Page 1

Installation Instructions

!

WARNING

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use infor-

mation can result in death, serious personal injury,

property damage, or damage to the equipment.

Keep this Manual for future reference.

!

WARNING

You are required to consult the local building and plumbing

codes prior to installation. If the information in this manual

is not consistent with local building or plumbing codes,

the local codes should be followed. Inquire with governing

authorities for additional local requirements.

!

WARNING

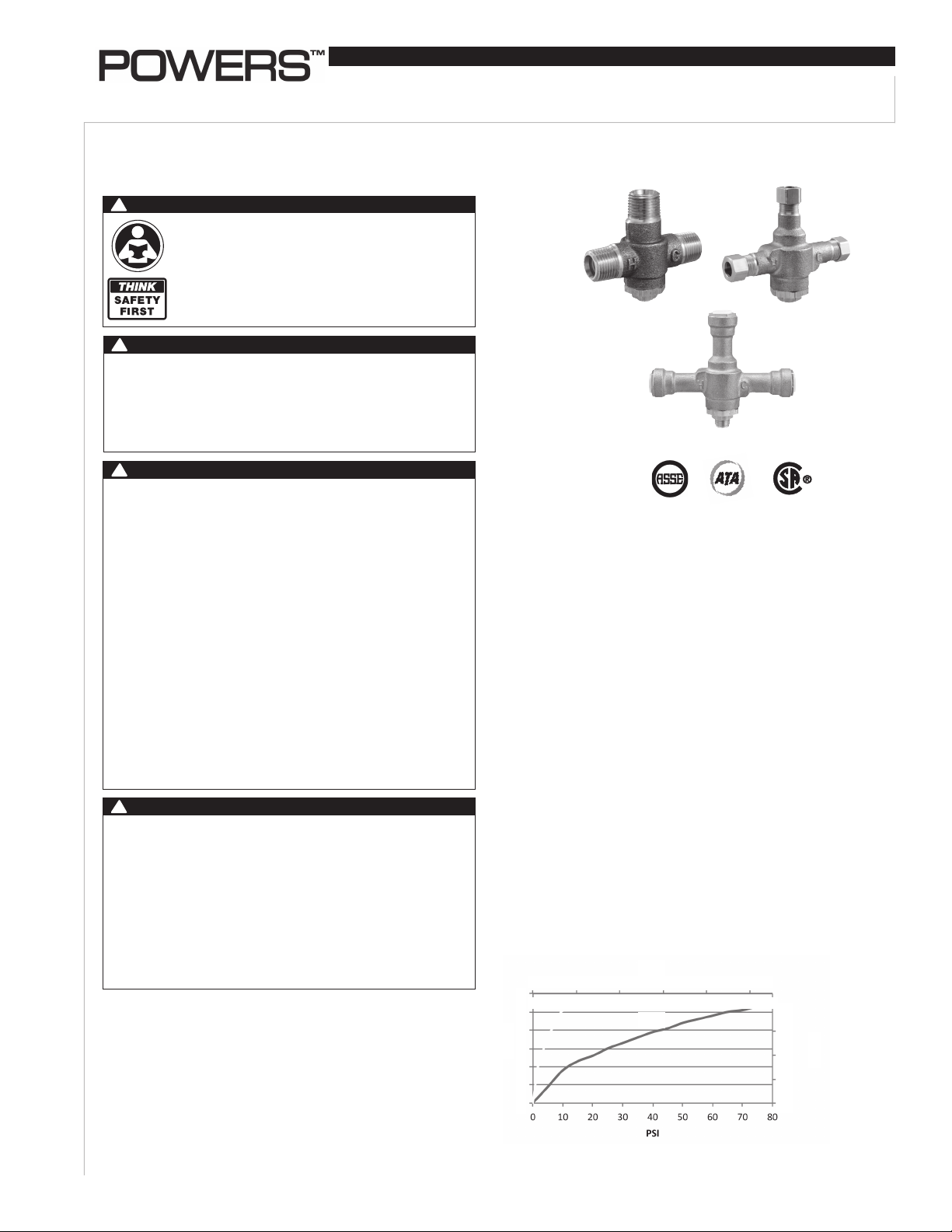

HydroGuard

®

Series LFe480

Lavatory Tempering Valve

LFe480-00

LFe480-50

LFe480-10

IS-P-e480

FAILURE TO COMPLY WITH PROPER INSTALLATION

AND MAINTENANCE INSTRUCTIONS COULD

CONTRIBUTE TO THE VALVE FAILURE, RESULTING IN

INJURY AND/OR DEATH.

TO ENSURE THE ACCURATE AND RELIABLE OPERATION

OF THIS PRODUCT, IT IS ESSENTIAL TO:

• Properly design the system to minimize pressure and

temperature variations.

• This valve is factory preset. However, it can be adjusted to deliver scalding temperatures. Check outlet tem-

perature to ensure it does not exceed 105°F (41°C).

Make sure temperature limit stop is properly re-set to

maximum 105°F (41°C) following valve maintenance or

repair. Tampering with limit stop in any way may result

in scalding temperature causing serious bodily harm

and/or death.

!

WARNING

Need for Periodic Inspection and Yearly Maintenance:

Periodic inspection and yearly maintenance by a licensed

contractor is required. Corrosive water conditions, inlet

temperatures over 200°F (93°C), and/or unauthorized adjustments or repair could render the valve ineffective for service intended. Regular checking and cleaning of the valve’s

internal components and check stops helps assure maximum life and proper product function. Frequency of cleaning and inspection depends upon local water conditions.

Advanced Thermal

Actuation

Description n

Powers Series LFe480 are designed for lavatory applications

where the temperature of the hot water must be controlled for

safe, economic use. An advanced thermal actuator quickly

senses and compensate for outlet temperature fluctuations

induced by water temperature and pressure changes in

the supply line.

Specifications n

Maximum Operating Pressure: .......................... 125psi (861 kpa)

Maximum Hot Water Temperature: ......................... 180°F (82°C)

Minimum Hot Water Supply Temp.: 5°F (3°C) Above Set Point**

Hot Water Inlet Temperature Range: ..... 120 – 180°F (49-82°C)

Cold Water Inlet Temperature Range: ........... 40 – 80°F (4-27°C)

Temperature Adjustment Range: ................ 80 – 120°F (27-49°C)

Minimum Flow: ..................................................... 0.5 gpm (1.9 lpm)

Listing: ............................................. ASSE 1070 and IAPMO cUPC

** With Equal Pressure

Flow Capacity n

kPa

0 100 200 300 400 500

6

0 10 20 30 40 50 60 70 80

5

G

4

P

3

M

2

1

0

PSI

20

15

L

P

10

M

5

0

Page 2

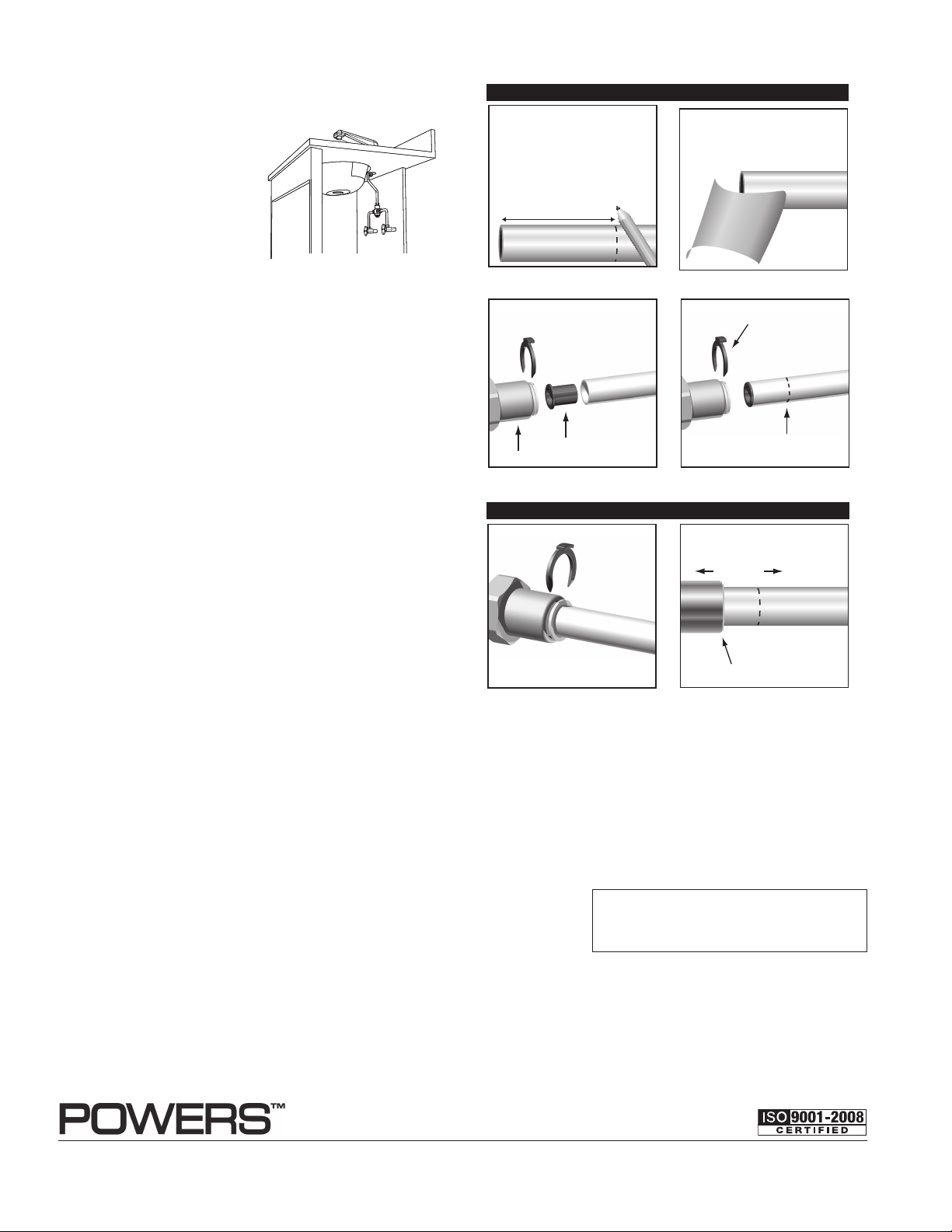

PEX

PEX tubing only

Pipe Stiffener

Mark

Collet clip

Collet

To Install n

1. Installation should be in accordance with acceptable

plumbing practices. Flush all piping thoroughly before

installation. Installation and

field adjustment are the responsibility of the installer.

2. Locate suitable place for the

tempering valve. Valve should

be accessible for service and

adjustment and as close to the

point-of-use as possible.

3. Connect hot and cold supplies

to valve and outlet of tempering valve to fixture (s) using 1/2"

or 3/8" compression connections. For Quick-Connect refer

to Quick-Connect installation section.

4. Turn on hot and cold water supplies. If any leaks are

observed, tighten connections as necessary to stop leaks

before proceeding.

5. Turn on fixture and allow water to flow for 2 minutes.

Measure water temperature at the outlet. If water is not at

desired temperature, adjust as necessary (see temperature

adjustment section). Maximum outlet temperature of 105°F

(41°C) is recommended.

Typical Installation

Quick-Connect Installation n

TO CONNECT

1 in. (25.4mm)

3

/8 in.Pipe (9.5mm)

1. Mark pipe as shown.

This is pipe insertion depth.

PEX tubing only

Tail Piece

3. If using PEX tubing, insert pipe stiffener (provided) into end of pipe.

Pipe Stiffener

2. Clean pipe end.

4. Push tubing into tailpiece up to mark.

5. Insert collet clip.

Collet clip

Mark

Temperature Adjustment n

1. Loosen locknut.

2. Turn on fixture and run water for at least two minutes to allow

supply temperature to stabilize.

3. Turn temperature stem counter-clockwise for hotter or

clockwise for colder outlet temperature.

4. Tighten locknut to prevent accidental or unauthorized

temperature adjustment.

5. Re-check outlet temperature.

Repair Kit n

Motor Repair Kit: .................................................................... 480 270

Warranty n

TO DISCONNECT

Collet depressed

1. Remove collet clip. 2. Depress collet.

WARNING: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

For more information: www.watts.com/prop65

3. Pull tubing from tailpiece .

The Seller warrants that the equipment manufactured by it and covered by this order or contract is free from defects in material and workmanship and, without

charge, equipment found to be defective in material or workmanship will be repaired, or at Seller’s option replaced F.O.B. original point of shipment, if written

notice of failure is received by Seller within one (1) year after date of shipment (unless specifically noted elsewhere), provided said equipment has been properly

installed, operated in accordance with the Seller’s instructions, and provided such defects are not due to abuse or decomposition by chemical or galvanic action.

THIS EXPRESS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, GUARANTEES, OR REPRESENTATIONS, EXPRESS OF IMPLIED. THERE ARE

NO IMPLIED WARRANTIES OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. The Seller assumes no responsibility for repairs made on the

Seller’s equipment unless done by the Seller’s authorized personnel, or by written authority from the Seller. The Seller makes no guarantee with respect to material

not manufactured by it.

A Watts Water Technologies Company

IS-P-e480 1336 EDP# 6512252 © 2013 Powers

USA: Phone: 1.800.669.5430 • Fax 1.847. 229.0526 • www.powerscontrols.com

Canada: Phone: 1.888.208.8927 • Fax 1.888 . 479.2887 • www.powerscontrols.ca

Loading...

Loading...