Powers 450-e700 User Manual

IS-P-450-700

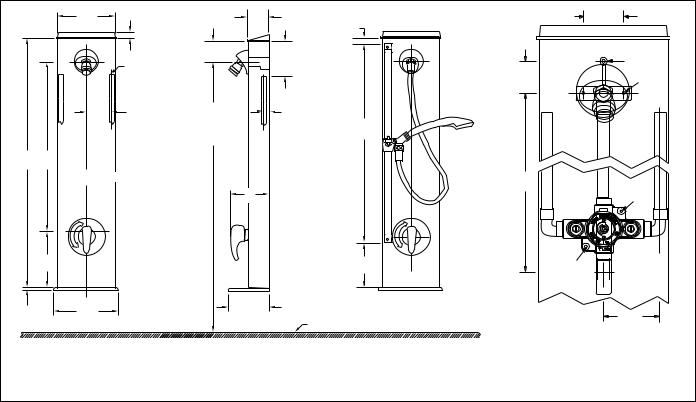

HydroPanel®II Shower System with HydroGuard® T/P Series e700 Combination Valve

Technical Instructions

Description ■

The Powers HydroPanel®II Shower System with HydroGuard® T/P Series e700 valve combines water control with the convenience of modular shrouding. HydroPanel®II stainless steel shrouding provides a concealed shower system where inwall piping does not exist or may not be practical.

The Series 450-7100 and 450-7050 HydroPanel®II comes complete with the stainless steel HydroPanel®II shrouding, Series e700 valve with checkstops, piping, showerhead, end cap and mounting hardware. Some models feature a stainless steel soap dish. An optional hand shower comes pre-assembled with a full spray push button hand shower, 60" hose, 18" mounted glide-bar and connectors. The Series e700 valve is CSA approved and ASSE type T/P listed.

The following instructions serve as guide for installation, general maintenance and parts replacement for HydroPanel®II Shower Systems with e700 T/P combination Valves. For detailed repair and maintenance instructions for the e700 valve or integral checkstops, please refer to Form ES-P-E700. For specification or installation of the HydroPanel®II Modular Shrouding for shower rooms, please refer to ES-P-450SH.

Operation ■

Hot and cold water enter respective ports in the valve and mix in a chamber containing an advanced thermal actuator. This actuator controls the position of the plunger and temperature.

Rotating the adjustment handle repositions the plunger in the cartridge assembly to produce the desired temperature. The mixed water passes over the shutoff disc to the outlet. If the hot or cold supply water temperature or pressure changes, the thermal actuator contracts or expands. This movement repositions the plunger to maintain the desired temperature. With the adjustment handle in full clockwise (OFF) position, the shutoff disc closes the mixing chamber from the outlet.

A high temperature limit stop restricts the movement of the control handle. All HydroGuard® T/P e700 valves are factory set to deliver tempered water up to 110°F (43°C) with equal supply pressures, with hot water temperature 140°F (60°C), cold water temperature 60°F (15.6°C).

Features ■

•Installation requires minimal hardware: Mount the brackets, connect supply piping and hang shrouding.

•All exposed surfaces are easy to clean stainless steel or chrome plated.

•Fixed (vandal resistant) and swivel showerheads are available.

•Single handle control and color coded dial offer quick and easy temperature selection.

•Optional hand-held showers with flexible hoses mount on 24" (610mm) glide rails for use in special applications.

HydroPanel®II |

HydroPanel®II |

Model 450-7100 |

Model 450-7054 |

•Optional HydroPanel®II Modular Shrouding offers convenient configuration of horizontal and vertical panels to cover all exposed shower room piping. See ES-P-450SH for details

on HydroPanel®II Modular Shrouding.

•HydroGuard® T/P Series e700 are CSA certified and ASSE 1016 type T/P listed.

Specifications ■

HydroPanel®II : Brushed 18 Gauge 304 SS. Dimensions: 31-1/8" H x 7-1/2" W x 6" D (791 mm H x 191 mm x 154 mm D).

Piping: 1/2" (15mm) copper tubing.

Showerhead: Fixed: Chrome plated brass, maximum flow 2.5 gpm @ 80psi (0.16 l/s @ 552 kPa). Adjustable Swivel: Chrome plated brass, 30° angle of rotation, maximum flow 2.5 gpm @ 80psi (0.16 l/s @ 552 kPa).

Valve Assembly and Trim: HydroGuard T/P Series e700 Combination Valve. Four port (bottom outlet plugged), cast brass body with chrome plated zinc or ABS lever handle. 1/2" (15mm) sweat inlet/outlet connections. Standard integral checkstops. Metal to metal limit stop.

Valve Operation: 4.0 gpm @ 45psi differential (15 l/min. @ 310 kPa). Maximum pressure (static)

125psi (862 kPa). Maximum inlet temperature 190°F (88°C).

Hand Shower: Full spray with pushbutton water control. Minimum flow 2.0 gpm @ 20psi (0.13 l/s @ 138 kPa). Maximum flow 2.5 gpm @ 80psi (0.16 l/s @ 138 kPa). 1/2" (15mm) chrome finished supply connections. 24" (610 mm) chrome finished brass glide bar, self-tensioned for easy height adjustment. Professional model: 60" (1499 mm) reinforced vinyl hose. Deluxe Model:

60" (1499 mm) metal spiral hose.

Installation ■

Before installation of any HydroPanel®II unit, rotate the stem

(or handle if attached) of the valve to its full clockwise position (OFF).

Position the HydroPanel®II Unit

(See Figures 1 and 2) Determine the horizontal position of the unit according to shower room layout, and mark the center line.

For multiple shower applications, the recommended minimum distance between the center line of two units is 36" (1914 mm).

6.For mounting the piping assembly lower bracket (C), drill one small holes in the wall 23-1/2" (587mm) below the showerhead on the centerline.

7.Install any mounting anchors as detailed by the individual room specifications.

8.Secure upper piping bracket B with mounting screws (not included).

9.Secure lower piping bracket C with mounting screw (not included).

|

|

|

11/16" |

|

|

|

|

|

7-3/32" |

(18) |

|

2-1/2" |

|

|

|

(180) |

|

|

(64) |

1-1/4" |

|

|

|

|

|

|

(32) |

|

|

|

|

2-3/4" |

|

4-1/8" |

|

|

|

1/2" |

(70) |

|

|

|

|

|

|

|

(105) |

|

|

|

|

Copper Inlets |

|

|

|

|

|

|

3-5/16" |

For Suggested |

|

1/2" |

|

|

|

(84) |

Showerhead |

|

(13) |

|

|

|

|

Height see |

|

24" |

|

|

|

|

General |

|

|

|

|

|

|

|

(610) |

|

|

|

|

|

Installation |

|

|

|

|

|

|

|

|

|

30" |

21-1/4" |

|

|

|

|

|

(762) |

(540) |

|

|

|

|

|

|

|

C for HydroPanel II™ unit |

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

6" |

|

|

|

|

|

|

(152) |

|

|

|

OFF |

|

|

|

|

|

C O |

LD |

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

O |

|

|

|

|

|

|

H |

|

|

|

|

|

|

6" |

|

|

|

|

4-3/4" |

|

(154) |

|

|

|

|

|

|

|

|

|

|

(121) |

|

|

|

|

|

|

|

|

|

|

7-1/2" |

|

|

4-3/4" |

|

7/16" |

|

|

|

(121) |

|

|

|

(191) |

|

|

|

||

(11) |

|

|

|

|

|

FLOOR LINE |

|

|

|

|

|

|

|

|

OFF |

C O |

LD |

|

|

T |

|

O |

|

H |

|

|

2-1/4" |

|

|

(57) |

|

|

END CAP |

|

1-3/4" |

A |

|

B |

||

(44) |

23-1/2"

(597)

D

D

C

C

3-5/16"

(84)

Figure 1:

Front dimensions HydroPanel®II Model 450-7100

Figure 2:

Side dimensions HydroPanel®II Model 450-7100

Figure 3: |

Figure 4. |

Front dimensions |

|

HydroPanel®II |

|

Model 450-7104. |

|

1.Determine the floor-to-showerhead height for the unit. Recommended heights are listed below:

Men - |

77" (1956 mm) |

Youth - 66" (1676 mm) |

Women - 70" (1778 mm) |

Youth - 60" (1524 mm) |

|

2.The pre assembled copper tubing supply water inlets are 4-1/8”(105 mm) from the top of the shroud, and 3-5/16" (84mm) left and right of the center line. Adjust supply piping accordingly.

Install the Piping Assembly

The valve handle assembly, piping and HydroPanel®II shrouding must be separated before mounting to wall. For #450-7104, 7054, 7105, 7055, 7106 and 7056 HydroPanel®II units, the hand shower, hose and showerhead base come pre-assembled to the shrouding. Refer to Figure 4.

3.Detach the valve assembly by removing valve retaining screw, handle and collar. Undo the screws at D and take off the dial insert.

4.Remove the screw at A above the showerhead. Slide the piping out of the shrouding; the showerhead remains attached to the shroud.

5.For mounting the piping assembly upper bracket (B), use the bracket as a template and drill two small holes in the wall at showerhead height.

10. Connect the supply lines to the piping assembly.

Attach the Shrouding

Do not remove the entire chrome plated end cap from the shrouding. It functions as an end cap and gasket for shroud extension. Part of the end cap can be broken out to provide vertical and horizontal piping clearance.

11.To remove scored section, hit it sharply with a hammer.

12.To connect the showerhead on the shroud to the water outlet pipe, slide the showerhead nipple on the inside of the shroud into the piping assembly. The End Cap will slide over the supply piping. Secure the shrouding with the screw at A.

Test the System

Before final assembly, test the HydroPanel®II system.

13.Fit the handle onto the valve stem and turn clockwise to the shut off position.

14.Turn on water supply, and then rotate the valve handle counterclockwise. Water should come through the showerhead.

15.Now turn handle fully counterclockwise and measure the temperature of the outlet water. Wait until the temperature stabilizes for an accurate reading.

16.Turn off valve (fully clockwise) and check all connections (showerhead, pipe connections, valve bonnet) for leaks.

2

Loading...

Loading...