Powers HydroGuard T/P e705, e700 Series, HydroGuard T/P e707, HydroGuard T/P e710 Technical Instructions

Page 1

Technical Instructions

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use

information can result in death, serious personal

injury, property damage, or damage to the

equipment.

Keep this Manual for future reference.

Description n

The Series e700 HydroGuard T/P automatically mixes hot and

cold water to deliver blended water within a specified range.

Using an advanced thermal actuator, the Series e700 quickly

compensates for temperature fluctuations induced by water

temperature and pressure changes. In the event of cold

water failure, the thermostatic motor virtually shuts off the

flow of hot water. HydroGuard T/P meets the most stringest

performance criteria for temperature and pressure changes,

defined by ASSE 1016 (Type T/P).

Featuring heavy, cast-brass construction and an adjustable

brass to brass high limit temperature stop, self-contained

IS-P-e700

HydroGuard

®

T/P

Series e700

e705

e707

e710

cartridge, corrosion resistant internal component, integral

checks, and back to back shallow wall installation capability. All parts of the e700 Series valve are accessible from

the front of the valve. All Series e700 valves open in the cold

water position to ensure maximum bather safety and comfort.

The accuracy, reliability and water economy of the Series

e700 HydroGuard T/P make it preferable for applications that

require precise, consistent water

control: showers, baths, hospital hydrotherapy and

residential areas. All e700 valves meet the Americans with

Disabilities Act (ADA).

Specifications n

Valve Construction: Combination mixing valve, with heavy cast bronze body and brass stem. Concealed adjustable high

temperature limit stop. Available with ADA-compliant ABS or metal lever handle.

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2" Sweat Inlet/Outlet

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 gpm

Maximum Hot Water Supply Temperature . . . . . . . . . . . . . . . . . . . . . . . 190°F(88°C)

Minimum Hot Water Supply Temperature (Approach Temperature) . . . . . . . . 10°F (5.5°C) above set point

Maximum Operating Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 psig (862 kPa)

Temperature Ranges (for +/- 3°F performance) . . . . . . . . . . . . . . . . . . . . . ASSE 1016 Type T/P: 90 - 110°F (32 - 43°C)

ASSE 1016 Type T: 80 - 120°F (27 - 49°C)

High Temperature Limit Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Adjustable (factory set at 110°F [43°C])

Maximum Static Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 psig (862kPa)

Minimum Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 gpm (3.781 L/min)

Approved Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CSA B125.1, ASME 112.18.1 ASSE 1016 T/P

Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ASSE 1016, IAPMO cUPC

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 lbs. (1.6 kg)

All HydroGuard T/P Series e700 combination mixing valves

meet above performance specifications based on typical

operating conditions as stated in ASSE 1016 (45 psi pressure

differential, hot water supply between 140°-180°F (60°-82°C),

cold water supply less than 70°F (21°C).

If your operating conditions vary from those stated in the

standard, performance may vary as well. Consult your local

sales representative or a Powers factory engineer to discuss

your specific application. All Powers thermostatic mixing

valves perform to the requirements of standards ASSE 1016

and CSA B125.

Page 2

Operation n

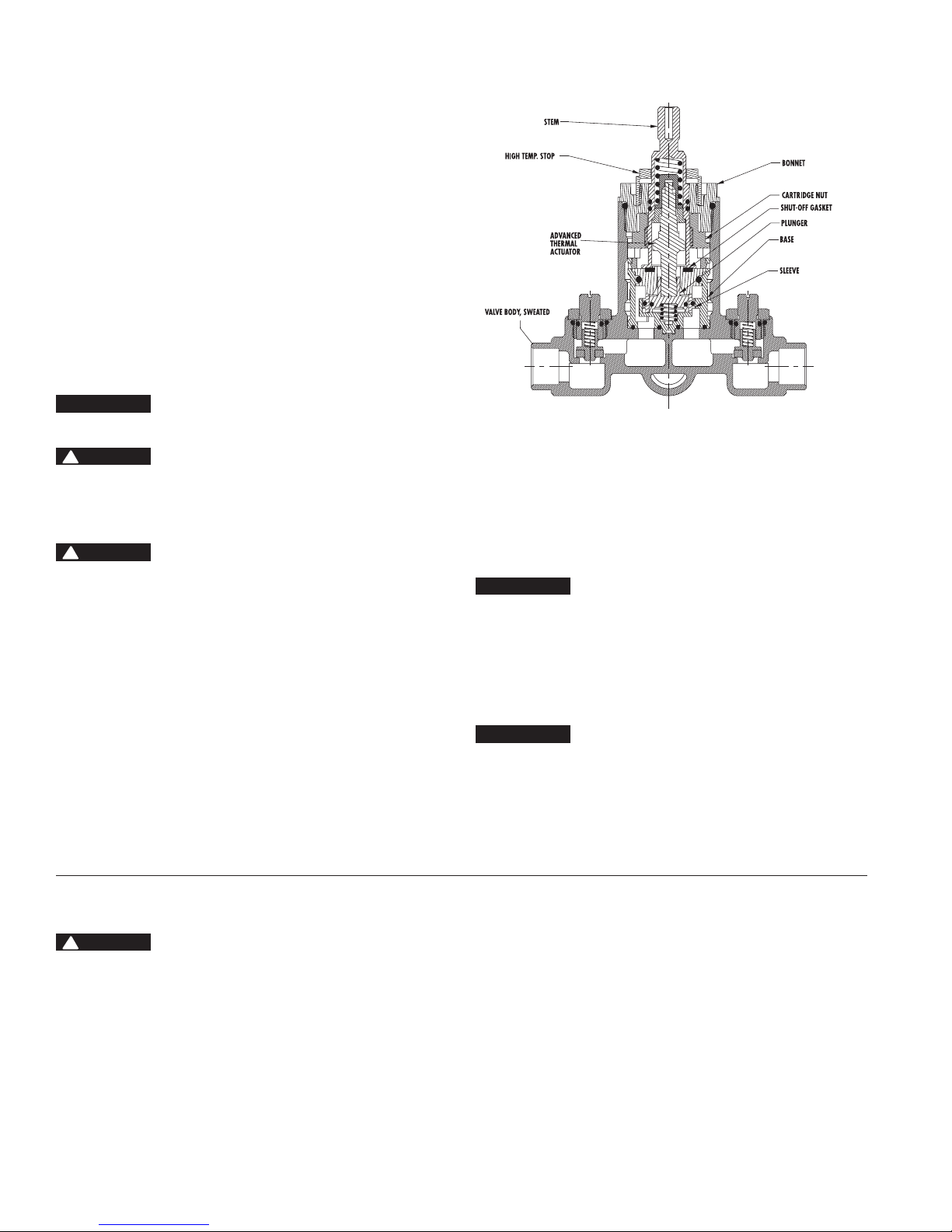

Hot and cold water enter respective ports in the valve and mix

in a chamber containing an advanced thermal actuator (refer to

cutaway view). This actuator controls the position of the plunger

and temperature.

Rotating the adjustment handle repositions the plunger in the

cartridge assembly to produce the desired temperature. The

mixed water passes over the shut-off disc to the outlet. If the

hot or cold supply water temperature or pressure changes, the

thermal actuator will contract or expand. This movement repositions the plunger to maintain the desired temperature. With the

adjustment handle in full clockwise (OFF) position, the shut-off

disc closes the mixing chamber from the outlet.

A high temperature limit stop restricts the movement of the

control handle. All HydroGuard T/P e700 valves are factory set

to deliver tempered water up to 110°F [43°C] with equal supply

pressures, with hot water temperature 140°F [60°C], cold water

temperature 60°F [15.6°C].

NOTICE

The handle rotation stop must be adjusted by the installer.

!

WARNING

Maximum Temperature Setting/Handle Rotation Stop

The handle rotation setting must be adjusted to limit the distance

the user can rotate the handle towards the full hot water position.

!

CAUTION

Any repair or modification of the valve may affect the high temperature setting. The maximum

temperature setting must be checked by the installer before use.

1. Remove the valve handle and sleeve.

2. Adjust the valve to the desired maximum outlet temperature

[110°F (43°C) max]. Screw on the high temp. limit stop until it

touches the stem shoulder.

3. Turn the stem clockwise until the water stops.

Open valve to full hot position and verify maximum outlet

temperature setting.

4. Place sleeve "O" Ring on the bonnet shoulder.

Slide sleeve over the "O" Ring until it stops.

5. Replace handle.

Reversed Inlets

Valve is factory-set for standard inlets If reversed inlets are

required due to back-to-back installation (Cold water supply on

the left and Hot water supply on the right), follow instructions a

through d below:

a. Connect cold inlet to hot port (“H”) and hot inlet to cold port

(“C”).

NOTICE

Do not turn valve upside down. If valve is upside down, water

will not flow properly through tub spout or showerhead.

b. Turn water off with checkstops, remove bonnet and

cartridge.

c. Reinstall cartridge. “H” on the cold side of the valve body

and “C” should be on the hot side of the valve body.

d. Reinstall bonnet with high temperature limit stop on it.

NOTICE

Be certain that valve opens in full cold!

e. Hot and Cold inlets should be re-identified for reversed inlets

to avoid confusion during future maintenance.

Preventive Maintenance n

!

WARNING

Before servicing checkstops or piping, always turn off the

upstream water supply.

EVERY 12 MONTHS:

•Openupthecheckstopsandcheckforfreemovementofthe

poppet. To access the checkstops, remove the handle assembly and trim plate.

•Beforeservicingthevalve,turnoffthewatersupplyupstream

OR close the checkstops. To close the checkstops, turn the

adjustment screw fully clockwise on each checkstop.

•Removethevalvebonnetandrinseallgritandimpuritiesfrom

the cartridges.

•Winterizevalvesthatareusedoutdoors.Removeandstore

the internal components and drain all water from the valve.

Page 3

Safety Requirement - All Models n

!

WARNING

Need for Periodic Inspection: Periodic inspection by a licensed

contractor is recommended. Corrosive water conditions, temperatures over 200°F, unauthorized adjustments or repair could render

the valve ineffective for service intended. Regular checking and

cleaning of thermostat assembly helps to assure maximum life

and proper product function. Frequency of cleaning depends upon

local water conditions.

Adherence to these guidelines and recommendations promotes

safe product use and ensures proper valve performance.

Troubleshooting n

What to look for if:

• The maximum temperature cannot be obtained...

a. Lime deposits may have accumulated in the hot water pipes,

restricting the hot water supply.

b. The hot water supply temperature may be too low.

c. The handle rotation setting may be too low. Remove valve

handle, and readjust the high temperature limit stop (see

page 2).

• Flow of water is less than desired…

a. The upstream supply valves may not be fully open.

b. The inlet supply pressure(s) may be low.

c. The showerhead may be clogged. Remove and clean the

showerhead.

d. The checkstops may be clogged. Refer to Preventive

Maintenance section.

!

CAUTION

The high temperature limit stop setting must be adjusted to limit

the distance the user can rotate the handle towards the full hot

water position.

NOTICE

Position the e700 valve as close as possible to outlet fixture to

avoid waste of energy and water.

• The valve opens with hot water ow rather than cold water

ow...

a. The inlet water supplies are connected to the wrong ports

or cartridge is installed improperly. See section on “Reverse

Inlets”.

• The tempered water is too cold, although cartridge has been

replaced, 0R the hot water temperature is below 115°F...

a. Raise the temperature of the hot water supply.

• Flow of water is completely shut off...

a. The upstream supply valves may be completely closed.

b. The hot or cold water supply pressure may have failed. The

e700 valve is designed to close down upon cold water supply

pressure failure.

c. The checkstops may be closed. Access the checkstops and

open by turning the adjustment screw fully counterclockwise.

Dimensional Data n

A

"

Part # Dim "A"

e705 6.5" (165mm)

e707 8.5" (216mm)

e710 6.5" (165mm)

Page 4

Exploded View and Parts List - e700 n

Index Description Part #

1 Valve Body N/A

2 Cartridge Kit 220 060

3 Checkstop Replacement Kit 900 050

4 Sleeve Kit 220 054

5 Metal Trim Plate Kit 220 051

6 ABS Trim Plate Kit 220 053

7 Metal Handle Kit 220 050

8 ABS Handle Kit 220 052

9 Dome Handle Kit 220 079

10 Metal Flat Trim Plate Kit 220 078

10

9

Repair Kits n

Description Troubleshooting Repair Kit No.

Cartridge Kit •Waterleaksatvalvestemand/orbonnet.

•Waterleaksatvalveshutoff.

•Watertemperaturechangesduringshower.

Checkstop

•Checkstopleaksorwillnotshutoffcompletely 900 050

Replacement Kit

Warranty n

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THIS EXPRESS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS, EXPRESS OF IMPLIED. THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

220 060

WARNING: This product contains chemicals known

to the State of California to cause cancer and birth

defects or other reproductive harm.

For more information: www.watts.com/prop65

A Watts Water Technologies Company

IS-P-e700 1515 EDP# 6512256 © 2015 Powers

USA: Tel: (800) 669-5430 • Fax: (847) 229-0526 • PowersControls.com

Canada: Tel: (905) 332-4090 • Fax: (905) 332-7068 • PowersControls.ca

Latin America: (52) 81-1001-8600 • Fax: (52) 81-8000-7091 • PowersControls.com

Loading...

Loading...