as close as possible to where the cable plugs

into the amplier. Placing the ferrite elsewhere on the cable

noticeably reduces its effectiveness.

FIGURE 4: Ferrite core installation on I/O wirings.

9 : 4.Chassis shielding

If not already present on the product, a full body metal

chassis or a shielding cage will provide best shielding of RF

emission. In order to achieve the highest shielding, minimize

the amount and size of holes or opening in the chassis.

Ferrite core

AC MAINS filter

Chassis shielding

FIGURE 6: Tools and best practice for improving

the electromagnetic compatibility.

Input

signal

Output signal

Amp module

inside

Ferrite core

9 : 5.Mains Fuse

Replace the fuses with the same type and rating: time

delay fuse of 10A rating (2x Littelfuse series 215).

9 : 6.Earth connection

Shielded pair

Highly immune

to RF noise

FIGURE 5: Cabling configuration.

9 : 3.Ferrite cores

Reject RF noise from input and output cabling by

installing ferrite shields. Powersoft suggests the KITAGAWA

4 | M-Drive | User guide

This device must be powered exclusively by earth

connected mains sockets in electrical networks

compliant to the IEC 364 or similar rules. Is absolutely necessary to verify this fundamental requirement of safety and,

in case of doubt, require an accurate check by a qualied

personal.

Is absolutely necessary to ground this device using the

proper earth connection on the metal frame of the chassis; use M4 nut and bolt with proper split washer – grover

washer – to secure the earth terminal lug.

Page 15

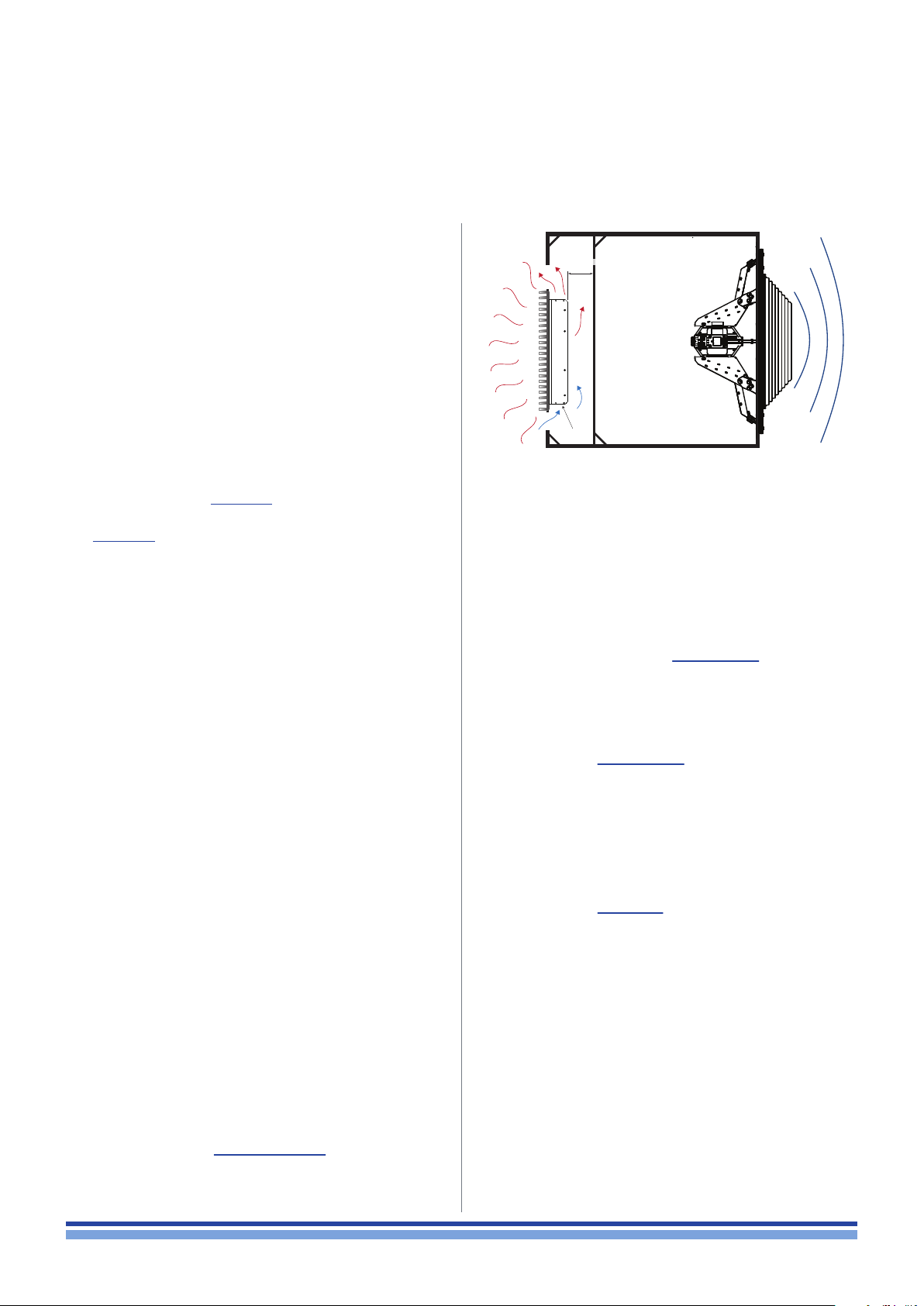

Mechanical drawings

MATERIAL

PROJECT

70

150

threaded M3 - max depth 3mm

torque 0,8 +/- 0,1 N/m

FIGURE 7: M-Drive mechanical drawing (all dimensions in millimetres).

Mechanical drawings | 5

Page 16

90°

2,5 m

FIGURE 8: Pressure sensor (all dimensions in millimetres unless otherwise stated)

6 | M-Drive | User guide

FIGURE 9: DPC interface board (all dimension in millimetres).

Page 17

Connections

11

DPC

interface

board

CN106

Micro Match

12 pin

Pressure

sensor

RS-485

interface

Audio

input

Audio link

(pass through)

Input

attenuator

CN101

CN102

Micro Match

18 pin

11 : 1.Interface board: bill of connectors

CODE FUNCTION TYPE

CN107

CN108

Audio link (pass through)

balanced

Audio input

balanced

1 1 22

3 3

COLD

GND

FIGURE 11: XLR pinout.

GND

XLR-M

XLR-F

HOTHOT

COLD

11 : 2.RS-485 interface

CODE FUNCTION TYPE

CN103 RS-485 RJ45

SW101 ID selector: units rotative knob

SW101 ID selector: tens rotative knob

Micro Match

16 pin

Micro Match

10 pin

CN103

Control

board

Amp

module

CN1

FIGURE 10: DPC interface to control board connections.

CN101CN109

CN102

11 : 3.Control board: bill of connectors

CODE FUNCTION TYPE

CN1

CN109 Pressure sensor input

CN101

CN102 FL0IS315 Interface

Not Used

(future development)

RS-485/ FL0IS315

Interface

8 pin

Micro Match Socket

10 pin

Micro Match Socket

16 pin

Micro Match Socket

18 pin

Micro Match Socket

Connections | 7

Page 18

BY11

BY41

BY41

BY21

BY41

BY31

PL1000

Default: closed (jumped)

Open only when using

DSP-C or DSP-D boards

11 : 4.Amp module: bill of connectors

ID Connector Model Connector Model

PL15 – L

PL15 – N AC mains input (Neutral)

GND M4 bolt Earth

FASTON

6.3x0.8mm

AC mains input (Line)

PL21

HOT

PL23 PL22

PL2

COLD

PL2000

SO1000

SO5

PL21 IDC 34p Header

S05 72p SIMM Socket

OUT1+

(HOT)

OUT2-

(COLD)

PL22

PL23

2x FASTON

6.3x0.8mm

2x FASTON

6.3x0.8mm

Molex

22-27-2031

For DSP/ Custom interface

board connection

Amplier output to M-Force-

motor Positive input*

Amplier output to M-Force-

motor Negative input*

Output to external FAN(s).

24Vdc, 100mA MAX current

(total)

*the polarity is directly dependant on the positioning and

conguration of the pressure sensor and motor.

Check Chapter 14 for more detailed information.

11 : 5.PL1000 pinout

Pin# Name IN OUT Impedance Description

1 BY31

2-4-5 BY41

3 BY21 RESERVED

6 BY 11 RESERVED

2.7 k� + 47 � Unbalanc ed Input

2.7 k� + 47 �

Unbalanced

Output

PL15LPL15

N

GND

8 | M-Drive | User guide

11 : 6.PL22 / PL23 pinout

Pin# Bias Description

1 – – 12 VDC OUT

2 + + 12 VDC OUT

3 – – 12 VDC OUT

Maximum available current:

100 mA

Page 19

11 : 7.PL21 pinout

PIN# NAME TYPE DESCRIPTION RANGE IMPEDANCE/NOTES

1 SDPWS

2 READY 1

IN

OUT

PSU shutdown. Active HI 3,3VDC<VIH<12V

DC

High when PWM is ON 3,3VDC<VOH<5VDC | 0VDC<VOL<1V

3 RESERVED

4 RESERVED DO NOT CONNECT

5 GND

6 I N 1+

7 IN 1-

8 GND

9 VOUTMON

10 PROTECT

11 IOUTMON

12 TEMPMON

13 +1 2V

14 -12V

15 MUTE

16 +VCCMON

17 -VCCMON

18 -VCCMON

19 +VCCMON

20 MUTE

21 -12V

22 +12 V

PWR

IN

IN

PWR

OUT Output voltage monitor

OUT Low when output is in protect

OUT Output current monitor

OUT Output temperature monitor

PWR Regulated +12VDC supply (+/-5%) MAX current (tot) = 0,5A Protected with series Polyswitch

DC

PWR Regulated -12VDC supply (+/-5%) MAX current (tot)= 0,5A Protected with se ries Polyswitch

DC

IN HW mute (PWM off ). Active LO V

OUT Positive rail bus monitor Scale fac tor= 20V/V 4,5KΩ

OUT Negative rail bus monitor Scale factor= 20V/V 4,5KΩ

OUT Negative rail bus monitor Scale factor= 20V/V 4,5KΩ

OUT Positive rail bus monitor Scale fac tor= 20V/V 4,5KΩ

IN HW mute (PWM off ). Active LO Shorted to pin 15

PWR Regulated -12VDC supply see pin 14

DC

PWR Regulated +12VDC supply se e pin 13

DC

Bal. IN (non-inverting)

Unbal. IN ( non-inv. p7 to GND) 20KΩ (unbal)

Bal. IN (inverting)

Unbal. IN ( inv. p6 to GND)

5,5V

input for full output

RMS

Absolute MAX input= 8V

0-8VAC (Scale factor= 20V/V ) 4,5KΩ

2VDC<VOH<10VDC | 0VDC<VOL<1V

0,17VDC min - 1VDC max (Scale Factor = 40A/ V) 4,5KΩ

0-5VDC (Scale factor)*

IL(max)

=0,2VDC | I

=20mA

sink

23~33 RESERVED

34 SDPWS

IN PSU shutdown. Active HI

see pin 1

RMS

(min)

1KΩ

DC

47KΩ - external cap. needed (1nF min)

DIFF= 20KΩ / CMODE= 20KΩ (bal)

DIFF= 20KΩ / CMODE= 20KΩ KΩ (bal)

10KΩ (unbal)

DC

Temperature dependant (≈7KΩ @25°C)

100KΩ

*TEMPMON table

Connections | 9

Page 20

11 : 8.SO5 pinout

PIN# NAME TYPE DESCRIPTION RANGE IMPEDANCE/NOTES

Output Voltage monitor. Positive

1 OU T+

2 GND

3 GND

4 IN+

5 IN-

OUT

PWR Ground 0V

PWR Ground 0V

IN

Unbal. IN ( non-inv. p7 to GND) 20KΩ (unbal)

IN

terminals

Bal. IN (non-inver ting)

Bal. IN (inverting) DIFF= 20KΩ / CMODE= 20KΩ (bal)

Unbal. IN ( inv. p6 to GND) 10KΩ (unbal)

5,5V

Absolute MAX input= 8VRMS

6 B Y11

7 BY21

8 B Y41

9 NC

10 IOUTMON

11 PROTECT

OUT Output current monitor 0,17 VDC min - 1VDC max (Scale Factor = 40A/ V) 4,5KΩ

OUT Low when output is in protect 2VDC<VOH<10VDC | 0VDC<VOL<1V

12

13

14

15

16 GPIO34

17 GPI O18

NC

OUT Hardware overcurrent protection

OUT Hardware overcurrent protection

Shorted to GND: OVC Prot status active

Shorted to GND: OVC Prot status active

18~21 RESERVED

22 GND

PWR Ground 0V

23~27 NC

28 TEMPMON

29 GND

30 +VCCMON

31 GND

32 -VCCMON

33 GND

34 -12V

35 +12 V

OUT Output temperature monitor 0-3,3VDC (Scale factor) See TEMPMON table

PWR Ground 0V

Positive rail bus monitor Scale factor= 20V/V 4,5KΩ

PWR Ground 0V

Negative rail bus monitor Scale factor= 20V/V 4,5KΩ

PWR Ground 0V

PWR Regulated -12VDC supply (+/-5%) MAX current (tot)= 0,5A Protected with se ries Polyswitch

DC

PWR Regulated +12VDC supply (+/-5%) MAX current (tot) = 0,5A Protected with series Polyswitch

DC

36

37

38 +12 V

39 -12V

40 GND

41 -VCCMON

PWR Regulated +12VDC supply (+/-5%) MAX current (tot) = 0,5A Protected with series Polyswitch

DC

PWR Regulated -12VDC supply (+/-5%) MAX current (tot)= 0,5A Protected with se ries Polyswitch

DC

PWR

OUT Negative rail bus monitor Scale factor= 20V/V 4,5KΩ

42 NC

43 +VCCMON

44 GND

45 TEMPMON

OUT Positive rail bus monitor Scale fac tor= 20V/V 4,5KΩ

PWR Ground 0V

OUT Output temperature monitor 0-3,3VDC (Scale factor) See TEMPMON table

46~49 RESERVED

50 NC

51 GND

PWR Ground 0V

160V 1kΩ

input for full output

RMS

DC

RESERVED

OPEN: normal operation

OPEN: normal operation

RESERVED

DIFF= 20KΩ / CMODE= 20KΩ (bal)

100KΩ

Apply 4,7kΩ external resistor.

Apply 4,7kΩ external resistor.

10 | M-Drive | User guide

Page 21

PIN# NAME TYPE DESCRIPTION RANGE IMPEDANCE/NOTES

52 SDPWS

I N PSU shutdown. Active HI 3,3VDC<VIH<12V

53~57 NC

58 MUTE

IN HW mute (PWM off ). Active LO V

IL(max)

=0,2VDC | I

59~62 NC

63 IOUTMON

OUT Output current monitor 0,17Vdc min - 1Vdc max (Scale Factor = 40A /V) 4,5KΩ

64 NC

65~69 RESERVED

70

71

GND

72 VOU T-

PWR Ground 0V

Output Voltage monitor. Positive

OUT

terminals

DC

=20mA

sink

(min)

160V 1kΩ

Connections | 11

Page 22

Hardware protections

12

The architecture of Powersoft’s ampliers encompass

several protection mechanisms triggered by harmful signal

and temperature. Protection systems and triggers are

independently implemented in the power supply section

(power supply protection) and the amplier section (amplier

protections). (ref. Chapter 15 : 3.Advance d param eters).

12 : 1.Thermal Protections and Fan Control

Fan starts to run as soon as the amp module measures

a temperature greater than 35°*, the fan control keeps fan

at maximum speed for the rst 2s, then its speed will be

controlled according to operating temperature.

When the amp module reaches 45°**, or when the

module reaches the 500 W threshold, the fan starts to run

at maximum speed.

At 60o the temperature Led will turn solid on, at 80o the

unit will shutdown.

The temperature of the Amplier section is monitored

and replicated on the 34 poles interface connector

according to the TEMPON table:

TEMP (OC) TEMPMON (V)

0 2.69

5 2.57

10 2.44

15 2.30

20 2.16

25 2.00

30 1.85

35* 1.70

40 1.55

45** 1. 41

50 1.28

55 1.15

60 1.04

65 0.93

70 0.84

75 0.76

80 0.68

85 0.61

90 0.55

95 0.50

100 0.46

12 : 2.Power supply protections

Power supply protections aim to isolate a faulty section

in electrical power system from the rest of the device in

order to prevent the propagation of the fault and limit device

damages.

12 : 2.1. Primary AC mains overcurrent protection

AC main overcurrent are ltered by two 10 A time-lag

fuses (also known as time-delay or low blow-fuse). The

purpose of the time lag fuses is to allow the supply in

electricity for a short time before the fuses actually blow. If

the time-lag fuses blow out, the amplier switch off; replace

the fuses with proper 10 A time-lag fuses in order to restore

the full functionality of the amplier.

12 : 2.2. Primary AC mains overvoltage protection

AC mains overvoltage threshold is set to 295 V

AC mains voltage exceeds 295 V

working; the device does not turn completely off but falls in

a “sleeping” mode: the power supply turns on again when

the AC mains voltage drops under 290 V

AC mains overvoltage are well tolerated by the power

supply: no damages can be caused to the system even in

case of severe overvoltage up to 400 V

the power supply stop

rms

.

rms

.

peak

. If the

rms

12 : 2.3. Primary thermal protection

The temperature is detected at power supply and triggers

the heat dissipated by the device: if the temperature rises

exceeding components tolerances, the primary hardware

thermal protection starts lowering the rails voltage in order

to lower the heat wasted and keep the overall efciency

high.

The process is drived by the DSP section of the Control

Board and is auto-adaptive, aiming to maintain the system

up even in heavy thermal condition.

12 : 3.Amplifier protections

The amplier section protections are managed by the

DSP section on the Control Board and can be customized

by means of the ArmoníaPlus software.

12 : 3.1. Auxiliary power protections

Auxiliary plugs are protected against short circuit: a

poliswitch opens the auxiliary circuits when the current

drawn exceeds 1 A.

12 : 3.2. Secondary overcurrent protection

A secundary protection on the load shuts down the

amplier section when an output current greater than 200 A

is detected.

peak

12 | M-Drive | User guide

Page 23

LED chart

13

13 : 2.SIMM board LED chart

D2 D8 D5

Color Code Signal Lighting

GREEN D2 +5V

RED D4 signal clip ON

GREEN D5 ready SOLID ON

RED D8 protection active ON

DC

SOLID ON

D4

13 : 1.Interface board LED chart

For a comprehensive control on system status refer

to the ArmoníaPlus metering interface (ref. Chap ter 15 : 5.

Metering).

Color Label Signal Lighting

Signal protection

RED PROTECT

RED LIMIT Limiter active SOLID ON

GREEN SIGNAL Input signal present SOLID ON

GREEN E.SAVE

YELLOW TEMP

GREEN READY

GREEN ON System on SOLID ON

active

No pressure sensor

connected

Energy save mode

active

Thermal protection

active

No faults, system

fully operating

SOLID ON

BLINKING

SOLID ON

SOLID ON

SOLID ON

13 | M-Drive | User guide

FIGURE 12: M-Drive interface plate.

Page 24

Pressure sensor

polarity ok

reverse polarity

polarity ok

14

In order to guarantee high system performance, the

proper placement of the pressure sensor on the loudspeaker

cabinet and the correct connection of the transducer to the

M-Drive are paramount.

WARNING!

Inadequate or wrong positioning of the

pressure sensor can easily damage the amp

module and the loudspeaker permanently.

The pressure sensor must be mounted on the front side

of the loudspeaker cabinet as close to the diaphragm as

possible.

The protruding black cylinder must be inserted in a 10

mm hole.

Cabinet

2. If the motor is mounted outside the cabinet and pointing inwards, and the pressure sensor is mounted inside the cabinet, pointing outwards, reverse the specied polarity when connecting the M-Force.

Pressure

sensor

M-Force

M-Drive

amp module

FIGURE 13: Pressure sensor placement

Note the polarity in the 3 possible congurations:

1. If both the motor and the pressure sensor are mounted

inside the cabinet, pointing outwards, follow the specied polarity when connecting the M-Force.

Pressure

sensor

M-Force

M-Drive

amp module

3. If both the motor and the pressure sensor are mounted

outside the cabinet, pointing inwards, follow the specied polarity when connecting the M-Force.

M-Drive

amp module

Pressure

sensor

M-Force

Pressure sensor | 14

Page 25

Initialization

15 : 1.DPC Programming System

The DPC technology represents the most effective tool available for the acoustic designer to achieve unprecedented results

in terms of control over the transducer displacement and system performance in low frequencies. Thanks to the differential

pressure control, the behavior of subwoofer and low frequency applications can be modeled in order to modify the systems

response, increase sound pressure level capabilities and enhance the overall efciency.

A DPC system is composed by:

Class-D amp module;

differential pressure sensor;

Zero-latency DSP board;

low impedance transducer

The DPC system performs a real time feedback between the actual acoustic emission of the loudspeaker and the

instantaneous displacement of the transducer. By knowing the pressure eld generated by the loudspeaker, the Zero Latency

DSP controls the transducer displacement and adaptively modify the system emission. The system is capable to overcomes

transducers non linearities, offering a complete control over sonic performance. In addition, DSP provides the needed

algorithms for a complete loudspeaker tuning.

Using ProManager Plus™ is possible creating a custom model based on Zero Latency DSP (included on M-Drive) or based

on an additional Powersoft DSP-4. Once you have created and exported the custom Armonía Plugin, the loudspeaker equipped

with M-Drive can be recognized and managed via ArmoníaPlus™ software.

Initialization | 15

Page 26

15 : 2.initialization framework

15 : 2.1. Initialization workflow

In order to initialize the DSP on board and external Powersoft DSP, the ProManager Plus™ proposes two approaches:

Powersoft init or Custom init. The former initializes your DSP with default settings, while the latter initializes the DSP with your

custom processing and it will allow ArmoníaPlus™ to identify your system as proprietary. As shown on the workow, before

directly proceeding with a custom initialization of the DSP, you are required to create a valid custom model for your product in

which the presets – previously created for the Powersoft model with ArmoníaPlus™ – will be included.

This process of initialization will allow the DSP to take care of the processing and the level of the input signal according to

the known

characteristics of the Powersoft amplier module to which the DSP is associated to.

Furthermore, this process will also identify your DSP as part of a Powersoft system, which will

permit you to discover the device when online in ArmoníaPlus™. The latter is a fundamental requirement in order to create

your original processing and your proprietary DSP presets designed for your whole nished system.

STA RT

Register on

armoniaproman.powersoft.it

Chapter 14 : 2.2OEM

Manufacturer

Registration

Obtain your

Manufacturer Code

Chapter 14 : 3.4.

DSP initialization as

Powersoft model

Chap te r 21.3

Program your DSP

as a Powersoft model

Chapter 14 :2. 3.

Software installation

Chapter 14 : 2.4.

Activation of the

Armonía ProManager

Initialize the DSP as a

Powersoft model with

ProManager Plus

Create your custom pre-

sets with ArmoníaPlus

Expor t your custom presets

Download and install

ArmoníaPlus

Download and install

ProManager Plus

Activate the

ProManager Plus

NOT YES

Already created your

CUSTOM MODEL

Chapter 25

DSP initialization

as Custom model

Initialize the DSP as you

CUSTOM MODEL with

ProManager Plus

END

Chapter 24

Create your

custom model

16 | M-Drive | User guide

Create your CUSTOM

MODEL in ProManager Plus

Page 27

15 : 2.2. OEM Manufacturer Registration

armoniaproman.powersoft.it

Register on

Obtain your

Manufacturer Code

To ensure exclusivity and private access to your Custom Armonía, Powersoft requires you to be registered on the

development scheme. Once registered, you will be provided of a unique Vendor Code which will grant condential access to

the ProManager Plus™.

1. Acces the the OEM Manufacturer webpage for

registration at:

http://armoniaproman.powersoft.it

2. Click on Register Here

3. Fill in all the cells with the required information

4. Accept the privacy policy

5. Click on Register

5. Go to your registered e-mail address’ account, and

check for the OEM Manufacturer Registration Conrmation

(within max 24h)

Save in your PC the attached License

6. Now, going Back to the OEM Manufacturer home

page

http://armoniaproman.powersoft.it

Have a login using User Name and Password just

registered. You will be able to see your registration details

and links where download ProManager Plus™

7. Download ProManager Plus™.

Initialization | 17

Page 28

15 : 2.3. Software installation

1. Install ArmoníaPlus™ before the ProManager Plus in

order to gain complete access to the default presets bank

ArmoníaPlus™ is the software for setting and monitoring

your system.

ArmoníaPlus™ allows you both on-line ans off-line

system setup, tuning and real-time management and

monitoring of all vital functions from a remote PC via a

single intuitive graphical user interface.

Download ArmoníaPlus™ from the Armonía web-site:

https://armonia.powersoft.it/

2. Install the ProManager Plus™.

3. Launch ProManager Plus™.

Do not run ProManager™ and

ArmoníaPlus™ at the same time

Take care to switch off ArmoníaPlus™ when you want to

initialize your M-Drive IK with the ProManager Plus™.

Since both softwares try to access the DSP on board of

the M-Drive IK, the system will become instable impeding

any conguration.

Download and install

ArmoníaPlus

Download and install

ProManager Plus

15 : 2.4. Software Activation

1. Open the ProManager Plus™: at the rst start up

the program will ask you to authenticate your account: in

this phase an internet connection is mandatory in order to

complete the activation process.

2. Fill in the cell with the information of your Account or

import the license received in attachment to conrmation

email, using Import button

3. You can now start using the ProManager Plus™ for

DSP initialization and for customizing your system.

Activate the

ProManager Plus

18 | M-Drive | User guide

Page 29

M-Drive DSP initialization

16 : 1.Required tools

Windows XP/7/8/10

15 : 2.5. Connection

1. Connect the amp module to the computer via the

RS485 connection on the interface board.

2. Set a unique ID number on the interface board by

means of the two rotary knobs: allowed values range from

01 to 99; 00 is reserved.

16

3. Turn the amplier module on.

16 : 2.Programming Cable and Adapter

PIN SIGNAL

1 GND

2 V

3 +

4 -

5 -

6 +

7 V

8 GND

In order to implement a RS-485 port on a personal

computer Powersoft recommend the use of the SPECTRA

USB 2.0 to RS-485 converter. A DB9 to RJ45 adapter is

needed as well.

ext

ext

M-Drive DSP initialization | 19

Page 30

16 : 3.DSP initialization as Powersoft model

1. Open ProManager Plus™

2. Click on the DSP Initializer button

3. Select the correct serial port by pressing Play

4. Press Discovery

5. Select the on-line system (Unknown model) and click

on Next

Initialize the DSP as a

Powersoft model with

ProManager Plus

6. Click on Powersoft model

Custom Model button is disabled until you will make at

least one custom model based on M-Drive.

7. Fill in the cells with the required info

8. Select what kind of preset you want to store on your

M-Drive; you nd the Pam Description for each selected le

then click on Start

20 | M-Drive | User guide

Page 31

9. Wait until DSP is successfully initilized

10. Close ProManager Plus™, only when the DSP has

been correctly initialized.

Create your custom pre-

16 : 4.Programming M-Drive DSP

At this stage you should have already initialized your DSP board as a Powersoft model. This includes also some default

presets’ schemes designed by Powersoft, which are intended to represent a good starting point for your evaluation of the

amplier, for a proper tuning of your speaker and for desired signal processing that you want to apply on your nished product.

The nal steps of this chapter will also guide through the process of exporting the presets that you have designed as .pam les.

The exportation of these presets is an essential action if you desire to create a custom model for ArmoníaPlus™. In fact, you

will be asked to import them on following steps.

sets with ArmoníaPlus

16 : 5.Setting M-Drive serial port

16 : 5.1. Automatic Discovery

1. Connect the amp module to the computer via the

RS485 connection on the interface board.

2. Set a unique ID number on the interface board by

means of the two rotary knobs: allowed values range from

01 to 99; 00 is reserved.

3. Turn the amplier module on.

4. Verify the name assigned to the RS485 communication

port on your PC operating system (this can be done through

Microsoft Windows® Device Manager): the name should be

something like COM5, COM6 or so on, depending on the

number of the system built-in COM ports.

5. Open ArmoníaPlus, press the cogwheel in the lower

right-hand corner select the tab “Communication Manager”

on the option menu.

6. Make sure that the shown serial port number

corresponds to the USB-to-RS485 converter and press

Play for activating it, then press Apply.

7. Close the Option menu by clicking on OK.

M-Drive DSP initialization | 21

Page 32

8. In the ArmoníaPlus™, go in the Match view and click

on Discovery button . All connected amp modules will be

detected and automatically shown on the amp list in the

Status section.

9. Drag the discovered model onto the workspace and

wait it becomes green (device is on-line)

10. Go in the Select view , double click on the model

11. M-Drive as should appear at rst opening

M-Drive DSP has two access levels based on kind of user:

1) Monitor view – for end user

2) Advanced view – for manufacturer

22 | M-Drive | User guide

Page 33

16 : 5.2. Monitor View

By clicking on the amplier module, at rst opening you enter the Monitor view of the module, designed for the end user. In

fact, all accessible settings do not permit to change internal DSP processing except delay, mute state and reverse polarity. The

gain fader behaves as an attenuator; the max level is provided than the gain amount set inside the DSP.

Clicking on Advanced view , is possible entering deep inside in DSP processing, of course this is permitted only for a

manufacturer with a pre-registered M-Drive license, Advanced view button does not show in case of missed license. When you

pass in Advanced view rst time after the initialization as Powersoft Model, no password will be requested.

16 : 5.3. Advanced View

The advanced view provides a set of algorithms for tuning loudspeaker, including the DPC and impedance control.

M-Drive DSP initialization | 23

Page 34

16 : 5.4. Global Settings

16 : 5.4.1. Input gain

Set the maximum volume of the

input signal. The attenuator knob

on the interface board modies

the signal volume in series with

the internal settings, it is possible

disabling the external gain in the

internal settings. In the Monitor view,

input gain behaves as attenuator with

a max value set than the gain value.

So, end user has the possibility just

to attenuate the signal.

16 : 5.4.3. Delay

The input signal can be delayed

by user denable amounts via the

delay processing block. Parameters

can be accessed

and set both from Advanced

view and Monitor view. Delay values

can be entered in the time domain

(us) or as physical linear distances

(in mm or in inches).

16 : 5.4.2. Polarity

The input signal can be phase

reversed by clicking on this button.

Polarity button is available for the

end user in the monitor view.

The Mute button is provided as

well to mute audio playback.

16 : 5.4.4. Safe mode and Mute

Some settings may bring to

system instability and critical

operating condition. The Safe Mode

button provides a protection against

critical settings: when activated, this

function will not allow the output

power to exceed a set limit (about

20W set on Power Limiter).

16 : 5.4.5. Parametric equalizer

A fully parametric equalizer processing blocks are available

to ne tune the system’s sound.

Each individual selected lter can however be enabled switching on the on/off switch. A list of parameter presets of commonly

used equalization schemes is available under Type combo box. For each kind of equalization, you can set Frequency, Q, Gain

(when available) using the sliding box. A log scale diagram of each lter’s effect is presented, the slider on lters allows

real time variations of lter parameters such as the lter’s central frequency, gain, Q.

24 | M-Drive | User guide

Page 35

16 : 5.5. Pressure Model Operating Mode

The amplier’s output signal is modied in real time as a result of the combination of the input audio signal and the feedback

loop. The alteration is applied to the input stage so to minimize the difference between the desired output and that measured

and reported by interpolating two the feedback loops.

16 : 5.5.1. Pressure Control (pressure feedback loop)

This loop brings the pressure level measured at the radiating sound eld, back to the input stage. This is achieved by

feeding the pressure sensor measurement through a rst order low pass lter (LPF) and a linear amplier. The parameters that

can be set by the user for this feedback-loop therefore are:

The loop gain, expressed in dB and limited by the system’s stability, dening the

strength of the feedback effect;

The LPF bandwidth, dening the top frequency of the band at which this feedback loop

is active;

The HPF bandwidth, dening the bottom frequency of the band at which this feedback

loop is active.

It is important to set the loop gain carefully, as too high a value will bring the system to instability. This results in a loud

“ship’s horn” sound which can potentially damage the system if not silenced after a short time. This can be done by lowering

the feedback loop gain until the sound stops. The entire pressure feedback loop can be bypassed by entering

16 : 5.5.2. Impedance Control (current feedback loop)

This loop brings back a voltage signal proportional to the current present at the output stage to the system’s input. The

signal taken from the output is rst ltered by a rst order low pass lter. Following this step, the current/voltage translation is

carried out by a virtual resistor named “Re”. The importance of this series resistor relies in the difference between traditional

transducers and M-Force.

M-Force has an extremely low impedance. This means that they manifest a

violent, extremely high Q resonant peak which can result in an unnatural sound

reproduction. By adding a virtual series resistor Re, the entire system’s resonant

peak will be slightly attened and widened in a way that mimic’s a traditional

speaker’s lower Q resonance. This resistor will however not affect the power

transfer from input to output as this is not a “real” physical resistor subject to

ohmic heating. The parameters the user can set for this feedback loop therefore

are:

The “added Re” value, dening the additional series resistor inserted to simulate a traditional

speaker behavior. This is usually a small number, which aims to return the apparent

loudspeaker resistance to a traditional 2-4 Ohm value;

The LPF bandwidth, dening the range of frequency at which this feedback loop is active.

16 : 5.6. Internal parameters

Click on the cogwheels button to access the Internal parameters window.

M-Drive DSP initialization | 25

Page 36

16 : 5.6.1. Disable External Knob

By clicking on this box is possible disabling the external attenuation knob, this must be

done in case of external processor like DSP-4 connected to M-Drive.

16 : 5.6.2. Current Limiter

Set a threshold limit and the attack/release time for the average (rms) output current.

16 : 5.6.3. Power Limiter

Ensures that the real part of the average output power does not exceeds the limits set

by the user.

16 : 5.6.4. Current Clamp

The Current Clamp is a faster acting current limiter. Current Clamp is meant to limit

spikes of current, effectively protecting the output stage and the connected loudspeaker

from dangerous high peak current: this is different respect the short circuit protection that

works by sensing decreasing rails values. The current threshold value does not indicate the

maximum output current, but the current level at which the limiter will start sensing spikes

of current. Output current level can exceed the clamp threshold considerably due to the

internal limiter design.

16 : 5.6.5. Efficiency Protection

Set the minimum threshold limit of the measured efciency that triggers the protections

on the amp module. The pressure sensor continuously measures the acoustical output

power developed by the diaphragm: when the acoustical output power falls under

the expected output power, the efciency of the system lower accordingly. This can

be occasionally caused by a fault either in the amp module or in the transducer motor.

Powersoft recommends to set the efciency protection at least to 1/3 of the value of the

reference loudspeaker efciency (Ref eff. no%, see below). The value 0 (zero) switches off

the efciency protection. If the pressure sensor is not used, set the efciency protection to

0 (zero).

16 : 5.6.6. Excursion Limiter

The excursion limiter keeps the loudspeaker cone displacement within a user dened

range. The threshold cone excursion is set in mm. The excursion limiter works through

a current loop, dynamically changing the value of a resistance proportionally to the

displacement of the cone with respect to its resting position. It is important to note that

this position is estimated; its accuracy depends on the precision of the connected speaker

physical parameters entered in the Physical Speaker Parameters section in the advanced

parameters window (see below). The Gain (ohm/cm) parameter sets the displacement/

resistance conversion factor, so as to regulate the intensity of the limiting effect. For a given

cone displacement, a higher gain value yields a more severe limiting action. The release

time determines the time needed for the limiter to release the cone. Please note that the

maximum cone excursion set in this window only determines the cone displacement value

that activates the effect of the limiter; it does not represent the maximum excursion the

cone will display. The limiter’s internal design allows for a certain margin between maximum

displacement threshold value and effective cone displacement, the latter being potentially

higher.

26 | M-Drive | User guide

Page 37

16 : 5.6.7. Gate

The system is equipped with a gate output block intended to improve the overall signalto-noise ratio. The gate reduces the output gain for small signals interpreted as noise. The

hold time indicates how long the gain reduction occurs after the output signal falls below

the threshold. The attenuation parameter indicates the amount by which then output gain is

decreased withn respect to no attenuation. Note that the system gain changes slowly and

not abruptly so the effect is unnoticeable.

16 : 5.6.8. Voltage RMS Limiter

Set a threshold limit and the attack/release time for the average (rms) output voltage.

16 : 5.7. Metering

Metering are divided in two parts, one regarding M-Drive amplier and one regarding the M-Force and loudspeaker volume.

Where is present, the red line indicates the threshold level in according with respective limiter.

16 : 5.7.1. M-Drive metering

Input (Vpk) – Input peak voltage measured before input gain/attenuation processing: the meter therefore represents the

signal level entering the system before any processing is performed.

Output Voltage (Vpk) – Output voltage peak level. The Limit red LED underneath the meter strip lights when the measured

output voltage is being clipped to the system’s maximum possible voltage level.

Output Voltage (V

) – Output voltage rms level. The Limit red LED underneath the meter strip lights when the measured

rms

output voltage is being clipped to the system’s maximum possible voltage level. Red line refers to Voltage RMS Limiter threshold.

Output Current (Apk) – Peak output current. The Limit red LED underneath the meter strip lights when the measured output

peak current rises above the limit set in the current clamp threshold. Red line refers to Current Clamp threshold.

Output Current (A

) – Root mean square current value. The Limit red LED underneath the meter strip lights when the

rms

measured output average current exceeds the limit set in the current limiter threshold. Red line refers to Current Limiter

threshold.

Output Peak Power (VApk) – Peak output power.

Output Avarange Power (W

) – Average output power. The Limit red LED underneath the meter strip lights when the

avg

measured average power rises above the limit set in the power limiter threshold section. Red line refers to Power Limiter

threshold, when Safe mode is engaged, threshold set to 20W.

16 : 5.7.2. M-Force metering

Excursion (mmpk) – Peak estimated cone excursion with respect to the central resting position. The Limit red LED

underneath the meter strip lights when the estimated cone excursion goes beyond the limit set in the excursion limiter threshold

section. Red line refers to Excursion Limiter threshold.

Acoustic Pressure (g/cm2pk) – Peak pressure level as measured by the pressure sensor.

Acoustic Power (W

Impedance (Rayls) – Estimated average acoustic impedance.

Acoustic Efficiency (%

) – Estimated average acoustic power.

awg

) – Estimated acoustic efciency.

eta

M-Drive DSP initialization | 27

Page 38

16 : 5.8. Locking

Normally the manufacturer take care for locking this view after he nished loudspeaker tuning, since DSP processing is part

of his know-how. When you enter in the Advanced view rst time, no password required, by pressing Lock button rst time, a

pop up, where you can set password, will appear; until you press Lock button, M-Drive and so pam les exported remain not

locked by password.

Make attention: password is saved on board M-Drive and in the pam le when you export it, only pam les with a same

password than M-drive will open.

Each time you press Lock button you will pass to monitor view directly; if you want to pass again to advanced view you

need to type the password for opening. Use monitor view button for closing the advanced view and return to Monitor view

maintaining the M-Drive not locked by password, in this case if you want to pass again to advanced view, no password will be

requested.

M-Drive Export Pam files

Not Locked M-Drive

Locked M-Drive

Change Password Password changed only for M-Drive

M-Drive accepts all pam le from M-Drive not

locked

M-Drive accepts all pam le with the same

locking password

Pam les compatible with all not locked M-Drive

Pam les compatible with M-Drive has same password

Pam les previously exported from M-Drive with old password become

not compatible.

Expor t your custom presets

16 : 6.Export Custom Presets

Once you reached the best performance in terms of DSP processing as you want, export your preset returning in the Select

view.

1. Right click on the device

2. Select PAM > Export

3. Assign a name to your Preset and save

28 | M-Drive | User guide

Page 39

Create your CUSTOM

Creating Custom models

On this chapter we will give birth to the custom model, which represents your nished product (speaker, rack amp) that you

aim to manage using ArmoníaPlus™. In fact, we will create a software plugin so that the ArmoníaPlus™ is able to accept and

to recognise your custom model as it was dened.

MODEL in ProManager Plus

17

17 : 1.DPC Custom Model Builder

1. Open ProManager Plus™

2. Click on the Custom Models Builder button

This is the model list, in this window are listed all custom

model you will create.

3. Click on New Model on the bottom-right corner

4. Fill in the cells with the required informations:

Based on: DSP in use

Product name: your product name

Family: your product version

Series Name: your product serie

Description: the description of your device that will

appear in ArmoníaPlus

Choose a suitable image for your system/model,

suggested size: 350 max width, 250 max height

Preset: Load the presets that you have previously

exported from ArmoníaPlus™

Click Save and conrm

Creating Custom models | 29

Page 40

17 : 2.Export Custom Model

When you nish creating custom models you can export all building to plug-in to install. You cannot export single models;

custom model builders will take all listed models. Exported Plug-in will override all its content each time is installed.

1. Click on Export

17 : 3.Install Custom Model

1. Go to the path previously specied and double click

on the le (.exe)

2. Follow the installation wizard of your custom model

library for ArmoníaPlus™

3. Share the plugin le with your clients

30 | M-Drive | User guide

Page 41

Initialize the DSP as you

CUSTOM MODEL with

17 : 4.Initialize M-Drive DSP as Custom Model

If you have come to this stage it means that you have created a software plug-in for ArmoníaPlus™ which contains all the

parameters, names, descriptions and presets that characterize your nished product. Here we show how to straightforwardly

initialise each of your products with custom settings. This may represent a good solution if, in ArmoníaPlus™, you want to

immediately identify your proprietary product with the parameters that characterize it. Please note that the Custom Init button

is disabled if no Custom model are yet available on your list.

1. Open ProManager Plus™

2. Click on the DSP Initializer button

3. Discover the M-Drive using selected Com port as

shown previously and press Next

ProManager Plus

4. Select Custom Model

5. Select the model you have created during earlier

stages

6. Specify the product serial assigned to your system/

model

7. Choose a rmware version to be stored on your DSP

or tip the Skip rmware update check box

8. Press Start and wait until the DSP is successfully

initialized. At the end of initialization, device will be ready to

be recognized by Plugin previously installed.

Creating Custom models | 31

Page 42

17 : 5.Add online Custom Model

From this step onwards, your product will appear and will be recognized in ArmoníaPlus™ as custom and the model will

include all the proprietary processing and customization that you have applied using the ProManager™.

1. Open ArmoníaPlus™

2. Enable the serial virtual com port in the communication

manager

3. Go in the Match view , click on Discovery and see your

system branded as proprietary

4. Drag your custom model onto the workspace

5. You can now manage your system on Armonía

17 : 6.Add offline Custom Model

As soon as you installed plugin, you can manage the custom model not only with an online device but even adding a virtual

powered speaker.

1. Go in the Add view

2. Click Powered Speaker

3. Choose your brand, family, model and kind of

application.

4. Press Add & Close

5. Blue frame means virtual Power speaker.

32 | M-Drive | User guide

Page 43

DSP-4 Initialization

18 : 1.Required Tools

Windows XP/7/8/10

18 : 2.Connection

1. Connect DSP-4 to the computer via Ethernet cable.

2. Turn the amplier module on.

18

18 : 3.DSP-4 initialization as Powersoft model

1. Open Armonía ProManager Plus™

2. Click on the DSP Initializer button

Initialize the DSP as a

Powersoft model with

ProManager Plus

DSP-4 Initialization | 33

Page 44

3. Select the Network Card where DSP-4 connected

pressing Play

4. Press Discovery

5. Select the on-line system (Unknown model) and click

on Next

6. Click on Powersoft model

Custom Model button is disabled until you will make at

least one custom model based on DSP-4.

7. Select Initializer as operating mode

8. Fill in the cells with the required info selecting

DSP40004 as DSP in couple with M-Drive.

9. Specify the product serial assigned to your system/

model

10. Choose a rmware version to be stored on your DSP

or tip the Skip rmware update check box

11. Press Start and wait until the DSP is successfully

initialized. At the end of initialization, device will be ready to

be recognized by Plugin previously installed.

12. Wait until DSP is successfully initilized

13. Close ProManager Plus™, only when the DSP has

been correctly initialized.

34 | M-Drive | User guide

Page 45

Create your custom pre-

18 : 4.Programming DSP-4

At this stage you should have already initialized your DSP board as a Powersoft model. This includes also some default

presets’ schemes designed by Powersoft, which are intended to represent a good starting point for your evaluation of the

amplier, for a proper tuning of your speaker and for desired signal processing that you want to apply on your nished product.

The nal steps of this chapter will also guide through the process of exporting the presets that you have designed as .pam les.

The exportation of these presets is an essential action if you desire to create a custom model for ArmoníaPlus™. In fact, you

will be asked to import them on following steps.

1. Open ArmoníaPlus™, press the cogwheel in the lower

right-hand corner select the tab “Communication Manager”

on the option menu.

2. Select the Network Card where DSP-4 connected

pressing Play, then press Apply.

3. Close the Option menu by clicking on OK.

4. In the ArmoníaPlus™, go in the Match view and click

on Discovery button. All connected amp modules will be

detected and automatically shown on the amp list in the

Status section.

sets with ArmoníaPlus