Page 1

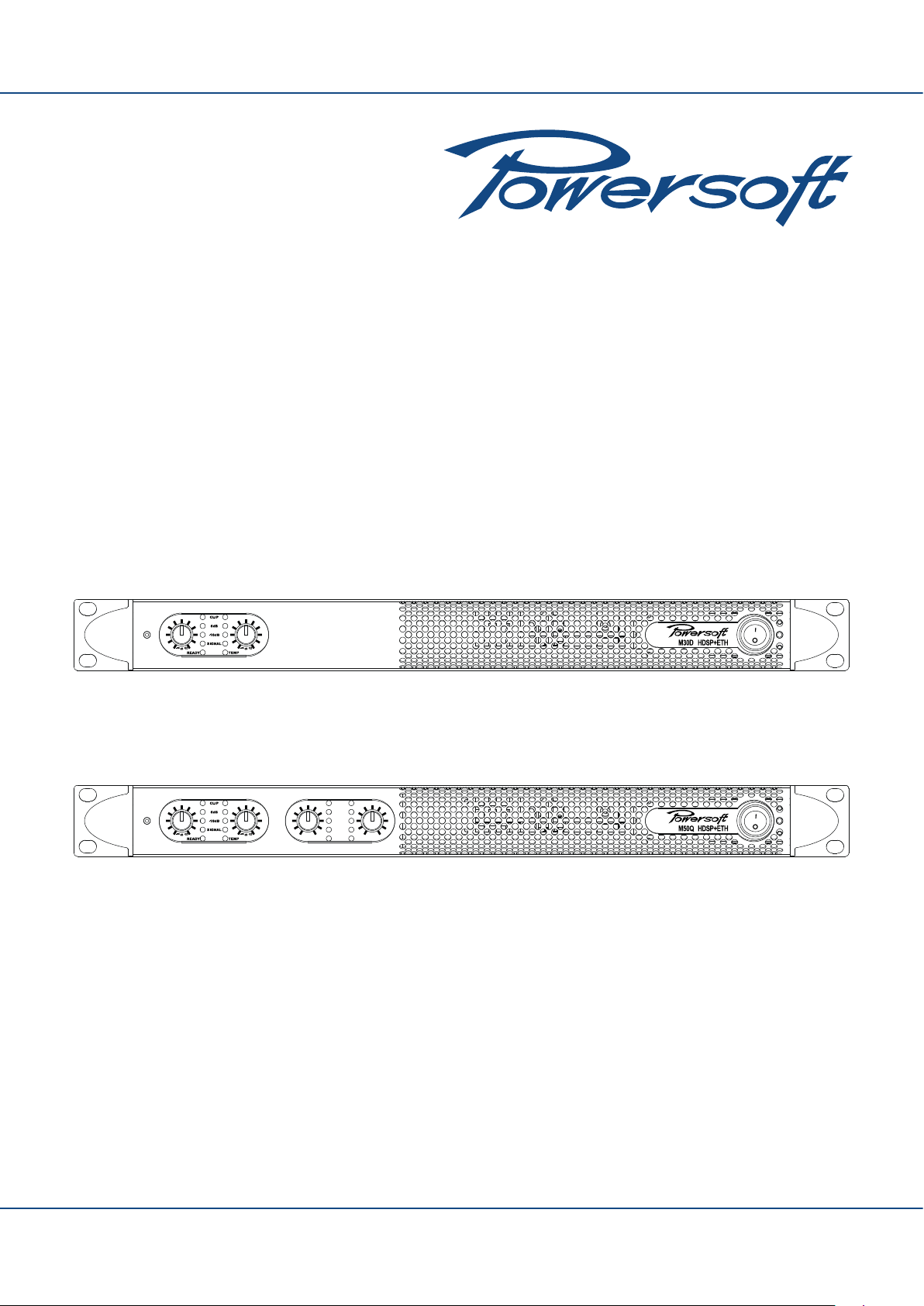

M Series ampliers

M30D / M30D HDSP+ETH

M20D / M20D HDSP+ETH

M14D / M14D HDSP+ETH

M50Q / M50Q HDSP+ETH

M28Q / M28Q HDSP+ETH

CLIP

6dB

-18dB

SIGNAL

8

-

+32

dB

READY

8

-

+32

dB

TEMP

powersoft_MSeries_uguide_en_v2.6

user guide

REV 1.1 August 2013

DO000100

Keep This Manual For Future Reference© 2012 - 2013 Powersoft

Page 2

Table of contents

1 Important safety instructions 4

2 Precautions regarding installation 4

2.1 Location 4

2.2 Wiring 5

2.3 Speaker damage 5

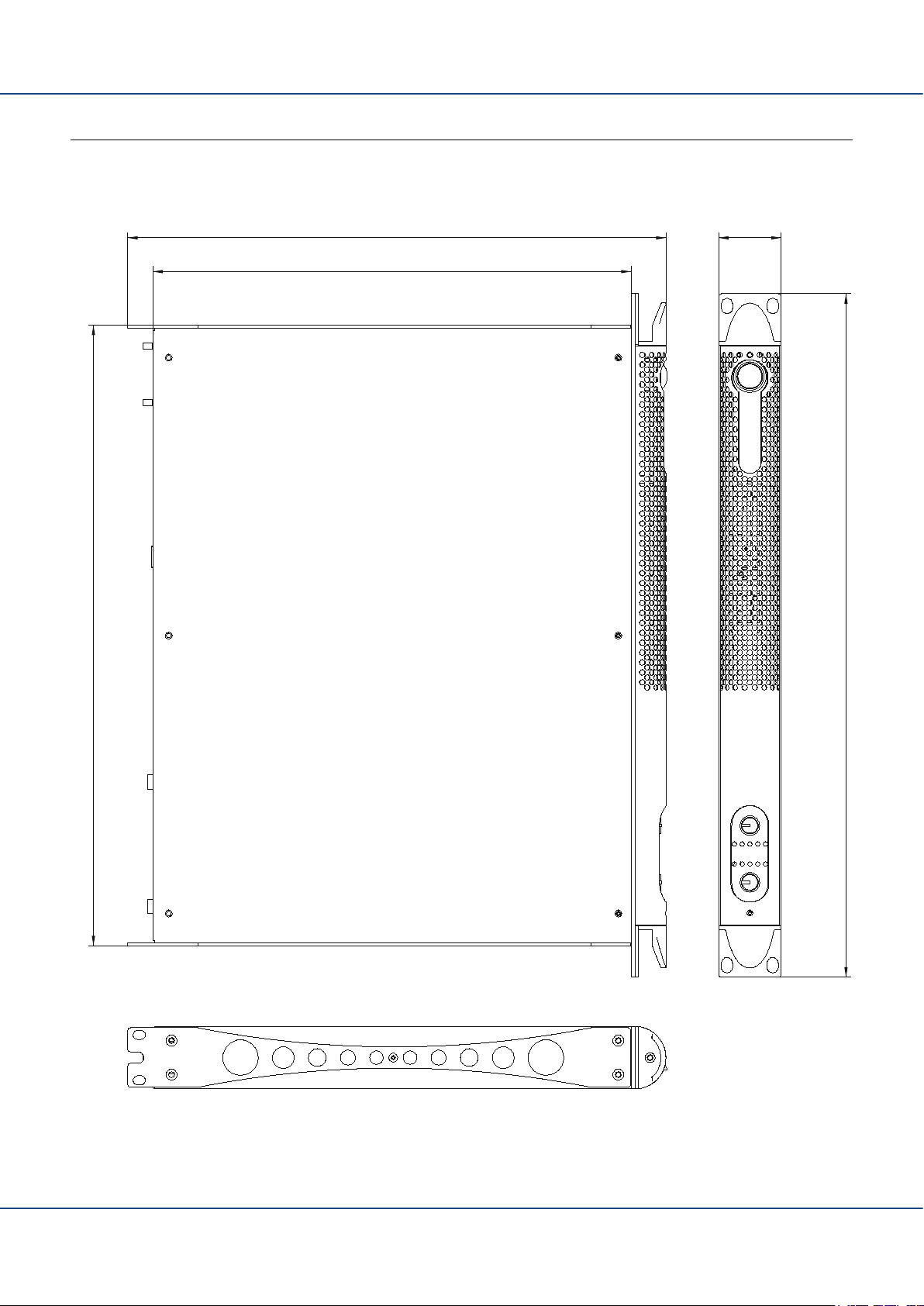

3 Mechanical drawings 6

4 Interfaces 7

5 Welcome 9

6 The M Series 9

6.1 More sound and less weight 9

7 Installation 9

7.1 Unpacking 9

7.2 Mounting 10

7.3 Cooling 10

7.4 Operating precautions 10

7.5 Grounding 10

7.6 AC mains connection 10

8 Connections and Operation 10

8.1 Front panel air lters access 10

8.2 Front panel adjustments 11

8.3 Front panel monitoring 11

8.4 Connecting audio inputs 11

8.4.1 MxxD models 11

8.4.2 MxxQ models 11

8.5 Connecting audio outputs 11

8.5.1 Lo-Z and 70V/100V operations 11

8.5.2 Bridge Mode Connection 11

9 M Series HDSP+ETH operation 12

9.1 Rear Panel LEDs 12

9.2 Ethernet por t and remote ID selection 12

9.3 V Ext 12

9.4 DSP features and operations 12

9.4.1 DSP Features 12

9.4.2 Input routing selection and internal signal route 13

9.4.3 Input section 13

9.4.4 Output section 13

9.5 Internal processing layout 13

9.5.1 Input routing 13

9.5.2 Input section 13

9.5.3 Output section 13

9.6 Locking 14

9.7 On/Off 14

9.8 Preset Management 14

10 Remote control 14

10.1 Networking 14

10.1.1 Discovery device 14

10.1.2 DHCP 14

10.1.3 AUTOIP 15

10.1.4 Static IP 15

10.1.5 Rever t from static IP 15

10.2 Setup device 16

10.2.1 Virtual device 16

10.2.2 Congure layout 16

10.2.3 Real device 16

10.3 File operations 17

10.3.1 Binary preset le .preset 17

10.4 Input/output curves .icp, .ocp 17

10.5 Channel preset .chp 17

10.6 Device preset le .pam 18

10.7 System File .paw 18

10.8 DSP remote operations 18

10.8.1 Routing 18

10.8.2 Input eq 18

10.8.3 Output eq 19

2

Page 3

M Series

User Guide

10.8.4 Limiters 19

10.8.5 RMS limiter 19

10.8.6 Peak limiter 19

10.8.7 Damping factor correction 19

10.9 Locking 20

10.10 On board preset operations 20

10.11 Copy and paste operations 21

10.12 Input/output eq curves 21

10.13 Channels 21

10.14 Workspace 21

11 Protection 21

11.1 Turn on/Turn off muting 21

11.2 Short circuit protection 21

11.3 Thermal protection 21

11.4 Thermal warning 22

11.5 Thermal shutdown 22

11.6 DC fault protection 22

11.7 Input/output protection 22

12 User Maintenance 22

12.1 Cleaning 22

12.2 Service 22

12.3 Dust Removal 22

18 Specications 25

M14D and M14D HDSP+ETH 25

M20D and M20D HDSP+ETH 26

M30D and M30D HDSP+ETH 27

M28Q and M28Q HDSP+ETH 28

M50Q and M50Q HDSP+ETH 29

Annex A: IP management and recovery 30

A.1.1 Reset IP conguration 30

13 Warranty 22

13.1 Product warranty 22

13.2 Return of Goods 22

13.3 Repair or replacement 22

13.4 Cost and responsibility of transport 22

14 Assistance 23

15 M Series power rating 24

16 Output SpeakON connection polarities 24

17 M Series load compatibility chart 24

3

Page 4

1 Important safety instructions

!

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT ATTEMPT TO OPEN ANY PART OF THE UNIT. NO

USER-SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THIS APPARATUS TO RAIN OR

MOISTURE. OBJECTS FILLED WITH LIQUIDS, SUCH AS VASES, SHOULD NOT BE PLACED ON THIS APPARATUS.

TO COMPLETELY DISCONNECT THIS APPARATUS FROM

THE AC MAINS, DISCONNECT THE POWER SUPPLY CORD

PLUG FROM THE AC RECEPTACLE.

THE MAINS PLUG OF THE POWER SUPPLY CORD MUST

REMAIN READILY ACCESSIBLE.

NOTES: This equipment has been tested and found to comply

by Competent Body (Directive 2004 /108 / EC) pursuant to the

product family standard for audio professional use: EN 55103-1

and EN 55103-2 standard.

This equipment has been tested and found to comply by Notied

Body 2014 (Directive 2006 / 95 / EC) pursuant to the audio apparatus safety requirements: EN 60065 and EN 6006/A1 standard.

EXPLANATIONS OF GRAPHICAL SYMBOLS

The Lightning Flash with arrowhead symbol within an

equilateral triangle is intended to alert the user to the

presence of uninsulated “dangerous voltage” within the

product enclosure that may be of sufcient magnitude to

constitute a risk of shock to persons.

The Exclamation Point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in the

literature accompanying the product.

2 Precautions regarding installation

2.1 Location

SAFEGUARDS: This unit has been engineered and manufactured

to assure your personal safety. Improper use can result in potential

electrical shock or re hazards. In order not to defeat the safeguards, observe the following instructions for its installation, use

and servicing.

f Read these instructions.

f Keep these instructions.

f Heed all warnings.

f Follow all instructions.

f Do not use this amplier near water.

f Clean only with a dry cloth.

f Ensure a proper ventilation.

f Install in accordance with Powersoft’s instructions.

f Do not install near any heat sources or apparatus that

produce heat.

f Protect the power cord from being walked on or pinched

particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

f Do not defeat the safety purpose of the polarized or

grounding-type plug. A polarized plug has two blades with

one wider than the other. A grounding type plug has two

blades and a third grounding prong. The wide blade or the

third prong are provided for your safety. If the provided

plug does not t into your outlet, consult an electrician for

replacement of the obsolete outlet.

f Unplug this amplier during lightning storms or when unused

for long periods of time.

f Contact the authorized service center for ordinary and

extraordinary maintenance.

f Only use attachments/accessories specied by Powersoft.

Install the amplier in a well-ventilated location where it

will not be exposed to high temperature or humidity.

Do not install the amplier in a location that is exposed to direct

sun rays, or near hot appliances or radiators. Excessive heat can

adversely affect the cabinet and internal components. Installation

of the amplier in a damp or dusty environment may result in

malfunction or accident.

Placing and using the amplier for long periods of time on

heat generating sources will affect its performance. Avoid

placing the amplier on heat generating sources. Install this amplier as far as possible from tuners and TV sets. An amplier

installed in close proximity of such equipment may experience

noise or generic performance degradation.

No naked ame sources such as lighted candles should be

placed on the amplier.

Do not spill water or other liquids into or on the amplier.

WARNING

To prevent re or electric shock:

f The ventilation openings must not be impeded by any item

such as newspapers, tablecloths, curtains etc; keep a distance

of at least 50 cm from the front and rear ventilation openings

of the amplier.

f Do not expose this amplier to rain or moisture.

f This equipment must not be exposed to dripping or splashing

liquids: objects lled with liquids, such as vases, must not be

placed on the amplier.

4

Page 5

2.2 Wiring

This device must be powered exclusively by ear th con-

nected mains sockets in electrical networks compliant to

the IEC 364 or similar rules. It is absolutely necessary to verify this

fundamental requirement of safety and, in case of doubt, require

an accurate check by qualied personnel.

POWERSOFT cannot be considered responsible for eventual

damages caused to persons, things or data due to an improper

or missing ground connection.

f Before powering this amplier, verify that the correct voltage

rating is being used.

f Verify that your mains connection is capable of satisfying the

power ratings of the device.

f Do not use this ampliler if the electrical power cord is frayed

or broken.

f Do not remove the cover. Failing to do so will expose you to

potentially dangerous voltage.

f Provide a sectioning breaker between the mains connections

and the amplier. The suggested device is a 16A/250V AC, C

or D curve, 10 kA.

f Switching mode amplier is capable of producing hazardous

output voltages. To avoid electrical shock, do not touch any

exposed speaker wiring while the amplier is operating.

This manual contains important information on operating your

Powersoft amplier correctly and safely. Please read it carefully

before operating your amplier. If you have any questions, con-

tact your Powersoft dealer.

2.3 Speaker damage

Powersof t switching mode ampliers are among the most

powerful professional ampliers available and are capable

of producing much more power than many loudspeakers can handle. It is the user’s responsibility to use speakers suitable to the

amplier and to use them in a sensible way that will not cause

damage.

Powersoft will not be held responsible for damaged speakers.

Consult the speaker manufacturer for power handling recommendations.

Even if you reduce the output volume using the amplier’s

front panel attenuation controls, it is still possible to reach full

output power if the input signal level is high enough.

A single high-power tone can damage high frequency drivers

almost instantaneously, while low frequency drivers can usually

withstand very high, continuous power levels for a few seconds

before they fail. Reduce power immediately if you hear any

speaker “bottoming out”: harsh pops or cracking distor tion that

indicate that the speaker voice coil or diaphragm is striking the

magnet assembly.

Powersof t recommends that you use ampliers in this power

range for more headroom (cleaner sound) rather than for increased volume.

5

Page 6

3 Mechanical drawings

437,6

379,5

337,3

44,1

482

FIGURE 1: M Series mechanical drawing. All dimensions in millimiters.

6

Page 7

1 2 3 4

6 7

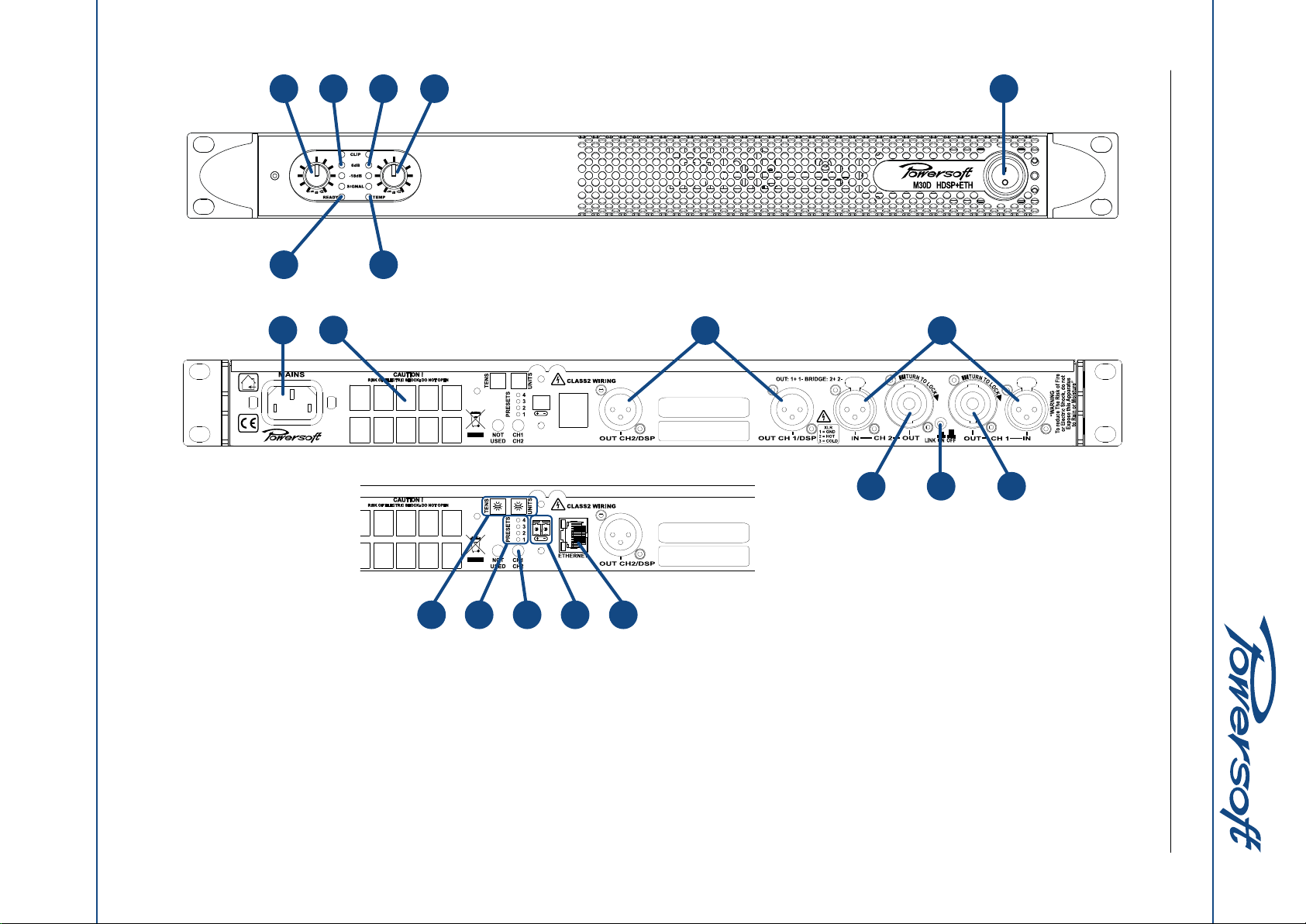

4 Interfaces

5

FIGURE 2: M Series – MxxD front panel view.

8

9

PAT. PEND.

10 11

Made in Italy

FIGURE 3: M Series – MxxD (non HDSP+ETH) rear panel view.

3

3

2

2

4

4

1

1

5

0

5

0

6

6

9

9

7

7

8

8

Made in Italy

12

13 14

FIGURE 4: M Series

15 16 17 18 19

1. Channel 1 input attenuator

2. Channel 1 meter LEDs

3. Channel 2 meter LEDs

4. Channel 2 input attenuator

5. On/off power switch

6. Channels 1&2 ready LED

7

7. Channels 1&2 temperature warning LED

8. AC mains power plug

9. Air vents

10. Channels 1&2 line output XLR connector

11. Channels 1&2 line input XLR connector

12. Channel 2 output Speakon connector

13. Link switch channels 1-2

14. Channel 1 output Speakon connector

HDSP+ETH

rear panel view.

15. Amplier’s remote ID selector

16. Preset LEDs

17. Preset selector button

18. AUX supply plug

19. Ethernet port

Page 8

8

1 2 3 4

5

CLIP

6dB

-18dB

SIGNAL

8

-

+32

dB

READY

TEMP

8

-

+32

dB

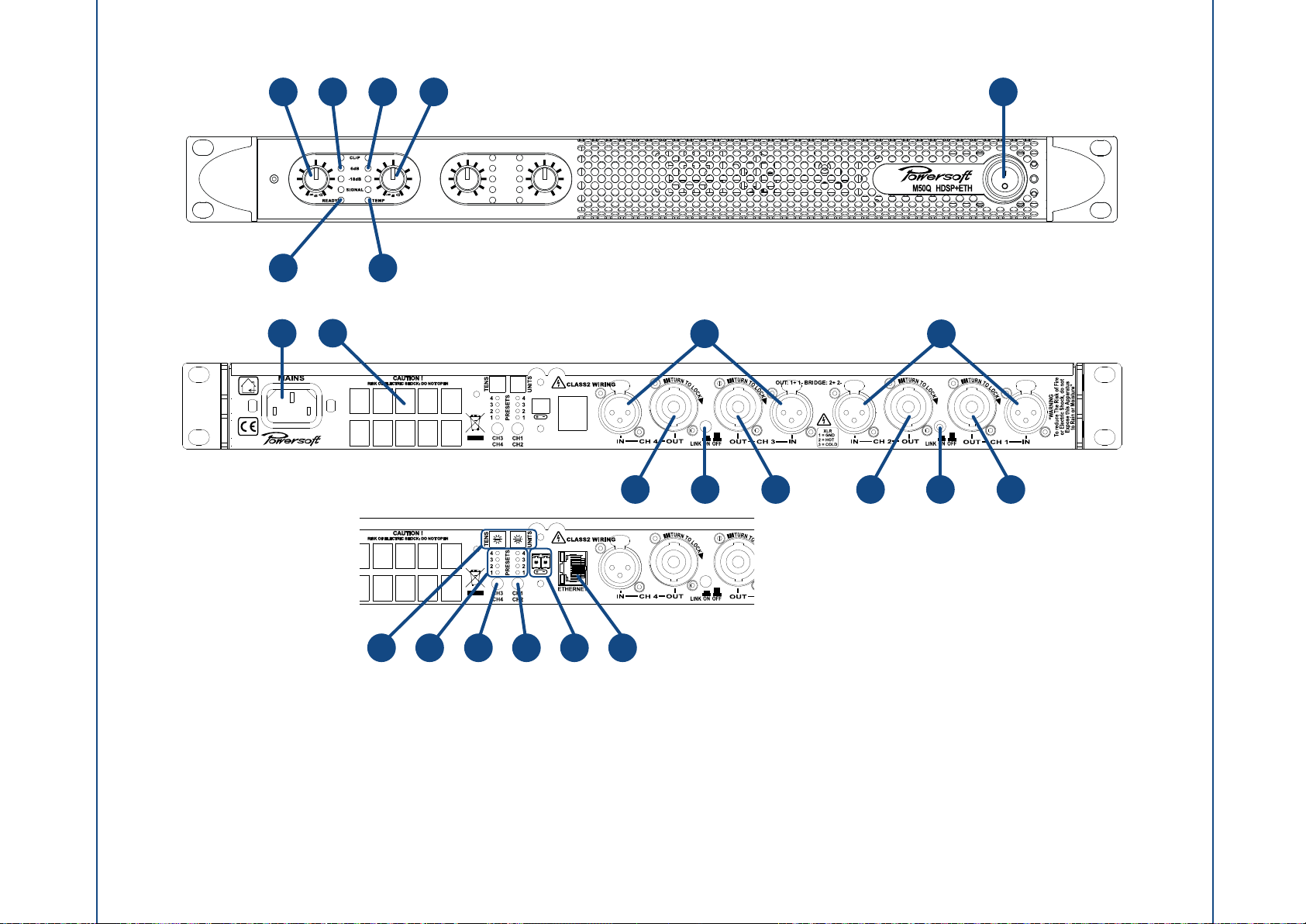

FIGURE 5: M Series – MxxQ front panel view.

6 7

8

9

PAT. PEND.

FIGURE 6: M Series – MxxQ (non HDSP+ETH) rear panel view.

18 2019 21 22 23

1. Channel 1 input attenuator

2. Channel 1 meter LEDs

3. Channel 2 meter LEDs

4. Channel 2 input attenuator

5. On/off power switch

6. Channels 1&2 ready LED

7. Channels 1&2 temperature warning LED

8. AC mains power plug

9. Air vents

10 11

Made in Italy

3

3

2

2

4

4

1

1

5

0

5

0

6

6

9

9

7

7

8

8

Made in Italy

FIGURE 7: M Series

HDSP+ETH

rear panel view.

10. Channels 3&4 line input XLR connector

11. Channels 1&2 line input XLR connector

12. Channel 4 output Speakon connector

13. Link switch channels 3-4

14. Channel 3 output Speakon connector

15. Channel 2 output Speakon connector

16. Link switch channels 1-2

17. Channel 1 output Speakon connector

1512

1613 1714

18. Amplier’s remote ID selector

19. Preset LEDs

20. Preset selector button channels 3&4

21. Preset selector button channels 1&2

22. AUX supply plug

23. Ethernet port

Page 9

M Series

User Guide

5 Welcome

Congratulations on buying a Powersoft M Series amplier!

Powersof t is a leading company in the eld of high efciency

audio power management. The Powersoft Class D technology

has changed the way the world looks at professional audio

amplication: no other amplier’s performance comes close for

applications demanding high power and long term reliability.

Thanks to amazing reductions in heat output and weight, without

sacricing output powers, Powersoft ampliers can be used in an

unlimited range of PA applications such as opera houses, theaters,

churches, cinema, and theme parks.

6 The M Series

M Series ampliers are specically designed for touring and live

applications. The ampliers in this series offer smaller dimensions,

lighter weight and the traditionally amazing sound quality and

reliability of all Powersoft products. M Series ampliers have

power ratings suitable for a vast range of common applications

including 70V/100V distributed line systems.

6.1 More sound and less weight

Switching mode technology based ampliers are highly

efcient, delivering greater power to speakers with reduced heat

dissipation: typical running efciency of output stages is 95%, with

only 5% of input energy dissipated as heat. This allows for smaller

dimensions, weight and power consumptions.

Contrary to conventional ampliers which achieve highest

efciency only at full rated power output, Class D efciency is

almost independent of output level. Music has an average power

density of 40% of its peak value; this means that other (nonclass D) ampliers can easily generate 10 times more heat than

Powersof t products for the same sound pressure level.

The units in the M Series are designed to work with lo-Z (from

4 �) and with 70V/100V distributed lines. They can deliver up to

1500 W per channel (at 4 �) or 3000 W in bridge mode on 8 �.

The HDSP+ETH versions of all ampliers in this series allow single

channel processing and remote control capabilities.

Powersof t ampliers deliver crystal-clear highs, and a tight,

well-dened low end: the most accurate reproduction of an audio

signal. Solid time proven design features ensure extremely high

performance in terms of super low total harmonic distor tion,

optimal frequency response, high power bandwidth and damping

factor across a vast number of application scenarios. Powersoft’s

multi patented application of Pulse Width Modulation (PWM)

high frequency sampling techniques is just one of the many factors

contributing to the M Series’ high performance ratings across the

audio bandwidth.

The M Series offers complete protection against any possible

operation error. Every amplier in this series is designed to work

under a large range of possible conditions, delivering maximum

power with maximum safety and an outstanding long term

reliability. Anticipating potential problems at the design stage

means your show always goes on!

7 Installation

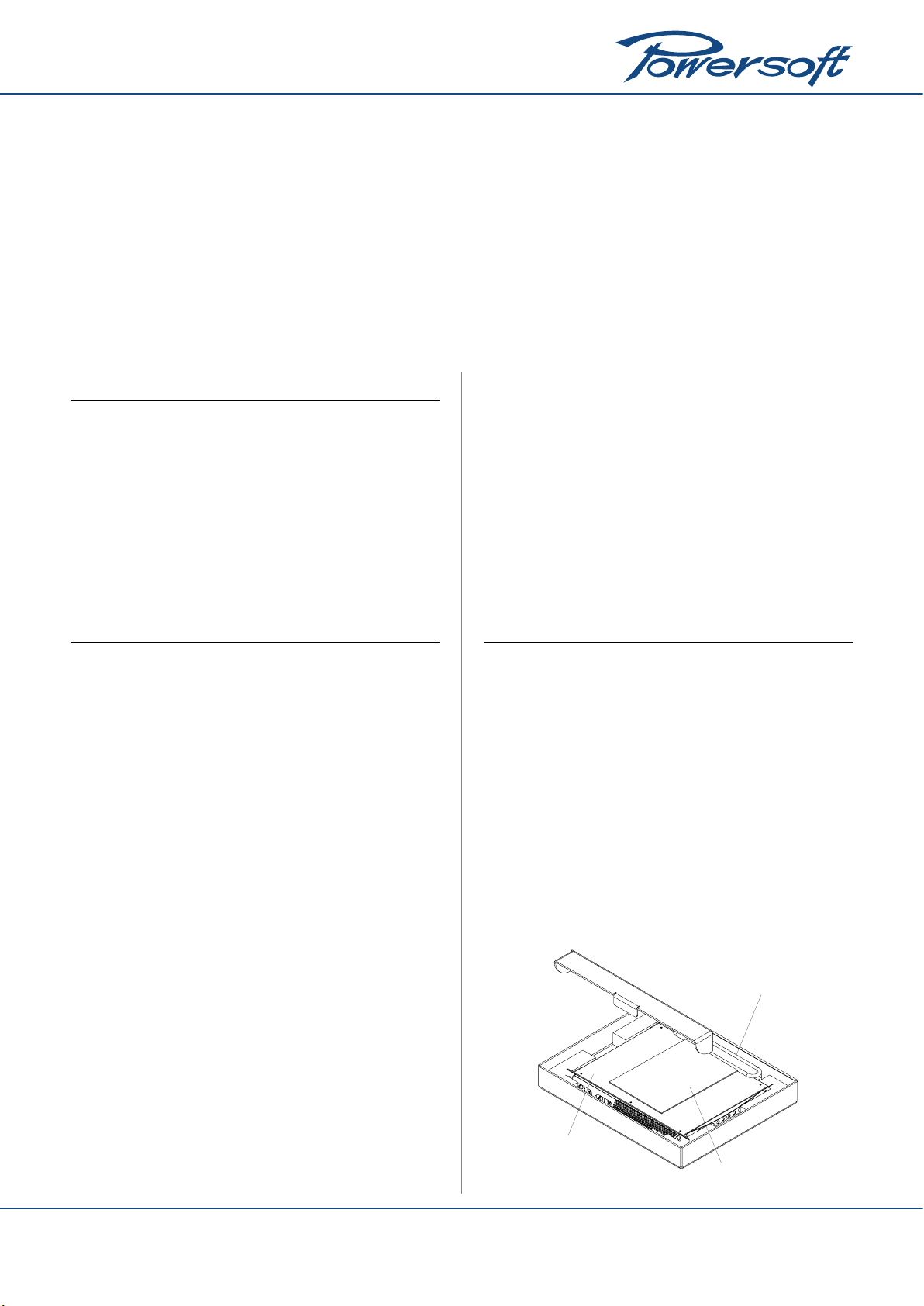

7.1 Unpacking

Carefully open the shipping car ton and check for any noticeable

damage; the FIGURE 8 shows the packing view. Every Powersoft

amplier is completely tested and inspected before leaving the

factory and should arrive in pristine condition. In the unlikely event

that you should encounter any damage, please notify the shipping

company immediately. Be sure to save all packing materials for the

carrier’s inspection.

Every M Series amplier box contains the following:

f 1 M Series amplier.

f 1 x AC Mains cord with 3-pin plug 15 A for US or

IEC ‘Schuko’ 16 A for every other nation.

f 1 x User Guide.

mains cable

amplifier

manual

FIGURE 8: M Series package.

9

Page 10

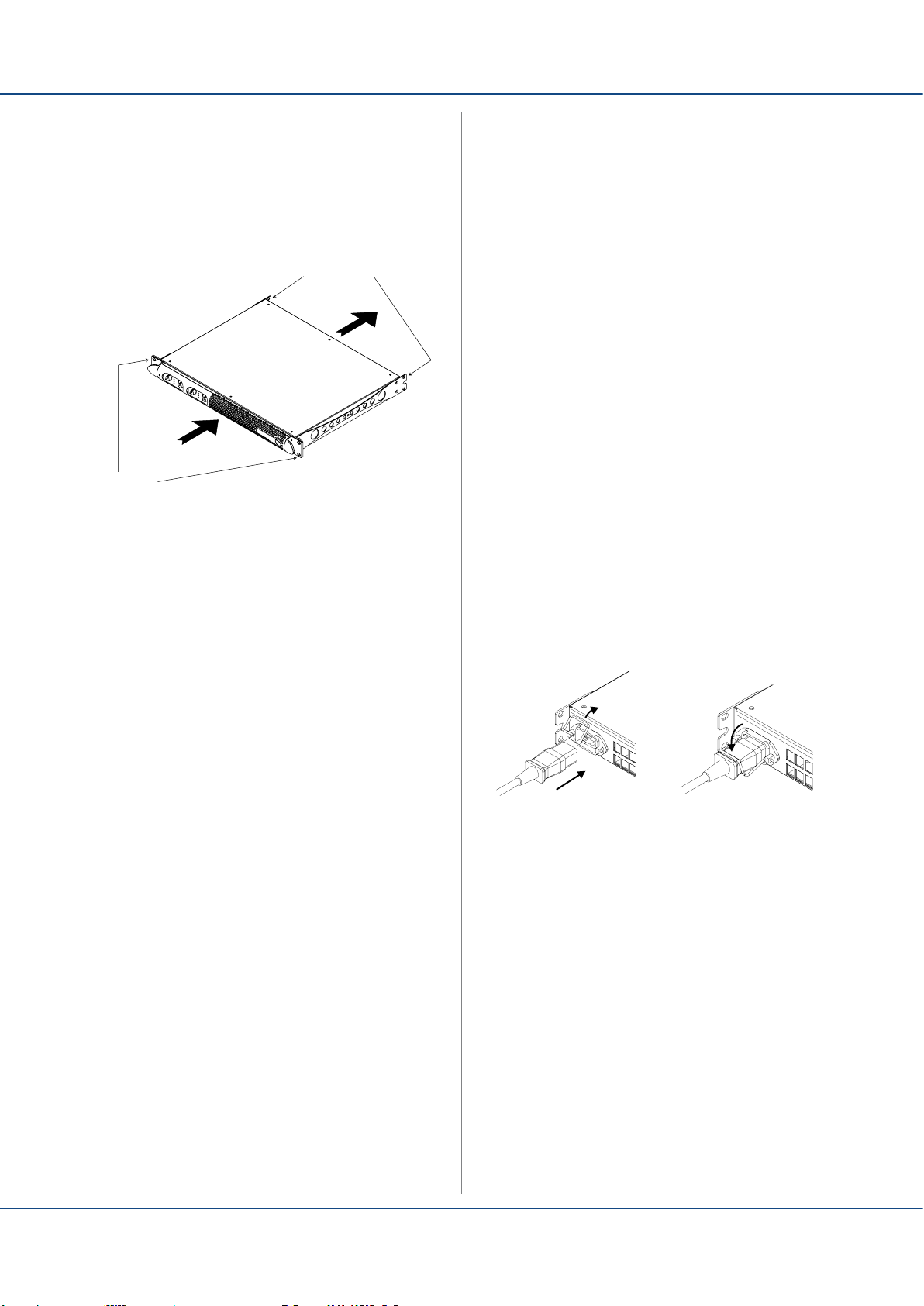

7.2 Mounting

All Powersoft ampliers are designed for standard 19” rack

mounting with four front panel holes and two rear-lateral holes. In

order to limit the risk of mechanical damages, ampliers must be

xed to the rack using both frontal as well as rear mounting holes

(see FIGURE 9).

brackets

air flow

mains standard. Damage caused by connecting the amplier to an

improper AC mains voltage is not covered by the warranty.

By using good quality input and speaker cables, the likelihood

of erratic signal behavior is reduced to a minimum. Whether you

make them or buy them, look for good quality wires, connectors

and soldering techniques.

7.5 Grounding

There is no ground switch or terminal on the M Series ampliers.

All shield terminals of input connections are directly connected to

the chassis. This means that the unit’s signal grounding system is

automatic. In order to limit hum and/or interference entering the

signal path, use balanced input connections.

In the interests of safety, the unit MUST always operate with

electrical safety earth connected to the chassis via the dedicated

wire in the 3-wire cable. Never disconnect the ground pin on the

AC mains power cord.

mounting

holes

FIGURE 9: M Series air ow.

7.3 Cooling

All Powersoft ampliers implement a forced-air cooling system

to maintain low and constant operating temperatures. Drawn by

an internal fan, air enters through the slots in the front panel and

is forced over all components, exiting at the back of the amplier.

Th e amplie r ’s co oling sy s t em feat ures an “in telli gent” var iable-

speed DC fan which is controlled by heat sink temperature sensing

circuits: the fan speed will increase only when the temperature

recorded by the sensors rises over carefully predetermined values.

This ensures that fan noise and internal dust accumulation are kept

to a strict minimum. Should however the amplier be subject to

an extreme thermal load, the fan will force a very large volume

of air through the heat sink. In the extremely rare event that the

amplier should dangerously overheat, sensing circuits shut down

all channels until the amplier cools down to a safe operating

temperature. Normal operation is resumed automatically without

the need for user intervention.

Caution regarding heat escape should be exercised when

mounting M Series ampliers. Exhaust cooling air is forced out

through the rear of the chassis (see FIGURE 9); make sure there

is enough space around the back of the amplier for this air to

escape. M Series ampliers can be stacked one on top of the other

due to the efcient cooling system they are equipped with. There

is however a safety limit to be obser ved: in case a rack with closed

back panels is used, leave one rack unit empty every four installed

ampliers to guarantee adequate air ow.

7.4 Operating precautions

Make sure the power switch is off before attempting to make

any input or output connections.

Make sure the AC mains voltage used is within the acceptable

operating voltage range specied in the M Series documentation

(factory selected 115 V / 230 V ±15%), depending on your country

7.6 AC mains connection

The AC Mains connection is made via the IEC type connector

on the back of the amplier. Please make sure your AC mains

power source operates within the voltage limits indicated on this

manual (factory selected 115 V / 230 V ±15%).

Safety warning!

Ground wires must be connected!

Do not use adapters that disable grounding.

open the lock and

insert the plug

FIGURE 10: AC mains plug connection.

lock the plug

8 Connections and Operation

This section provides information on amplier connection and

operation. For optimal amplier performance, it is important to

understand the meaning of the information that each M Series

amplier can provide regarding its status and conguration. This

information is available to the user via front panel indicators as well

as through specic LEDs the back of the unit (for HDSP versions

only). This chapter will break down all the front panel and back

panel functions. The remaining par t of the chapter will explain

how to correctly connect the amplier’s inputs and outputs.

8.1 Front panel air lters access

The blue front panel of all M Series ampliers can be removed

to access the air lters. This is useful when the air lters need to

be cleaned due to dust accumulating and clogging the lters thus

hindering proper air circulation vital for cooling purposes.

10

Page 11

To take off the blue colored front panel, remove the two

1

GND

Balanced input Unbalanced input

COLD –

HOT +

2

3

1

GND

HOT +

2

3

screws highlighted in with a Philips screwdriver. The panel will

easily separate from the amplier exposing the sponge-like air

lters.

CLIP

6dB

-18dB

SIGNAL

8

8

-

-

+32

+32

dB

dB

TEMP

READY

FIGURE 11: Unscrew and remove the front panel.

Before replacing the front panel, remember to reposition the

air lter on the chassis by placing it on its designated area, then

reposition and tighten the two frontal screws.

8.2 Front panel adjustments

The front panel of all M Series ampliers has one

stepped attenuation pot for each channel. Turning the pot

counterclockwise, the user can modify the level of the input

signal in steps corresponding to a gain reduction ranging in:

-∞, 4, 14, 18, 20, 22, 24, 26, 28, 30, 32 dB.

8.3 Front panel monitoring

8.4 Connecting audio inputs

8.4.1 MxxD models

Audio input connections are made via two XLR connectors

found on the rear of the amplier. Signal looping (i.e. link thru) is

possible using the two XLR male connectors which are also found

on the back panel. The Link on/off button allows to connect input

channels 1 and 2 in parallel.

8.4.2 MxxQ models

Audio input connections are made via four XLR connectors

found on the rear of the amplier. Signal looping (i.e. link thru) is

possible using the two XLR male connectors which are also found

on the back panel. The Link on/off buttons allows to connect input

channels 1 and 2 (and/or channels 3 and 4) in parallel.

The M Series front panel provides important information on

the state of the amplier. It is important to know and understand

the meaning of every front panel indicator LED in order to have

crucial information on the amplier status.

There are two sets of LEDs on the M Series front panel:

channel indicators and status indicators. Channel indicators: each

channel has its own column set of 4 LEDs. The top LED is red, and

the following three are green. Status indicators: each channel pair

has one set of two green status indicator LEDs.

The function of both families of LEDs is summarized in TABLE 1.

Channel indicators

LED Color Solid ON Label

Channel output level has

RED

GREEN

GREEN

reached clipping limits

Shor t circuit protection has

Channel output level is above

-6 dB of max output level

Channel output level is above

-18 dB of max output level

OR

been engaged

CLIP

-6 dB

-18 dB

GREEN Input signal presence SIGNAL

Status indicators

LED Color Solid ON Label

GREEN Channel is ready RE ADY

YELLOW

* Should the tempe rature exceeds 8 5° C, th e LED will st ay on an d the ch anne l will b e mute d.

The ampl ier will r esum e no rma l fu nct ioni ng a nd t he LED will tur n of f a utomatically wh en t he

temperature f alls b elow 75° C .

Output power is being

reduced due to heat sink

temperature exceeding 75° C

TEMP

*

TABLE 1: M Series LEDs chart.

FIGURE 12: Balanced and unbalanced input XLR connections.

8.5 Connecting audio outputs

WARNING!

Lethal voltage levels may be present at the loudspeaker

connectors when the amp is turned on!

All output connections are made via speakON connectors.

Both bridge as well as single channel output connection modes

are available. In the single channel mode wiring, the 1+ pin of the

connector corresponds to the positive output of the channel, the

1– to ground (see FIGURE 13); for bridge mode refer to Section

8.5.2.

All 4 channel amplier (MxxQ) manage bridge and single

channel mixed conguration; for example, channels 1 and 2 can

be set in bridge mode, and channels 3 and 4 single-ended.

M Series ampliers are designed to be connected both to lo-Z

loudspeakers as well as hi-Z, 70V / 100V distributed lines directly.

8. 5.1 Lo-Z and 70V/100V operations

High impedance loudspeakers can be paralleled in 70V/100V

distributed lines and directly managed by the M Series ampliers.

High output voltage per channel of M20D, M30D and M50Q

ampliers guarantees direct connection to hi-Z loudspeakers in a

line (see FIGURE 13).

8.5.2 Bridge Mode Connection

Bridge mode connection of outputs is possible only in lo-Z

operational mode. Bridging of adjacent channels is possible for the

following pairs: channels 1 with 2 for all models and channels 3

with 4 for MxxQ models. Bridging is NOT possible for other pairs,

for example channels 1 and 3.

11

Page 12

speakON

connector

1–

Channel 1

speakON

connector

1–

speakON

connector

1–

a

Single channel mode

on channels 1 and 2, while the second column refers to the preset

selected for channels 3 and 4. A signal can be sent remotely to the

amp to force all preset LEDs to blink for 30 s; this can be useful in

1+

2–

2+

a situation where many ampliers are networked together and it

is necessary to identify which amplier corresponds to a particular

network address.

9.2 Ethernet port and remote ID selection

The ID selection doesn’t implement a communication function

but is necessary in order to recognize the ID of the amplier when

b

Biamp

CH1

remotely connected. This two digits number is set via the encoders

by choosing tens digits through the lef t hand rotary selector and

unit digit through the right hand rotary selector.

ID number 00 is not allowed.

1+

2–

2+

CH2

9.3 V Ext

The “V Ext” plug, located on the rear panel of M HDSP Series

ampliers, is used to supply the amplier’s internal Ethernet

controller with the minimum power required for remote on/off

switching operations. When the V Ext port is powered by an

external 9 V – 12 V DC (900 mA) power supply, the Ethernet

controller is enabled to listen for incoming connections such as

device power-on commands.

c

Bridge mode

1+

2–

2+

3

3

2

2

4

4

1

1

0

5

5

0

6

6

9

9

7

7

8

8

a) single channel mode, low impedance loudspeaker;

FIGURE 13: Loudspeaker wiring;

b) single channel biamplied w/ active crossover: CH1 high, CH2 low;

c) bridge mode.

In order to set the output in bridge mode:

f parallel the input by pressing on the link button;

f connect the loudspeaker to just one speakON: 2+ pin is the

positive and the 2– the negative;

f minimum load impedance shall be 8�.

9 M Series HDSP+ETH operation

9.1 Rear Panel LEDs

The rear panel of the M Series with optional HDSP has a

4-green-LED column per channel pair. The LED lights to indicate

which preset is active for that specic channel pair. Preset

parameters are dened, set and modied by connecting the M

Series amplier with the optional HDSP to a computer running the

Armonía Pro Audio Suite. In case of a 4-channel amplier (MxxQ

models), the rst LED column indicates the selected preset active

Made in Italy

FIGURE 14: Ethernet port ID selector and VExt plug.

9.4 DSP features and operations

The main purpose of Digital Signal Processing (DSP) operations

is to allow the end user to program signal handling and processing

in order to:

f Select and handle the source signal;

f Process the signal for system operationM

f Process the signal to improve multi way speaker sound quality

and protect speaker drivers.

Furthermore, the DSP allows access to real-time information

on the internal device operation. This provides the end user with

reliable information on the internal state of the device as well as

better and faster amplier response in terms of control.

9.4.1 DSP Features

The M Series amplier HDSP is based on the DSP-D board

platform and the Analog Device ADAU 1701.

The DSP-D board’s exible design caters a wide range of users:

from the speaker manufacturer to the end user of rack ampliers.

The DSP-D provides both a completely programmable DSP to the

12

Page 13

experienced user as well as a complete tool with remote control

for the end user. The ADAU 1701 device is a xed point DSP

with 28-bit resolution for the internal path and 56-bit for internal

processing. The board also provides full remote control through

Armonía Pro Audio Suite.

The M Series DSP is modular for any channel pair, meaning,

for example, that on a MxxD one module is available for channels

1 and 2 while on a MxxQ there are two modules available: one

for channels 1 and 2 and another for channels 3 and 4. Keep in

mind that the modules are physically separated, therefore input or

output from different modules can’t be mixed together.

9.4. 2 Input routing selection and internal signal route

Due to the internal amplier structure, it is impossible to mix

signals from non adjacent channels: for example, channel 1 and 4

cannot be mixed together but only channels 1-2 and channels 3-4

(on MxxQ models) can. The following congurations are possible

for any channel pair:

f 1 input – 2 outputs

f 2 inputs – 2 outputs

f 2 mixed inputs – 2 outputs

9.4. 3 Input section

The input section allows system operation to improve sound

for a specic zone, group of speakers, room, etc. The input section

provides an input eq for any input channel with the following

features:

f 5 biquad lters, any lter can become PEQ, shelving hi-lo

pass, all pass

f Delay: up to 170 ms for 2 in/2 out and up to 340 ms for 1

in/2 out congurations

f Gain between -40 dB and 6 dB

f Mute

f Reverse polarity

9.4.4 Output section

The output section allows multiway cabinet equalization and

protection. The output section comprises an output eq and a

limiter (peak and RMS) for each channel.

f Eq feature:

f

12 biquad lters, any lter can become PEQ, shelving hi-lo

pass, all pass. The crossover functions are obtained using

one to four biquad lters for each crossover.

f

Delay of 10 ms

f

Gain between -40 dB and 6 dB

f

Mute

f

Reverse polarity

f Peak limiter feature:

f

Threshold, 20 – 135 V. With 1 V steps

f

Hold time, 0 – 2 sec. With 1 ms steps

f

Release time, 0 – 2 sec. With 1 ms steps

f

Release time, 4 – 4500 ms. With 1 ms steps

f

Two biquad lters for frequency shaping. Frequency

shaping is a function obtained by pre and post limiter eq.

The same eq (with opposite gain) is applied before and

after the limiter.

f Damping control:

f

Impedance correction between -2 � to +2 � with 0.1 � steps.

9.5 Internal processing layout

The following two layouts are available for each module (and its

associated channel pair):

f 1 In / 2 out basic layout

f 2 In / 2 out basic layout with mono mix capabilities.

Due to the internal structure of the DSP, in order to optimize

performance, two different binary presets for 1 input / 2 output

congurations and for 2 input / 2 output congurations must be

used. Be aware that any change in the binary preset causes an

audio interruption while the M Series microprocessor loads the

preset data into the DSP. This means that a change in conguration

(e.g. going from 1 input to 2 inputs ) or reloading a preset from

the internal memory results in an audio interruption.

NOTE: The following information is valid for any single DSP

module (2 channels). Devices with 4 channels are formed by 2

completely independent modules.

9.5.1 Input routing

The two following congurations are available:

f 1 In / 2 out, the input is routed from channel 1.

f 2 In / 2 out, the input is routed from channel 1 and channel 2.

It is possible to mix the two signals together; the mono mix

function sums the two sources and halves their summed level.

9.5.2 Input section

The input section is formed by the input eq alone, one for

each channel of the loaded layout. For example, in the 1 input /

2 output module layout there is only 1 input eq for both output

channels. Every input eq has 5 biquadratic lters which can be

chosen and assigned from the set of standard IIR lters.

9.5.3 Output section

Every module provides each channel with a set of 12 biqaudratic

lters and a complete set of limiters for protection purposes:

f Output eq: 12 biquad lters can be chosen for shaping (PEQ,

shelving, etc) but these are shared between the crossovers.

Each crossover can consume 1 to 4 biquad lters, depending

on the crossover slope. TABLE 2 and TABLE 3 illustrate

a number of crossover congurations. Mixed crossover

congurations are possible (e.g. HP 12 dB/oct, LP 24 dB/oct).

f Peak limiter for every output.

f RMS limiter feature:

f

Threshold, 13 – 312 W @ 8 �. With 1 W steps

f

Attack time, 2 – 4500 ms. With 1 ms steps

f

Hold time, 0 – 1 sec. With 1 ms steps

f RMS limiter for ever y output.

f Frequency shaping.

f Damping control for ever y output.

13

Page 14

First crossover

Free biQuad

lters remaining

Slope

6/12 d B /oct

Slope 18/24

dB/o ct

11 10 9 8

Slope 3 0/36

dB/o ct

Slope 4 0/48

dB/o ct

TABLE 2: First crossover lters.

Second crossover

Free biQuad

lters remaining

Slope

6/12 d B /oct

Slope 18/24

dB/o ct

10 8 6 4

Slope 3 0/36

dB/o ct

Slope 4 0/48

dB/o ct

TABLE 3: Second crossover lters.

9.6 Locking

The locking mechanism allows to lock macro proper ty values

based on the functional sub section and on the channel base of the

device; the lockable sub sections are:

f Input routing:

f

Mono mix

f

Input Section:

f

Equalizer

Signal

routing

Input

input

eq

output

eq

peak lim.

rms lim.

damping

Input

FIGURE 15: DSP internal layout.

WARNING! Selecting a preset with a rear button or via

remote control will interrupt the audio stream

for some seconds.

WARNING! Store the modied preset before turning the unit

off or all changes will be lost.

NOTE: Selecting presets with the rear button is enabled only

if remote control is NOT active.

10 Remote control

f Output Section:

f

Equalizer

f

RMS Limiter

f

Peak Limiter

f

Damping Control

Every channel subsection is independently lockable.

9.7 On/Off

The on/off function is available when an ex ternal voltage is

supplied. Please refer to Section 9.3 for further information.

9.8 Preset Management

The DSP allows to manage up to 4 presets per module and its

associated channel pair. Each preset contains information on the

following:

f Input routing

f Input Section

f Output Section

f Properties locking

The preset is handled by the client as a le with the .preset

extension.

These presets can be selected via a preset selection button

on the rear panel of the amp. There is one button for each DSP

module. The manual preset selection function is disabled if the

amplier is remotely controlled by any client.

Ampliers in the M Series are shipped with 4 default factory

presets: positions one and two store a 2 in / 2 out routing preset

each with an input delay of 170 ms. Positions three and four store

a 1 in / 2 out preset with 340 ms input delay each.

The M Series HDSP+ETH boards allow full amplier remote

control with Powersof t’s software client Armonía Pro Audio Suite.

Other third par ty clients are also available.

Armonía Pro Audio Suite is a sof tware environment entirely

developed in-house by Powersoft featuring full end user remote

control of Powersoft’s ampliers and audio signal processing. The

intuitive interface provides reliable information and real time

control of all DSP functions. Refer to the Armonía manual for

installation and conguration of the client software.

10.1 Networking

M Series HDSP+ETH ampliers come with one rear RJ45 port

for remote device communication, using the IP layer and the UDP

protocol. Factory default settings are DHCP/AutoIP, but a xed IP

policy can also be adopted.

10.1.1 Discovery device

In order to star t remote

operation on the device

connected to your network,

it must be discovered and

impor ted into the Armonía

workspace.

It may happen that a static

IP in a different subnet with

respect to Armonía has been

assigned to your M Series amplier (i.e. 10.0.x.y versus 169.254.x.y):

if this is the case Armonía does not recognize the amplier. You

have to reset the IP conguration of your M Series amplier: see

Annex 1 for the right procedure.

10.1.2 DHCP

When the data cable is connected the amplier begins DHCP

handshaking. If a DHCP ser ver is present on the network, the unit

is ready to be remotely controlled.

14

Page 15

10.1.3 AUTOIP

Every device tries to set up network communication when the

data cable is plugged in and connected to another device (PC,

switch, etc.). If a DHCP server is not active in the device network

the units initiates a stateless address auto-conguration. It self

assigns a link-local address of the type 169.254.x.y with a subnet

mask 255.255.0.0. Please make sure that your PC is in the same

subnet of the unit. Modern operating systems provide Zeroconf

features for network auto-conguration.

10.1.4 Static IP

M Series devices can be set up with a static IP (or any other IP

policy) with the Armonía control sof tware. In order to set up the

IP address please follow these steps.

1. Connect the device in a network with or without DHCP (see

Section 10.1.2).

WARNING! The device is reachable only from PCs in the same

subnet mask, if this information is lost you will need to re-init

the network device with a third-party software.

When done, the device network will restart automatically. The

device will reconnect in approximately 15 seconds.

10.1.5 Revert from static IP

If for any reason re-programming the IP address or the IP policy

of your unit should be necessary, follow the instructions in the

previous chapter and make a different selection when assigning

the IP. For example, should you need to revert the device to the

automatic (DHCP, Zeroconf ) IP settings, please follow these

steps. Connect the device in a network with or without DHCP

(see Section 10.1.2).

FIGURE 16: Push on the Network setting button.

2. Discover the device and import it in the workspace (see

Section 10.1.1 or refer to the Armonía user guide).

3. Go to the device scheme tab and select the Network settings

button.

4. Select the Static addressing mode from the combo box.

FIGURE 17: Select the static IP policy.

5. Inser t the desired IP Address and network mask. Specifying

the gateway is necessar y only in complex LANs.

FIGURE 19: Enter the network settings.

1. Discover the device and impor t in the workspace (see Section

10.1.1 or refer to the Armonía user guide). Device and PC

must use the same subnet. If you are not able to reconnect

the device please refer to “Annex A: IP management and

recove r y ”.

2. Go to the device scheme tab and select the Network settings

FIGURE 20: Select Auto addressing.

button.

3. Select the Auto addressing mode from the combo box.

4. Click apply settings button.

When done, the device network will restart automatically.

The device will reconnect in approximately 15 seconds.

FIGURE 18: Fill in the IP, subnet, and net mask.

6. Click apply settings button.

15

Page 16

10.2 Setup device

There are two ways to congure the device, based on your

needs and on the availability of the real device. The main difference

is that you can either work with vir tual devices before going online

and then send the setup to the units remotely or you can operate

on the physical unit directly.

10.2.1 Virtual device

If for some reason the devices are not available, conguration

must be carried out via virtual devices or a system of virtual

devices.

1. Select the device from the models

window

2. Drag and drop in the Workspace

3. If you already have a device preset

(.pam) you can import it by right

clicking on the device (see FIGURE

21).

4. You can modify any DSP value

following the instructions Section

10.8.

At this point you can save and

load the system le (.paw) at a later

time. Please refer to the Armonía

documentation. If the devices are ready

for remote control you can associate

the vir tual device to the real device. To

do so, please follow the instructions in

the next section.

FIGURE 21: Left click to select (the blue rectangle appears)

and right click for import.

10.2.2 Congure layout

Virtual devices allow the use to

select the processing layout for any

single DSP module. Select the desired

layout in the preset tab of any vir tual

device (see FIGURE 22).

10.2.3 Real device

Working on the real device remotely

is also possible. In this case all changes

made to a device are immediately

audible. In order to work on a real device:

1. Connect the device and discover the connected units (see

Se c t i on 10.1).

2. Drag the remote device into the workspace onto the virtual

device (see FIGURE 23).

3. If the internal device setup is different you’ll be

prompted to select the realignment direction.

By selecting yes the device setup is transmitted from the

virtual device to the real device. By selecting no the device

setup is transmitted from the real device to the vir tual one.

WARNING! By answering “yes” to the realignment question,

the M Series device loses data on the selected preset slot.

FIGURE 22: Select the desired layout in the combo-box.

FIGURE 23: Drop the discovered device on the virtual device; when

the arrow appears, release the left mouse button

It is now possible to operate on the device.

16

FIGURE 24: Realign window, asking for synchronization.

Page 17

WARNING! Remember that turning off or disconnecting the

power plug without saving changes on any internal memory slot leads

to data loss. Before turning off, save the data on any internal slot or

export to a .pam le.

10.3 File operations

IMPORT: save a .preset le on the selected slot and recall that slot.

WARNING! This leads to a couple of seconds interruption of

the audio stream.

WARNING! The data contained in a .preset le irreversibly

modies a preset slot and its internal layout.

There are several import/export possibilities from/to les on a

M Series unit. This section contains an explanation of all possible

cases.

WARNING! Due to the internal structure of the device, some of

these le operations can cause a temporary interruption of audio.

10.3.1 Binary preset le .preset

Handling of the internal binary preset of an M Series DSP

module is possible in the preset tab of the device.

10.4 Input/output curves .icp, .ocp

From the input or output tab of an M Series device, import/

expor t of the current equalization curve is a straightforward

procedure.

WARNING! All changes will be lost if the preset is NOT

stored on board before unplugging the unit from the mains.

FIGURE 27: The output eq: there are 4 possible choices

to handle the cur ve.

FIGURE 25: MxxD have only one DSP module.

FIGURE 26: MxxQ have two DSP modules. It is therefore necessary

to change both slots.

EXP O RT: export the actual preset slot to a .preset le.

WARNING! If the actual playing preset wasn’t saved before

export, the exported binary will be the last stored binary and

not the current playing preset.

10.5 Channel preset .chp

Impor t /export of the current playing processing from/to a le

is possible by star ting from the device’s layout.

FIGURE 28: All possible channel operations are available by right

clicking on the respective channel.

WARNING! All changes will be lost if the preset is NOT

stored on board before unplugging the unit from the mains.

NOTE: Impor ting channel preset les doesn’t modify the

internal structure of a device. For example, a channel expor ted

from a 1 in / 2 out conguration doesn’t affect the internal

structure when imported in 2 in / 2 out processing layout.

17

Page 18

NOTE: In the 1 in / 2 out conguration, the input eq is expor ted

(or applied) to both input eq’s. For example, exporting 1 in / 2 out

congurations exports the unique input eq to both channels.

10.6 Device preset le .pam

The preset le allows to impor t/expor t entire dumps of the

device. An exported .pam le allows to completely replicate the

DSP process on another device. In order to import/expor t a .pam

le:

f Select the device (a blue rectangle will appear)

f Right click on the selected device

f Click on import/export

When importing a .pam le you’ll be prompted for a decision

on the realignment policy to adopt.

By selecting yes, the device setup is transmitted from the

virtual device to the real device. By selecting no, the device setup

is transmitted from the real device to the vir tual device.

WARNING! Importing a .pam le leads to a short interruption

of the audio stream.

WARNING! Importing a .pam le overwrites the current preset

slot on the device. Any previous data on the slot will be erased.

f yes, the device specied in the window will be aligned to the

data in the .paw le;

f yes to all, all the devices will be aligned to the data in the

.paw le;

f no, the device specied in the window will NOT be aligned

to the data in the .paw le but the data will be reloaded from

the device.

f no to all, all the devices will NOT be aligned to the data in

the .paw le but the data will be reloaded from the devices.

WARNING! During import or preset manager operations the

save .paw function is disabled.

10.8 DSP remote operations

WARNING! Due to the internal structure of the system some of

the following le operations can lead to a short audio interruption.

WARNING! All changes will be lost if the preset is NOT

stored on board before unplugging the unit from the mains.

10.8.1 Routing

The input routing is based on the processing layout used: the

1 in / 2 out conguration, for example, allows input on odd

channels only. On the other hand, the 2 in / 2 out conguration

allows input on every channel. In this conguration, a mono mix

from both channels is also allowed: the two channels are added

together and their sum divided by two to normalize the resulting

level. Available congurations are listed in TABLE 4 and TABLE 5.

FIGURE 29: The .pam import/export operation from the workspace.

Note the blue rectangle on the selected device.

10.7 System File .paw

Saving or opening a system le permits the storage of the entire

processing of the current device imported in the workspace. For

more information on system conguration, please refer to the

Armonía manual.

The save operation may be seen as a large .pam expor t of the

entire device; on the other hand, opening a .paw le is equivalent

to performing a large .pam import on multiple devices. The user

will be prompted for multiple realignment decision on any de-

synchronized devices.

If the question is answered with:

Module 0 conguration Input M odule 0 Output Module 0

1 In / 2 Out Ch1 Ch1/Ch2

2 In / 2 Out Ch1/Ch2 Ch1/Ch2

TABLE 4: MxxD ampliers routing.

Module 0 conguration Input M odule 0 Output Module 0

1 In / 2 Out Ch1 Ch1/Ch2

2 In / 2 Out Ch1/Ch2 Ch1/Ch2

Module 1 conguration Input Module 1 Output Module 1

1 In / 2 Out Ch3 Ch3/Ch4

2 In / 2 Out Ch3/Ch4 Ch3/Ch4

TABLE 5: MxxQ ampliers routing.

10.8.2 Input eq

The input eq is intended for system operations. The input eq provides

a range of biquad lters that can act as any generic IIR lter. From the

input eq page, the frequency response of each channel can be adjusted

in several ways. Discrete time delays can also be inserted. The presence

of every input eq used in the device layout is reported on the tabbed

channel on the bottom left hand side of the screen. The frequency

response cur ves, together with other View items, are color coded: blue

for channel 1, red for channel 2, green for channel 3, orange for channel

4. Every channel allows regulation of lters, mute, gain, delay and polarity.

The frequency response (and/or phase response) curve displayed is

always obtained as the combined response of all currently active lters.

18

Page 19

FIGURE 30: The input eq layer.

10.8.3 Output eq

This page’s general appearance is similar to that of the Input

Equalizer page, but presents several important differences.

The Output Eq. cur ve the amplier employs is meant to be

created from the speaker manufacturer’s data for the par ticular

loudspeaker cabinets or arrays the amplier will be driving. It

provides a range biquad lter that can act as crossover or generic

IIR lter. From this page, the frequency response of each channel

can be adjusted in several ways. Discrete time delays can also be

inser ted. The presence of ever y output eq. present in the device

layout is repor ted on the tabbed channel on the bottom left

hand side of the screen. The frequency response curves, together

with other View items, are color coded: blue for channel 1, red

for channel 2, green for channel 3, orange for channel 4. Every

channel allows regulation of lters, mute, gain, delay and polarity.

The displayed frequency response (and/or phase response) curve

is always obtained as the combined response of all currently active

lters.

FIGURE 32: The limiters dialog window.

drivers from burning out due to excess power being delivered over

an extended period of time. The RMS limiter is set by selecting a

desired maximum power value but acts by limiting output voltage;

by applying Ohm’s law with a xed reference 8 � load, the output

voltage level corresponding to the desired maximum output

power value is calculated as the square root of power times the

load resistance (8 �). It is possible to set the values of:

f Threshold in watts, with respect to an 8 � load.

f Attack time is the time between the moment the output

voltage exceeds the threshold and the moment of the onset

of the limiting action.

f Hold time is the length of time during which the limiting action

is maintained before the gain returns to normal levels because

the output voltage drops below the threshold level.

f Release time is the length of time over which the limiting

action is reduced and the gain is returned to normal following

the drop of the output voltage below the threshold level.

10.8.6 Peak limiter

The function of the peak limiter is to protect voice coils from

excessively large signal peaks by limiting the maximum output

voltage of the amplier. It’s possible set the values of:

FIGURE 31: The output eq layer.

10.8.4 Limiters

The function of the limiters is to protect voice coils from

burning out due to excess power being delivered over an extended

period of time or from excessively large signal peaks by limiting the

maximum output voltage of the amplier. The limiter window is

accessible by clicking on the limiter block in the device layout view.

Every channel limiter is color coded: blue for channel 1, red for

channel 2, green for channel 3, orange for channel 4.

10.8.5 RMS limiter

Electromechanical transducers are highly inefcient; as such

they transform a signicant amount of input power into heat. The

function of the RMS limiter is to protect the voice coils of speaker

f Threshold in volts, is the amplier max output voltage level

corresponding to the maximum displacement of the speaker

diaphragm.

f Hold time is the time over which the limiting action is

maintained before the gain level is returned to normal after

the output voltage drops below the threshold.

f Release time is the length of time over which the limiting

action is reduced and the gain is returned to normal following

the drop of the output voltage below the threshold level.

10.8.7 Damping factor correction

The effect of cable resistance on a high power amplier

performance becomes signicant at low frequencies, as the cable

resistance can affect the output stage damping factor. Powersoft

Damping Control is a proprietary algorithm which compensates

for cable resistance. The user can enter cable parameters and the

algorithm calculates and applies the appropriate correction. A tool

to calculate the cable resistance is provided.

Damping factor correction can also be used to ne tune low

end nuances: a negative resistance leads to a punched bass while a

positive resistance leads to a tailed bass.

19

Page 20

The following values can be set by the user:

f Enable: enables the correction algorithm.

f Resistance compensation: set the negative or positive resistance

value added to the output circuitry.

The cable resistance tool allows to set:

f Cable dimensions: enter the gauge of the wire used in the

speaker cable and the cable length into the Wire gauge

dropdown list and the Wire length spinbox respectively.

The upper drop-down list allows to choose between metric

(international) and imperial units. The range of imperial wire

gauges is 6 AWG to 23 AWG, and of metric wire gauges 0.25

2

mm

to 10 mm2. Maximum cable lengths are correspondingly

3280 ft or 1000 m.

f Resistance compensation: clicking Apply sets the cable

resistance value calculated as the correction factor. The fader

and its spinbox assume this value. However, the user can

manually modify this calculated nominal value to obtain, for

example, an enhanced LF response.

FIGURE 34: Click on the preset locking button in the

layout tab of the device.

FIGURE 33: The damping control window.

10.9 Locking

The locking mechanism allows the user to prevent changes to a

whole preset or a part of a preset. The locking interface is divided

in DSP module(s) and macro processing. Every module needs to

be locked separately; the lock status is preserved with the import/

expor t from/to le and copy/paste operations. In order to lock/

unlock an entire module or par ts of a module:

1. Access the locking interface.

2. If the module you want to modify is already locked, you need

to inser t the unlocking password for that module.

3. In order to lock the module with the selected layout, insert

the locking password and press the button Apply.

FIGURE 35: Functions and symbols in the preset locking window:

1. Select module; 2. Select channel for the macro property.

3. A padlock indicates a locked property; 4. A pencil indicates a

writable property; 5. The combo box allows to change the

single macro property.

10.10 On board preset operations

The preset tab of all M Series devices allows handling of the

internal binary preset of an M Series DSP module.

FIGURE 36: MxxD preset handling.

FIGURE 37: MxxQ preset handling.

SAV E: allows saving of the current DSP processing on the

selected preset slot.

A number of operations are allowed here. Please refer to for

an explanation of the various functions and symbols.

20

LOAD: recalls the selected preset slot.

Page 21

WARNING! (re)Loading a preset causes a couple of seconds of

interruption of the audio stream.

10 .11 Copy and paste operations

Any paste operation does not affect the DSP binary and its

corresponding structure; therefore, applying data with the paste

command does not lead to audio interruption.

WARNING! Any data pasted into a device needs to be saved in

a preset slot, otherwise any turn off/on cycle leads to data loss.

10.14 Work space

The copy/paste function from an M Series device to another M

Series device is limited to:

The same family device (e.g. source M20D, target M20D).

The same internal processing layout (e.g. source 1IN/2OUT,

tar get 1I N/2O U T ).

WARNING! All changes will be lost if the preset is NOT

stored on board before unplugging the unit from the mains.

10.12 Input/output eq curves

In order to copy/paste an eq curve, copy the source curve with

the dedicated copy function and paste to the destination eq. with

the dedicated paste function.

WARNING! All changes will be lost if the preset is NOT

stored on board before unplugging the unit from the mains.

FIGURE 38: The output eq, there are 4 possible alternatives to

handle the curve.

10.13 Channels

Copy and paste of the current playing processing setup from/to

the clipboard is possible from the device layout.

WARNING! All changes will be lost if the preset is NOT

stored on board before unplugging the unit from the mains.

NOTE: pasting a channel preset le doesn’t modify the internal

structure of a device. For example, a channel copied from a

1 in / 2 out conguration doesn’t affect the internal structure

when pasted in a 2 in /2 out processing layout.

NOTE: in the 1 in / 2 out conguration the input eq is copied (or

applied) to both input eq’s. For example, copying the conguration

of both channels (1 in /2 out conguration) leads to pasting the

unique input eq to both channels.

11 Protection

In order to protect your device and your speakers from

accidental damage, M Series ampliers include an extensive

automatic protection system. In the following sections, potentially

dangerous scenarios and the ampliers’ corresponding protective

response are explained in detail.

11.1 Turn on/Turn off muting

Class D ampliers may cause severe speaker damage at power

up due to the high voltage levels at the output stage. In order to

avoid this, the outputs are muted for less than 2 seconds (less

than 5 seconds for DSP models) after turn on. Similarly, turning

off the amplier can cause the same problem: outputs are muted

immediately at turn off.

11. 2 Short circuit protection

Shor t circuits or ver y low impedance loads may destroy the

output stage of any amplier. In order to protect the amplier

from the dangerously high current surges arising from accidental

output short circuits or low impedance loads, all M series amps

block channel activity when the current drawn from the load rises

above a set value. The channel is muted for 2 seconds after which

the amplier will unmute the channel and check whether the

current draw is still over the safety threshold. Should this be the

case, the amplier will mute the channels for another 2 seconds

and the procedure will reiterate. The red “CLIP” LED will be

turned off only when the output current draw will have returned

within safe limits.

11. 3 Thermal protection

All Powersoft ampliers have variable speed fans to assist

cooling. If for some reason the cooling system can’t dissipate

the produced heat correctly, a thermal protection system is

automatically activated to avoid permanent damages. Every

channel pair has a temperature sensor on the output stage

heat sink. Two different protection strategies are implemented

depending on the severity of the overheating. In order to protect

internal components, the amplier may automatically reduce

output power until the internal temperature returns to safe levels.

21

Page 22

11. 4 Thermal warning

12.3 Dust Removal

If the heat sink reaches a temperature of approximately 75°C,

the front panel red “TEMP” LED corresponding to the overheated

channel pair turns on to warn the user of a potentially dangerous

thermal event. Output power is reduced to prevent damages to

the output stage.

11. 5 Thermal shutdown

If the heat sink temperature rises above 85°C, the thermal

sensing circuitry will mute each power section of each

compromised channel pair. Only after the heat sink has cooled

down to below 75°C the channel pair will automatically unmute

and the red “TEMP” LED will be turned off.

11. 6 DC fault protection

In order to protect your speakers from mechanical damage

caused by a DC signal coming from the amplier’s output, a DC

detection circuit is placed between the amplier’s output stage

and power supply. If a DC signal or excessive subsonic energy

appears at a channel output an instantaneous protection circuit

will mute the compromised channel pair. The red “CLIP” LED will

turn on to signal that protective measures have been engaged.

11. 7 Input/output protection

Inter ference protection is implemented in the M Series to limit

out of band noise carried by the input lines. Disturbing frequencies

can interact with the output stage, causing unpredictable amplier

behavior. A ltering system is used to stop infrasonic and VHF

signals from entering the signal path.

12 User Maintenance

In dusty environments, the front side air lters clog with dust

after prolonged use. The dust gathered in the lters will inter fere

with cooling. You may use compressed air to remove the dust

from lters. To remove air lters please refer to the front panel

removal procedure (see Section 8.1). Air lter cleaning should be

scheduled according to the dust levels in the amplier’s operating

environment.

13 Warranty

13.1 Product warranty

Powersof t guar antees its m anufact ured produ cts to be fr ee from

defective components and factory workmanship for a period of 48

(forty eight) months, starting from the date of purchase printed on

Powersof t’s (or any of its Authorized Dealer’s) invoice to the end

customer. All warranty repairs and retrots must be performed at

Powersof t facilities or at an Authorized Service Center at no cost

for the purchaser. Warranty exclusion: Powersoft’s warranty does

not cover product malfunctioning or failure caused by: misuse,

abuse, repair work or alterations performed by non-authorized

personnel, incorrect connections, exposure to harsh weather

conditions, mechanical damages (including shipping accidents), and

normal wear and tear. Powersoft will per form warranty services

provided that the product is not damaged during transpor tation.

13. 2 Return of Goods

Goods can be returned to Powersoft only af ter they have been

granted a Return Merchandise Authorization (RMA) number to be

attached to the external packaging. Powersoft (or its Authorized

Service Center) has the right to refuse any returned good without

a RMA number.

12.1 Cleaning

Before attempting to clean any part of the amplier, rst

disconnect the AC main source. Use a soft cloth and mild nonabrasive solution to clean the faceplate and chassis.

WARNING! Never let any liquid reach the internal parts of

the amplier.

12.2 Service

There are no user-serviceable par ts in your amplier. Refer

servicing to qualied technical personnel. In addition to having an

in-house service department, Powersoft supports a network of

authorized service centers. If your amplier needs repair contact

your Powersoft dealer (or distributor). You can also contact the

Powersof t Technical Ser vice depar tment to obtain the location of

the nearest authorized ser vice center.

22

13. 3 Repair or replacement

Powersof t reserves the right to repair or replace any defective

goods covered by product warranty at its sole discretion and as

it deems best.

13.4 Cost and responsibility of transport

The purchaser (or end user/customer) is solely responsible

for all transportation costs and risks associated with sending

warranty covered goods to Powersoft or its Authorized Service

Center. Powersoft will assume full responsibility and cover all costs

incurred to send the goods back to the purchaser (or end user/

customer).

Page 23

14 Assistance

Even though most product malfunctioning can be solved

at your premises through Powersoft Customer Care or your

direct knowledge, occasionally, due the nature of the failure, it

might be necessary to return defective products to Powersoft for

repair. In the latter case, before shipping, you are kindly asked

to follow step by step the procedure described below: Obtain

the “Defect Repor t Form” by contacting our Customer Care

Depar tment via email: ser vice@Powersoft.it or download the

“Defect Report Form”.

Fill out one “Defect Repor t form” for each returned

item (the form is an editable tab guided document) and

save as your name, amp model and serial Number (for

example: distributornamek10sn17345.doc) providing all

required information except the RMA code/s and send it to

service@powersoft.it for Powersoft approval.

In case of defect reports approved by the Powersoft Customer

Service Representative you will receive an RMA authorization

code (one RMA code for each returning device). Upon receiving

the RMA code you must package the unit and attach the RMA

code outside the pack, protected in a waterproof transparent

envelope so it is clearly visible.

All returning items must be shipped to the following address:

Power soft

Via Enrico Conti, 13-15

50018 Scandicci (FI) Italy

In case of shipment from countries NOT belonging to the

European Community make sure you have also followed the

instructions described in the document available for download at the

TEMPORARY EXPORTATION / IMPORTATION PROCEDURE

link at http://www.Powersoft-audio.com/en/support/service.html

Thank you for your understanding and cooperation and

continued support as we work to improve our partnership.

23

Page 24

15 M Series power rating

Model name

2 channel

ampliers

4 channel

ampliers

1 with an exte rna l high pa ss l ter fo r non HD SP mod els an d with an HDS P preset wi th a hig h pass lter and ou tput volt age limite r for models with HDSP.

2 with an exte rna l high pa ss l ter and out put vo ltage limi ter fo r non HDSP mod els an d wit h an HDS P pre set wi th a hig h pass lte r and ou tpu t volt age li mite r for models w ith H DSP.

3 with an exte rna l high pa ss l ter fo r non HD SP mod els an d with an HDS P preset wi th a hig h pass lter for mod els wi th HD SP.

M14D /M14D H D SP+ E TH 700 W 360 W — — 140 0 W

M20D/M20D HDSP+ETH 12 0 0 W 600 W 120 0 W

M30D/M30D HDSP+ETH 15 0 0 W 900 W 120 0 W

M28Q/M28Q HDSP+ETH 700 W 360 W — — 140 0 W

M50Q/M50Q HDSP+ETH 1250 W 750 W 1000 W

Single-channel mode Distributed lines

4 � 8 � 70 V 10 0 V 8 �

1

2

2

— 2400 W

3

150 0 W

3

1250 W

16 Output SpeakON connection polarities

CH2–

Channel 2

speakON

connector

CH2+

1–

1+

2+

2–

Channel 1

speakON

connector

CH2–

CH1–

CH1+

1–

1+

2+

2–

Mono-bridge

mode

3000 W

2500 W

CH2–

CH1+

CH1+

17 M Series load compatibility chart

Model lo-Z loads 70 V distributed line 100 V distributed line

M14D yes no no

M14D HDSP +ETH yes no no

M20D yes yes with an external high pass lter no

M20D HDSP+ETH yes yes with an HDSP preset with a high pass lter no

M30D yes

M30D HDSP+E TH yes

M28Q yes no no

M28Q HDSP+ETH yes no no

M50Q yes

M50Q HDSP+E TH yes

yes with an ex ternal high pass lter and

yes with an HDSP preset with a high pass lter and

yes with an ex ternal high pass lter and

yes with a DSP preset with a high pass lter and

peak limiter

an output voltage limiter

peak limiter

an output voltage limiter

yes with an ex ternal high pass lter

yes with an HDSP preset with a high pass lter

yes with an ex ternal high pass lter

yes with a DSP preset with a high pass lter

24

Page 25

18 Specications

M14D and M14D HDSP+ETH

General

Number of channels 2 mono, bridgable per channel pair

Max output power per channel

Max output voltage 85 V

AC Mains Power

Power supply Universal, regulated switch mode

Nomin al power requiremen ts AC 115 V - 230 V (factory selec tion), 50/60 Hz

Operating range AC 97 V - 264 V

Inrush current < 26 A

Consumptio n / curre nt draw 230 V 11 5 V

Idle 39 W 0.3 A 39 W 0.6 A

I/8 of max power @ 4 � 283 W 1.9 A 238 W 3.8 A

I/4 of ma x power @ 4 � 53 8 W 3.5 A 538 W 7 A

Thermal

Environmental operating temperature 0° - 45° C / 32° - 113° F

Thermal dissipation Fan, variable speed, temperature controlled front to rear air ow

Idle 133 B TU /h 33 kcal/h

I/8 of max power @ 4 � 368 BTU/h 93 kcal/h

I/4 of ma x power @ 4 � 6 41 BT U/ h 162 kcal/h

Audio

Gain 32 dB, 30 dB, 28 dB, 26 dB, 24 dB, 22 d B, 20 d B, 18 dB , 14 dB, 4 dB, -∞, user selectable

Frequency response 20 Hz - 20 kHz ±1 dB @ 1 W, 8 �

S/N ratio (amp lier section) > 109 dB (20 Hz - 20 kHz , A weighted)

Crosstalk separation >70 dB @ 1 kHz, 4 �

Input sensitivity @ 8 � 1.4 V

Max input level 6 V

Input impedance 10 k� balanced

THD+N / D IM100 IM D < 0.02% (t ypic ally < 0.0 05%) @ 4 �

Slew rate 40 V/µs @ 8 � input filter bypassed

Damping factor > 500 0 @ 100 Hz

***

DSP

A/D converter CS5381, 2 channels, 24 bit / 48 kHz, 120 dB SNR

D/A converter CS4398, 2 c hannels, 24 bit / 48 kHz, 120 dB S NR

Frequency re sponse @ -3 dB 7 Hz - 22 kHz

THD < 0.01% (20 Hz - 20 kHz)

Presets Bank of 4 presets, mana gement and up load via Armonía Pro Audio Suite™

Delay for time alignment 10 ms per output

Crossover lters Butter wor th, Linkw itz- Riley, Besse l, 6 dB/oct to 4 8 dB/oc t

Output equalizer up to 12 biqu ad full y parametric per c hannel: peaking, hi/lo shelving, hi/lo pass, band pass, b and st op, all pass.

Input equalizer up t o 5 biquad lte rs (PE Q, shelving, band pass, b and stop, all p ass)

Limiters Peak limiter, RMS limiter, freque ncy de pendent RM S limiter

Damping control < 120 Hz, range ± 2 Ω

System Delay up to 170 ms for 2 IN /2 OUT or 340 ms for 1 IN/ 2 OUT

Front panel

Indicators 4 LEDs per channel: 3 x green , 1 x red; 2 status LEDs: 1 x green , 1 x yellow

Controls 1 stepped leve l attenuat or pot pe r chan nel; mains sw itch

Maintenance Dust lter foam behind front panels

Rear panel

Controls 1 x link switch , linking analog inputs 1 & 2

Input / Output connectors

Network dat a por t Ethernet

DSP preset selection

Aux voltage

***

***

AC main s IEC C13 16 A connector; AC mains cord with 3 -pin plug 15 A for U S, IEC Schuko 16 A for every other nation

Construction

Dimensions L x W x H: 483 mm x 44.5 mm x 379 mm / 19” x 3. 5” x 14.9”

Weig ht 7.3 kg (16 lb)

* EIAJ Tes t Standar d, 1 kH z, 1% THD, a ll cha nnel s dri ven. * ** HDSP+E TH ver sio n only.

*

4 � / Ch 8 � / Ch 8� / Ch pair

700 W 360 W 140 0 W

2 x Neutrik® S peakon NL4M D, 2 x Neutrik ® XLR male hardwired to the corresponding input

***

single channel mode bridge mode

peak

/ 65 A

peak

rms

170 V

230 V

/ +5.14 dBu

rms

/ +17.8 dBu

rms

2 x balanced Neutrik® XLR female

1 x RJ45 with activity LED with 2 rotary address switches

1 x Pushb utton (stepping t hrough bank of 4 presets); 1 x 4 LED preset i ndicators

1 x 2-pin P hoenix type MC 1.5/ 2-ST-3.81

peak

/ 65 A

peak

25

Page 26

M20D and M20D HDSP+ETH

General

Number of channels 2 mono, bridgable per channel pair

Max output power per channel

Max output voltage 116 V

AC Mains Power

Power supply Universal, regulated switch mode

Nomin al power requiremen ts AC 115 V - 230 V (factory selec tion), 50/60 Hz

Operating range AC 97 V - 264 V

Inrush current < 28 A

Consumptio n / curre nt draw 230 V 11 5 V